Patents

Literature

92results about How to "Not uneven" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flip-chip single-face three-dimensional circuit fabrication method by etching-first and packaging-second and packaging structure of flip-chip single-face three-dimensional circuit

ActiveCN102723280ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityElectroplating

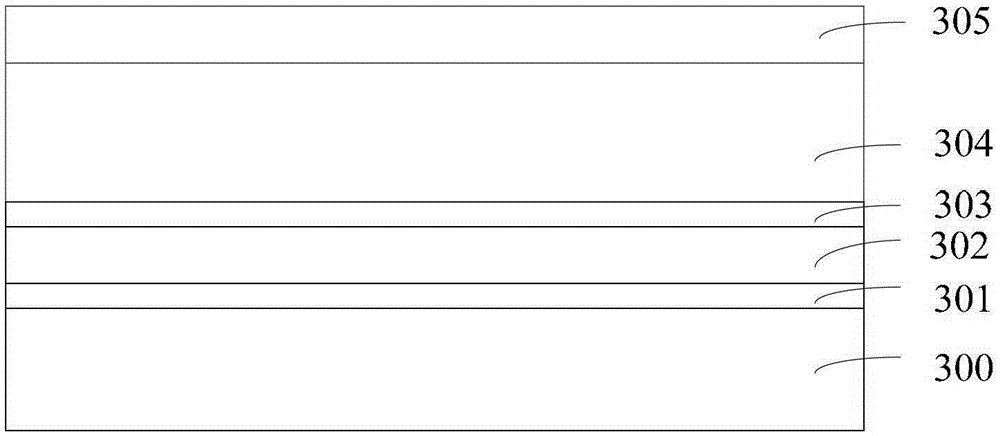

The invention relates to a flip-chip single-face three-dimensional circuit fabrication method by etching-first and packaging-second and a packaging structure of a flip-chip single-face three-dimensional circuit. The method includes following steps: picking a metal substrate, pre-coppering the surface of the metal substrate, sticking photo-resistant films, removing part of the photo-resistant films on the back of the metal substrate, electroplating an inert metal circuit layer, electroplating a metal circuit layer, removing the photo-resistant films, packaging, processing a hole on the surface of plastic-packaged materials, grooving, electroplating conductive metal, pretreating before metallization, electroplating a metal circuit layer, chemically etching, electroplating a metal circuit layer, mounting a chip and filling at the bottom of the chip, cleaning, balling and cutting to obtain a finished product. The flip-chip single-face three-dimensional circuit fabrication method by etching-first and packaging-second and the packaging structure of the flip-chip single-face three-dimensional circuit have the advantages that fabrication cost is lowered, safety and reliability of a packaged body is improved, environmental pollution is reduced, and design and fabrication of high-density circuits can be truly realized.

Owner:JCET GROUP CO LTD

Etching-first and packaging-later manufacturing method for chip formal double-surface three-dimensional circuit and packaging structure of chip formal double-surface three-dimensional circuit

ActiveCN102723282ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesEtchingMetal substrate

The invention relates to an etching-first and packaging-later manufacturing method for a chip formal double-surface three-dimensional circuit and a packaging structure of the chip formal double-surface three-dimensional circuit. The method comprises the following steps of taking a metal substrate; pre-plating copper on the surface of the metal substrate; coating the surface of the metal substrate with green paint; removing a part of the green paint from the back surface of the metal substrate; electro-plating an inert metal circuit layer; electro-plating a metal circuit layer; coating the back surface of the metal substrate with the green paint; removing a part of the green paint from the back surface of the metal substrate; electro-plating the metal circuit layer; coating the back surface of the metal substrate with the green paint; removing a part of the green paint from the back surface of the metal substrate; coating a circuit screen board; pre-processing of metallization; removing the circuit screen board; electro-plating the metal circuit layer; coating the back surface of the metal substrate with the green paint; removing a part of the green paint from the front surface of the metal substrate; chemical-etching; electro-plating the metal circuit layer; coating bonding materials; installing a chip; bonding with metal wires; packaging; tapping at the back surface of the metal substrate; cleaning; implanting a metal ball; and cutting a finished product. The method disclosed by the invention has the beneficial effects that the manufacturing cost is lowered, the safety and the reliability of a packaging body are increased, the environment pollution is reduced, and the design and the manufacturing of a high-density circuit can be really realized.

Owner:JCET GROUP CO LTD

Normal chip single-faced three-dimensional circuit manufacture method by encapsulation prior to etching and normal chip single-faced three-dimensional circuit encapsulation structure

ActiveCN102723289ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesEtchingHigh density

The invention relates to a normal chip single-faced three-dimensional circuit manufacture method by encapsulation prior to etching. The method includes: taking a metal substrate; preplating copper to the metal substrate surface; coating with green paint; partially removing the green paint on the front of the metal substrate; electroplating inert a metal circuit layer; electroplating a metal circuit layer; coating with green paint; partially removing the green paint on the front of the metal substrate; electroplating a metal circuit layer; coating with green paint; partially removing the green paint on the front of the metal substrate; coating a circuit screen plate; performing metallization pretreatment; removing the circuit screen plate; electroplating metal circuit layer; coating bonding material; mounting a chip; performing metal circuit bonding; encapsulating; partially removing the green paint on the back of the metal substrate; performing chemical etching; electroplating a metal circuit layer; coating with green paint; reserving holes on the green paint; cleaning; attaching balls; and cutting finished products. The normal chip single-faced three-dimensional circuit manufacture method by encapsulation prior to etching has the advantages that manufacture cost is lowered, safety and reliability of encapsulation are enhanced, environmental pollution is reduced, and design and manufacture of high density circuit are really achieved.

Owner:JCET GROUP CO LTD

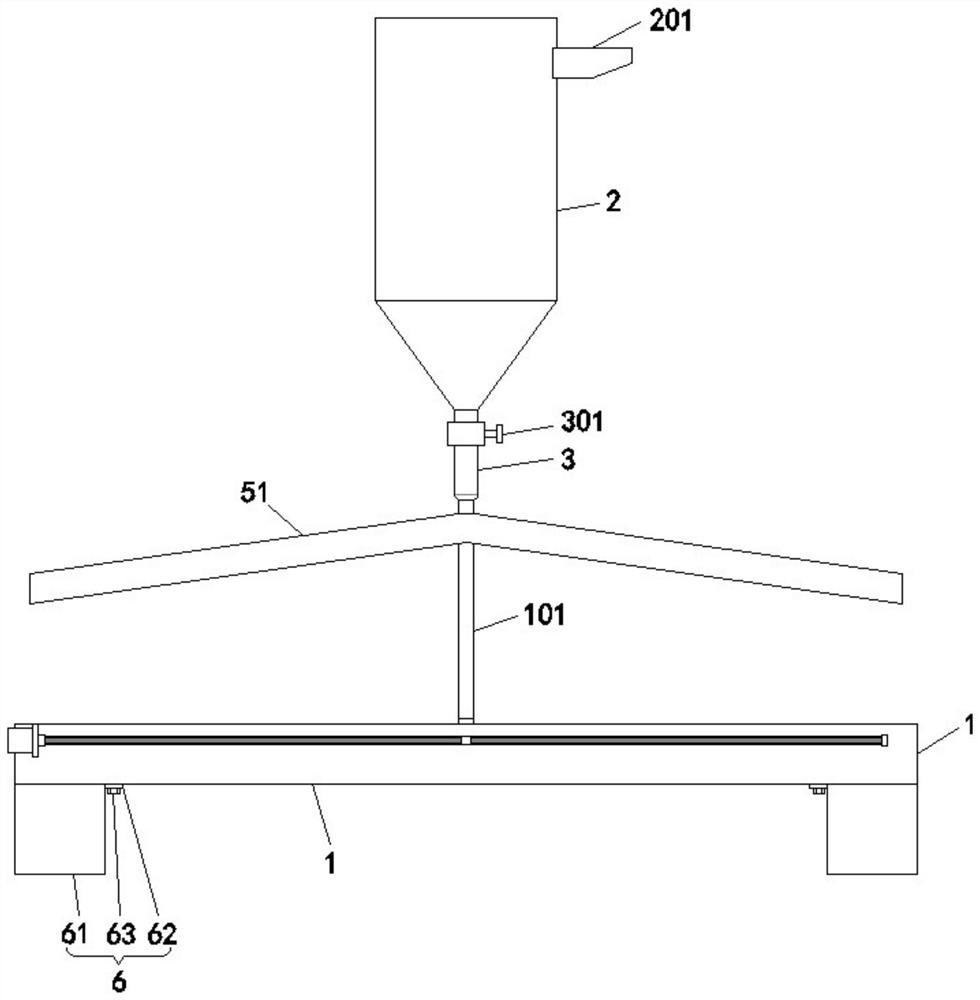

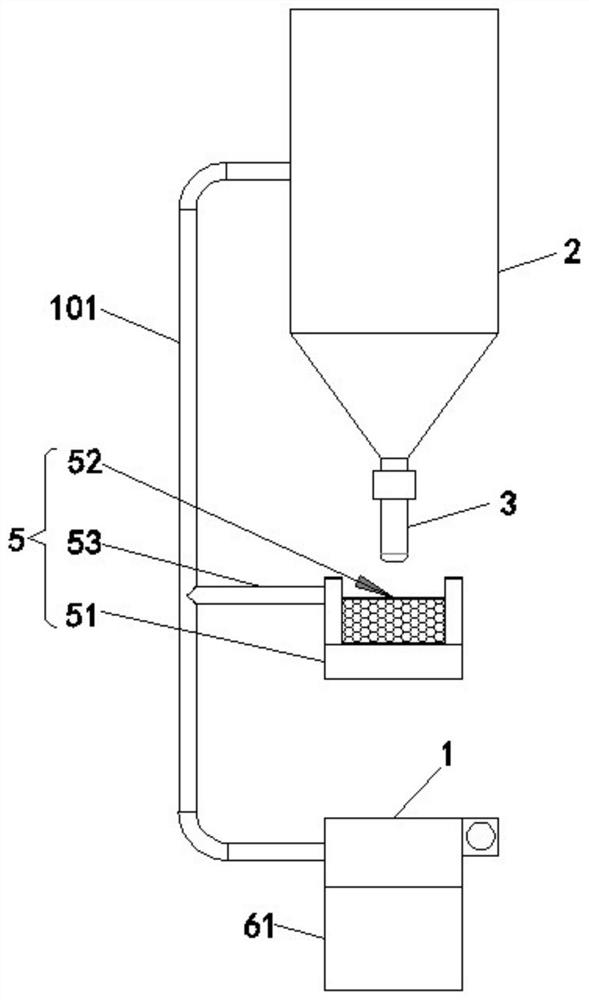

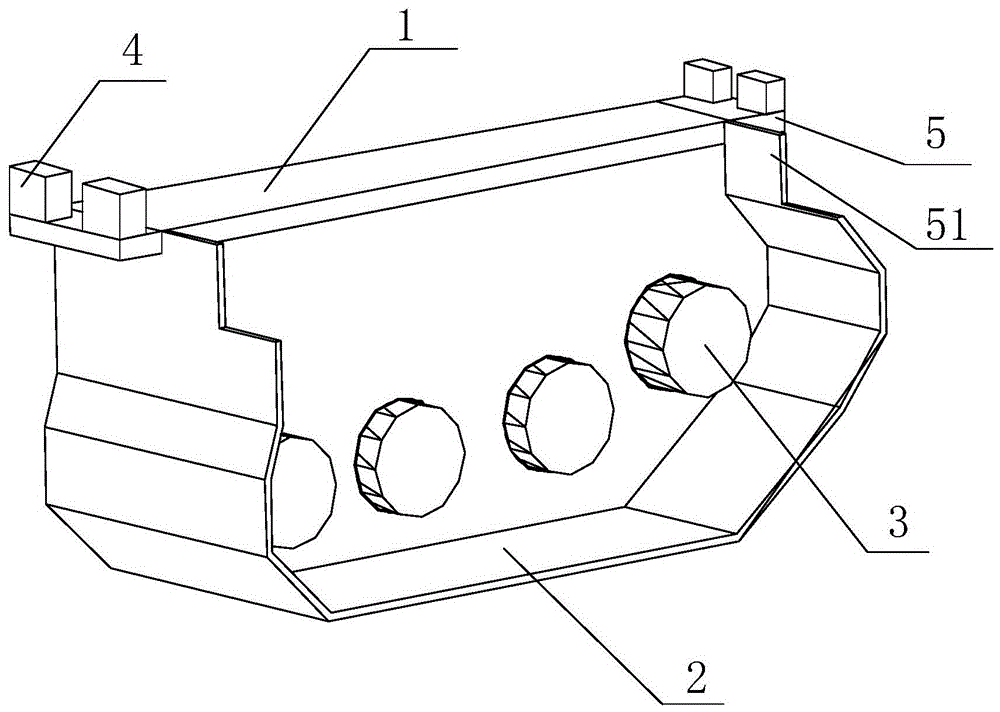

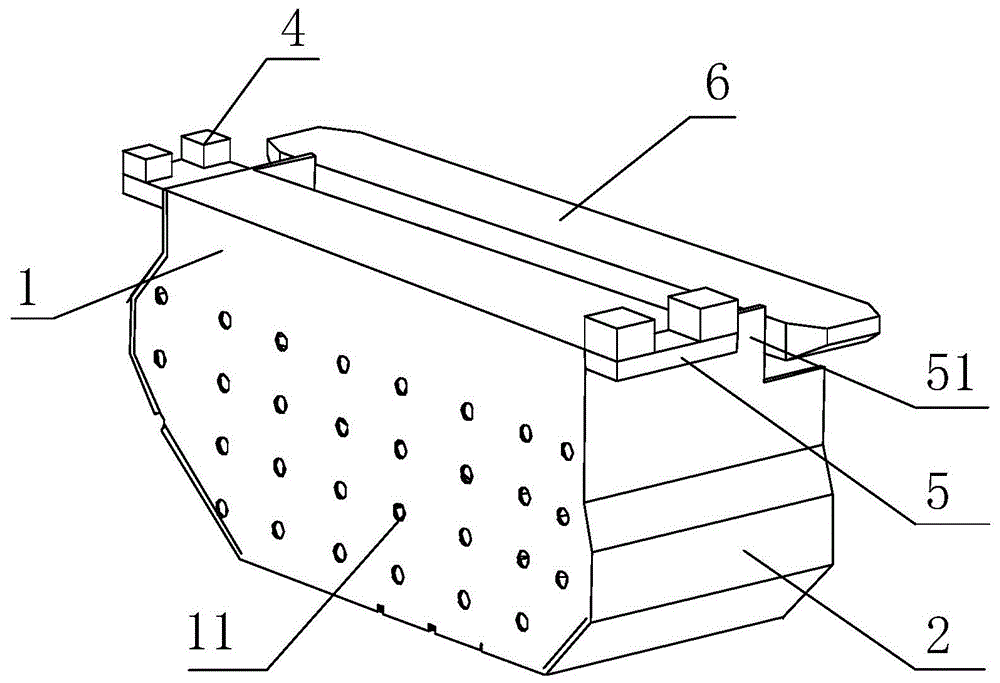

Cement terrace pouring device for water conservancy construction

ActiveCN110219464AAvoid accumulationReduce workloadBuilding material handlingArchitectural engineeringBuilding construction

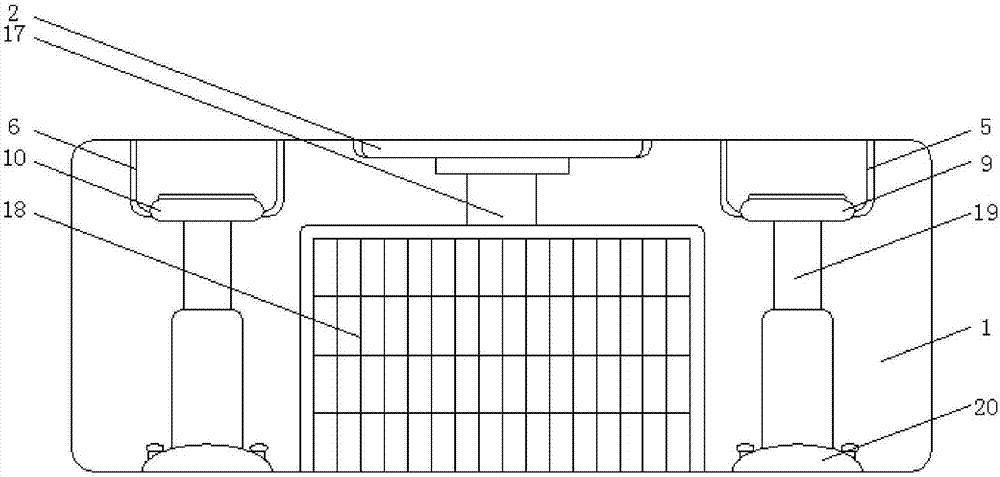

The invention discloses a cement terrace pouring device for water conservancy construction, and relates to the technical field of water conservancy construction machinery. The cement terrace pouring device comprises a supporting frame, and travelling wheels are rotatably arranged at the bottom of the supporting frame; a storage barrel is fixed to the supporting frame, and a horizontal frame is fixed into the supporting frame; and the bottom of the horizontal frame is provided with a reciprocating mechanism used for driving a discharging hood to horizontally move, a storage encircling plate isfixed to the bottom of the horizontal frame, and a levelling mechanism for levelling concrete is arranged in the storage encircling plate in a lifting mode. The arranged reciprocating mechanism can drive the discharging hood to horizontally move back and forth, thus the concrete flowing out from the discharging hood can be evenly laid on different positions to be prevented from being accumulated,the workload of subsequent levelling operation is also greatly lowered, and the pouring effect of a cement terrace is better; and meanwhile, the arranged levelling mechanism can level the poured concrete in time, thus it is guaranteed that the poured concrete is not uneven, and the quality of the cement terrace is effectively improved.

Owner:GUANGDONG YUANTIAN ENG

Multifunctional vehicle carrying device

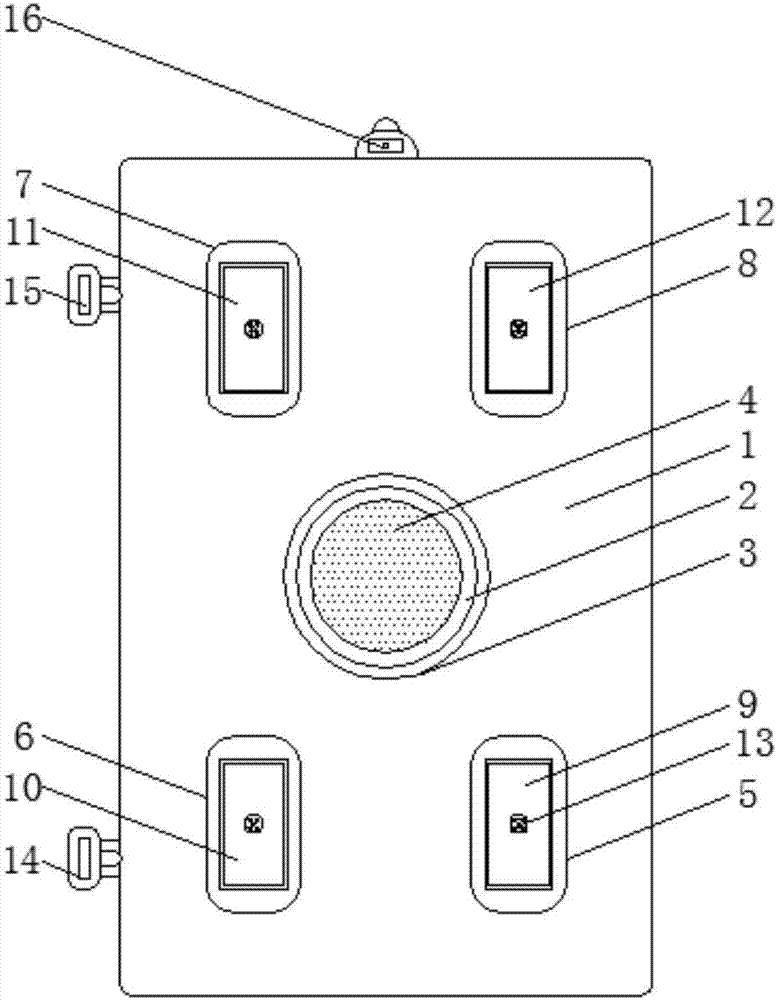

The invention discloses a multifunctional vehicle carrying device which comprises a vehicle carrying board, a rotary pallet, a first electric lifting support column, a second electric lifting support column and a controller. A vehicle carrying board body is formed by combining a steel plate layer with an alloy reinforced base layer, a photoelectric transmitter is mounted on one side of the vehicle carrying board through a bolt, a first laser displacement sensor and a second laser displacement sensor are mounted at the edge of the vehicle carrying board on one side of a second limit groove and a third limit groove, gravity sensors are mounted in the middles of the surfaces of a first lifting plate, a second lifting plate, a third lifting plate and a fourth lifting plate, the rotary pallet is mounted at an output end of the first electric lifting support column through an electric turntable bearing, and a controller is mounted on the surface of one side of a storage battery through a bolt. By the aid of a series of structures, vehicles can be effectively controlled and adjusted in the vehicle carrying process by the device.

Owner:HEFEI WEIHUA INTELLIGENT PARKING EQUIP

Unfilled corner repairing device for gypsum bricks

ActiveCN112718380APromote repairImprove work efficiencyLiquid surface applicatorsCoatingsBrickMining engineering

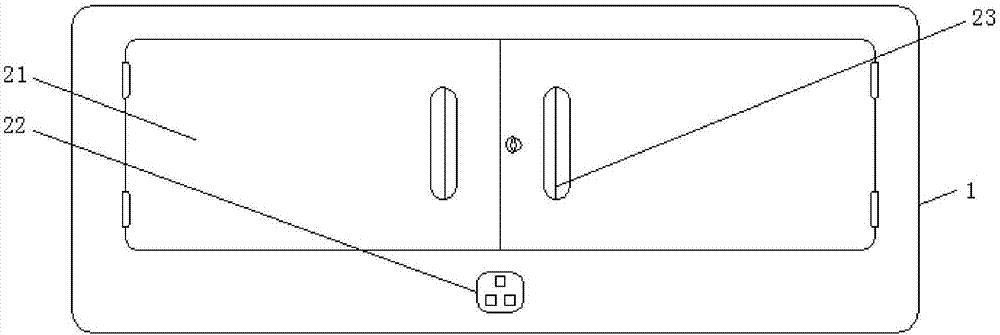

The invention discloses an unfilled corner repairing device for gypsum bricks, and belongs to the technical field of gypsum processing. The unfilled corner repairing device for the gypsum bricks comprises a workbench, a loading device, a pushing device, a clamping device, a fixing device, a stirring and extruding device, a trowelling device, a manipulator, a collecting box, an observer, a transmission belt and two conveying belts, wherein the workbench is placed on the horizontal plane; and the two conveying belts are symmetrically arranged on the workbench, the transmission belt is installed on the workbench, the observer is installed on the workbench, the loading device is installed on the workbench and located between the two conveying belts, and the pushing device, the clamping device, the fixing device, the stirring and extruding device, the trowelling device, the manipulator and the collecting box are all installed at the top of the workbench. According to the invention, the surfaces, with unfilled corners, of the gypsum bricks are adjusted through the loading device, so that the working efficiency of the overall working is increased.

Owner:常德环创力达环保科技有限公司

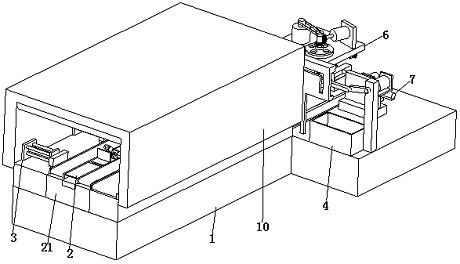

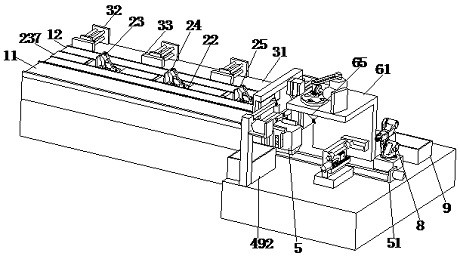

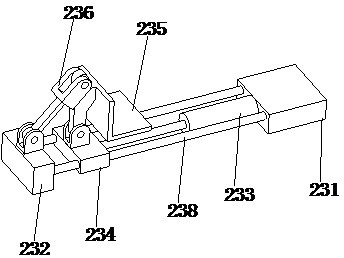

Automatic cutting device for floor heating PERT tube

InactiveCN108177179AShorten the timeSave energyMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic cutting device for a floor heating PERT tube. The automatic cutting device comprises a base plate; the upper surface of the base plate is fixedly connected with afirst sliding rod; the outer surface of the first sliding rod is connected with a first sliding sleeve in a sleeving manner; the left side surface of the first sliding sleeve is fixedly connected witha first fixing block; the lower surface of the first fixing block is fixedly connected with a rope; and the other end of the rope is fixedly connected with the outer surface of a second driving device. The automatic cutting device for the floor heating PERT tube is provided with a first driving device, the second driving device, the first sliding rod, the first sliding sleeve, a telescopic deviceand a pressing plate; a first motor is controlled to work to make a cutting wheel rotate; subsequently an output shaft of a second motor is controlled to rotate forwards so that the cutting wheel canbe used for automatically cutting a floor heating tube on a carrying plate, thus a worker does not need to use a tool to implement manual cutting, therefore the time and physical strength of the worker are saved, incision positions are smooth, and thus use of the floor heating tube is not affected.

Owner:四川德顿郎陈暖通设备有限公司

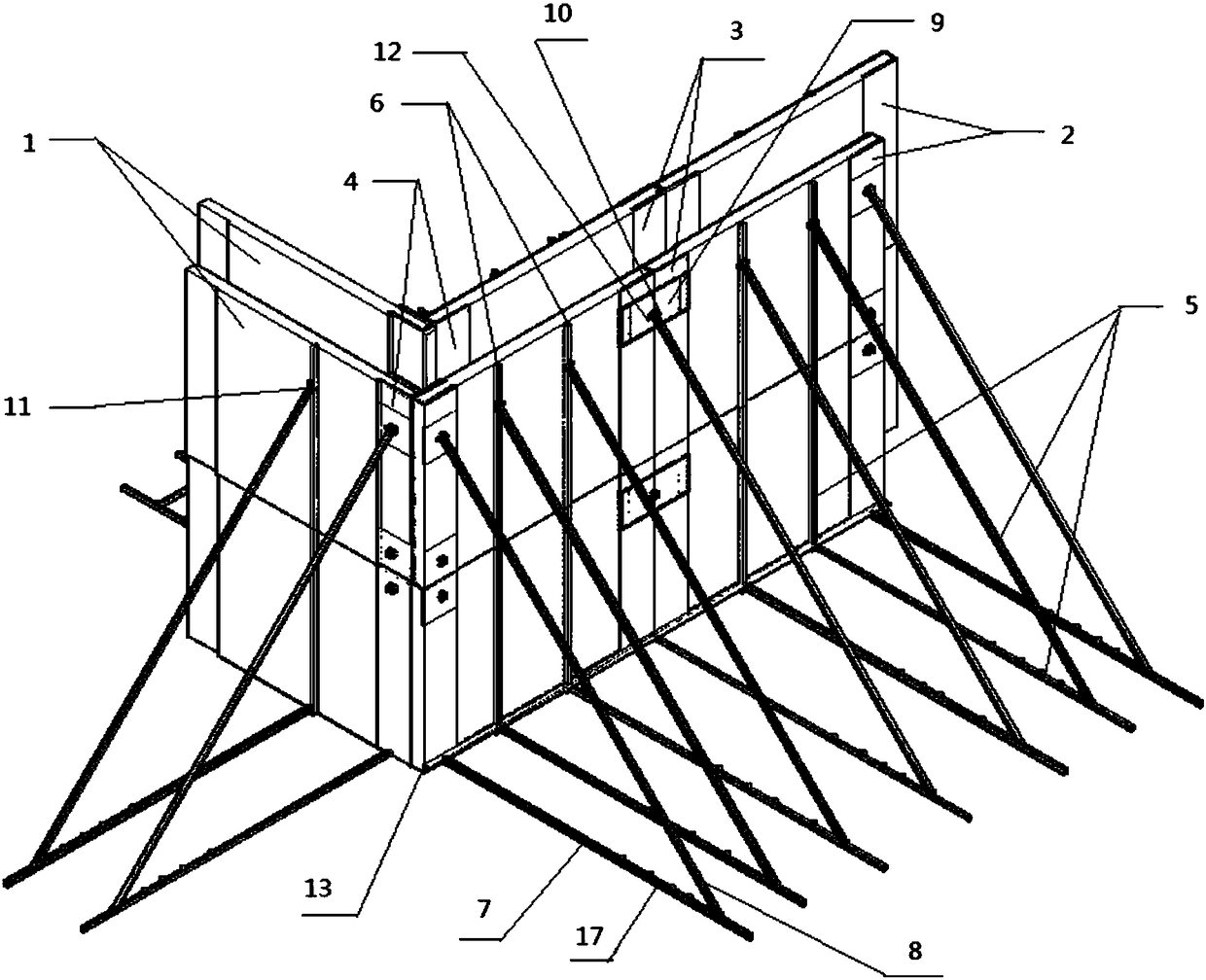

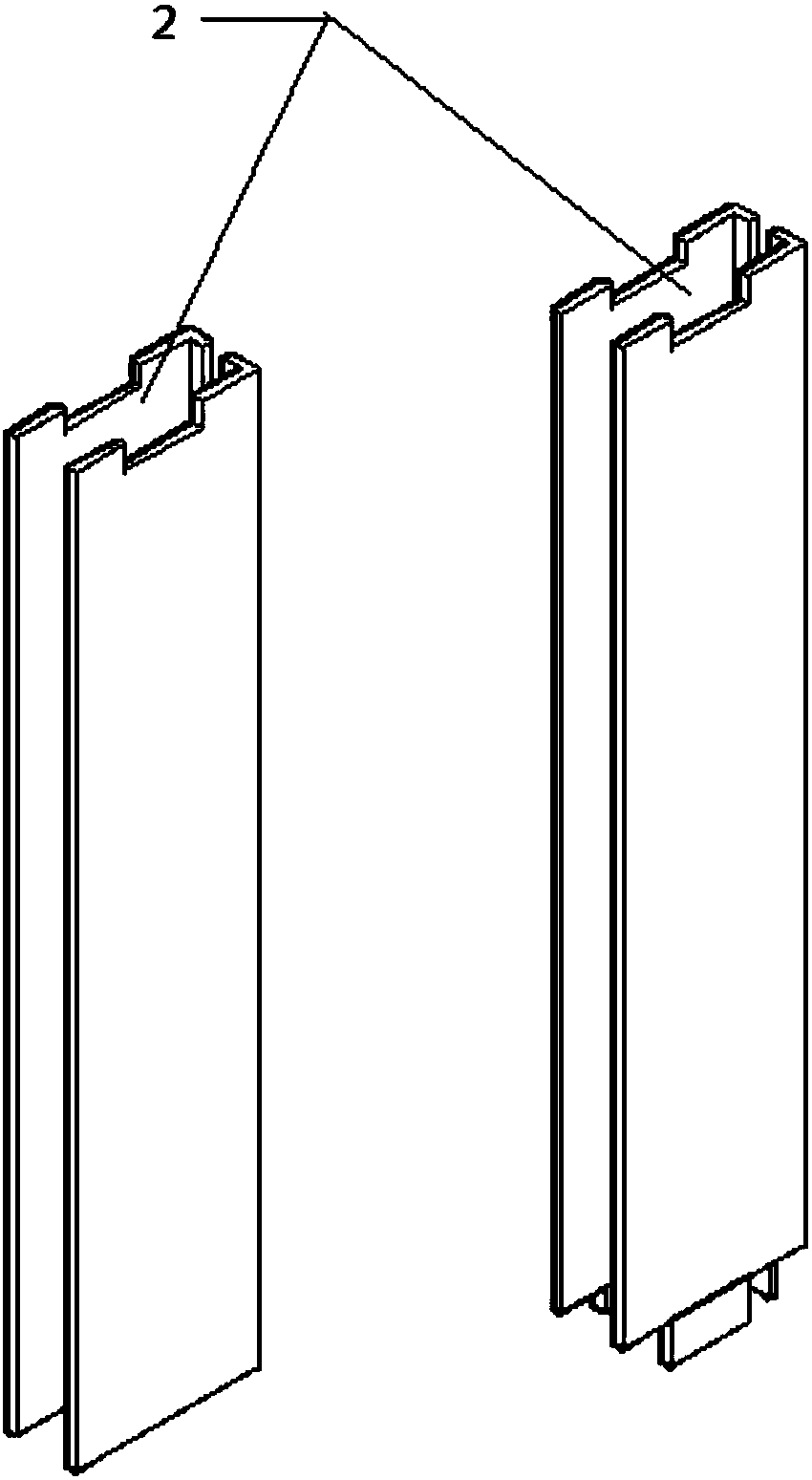

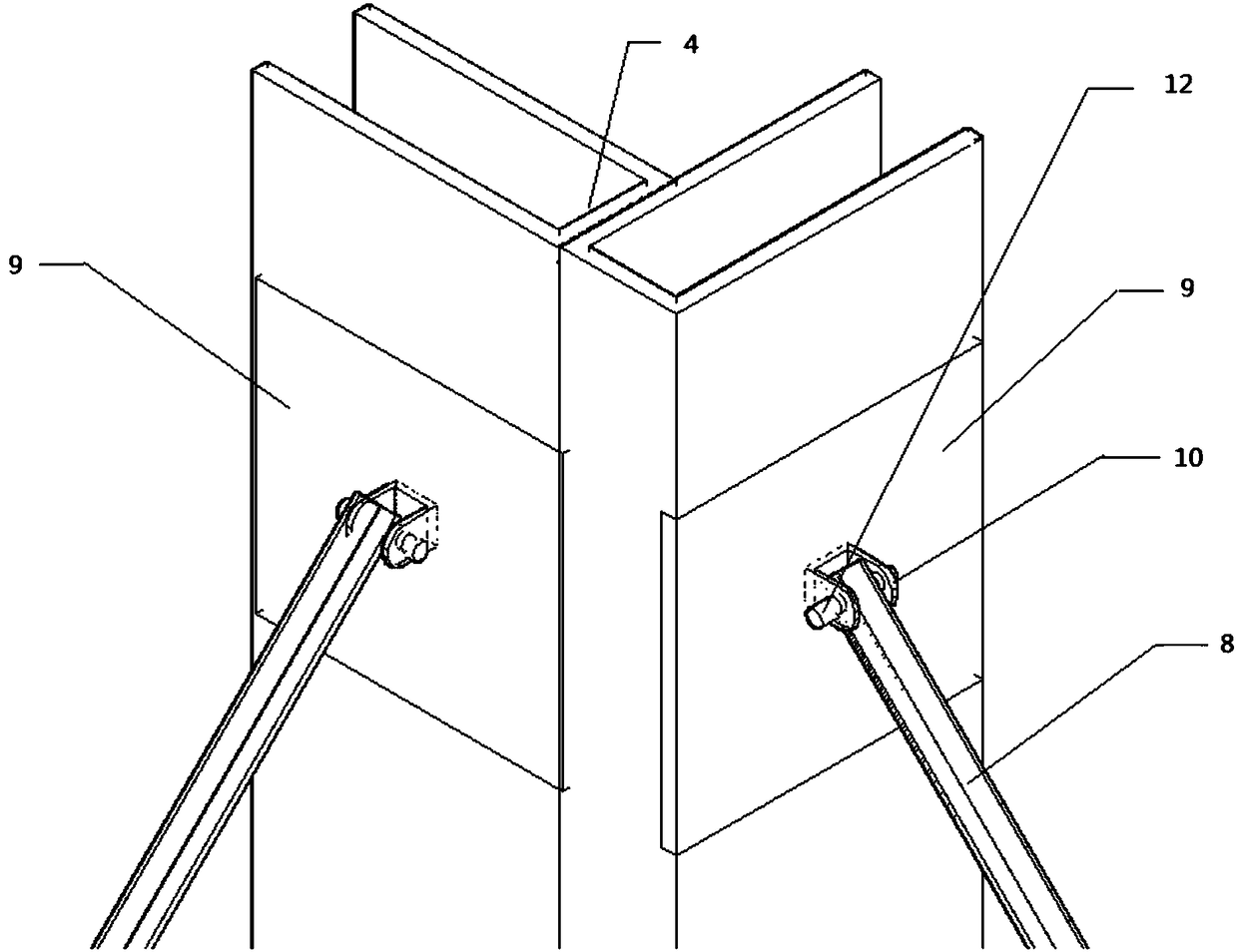

U-shaped anti-changing column and chute template system for rammed earth walls

PendingCN108571163AImprove general performanceQuality improvementForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupporting systemDynamic compaction

The invention discloses a U-shaped anti-changing column and chute template system for rammed earth walls, which can be used for special template for the construction of the linear rammer body and theL-shaped wall body. The supporting system mainly comprises three aspects: a wood-shaped smooth mold plate, a long-length U-shaped anti-changing column suitable for layer-by-layer compaction, and an adjustable high-strength section steel triangular support frame. The wooden mold plate is inserted into the standard fixed-type long-length U-shaped anti-variable column to form a whole, and the supportside is supported by the adjustable high-strength section steel triangular support frame., and mainly comprises a vertical rod, an inclined rod and a horizontal sliding rod. The two sides of the wallbody are symmetrically arranged to be supported to ensure the stable and follow layer-by-layer support and layer-by-layer compaction, the steel braced tripod square steel tube members are connected with the U-shaped anti-changing columns by pin bolts, and two U-shaped anti-changinge columns at L-shaped corner of rammed earth wall are welded together to ensure that the lateral pressure meets the strength requirements. The U-shaped anti-changing column and chute template system not only can satisfy the linear rammer, but also can realize the dynamic compaction of the L-type wall body with highquality.

Owner:TIANJIN CHENGJIAN UNIV

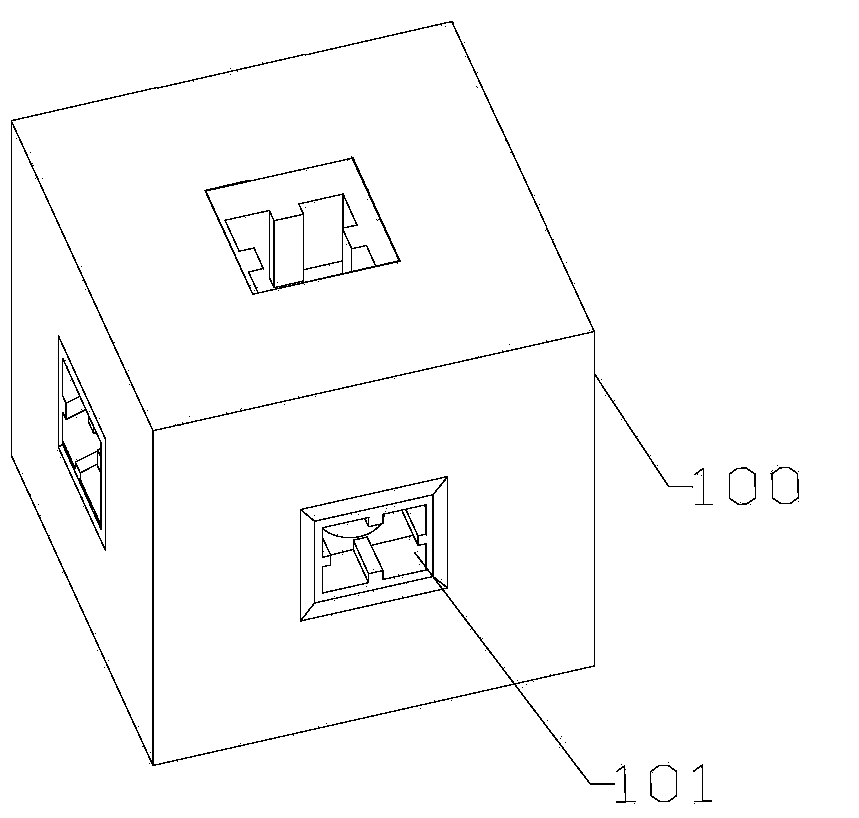

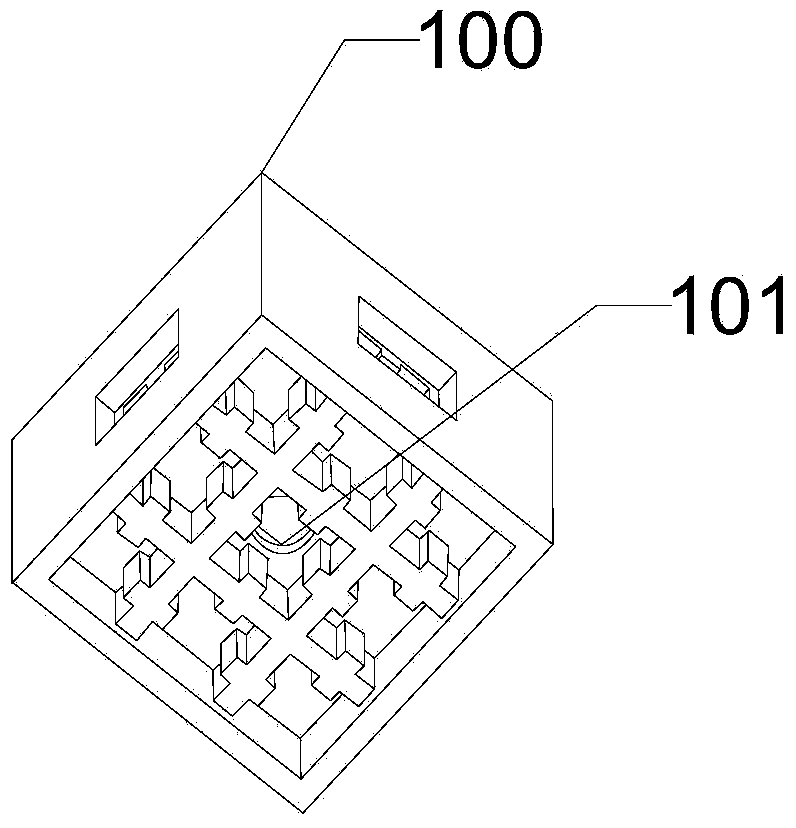

Building blocks

The invention discloses building blocks, and belongs to the field of dimensional batten toys. The building blocks comprise first core components and joining elements, wherein each first core component is a regular hexahedron; each first core component is provided with a concave hole; a corresponding joining element is inserted into each first concave hole in the length direction; each concave hole is matched with each joining element; the width of each first concave hole is matched with the width of each joining element. The invention aims to provide the building blocks to realize three dimensional splice of the building block.

Owner:雷雨

First packaged and then etched packaging structure with single chip normally installed and base islands buried and preparation method of structure

ActiveCN102856283ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesSmall holeElectrical and Electronics engineering

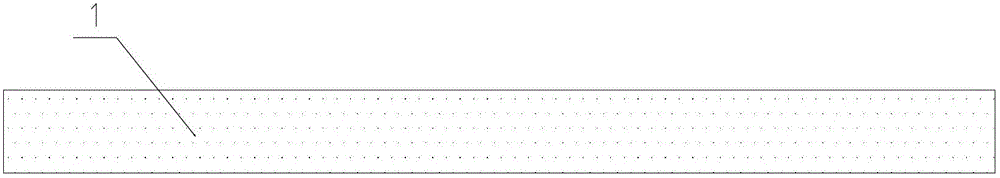

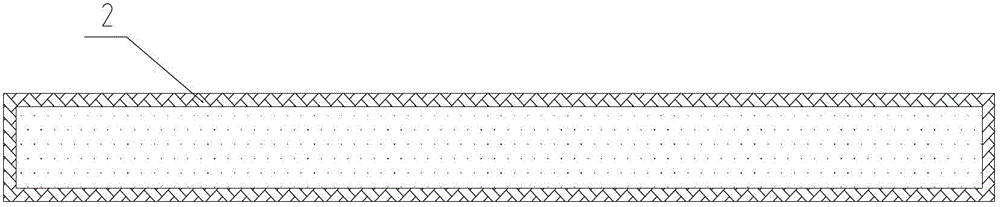

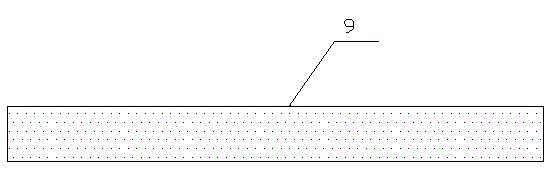

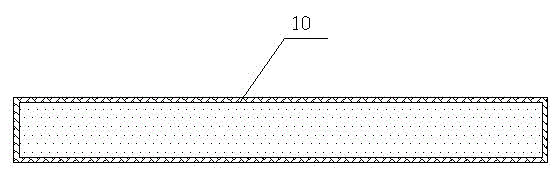

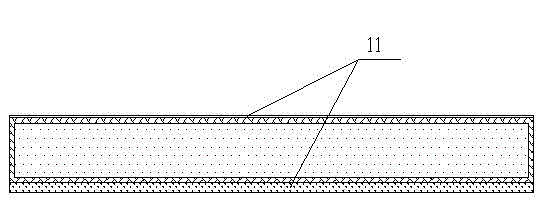

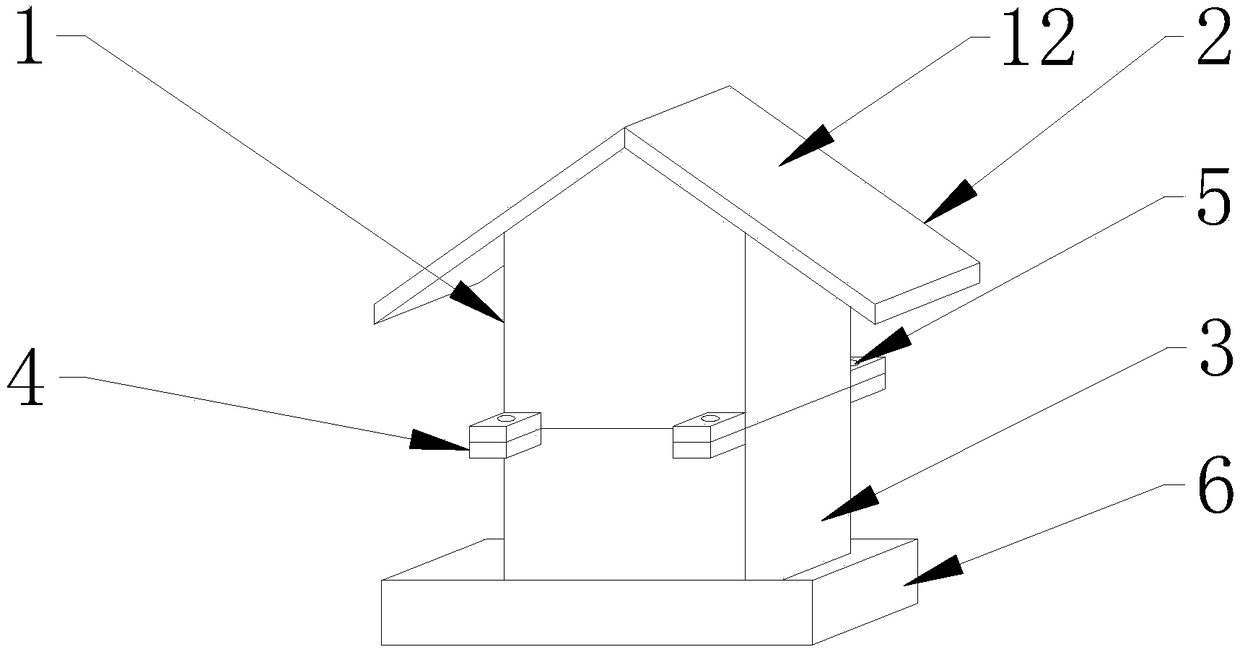

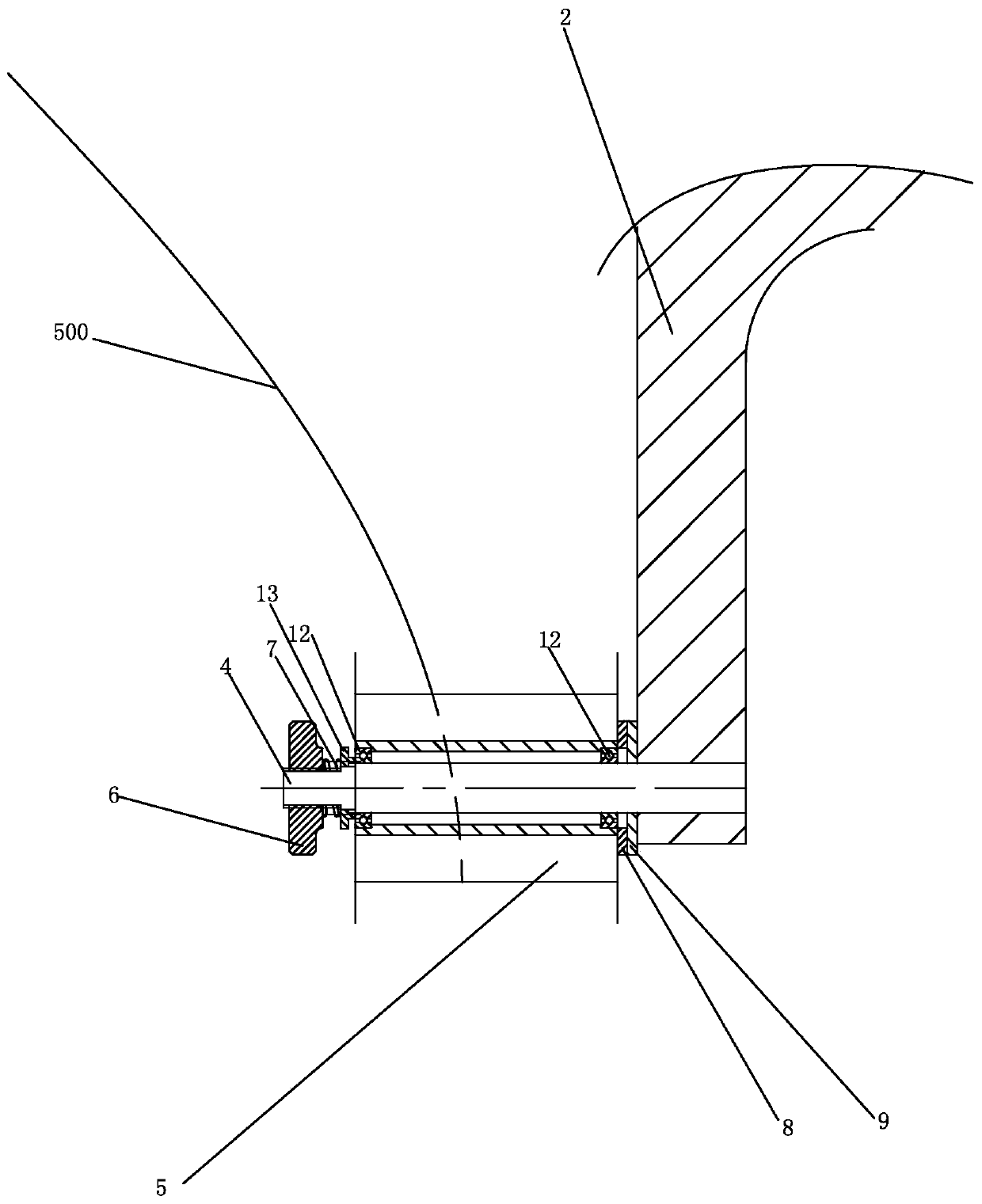

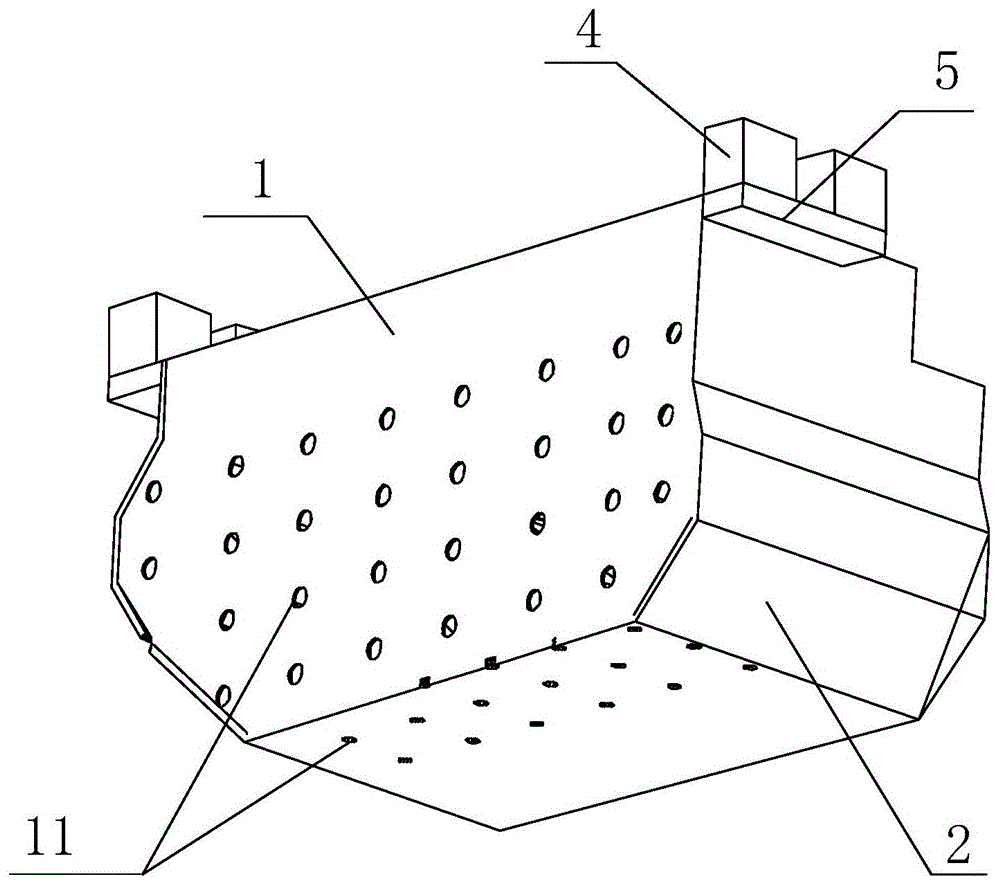

The invention relates to a first packaged and then etched packaging structure with a single chip normally installed and base islands buried and a preparation method of the structure. The structure comprises base islands (1) and pins (2), wherein a chip (4) is arranged on the fronts of the base islands (1); the front face of the chip (4) and the front faces of the pins (2) are connected by metal wires (5); plastic package materials (6) are arranged in the surrounding regions of the base islands (1) and the pins (2) and outside the chip (4) and the metal wires (5); small holes (7) are formed on the surfaces of the plastic package materials (6) on the lower parts of the pins (2); the small holes (7) are communicated with the backs of the pins (2); metal balls (9) are arranged in the small holes (7); and the metal balls (9) are contacted with the backs of the pins (2). The packaging structure and the preparation method have the following beneficial effects that the preparation cost is reduced; the safety and reliability of the packaging body are improved; environmental pollution is reduced; and design and preparation of high-density circuits are truly achieved.

Owner:JCET GROUP CO LTD

Packaging-first and etching-later manufacturing method for chip formal double-surface three-dimensional circuit and packaging structure of chip formal double-surface three-dimensional circuit

ActiveCN102723287ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityEtching

The invention relates to a packaging-first and etching-later manufacturing method for a chip formal double-surface three-dimensional circuit. The method comprises the following technology steps of taking a metal substrate; pre-plating copper material on the surface of the metal substrate; carrying out the operation of pasting a photo-resisting film; removing a part of the photo-resisting film from the front surface of the metal substrate; electro-plating an inert metal circuit layer; electro-plating a metal circuit layer; packaging; carrying out the operation of pasting the photo-resisting film; tapping on the surface of plastic package material; electro-plating the metal circuit layer; coating bonding materials; installing a chip; bonding with metal wires; packaging; carrying out the operation of pasting the photo-resisting film; chemical-etching; electro-plating the metal circuit layer; packaging; tapping on the surface of plastic package material; digging a groove on the surface of the plastic package material; electro-plating the metal circuit layer; coating a circuit screen plate; pre-processing of metallization; removing the metal screen plate; electro-plating the metal circuit layer; packaging; tapping on the surface of plastic package material; cleaning; implanting a metal ball; and cutting a finished product. The method disclosed by the invention has the beneficial effects that the manufacturing cost is lowered, the safety and the reliability of a packaging body are increased, the environment pollution is reduced, and the design and the manufacturing of a high-density circuit can be really realized.

Owner:JCET GROUP CO LTD

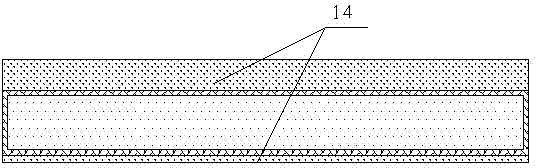

First etched and then packaged packaging structure with single chip reversedly installed and base islands buried as well as preparation method thereof

ActiveCN102856290ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densitySingle chip

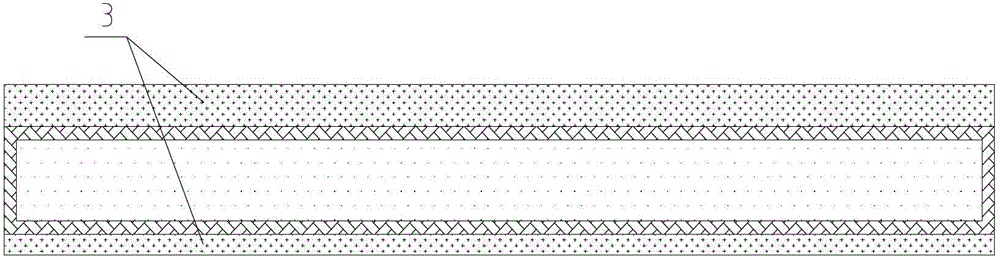

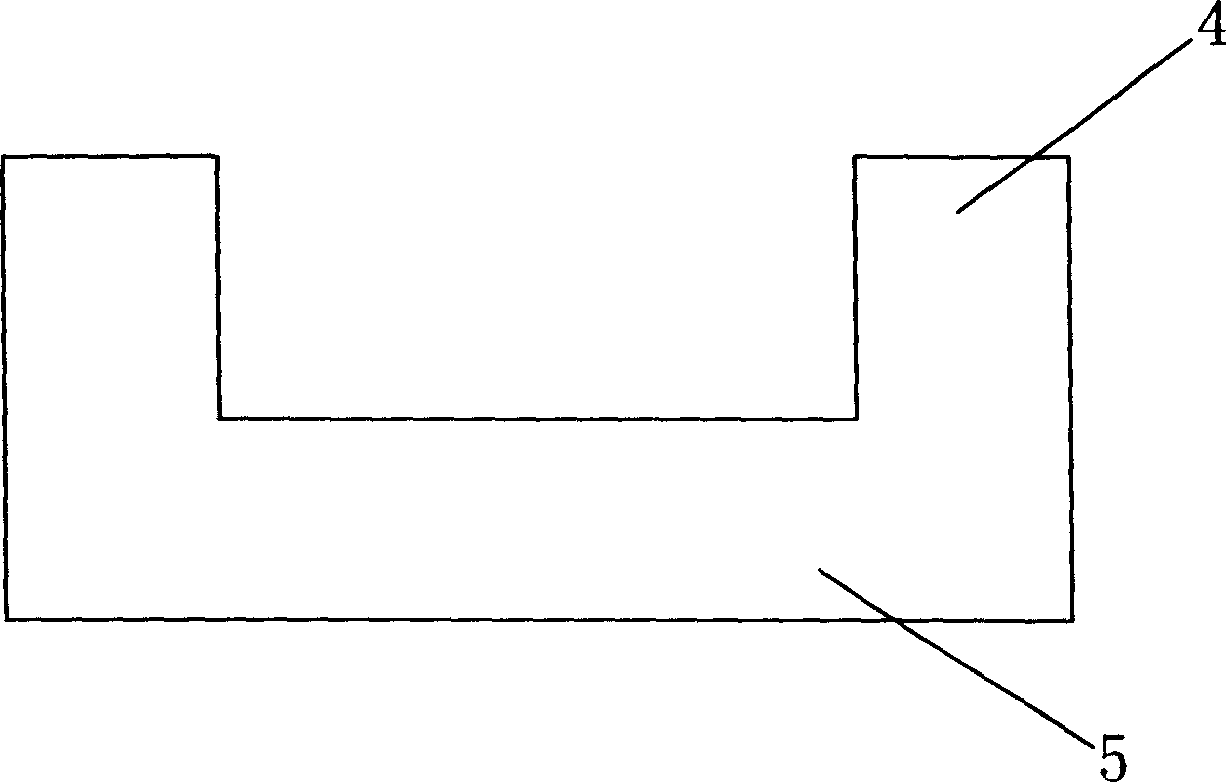

The invention relates to a first etched and then packaged packaging structure with a single chip reversedly installed and base islands buried as well as a preparation method thereof. The packaging structure comprises base islands (1), pins (2) and a chip (3), wherein the chip is reversedly installed on the fronts of the base islands and the fronts of the pins; underfills (14) are arranged between the bottom of the chip and the fronts of the base islands and the pins; plastic package materials (4) are arranged in the peripheral regions of the base islands, the regions between the base islands and the pins, the regions between the pins, the regions on the upper parts of the base islands and the pins and the regions on the lower parts of the base islands and the pins and on the periphery of the chip; small holes (5) are arranged on the plastic package materials on the backs of the pins and are communicated with the backs of the pins; and metal balls (7) are arranged in the small holes and are contacted with the backs of the pins. The packaging structure and the preparation method have the following beneficial effects that the preparation cost is reduced; the safety and reliability of the packaging body are improved; environmental pollution is reduced; and design and preparation of high-density circuits are truly achieved.

Owner:JCET GROUP CO LTD

Multi-chip horizontal packaging, etching-after-packaging and pad exposed packaging structure and manufacturing method thereof

ActiveCN102856287ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityBiomedical engineering

The invention relates to a multi-chip horizontal packaging, etching-after-packaging and pad exposed packaging structure and a manufacturing method thereof. The structure comprises pads (1) and pins (2). A plurality of chips (4) are arranged on the right sides of the pads (1), and the right sides of the chips (4) and the pins (2) are connected through metal wires (5). Molding compounds (6) are packaged on the peripheries of the pads (1) and the pins (2) and outside the chips (4) and the metal wires (5). Holes (7) are opened on the surfaces of the molding compounds (6) on the lower portions of the pads (1) and the pins (2). Metal balls (9) are arranged in the holes (7) and contacted with the reverse sides of the pads (1) or the pins (2). The multi-chip horizontal packaging, etching-after-packaging and pad exposed packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, reducing environmental pollution, and being capable of designing and manufacturing high-density lines.

Owner:星科金朋半导体(江阴)有限公司

Multi-chip reversely-arranged etched-encapsulated base island-exposed encapsulating structure and manufacturing method thereof

ActiveCN102867802ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityAdhesive

The invention relates to a multi-chip reversely-arranged etched-encapsulated base island-exposed encapsulating structure and a manufacturing method thereof. The structure comprises a base island (1), a pin (2) and a plurality of chips (3), wherein the chips (3) are reversely arranged on the front faces of the base island (1) and the pin (2); bottom filling adhesives (14) are arranged between the bottoms of the chips (3) and the front faces of the base island (1) and the pin (2); plastic sealing materials (4) are enveloped in a region on the periphery of the base island (1), a region between the base island (1) and the pin (2) and a region between adjacent pins (2) and outside the chips (3); the surfaces of the plastic sealing materials (4) on the lower parts of the base island (1) and the pin (2) are provided with small holes (5); and metal balls (7) are arranged in the small holes (5). The multi-chip reversely-arranged etched-encapsulated base island exposing encapsulating structure has the beneficial effects that the manufacturing cost is lowered, the safety and the reliability of an encapsulating body are enhanced, environmental pollution is lowered, and design and manufacturing of a high-density circuit are realized truly.

Owner:JCET GROUP CO LTD

Multi-chip flip, etching-after-packaging and pad exposed packaging structure and manufacturing method thereof

ActiveCN102856284ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityBiomedical engineering

The invention relates to a multi-chip flip, etching-after-packaging and pad exposed packaging structure and a manufacturing method thereof. The structure comprises pads (1), pins (2) and a plurality of chips (3). The plurality of the chips (3) are arranged on the right sides of the pads (1) and the pins (2) in an inverted mode. Bottom filling glue (14) is arranged between the bottoms of the plurality of the chips (3) and the right sides of the pads (1) and the pins (2). Molding compounds (4) are packaged in areas on the peripheries of the pads (1), between the pads (1) and the pins (2), among the pins (2) and outside the plurality of the chips (3). Holes (5) are opened on the surfaces of the molding compounds (4) on the lower portions of pads (1) and the pins (2), and metal balls (7) are arranged in the holes (5). The multi-chip flip, etching-after-packaging and pad exposed packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, reducing environmental pollution, and being capable of designing and manufacturing high-density lines.

Owner:JCET GROUP CO LTD

Multi-chip reversely-arranged etched-encapsulated base island-buried encapsulating structure and manufacturing method thereof

ActiveCN102867791ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityAdhesive

The invention relates to a multi-chip reversely-arranged etched-encapsulated base island-buried encapsulating structure and a manufacturing method thereof. The structure comprises a base island (1), a pin (2) and a plurality of chips (3), wherein the chips (3) are reversely arranged on the front faces of the base island and the pin; bottom filling adhesives (14) are arranged between the bottoms of the chips and the front faces of the base island and the pin; plastic sealing materials (4) are enveloped in a region on the periphery of the base island, a region between the base island and the pin, a region between adjacent pins, regions on the upper parts of the base island and the pin, regions on the lower parts of the base island and the pin and the peripheries of the chips; the plastic sealing materials on the back face of the pin are provided with small holes (5); and metal balls (7) are arranged in the small holes (5), and are contacted with the back face of the pins. The multi-chip reversely-arranged etched-encapsulated base island-buried encapsulating structure has the beneficial effects that the manufacturing cost is lowered, the safety and the reliability of an encapsulating body are enhanced, environmental pollution is lowered, and design and manufacturing of a high-density circuit are realized truly.

Owner:JCET GROUP CO LTD

Convenient-to-mount and convenient-to-dismount high-intensity steel formwork with high protection performance for house building

InactiveCN109372249APrevent rustImprove practicalityForming/stuttering elementsForm treatmentEngineeringSteel frame

The invention discloses a convenient-to-mount and convenient-to-dismount high-intensity steel formwork with high protection performance for house building. The high-intensity steel formwork comprisesa wall body steel formwork, wherein the top end of the wall body steel formwork is movably connected with a roof steel formwork; the top of the roof steel formwork is movably connected with a roof upper telescopic tube; the middle position inside the roof upper telescopic tube is movably connected with a roof steel module; the inner side of the bottom of a roof lower telescopic tube is fixedly connected with a roof connection threaded module; the middle position of the top end inside the wall body steel formwork is fixedly connected with a steel house beam module; and the middle position inside the wall body steel formwork is fixedly connected with a wall body cooling module. During the steel forging, liquid in a cast mold is subjected to temperature reduction and cooling; when a steel structure house prefabricated high-intensity steel formwork is used, the temperature reduction and cooling are also needed; through the wall body cooling module, a house steel frame casted by the steel structure house prefabricated high-intensity steel formwork can be cooled, so that the house steel frame can be fast put into use; and the work efficiency of the steel structure house prefabricated high-intensity steel formwork is effectively improved.

Owner:HUNAN WUXIN MACHINERY

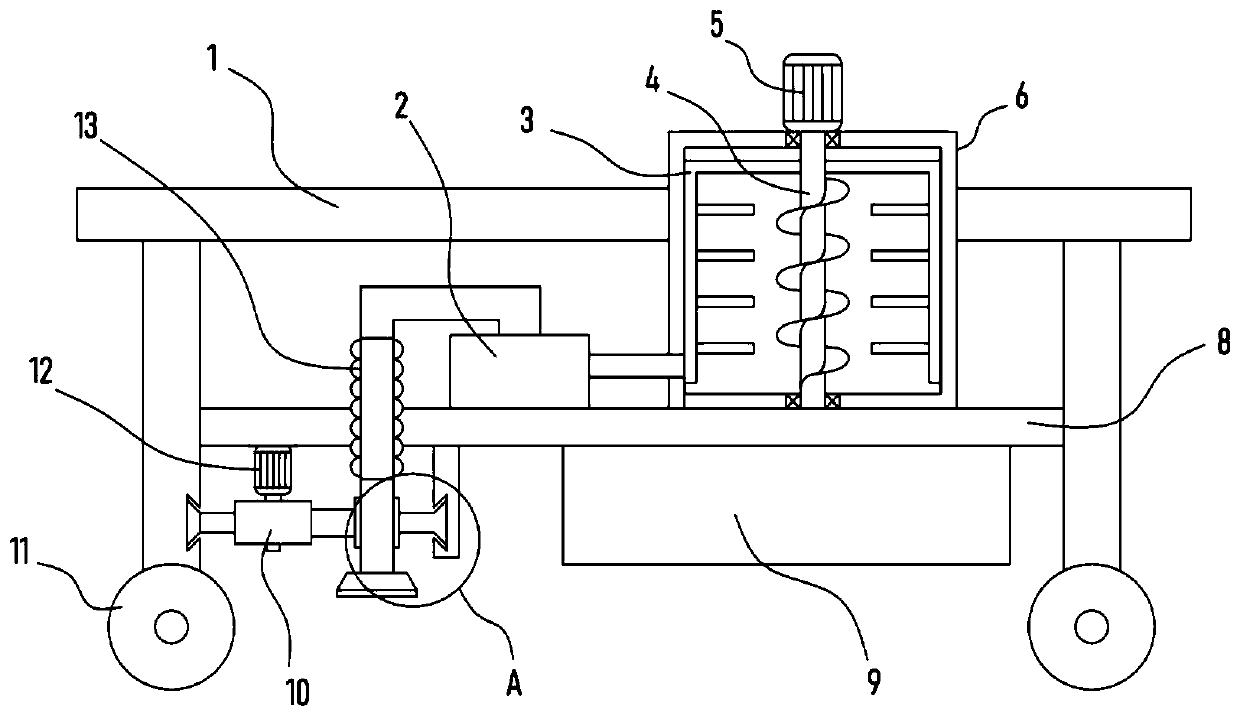

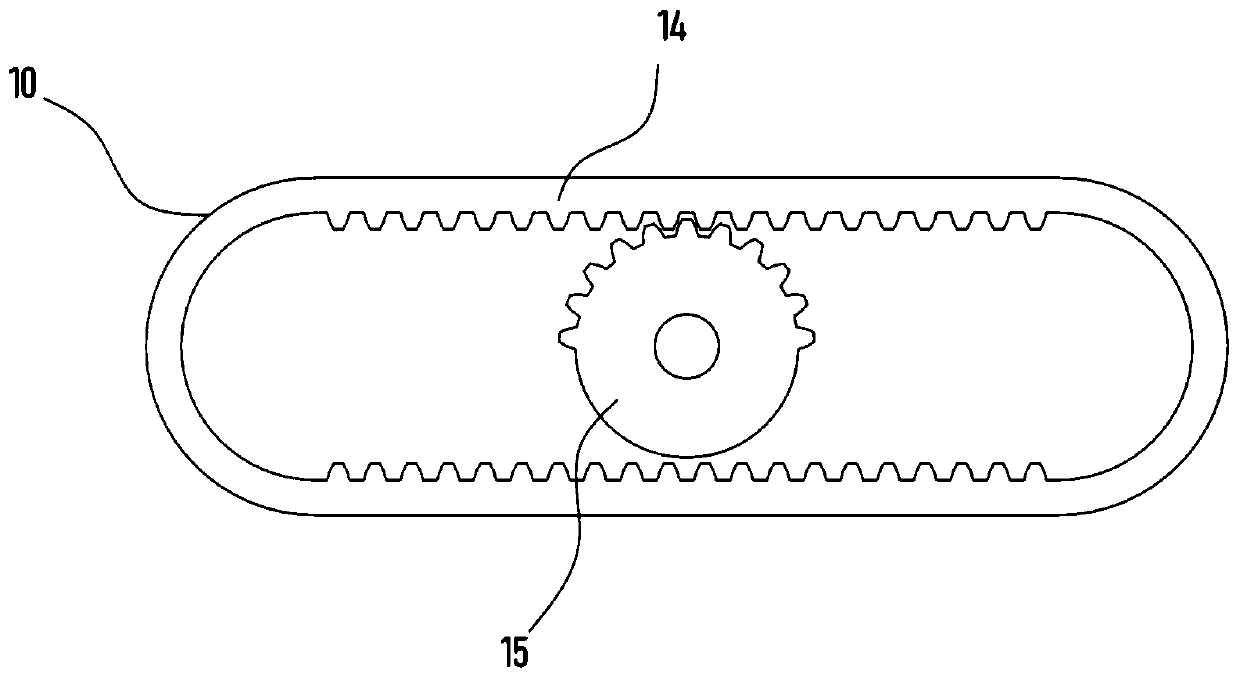

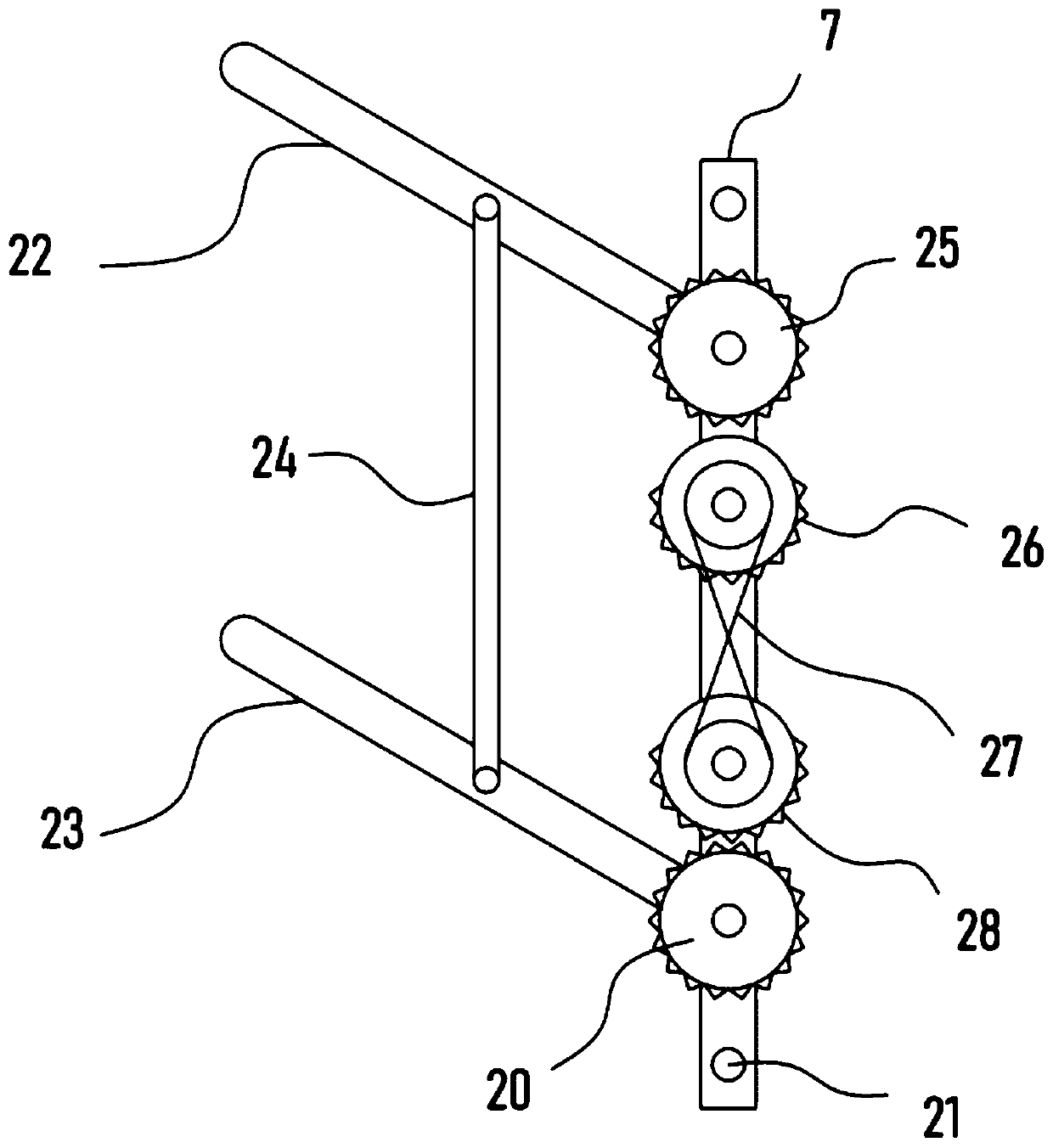

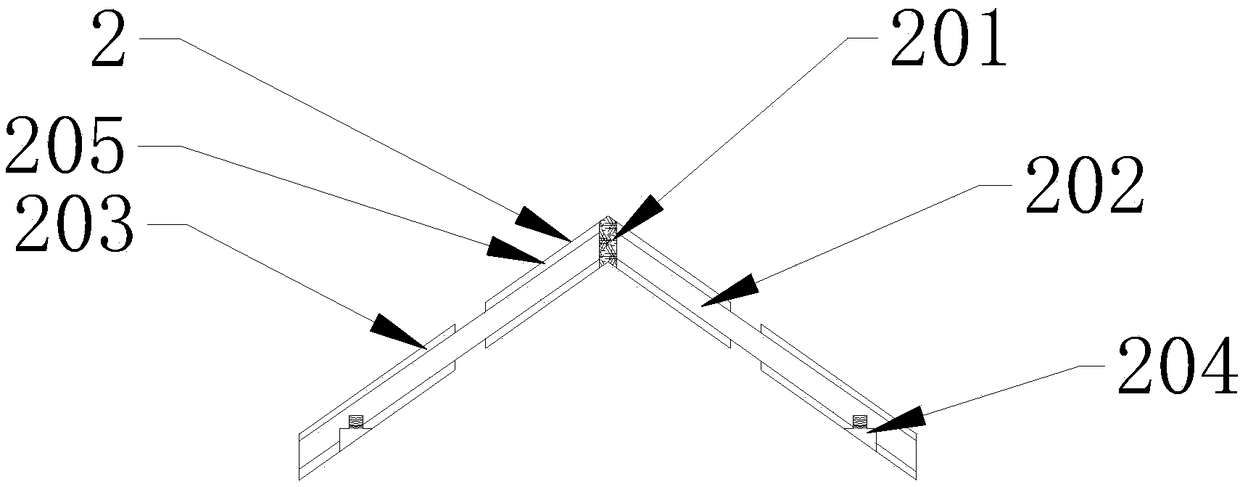

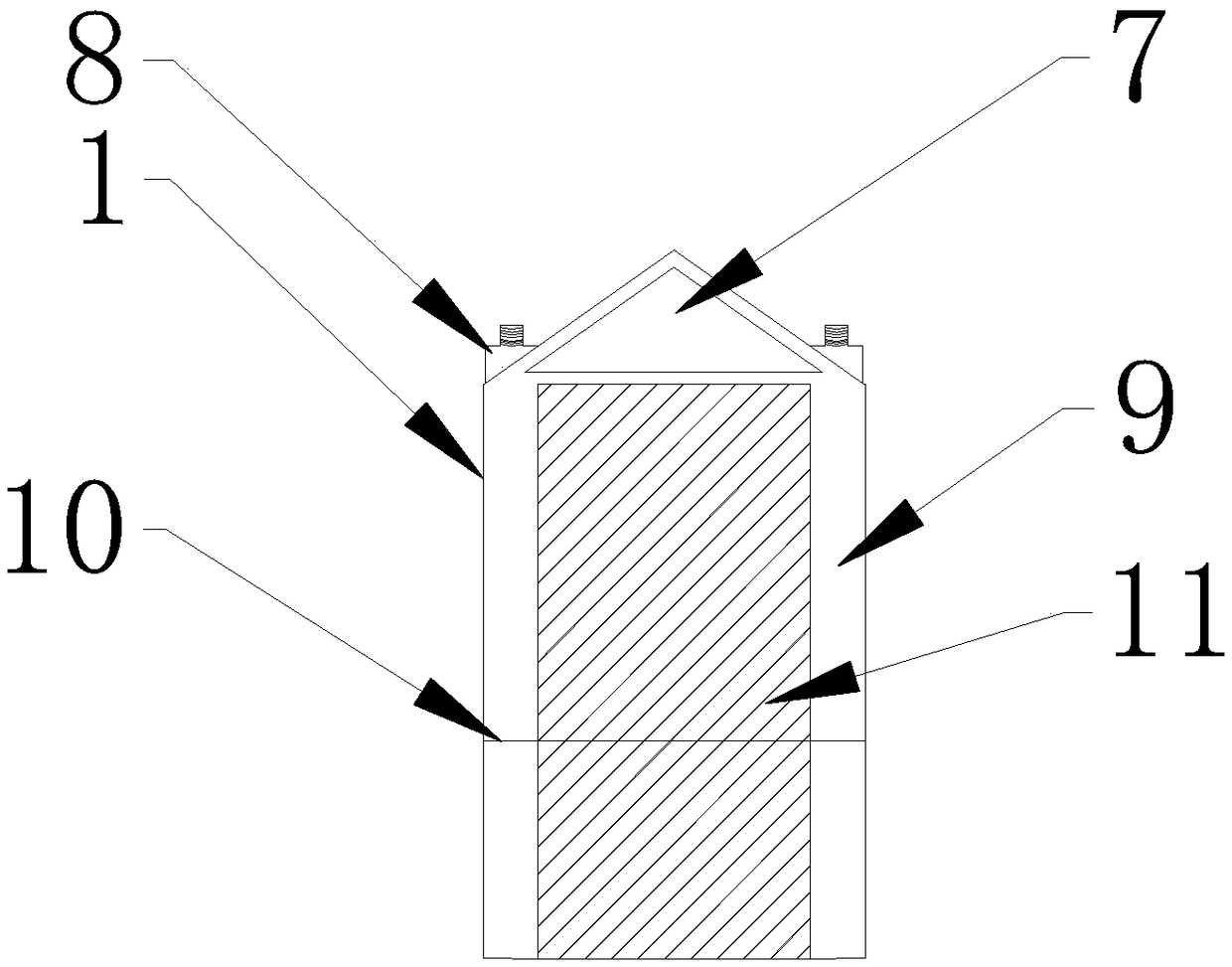

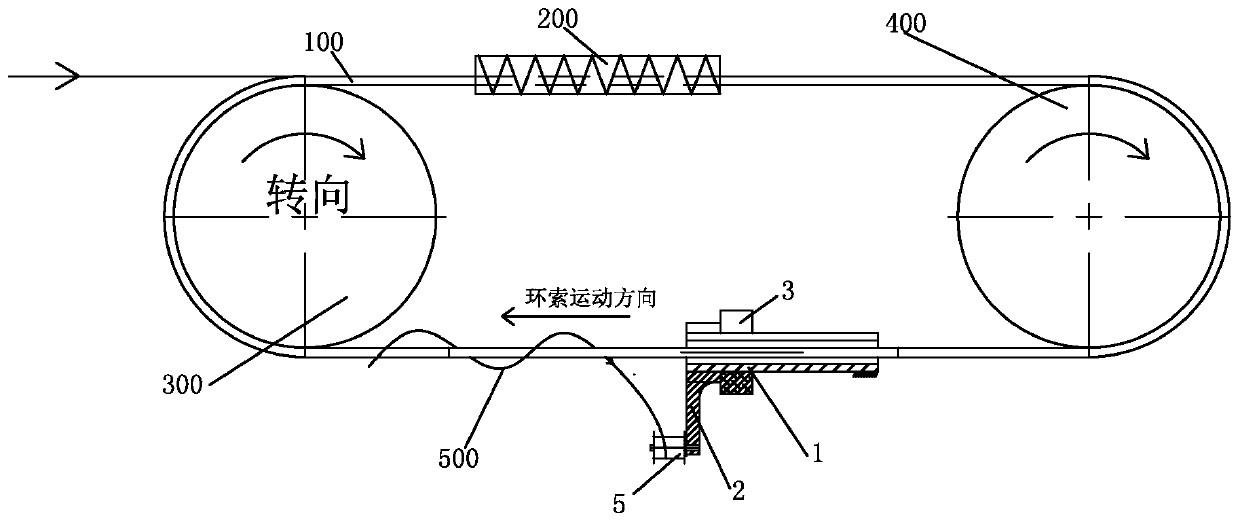

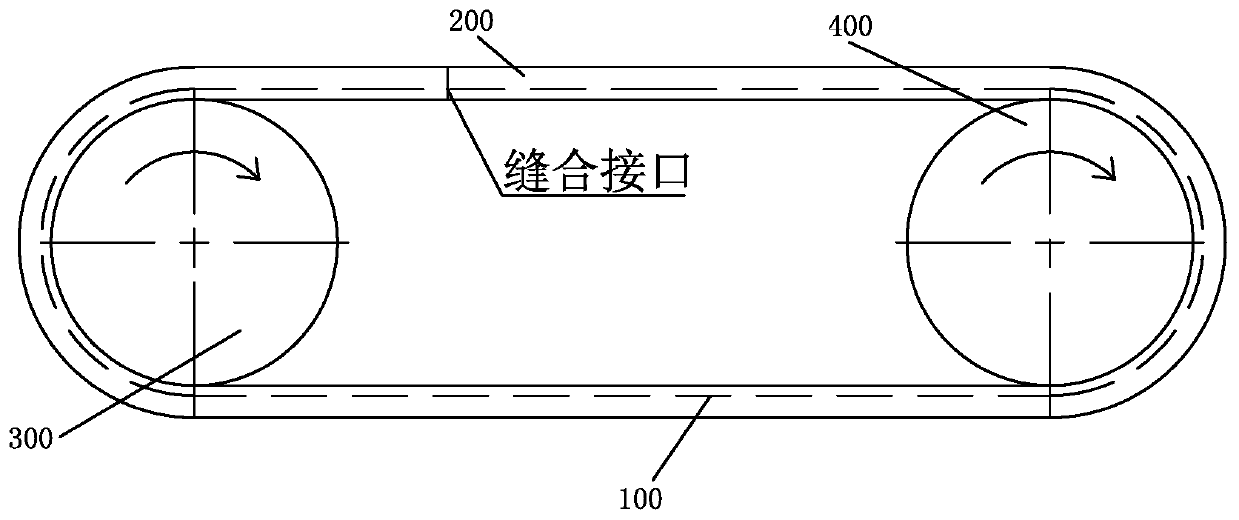

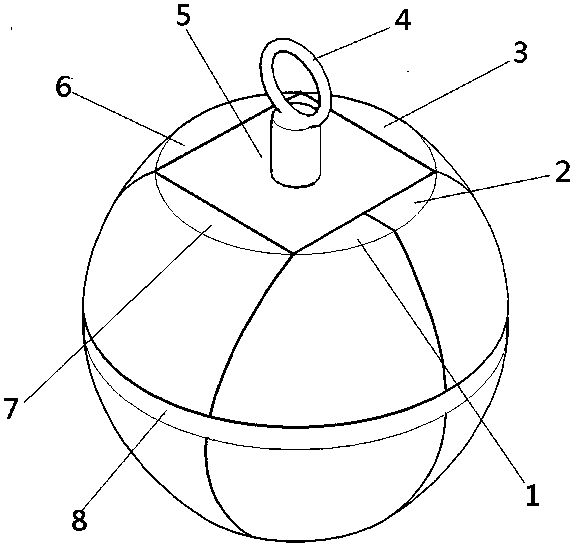

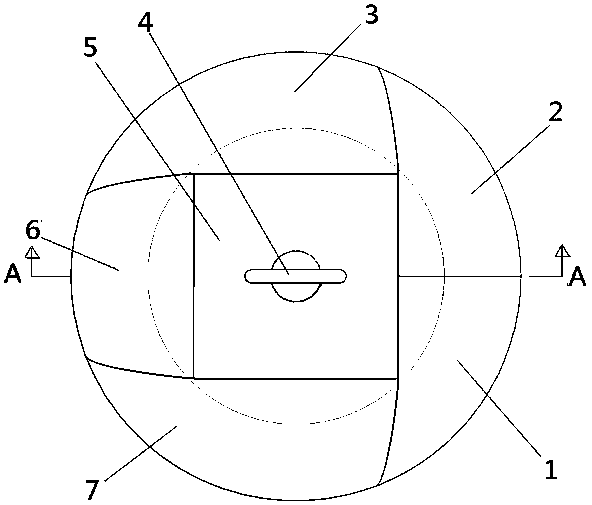

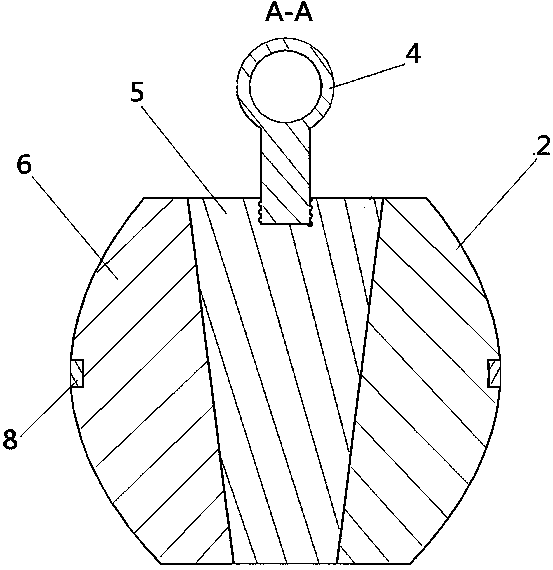

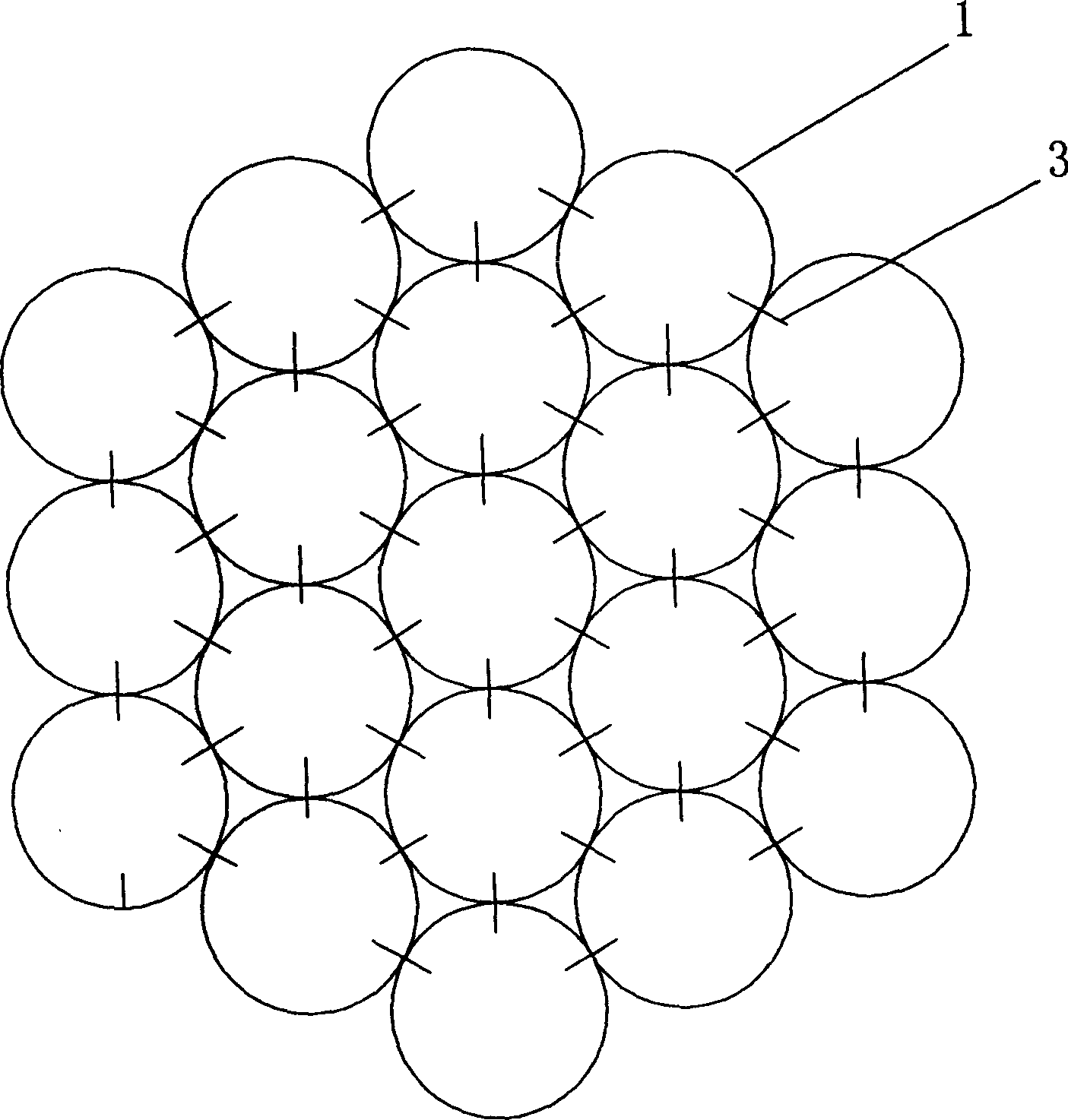

Method for manufacturing annular lifting belt with weft constraint

ActiveCN110241640AQuality improvementIncreased durabilityRope making machinesLoad-engaging elementsFiberDrive wheel

The invention provides a method for manufacturing an annular lifting belt with weft constraint. The method comprises the steps that a fiber tow penetrates through a sheath in a laminated state, and sheaths a driving wheel and driven wheel of winding equipment, and tensioning is carried out; a threadlet tow winds round the fiber tow; the winding equipment is started, a motor of the winding equipment drives the driving wheel to rotate, the driving wheel rotates to drive the annular fiber tow to rotate, at the same time, a rotating device drives the threadlet tow to wind round the fiber tow to constrain the fiber tow and a multi-bundle annular loop is formed through rotation, and the production of a bearing core of the annular lifting belt is completed; after the threadlet tow winds a certain number of turns, the sheath is pulled apart, and the two ends of the annular loop are stitched to complete the production of the annular lifting belt. The method for manufacturing the annular lifting belt with the weft constraint has the advantages that the threadlet tow is used for constraining the fiber tow to prevent the fiber tow from loosening and being misplaced, which can improve the utilization of the tow, reduce the production cost, and improve the use stability of the produced annular lifting belt.

Owner:JULI SLING

Single-side three-dimensional circuit chip upside-down-charging packaging-before-etching method and packaging structure thereof

ActiveCN102760668ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesPlastic packagingHigh density

The invention relates to a single-side three-dimensional circuit chip upside-down-charging packaging-before-etching method, which comprises the following process steps: taking a metal baseplate; pre-plating copper on the surface of the metal baseplate; pasting light resistant films; removing part of the light resistant films on the front surface of the metal baseplate; electroplating an inert metal circuit layer; electroplating a metal circuit layer; pasting light resistant films; removing part of the light resistant films on the front surface of the baseplate; electroplating a metal circuit layer; removing the light resistant films on the surface of the metal baseplate; encapsulating; processing before metallization; electroplating a metal circuit layer; removing the light resistant films on the surface of the metal baseplate; mounting a chip and filling the bottom of the chip; encapsulating; chemically etching; removing the light resistant films on the surface of the metal baseplate; electroplating a metal circuit layer; encapsulating; cutting holes in the surface of plastic packaging materials; washing; mounting balls; and cutting finished products. The method and the structure disclosed by the invention has the benefits that the manufacture cost is lowered, the safety and reliability of the packaged body are improved, and the environment pollution is reduced, so that design and manufacture of high-density circuits are realized actually.

Owner:JCET GROUP CO LTD

Packaging-first and etching-later manufacturing method for chip formal single-surface three-dimensional circuit and packaging structure of chip formal single-surface three-dimensional circuit

ActiveCN102723290ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityEtching

The invention relates to a packaging-first and etching-later manufacturing method for a chip formal single-surface three-dimensional circuit. The method comprises the following technology steps of taking a metal substrate; pre-plating copper material on the surface of the metal substrate; carrying out the operation of pasting a photo-resisting film; removing a part of the photo-resisting film from the front surface of the metal substrate; electro-plating an inert metal circuit layer; electro-plating a metal circuit layer; carrying out the operation of pasting a photo-resisting film; removing a part of the photo-resisting film from the front surface of the metal substrate; electro-plating the metal circuit layer; removing the photo-resisting film on the surface of the metal substrate; packaging; pre-processing of metallization; electro-plating the metal circuit layer; removing the photo-resisting film on the surface of the metal substrate; coating bonding materials; installing a chip; bonding with metal wires; packaging; carrying out the operation of pasting the photo-resisting film; removing a part of the photo-resisting film from the back surface of the metal substrate; chemical-etching; removing the photo-resisting film on the surface of the metal substrate; electro-plating the metal circuit layer; packaging; tapping on the surface of plastic package material; cleaning; implanting a metal ball; and cutting a finished product. The method disclosed by the invention has the beneficial effects that the manufacturing cost is lowered, the safety and the reliability of a packaging body are increased, the environment pollution is reduced, and the design and the manufacturing of a high-density circuit can be really realized.

Owner:JCET GROUP CO LTD

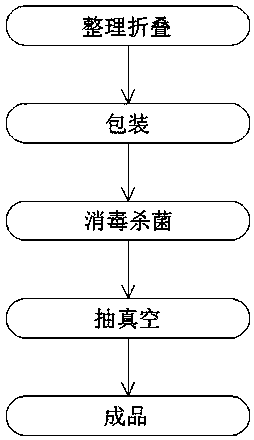

Vacuumizing disinfection method of underpants

InactiveCN110481910AAvoid contaminationAvoid breedingPackaging by pressurising/gasifyingChemicalsHazardous substanceEthylene oxide

The invention provides a vacuumizing disinfection method of underpants. The vacuumizing disinfection method of the underpants includes following steps: tidying and folding, packing, performing disinfection and sterilization, vacuumizing, and obtaining the finished products. The vacuumizing disinfection method of the underpants is reasonable in design, can pump out EO (ethylene oxide) gas possiblyremaining and other hazardous substances possibly existing after the sterilization is completed so as to form a vacuum tight environment, and can be prevented from infecting or breeding other harmfulbacteria in the preservation process, and is high in safety.

Owner:广州酷凯贸易有限公司

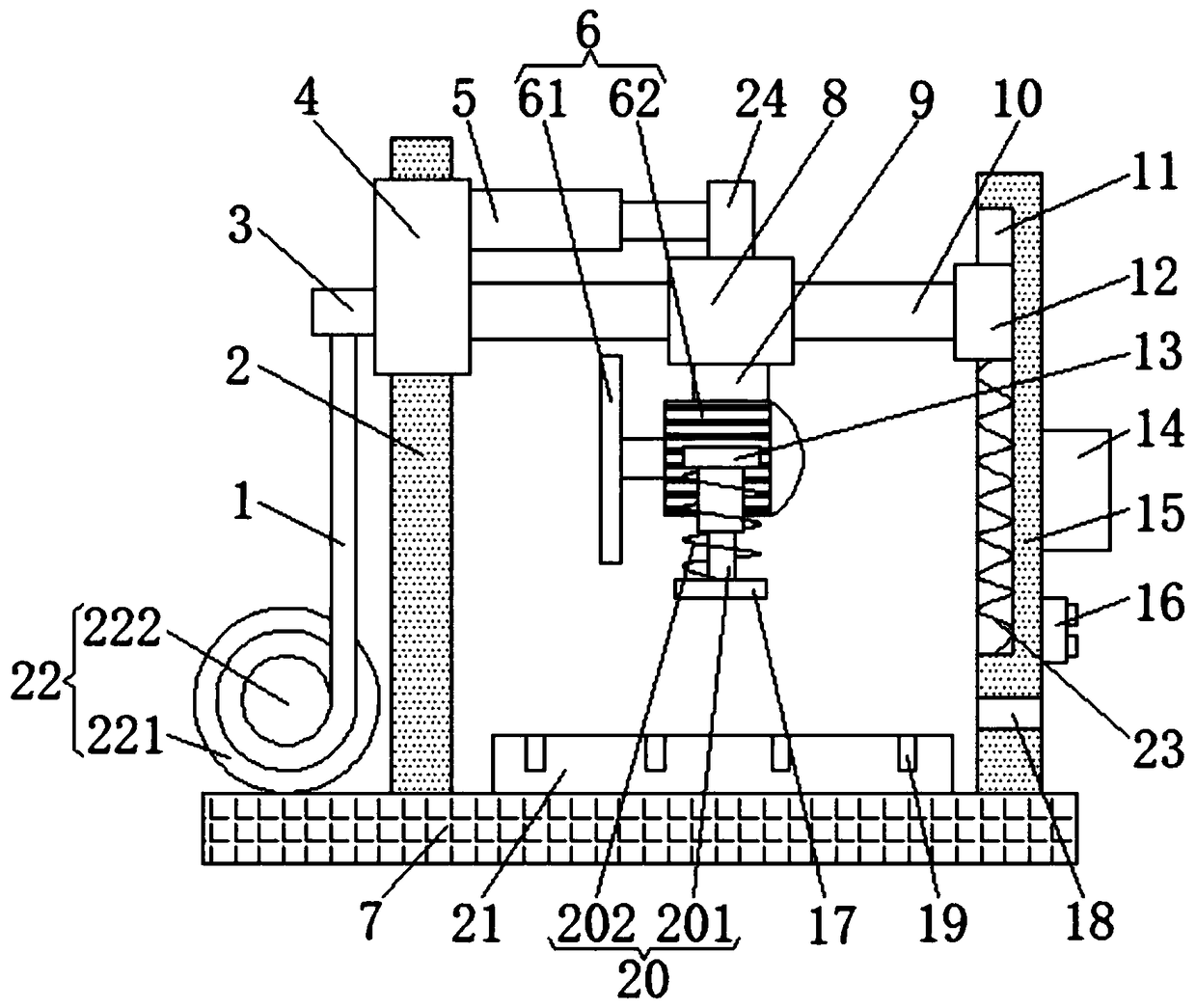

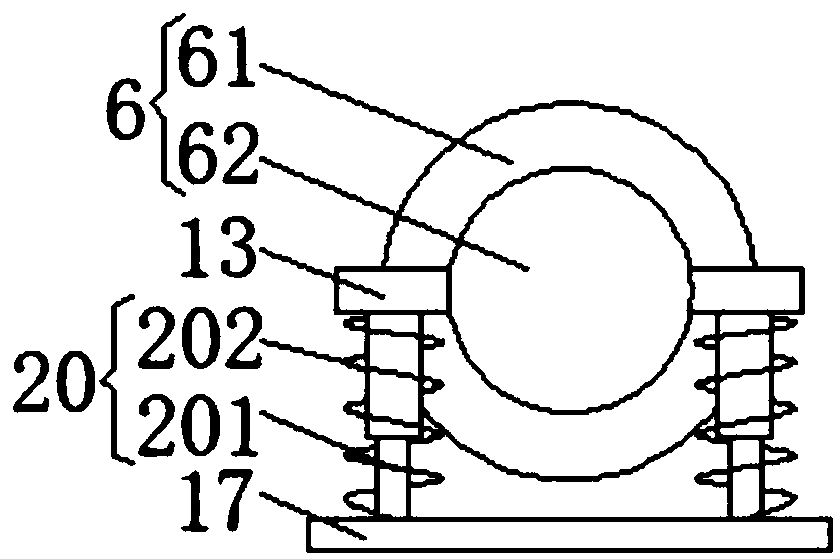

Knife grinder for hay cutter

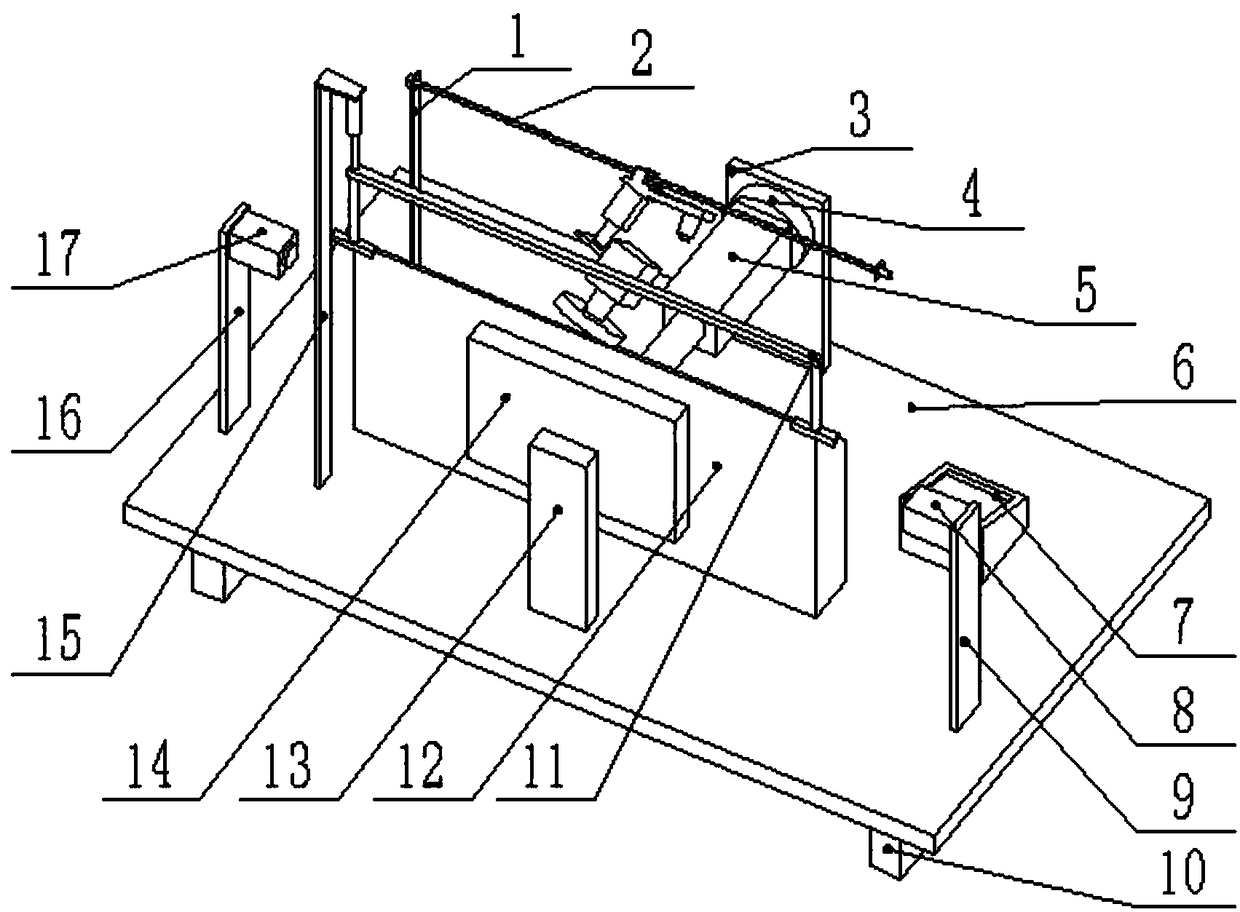

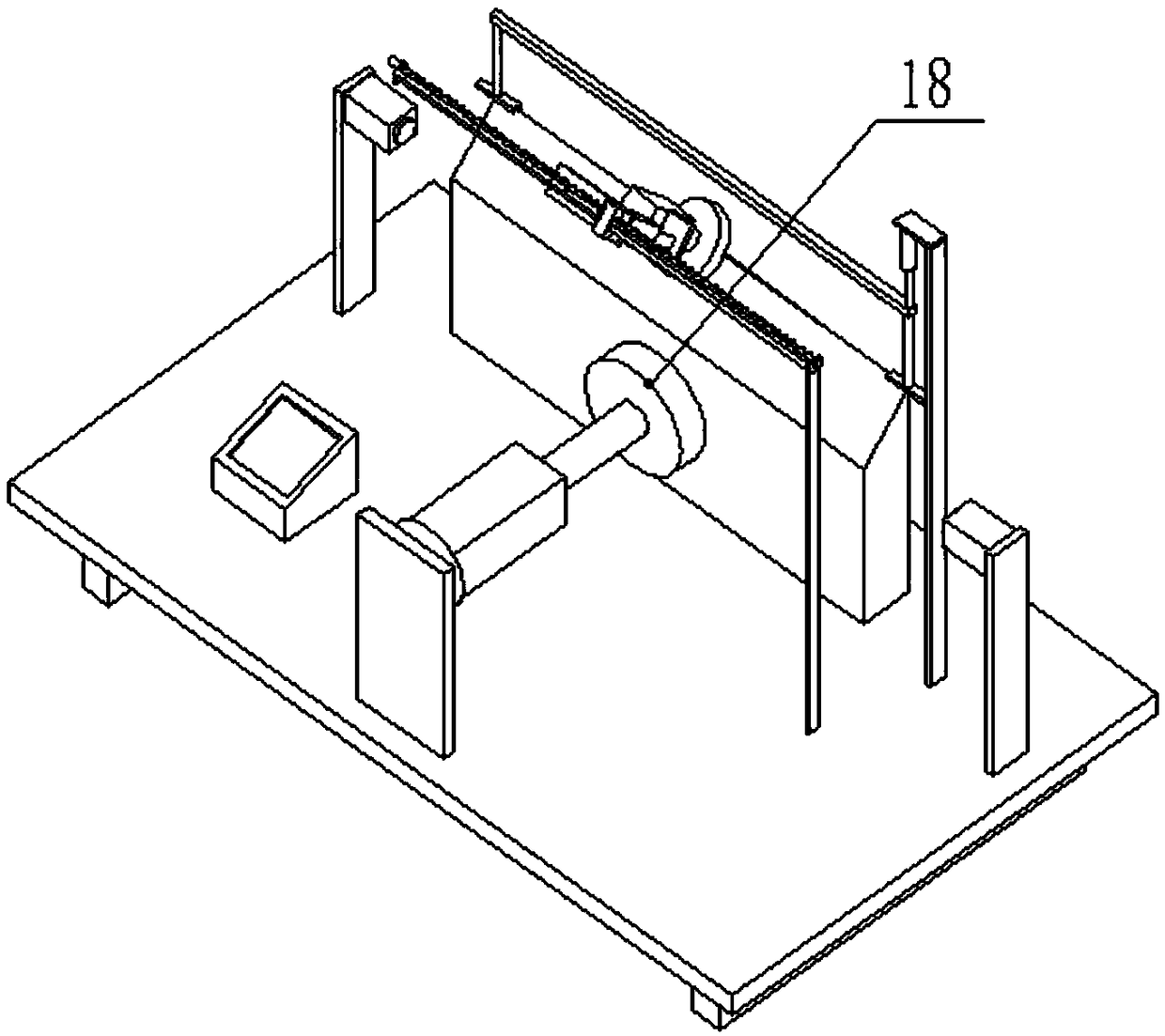

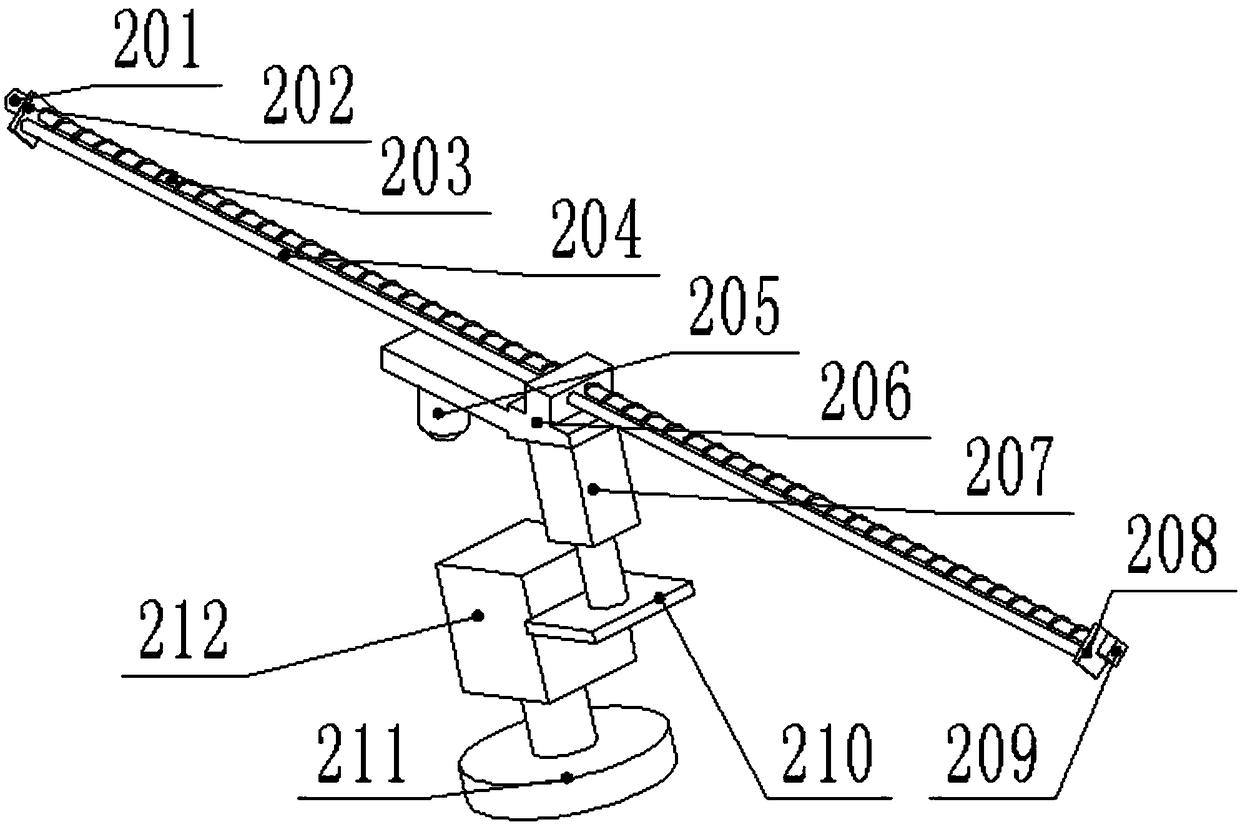

ActiveCN108381307ANo displacementNot unevenGrinding feed controlOther manufacturing equipments/toolsHydraulic cylinderUltrasonic sensor

The invention relates to a knife grinder for a hay cutter, and belongs to the field of agricultural production. A polishing device is arranged at the top end of a first support; a pressure sensor is arranged on a second support; a first hydraulic cylinder is arranged on the pressure sensor; a controller is arranged on a working table; a first ultrasonic sensor is arranged on a third support; a limiting device is arranged on a fifth support; a limiting plate is arranged on a fourth support; a second ultrasonic sensor is arranged on a sixth support; and a rubber pad is arranged on a main shaft of the first hydraulic cylinder. According to the knife grinder for the hay cutter provided by the invention, a blade is pressed on the limiting plate through the first hydraulic cylinder, a position of the blade is detected through the three ultrasonic sensors, a grinding wheel clings to a knife edge through the second hydraulic cylinder, and the knife edge is polished through reciprocating movement of the rotating grinding wheel by repetitive co-rotation and reverse rotation of a first electromotor, so that a manual knife edge polishing process is replaced, the polishing quality and the polishing efficiency are improved, and the safety of workers is ensured.

Owner:浙江双渔科技有限公司

Oval bamboo weaving mold

PendingCN110978176AEasy to combineEasy to useCane mechanical workingEngineeringMechanical engineering

The invention discloses an oval bamboo weaving mold. The oval bamboo weaving mold is characterized in that rubber band grooves are formed in the middles of a component A, a component B, a component C,a component D and a component E respectively, an annular rubber band is clamped into the rubber band grooves formed in the middles of the component A, the component B, the component C, the componentD and the component E respectively, an oval sphere with a vertical penetrating hole is formed through combination, a middle column is inserted in the component A, the component B, the component C, thecomponent D and the component E, and a handle is screwed into a screw hole formed in the center of the upper surface of the middle column. The oval bamboo weaving mold is convenient to combine, products are woven with the mold and are uniform and even in shape, free of irregularity and good in radian, and the mold is convenient to use.

Owner:贵州黔森源竹编工艺厂

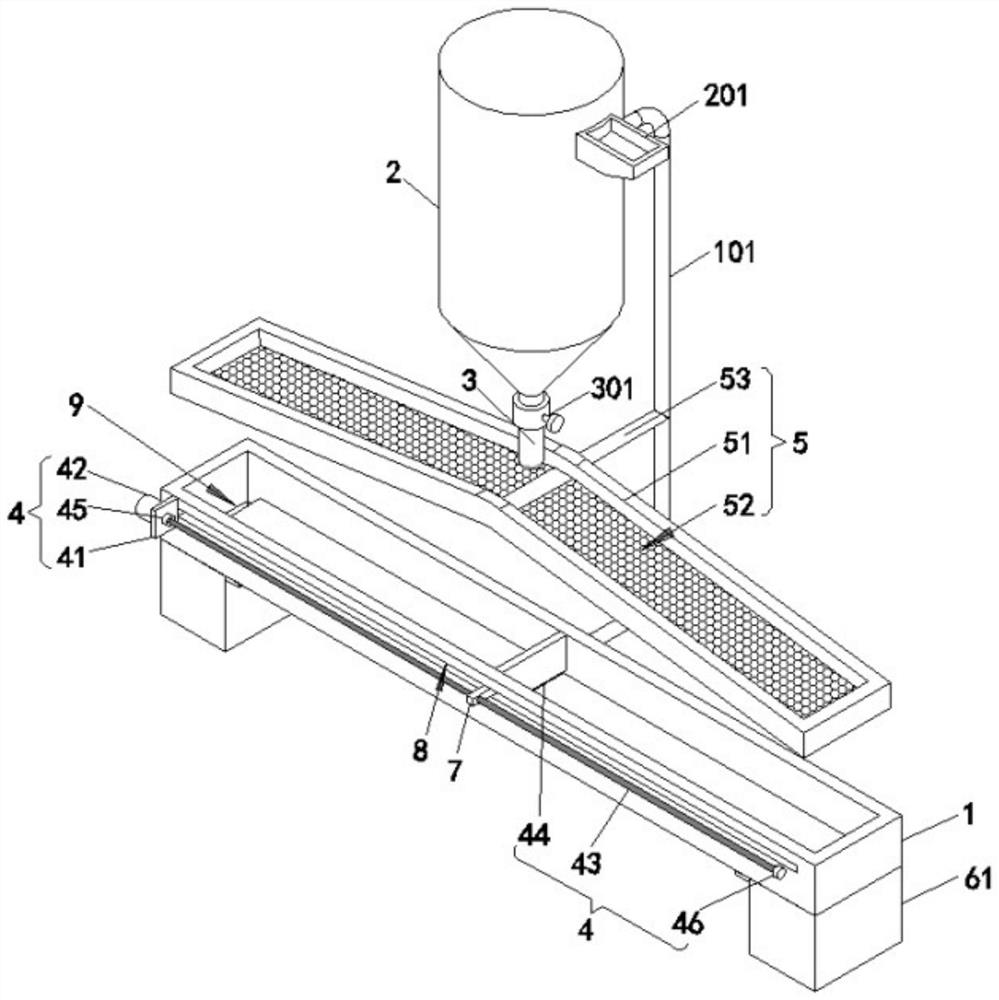

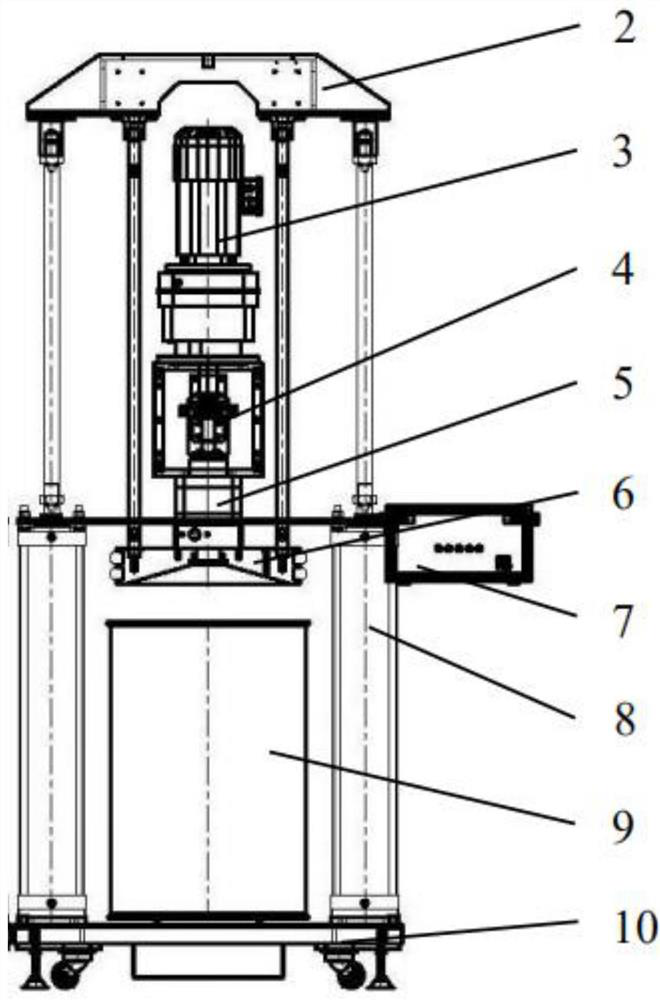

Automatic feeder capable of achieving even feeding for animal husbandry

InactiveCN112119927ANot unevenImprove uniformityAnimal feeding devicesHollow article cleaningAnimal scienceElectric machinery

The invention provides an automatic feeder capable of achieving even feeding for animal husbandry. The automatic feeder capable of achieving even feeding for the animal husbandry comprises a feeding trough, a cleaning mechanism, a dispersing mechanism and a collecting mechanism; a material barrel is fixedly installed on the side wall of the feeding trough through a supporting rod, a feeding hopperis fixedly installed on the side wall of the material barrel, a motor is fixedly installed on the side wall of a fixing plate, and a lead screw is fixedly connected with the output end of the motor;and a scraping plate is connected to the inner wall of the feeding trough in a sliding manner and is in threaded connection with the lead screw, the dispersing mechanism is installed on the supportingrod, and the collecting mechanism is installed at the bottom of the feeding trough. The automatic feeder capable of achieving even feeding for the animal husbandry has the advantages that the feedingtrough can be cleaned, the interior of the feeding trough is kept clean, the inner bottom wall of the feeding trough is located at the same height, feed in the feed barrel can be evenly distributed to all positions of the feeding trough, and live pigs can eat the feed conveniently.

Owner:惠晓利

Ship body insulation epoxy resin gluing equipment

The invention discloses ship body insulation epoxy resin gluing equipment which comprises a glue supply machine. The glue supply machine comprises a pressing disc, a glue inlet is formed in the pressing disc and communicates with a glue supply pump, the pressing disc is connected with a driving device, the pressing disc is used for being matched with a material containing space of a material barrel so that when the driving device drives the pressing disc to stretch into the material containing space, pressure can be generated between the pressing disc and glue located in the material containing space. The ship body insulation epoxy resin gluing equipment solves the technical problem that in the prior art, gluing work is not stable.

Owner:苏州振州机电科技有限公司

Method of composing several pressure relief storage unit barrel into large composite tank body

InactiveCN1556016AStable structureSave human effortLarge containersPackaging under vacuum/special atmosphereStructural engineering

Owner:北京福瑞通科技有限公司

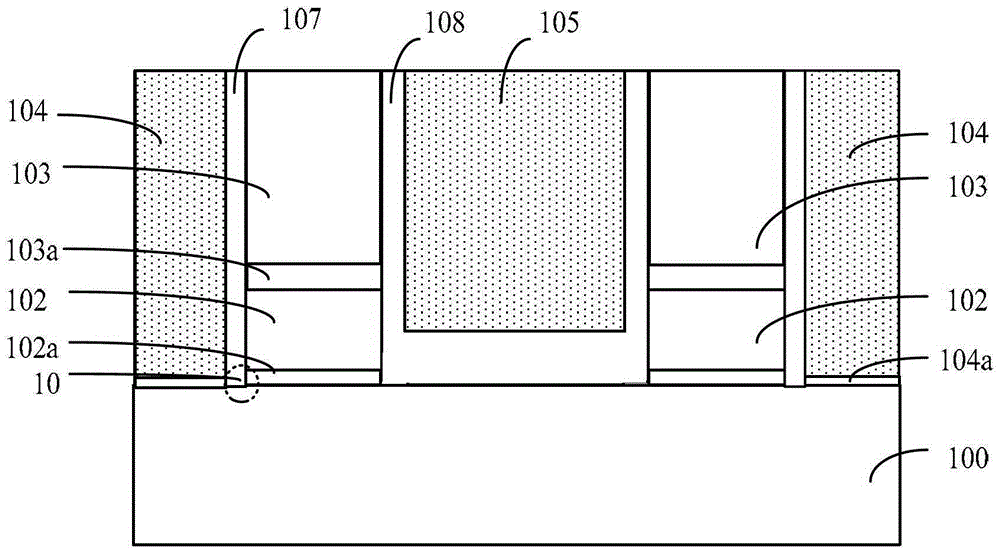

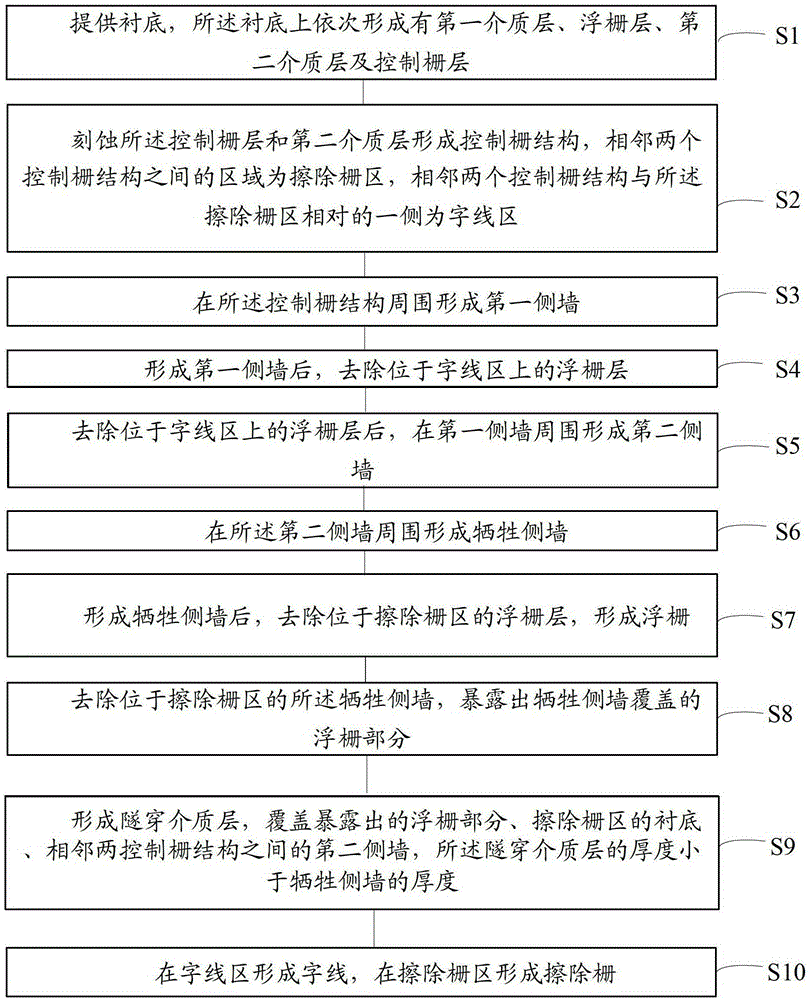

Discrete gate memory device and method of forming same

ActiveCN103715144BAvoid damageImprove uniformitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention provides a discrete gate storage device and a forming method thereof. The forming method of the discrete gate storage device includes: providing a substrate, forming a control gate structure on the substrate, the area between two adjacent control gate structures is an erasing gate area, and the two adjacent control gate structures are connected to the erasing gate structure. The opposite side of the gate area is the word line area; the first side wall is formed around the control gate structure; the second side wall is formed around the first side wall; the sacrificial side wall is formed around the second side wall; the floating gate is formed; Said sacrificial sidewall, exposing the part of the floating gate; forming a tunnel dielectric layer, forming a word line in the word line area, and forming an erasing gate in the erasing gate area. The invention also provides a discrete gate storage device. The first and second side walls of the present invention increase the isolation effect between word lines and control gates, word lines and floating gates, control gates and erasing gates, and improve the programming efficiency, uniformity and erasing efficiency of storage devices , uniformity, especially to reduce the leakage between the word line and the floating gate to solve the problem of write disturbance.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Single-chip flip, etching-after-packaging and pad exposed packaging structure and manufacturing method thereof

ActiveCN102856269ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringHigh density

The invention relates to a single-chip flip, etching-after-packaging and pad exposed packaging structure and a manufacturing method thereof. The structure comprises pads (1), pins (2) and a chip (3). The chip (3) is arranged on the right sides of the pads (1) and the pins (2) in an inverted mode. Bottom filling glue (14) is arranged between the bottom of the chip (3) and the right sides of the pads (1) and the pins (2). Molding compounds (4) are packaged in areas on the peripheries of the pads (1), between the pads (1) and the pins (2), among the pins (2) and outside the chip (3). Holes (5) are opened on the surfaces of the molding compounds (4) on lower portions of the pads (1) and the pins (2), and metal balls (7) are arranged in the holes (5). The single-chip flip, etching-after-packaging and pad exposed packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, reducing environmental pollution, and being capable of designing and manufacturing high-density lines.

Owner:JCET GROUP CO LTD

Multi-chip flip-chip etching first packaging structure without base island and its manufacturing method

ActiveCN102856271BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityBiochemical engineering

The invention relates to a multi-chip flip, packaging-after-etching and non-pad packaging structure and a manufacturing method thereof. The structure comprises pins (1) and a plurality of chips (2). The plurality of the chips (2) are arranged on the right sides of the pins (1) in an inverted mode; bottom filling glue (13) is arranged between the bottoms of the chips (2) and the right sides of the pins (1); molding compounds (3) are packaged in areas on the peripheries of the pins (1), among the pins (1), on the upper portions and the lower portions of the pins (1) and outside the chips (2); holes (4) are opened on the surfaces of the molding compounds (3) on the lower portions of the pins (1), and communicated with the reverse sides of the pins (1); and metal balls (6) are arranged in the holes (4) and contacted with the reverse sides of the pins (1). The multi-chip flip, packaging-after-etching and non-pad packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, and being capable of designing and manufacturing high-density lines.

Owner:JCET GROUP CO LTD

A kind of propelling embankment machine and its embankment method

The invention provides a push type diker and a diking method thereof. According to the push type diker and the diking method thereof, the diker is positioned to the position where diking needs to be conducted, and the diker is made to sink into silt gradually under the action of a jetting hole; then stones are thrown into a forming cabin of the diker, a piston rod of a pushing oil cylinder stretches out backwards to push the stones after the height of the stones is larger than that of the pushing oil cylinder on the diker, and forward counter-acting force can be provided for the whole diker by the stones due to the fact that firm silt behind the stones cannot be squeezed open by the stones; the jetting hole works all the time to activate and push open the silt in front and below, so that the diker advances to squeeze open the silt in front, and stones are thrown by the diker continuously when the diker advances, so that the lower portion of a sea dike is dump-filled; then the upper portion of the sea dike is dump-filled through a conventional method, so that construction of a dike body of the whole sea dike is completed. By the adoption of the push type diker and the diking method thereof, the constructed dike body can be well matched with a construction drawing, and stones can be saved; meanwhile, diking can be conducted under complicated geological conditions, and thus the push type diker and the diking method thereof are highly practical.

Owner:SHANGHAI XIONGCHENG SHIP ENG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com