Patents

Literature

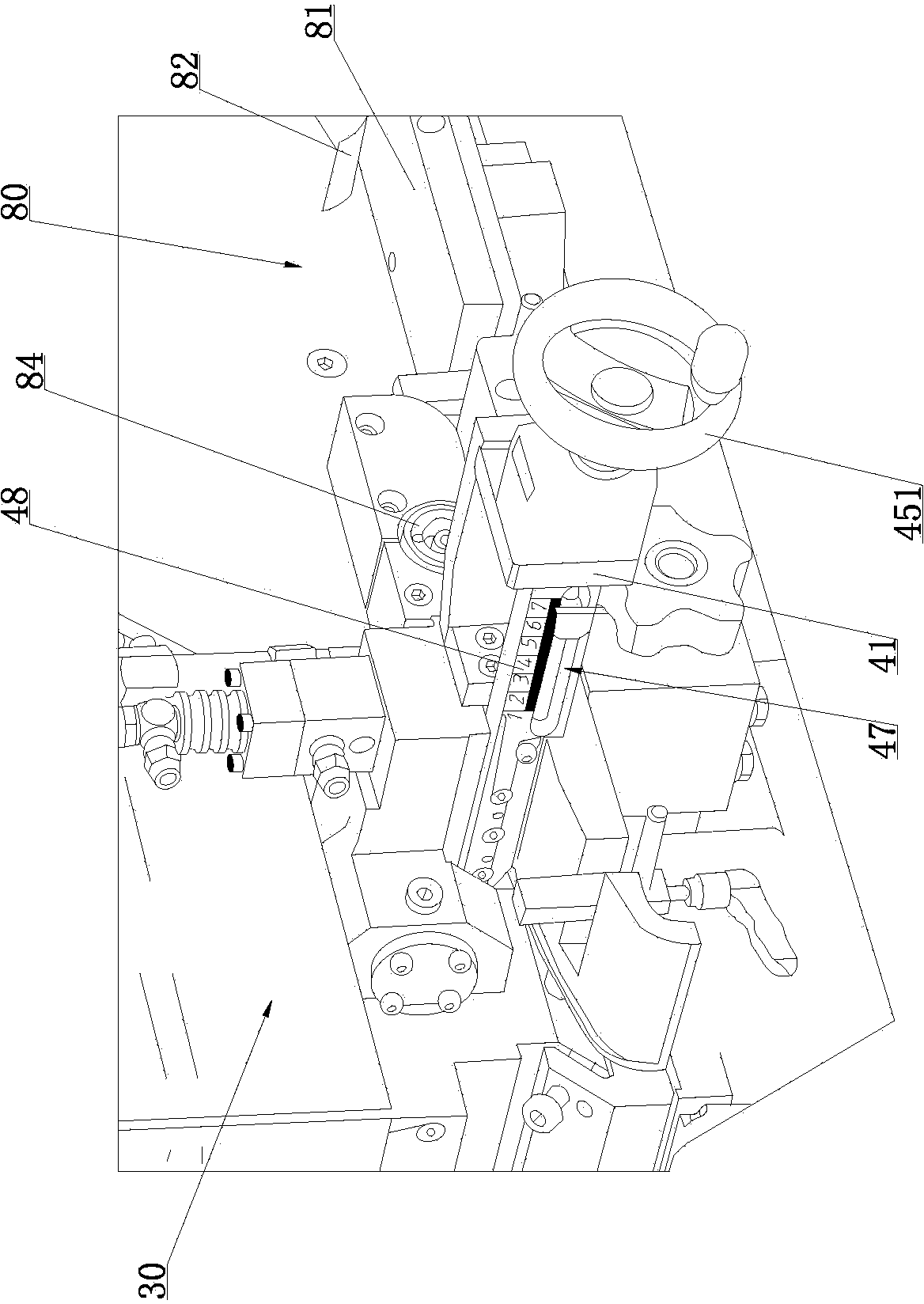

57results about How to "Glue stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

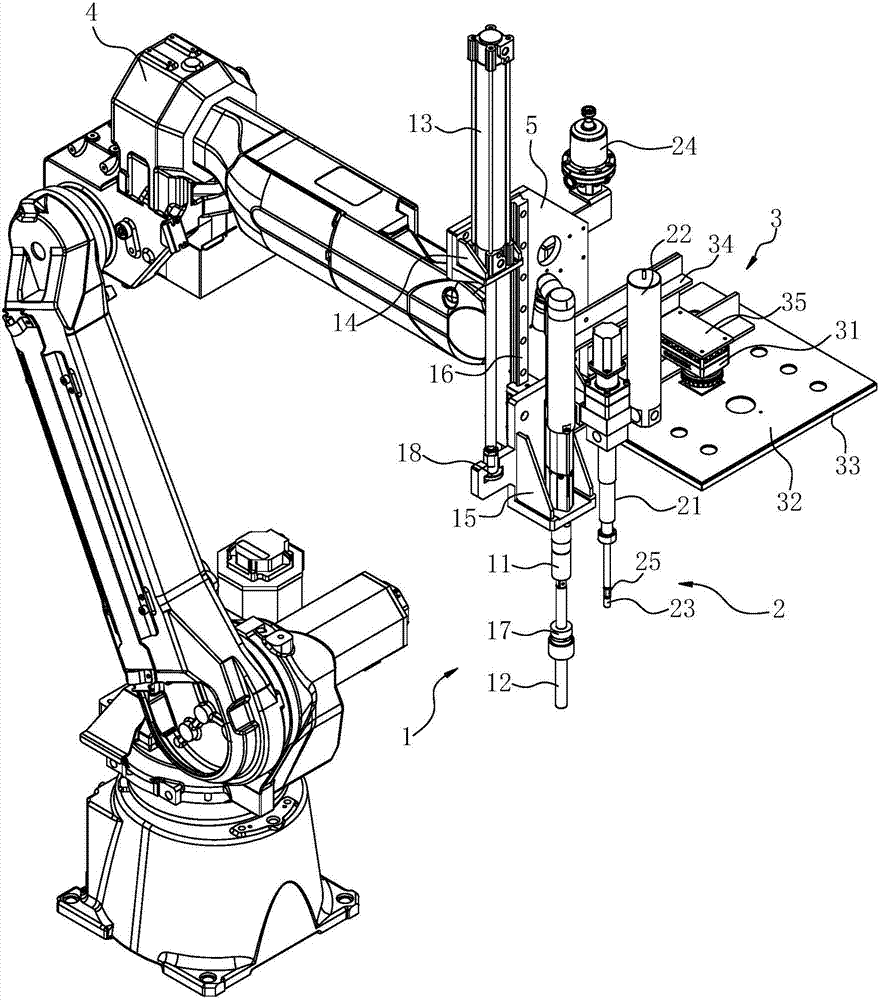

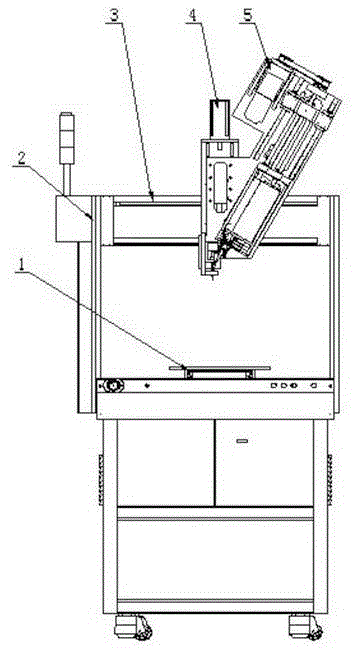

Integrated glue coating machine and operation method thereof

PendingCN106862009AReduce the difficulty of operationImprove operating precisionLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses an integrated glue coating machine and an operation method thereof. The integrated glue coating machine comprises a screwing device, a glue coating device, a detection device and a robot, wherein the screwing device comprises a screwing shaft capable of moving in the vertical direction, and the end portion of the screwing shaft is detachably provided with a sleeve matched with a bolt; the glue coating device comprises a quantitative glue gun, the glue inlet end of the quantitative glue gun is connected with a glue storing tank, and the glue outlet end of the quantitative glue gun is connected with a glue needle; the detection device comprises a detection part used for workpiece positioning, machine type recognition and glue coating qualification degree detection; and the robot is provided with an operation end, and the screwing device, the glue coating device and the detection device are all connected with the operation end. The screwing device, the glue coating device and the detection device are all integrated on the robot, the function that one machine is multipurpose is achieved, the floor area of equipment is reduced, the production efficiency is improved, meanwhile, the integrated glue coating machine can be better compatible with different machine types, flexible production and equipment maintenance are facilitated, and the machine replaces the manual work to meet the real demands of clients for reducing the production cost and improving the production efficiency.

Owner:GUANGZHOU SEAHAWN IND ROBOTICS

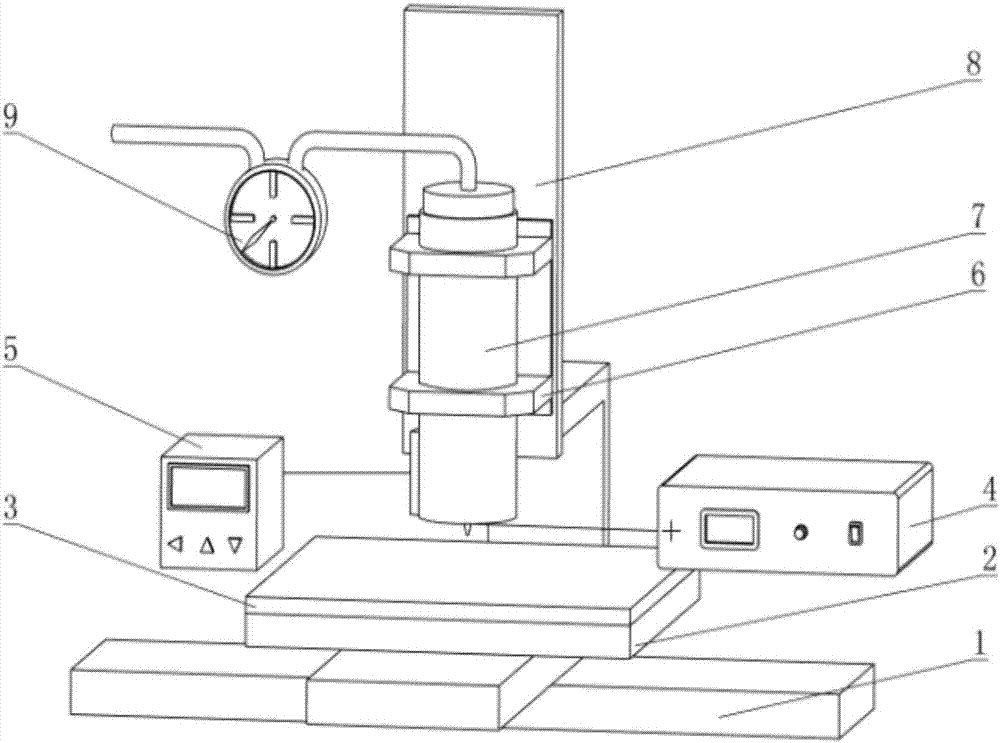

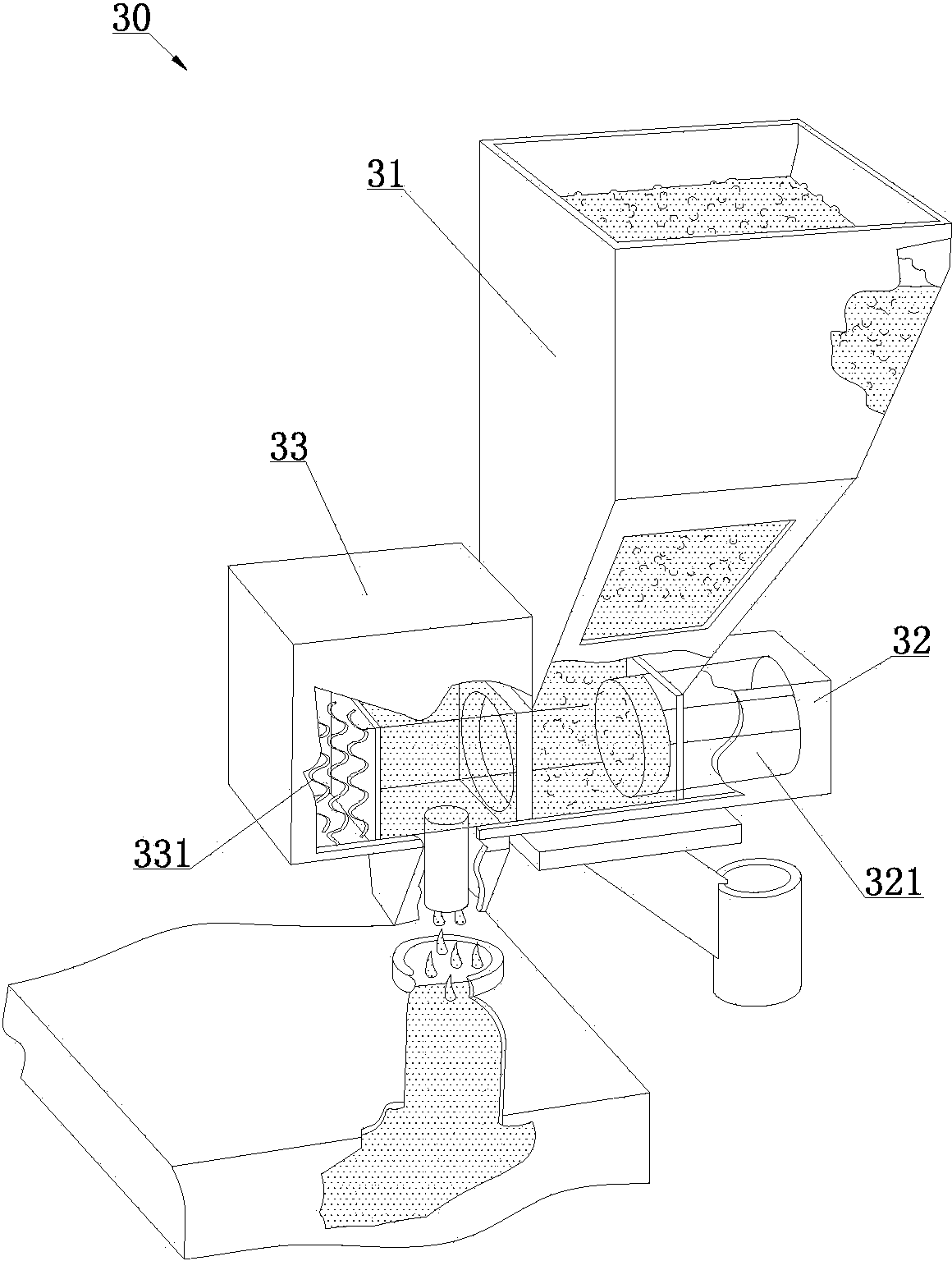

Molten jetting deposition 3D printing device driven by electric field, and working method thereof

InactiveCN107160685AAvoid cloggingEvenly heatedManufacturing heating elements3D object support structuresScale structureHigh pressure

The invention discloses a molten jetting deposition 3D printing device driven by an electric field, and a working method thereof. The problems that the molten droplet jetting 3D printing accuracy is low, the printing materials are limited and the micro-scale structure printing is hard to achieve are solved, and the high-accuracy and high-efficiency macro / micro-scale manufacturing of complex 3D structures using thermal phase transition and thermoplastic polymer materials and composite materials is achieved. According to the technical scheme, the 3D printing device comprises a two-dimensional stage which is provided with a printing bed, and an insulating thermal-conductive substrate is attached to the printing bed; a jetting unit is arranged above the insulating thermal-conductive substrate, and connected to a Z-axis workbench; the jetting unit comprises a print head comprising a nozzle and a material storage barrel which are connected to each other, and the print head is connected to the anode of a high-voltage pulse power supply; the nozzle is a musashi conductive nozzle; the material storage barrel is connected to a backpressure control unit; and a heater is sheathed outside the print head, and connected to a temperature control unit.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

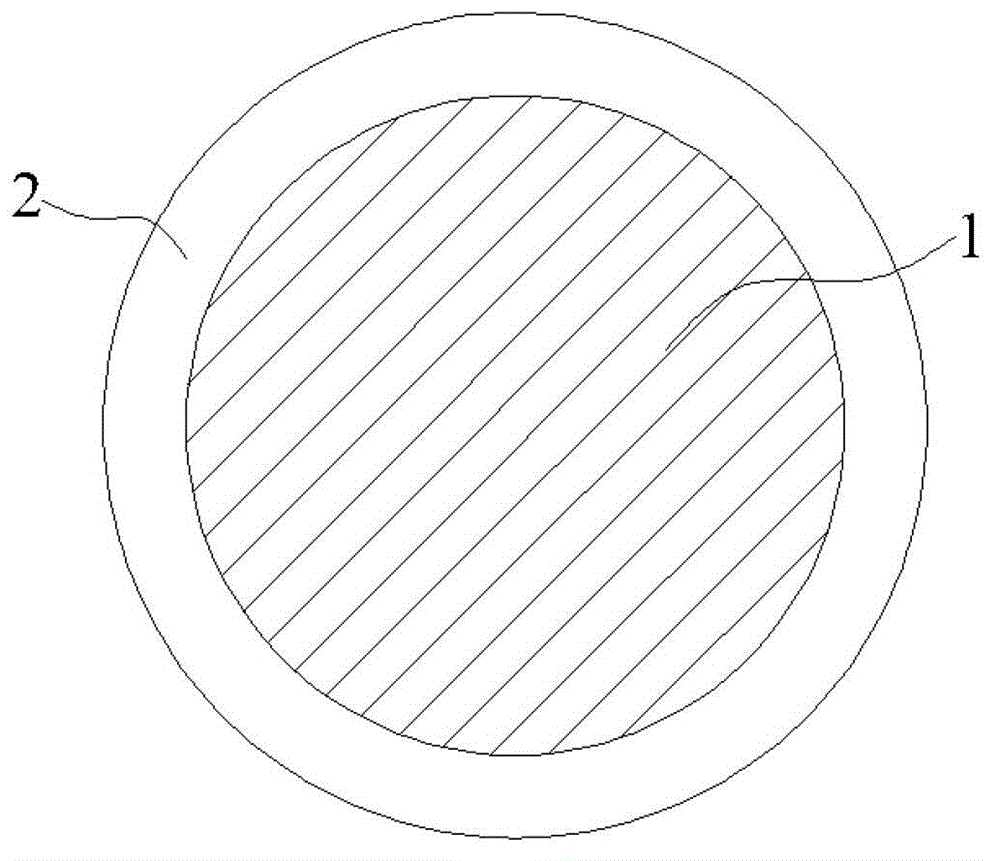

Low smoke zero halogen flame retardant sheath layer for optical cable

ActiveCN102977451ASolve the technical problem of outer diameter fluctuationReduced filling capacityFibre mechanical structuresAluminium hydroxideCarvacryl acetate

The invention discloses a low smoke zero halogen flame retardant sheath layer for an optical cable, wherein the optical cable comprises an optical cable core and a low smoke zero halogen flame retardant sheath layer covering the outer surface of the optical cable, and the low smoke zero halogen flame retardant sheath layer is composed of the following components in parts by weight: 65-75 parts of ethylene-vinyl acetate copolymer, 20-30 parts of high-pressure metallocene polyethylene, 10-20 parts of special modified polyethylene, 70-110 parts of aluminium hydroxide, 20-30 parts of magnesium hydroxide, 2-5 parts of silicone master batch, 1-3 parts of polyethylene wax, 30-50 parts of flowable agent, 0.15-0.45 parts of antioxidant and 2-5 parts of black master batch. The low smoke zero halogen flame retardant sheath layer for the optical cable enables the outer diameter of the optical cable to be even, thereby guaranteeing the shrinkage integrity of the optical cable core; as a result, signals can not be greatly attenuated in the transmission process in the cable; and simultaneously, the tensile strength of the cable is greater than or equal to 13 MPa, while the elongation at break is greater than or equal to 250% and the oxygen index is greater than or equal to 34%; and the cable has excellent mechanical properties.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

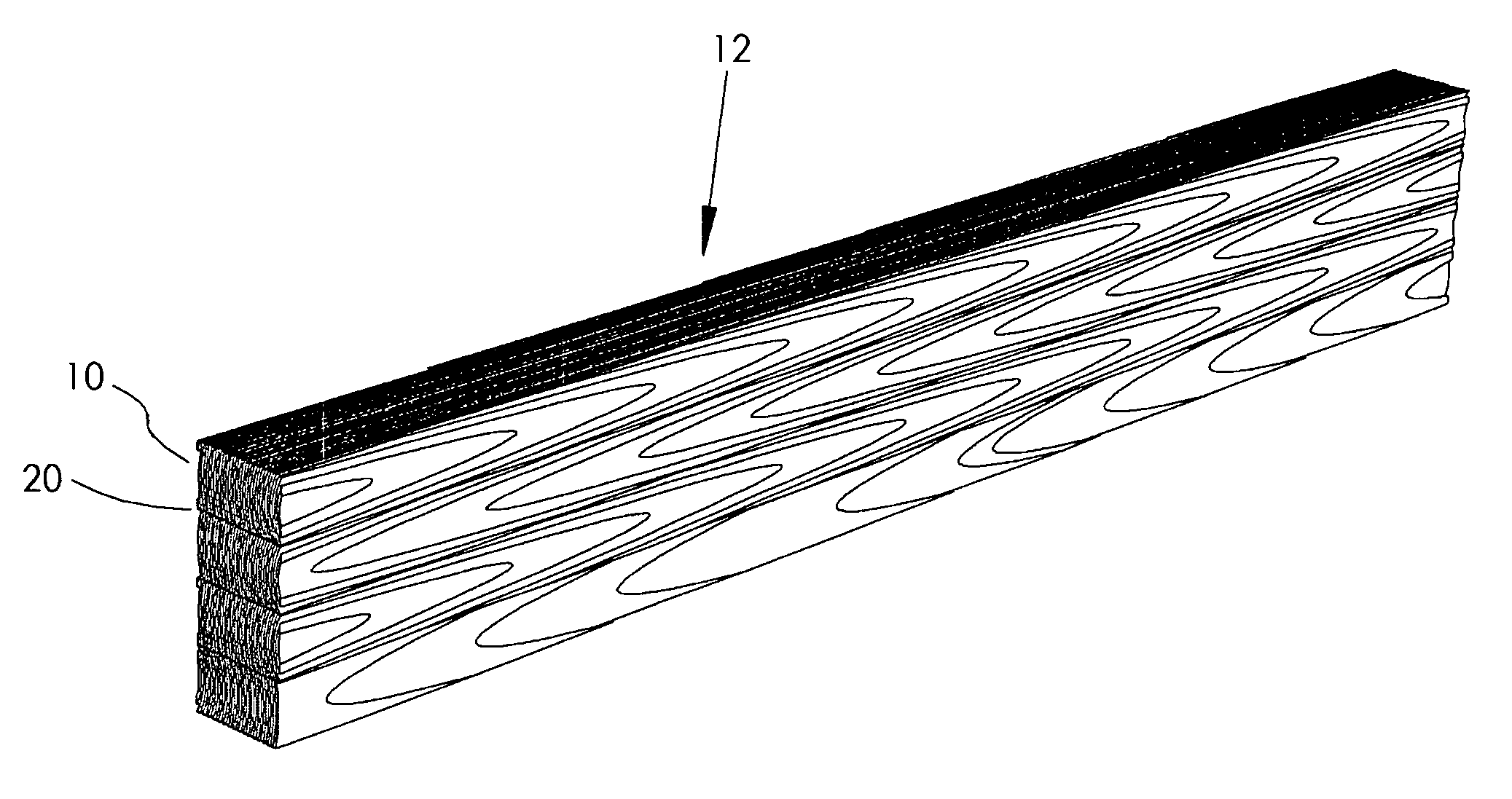

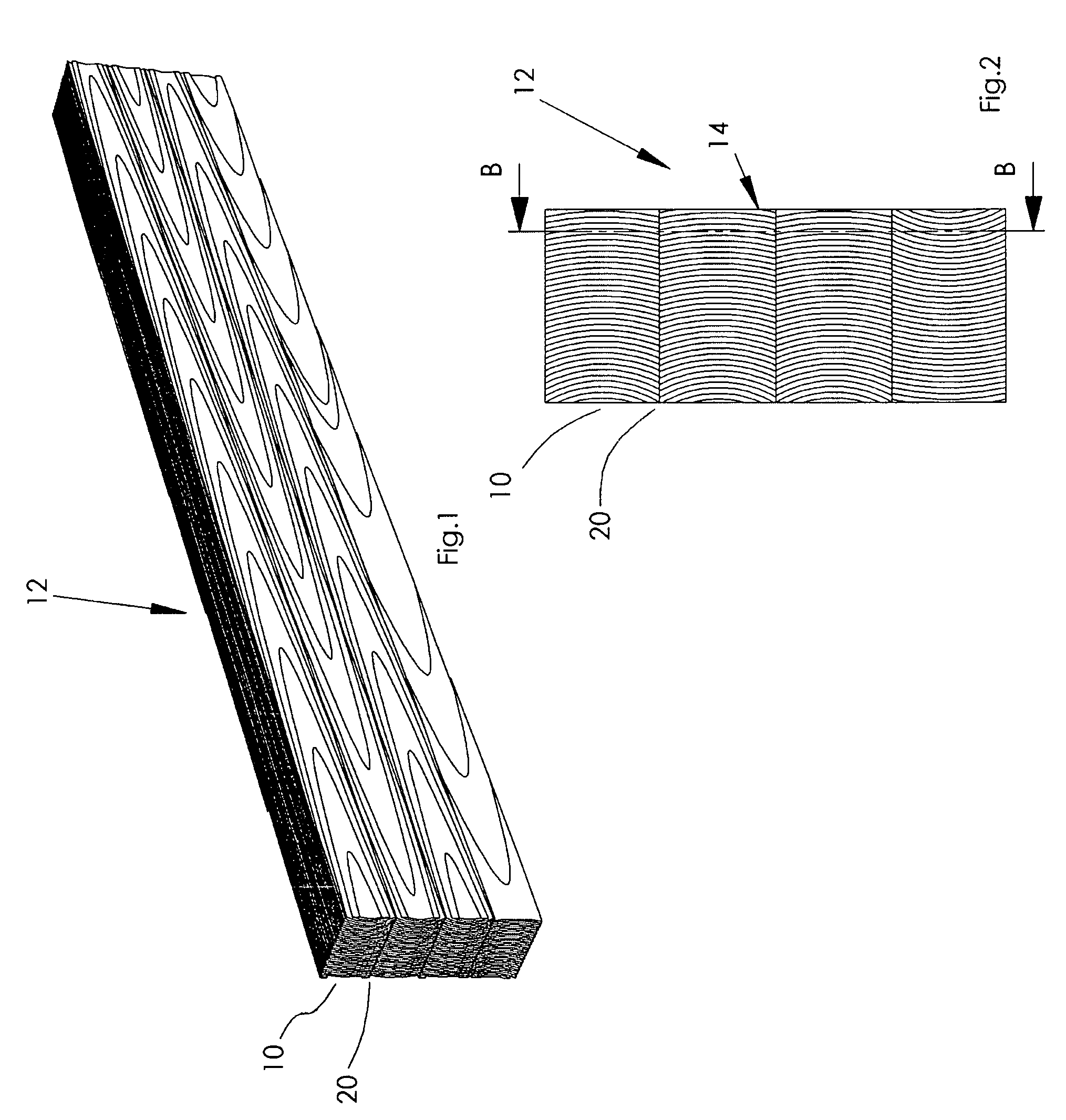

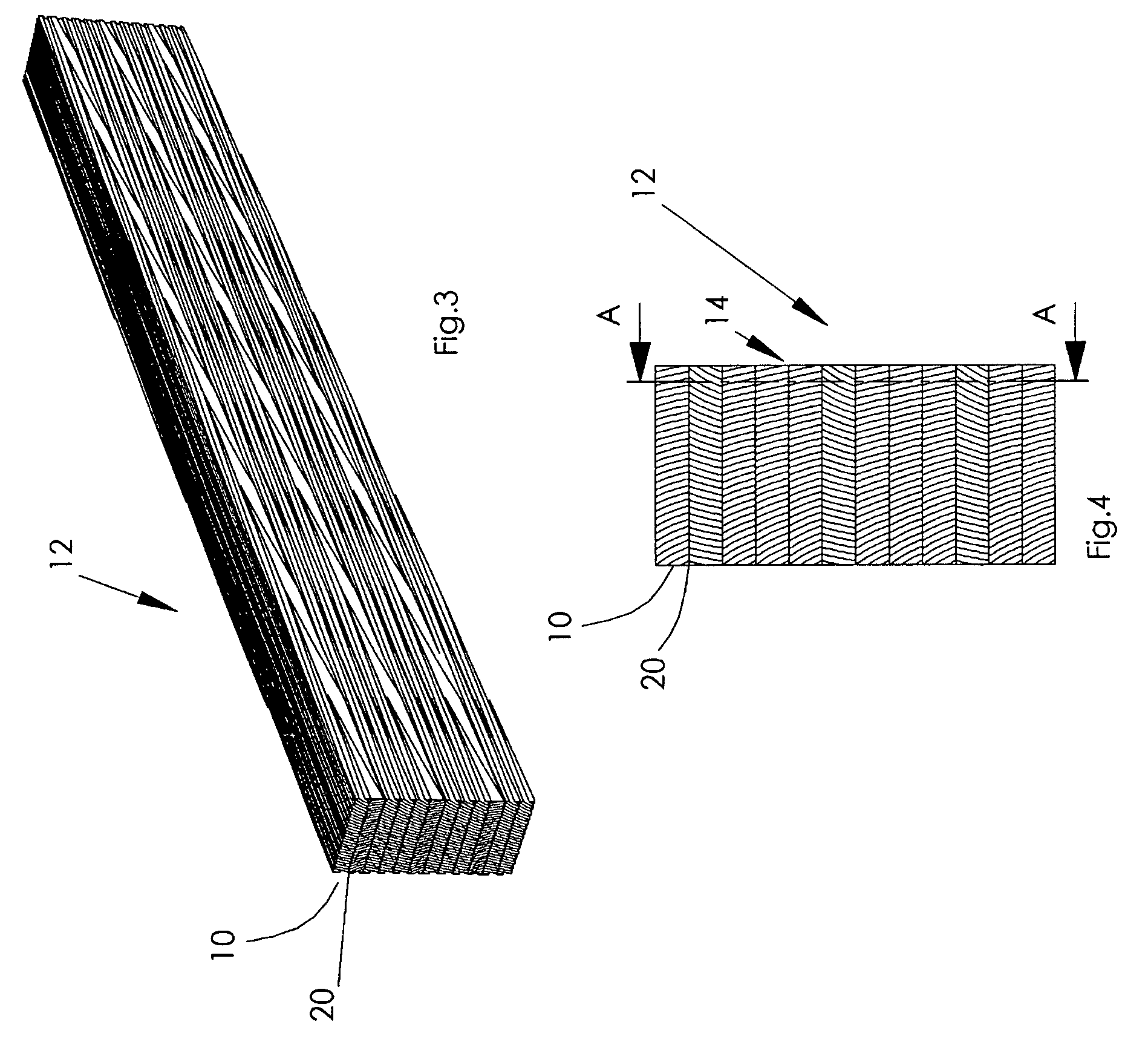

Process for the manufacture of a veneer

ActiveUS7347912B2Without affecting veneer propertyImprove economyLamination ancillary operationsManual label dispensersFiber saturation pointPulp and paper industry

A process for the manufacture of veneer comprises gluing board-like, plane pieces of wood together with an adhesive to form a beam-like block of wood. The humidity content of the beam-like block of wood is increased. Veneer is cut from the beam-like block of wood and dried until the humidity content is below a fiber saturation point. Because of the rules governing abstracts, this abstract should not be used to construe the claims.

Owner:HD WOOD TECH

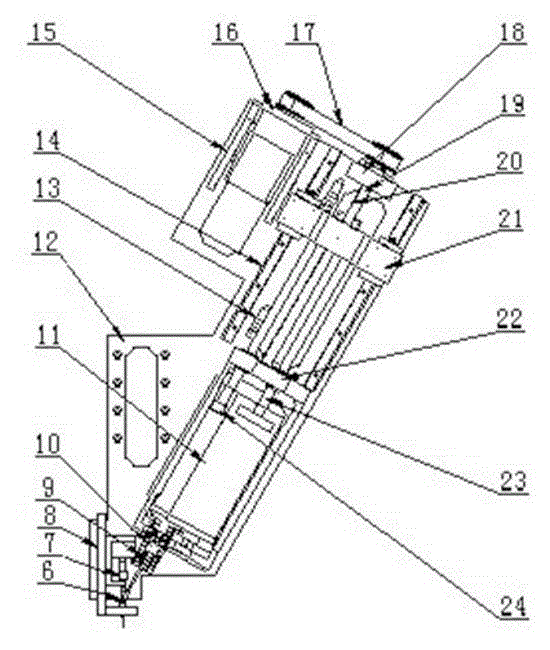

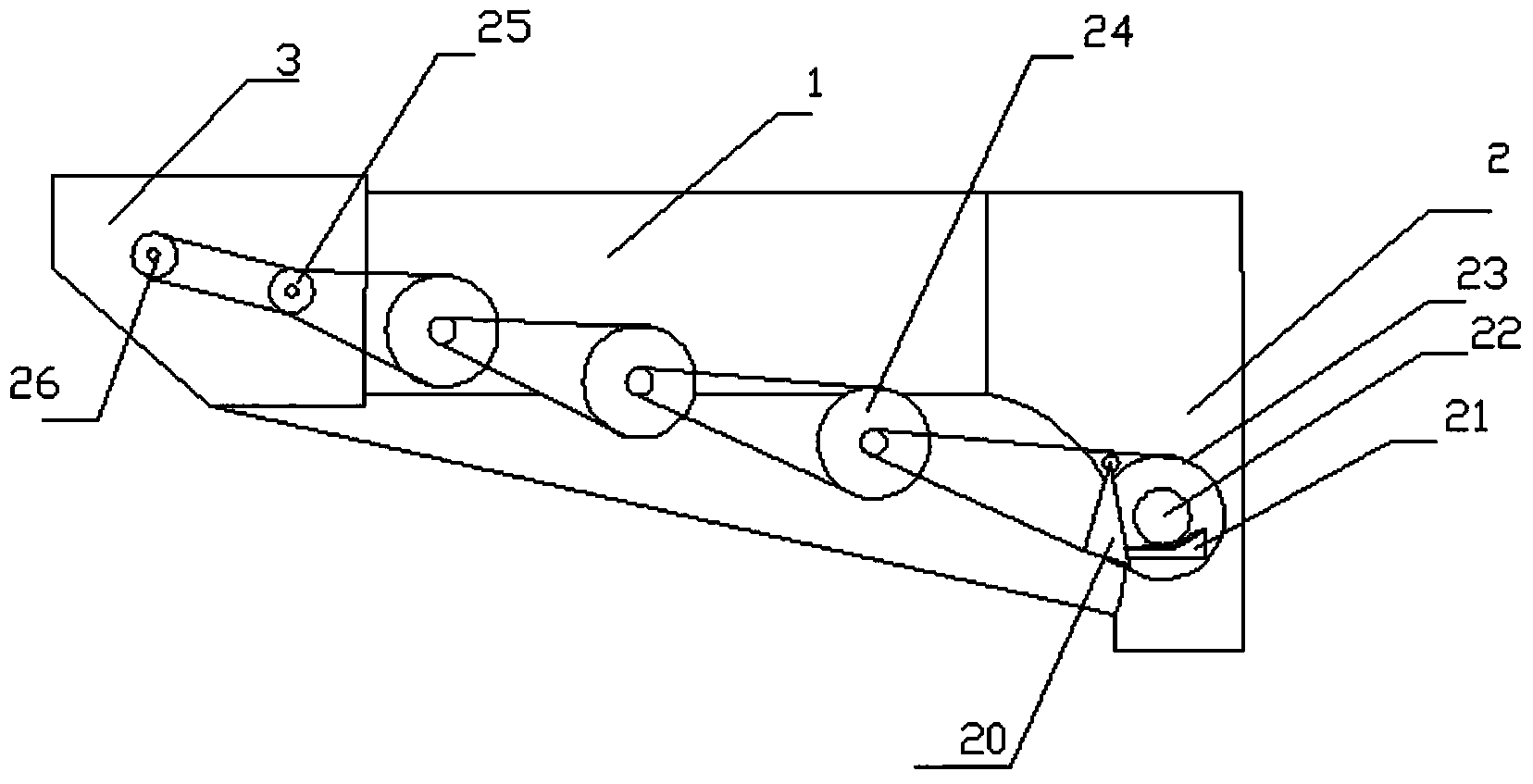

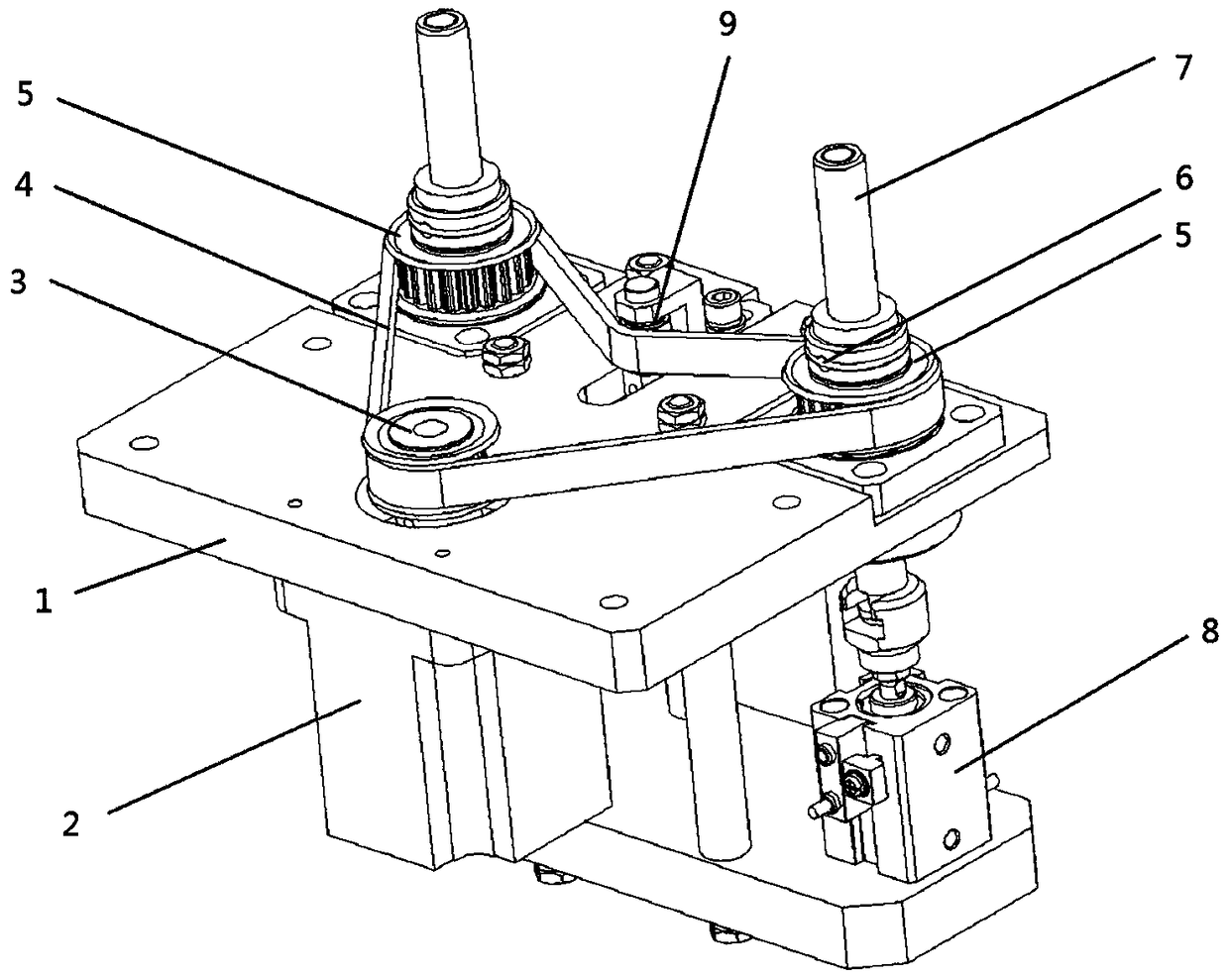

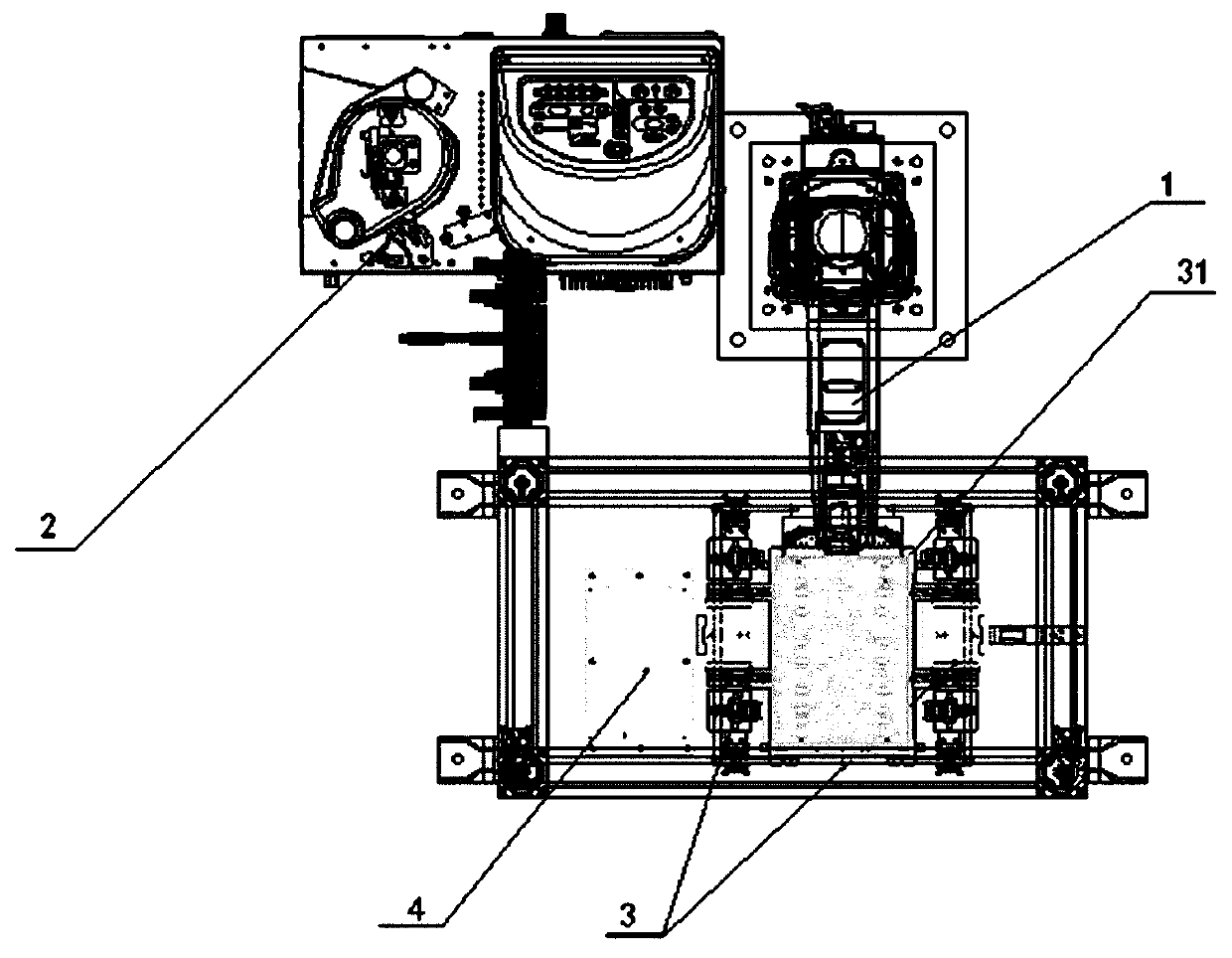

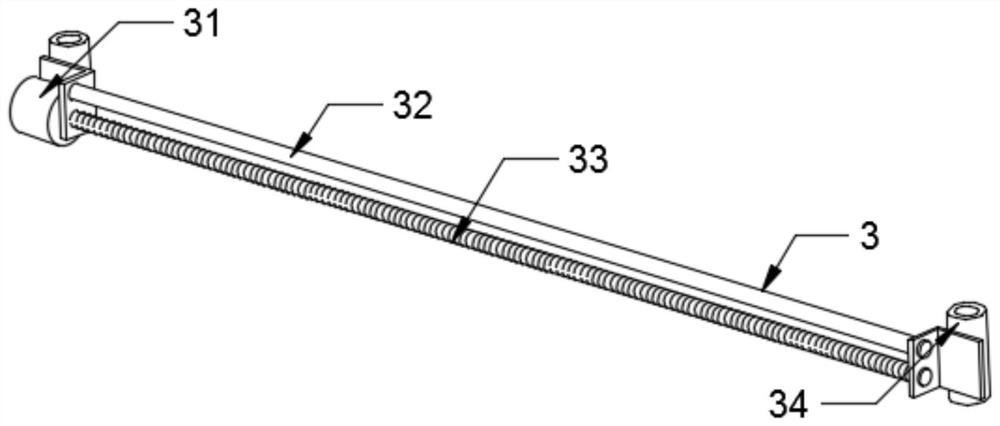

Large-barrel dispenser servo glue discharging device

InactiveCN104084353AShorten the timeCompact structureLiquid surface applicatorsCoatingsElectric machineryReducer

The invention discloses a large-barrel dispenser servo glue discharging device, and relates to the field of glue dispensing process. The large-barrel dispenser servo glue discharging device is characterized in that one end of a glue barrel is provided with a mixing pipe, the other end of the glue barrel is provided with a glue barrel fixing seat, the rubber barrel is provided with a large push rod and a small push rod, a soleplate is provided with a guide rail, the guide rail is provided with a slide block, the slide block is provided with a guide column, the middle part of the guide rail is provided with a sensor support, one end of the soleplate is provided with a motor support, one side of the motor support is provided with a motor installation plate, one side of the motor installation plate is provided with a synchronous belt driving device, one end of the synchronous belt driving device is provided with a servo motor and a speed reducer, the other end of the synchronous belt driving device is provided with a lead screw, and one end of the lead screw is provided with a lead screw installation plate. By adopting a Y-shaped dispensing valve and inclining a motion track at 30 degrees, the time for fluid glue flowing from the mixing pipe to the dispensing valve can be greatly shortened, a dispensing assembling part is compact in structure, and the space can be effectively saved. The large-barrel dispenser servo glue discharging device can be installed on different production lines at random, is capable of discharging glue stably without glue leakage or dropping and is convenient to maintain.

Owner:ZHUCHANG PRECISION STAMPINGSHANGHAICO

Anti-blocking low smoke zero halogen flame-retardant cable material for optical cable

ActiveCN103849063AFast demouldingGood compatibilityPlastic/resin/waxes insulatorsInsulated cablesMelt flow indexCarvacryl acetate

The invention discloses an anti-blocking low smoke zero halogen flame-retardant cable material for an optical cable. The anti-blocking low smoke zero halogen flame-retardant cable material comprises the following components in parts by weight: 65-75 parts of ethylene-vinyl acetate copolymer, 20-30 parts of high pressure metallocene polyethylene, 10-20 parts of modified polyethylene, 70-110 parts of aluminum hydroxide, 20-30 parts of magnesium hydroxide, 2-5 parts of silicone master batch, 1-3 parts of polyethylene wax, 30-50 parts of flowable agent, 0.15-0.45 part of antioxidant, and 2-5 parts of black master batch, wherein the content of VA in the ethylene-vinyl acetate copolymer is 20-28%, the melt index of 2.16Kg of high pressure metallocene polyethylene at 190DEG C is less than or equal to 3g / 10min, the density is less than 0.92g / cm<3>. By adopting the anti-blocking low smoke zero halogen flame-retardant cable material, the outer diameter of the optical cable is uniform, so that the shrinkage integrity of the core of the optical cable is guaranteed, the signal transmitted in the optical cable is not attenuated sharply; and in addition, the tensile strength of the cable is greater than or equal to 13MPa, the elongation at break is greater than or equal to 250%, the oxygen index is greater than or equal to 34%, and the cable has excellent mechanical property.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

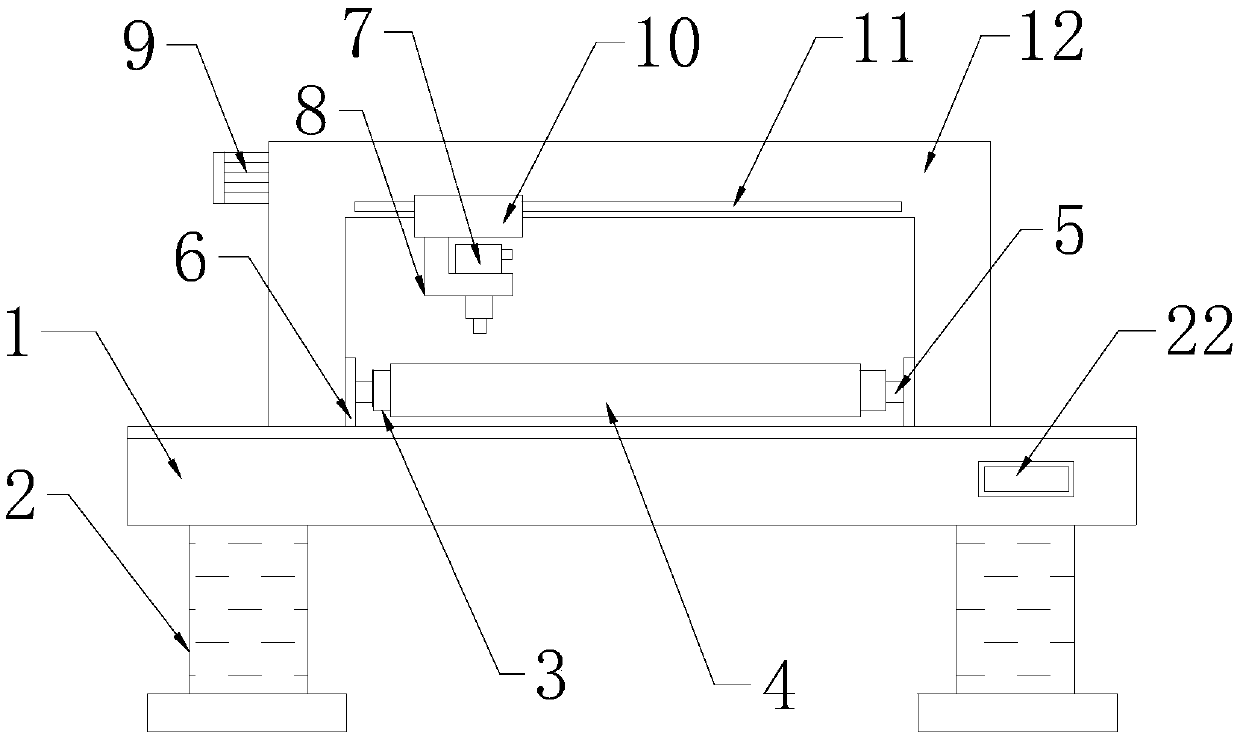

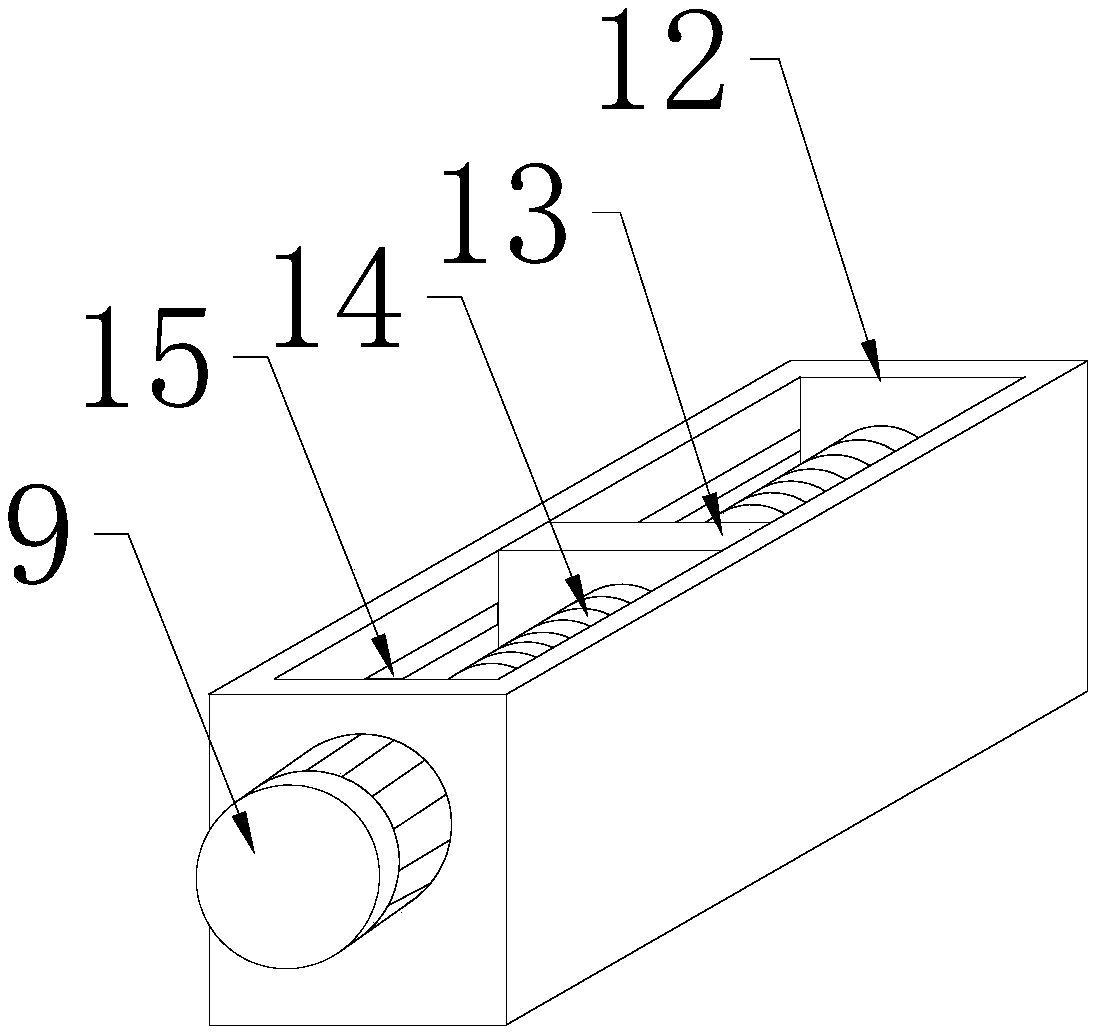

Scrape coating machine for edge banding

InactiveCN104226548AReduce volumeReduce manufacturing costLiquid surface applicatorsCoatingsPhysicsCooling channel

The invention relates to the technical field of edge banding production equipment, in particular to a scrape coating machine for an edge banding. The scrape coating machine comprises a machine tool provided with an unwinding plate, an adhesive melting device, a scrape coating device, an edge banding turning device, a cooling channel and a winding plate, wherein the unwinding plate is located above the front side of the machine tool, the adhesive melting device is located on the rear side of the machine tool, the scrape coating device is located on the front side of the machine tool and connected with the adhesive melting device, the edge banding turning device is connected with an output end of the scrape coating device, the cooling channel is connected with an output end of the edge banding turning device, and the winding plate is located on one side of an outlet end of the cooling channel. The scrape coating machine for the edge banding is small in size, lower in production cost and little in occupied space during use; the glue spreading edge sealing machine is suitable for coating the back side of the edge banding with a hot melt adhesive, is particularly suitable for the edge banding with the width ranging from 16 mm to 65 mm and the thickness ranging from 0.4 mm to 3 mm, the coating quantity is 50 -250 g / m<2>, the production efficiency is high, the adhesive coating is uniform and stable, and the adhesive coating quality is good.

Owner:DONGGUAN HUALI INDUSTRIES CO LTD

Immersion crepe paper and production method thereof

InactiveCN1793510ASolve quality problemsQuality improvementDefoamers additionSpecial paperCrêpe paperPulp and paper industry

The invention relates to immersion MeiWen base paper and its manufacturing technique. The immersion MeiWen base paper adopts 100% import wood pulp and paper technology to form. At lest its one surface is immersing 8-12g / m2 import latex layer. Its manufacturing technique includes the following steps: disintegrating; pulping, adding auxiliary materials; forming; dehydrating; vat pre-drying; cocking; infrared ray, two cylinder drying; taking-up; rewing parting cut; forming the MeiWen body paper; dipping it into import latex to make its surface form 8-12g / m2 import latex layer; drying; rolling; re-rolling cutting to complete the manufacturing technique. The invention has the advantages of simple technique, reliable product quality, satisfying userí»s demand, enlarging product using range, and convenient for popularization and application.

Owner:李建明

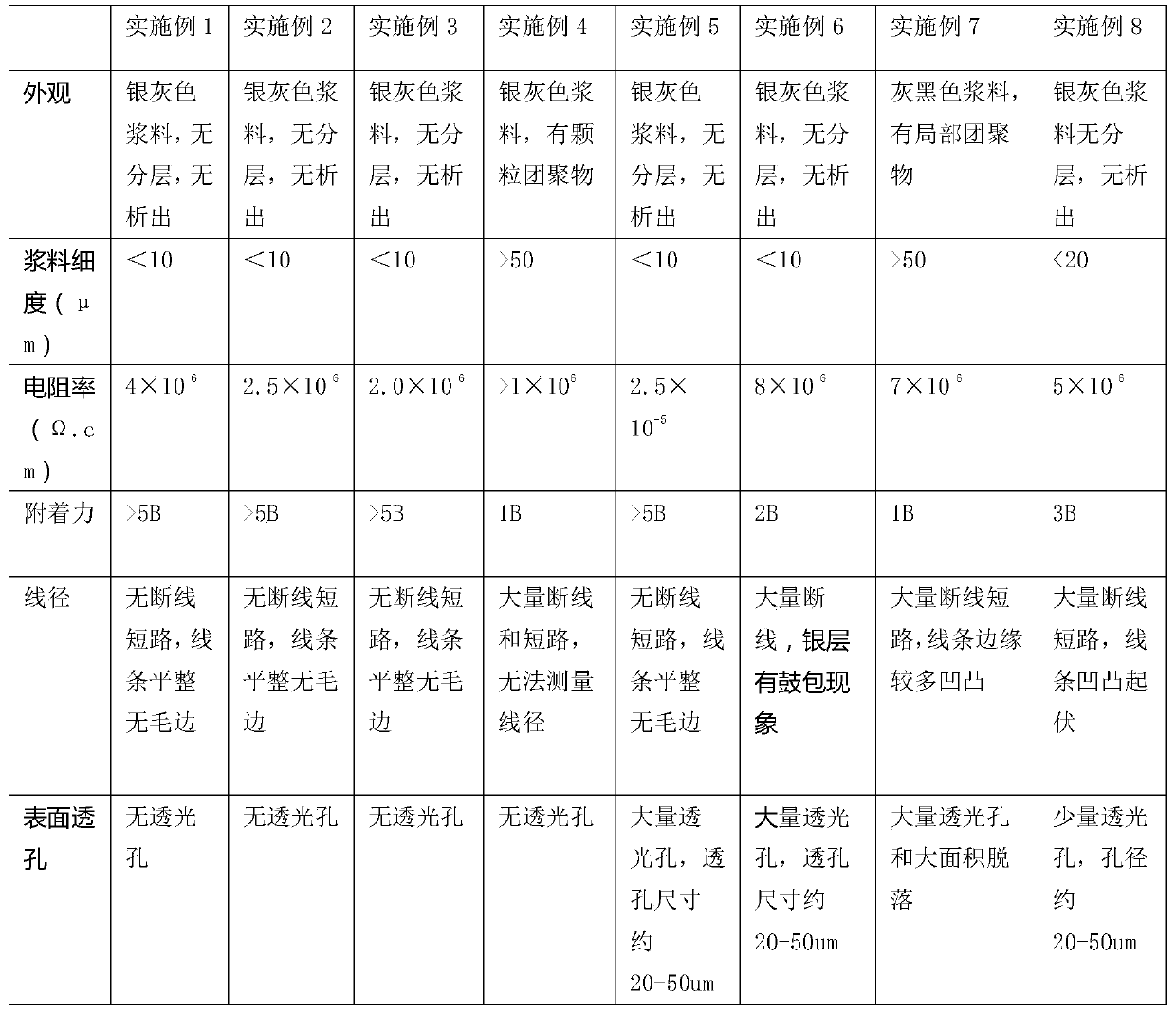

High-temperature sintering type yellow light conductive paste and preparation method thereof, conductive circuit and preparation method thereof

ActiveCN110335700AHigh resistivityImprove adhesionApparatus for heat treatmentNon-conductive material with dispersed conductive materialConductive pasteMelting temperature

The invention particularly relates to a high-temperature sintering type yellow light conductive paste and a preparation method thereof, a conductive circuit and a preparation method thereof. The high-temperature sintering type yellow light conductive paste comprises in percentage by weight: 75-90% of noble metal powder; 1%-5% of glass powder; and 8%-25% of photosensitive organic carrier, wherein the glass phase transition temperature Tg of the glass powder is 400-500 DEG C, and the melting temperature Tf is 500-600 DEG C. The noble metal powder is matched with the glass powder and the photosensitive organic carrier, so that the conductive paste is suitable for the high-temperature sintering; and the obtained conductive paste can achieve superfine wire diameter resolution, and has good resistivity and adhesive force after sintering. Glass powder with a proper glass phase transition temperature and a melting temperature is added to provide proper adhesive force for the metal conducting layer and the base material, and the optimized noble metal powder and the glass powder ensure that the sintered circuit does not have a shrinkage cavity and breakage and can reduce the resistivity; andmoreover, the photosensitive organic carrier with a proper monomer and an initiator in proper type and proportion has high resolution and a superfine line diameter after being developed.

Owner:乾宇微纳技术(深圳)有限公司 +1

Gluing flattening equipment for wine box processing and processing method thereof

The invention discloses gluing flattening equipment for wine box processing. The equipment comprises an operation table, wherein a cover plate is clamped at the top end of the operation table, a through hole is formed in the top of the cover plate, a plurality of air pumps are arranged in the operation table, the top end of the cover plate is fixedly connected with a supporting frame, fixing mechanisms are fixedly connected to the two sides of the bottom of the supporting frame, a roller is arranged between the two fixing mechanisms, the two sides of the top of the supporting frame are respectively provided with a first sliding chute, the top of the supporting frame is connected with a clamping plate in a sliding mode through a first sliding chute, a telescopic fixing frame is fixedly connected to the bottom end of the clamping plate, and a gluing mechanism is arranged inside the telescopic fixing frame. The equipment discloses the gluing flattening equipment for the wine box processing and the processing method thereof, gluing can be carried out more stably through a servo motor, meanwhile, continuous gluing can be carried out, the stability and the gluing efficiency during gluingare improved, when the wine box is placed, the wine box can be fixed through a magnet, the wine box is simple and convenient, and damage to the wine box cannot be caused.

Owner:JIANGSU MEIJIA PACKAGE

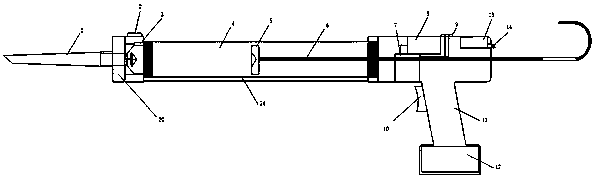

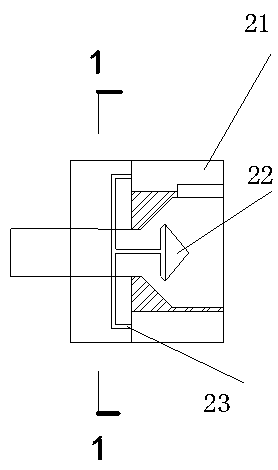

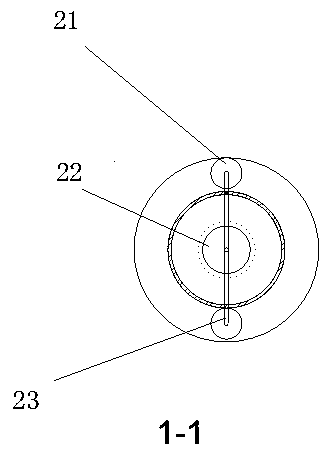

Intelligent glue gun

InactiveCN108745806AStable pressureAvoid wastingLiquid surface applicatorsCoatingsEngineeringSingle chip

The invention discloses an intelligent glue gun. A gun nozzle (1) is installed at the front end of a gun body (4); a glue tank (24) is installed on the middle portion of the gun body (4); the glue tank (24) and the gun nozzle (1) are connected through a glue port opening controller (20); a gun handle (11) is installed on the rear lower portion of the gun body (4); a switch (10) is arranged on thegun handle (11); an infrared speed measuring device (2) is arranged at the front end of the gun body (4); a pressure sensor (3) is arranged at the front end of the glue tank (24); a screw (6) penetrates through a screw transmission (7) located on the rear portion of the gun body (4), the front end is connected with a gun bowl (5) located in the glue tank (24), and the rear end is located outside the gun body (4); a propelling speed adjusting motor (8) and a transmission clutch (9) are installed on the screw transmission (7); a single-chip microcomputer processor (13) is installed at the tail end of the gun body (4); and a propelling speed relevance adjustor (14) is installed on the single-chip microcomputer processor (13). The intelligent glue gun can adjust the glue discharging speed in aself-adaptive manner, glue discharging is stable, the gluing efficiency can be improved, the labor intensity of personnel is relieved, and materials are saved.

Owner:贵州建工集团第七建筑工程有限责任公司

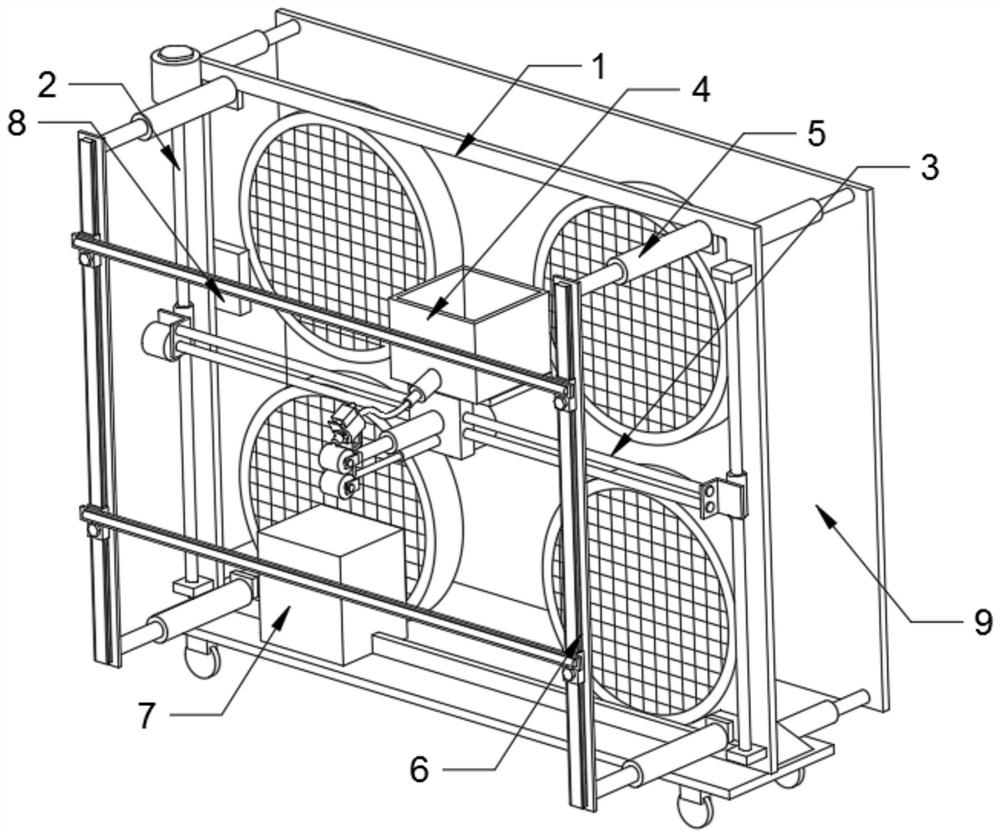

Butyl rubber coating machine

ActiveCN105946334AChange the squeegee angleGlue accurateControlling laminationLaminationMagnetic powderTension control

The invention discloses a butyl rubber coating machine which comprises first and second unreeling mechanisms, an automatic skew adjustment mechanism, a rubber scraping and coating mechanism, a compounding mechanism, a cooling forming mechanism and a rolling-up mechanism, and is characterized in that a first discharge material of the first unreeling mechanism enters the compounding mechanism after passing through the automatic skew adjustment mechanism, a first tension control roller and the rubber scraping and coating mechanism; a second discharge material of the second unreeling mechanism enters the compounding mechanism after passing through a second tension control roller; a compound material compounded by the compounding mechanism enters the rolling-up mechanism after passing through the cooling forming mechanism and a third tension control roller; the first, second and third tension control rollers are respectively arranged on first, second and third tension sensors; the first tension sensor is electrically connected with a first magnetic powder brake of the first unreeling mechanism; the second tension sensor is electrically connected with a second magnetic powder brake of the second unreeling mechanism; and the third tension sensor is electrically connected with a third magnetic powder brake of the rolling-up mechanism. The butyl rubber coating machine can be applicable to coating of poor materials of high-viscosity runners, such as butyl rubber, is good in coating quality, and can improve the production efficiency.

Owner:RUIAN JIAYUAN MACHINERY

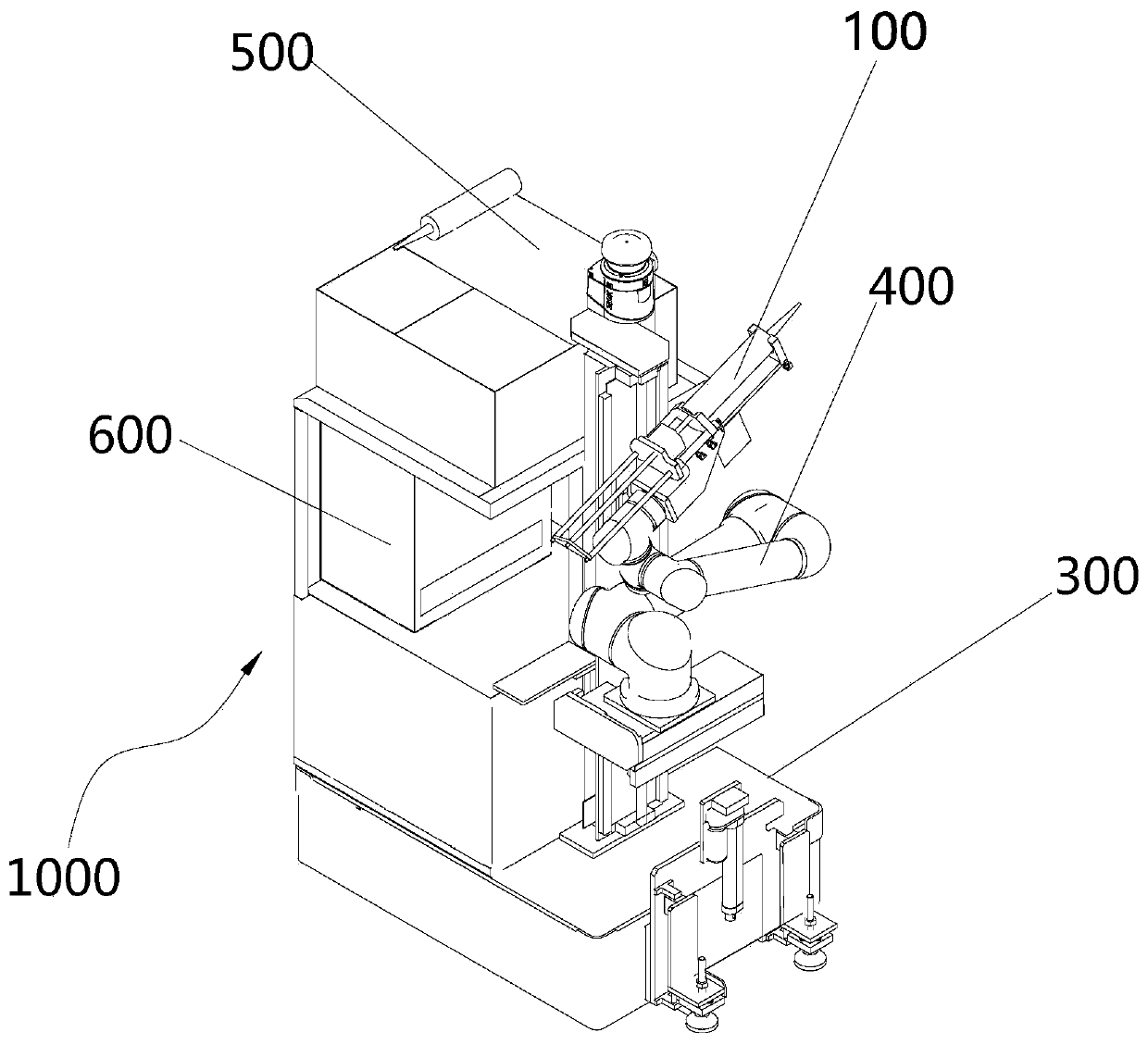

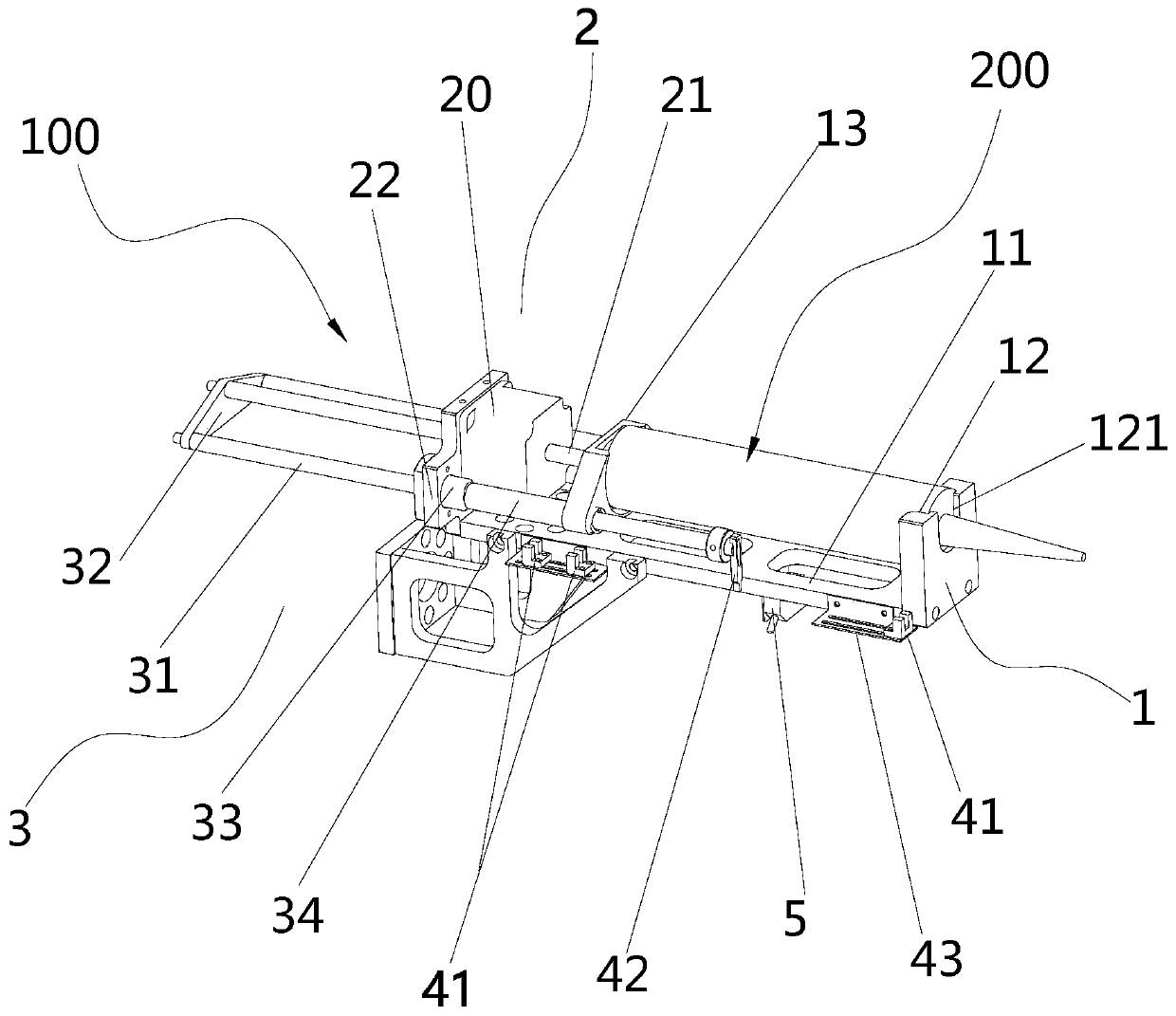

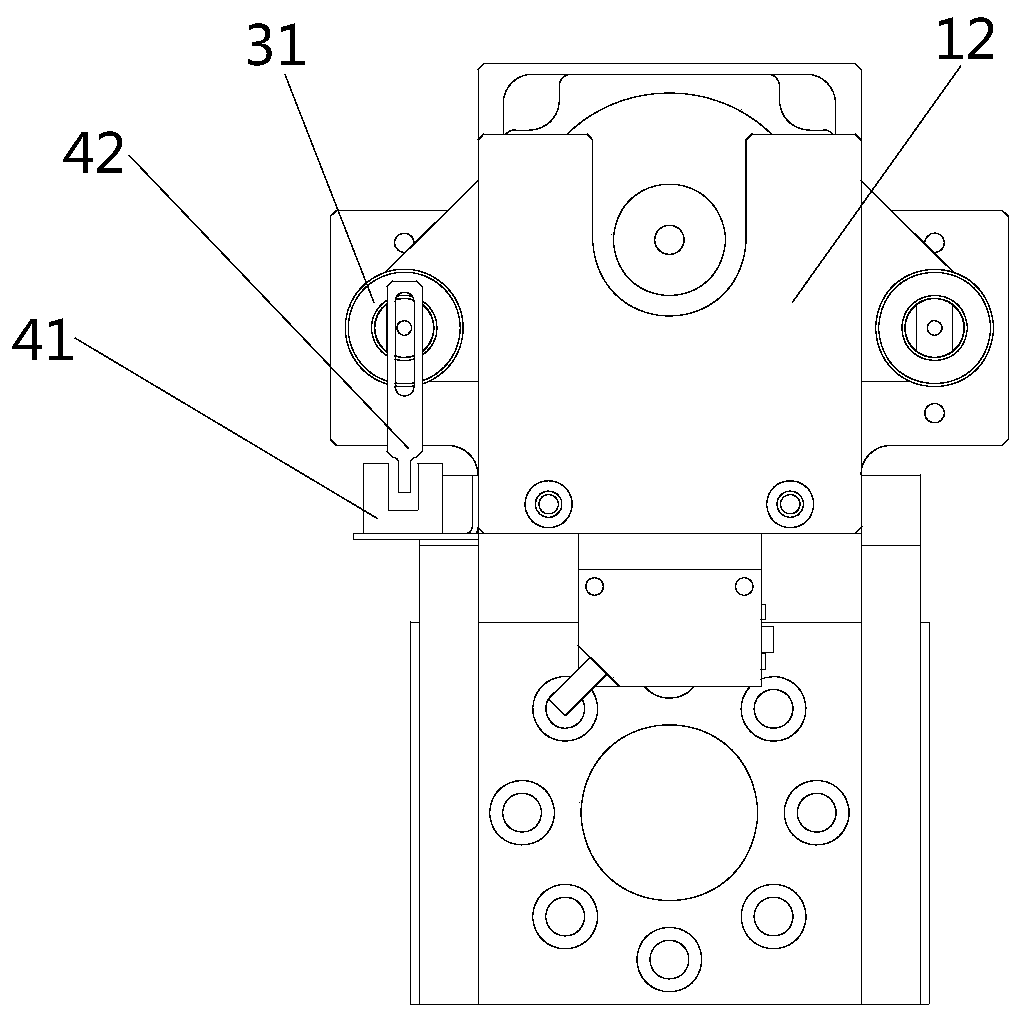

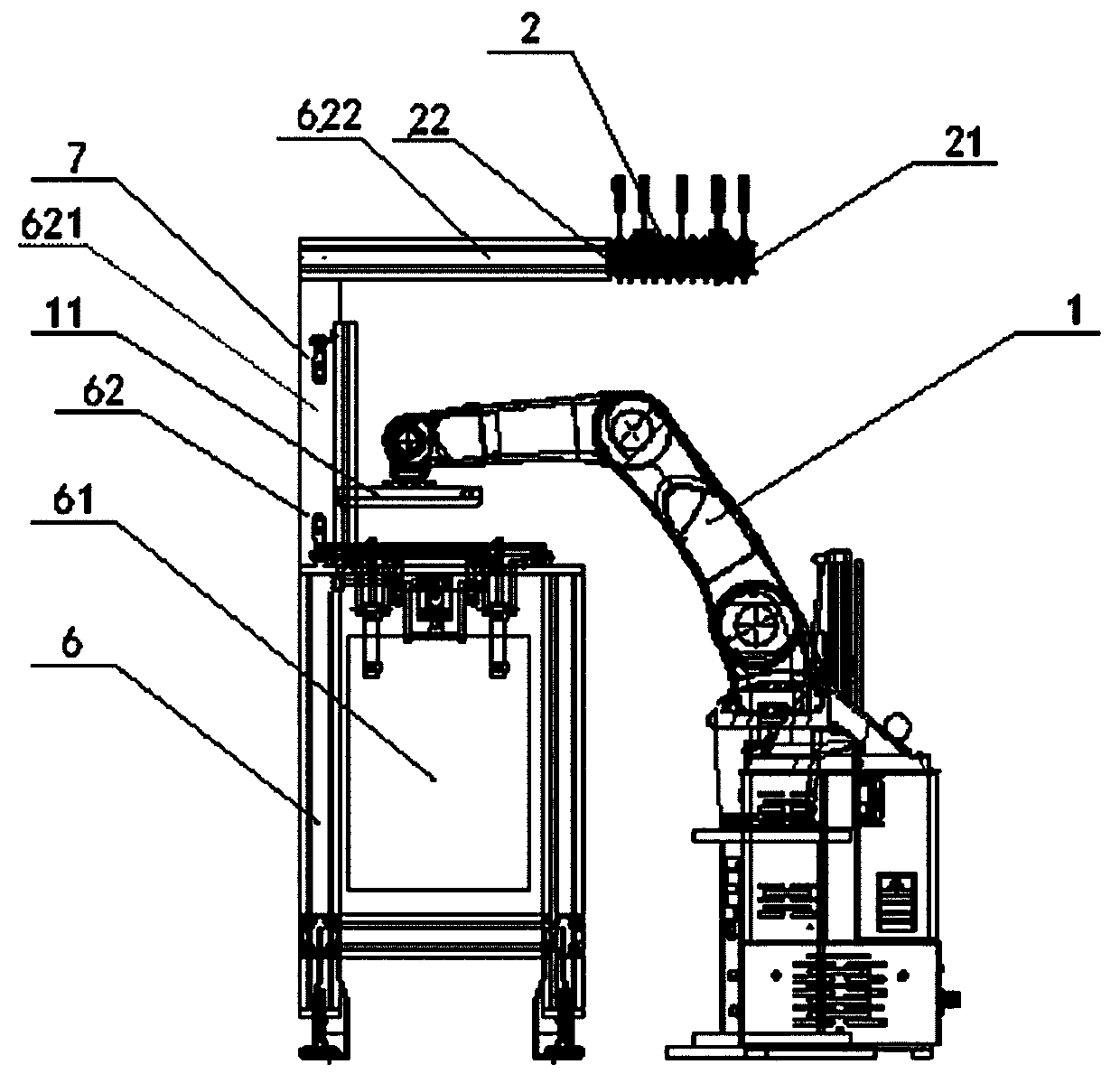

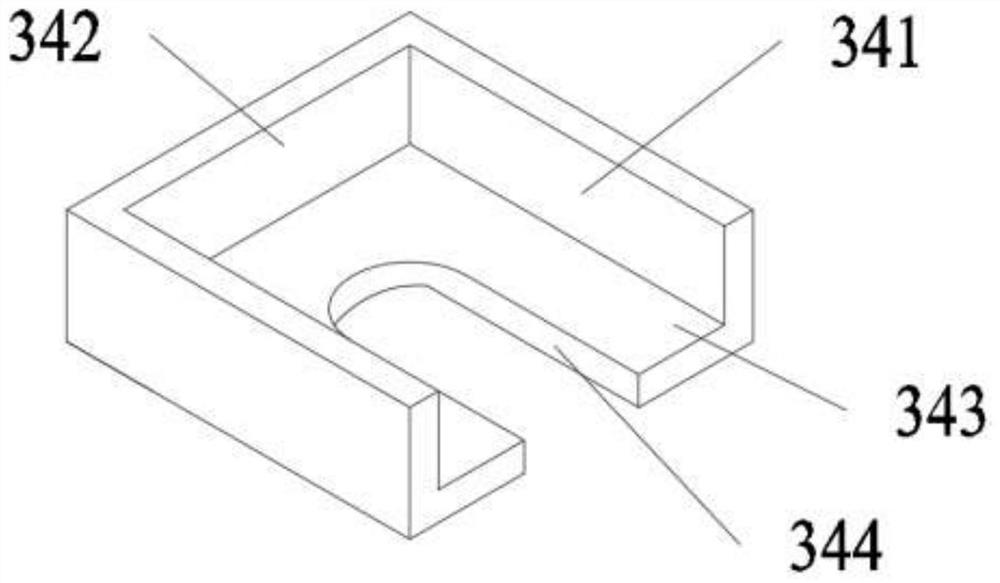

Gluing robot and glue applying device thereof

ActiveCN110961314ARealize automatic replacement functionReduce participationLiquid surface applicatorsCoatingsEngineeringElectric drive

The invention provides a gluing robot and a glue applying device thereof. The glue applying device comprises a glue cylinder clamping mechanism and a gluing mechanism. The glue cylinder clamping mechanism comprises a bottom plate, a front end plate fixedly arranged on the bottom plate and used for supporting the front end of the glue cylinder, and a tail end plate capable of being driven to be close to or away from the front end plate to act on the tail end of the glue cylinder. The gluing mechanism comprises a push rod, and the push rod is connected to the tail end plate and can be driven toact on an inner cover in the glue cylinder so as to extrude glue liquid. The front end plate of the glue cylinder clamping mechanism is fixed with the bottom plate, the tail end plate can be driven tomove relative to the front end plate, so that the glue cylinder can be clamped or loosened; the push rod is electrically driven to push glue, the glue applying device can automatically glue and replace the glue cylinder, personnel participation can be reduced in the construction process of the gluing robot, the labor cost is reduced, and the gluing quality is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Roof gluing equipment and roof gluing method

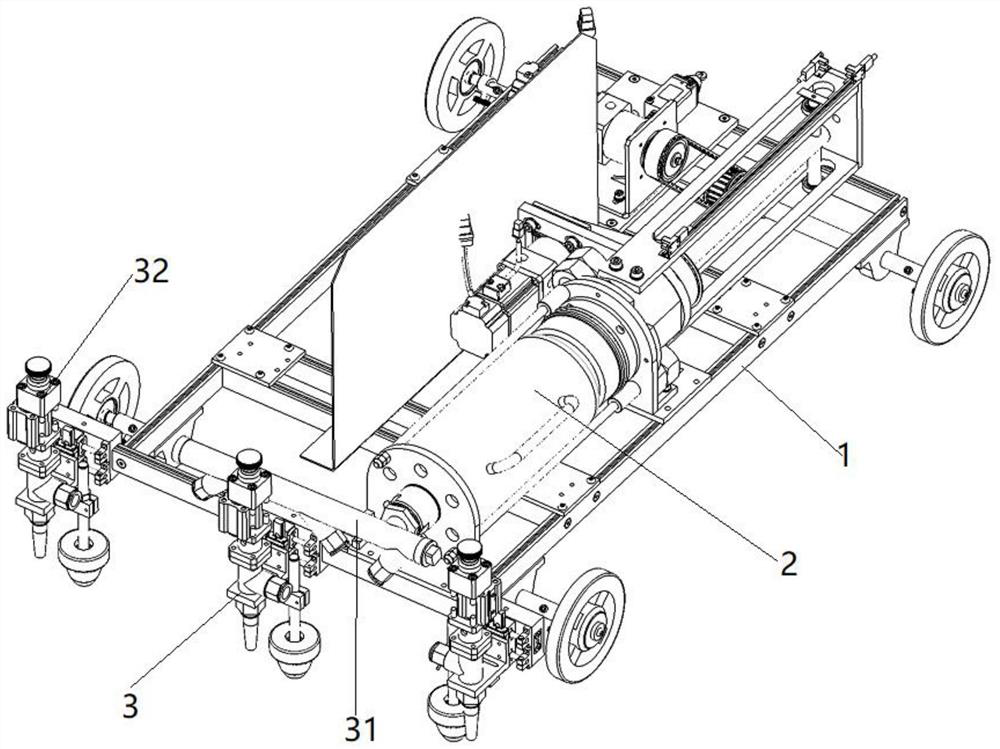

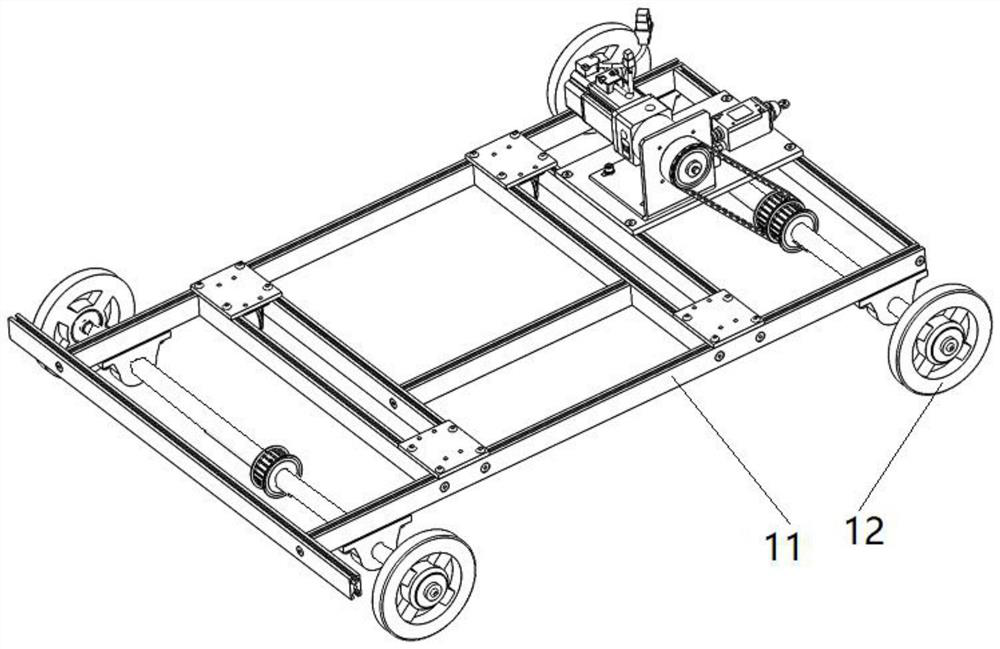

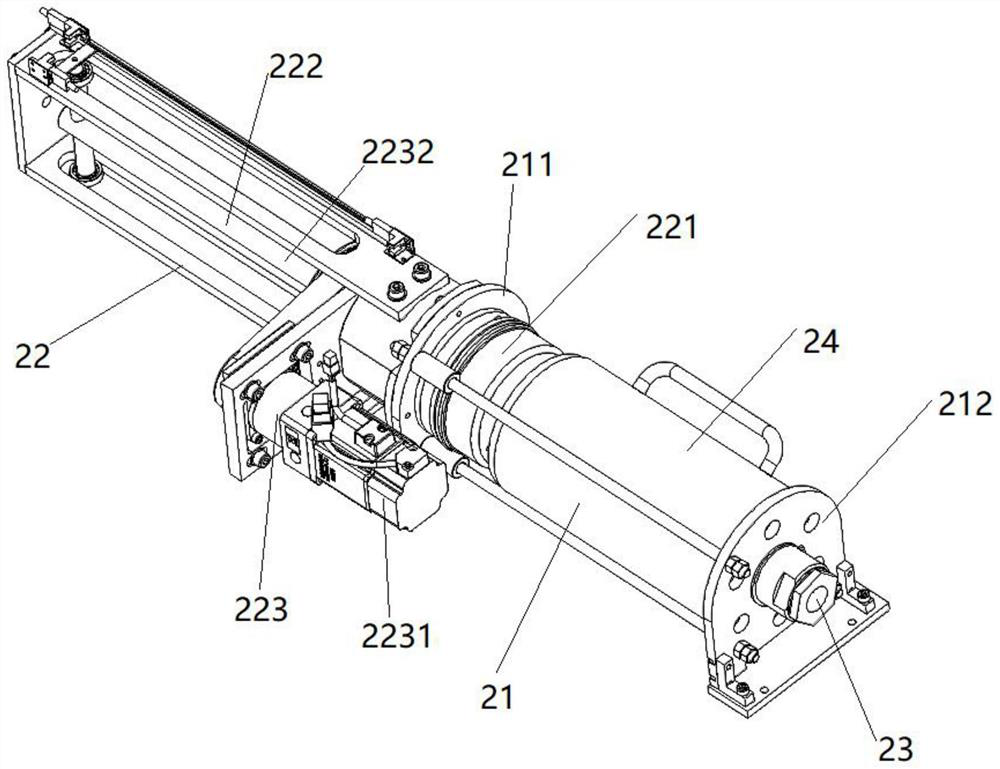

ActiveCN112221851AReduce the difficulty of homeworkImprove gluing qualityLiquid surface applicatorsRoof toolsStructural engineeringMechanical engineering

The invention discloses roof gluing equipment and a roof gluing method. The roof gluing equipment comprises a walking mechanism, a glue squeezing mechanism and a gluing mechanism, wherein the walkingmechanism is provided with the glue squeezing mechanism, the glue squeezing mechanism is connected with the gluing mechanism, the glue squeezing mechanism comprises a glue barrel clamping mechanism and a glue pushing mechanism, and the gluing mechanism comprises a plurality of gluing valves. The walking mechanism walks on a roof to drive the glue extruding mechanism and the gluing mechanism to move on the roof, the glue extruding mechanism is used for squeezing glue and squeezing materials into the gluing mechanism while the walking mechanism moves, and the gluing mechanism is used for gluing,so that the manual gluing difficulty can be effectively reduced, and the gluing quality and the gluing efficiency are improved.

Owner:CHENGDU GREATER AUTOMATION EQUIP CO LTD

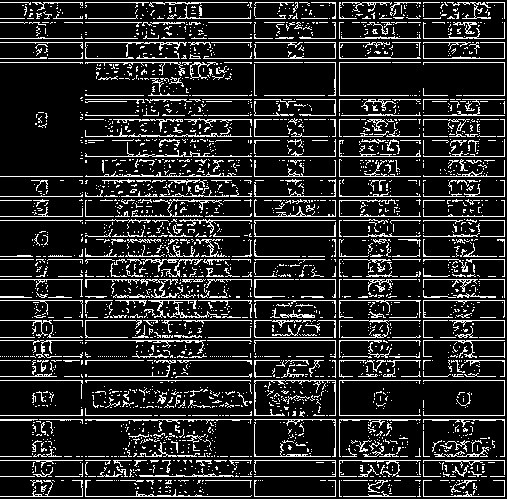

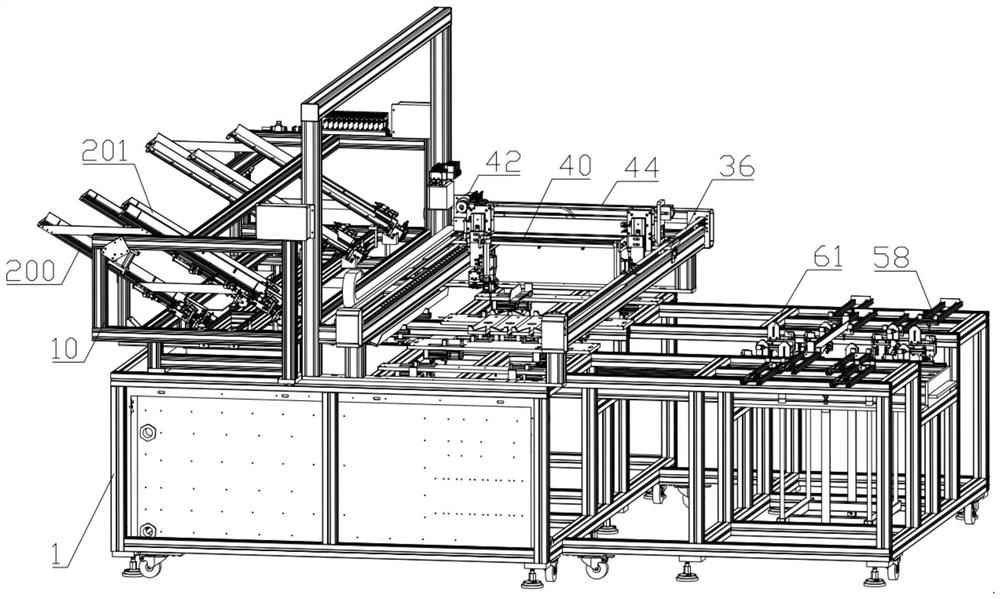

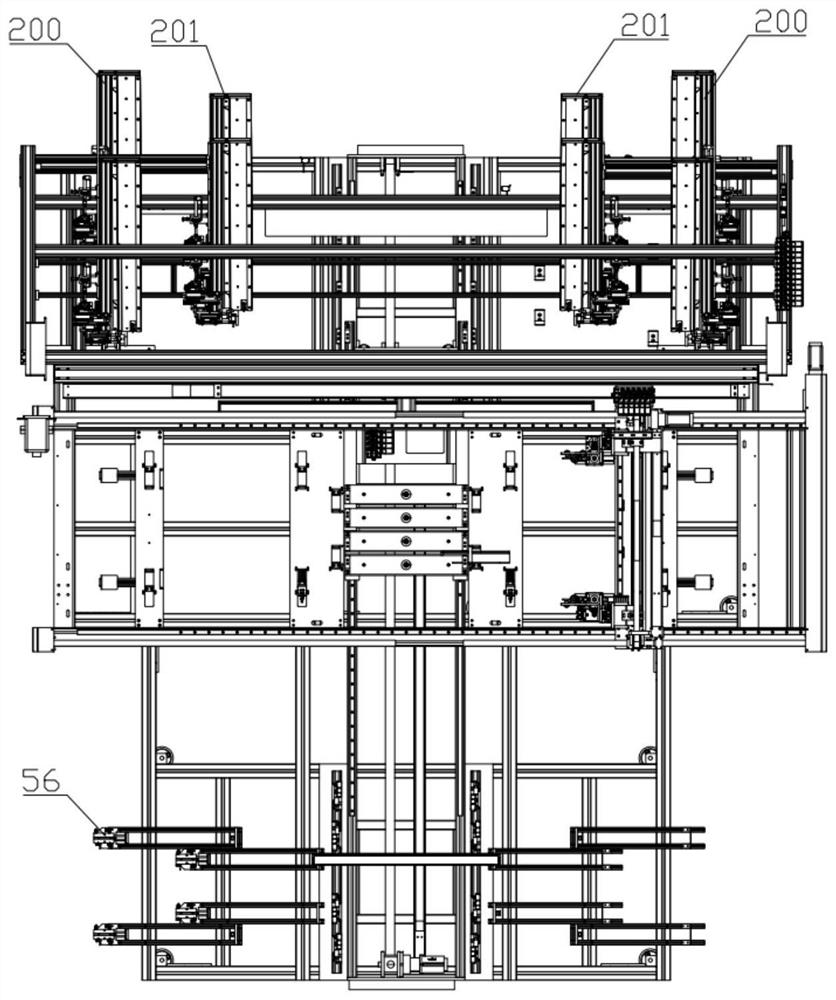

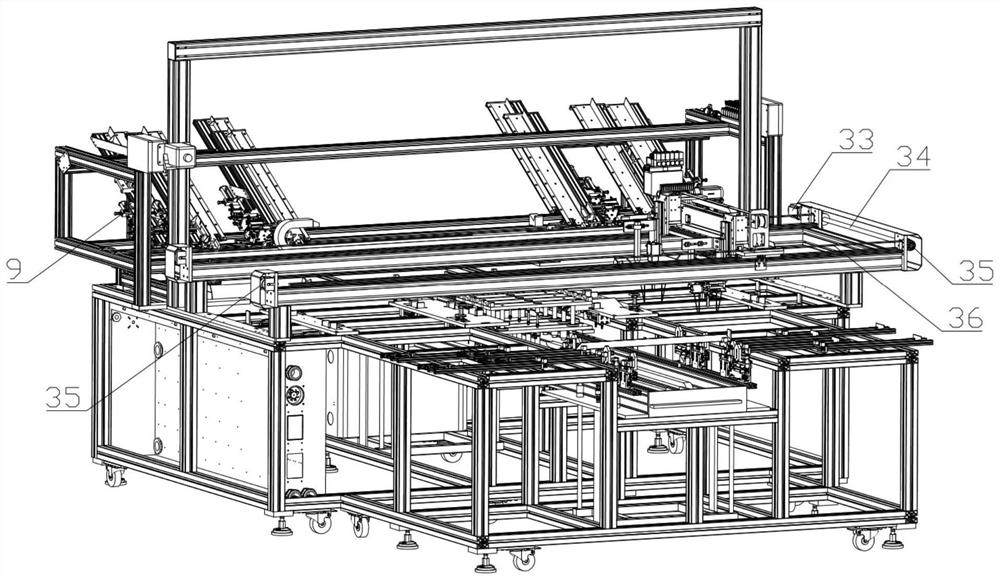

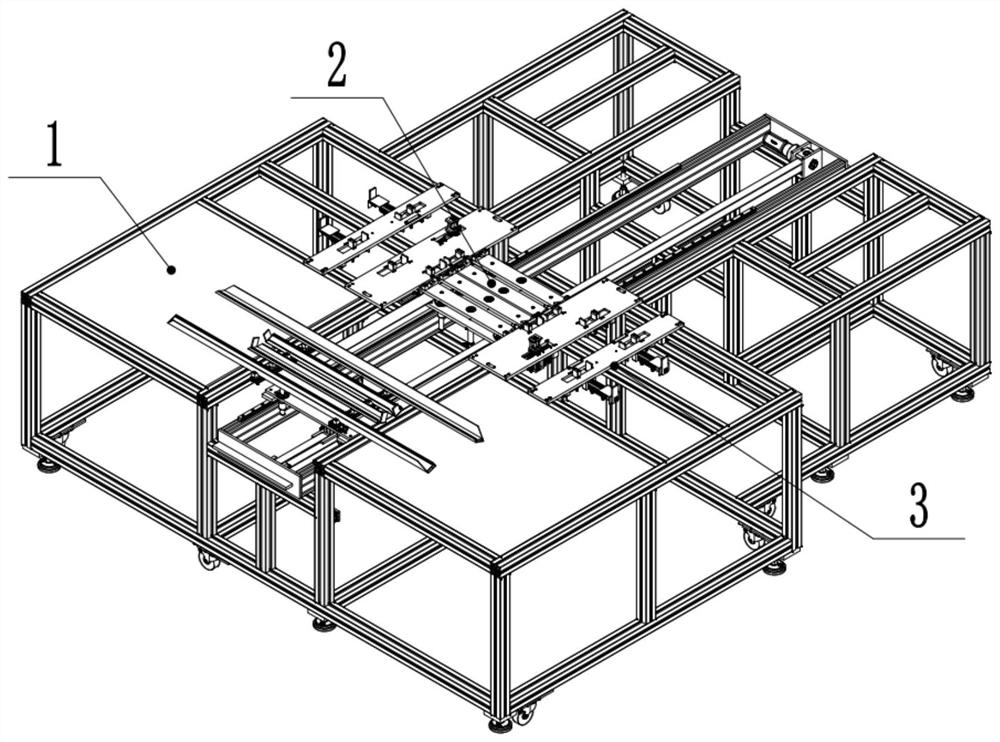

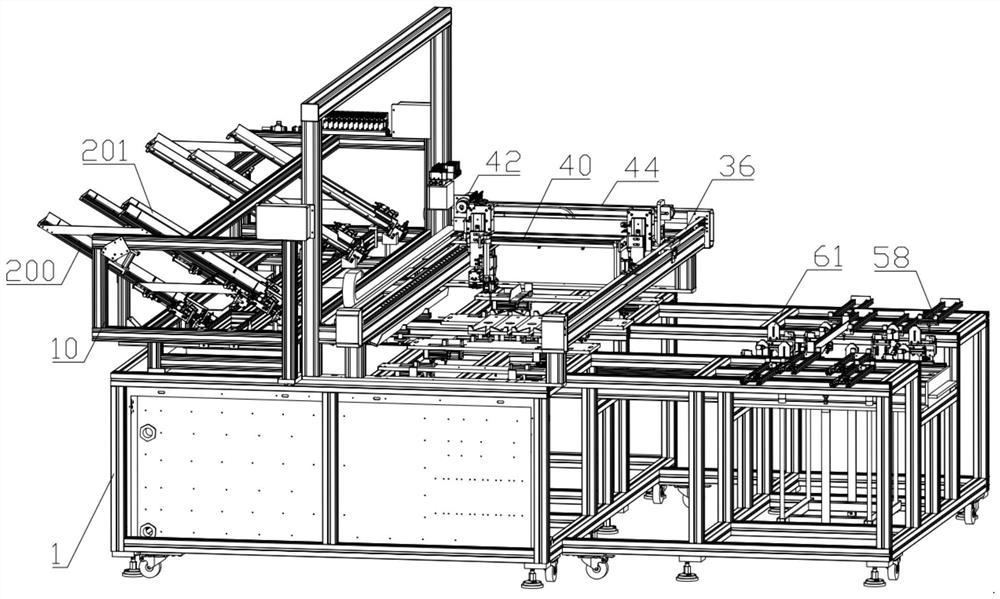

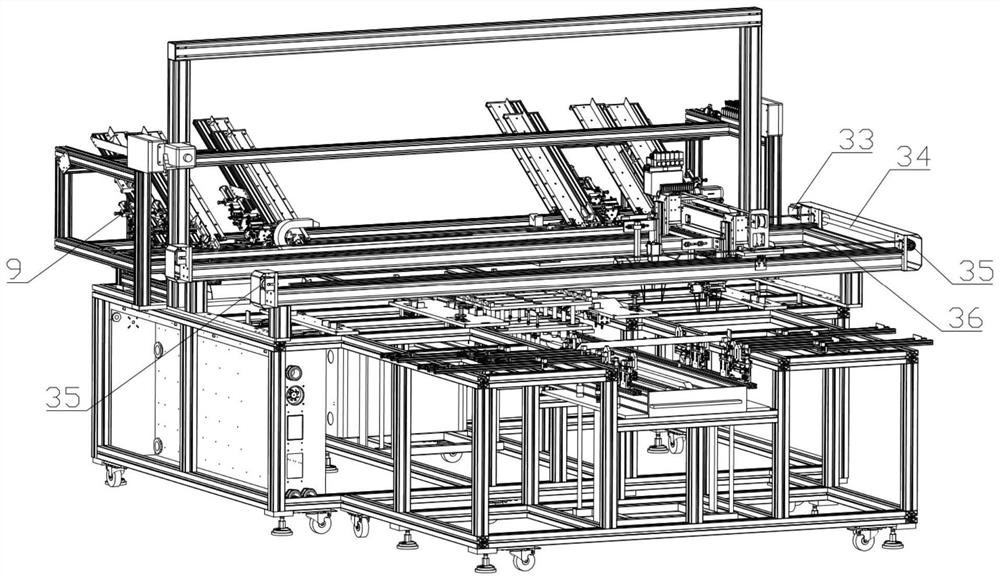

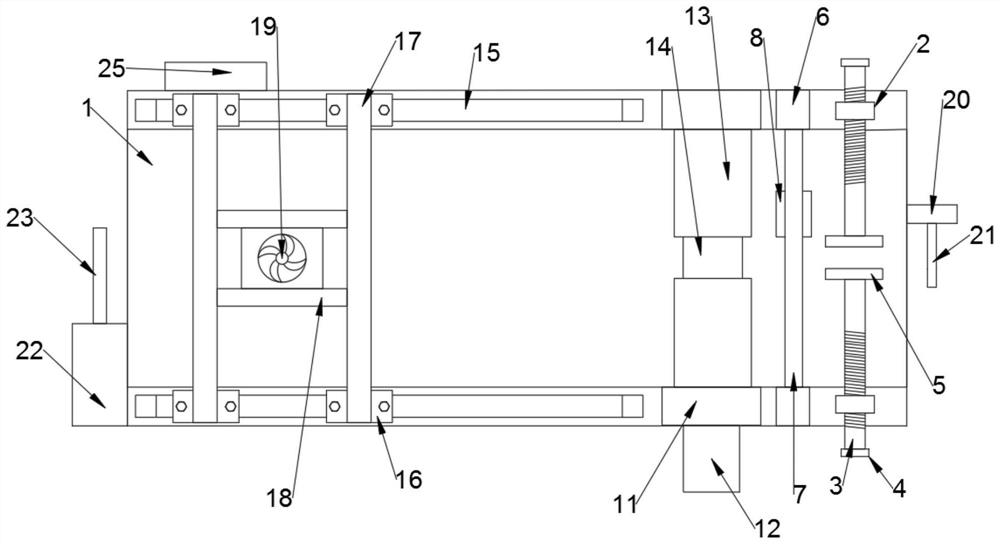

Efficient flexible double-gluing-head frame gluing machine

ActiveCN112934612AGuaranteed practicality and efficiencyImprove work efficiencyLiquid surface applicatorsCoatingsManufacturing engineeringIndustrial engineering

The invention discloses an efficient flexible double-gluing-head frame gluing machine. At present, a frame gluing machine integrating discharging of a storage bin, feeding of a transfer platform, gluing of a gluing system, discharging of the transfer platform and frame restoration does not exist. According to a double-load displacement separation feeding device disclosed by the invention, fallen materials of a storage bin falling device are conveyed to the double-glue-head gluing device for gluing, and a glued frame is conveyed to a frame restoration device for restoration. According to the gluing machine, the processes of discharging of the storage bin, feeding of the transfer platform, gluing of the gluing system, discharging of the transfer platform and frame restoration are integrated; The storage bin falling device realizes ordered falling of frames with different lengths and different widths; the double-glue-head gluing device is provided with a double-nozzle rotary gluing head and is provided with an online bilateral detection device, so that the application range is widened, and the gluing efficiency is improved; and the frame restoration device at the rear end of the gluing area meets the requirements of the industry on the arrangement and posture of the glued frame, and meanwhile, the working efficiency of a production line is further improved.

Owner:上海盛普流体设备股份有限公司 +1

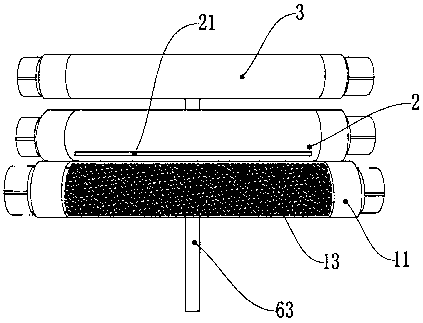

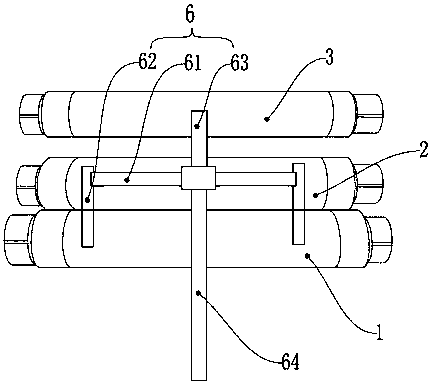

Convenient and fast antithetical couplet pasting device

The invention discloses a convenient and fast antithetical couplet pasting device. The device comprises, from bottom to top in sequence, a glue distributing roller, an antithetical couplet winding roller and a pressure roller which are arranged and connected transversely. The glue distributing roller comprises a glue distributing barrel, a baffle and a bristlebrush roller body; glue inlets are formed in the two ends of the glue distributing barrel correspondingly; the baffle is mounted in the glue distributing barrel and partitions the glue distributing barrel into a front glue outlet cavity and a rear glue inlet cavity; a glue applying port is formed in the front glue outlet cavity; the rear glue inlet cavity communicates with the corresponding glue inlet; the front glue outlet cavity communicates with the rear glue inlet cavity through through holes which are uniformly distributed and formed in the surface of the baffle; the bristlebrush roller body is mounted in the front glue outlet cavity and right faces the glue applying port; an antithetical couplet outlet is formed in the front end of the side surface of the antithetical couplet winding roller; and the glue distributing roller, the antithetical couplet winding roller and the pressure roller roll synchronously from top to bottom. The convenient and fast antithetical couplet pasting device has the advantages that glue applying is uniform and stable, and sticking is fast and flat.

Owner:佛山市禅城区下朗小学

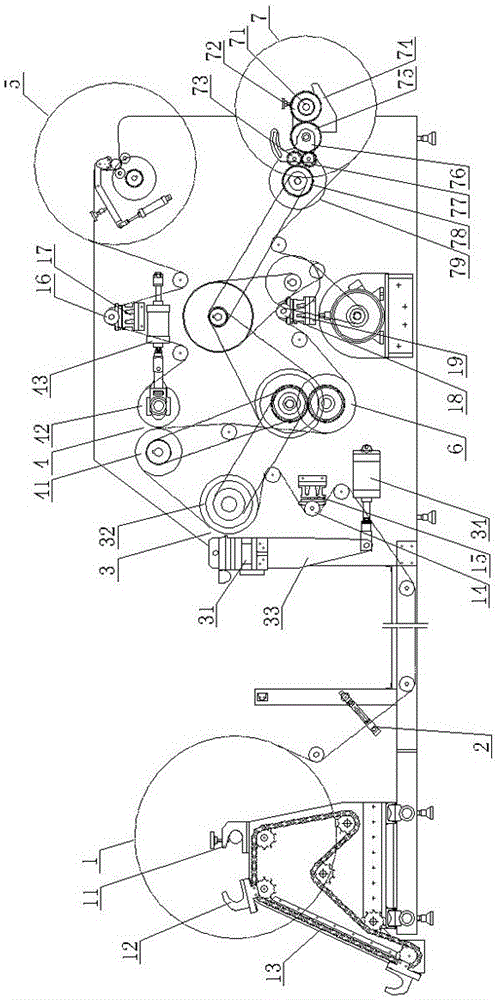

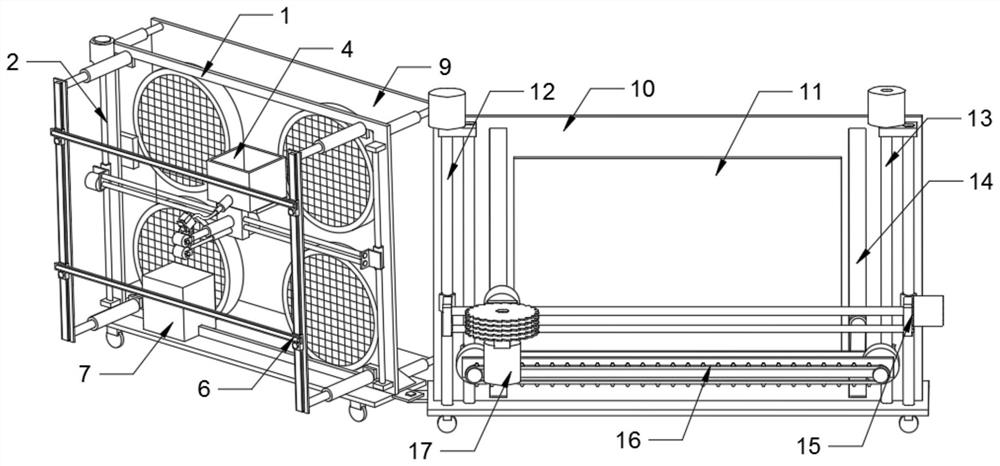

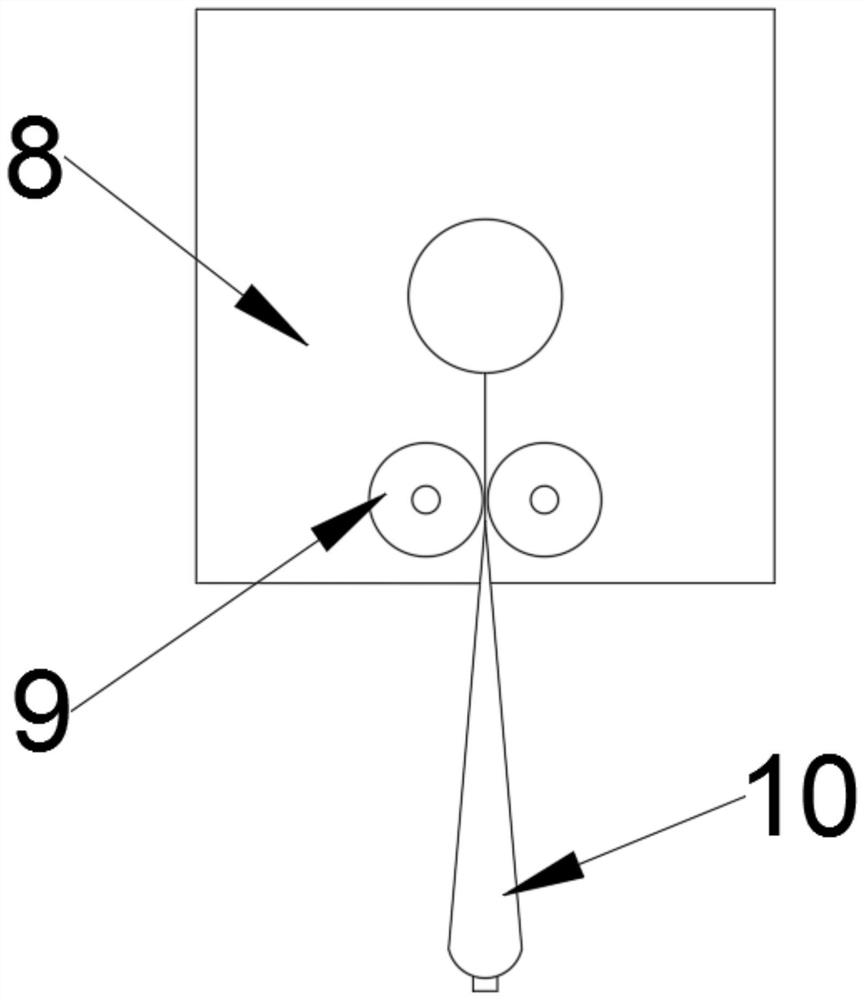

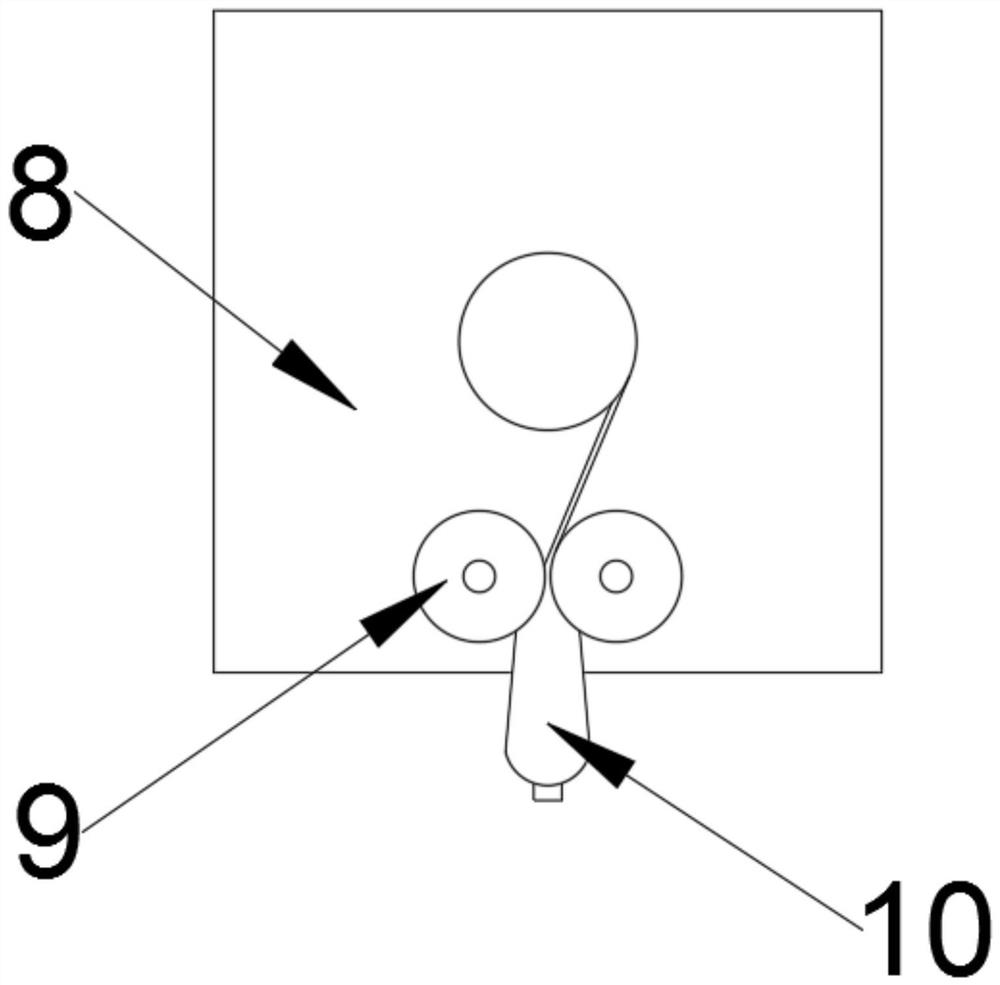

Carbon fiber fabric reinforced PPS prepreg production process and equipment

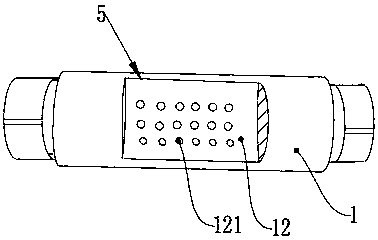

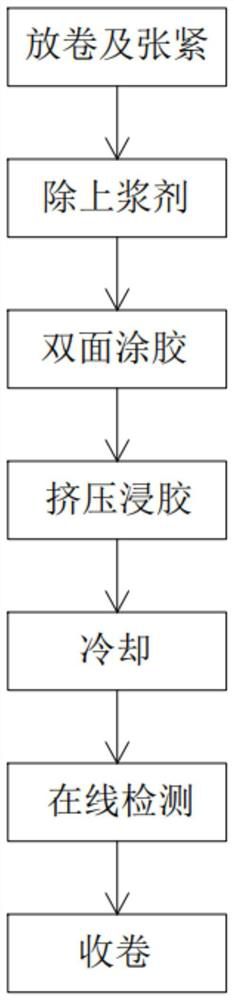

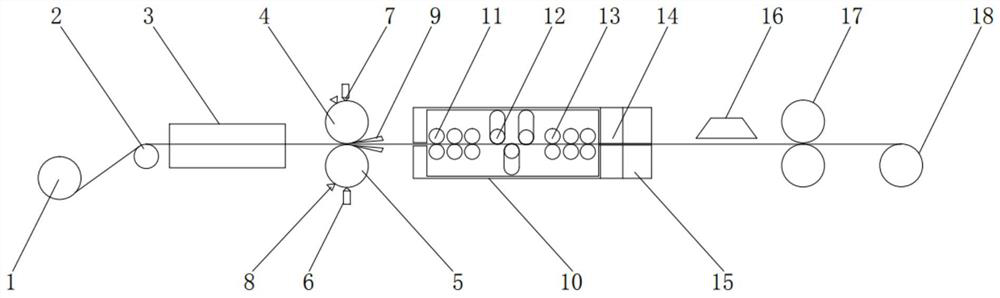

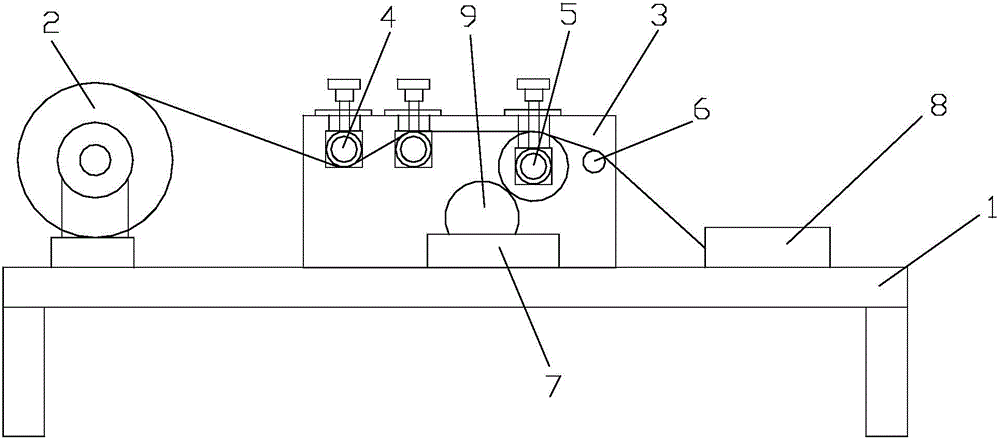

PendingCN113352501AUniform and stable coatingEase of industrial productionCoatingsCarbon fibersRetting

The invention discloses a carbon fiber fabric reinforced PPS prepreg production process and equipment, relates to the technical field of carbon fiber fabric reinforced PPS prepreg production, and is mainly used for solving the problem that domestic carbon fiber fabric reinforced PPS prepreg does not have industrial production conditions at present. The carbon fiber fabric reinforced PPS prepreg production process comprises the following steps of 1, unwinding and tensioning; 2, removing a sizing agent; 3, gluing on the double sides; 4, extruding and impregnating; 5, cooling; 6, online detecting; and 7, winding. The equipment structurally comprises an unwinding device, a front-section guide roller, a first drying oven, a gluing roller set, a second drying oven, a heat insulation cavity, a cooling cavity, an on-line weighing instrument, a traction roller set and a winding device. According to the carbon fiber fabric reinforced PPS prepreg production process and the equipment provided by the invention, the industrial production of the carbon fiber fabric reinforced PPS prepreg can be completed by utilizing the process and the equipment.

Owner:SICHUAN XIN WAN XING CARBON FIBER COMPOSITES

Aluminum foil gluing device

InactiveCN105642495ASimple structureReasonable designLiquid surface applicatorsCoatingsEngineeringAluminum foil

The invention discloses an aluminum foil gluing device. The aluminum foil gluing device comprises a support. An unwinding rack and a traction mechanism are arranged on the support. A box body is arranged between the unwinding rack and the traction mechanism. Guide rollers used for guiding and tensioning aluminum foil coming from the unwinding rack are installed in the box body. A first gluing roller used for gluing the surface of the aluminum foil is installed in the position, downstream the guide rollers, in the box body. A glue uniformizing roller used for uniformizing glue on the surface of the aluminum foil after gluing is installed in the position, downstream the first gluing roller, in the box body. A glue storage tank used for storing the glue is arranged at the bottom of the box body. A second gluing roller is installed in the position, above the glue storage tank and under the first gluing roller, in the box body. The second gluing roller makes contact with the first gluing roller and rotates along with rotation of the first gluing roller. The bottom of the second gluing roller is immersed in the glue in the glue storage tank. The aluminum foil gluing device is simple in structure and reasonable in design, and mass continuous production is easy to achieve.

Owner:陕西银河网电科技有限公司

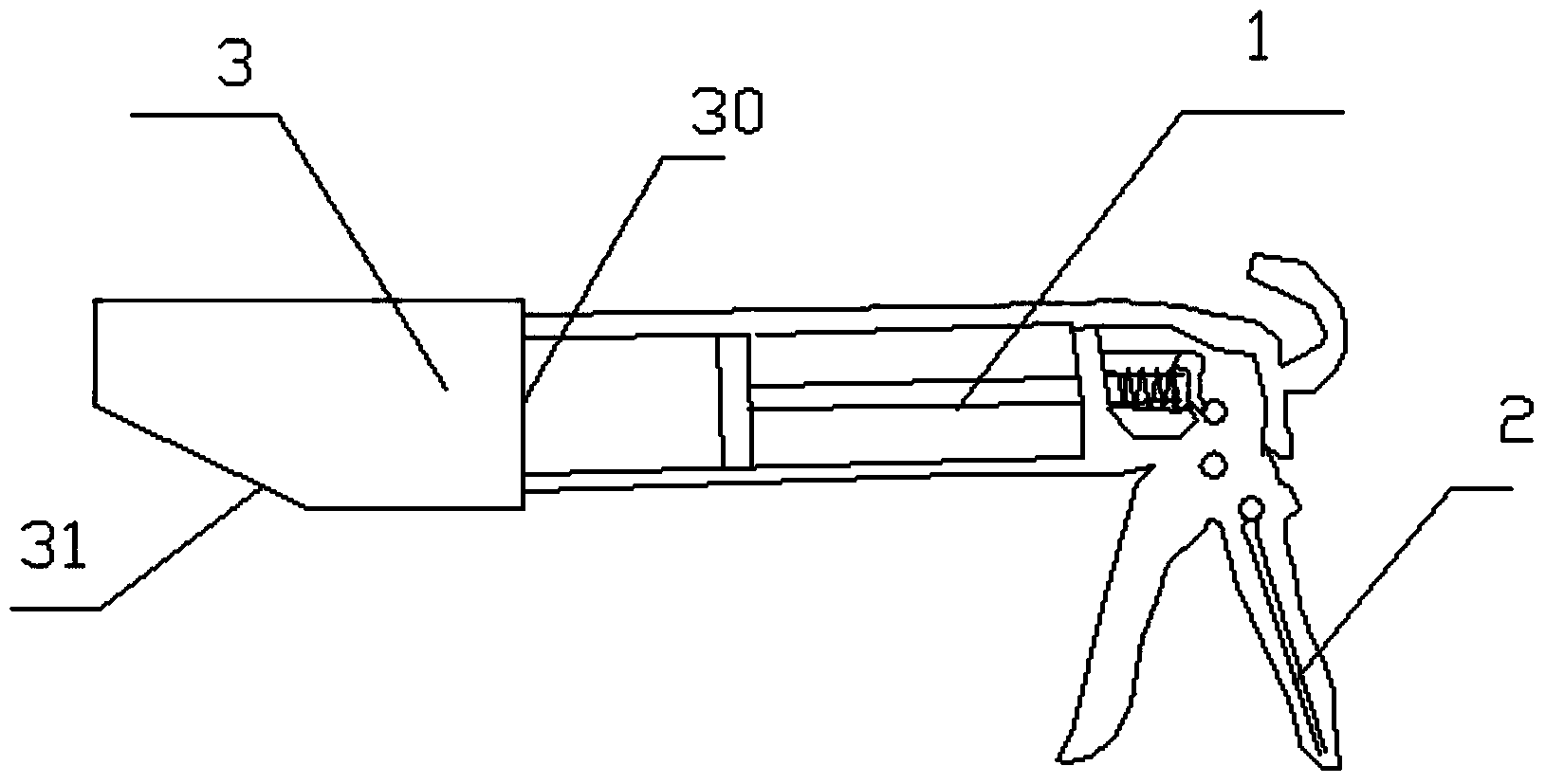

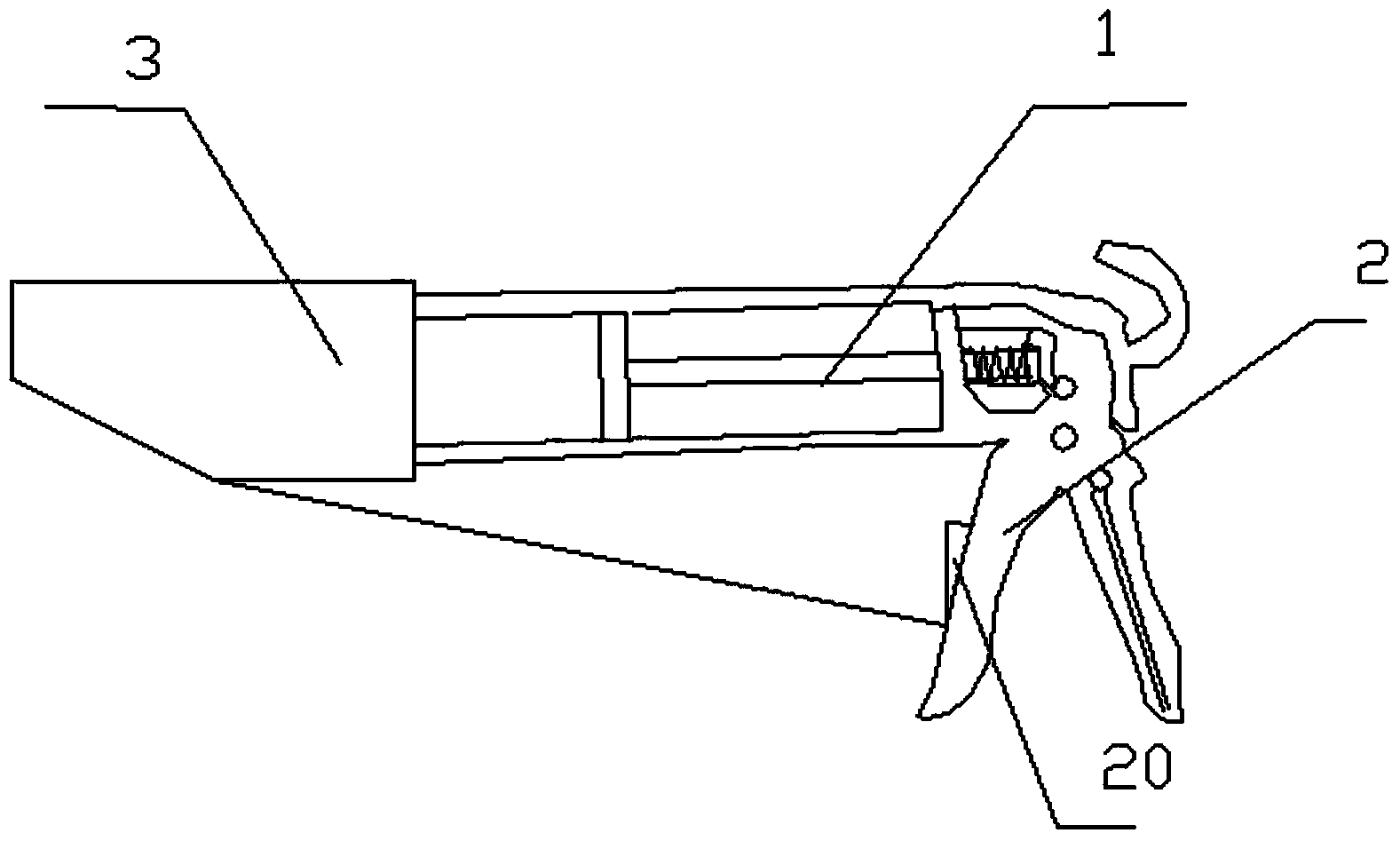

Gluing gun

ActiveCN104107792AGlue flow rate decreasesEasy to controlLiquid surface applicatorsCoatingsComing outGlue line

The invention relates to a gluing gun, comprising a gun holder and a gun body. The gluing gun also comprises a gluing pipe connected to the gun body. Two ends of the gluing pipe are open; one end of the gluing pipe is a planar opening; and the other end of the gluing pipe is an inclined opening. The planar opening is communicated with a glue outlet; the planar opening is used for communicating the glue outlet and the gluing pipe of the gluing gun; glue in the gluing gun comes out from the glue outlet and enters the gluing gun; the other end of the gluing pipe is the inclined opening; and the glue is extruded out from the inclined opening. Since the opening is changed into the inclined opening, glue output flow is reduced and can be controlled easily, thereby saving the glue. Meanwhile, the glue output of the inclined opening is more stable; the extruded glue is uniform; and an extruded glue line is regular and beautiful.

Owner:湖州水平玻璃有限公司

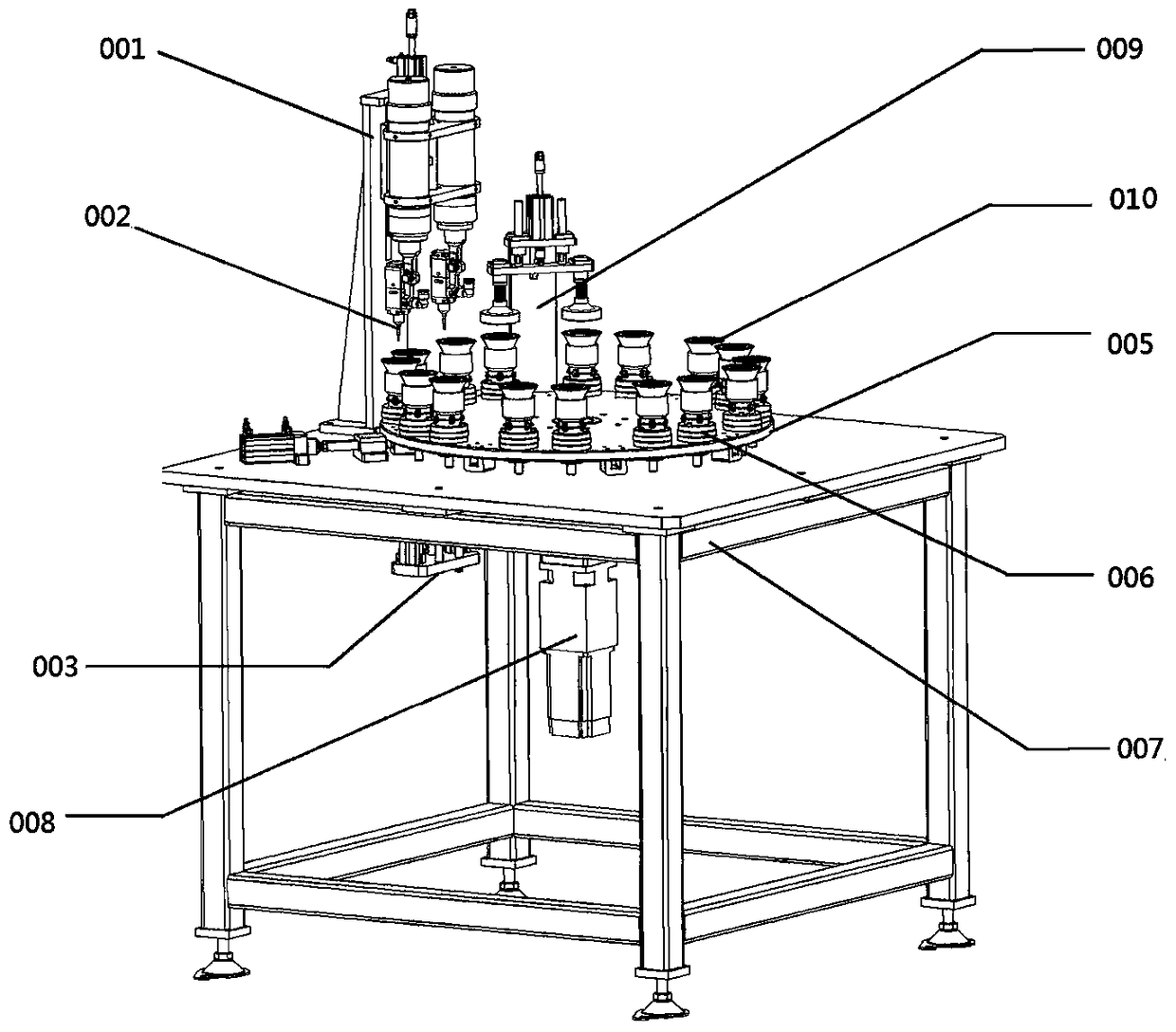

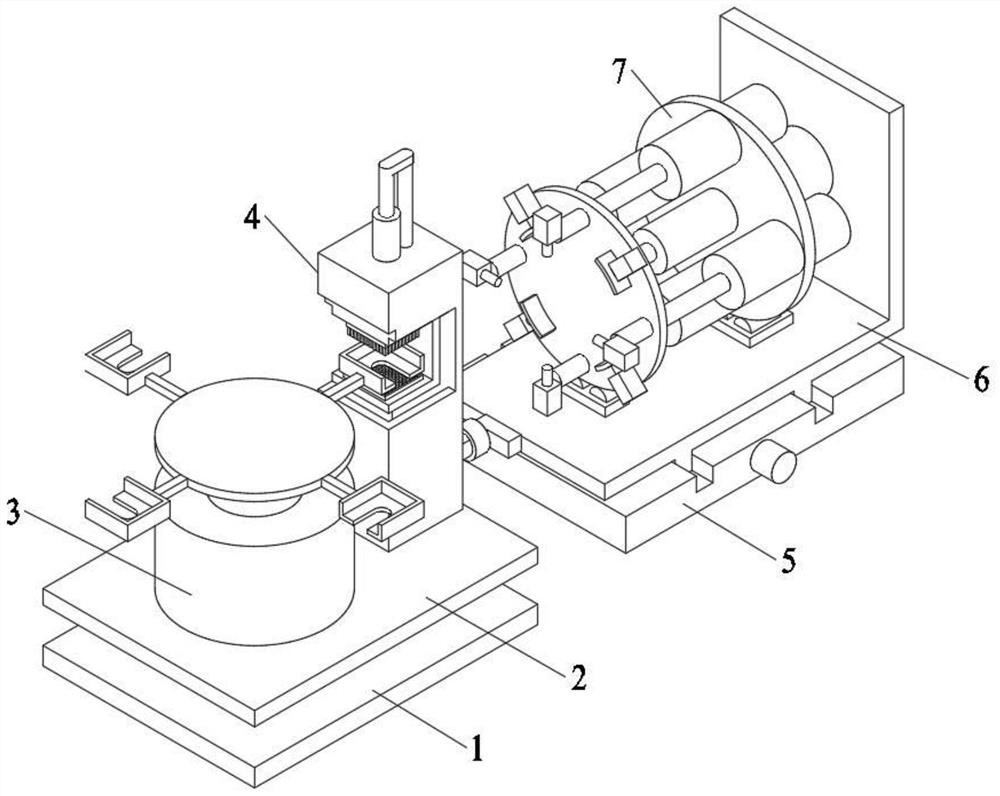

A kind of led lamp base dispensing machine

ActiveCN104492657BGlue stableDispensing effect is easy to controlLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention relates to the technical field of automatic LED lamp production equipment and in particular relates to an LED lamp cap dispenser. The LED lamp cap dispenser comprises a dispensing assembly, a dispensing needle, a dispensing rack, a rotary driving assembly, a base mounting disc, a lamp cap positioning seat and a mounting disc motor, wherein the base mounting disc is rotationally arranged on the dispensing rack; the mounting disc motor is arranged on the dispensing rack and can drive the base mounting disc to rotate; the lamp cap positioning seat is rotationally arranged on the base mounting disc; and the rotary driving assembly can drive the lamp cap positioning seat to rotate. According to the LED lamp cap dispenser disclosed by the invention, the lamp cap positioning seat is driven to rotate, rotation of the LED lamp cap on the automatic production line is realized, the dispensing needle is stationary in the dispensing process, stable dispensing in the operation of the dispensing assembly is promoted, the problem that the dispensing needle is vibrated and collided is solved, and the dispensing effect is easy to control.

Owner:佛山市顺德区格律诗自动化科技有限公司

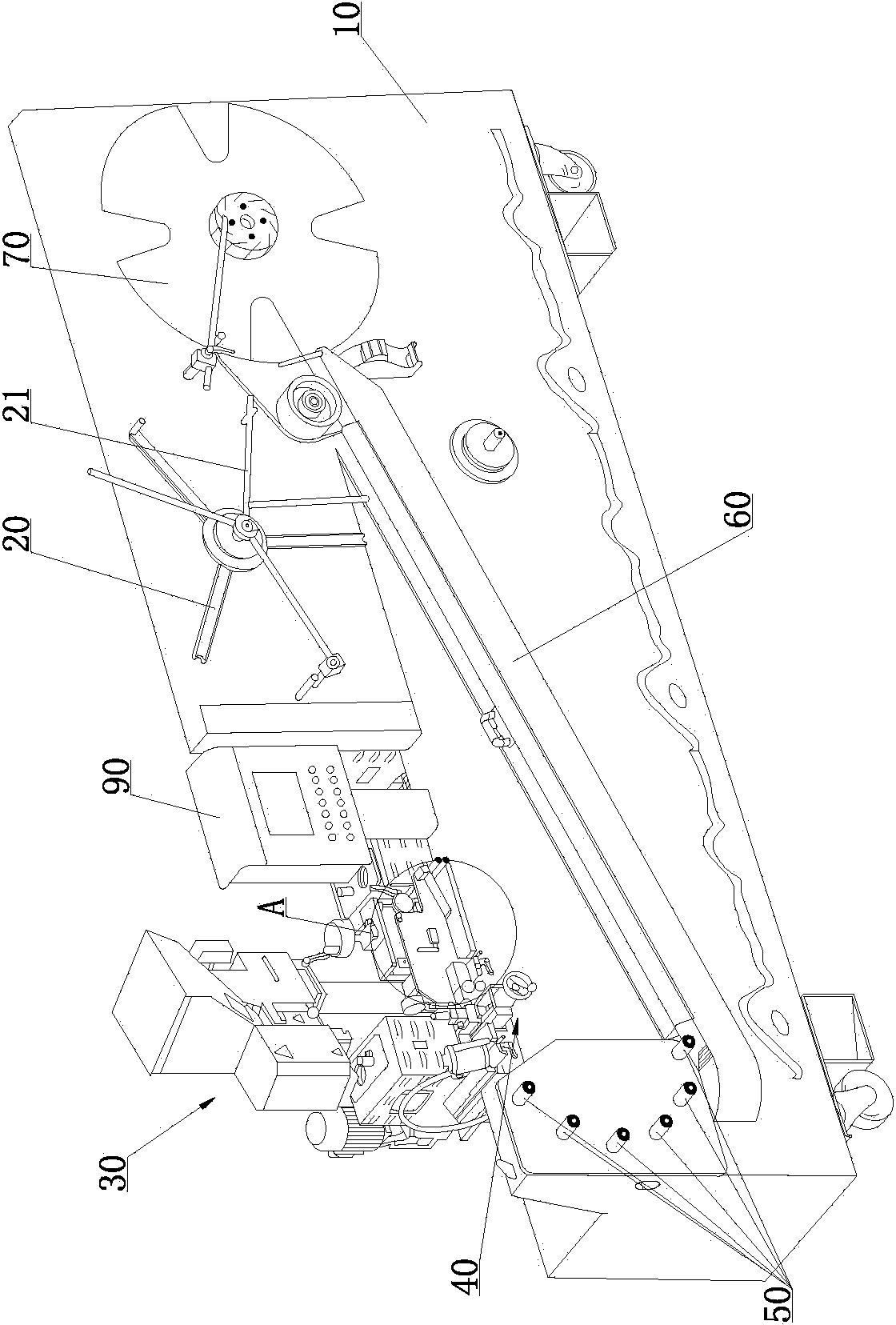

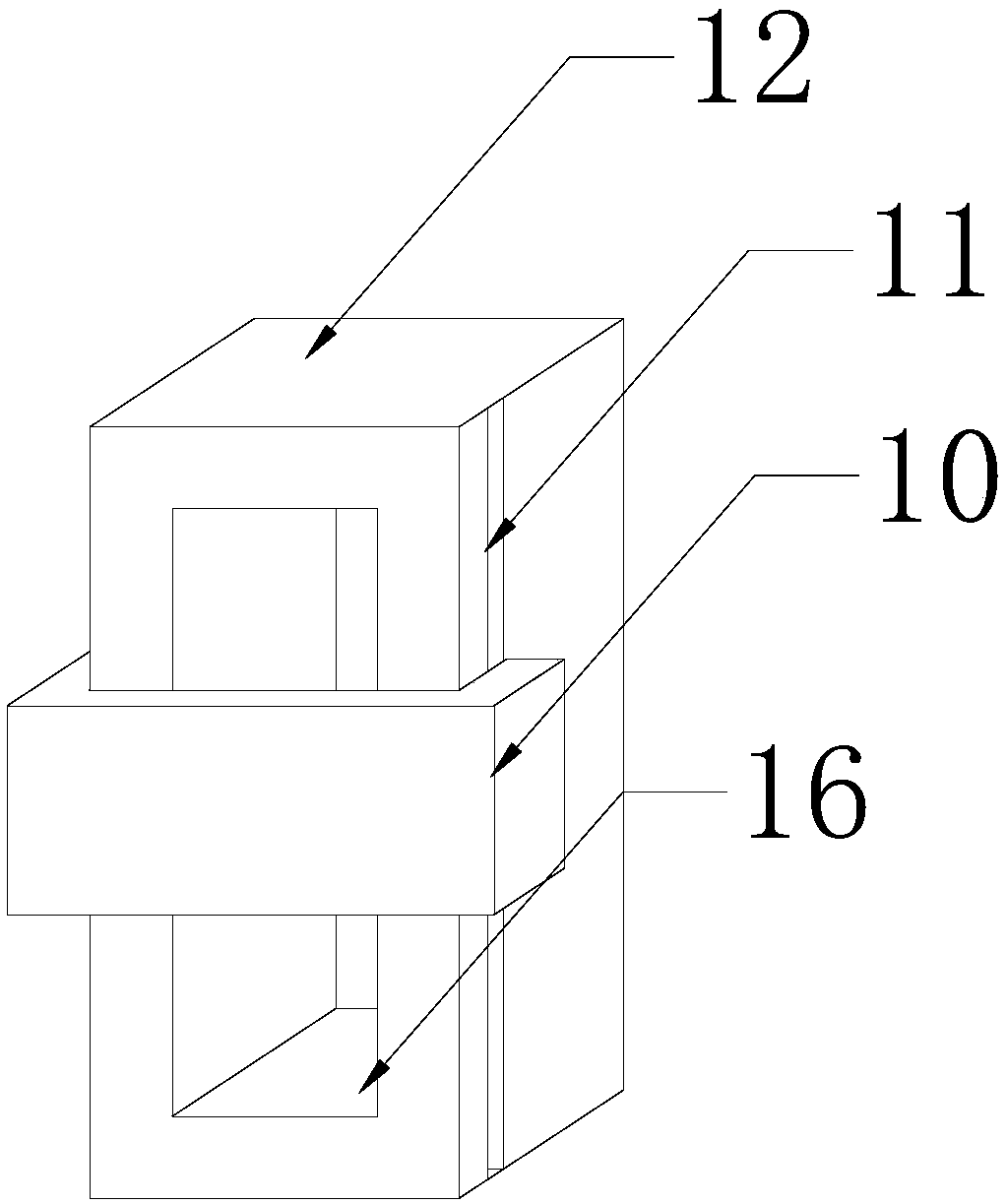

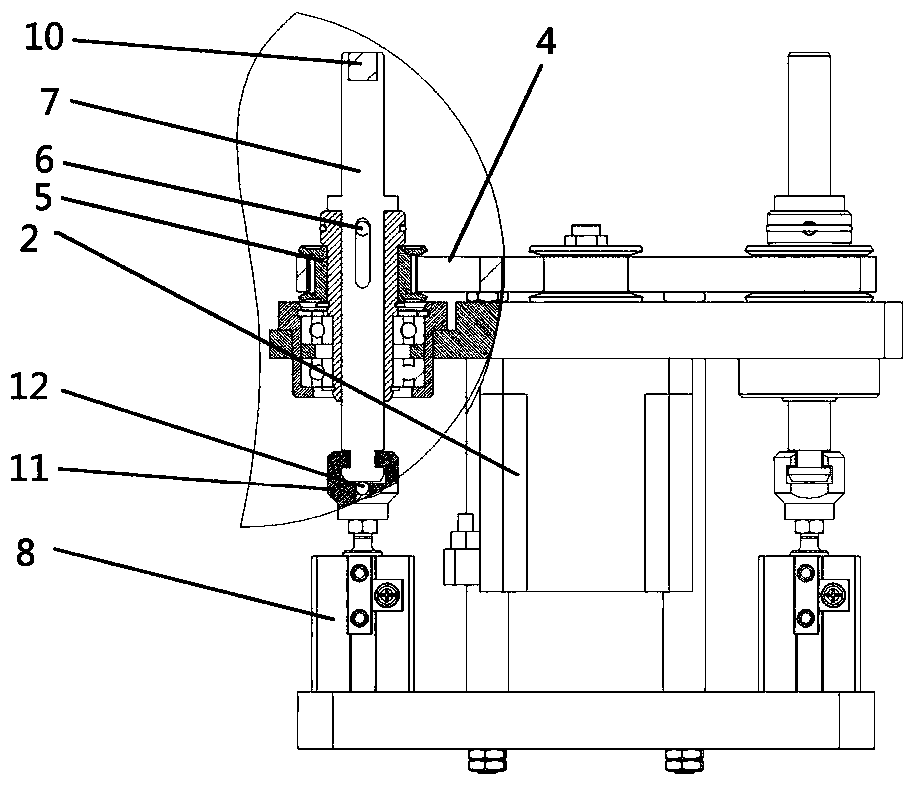

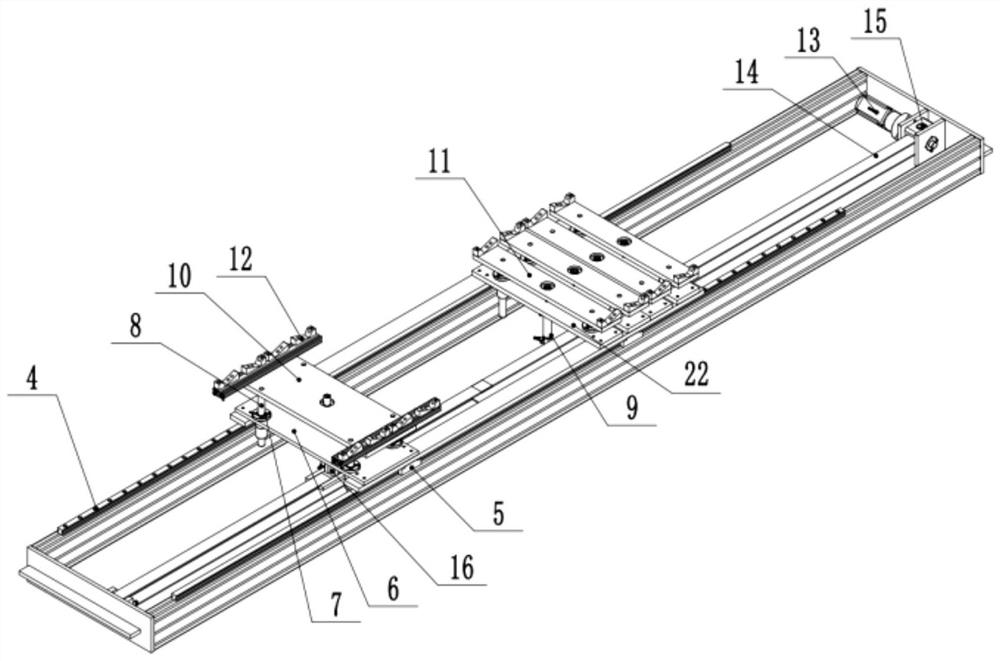

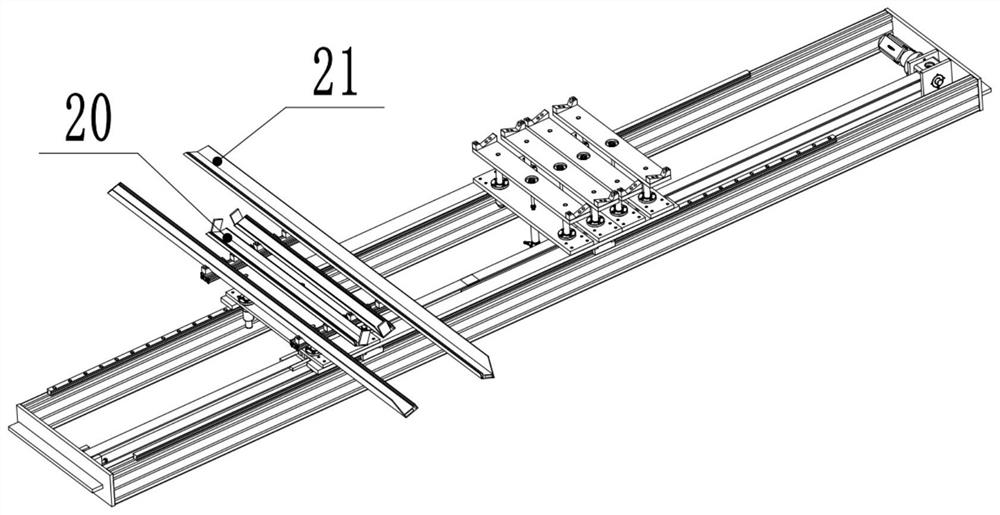

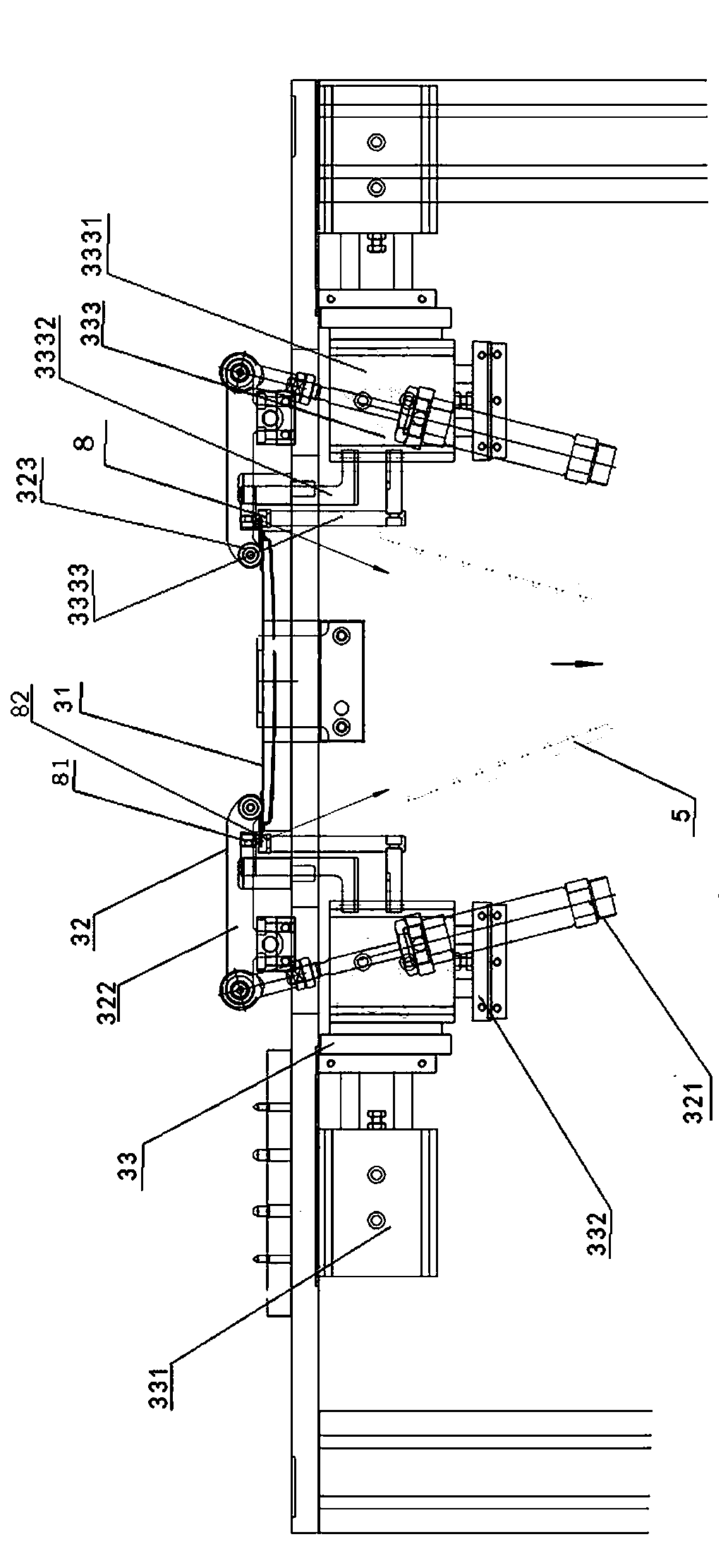

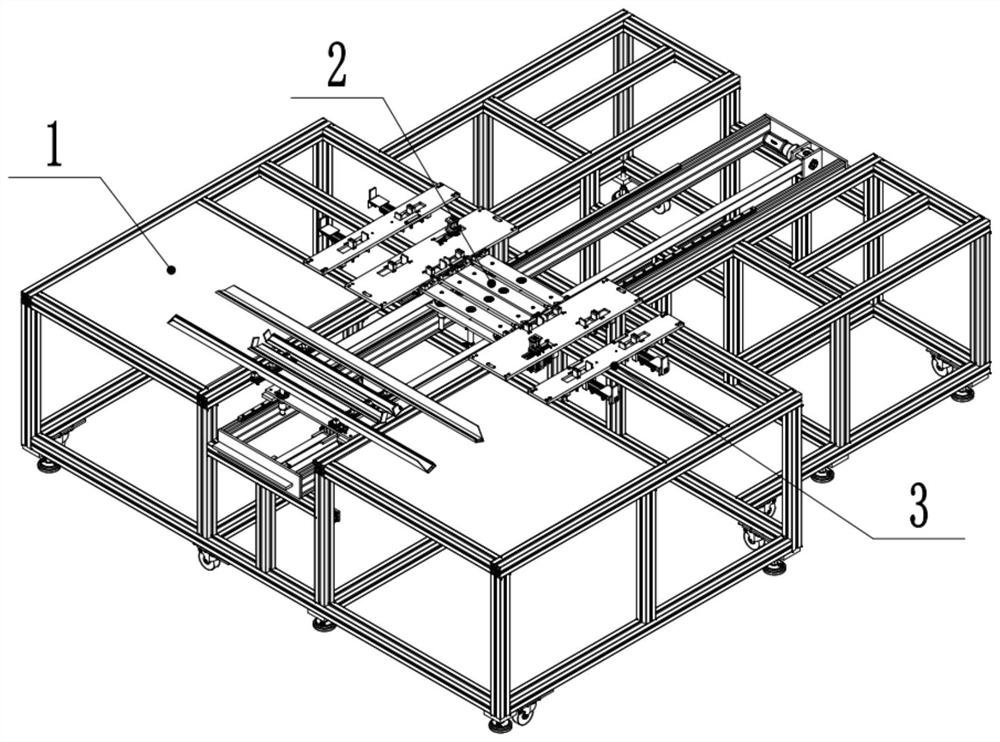

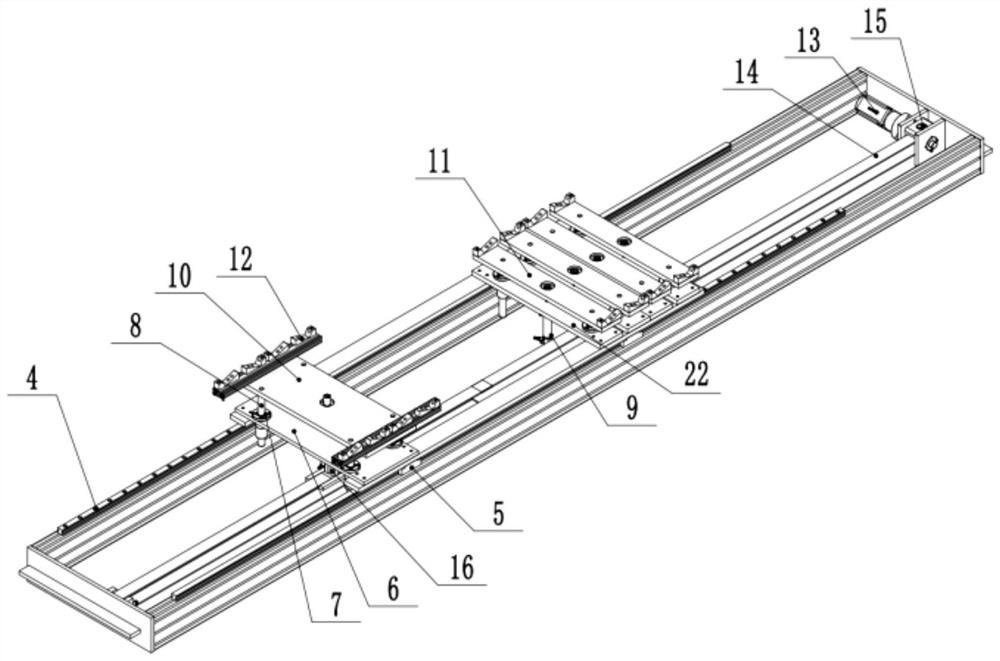

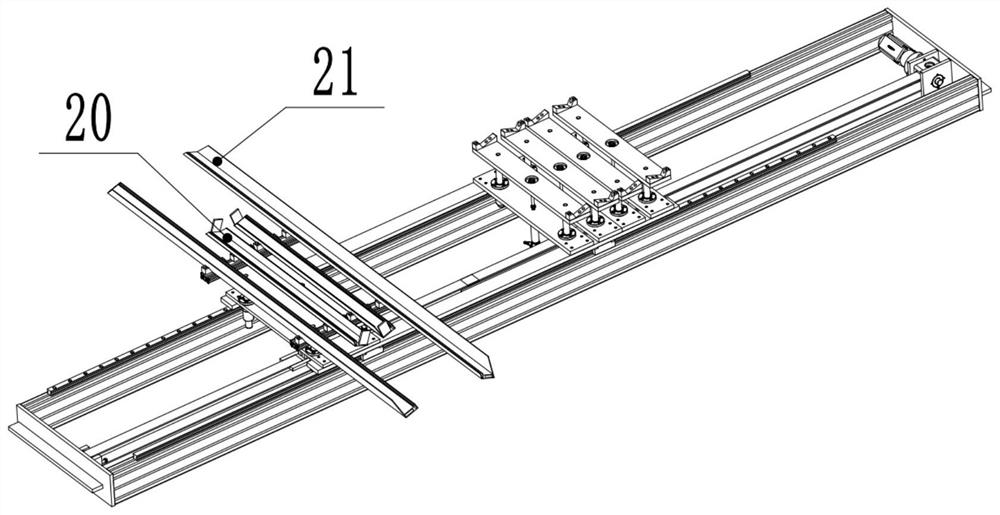

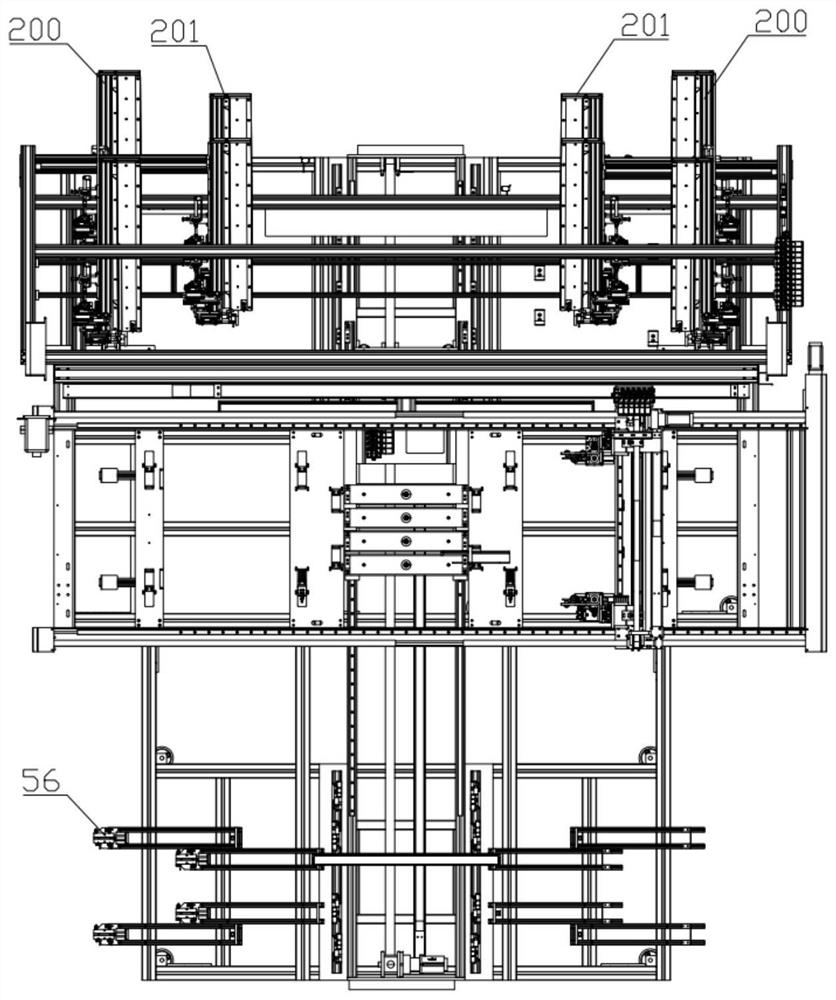

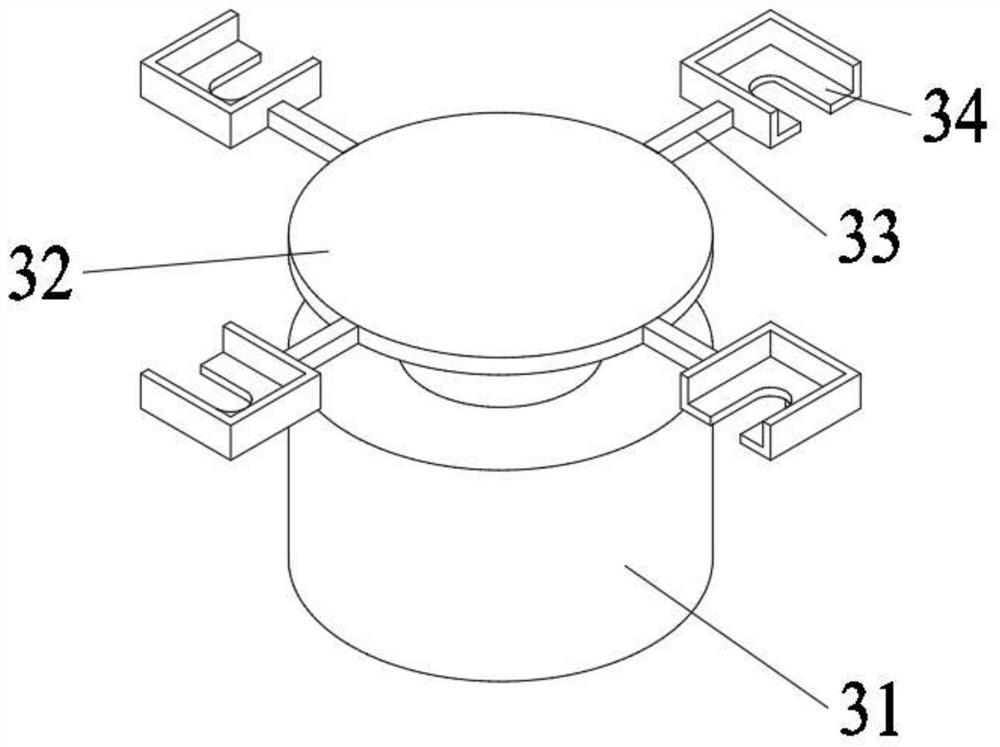

Double carrying position transfer and separation frame feeding device and feeding method thereof

ActiveCN112960380AReasonable supportSmooth gluing processLiquid surface applicatorsCoatingsLong spanMechanical engineering

The invention discloses a double carrying position transfer and separation frame feeding device and a feeding method thereof. An existing frame gluing feeding device not only carries glue but also is taken as a gluing platform, is small in span of fixing position, and will generate vibration to affect the gluing effect. The device comprises a rack, a double carrying position platform and a gluing platform. The double carrying position platform charges and feeds glue to the gluing platform and discharges glue. The gluing platform is fixed and is suitable for multi-dimensional stabilization and fixation of different lengths of frames via various air cylinders. The gluing platform of the prevent invention is more reasonable in supporting force to the frame by way of large span, multiple position and multidirectional fixation and support, such that a phenomenon that two ends of the frame due to over-length of the frame droop is avoided; four back carrying positions, a lifting air cylinder and platform assemblies on the back carrying positions are included, and each assembly moves independently, such that the discharging step can output two short frames and two long frames on the carrying position discharging station by way of different separation spaces.

Owner:上海盛普流体设备股份有限公司 +1

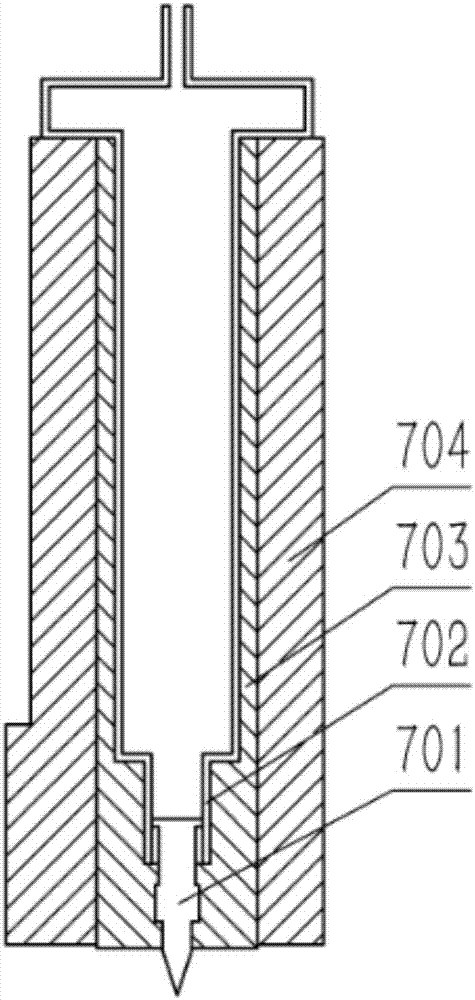

Process method for filling closed cavity of temperature sensor with glue

PendingCN113210223AGlue stableReduce shockLiquid surface applicatorsCoatingsAdhesive glueProcess engineering

The invention discloses a process method for filling a closed cavity of a temperature sensor with glue, and belongs to the technical field of glue dispensing. The process method includes the following steps that (1), on the basis of a dispensing process, a closed cavity substrate containing a glue inlet hole and an exhaust hole and a glue filling needle head are oppositely assembled; (2), the glue filling needle head enters the glue inlet hole, the glue filling needle head and the inner surface of the closed cavity substrate can reach the glue dispensing height, and the closed cavity is filled with the glue in a pneumatic glue discharging manner; and (3), after glue filling is finished, the glue filling needle head is lifted and then stays, and glue filling in the closed cavity of the temperature sensor is completed. According to the process method for filling the closed cavity of the temperature sensor with the glue, the problem that glue filling is not stable in the glue filling operation of temperature sensing products is solved, and the process defects that in the prior art, glue cannot be diffused, glue splashes, lines are punched during glue filling, and glue filling is not full are overcome.

Owner:HUATIAN TECH XIAN

Automatic gluing device

PendingCN110000051AAutomatic fast glue applicationImprove gluing efficiencyLiquid surface applicatorsGripping headsSpray nozzleEngineering

The invention provides an automatic gluing device which comprises a manipulator, a glue spraying mechanism and a trimming and assembling mechanism. The manipulator drives a vacuum chuck to move; the glue spraying mechanism comprises multiple glue spraying nozzles; the trimming and assembling mechanism comprises a panel placement part and a panel limiting mechanism; a trimming mechanism is arrangedon the side part of the panel placement part and comprises a horizontal telescopic mechanism and an up-and-down vibration mechanism; and the up-and-down vibration mechanism moves horizontally under the drive of the horizontal telescopic mechanism and drives the trimming assembly to move up and down. The device can be used for automatically and quickly gluing cloth strips, cutting aluminum panelsand pasting the cloth strips and the aluminum panels.

Owner:安德佳(福建)铝饰科技有限公司

Ship body insulation epoxy resin gluing equipment

The invention discloses ship body insulation epoxy resin gluing equipment which comprises a glue supply machine. The glue supply machine comprises a pressing disc, a glue inlet is formed in the pressing disc and communicates with a glue supply pump, the pressing disc is connected with a driving device, the pressing disc is used for being matched with a material containing space of a material barrel so that when the driving device drives the pressing disc to stretch into the material containing space, pressure can be generated between the pressing disc and glue located in the material containing space. The ship body insulation epoxy resin gluing equipment solves the technical problem that in the prior art, gluing work is not stable.

Owner:苏州振州机电科技有限公司

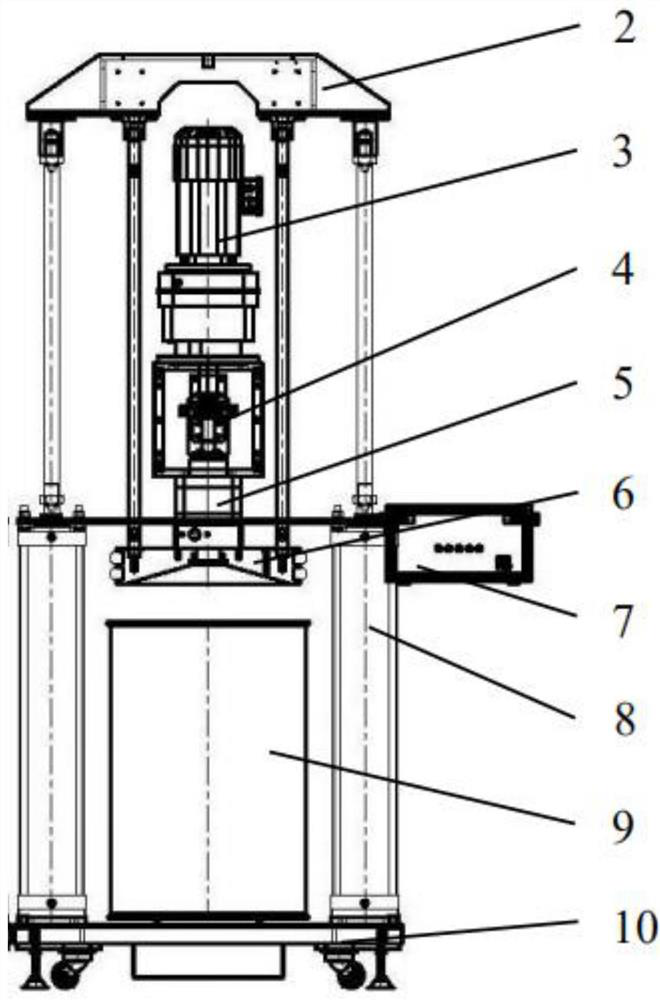

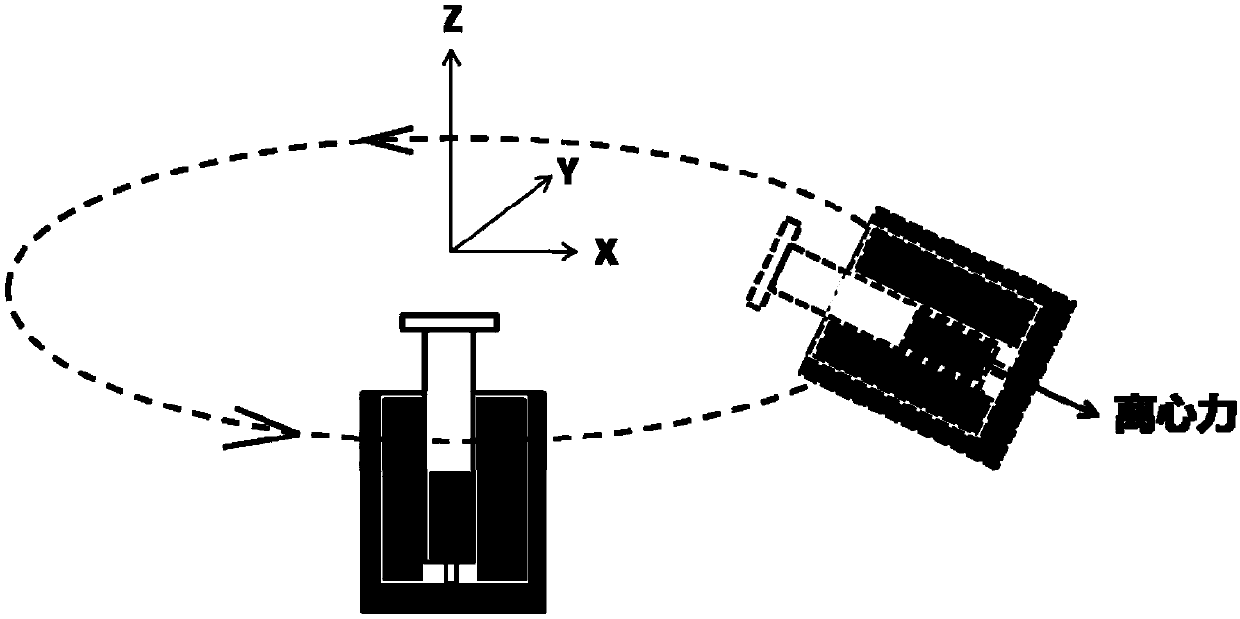

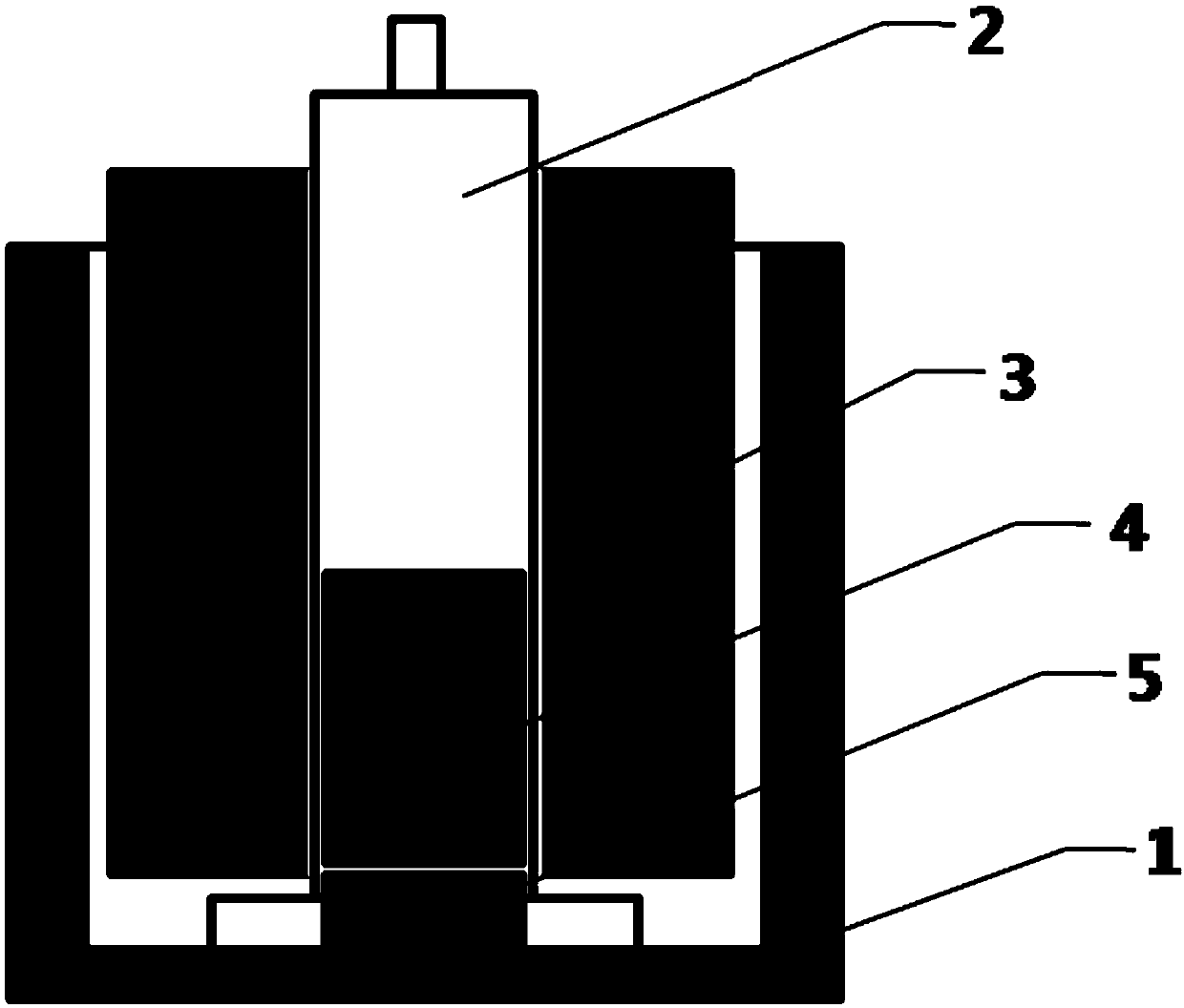

Inverted defoaming device for conductive adhesive and application method thereof

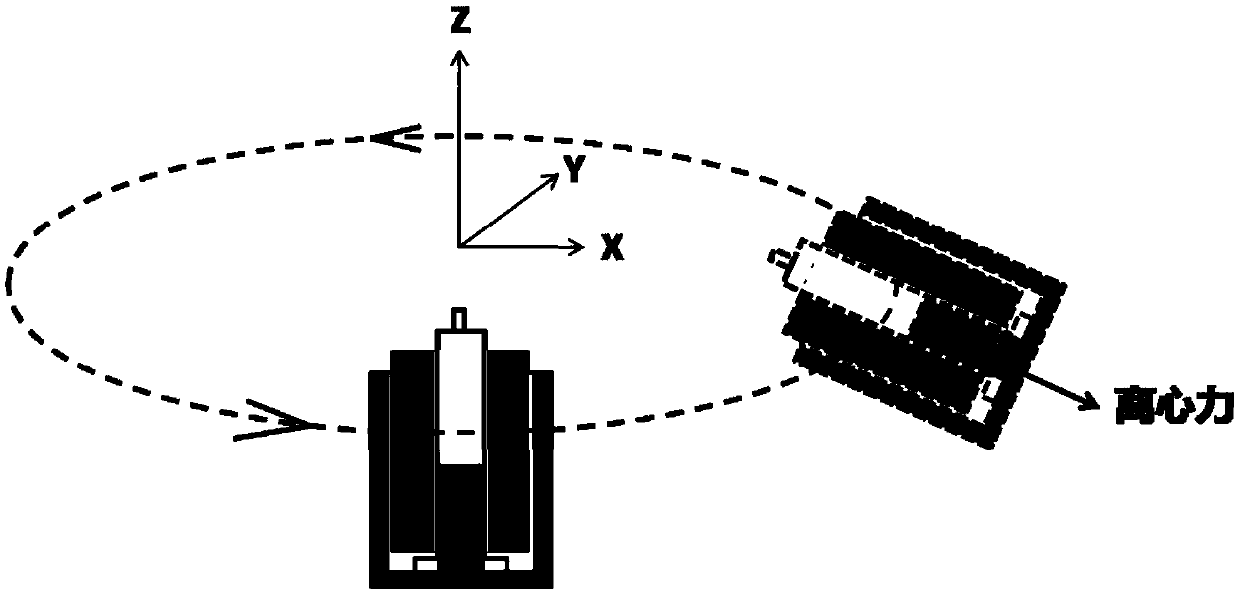

InactiveCN109663389AEfficient removalGlue stableSemiconductor/solid-state device manufacturingFoam dispersion/preventionSurface mountingAdhesive

The invention relates to the technical field of surface mounting processes in integrated circuit processes, in particular to an inverted defoaming device for conductive adhesive and an application method thereof. The inverted defoaming device for conductive adhesive comprises a centrifuge; a base, a needle tube fixture and a conductive adhesive fixing device are arranged on the centrifuge; the base matches with the centrifuge in shape; the base is hollowed inside and has an inner surface that is of threaded structure; the needle tube fixture is a ring column; the outer surface of the needle tube fixture is of threaded structure and matches with the threaded structure of the inner surface of the base; the conductive adhesive fixing device includes a piston and a needle tube; the needle tubeis of cylindrical hollow structure; the top of the needle tube is of pinhole structure; the bottom of the needle tube is extended out to form an outer ring; the outer radius of the outer ring is greater than the inner diameter of the needle tube fixture. The inverted defoaming device for conductive adhesive has the advantages that foam in conductive adhesive can be effectively removed, adhesive discharging for adhesive dispensing is more stable, the problems of unstable adhesive discharging, dispensing interruption, dispensed adhesive scattering and the like due to the inner foam in the conductive adhesive are solved, and the operating method is simple and convenient.

Owner:NO 24 RES INST OF CETC

A double-loading transfer and separation frame feeding device and feeding method thereof

ActiveCN112960380BReasonable supportPrevent saggingLiquid surface applicatorsCoatingsLong spanControl theory

The invention discloses a double-loading transfer and separation frame feeding device and a feeding method thereof. The existing frame gluing and feeding device not only transfers but also serves as a gluing platform, and the fixed position span is small, which will generate vibration and affect the gluing effect. The invention includes a frame, a double-carrying platform and a gluing platform; the double-carrying platform completes the work of loading, feeding to the gluing platform and discharging; the gluing platform adopts a fixed type, and adapts to different length frames through various cylinders. Multi-dimensional stability and fixation. The gluing platform of the present invention adopts a large-span, multi-position, and multi-directional fixed support mode, which has a more reasonable supporting force on the frame, and avoids the phenomenon of sagging at both ends of the frame caused by the excessive length of the frame; four rear loading bases, lifting cylinders And the upper platform assembly on the rear loading position, each assembly moves independently, so that the discharging process can realize the output of two short frames and two long frames on the loading and unloading station with different spacing.

Owner:上海盛普流体设备股份有限公司 +1

A high-efficiency flexible double-applicator head frame gluer

ActiveCN112934612BRealize integrationReliable blankingLiquid surface applicatorsCoatingsProduction lineProcess engineering

The invention discloses a high-efficiency flexible double-glue-head frame gluer. At present, there is no frame gluing machine that realizes the integration of storage bin discharge, transfer platform feeding, gluing system gluing, transfer platform discharge and frame normalization. The double-load displacement load-separation feeding device of the present invention conveys the blanking material from the bin blanking device to the double glue head gluing device for gluing, and transports the frame that has been glued to the frame correcting device for normalization. The invention realizes the integration of storage bin discharge, transfer platform feed, gluing system gluing, transfer platform discharge and frame normalization process; the silo blanking device realizes orderly drop of frames of different lengths and widths material; the double glue head gluing device is equipped with a double nozzle rotary gluing head, and has an online bilateral detection device to improve the scope of application and gluing efficiency; the frame correction device at the back end of the gluing area meets the requirements of the industry for gluing The work efficiency of the production line is further improved while the frame arrangement and posture requirements are met.

Owner:上海盛普流体设备股份有限公司 +1

An archaeological excavation device for mural protection

ActiveCN111976368BGlue stableAvoid offsetPaperhangingWorking accessoriesStructural engineeringMechanical engineering

Owner:南昌保莱科技有限公司

Glue supply assembly and gluing device for anti-puncture tire production

InactiveCN114289264AAvoid manual loadingGuarantee job securityLiquid surface applicatorsCoatingsRubber materialSprayer

Owner:缙云县吉祥机械制造厂

Light bar curing device for LED lamp tube production

PendingCN112354794AGlue stableImprove curing stabilityMaterial gluingPretreated surfacesEngineeringAir drying

The invention discloses a light bar curing device for LED lamp tube production. The device comprises a workbench erected on the ground, and further comprises a limiting device, a curing and glue discharging device, a pressing device, an adjusting device and an air drying device; the limiting device is arranged at one end of the upper end of the workbench; the curing and glue discharging device islocated at the upper end of the workbench and located at the inner side of the limiting device; the pressing device is located at the inner side of the curing and glue discharging device; the adjusting device is located at the other side of the upper end of the workbench; and the air drying device is located at the upper end of the adjusting device. The light bar curing device for LED lamp tube production has the beneficial effects that the limiting device can limit lamp bars of different specifications, so that the lamp bars run along a specified trajectory to avoid the deviation in the process of curing the lamp bars; the curing and glue discharging device can discharge glue at a constant speed, and the glue discharging is stable, so that the quality of a LED lamp tube is convenient to guarantee; the pressing device can press the lamp bars, so that the curing stability is improved; and the adjusting device can adjust the position of the air drying device according to the characteristics of silica gel, and the light bar is air-dried at a specified position.

Owner:TIANJIN TIANXING ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com