Method of composing several pressure relief storage unit barrel into large composite tank body

A technology of combining and combining tanks, which is applied to large containers, packaging objects, containers under special gas conditions, etc., can solve the problems of large labor consumption, increased volume, large consumption, etc., and is conducive to structural stability, processing and production. Convenience and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

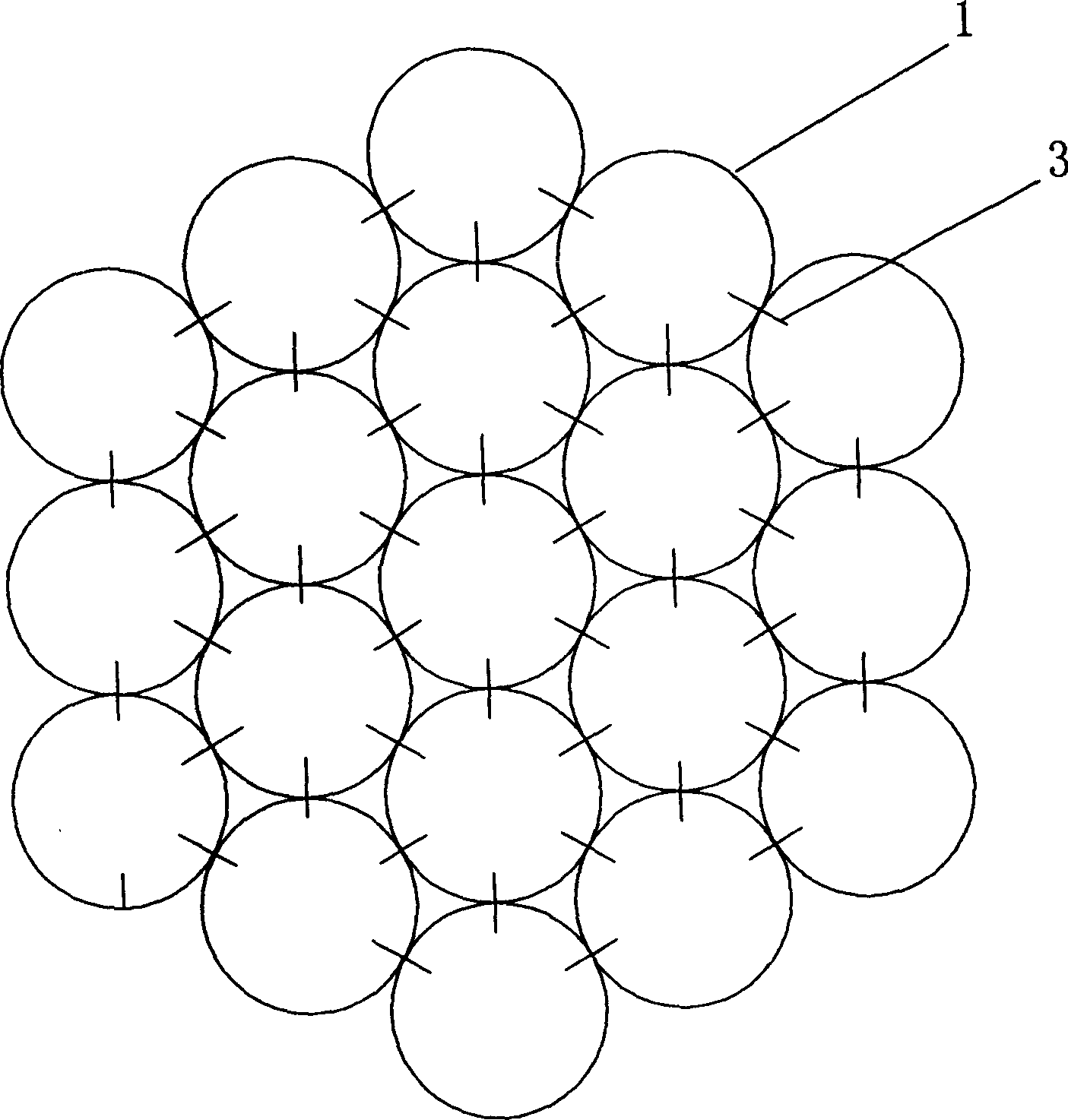

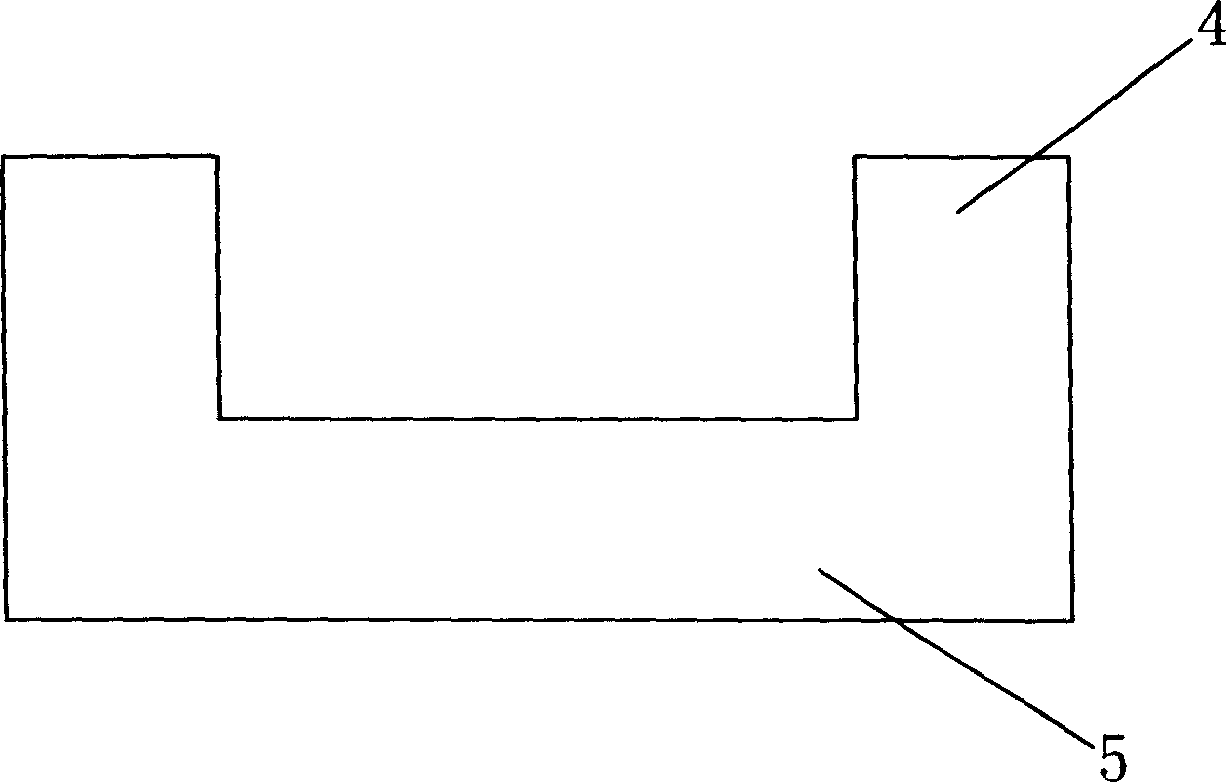

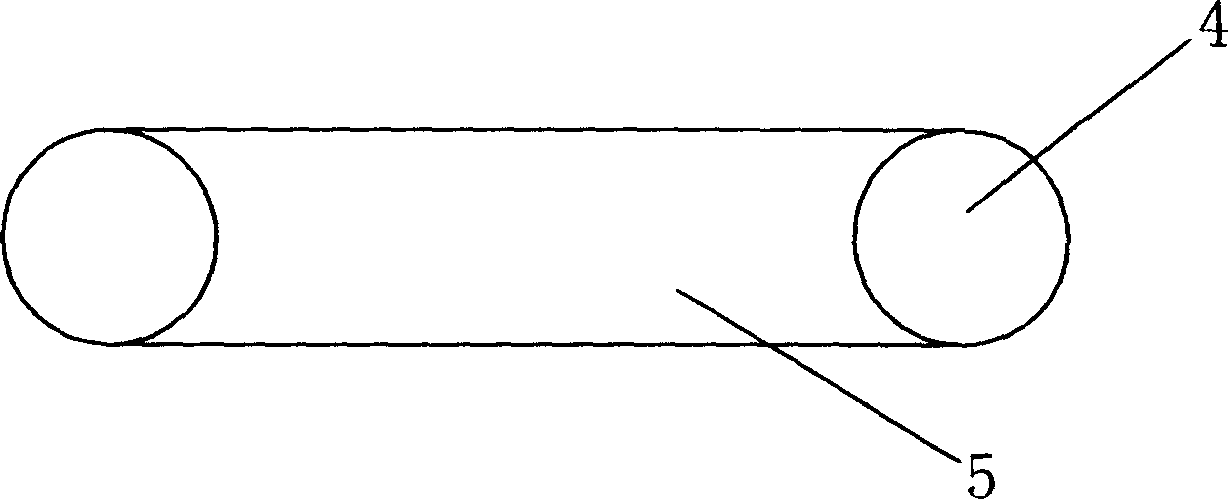

[0028] Such as figure 1 In the combined tank shown, several unit barrels 1 are closely arranged to form a hexagonal prism combined tank whose top surface of each layer is a plane regular hexagon. The implementation steps are as follows: (1) select decompression storage unit barrels of the same specification and size on the same floor, and the unit barrels are cylindrical; unit barrels, and make the unit barrels on the edge of the same layer form a regular hexagon. Obviously, in actual operation, there are routine steps such as cleaning, loading, and quality inspection. The barrel lids of the unit barrels located in the middle layer and the bottom layer are equivalent to a positioning sleeve, which serves as both the barrel lid of the lower layer and the bottom of the upper layer. In actual use, figure 1 The combined tank body shown has a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com