Cement terrace pouring device for water conservancy construction

A cement and floor technology, applied in the construction, building structure, construction material processing and other directions, can solve the problems of poor concrete pouring and forming effect, and the concrete cannot be fully and evenly spread, so as to improve the quality and reduce the workload. , good pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

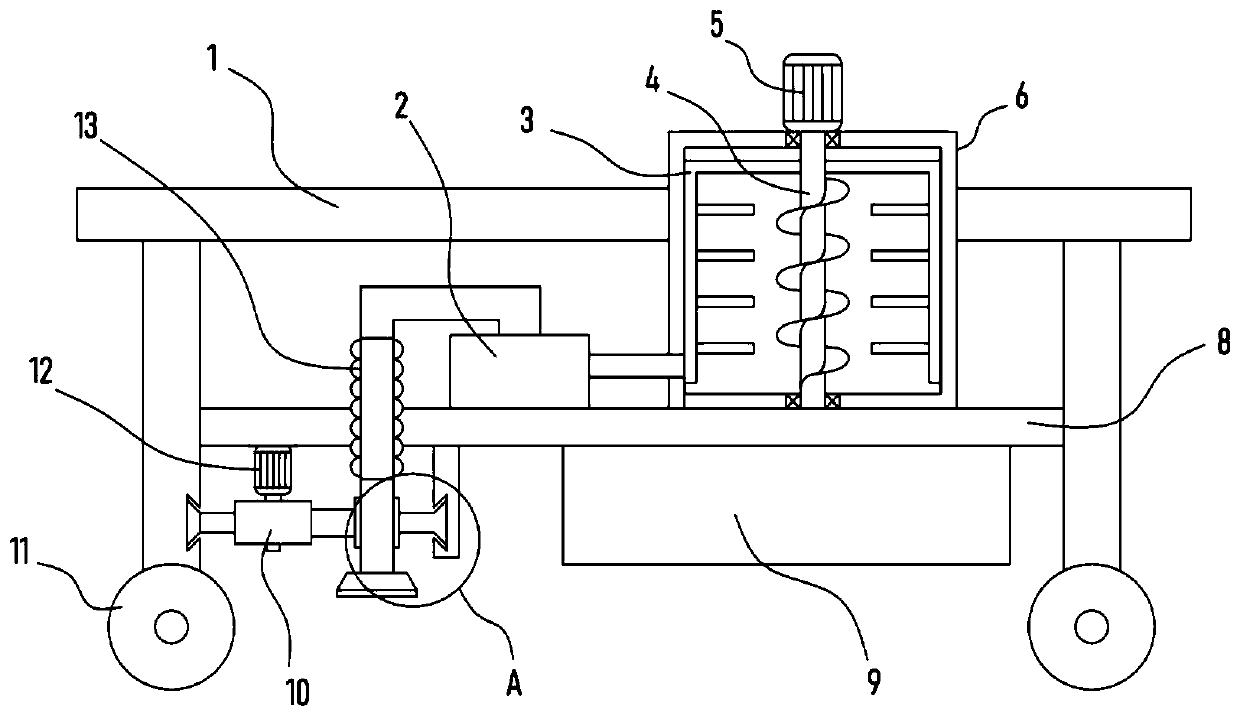

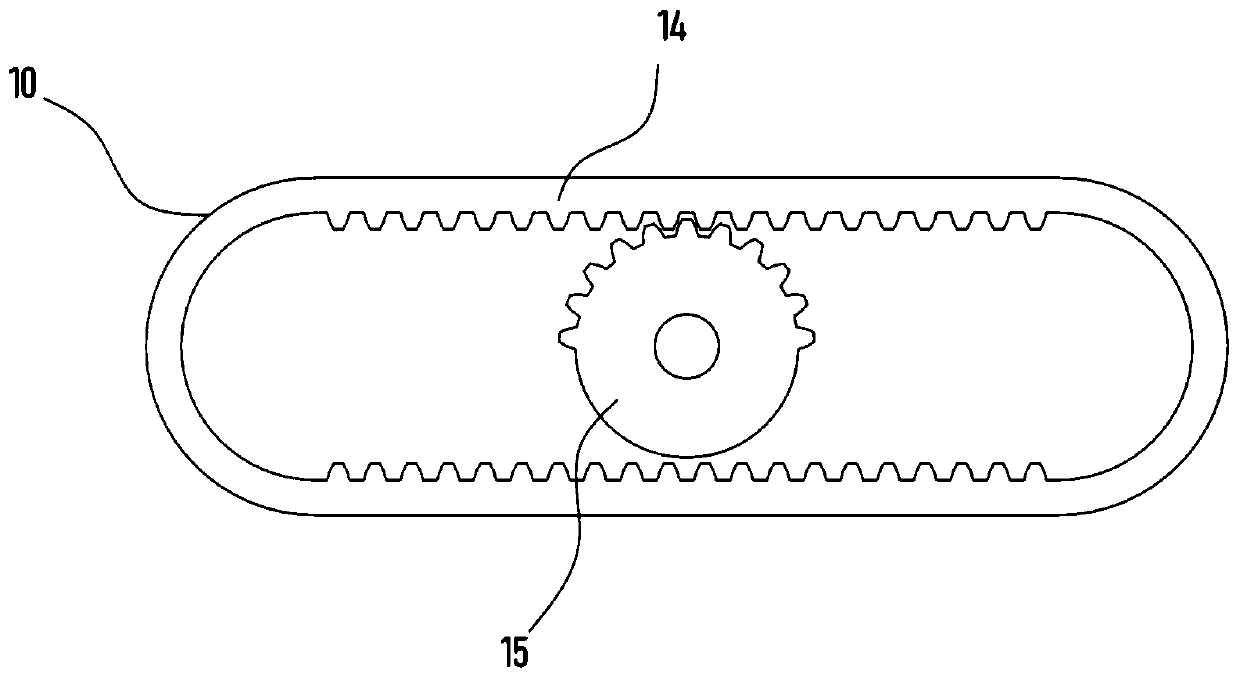

[0024] see Figure 1-6 , a cement floor pouring device for water conservancy construction, comprising a support frame 1, the bottom of the support frame 1 is rotatably provided with traveling wheels 11, the support frame 1 is fixed with a storage tank 6, and the support frame 1 is fixed with a horizontal frame 8, The horizontal frame 8 is provided with a delivery pump 2 connected to the storage tank 6 pipelines, the outlet end of the delivery pump 2 is connected with a vertically arranged discharge cover 17 through a delivery hose 13, and the bottom of the horizontal frame 8 is provided with a discharge cover for driving. 17. A reciprocating mechanism that moves horizontally. The bottom of the horizontal frame 8 is fixed with a storage coaming 9, and a leveling mechanism for leveling concrete is provided in the lifting type of the storage coaming 9.

[0025] The storage tank 6 is used to store the concrete to be poured, and the concrete is pumped through the delivery pump 2 co...

Embodiment 2

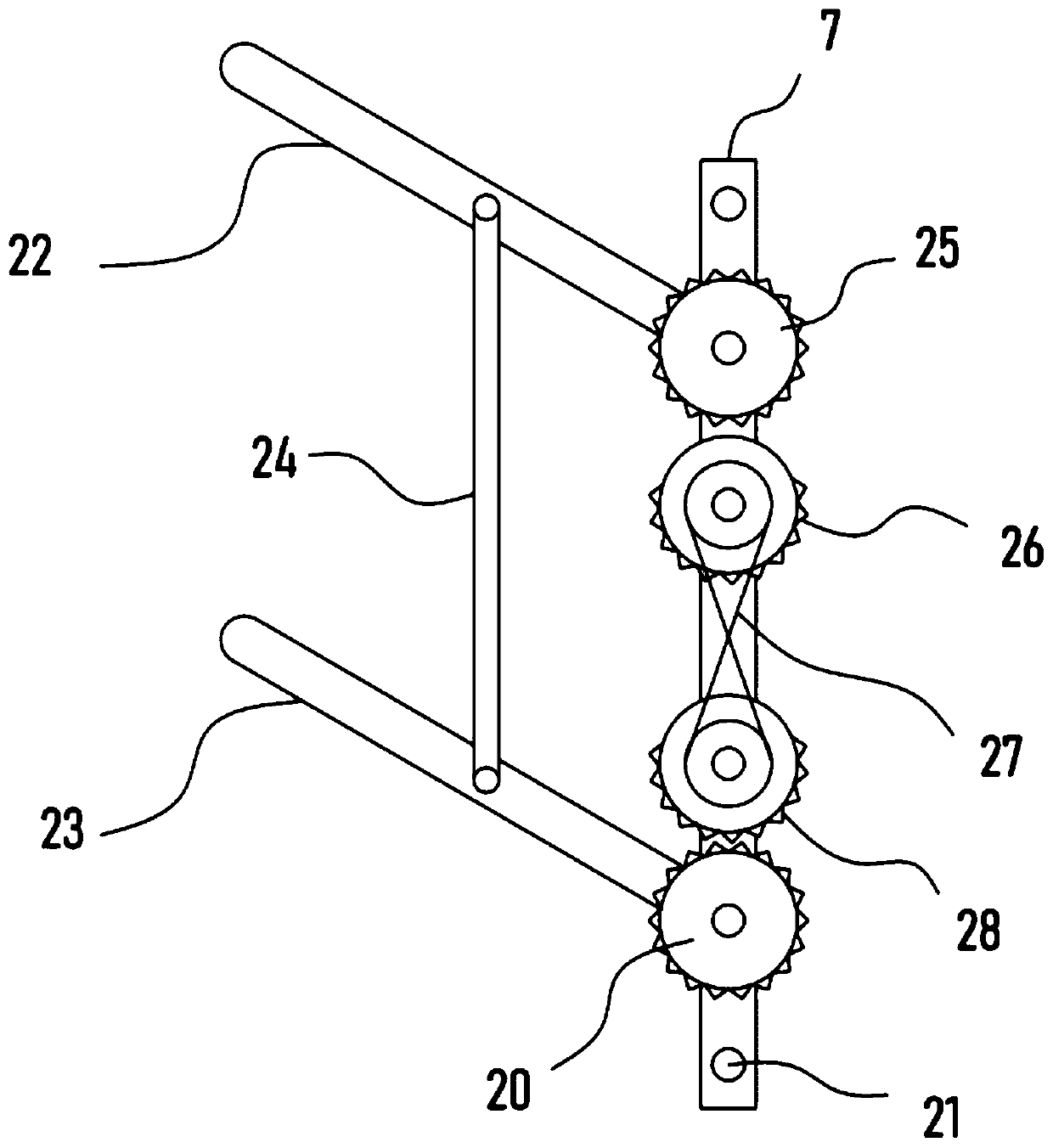

[0030] After the concrete is poured and before it is completely solidified, it is necessary to perform a leveling operation according to the design elevation of the floor and the process of flatness. For this reason, on the basis of Embodiment 1, the device is also provided with a leveling mechanism, which includes a connecting plate 7, Scraper I22 and scraper II23 arranged in parallel are hinged on connecting plate 7, and gear II25 and gear I20 are respectively fixed on scraper I22 and scraper II23, and are connected between gear II25 and gear I20 for driving gear II25 and gear I20 In the rotating reversing mechanism, a transmission rod 24 parallel to the connecting plate 7 is hinged between the scraper I22 and the scraper II23.

[0031] Through the above settings, when the scraper I22 swings, the scraper I22 can drive the scraper II23 to swing synchronously through the transmission rod 24, and then realize the leveling effect on the cement floor. Due to the reversing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com