Patents

Literature

78results about How to "Printing position is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

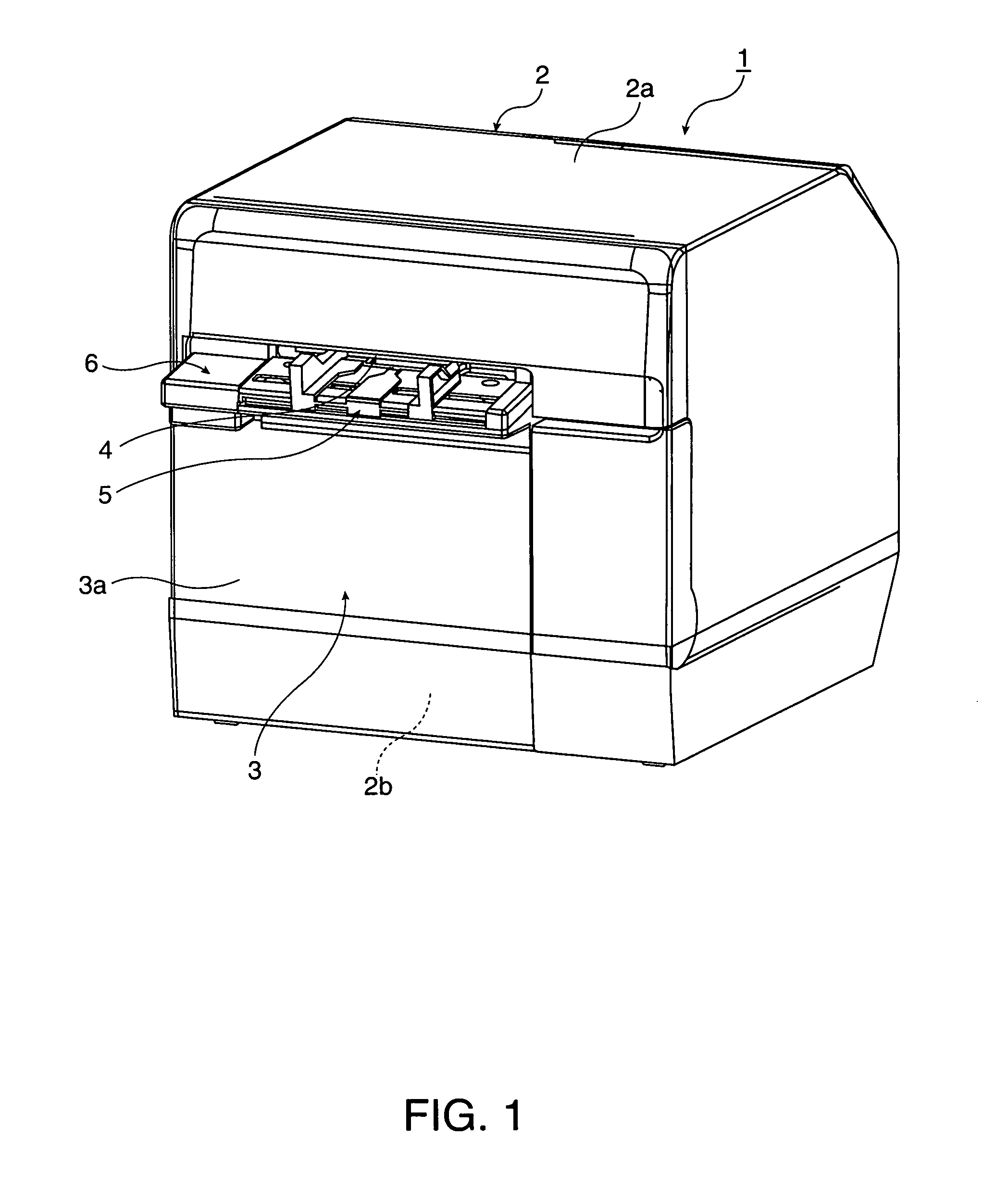

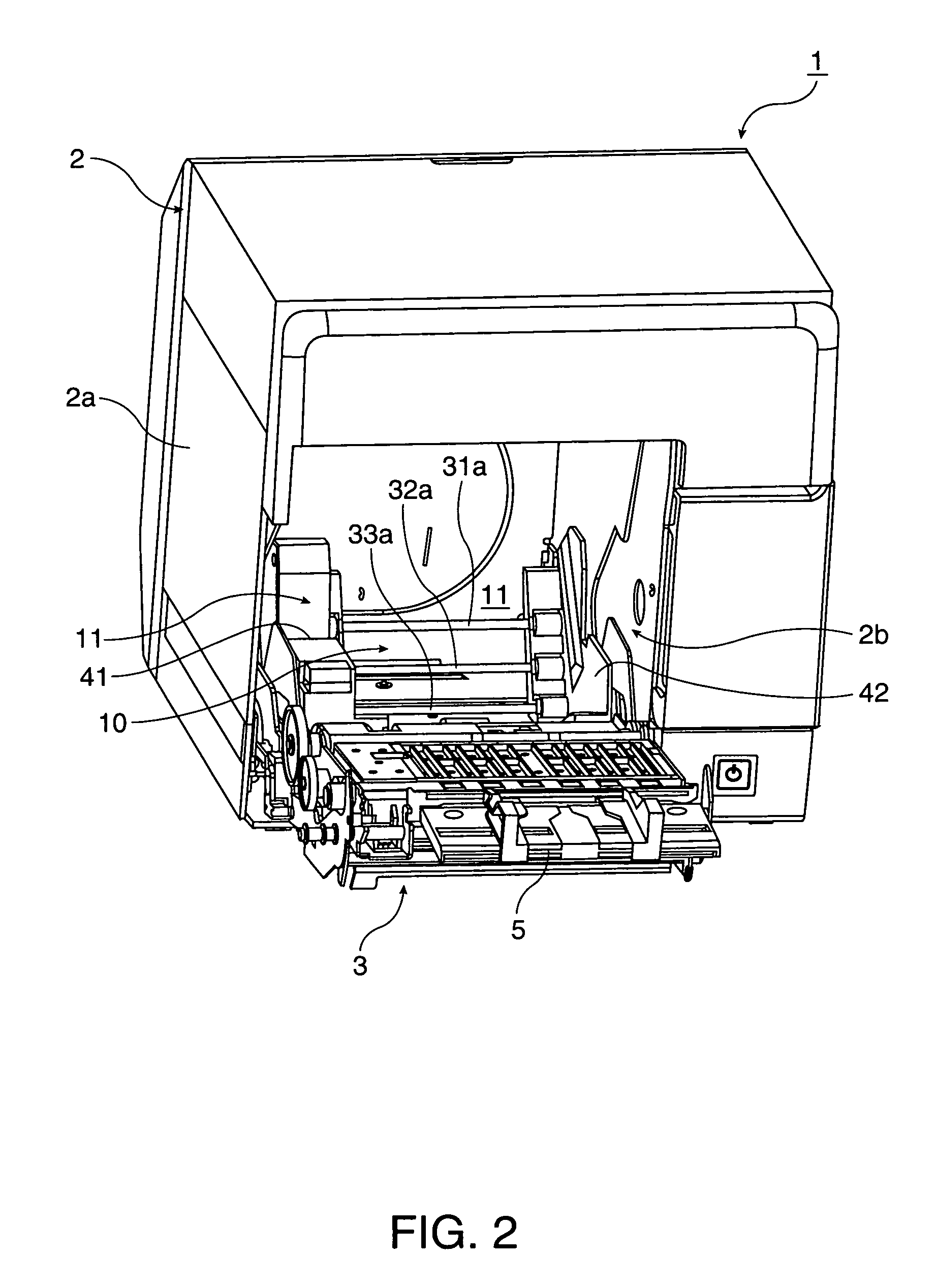

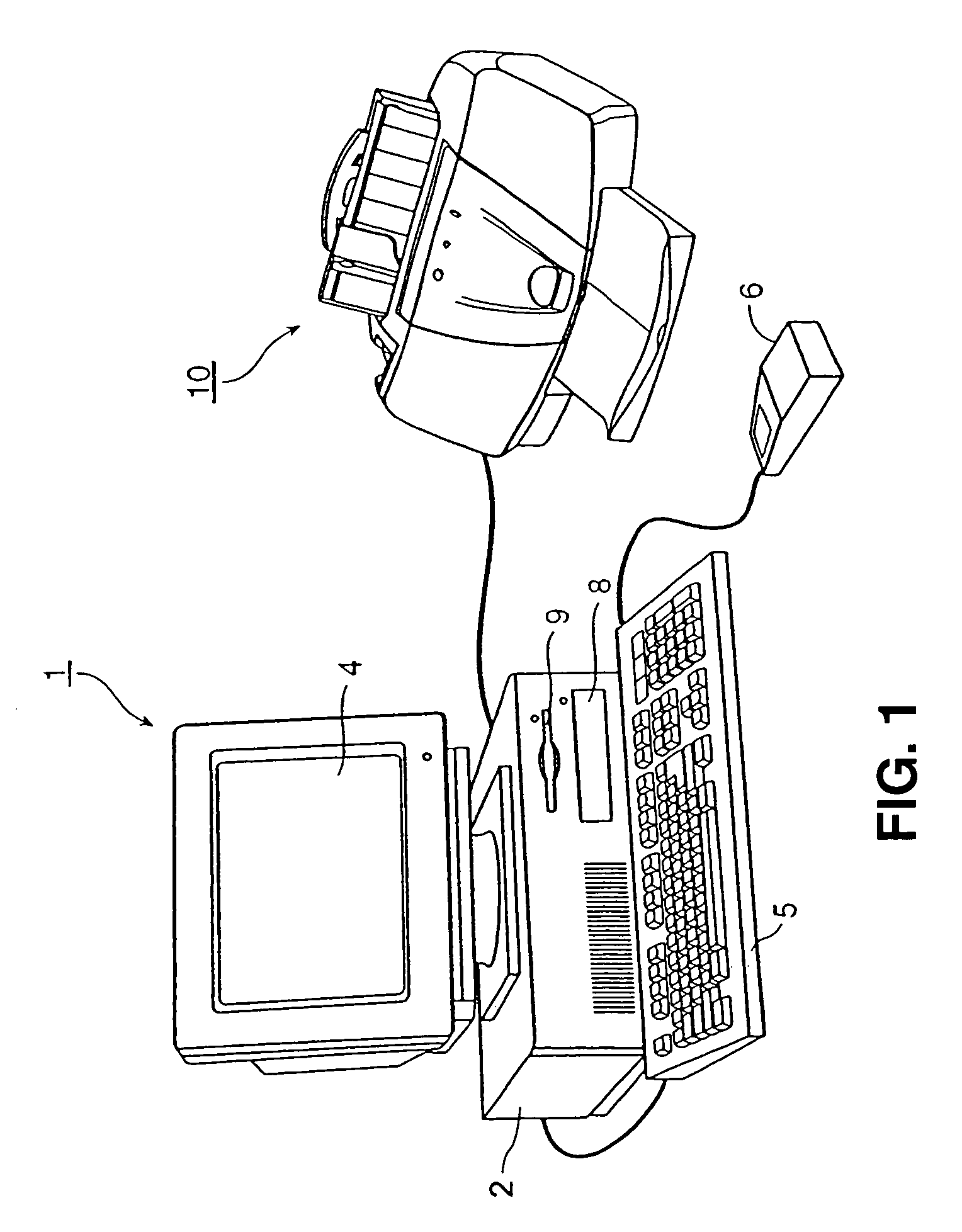

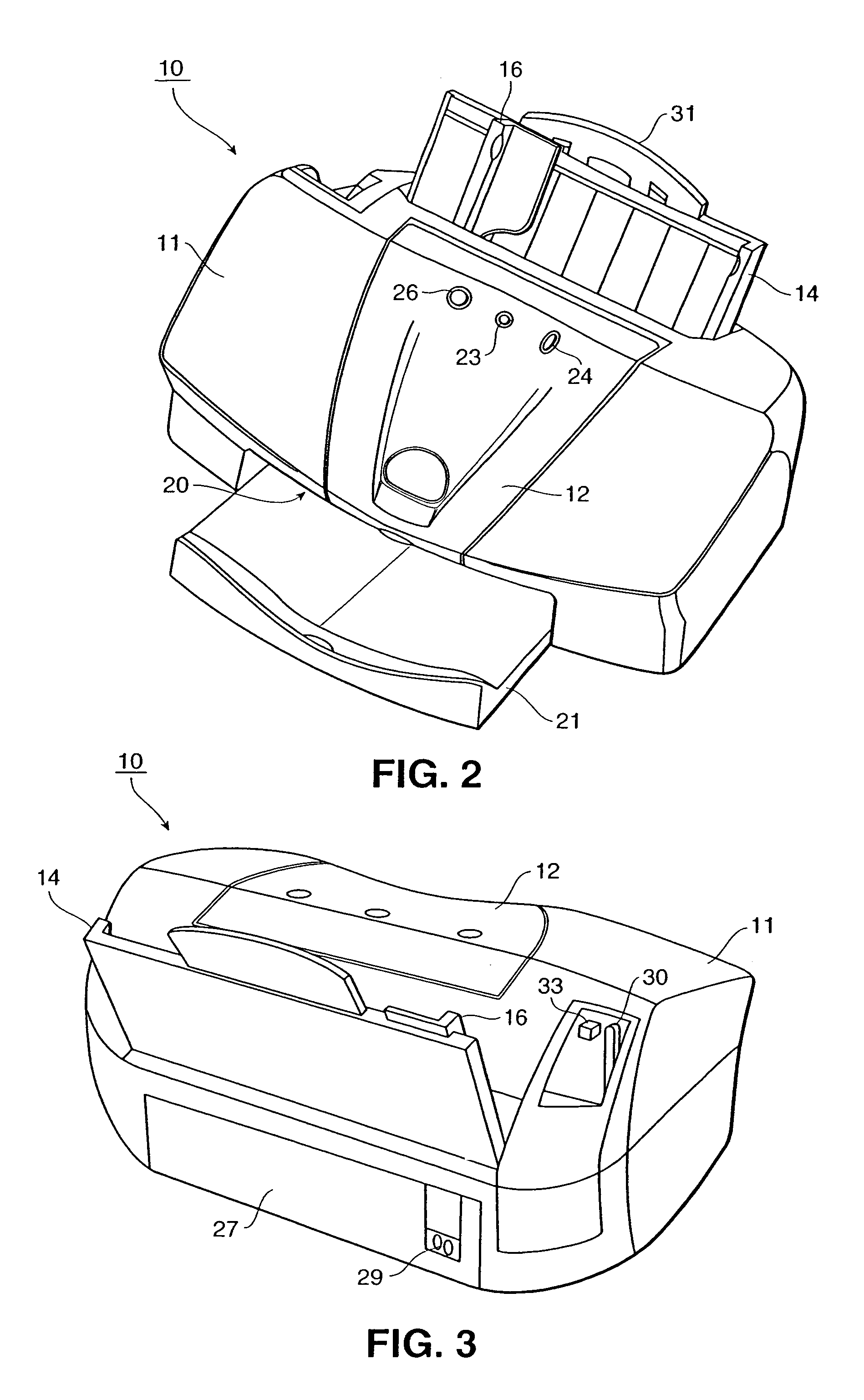

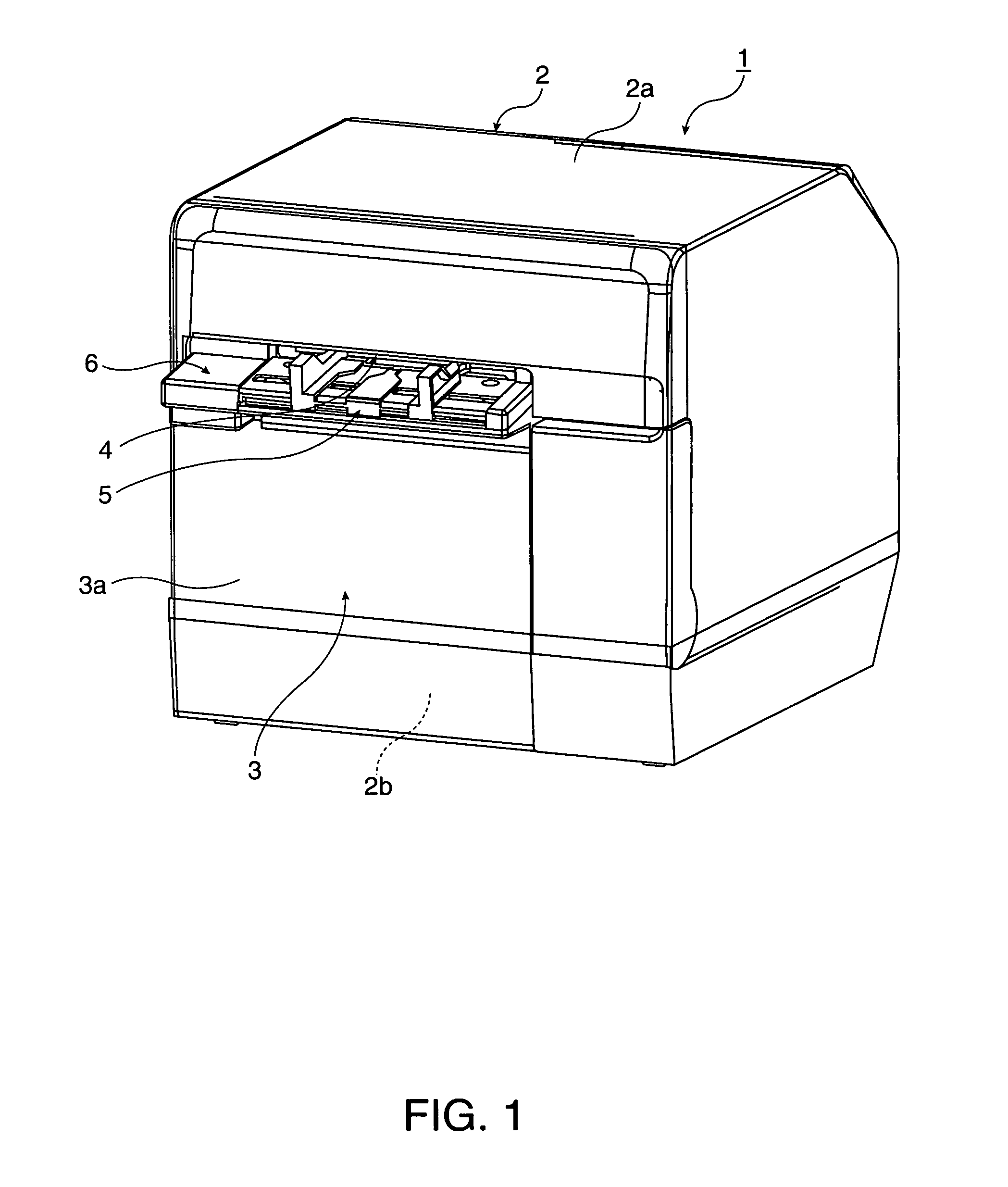

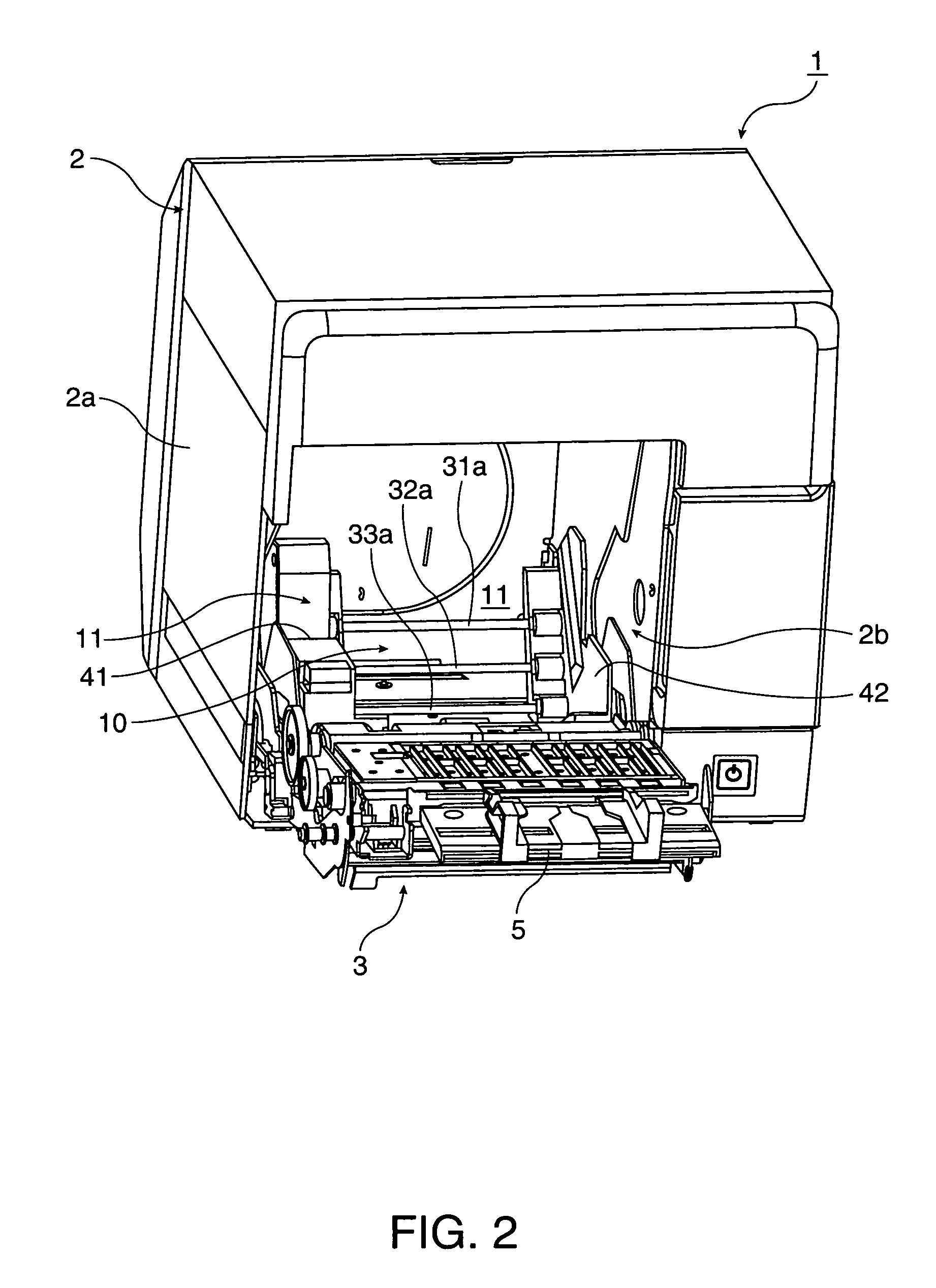

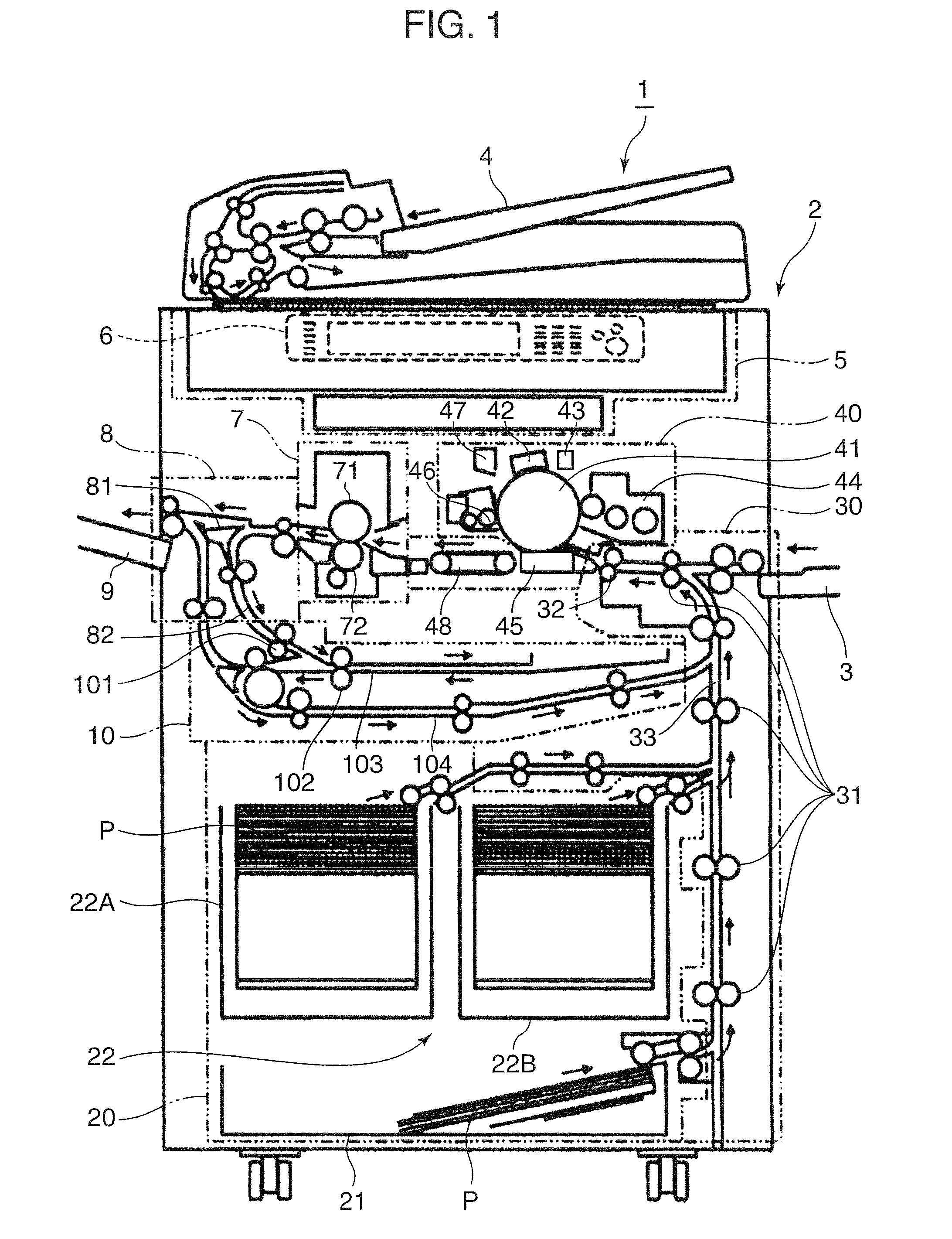

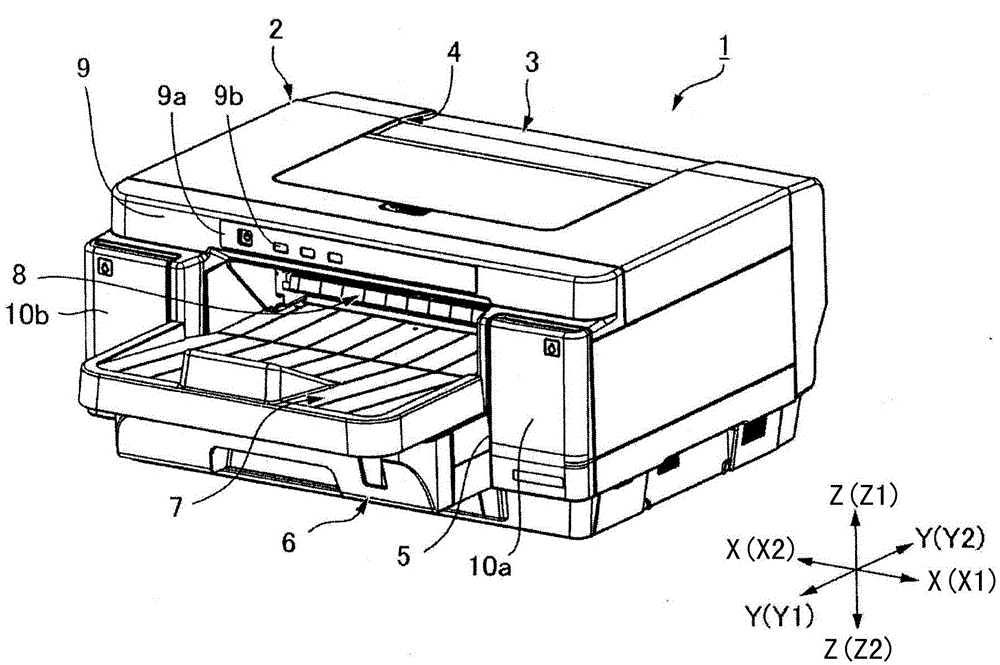

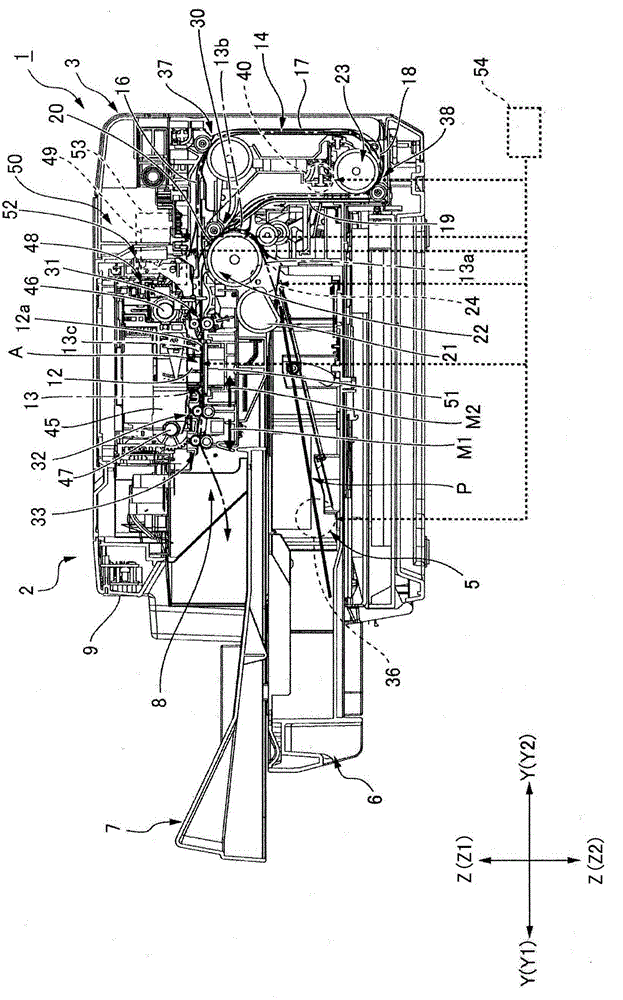

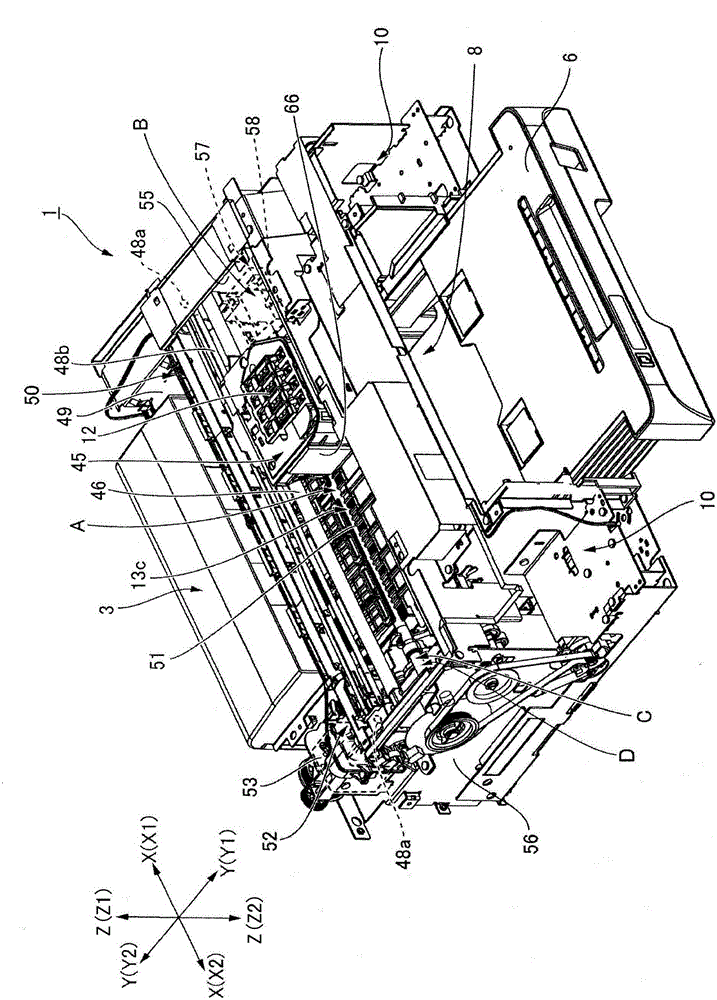

Ink jet printer, printer control unit, printer system including the same, and storage medium with the operation program of the printer control unit stored for controlling double-side printing

InactiveUS20050253886A1Reduce the hassle of operationQuality improvementRegistering devicesVisual representation by matrix printersComputer printingInk printer

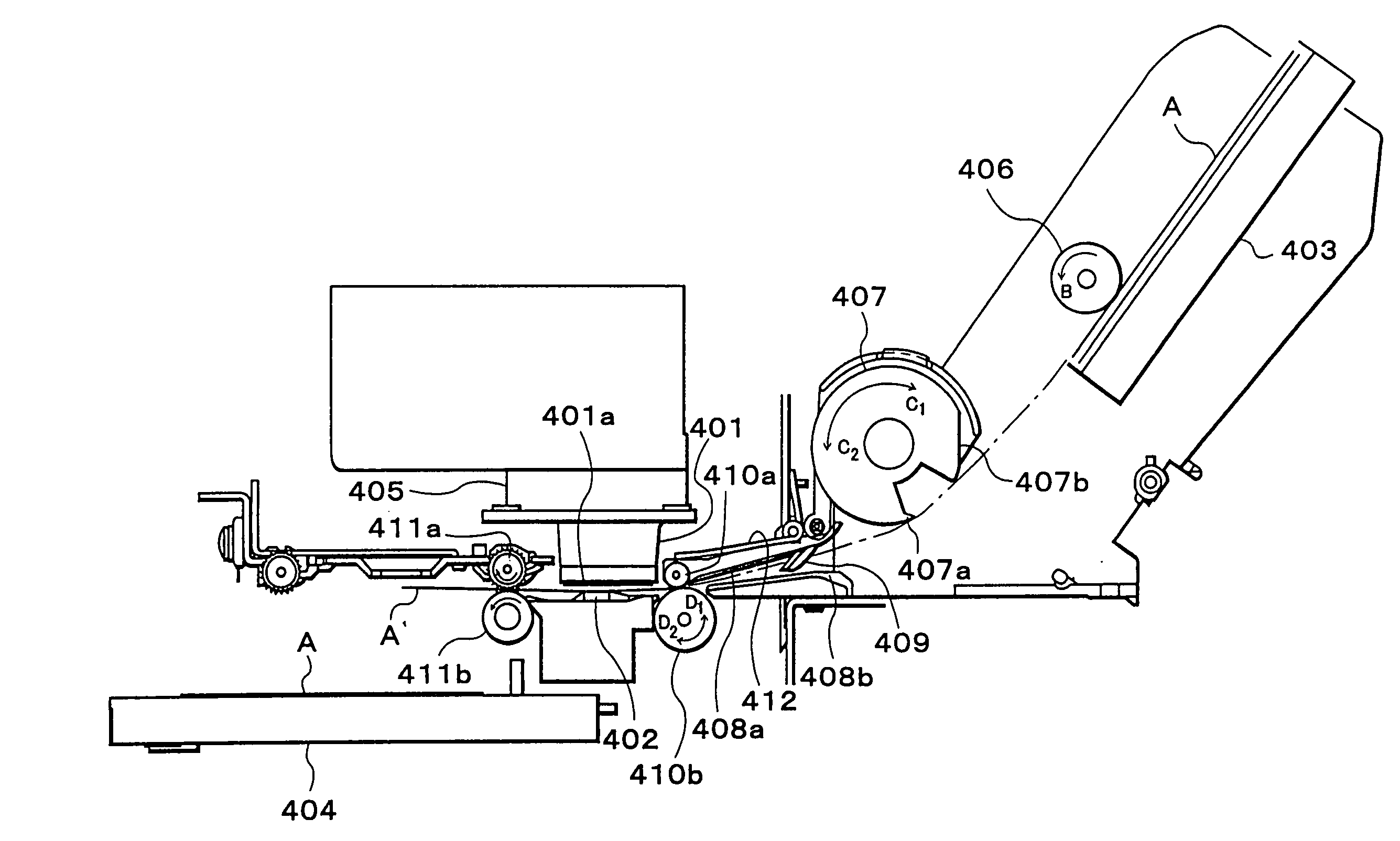

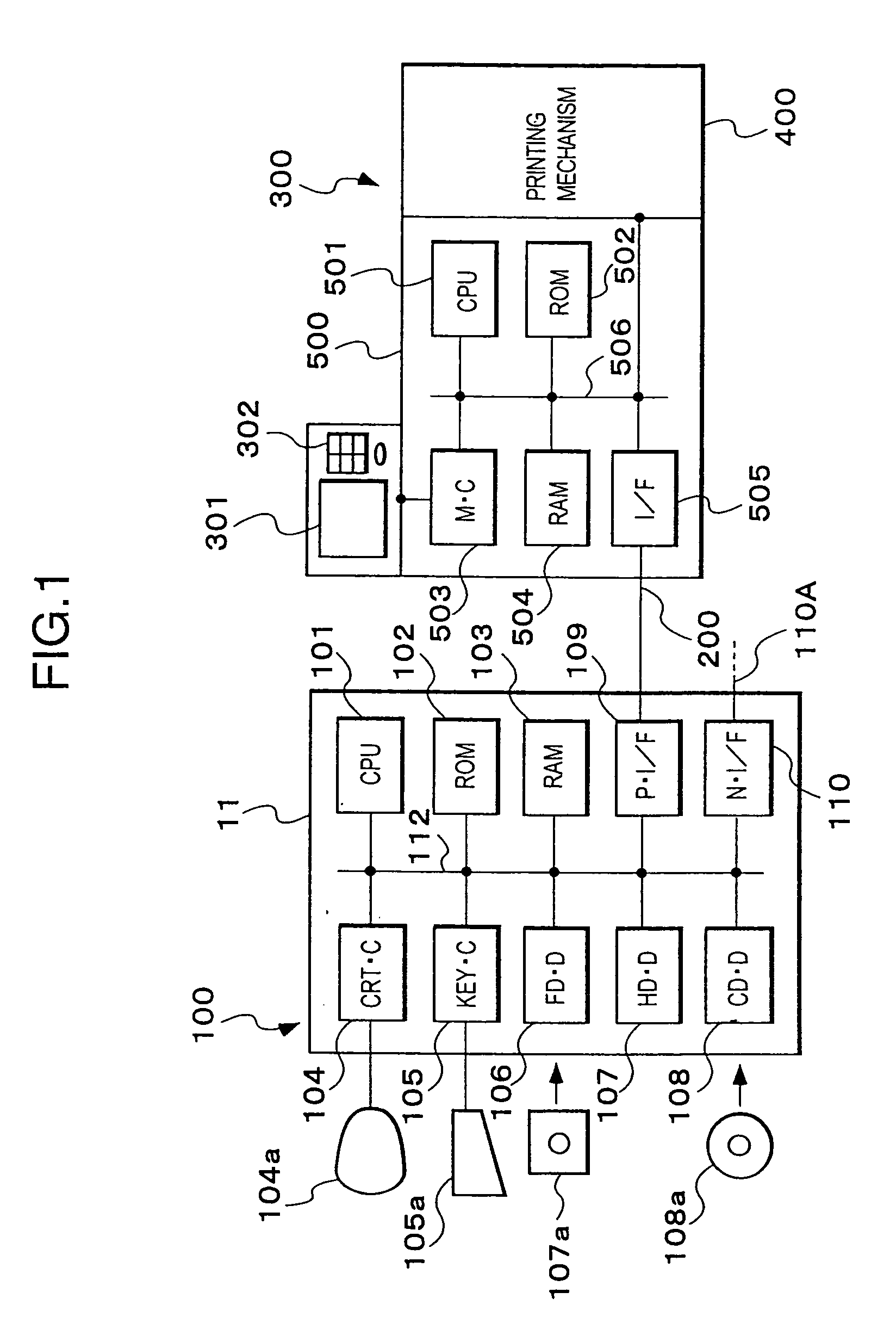

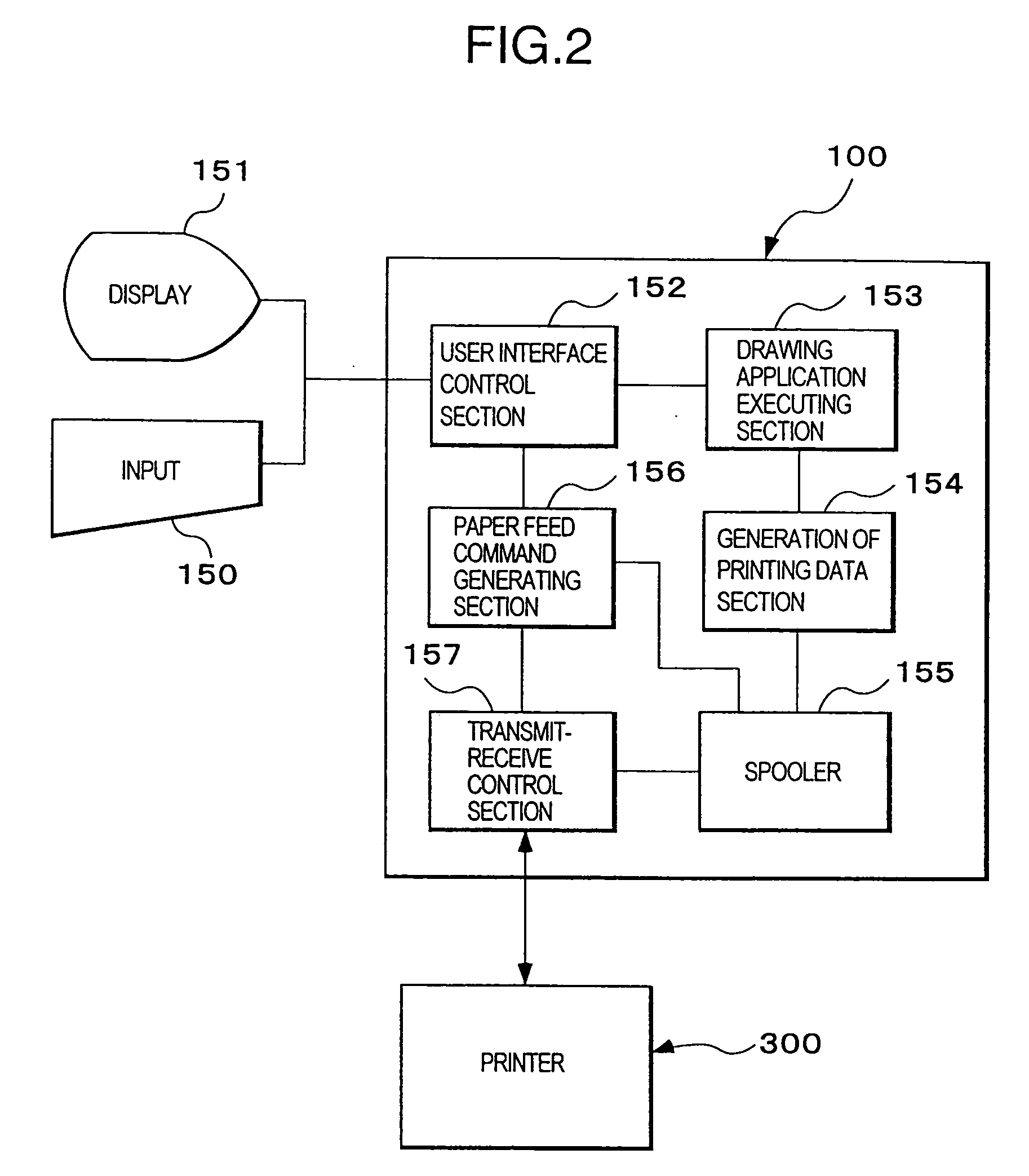

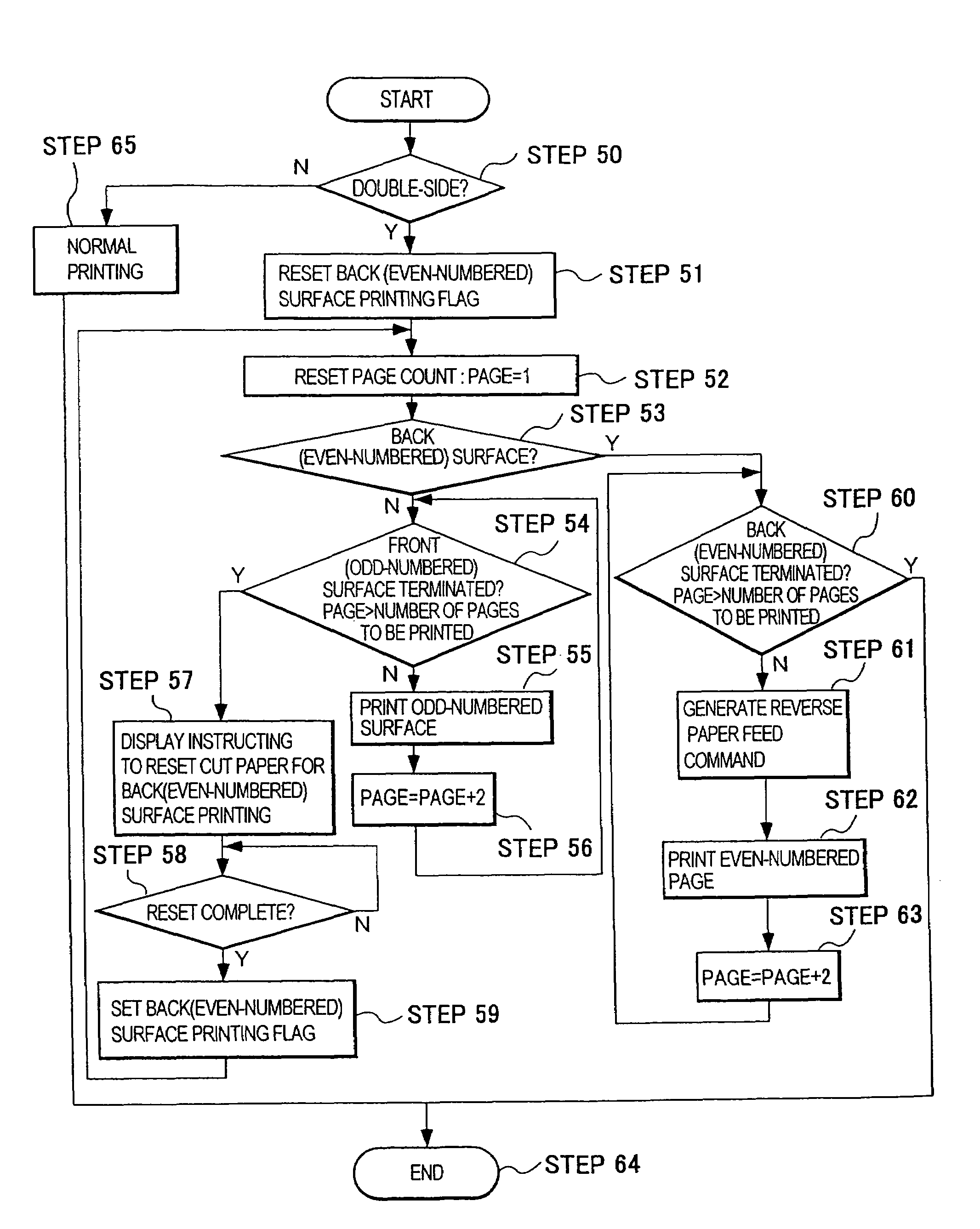

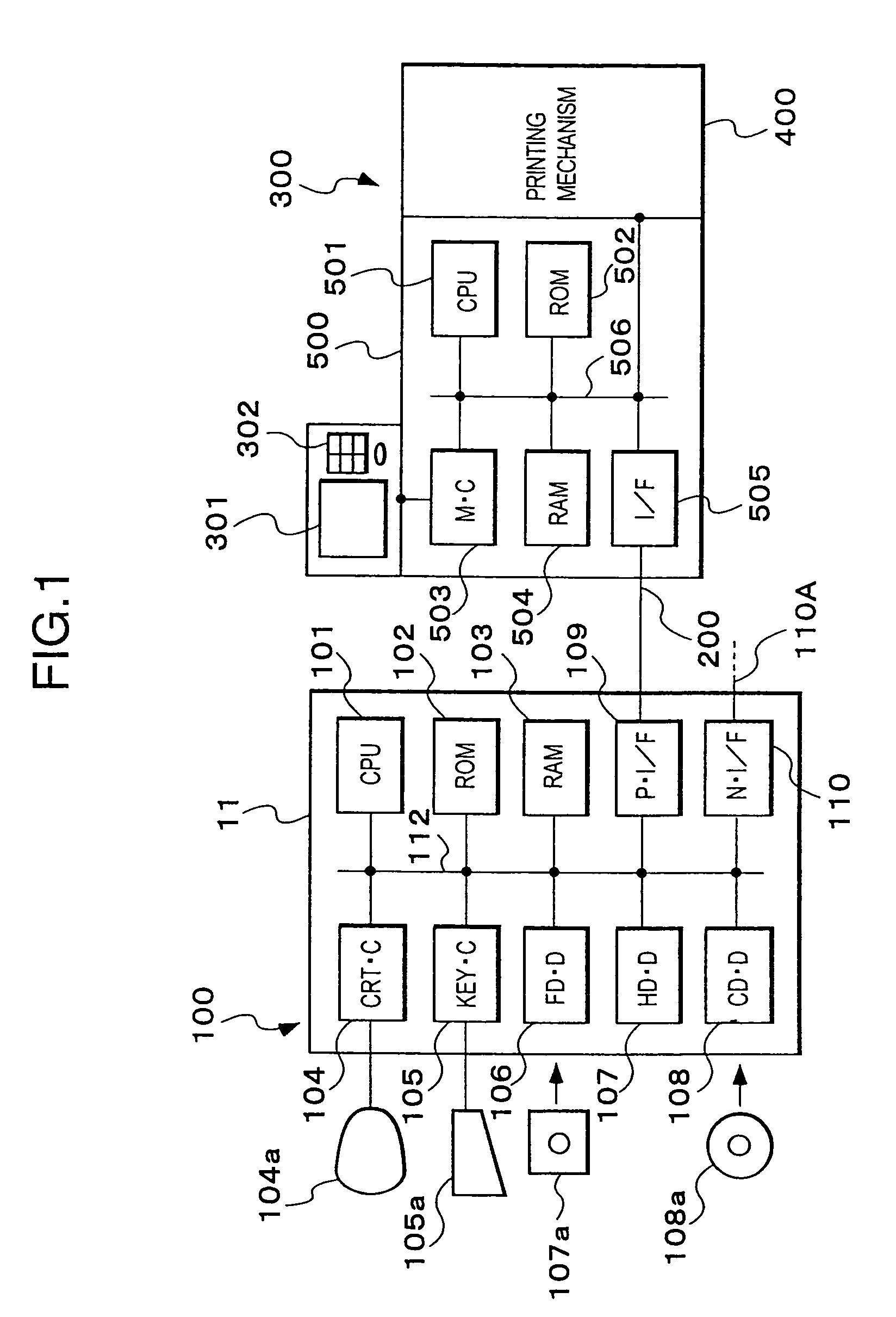

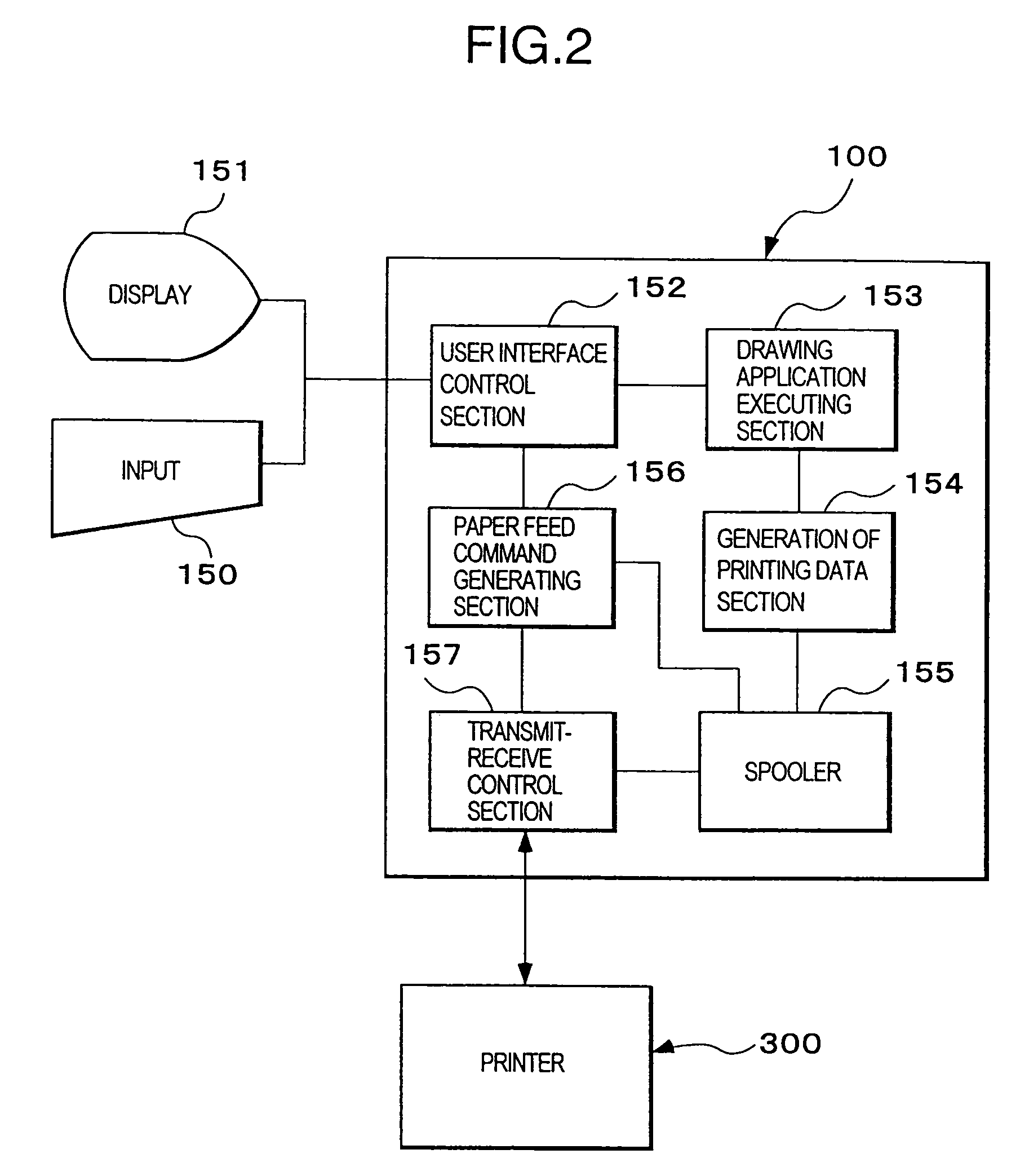

An ink jet printer with a double-side printing function enables to print page images at a proper position on both surfaces of a cut paper, is provided. When feeding the cut paper A having an image printed on the front surface, the feeding roller 407 is rotated in the direction C1 to feed the cut paper A and simultaneously the registering rollers 410a, 410b are rotated in the direction D1 to push back the cut paper. In addition, the double-side printing is easily realized in both of the cases where the ink jet printer with the double-side printing function is connected to the host, and where the ink jet printer without double-side printing function is connected to the host by having the host make an inquiry of the printer whether or not double-side printing is available (step 6). Based on the results of the inquiry, printing commands are generated and sent to the printer.

Owner:SEIKO EPSON CORP

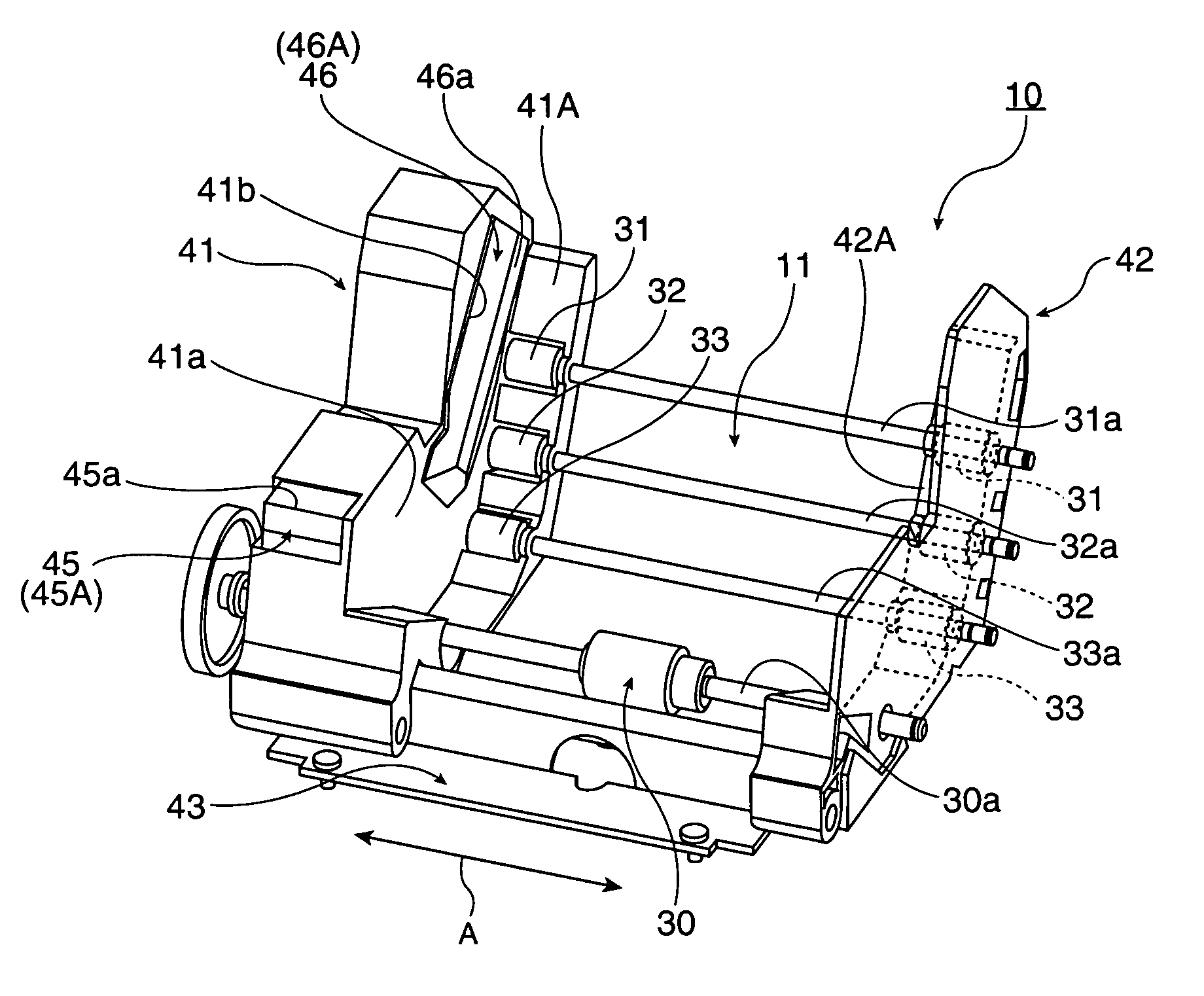

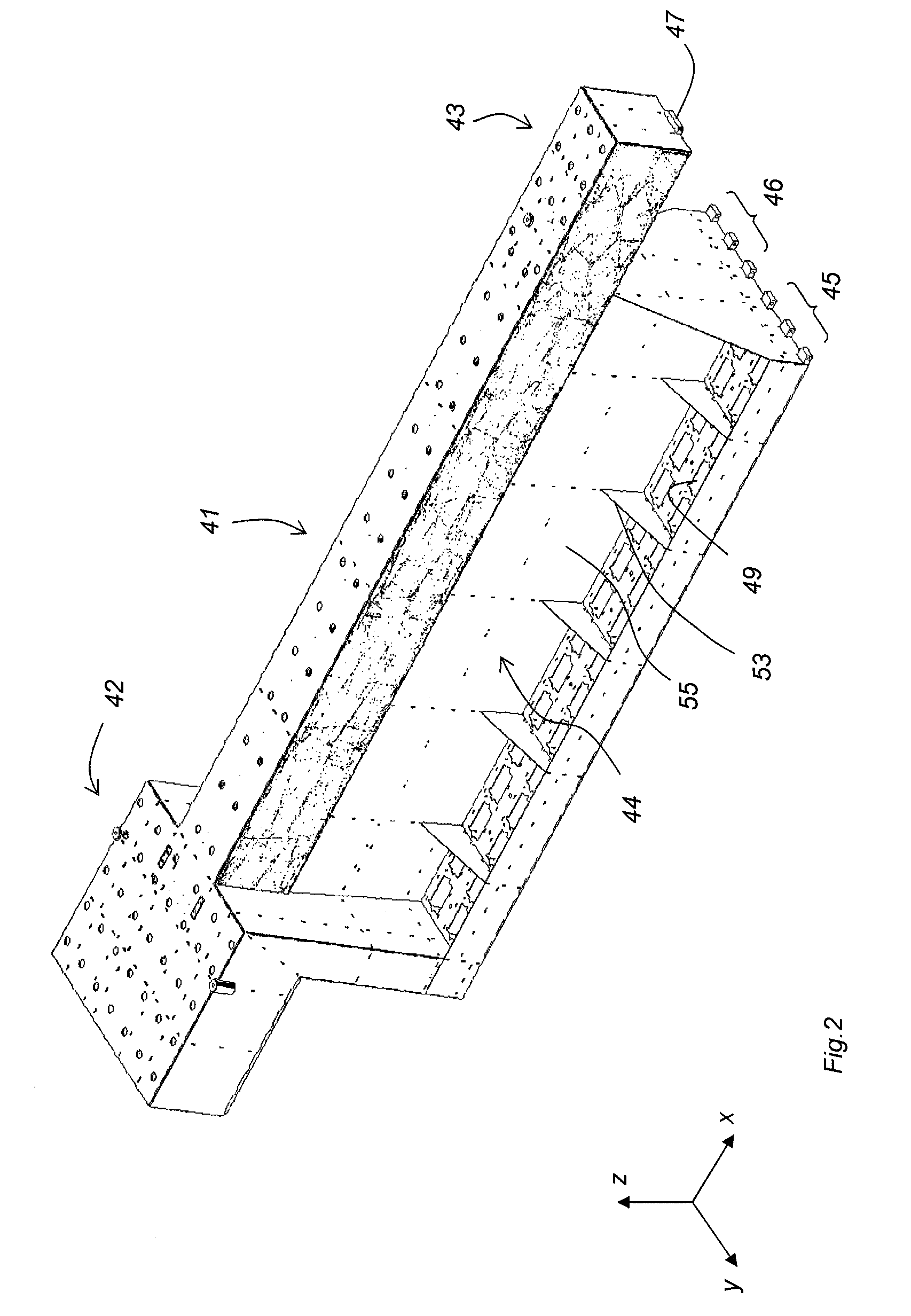

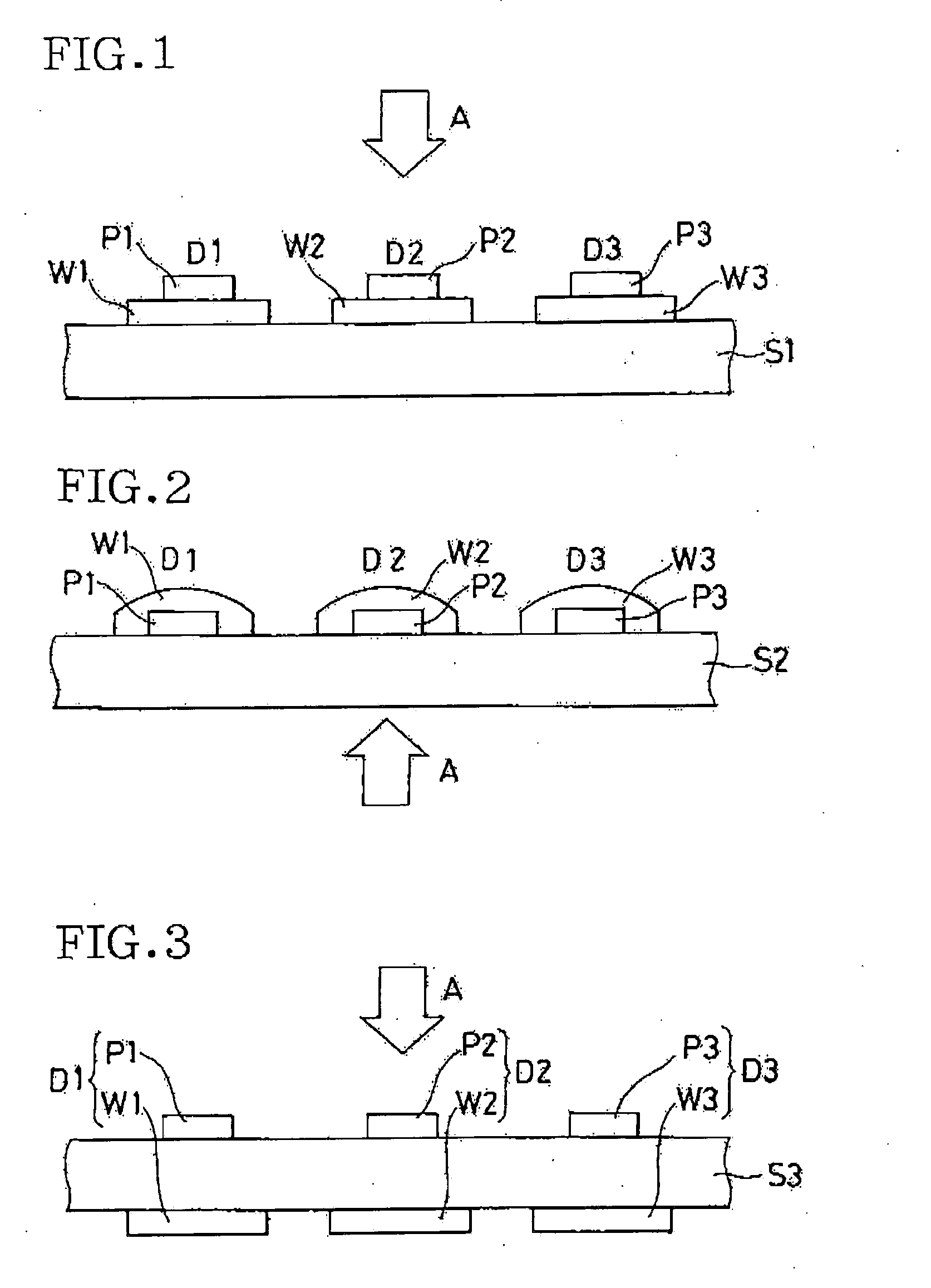

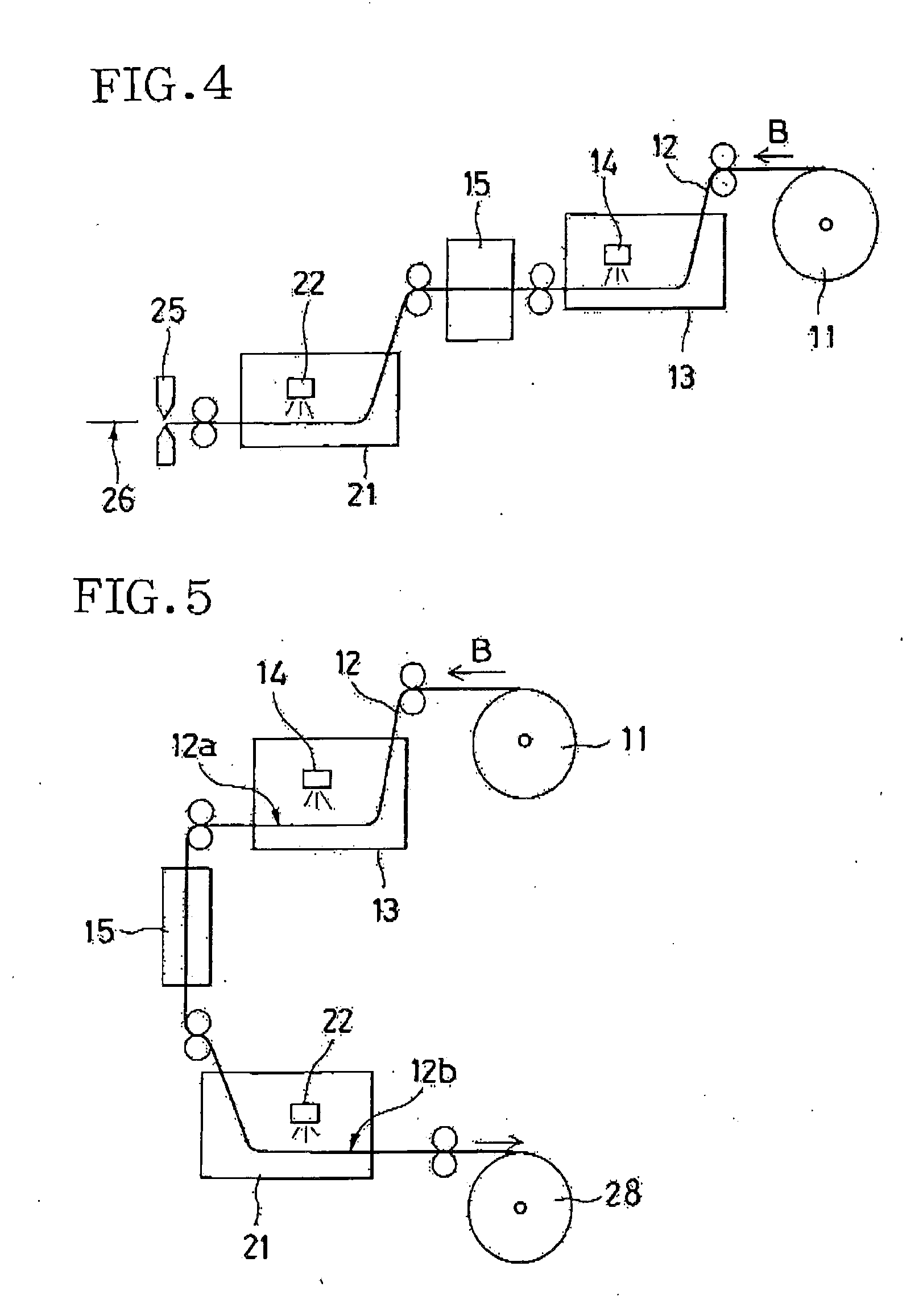

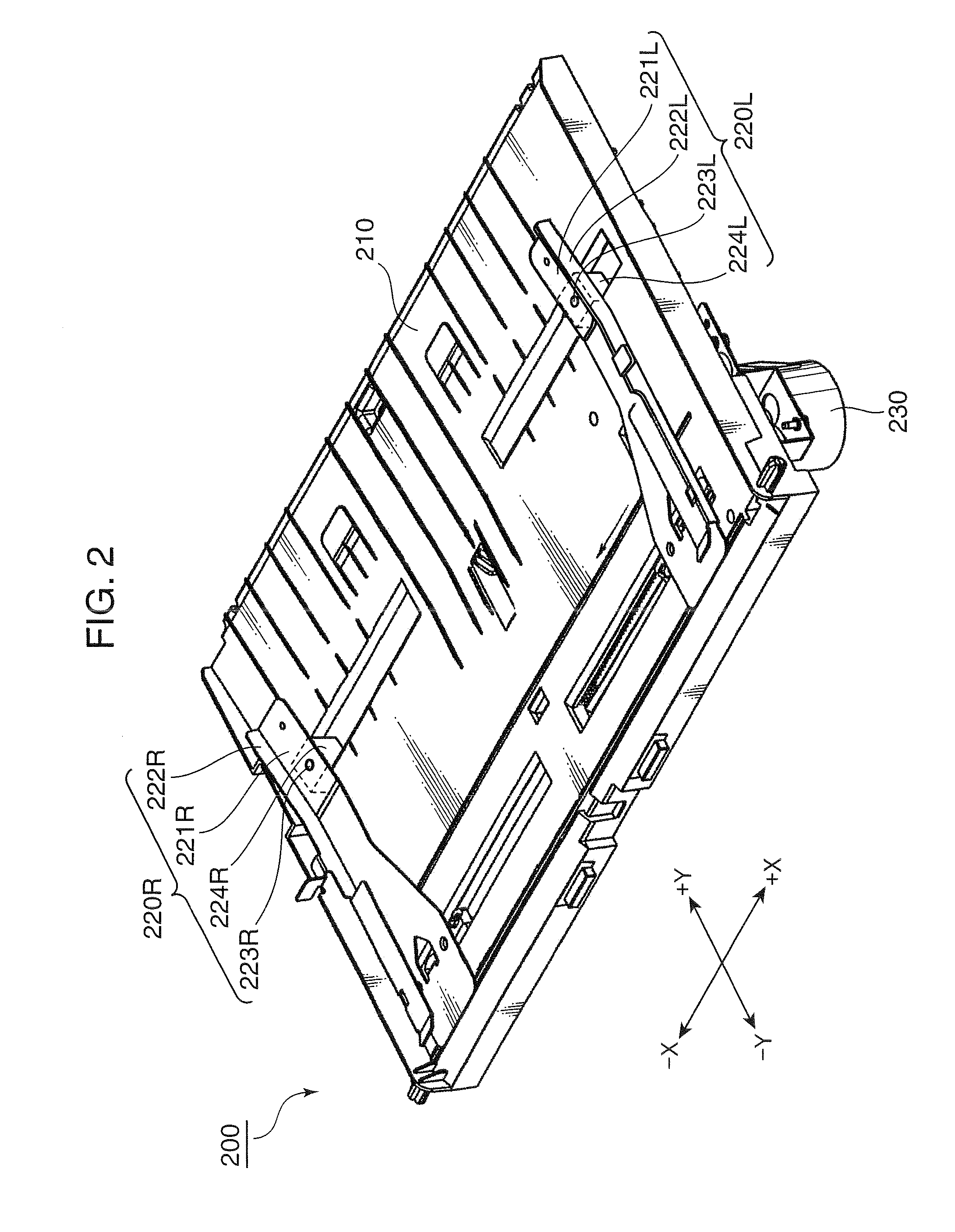

Paper supply mechanism and roll paper printer

ActiveUS20090114758A1Easily moved widthwiseIncrease loadProjector film strip handlingCamera film strip handlingRolling paperLocking mechanism

Owner:SEIKO EPSON CORP

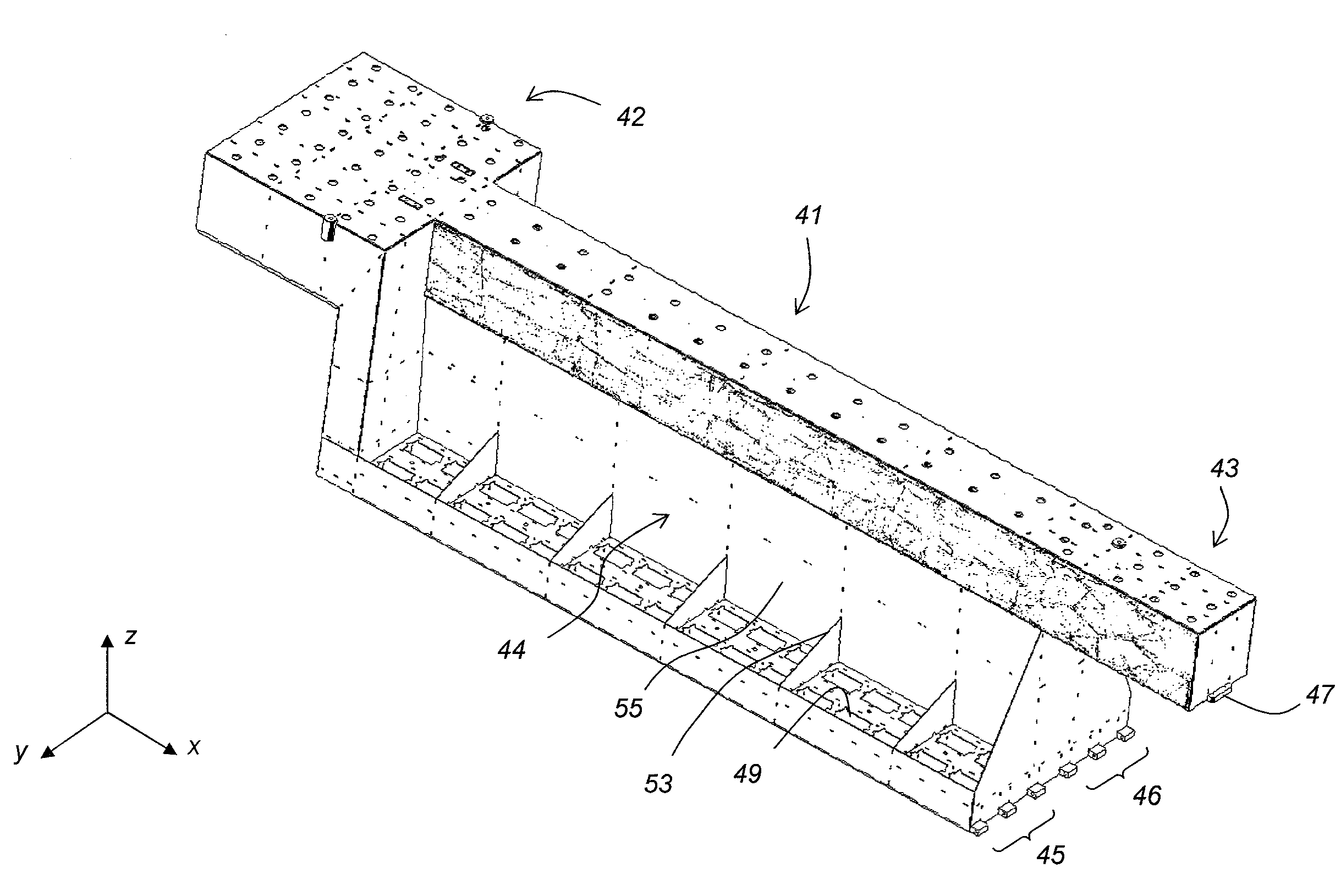

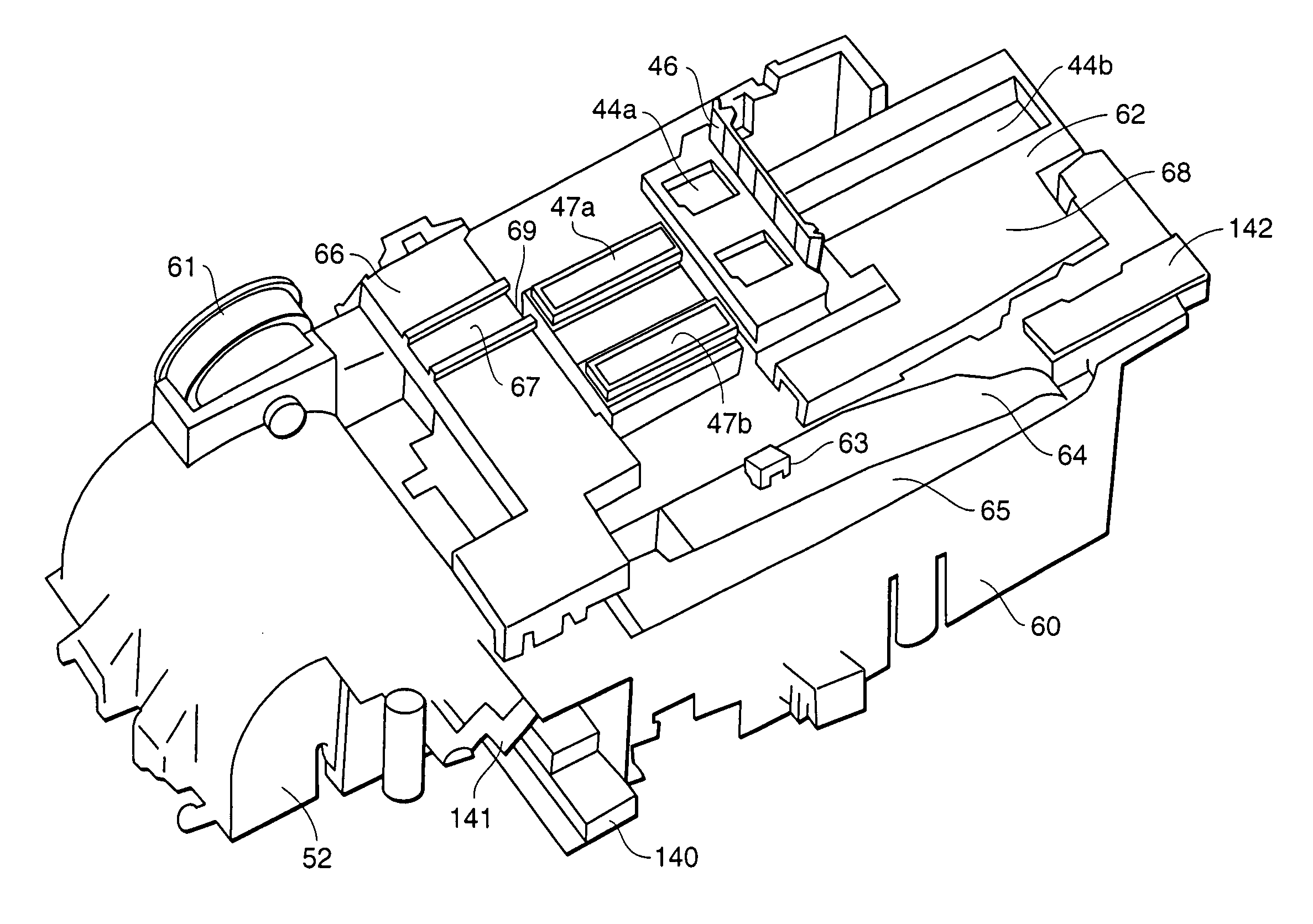

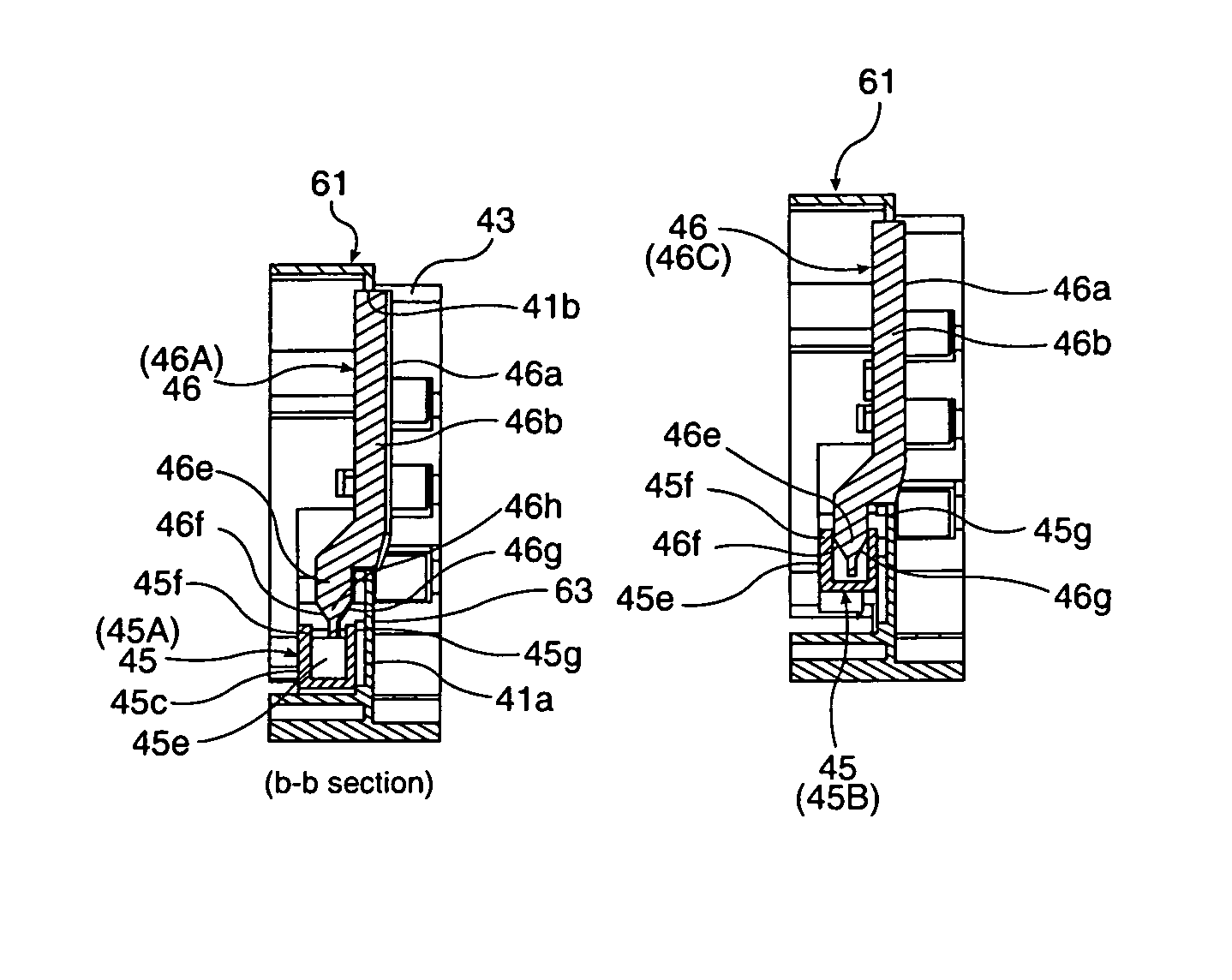

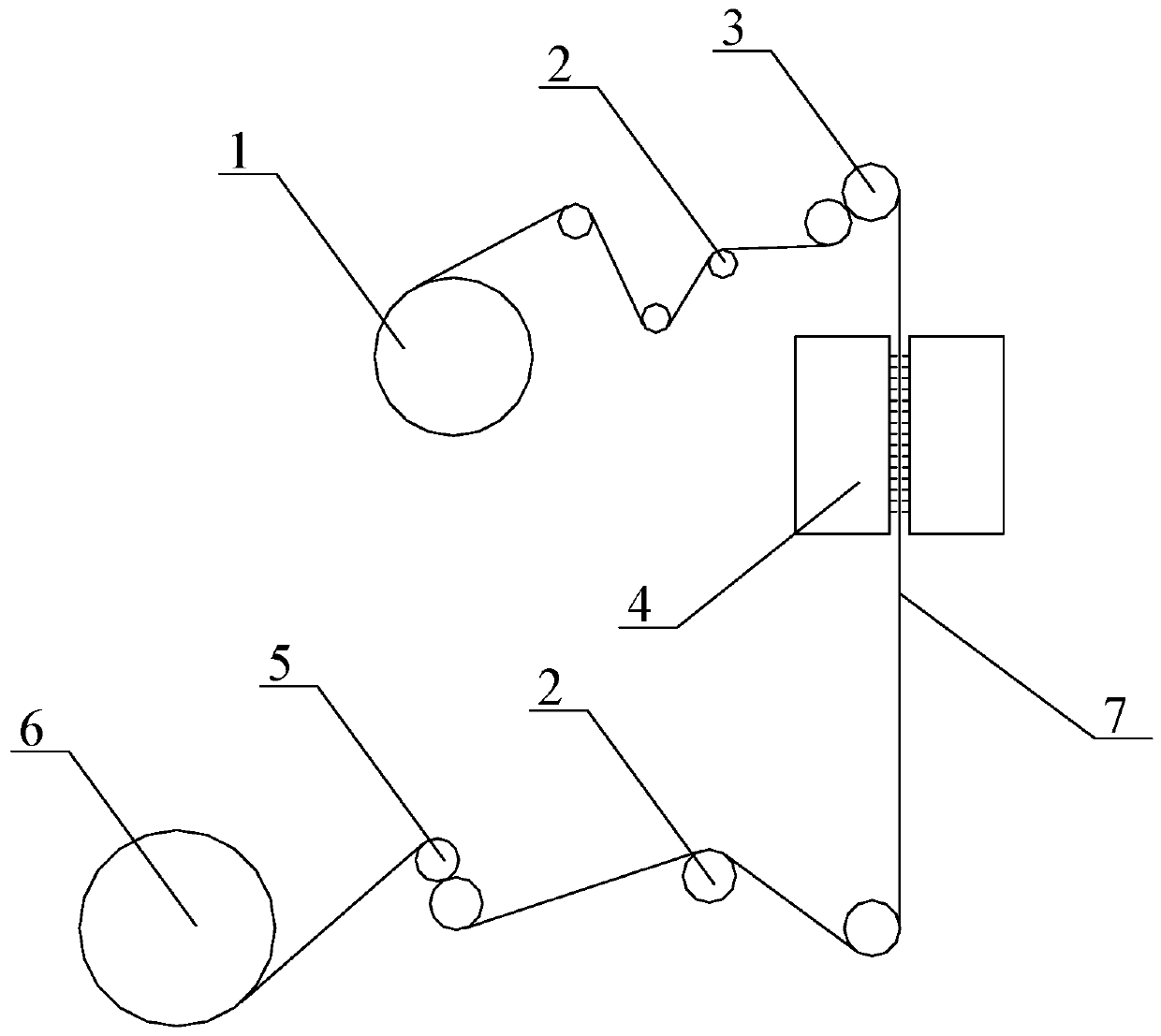

Print Head Shuttle with Active Cooling

InactiveUS20080273910A1Printing position is accurateStable printingInking apparatusPower drive mechanismsActive coolingEngineering

A print head carriage for holding a print head in a printing system includes a print head carriage framework having a plurality of print head positioning references for defining a position of the print head onto the print head carriage framework, and a cooling channel in thermal contact with the print head carriage framework for controlling the temperature of the print head carriage framework such that the positional stability of the plurality of print head positioning references on the print head carriage framework is preserved.

Owner:AGFA NV

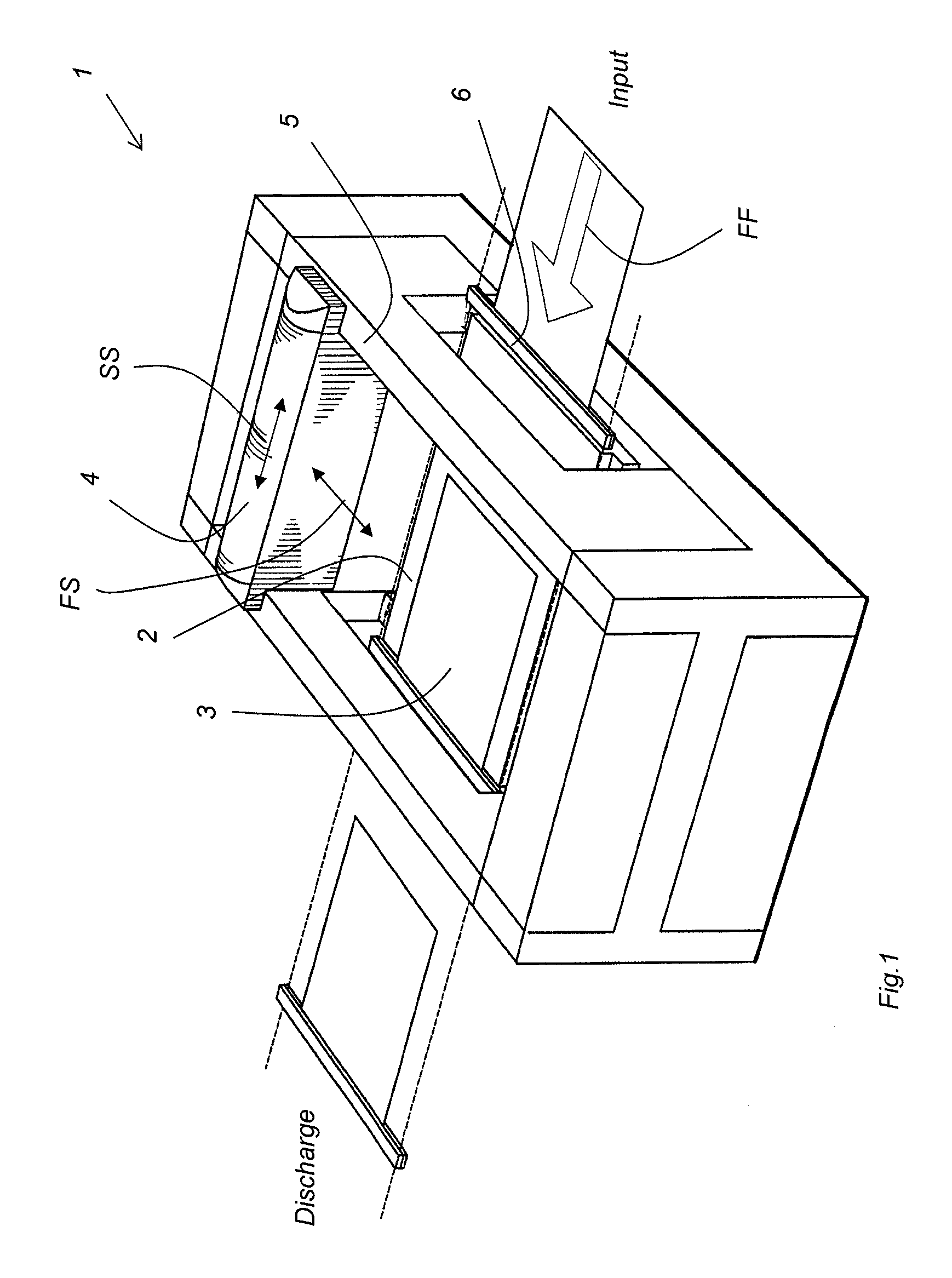

Print head recovery

InactiveUS7052106B1Accurate of print conditionReduce contaminationPrintingEngineeringElectrical and Electronics engineering

A printing device for performing recording on a recording medium, the printing device comprising a carriage slidably mounted on the printing device in a lateral direction to scan the recording medium, and movable in a vertical direction to a plurality of predetermined distances above the recording medium during printing, a print head mounted on the carriage, the print head having a discharge surface with a discharge nozzle located therein, the discharge nozzle for ejecting ink on the recording medium, and a recovery mechanism for performing recovery of the print head when the carriage is positioned above the recovery mechanism, the recovery mechanism including a carriage lever to engage the carriage and move the carriage in the vertical direction to a predetermined position above the recovery mechanism.

Owner:CANON KK

Ink jet printer, printer control unit, printer system including the same, and storage medium with the operation program of the printer control unit stored for controlling double-side printing

InactiveUS7576875B2Reduce the hassle of operationQuality improvementDigitally marking record carriersRegistering devicesEngineeringControl unit

An ink jet printer with a double-side printing function enables to print page images at a proper position on both surfaces of a cut paper, is provided. When feeding the cut paper A having an image printed on the front surface, the feeding roller 407 is rotated in the direction C1 to feed the cut paper A and simultaneously the registering rollers 410a, 410b are rotated in the direction D1 to push back the cut paper. In addition, the double-side printing is easily realized in both of the cases where the ink jet printer with the double-side printing function is connected to the host, and where the ink jet printer without double-side printing function is connected to the host by having the host make an inquiry of the printer whether or not double-side printing is available (step 6). Based on the results of the inquiry, printing commands are generated and sent to the printer.

Owner:SEIKO EPSON CORP

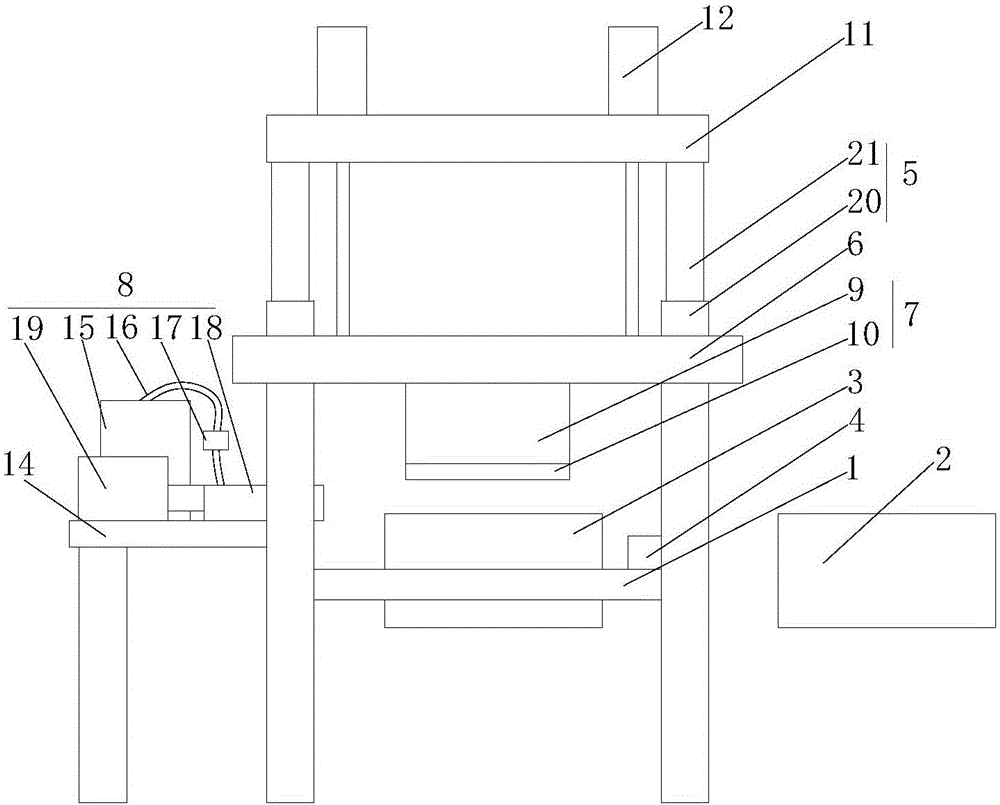

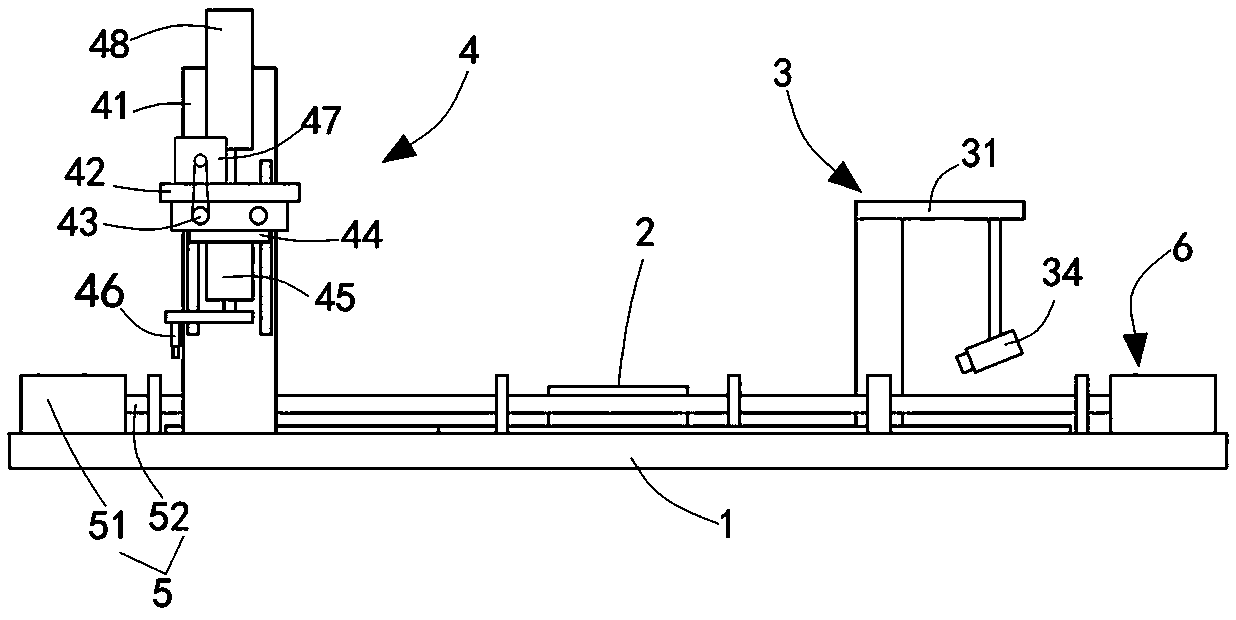

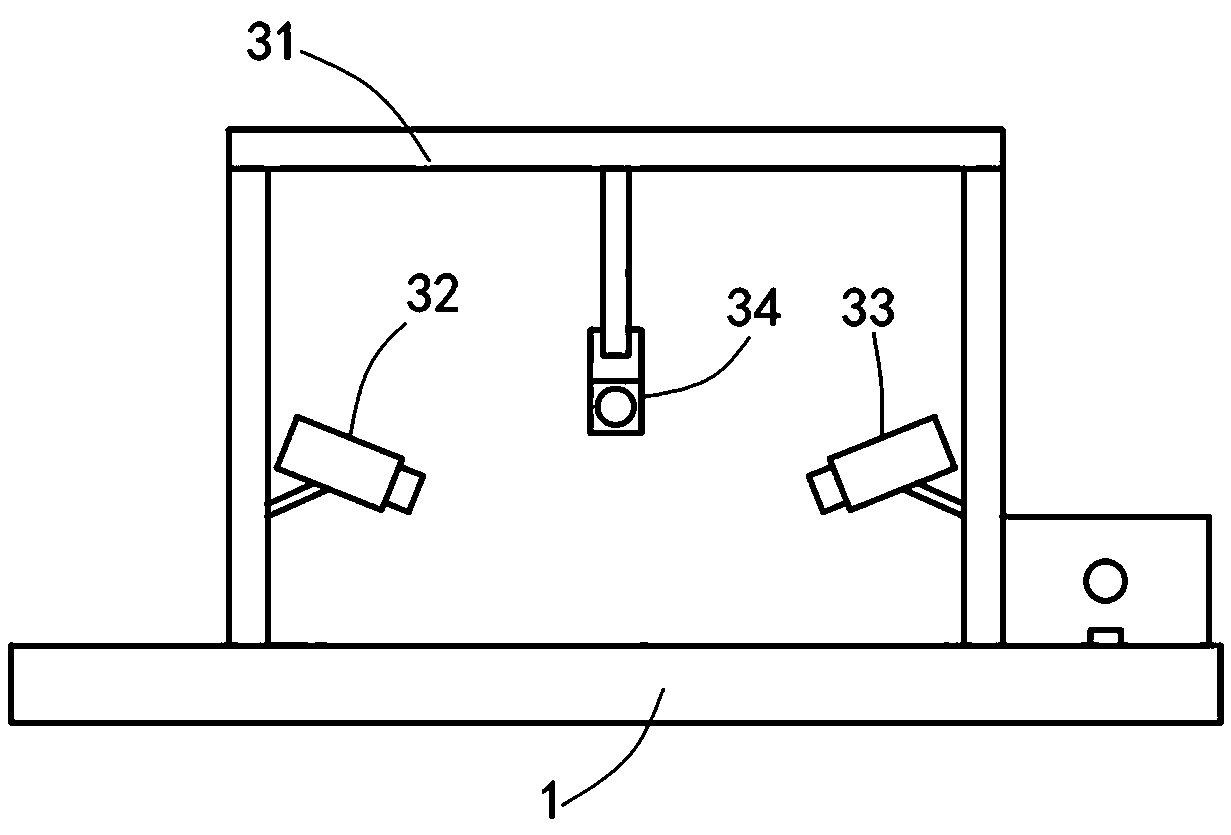

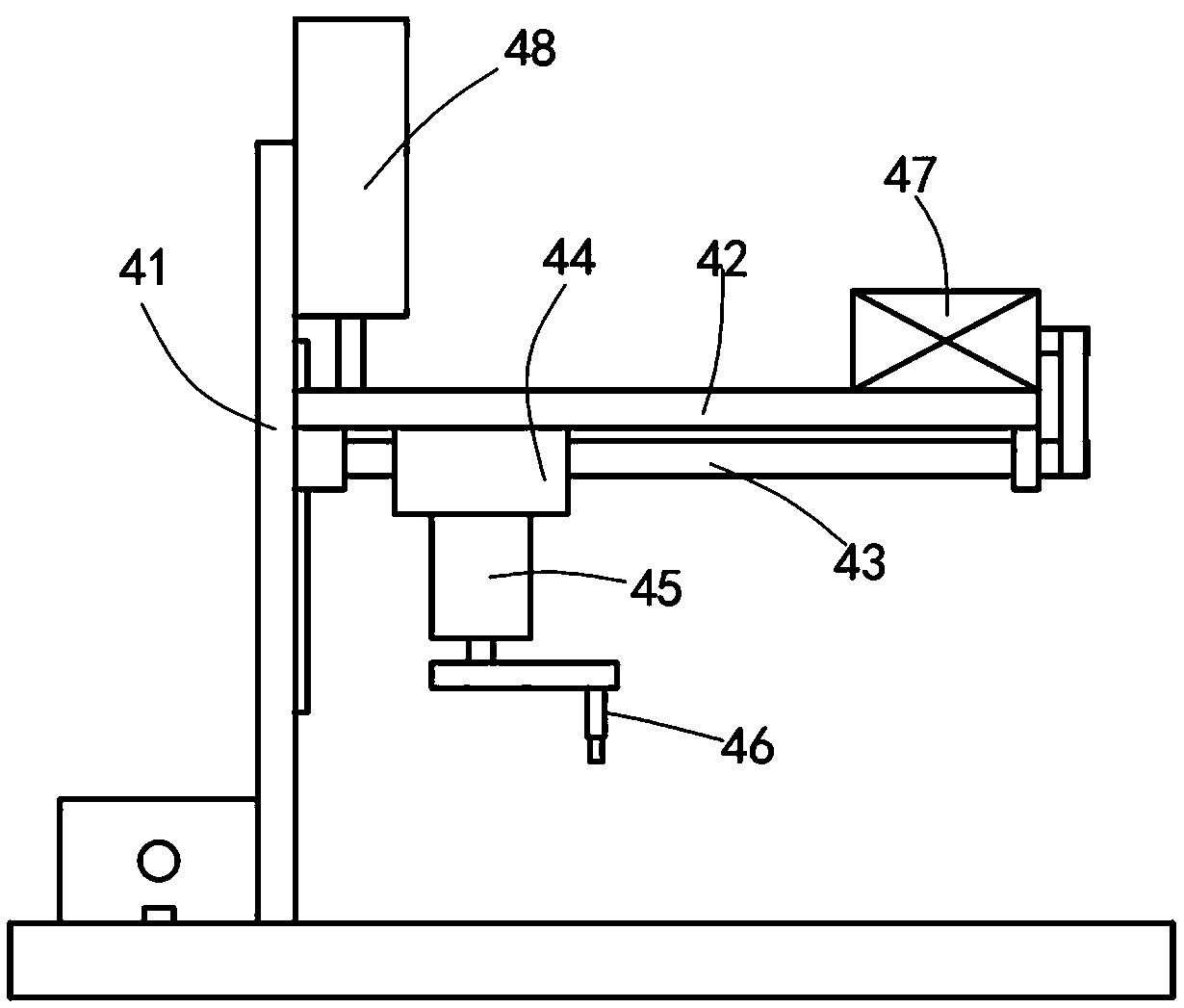

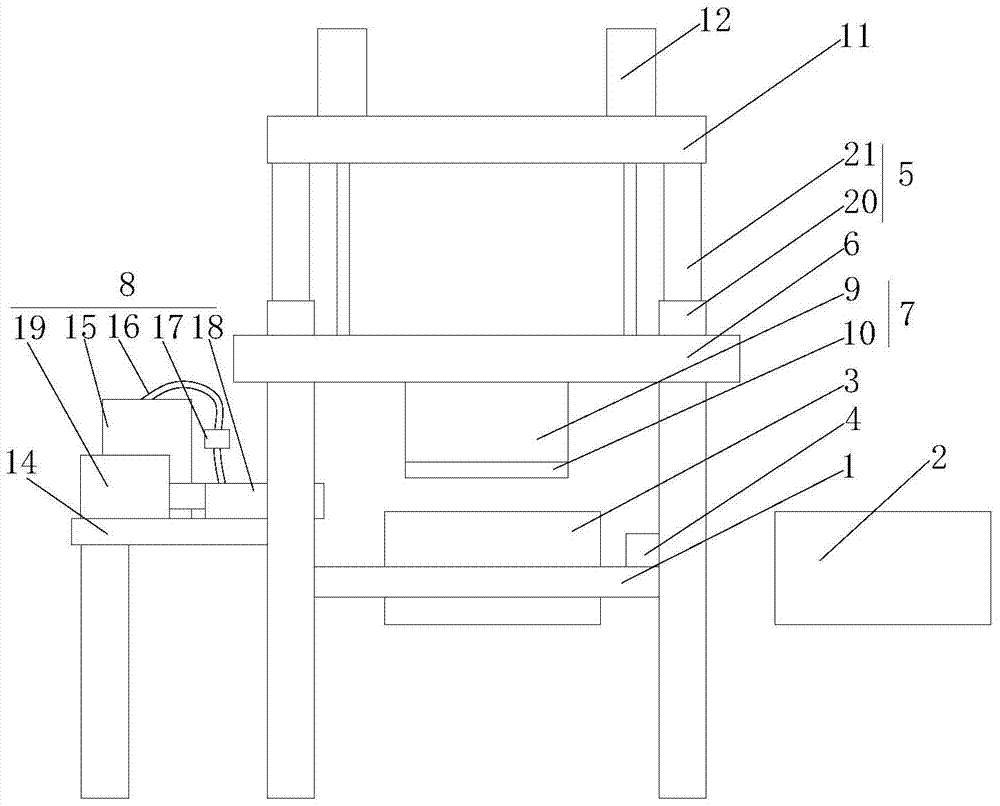

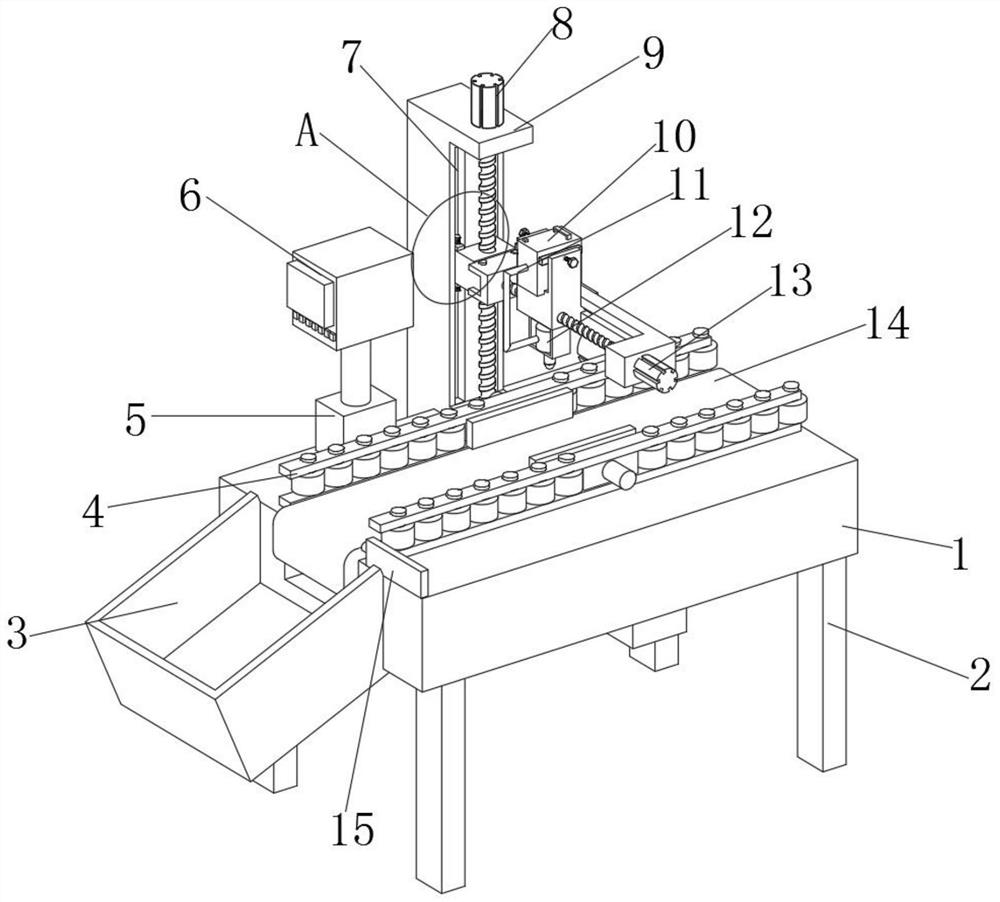

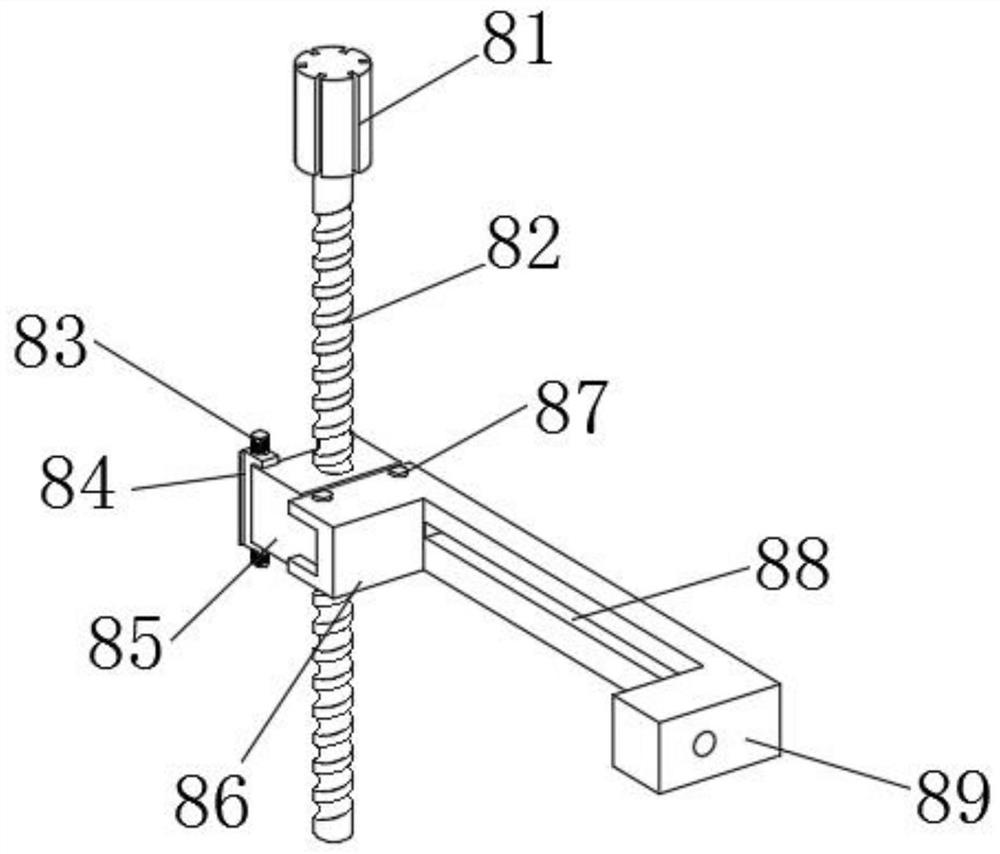

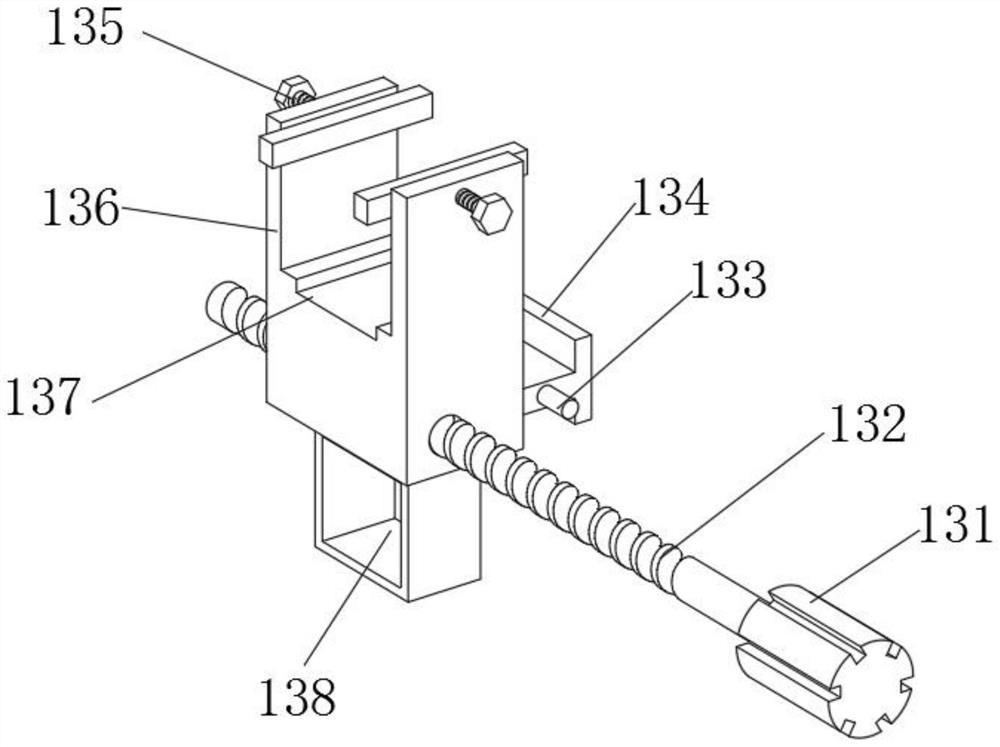

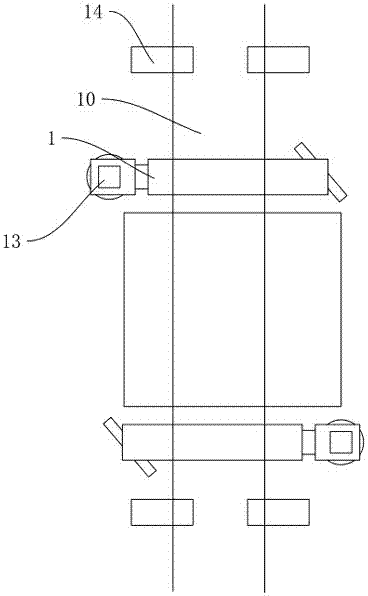

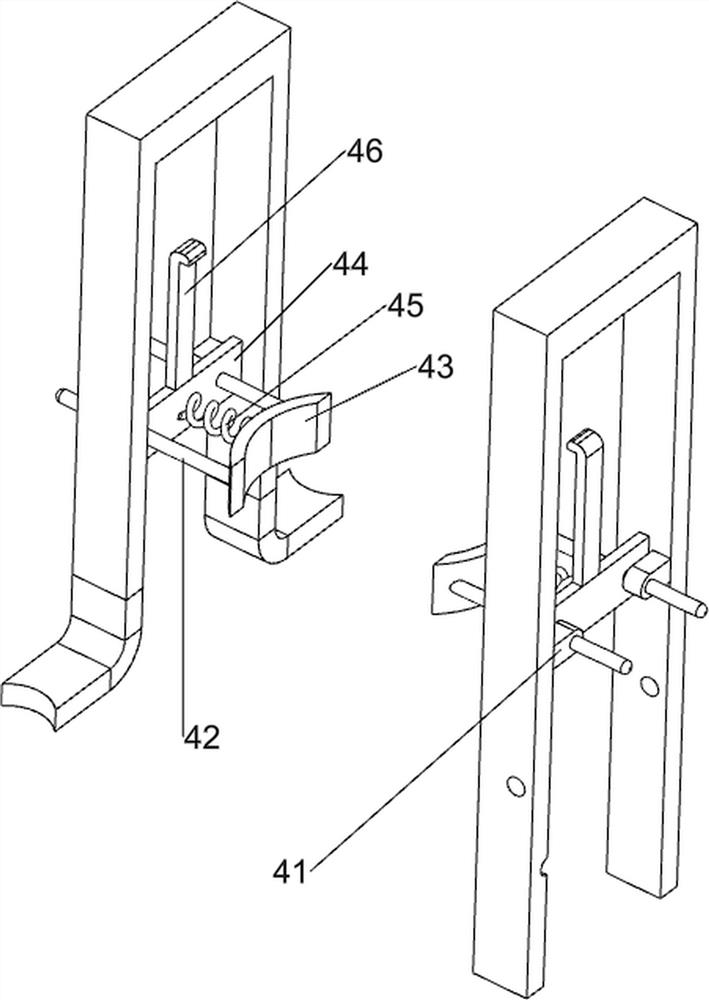

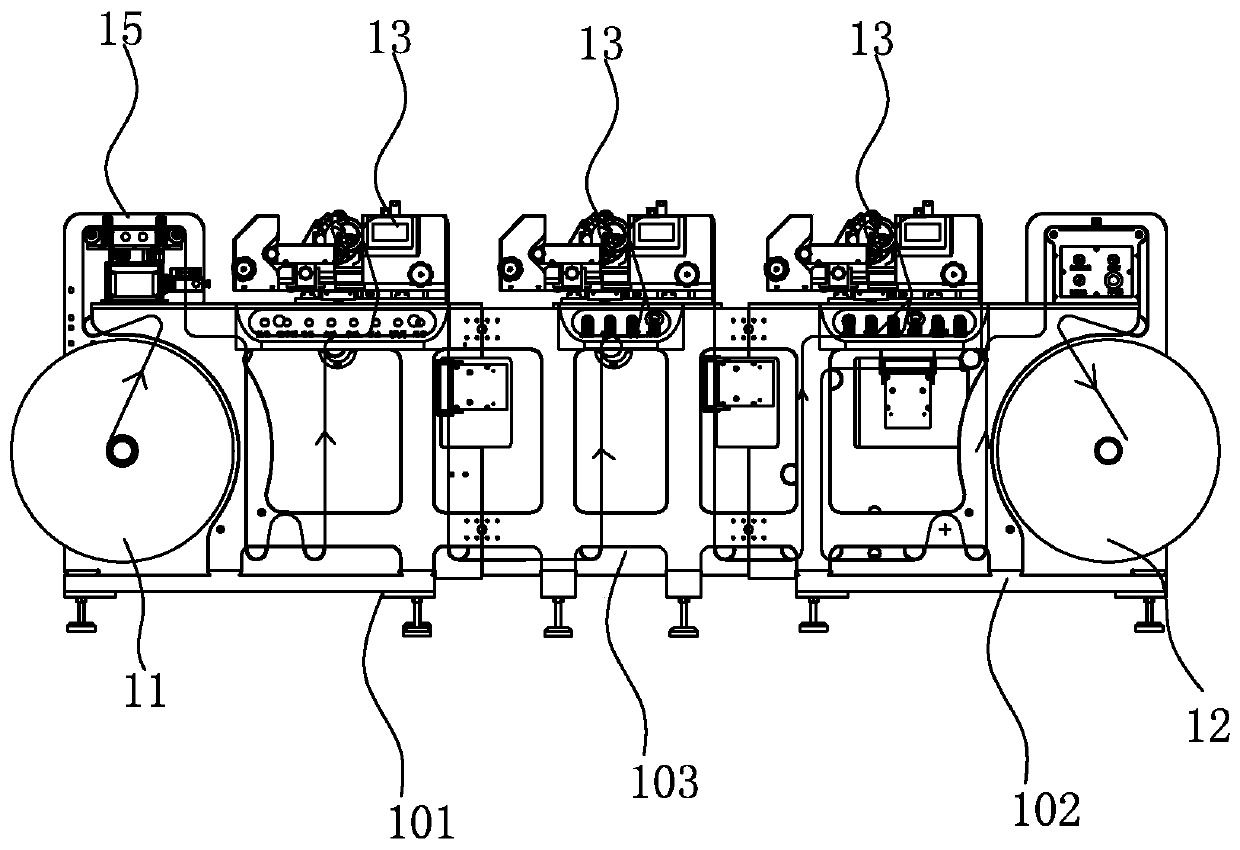

Package printing equipment

ActiveCN105109197ASlide up and down smoothlyIncrease printing speedRotary pressesSolenoid valvePrinting press

The invention provides package printing equipment which comprises a workbench, a feeding mechanism, a discharging mechanism, a sensor, stand columns, a printing machine seat, a printing machine, an inking device and a controller. The two sides of the workbench are each provided with two corresponding stand columns, and the four stand columns are arranged in a quadrangle shape. The printing machine seat is arranged on the four stand columns in a sliding and sleeving manner, and the printing machine is fixed below the printing machine seat, right faces the workbench and comprises a printing body and a soft printing plate. A supporting plate is arranged at the tops of the stand columns and located above the printing machine seat, an air cylinder is arranged on the supporting plate, and the output end of the air cylinder is connected with the printing machine seat. The inking device is arranged on a boss on the side faces of the stand columns and comprises an ink box, an inking pipe, a solenoid valve, an inking brush and a second drive mechanism. The feeding mechanism, the discharging mechanism, the sensor, the air cylinder, the second drive mechanism and the solenoid valve are connected with the controller. The package printing equipment is simple in structure, practical and reliable in work, the mechanisms are controlled by the controller for coordination work, and automatic printing is achieved.

Owner:安徽聚祥升酒类包装有限公司

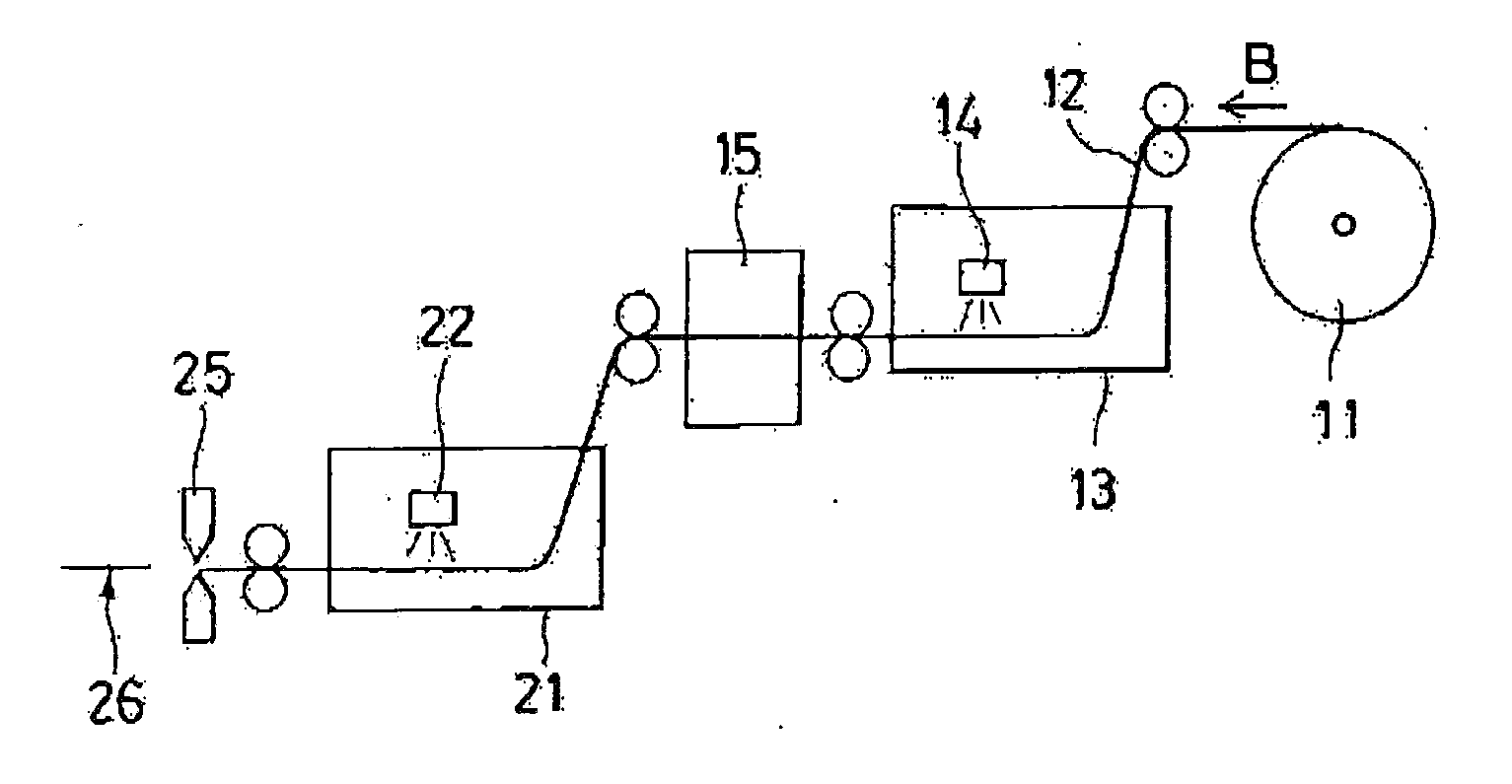

Ink Jet Recording Method for Recording Pattern Layer and White Overlaying Layer on Longitudinal Sheet

ActiveUS20120287211A1High quality printingSatisfied levelMeasurement apparatus componentsDuplicating/marking methodsComputer scienceRecording media

Owner:SEIKO EPSON CORP

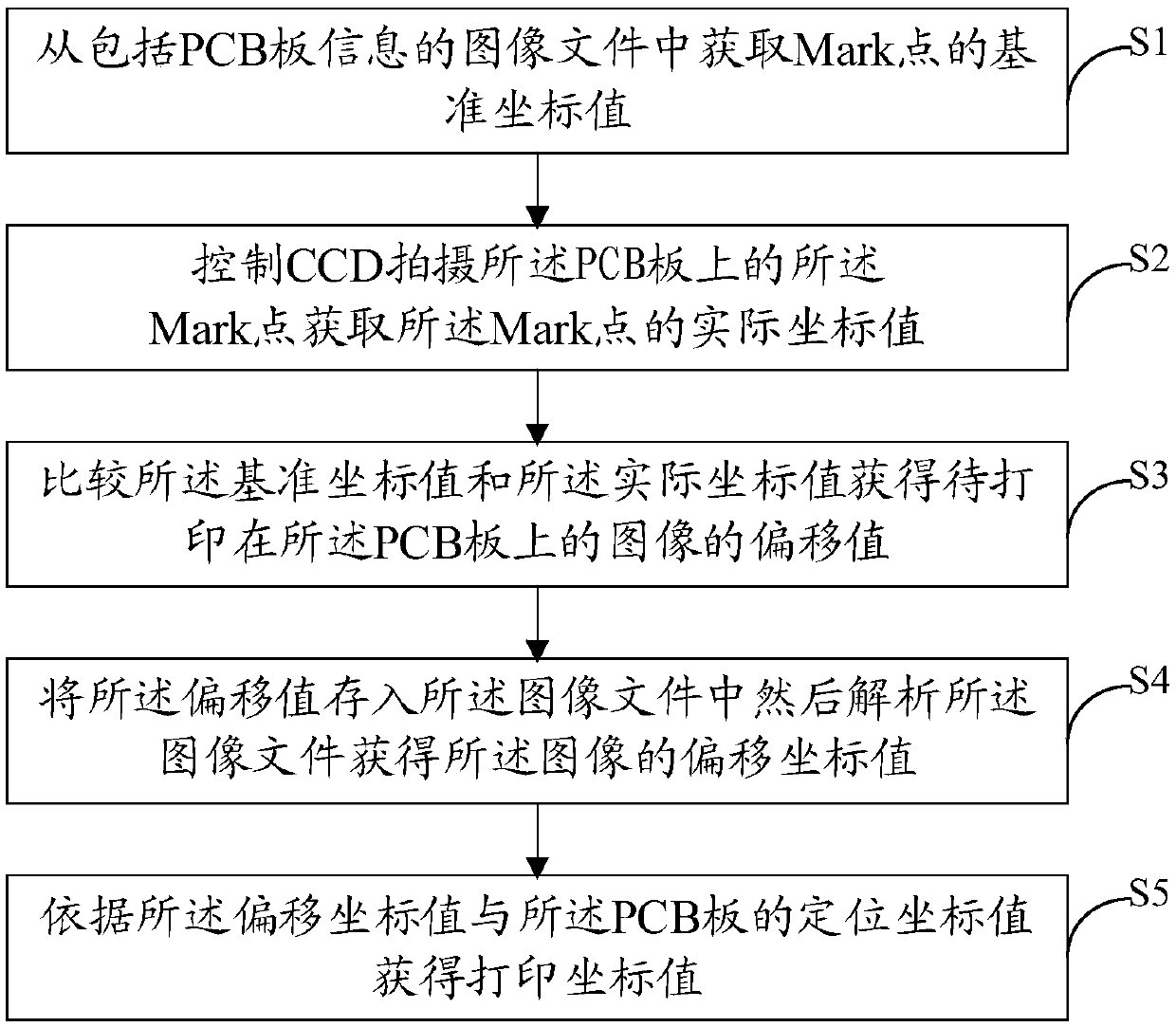

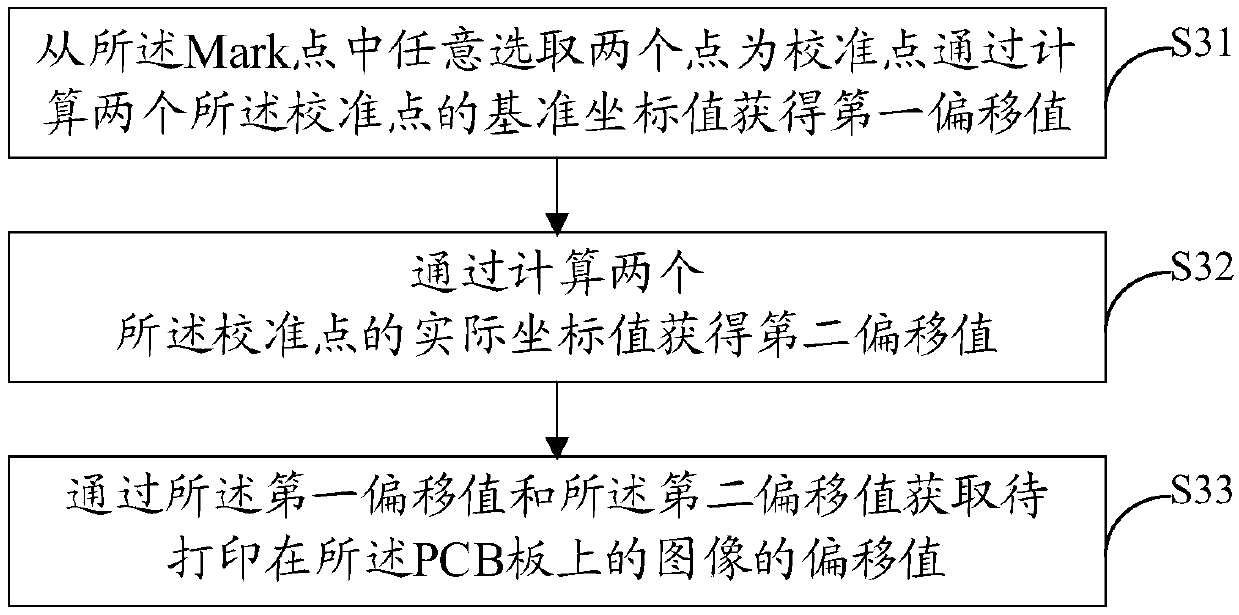

PCB positioning error calibration method, device and equipment and storage medium

PendingCN109685784AEasy to operateReduce mistakesImage enhancementImage analysisComputer graphics (images)Automation

The invention discloses a PCB positioning error calibration method, device and equipment and a storage medium. The method comprises the steps of obtaining a reference coordinate value of a Mark pointfrom an image file comprising PCB information; Controlling a CCD to shoot the Mark point on the PCB to obtain an actual coordinate value of the Mark point; Comparing the reference coordinate value with the actual coordinate value to obtain an offset value of an image to be printed on the PCB; Storing the offset value in the image file, and analyzing the image file to obtain an offset coordinate value of the image; And obtaining a printing coordinate value according to the offset coordinate value and the positioning coordinate value of the PCB. According to the method, manual participation is not needed, automation is high, efficiency is high, and the printing position of the image on the PCB is accurate after recalculation.

Owner:SENDA SHENZHEN TECH CO LTD

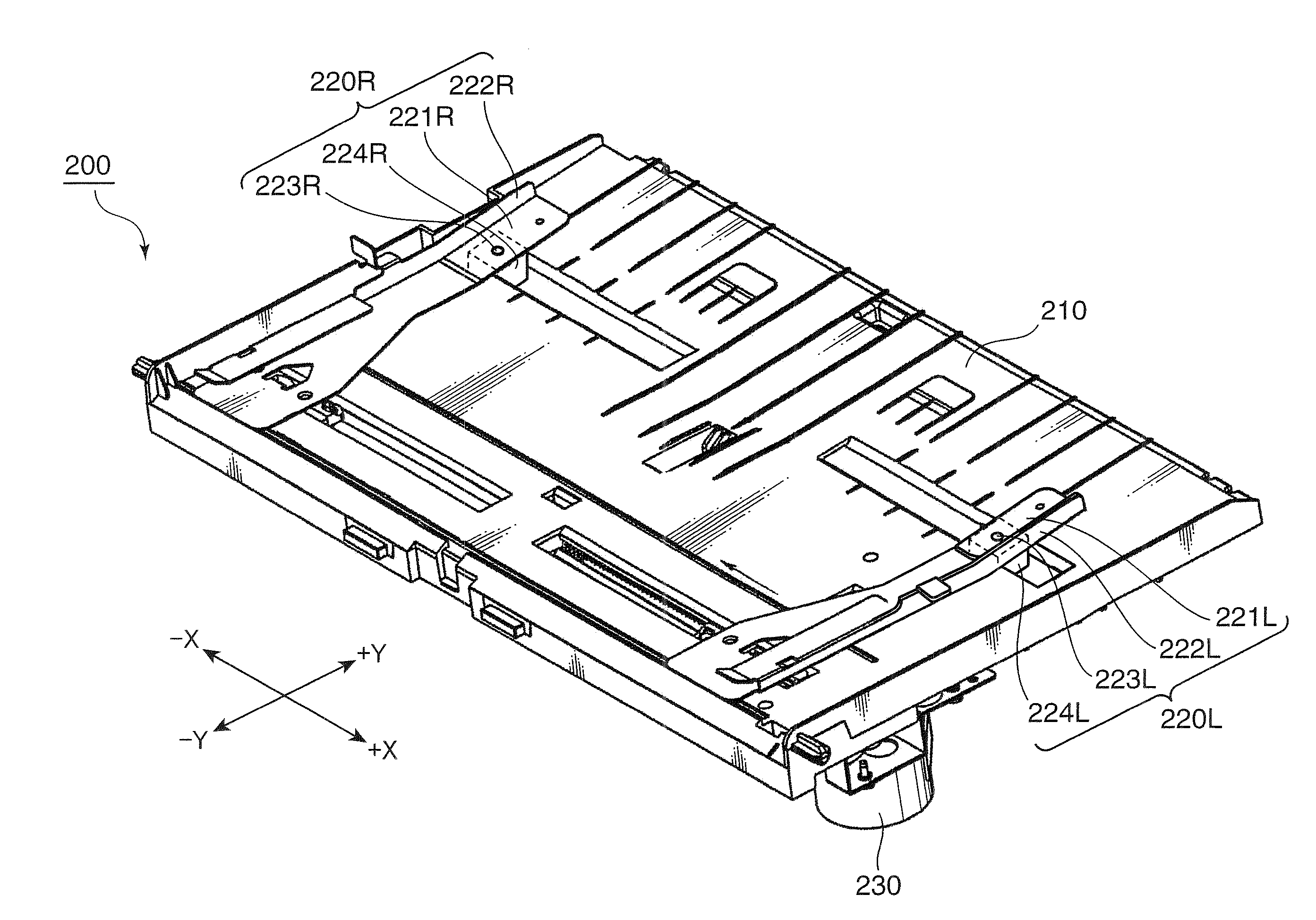

Paper supply mechanism and roll paper printer

ActiveUS8047462B2Easily moved widthwiseIncrease loadProjector film strip handlingFilament handlingRolling paperLocking mechanism

Owner:SEIKO EPSON CORP

Patching method and device

ActiveCN109561603APrinting position is accurateGuaranteed accuracyPrinted circuit assemblingElectrical componentsSolder pasteVisual detection

Owner:惠州市协昌电子有限公司

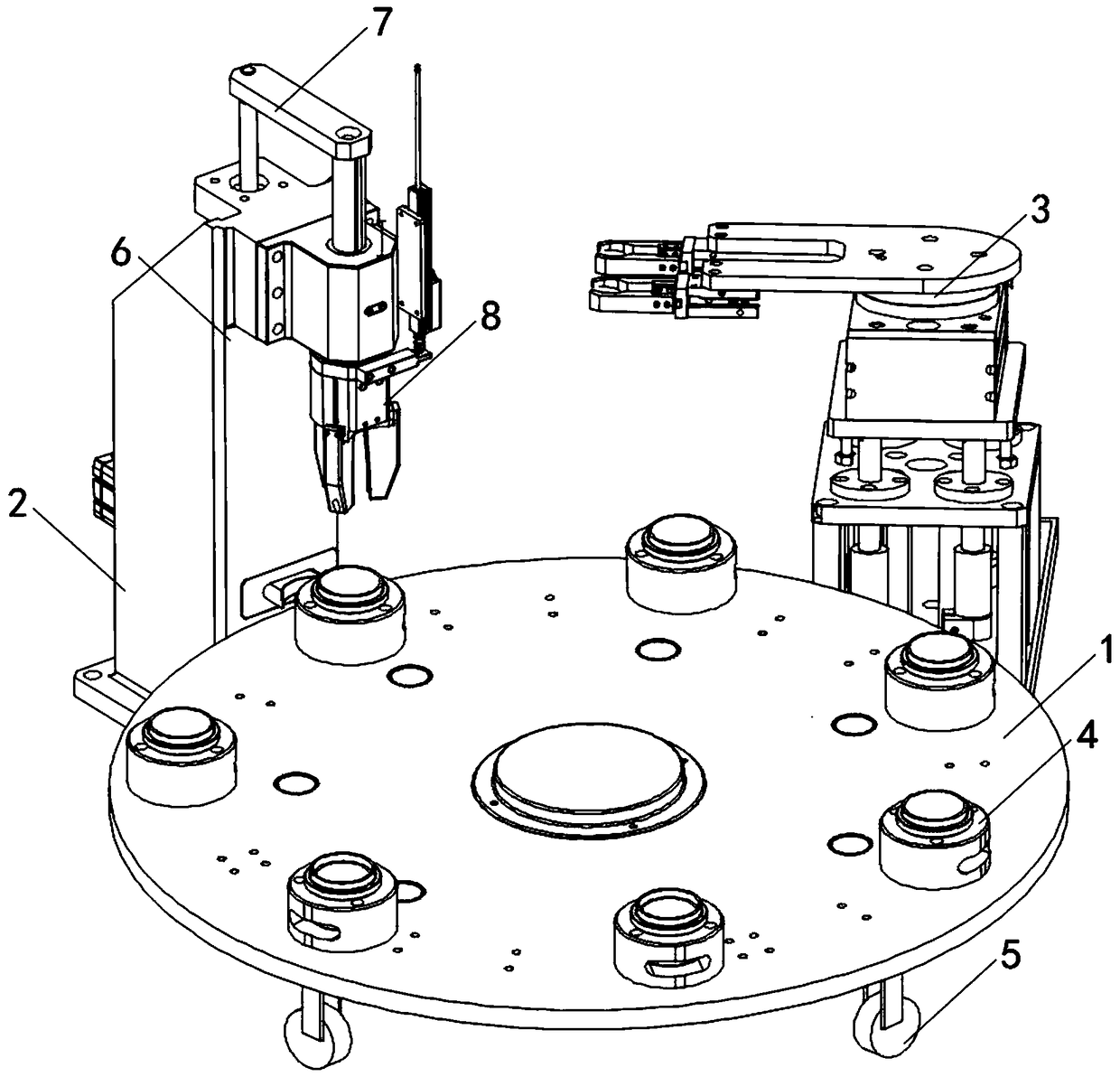

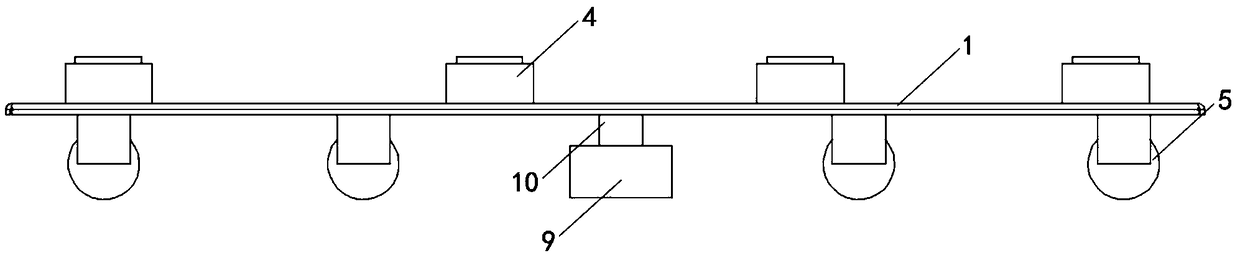

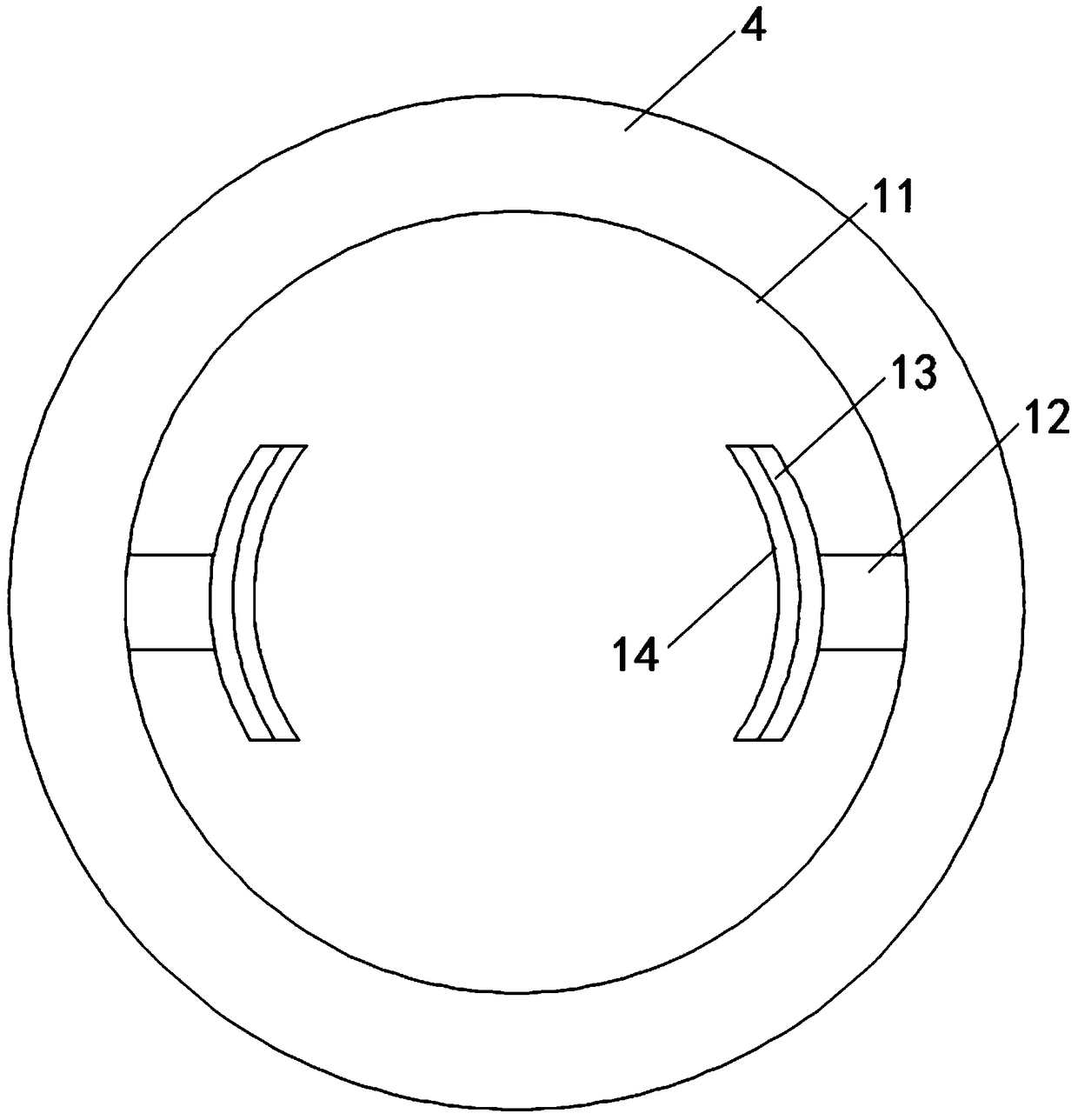

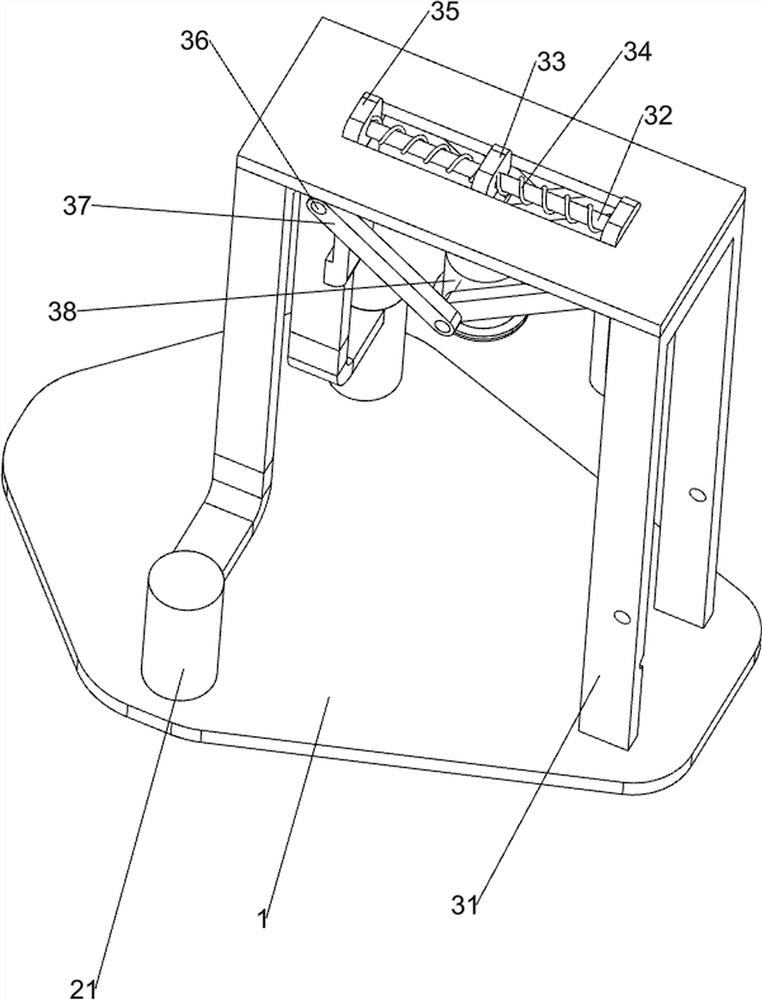

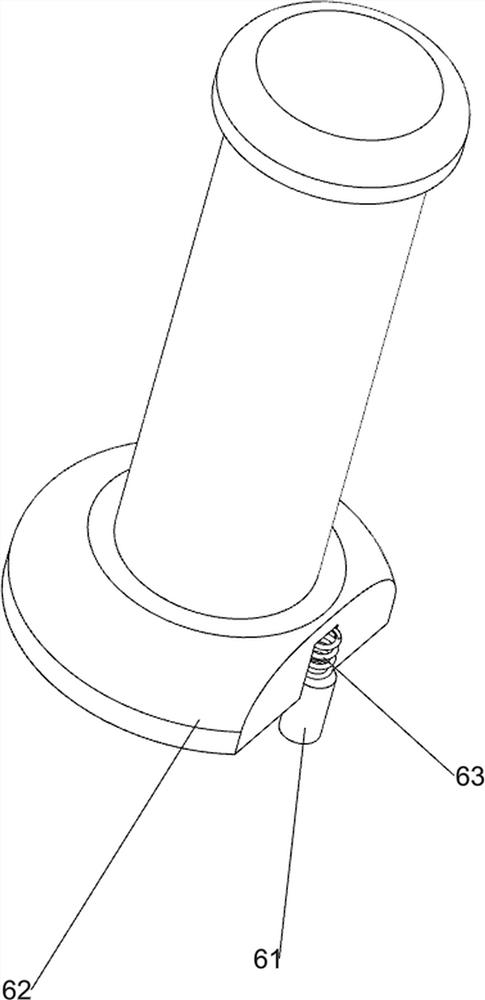

Digital printing process of ring-pull can body and printing equipment thereof

ActiveCN108995397AImprove printing efficiencyPrinting position is accurateTypewritersSocial benefitsElectric machinery

The invention discloses a digital printing process of a ring-pull can body and printing equipment thereof. The printing equipment comprises a rotary table, a printing seat, a putting and sending disc,sleeve seats and a roller, wherein the rotary table is of a circular structure, the printing seat is longitudinally arranged on one side of the rotary table, the putting and sending disc is arrangedon the other side of the rotary table, and a plurality of hollow cylindrical sleeve seats are arranged at the edge of the upper end surface of the rotary table at an equal radian. The digital printingprocess has the beneficial effects that three printing blocks are driven to rotate by a fourth motor so as to print a ring-pull can, and the can body in the plurality of sleeve seats is continuouslydriven to move below the printing blocks at regular time by the rotary table so as to continuously print, so that the printing efficiency of the equipment is improved; a swing block is driven to moveto the position of the rotary table by a rolling belt, and the can body is driven to swing and put into the sleeve seats by the swing block, so that on one hand, the working efficiency of the equipment is improved, and on the other hand, the degree of automation of the equipment is high during operation; and the equipment has the advantages of firmness and durability, has good social benefits andeconomic benefits and is suitable for popularization and use.

Owner:昇兴(安徽)包装有限公司

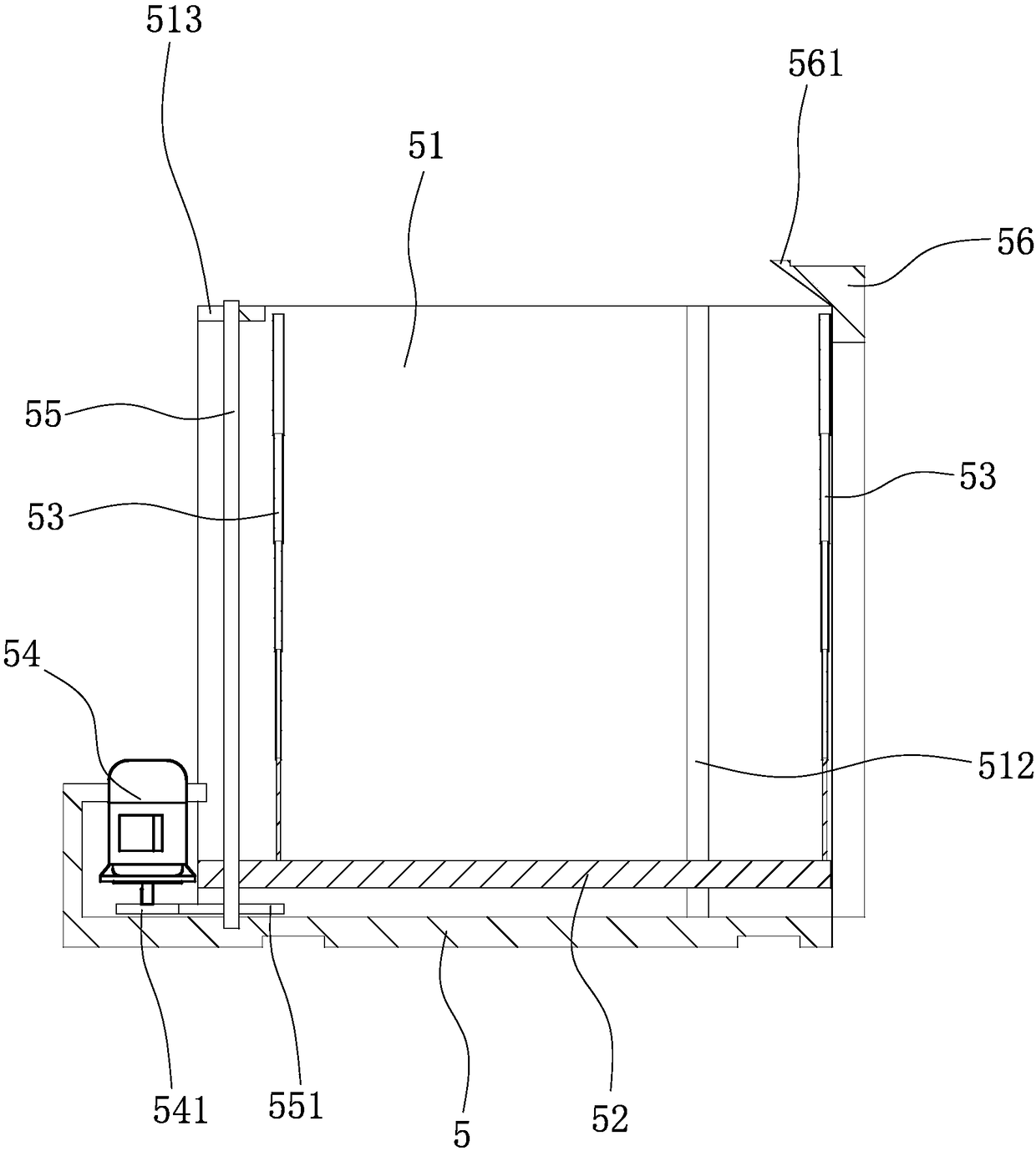

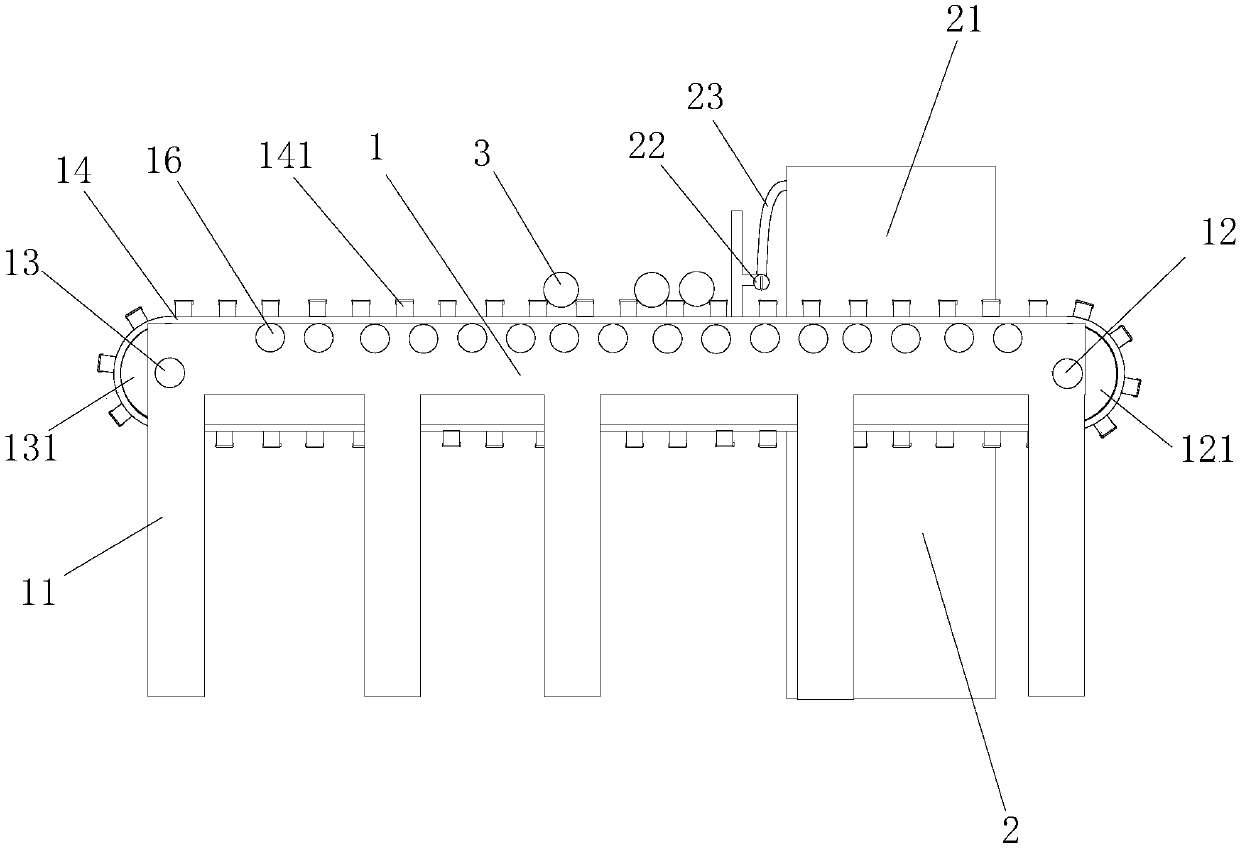

Printing equipment

ActiveCN108340686AAccurate and neatly stackedNeatly stackedTypewritersPile receiversPulp and paper industryPaper sheet

The invention provides printing equipment, and belongs to the technical field of printing. The printing equipment solves the technical problem that the positions of patterns on outer packing paper obtained through existing printing equipment are not unified. The printing equipment comprises a rack, a conveying belt rotationally arranged on the rack and multiple printing spray heads fixed to the rack and located over the middle segment of the conveying belt. The position, located at the front end of the conveying belt, of the rack is rotationally connected with an unwinding roller. A paper collection mechanism is arranged at the position, located under the conveying belt, in the rack. The conveying belt can adsorb glass paper located on the conveying belt onto the surface of the conveying belt, the conveying belt located over the paper collection mechanism enables the glass paper adsorbed to the conveying belt to be separated, and an ink drying mechanism capable of accelerating drying of ink on the glass paper is arranged at the position, right facing the rear end of the conveying belt, of the rack. The printing equipment has the advantage that the printing positions of patterns ofouter packing paper obtained through printing are unified.

Owner:MATSUOKA PRINTING

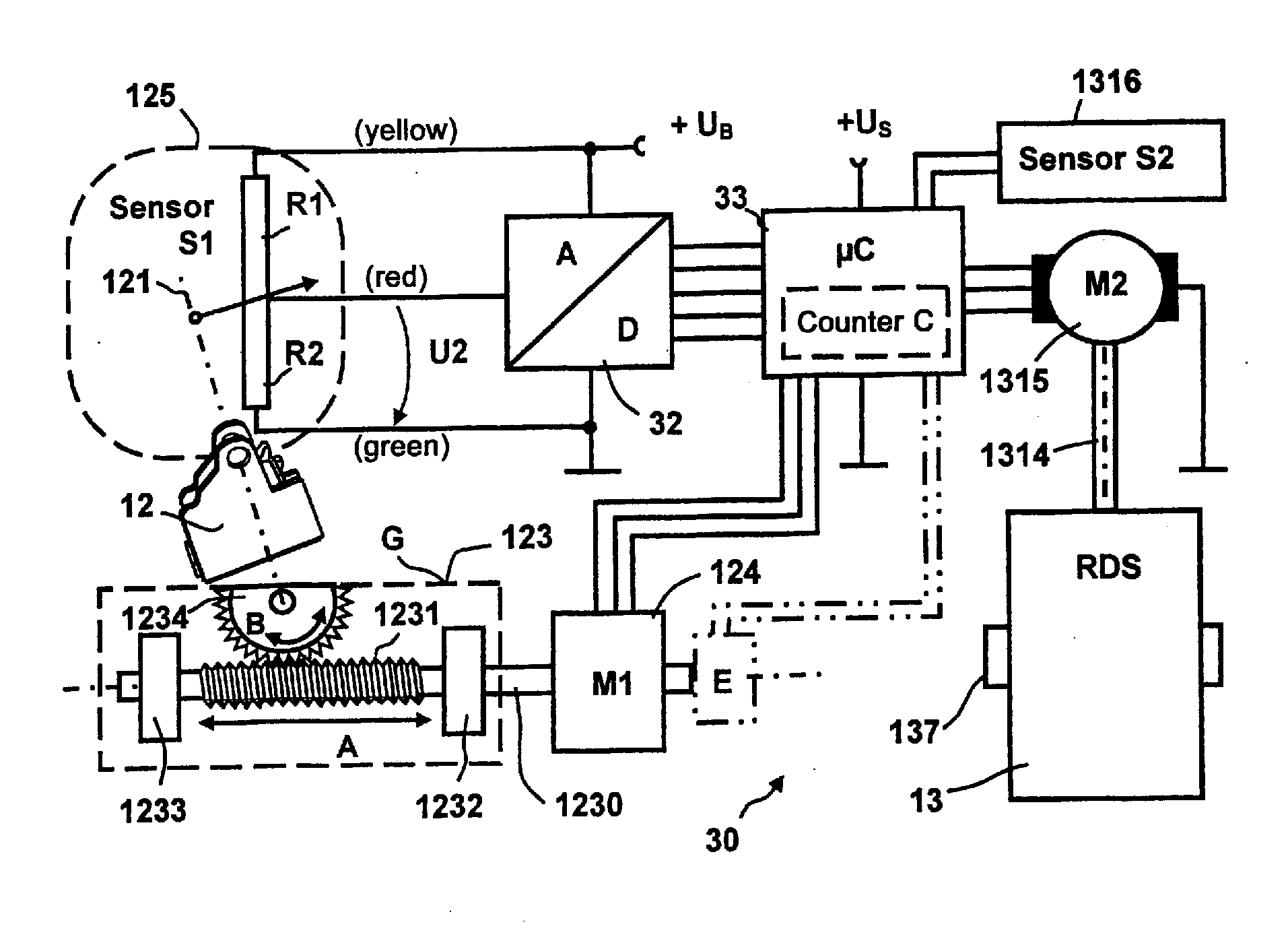

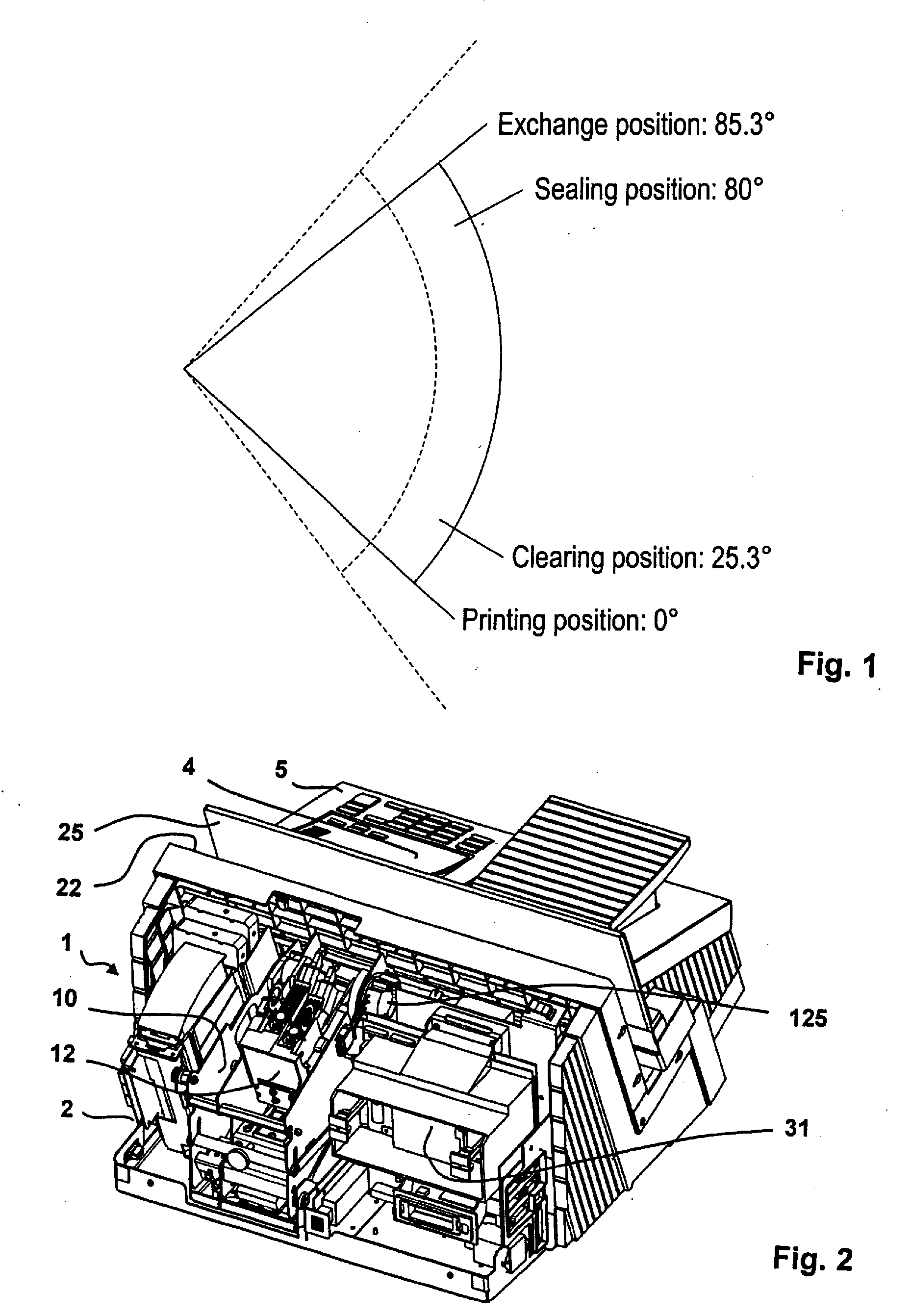

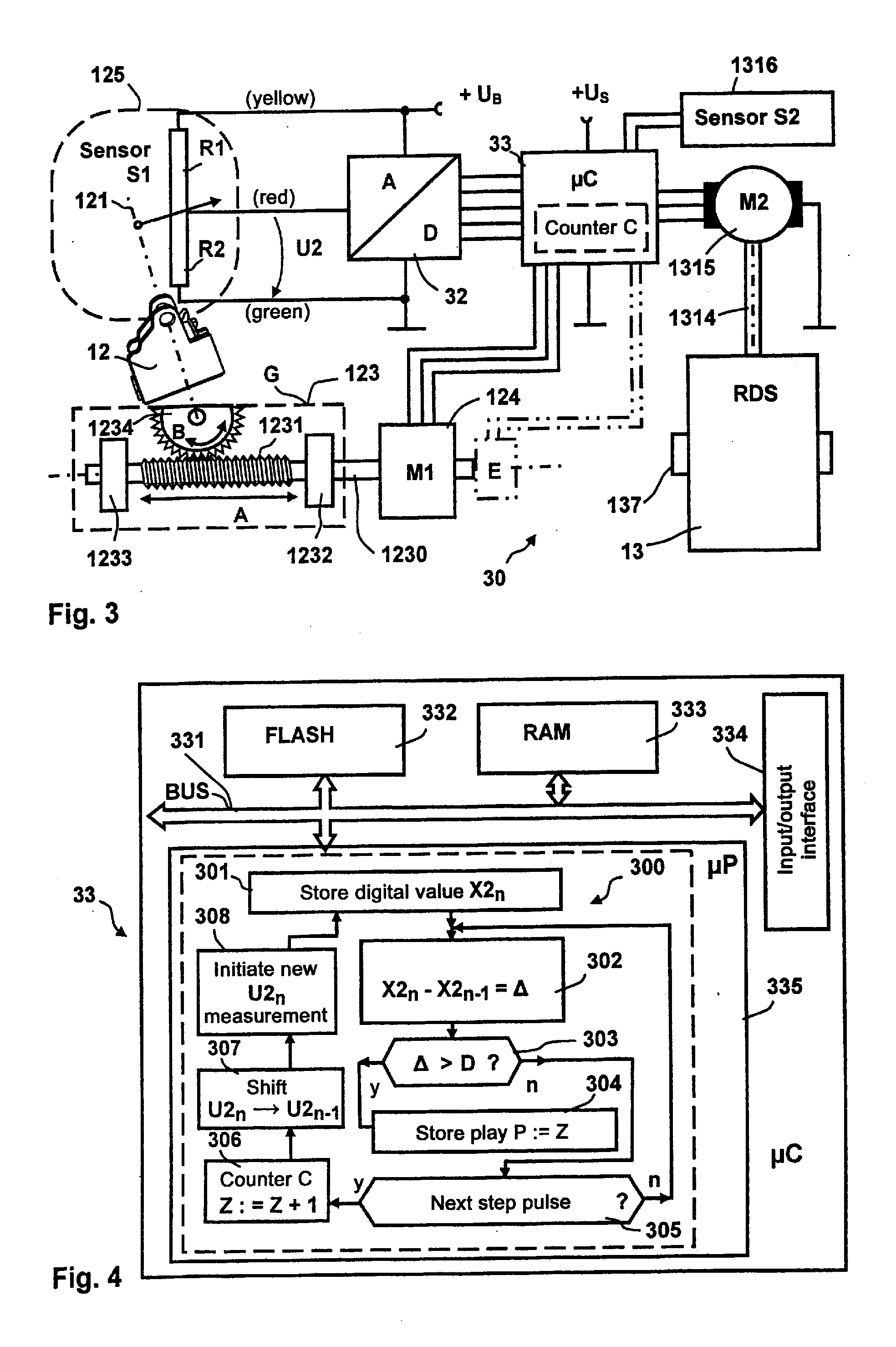

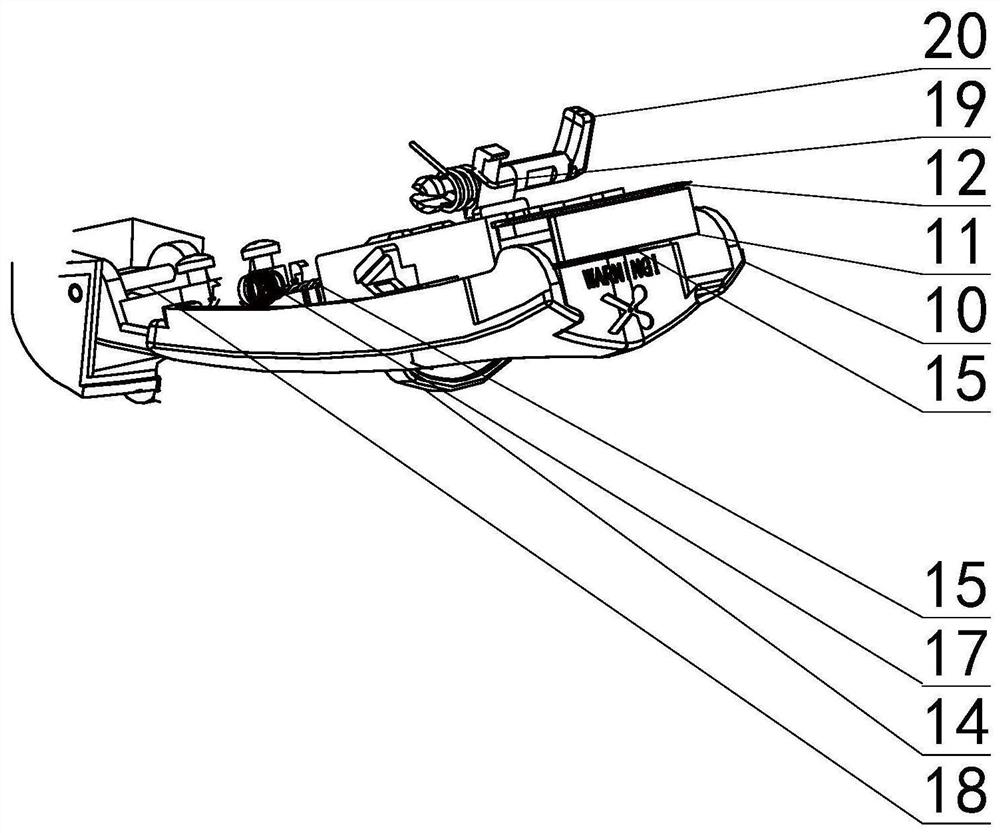

Measuring method and arrangement to determine the play of an ink jet cartridge pivot unit

InactiveUS20090033706A1Time durationPrinting position is accuratePower drive mechanismsOther printing apparatusEngineeringGear train

A measuring arrangement and measurement method determine the play of a cartridge pivot unit of an inkjet printing system that has at least one stop for the cartridge pivot unit. The cartridge pivot unit is driven by a first motor via a gear train and is equipped with a first movement sensor to establish a movement of the cartridge pivot unit upon leaving the stop. The cartridge pivot unit moves only when the play of the gear train is overcome. The stop for the cartridge pivot unit is formed by a mobile cleaning and sealing station. A counter is provided to count pulses, the count being representative of the play of the gear train of the cartridge pivot unit counting begins with leaving the mobile stop and continues until the movement of the cartridge pivot unit upon leaving the stop again ensues in conformity with the actuation by the first motor.

Owner:FRANCOTYP POSTALIA

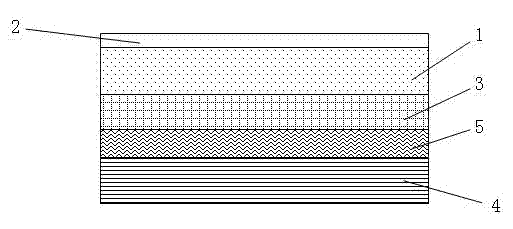

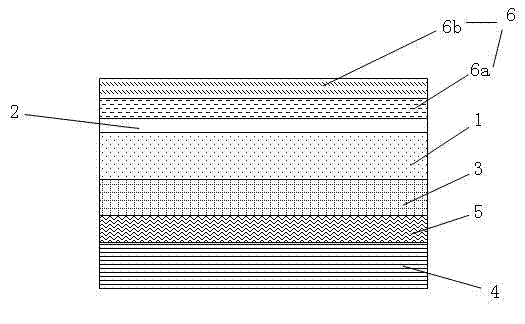

Energy rating label and production method thereof

InactiveCN102176296AReduce duplicationLow costStampsSpecial ornamental structuresGraphicsInformation layer

The invention discloses an energy rating label, which comprises covering paper, a gum layer and backing paper, wherein the covering paper is thermal sensitive paper. Energy information displayed on the energy rating label comprises two parts, wherein one part is fixed graphics and text information directly printed on the upper surface of the covering paper by ink according to related national regulations, and forms an information layer bearing the fixed graphics and text information; and the energy information of the other part is variable information which is formed by the heating discoloration of the thermal sensitive paper in the printing and is displayed by the information layer. The production method for the energy rating label comprises the following steps of: printing the same fixed graphics and text information on the surface layer of the covering paper in advance, wherein a plurality of products using the energy rating labels can adopt blank energy rating labels with the same fixed information; and then printing the variable information corresponding to different products is printed at blank positions of the blank energy rating labels according to actual conditions respectively, thereby producing the energy rating label for a certain given product to further reduce the repetitive mould opening or composition cost of the energy rating label in the printing process.

Owner:TIANJIN MAIKEWEI TECH

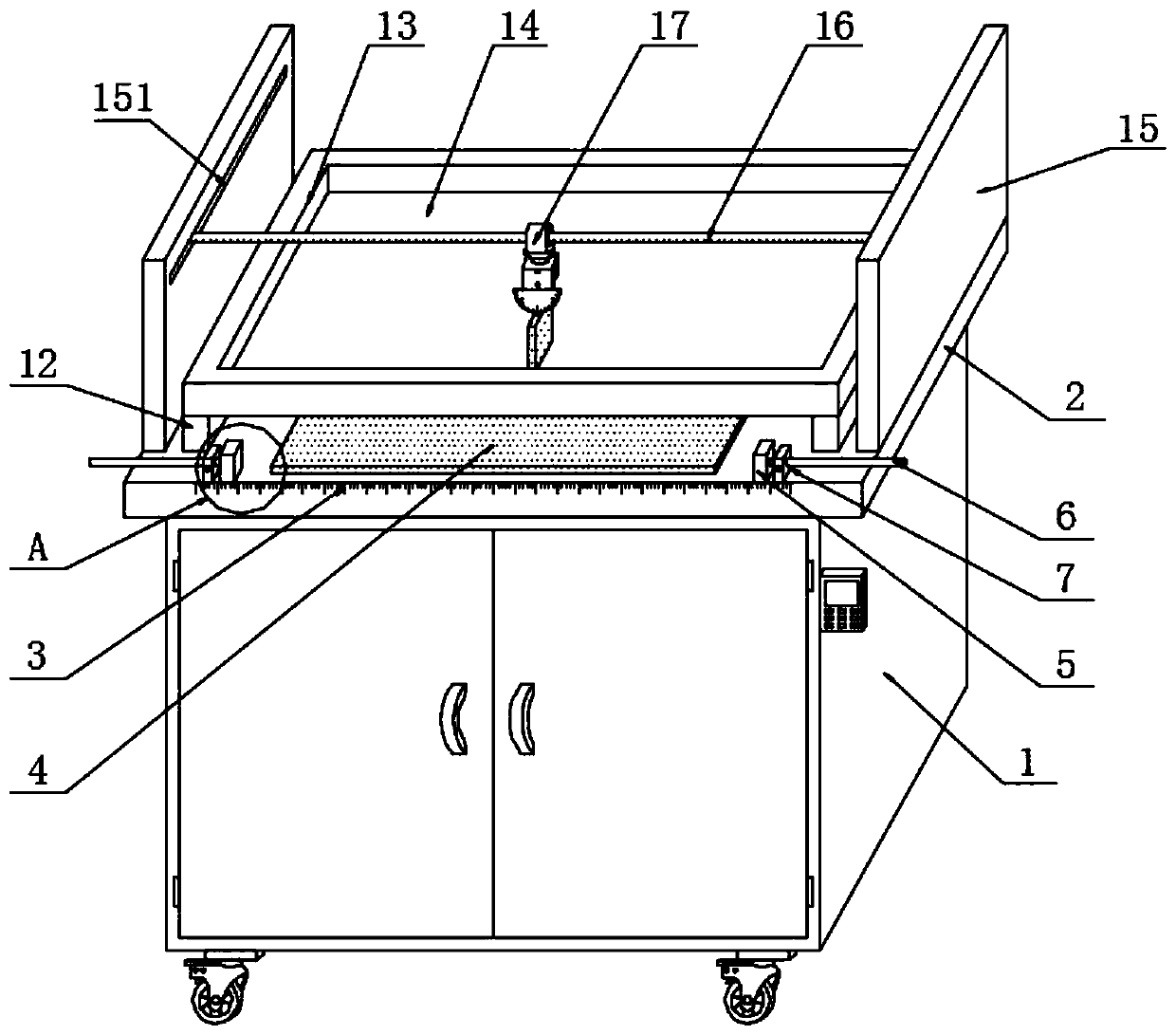

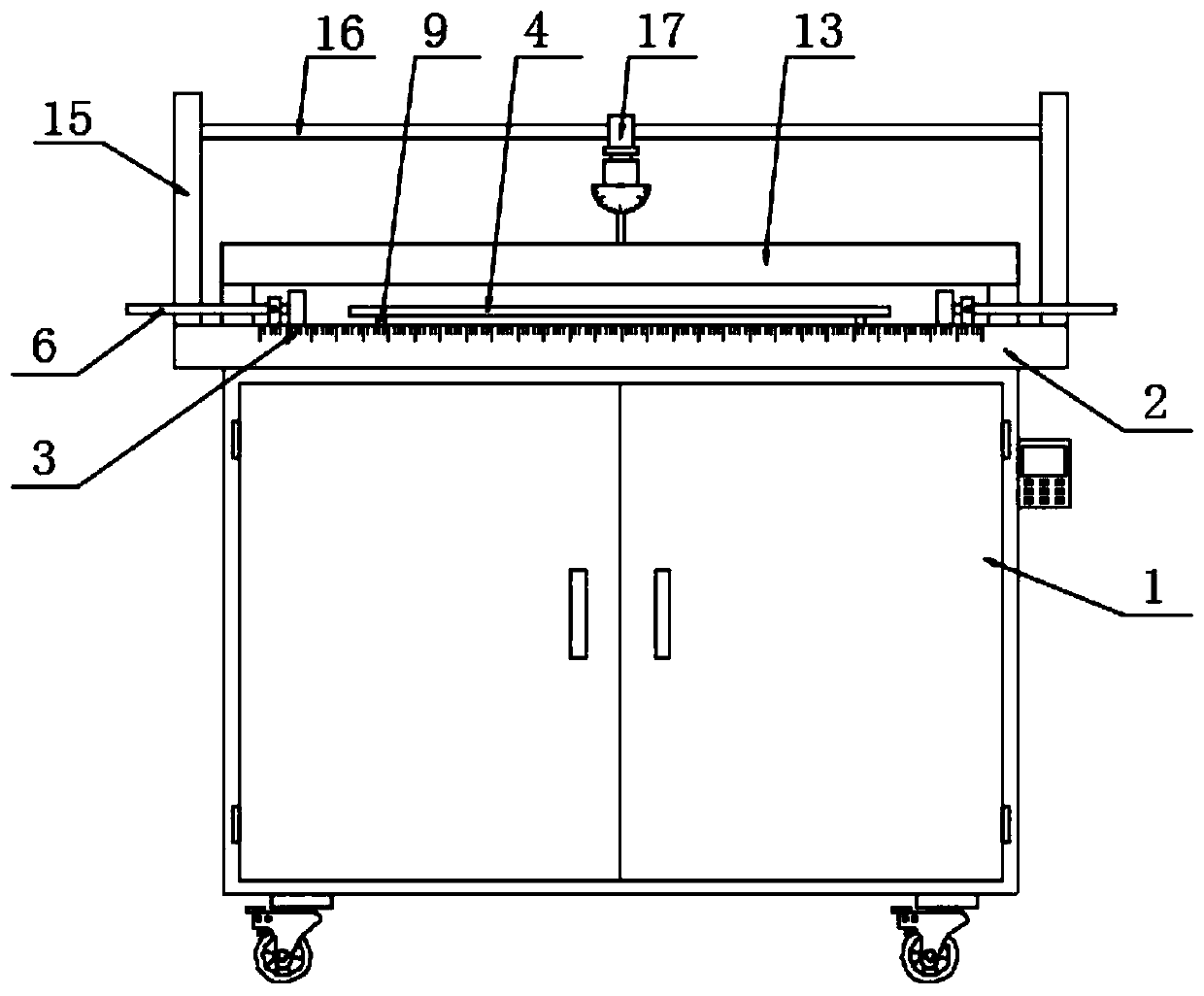

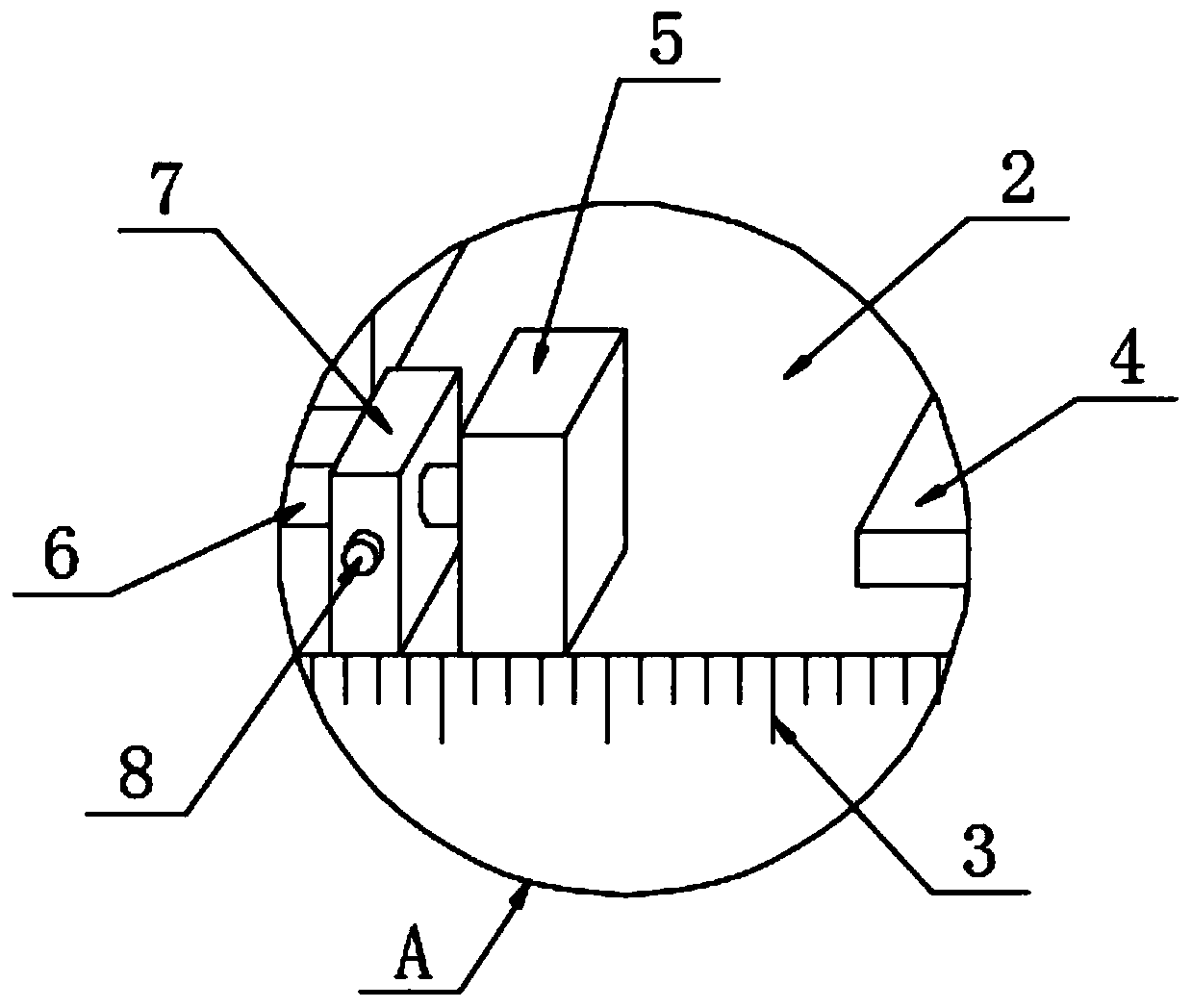

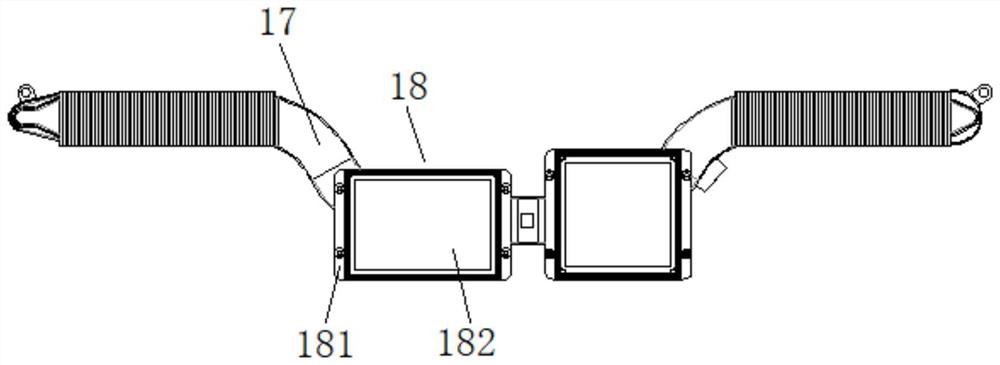

Silk-screen printing device of polymer quantum device

The invention discloses a silk-screen printing device of a polymer quantum device, and particularly relates to the technical field of silk-screen printing. The device comprises a fixed seat, wherein the top end of the fixed seat is connected with a workbench; a scale line is arranged on the front surface of the top of the workbench; a bearing plate is arranged at the position, close to the inner side of the scale line, above the workbench; limiting mechanisms are installed at the positions, at the two sides of the bearing plate, of the front edge of the top end of the workbench; fixing framesare arranged at the positions, on the two sides of the bearing plate, of the top end of the workbench; the fixing frames are fixedly connected with the workbench and located on the rear side of the limiting mechanisms; and the top ends of the fixing frames are connected with a frame. According to the device, the deviation of the printed position during printing of the to-be-printed object is avoided, a screen plate is convenient to mount, dismount and clean; and meanwhile, the scraping angle adjusting mode of a scraper blade is better, so that the scraper plate moves more stably in the horizontal direction.

Owner:青岛菲木科技有限公司

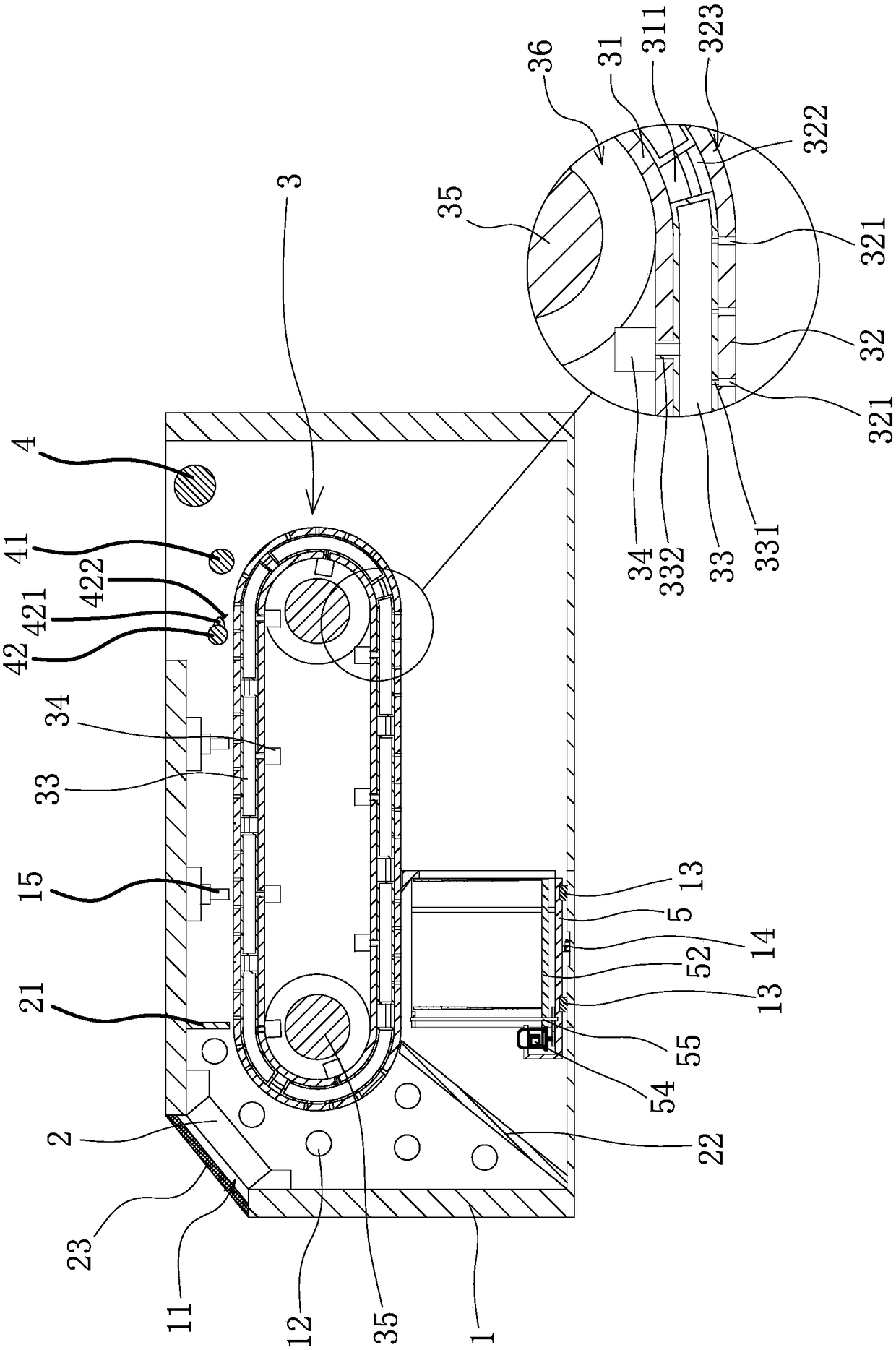

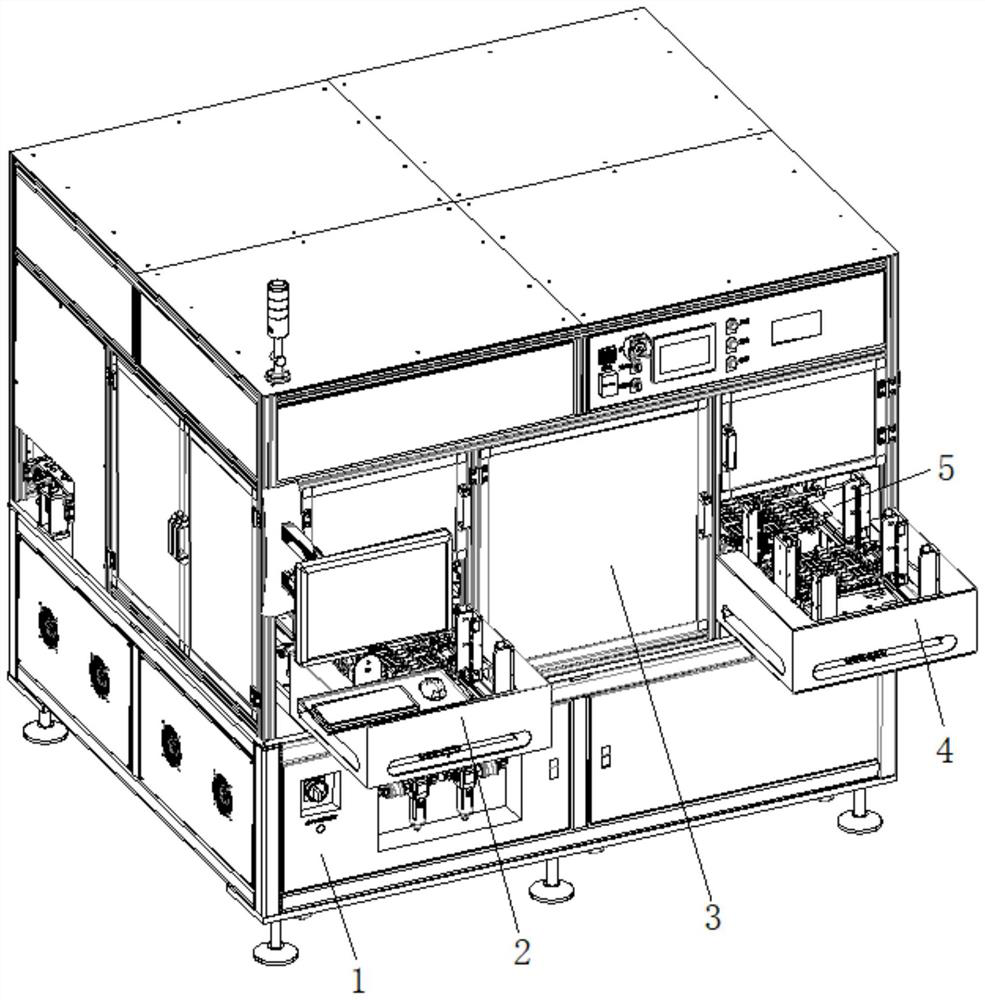

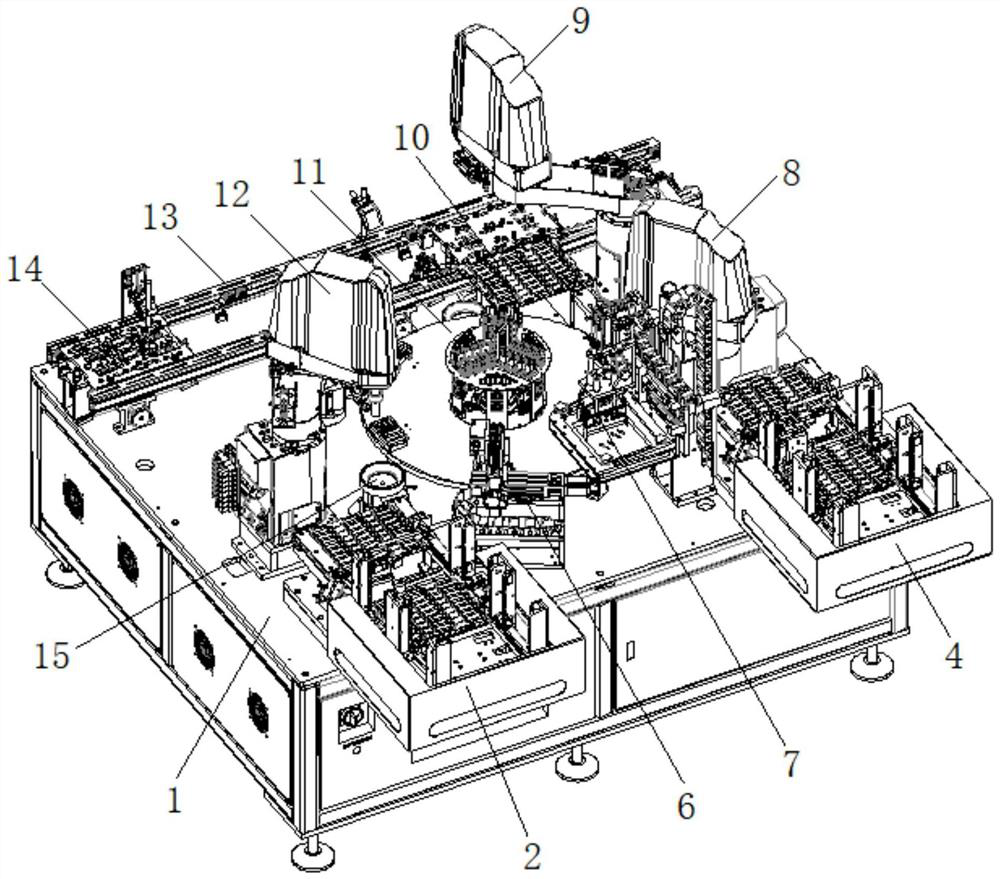

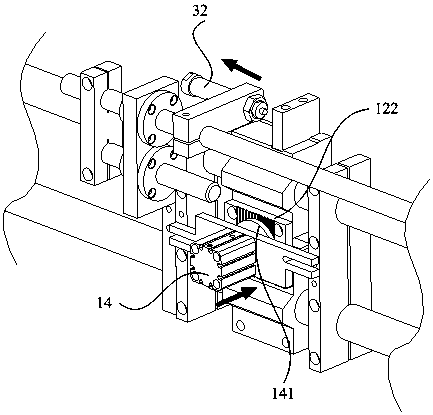

Automatic assembling and feeding machine for heat conduction blocks

PendingCN112676672AImprove assembly accuracyReduce defective rateElectrical componentsSoldering auxillary devicesEngineeringPrinting press

The invention relates to an automatic assembling and feeding machine for heat conduction blocks. The automatic assembling and feeding machine comprises a rack, a rotary table mechanism, a copper sheet supply mechanism, an iron cover supply mechanism, a copper sheet taking manipulator, a solder paste printing mechanism, a solder paste detection mechanism, an iron cover taking manipulator, a feeding manipulator and a feeding conveying line, wherein the rotary table mechanism, the copper sheet supply mechanism, the iron cover supply mechanism, the copper sheet taking manipulator, the solder paste printing mechanism, the solder paste detection mechanism, the iron cover taking manipulator, the feeding manipulator and the feeding conveying line are arranged at the upper end of the rack; the copper sheet taking manipulator, the solder paste printing mechanism, the solder paste detection mechanism, the iron cover taking manipulator and the feeding manipulator are sequentially arranged around the rotary table mechanism, and five positioning jigs corresponding to the mechanisms are arranged on the rotary table mechanism; the copper sheet supply mechanism and the iron cover supply mechanism correspondingly supply materials for the copper sheet taking manipulator and the iron cover taking manipulator respectively; and the feeding manipulator is used for sucking the heat conduction blocks and conveying the heat conduction blocks to the feeding conveying line. The automatic assembling and feeding machine can be used for automatically assembling and feeding the heat conduction blocks, so that the production efficiency is improved, the labor intensity is alleviated, meanwhile, the assembling precision is high, and the solder paste printing thickness and printing shape are easy to control.

Owner:苏州方桥机电有限公司

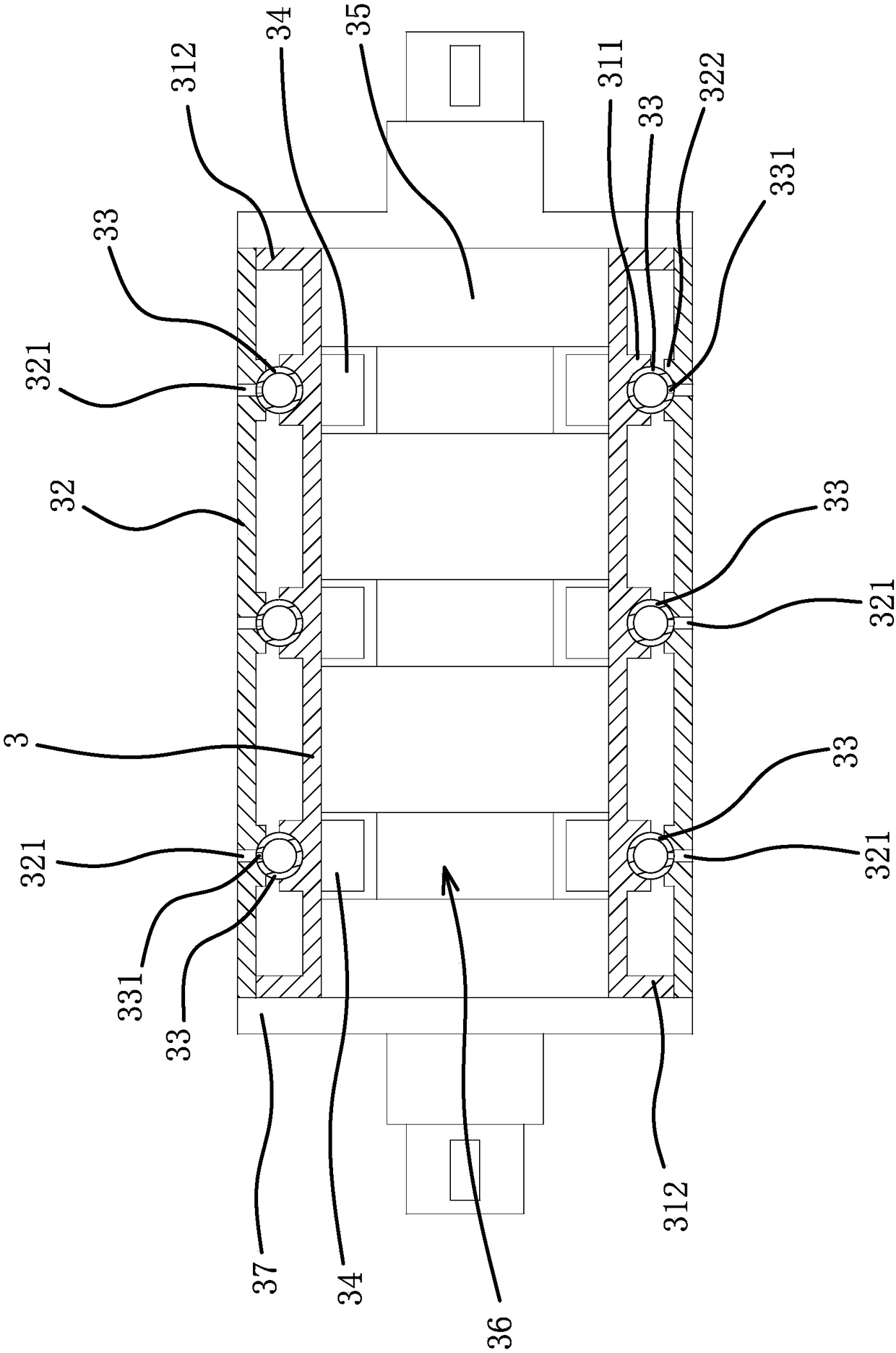

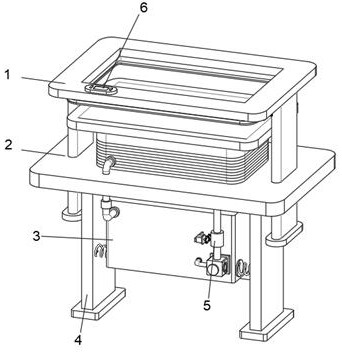

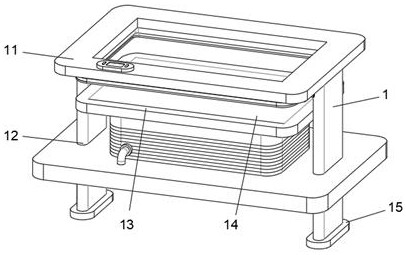

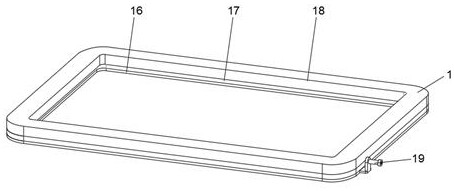

A packaging and printing equipment

ActiveCN105109197BSlide up and down smoothlyIncrease printing speedRotary pressesSolenoid valvePrinting press

The invention proposes a packaging and printing equipment, which includes a worktable, a feeding mechanism, a feeding mechanism, a sensor, a column, a printing machine base, a printing machine, an inking device and a controller; two Columns, the four columns are arranged in a quadrangular shape; the printing machine base is slidably set on the four columns, the printing machine is fixed under the printing machine base, and is facing the workbench, and the printing machine includes a printing body and a soft printing plate; There is a support plate on the top of the column, the support plate is located above the printing machine base, a cylinder is arranged on the support plate, and the output end of the cylinder is connected with the printing machine base; the inking device is arranged on the boss on the side of the column, including ink cartridges, ink Tube, solenoid valve, ink feeding brush and second driving mechanism; feeding mechanism, unloading mechanism, sensor, cylinder, second driving mechanism and solenoid valve are respectively connected with the controller. The invention has the advantages of simple structure, practicality and reliable operation, and realizes automatic printing by controlling various mechanisms to work in coordination through a controller.

Owner:安徽聚祥升酒类包装有限公司

Sheet width aligning device, sheet transport device and image forming apparatus

InactiveUS7918452B2Printing position is accurateRegistering devicesFunction indicatorsEngineeringElectrical and Electronics engineering

A sheet width aligning device includes two width aligning members which respectively contact widthwise ends of a sheet to regulate a widthwise position of the sheet. A first detector detects one widthwise end of the sheet and a second detector detects the other widthwise end of the sheet. A moving mechanism moves the first and second detectors located at initial positions at outer sides of the sheet towards the center of the sheet in the widthwise directions. A determining section determines the positions of the width aligning members based on a detection timing, at which the first detector detected the one widthwise end, and a detection timing, at which the second detector detected the other widthwise end. A driving mechanism drives the width aligning members to move to the positions determined by the determining section.

Owner:KYOCERA DOCUMENT SOLUTIONS INC

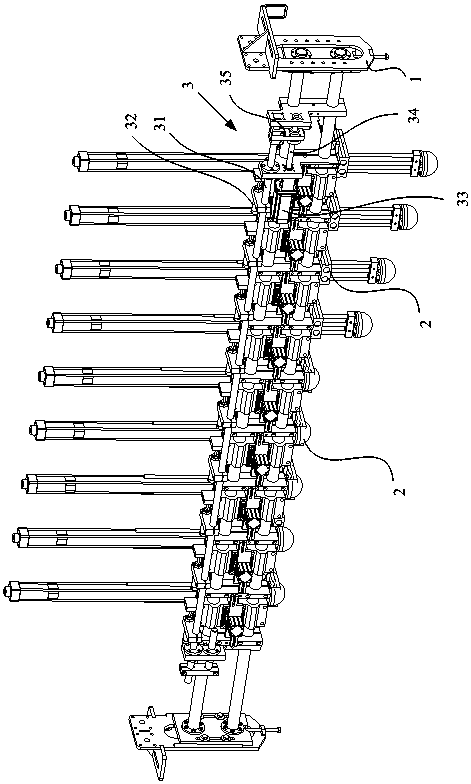

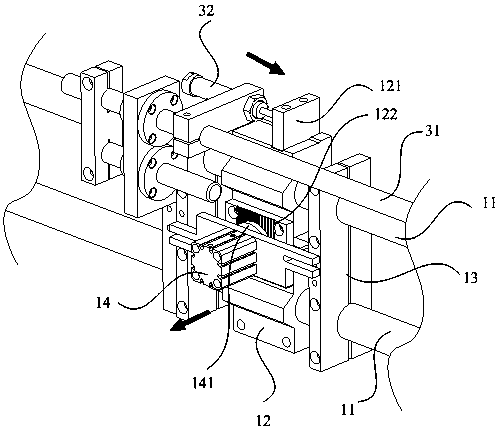

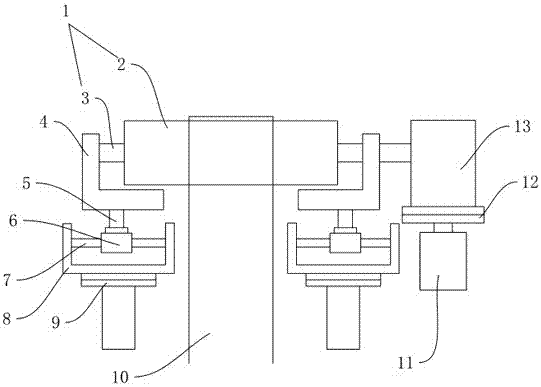

Single-axis multi-point positioning printing device, glove production line and printing control method

InactiveCN108189547APrinting position is accurateImprove printing qualityRotary pressesProduction lineEngineering

The invention provides a single-axis multi-point positioning printing device, a glove production line and a printing control method. The device comprises a rack, a linear moving assembly and a plurality of printing head assemblies, wherein a linear guide rail is arranged on the rack; a plurality of sliding seats are arranged on the linear guide rail; a mounting plate is arranged at one side of each sliding seat; a returning spring is arranged between each sliding seat and the corresponding mounting plate; a first cylinder is arranged on each mounting plate, and a braking plate which is opposite to the corresponding sliding seat is arranged on each first cylinder; sensors for detecting hand touch positions are arranged on the sliding seats; the linear moving assembly comprises a mounting axis and a driving mechanism; the mounting axis is provided with a plurality of second cylinders; baffle plates fitting the second cylinders are arranged on the sliding seats; each printing head assembly comprises a printing head for printing a glove which sleeves a hand model; the printing head assemblies are mounted on the corresponding sliding seat. With the adoption of the device, the printing quality and efficiency can be improved, and the rejection rate is reduced.

Owner:李振义 +1

Counting and code spraying equipment for production line

The invention discloses a counting and code spraying equipment for production line. The equipment comprises a base, supporting rods are fixedly connected to the four corners of the lower end of the base, a material receiving box is fixedly connected to the left end of the base, a conveying belt is in transmission connection with the middle of the upper end of the base, a lifting device is fixedly connected to the upper end of a supporting frame, the front end of the lifting device is fixedly connected with a displacement device, the other end of the conveying pipe is fixedly connected with an ink-jet printer, the left portion of the upper end of the base is fixedly connected with a stabilizing seat and an infrared sensor, the front portion and the rear portion of the upper end of the base are fixedly connected with auxiliary devices, the two auxiliary devices are located on the two sides of the conveying belt, and the left portion and the right portion of the front end of the supporting frame are each provided with a first sliding groove. According to the counting and code spraying equipment for the production line, the whole equipment is reasonable in structural design, the adjusting steps are simple, the code spraying position of a machined part is accurate, the code spraying quality of the machined part is high, and the counting and code spraying equipment is suitable for wide application.

Owner:江苏精仪达科技有限公司

Printer, and paper position detection method of a printer

InactiveCN104553316AAchieve positioningPrinting position is accurateOther printing apparatusTransverse axisPulp and paper industry

Airborne ink mist is prevented from sticking to the detector part of a paper detector disposed on a carriage without using a configuration for capturing the ink mist. A printer has a conveyance path that conveys paper past the print position of a printhead; a carriage that carries the printhead; and a carriage moving mechanism that moves the carriage bidirectionally on the transverse axis of the printer. A paper detector and a shutter that opens and closes the detection part of the paper detector are disposed on the carriage. When the carriage moves to one end of the range of carriage movement, a shutter operating member disposed on a second side frame facing the carriage contacts the shutter and moves the shutter from its open position or closed position to the other position.

Owner:SEIKO EPSON CORP

Cell roll printing rectification system

ActiveCN107364231APrinting position is accurateGuaranteed printing qualityPrinting press partsWind systemEngineering

The invention relates to a flexible solar cell roll printing rectification system. The problems that during printing of an existing flexible solar cell, locating is inconvenient, misprints or printing deviations are liable to occur, and printing quality is influenced are solved. The flexible solar cell roll printing rectification system comprises a winding system, a rectification device, an online quality monitoring system and a corresponding control platform. The control platform controls the winding system to conduct roll-to-roll winding and controls the rectification device to conduct rectification. The control platform receives feedback of the online quality monitoring system to adjust the winding system and the rectification device. Unwinding and winding is conducted on a cell roll through the winding system, and meanwhile, power of a cell roll system is provided. The rectification device conducts rectification on a flexible solar cell assembly, the precise printing position of the flexible solar cell assembly is ensured, and printing quality is ensured. The online quality monitoring system monitors the printing quality of the cell roll, the control platform conducts control, and finally the printing quality of the cell roll is ensured.

Owner:浙江尚越新能源开发有限公司

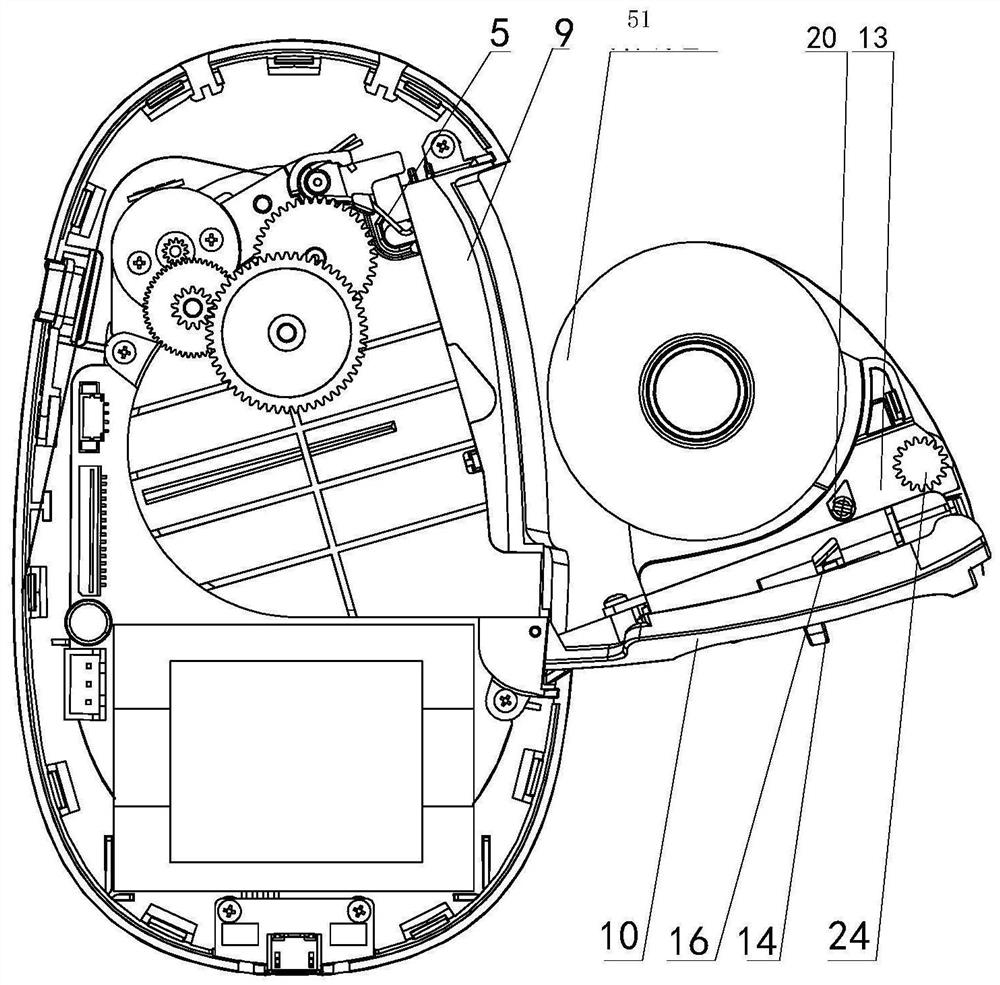

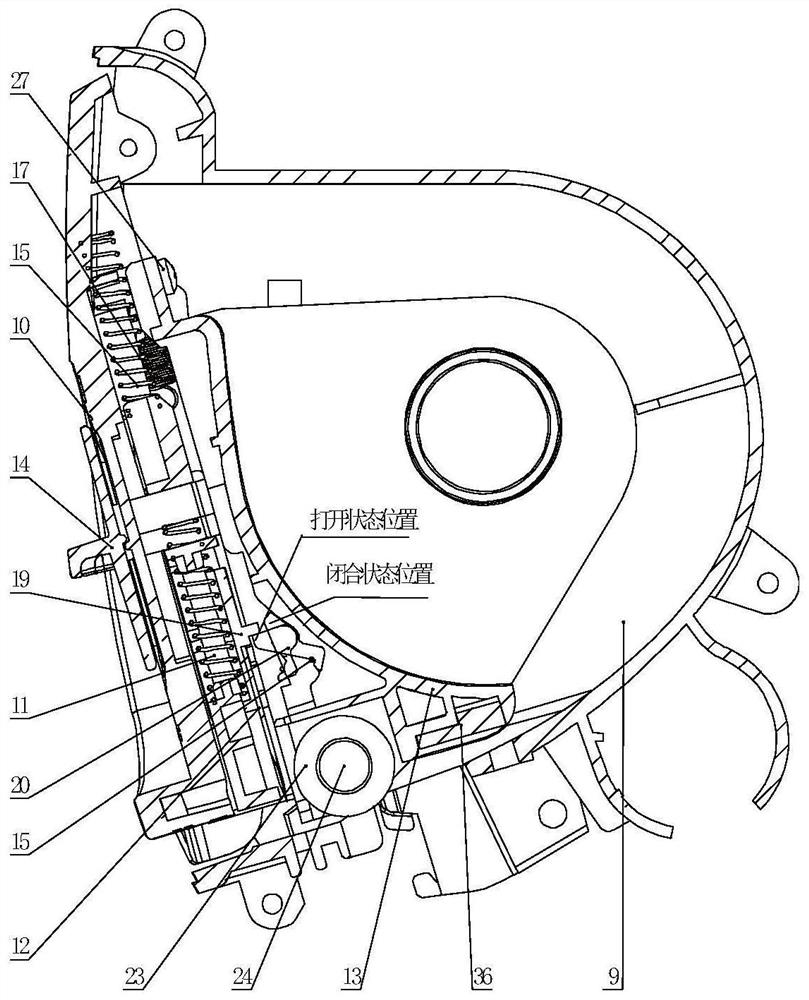

Label printer and outer turn cover assembly thereof

ActiveCN111660683AAvoid loose rollsAvoid accuracyTypewritersPower drive mechanismsComputer printingEngineering

The invention discloses a label printer and an outer turn cover assembly thereof, and belongs to the field of printing. The label printer comprises a machine core assembly, a printing head assembly and the outer turn cover assembly, wherein the machine core assembly comprises a machine core and a main control panel and is used for controlling the printing head assembly; the printing head assemblycomprises a printing head, a printing head substrate and an FPC (flexible printed circuit) arranging wires, and the main control panel is connected with the printing head through the FPC arranging wires; the outer turn cover assembly comprises a side turn cover casing and an inner casing connected to one side of the side turn cover casing, a consumable bin used for mounting label consumables is arranged on the inner casing, a shaft hole is formed in one end of the side turn cover casing, a pressing rotating shaft is mounted in the shaft hole and assembled with the machine core assembly, and therefore, the outer turn cover casing can be opened or closed relative to the machine core assembly; and when the outer turn cover assembly and the machine core assembly are closed, the machine core, the printing head and the side turn cover casing form a paper feeding channel. According to the label printer, the consumable bin is arranged on the outer turn cover assembly, the label consumables areconvenient to replace, and the problem that the consumables are prone to loosening is solved.

Owner:北京硕方信息技术有限公司

Fine ceramic surface printing equipment

PendingCN113427894ASimple printing processPrinting position is accurateRotary pressesOther printing apparatusTextile printerMechanical engineering

The invention relates to printing equipment, in particular to fine ceramic surface printing equipment. The invention aims to provide the fine ceramic surface printing equipment which is simple in manufacturing procedure, does not cause material damage and is accurate in printing position. According to the technical scheme, the fine ceramic surface printing equipment comprises a base, a placing mechanism and a printing mechanism, the placing mechanism is arranged on the left side of the base, and the printing mechanism is arranged on the right side of the base. Ceramic is placed under the printing mechanism through the placing mechanism in turn for printing, and the effect that the printing manufacturing procedure is simple is achieved; and through a clamping assembly, the position of ceramic can be fixed during printing, and the effect that the printing position is accurate is achieved.

Owner:杨松

Package bottle code spraying machine

The invention discloses a package bottle code spraying machine. The machine comprises a conveying device and a code spraying device, wherein the conveying device comprises a supporting frame, a driving shaft with a driving wheel, a driven shaft with a driven wheel, a conveying belt and a driving device for driving the driving shaft to rotate; the driven wheel is driven by the driving wheel to rotate through the conveying belt; a plurality of limiting blocks are arranged on the surface of the conveying belt; every two adjacent limiting blocks cooperate with the conveying belt to form a limitinggroove; the code spraying device comprises a code spraying box, a code spraying gun and an ink conveying tube; the code spraying gun communicates with the code spraying box through the ink conveyingtube; and the code spraying gun is arranged above one side of the conveying belt. Compared with the prior art, the machine disclosed by the invention has the advantages that the limiting blocks are arranged on the conveying belt and every two adjacent limiting blocks cooperate with the conveying belt to form the limiting groove to ensure that package bottles which are put in the limiting grooves cannot roll, so that the package bottles cannot shake when passing through the code spraying gun, sprayed codes are more clear, the quality is better and the code spraying position is more accurate.

Owner:广东弘彩新材料有限公司

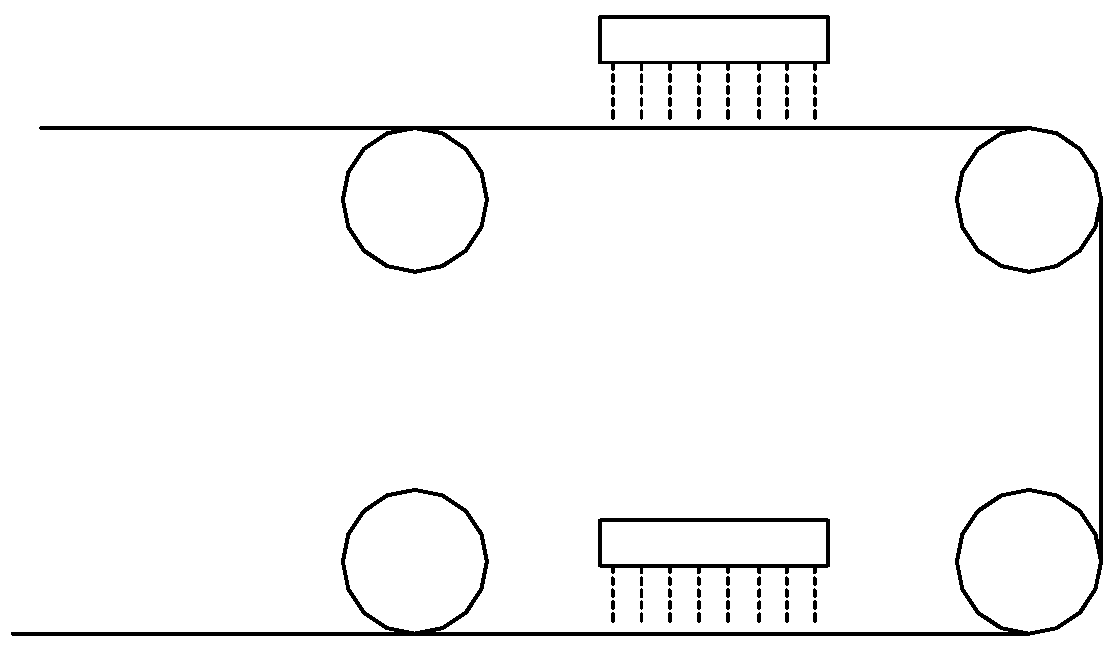

Rolling silk-screen printing equipment as well as multi-color printing equipment and method thereof

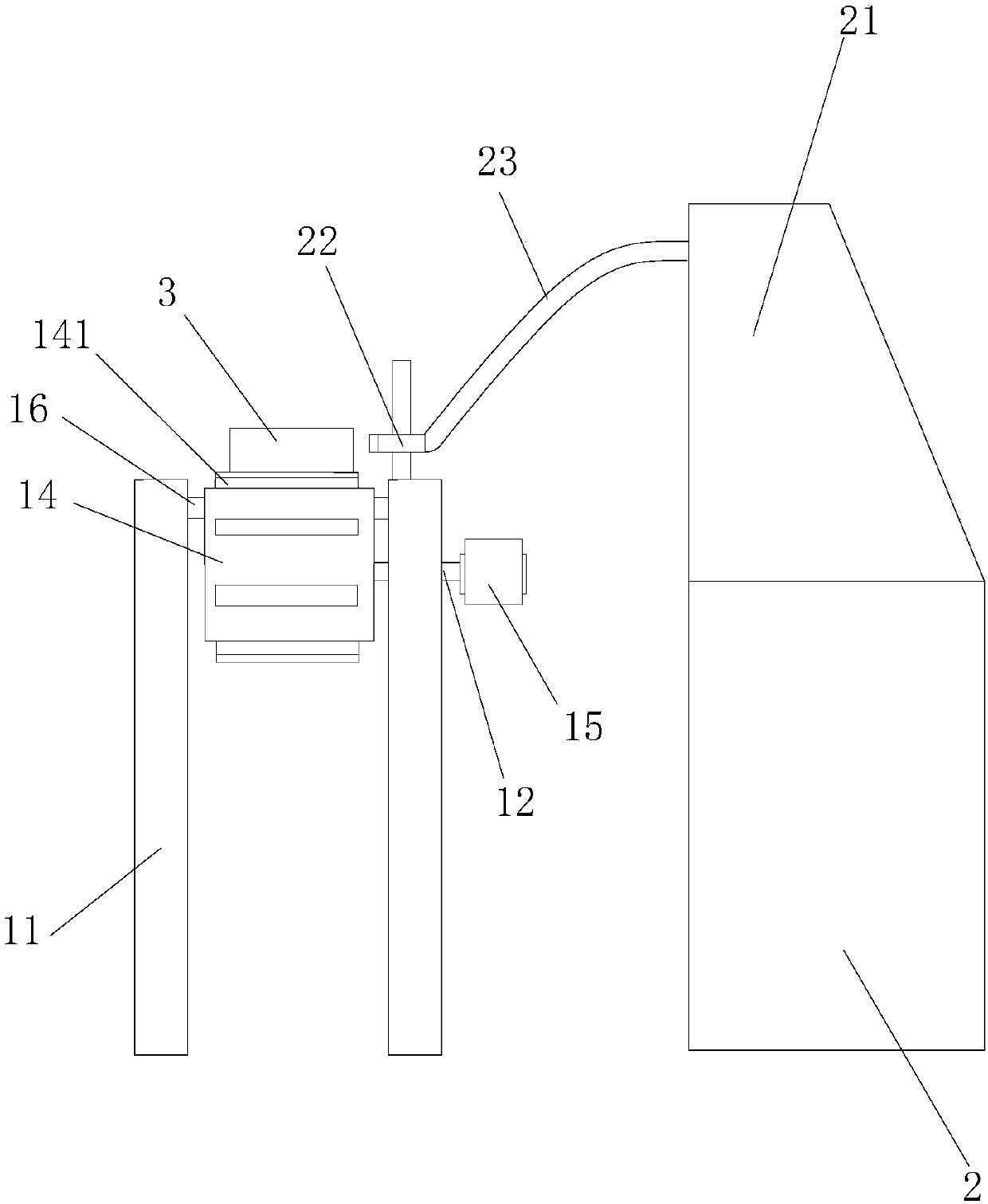

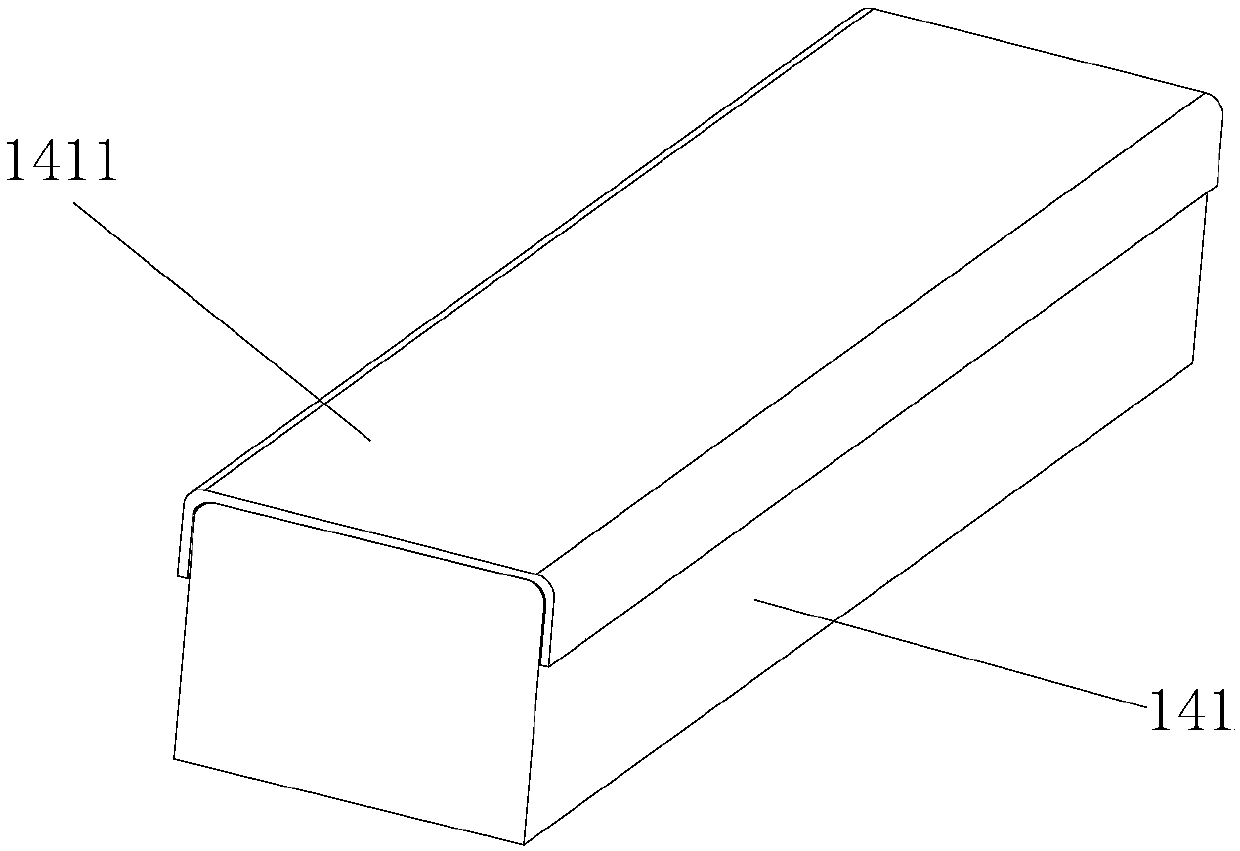

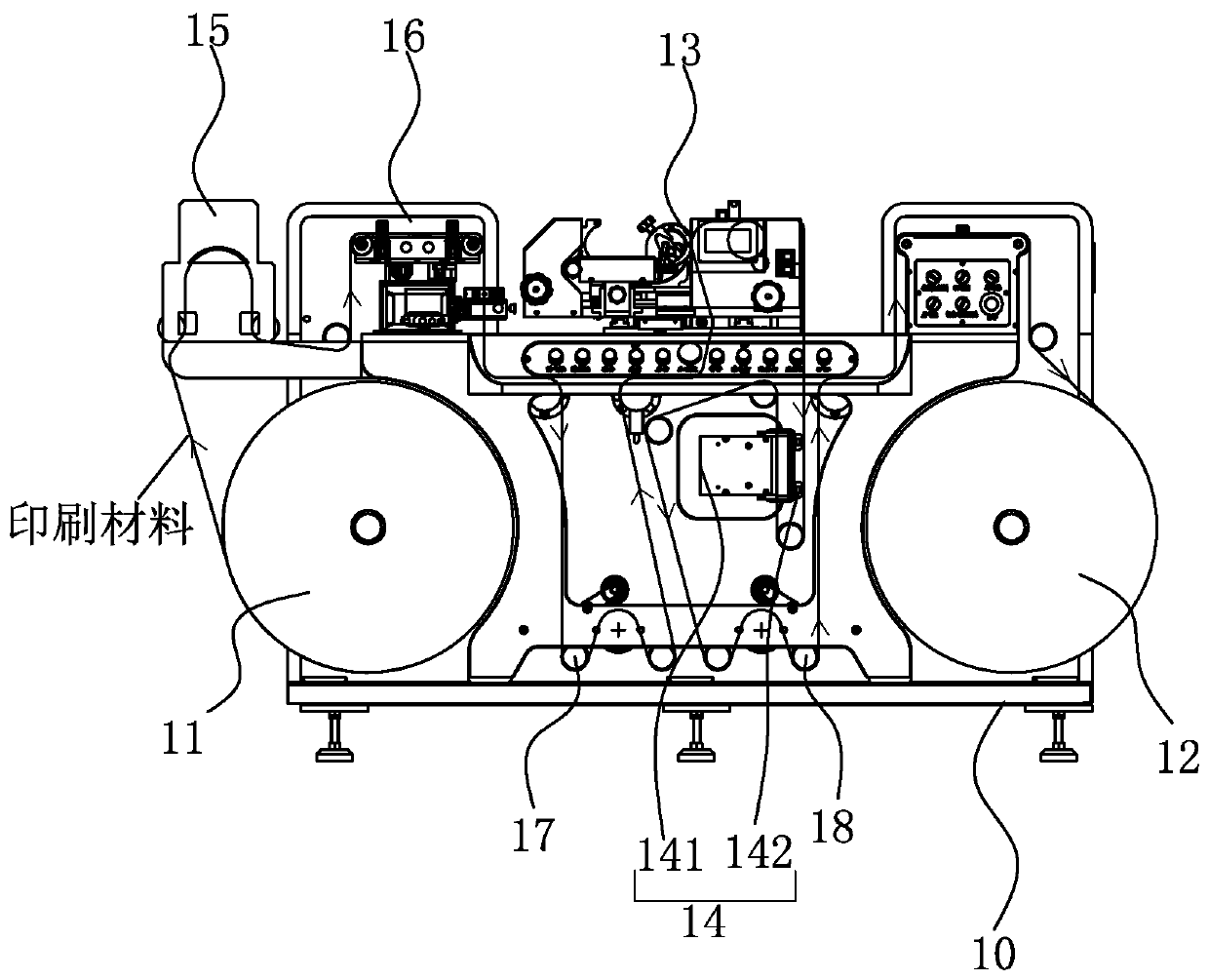

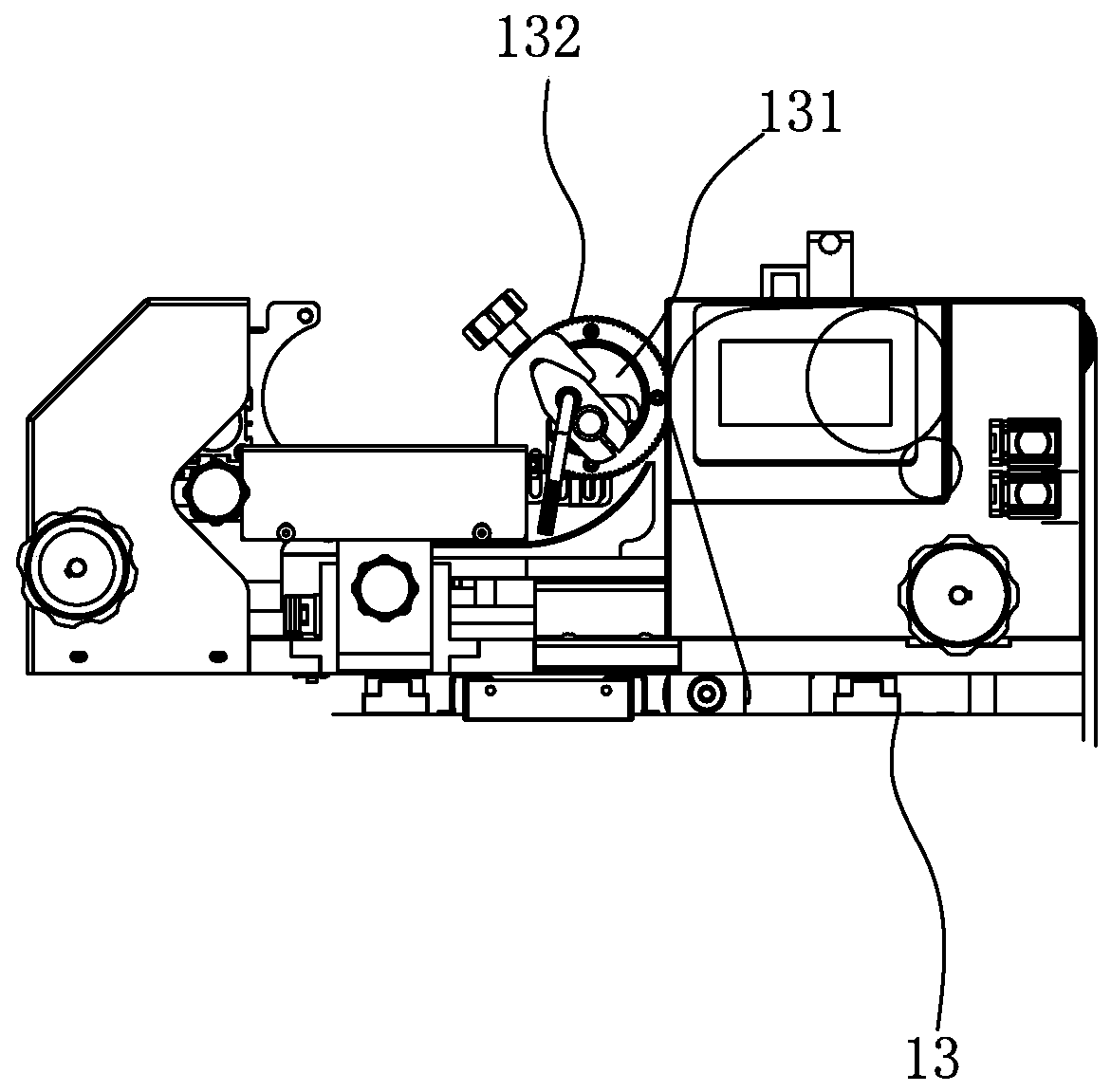

PendingCN109823032ACompact structureReduce volumeScreen printersOther printing apparatusColor printingEngineering

The invention relates to rolling silk-screen printing equipment as well as multi-color printing equipment and method thereof. The rolling silk-screen printing equipment comprises a rack, an unwindingmechanism and a winding mechanism arranged at the two ends of the rack separately, and a silk-screen printing mechanism arranged between the unwinding mechanism and the winding mechanism; the unwinding mechanism unwinds printing material; the silk-screen printing mechanism prints the printing material and dries the printing mechanism through a drying mechanism; and the winding mechanism winds theprinting mechanism. The rolling silk-screen printing equipment is compact in structure, small in size and occupied area, and convenient to place. In addition, the unwinding mechanism continuously unwinds, and the winding mechanism continuously winds, so that the silk-screen printing mechanism can continuously carry out rolling printing, and the printing efficiency is high; a deviation rectifying mechanism rectifies the printing material, so that the printing position is precise, and the defective percentage is reduced; the printing material is naturally dried through a plurality of conveying roll wheels and is also rapidly dried by the drying mechanism.

Owner:VOORUN AUTOMATION CO LTD

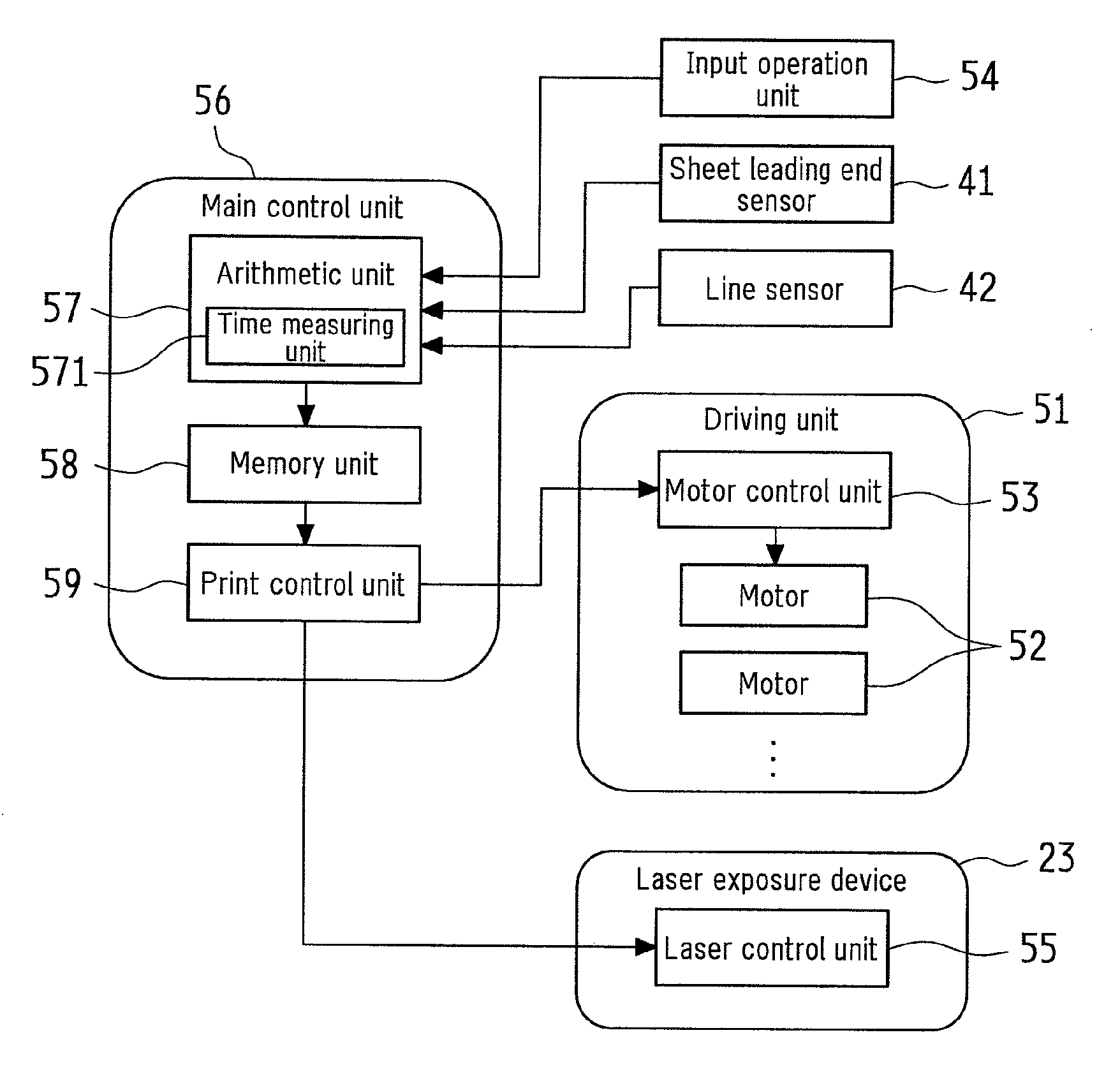

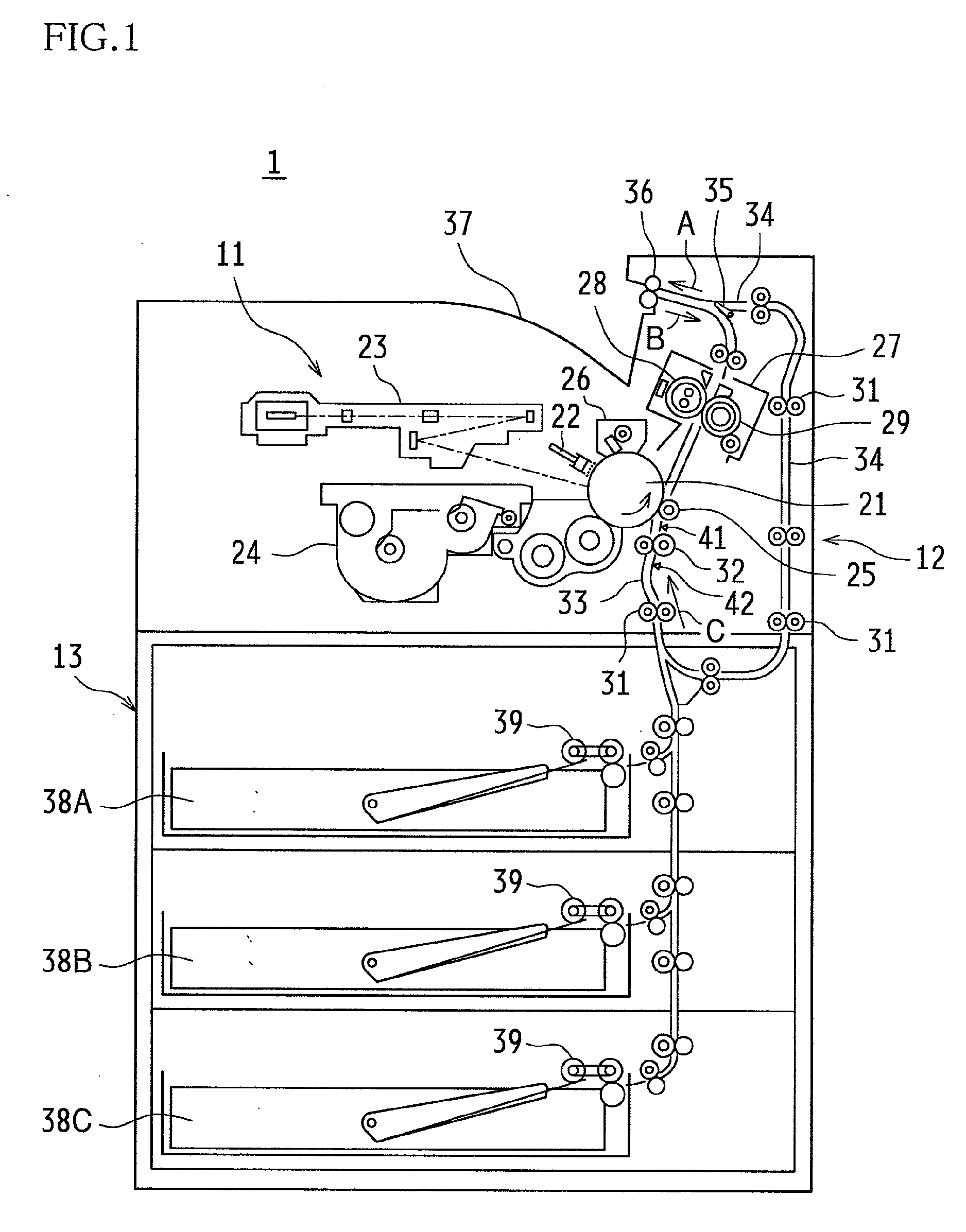

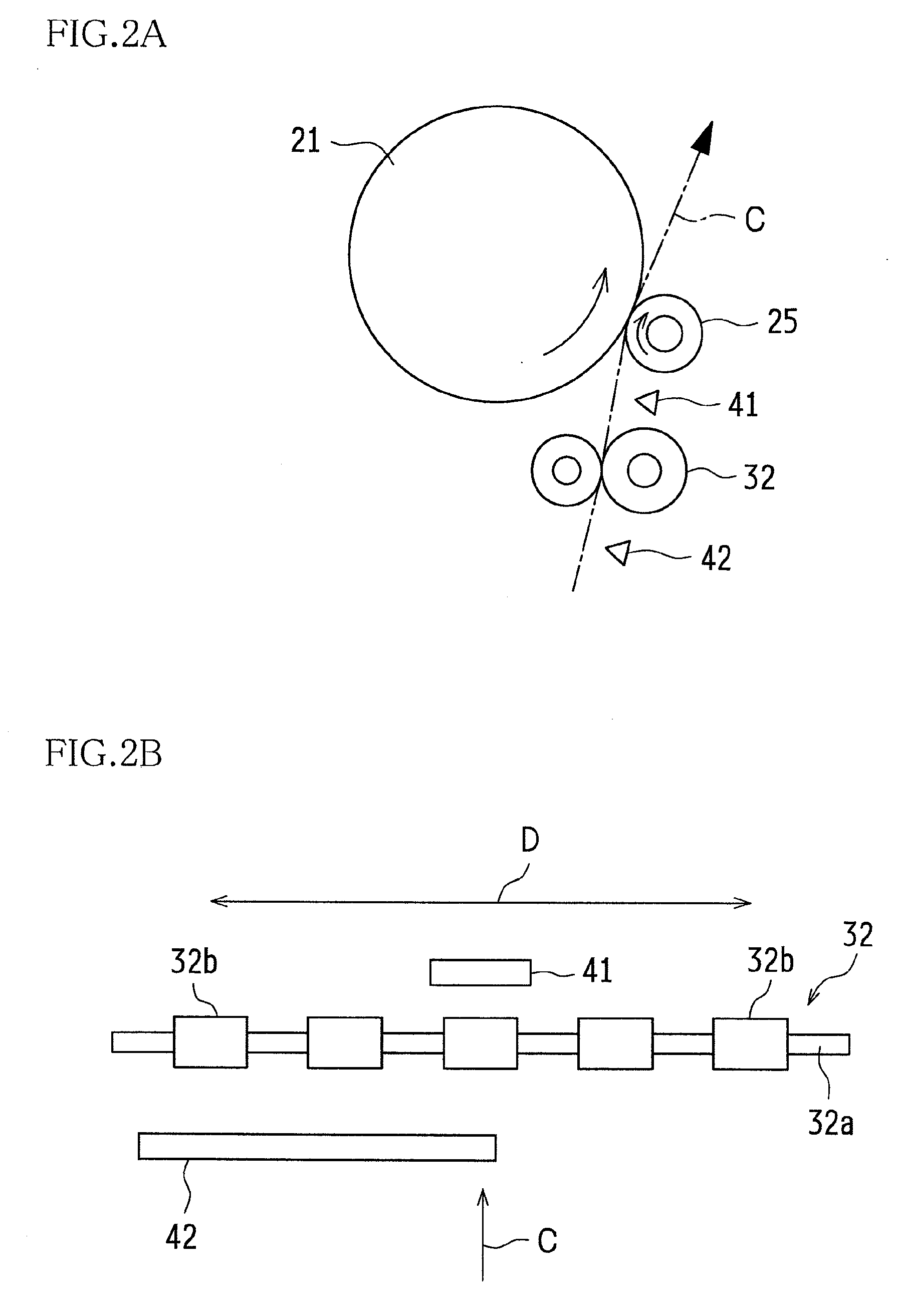

Image forming apparatus

ActiveUS20120275802A1Simplify the setup processPrinting position is accurateElectrographic process apparatusImage formationReference image

The image forming apparatus includes: a paper feed unit; a print unit; a registration roller; a sheet leading end sensor provided downstream, in a transport direction of the recording paper, of the registration roller; a time measuring unit for measuring a time from a start point of transportation of the recording paper by the registration roller to a point of detection of the leading end of the recording paper by the sheet leading end sensor; a memory unit for storing a reference image forming time and a reference time; a print control unit; and an arithmetic unit for obtaining a difference between the reference time and the time detected by the time measuring unit. The print control unit adjusts the length of the image forming period in accordance with the adjusted image forming time determined based on the difference obtained by the arithmetic unit and the reference image forming time.

Owner:SHARP KK

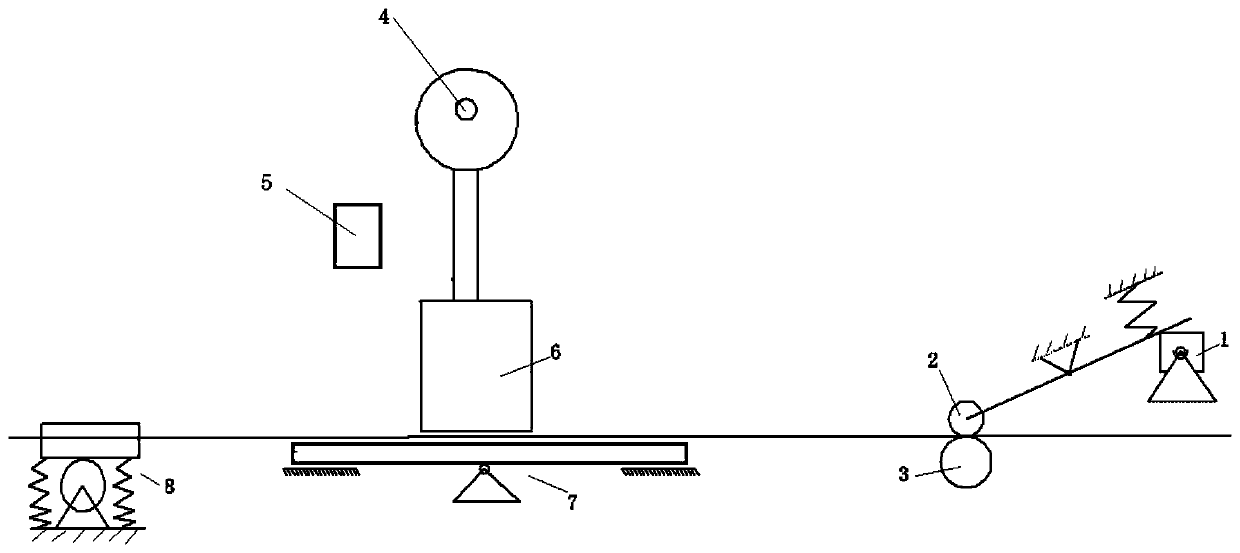

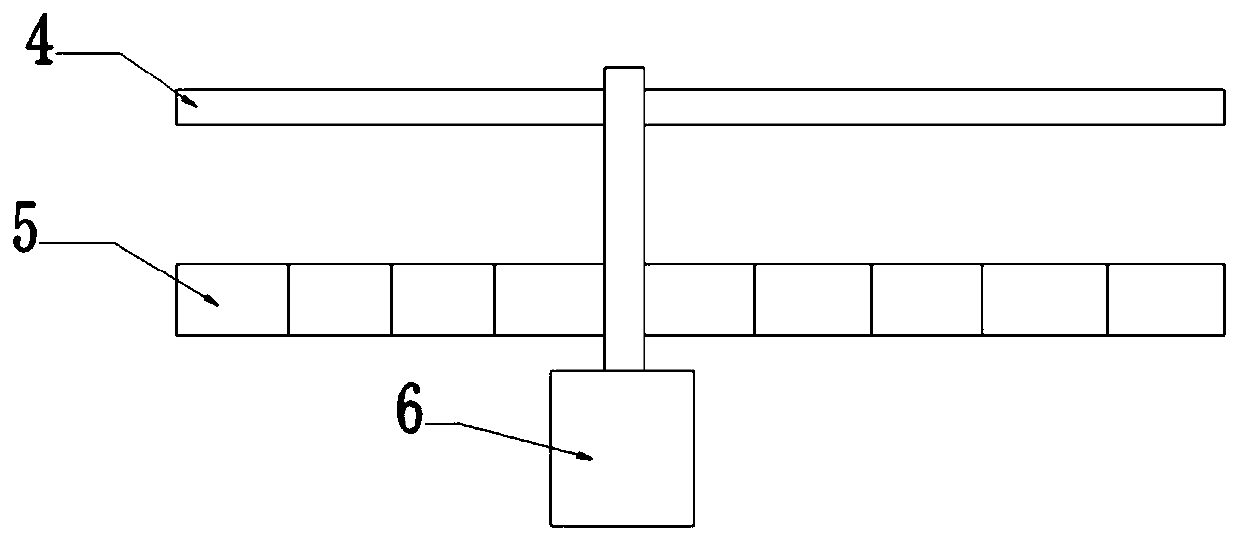

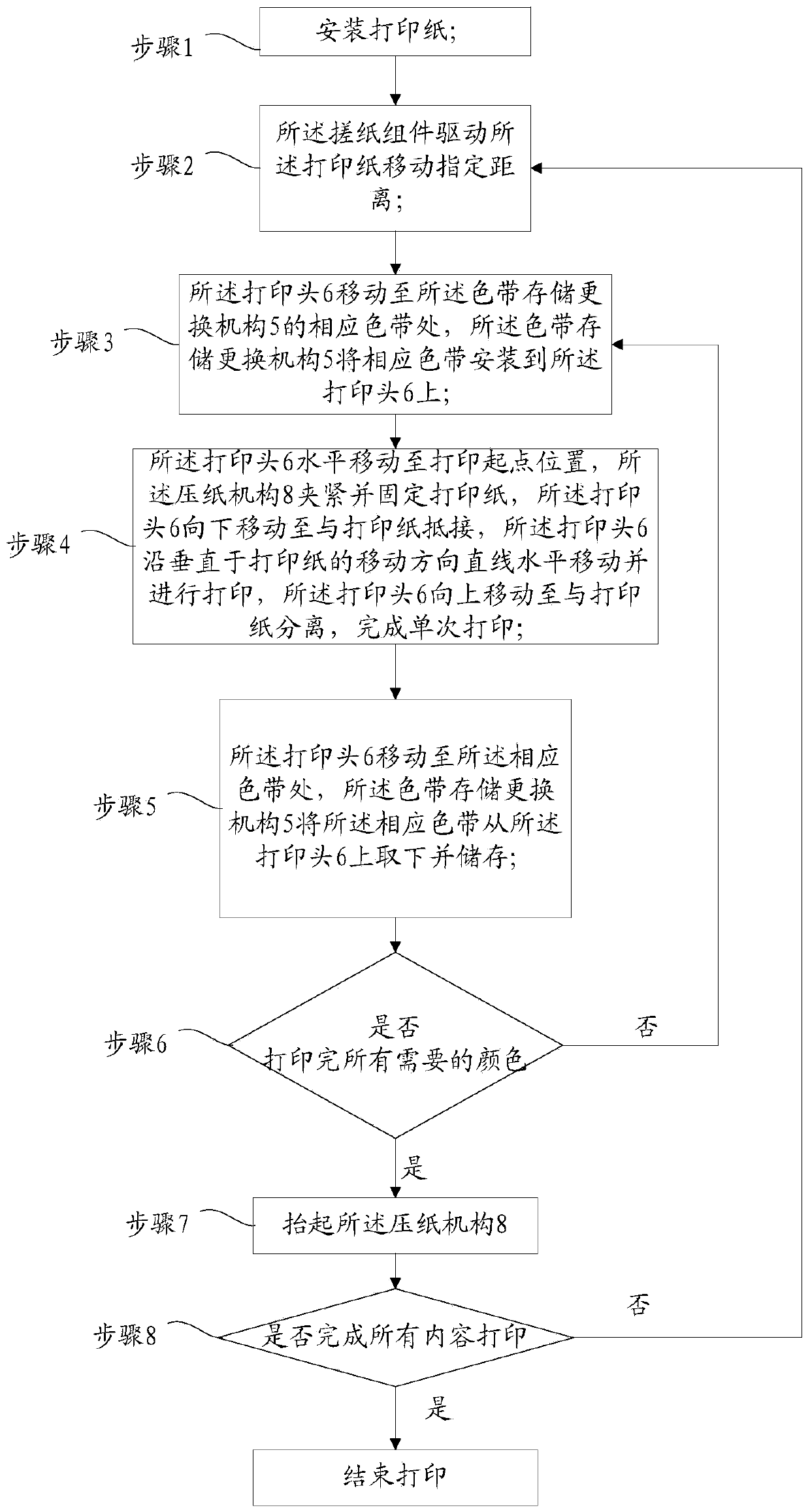

Heat transfer printing printer and printing method

PendingCN110948999ACompact structureSmall footprintTransfer printingTypewritersComputer printingMechanical engineering

The invention relates to a heat transfer printing printer and a printing method. The heat transfer printing printer comprises a paper rubbing assembly, a printing head, a colored tape storing and replacing mechanism and a paper pressing mechanism. The paper rubbing assembly and the paper pressing mechanism are successively arranged in the moving direction of printing paper, the printing head and the colored tape storing and replacing mechanism are mounted between the paper rubbing assembly and the paper pressing mechanism, the printing heat is located above the printing paper and can move linearly in a reciprocating manner horizontally in the direction perpendicular to the moving direction of the printing paper and move up and down, the colored tape storing and replacing mechanism is horizontally arranged perpendicular to the moving direction of the printing paper, and the colored tape storing and replacing mechanism is used for storing colored tapes of different colors and replacing the colored tapes to the printing head. The heat transfer printing printer has the beneficial effects that the colored tape storing and replacing mechanism replaces the colored tapes, so that the printing head can print a plurality of colors; the paper rubbing assembly drives the printing paper to move; and the paper pressing mechanism is used for fixing the printing paper when the printing head executes a printing operation to prevent the printing effect from being affected as the printing paper moves. The printer is compact in structure and small in occupied area.

Owner:湖南鼎一致远科技发展股份有限公司

Assembly line conveying and fixing device for wine box packaging and printing

ActiveCN113334921AReduce accidental shakingPrinting position is accurateRotary pressesOther printing apparatusThermodynamicsProcess engineering

The invention provides an assembly line conveying and fixing device for wine box packaging and printing, and relates to the technical field of wine box printing. The assembly line conveying and fixing device for wine box packaging and printing comprises a mounting plate, a magnetic force fixing mechanism and a supporting mechanism with a heating function, wherein the lower surface of the mounting plate is fixedly connected with supporting legs used for being connected with a conveying belt; the magnetic force fixing mechanism is connected with the mounting plate; and the supporting mechanism with the heating function is connected with the mounting plate, the supporting mechanism with the heating function is further connected with the magnetic force fixing mechanism, and the supporting mechanism with the heating function exchanges heat with the magnetic force fixing mechanism. The assembly line conveying and fixing device for wine box packaging and printing has the advantage that the printing quality is improved.

Owner:常州市恒鑫包装彩印有限公司

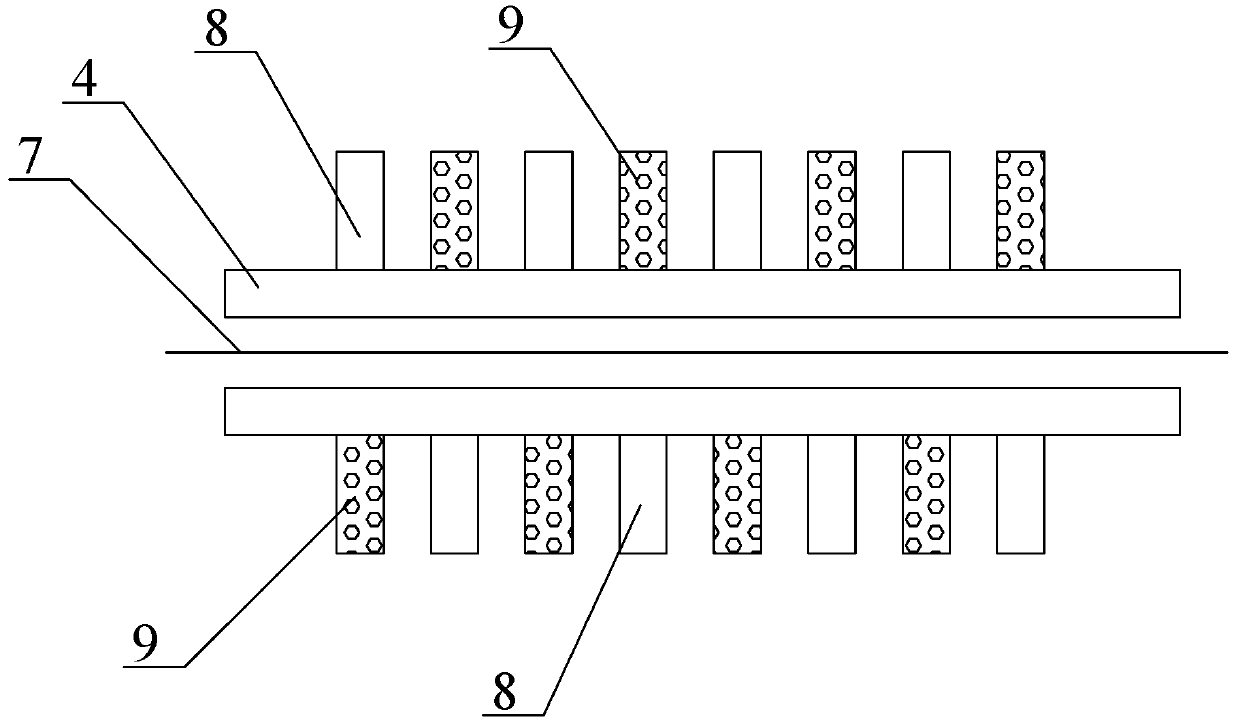

A digital printing machine with double-sided jet printing

ActiveCN107901626BImprove printing efficiencyImprove printing qualityTypewritersEngineeringDigital printing

Disclosed is a double-sided spray-printing digital printing machine, comprising at least two vertically-arranged sprayer sets (4), wherein ink spraying directions of sprayers (8) on the sprayer sets (4) are horizontal; and a space for a textile (7) to pass is formed between the two sprayer sets (4). Two sides of the textile can be simultaneously spray-printed by means of the digital printing machine, thus improving the efficiency of spray-printing. Meanwhile, the location of spray-printing is accurate, the patterns on both sides of the textile easily completely overlap, and the spray-printing quality is high.

Owner:HAIJIE DIGITAL TECH SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com