Fine ceramic surface printing equipment

A fine ceramics and printing technology, applied in printing, printing machines, printing devices, etc., can solve the problems of complicated printing procedures, easy position deviation, and damage to materials, etc., and achieve the effect of simple printing production procedures and accurate printing positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

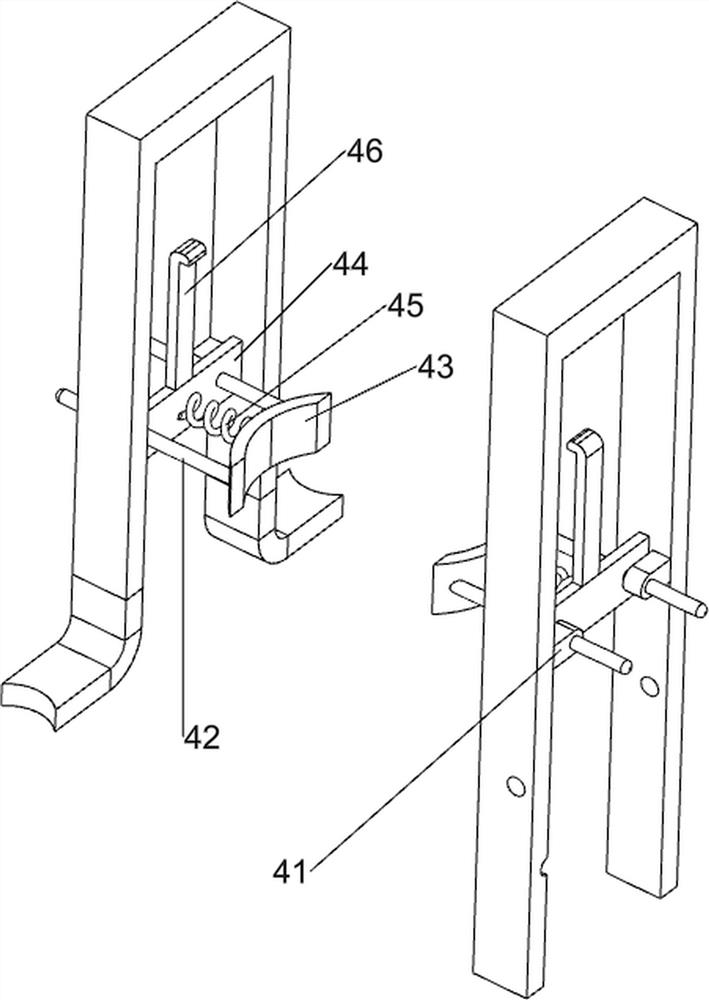

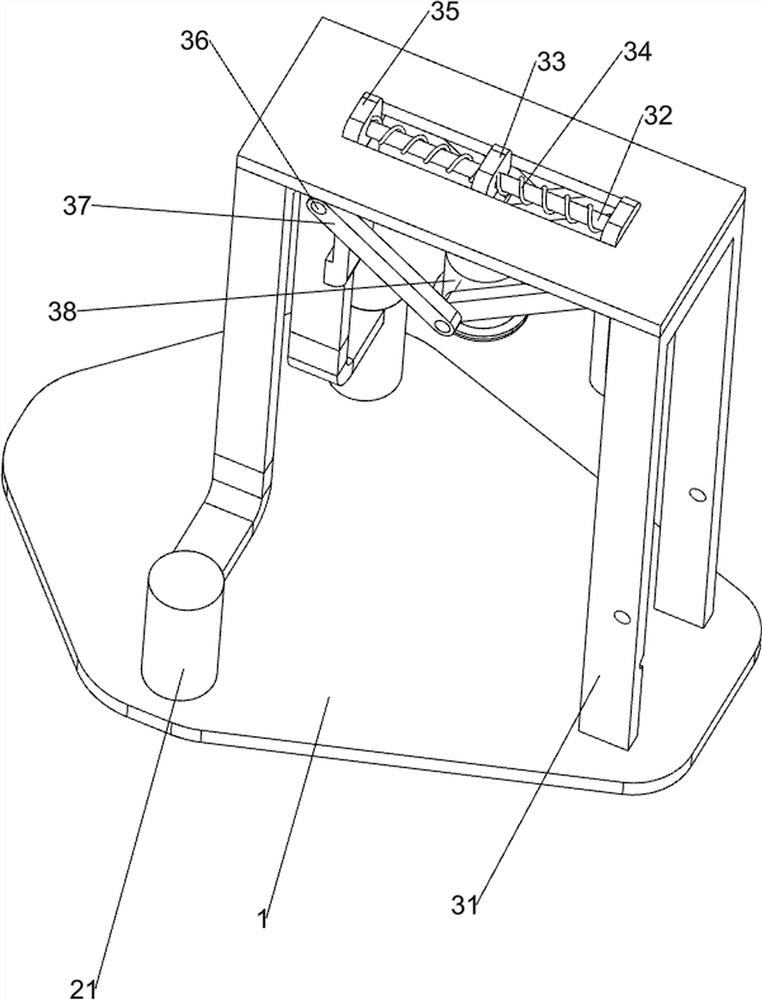

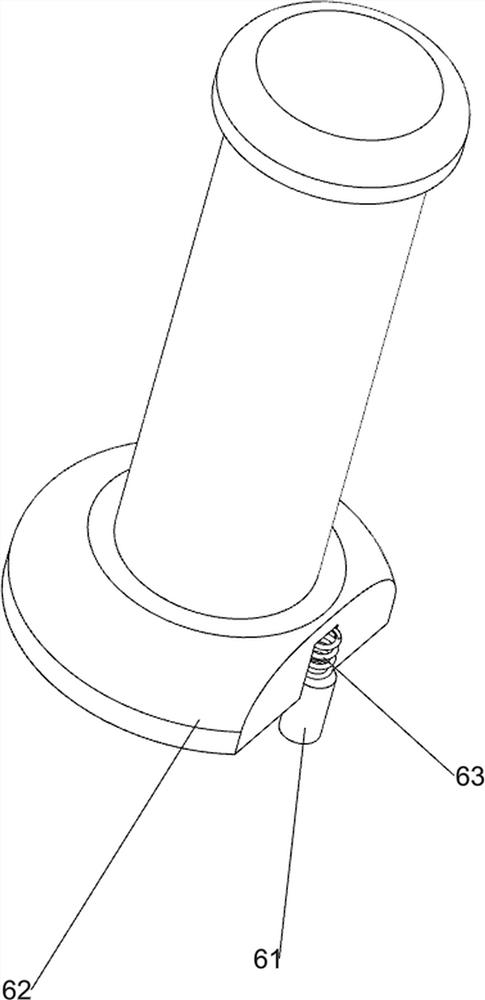

[0026] A fine ceramic surface printing equipment, such as Figure 1-8 As shown, it includes a base 1, a placing mechanism 2 and a printing mechanism 3, the left side of the base 1 is provided with the placing mechanism 2, and the right side of the base 1 is provided with the printing mechanism 3.

[0027] When people are going to print the ceramic surface, put the ceramics upside down in the placement mechanism 2, start the placement mechanism 2, and move the ceramics to the lower side of the printing mechanism 3, and the printing mechanism 3 moves down to the ceramic surface for printing and lifts it up. After ceramics finished stamping, people close placement mechanism 2.

[0028] The placement mechanism 2 includes a support column 21, a limit ring 22, a gear ring 23, a support rod 24, a sponge pad 25, a servo motor 26, a missing gear 27 and a guide ring 28, and four support columns are symmetrically arranged on the left side of the base 1. 21, a limit ring 22 is provided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com