Grouting material and perfusion of same into enclosed steel die for reinforcement of steel concrete beams and columns

A technology of reinforced concrete beams and reinforced concrete columns, which is applied in the field of civil engineering reinforcement, can solve problems such as difficult entry of coarse aggregate, difficulty of concrete pouring and compaction, difficulty of vibration, etc., and achieves the effects of saving construction period, simple construction and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Embodiment 1: The grouting material of this embodiment is made by mixing P.O52.5 ordinary Portland cement, UEA expansion agent, FDN high-efficiency water reducing agent and water, wherein P.O52.5 ordinary Portland cement is mixed with The weight ratio of water is 1:0.3~0.5, the weight of UEA expansion agent accounts for 6~8% of the weight of P.O52.5 ordinary Portland cement, and the weight of FDN high-efficiency water reducer accounts for P.O52.5 ordinary silicic acid 0.6-0.8% by weight of salt cement.

specific Embodiment approach 2

[0011] Specific embodiment two: The weight ratio of P.O52.5 ordinary Portland cement and water described in this embodiment is 1: 0.4, and the weight of UEA expansion agent accounts for 7% of P.O52.5 ordinary Portland cement weight , The weight of FDN high-efficiency water reducer accounts for 0.7% of the weight of P.O52.5 ordinary Portland cement. High strength and good fluidity. Others are the same as in the first embodiment.

specific Embodiment approach 3

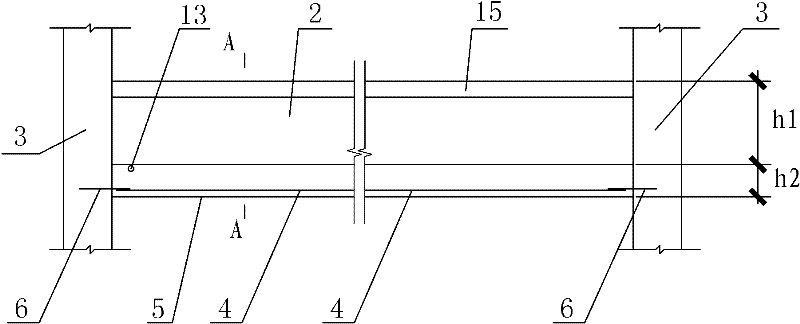

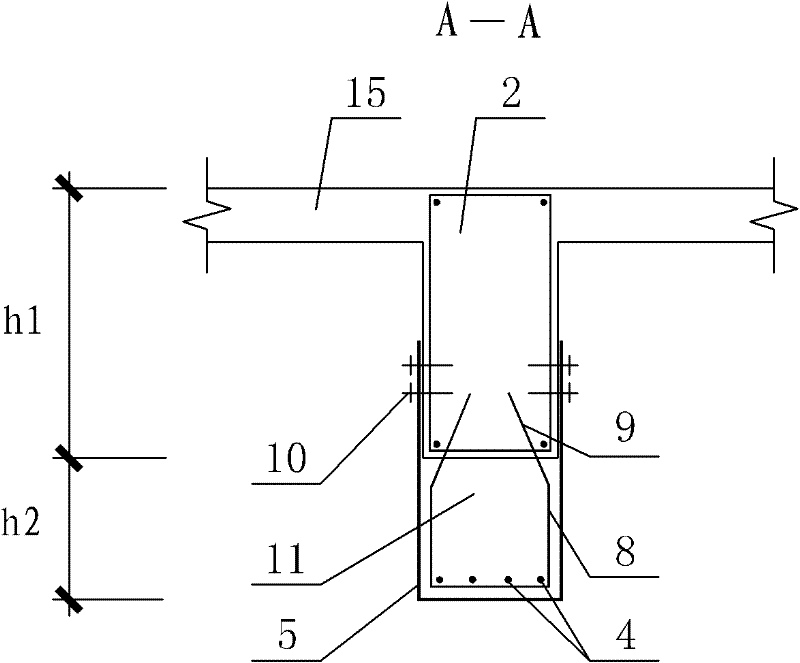

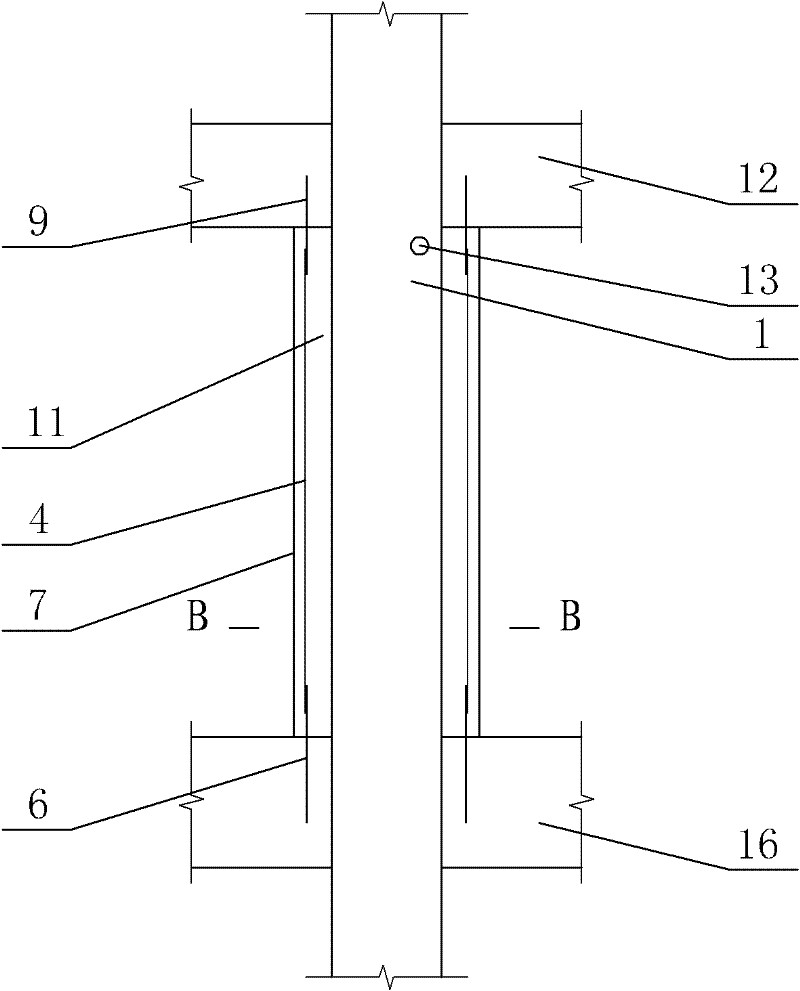

[0012] Specific implementation mode three: combination figure 1 with figure 2 Explain that this embodiment uses the grouting material in the first or second embodiment to pour the welded closed steel mold to strengthen the reinforced concrete beam, and the grouted material poured into the welded closed steel mold to strengthen the reinforced concrete beam. 8. Multiple stressed steel bars 4, multiple first connecting steel bars 9, multiple second connecting steel bars 6 and multiple nails or multiple anchor bolts 10, between the bottom surface of the U-shaped channel steel mold 5 and the side wall of the groove The intersection angle formed between them is a right angle; multiple stirrups 8 are arranged directly below the original reinforced concrete beam 2, and multiple stirrups 8 are arranged side by side at equal intervals along the length direction of the original reinforced concrete beam 2, and the upper end of each stirrup 8 Weld with one end lap of the first connecting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com