A packaging and printing equipment

A packaging printing and equipment technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of poor effect, difficult printing, poor printing quality, etc., to improve printing speed and effect, high printing quality, and applicable The effect of increasing the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

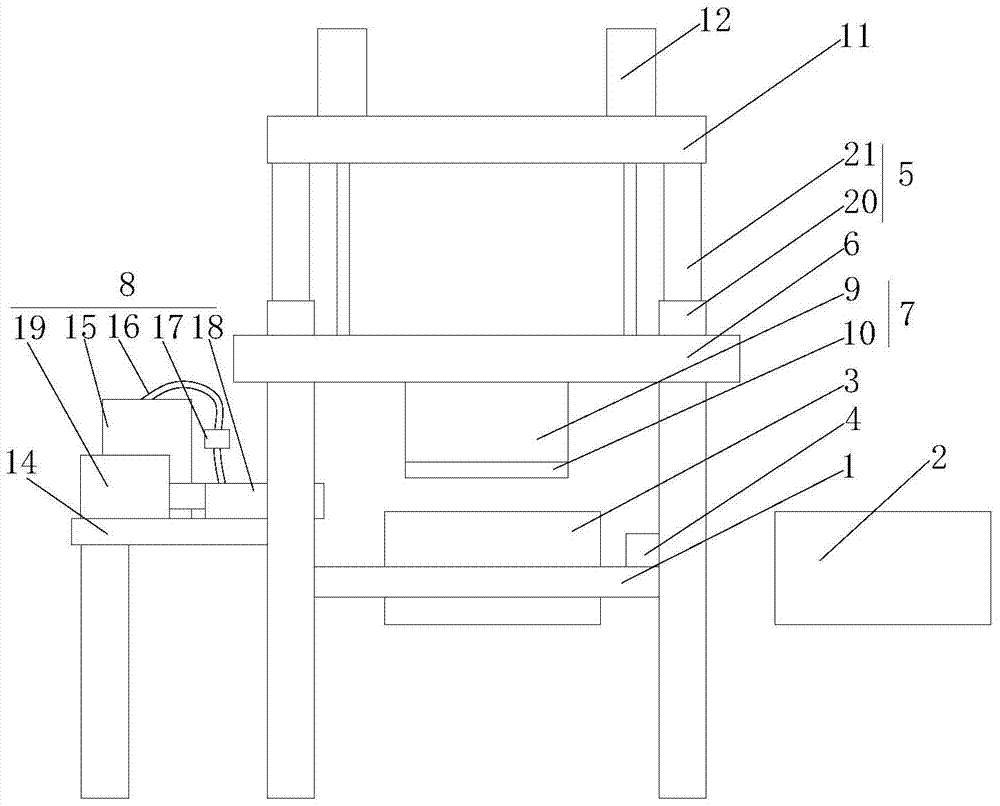

[0019] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a package printing device proposed by the present invention.

[0020] refer to figure 1 , a kind of packaging printing equipment that the present invention proposes, comprises workbench 1, feeding mechanism 2, unloading mechanism 3, sensor 4, column 5, printing machine base 6, printing machine 7, inking device 8 and controller;

[0021] The feeding mechanism 2 is used to put the materials to be printed on the workbench 1, and the unloading mechanism 3 is used to remove the printed materials from the workbench 1. The workbench 1 is provided with a material positioning mechanism for accurately positioning the materials, thereby To achieve printing at an accurate position, a sensor 4 is provided on the workbench 1 to sense the material on the workbench. In this embodiment, the sensor 4 is a photoelectric sensor, and two columns 5 are arranged on both sides of the workbench 1. Four columns 5 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com