Single-cable-replaceable type anchorage pre-stressed anchor device and installation and cable replacement methods thereof

An anchoring device and replaceable technology, applied in the direction of suspension bridges, bridge forms, bridge parts, etc., can solve the problems of increasing operation and maintenance costs, grease leakage of anchoring systems, and insufficient understanding of sealing performance, so as to solve the problems of beam penetration and sealing Can not take into account, the construction is convenient, the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

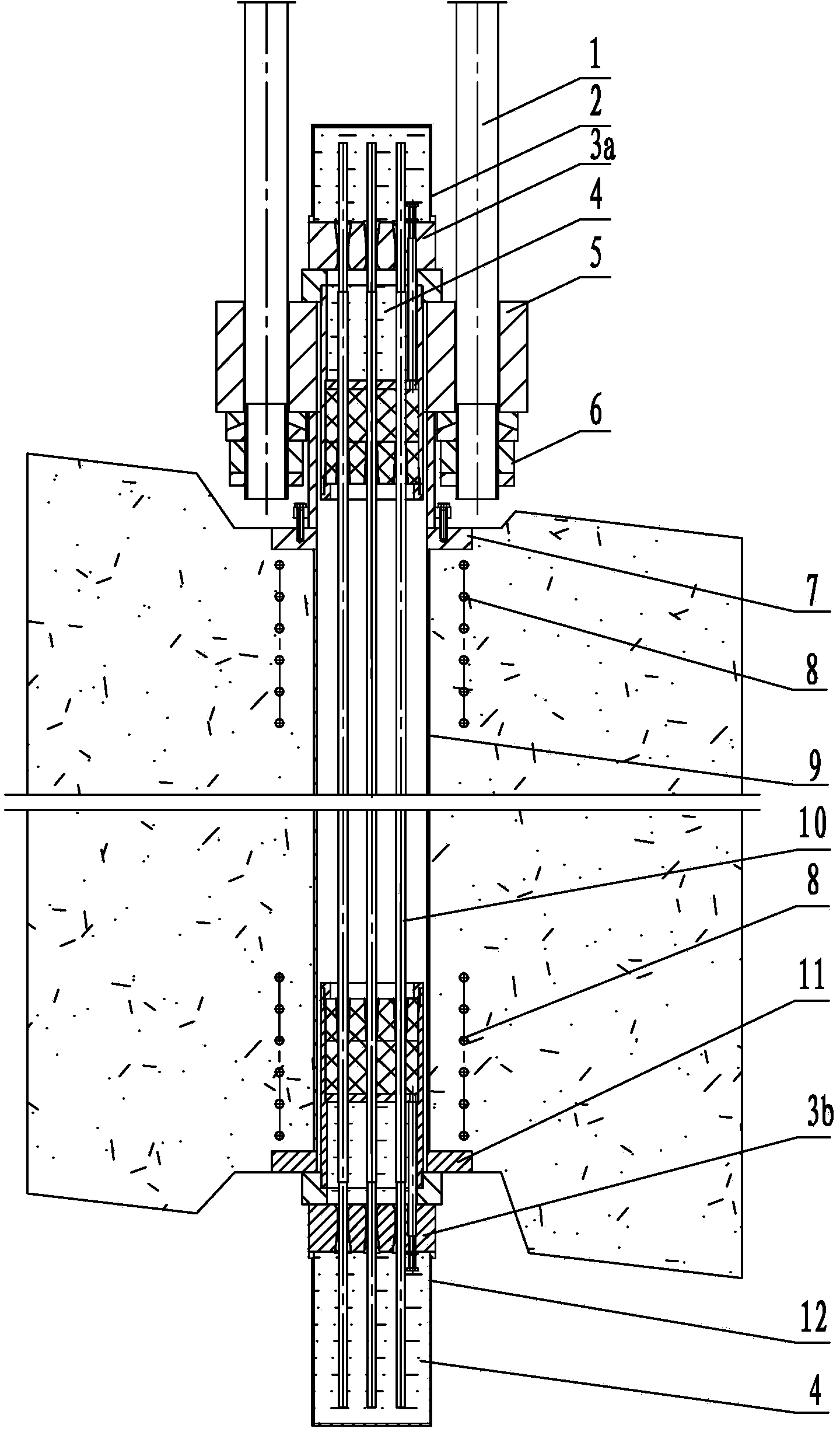

[0054] A single replaceable anchor prestressed anchoring device, such as figure 1 As shown, the single replaceable anchor prestressed anchoring device includes a pull rod 1, a front protective cover 2, an anchor assembly 3, a connector 5, a pull rod nut assembly 6, a front anchor plate 7, a spiral rib 8, a pre-embedded Pipe 9, unbonded PE steel strand 10, rear anchor plate 11 and rear protective cover 12;

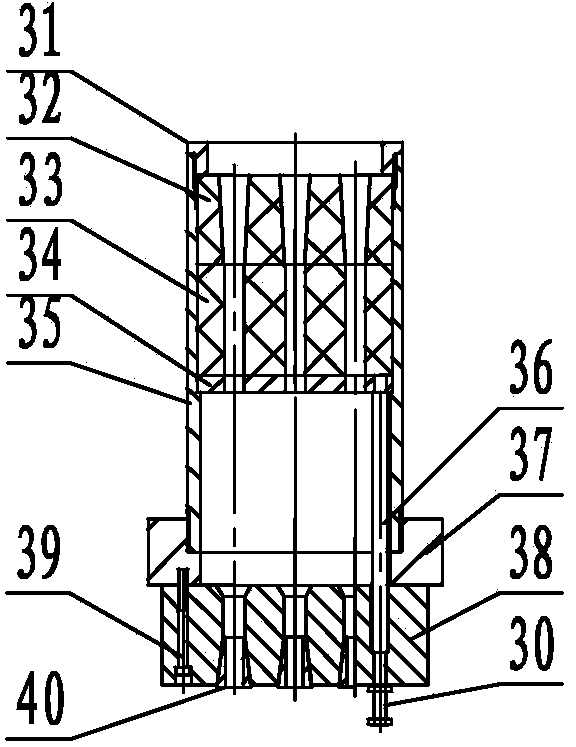

[0055] The anchor assembly 3 has two sets, namely the front anchor assembly 3a and the rear anchor assembly 3b, and each set of anchor assemblies consists of a gland 31, an outer sealing plate 32, an inner sealing plate 33, and a positioning plate 34 connected in sequence. , sealing cylinder 35, ejector rod 36, backing plate 37, anchor plate 38, bolt 39, screw rod 30 and working clip 40, outer sealing plate 32 and inner sealing plate 33 constitute the sealing device of the anchorage assembly, positioning plate 34 and The sealing cavity of the anchor assembly is formed betw...

Embodiment 2

[0065] A method of installation and construction of a single replaceable anchor prestressed anchorage device, the replaceable anchor prestressed anchorage device is the single replaceable anchor prestressed anchorage device described in Embodiment 1, which The installation construction method includes the following steps:

[0066] Step 1: Install the embedded parts: pre-embed the rear anchor plate 11, spiral reinforcement 8, embedded pipe 9 and front anchor plate 7 at the construction site and pour concrete, and then maintain the concrete to the design strength;

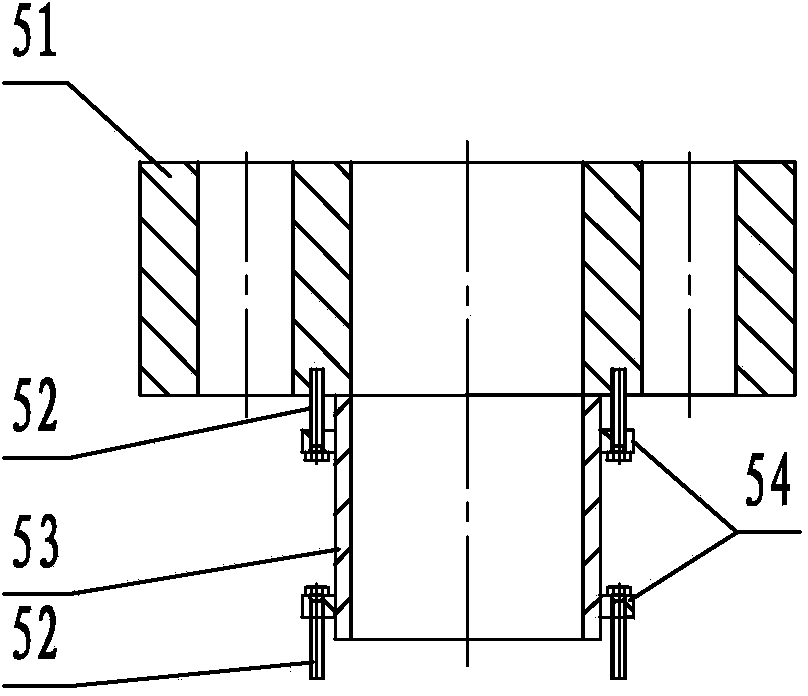

[0067] Step 2: Install the connector: at the front anchor, use the bolt 52 to install the connector 5 on the front anchor plate 7;

[0068] Step 3: Install the anchor assembly: at the front anchor, install the front anchor assembly 3a on the end face of the connector 5; at the rear anchor, temporarily place the rear anchor assembly 3b directly under the rear anchor pad 11;

[0069] Step 4: thread unbonded PE steel s...

Embodiment 3

[0076] A method of changing cables for a single replaceable anchor prestressed anchorage device, the replaceable anchor prestressed anchorage device is the single replaceable anchor prestressed anchorage device described in Embodiment 1, Its cable-changing construction method comprises the following steps:

[0077] Step 1: Remove the front protective cover 2 and the rear protective cover 12, remove the non-drying anti-corrosion material 4 on the anchor plate 38, and loosen the screw 30;

[0078] Step 2: At the rear anchor, use a single tension jack to unload the unbonded PE steel strand 10 to be replaced, and take out the working clip 40 from the rear anchor plate 38;

[0079] Step 3: At the rear anchor, connect the old and new strands with strand connectors;

[0080] Step 4: At the front anchor, use a single tension jack to unload the unbonded PE steel strand 10 to be replaced, and pull out the old steel strand upwards while inserting the new steel strand;

[0081] Step 5: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com