Bagged cement automatic bag-opening and discharging device for nuclear power station

A technology of unloading device and nuclear power plant, which is applied in the directions of packaging, transportation and packaging, and unsealing of objects, etc., which can solve the problems of inconvenient maintenance, high labor intensity, and high cost, and achieve convenient use and maintenance, good sealing effect, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

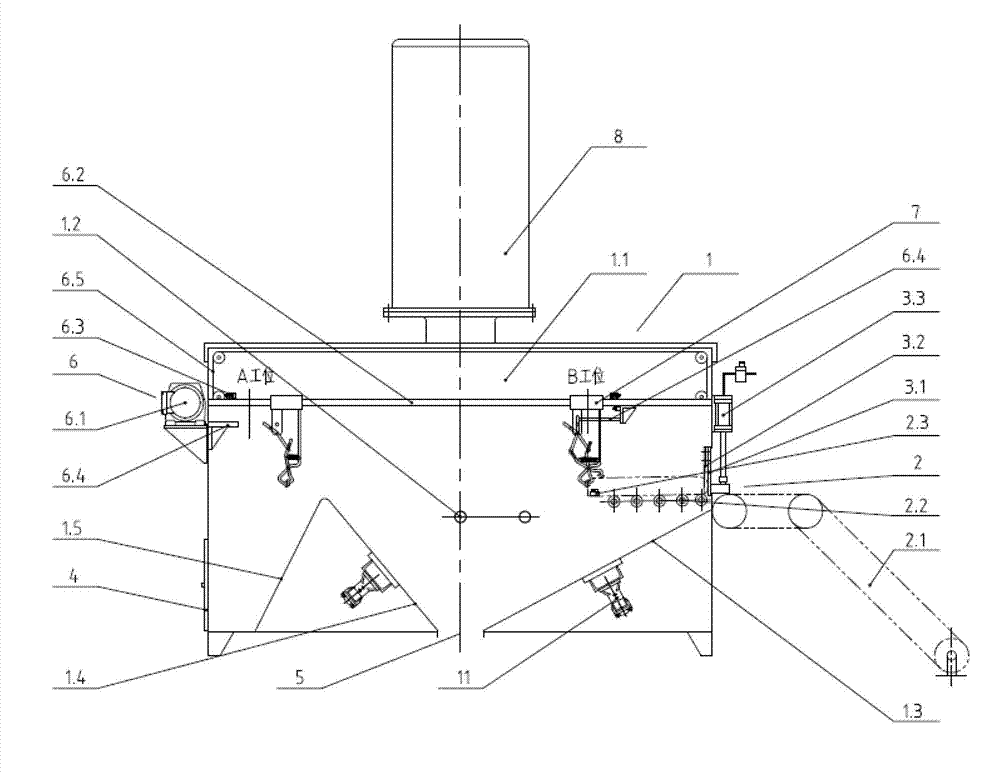

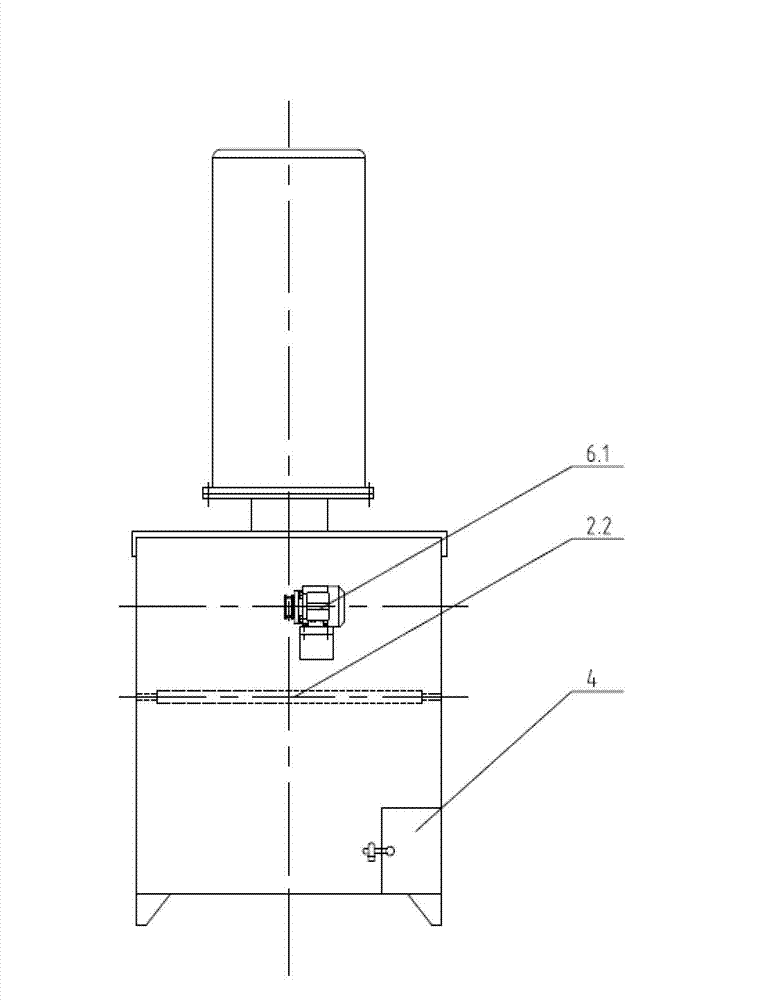

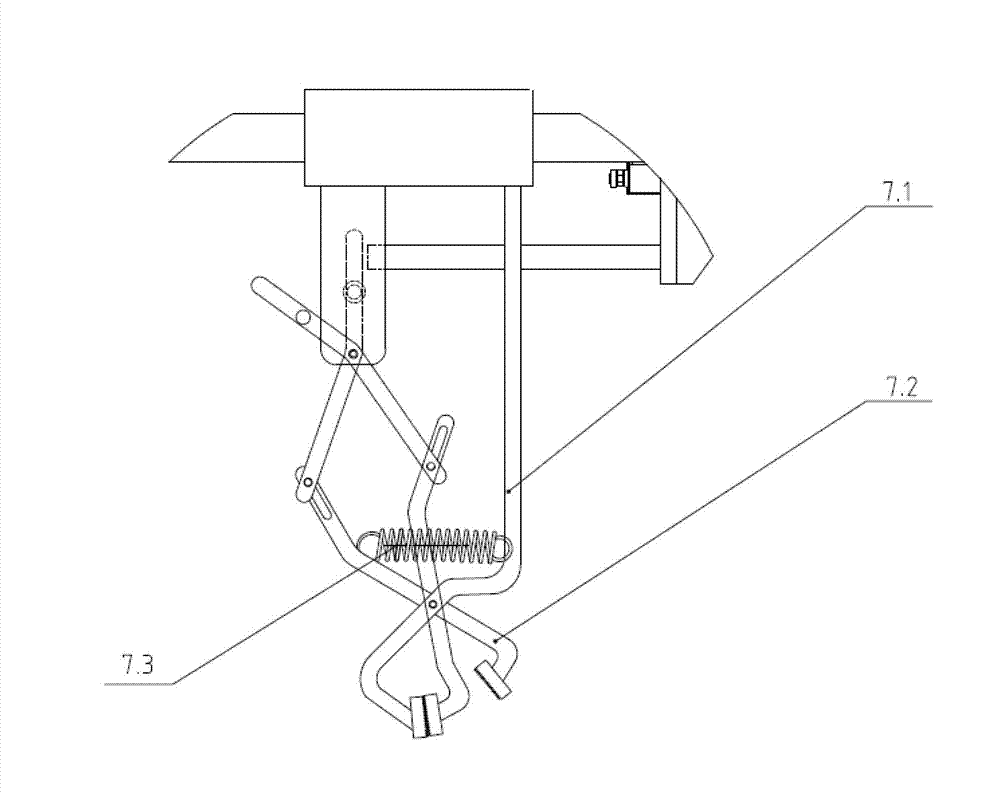

[0020] The bagged cement automatic opening and unloading device for nuclear power plants shown in the figure includes a closed box 1, a conveying mechanism 2, a controller 9 and a start button 10. The closed box 1 is composed of a casing 1.1, a beam 1.2, a first inclined plate 1.3, The second slant plate 1.4 and the third slant plate 1.5 are composed. The conveying mechanism 2 is composed of a belt conveyor 2.1, a non-powered roller table 2.2 and a photoelectric sensor 2.3. The front end of the shell 1.1 is provided with a vertical lifting door 3.1, and the rear of the shell 1.1 The end face is provided with a cement bag recovery door 4, the bottom of the shell 1.1 is provided with a cement outlet 5, a cutting knife 3.2 is fixed on the inner surface of the vertical lift door 3.1, the vertical lift door 3.1 is driven by the power mechanism 3.3, and the unpowered roller table 2.2 is driven by It is composed of a plurality of mutually parallel rollers installed on both sides of th...

Embodiment 2

[0024] In the solution of Embodiment 1, the power mechanism 3.3 is a pneumatic actuator.

Embodiment 3

[0026] In the solution of embodiment 1 or embodiment 2, vibrators 11 are respectively provided on the lower surfaces of the first slant plate 1.3 and the second slant plate 1.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com