Self-heating type cement pipe pouring mould

A technology for pouring molds and cement pipes, which is applied in the field of self-heating cement pipe pouring molds, can solve the problems of long time for concrete mortar to solidify and dry up, high cost, etc., and achieve better pouring effect, improve pouring efficiency, and overcome the effects of influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with each accompanying drawing, the present invention is described in detail.

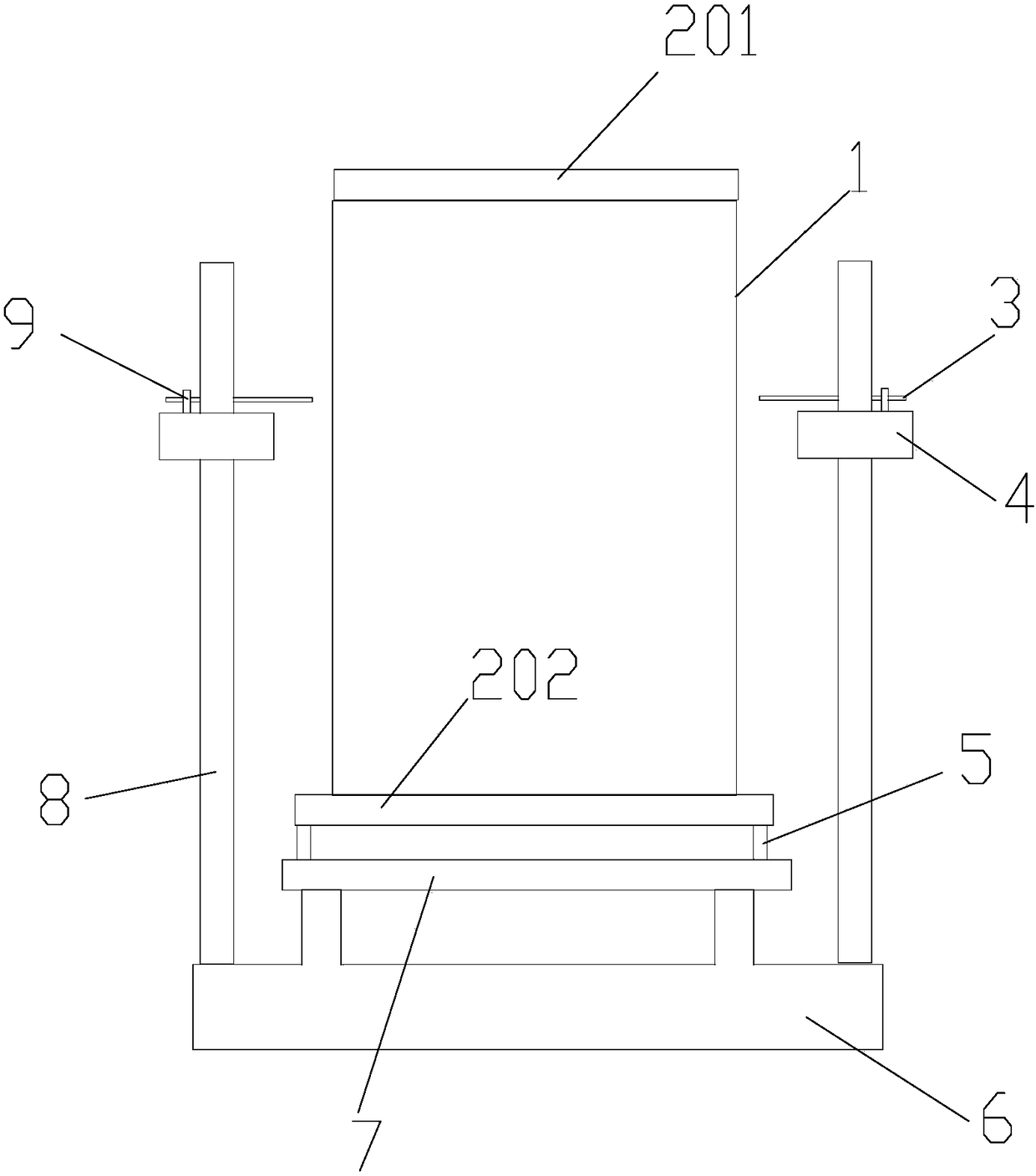

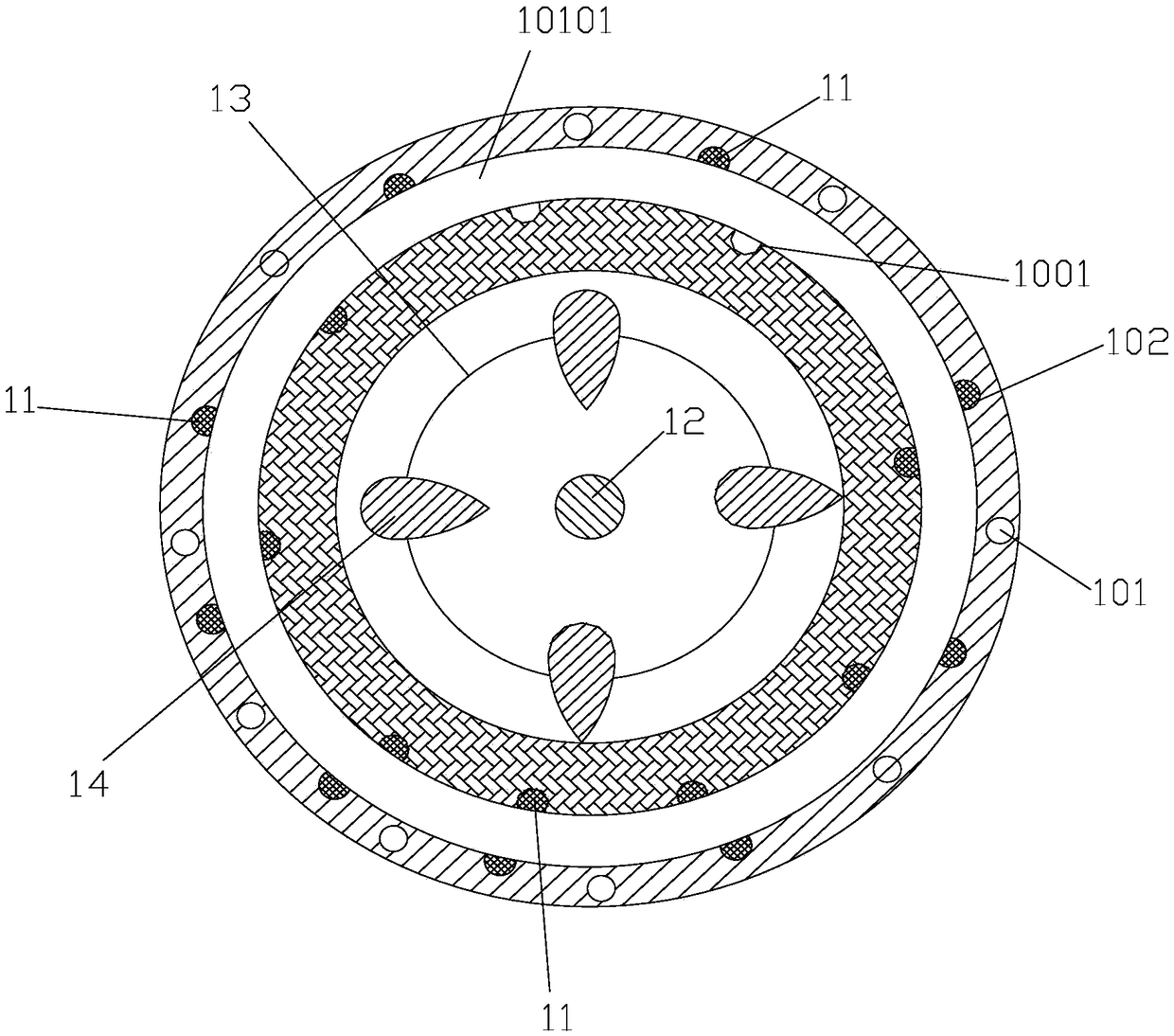

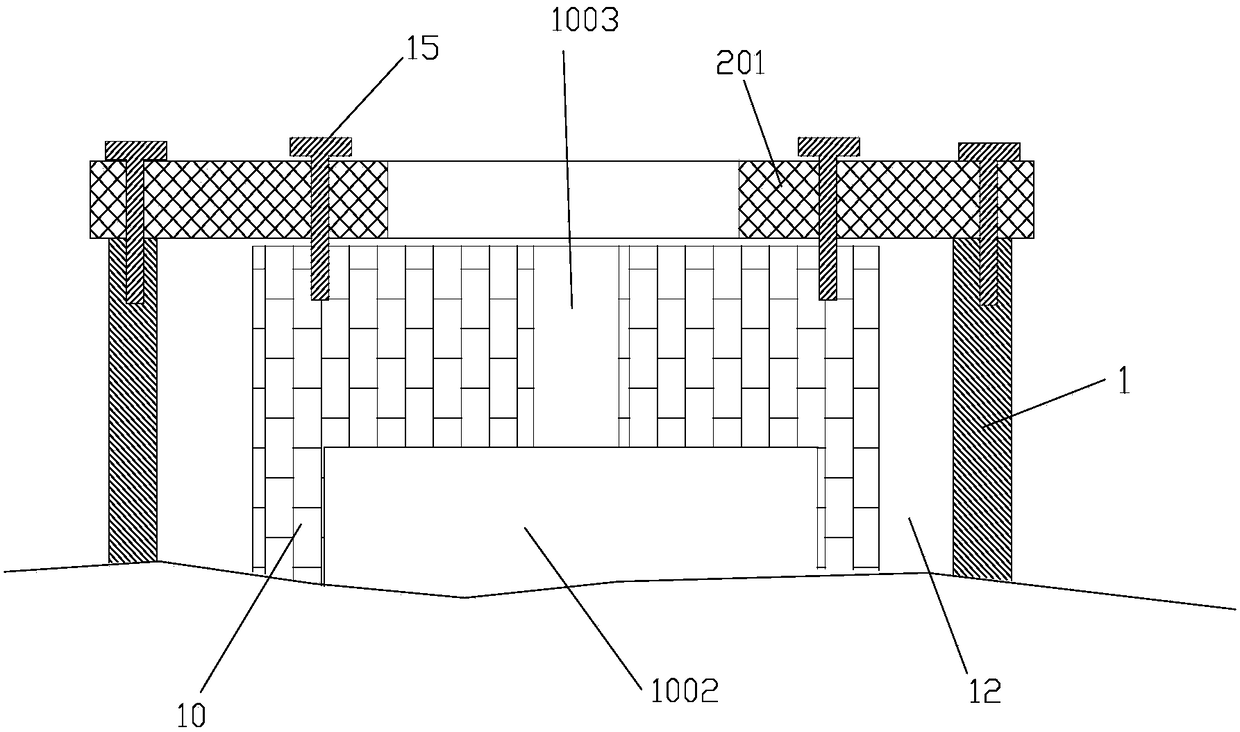

[0042] as attached figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9 and 10, a self-heating cement pipe casting mold, including at least one pair of primary and secondary sealing end caps, a heater, an inner cylinder 10 and an outer sleeve 1 ; The inner cylinder 10, the outer ring sleeve 1, the main sealing end cover 202 and the auxiliary sealing end cover 201 are detachably matched together to form a pouring space, and the pouring space is used to place steel cages and concrete mortar; Cavity 1002, an air inlet 1004 is provided on one end surface of the inner cylinder 10, an air outlet 1003 is provided on the other end surface of the inner cylinder 10, a number of hot air passage holes 101 are opened on the outer sleeve 1, and the hot air passage holes 101 are not It communicates with the pouring space, the air outlet 1003 on the inner cylinder 10 communicates with the hot air hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com