A kind of led lamp base dispensing machine

A technology of LED lamp head and glue dispenser, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of inaccurate glue dispensing and uneven distribution of glue quantity, and achieve stable and accurate rotation and improved dispensing effect. , The dispensing effect is easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

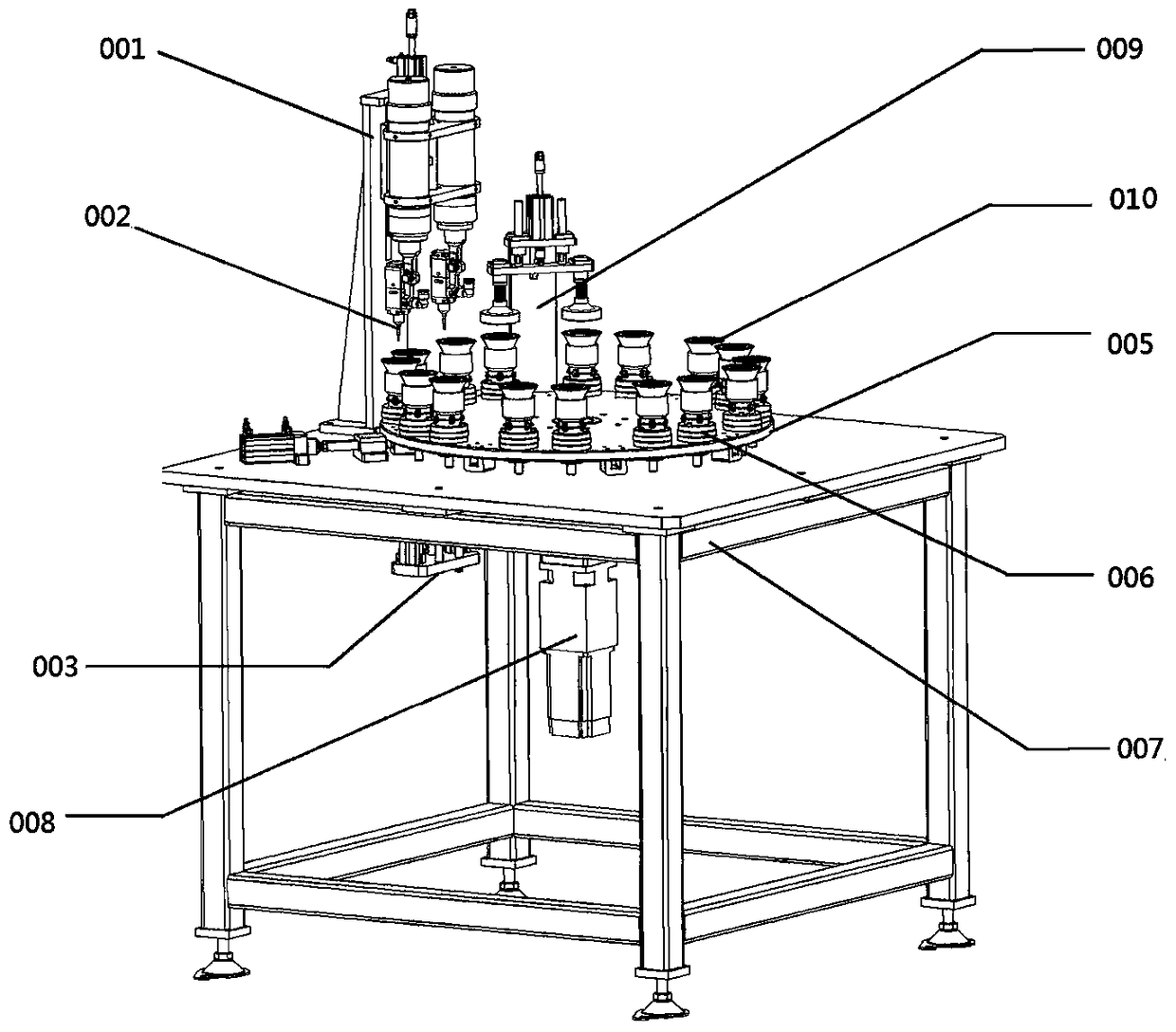

[0033] figure 1 It is a schematic diagram of the structure of the LED lamp holder dispensing machine in this embodiment, consisting of dispensing assembly 001, dispensing needle 002, dispensing frame 007, rotating drive assembly 003, base mounting plate 005, lamp base positioning seat 006, mounting plate motor 008 The base mounting plate 005 is rotatably mounted on the dispensing frame 007, the mounting plate motor 008 is mounted on the dispensing frame 007 and can drive the base mounting plate 005 to rotate, and the lamp head positioning seat 006 is rotatably mounted on the base mounting plate 005 Above, the rotation drive assembly 003 can drive the lamp head positioning seat 006 to rotate. In this embodiment, the rotary drive assembly 003 is preferably used to drive the lamp head positioning seat 006 to rotate through magnetic components.

[0034] Such as Figure 5 As shown, more specifically, the dispensing assembly 001 is composed of a second lifting cylinder 16, a rubbe...

Embodiment 2

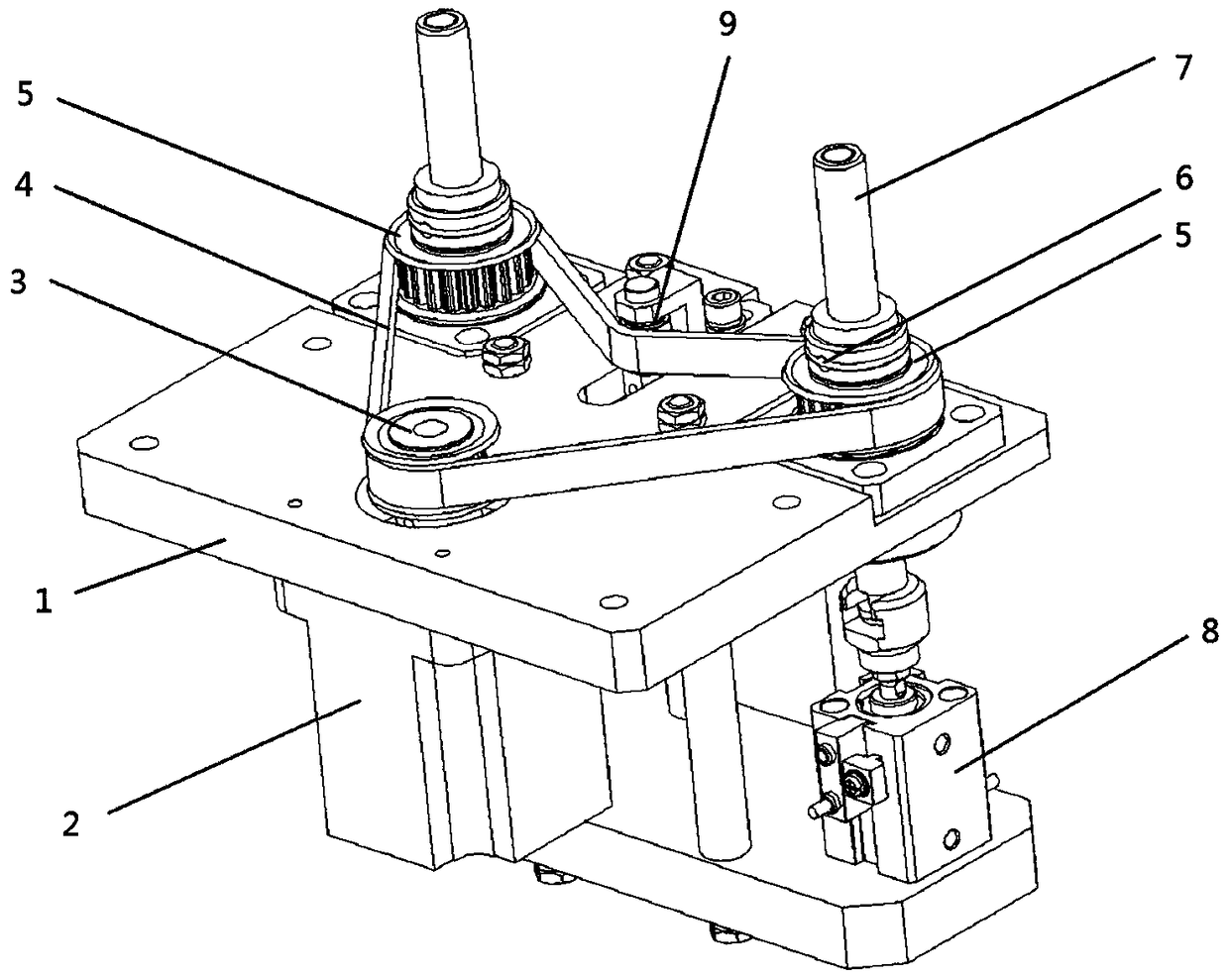

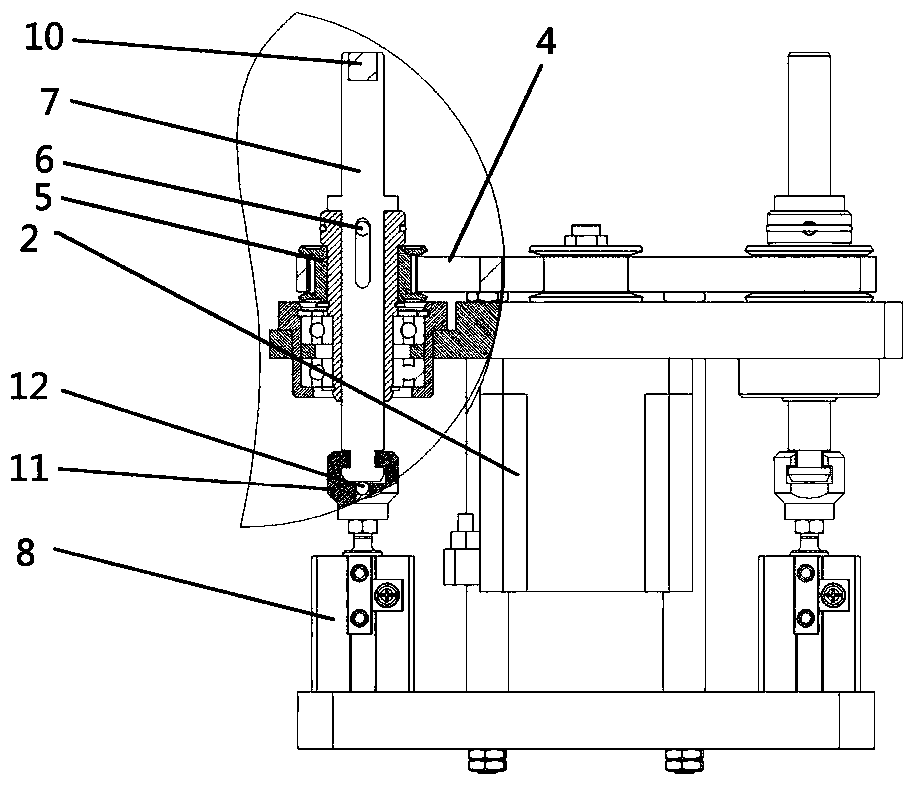

[0038] As a further step in Example 1, such as figure 2 , 3 , 4, the structure of the rotary drive assembly 003 consists of a mounting bracket 1, a driving motor 2, a driving pulley 3, a transmission belt 4, a driven pulley 5, a limit pin 6, a transmission connecting rod 7, a lifting cylinder 8, and a tensioner 9, magnetic block 10, connecting claw 11, rod sleeve 14, rod sleeve bearing 15 are formed.

[0039] The driving motor 2 and the lifting cylinder 8 are installed on the mounting bracket 1, the driving pulley 3, the driven pulley 5, and the tensioning pulley 9 are connected through the transmission belt 4, and the driving motor 2 drives the driving pulley 3 to rotate and then drives the driven pulley 5 rotation, the drive motor 2 and the driving pulley 3, the transmission belt 4, the driven pulley 5, and the tensioner 9 are designed to realize the function of driving the transmission connecting rod 7 to rotate. Other similar transmission structures are not mentioned one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com