Patents

Literature

36results about How to "Avoid manual loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

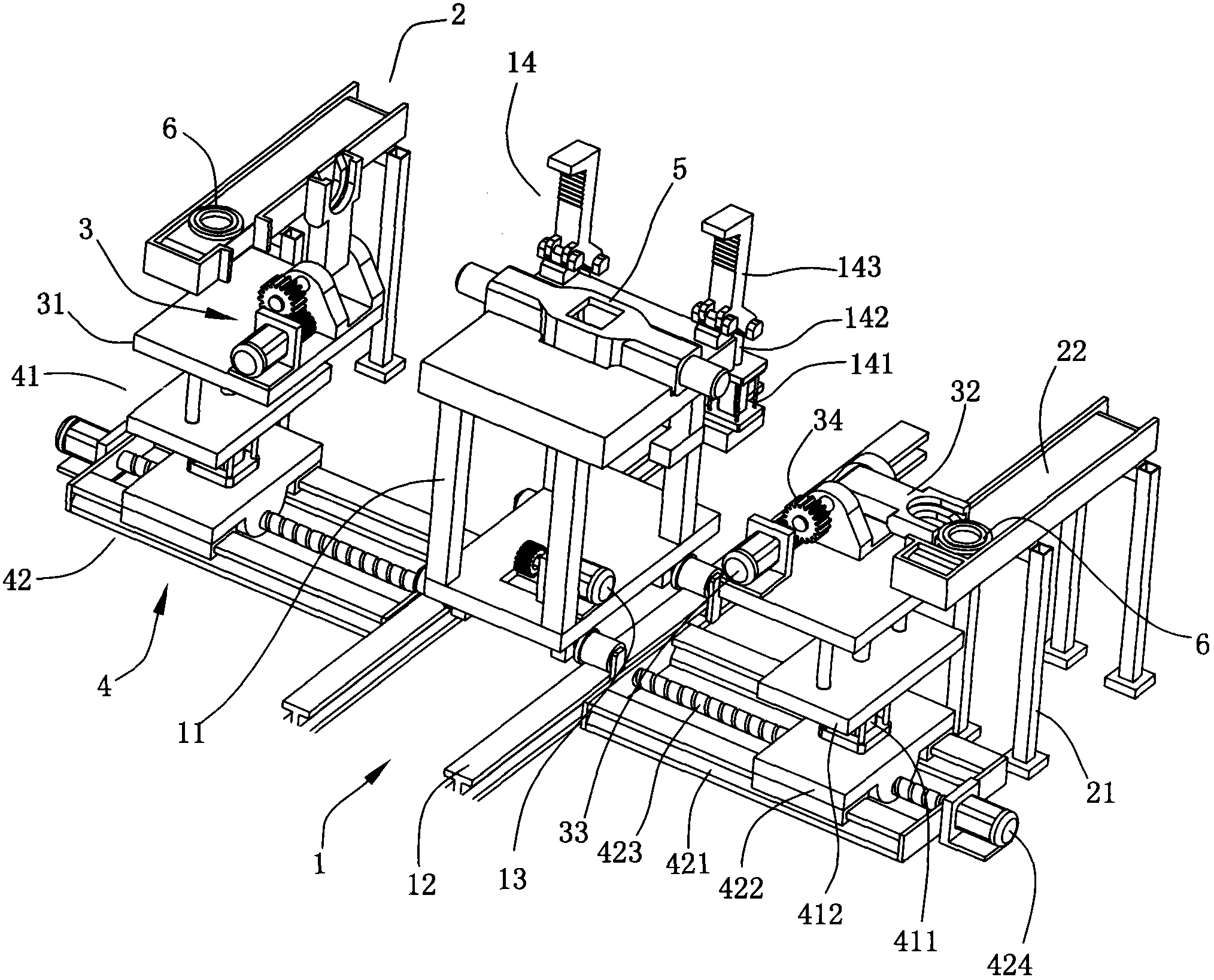

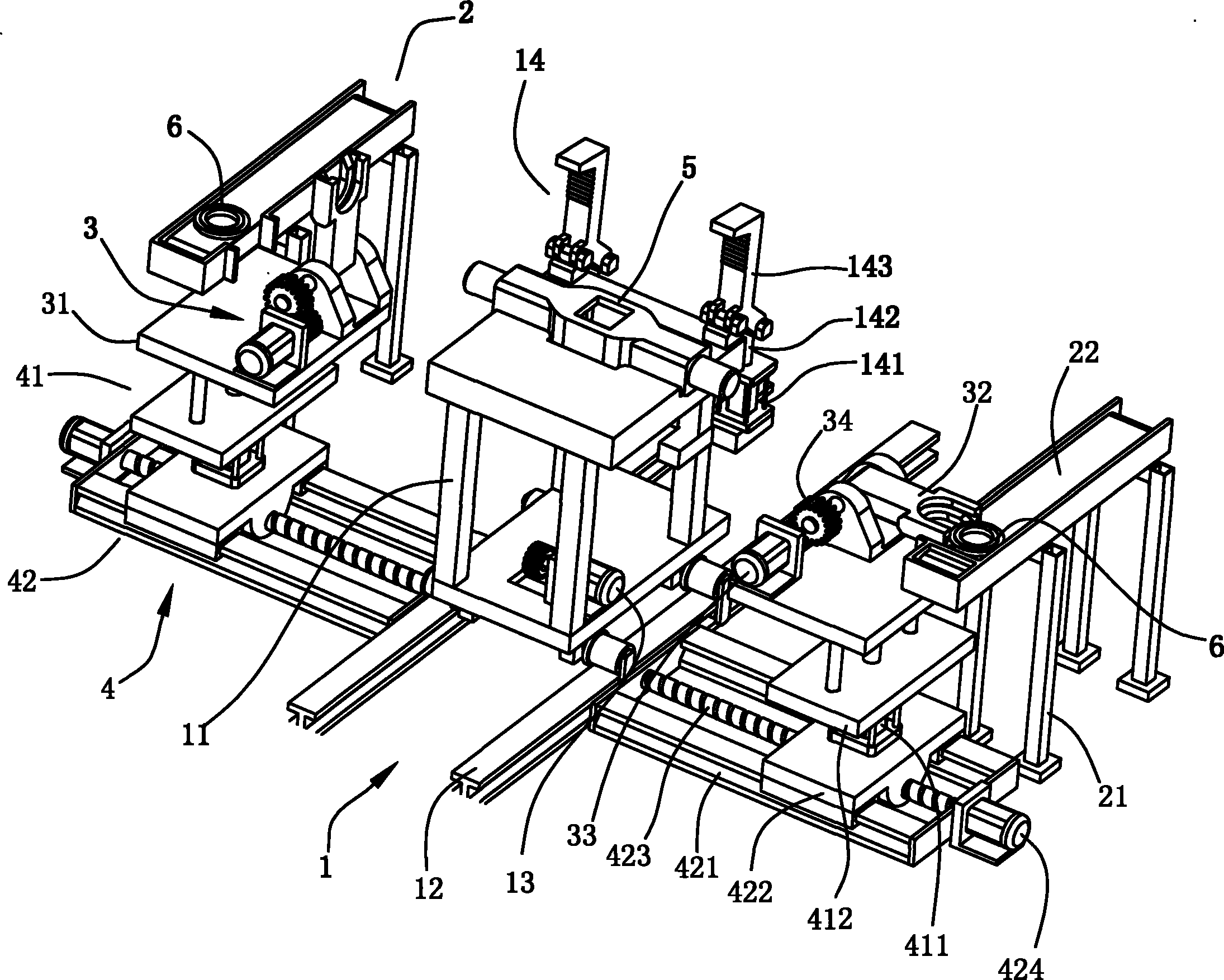

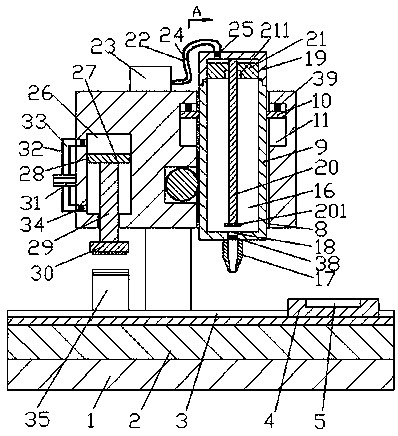

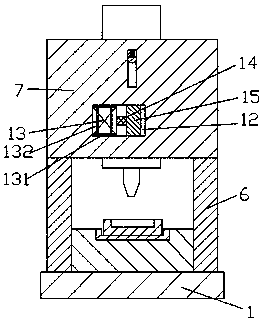

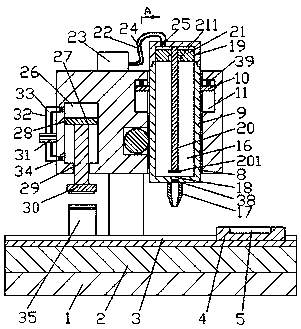

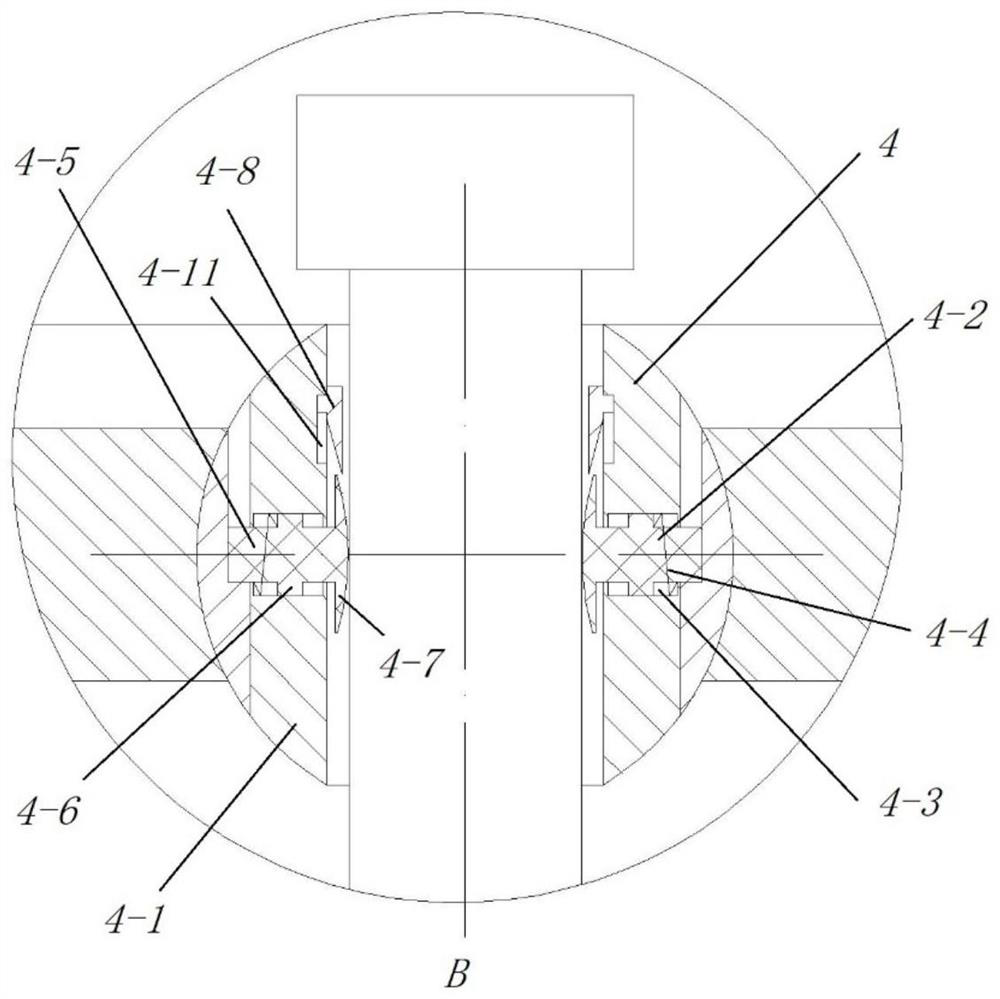

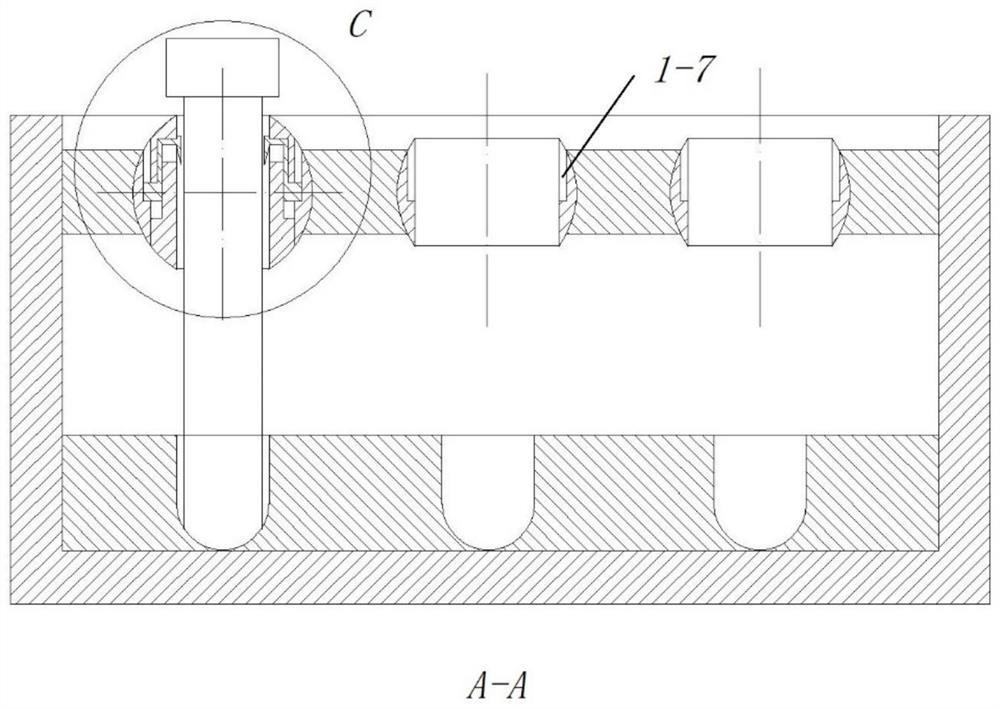

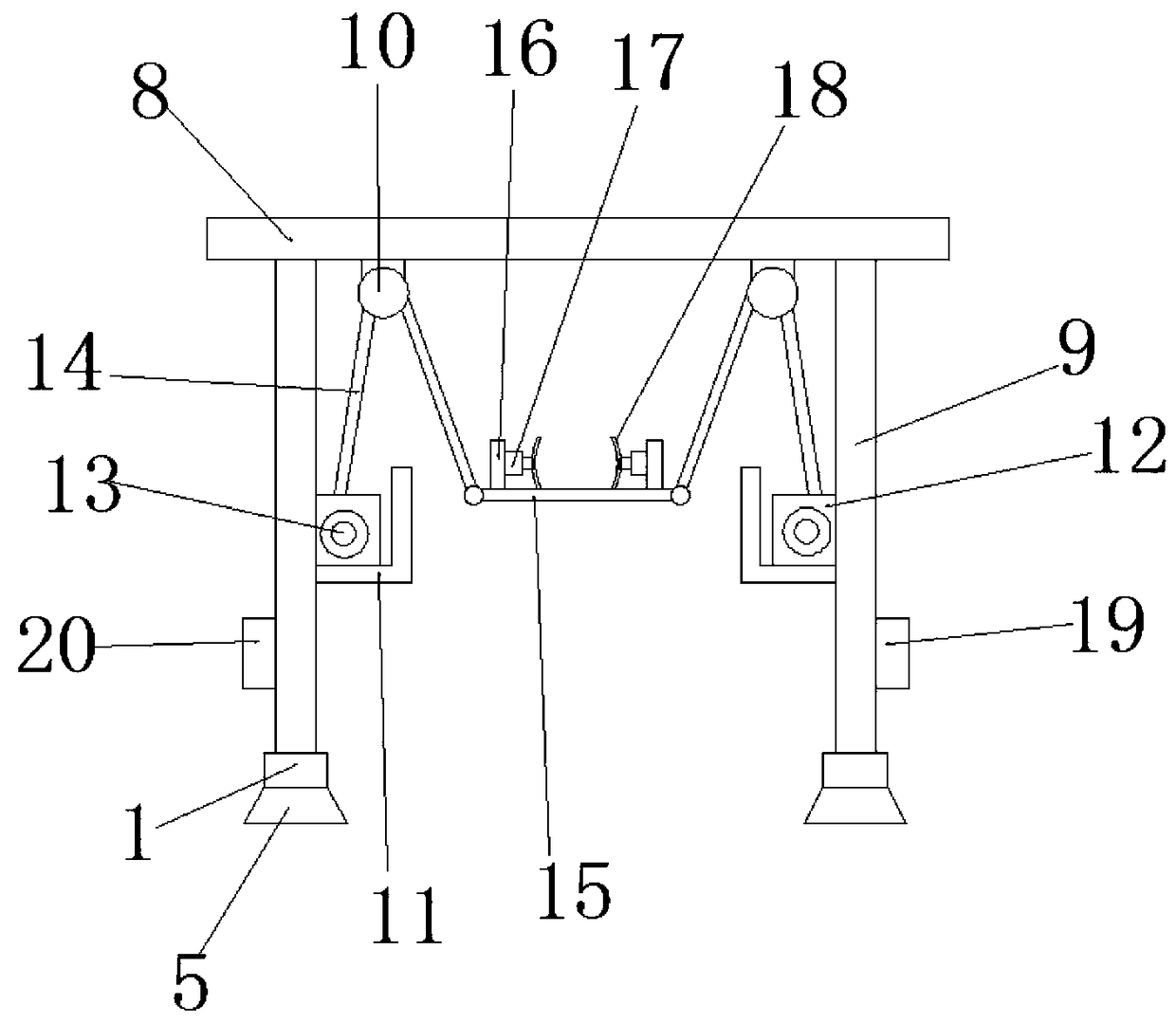

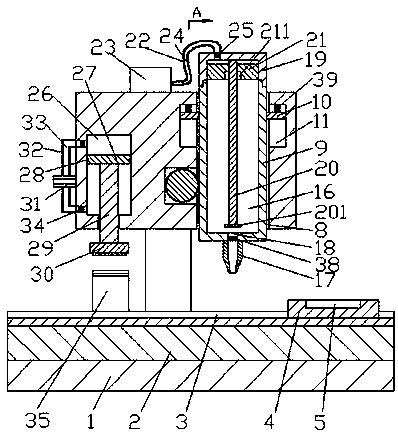

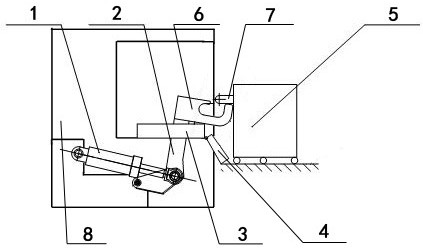

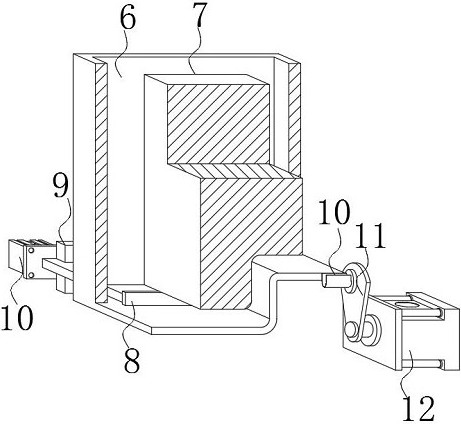

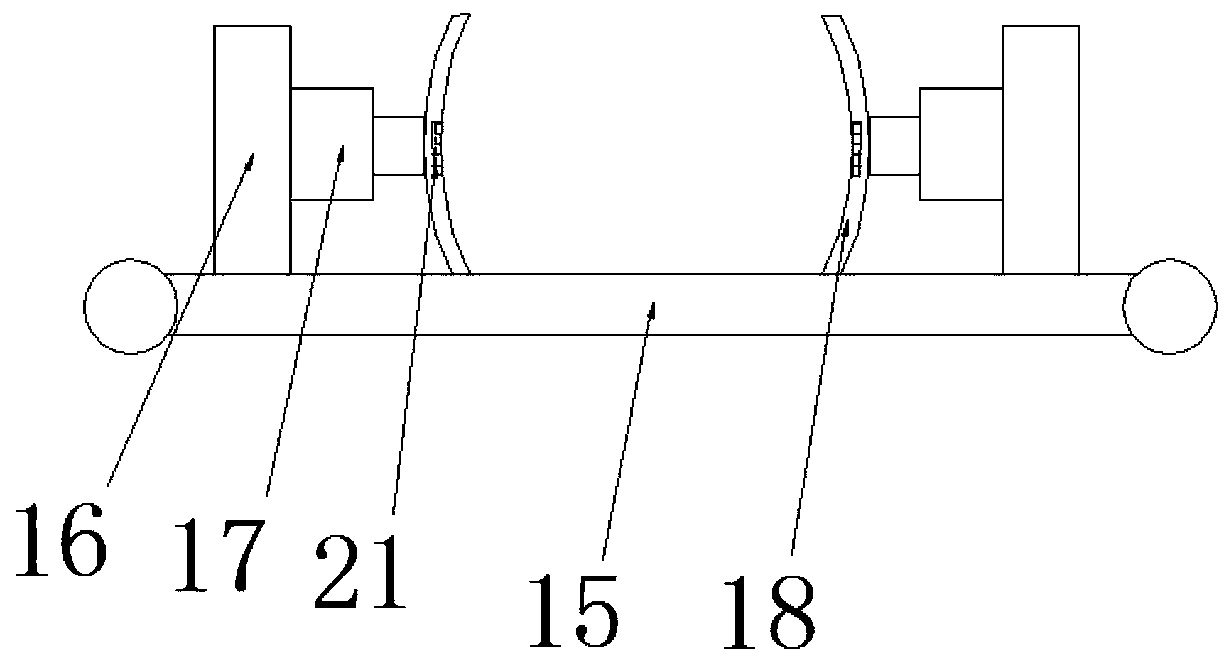

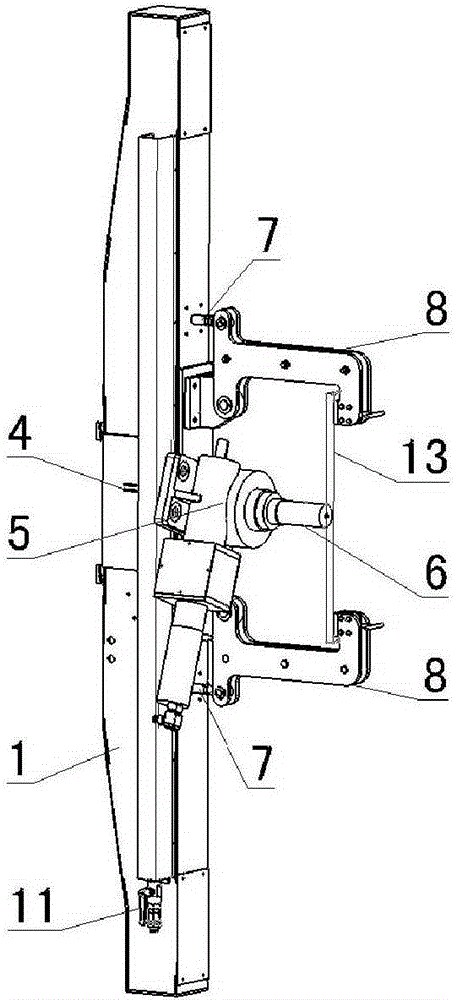

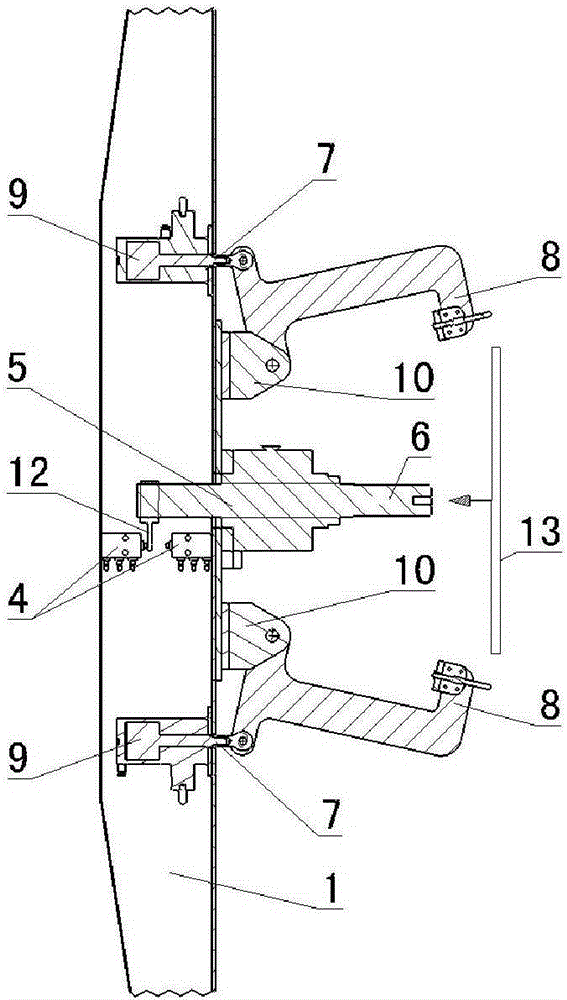

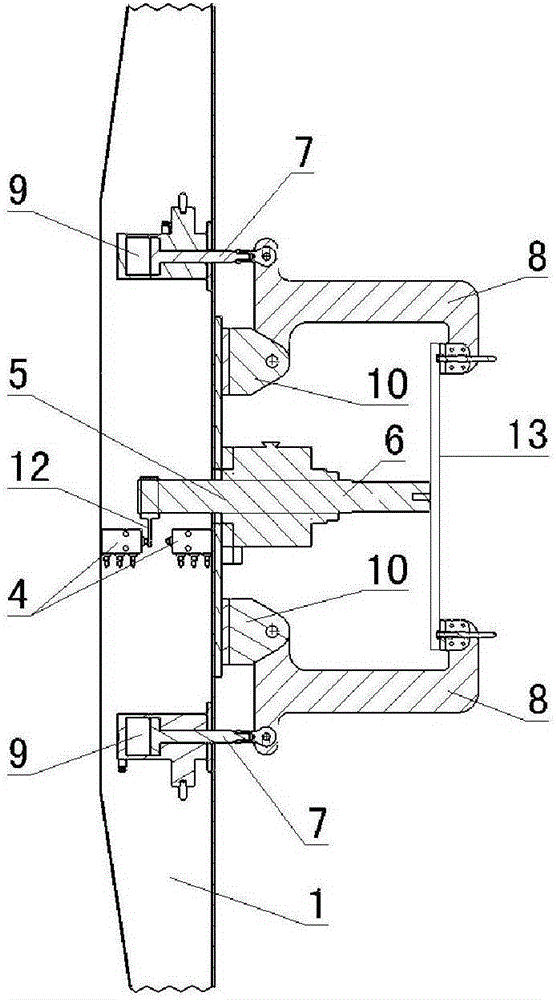

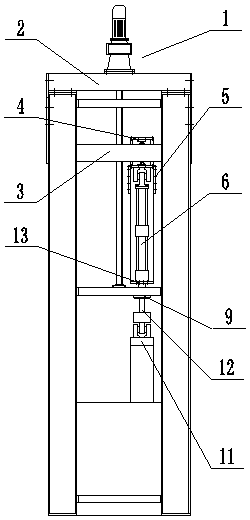

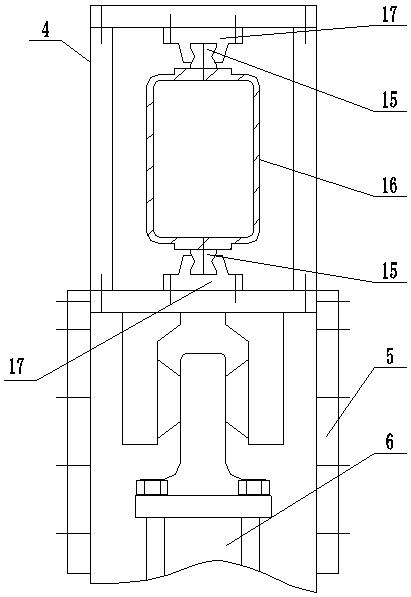

Double-head connection installation method for flange plate of automobile axle housing and mechanism assembly of double-head connection installation method

InactiveCN102672453AQuick assemblySimple processMetal working apparatusAutomatic controlControl system

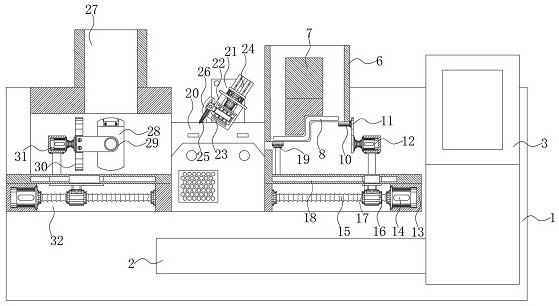

The invention discloses a double-head connection installation method for a flange plate of an automobile axle housing and also discloses a mechanism assembly for implementing the double-head connection installation method. The mechanism assembly comprises an automatic control system, a pressure grasping machine, two flange plate conveying devices, two flange plate mechanical arms and two flange plate material loading devices, wherein the pressure grasping machine, the flange plate conveying devices, the flange plate mechanical arms and the flange plate material loading devices are respectively connected with the automatic control system and are controlled by the automatic control system. The double-head connection installation method provided by the invention is concise in process and high in degree of automation, and operation action of assembling a flange plate on the automobile axle housing can be full-automatic, fast and accurately completed by the double-head connection installation method. The mechanism assembly provided by the invention has a simple structure and mechanical automation application. With the adoption of the mechanism assembly, working states of the pressure grasping machine, the flange plate conveying devices, the flange plate mechanical arms and the flange plate material loading devices can be controlled only by inputting corresponding parameters and control instructions to the automatic control system to realize the purpose of automatically assembling the flange plate on the automobile axle housing, dangers caused by manual material loading and installation of the flange plate are effectively avoided, the labor intensity is low, and the work efficiency is high.

Owner:DONGGUAN JIALONG LEATHER MACHIERY

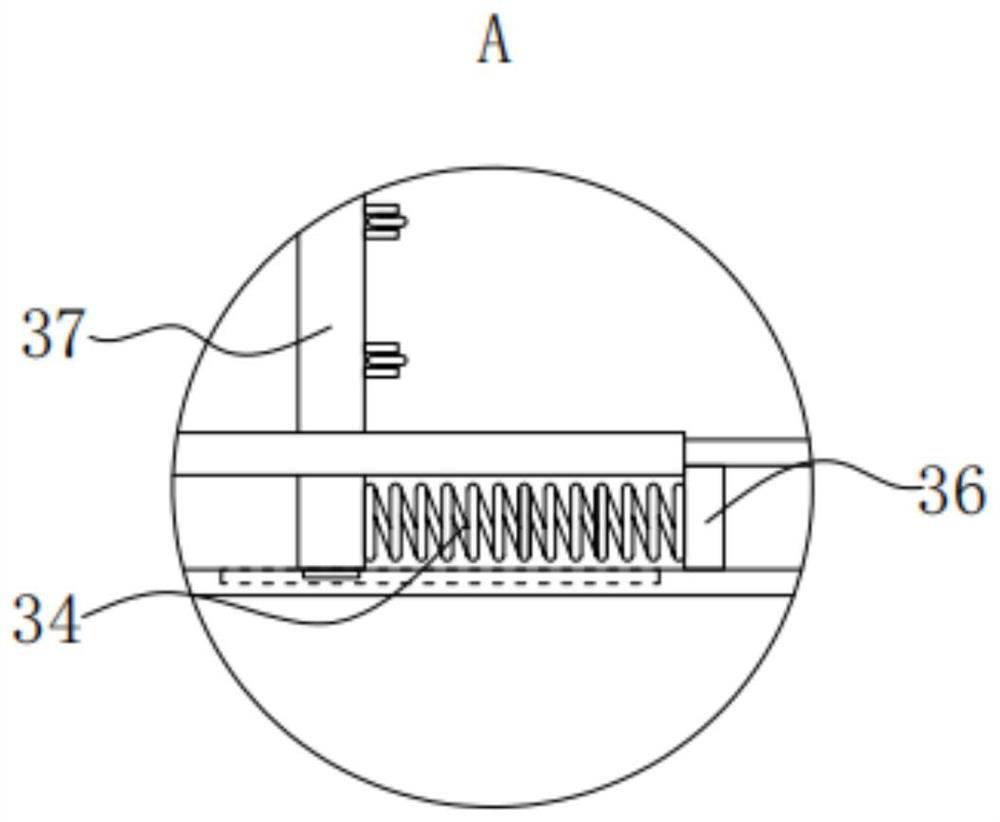

Novel slice type semiconductor ultra-thin packaging device

ActiveCN108538759AAvoid cloggingReduce workloadSemiconductor/solid-state device manufacturingEngineeringAssembly line

The invention discloses a novel slice type semiconductor ultra-thin packaging device comprising a fixed base. A conveying assembly line extending left and right is arranged in the middle of the upperend surface of the fixed base. Sealing space is formed in the left side inside a fixed case; a hydraulic rod is fixedly connected to the central position of the lower end surface of a sealing plate; the lower end of the hydraulic rod passes through the lower end wall of the sealing space and is fixedly connected with a press-fit plate; a resin conveying device is arranged right below the press-fitplate and includes a winding mechanism and a pulling mechanism. When the packaging device is working, an extruding plate moves up and down along a guiding rod without falling based on cooperation ofan annular clamp plate and an annular clamp slot; the extruding plate can fall to be in contact with the lower end wall of glue storage space to prevent plugging of a glue coating needle due to solidification of lower-end glue liquid not in use for long time; and the resin sheet that is not used can be switched automatically, so that precision is improved and the work efficiency is enhanced.

Owner:广东协铖微电子科技有限公司

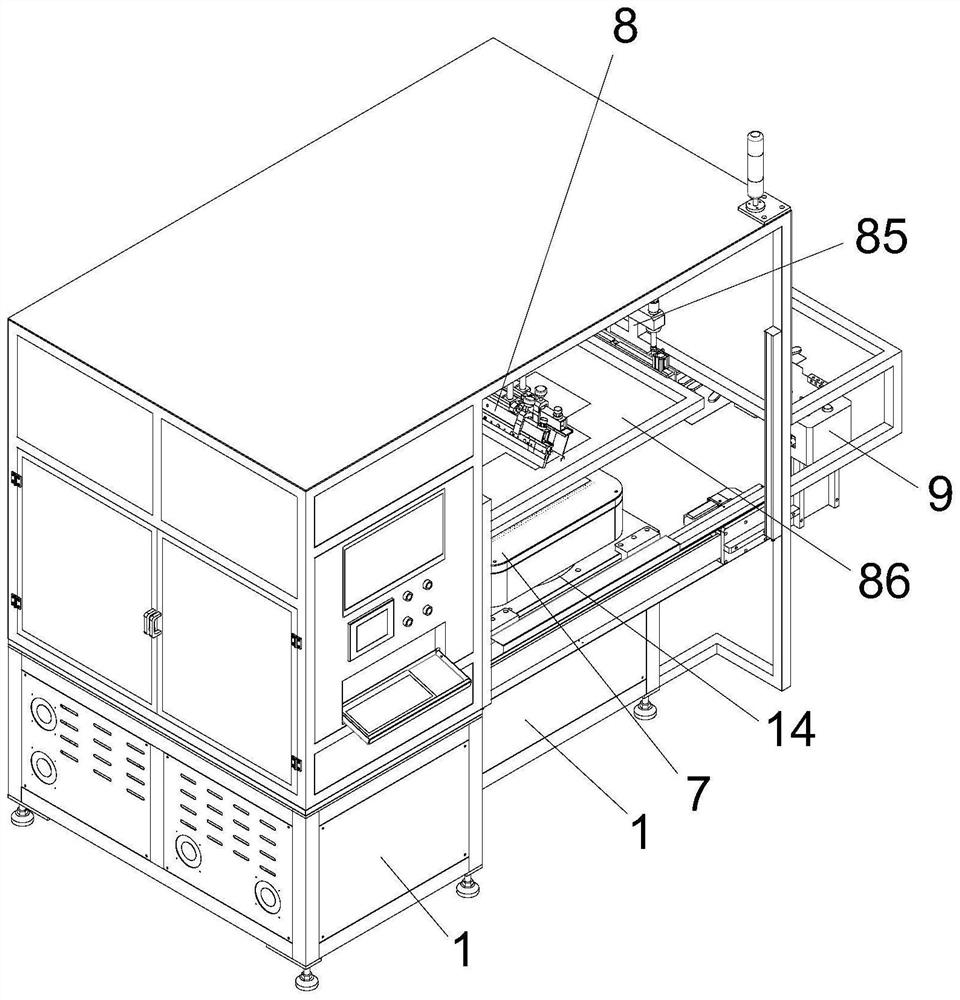

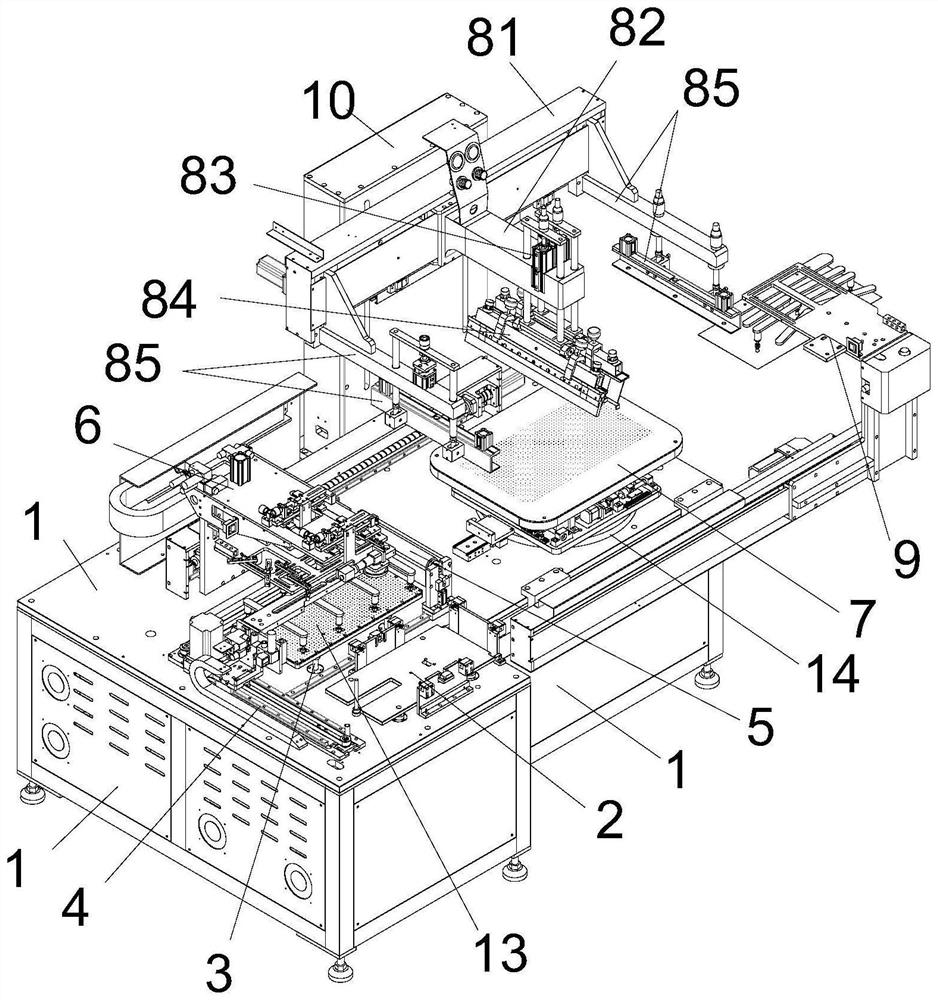

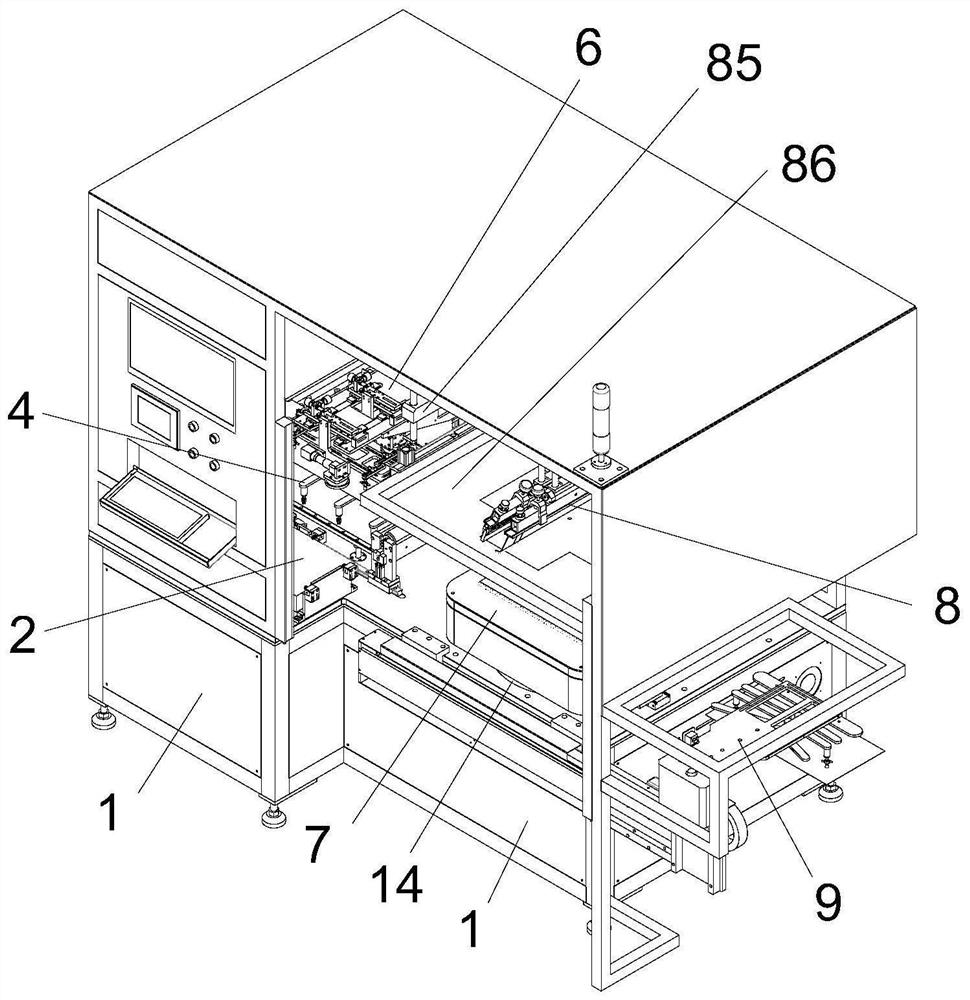

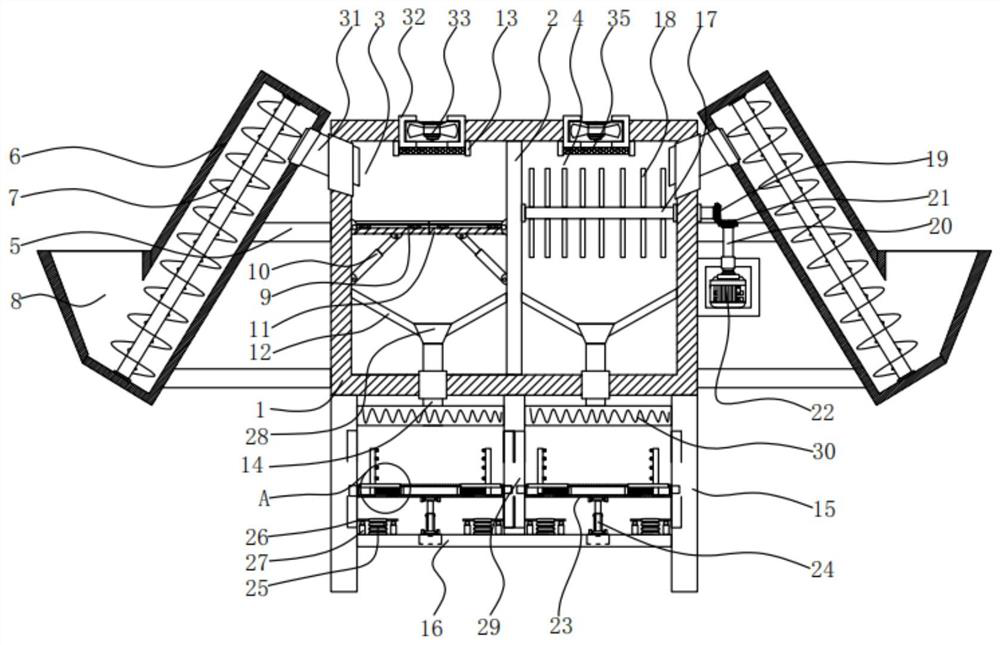

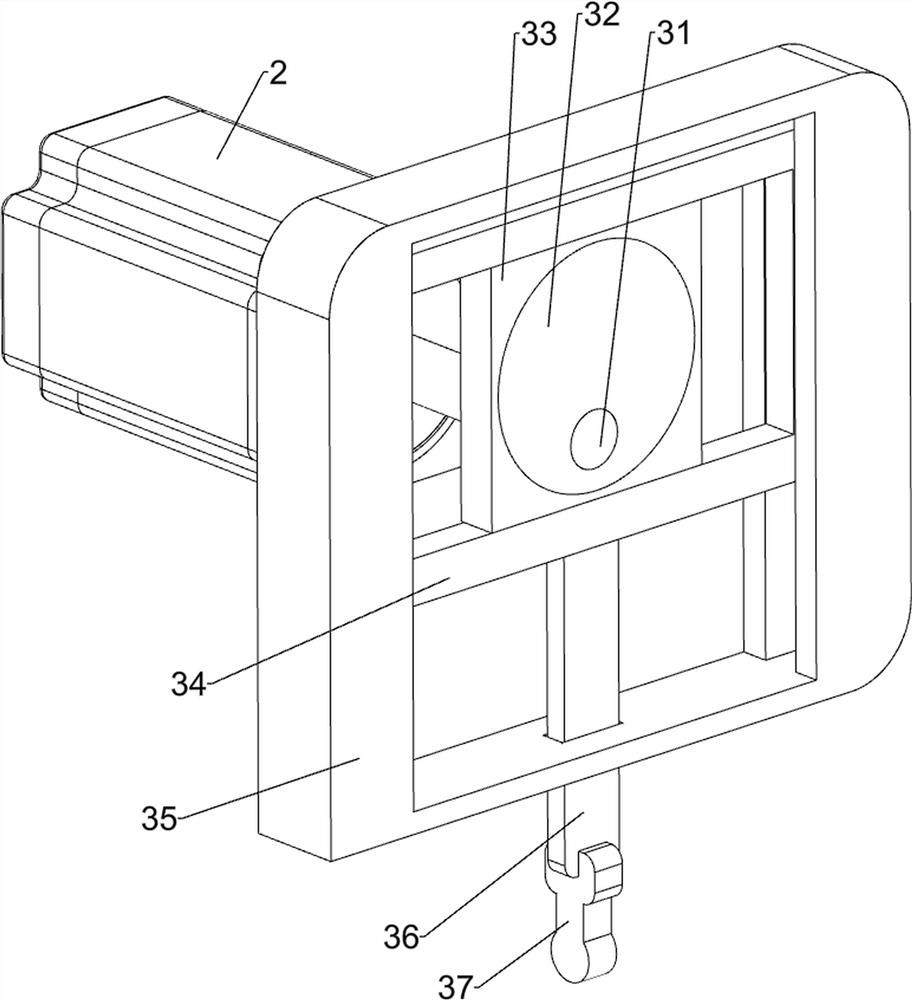

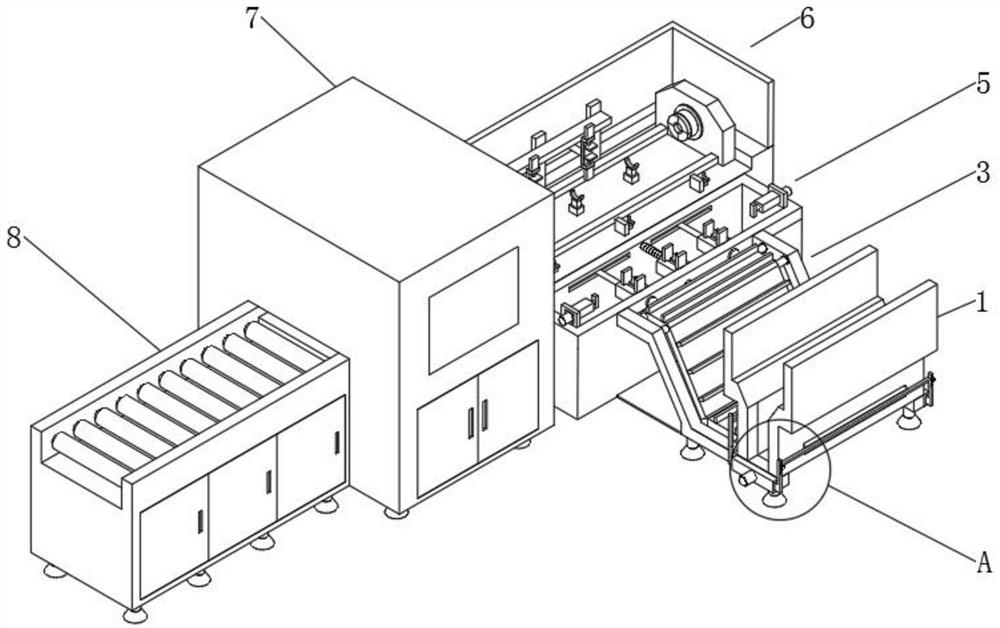

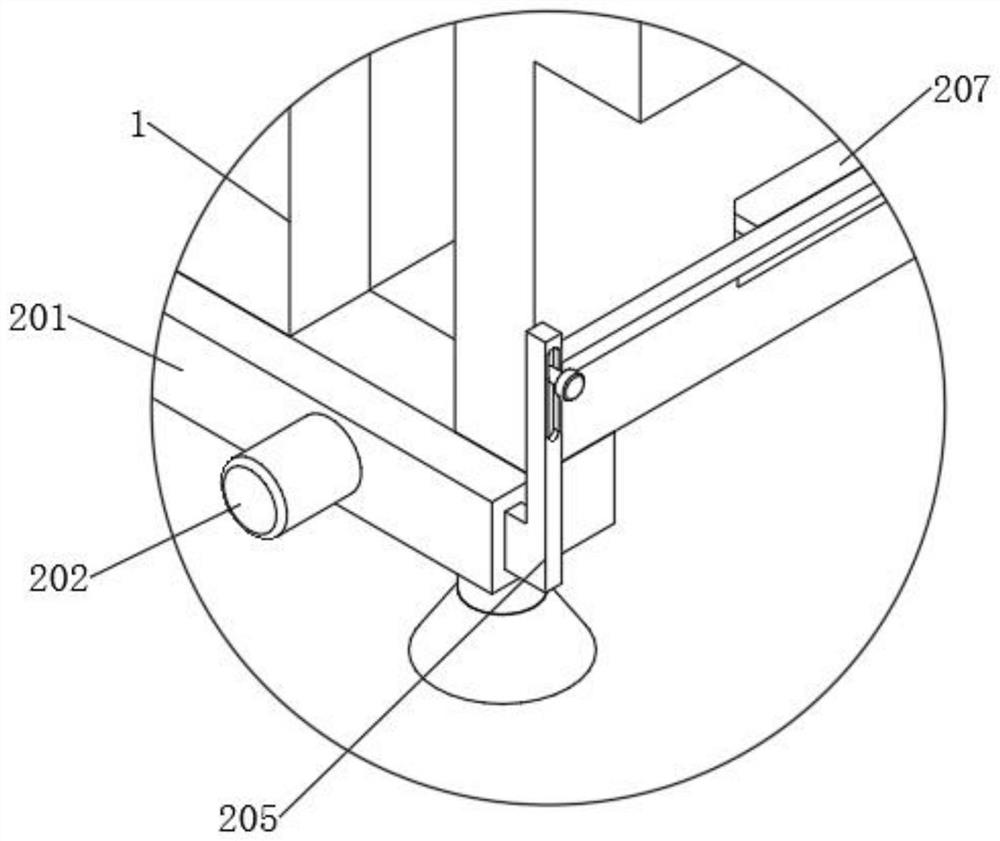

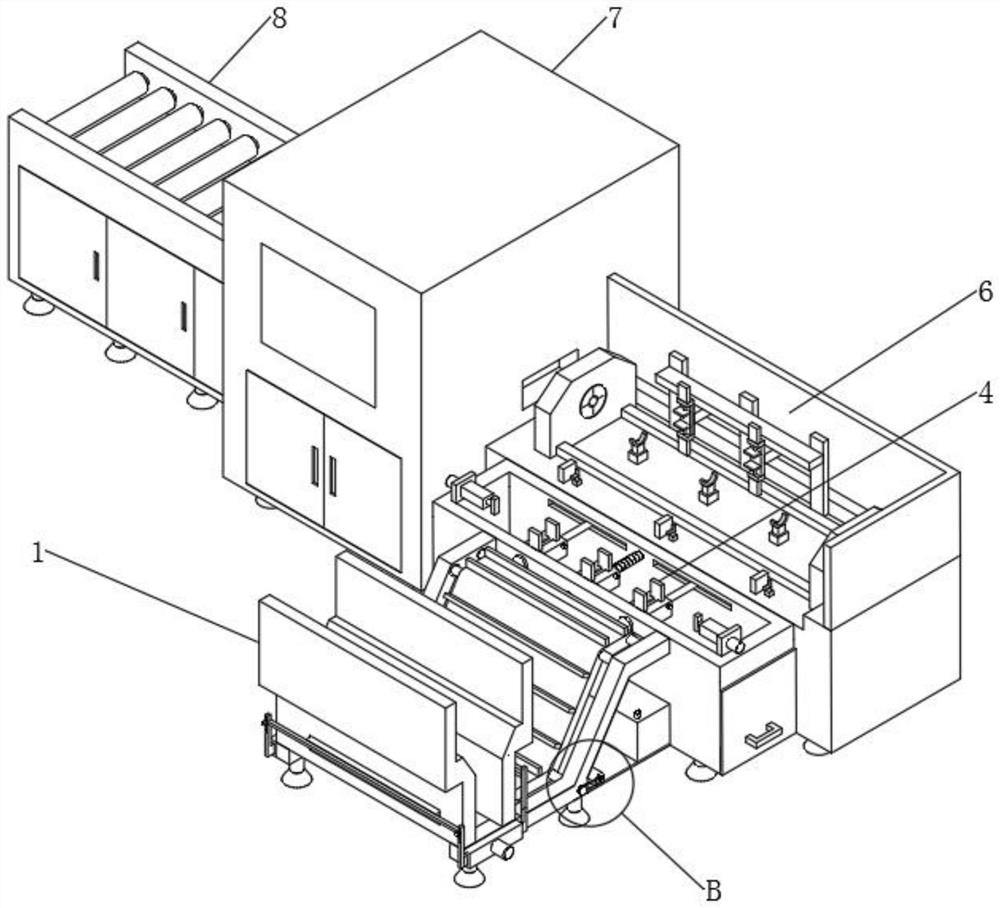

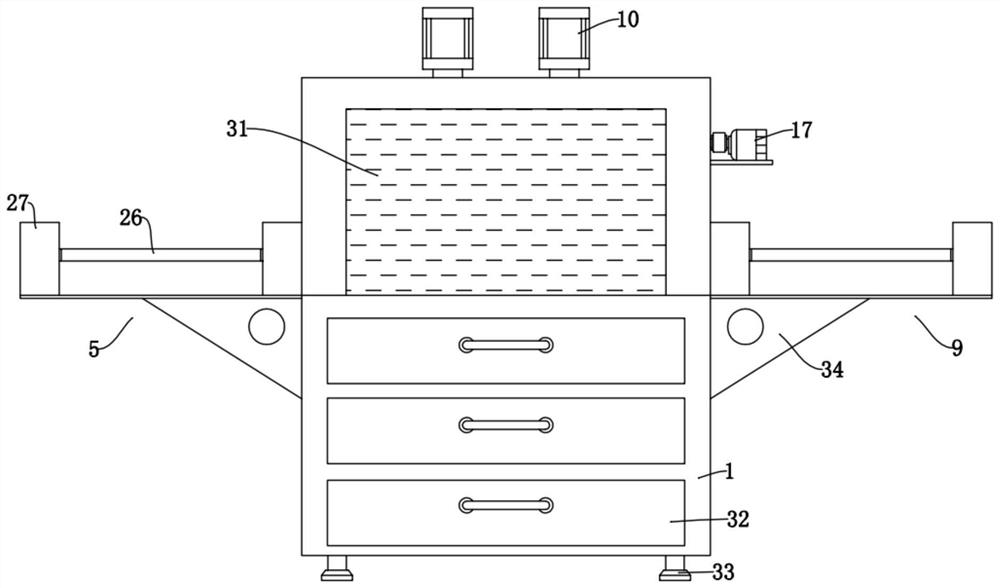

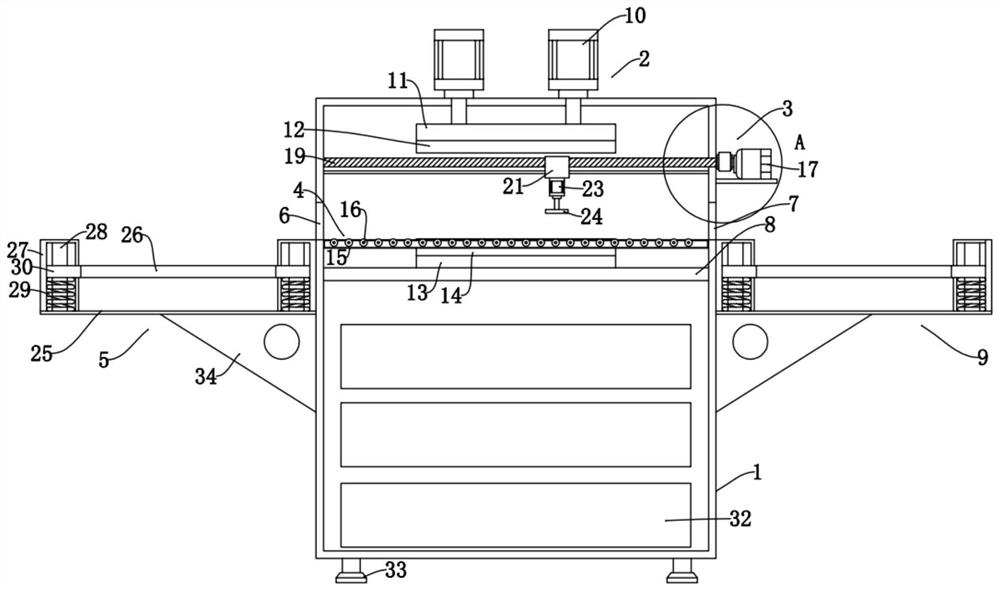

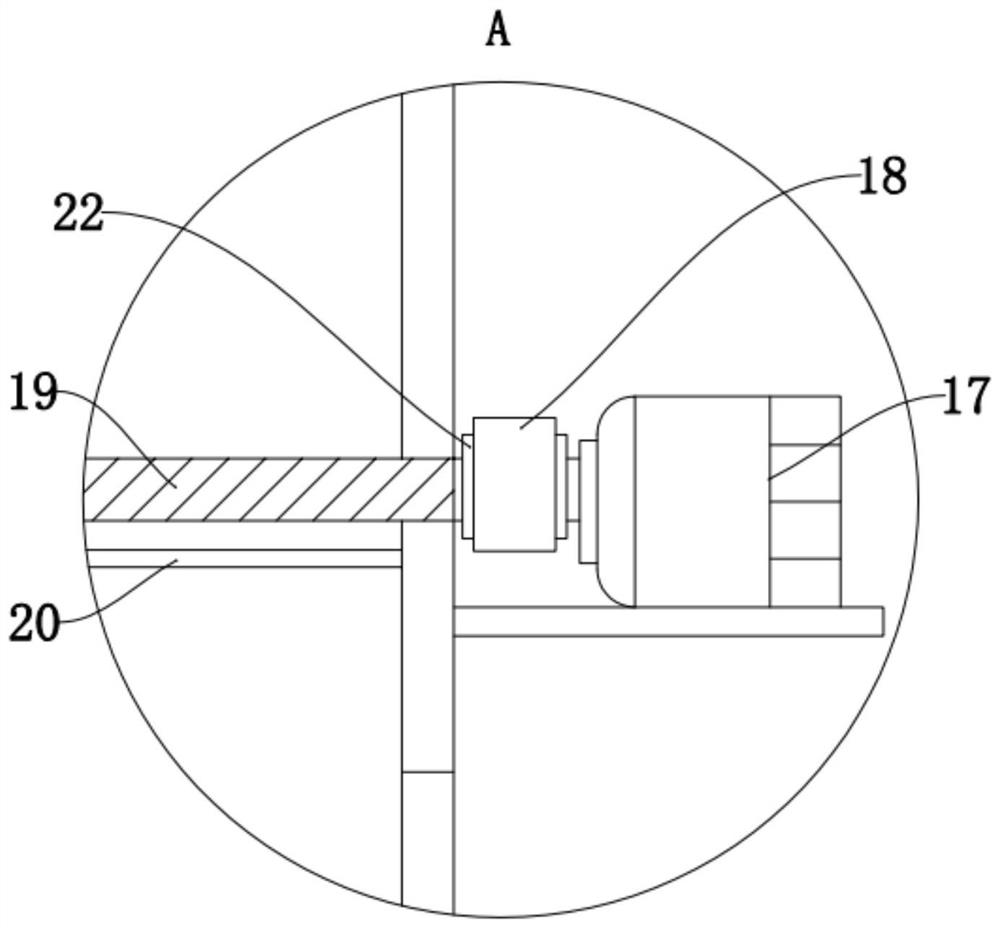

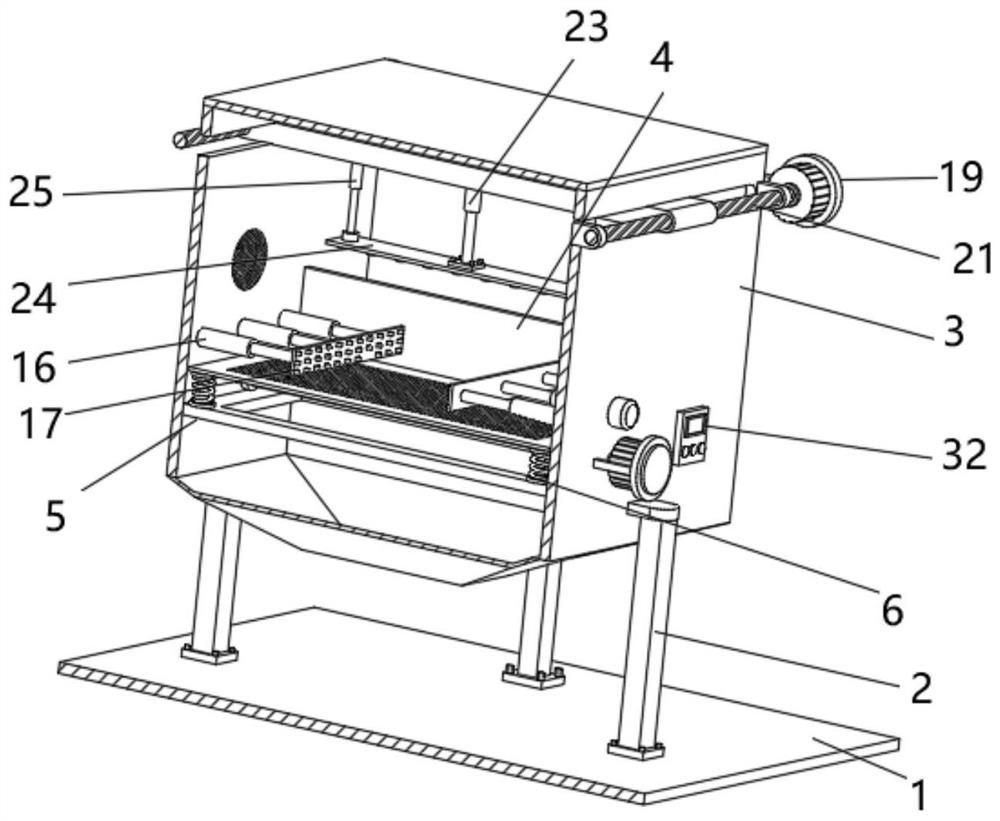

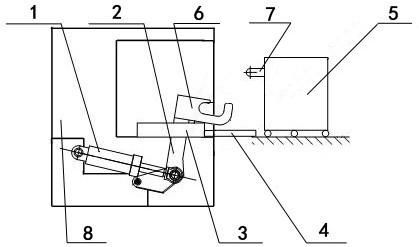

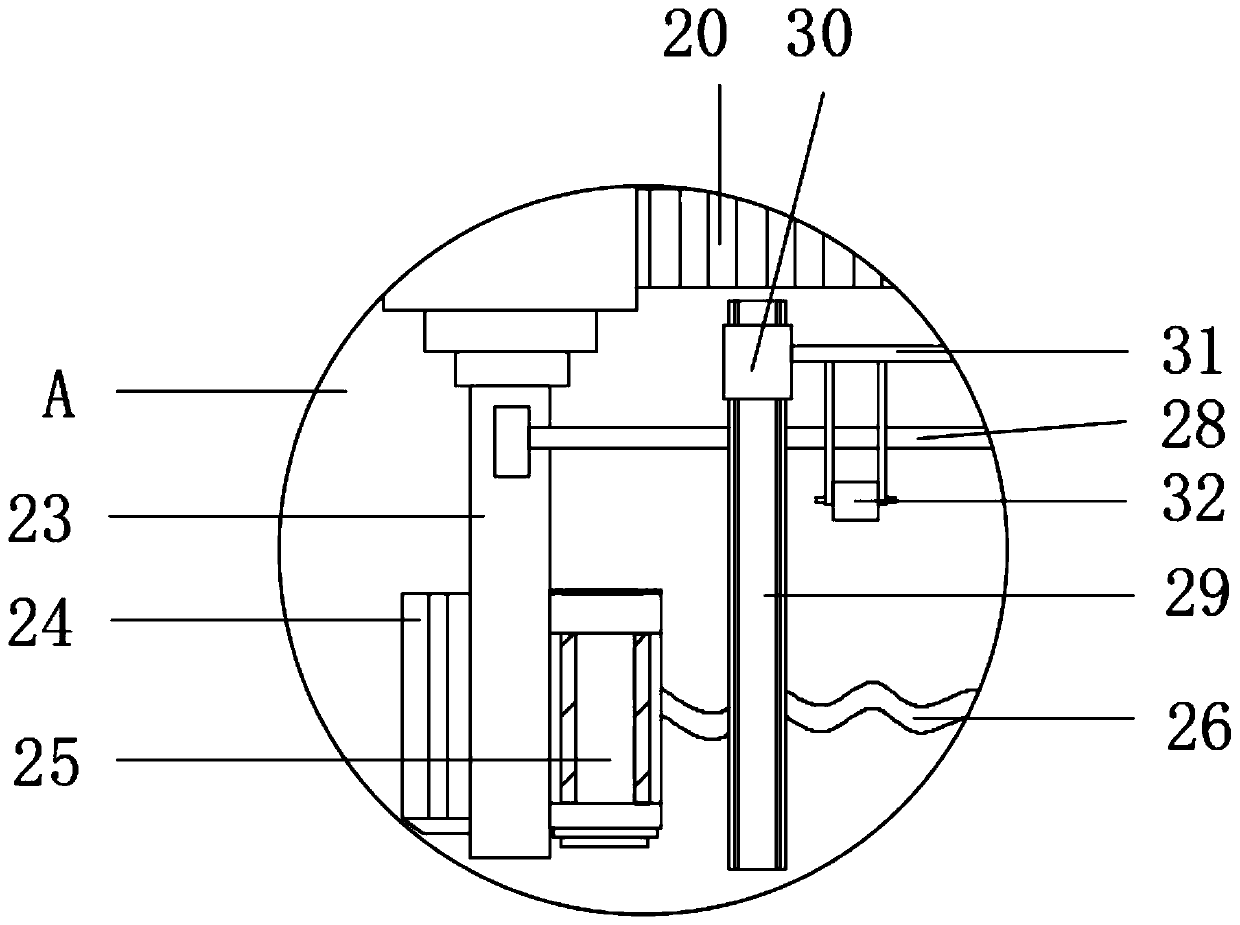

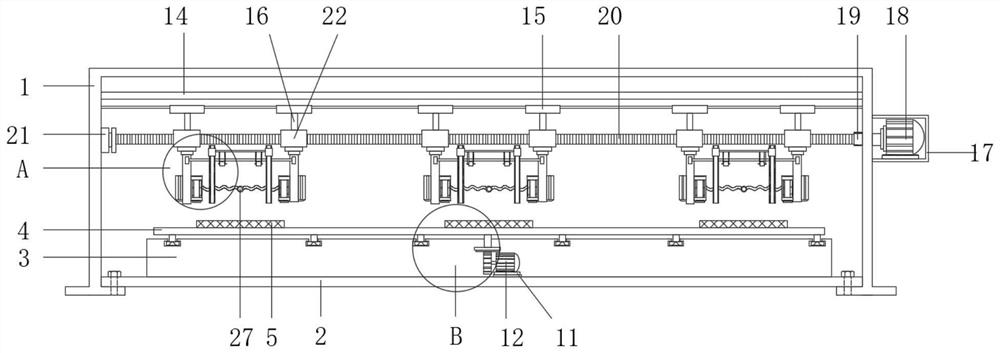

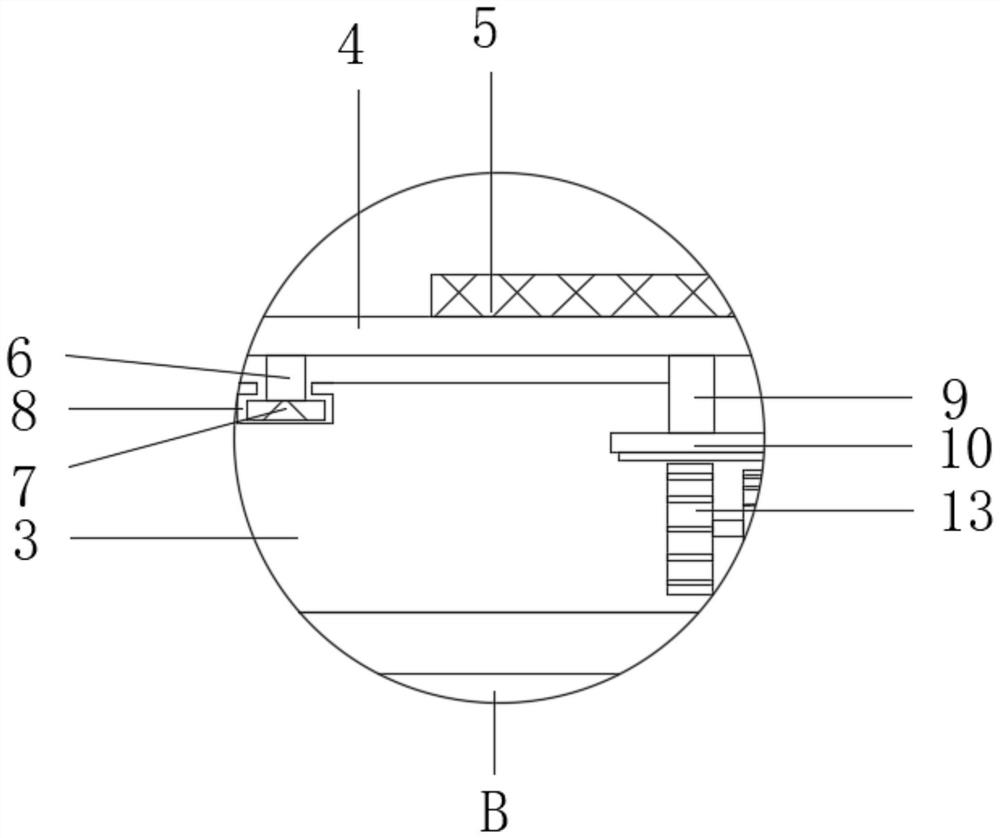

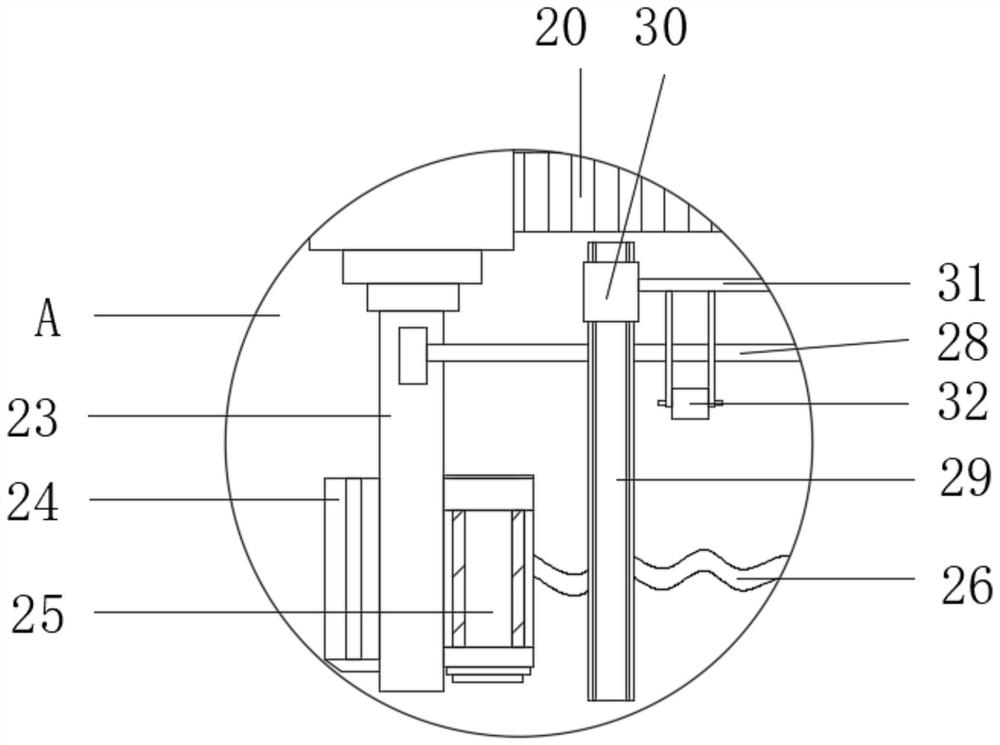

Automatic CCD printing machine

PendingCN111823703ARealize automatic printingAvoid manual loadingScreen printersConductive pattern formationDust controlPrinting press

The invention discloses an automatic CCD printing machine and relates to the technical field of printing. A machine cabinet is included; a lifting material stack mechanism, a feeding turning connection table, a first feeding mechanism, a dust removing mechanism, a second feeding mechanism, a printing platform, a printing mechanism and a discharging mechanism are installed above the machine cabinet; the lifting material stack mechanism is arranged in front of the feeding turning connection table; the first feeding mechanism is arranged on the left of the feeding turning connection table and thelifting material stack mechanism; the feeding turning connection table is arranged on the middle portion of the dust removing mechanism; the printing platform is arranged on the right of the feedingturning connection table; the second feeding mechanism is arranged behind the printing platform and the feeding turning connection table; the rear portion of the printing mechanism is fixedly providedwith a lifting mechanism; the lower end of the lifting mechanism is fixedly installed on the rear portion of the machine cabinet; the printing mechanism is arranged above the printing platform; the discharging mechanism is arranged in front of the printing platform; and the right end of the discharging mechanism extends out of the machine cabinet to be arranged. Manual feeding and discharging areavoided, and the positioning precision and the overall printing efficiency are improved.

Owner:深圳市欣荣自动化智能设备有限公司

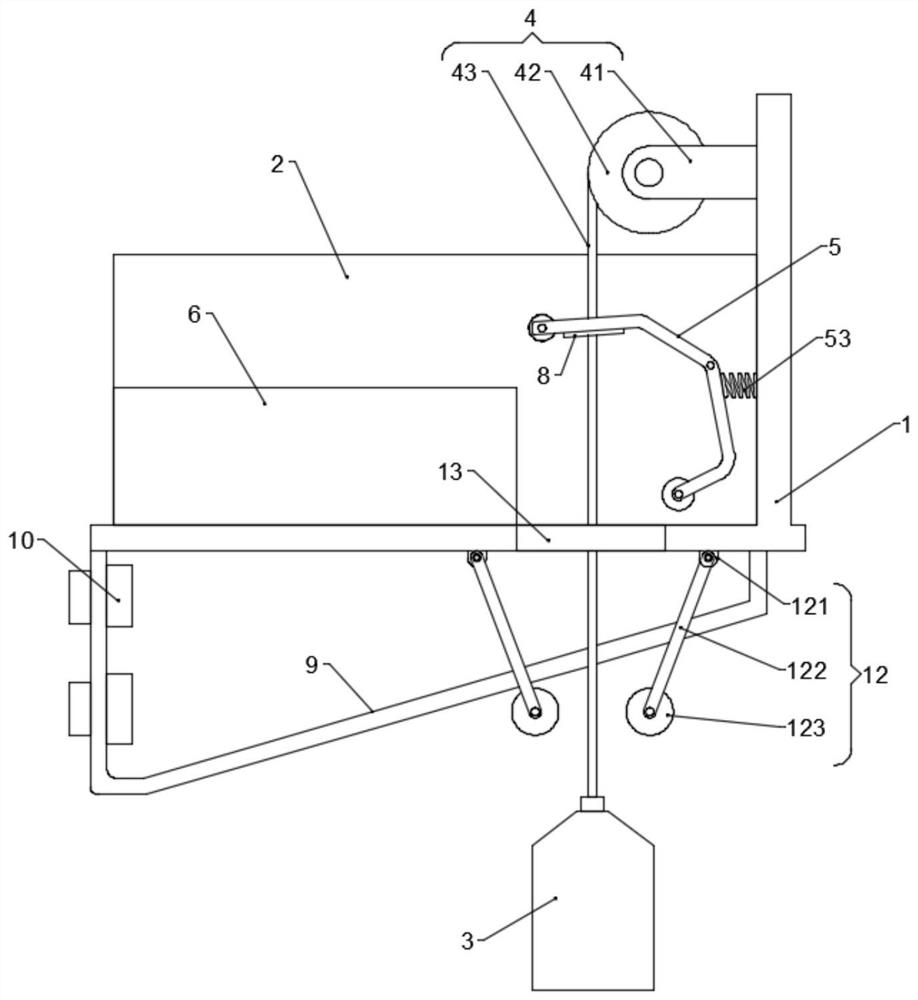

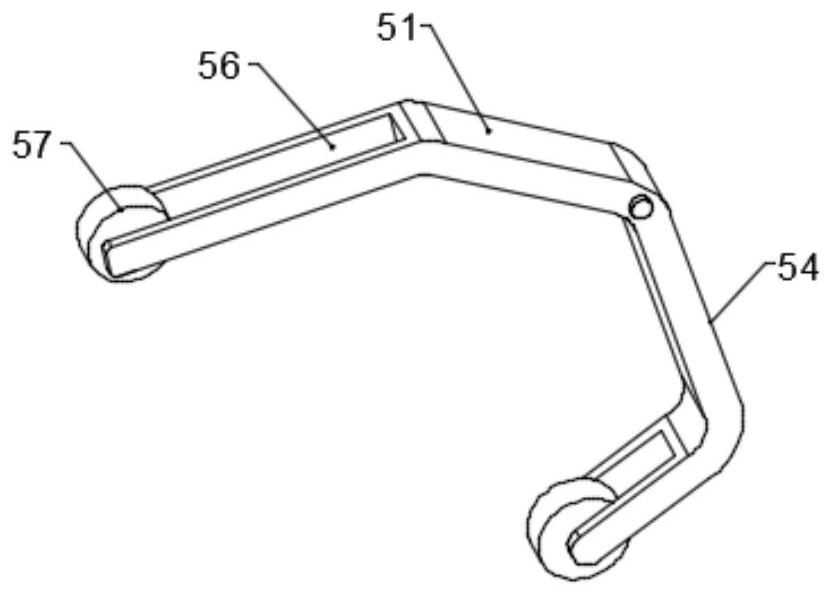

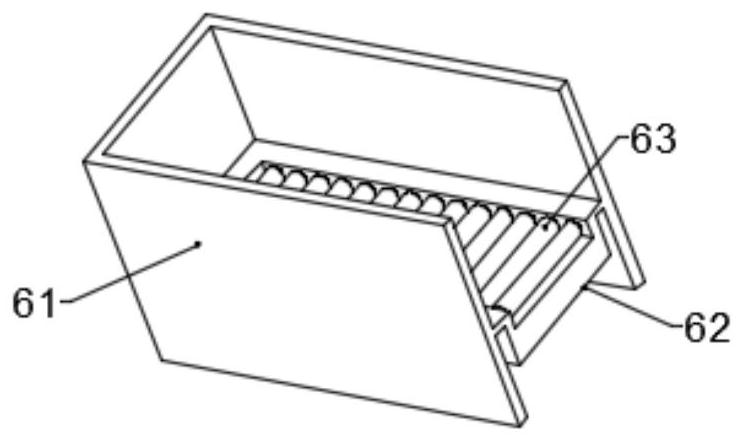

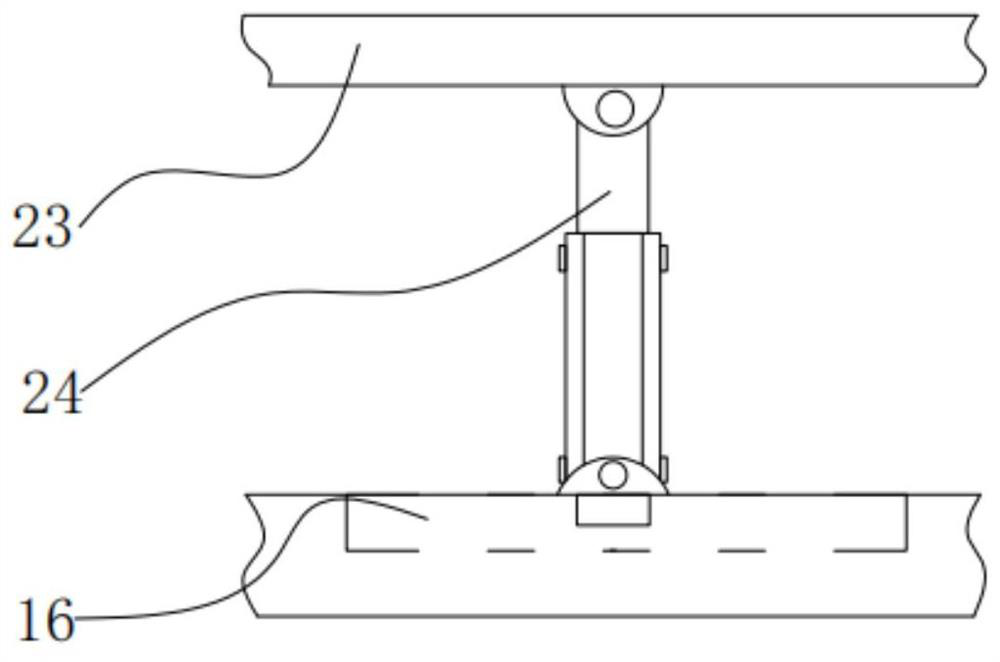

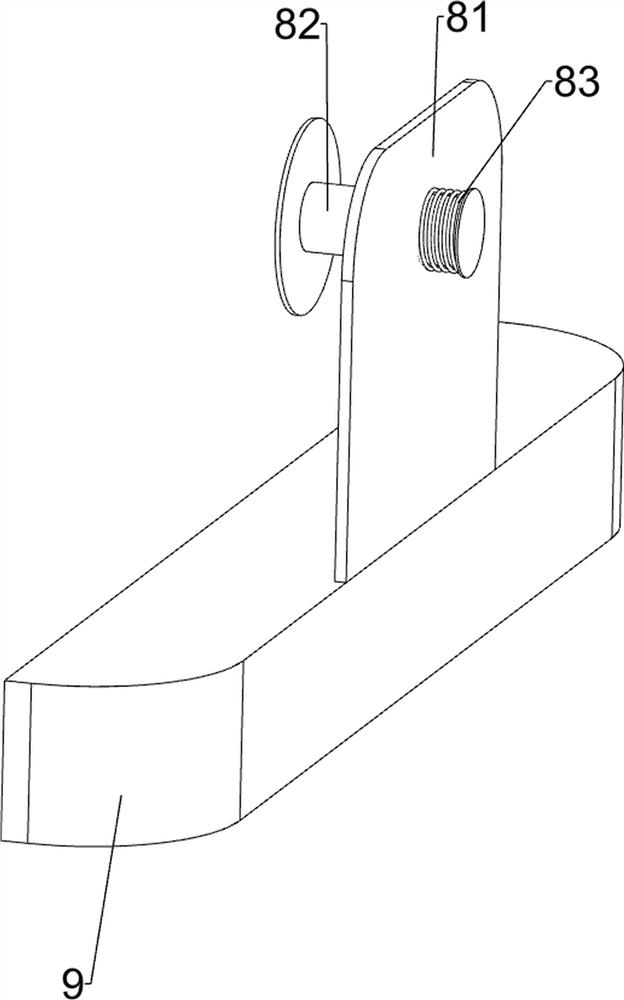

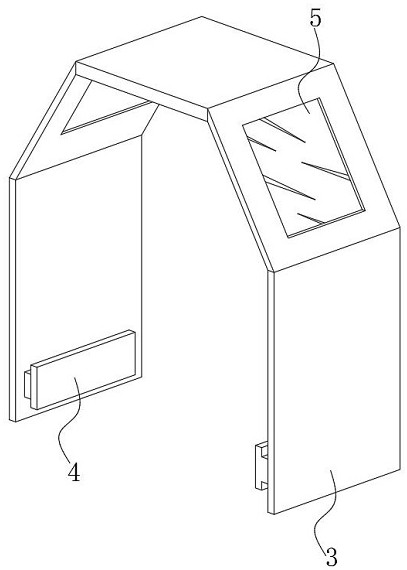

A high-rise steel structure construction platform

ActiveCN113089990BInfluence detachmentAvoid manual loadingBuilding material handlingScaffold accessoriesArchitectural engineeringMechanical engineering

The invention discloses a high-rise steel structure construction platform, which relates to the technical field of building construction. The construction platform comprises a platform bearing frame suspended on the side of a high-rise wall surface, a protective enclosing frame and at least one loading material for lifting a material box. The feeding mechanism includes a carrier and a lifting assembly, as well as a storage part, a guide frame and a toggle, the guide frame is arranged on the side of the horizontal part of the platform carrier, and the storage part and the toggle It is located on the side of the protective enclosure frame and is oppositely arranged. The middle part of the toggle member is rotatably connected to the side portion of the protective enclosure frame through the connecting piece. The power rotates around the connector and one end pushes the bin on the carrier into the storage part. The present invention has a simple structure, is convenient for automatically loading a material box equipped with a steel structure construction tool, avoids manual operation for material loading, is convenient, improves safety, and has strong practicability.

Owner:致邦住宅工业集团有限公司

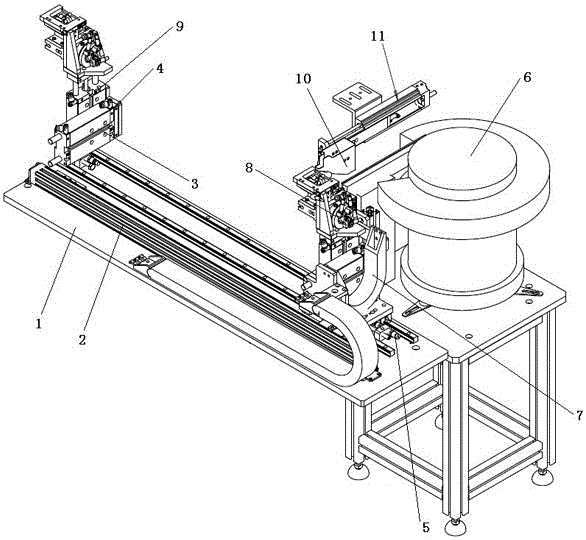

Rivet conveyor

Owner:MAGNETI MARELLI AUTOMOTIVE COMPONENTS WUHU

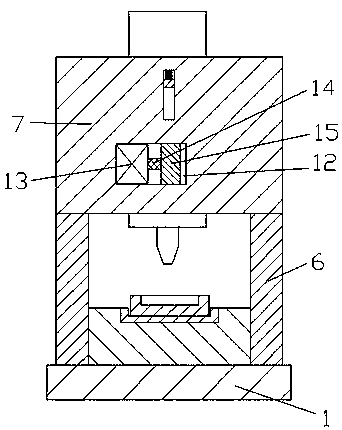

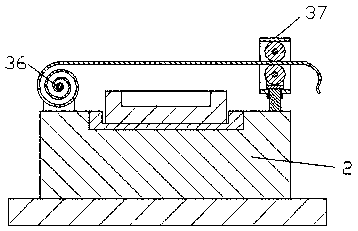

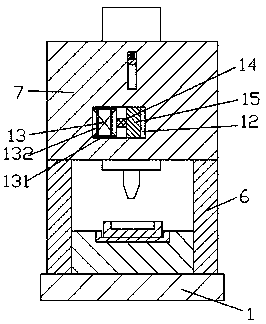

Chip-type semiconductor ultrathin packaging device

InactiveCN108695168AAvoid cloggingReduce workloadSemiconductor/solid-state device manufacturingAssembly lineSemiconductor

The invention discloses a chip-type semiconductor ultrathin packaging device, and the device comprises a fixed substrate. The center of the upper end face of the fixed substrate is provided with a conveying assembly line which extends in a left-right direction. The left side of the interior of a fixed cabinet is provided with a closed space, and the center of the lower end face of the sealing plate is fixedly connected with a hydraulic rod. The lower end of the hydraulic rod passes through the lower end wall of the closed space and is fixedly connected with a pressing-fit board. A resin sheetconveying device is disposed exactly below the pressing-fit board, and comprises a winding mechanism and a pulling mechanism. In operation, the cooperation of an annular clamping board and an annularclamping groove can enable an extruding plate not to fall off when the extruding plate move up and down along a guide rod, and the extruding board can fall to make contact with the lower end wall of aglue storing space, thereby preventing the solidification of glue at lower end from causing the blocking of a glue coating needle after the glue is not used for a long time period. Meanwhile, resin sheets which are not used can be automatically switched, thereby improving the precision, and improving the work efficiency.

Owner:岑森参

Test tube transfer device and transfer method

ActiveCN114313601AAvoid the trouble of searching one by oneImprove inspection efficiencyExternal fittingsInternal fittingsStructural engineeringMechanics

According to the test tube transfer device and the transfer method, aiming at the problem that after a test tube is inserted into a loader, label information on the side edge of the test tube is covered, so that an inspector can be influenced to select a target test tube, a detachable label sleeve capable of transmitting test tube label information which is easy to identify is used; the test tubes can be easily identified through the label sleeves no matter how deep the test tubes are placed, the problem of disorder among the test tubes can be avoided by arranging the label sleeves with different colors, the label sleeves are detachably arranged outside the test tubes and can be repeatedly used, the cost is further saved, and in the test tube transferring device, the test tubes can be conveniently and rapidly transferred. According to the technical scheme, the transportation supporting leg comprises the main body part and the deformation part, rapid barrier passing is achieved through deformation of the deformation part and sliding of the main body part, compared with an existing mode that the transportation supporting leg needs to be assembled every time, the test tube transferring efficiency is further improved, and a new barrier passing method is creatively provided; the method does not exist in the prior art.

Owner:福州市第二医院

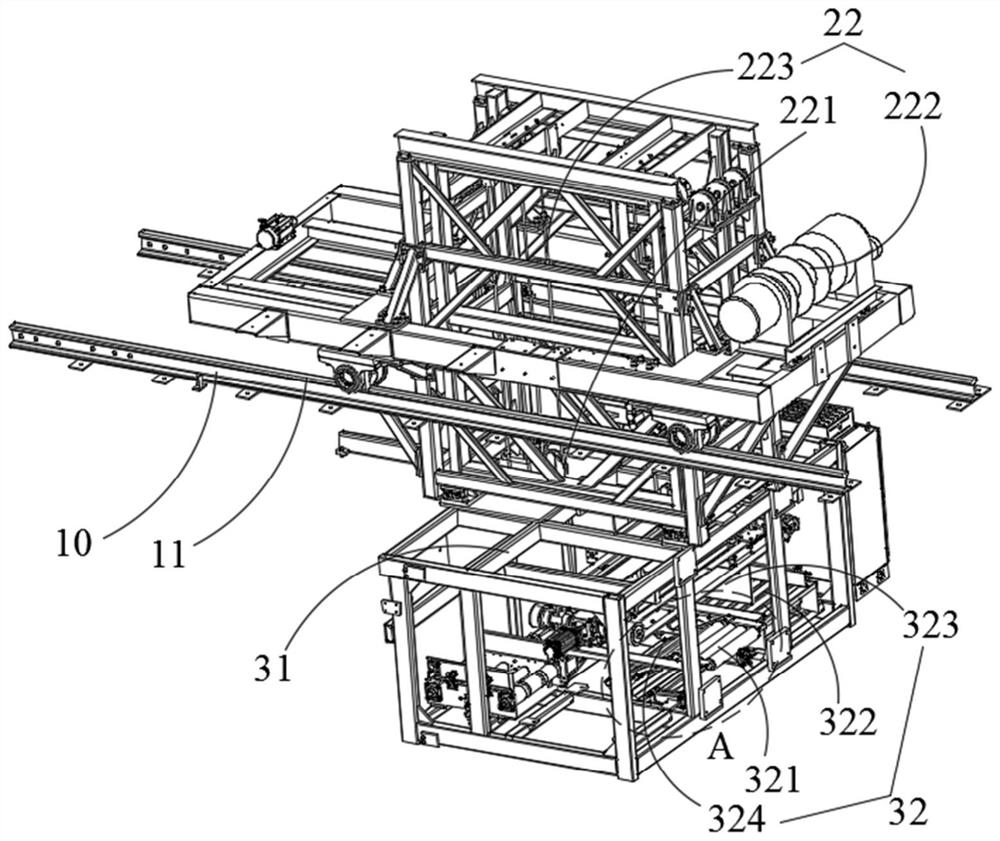

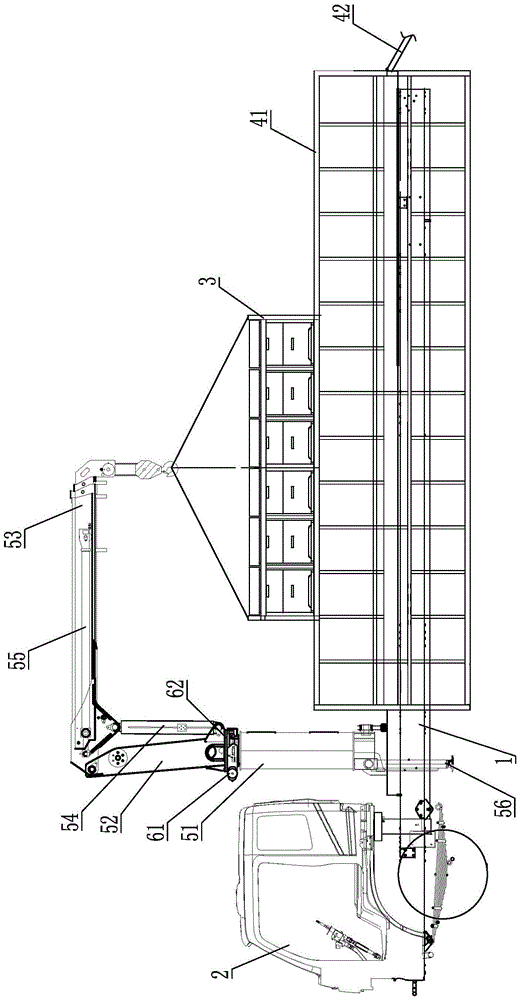

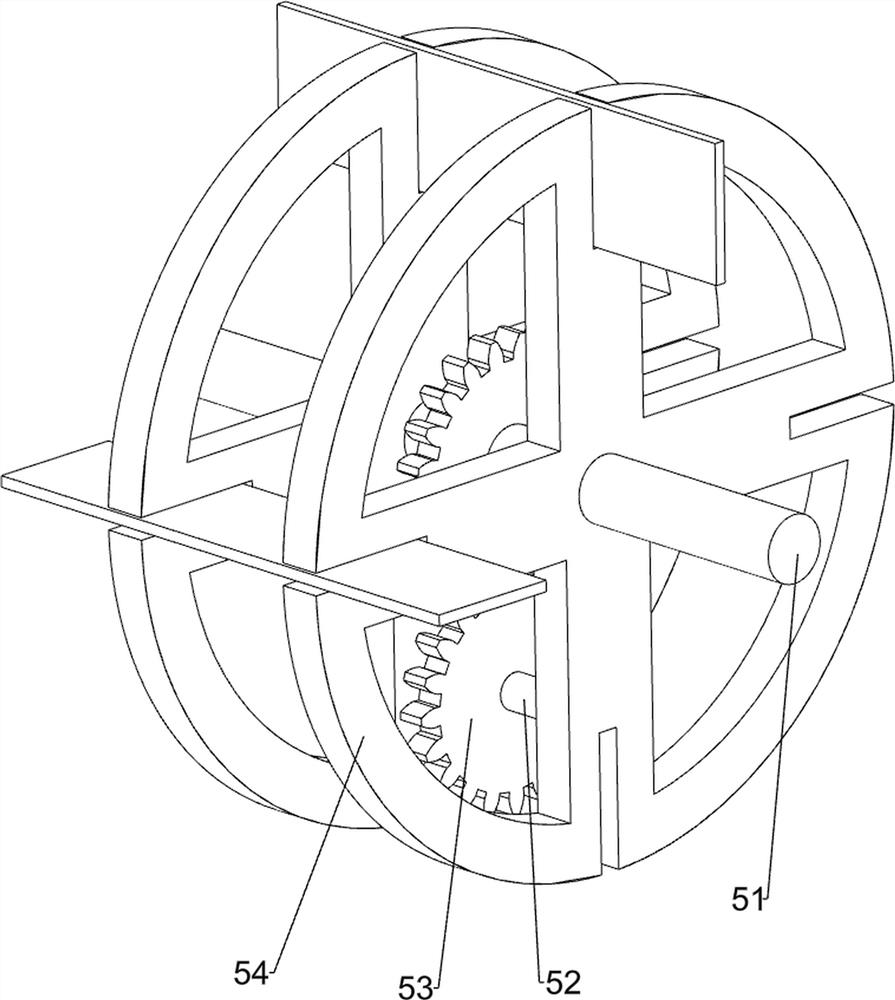

Car loader

PendingCN114803558AAvoid manual loadingImprove loading efficiencyConveyorsLoading/unloadingControl theoryMechanical engineering

The invention provides a car loader which comprises a track base, a moving car mechanism and a material code packaging car mechanism, and a moving car assembly is movably installed on the track base; the lifting assembly is installed on the moving trolley assembly and driven by the moving trolley assembly to move. The lifting assembly comprises a liftable lifting hook; the truss is connected with the lifting hook and supports the feeding assembly and the multi-stage mechanical arm assembly. The feeding assembly is used for outputting materials; the multi-stage mechanical arm assembly is arranged on one side of the feeding assembly, clamps or conveys materials conveyed by the feeding assembly and stacks the materials in the height direction, the lifting assembly and the material stacking and packaging trolley mechanism are driven by the moving trolley assembly to move, and the material stacking and packaging trolley mechanism is driven by a lifting hook of the lifting assembly to integrally ascend and descend. The multi-stage mechanical arm assembly is arranged on the material stacking and loading mechanism so that the position of the material stacking and loading mechanism can be adjusted in the horizontal direction and the vertical direction, and the multi-stage mechanical arm assembly clamps or conveys the materials conveyed by the feeding assembly and stacks the materials in the height direction.

Owner:杭州明度智能科技有限公司

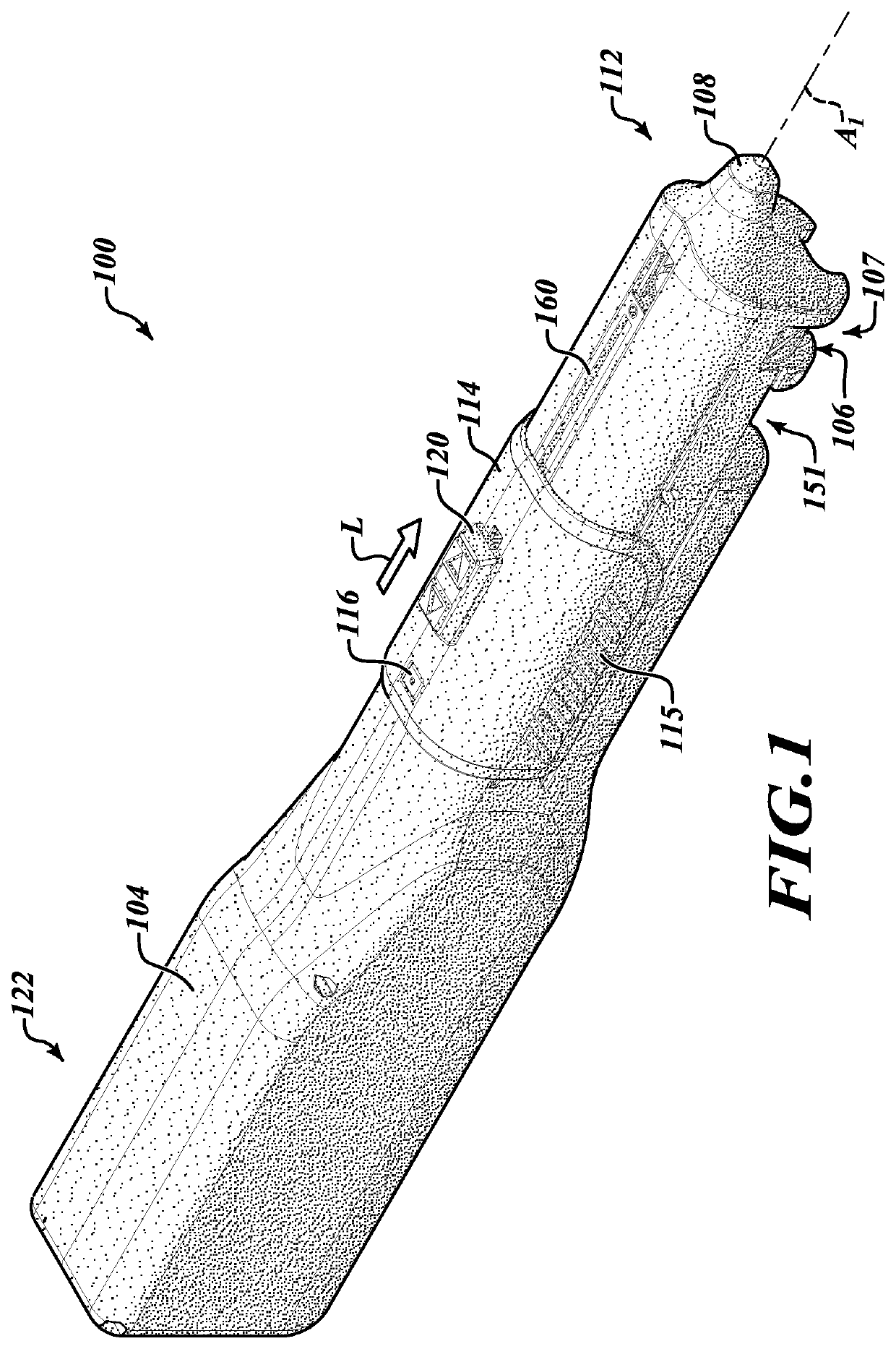

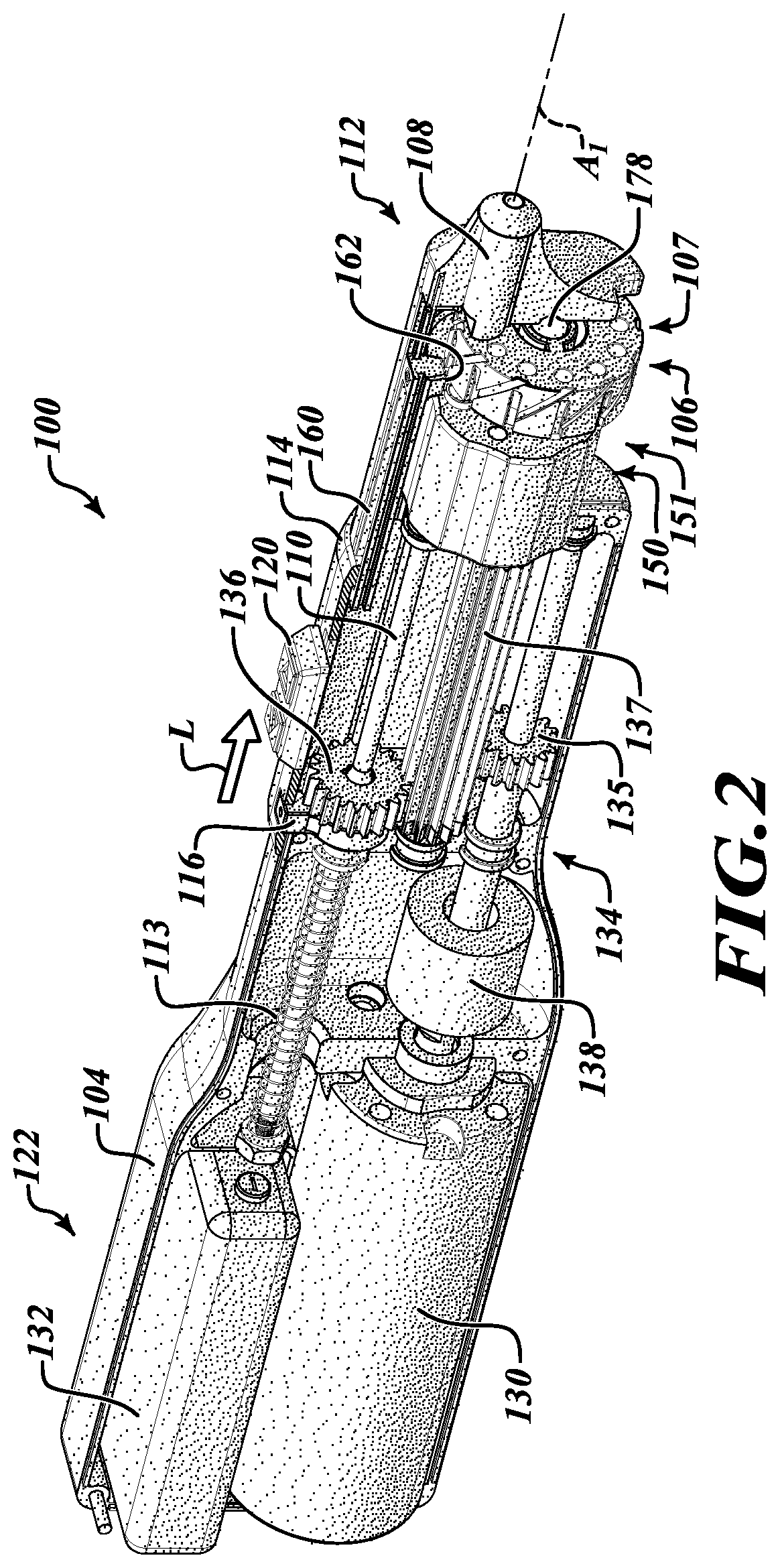

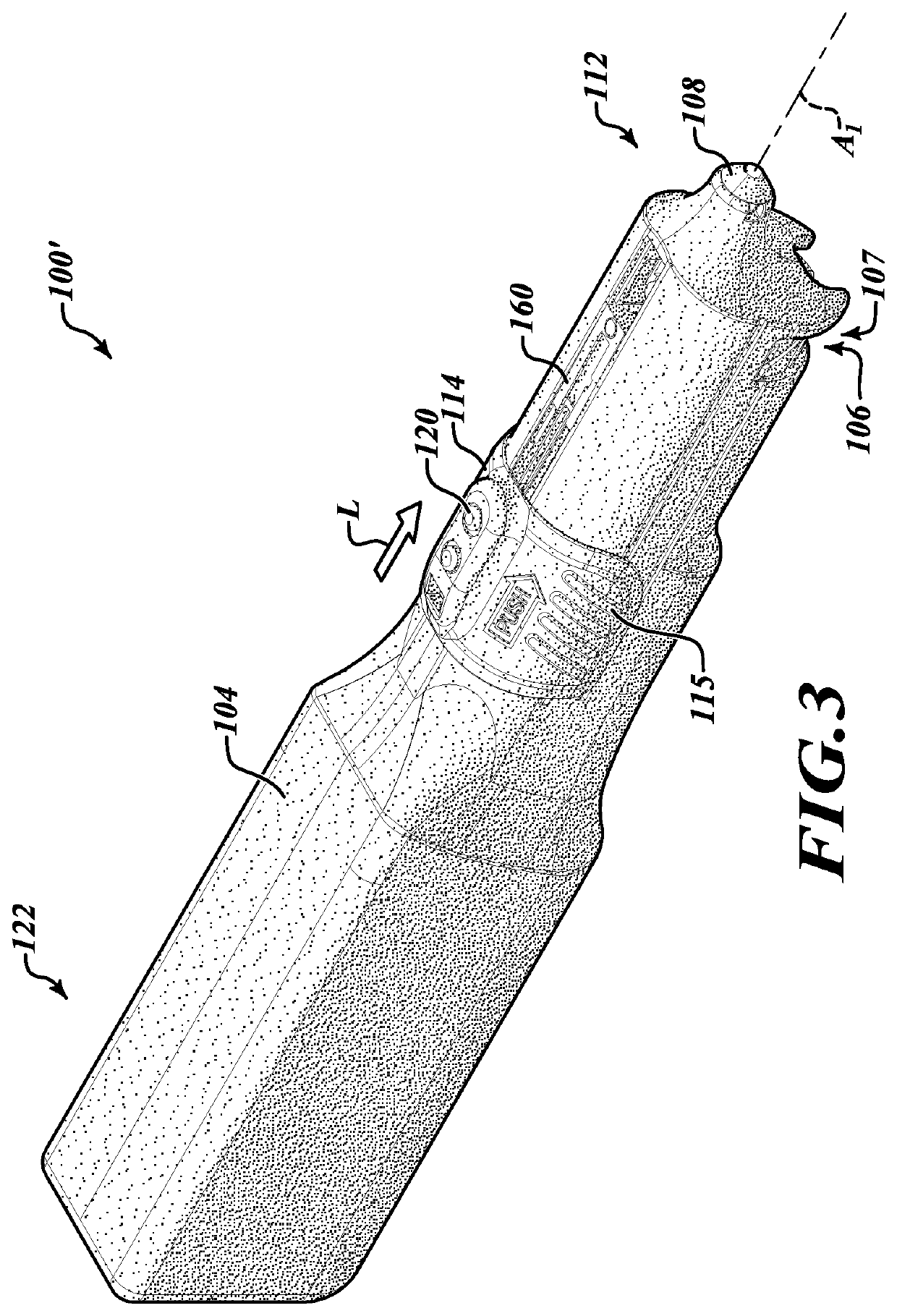

Autoloading screwdriver apparatus

An autoloading screwdriver apparatus is provided which includes a base; a screw cartridge received by the base; a driver supported within the base that is selectively engageable with a screw of the screw cartridge by manually displacing the driver toward a working end of the autoloading screwdriver apparatus; and a handle grip movably coupled to the base and configured to be manually displaced in a longitudinal direction toward the working end of the autoloading screwdriver apparatus to move the driver into engagement with the screw and to displace the screw to the working end of the autoloading screwdriver apparatus for presenting the screw to be screwed into a target substrate. The autoloading screwdriver apparatus may further include a control element manipulable by a user to activate rotational movement of the driver to drive the screw into the target substrate.

Owner:BIO MED PRO LLC

Double-station weighing intelligent metering special machine

InactiveCN112432688AEase of workMeet different production needsWeighing apparatus with automatic feed/dischargeMachineControl theory

The invention discloses a double-station weighing intelligent metering special machine which comprises a box body, a feeding box is obliquely arranged at the outer end of each supporting plate, an inner cavity of each feeding box is rotatably parallel to a spiral shaft of the corresponding feeding box, and a telescopic rod is rotatably arranged between the lower surface of a rotating plate and theinner side wall of a first cavity; a weight sensor is arranged on the upper surface of each rotating plate, and a stirring column is arranged on the surface of a stirring shaft. According to the invention, the rotating plates at the top ends of telescopic rods are jacked up through extension of the telescopic rods in the first cavity, so that the two telescopic rods are flush and are in a horizontal state, and materials in gaps are prevented from falling off; the weight of materials on the upper surfaces of the rotating plates can be sensed through the weight sensors on the upper surfaces ofthe rotating plates, different materials can be processed through the first cavity and a second cavity which are independent of each other, the different materials are metered, the application range of the device is widened, and the functions of the device are increased.

Owner:常州普和软件有限公司

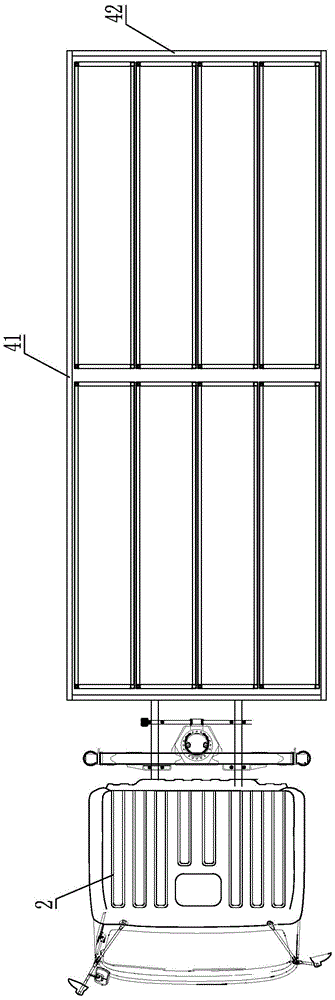

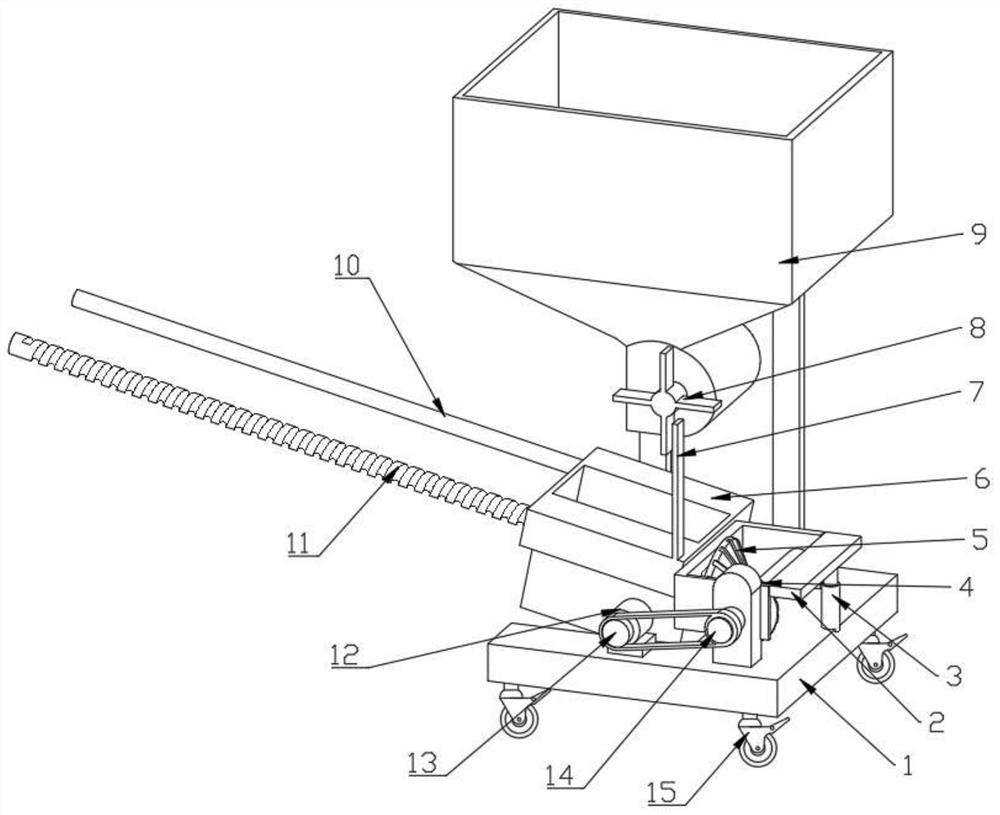

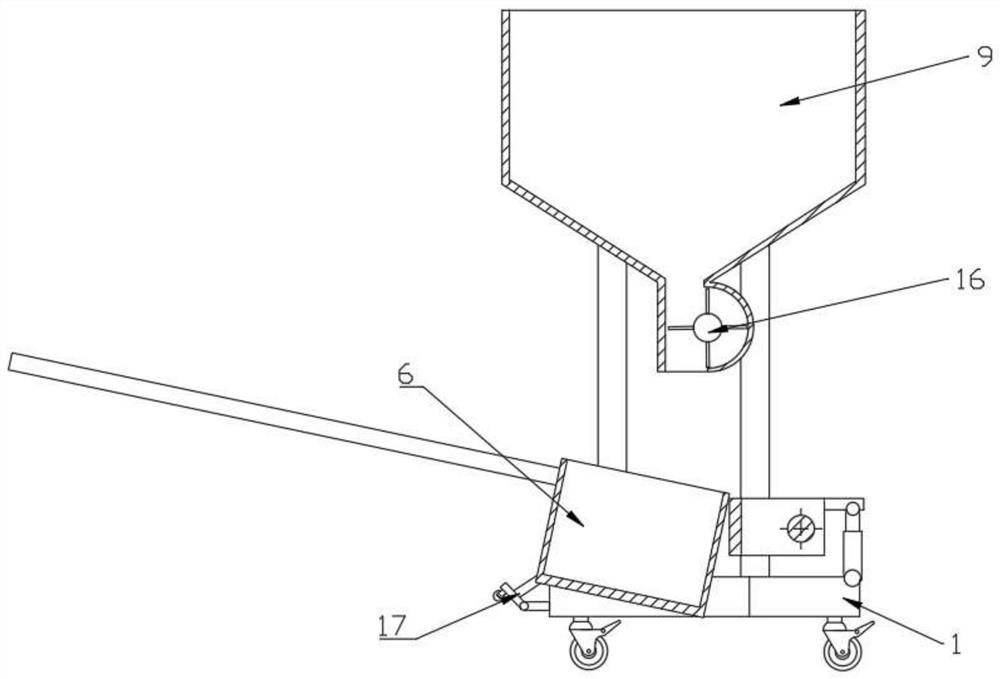

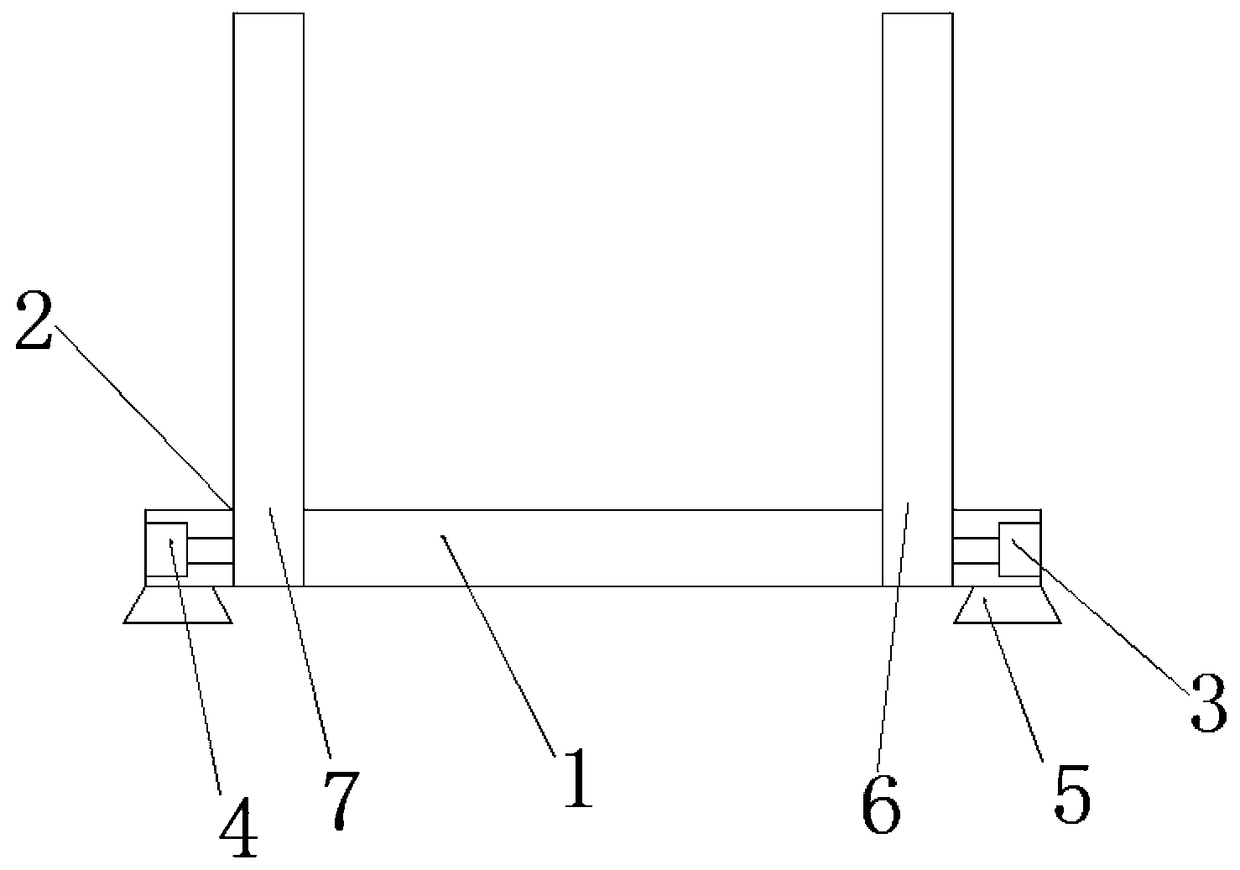

Automatic loading and unloading type special vehicle for beekeeping

InactiveCN105620339AAvoid manual loadingAvoid manual loading and unloadingVehicles with cranesTransportation itemsEngineeringBeekeeping

The invention discloses an automatic loading and unloading type special vehicle for beekeeping. The special vehicle comprises a class-II chassis, wherein a cabin is mounted at the front end part of the class-II chassis, and a plurality of movable beehive storage racks are placed at the rear end part of the class-II chassis; a plurality of beehives are placed on the movable beehive storage racks; a warehouse railing which is arranged around the movable beehive storage racks is mounted on the chassis; a truck lifting gear is mounted on the class-II chassis between the cabin and the movable beehive storage racks; during transportation, the beehives are piled on the movable beehive storage racks, the lifting gear is used for carrying the movable beehive storage racks on a truck, so that the condition that people need to carry the beehives to and from the truck is avoided, the labor intensity is reduced, and the carrying efficiency is improved.

Owner:WUZHENG

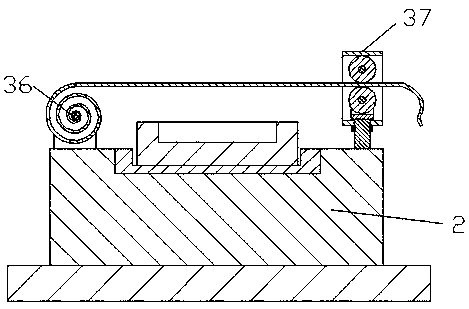

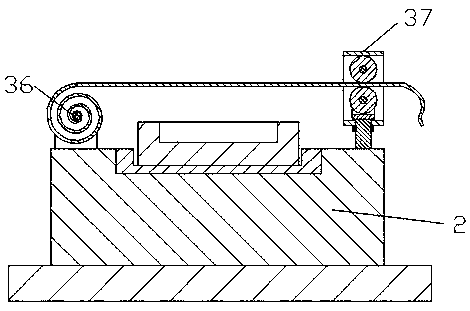

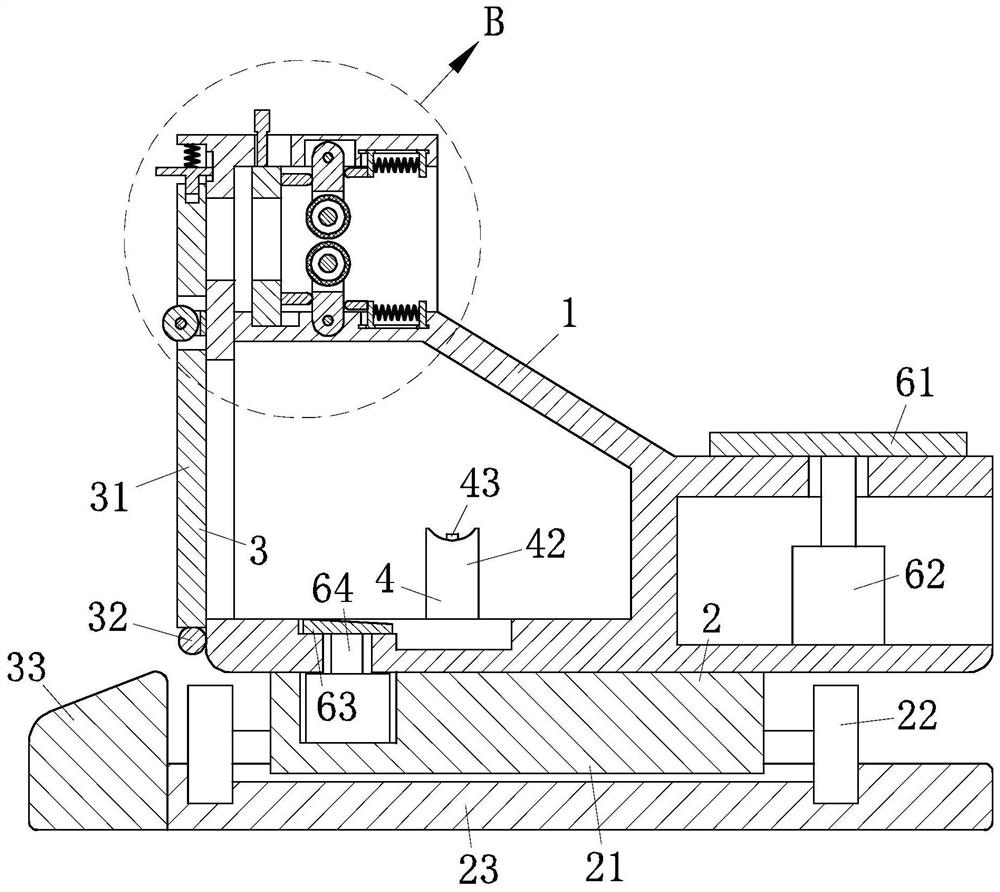

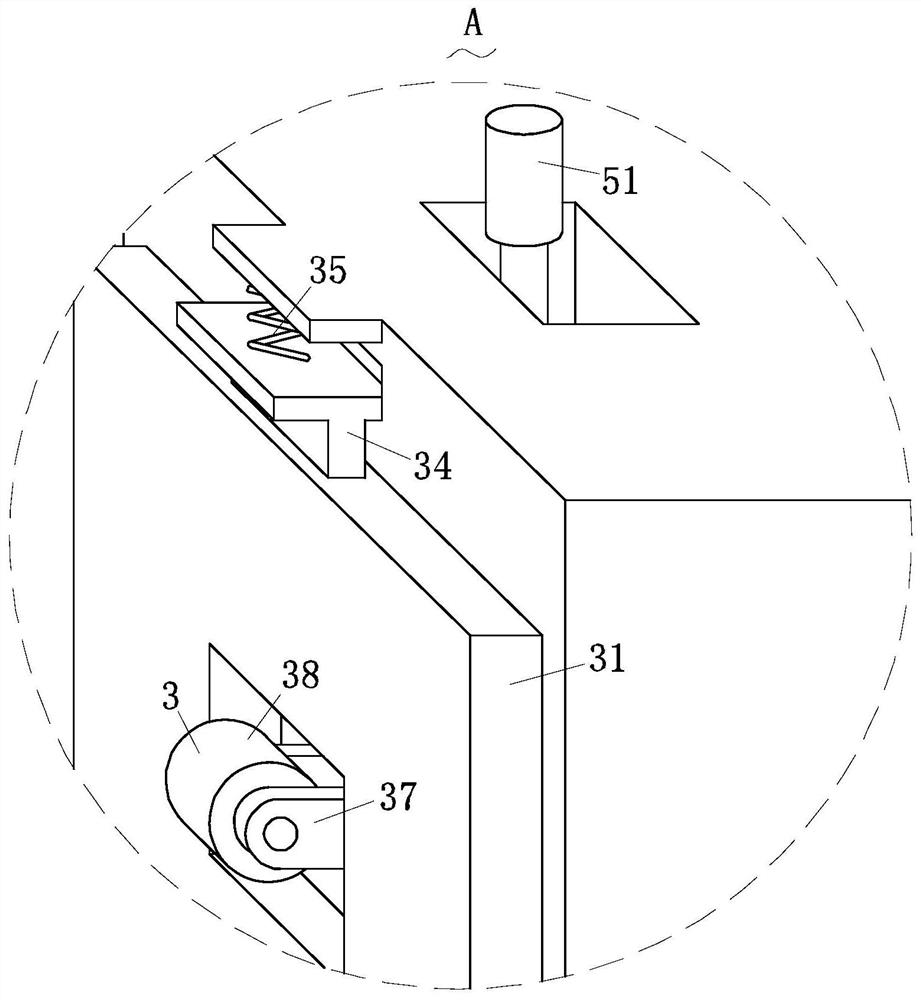

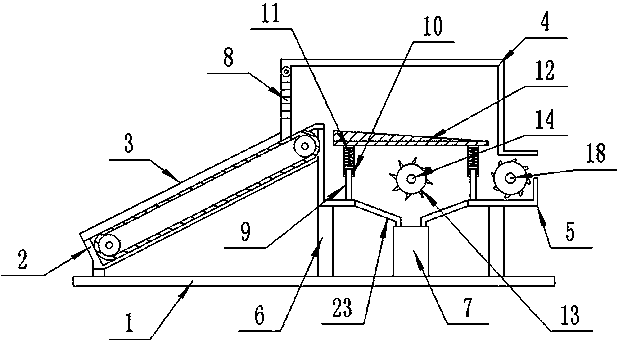

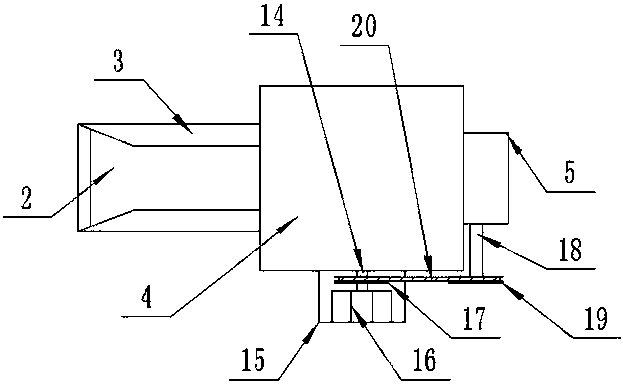

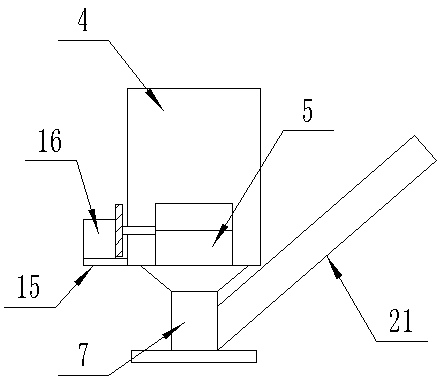

R-shaped buckle forming device for sewage treatment

ActiveCN112355072ARealize automatic feeding processRealize functionStructural engineeringSewage treatment

The invention relates to a forming device, and particularly relates to an R-shaped buckle forming device for sewage treatment. The R-shaped buckle forming device for sewage treatment can automaticallyfeed, convey, extrude, form and discharge iron sheets, and manufactured R-shaped buckles are consistent in shape and size. The R-shaped buckle forming device for sewage treatment comprises a mountingplate, a servo motor, a storage box body and an extruding mechanism, wherein the servo motor is arranged on one side of the top of the mounting plate; the storage box body for collecting the formed R-shaped buckles is arranged on one side of the top of the mounting plate; and the extruding mechanism is arranged between the upper part of one side of the mounting plate and an output shaft of the servo motor. Through cooperation of the extruding mechanism, a conveying mechanism, a first discharge mechanism, an extruding return mechanism and a second discharge mechanism, the functions of automatic feeding and automatic conveying of the iron sheets can be realized, and the iron sheets can be automatically extruded and formed as the R-shaped buckles, so that the working efficiency of people isimproved.

Owner:营口思净环保科技有限公司

Water-borne coal transport ship

InactiveCN111960140AImprove applicabilityEasy to operateLoading/unloadingMarine engineeringStructural engineering

The invention is applicable to the technical field of ships, and provides a water-borne coal transport ship. The water-borne coal transport ship comprises a base, at least one lead screw, a transportship body, a rotating driving part, a first telescopic driving part and a hopper, wherein an installation frame is rotatably arranged on the upper surface of the base, the lead screw is rotatably arranged on the installation frame, the transport ship body is cooperatively arranged on the lead screw and used for transporting coal powder, the rotating driving part is connected with the lead screw through a transmission part and used for driving the lead screw to rotate, the first telescopic driving part is rotatably installed on the base, rotatably connected with the installation frame and usedfor driving the installation frame to rotate, and the hopper is installed on the base and used for containing the coal powder. A feeding roller for controlling feeding is rotatably connected to the bottom of the hopper, a one-way stirring roller is connected to the feeding roller, a stirring rod is connected to the transport ship body, and the stirring rod cooperates with the one-way stirring roller to control feeding. The water-borne coal transport ship has the advantages of being simple in structure, convenient to operate, small in workload, high in working efficiency, capable of saving energy, good in synchronism and convenient to implement and popularize.

Owner:李绍鑫

Glue supply assembly and gluing device for anti-puncture tire production

InactiveCN114289264AAvoid manual loadingGuarantee job securityLiquid surface applicatorsCoatingsRubber materialSprayer

Owner:缙云县吉祥机械制造厂

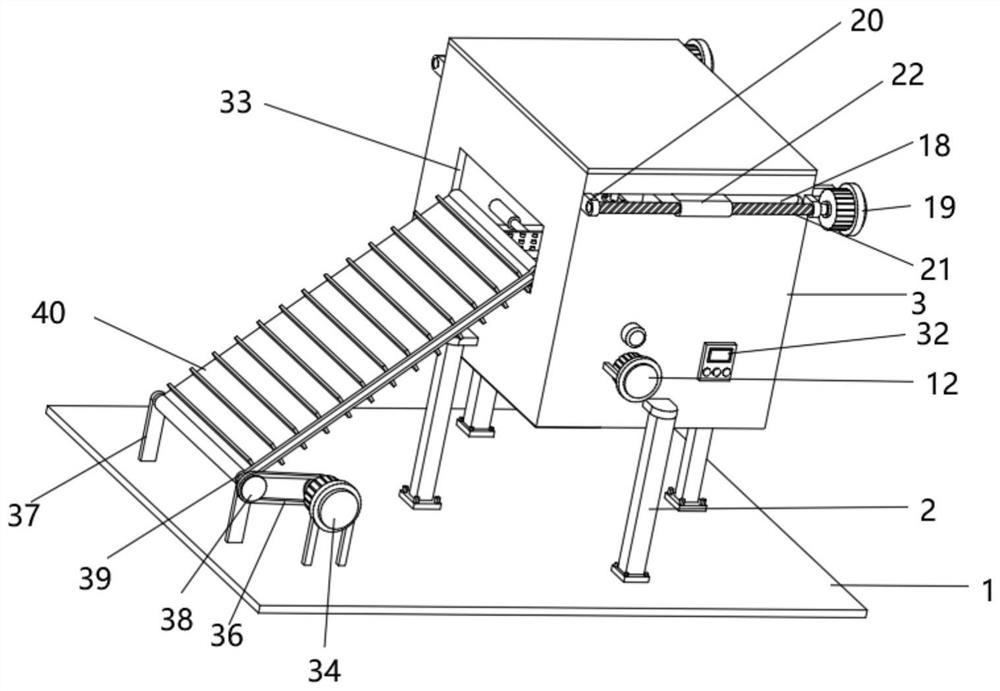

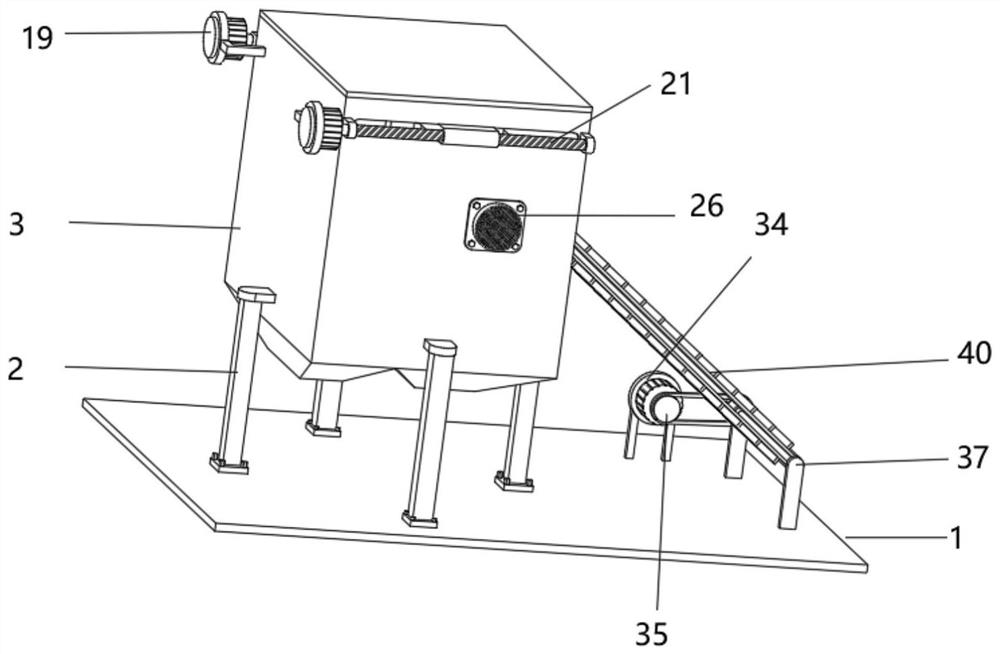

Profile cutting method of laser cutting automatic production line

ActiveCN112372156APlay a blocking roleAvoid Stuck SituationsLaser beam welding apparatusLaser cuttingManufacturing line

The invention discloses a profile cutting method of a laser cutting automatic production line. The profile cutting method comprises the following steps that S1, an operator adjusts the parameters of the laser cutting automatic production line according to the shape and the diameter of a profile needing to be cut, and after the parameters are adjusted, the profile needing to be cut is added into afeeding frame; and S2, a reciprocating type sorting and discharging mechanism is installed on the feeding frame, and the profile needing to be cut in the feeding frame is discharged in order through the reciprocating type sorting and discharging mechanism. According to the profile cutting method, the reciprocating type sorting and discharging mechanism and a clamping correction mechanism are additionally arranged on a feeding mechanism in the laser cutting automatic production line, so that the feeding efficiency of the feeding mechanism is remarkably improved, the feeding frequency of the operator is greatly reduced, the working efficiency of the laser cutting automatic production line is improved, the situation that manual feeding needs to be carried out by the operator in the productionprocess is avoided, and the potential safety hazards in the production process are greatly reduced.

Owner:王永凤

High-safety sheet metal part production equipment and production method thereof

PendingCN114472646AStamping is precise and stableAccurate and fast deliveryMetal-working feeding devicesPositioning devicesIndustrial engineeringMaterial storage

The high-safety sheet metal part production equipment comprises an equipment shell, a stamping structure, a transmission structure, an auxiliary conveying structure and a storage structure, the equipment shell is of a cavity structure with an opening in the front side face, and a feeding port and a discharging port are formed in the two opposite side walls of the equipment shell; a stamping supporting plate is arranged in the equipment shell, the stamping structure is arranged on the inner top wall of the equipment shell, the transmission structure is arranged above the stamping supporting plate, the auxiliary conveying structures are arranged on the side wall of the equipment shell and located below the transmission structure, and the number of the auxiliary conveying structures is two. The material storage structure comprises a first material storage structure and a second material storage structure, and the first material storage structure is arranged on the side wall of the equipment shell and located below the feeding port. The invention relates to the technical field of sheet metal part machining, and particularly provides high-safety sheet metal part production equipment capable of achieving automatic feeding and discharging functions and effectively preventing metal splashing and a production method of the high-safety sheet metal part production equipment.

Owner:昆山市固展金属有限公司

Feeding device for processing bamboo and wood products

ActiveCN108058245AAvoid manual loadingRealize automatic feedingMulti-purpose machinesCane mechanical workingEngineeringWood product

The invention discloses a feeding device for processing bamboo and wood products. The feeding device comprises supporting blocks, sliding grooves are formed in the upper surfaces of the two supportingblocks, and a first electric pushing rod and a second electric pushing rod are fixedly connected to the two opposite side walls of each sliding groove correspondingly; the two sliding grooves are slidably connected with first feeding frames and second feeding frames through sliding blocks correspondingly, and the first feeding frames and the second feeding frames are fixedly connected with the first electric pushing rods and the second electric pushing rods correspondingly; the first feeding frames comprise top plates, the lower surfaces of the top plates are perpendicularly and fixedly connected with two supporting legs and two rotating shafts in sequence in the horizontal direction, and the two rotating shafts are located between the two supporting legs; L-shaped supporting blocks are fixedly connected to the two opposite side walls of the two supporting legs, rotating rotors are fixedly connected to the upper surfaces of the horizontal ends of the L-shaped supporting blocks, and the output ends of the rotating motors are fixedly connected with wire reels. According to the feeding device for processing the bamboo and wood products, the structure is simple, manual feeding of workers cannot be required, more stability and firmness are achieved in the feeding process, and demands of people are met.

Owner:浙江亿奇木业有限公司

Glue material supply component for puncture-proof tire production and gluing device for puncture-proof tire production

InactiveCN112387538AAvoid manual loadingGuarantee job securityLiquid surface applicatorsCoatingsSprayerIndustrial engineering

The invention belongs to the technical field of tire manufacturing, and particularly relates to a glue material supply component for puncture-proof tire production and a gluing device for puncture-proof tire production. The glue material supply component for puncture-proof tire production comprises a second base, a feeding component, a glue melting component, a fourth base and a rotary clamping component. The feeding component comprises a first motor, a rotary disc and a plurality of groups of glue filling boxes. The glue melting component comprises a glue sprayer, a box body and a glue filling component. The glue filling component comprises an upper glue filling plate and a lower glue filling plate. The upper glue filling plate and the lower glue filling plate are movably mounted in the box body. The fourth base comprises a second bottom plate and a second side plate; and the rotary clamping component comprises a third motor, a third connecting plate and a fourth connecting plate. According to the glue material supply component for puncture-proof tire production and the gluing device for puncture-proof tire production, manual feeding is avoided through the feeding component, the safety of feeding work is guaranteed, glue melting is faster through the glue melting component, and finally, the inner surface of a tire is glued more evenly during gluing through the rotary clampingcomponent, and the gluing quality is high.

Owner:缙云县吉祥机械制造厂

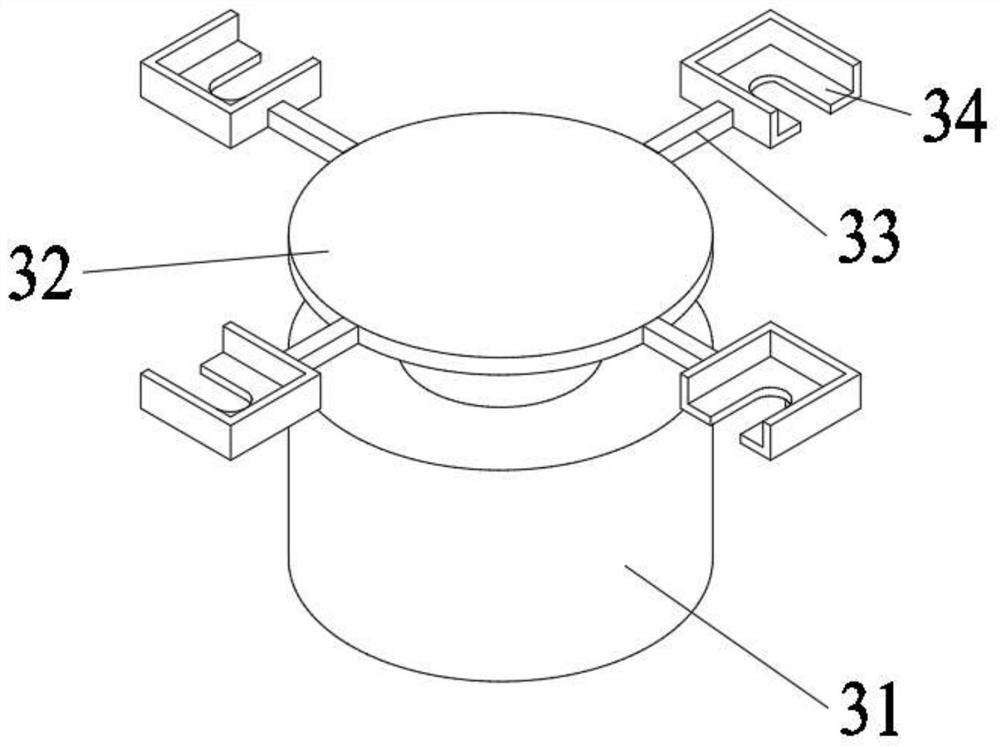

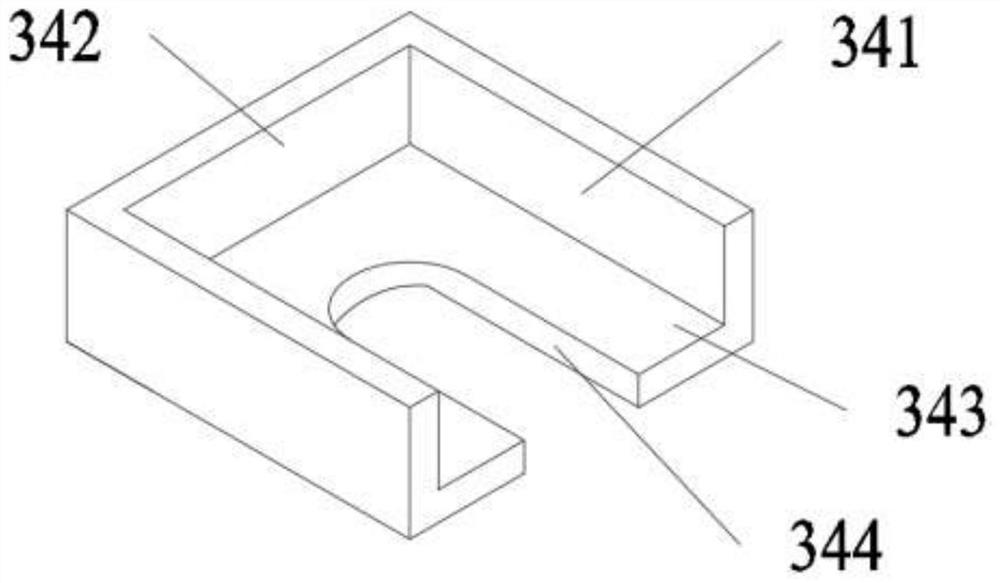

Building waste recycling device for building engineering

InactiveCN113145204AReduce wasteIncrease profitDirt cleaningMagnetic separationDrive wheelTransmission belt

The invention belongs to the technical field of building waste recycling, and discloses a building waste recycling device for building engineering. The building waste recycling device comprises a bottom plate, a shell and a belt, wherein a partition plate is arranged in the shell, a supporting plate is arranged in the shell, and the supporting plate is located on one side of the partition plate. Four vibration mechanisms are arranged on the supporting plate, each vibration mechanism comprises a bottom block, a spring and a fixing block, the bottom blocks are arranged on the supporting plate, the springs are fixedly connected to the bottom blocks, the fixing blocks are fixedly connected to the springs, a fourth driving motor is arranged on the bottom plate, a driving wheel is arranged at the output end of the fourth driving motor, a pair of second supporting blocks is arranged on the bottom plate, a second rotating column is rotationally connected between the two second supporting blocks, a driven wheel is arranged on the second rotating column, the driving wheel and the driven wheel are in transmission connection through the belt, another second rotating column is rotationally connected to the interior of a feeding port, and a conveying belt is in transmission connection between the two second rotating columns. According to the building waste recycling device, concrete and iron products can be conveniently separated, and the concrete and the iron products can be conveniently collected and utilized again.

Owner:崔金科

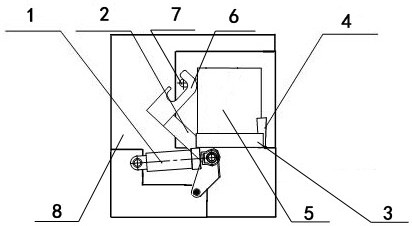

Circuit board processing mold

InactiveCN113263545AImprove securityAvoid manual loadingMetal working apparatusTool bitElectric machinery

The invention discloses a circuit board processing mold, and relates to the technical field of circuit boards. The circuit board processing mold comprises a first cylinder, a support plate, an upper mold, a lower mold and guide pillars, wherein the lower mold is located below the upper mold; the guide pillars penetrate through the upper mold; the support plate is fixed to the tops of the guide pillars; the first cylinder is installed at the top of the support plate; a piston rod of the first cylinder is connected with upper mold; the bottoms of the guide pillars are fixed to the lower mold; stamping tool bits are installed at the bottom of upper mold; and a controller is arranged on one side of top of lower mold. In the circuit board processing mold, vertical plates can move back and forth by controlling the rotation direction of forward and reverse motors in cooperation with the action of bottom plates; and meanwhile, under the action of second cylinders, two top plates move towards or away from each other, so that a circuit board can be clamped and conveyed, the feeding and discharging processes in the circuit board machining process are completed, manual feeding is avoided, and then the safety during feeding and discharging in the circuit board machining process is improved.

Owner:深圳市豪博讯电子科技有限公司

A chip semiconductor packaging device

ActiveCN108538759BAvoid cloggingReduce workloadSemiconductor/solid-state device manufacturingSemiconductor packageAssembly line

The invention discloses a novel slice type semiconductor ultra-thin packaging device comprising a fixed base. A conveying assembly line extending left and right is arranged in the middle of the upperend surface of the fixed base. Sealing space is formed in the left side inside a fixed case; a hydraulic rod is fixedly connected to the central position of the lower end surface of a sealing plate; the lower end of the hydraulic rod passes through the lower end wall of the sealing space and is fixedly connected with a press-fit plate; a resin conveying device is arranged right below the press-fitplate and includes a winding mechanism and a pulling mechanism. When the packaging device is working, an extruding plate moves up and down along a guiding rod without falling based on cooperation ofan annular clamp plate and an annular clamp slot; the extruding plate can fall to be in contact with the lower end wall of glue storage space to prevent plugging of a glue coating needle due to solidification of lower-end glue liquid not in use for long time; and the resin sheet that is not used can be switched automatically, so that precision is improved and the work efficiency is enhanced.

Owner:广东协铖微电子科技有限公司

A vehicle with automatic battery replacement

InactiveCN109693527BAvoid manual loadingReduce workloadCharging stationsElectric propulsion mountingVehicle frameBattery cell

The invention relates to a vehicle for automatically replacing a battery box. The vehicle for automatically changing a battery box includes a vehicle frame. The vehicle frame is provided with a bracket for placing the battery box. The bracket and the push-pull mechanism for pulling the charged battery box back to the bracket, the push-pull mechanism has a connection structure for pushing and pulling the battery box to perform corresponding actions. Compared with the prior art, the vehicle provided by the present invention integrates a push-pull mechanism. When the battery box needs to be replaced manually, the vehicle for automatically replacing the battery box provided by the present invention can automatically push or pull the battery box back to the bracket, avoiding manual replacement. Loading the battery box reduces the workload of the operator, and at the same time avoids the hidden danger that the battery box may fall when removing or installing the battery box, which may endanger the safety of the operator.

Owner:HENAN BENMA

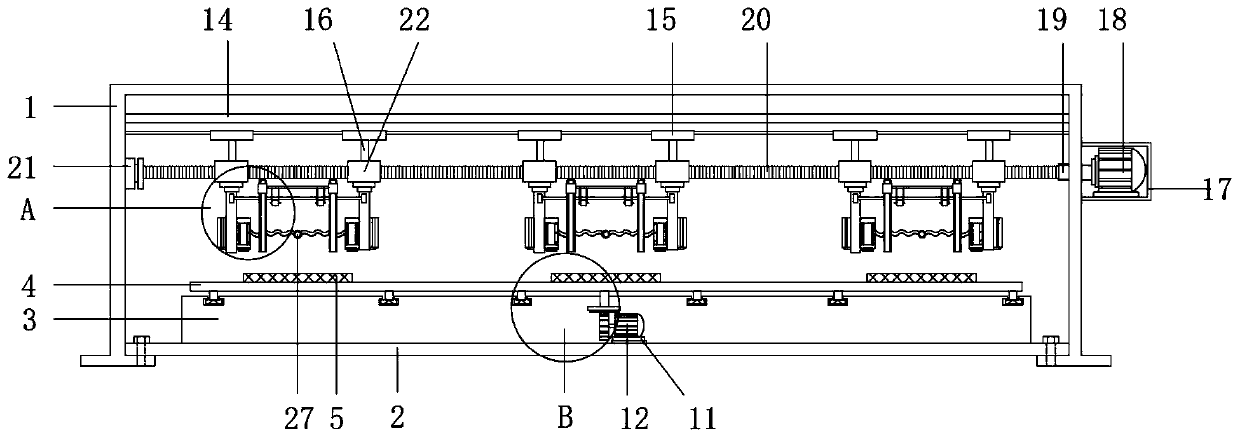

Multi-station reinforcing sheet laminating device for flexible circuit board production

ActiveCN110662362AImprove fitReduce manufacturing costCircuit bendability/stretchabilityPrinted circuit secondary treatmentFlexible circuitsStructural engineering

The invention discloses a multi-station reinforcing sheet laminating device for flexible circuit board production, which comprises a fixing support, and is characterized in that a welding bottom plateis fixedly connected between two side walls of the bottom end of the fixing support, a workbench is arranged at the upper end of the welding bottom plate, a plurality of sliding grooves are evenly formed in the surface, which is away from the welding bottom plate, of the workbench, a first sliding block is slidably connected in each sliding groove, the upper end of the first sliding block is fixedly connected with a first connecting rod, and a movable carrier plate is arranged above the workbench. According to the invention, the movable carrier plate is arranged and is matched with an electric sucker, so that the reinforcing sheet can be fed, the manual feeding is avoided, the manual labor time is saved, and the production cost of the factory is reduced. Meanwhile, compaction rollers aredriven down by a single-track servo electric cylinder, and the laminating effect of the reinforcing sheet can be increased under the movement of the movable carrier plate. The mechanism adopted in thedesign is simple, high in efficiency and easy to repair and maintain, the workload of workers can be reduced, and the laminating operation efficiency is greatly improved.

Owner:WENZHOU UNIVERSITY

A multi-station reinforcing sheet bonding device for flexible circuit board production

ActiveCN110662362BImprove fitReduce manufacturing costCircuit bendability/stretchabilityPrinted circuit secondary treatmentFlexible circuitsStructural engineering

Owner:WENZHOU UNIVERSITY

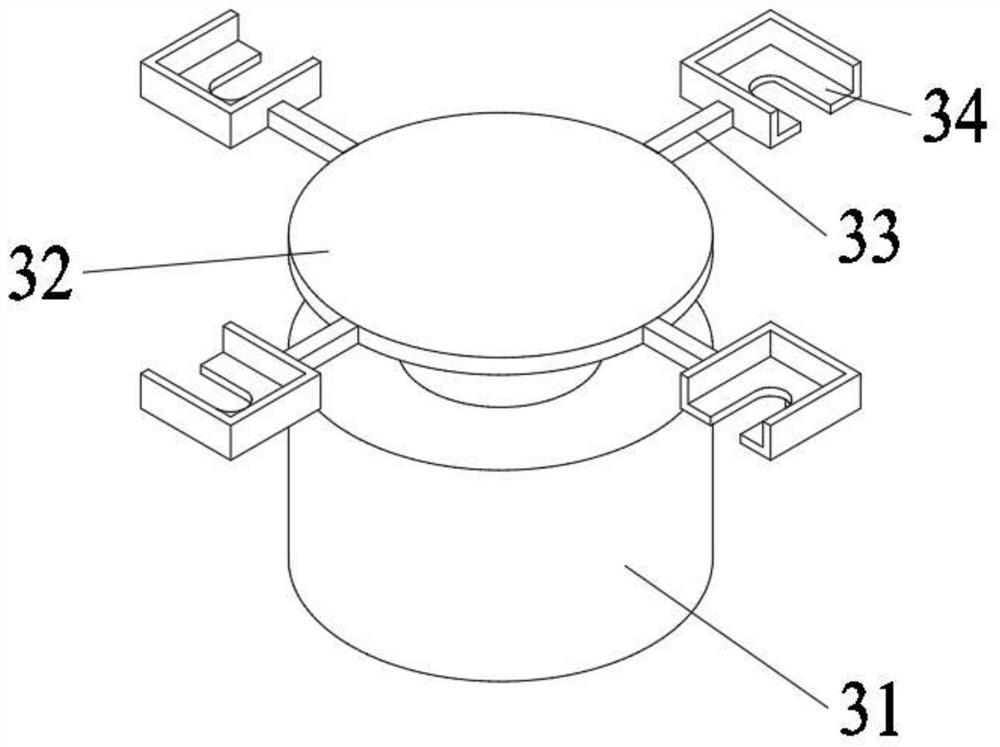

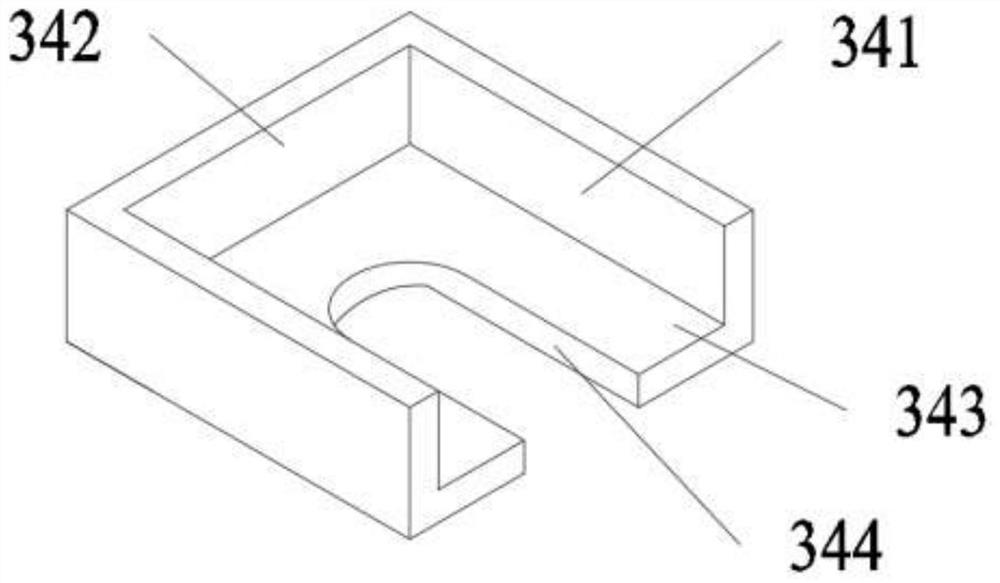

Automobile gear lever producing and machining equipment with positioning function and multi-angle welding function

InactiveCN112338382AEasy to weldAvoid manual loadingWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMachine

The invention discloses automobile gear lever producing and machining equipment with the positioning function and the multi-angle welding function. The equipment comprises a bottom rack, a protectivecover is arranged on the right side surface of the bottom rack, and a gear lever feeding box is fixedly welded to the position, located at the left side of the protective cover, of the right side of the center line of the upper surface of the bottom rack; and a clamping ring feeding box is arranged above the left side of the surface of the bottom rack, and a second pushing assembly is arranged atthe bottom of an inner cavity of the bottom rack. According to the equipment, the gear lever feeding box and the clamping ring feeding box are oppositely arranged at the two sides of the surface of the bottom rack, through arrangement of the gear lever feeding box and the clamping ring feeding box, an automatic feeding structure is conveniently formed for a gear lever and a clamping ring, positioning and calibration after manual feeding by personnel are avoided, and meanwhile, a welding machine box and a welding head are arranged in the space between the gear lever feeding box and the clampingring feeding box, so that the gear lever and the clamping ring can be conveniently matched for welding, the working efficiency is favorably improved, and an automatic structure is formed.

Owner:东莞市夯实科技有限公司

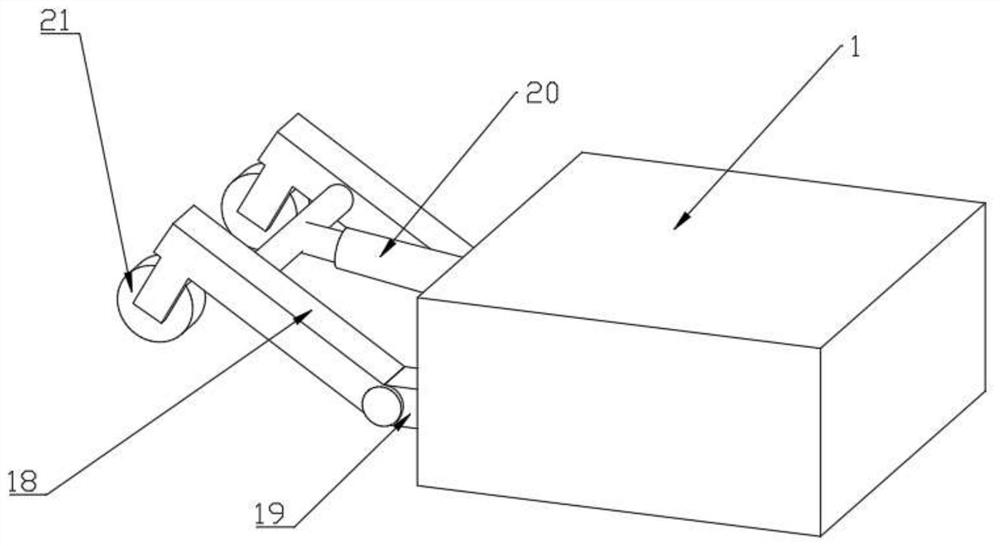

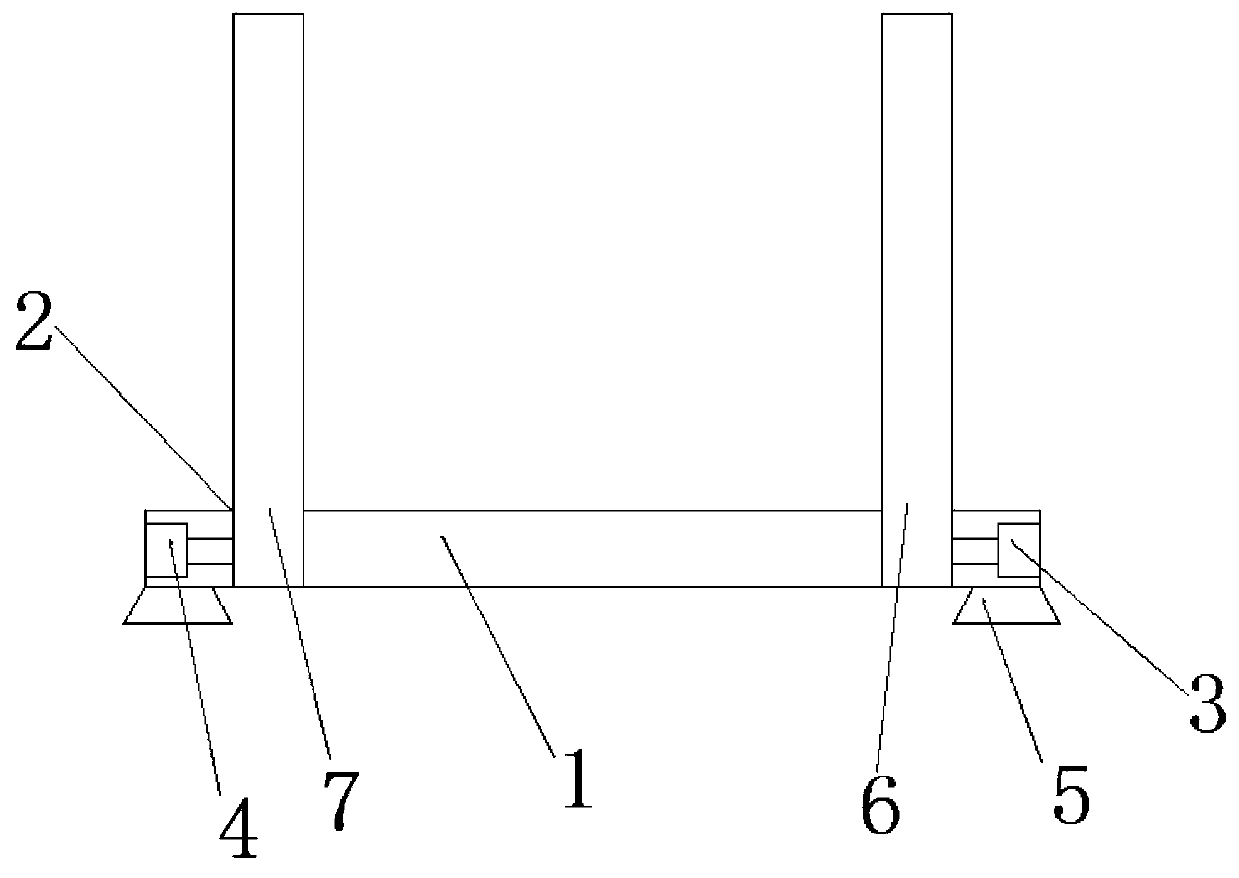

Withdrawal and straightening machine feeding trolley

The invention relates to the field of thin plate machining, in particular to a withdrawal and straightening machine feeding trolley which comprises a trolley body, a moving structure, a rotating structure, a placing structure, a guiding structure and a driving structure. Through the arrangement of the rotating structure, a coiled thin steel plate can be conveniently placed in a trolley body, so that follow-up feeding work is facilitated, and through the arrangement of the placing structure, the thin steel plate can be placed in the trolley body, the thin steel plate can rotate during withdrawal and straightening, for cooperating the continuous movement of the thin steel plate, the thin steel plate is convenient to feed, manual feeding is avoided, through the arrangement of the moving structure, the trolley body is convenient to move, so that when withdrawal and straightening operations are not performed, the trolley body is moved away from a withdrawal and straightening machine, so that a steel plate roll can be conveniently put into the trolley body, and the thin steel plate pulled down from the steel plate roll can be clamped in the withdrawal and straightening process through the arrangement of the guide structure, so that the thin steel plate can be neatly moved from the trolley body.

Owner:冠县仁泽复合材料有限公司

A feeding device for bamboo and wood product processing

ActiveCN108058245BAvoid manual loadingRealize automatic feedingMulti-purpose machinesCane mechanical workingAgricultural engineeringElectric machinery

The invention discloses a feeding device for processing bamboo and wood products. The feeding device comprises supporting blocks, sliding grooves are formed in the upper surfaces of the two supportingblocks, and a first electric pushing rod and a second electric pushing rod are fixedly connected to the two opposite side walls of each sliding groove correspondingly; the two sliding grooves are slidably connected with first feeding frames and second feeding frames through sliding blocks correspondingly, and the first feeding frames and the second feeding frames are fixedly connected with the first electric pushing rods and the second electric pushing rods correspondingly; the first feeding frames comprise top plates, the lower surfaces of the top plates are perpendicularly and fixedly connected with two supporting legs and two rotating shafts in sequence in the horizontal direction, and the two rotating shafts are located between the two supporting legs; L-shaped supporting blocks are fixedly connected to the two opposite side walls of the two supporting legs, rotating rotors are fixedly connected to the upper surfaces of the horizontal ends of the L-shaped supporting blocks, and the output ends of the rotating motors are fixedly connected with wire reels. According to the feeding device for processing the bamboo and wood products, the structure is simple, manual feeding of workers cannot be required, more stability and firmness are achieved in the feeding process, and demands of people are met.

Owner:浙江亿奇木业有限公司

Convenient-to-use feeding device for synthesis workshop

InactiveCN110884860AAvoid cloggingAvoid pollutionBags openingConveyor partsScrew conveyorIndustrial engineering

The invention discloses a convenient-to-use feeding device for a synthesis workshop. The convenient-to-use feeding device for the synthesis workshop comprises a base plate, wherein a support frame isvertically and fixedly arranged at the upper end of the base plate, a cutting box is fixedly arranged at the upper end of the support frame, a conveying device is fixedly arranged at the center position of the left side of the cutting box, blocking cloth is arranged on the left side of the cutting box, thin rods are vertically, upwardly and fixedly arranged at two sides in the cutting box, thick rods are sleeved at the upper ends of the thin rods, springs are connected between the upper surfaces in the thick rods and the upper ends of the thin rods, movable plates are fixedly arranged at the upper ends of the thick rods, the right sides of the movable plates slope down for 30 degrees, and the interval among the movable plates is 5-10 centimeters. According to the invention, raw materials are discharged into a screw conveyor through a discharge port after being guided by a guide plate and then transported into processing equipment through the screw conveyor, so that manual loading is avoided, and meanwhile, the problem of material leakage pollution is avoided during the feeding process; the feeding device has the advantages of simple structure, convenient use and good using effect.

Owner:钱文龙

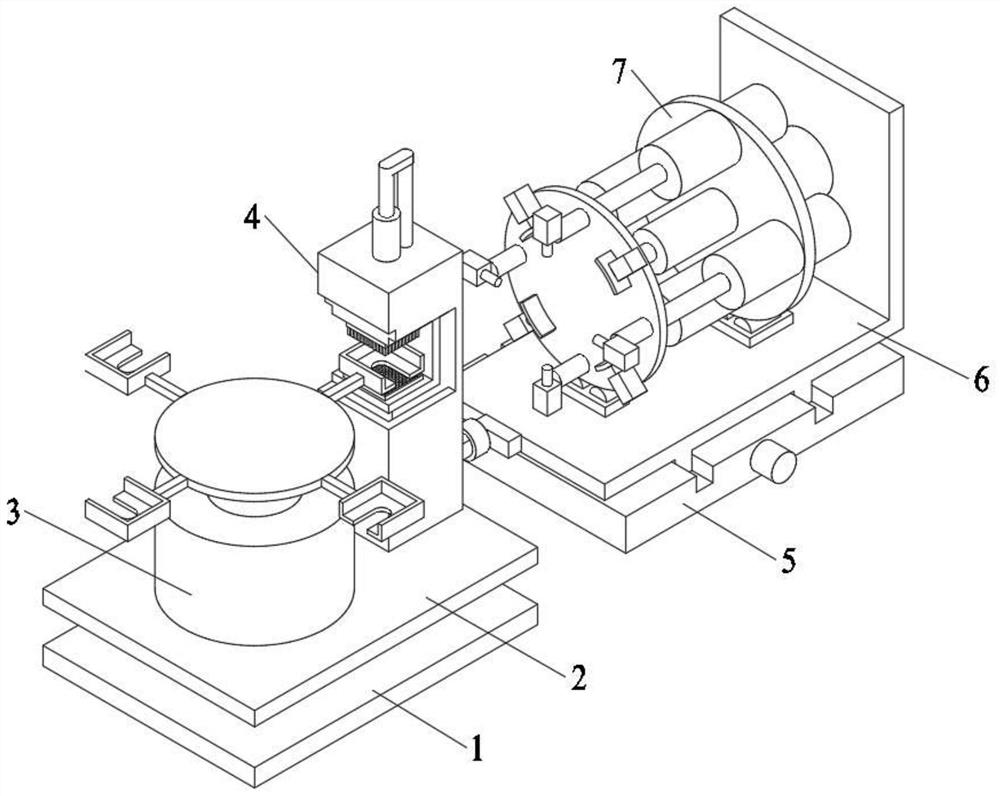

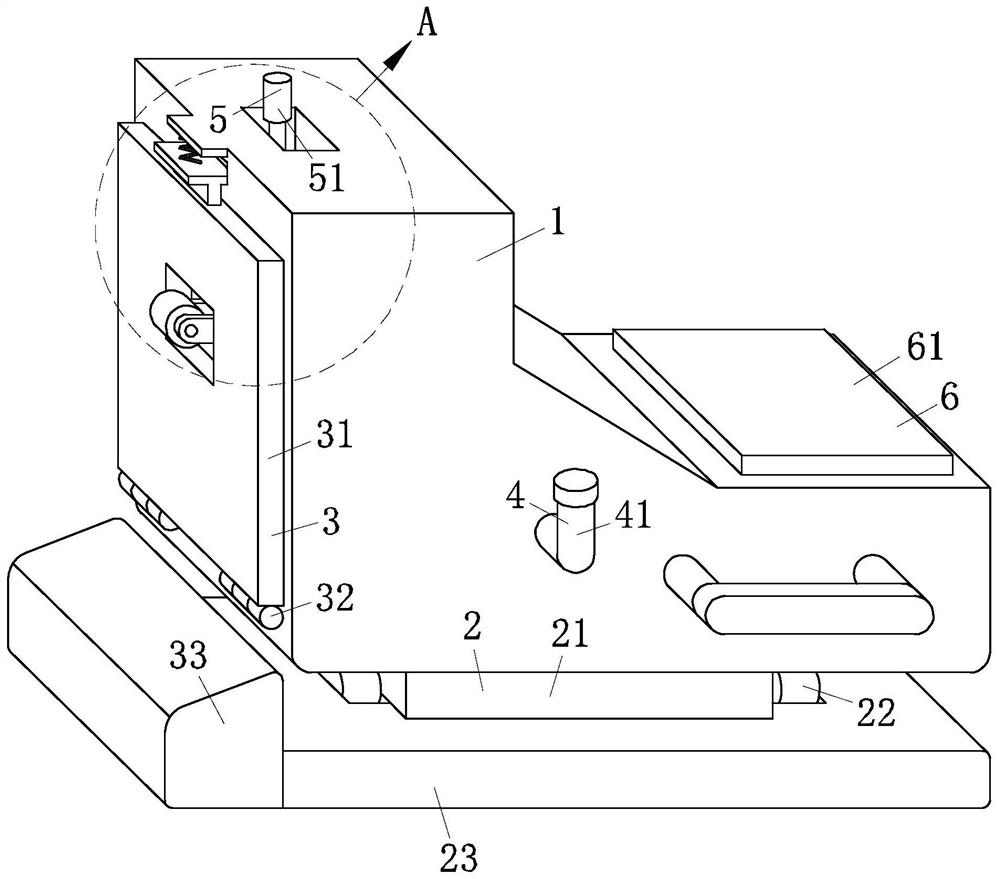

An automatic prestressing fixture

ActiveCN103753408BAvoid manual loadingAvoid disassemblyWork holdersAbrasive machine appurtenancesEngineeringLimit switch

The invention discloses an automatic prestress clamp which comprises a force bearing upright, a force applying mechanism and a force bearing mechanism, wherein the force applying mechanism and the force bearing mechanism are fixed on the force bearing upright, and are combined to apply prestress to a workpiece; the force bearing mechanism is composed of a group of symmetric mechanical force arms; the two mechanical force arms are fixed at the proper positions of the side surface of the force bearing upright respectively; the front ends of the two mechanical force arms are bent respectively to form force bearing points; the other end of each mechanical force arm extends out to form two fixed points; the main body of the force applying mechanism is a worm gear jack; the body of the work gear jack is fixed on the force bearing upright and positioned in the center of the connection line of the two mechanical force arms; the front end of an ejector rod of the work gear jack serves as a force applying point, and the other end of the ejector rod extends into a cavity of the force bearing upright; a limiting switch of the ejector rod is fixed in the cavity of the force bearing upright.

Owner:XI'AN AIRCRAFT INTERNATIONAL

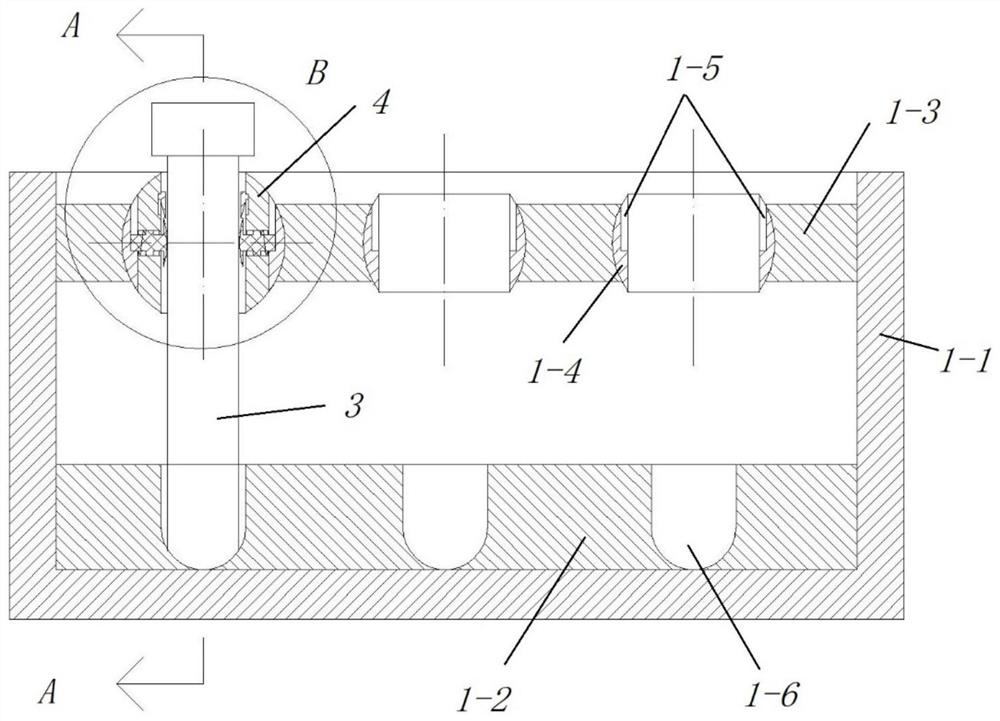

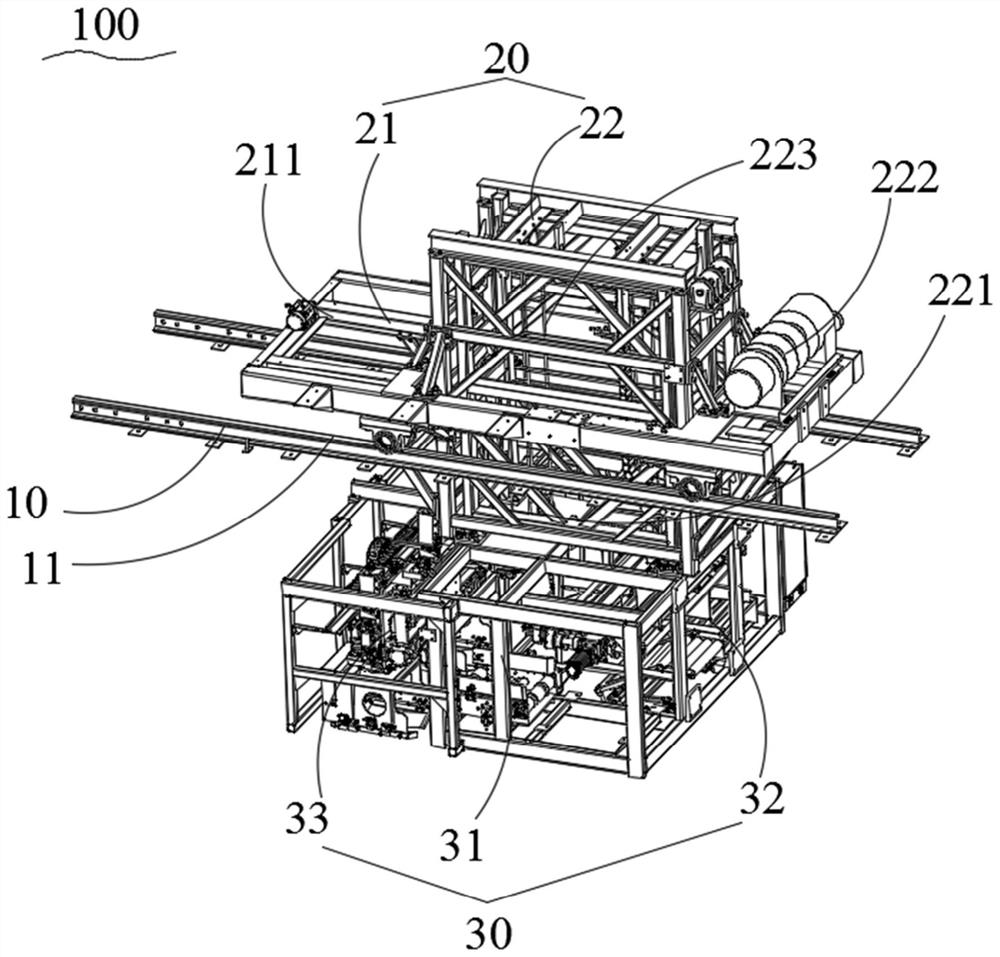

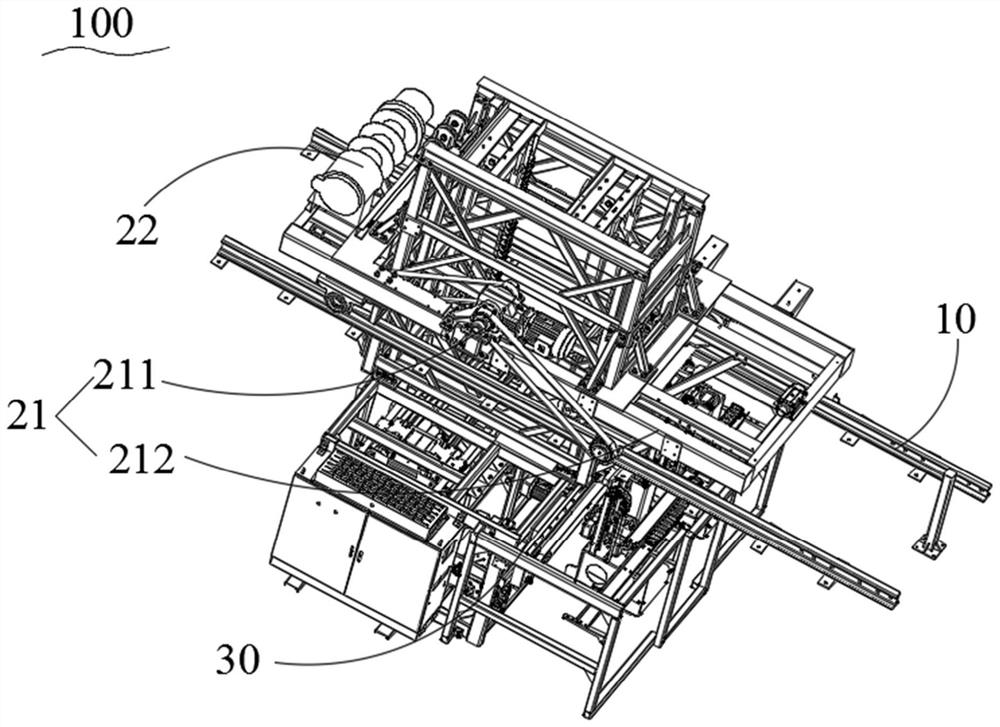

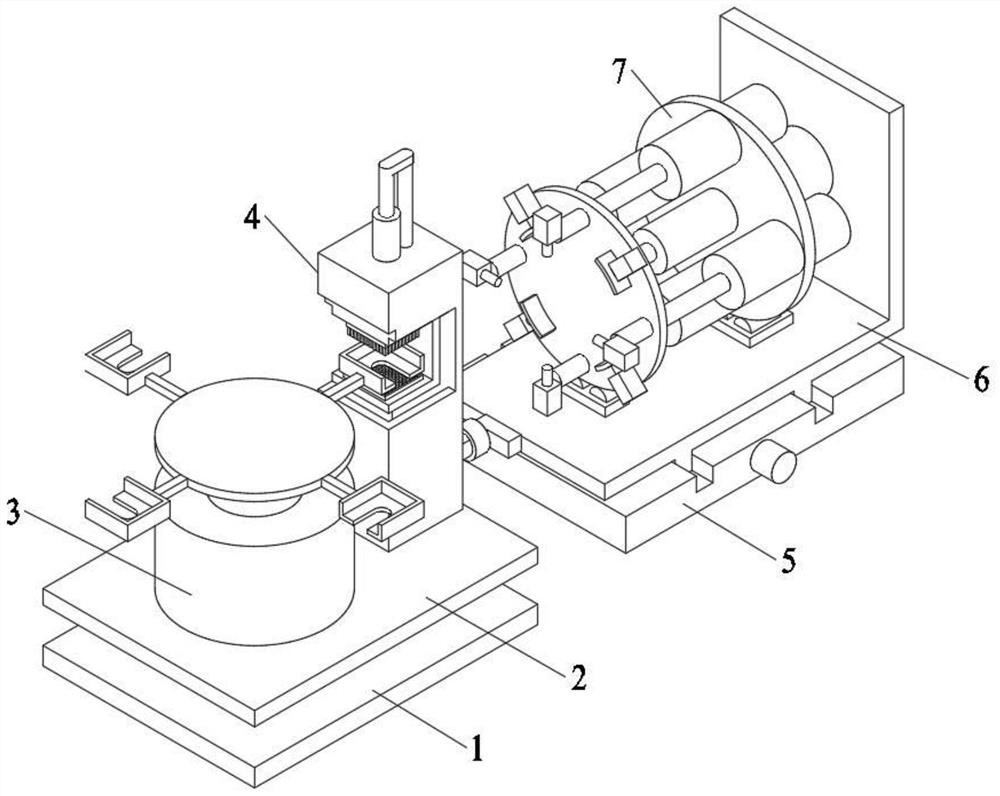

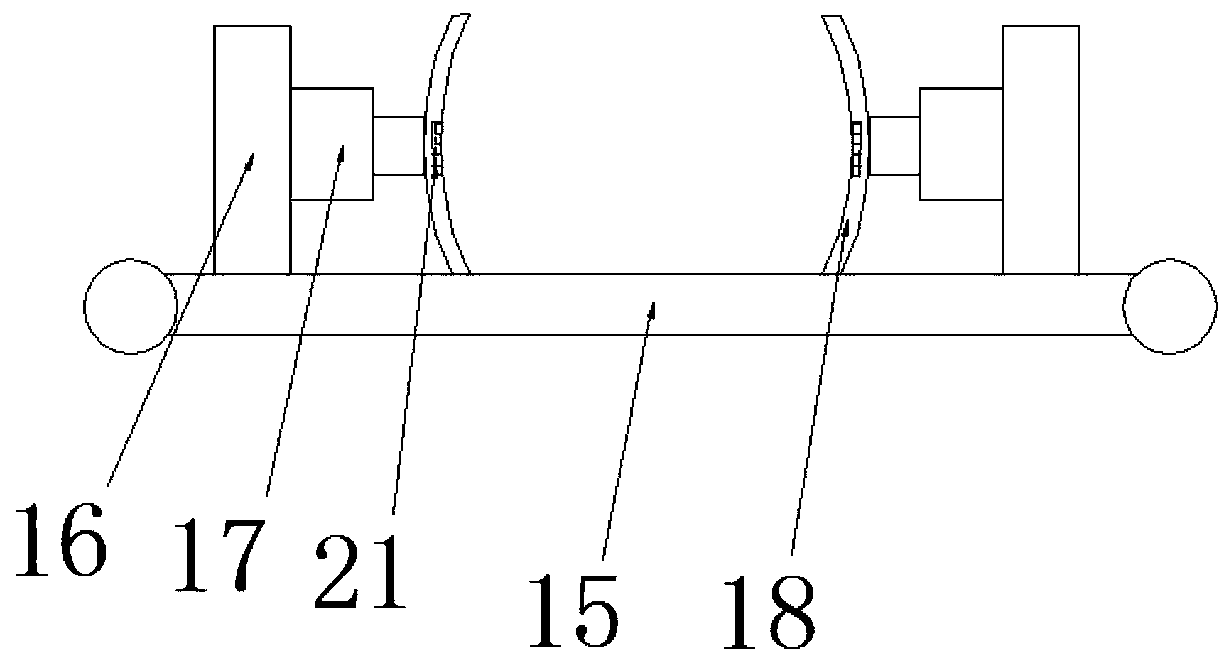

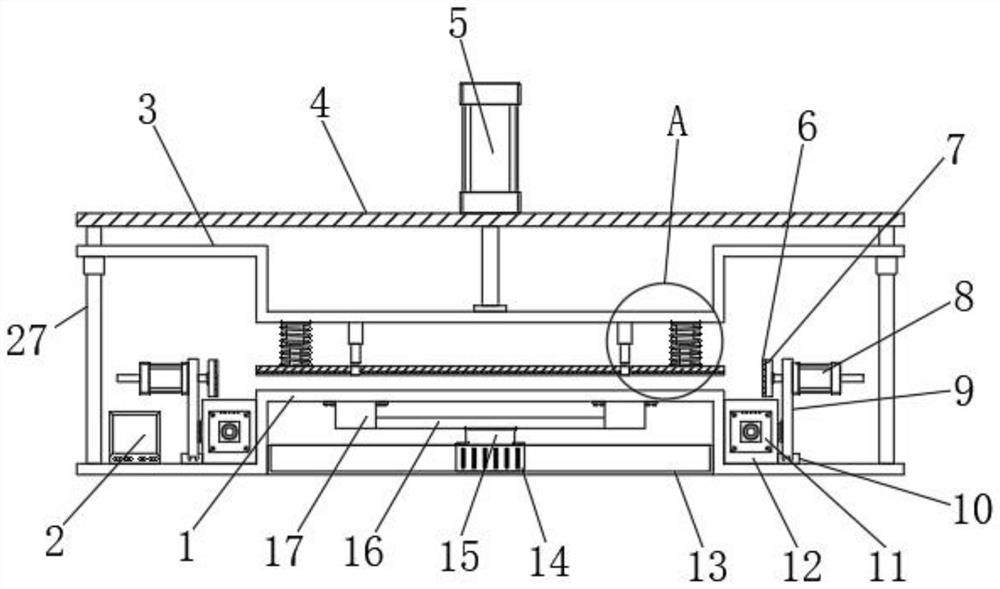

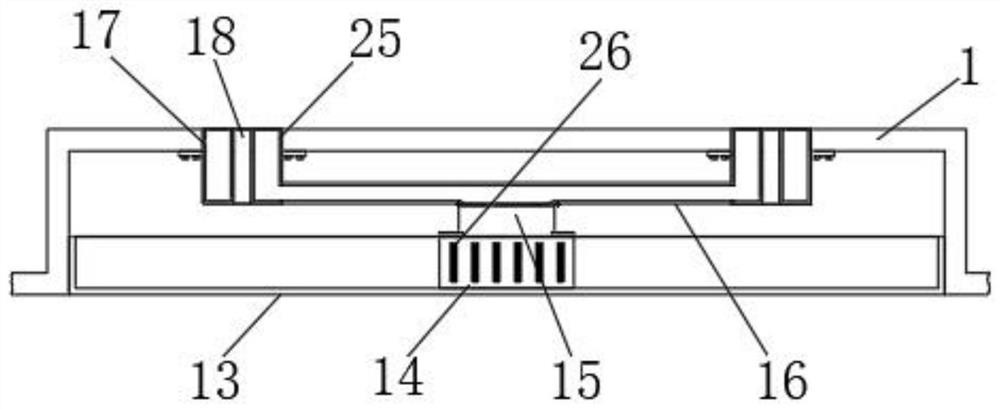

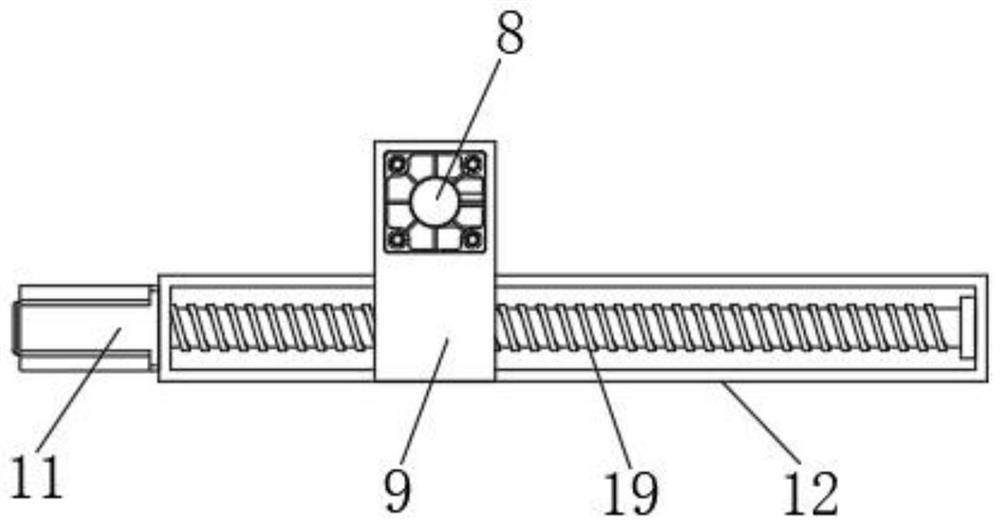

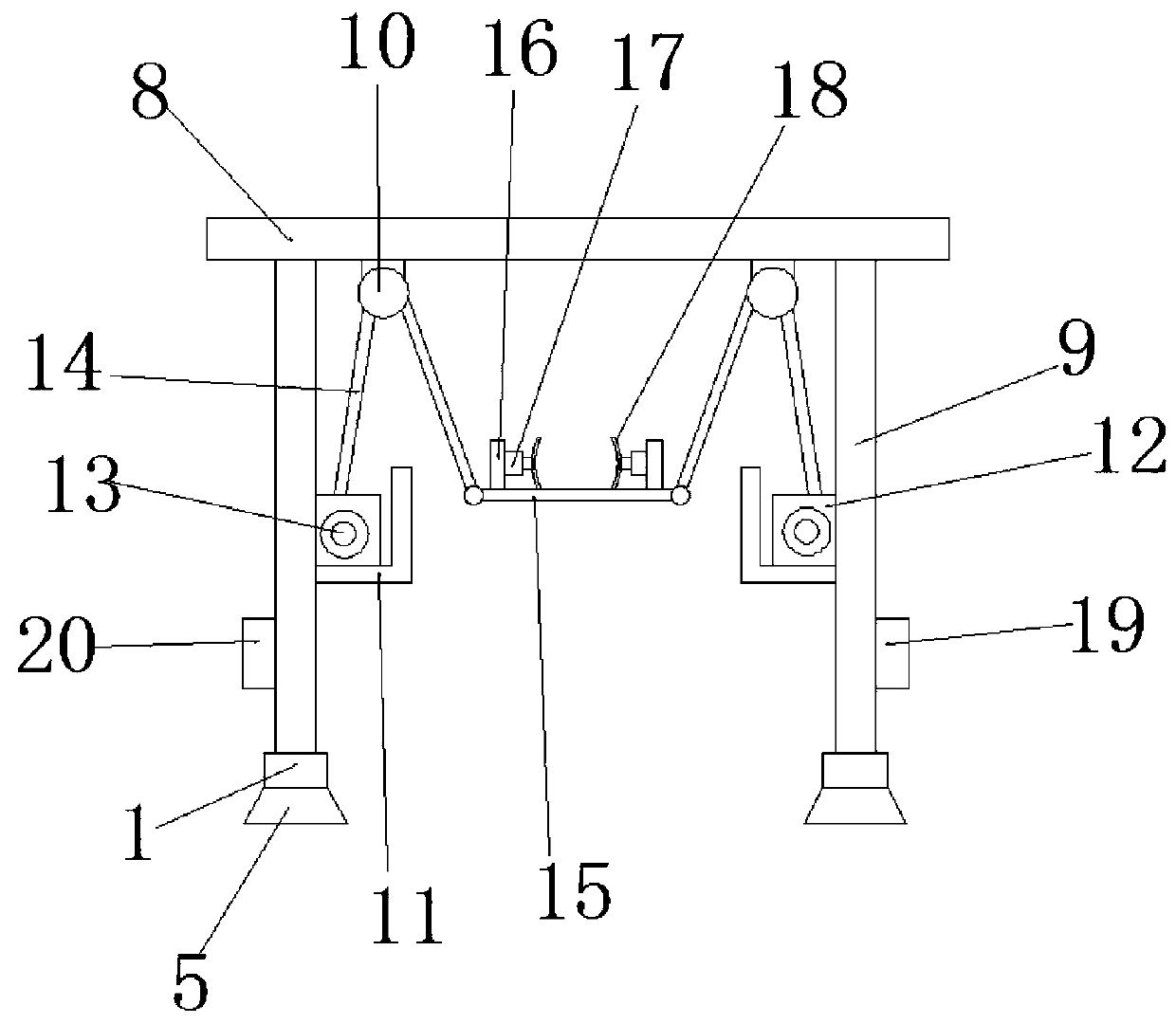

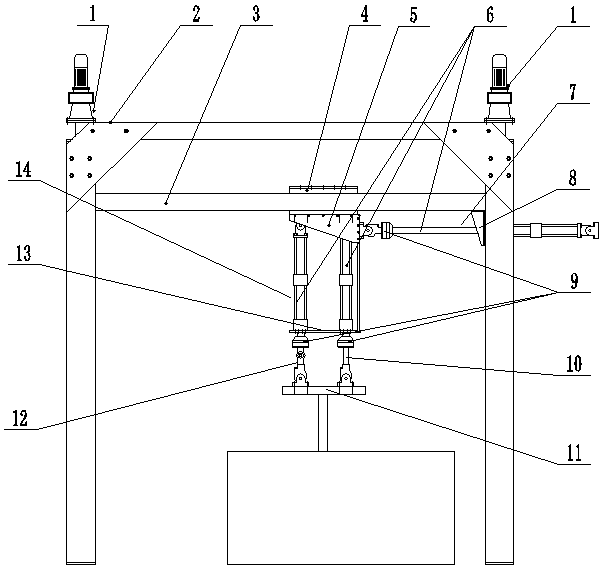

Composite loading test system for power transmission foundation

ActiveCN105510019BDisplacement real-time controlImprove test accuracyMachine part testingComponent LoadHorizontal force

Owner:NORTHEAST DIANLI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com