Patents

Literature

99results about How to "Realize automatic printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent fueling management system and method based on cloud platform

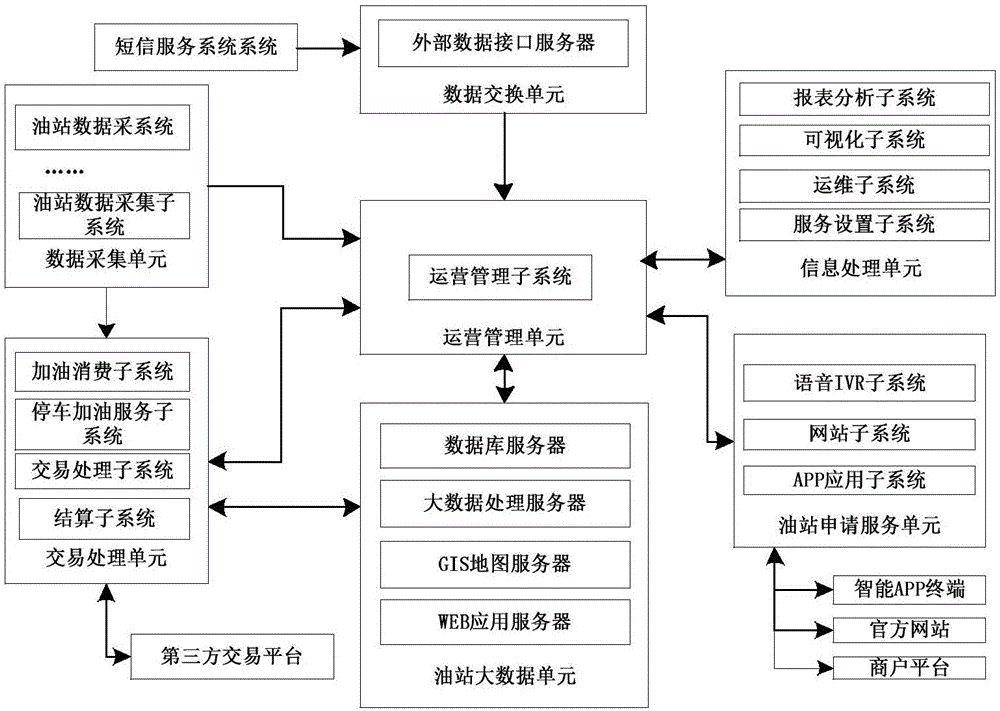

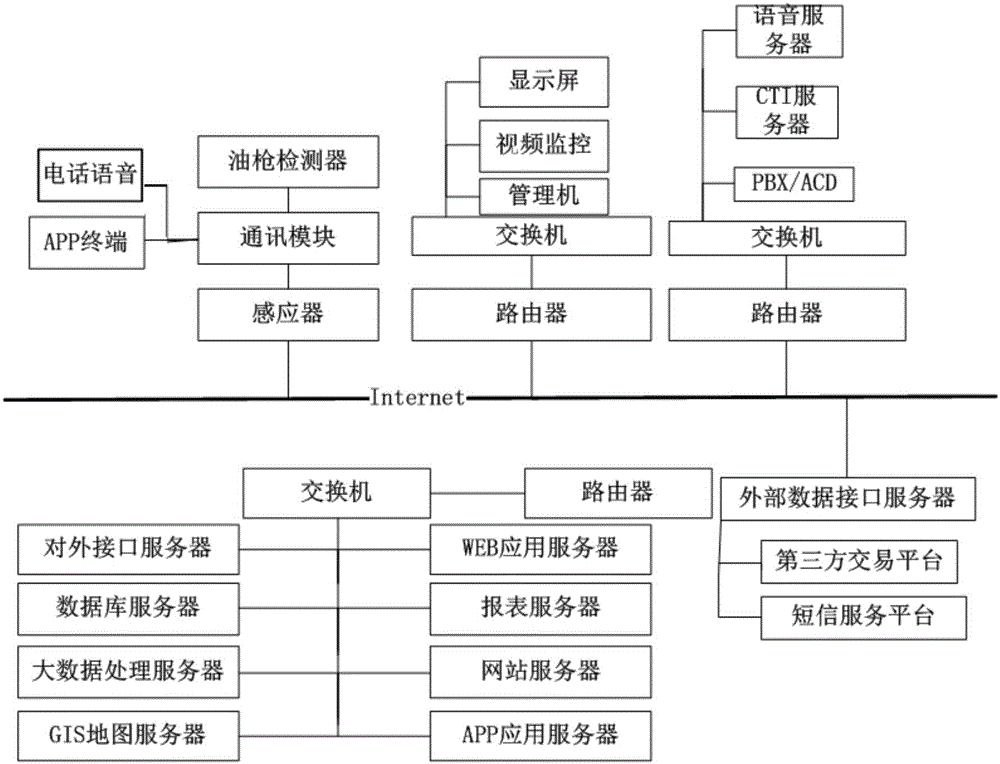

InactiveCN106529690ASimple structurePowerfulReservationsPayment architectureReal time acquisitionManagement system

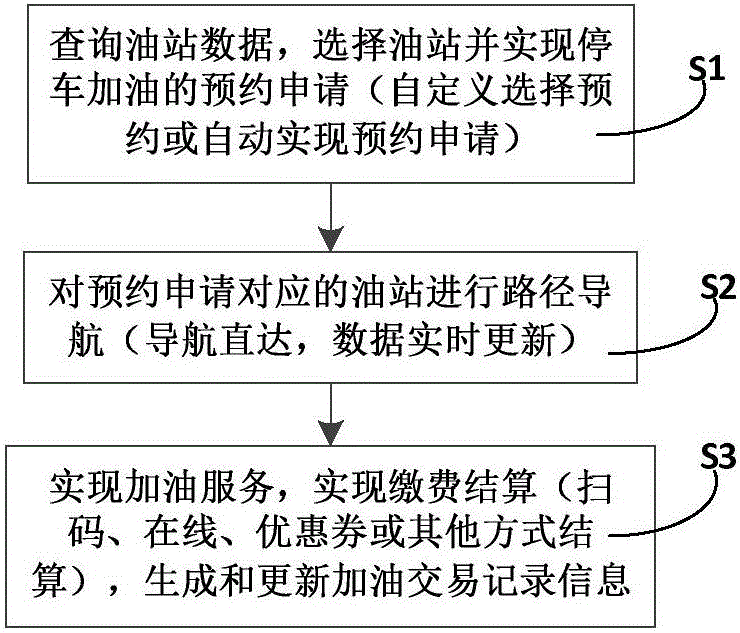

The invention provides an intelligent fueling management system and method based on cloud platform. The intelligent fueling management system comprises: an operation management unit for monitoring and managing the gas station data and gas station equipment of each gas station in real time; a gas station big data unit using a cloud platform server to save and process gas station data; a data acquiring unit for acquiring the gas gun state data of the gas station in real time through the various gas guns arranged in the gas station and accomplishing the data uploading of the gas gun state data; a gas station service application unit for checking gas station data and accomplishing booked applications and transaction checks; and a transaction processing unit for matching the booked application of parked cars for fueling and the gas gun state data, generating fees and accomplishing fee settlement. The structure of the system is simple; the operation is fast, convenient, safe and reliable. So, the system and the method can effectively increase the automation of fueling, can effectively reduce pressure on gas stations and can enhance the reception ability of gas stations in rush hours.

Owner:KAIDAER SCI & TECH DEV SHENZHEN

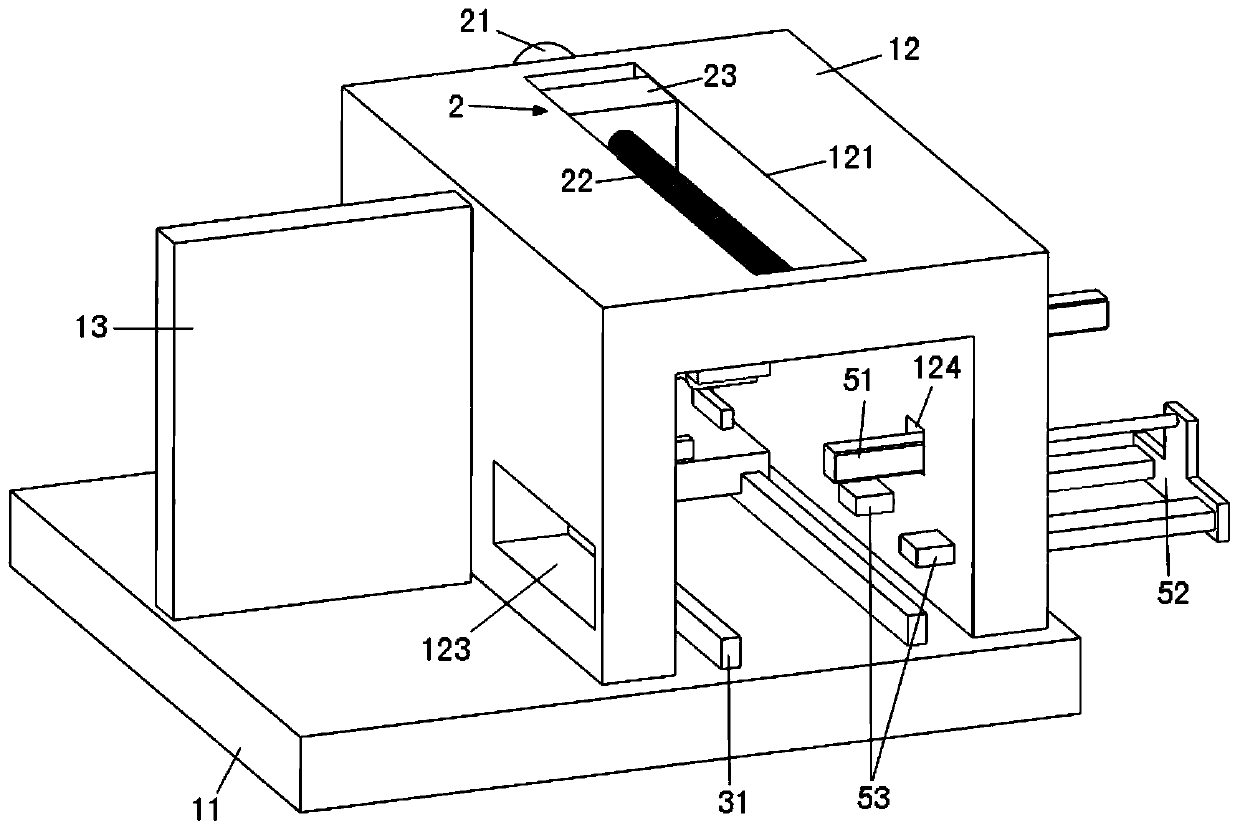

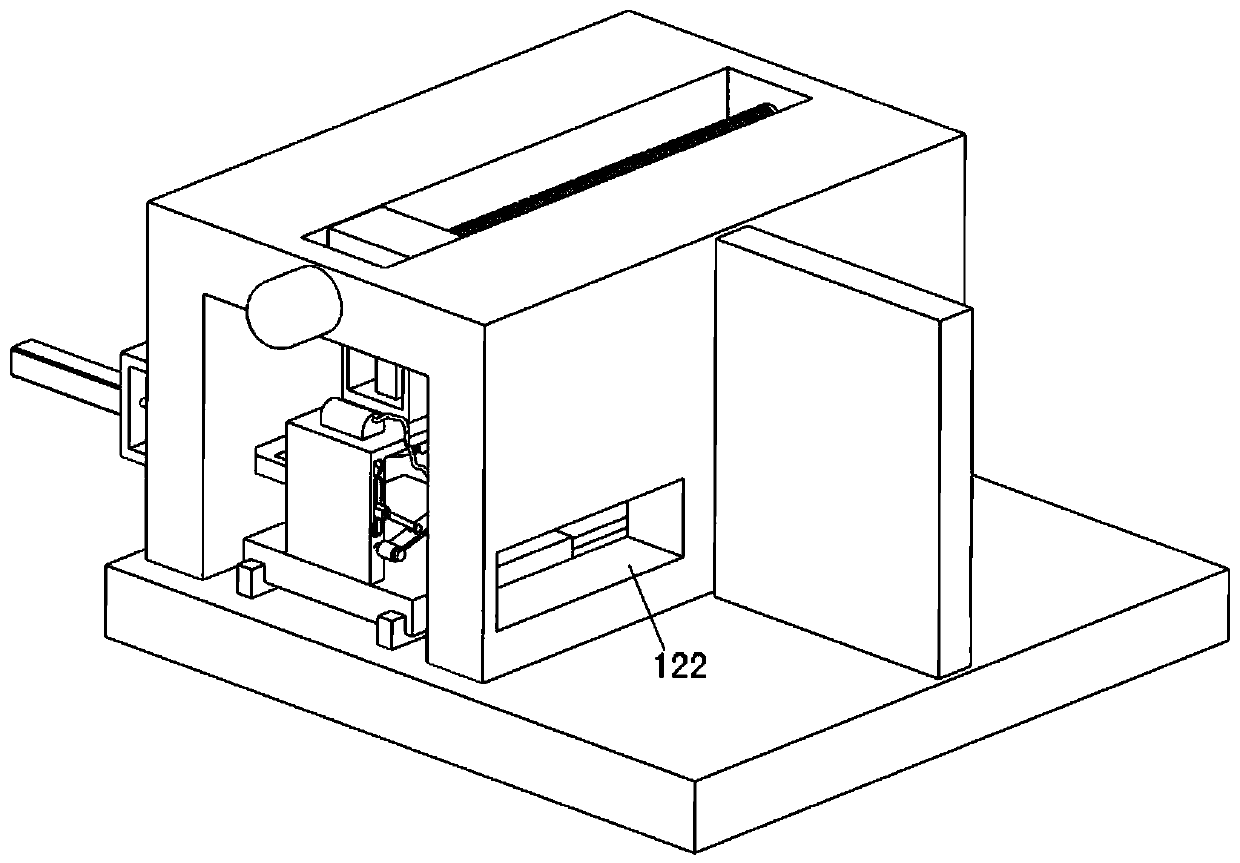

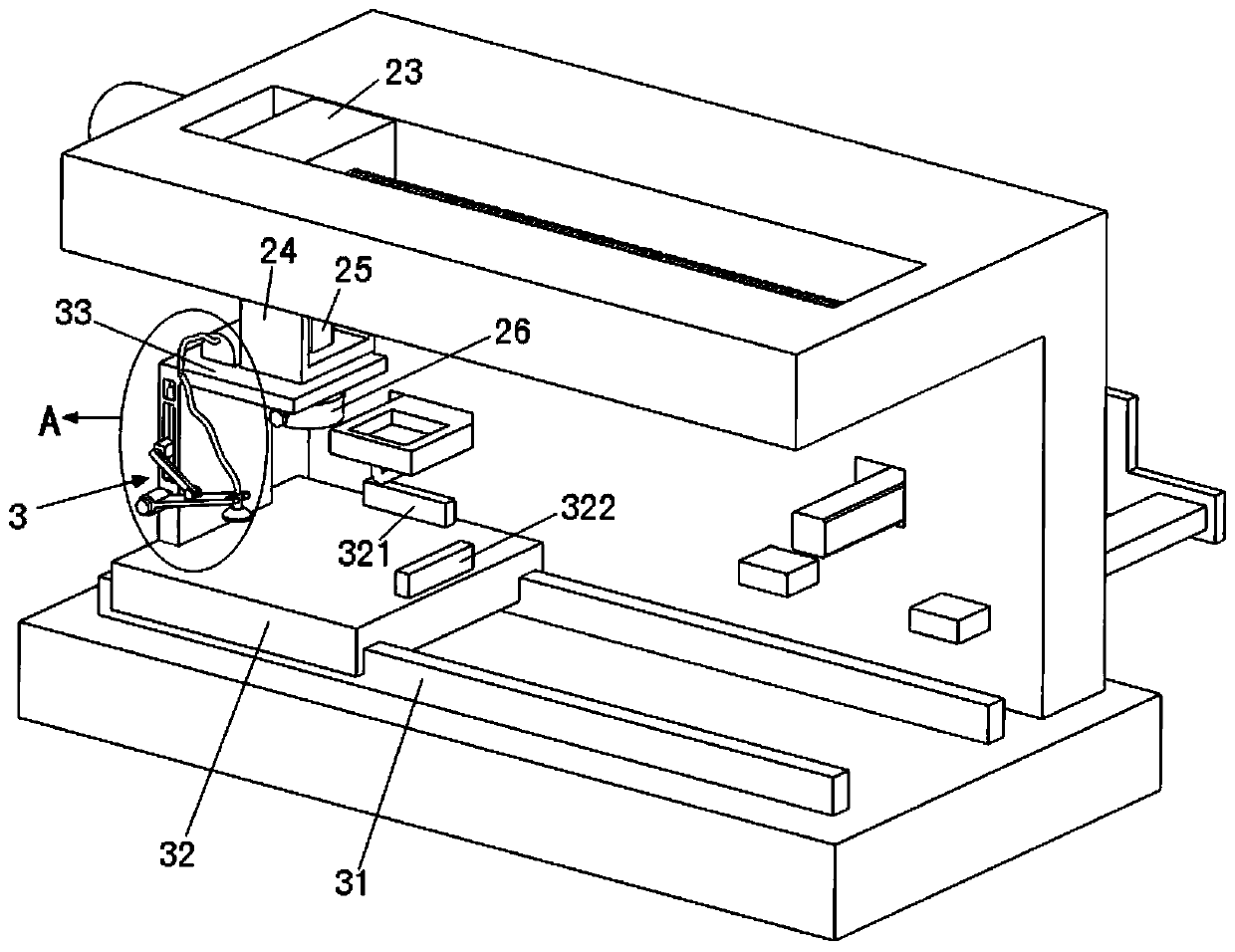

Printing device for plates

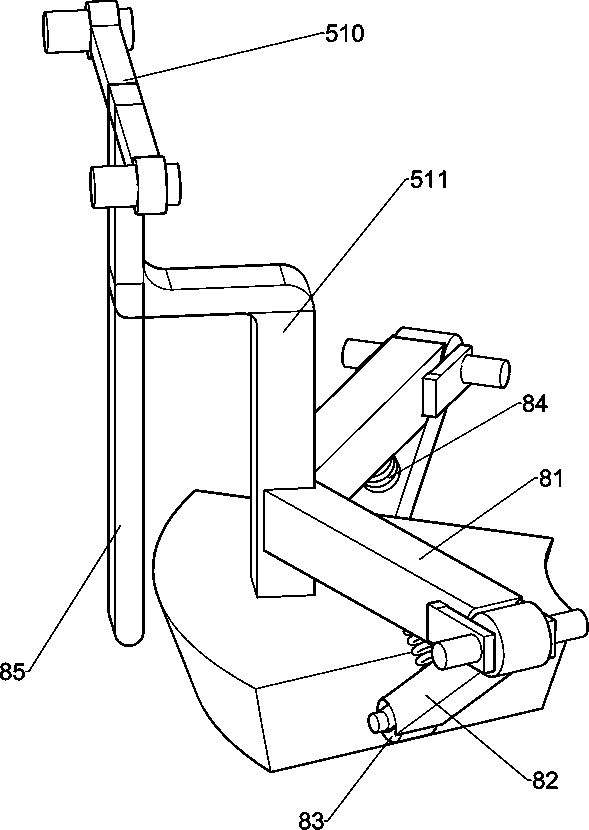

InactiveCN111361316ARealize automatic printingImprove printing efficiencyStampingTextile printerEngineering

The invention relates to a printing device, in particular to a printing device for plates. The technical problem is providing the printing device for plates, which is characterized in that the devicecan automatically carrying out printing on the plates by replacing manual work, one plate is dipped in red ink paste only once, and the printing efficiency is improved. According to the technical scheme, the printing device for the plates comprises a base, a red ink paste tray and a printing mechanism; a mounting table is arranged on the side portion of the base, a workbench is arranged between the two sides of the base, the workbench is arranged in the horizontal direction, and the workbench is located below the mounting table; the red ink paste tray is arranged at the side portion of the side, close to the mounting table, of the base; and the printing mechanism is arranged at the top of the side, close to he red ink paste tray, of the mounting table. According to the device, through theprinting mechanism, automatic printing on the plates is achieved; meanwhile, the shape of a sponge seal is consistent with the shapes of the plates so that the sponge seal can be in contact with the whole surface of each plate at a time; and through a bolt, the position of the red ink paste tray can be fixed, so that the situation that the sponge seal drives the red ink paste tray to move in the moving process is avoided.

Owner:卢菲

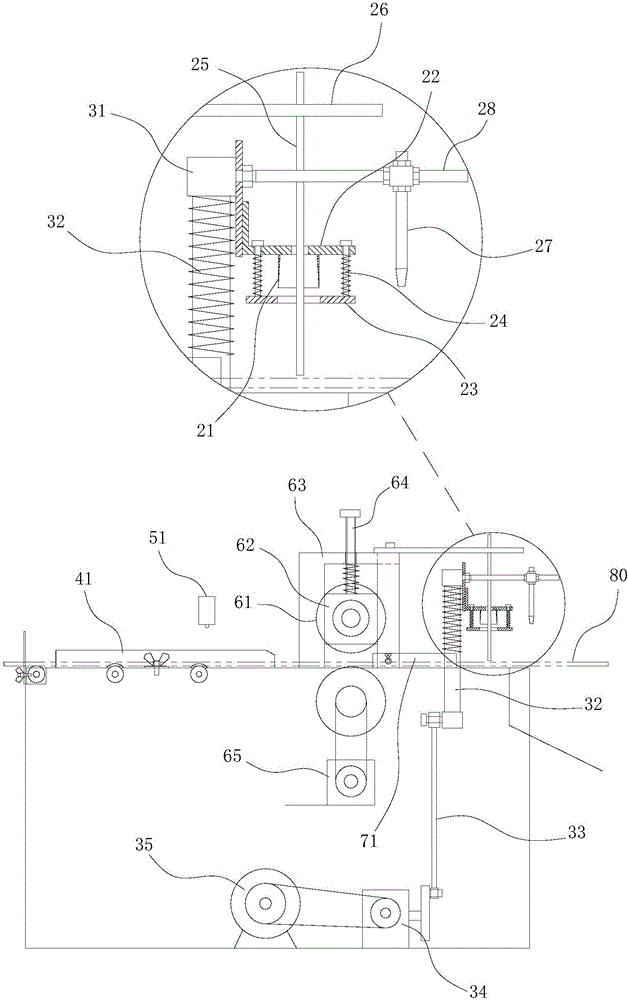

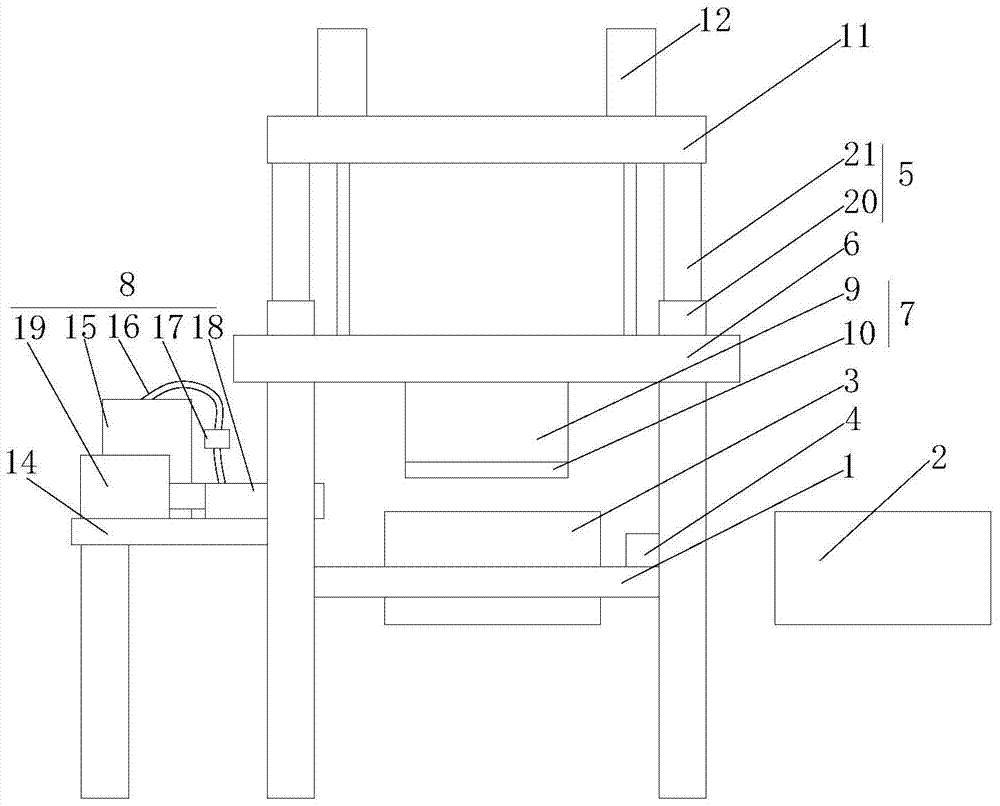

Package printing equipment

ActiveCN105109197ASlide up and down smoothlyIncrease printing speedRotary pressesSolenoid valvePrinting press

The invention provides package printing equipment which comprises a workbench, a feeding mechanism, a discharging mechanism, a sensor, stand columns, a printing machine seat, a printing machine, an inking device and a controller. The two sides of the workbench are each provided with two corresponding stand columns, and the four stand columns are arranged in a quadrangle shape. The printing machine seat is arranged on the four stand columns in a sliding and sleeving manner, and the printing machine is fixed below the printing machine seat, right faces the workbench and comprises a printing body and a soft printing plate. A supporting plate is arranged at the tops of the stand columns and located above the printing machine seat, an air cylinder is arranged on the supporting plate, and the output end of the air cylinder is connected with the printing machine seat. The inking device is arranged on a boss on the side faces of the stand columns and comprises an ink box, an inking pipe, a solenoid valve, an inking brush and a second drive mechanism. The feeding mechanism, the discharging mechanism, the sensor, the air cylinder, the second drive mechanism and the solenoid valve are connected with the controller. The package printing equipment is simple in structure, practical and reliable in work, the mechanisms are controlled by the controller for coordination work, and automatic printing is achieved.

Owner:安徽聚祥升酒类包装有限公司

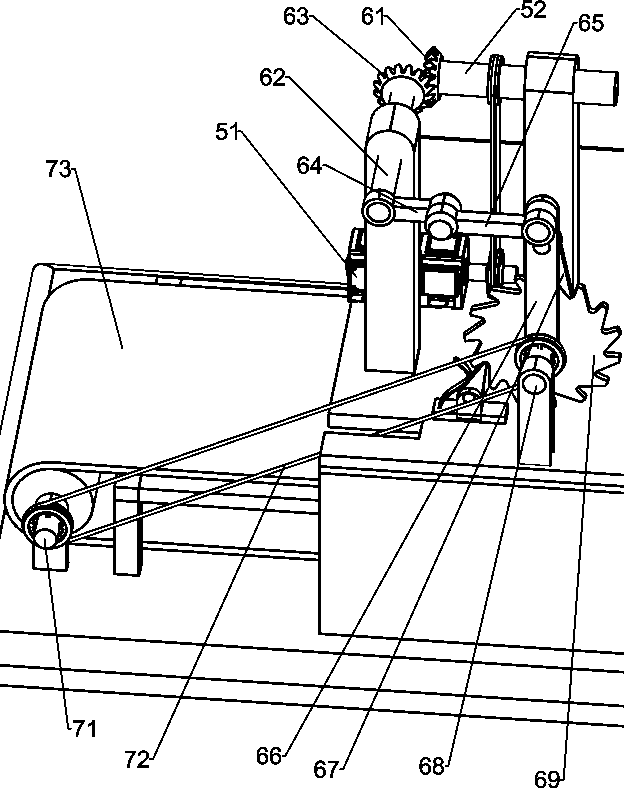

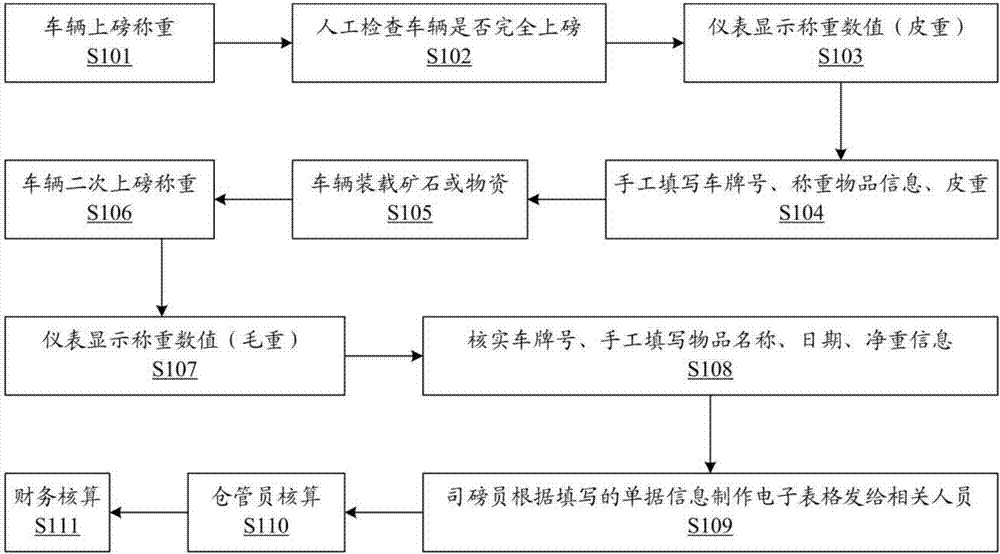

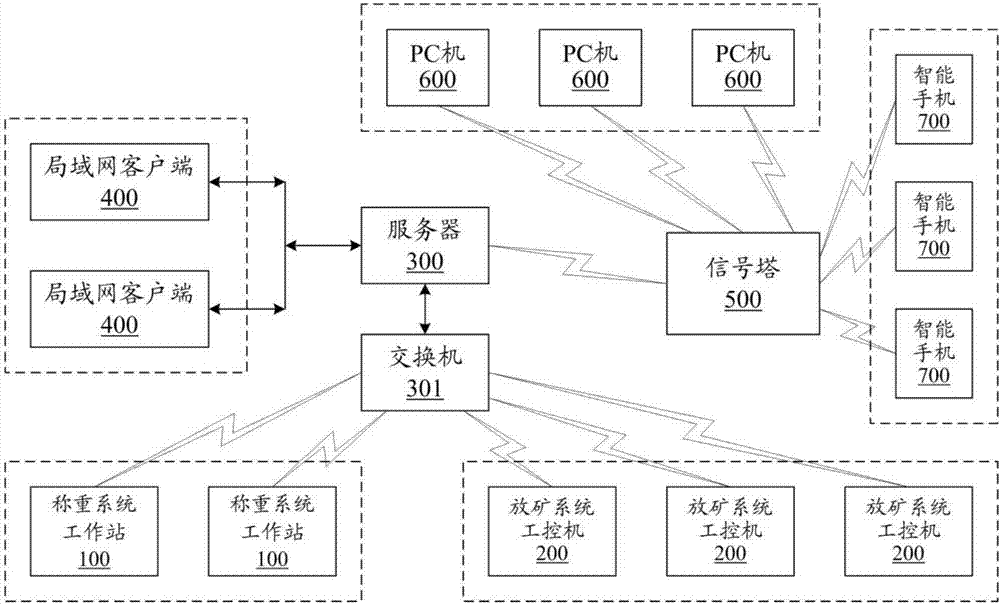

Unattended operation automatic weighing system for mines

InactiveCN107121182APrevent cheatingEffective control of cheating behaviorWeighing auxillary devicesSpecial purpose weighing apparatusClient-sidePaper document

The present invention discloses an unattended operation automatic weighing system for mines. The system comprises a plurality of weighing system workstations, a plurality of ore drawing system industrial personal computers, a server, a switch, a plurality of local area network clients, a signal tower, a plurality of personnel computers and a plurality of intelligent mobile phones. The plurality of weighing system workstations and the plurality of ore drawing system industrial personal computers are respectively connected with the server through the switch. The plurality of local area network clients are connected directly with the server through data lines. The plurality of personnel computers and the plurality of intelligent mobile phones are all equipment arranged outside a mine, and are in wireless connection with the signal tower having the wireless data transmitting and receiving function. The signal tower is in wired or wireless connection to the server. According to the technical scheme of the invention, the weight information of an automatic weighing instrument can be automatically collected, and then the net weight and the total amount are automatically counted. The automatic printing of a metering document is realized. Meanwhile, data are stored in the server, so that leaders and related people can conveniently monitor and search the data.

Owner:YANTAI ZHIBEN INTPROP OPERATIONS MANAGEMENT CO LTD

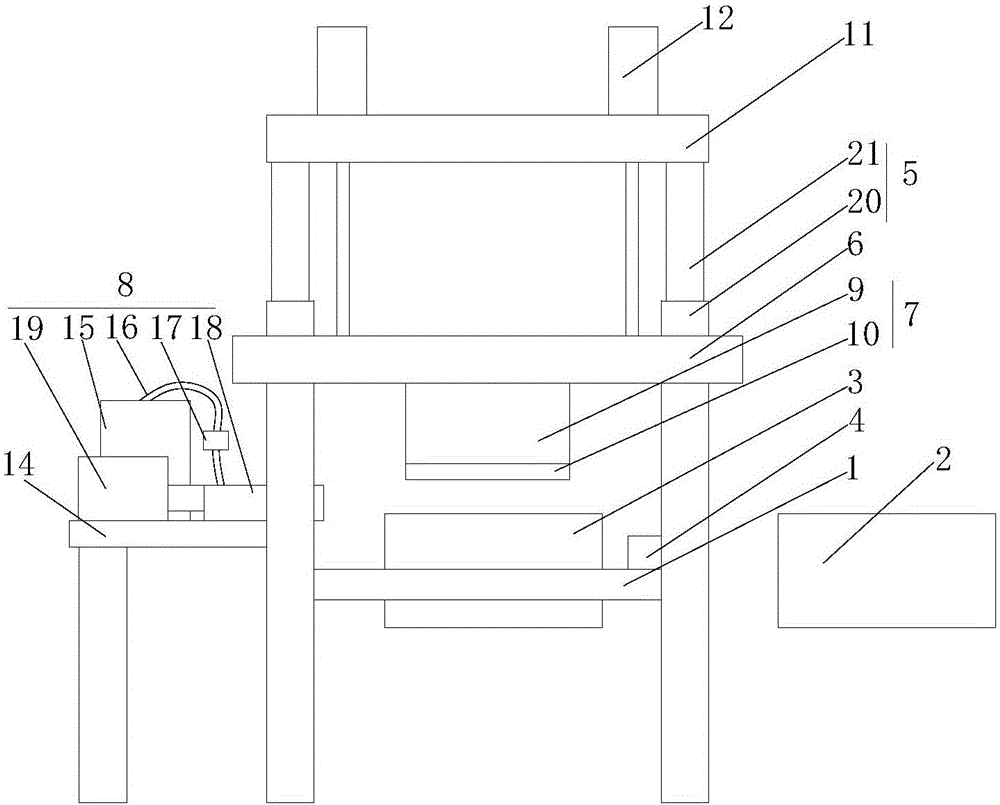

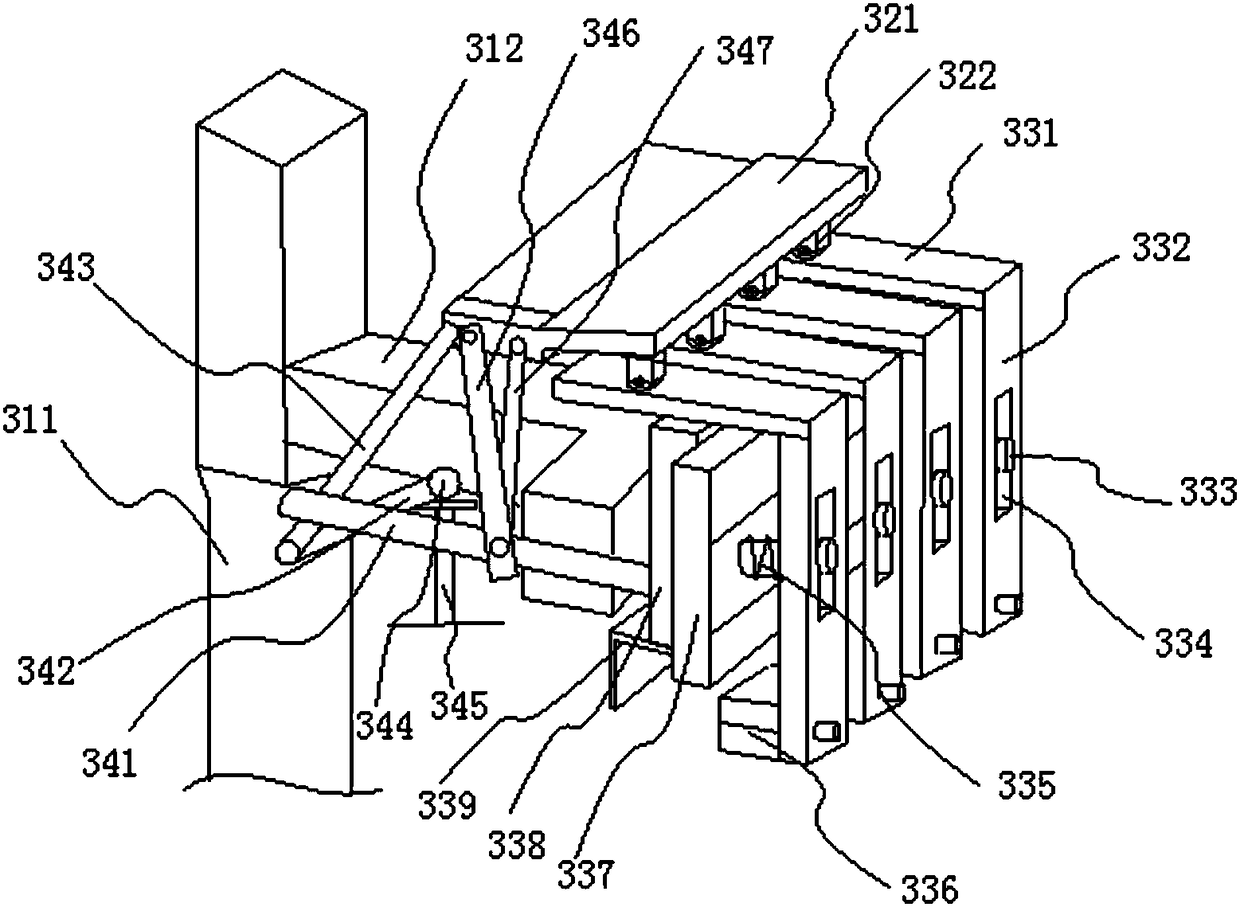

Certificate repairing equipment for real estate certificate

ActiveCN107933132APrevent rollbackRealize automatic printingTypewritersBook making processesComputer printingDatabase

The invention discloses certificate repairing equipment for a real estate certificate. The certificate repairing equipment comprises a rack. The rack is provided with a first page overturning and printing mechanism for page overturning and printing of the blank certificate, a first stamp, a movable clamp, a first mechanical arm, a second page overturning and printing mechanism, a certificate limiting groove, a paper pasting mechanism, a second stamp, a page combining assembly and a certificate discharging distributing mechanism receiving the certificate obtained after page combining. The firstmechanical arm clamps the first stamp to stamp the certificate and clamps the movable clamp to move the certificate. The second page overturning and printing mechanism conducts page overturning and printing on the certificate from the first page overturning and printing mechanism. The certificate limiting groove is used for receiving the certificate from the second page overturning and printing mechanism. The paper pasting mechanism is used for pasting paper to the certificate pages in the certificate limiting groove and comprises a second mechanical arm. The second stamp is clamped by the second mechanical arm, and stamps the certificate pages in the certificate limiting groove. The page combining assembly is used for combining the certificate. The certificate repairing equipment can prepare the real estate certificate through the machine, and compared with manual preparing, the labor intensity is lowered, and efficiency is improved.

Owner:HANGZHOU MOKO COMMERICAL DEVICE

Equipment and method for coating surfaces of objects with three-dimensional patterns

InactiveCN105562313AStrong three-dimensional senseGood continuous printingPretreated surfacesCoatingsScreen printingTrademark

The invention discloses equipment and a method for coating surfaces of objects with three-dimensional patterns, belongs to the industry of printing equipment and is used for coating surfaces of clothing or ornaments or the objects with polyurethane patterns or cartoons or trademarks. The equipment comprises silk-screen printing equipment and a double-station workbench or a multi-station rotating workbench, wherein the silk-screen printing equipment has an X-axis, Y-axis and Z-axis linkage function, a silk-screen printing scraper is fixed on a Z axis of the silk-screen printing equipment, a silk screen plate A or a silk screen plate B has pattern or cartoon or trademark leak holes, a cutting edge of the silk-screen printing scraper abuts against the silk screen plate A or the silk screen plate B for movement, polyurethane ink is printed onto workpieces, the workpieces are heated to the temperature of 20-70 DEG C after being printed, and the patterns or the cartoons or the trademarks are quickly set or foamed and have colored or fluorescent or light-emitting and foamed or unfoamed three-dimensional effects. The patterns are good in reflective effect, attractive in appearance, elegant and particularly suitable to be applied to sportswear, clothing of sanitation or rescue workers, luggage of field operators, artware, toys, sports goods and markers.

Owner:DALIAN HUAGONG INNOVATION TECH

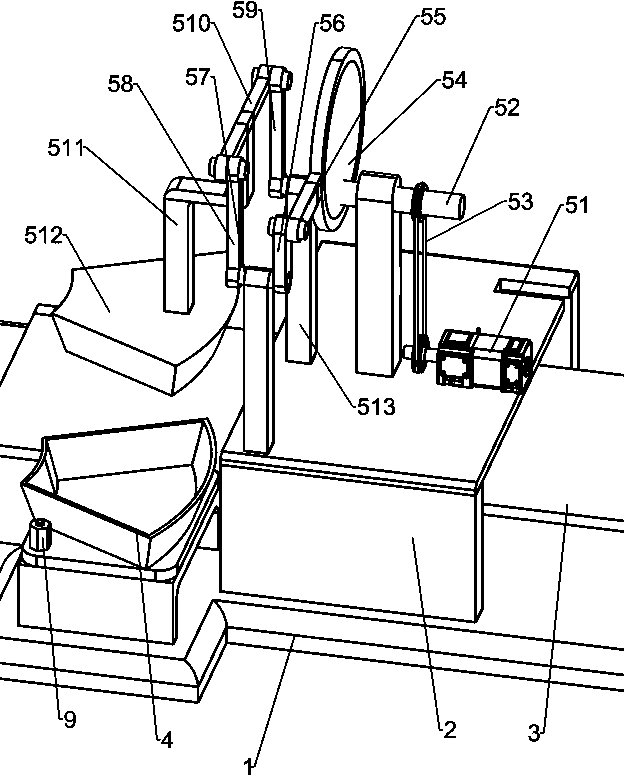

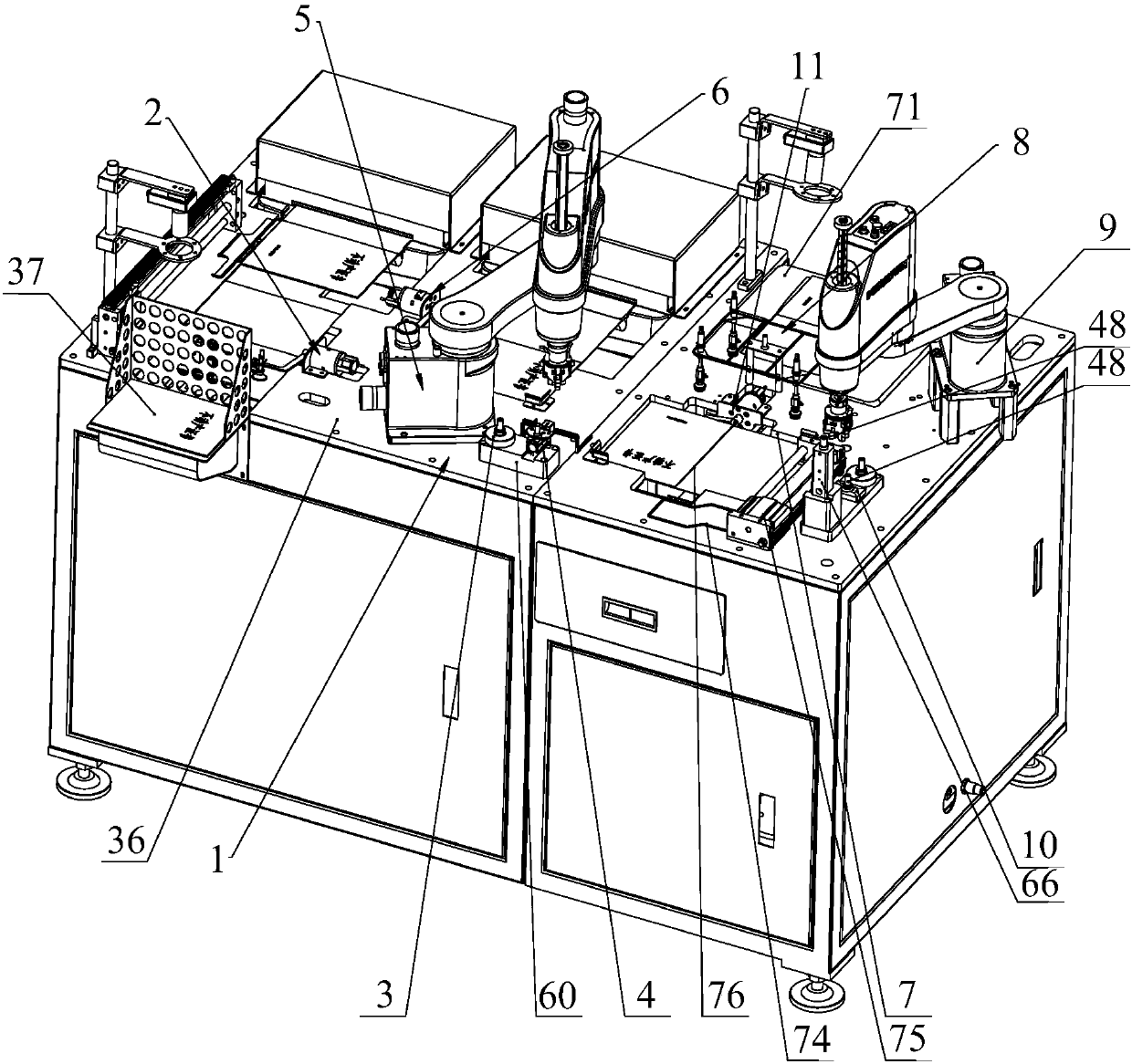

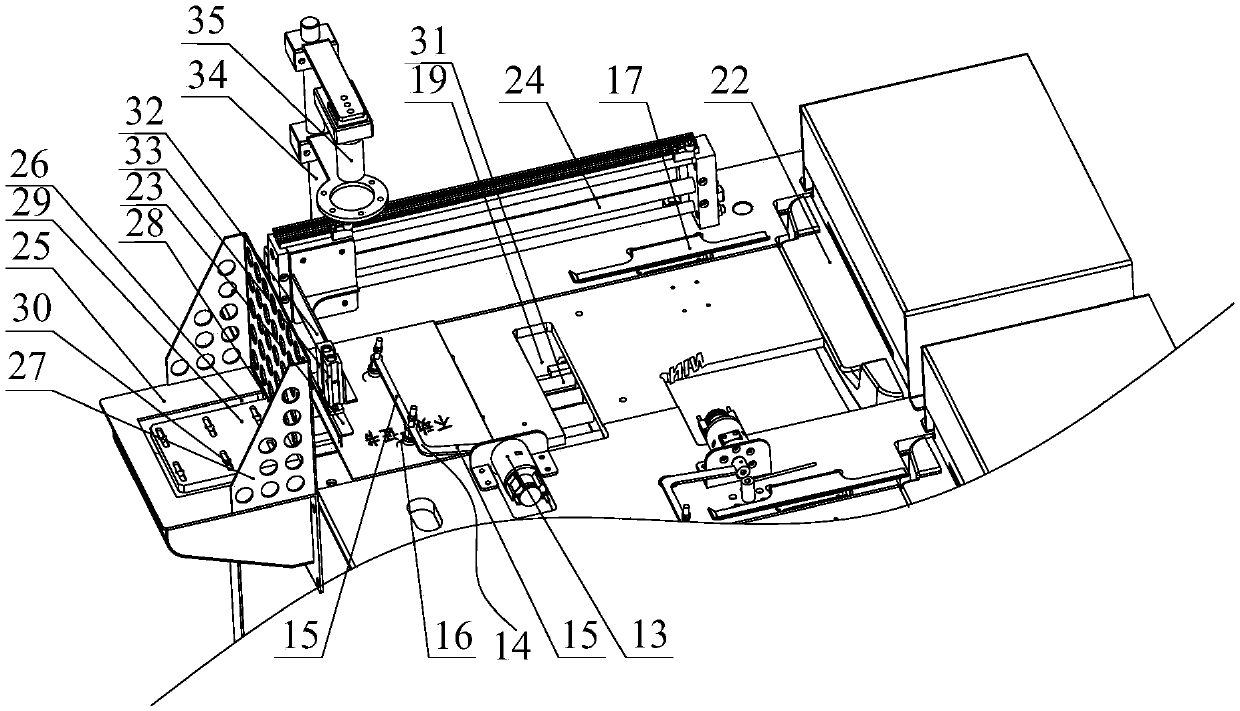

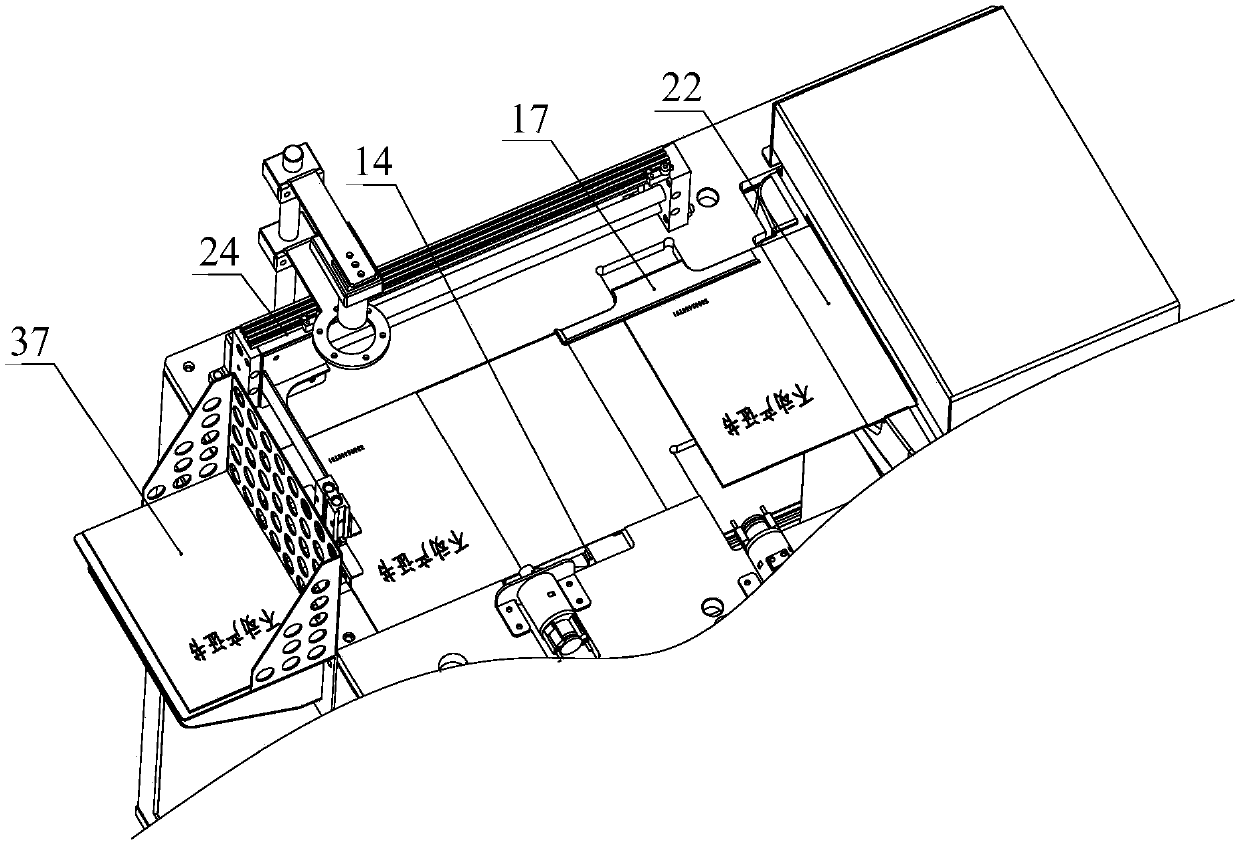

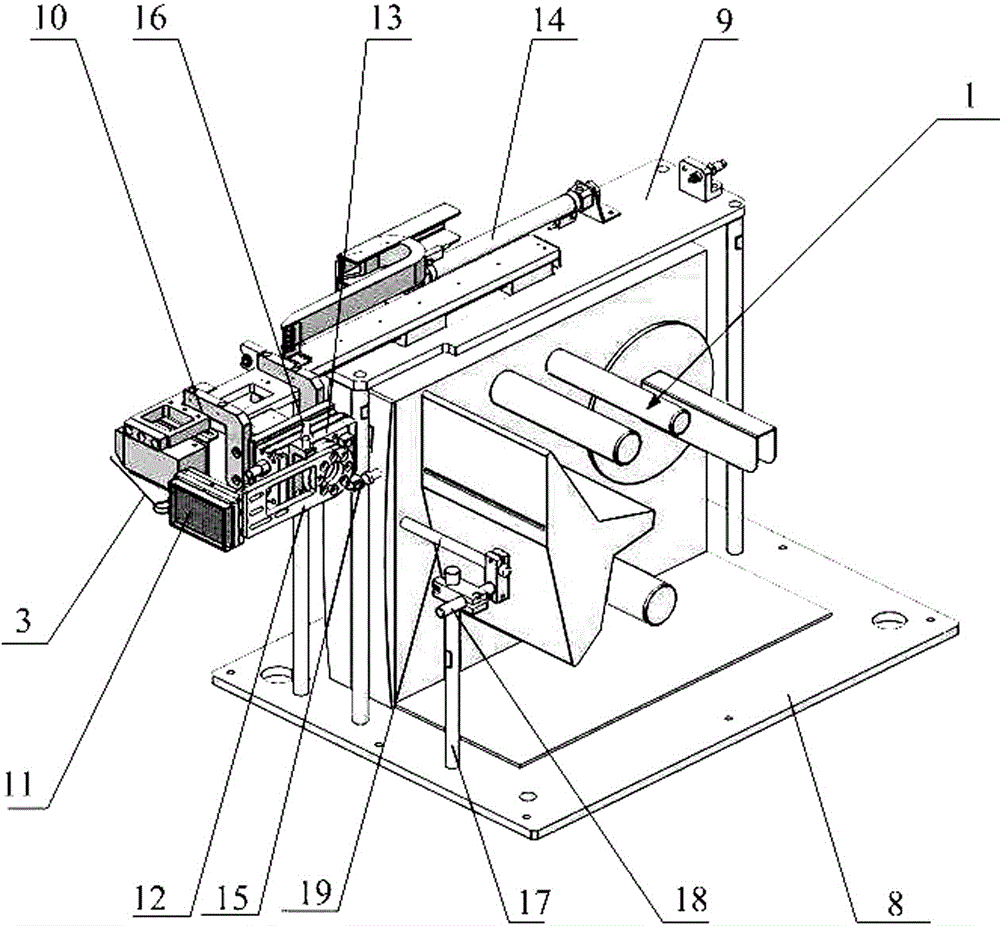

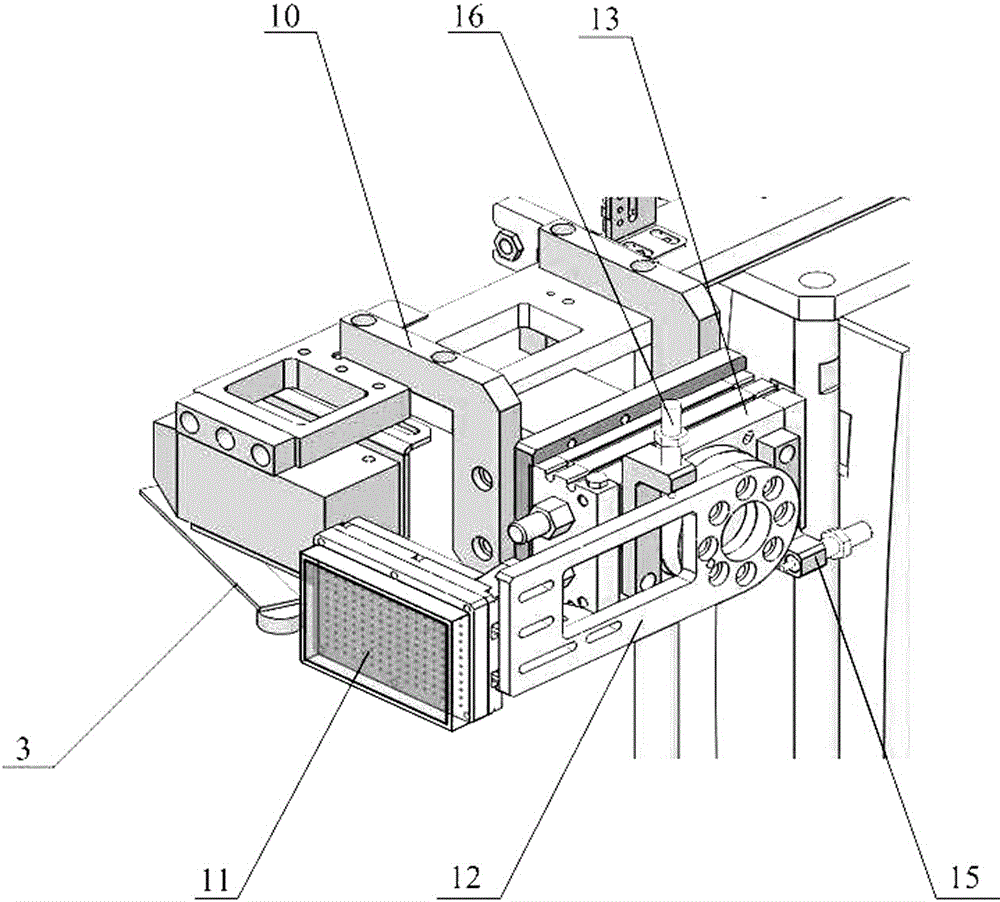

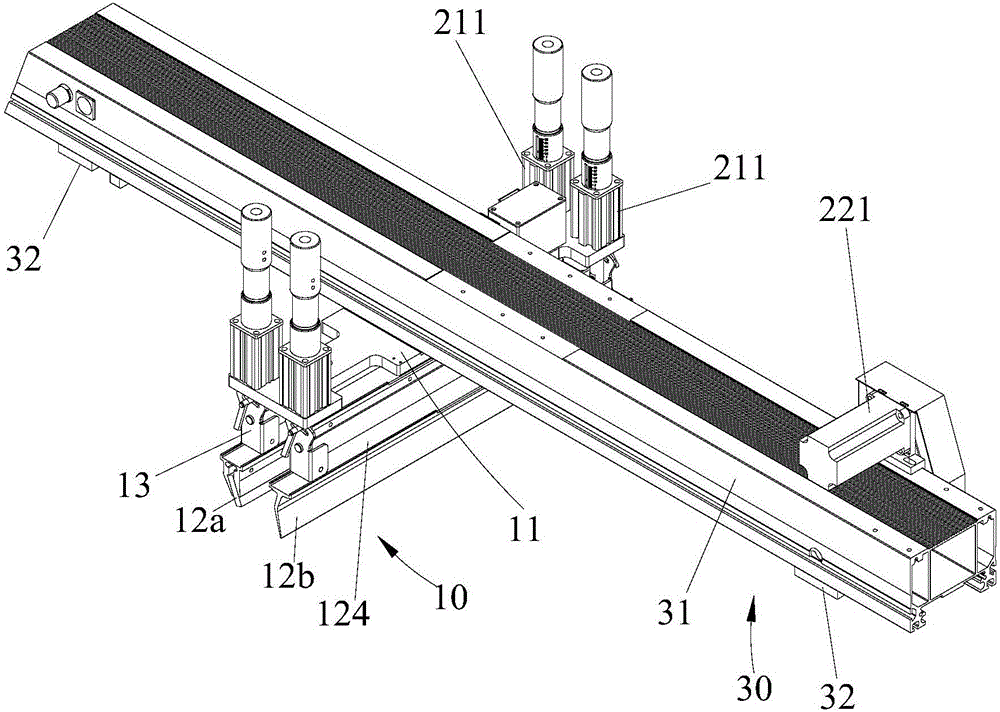

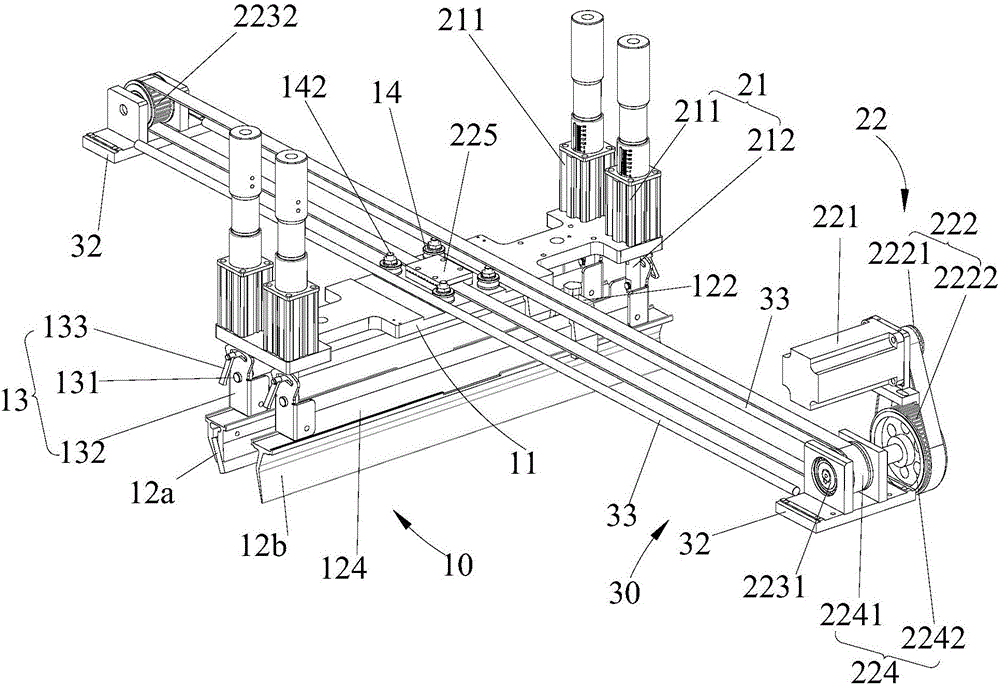

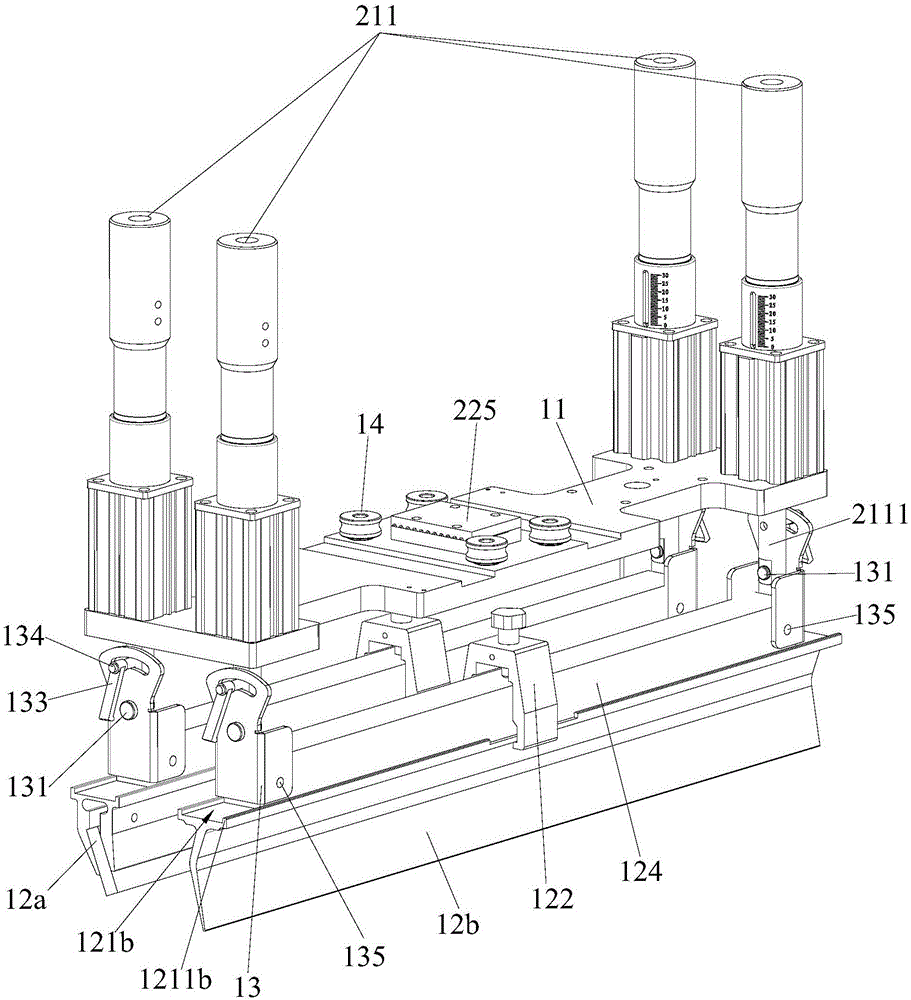

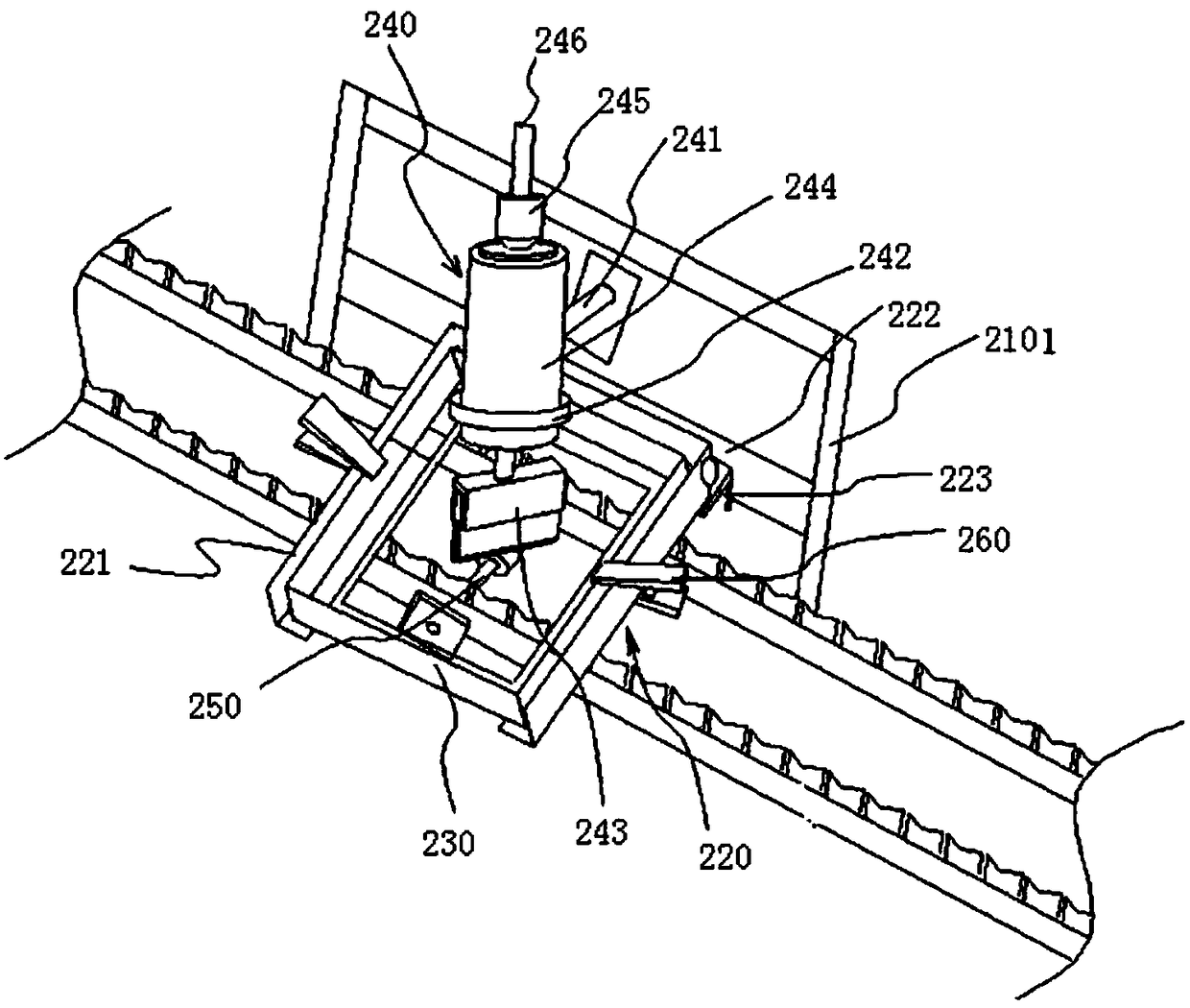

Automatic midsole printing machine

InactiveCN107901588ARealize automatic printingLabor savingScreen printersPrinting press partsElectric machineryEngineering

The invention discloses an automatic midsole printing machine. The automatic midsole printing machine is characterized by comprising a midsole conveying belt and a midsole printing part, wherein the midsole conveying belt is transversely arranged, and the midsole printing part is arranged above the midsole conveying belt; the midsole conveying belt is driven by a main motor to perform a stepping feeding action; a feeding part and a feeding clamping part are arranged at a feeding end of the midsole conveying belt, and a discharging end of the midsole conveying belt is provided with a discharging part and a discharging clamping part; the feeding clamping part and the discharging clamping part comprise clamping sliding tables and pin punching assemblies, wherein the clamping sliding tables slide between the midsole conveying belt and the feeding part and between the midsole conveying belt and the discharging part correspondingly, the sliding actions of the clamping sliding tables are driven by sliding table motors, the multiple sets of pin punching assemblies are longitudinally arranged, and the pin punching assemblies are arranged on lifting plates; and the lifting plates are movablyarranged below the clamping sliding tables in an up-and-down mode, and are pushed by lifting air cylinders, and the lifting air cylinders are fixedly installed on the clamping sliding tables. The automatic midsole printing machine is specially used for automatic printing of a shoe midsole, and has the advantages that labor is reduced, and the working efficiency is improved.

Owner:RUIAN HONGDA LEATHER & PLASTIC MACHINERY FACTORY

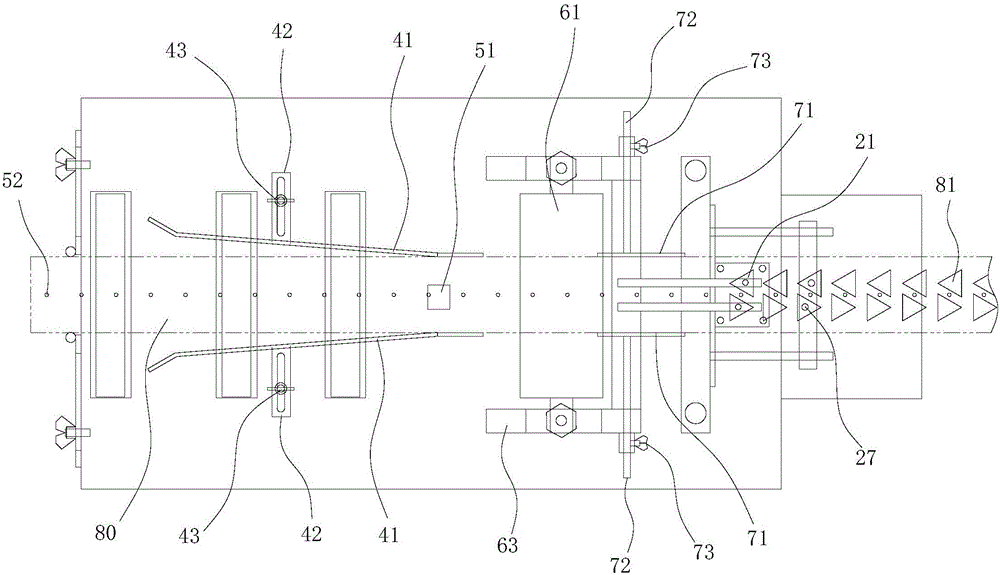

Automatic section bar printing and labeling device

ActiveCN105129177ARealize automatic printingRealize automatic pasting operationLabelling machinesComputer printingControl engineering

The invention relates to the technical field of labeling machines, in particular to an automatic section bar printing and labeling device. The automatic section bar printing and labeling device comprises an electrical control part, a printing machine, a labeling machine, and a position sensor capable of detecting whether a section bar reaches a position or not, wherein a signal output end of the position sensor is electrically connected with a signal input end of the electrical control part; a first order output end of the electrical control part is electrically connected with an order input end of the printing machine; a second order output end of the electrical control part is electrically connected with an order input end of the labeling machine; the labeling machine is provided with a first working position capable of absorbing labels from a label output end of the printing machine, and a second working position capable of pasting and covering the labels on the section bar. The automatic section bar printing and labeling device is reasonable and compact in structure, convenient in use, realizes automatic printing and automatic pasting and covering work of a PVC section bar certificate label, relieves labor intensity of a worker, improves operation efficiency, avoids the condition that wrong filling is labile to cause by writing and handwriting is not easy to recognize, and has the characteristics of being safe, labor-saving, simple and convenient, and efficient.

Owner:新疆蓝山屯河型材有限公司

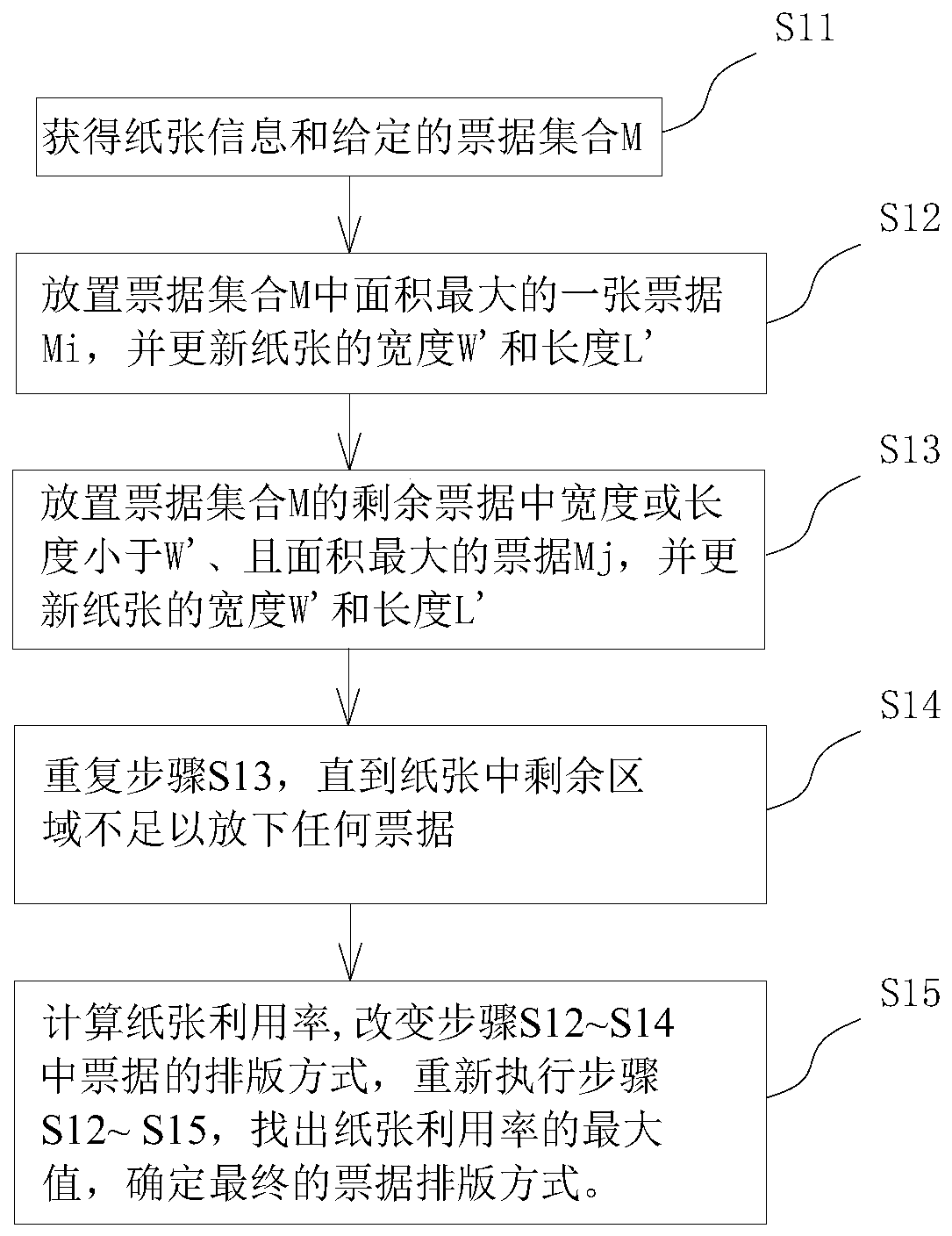

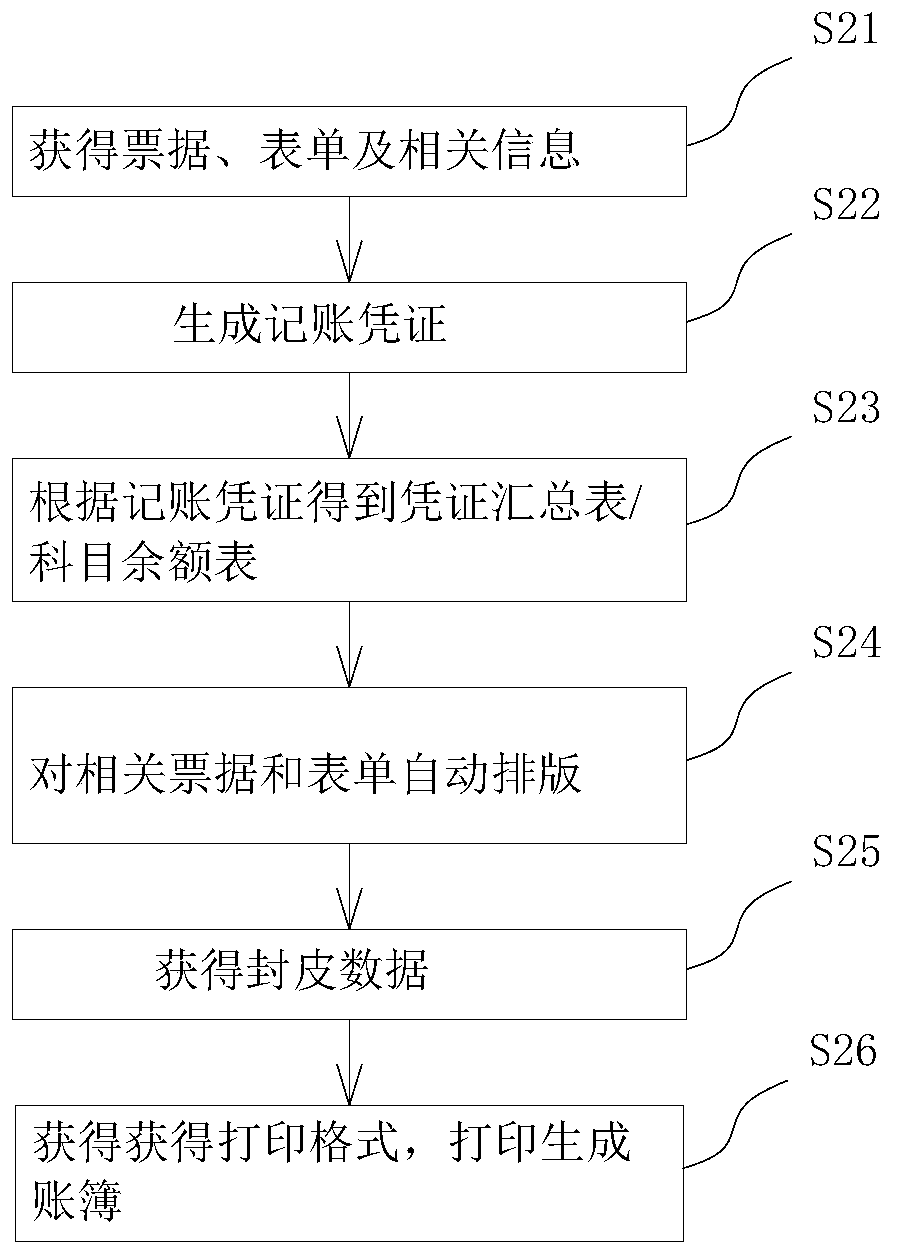

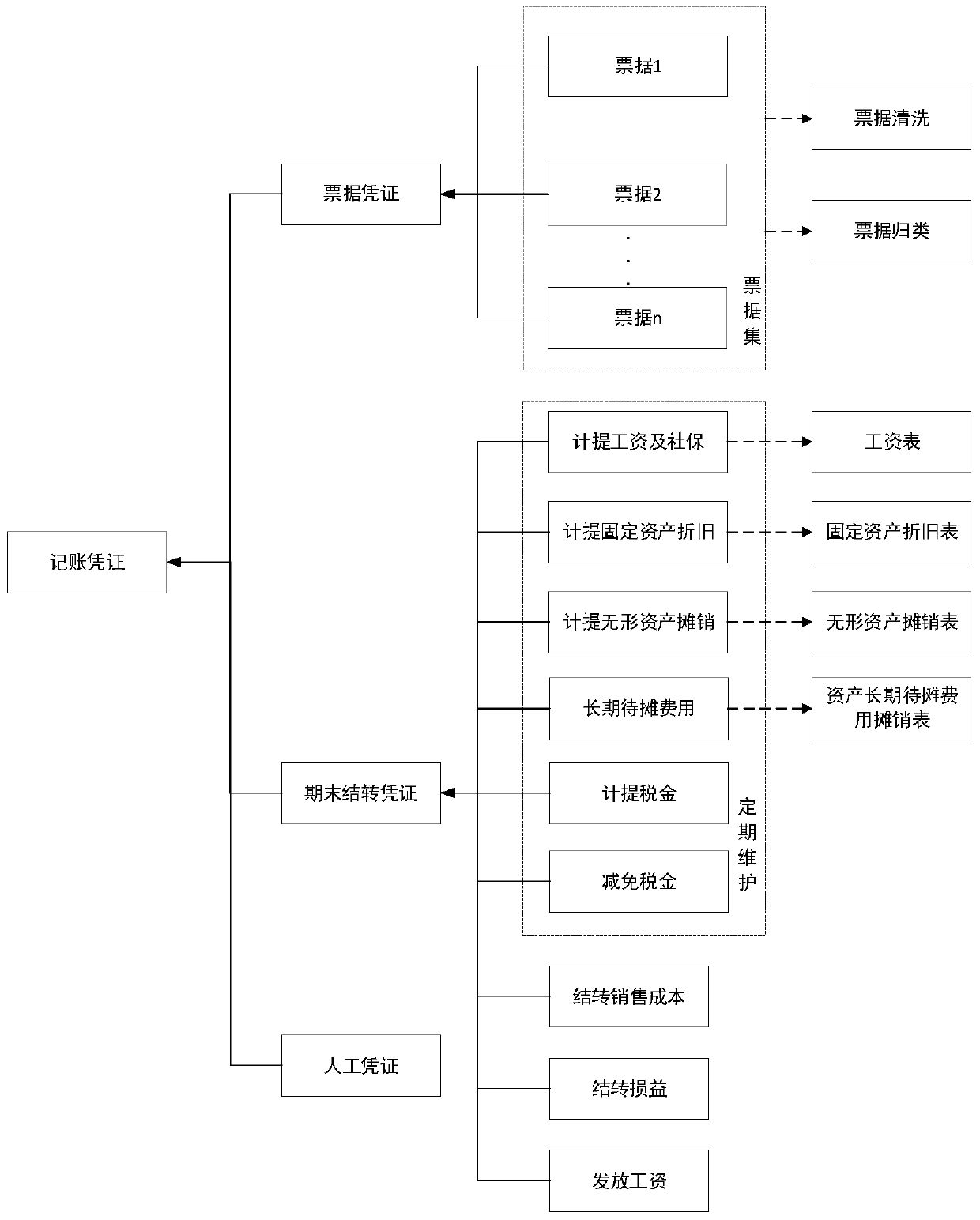

Automatic typesetting method and automatic accounting book generating method

PendingCN111046647AMake the most of utilizationIncrease profitFinanceCharacter and pattern recognitionData scienceIndustrial engineering

The invention belongs to the technical field of intelligent account making, and provides an automatic typesetting method and an automatic accounting book generation method, which comprises the following steps of: obtaining a bill uploaded by a user, and obtaining a form and related information; generating an accounting voucher; obtaining a voucher summary table / subject balance table according to the accounting voucher; automatically typesetting related bills and forms; obtaining envelope data; and obtaining a printing format, and performing printing to generate an account book. By means of thetechnical scheme, the problems that in the prior art, the accounting book generating process is tedious, and the error rate is high are solved.

Owner:西安网算数据科技有限公司

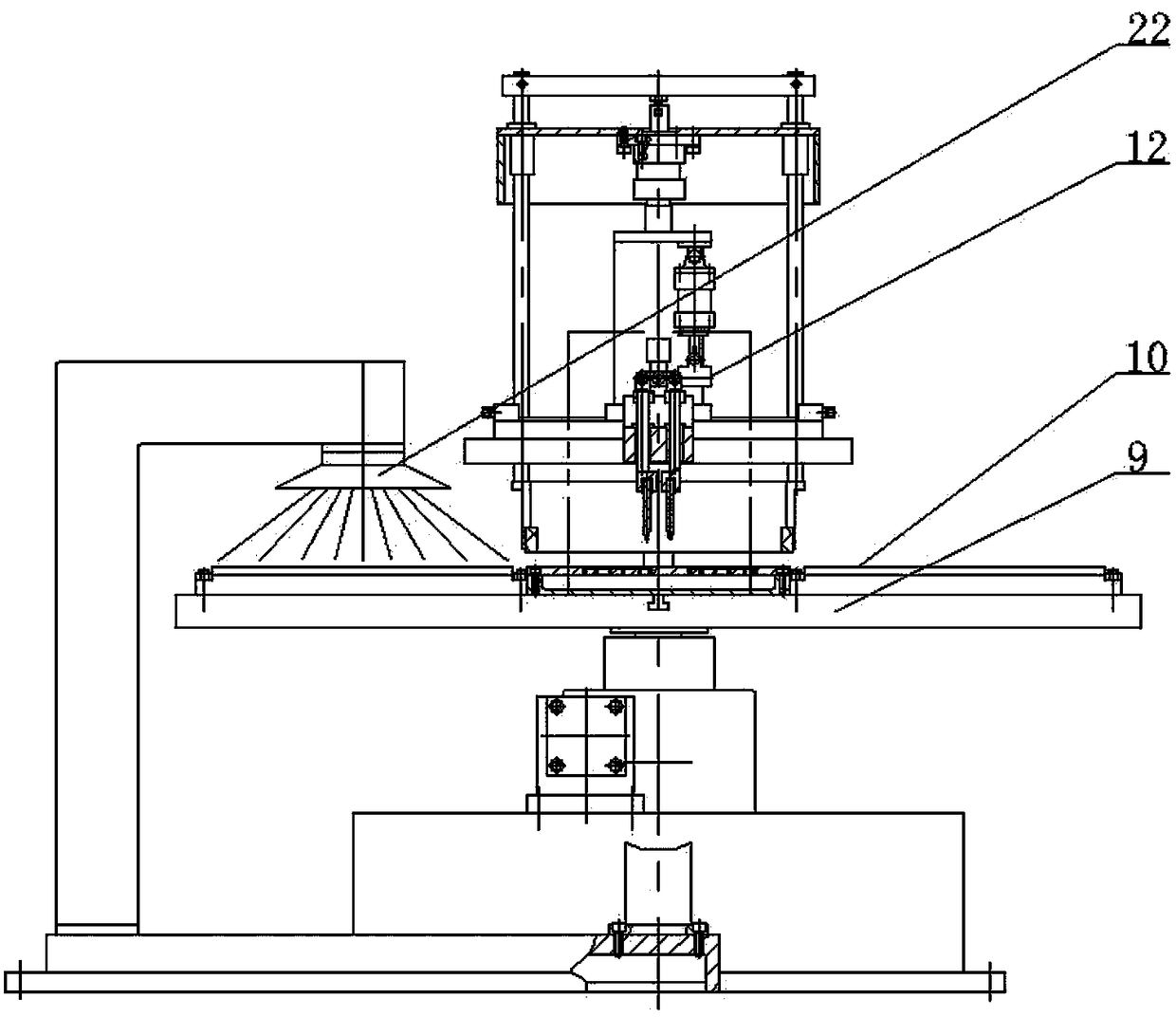

Automatic page turning type book stamping mechanism

ActiveCN109927428ARealize automatic page turningRealize automatic printingStampingEngineeringMechanical engineering

The invention discloses an automatic page turning type book stamping mechanism. The automatic page turning type book stamping mechanism comprises a working bottom plate, a rack is fixed on the right side of the top surface of the working bottom plate, and a movable page turning device is arranged in the rack; the movable page turning device comprises a movable base, a connecting backup plate is fixedly arranged on the rear side of the top surface of the movable base, a driving mechanism is arranged on a top plate of the rack, a stamping device is arranged between the connecting backup plate and the driving mechanism, and a page turning mechanism is arranged on the connecting backup plate; and the page turning mechanism comprises a rotating plate, and a sucker is rotationally connected to agroove formed in the front end of the rotating plate. The automatic page turning device has the advantages that automatic page turning of books can be achieved, and automatic stamping of the books can be achieved after page turning, a conveying device is connected with the stamping device, so that the rapid transportation of the books after the books are stamped is realized, and the stamping efficiency is greatly improved.

Owner:嘉兴倍创网络科技有限公司

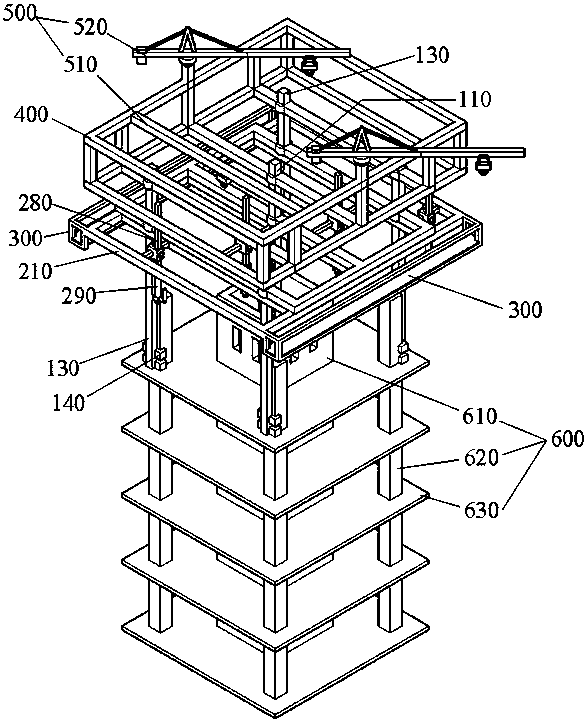

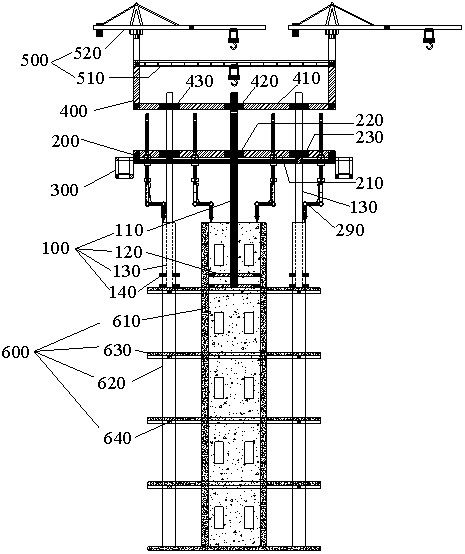

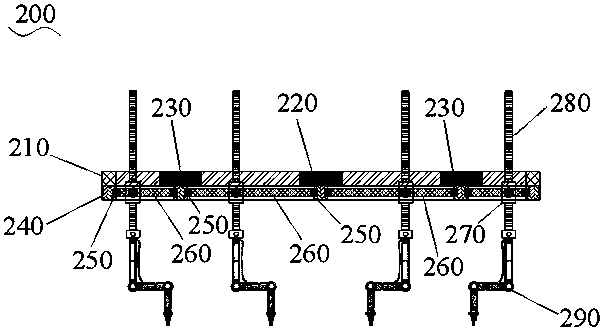

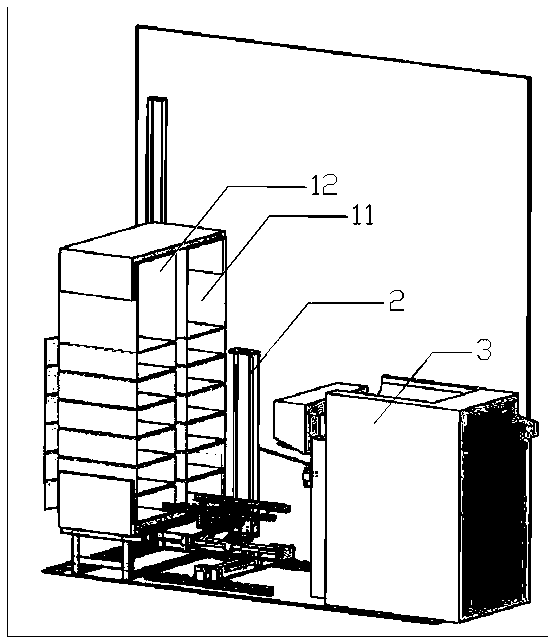

3D printing device and method for super high-rise building

ActiveCN108868141ARealize automated integrated constructionExpand the scope of workAdditive manufacturing apparatusBuilding material handlingEngineeringHigh rise

The invention relates to 3D printing device and method for a super high-rise building, and belongs to the technical field of construction. The 3D printing device comprises a guide rail component, an alternate climbing type 3D printing component, a guide rail lifting component and a material lifting component, wherein the guide rail component comprises a core guide rail, a telescopic adhesion connector, a peripheral guide rail and a fastening type adhesion connector; the alternate climbing type 3D printing component comprises a lifting frame I, a printing head guide mechanism and a 3D printinghead; the guide rail lifting component comprises a lifting frame II fixed on the core guide rail and the peripheral guide rail through a core lifting drive brake II and a peripheral lifting drive brake II. The 3D printing method for a super high-rise building comprises the following steps: synchronously printing a core tube and an outer frame of the super high-rise building by using the alternateclimbing type 3D printing component; hoisting a steel beam and a profiled steel sheet by the material lifting component; printing a floor plate by the alternate climbing type 3D printing component, wherein the printing range is expanded through alternate climbing of the guide rail lifting component.

Owner:SHANGHAI CONSTRUCTION GROUP +1

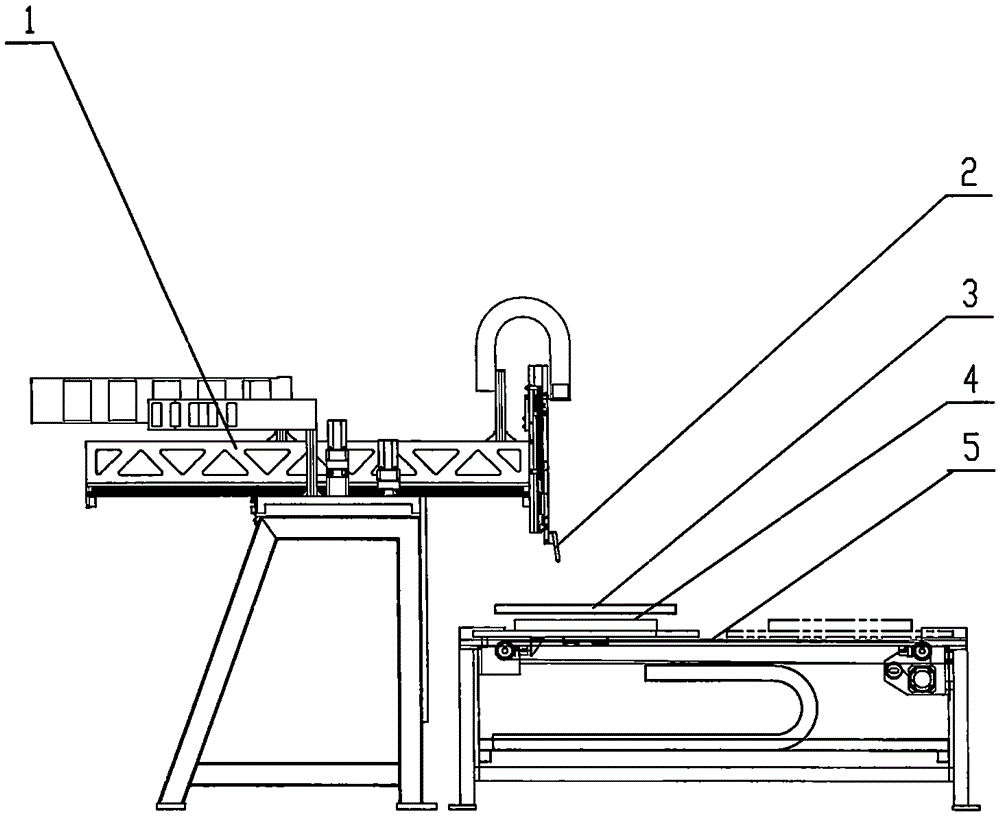

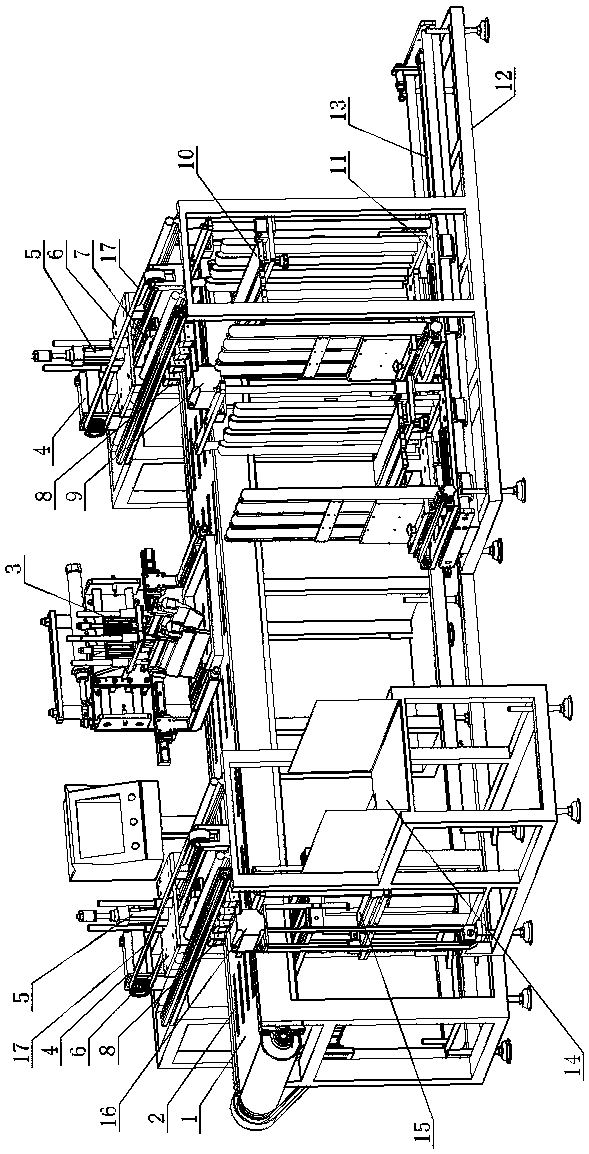

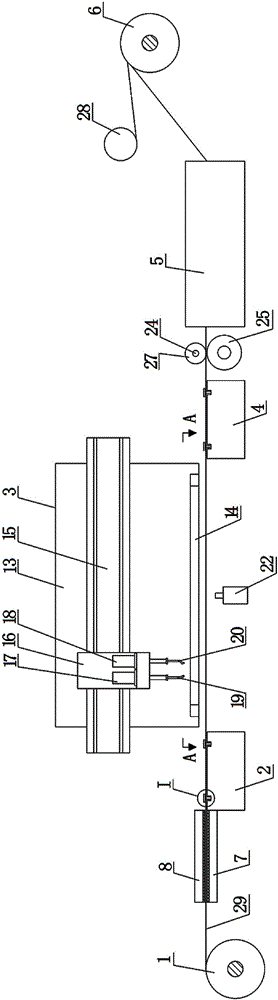

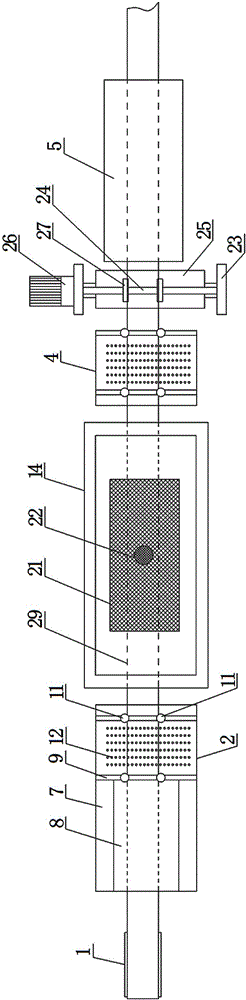

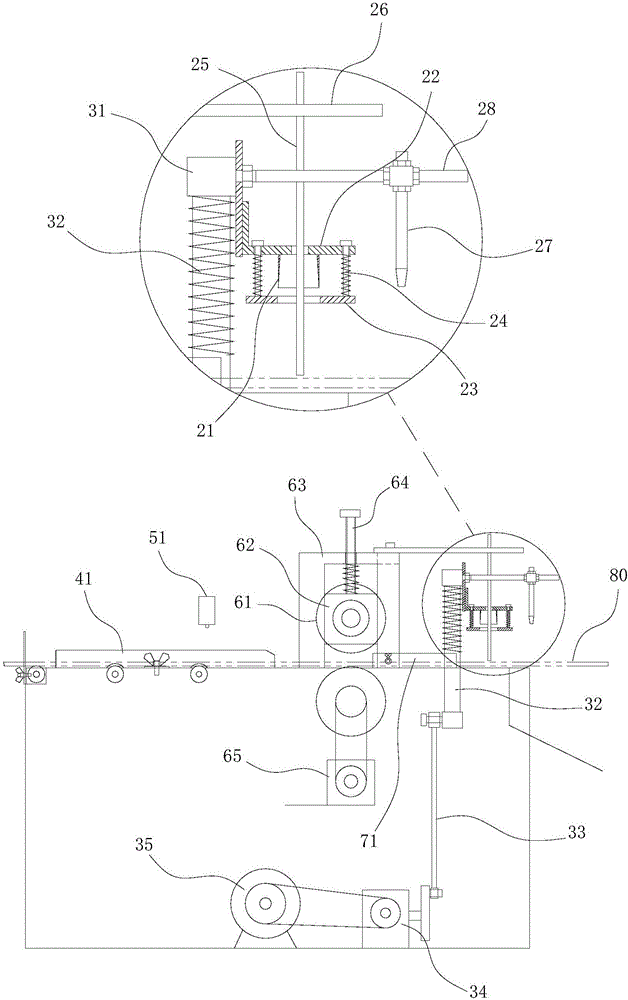

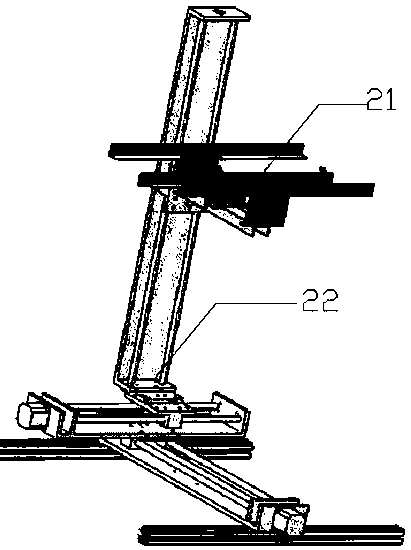

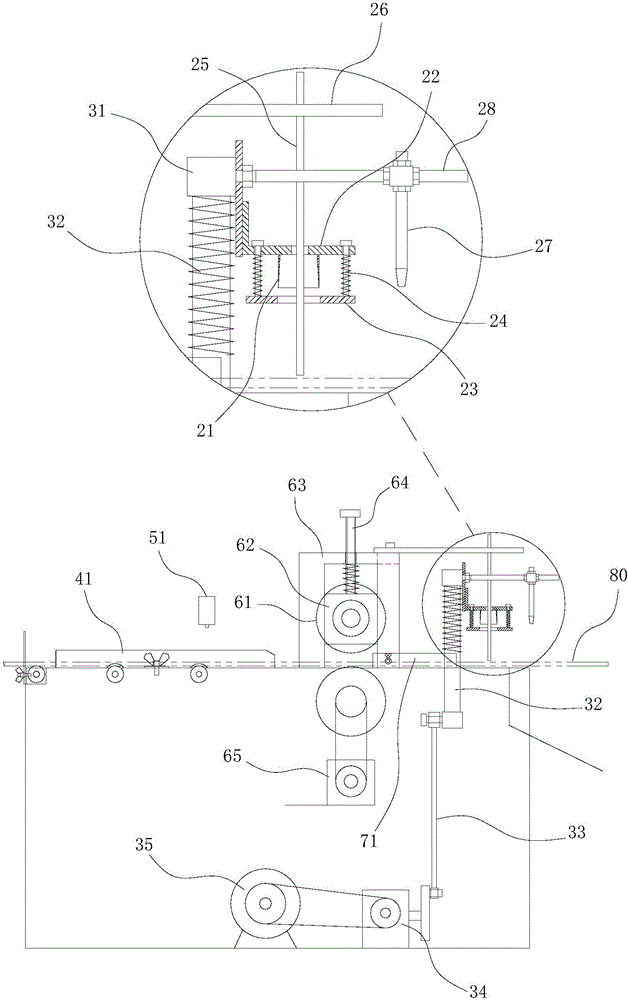

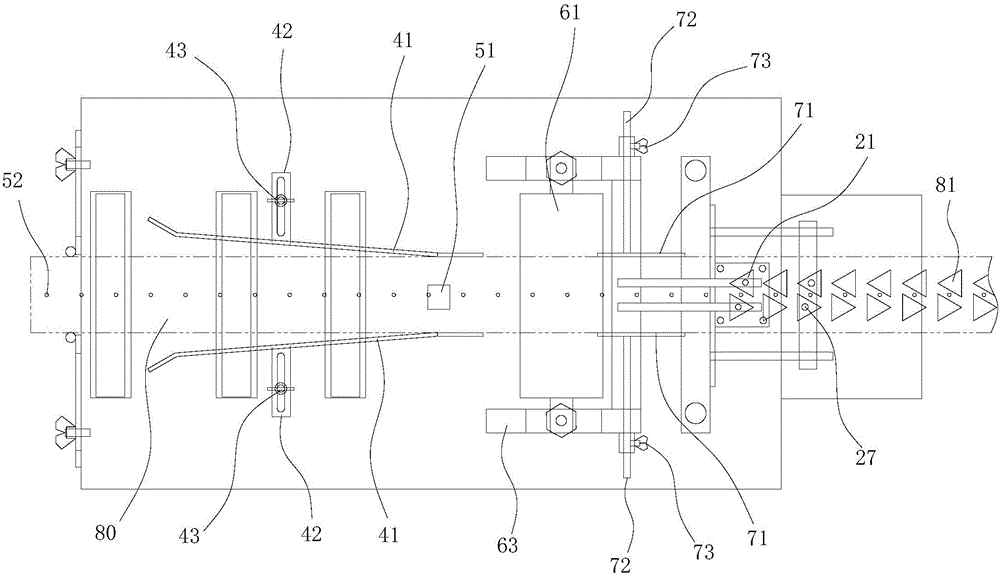

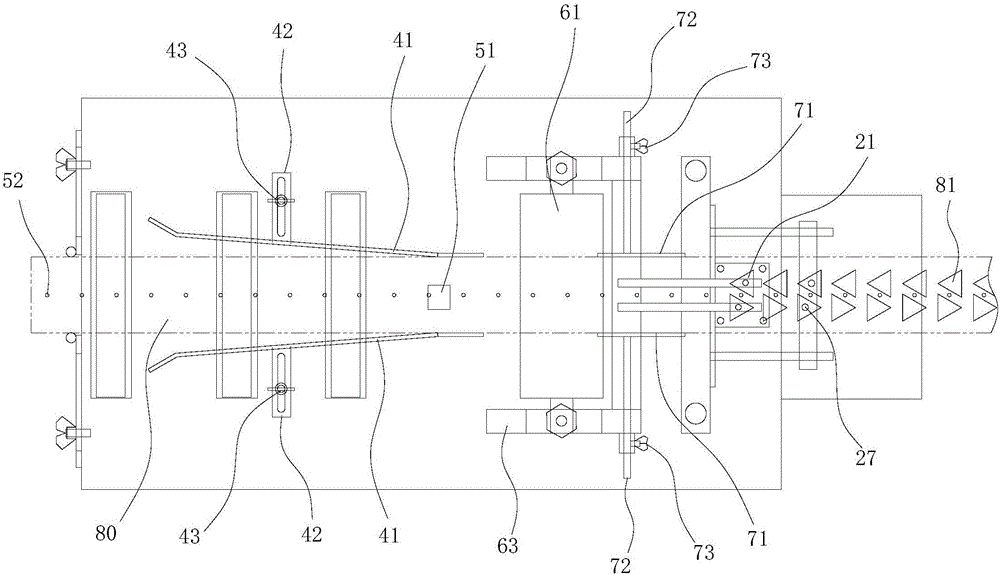

Production line and printing process for printing paint on metal sheet material

ActiveCN105856811AWith automatic printingReduce cumulative errorScreen printersOther printing apparatusProduction lineMetal sheet

The invention discloses a production line for printing paint on a metal sheet material. The production line comprises a metal plate unreeling mechanism (1), an ash wiping device, a left suction box (2), an automatic printing device (3), a right suction box (4), a traction mechanism, a paint drying device (5) and a finished product reeling mechanism (6), which are arranged in sequence from left to right; an optical fiber sensor (22) is mounted at the lower part of a screen mesh plate (21) and is located at the center of the screen mesh plate (21); the traction mechanism is composed of a rack (23), a fixed shaft (24), a rolling shaft (25) which is rotatably mounted in the rack (23) and a motor (26) connected with the rolling shaft (25); the fixed shaft (24) is arranged on the rack (23) and is arranged above the rolling shaft (25); and the paint drying device (5) is internally provided with a conveyor belt. The production line for printing the paint on the metal sheet material has the beneficial effects that continuous printing of the paint is realized, the paint can be accurately printed on a specified position of the metal sheet material, and the automation degree is high.

Owner:CHENGDU ZHENGSHUO TECH CO LTD

Slurry scraping equipment

InactiveCN106494076ARealize automatic printingImprove product qualityScreen printersScreen printingReciprocating motion

The invention is suitable for the technical field of printing and provides slurry scraping equipment which comprises a guide rail beam, a slurry scraping mechanism, a lifting drive mechanism and a transverse drive mechanism; a supporting plate is arranged on the guide rail beam in a sliding manner; a scraper and an ink covering blade are arranged on the supporting plate; the lifting drive mechanism is used for driving the scraper and the ink covering blade to move up and down in the vertical direction; and the transverse drive mechanism is used for driving the supporting plate to carry out transverse reciprocating motion along the guide rail beam. According to the slurry scraping equipment, the scraper and the ink covering blade are driven by the lifting drive mechanism to finish ink scraping operation and ink covering operation sequentially, and meanwhile, the supporting plate is driven by the transverse drive mechanism to carry out transverse reciprocating motion relative to the guide rail beam so as to realize automatic screen printing in a preset region, thus the production quality is stable.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

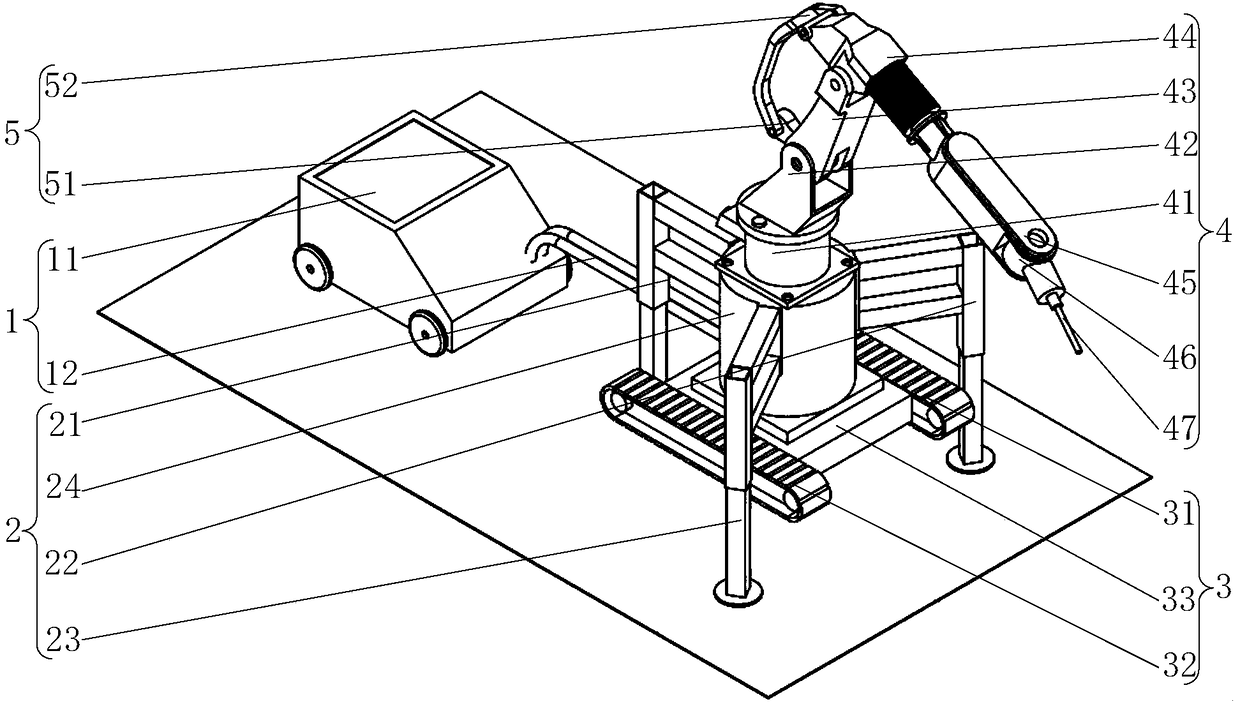

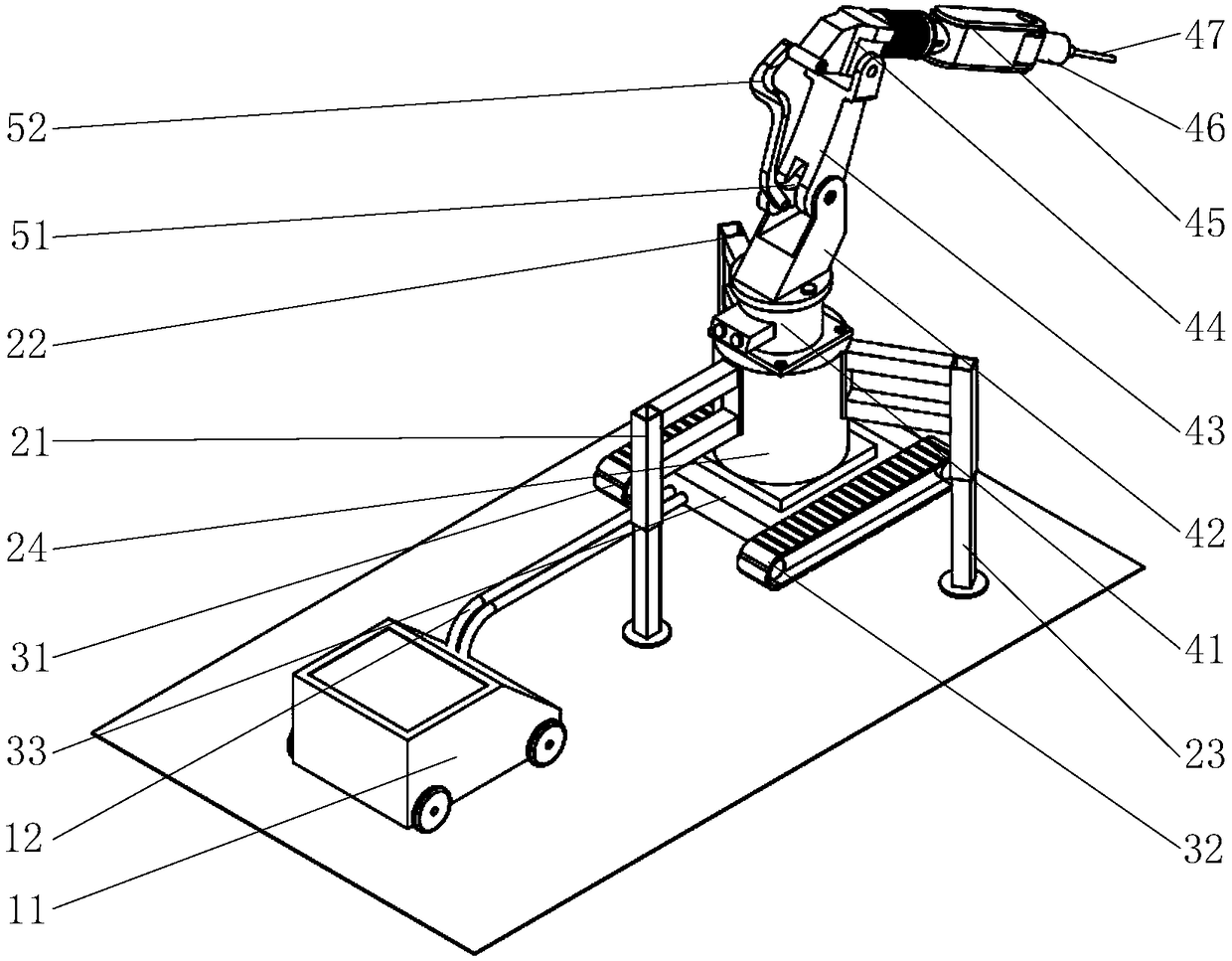

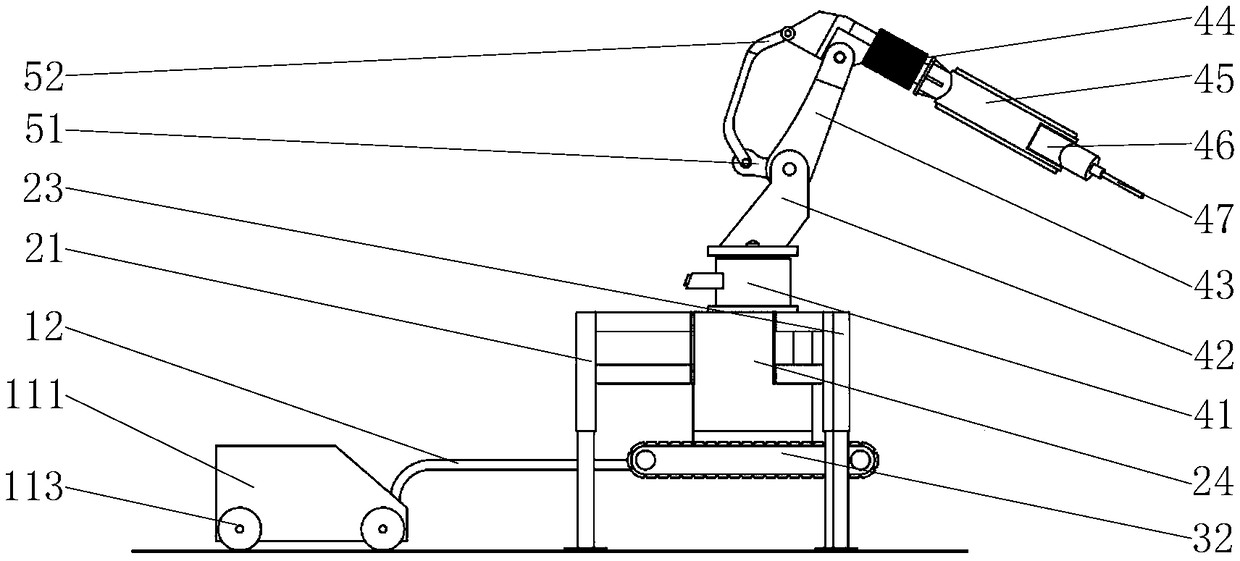

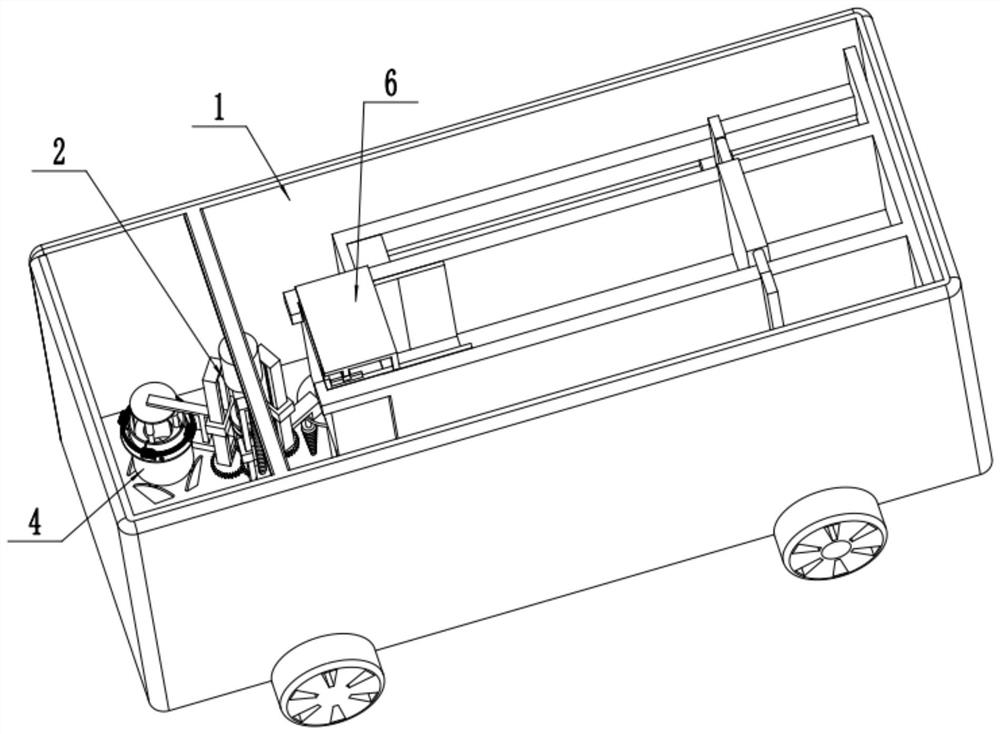

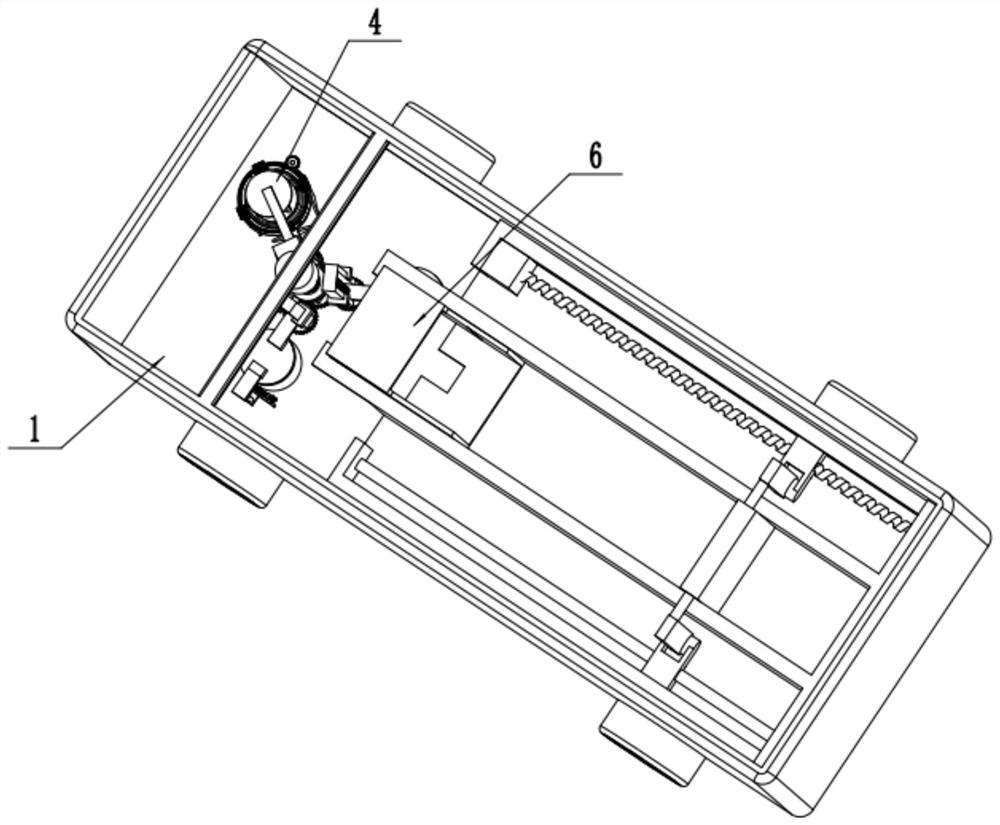

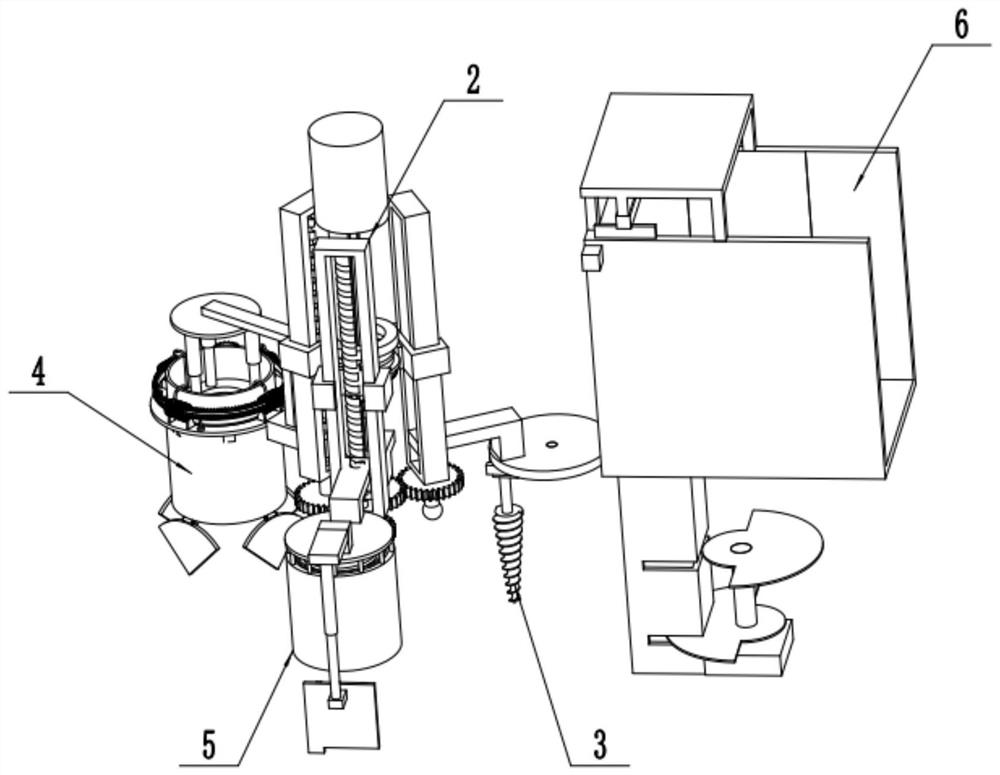

3D printing robot and printing system

PendingCN109049269AImprove mechanical propertiesImprove efficiencyAdditive manufacturing apparatusCeramic shaping apparatusHouse building3d printer

The embodiment of the invention discloses a 3D printing robot and a printing system, and relates to the technical field of house building. The 3D printing robot comprises a feeding assembly, a regulation assembly, a movement assembly and a printing assembly. A control assembly is connected with the feeding assembly, the regulation assembly, the movement assembly and the printing assembly respectively. The feeding assembly is connected with the printing assembly and is set to convey materials into the printing assembly. The regulation assembly is arranged below the printing assembly and is setto regulate the printing assembly. The movement assembly is arranged below the regulation assembly and is set to drive the regulation assembly and the printing assembly to move. Under coordinate control of the control assembly, the feeding assembly, the regulation assembly, the movement assembly and the printing assembly are used in cooperation to achieve the functions of automatic feeding of thematerials, and automatic printing; and the 3D printing robot can complete automatic printing to build a house, mechanical construction of constructional engineering is leveled up, and the efficiency of constructional engineering is improved, and consumption of building materials and energy sources is reduced.

Owner:北京依蓝时代商贸有限公司

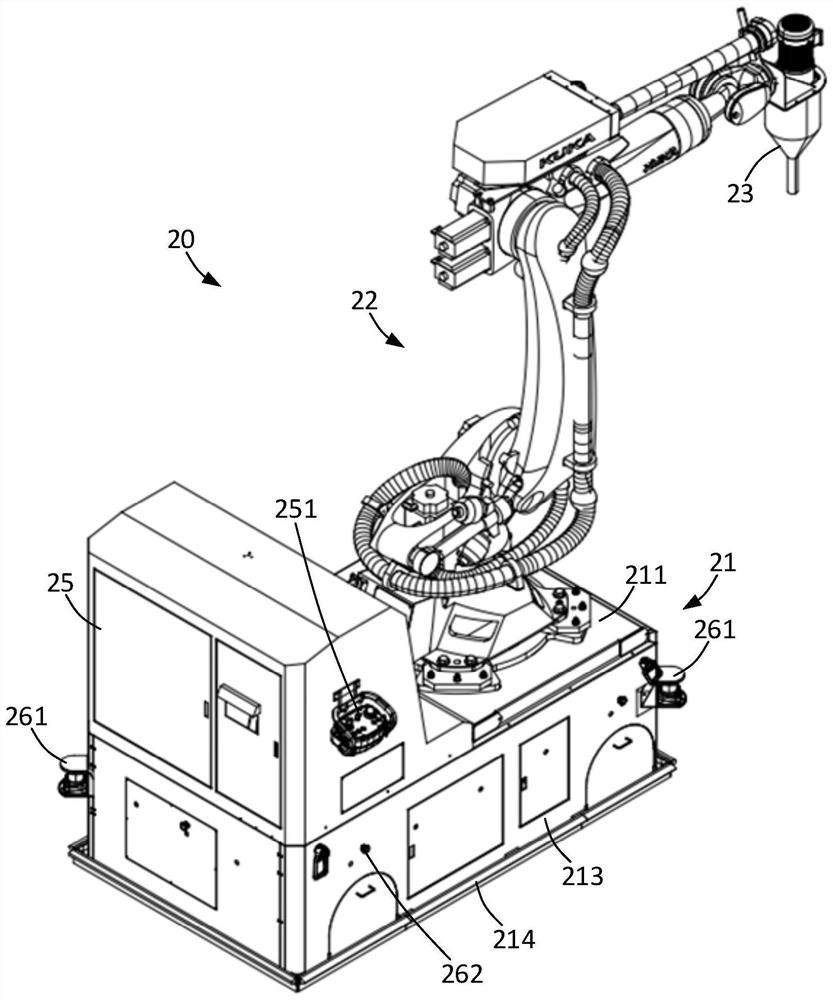

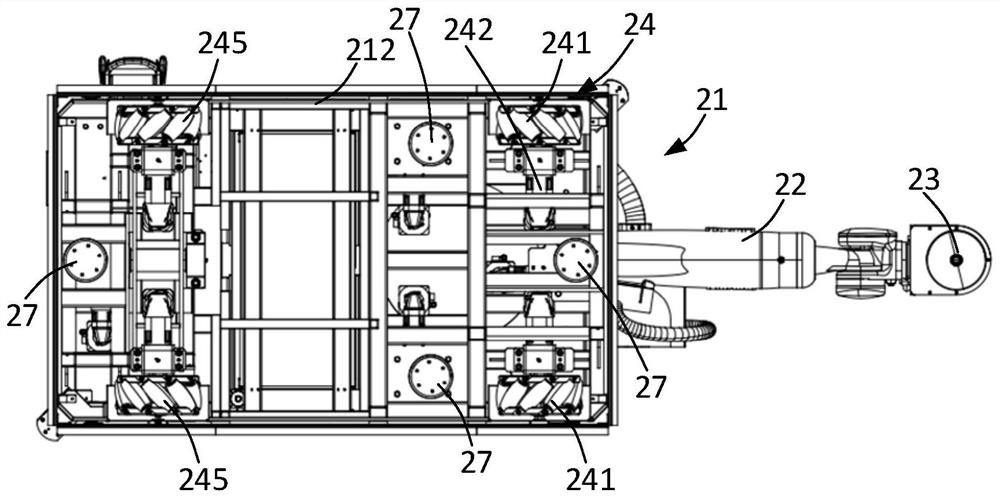

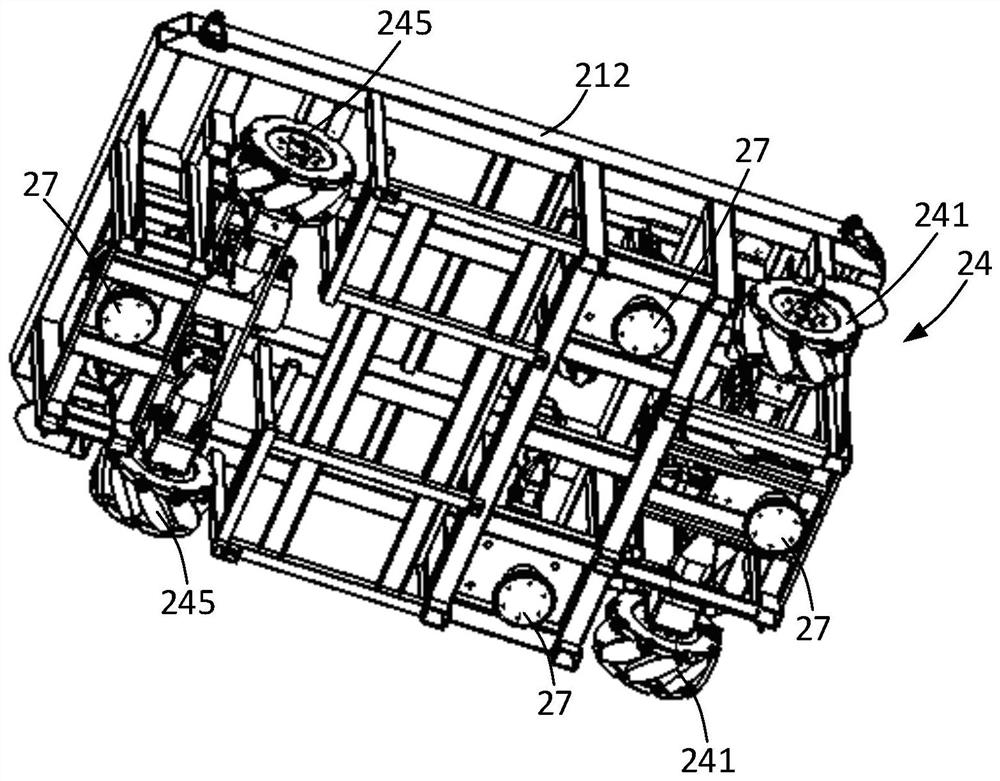

Building 3D printing robot equipment and control method and system therefor

PendingCN112207944AWith mobile capabilitiesIncrease flexibilityAdditive manufacturing apparatusAuxillary shaping apparatus3d printComputer printing

The invention relates to building 3D printing robot equipment and a control method and system therefor. The equipment comprises a rack, a mechanical arm, a printing head, a movement mechanism and a control module, wherein a workbench is arranged at the top of the rack; the mechanical arm is arranged on the workbench, and the position of the tail end of the mechanical arm can be movably adjusted; the printing head is arranged at the tail end of the mechanical arm and is used for realizing 3D printing; the movement mechanism is arranged at the bottom of the rack; and the control module is arranged on the rack, is in control connection with the mechanical arm, the printing head and the movement mechanism, controls the movement mechanism to move according to a 3D printing operation task needing to be completed and drives the rack to move to a 3D printing operation position, and further controls the mechanical arm to move the tail end of the mechanical arm along a printing path, so that themechanical arm drives the printing head to move along the printing path to complete 3D printing operation. The mechanical arm and the printing head are arranged on the rack, so that integration is high, the size is small, mounting and dismounting are not needed, manual labor is reduced to a great extent, and the labor cost is reduced.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

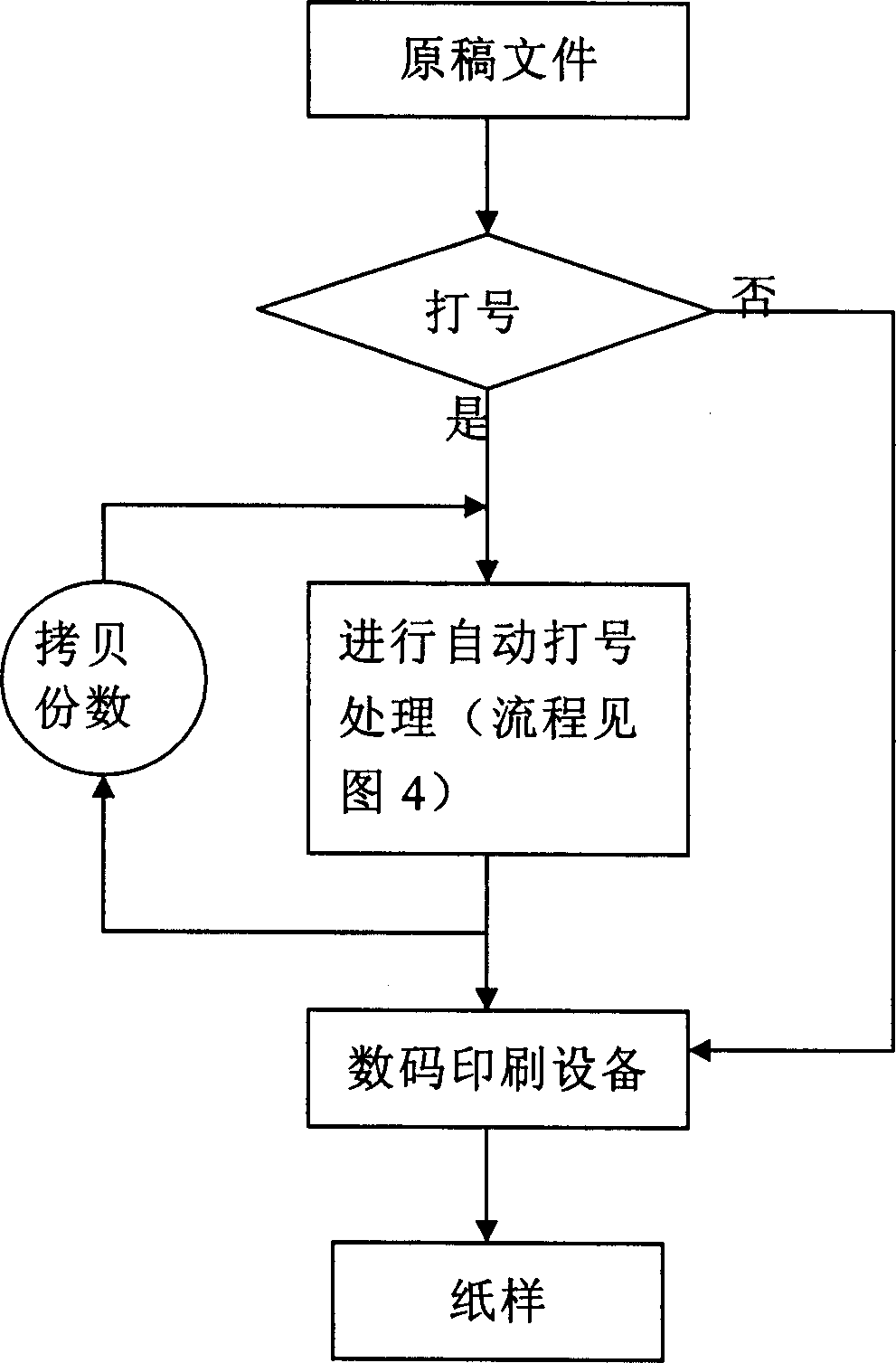

Processing method for automatic marking

ActiveCN1790253ARealize automatic printingImprove bindingDigital output to print unitsControl dataPrinting press

The invention discloses a self-marking method in the computer information disposal domain, which is characterized by the following: generating TrueType font according to the marking machine; forming the number data according to the control data; binding the file data and number data; outputting the entire file once through digital printer. The method displays high effective, automatic and flexible output effect through setting parameter and selecting font.

Owner:BEIJING FOUNDER ELECTRONICS CO LTD +1

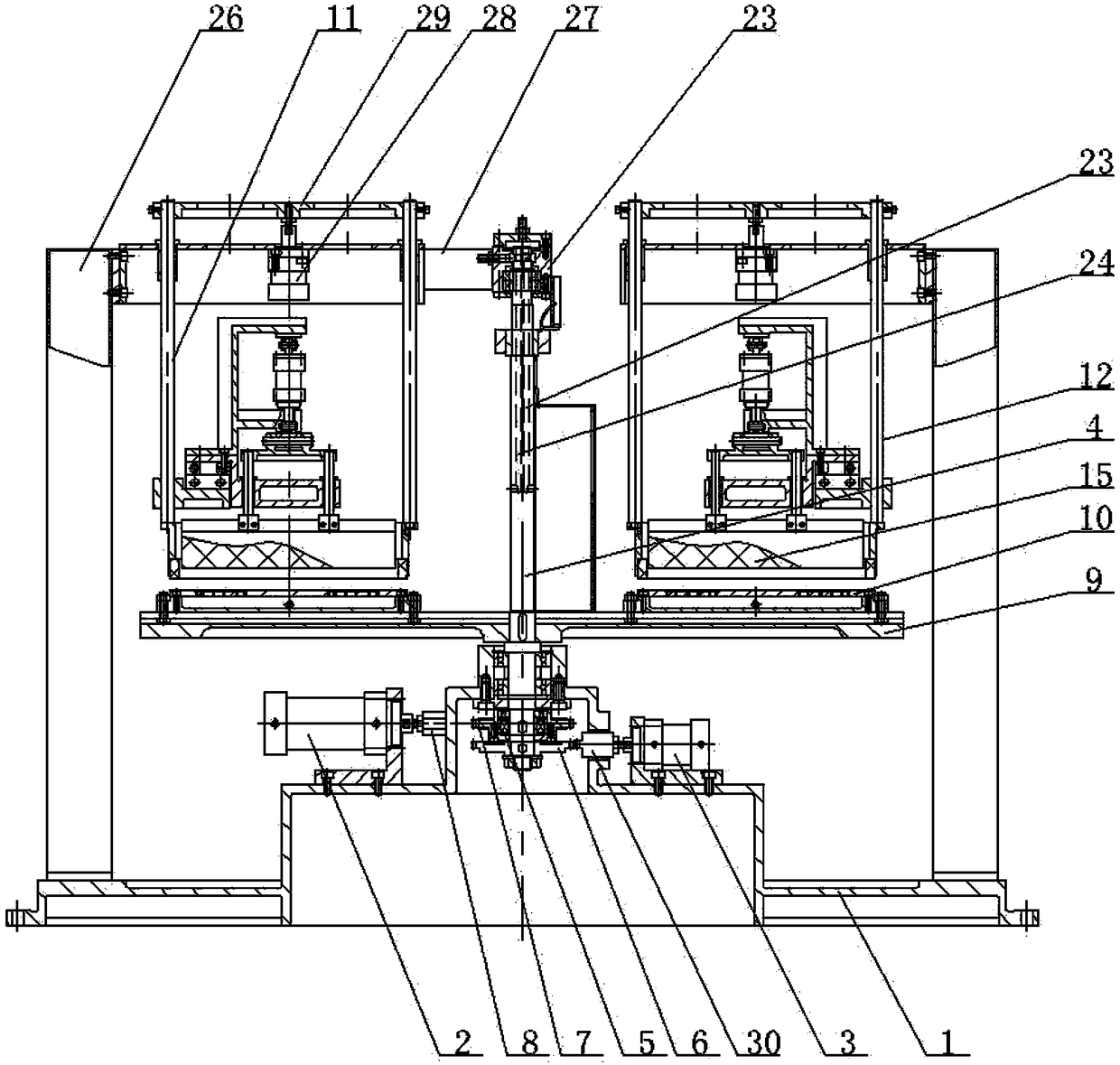

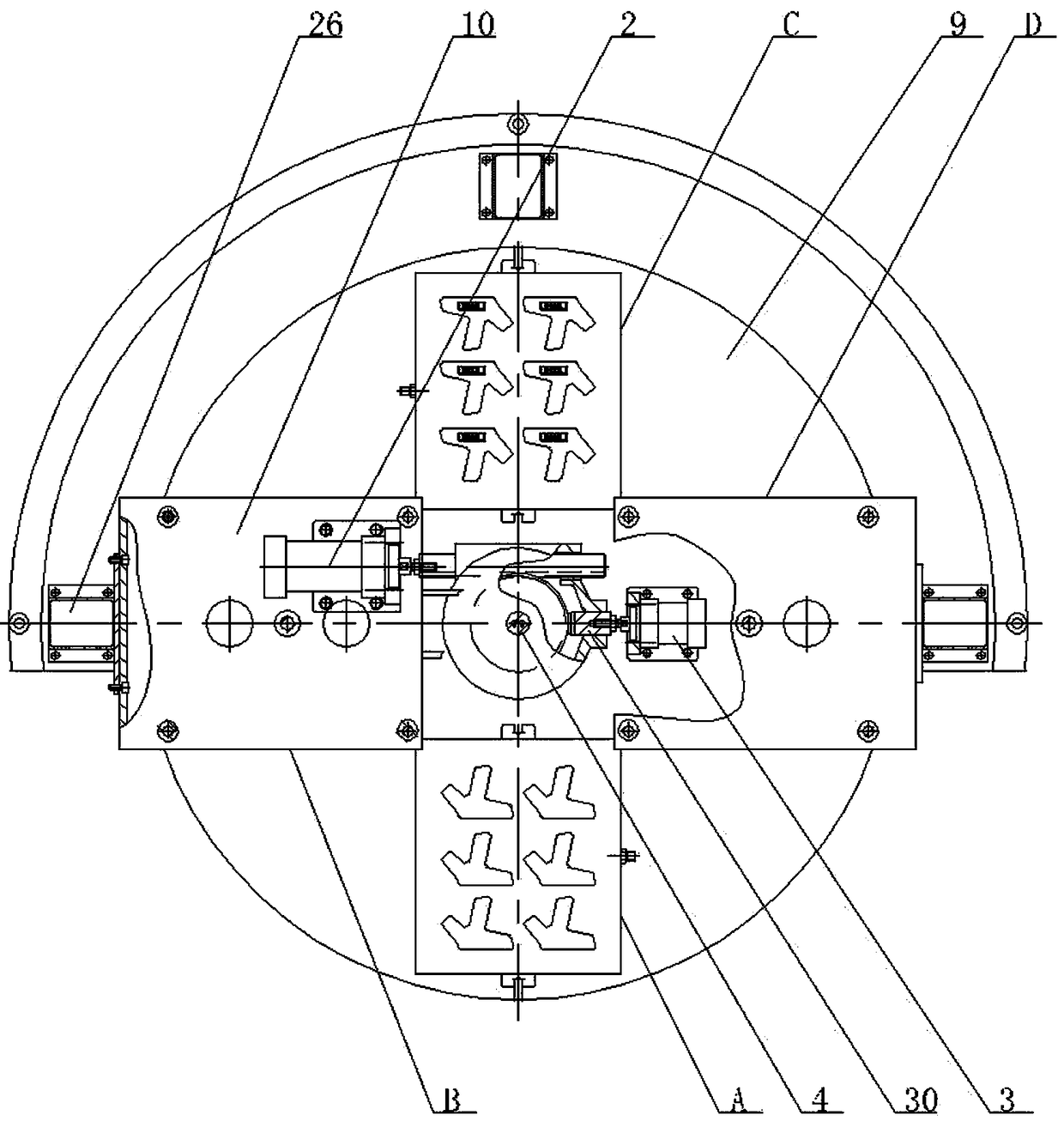

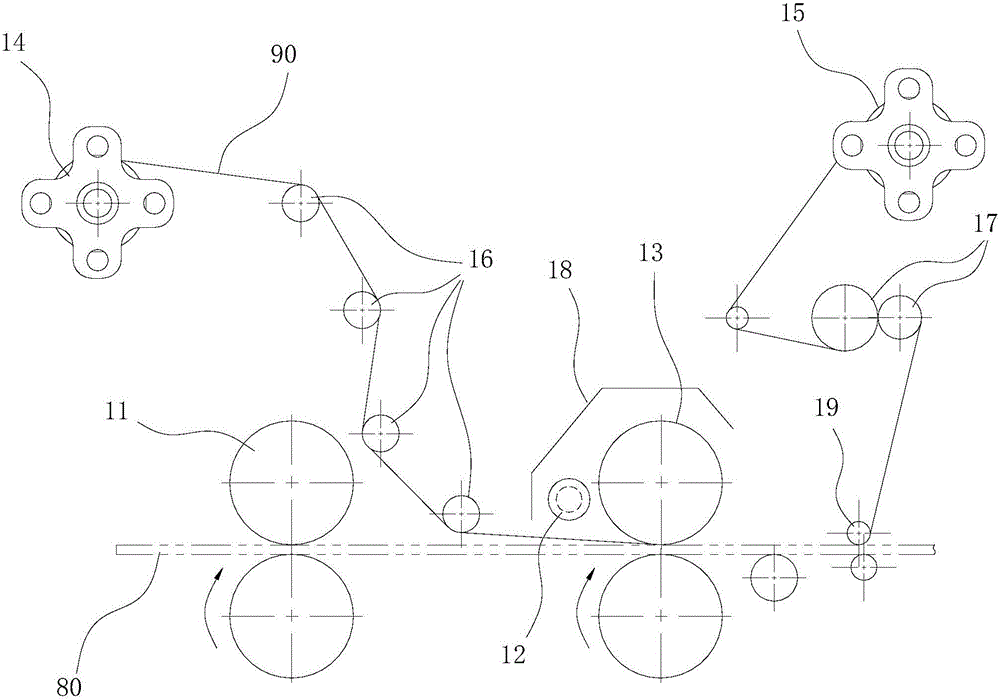

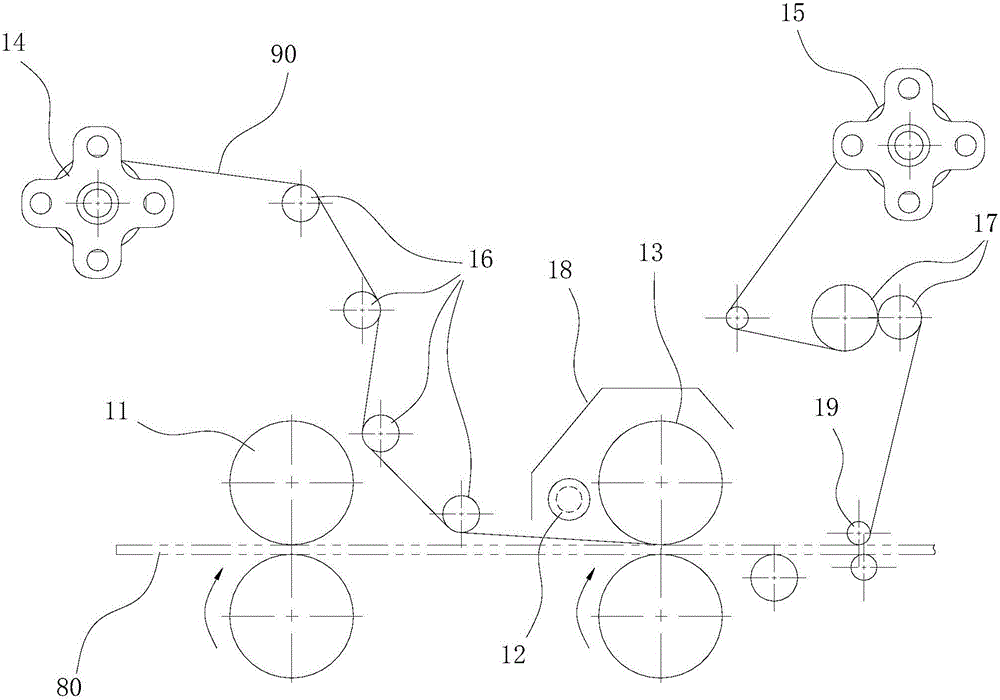

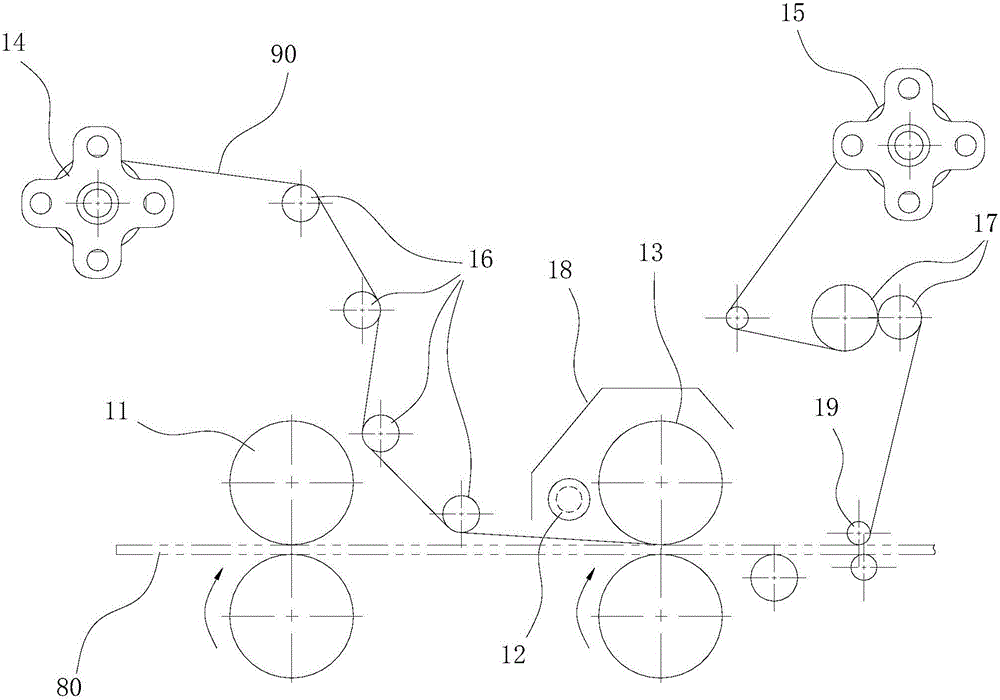

High-adaptability multi-color automatic screen printing machine

ActiveCN109177455ARealize automatic printingConsistent pressureScreen printersScreen printingEngineering

The invention relates to a high-adaptability multi-color automatic screen printing machine. The problems that when shoe ornament printing adopts manual operation, time and labor are wasted, the laborintensity of workers is high, the working efficiency is low, and the printing quality is poor are mainly solved. The high-adaptability multi-color automatic screen printing machine is characterized inthat an indexing air cylinder (2), a positioning air cylinder (3) and a central shaft (4) are installed on a machine base (1), four vacuum absorption workbenches (10) are evenly fixed to the upper portion of a rotation disc (9) in the circumferential direction, a first screen printing device (11) and a second screen printing device (12) are arranged on a first screen printing station (B) and a second screen printing station (D) respectively, scraper blades (15) are installed at the lower ends of scraper blade assemblies (21), the scraper blade assemblies (21) are connected with piston rods ofscraper blade vertical air cylinders (20), and infrared drying lamps (22) are arranged on drying stations (C). According to the high-adaptability multi-color automatic screen printing machine, automatic printing of shoe ornaments can be achieved, the working efficiency is effectively improved, the scraper blade pressing force is consistent, no color aberration can occur, and the printing qualityis good.

Owner:WENZHOU UNIVERSITY

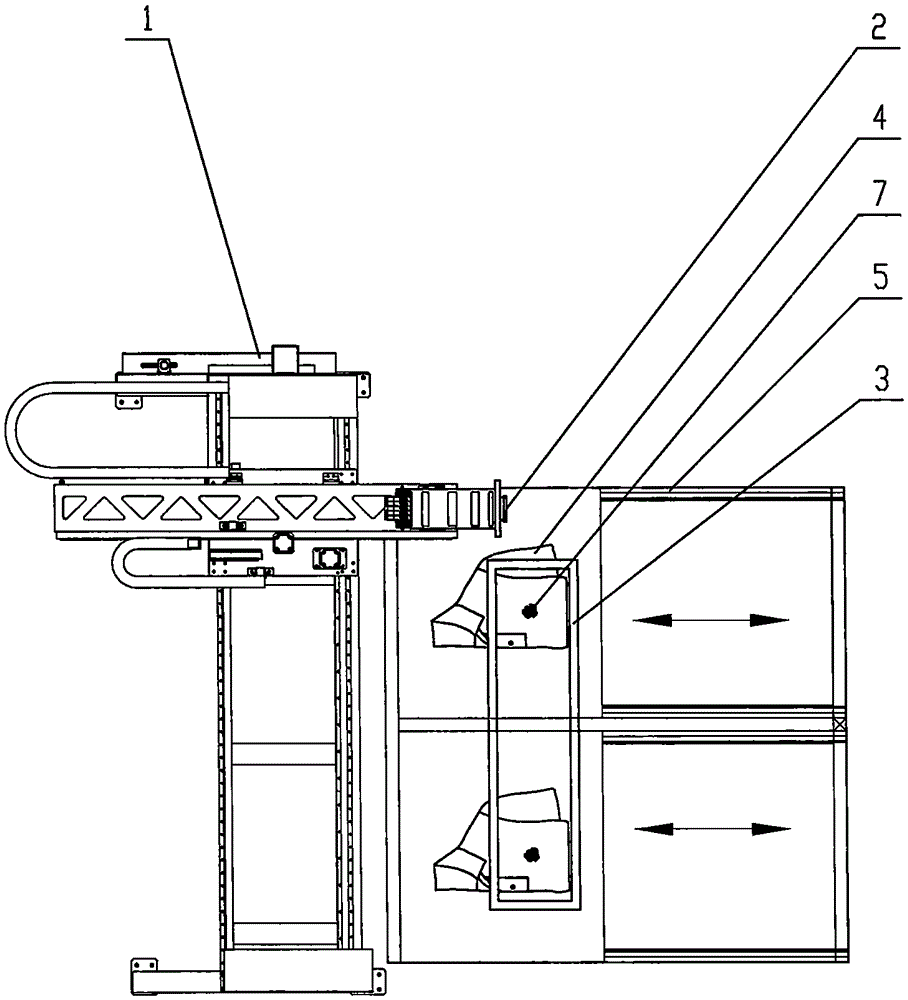

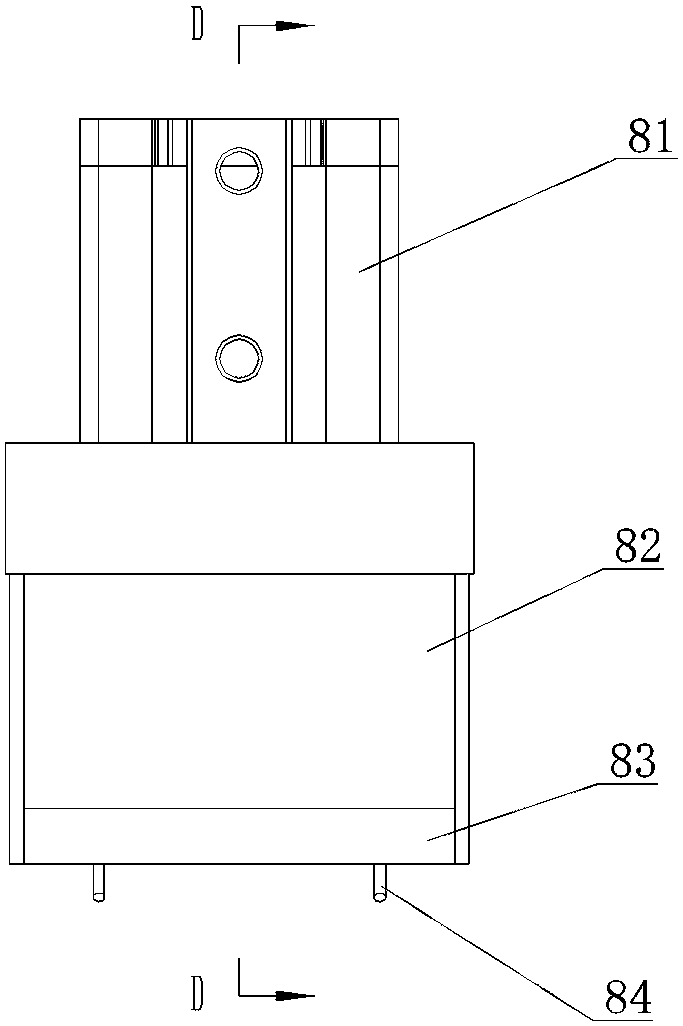

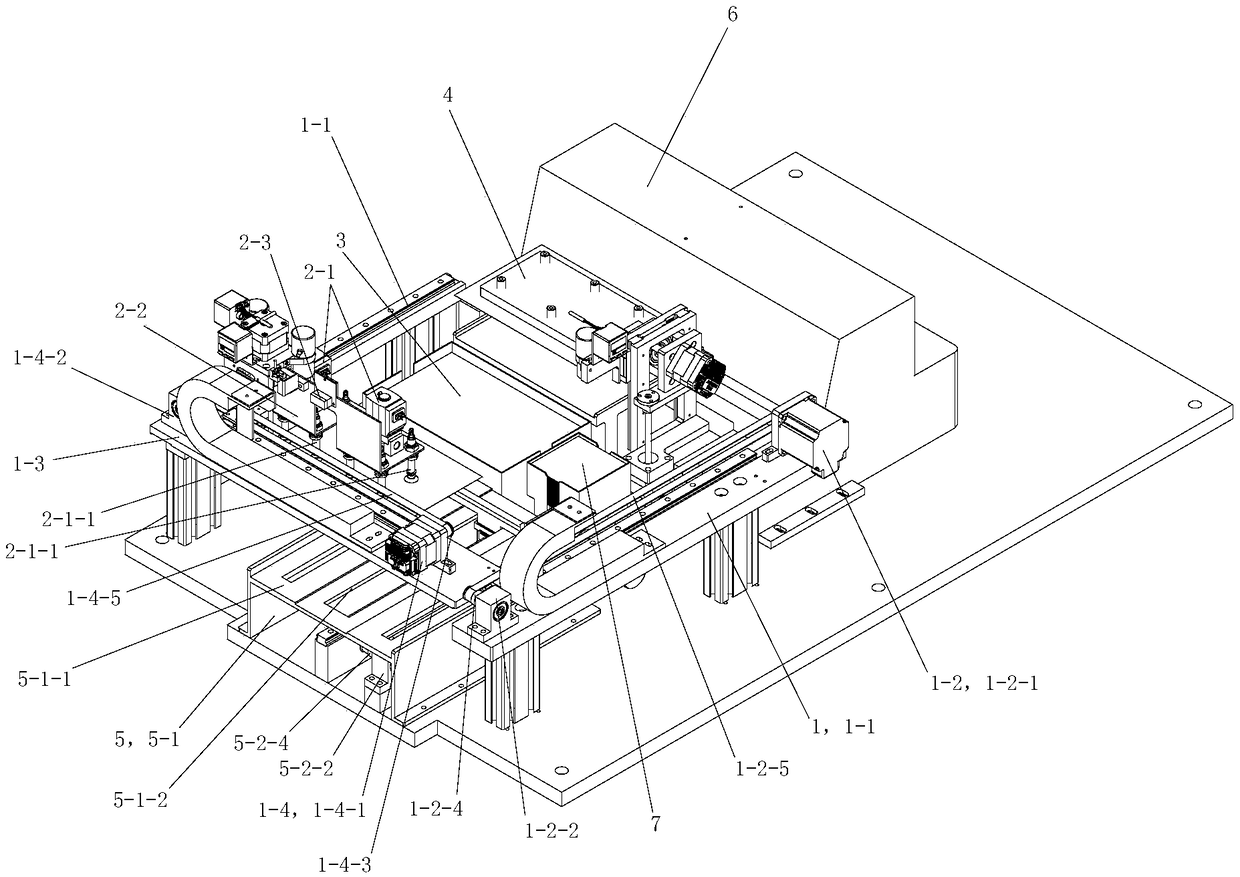

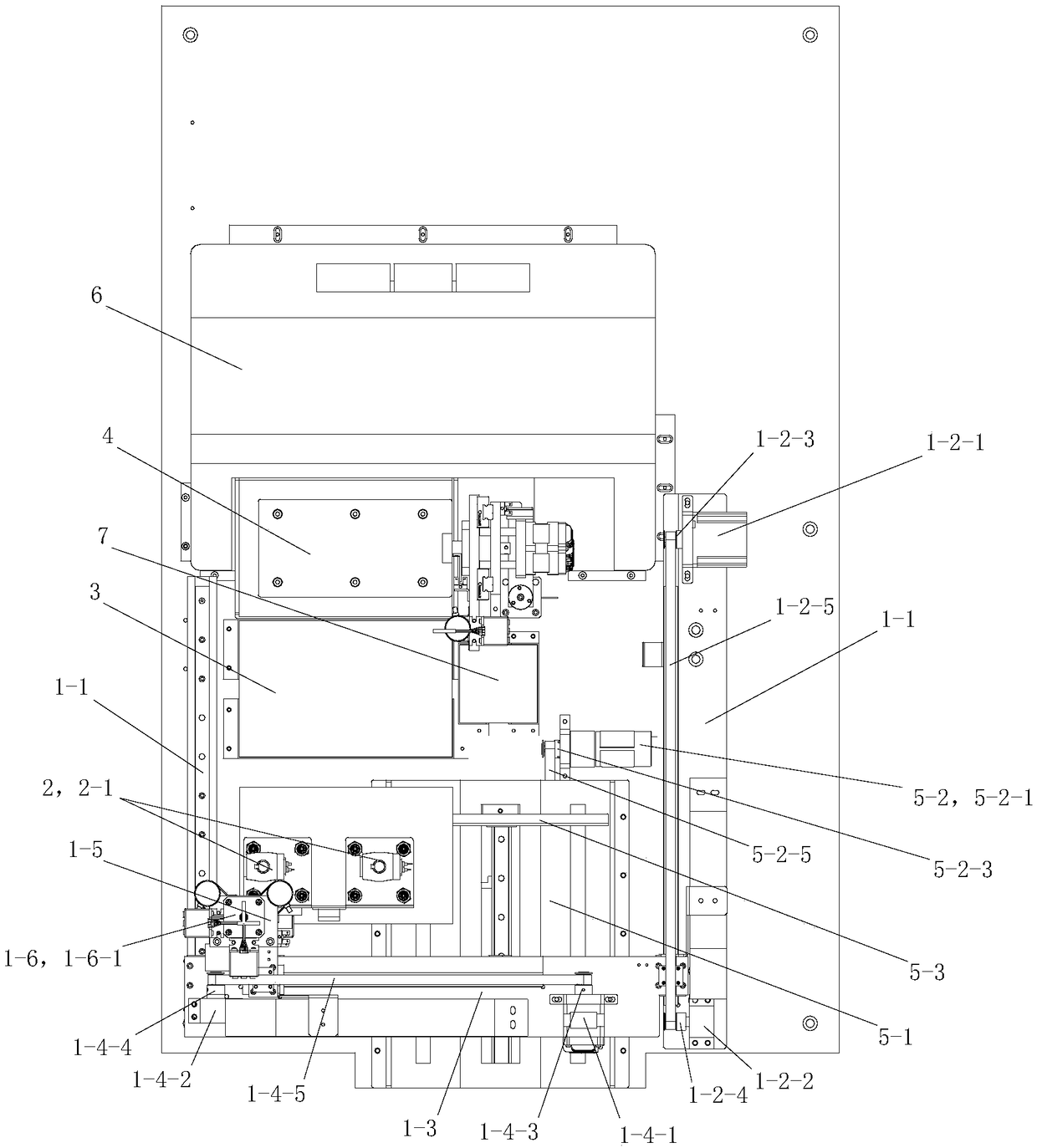

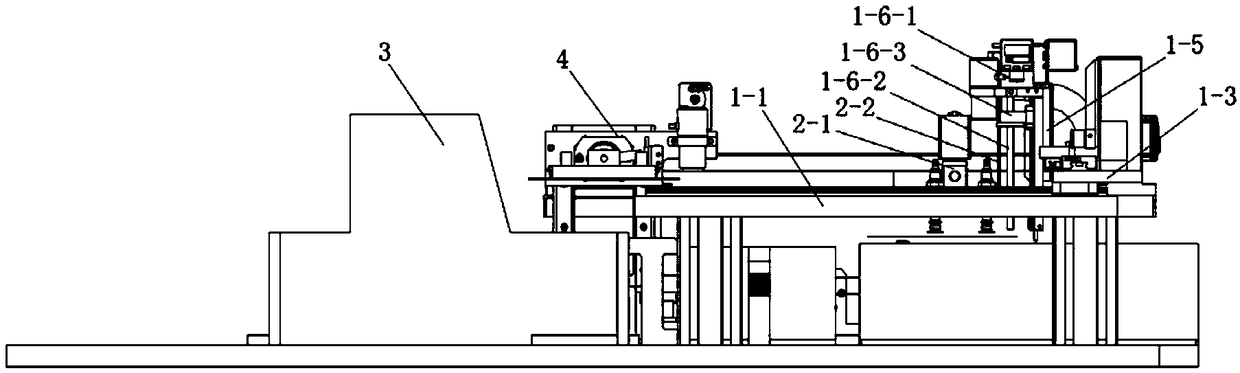

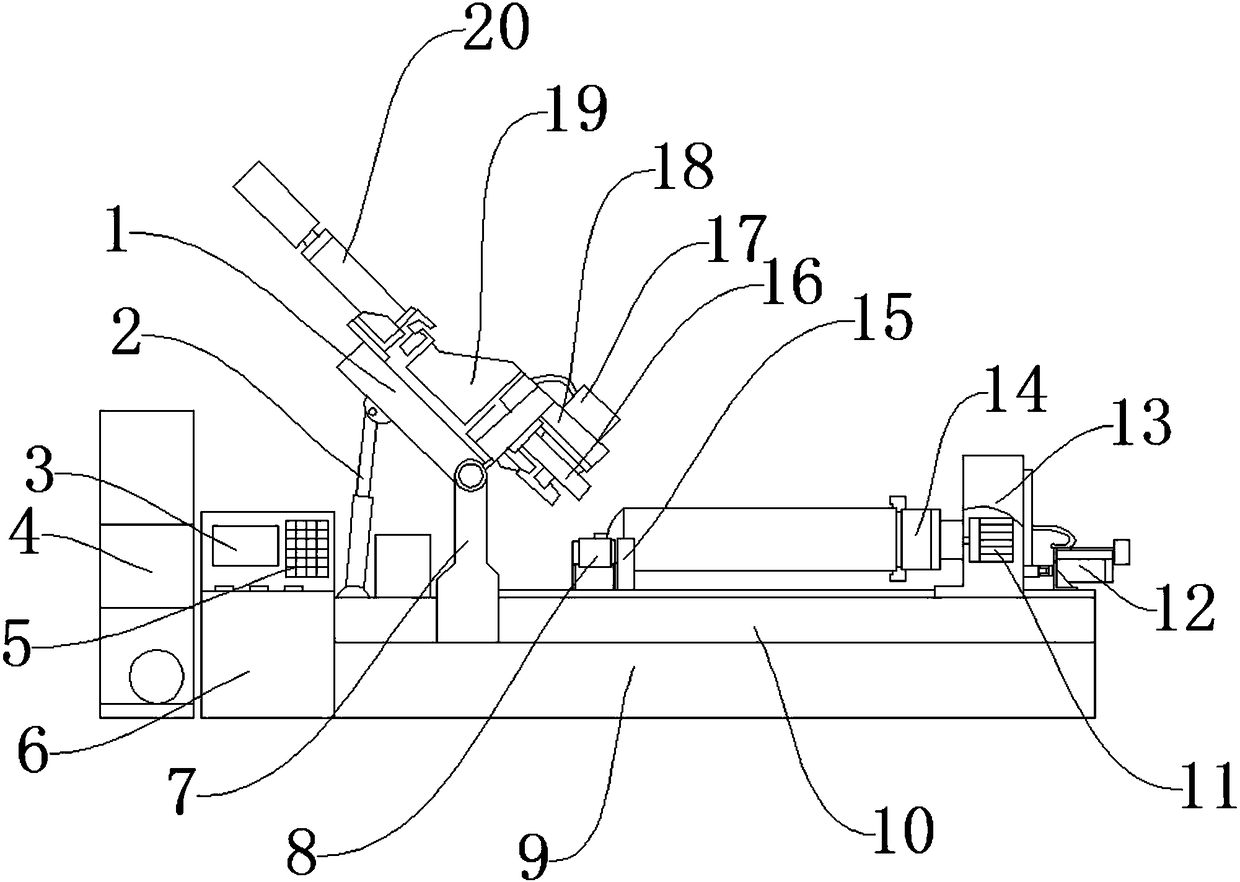

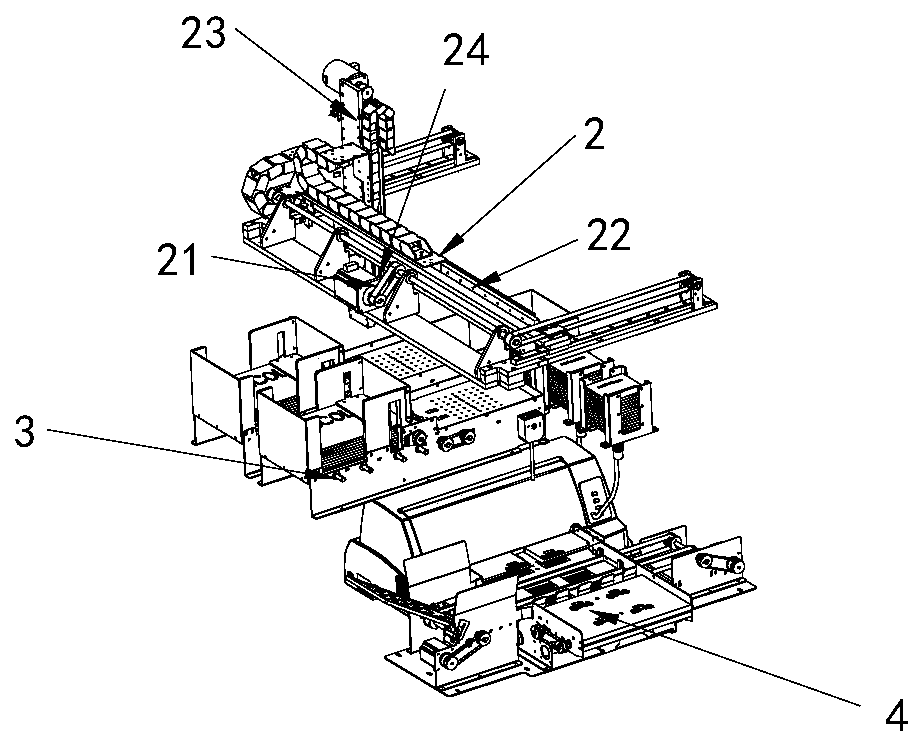

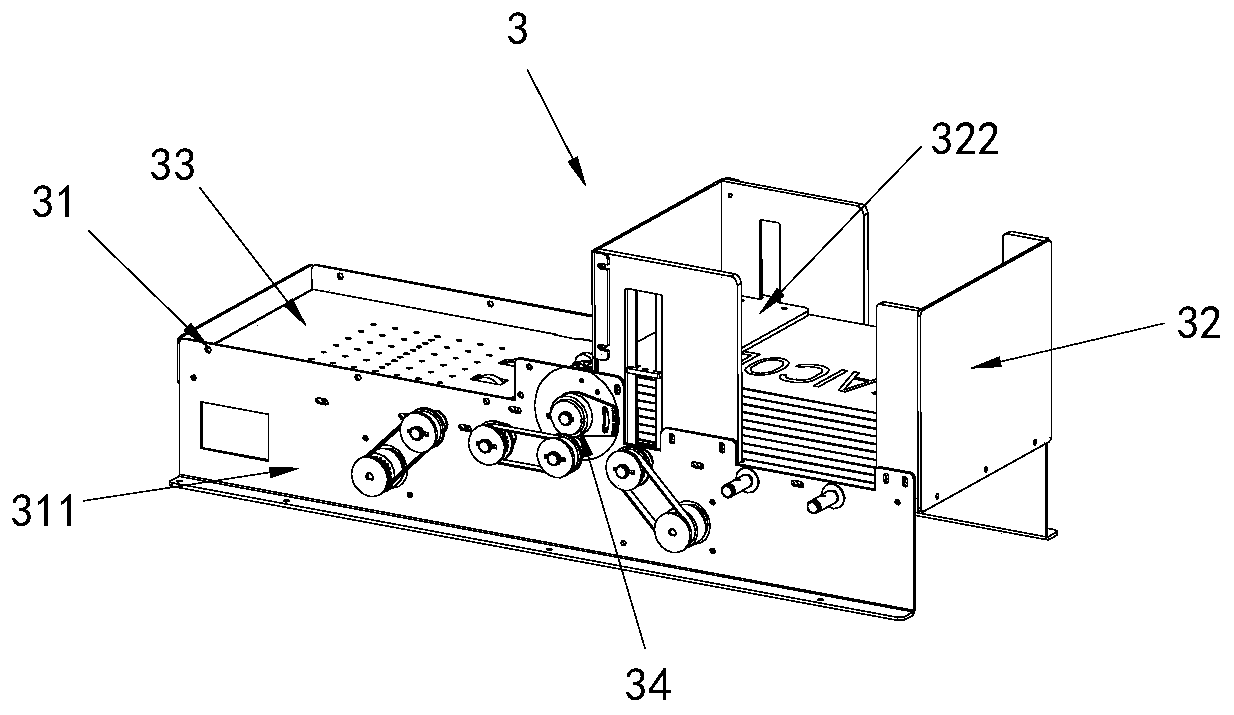

Temporary license plate issuing device

PendingCN109383138AIngenious structureImprove work efficiencyGripping headsTypewritersManipulatorEngineering

The invention discloses a temporary license plate issuing device, which comprises a displacement mechanism, a manipulator component, a temporary license plate storage bin, a printing mechanism, a turning mechanism and a discharging mechanism. The displacement mechanism drives the manipulator component to carry out XYZ triaxial movement; the temporary license plate storage bin, the printing mechanism, the turning mechanism and the discharging mechanism are all arranged within the moving range of the manipulator component; the manipulator component is used for grasping materials in the temporarylicense plate storage bin and putting the materials into a printing mechanism for printing; the turning mechanism is used for turning the materials requiring double-sided printing for re-printing after the single-sided printing is completed; the discharging mechanism is used for discharging the printed materials. The device has an ingenious structure, realizes the automatic printing of temporarylicense plates and pushing of the printed temporary license plates, does not need manual participation, and improves the working efficiency.

Owner:GUOGUANG ELECTRONICS INFORMATION TECH

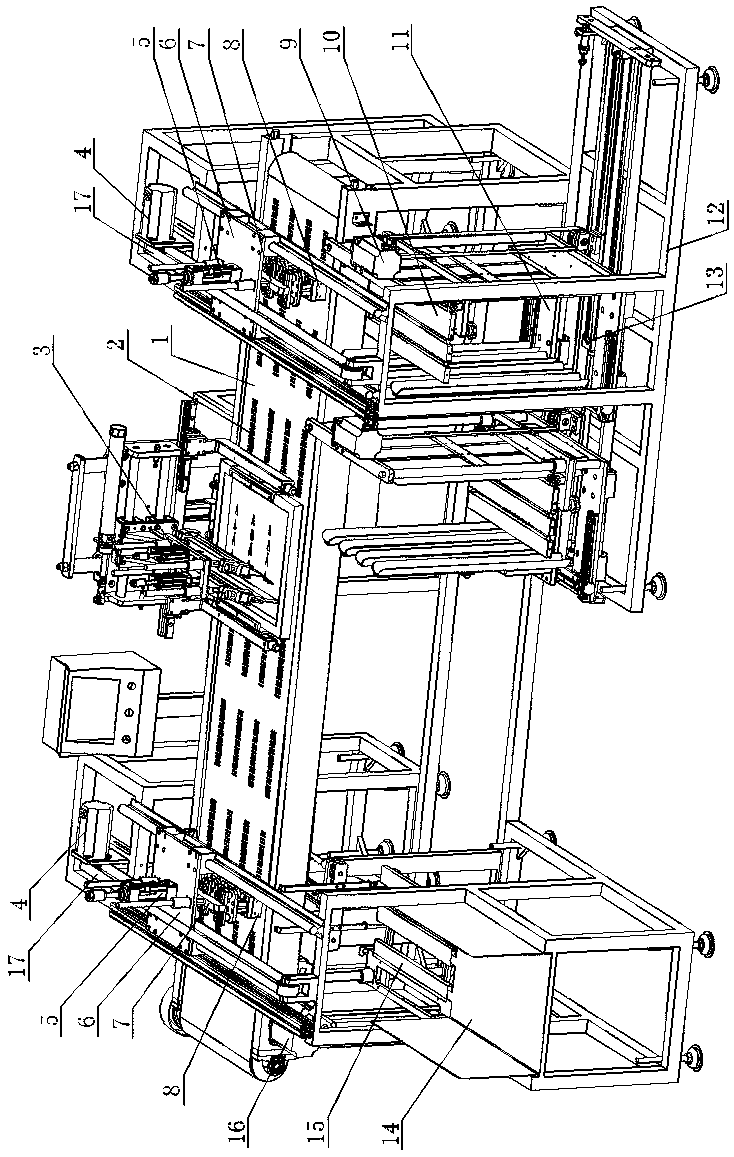

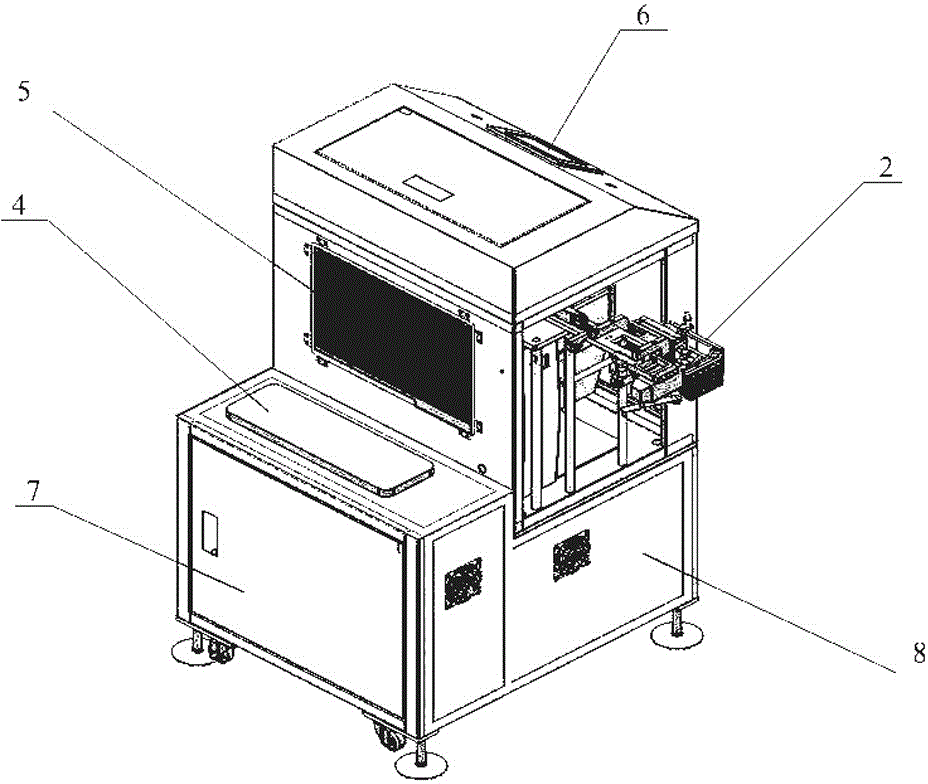

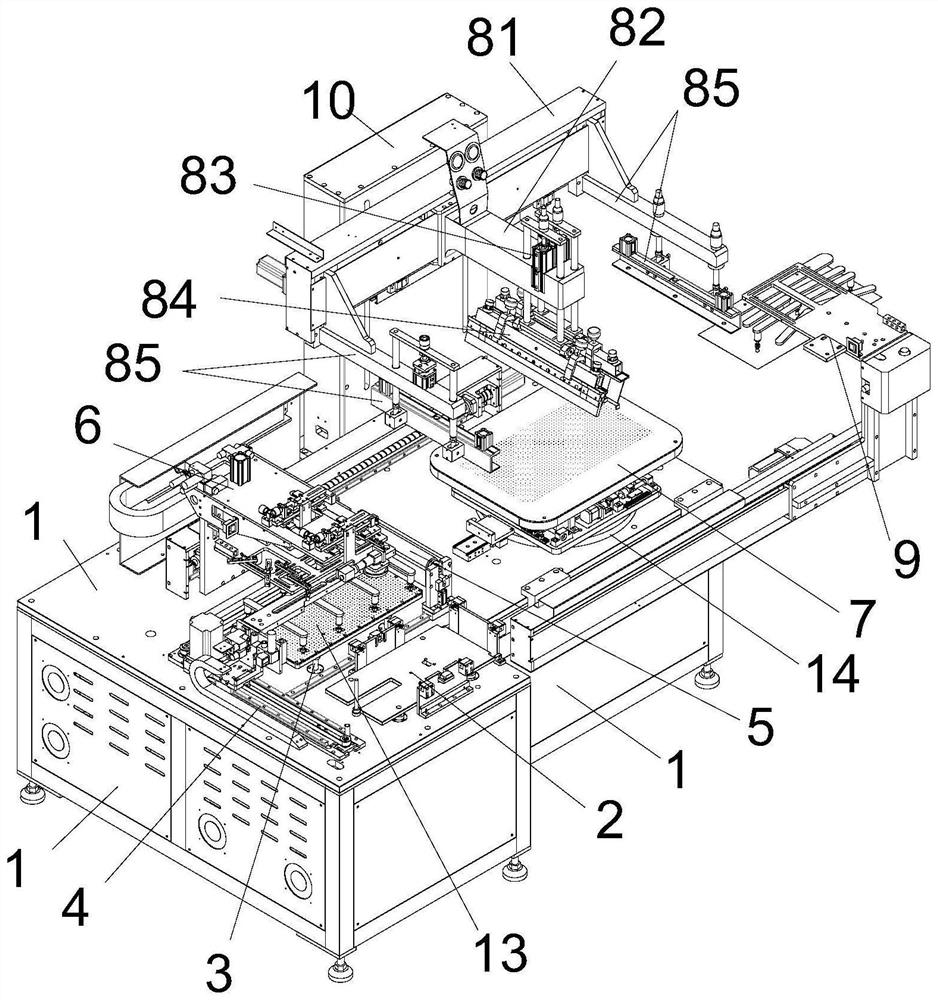

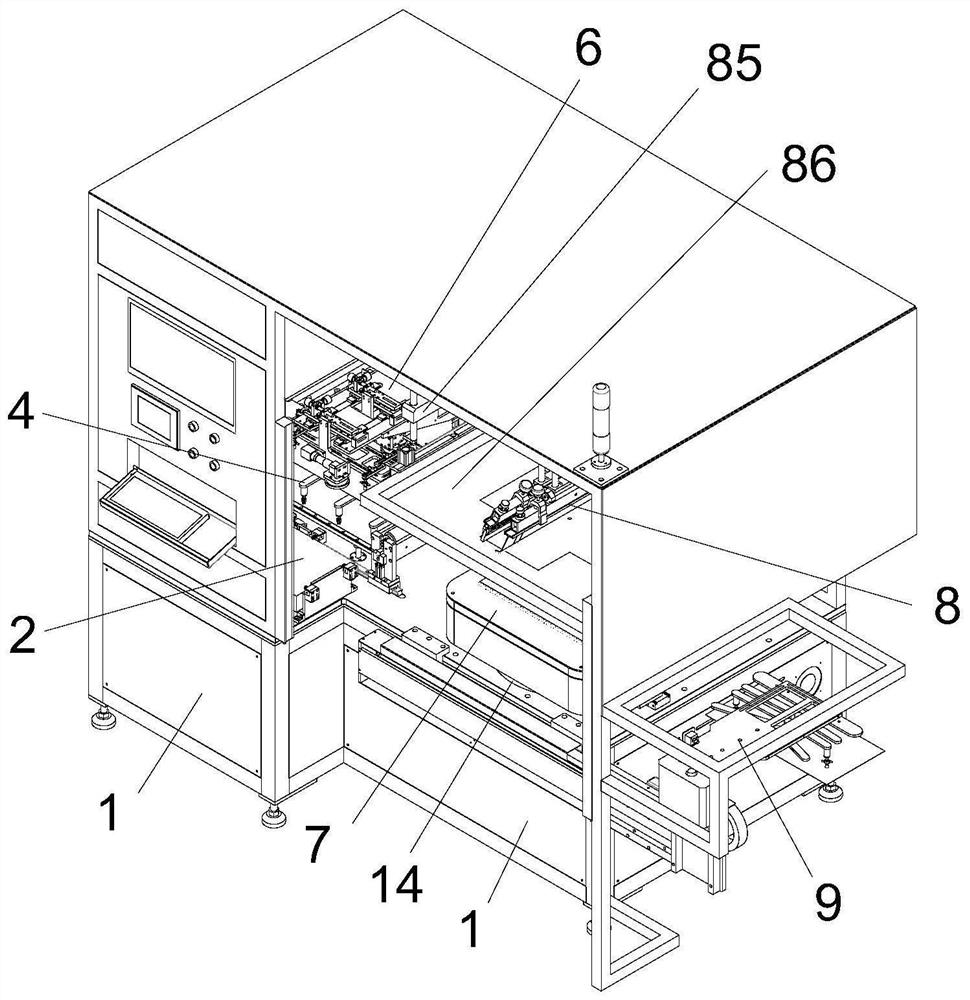

Automatic CCD printing machine

PendingCN111823703ARealize automatic printingAvoid manual loadingScreen printersConductive pattern formationDust controlPrinting press

The invention discloses an automatic CCD printing machine and relates to the technical field of printing. A machine cabinet is included; a lifting material stack mechanism, a feeding turning connection table, a first feeding mechanism, a dust removing mechanism, a second feeding mechanism, a printing platform, a printing mechanism and a discharging mechanism are installed above the machine cabinet; the lifting material stack mechanism is arranged in front of the feeding turning connection table; the first feeding mechanism is arranged on the left of the feeding turning connection table and thelifting material stack mechanism; the feeding turning connection table is arranged on the middle portion of the dust removing mechanism; the printing platform is arranged on the right of the feedingturning connection table; the second feeding mechanism is arranged behind the printing platform and the feeding turning connection table; the rear portion of the printing mechanism is fixedly providedwith a lifting mechanism; the lower end of the lifting mechanism is fixedly installed on the rear portion of the machine cabinet; the printing mechanism is arranged above the printing platform; the discharging mechanism is arranged in front of the printing platform; and the right end of the discharging mechanism extends out of the machine cabinet to be arranged. Manual feeding and discharging areavoided, and the positioning precision and the overall printing efficiency are improved.

Owner:深圳市欣荣自动化智能设备有限公司

Locating and conveying cutting equipment of eraser strip

ActiveCN106042057ARealize automatic printingRealize the cutting operationMetal working apparatusReciprocating motionBarrel Shape

The invention relates to the technical field of eraser producing and machining, in particular to locating and conveying cutting equipment of an eraser strip. The locating and conveying cutting equipment comprises a stamping device, a guide-in device and a stroke detection unit. The stamping device comprises a stamping die and an intermittent feed mechanism. The stamping die comprises a barrel-shaped tool. The barrel-shaped tool does reciprocating motion in the vertical direction and is used for obtaining eraser blocks on the flat eraser strip in a blanking manner. The intermittent feed mechanism is used for conveying the flat eraser strip to feed the flat eraser strip intermittently towards the portion below the stamping die; and according to the specific process, the flat eraser strip is fed forwards when the barrel-shaped tool ascends, and feeding of the flat eraser strip is stopped when the barrel-shaped tool descends. According to the locating and conveying cutting equipment, automatic printing and cutting operation of an eraser can be achieved, no manual operation is needed in the production process, and the production efficiency is greatly improved.

Owner:宿州市超晟文具有限公司

Manual feeding-discharging steel cylinder roll-printing device

InactiveCN108928143ARealize automatic printingHigh degree of intelligenceStampingEngineeringSteel cylinder

The invention discloses a manual feeding-discharging steel cylinder roll-printing device which comprises a base and a rolling print wheel. A sliding rail is arranged on the base, a sliding seat is arranged on the tail portion of the sliding rail, and a servo motor is arranged in the sliding seat. A fixing chuck is arranged at the front end of the sliding seat, and a tail oil cylinder is arranged on the rear portion of the sliding seat. A bottle head rotating roller is arranged above the head portion of the sliding rail, and a bottle body support is arranged on the side, close to the sliding seat, of the bottle head rotating roller. A supporting seat is arranged above the head portion of the sliding rail, an upper seat is arranged above the supporting seat, and an upper sliding seat is arranged on the upper seat. A character pressing oil cylinder is arranged on the rear portion of the upper sliding seat, a print wheel fixing seat is arranged at the front end of the upper sliding seat, and the rolling print wheel is arranged on the lower surface of the print wheel fixing seat. The manual feeding-discharging steel cylinder roll-printing device has the beneficial effects that the roll-printing lettering work can be automatically completed, automatic stamping can be realized, the intelligent degree is high, the operation is easy and convenient, and the working efficiency is improved.

Owner:浙江昌兴科技有限公司

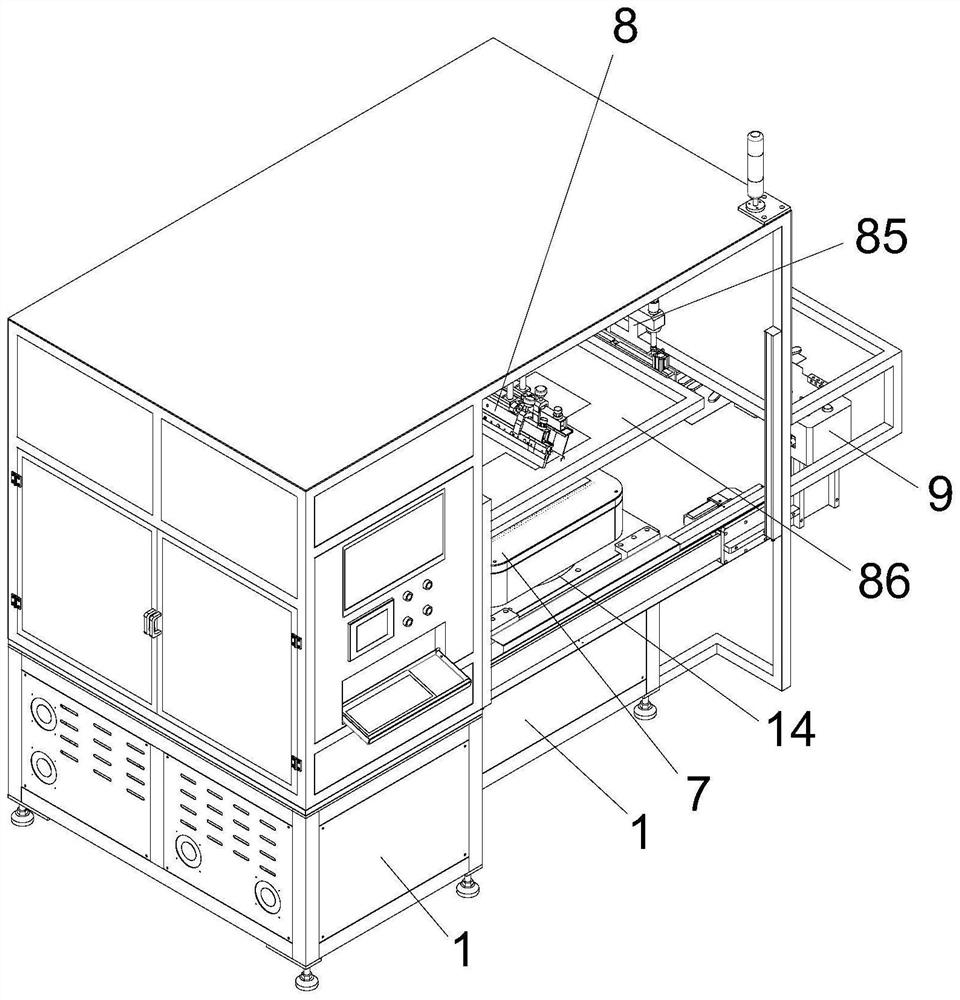

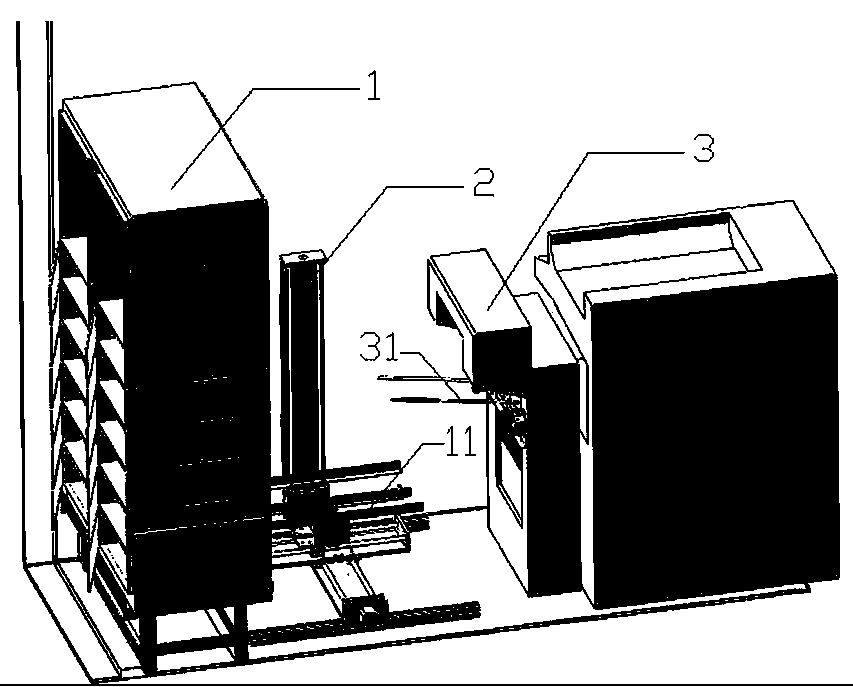

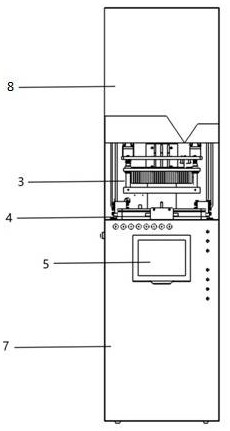

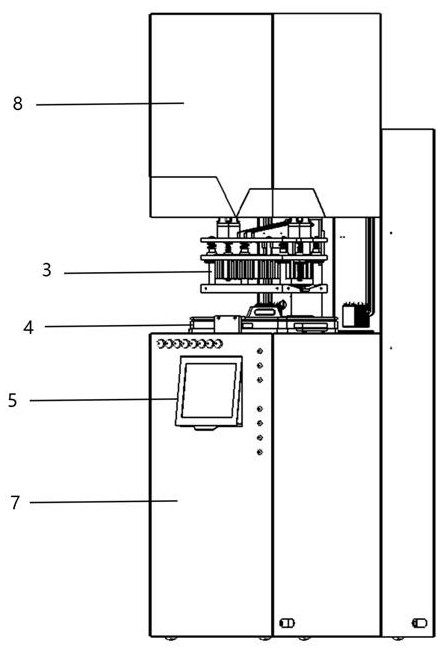

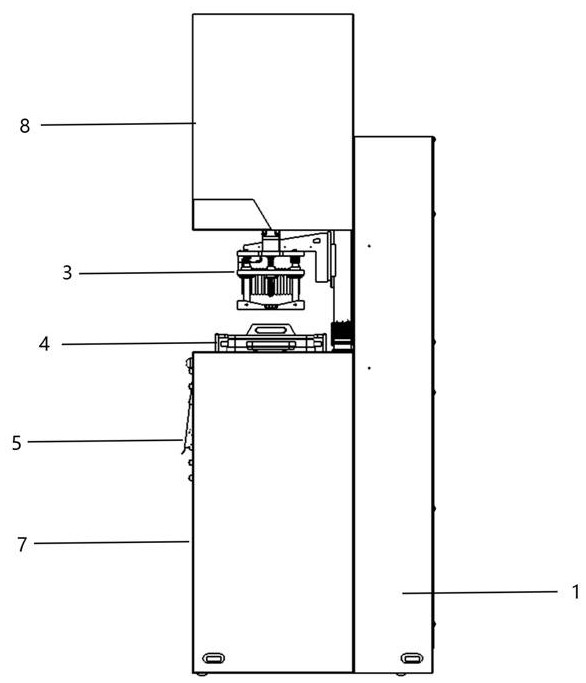

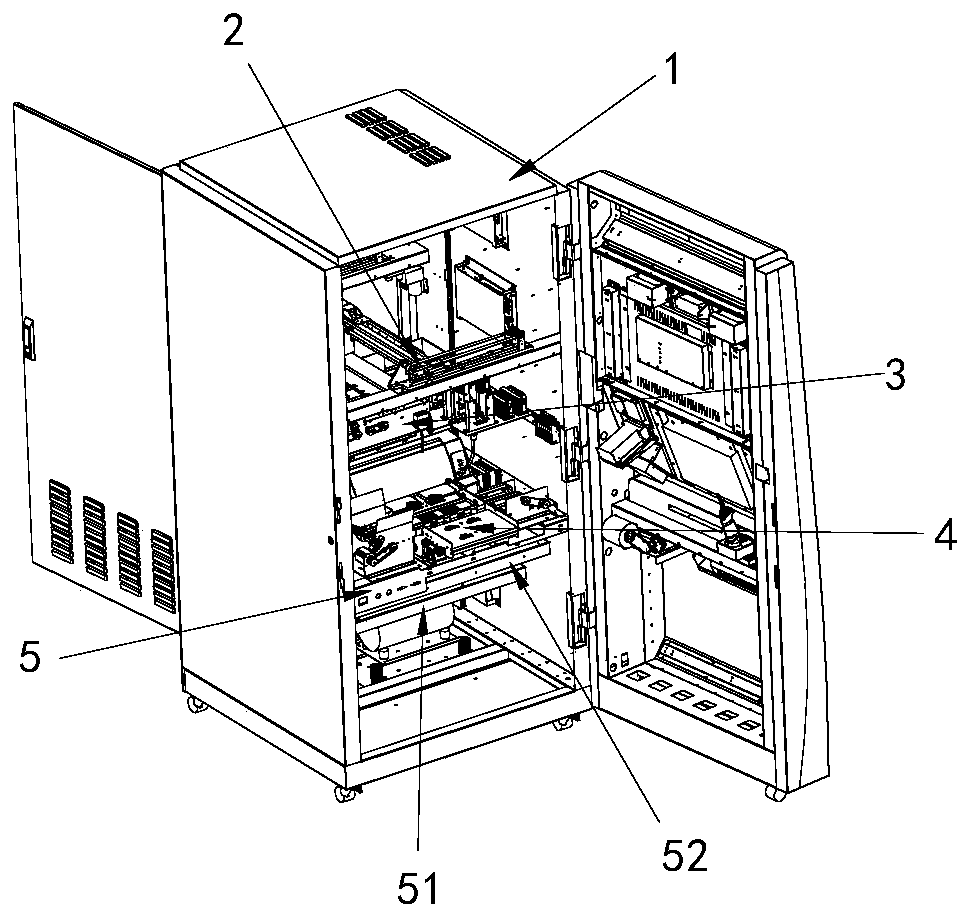

Intelligent printing cloud cabinet

PendingCN110154551ARealize automatic printingNo human interventionProgramme-controlled manipulatorTypewritersEngineeringManipulator

The invention relates to an intelligent printing cloud cabinet and belongs to the technical field of automatic office supplies. The intelligent printing cloud cabinet comprises an automatic storage cabinet part, a three-coordinate transportation part and a printing output part, wherein the three-coordinate transportation part is arranged between the automatic storage cabinet part and the printingoutput part and is used for transporting printed finished paper of the printing output part to the automatic storage cabinet part; a user can perform network printing through the Wechat public platform, the intelligent printing cloud cabinet automatically stores the printed finished paper in batches and independently, and finally the user can extract the paper intelligently through a mobile client, so that network printing, batch filing and code scanning extraction are available for multiple users in the same time period or in different time periods without attending by a special person, and accordingly the users do not need to wait in lines. The intelligent printing cloud cabinet is a modern office facility integrating printing equipment, a manipulator and a storage cabinet.

Owner:上海市工业技术学校

Eraser machining equipment

ActiveCN106113459AIncrease productivityRealize automatic printingMetal working apparatusEngineeringMachining

The invention relates to the technical field of eraser production and machining, in particular to eraser machining equipment. The eraser machining equipment comprises a pattern pasting device, a stamping device, a leading-in device, a holding mechanism, a stroke detection unit and a stamping die driving mechanism. The stamping device comprises a stamping die and an intermittent feeding mechanism. The stamping die comprises a cylindrical tool. The cylindrical tool moves back and forth in the vertical direction and is used for cutting eraser blocks from a flat eraser strip through blanking. The intermittent feeding mechanism is used for conveying the flat eraser strip and feeding the flat eraser strip to the position below the stamping die intermittently. Specifically, when the cylindrical tool is lifted, the flat eraser strip is fed forwards; and when the cylindrical tool falls, the flat eraser strip stops being fed. By the adoption of the eraser machining equipment, automatic printing and cutting of erasers can be achieved, manual operation is not needed in the production process, and the production efficiency is greatly improved.

Owner:宿州市超晟文具有限公司

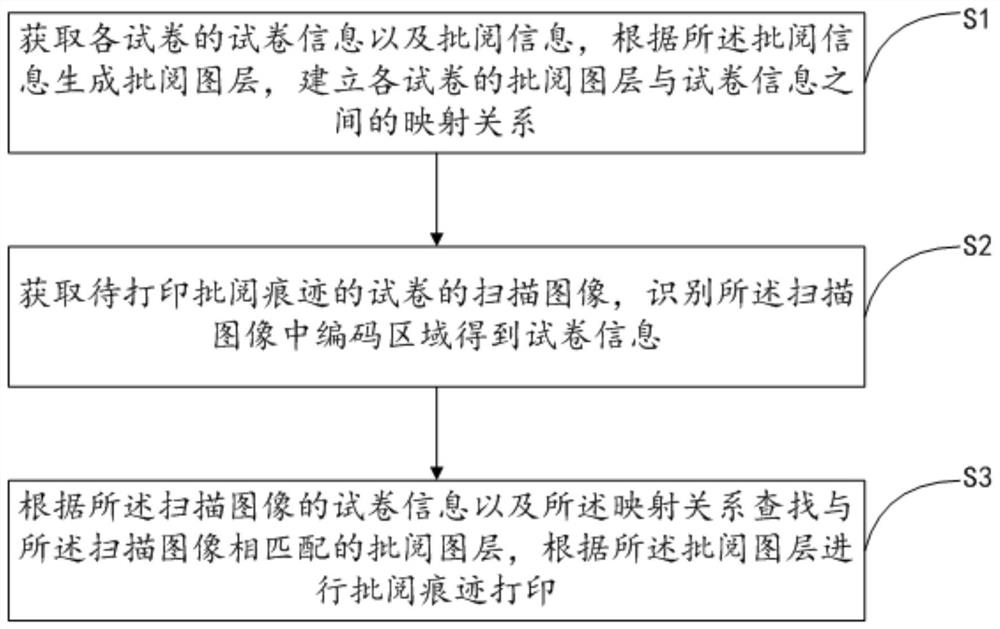

Method and device for printing test paper marking traces

PendingCN112000300ARealize automatic printingAccurate printingCharacter and pattern recognitionDigital output to print unitsAlgorithmIndustrial engineering

The invention relates to the technical field of electronic paper marking, and discloses a method for printing test paper marking traces, which comprises the following steps of: obtaining test paper information and marking information of each piece of test paper, generating a marking layer according to the marking information, and establishing a mapping relationship between the marking layer of each piece of test paper and the test paper information; obtaining a scanning image of test paper with to-be-printed marking traces, and identifying a coding region in the scanning image to obtain test paper information; according to the test paper information of the scanning image and the mapping relationship, searching a review layer matched with the scanning image, and printing a review trace according to the review layer. The method and the device have the technical effect of high marking trace printing efficiency of electronic paper marking.

Owner:武汉诺必答科技有限公司

LCD light-curing 3D printer

InactiveCN112339267AHigh speedIncrease printing speedAdditive manufacturing apparatus3D object support structuresComputer control systemComputer printing

The invention discloses an LCD light-curing 3D printer. The LCD light-curing 3D printer comprises a rack, a stripping system, a molding platform, an LCD display screen, a box body, a light source system, a computer control system, a material slot and a lifting device, wherein the rack is used for mounting a printer assembly; the stripping system is used for stripping a printed product from the molding platform; the molding platform is taken as a molding plane of the printed product; the LCD display screen is used for receiving a 3D component model; the box body is used for mounting a light source system and a computer control system; the light source system is used for generating light, and irradiating a layered picture in the model to the bottom of the molding platform, so that the light-curing material is cured into a corresponding pattern cured layer; the computer control system is used for controlling operation of a printer; the material slot is used for storing the light-curing material; and the lifting device is used for regulating a distance between the stripping system and the material slot. The 3D printer disclosed by the invention has the advantages of being high in printing precision, high in speed, great in printing dimension, long in service life and the like.

Owner:上海幻嘉信息科技有限公司

Comprehensive eraser processing equipment

ActiveCN106113152ARealize automatic printingRealize the cutting operationTransfer printingMetal working apparatusMechanical engineeringEngineering

The invention relates to the technical field of eraser producing and processing, in particular to comprehensive eraser processing equipment which comprises a pattern pasting device, a stamping device, a guiding-in device, a holding mechanism and a travel detecting unit. The stamping device comprises a stamping die and an intermittent feeding mechanism; the stamping die comprises a cylindrical tool which reciprocates in the vertical direction and is used for stamping eraser blocks out of a flat eraser strip; and the intermittent feeding mechanism is used for conveying the flat eraser strip and feeding the flat eraser strip to the position below the stamping die in an intermittent mode, specifically, when the cylindrical tool is lifted, the flat eraser strip is fed forwards, and when the cylindrical tool falls, the flat eraser strip is stopped feeding. By means of the comprehensive eraser processing equipment, automatic printing and cutting of erasers can be achieved, manual operation is not needed in the production process, and the production efficiency is greatly improved.

Owner:宿州市超晟文具有限公司

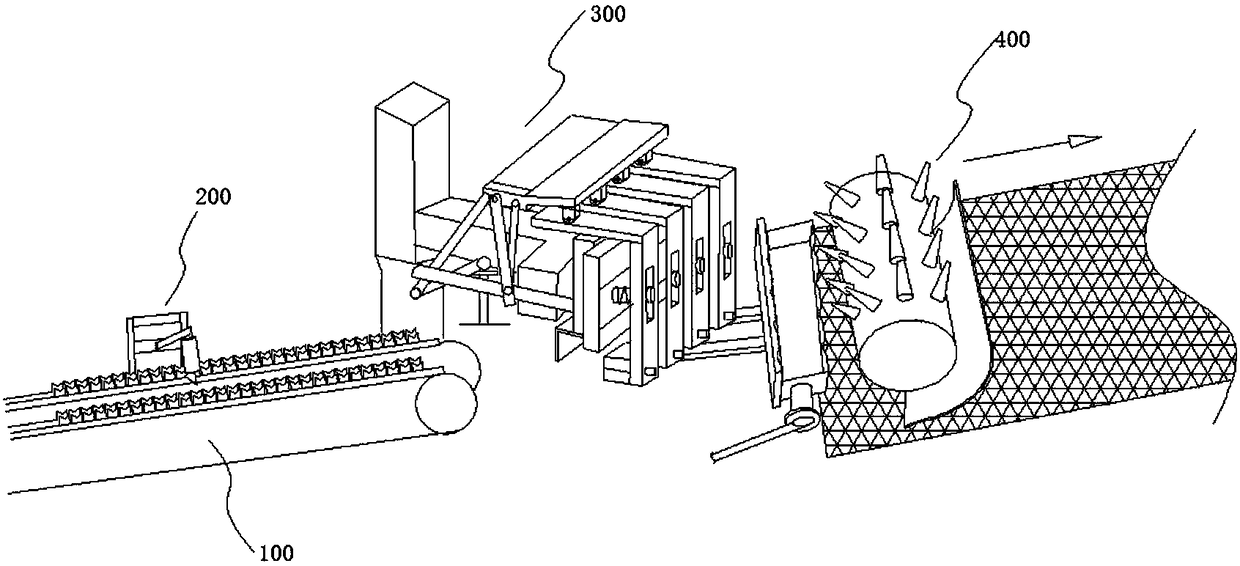

Full-automatic machine for installing hectometer piles

ActiveCN113005938AAccurate locationLow costSpraying apparatusSoil-shifting machines/dredgersElectric machineryDrill bit

A full-automatic machine for installing hectometer piles comprises a vehicle body part, a driving mechanism, a pit digging mechanism, a soil collecting and filling mechanism, a spraying mechanism and a pile placing mechanism. When earth cutting is needed, the driving mechanism drives the pit digging mechanism to move to the position of the round hole in the bottom of the vehicle shell, meanwhile, the driving mechanism drives the pit digging mechanism to move up and down, and a pit can be dug at a certain depth, so that a drill bit drills earth and digs the pit at the same time, a traditional earth cutting mode is abandoned, a machine is adopted for automatic earth cutting, and the position is accurate; the defects of a large excavator are overcome, and the cost is reduced; when a plurality of hectometer piles are needed and the hectometer piles at the rear position in the pile placing frame are used up, a motor in an upper control plate is started to drive a cam to rotate, then a small push plate on one side moves leftwards, the small push plate pushes the hectometer piles to move, the hectometer piles fall into a pile lowering pipeline from a square hole in the lower end of the pile placing frame, and the hectometer piles can be continuously installed; and the hectometer piles are automatically placed, so that the working time is greatly saved, and the manpower is saved.

Owner:MINGDA MARINE ENG CO LTD

Continuous automatic ink printing and baking device

InactiveCN108569020ARealize automatic printingRealize automatic handlingScreen printersScreen printingScreen printingEngineering

The invention discloses a continuous automatic ink printing and baking device which comprises a conveyor belt, a stamp seal assembly, a transferring mechanical arm and a baking and conveying assembly.The total structure of the device disclosed by the invention is of a cam-linkage transmission manner, the operating reliability is high, and the cost is low; automatic printing on the bottle surfacecan be realized, and the bottle body and a silk-screen printing template can synchronously move, so that printing specifications are regular; the bottle body can be automatically transported, and thebottle body can be in a vertical state while entering a conveyor mesh chain of a baking oven, so that the ink can be uniformly baked, and the two-tone color problem of the ink is solved.

Owner:江苏伊度医疗科技有限公司

A packaging and printing equipment

ActiveCN105109197BSlide up and down smoothlyIncrease printing speedRotary pressesSolenoid valvePrinting press

The invention proposes a packaging and printing equipment, which includes a worktable, a feeding mechanism, a feeding mechanism, a sensor, a column, a printing machine base, a printing machine, an inking device and a controller; two Columns, the four columns are arranged in a quadrangular shape; the printing machine base is slidably set on the four columns, the printing machine is fixed under the printing machine base, and is facing the workbench, and the printing machine includes a printing body and a soft printing plate; There is a support plate on the top of the column, the support plate is located above the printing machine base, a cylinder is arranged on the support plate, and the output end of the cylinder is connected with the printing machine base; the inking device is arranged on the boss on the side of the column, including ink cartridges, ink Tube, solenoid valve, ink feeding brush and second driving mechanism; feeding mechanism, unloading mechanism, sensor, cylinder, second driving mechanism and solenoid valve are respectively connected with the controller. The invention has the advantages of simple structure, practicality and reliable operation, and realizes automatic printing by controlling various mechanisms to work in coordination through a controller.

Owner:安徽聚祥升酒类包装有限公司

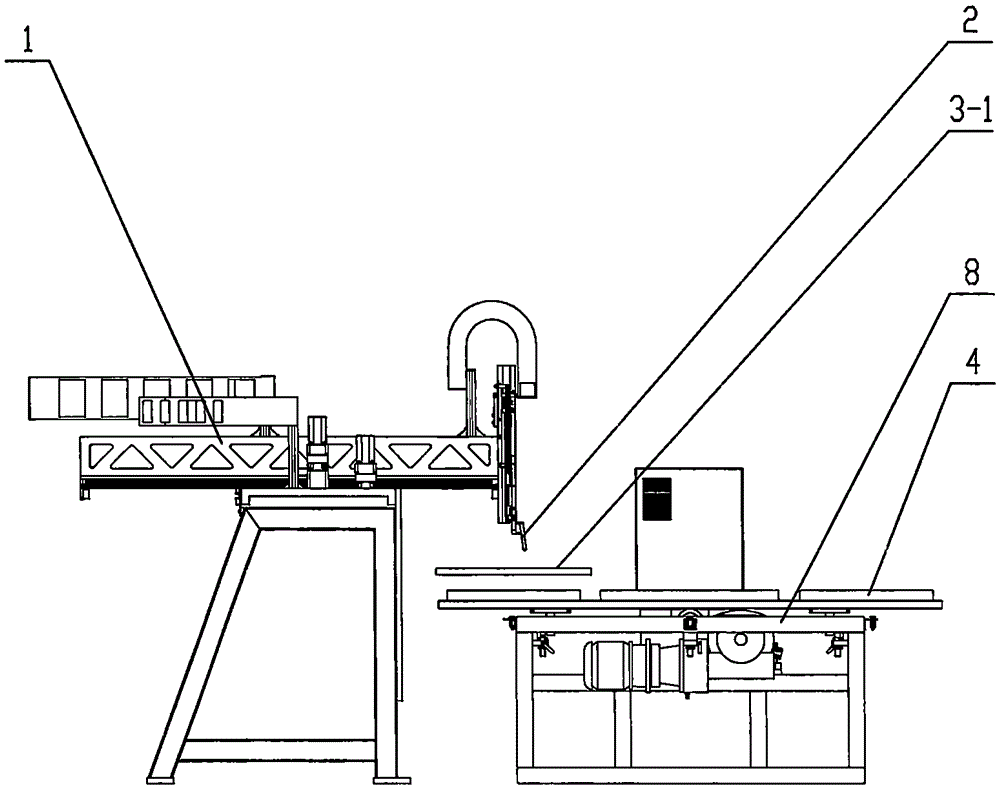

Equipment for integrated printing of temporary licenses and exempted from inspection standards

PendingCN110861940ARealize automatic printingNo human intervention requiredOverturning articlesTypewritersPaper sheetManufacturing engineering

The invention discloses equipment for integrated printing of temporary licenses and exempted from inspection standards. The equipment comprises a chassis, an XYZ three-axle mechanical arm module, a paper separation module, a printing page turning output module and a control module; the control module controls the XYZ three-axle mechanical arm module to automatically suck papers separated out fromthe paper separation module and to feed in the printing page turning output module for printing to realize automatic printing of the temporary licenses and six-year exempted from inspection standardsand pushing of the printed temporary licenses and six-year exempted from inspection standards, so that the manual participation is not needed, and the working efficiency is improved. The equipment isused for the field of automatic equipment.

Owner:珠海方图智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com