Patents

Literature

165results about How to "Simple printing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Meltable ink for an inkjet printer and a method of selecting such an ink

InactiveUS6923853B2Specific visco-elastic propertyEffect print qualityMeasurement apparatus componentsDuplicating/marking methodsRoom temperatureEngineering

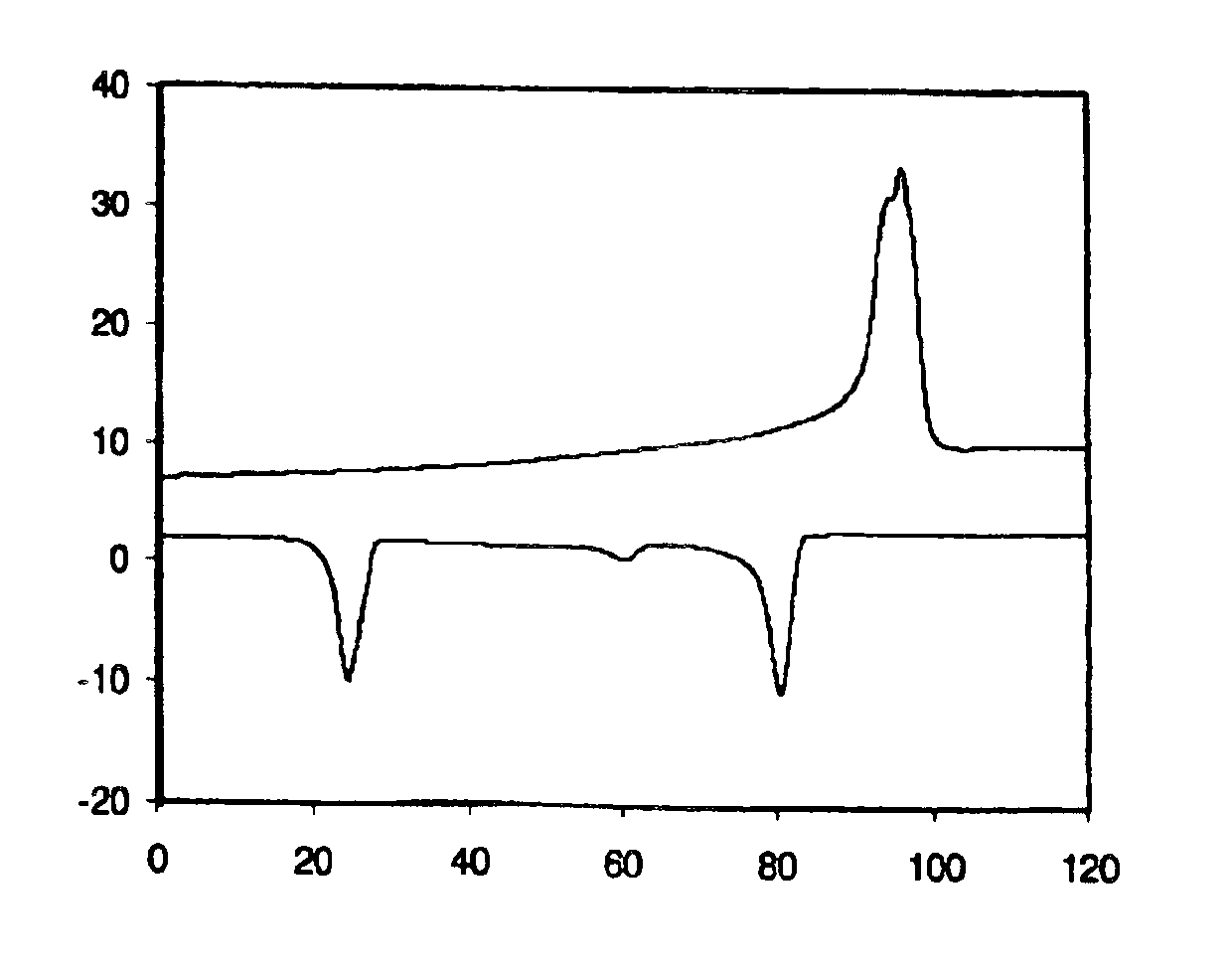

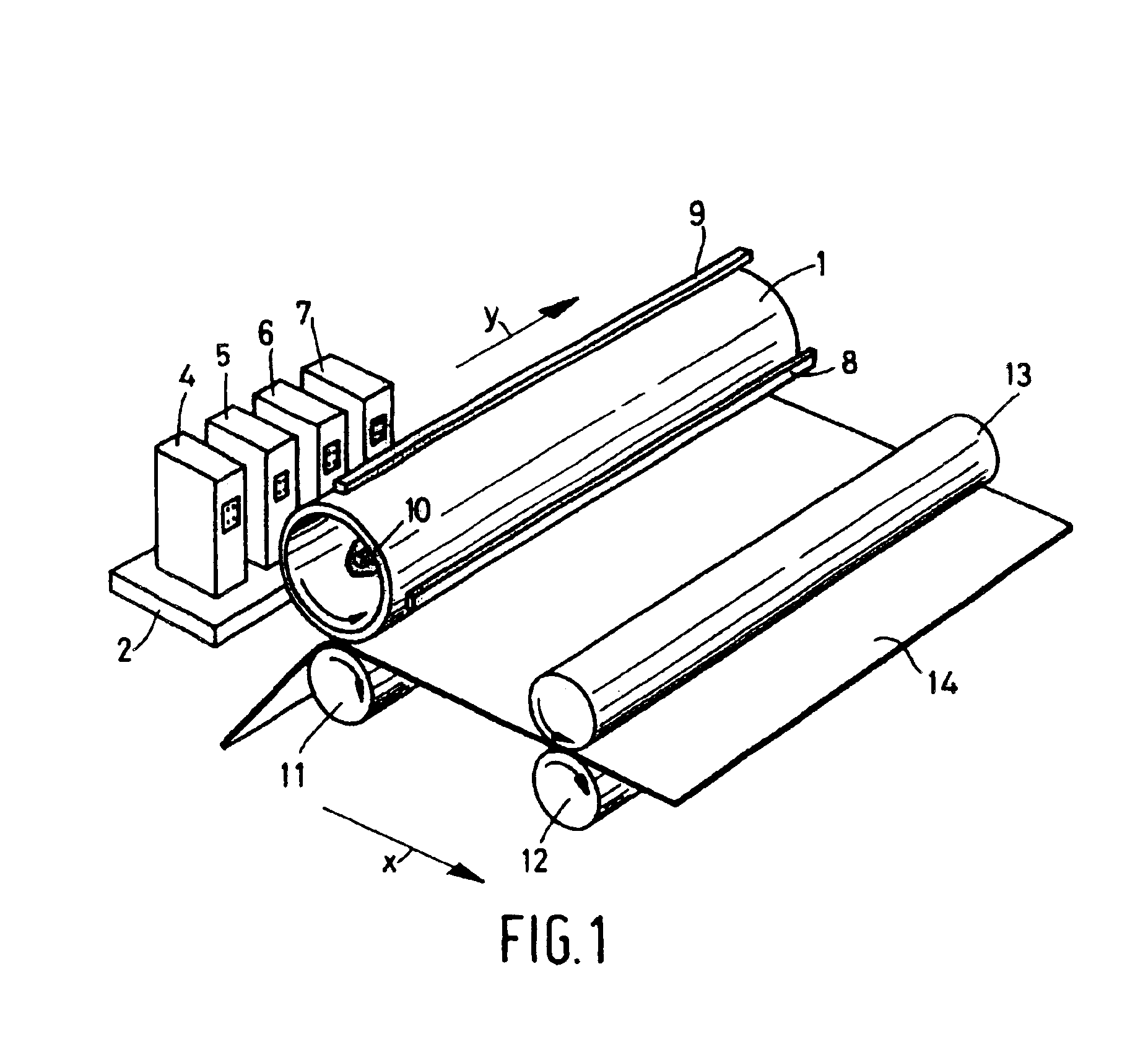

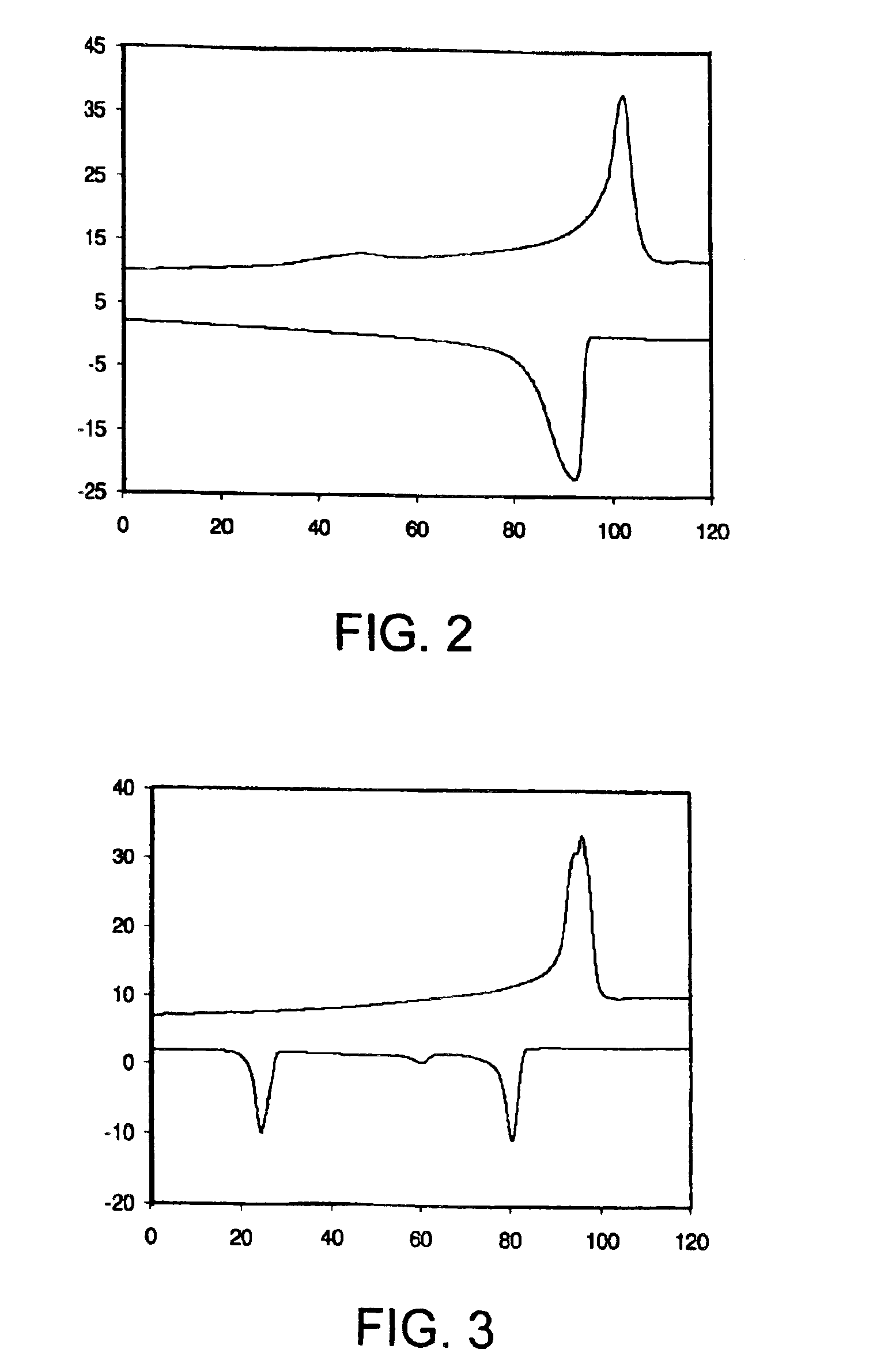

A meltable ink which is solid at room temperature, which ink is suitable for use in an indirect printing process, in which printing process the ink is transferred, by the use of an inkjet printhead, to a transfer element, whereafter the ink is transferred to a receiving material under pressure from the transfer element, the ink having a composition such that it is pressure-transferable at a temperature between a bottom temperature limit and a top temperature limit, wherein the ink has a deformation energy of less than 20×105 Pa.s at a temperature equal to said top temperature limit.

Owner:OCE TECH

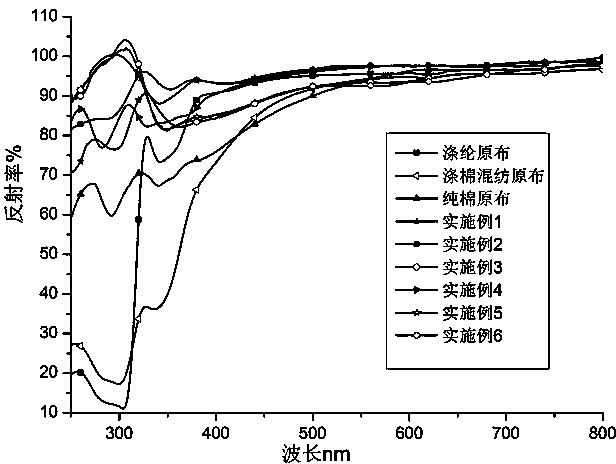

White printing paste, preparation method and application of white printing paste

The invention discloses white printing paste, a preparation method and application of white printing paste. The white printing paste comprises the following components in parts by weight: 1 to 20 parts of white pigment, 2 to 5 parts of a thickening agent, 5 to 30 parts of an adhesive, 0.1 to 2 parts of a dispersing agent, and 43 to 91.9 parts of deionized water. The preparation method comprises the following steps: adding the dispersing agent and white pigment to deionized water under normal temperature; oscillating to uniformly disperse the pigment; then adding the thickening agent and the adhesive; agitating to obtain white printing paste; uniformly printing the white printing paste to a base fabric through a screen printing machine; preliminarily drying and then drying again; and then performing standard water washing to obtain snow pretending protective fabrics. According to the white printing paste and the preparation method, the printing technique is simple, the process is short; and the printed fabrics have snow pretending and ultrasonic proofing effects, and are also outstanding in wearability.

Owner:ZHEJIANG SCI-TECH UNIV +1

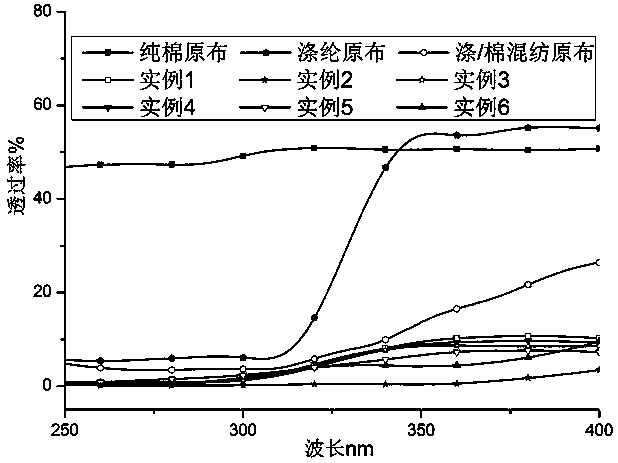

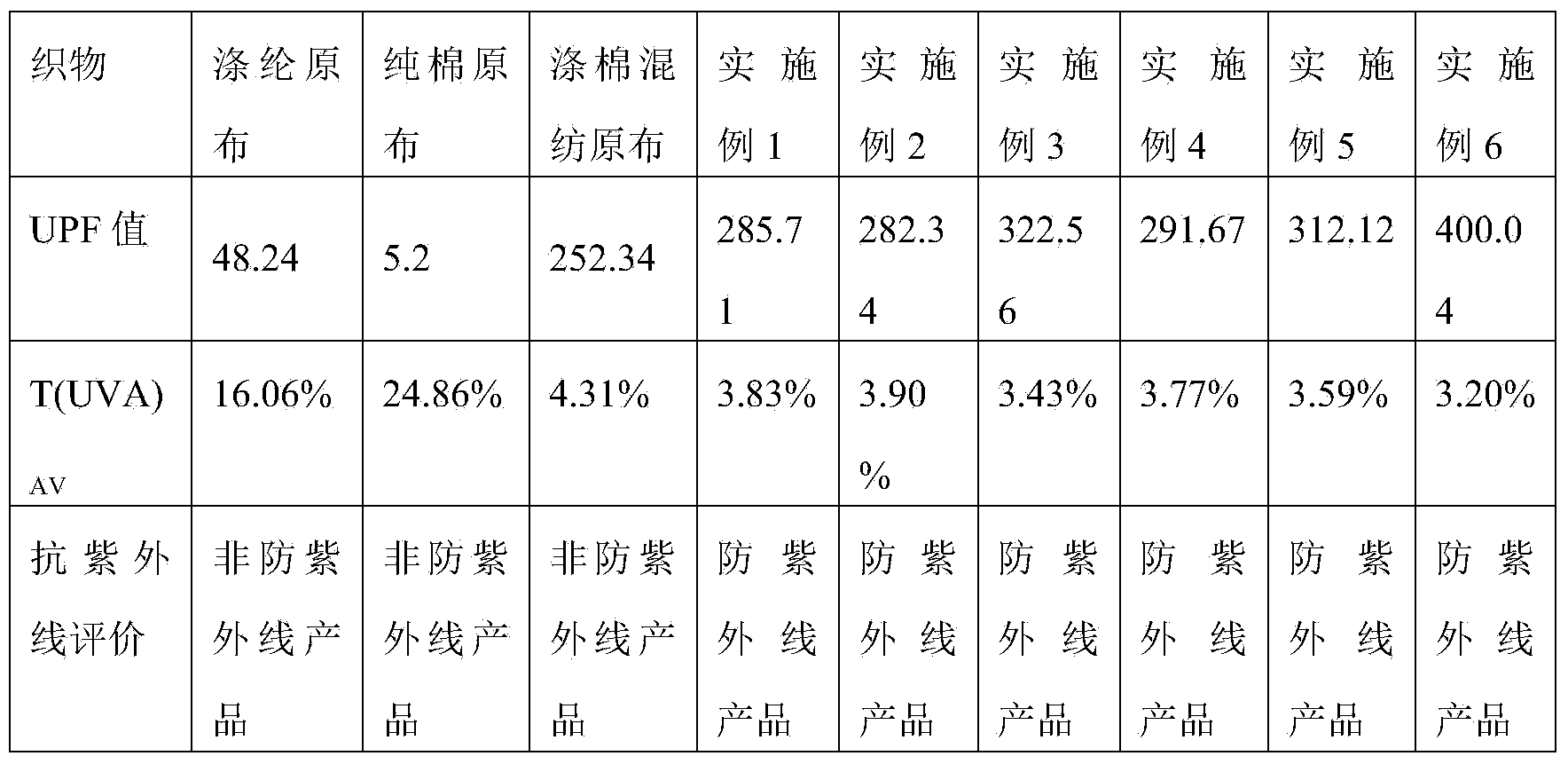

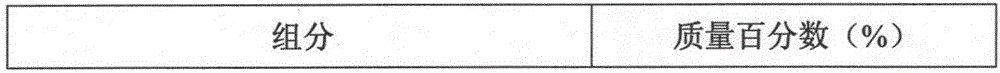

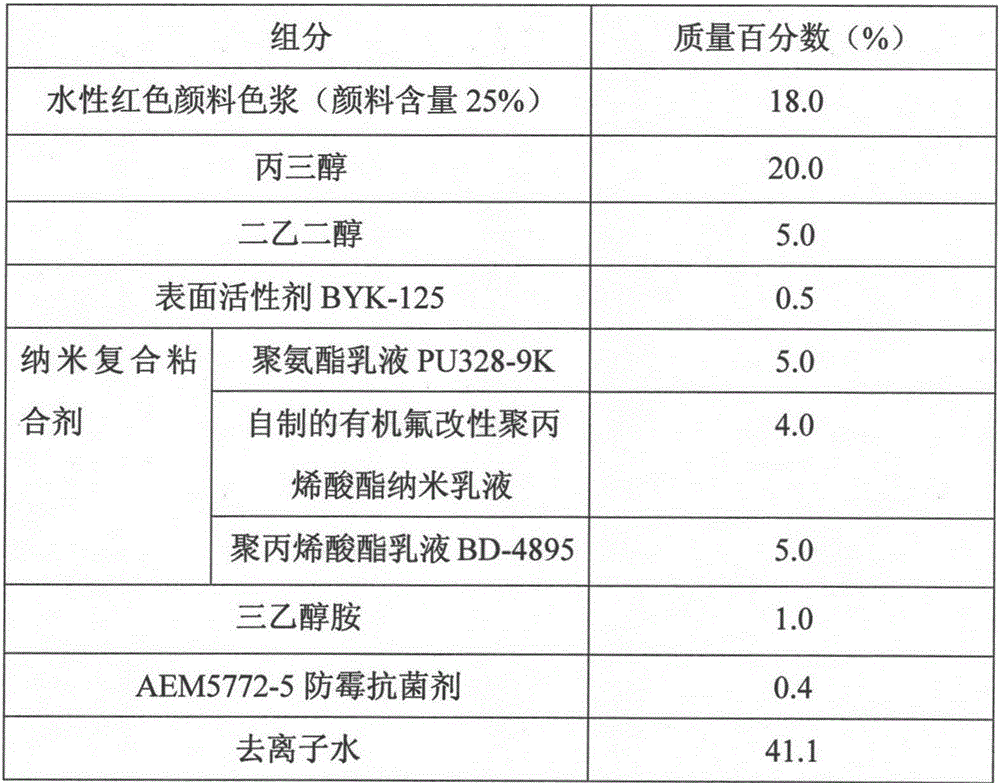

Water-based pigment digital ink-jet textile printing ink and preparation and use methods thereof

ActiveCN106567267AImprove washing fastnessImprove hydrophobicityDuplicating/marking methodsInksWater basedTextile printer

The invention provides a water-based pigment digital ink-jet textile printing ink and preparation and use methods thereof. The water-based pigment digital ink-jet textile printing ink is characterized by containing a pigment color paste, a nano composite adhesive and deionized water, wherein the nano composite adhesive comprises a polyurethane emulsion, an organic fluorine modified polyacrylate nano emulsion and another polyacrylate emulsion. With use of the nano composite adhesive, the problem of low water washing fastness of a water-based pigment ink-jet printing ink on a printing fabric is solved emphatically, and a new solution is provided for industrialized application of the water-based pigment ink-jet printing ink in the field of fabric digital ink-jet printing.

Owner:上海英威喷墨科技有限公司

Ready-made clothes grade cloth burnt-out printing process

ActiveCN101187180ASimple printing processShort timePattern makingFibre treatmentScreen printingDistilled water

The invention relates to a ready-made clothes cloth burnt-out process, which belongs to the field of fabric pattern or design embroidery in the fabric industrial production, wherein the process adopts material composed of cotton, nylon or artificial cotton and comprises steps of cracking down the cloth, making the pattern printing screen plate, mixing pattern slurry, burnt-out pattern printing, baking and washing. The process is characterized in that: firstly cracking down the material into pieces according to the design of the ready-made clothes, then according to the ready-made clothes pattern processing the screen printing plate, according to the pattern design color, mixing the printing slurry, then processing the burnt-out printing on the cloth pieces by use of the printing screen plate and the printing slurry, that is, the slurry penetrates the cracked pieces to erode the cotton, nylon or artificial cotton in the cracked pieces and after baking to finish the washing of the cracked pieces of the burnt-out printing. The printing slurry is made by charging concentrated sulfuric acid into the common slurry or by mixing the ready-made clothes printing slurry which can be bought in the market and contains acid component with the auxiliary agent in the distilled water. The process has low energy consumption per unit of ready-made clothes and simple process with low requirements on production field and devices and is suitable for industry production.

Owner:QINGDAO TENGHUA APPAREL CO LTD

Inkjet printing process of cotton fabric

ActiveCN103469642AEnhanced wash resistance and sorptionSmooth printingDry-cleaning apparatus for textilesDyeing processPre treatmentSizing

The invention discloses an inkjet printing process of a cotton fabric. A technological process which comprises the processes of sizing pre-treatment, drying, inkjet printing, steaming and colour fixing, after treatment, washing and drying is adopted, preshrinking process treatment is carried out firstly before the sizing pre-treatment, so that the phenomenon that printed flowers are irregular owning to shrinkage of the cotton fabric in the inkjet printing process is effectively avoided; besides, idiosyncratic inkjet printing pigment ink is adopted for carrying out inkjet printing, cold water and hot water are alternate for multiple times in a washing process, chemical tolerance of a pigment is stimulated, and washing resistance and adsorption rate of the cotton fabric are improved. The inkjet printing process of the cotton fabric has the advantages of smooth printing, appropriate colouring depth, difficulty in colour fading and simple technology.

Owner:溆浦县顺成服装有限公司

novel carpet RIP printing technology

The invention relates to a novel carpet RIP printing technology. The novel carpet RIP printing technology utilizes high-fastness eight-color dispersible ink or cationic ink and color matching software of RIP and comprises steps of spray printing design, color matching, ink-jet printing and drying color-development; and according to the novel carpet RIP printing technology, patterns are directly spray-printed on the surface of a carpet by a carpet ink-jet printing machine and the color is fixated. Through the novel carpet RIP printing technology, fixation fastness is high, after-treatment processes such as water washing and ageing are avoided after spray printing, small-batch and fast-response RIP printing production is really realized, and production batch is not limited. The novel carpet RIP printing technology solves the problem that the existing printing technology produces dye waste and discharges a large amount of printing and dyeing waste water thereby causing environmental pollution. The novel carpet RIP printing technology reduces enterprise burden and satisfies environmental protection requirements. The novel carpet RIP printing technology is suitable for printing production of carpets, tapestries and blanket fabric prepared from various vegetable fibers, chemical fibers and synthetic fibers.

Owner:NANYANG HAOHAI TECH CO LTD

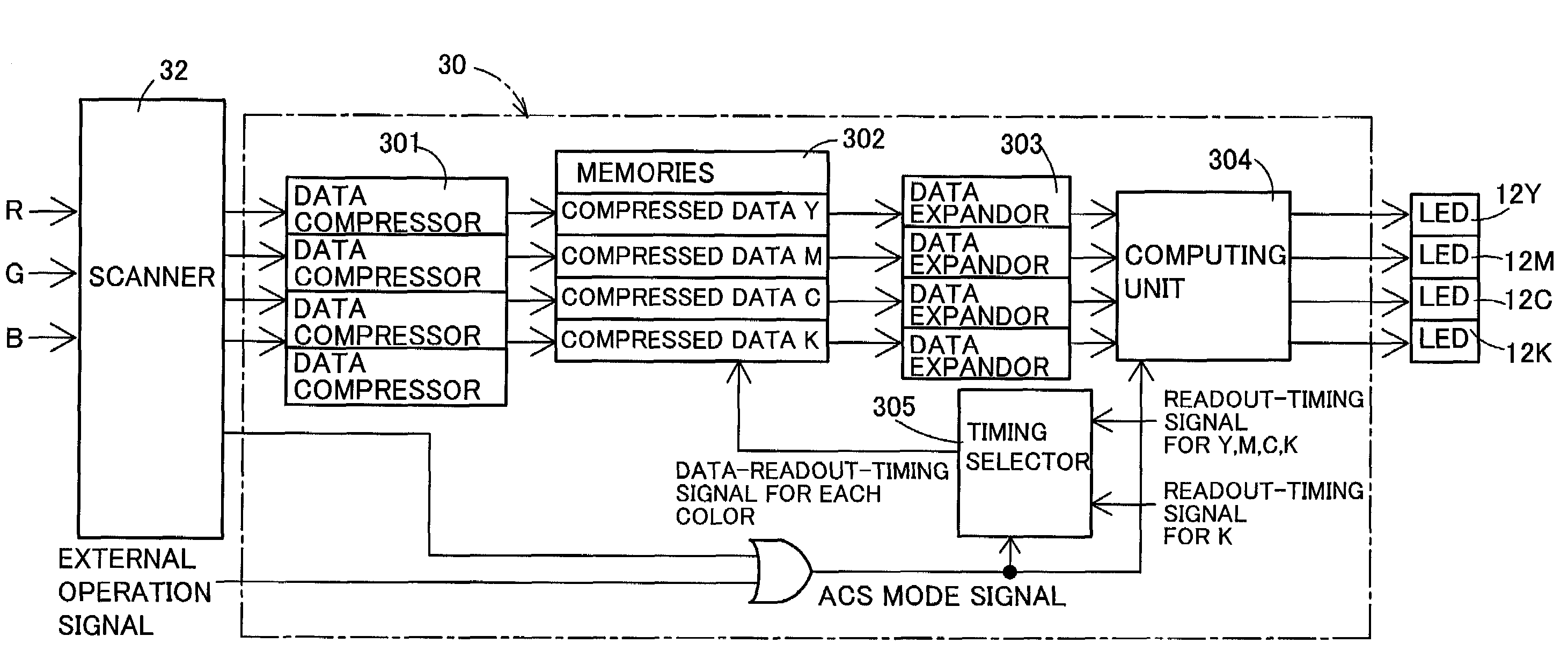

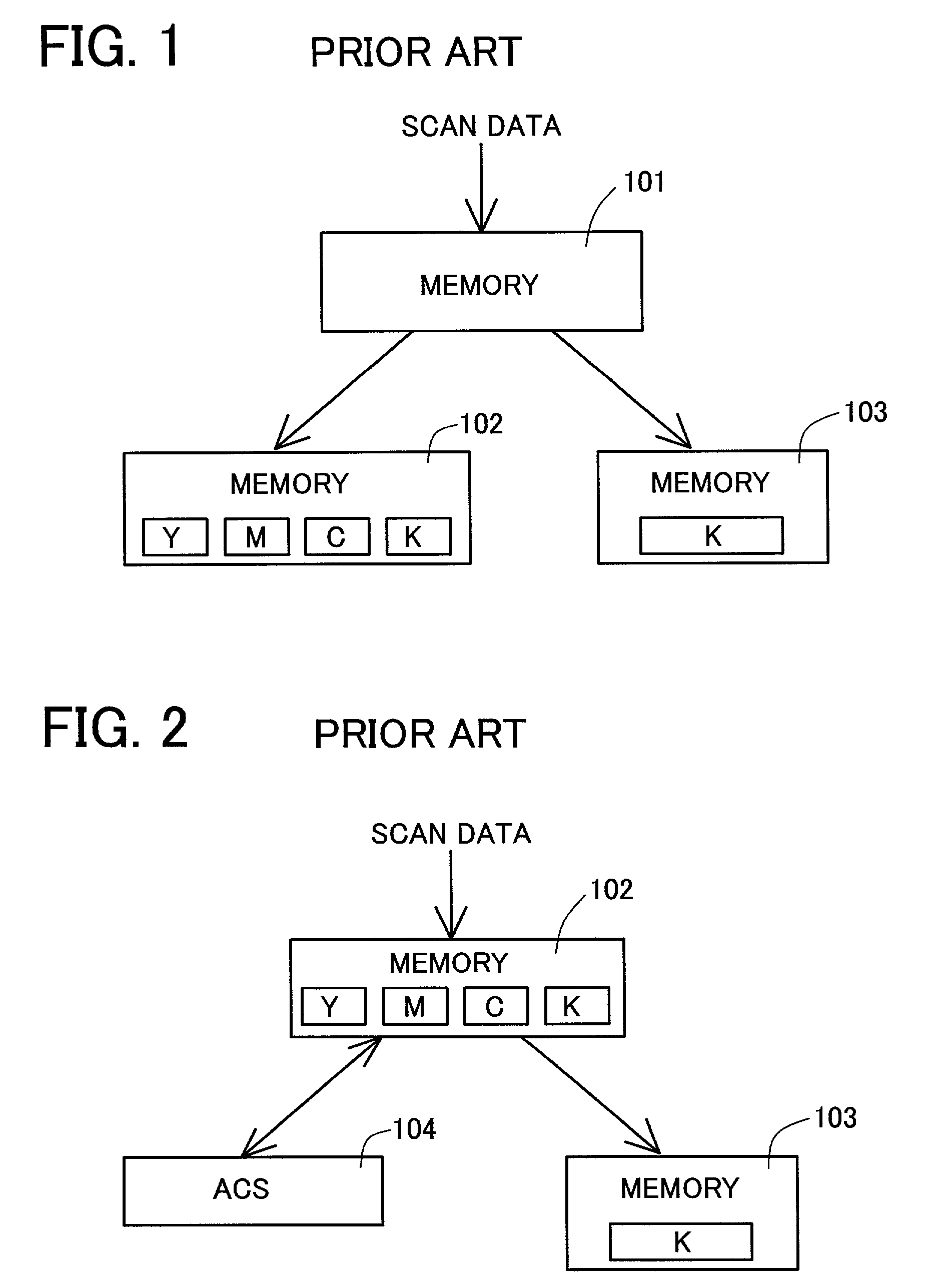

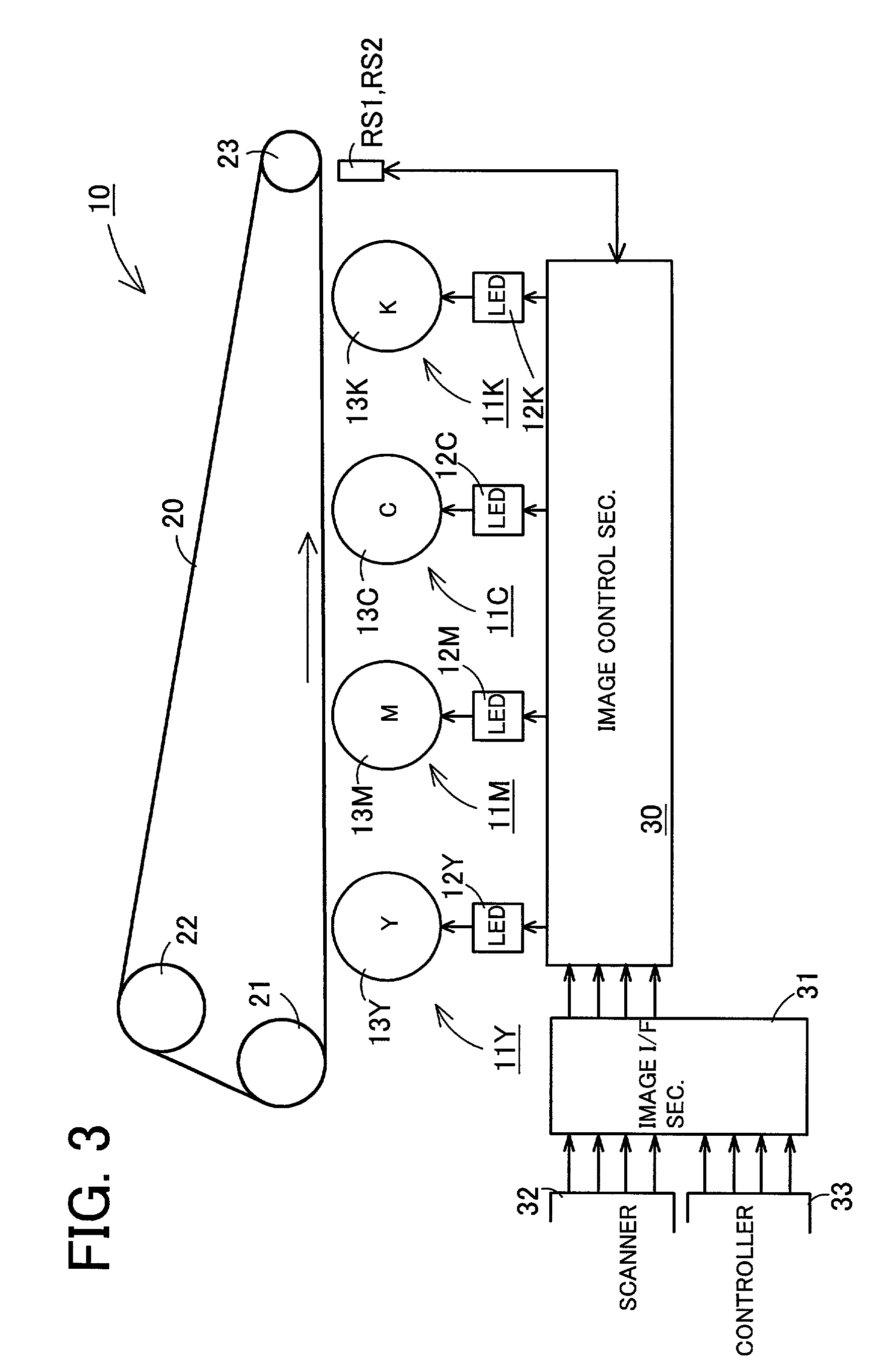

Image processing apparatus, image forming apparatus, image processing method, and program product thereof

ActiveUS7268914B2Reduce memory capacitySimple printing processImage enhancementDigitally marking record carriersProduction rateImaging processing

It is objected to provide an image processing apparatus achieving decrease of memory volume to be used, simplified print process, and enhancement of productivity. Firstly, a plurality of image data are recorded in memories provided for respective colors. Based on the image data or mode selection by a user, it is determined that whether a multi-color image or a monochrome image is to be outputted. Next, memories 302 of respective colors transmit image data of respective colors to a computing unit 304 in accordance with readout-timing signals from a timing selector 305. In case a multi-color image is to be outputted, the timing selector 305 transmits readout-timing signals of respective colors taking time difference length of which is predetermined for each color. In case a monochrome image is to be outputted, the timing selector 305 transmits readout-timing signals of respective color simultaneously. A computing unit 304 forms monochrome image data in accordance with image data of respective colors, whereby process of monochrome print is simplified.

Owner:KONICA MINOLTA INC

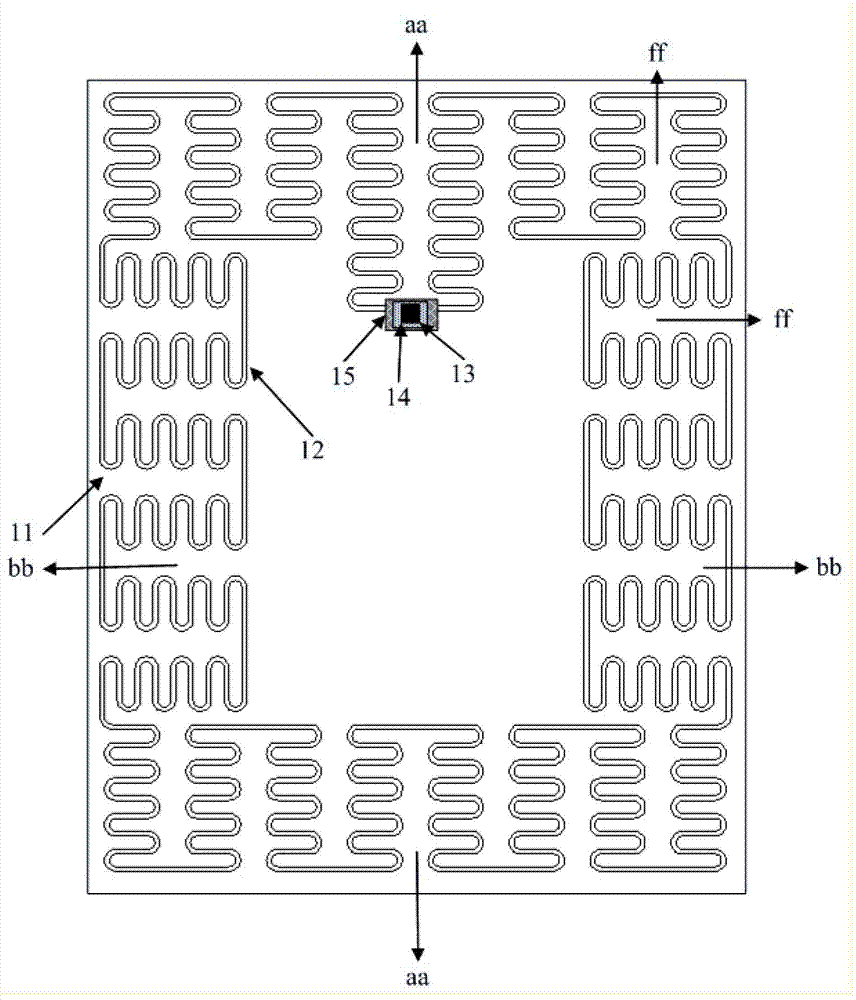

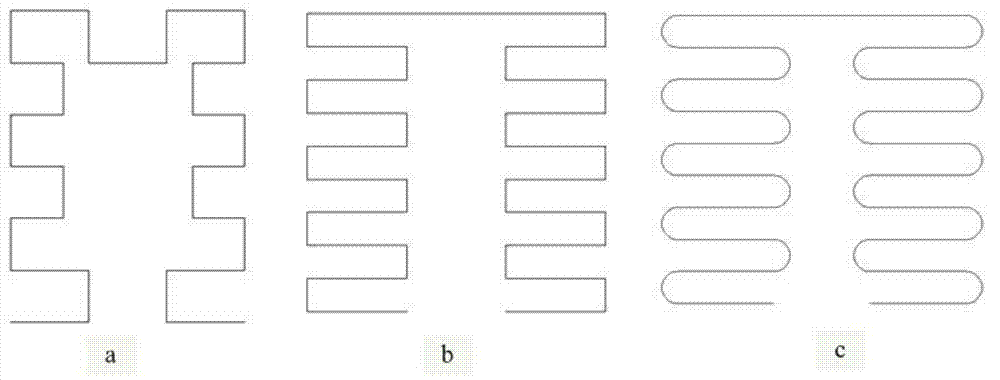

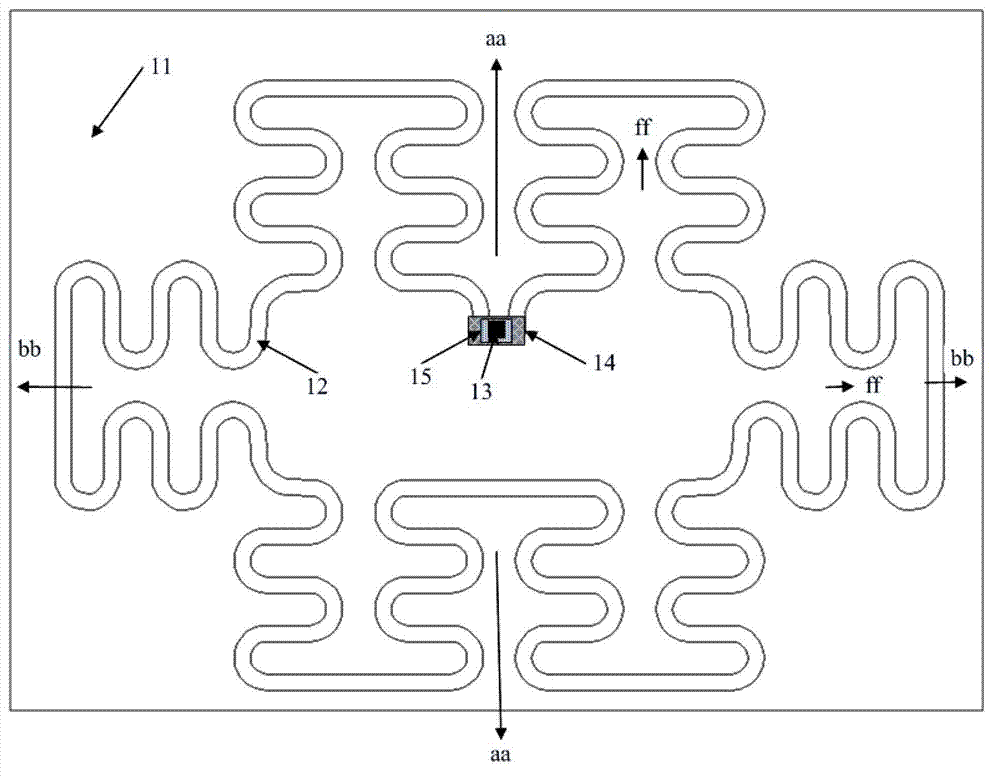

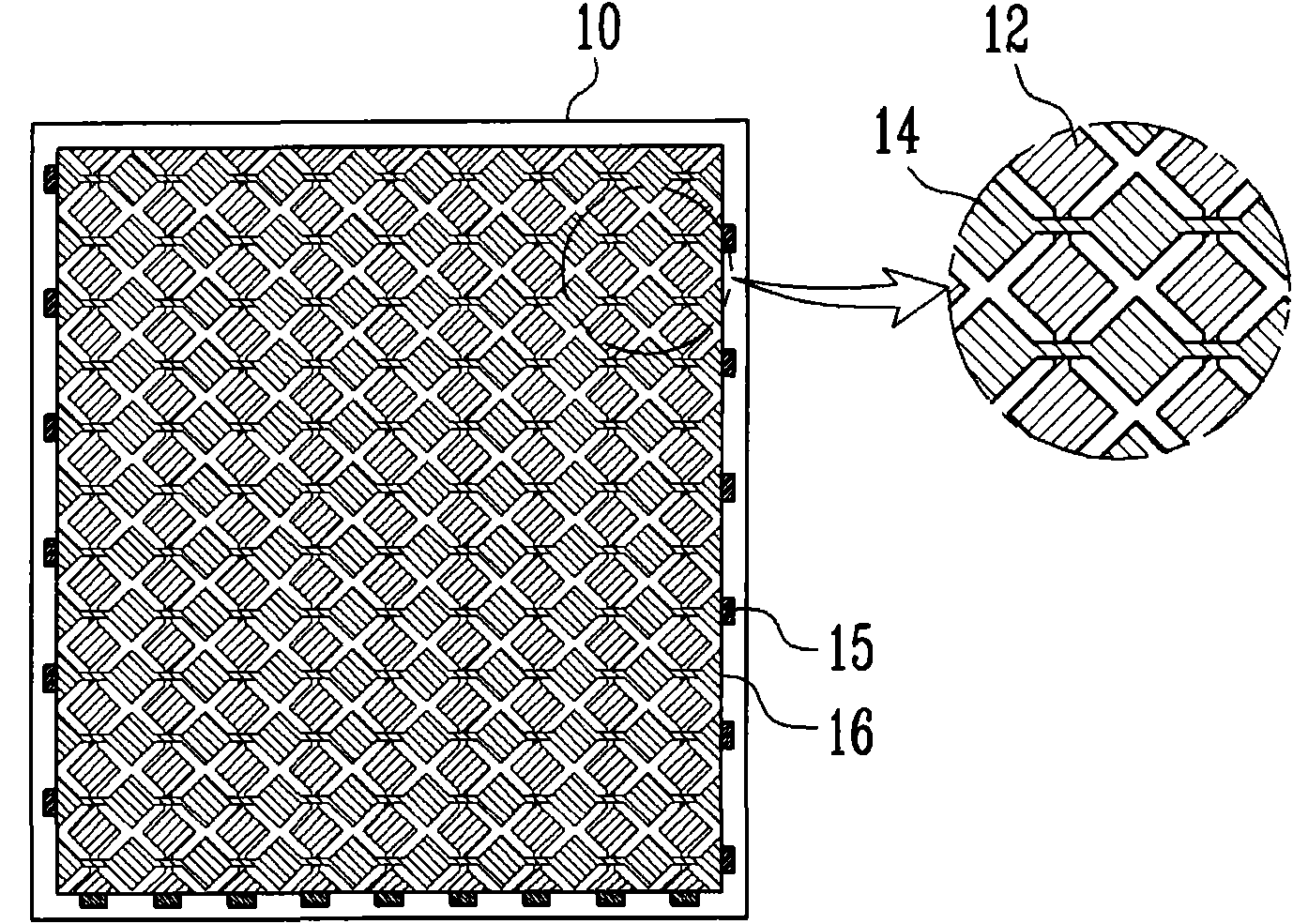

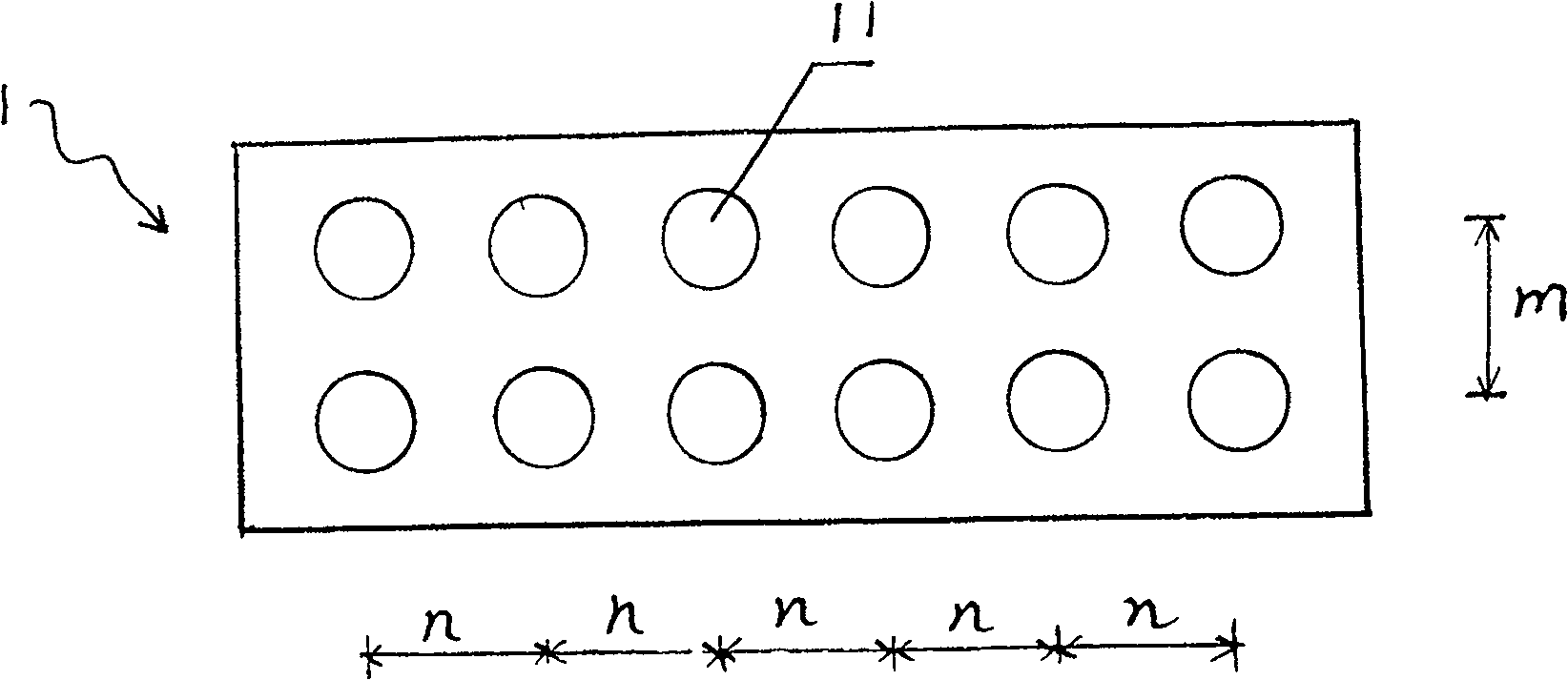

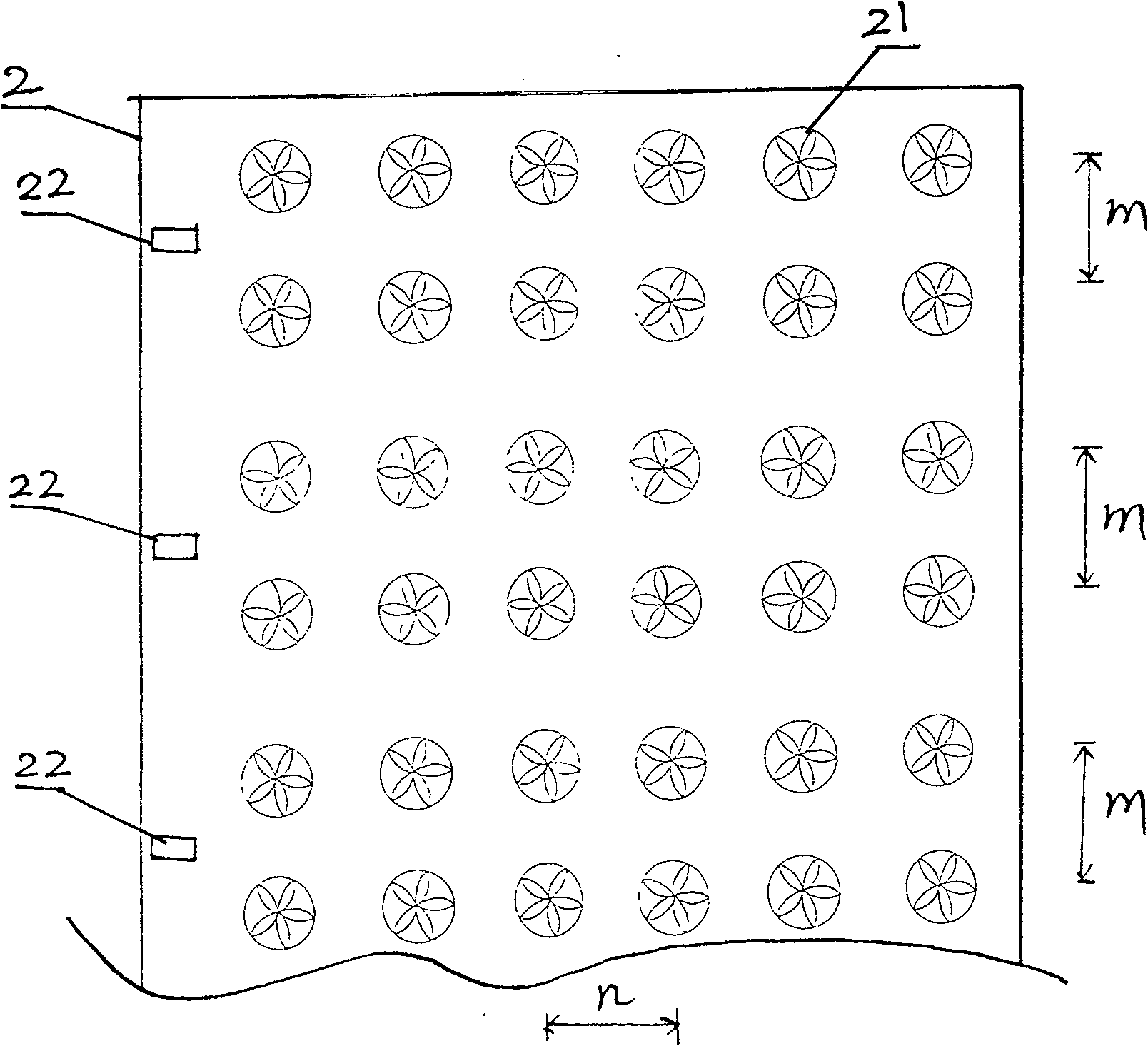

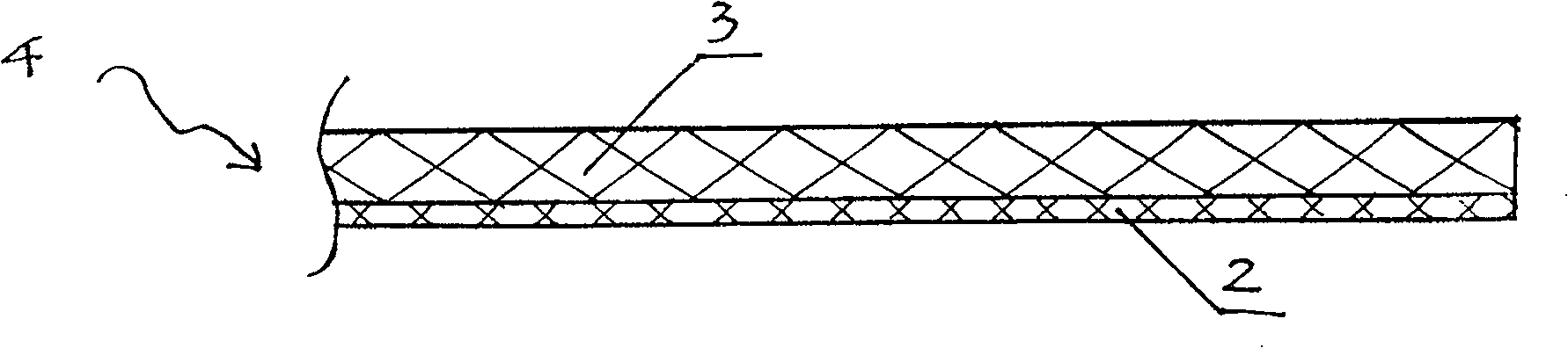

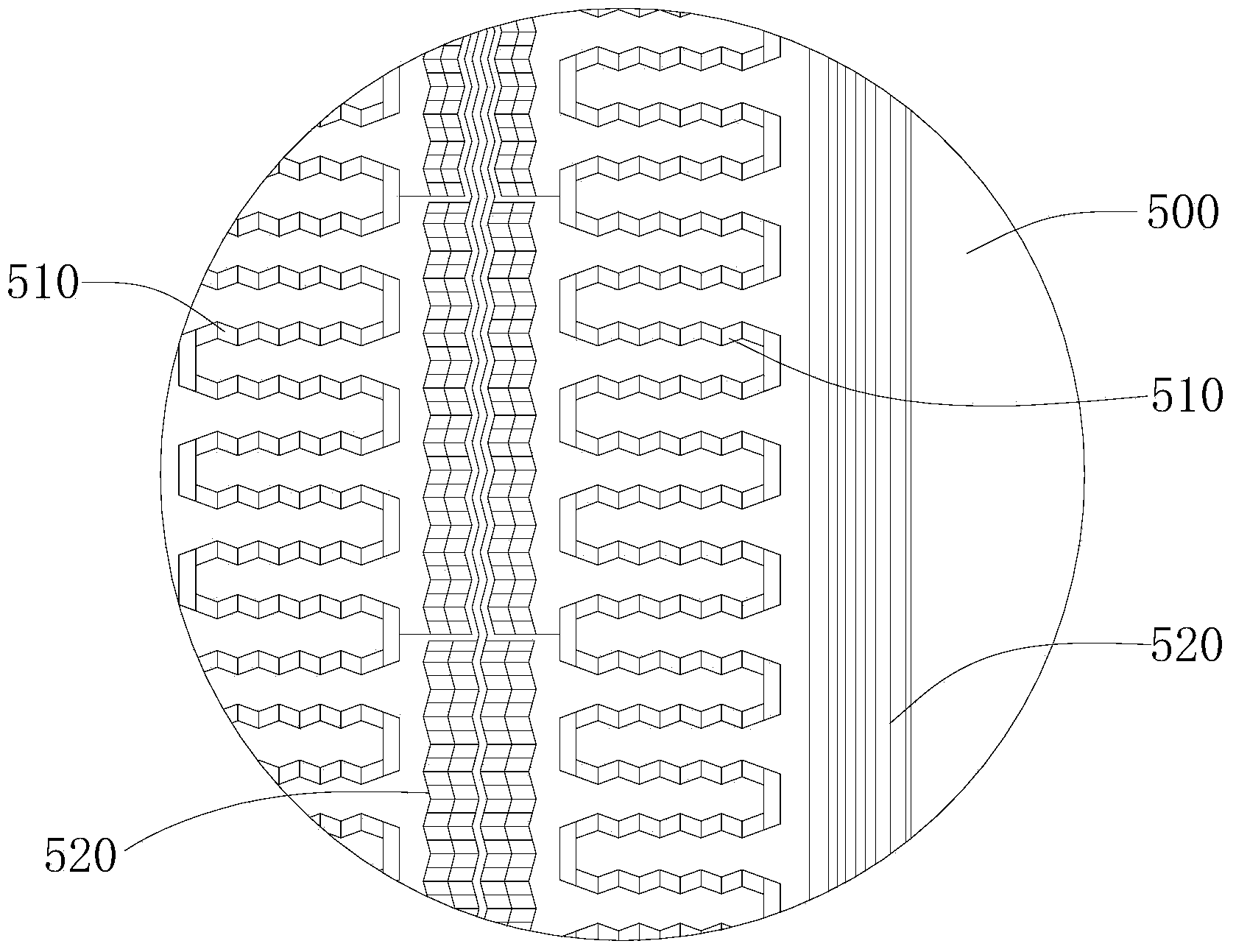

RFID (radio frequency identification) electronic tag based on fractal spring structure, radio frequency antenna based on fractal spring structure, and preparation method of RFID electronic tag

ActiveCN103116803ALarge deformation redundancyImprove bending deformation abilityRadiating elements structural formsRecord carriers used with machinesEngineeringLarge deformation

The invention discloses an RFID (radio frequency identification) electronic tag radio frequency antenna based on a planar fractal spring structure. The electronic tag radio frequency antenna is a closed coil formed by multiple coil sections, of a fractal spring structure, which are in sequential end-to-end connection. The invention further provides an RFID electronic tag based on the radio frequency antenna, the radio frequency antenna is attached to a substrate, the telescoping direction of a spring of each coil section is consistent with the stretching direction of the substrate at position of the coil section. The invention further provides a preparation method of the RFID electronic tag. Radio frequency antennas which are of a multi-level spring fractal structure and consistent with stretching direction of the substrate are disposed transversely and longitudinally on the substrate, large deformation redundancy is achieved, axial and transverse stretching and compression can be borne, large bending deformation capability is achieved, and accordingly the RFID electronic tag can be attached to object surfaces which may generate complex elastic deformation, such as human skin and clothes, and application range of RFID electronic tag is expanded.

Owner:HUAZHONG UNIV OF SCI & TECH

Surface gradual change printing technology and product thereof

The invention discloses a surface gradual change printing technology. The technology mainly comprises the following steps that firstly, printing ink is diluted, and printing ink of at least two different colors is taken to be diluted; secondly, screen inlet mixing is carried out, the diluted printing ink of the at least two different colors is guided in a blank screen printing plate and is linearly arranged according to the gradual change sequence, and a stacking layer of overlapped printing ink of two different colors is formed between adjacent printing ink of every two different colors; thirdly, stacking layer color matching is carried out, and complete mixing and color matching are carried out on the printing ink of the stacking layer through a silica gel scrapper till colors are mixed evenly; fourthly, one-time printing is carried out, a printed material is printed with a gradual change printing ink layer through the blank screen printing plate and the printing ink with even color matching on the blank screen printing plate. The non-screen-point gradual change silk-screen printing is adopted, the manufacturing procedure is simple, convenient and effective, and the product has very even transition and natural non-screen-point gradual change effects.

Owner:FUJIAN RICHES ELECTRONICS SCI & TECH

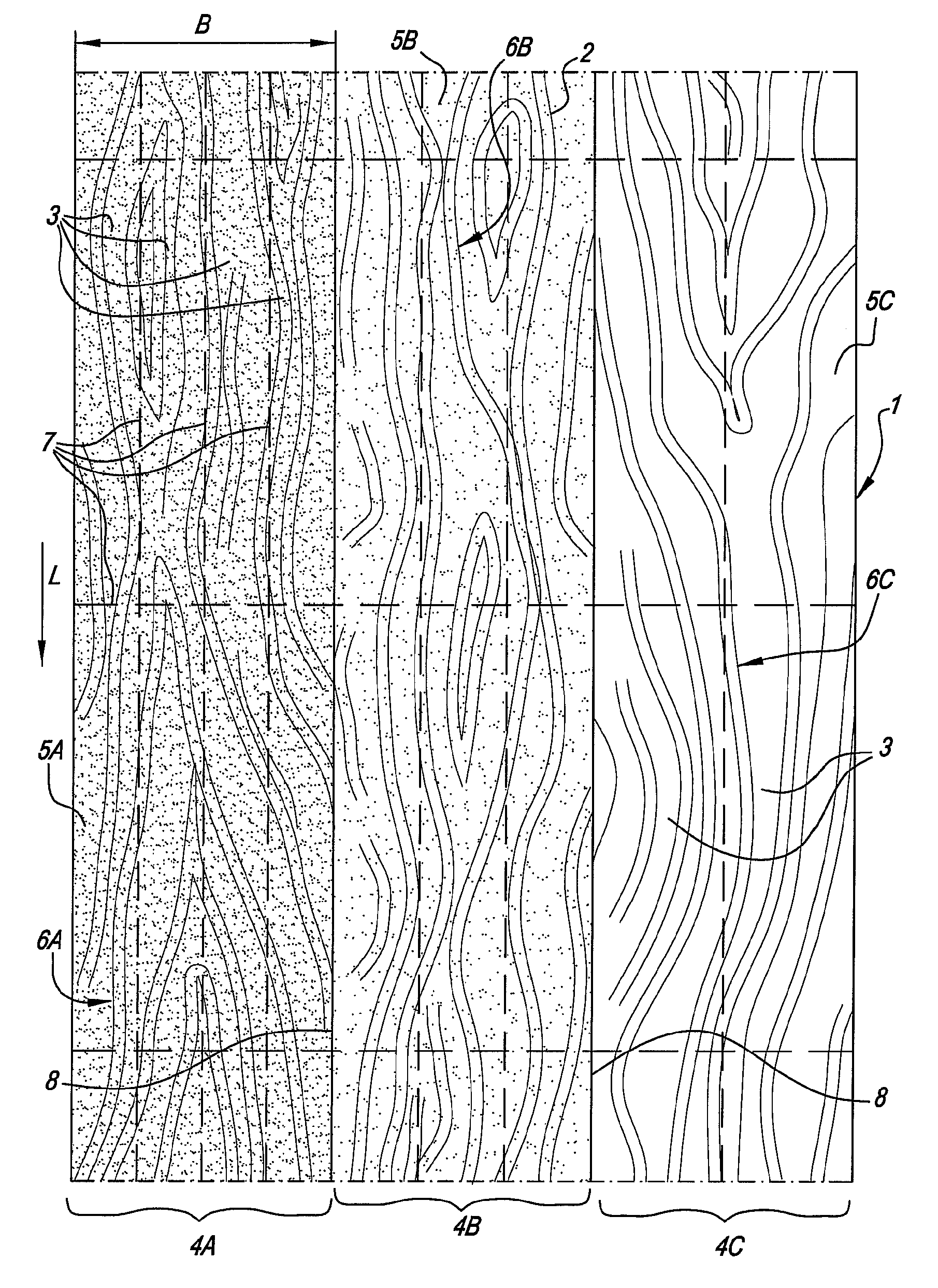

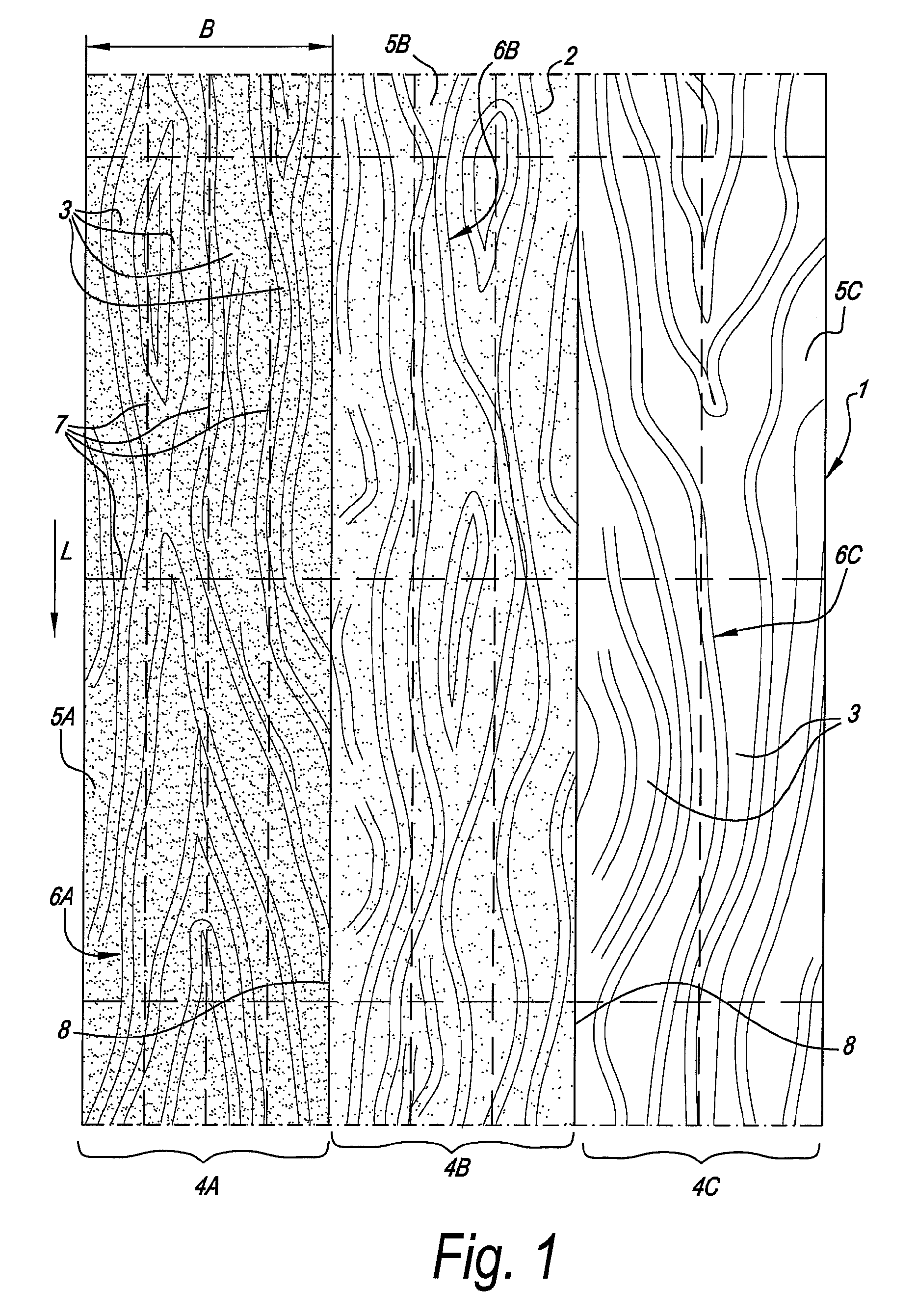

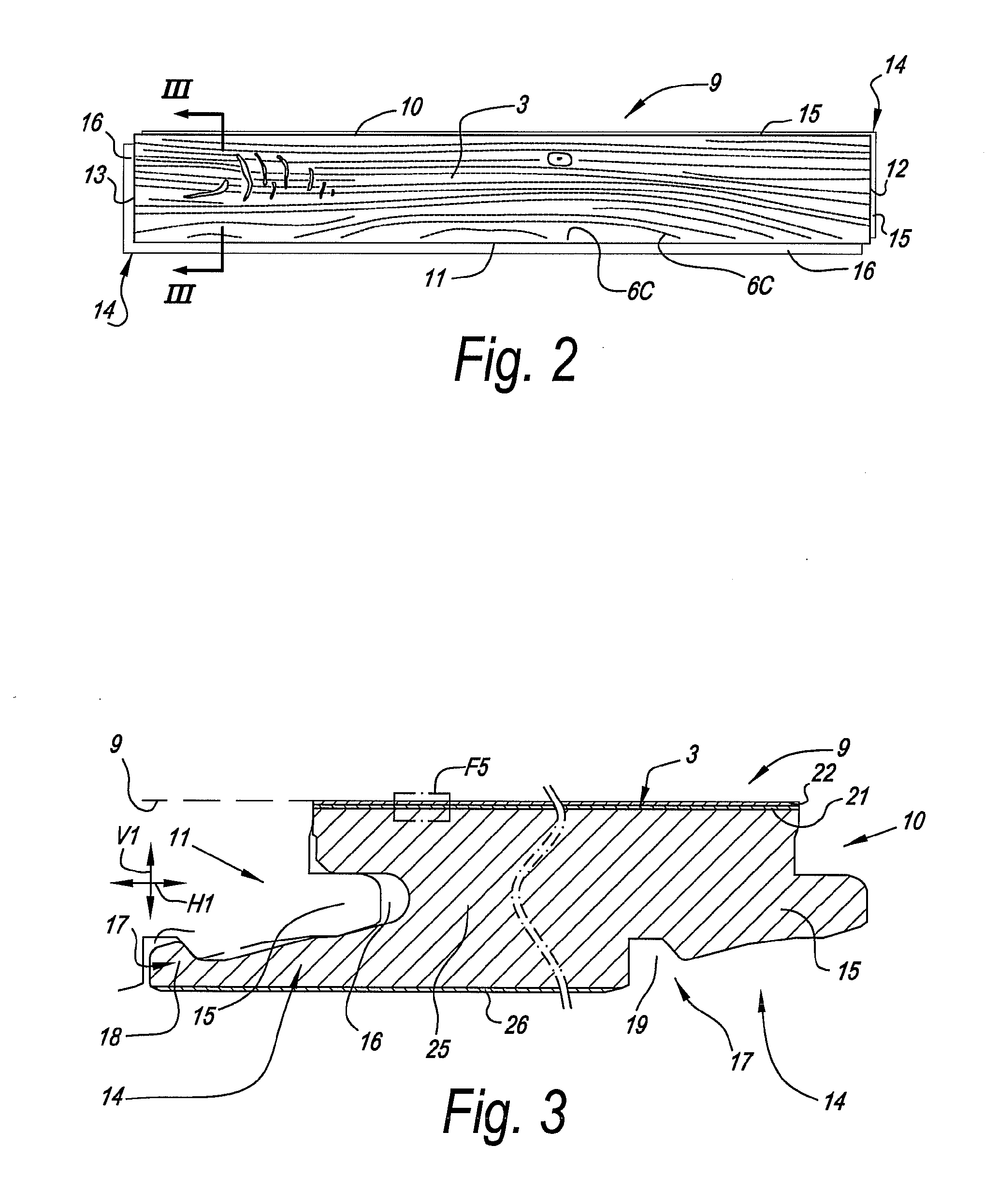

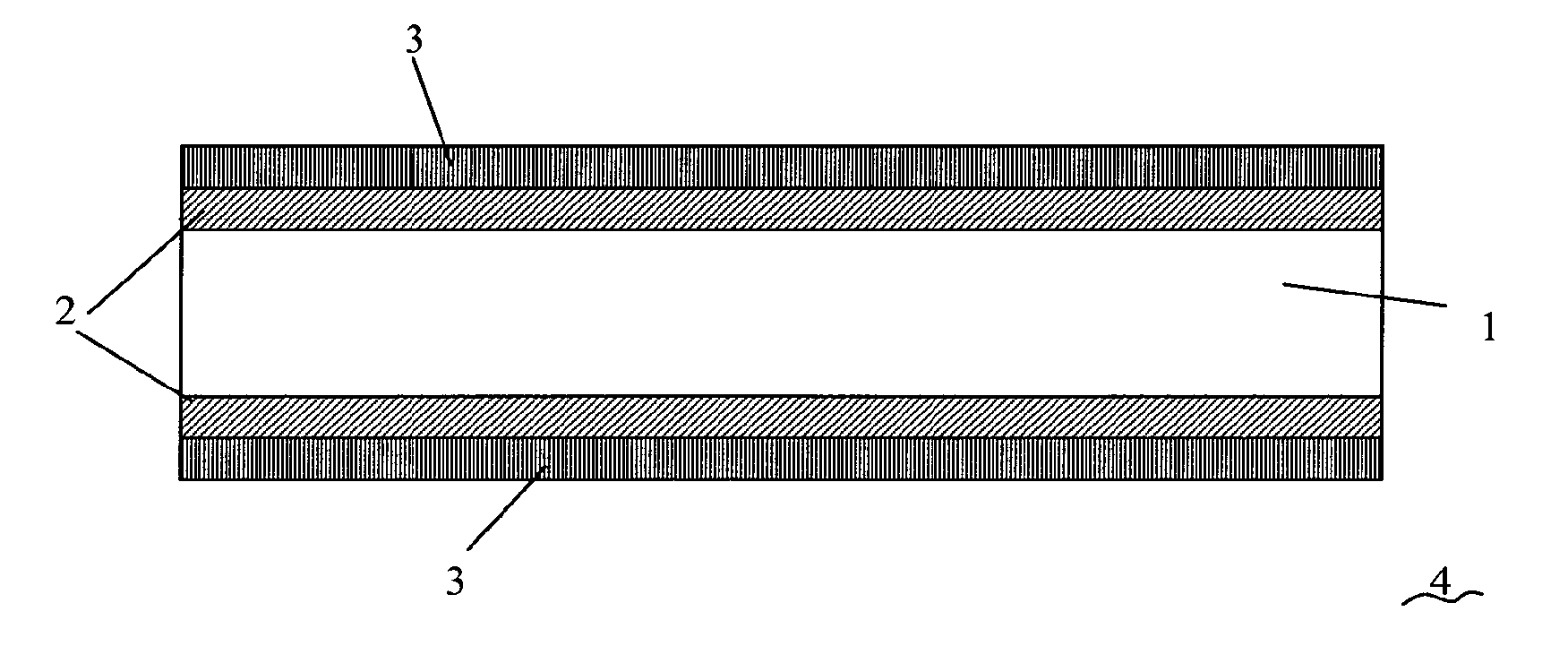

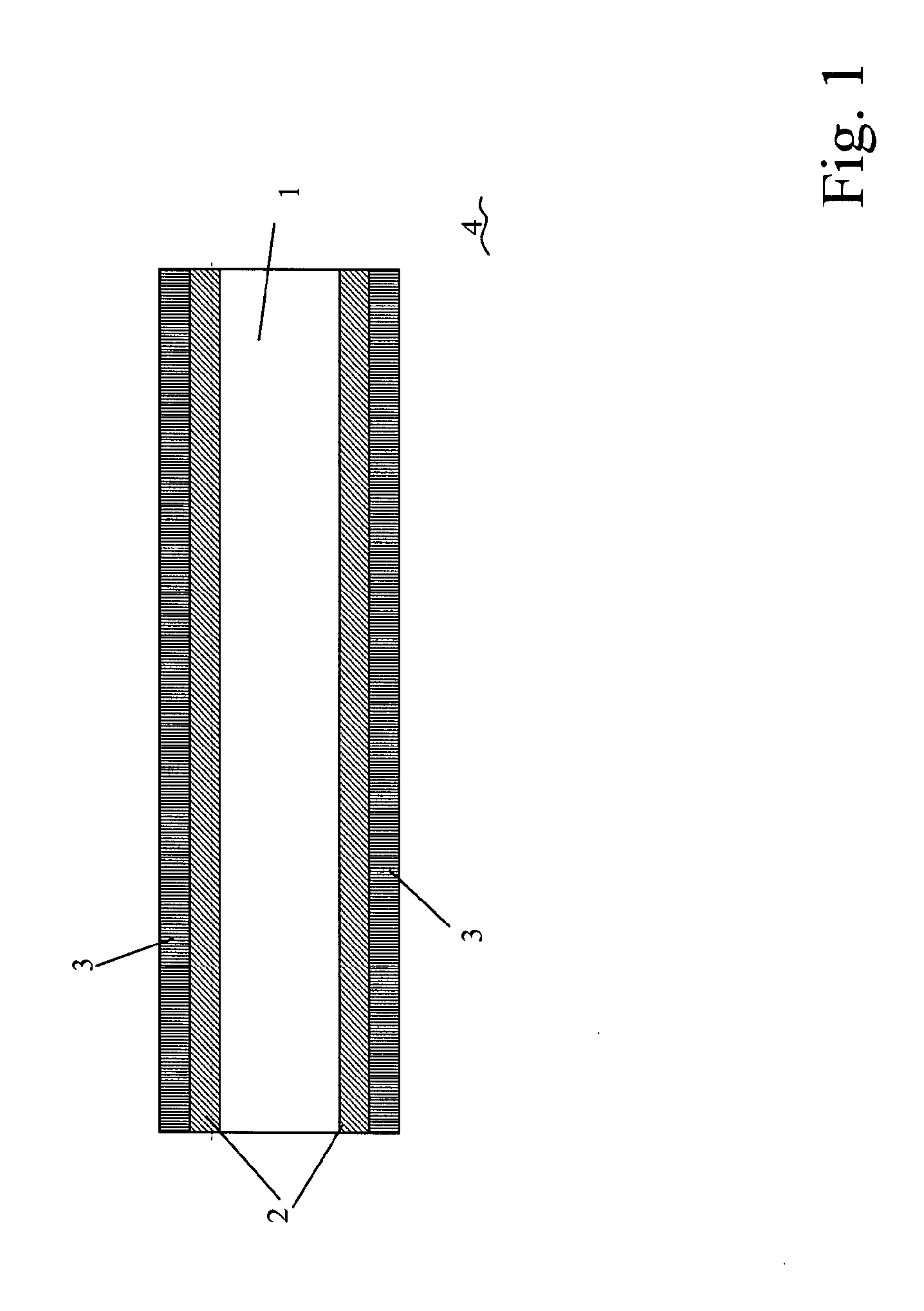

Printed substrate, method for manufacturing floor panels and method for manufacturing printed substrates

InactiveUS20090305009A1Easy to manufactureSmooth divisionLamination ancillary operationsDecorative surface effectsEngineeringSurface plate

Owner:FLOORING IND LTD

Bamboo charcoal printing textile and manufacture method thereof

The invention relates to a bamboo charcoal print fabric, which uses powder bamboo charcoal, adhesive, thickening agent, penetrant, deepening agent, and permeability-reducing agent to prepare the print slurry; using said slurry to print the fabric, then baking, washing and finishing to print; then baking at 120-160Deg. C for 1-5min, washing at 40-60Deg. C, and finishing. The invention can improve the appearance of fabric, and since the bamboo charcoal can resist to electromagnetic wave, purify water, and adjust humidity. The inventive product has wide application.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Method for producing thermal-formation products of plastic sheet material

A thermally shaping method for preparing the product from plastic sheet includes such steps as printing patterns and locating marker on transparent plastic film, attaching the plastic film onto surface of a plastic sheet, heating the plastic sheet for softening it, moving it into a moulding cavity, applying pressure to make it close to the inner surface of moulding cavity, cooling, demoulding and punch shearing.

Owner:广东日烽吸塑包装实业有限公司

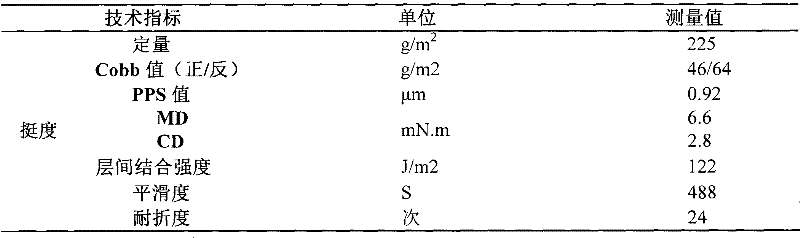

Novel cigarette packet paperboard

ActiveCN102127878ACover up wood pulp woody smellImprove adaptabilitySynthetic cellulose/non-cellulose material pulp/paperSurface layerPaperboard

The invention relates to novel cigarette packet paperboard, which comprises a core layer, a surface layer and a back layer. The surface layer and the back layer of the paperboard are mixed fiber pulp paper containing tobacco fibers and hemp fibers; and mixed fiber pulp comprises the following components in percentage by weight: 6 to 30 percent of tobacco fiber pulp, 5 to 25 percent of hemp pulp, 0 to 25 percent of bleached softwood pulp and 40 to 70 percent of bleached hardwood pulp. A part of bleached softwood pulp or bleached hardwood pulp used by the surface layer and the back layer of the cigarette packet paperboard is replaced by the tobacco fibers and the hemp fibers, so that cost can be reduced, quality can be ensured, and strength is qualified.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

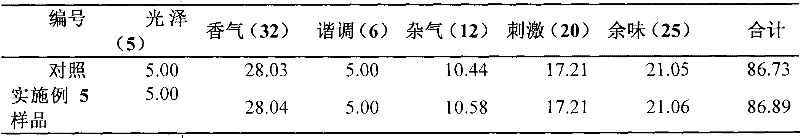

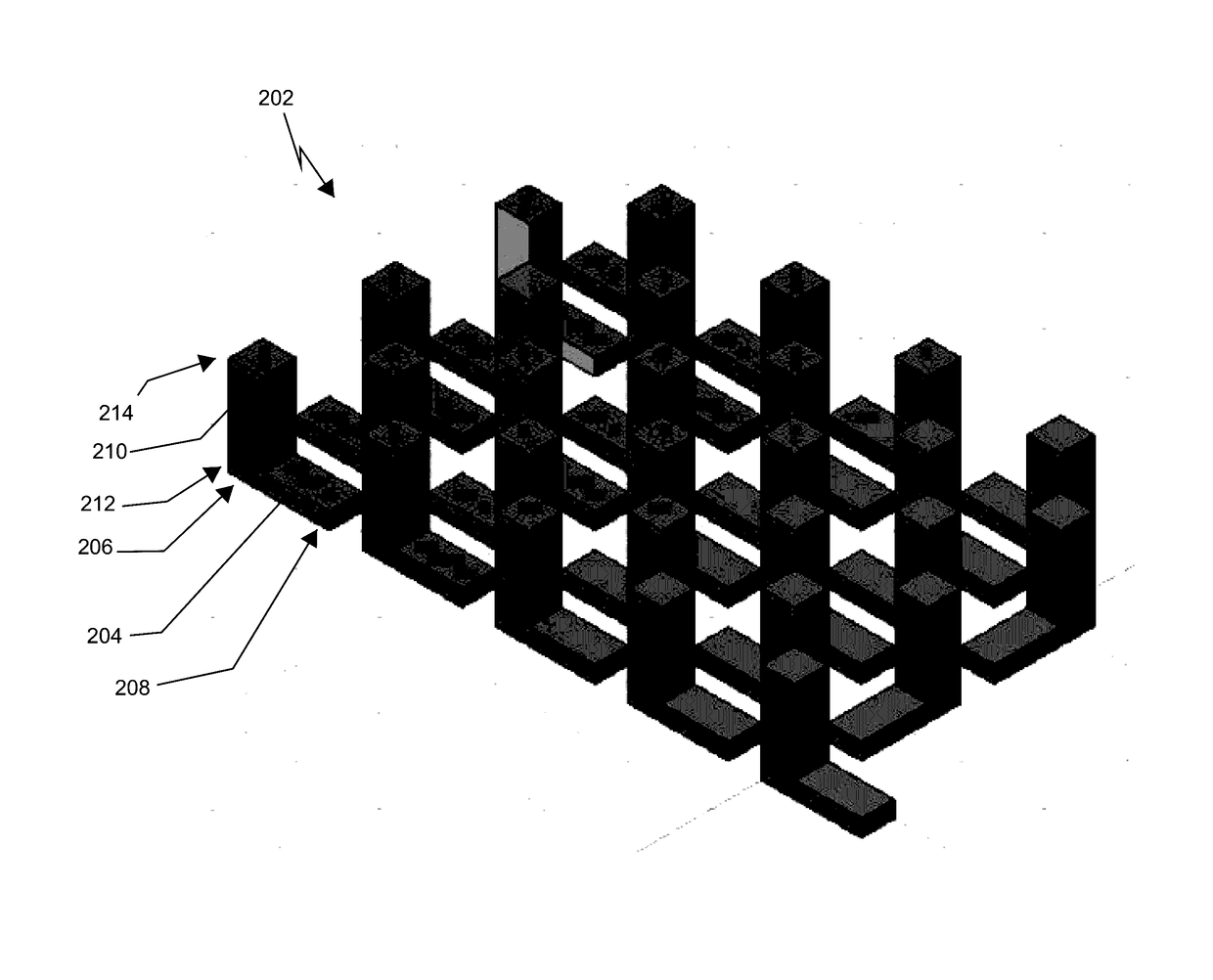

Thermoelectric Devices

ActiveUS20170069817A1Rapid facile inexpensive fabricationImprove conductivityAdditive manufacturing apparatusThermoelectric device with peltier/seeback effectEngineeringAdditive layer manufacturing

This disclosure relates to methods for manufacturing devices capable of functioning as thermoelectric generators and related objects by the process of additive manufacturing or by 3-D printing or by casting. This disclosure also particularly relates to the uses of the thermoelectric generators and related objects produced by these methods.

Owner:XILICO LLC

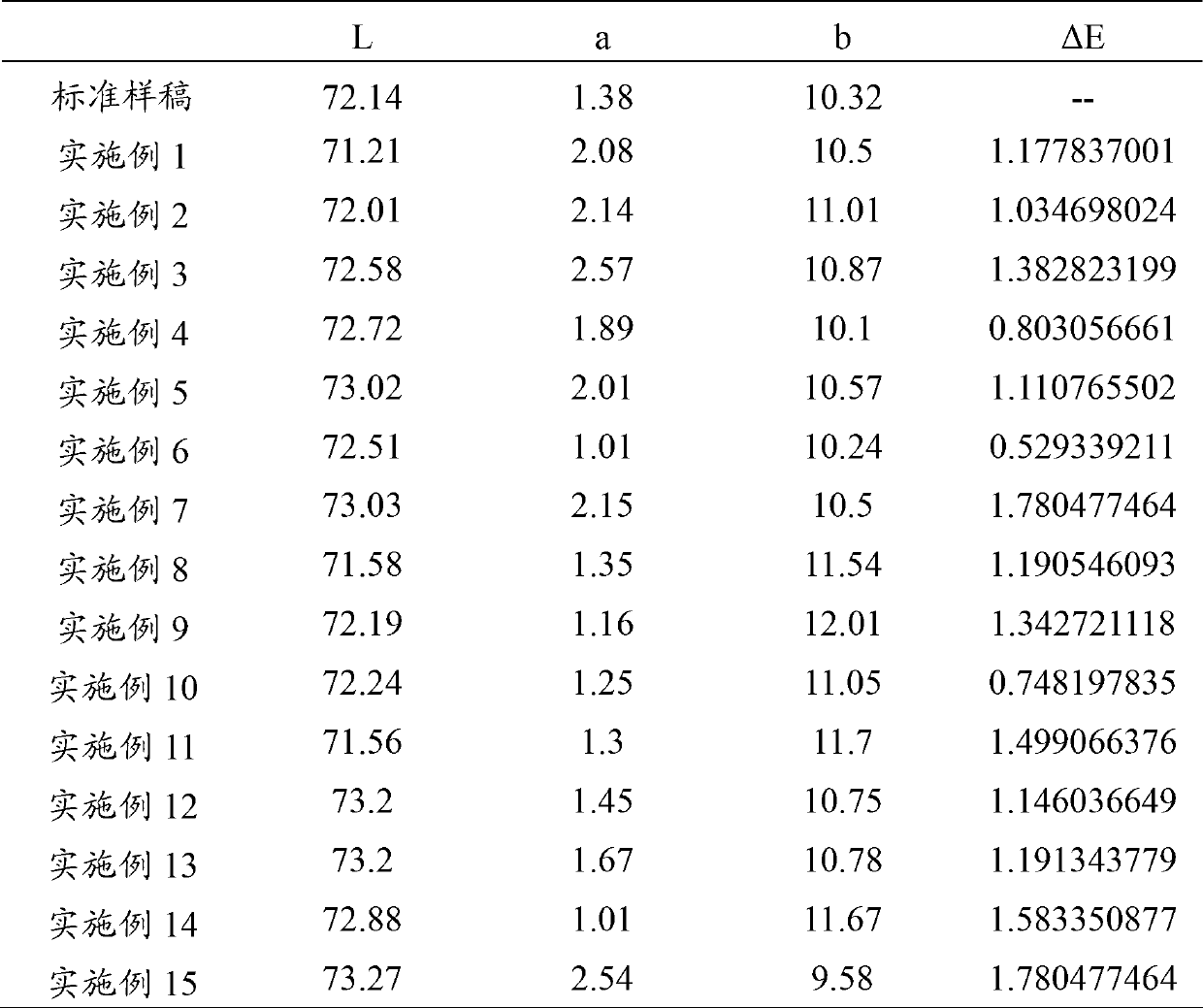

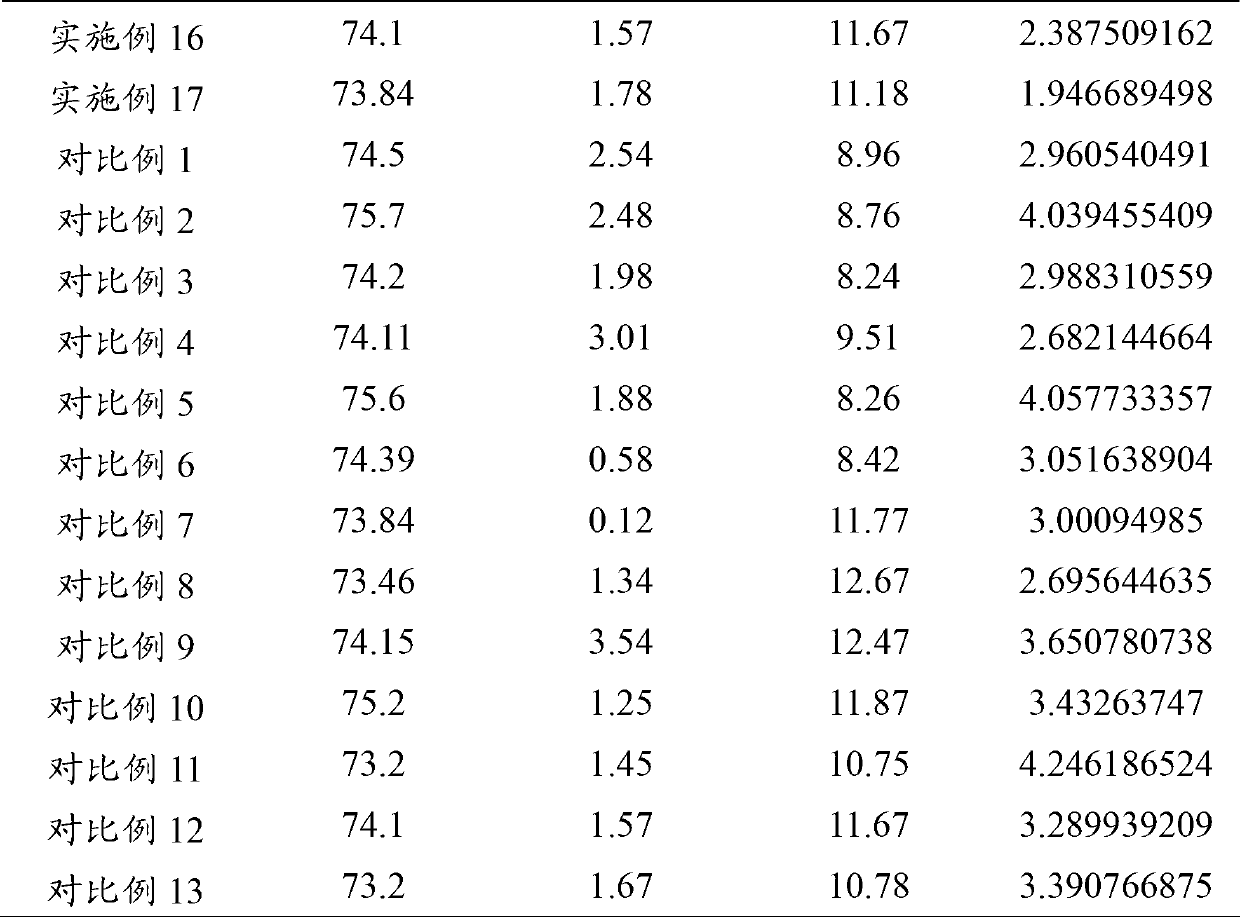

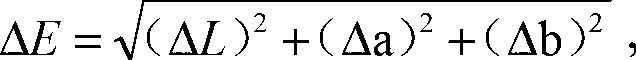

Preparation method of gold imitated card paper, bar code printing method and packaging product processing method

The invention provides a preparation method of gold imitated card paper. According to the preparation method provided by the invention, gravure printing is adopted for transferring gold imitated gravure ink composition onto the surface of a silver card paper, and drying and curing are carried out, so that the gold imitated card paper is obtained. When the gold imitated card paper is taken as a printing stock during printing, the gold imitated card paper is not influenced by a printing process, hue of the gold imitated card paper is consistent with the hue of standard sample manuscript gold card paper, stable hue of the gold imitated card paper can be guaranteed, and a printing technology of the gold imitated card paper is simple. The invention also provides a bar code printing method. According to the bar code printing method provided by the invention, the gold imitated gravure ink composition is printed on the surface of the sliver card paper except a region in which a bar code is required to be printed, so that the region in which the bar code is required to be printed can not contain the gold imitated gravure ink composition and is in the colour of the silver card paper; and white gravure ink is overprinted in the region in which the bar code is required to be printed, and sign contrast between black bars is increased, so that the grade standard of the bar code is met.

Owner:CHANGDE JINPENG PRINTING

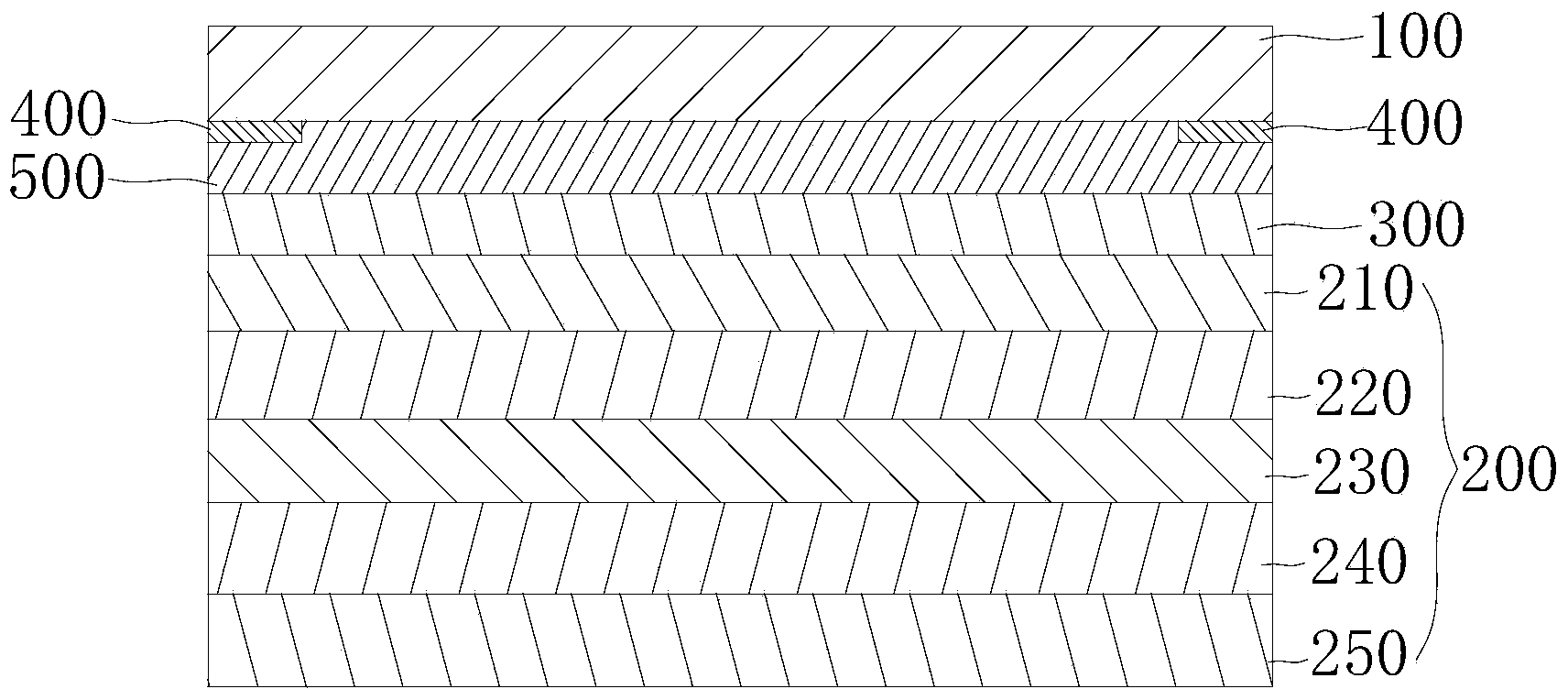

Solar battery string, solar battery component and preparation method of solar battery string

ActiveCN109326665AReduce back silver paste wasteSimplify the screen printing processPhotovoltaic energy generationSemiconductor devicesBusbarAluminium

The invention relates to a solar battery string, comprising more than two cells serially connected in stack form, where each cell includes an aluminum back field, a back passivated layer, a polysilicon substrate, a positive passivated layer, an antireflective film, positive silver fingers and a positive silver electrode which are arranged sequentially from bottom to top; in two cells serially connected in stack manner, the positive silver electrode of the front cell is connected with the aluminum back field of the rear cell via conductive glue; in the cells serially connected in stack manner,a busbar is connected with the aluminum back field of the first cell via conductive glue, and a busbar is connected or directly welded to the positive silver electrode of the last cell via conductiveglue. The solar battery string herein has the advantages that the usage of back silver paste can be decreased, the silkscreen printing process is simplified, and the material cost is low; the back silver electrodes are omitted while the conducting capacity is equivalent to that of the string having the back silver electrodes; conductive connection is reliable and stable; the passivated area of thealuminum back field is enlarged, so that photon utilization efficiency is improved; in addition, the requirement on aligning precision of the stack process is lowered; gaps among the modules are utilized, and the cells that can be added under the same area are 13% and above more than those in conventional modules.

Owner:CHANGCHUN YONGGU TECH

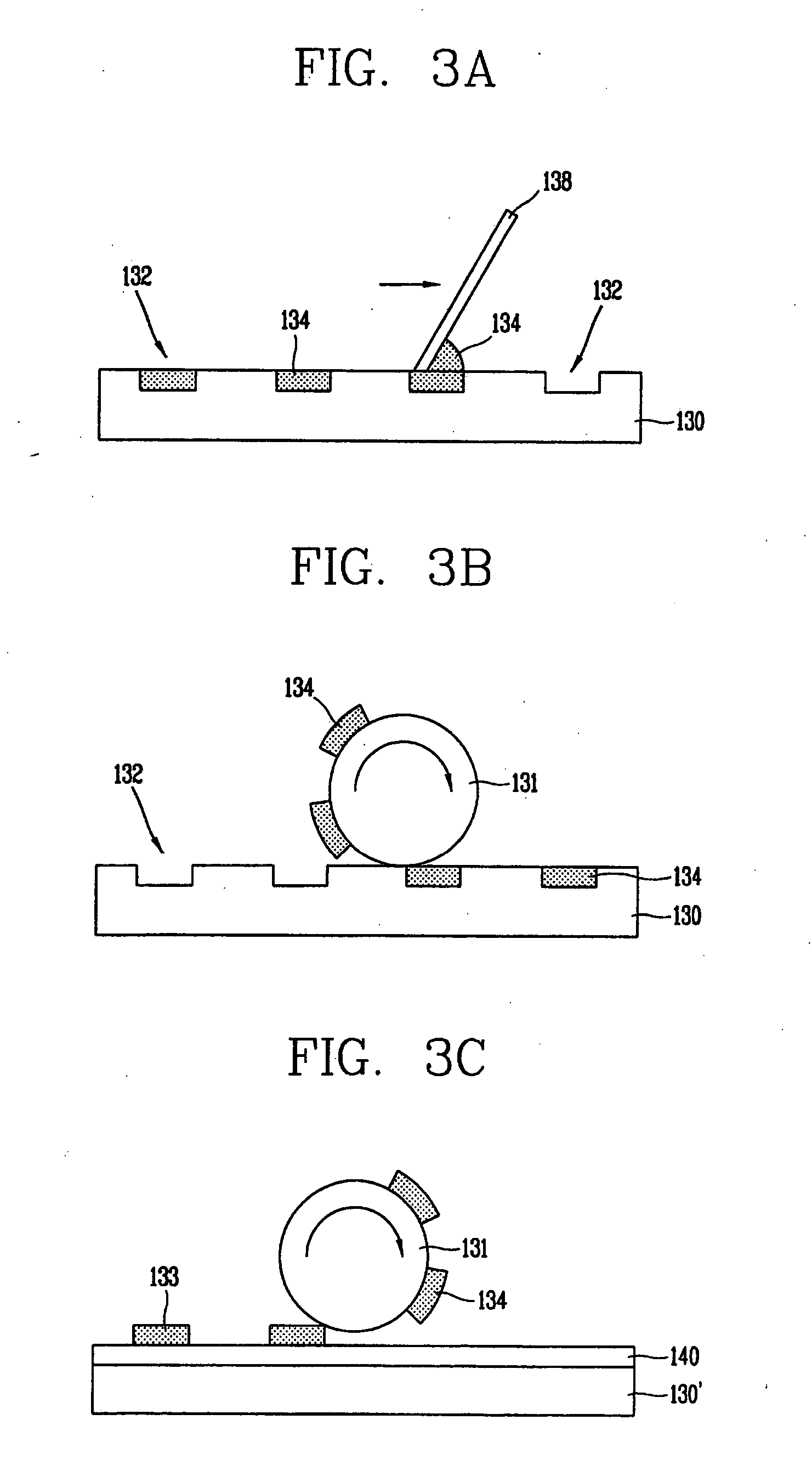

Method for forming pattern using printing method

ActiveUS20050244990A1Improve productivitySimple printing processPlaten pressesLighting and heating apparatusElectrical and Electronics engineering

A method for forming a patterns includes applying ink onto an etching object layer; forming ink patterns on the etching object layer as a printing roll having convex patterns thereon rotates on the ink and removes portions of the ink which contact the convex portions of the printing roll, thereby forming ink patterns; and hardening the ink patterns.

Owner:LG DISPLAY CO LTD

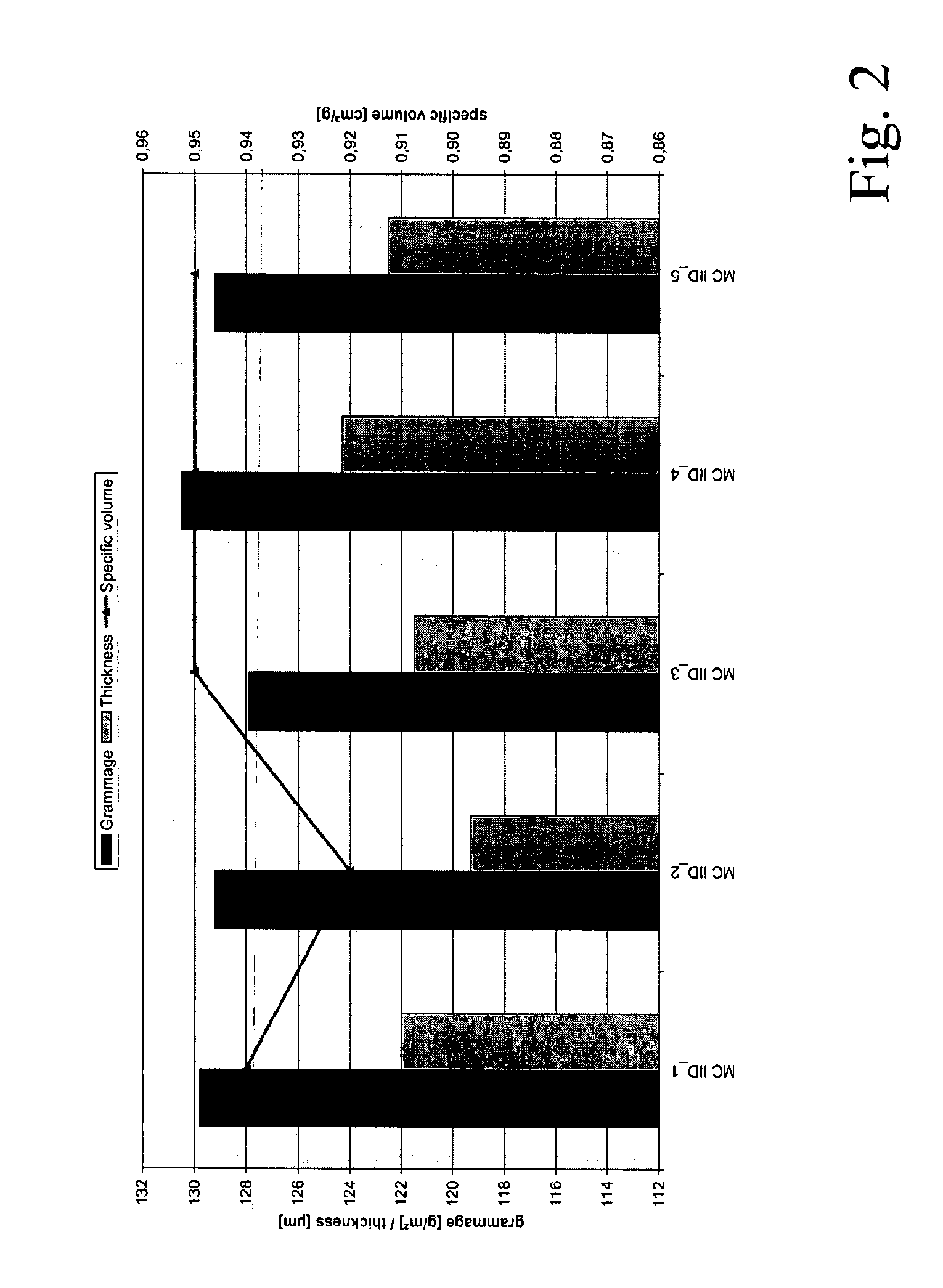

Coated Paper for Sheet-Fed Offset Printing

InactiveUS20080261021A1Simple printing processShorter reprinting time timeCylinder pressesNon-fibrous pulp additionDusting powdersPrinting press

The specification pertains to a single or multiple coated printing sheet in particular but not exclusively for sheet-fed offset printing with an image receptive coating layer on a paper substrate. The printing sheet has the property that it can be printed in an offset printing process without spraying a fine powder, usually called offset powder or dust powder, on the sheet as it comes off the press to prevent the ink from transferring to the back side of the next sheet. Also irradiative (UV or IR) drying on the sheet fed press is not necessary and / or the use of overprint varnish is not required. In addition to that, unexpectedly short times until reprinting and converting can be achieved. Furthermore methods for making such a printing sheet and uses of such a printing sheet are disclosed.

Owner:SAPPI NETHERLANDS SERVICES

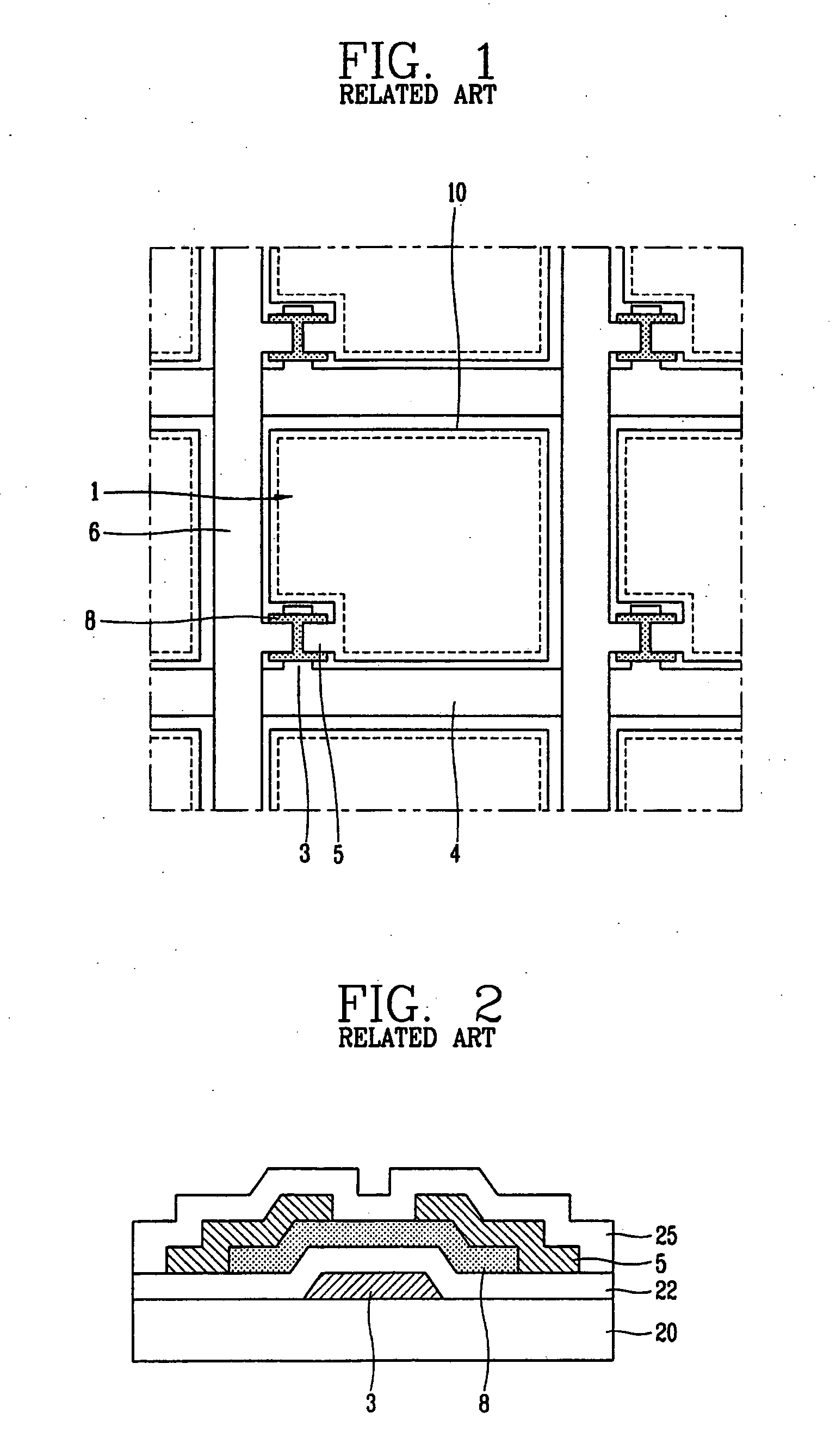

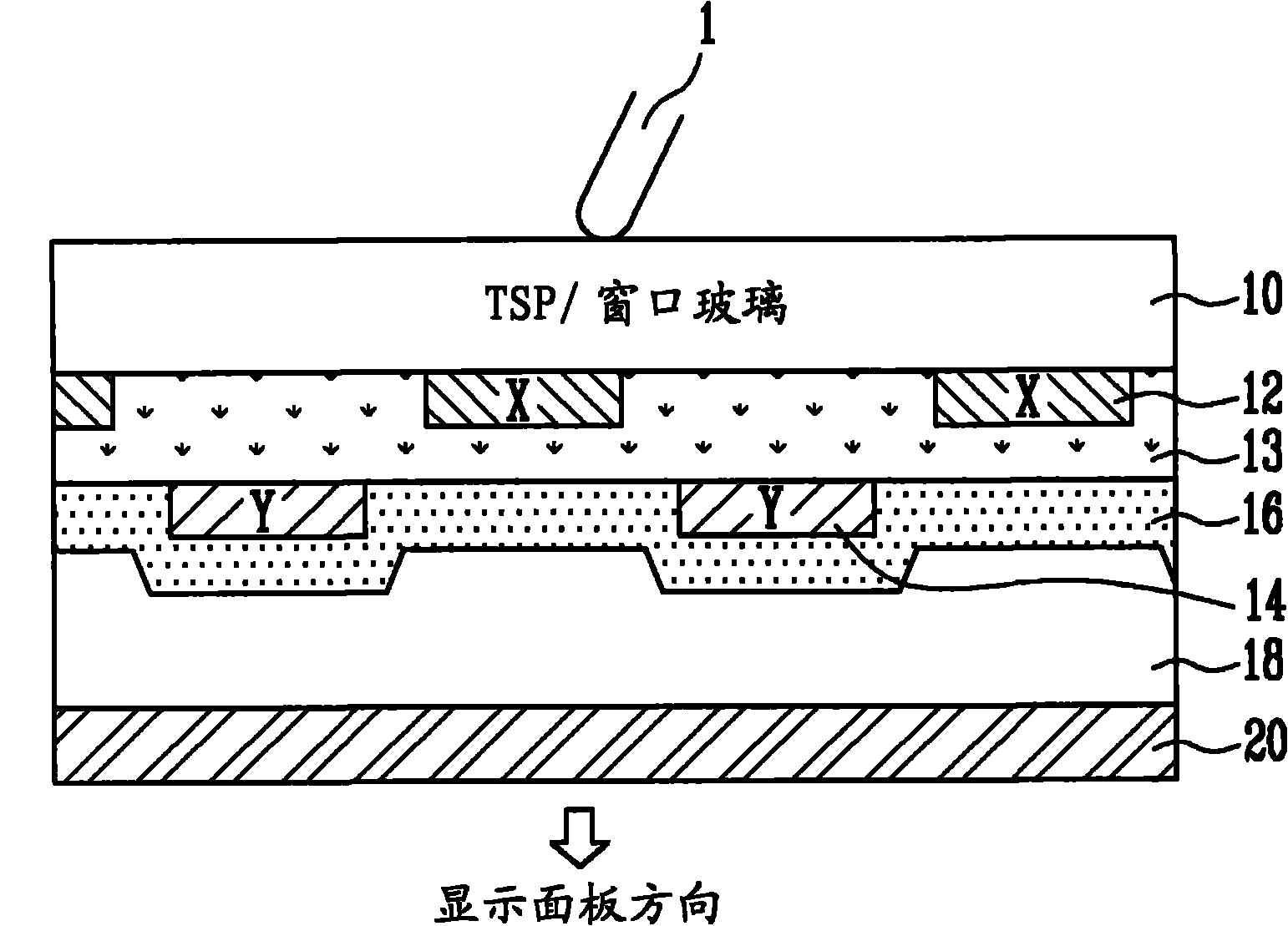

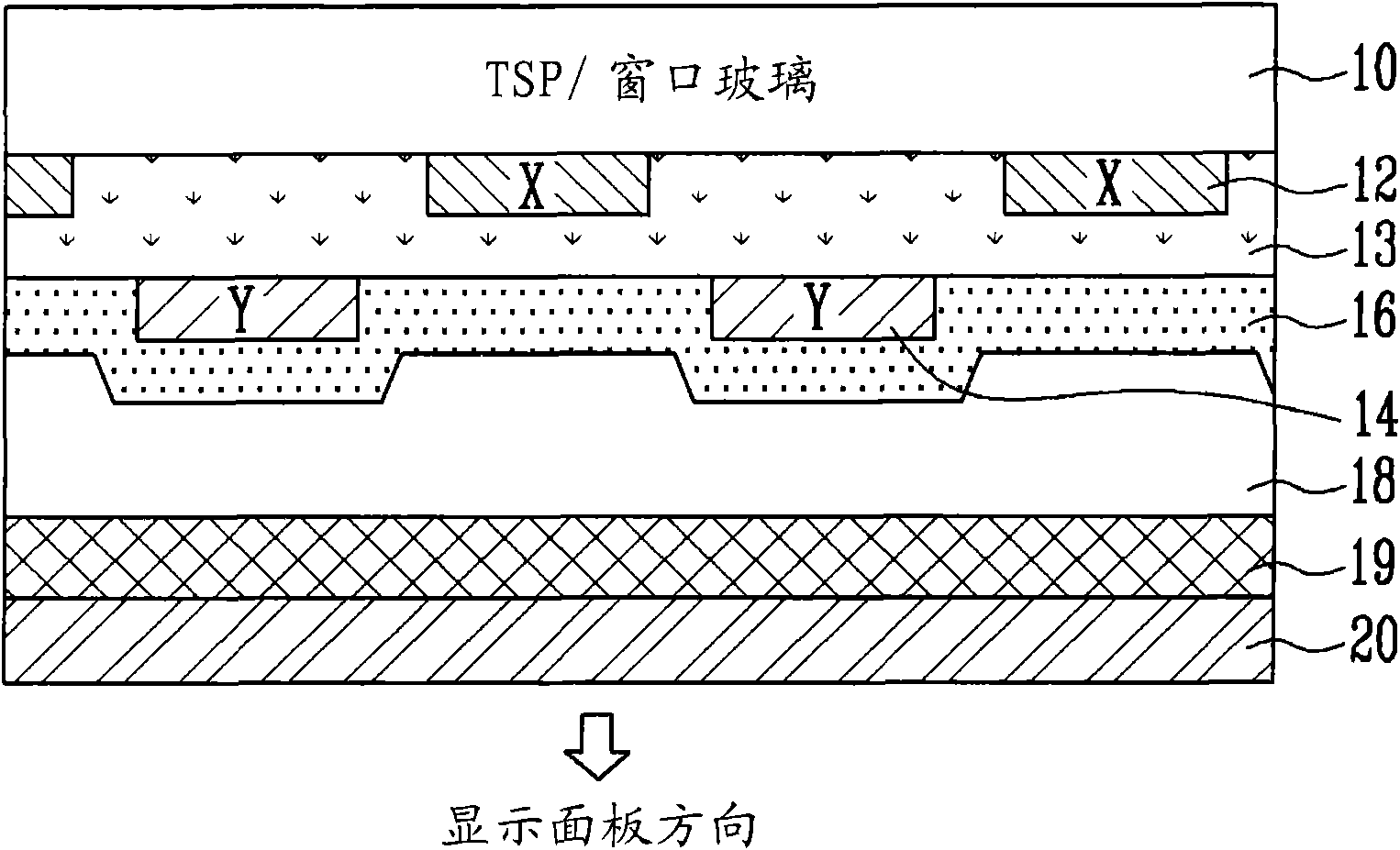

Touch screen panel

ActiveCN101782820AIncreased durabilitySimple printing processInput/output processes for data processingEngineeringTouchscreen

Owner:SAMSUNG DISPLAY CO LTD

Braille printing technology

InactiveCN101323219AEasy to printSimple printing processPattern printingOther printing apparatusChinese charactersSheet film

The invention relates to a braille printing technology, comprising the following steps: professional braille typesetting, that is, the automation of letter input, compilation, typesetting, inspection, collation and even output of the braille in the publishing process is realized through the professional braille and the Chinese characters comparison compilation and typesetting system provided by the Chinese braille computer system; film outputting - the laser typesetting machine is used for putting out the braille symbol in the graphic form; silk screen forme curing - the tension is controlled within 0.8-1.1 (N / cm), the adopted mesh number is 40-60 meshes / centimeters, extrusion coating is 12-16 layers with a 0.2 - 0.5mm thickness; preparing printing ink with uv varnish material and thickener; page making up and adjusting; oil layer extrusion coating; infrared heating and leveling; ultraviolet uv solidifying. The braille printing technology is rapid in print speed, good in printed letters and adhesion of patterns, colorless and transparent, press resistant, wear resistant, low in cost, etc. The braille can be directly printed on reading matters with letters. The double-side printing can be performed and the printing quality is not affected. The ideal braille printing effect can be acquired. The printing can be performed on the ordinary printing materials. The printing carrier of the braille is widened.

Owner:张小文

Tencel fabric and printing process thereof

InactiveCN102733200AImprove breathabilityGood drapabilityDyeing processOther printing apparatusYarnEconomic benefits

The invention discloses a tencel fabric which is formed by interweaving 60-70% of tencel yarn, 20-25% of cotton yarn and 5-20% of silk yarn, and has the advantages of being soft, comfortable, good in air permeability, smooth, cool and good in drapability. Meanwhile, by improving the printing process, the printing cost is reduced, and the economic benefit and the market competitiveness are improved when the printing color fastness is guaranteed; and the process is simple and easy to realize.

Owner:TAICANG QISHENG CHEM FIBER FACTORY

Wallpaper with gold stamping effect and preparation method thereof

ActiveCN105525538AImprove adhesionStrong metal feelingSpecial visual effect coatingsCovering/liningsScreen printingWater based

The invention relates to the technical field of wallpaper printing, in particular to wallpaper with a gold stamping effect and a preparation method thereof. The wallpaper with the gold stamping effect comprises a substrate layer, a water-based ink layer and an imitated gold stamping layer from bottom to top, wherein the substrate layer, the water-based ink layer and the imitated gold stamping layer are connected in sequence; the preparation method comprises the following preparation steps: A: substrate pretreatment: putting a prepared wallpaper substrate in a conveyer, and properly adjusting transfer tension and transfer rate of the substrate, wherein the transfer tension is 200 to 600 N / m, and printing speed is 10 to 150 m / min; B: water-based ink layer printing: printing the surface of the substrate with water-based ink, and drying; C: imitated gold stamping layer printing: printing the surface of the water-based ink layer with the imitated gold stamping layer, and baking for drying, wherein a printing method is silk-screen printing or direct etching gravure printing; a refractive index of the imitated gold stamping layer is 1.93 to 3.92, and baking temperature is 30 to 150 DEG C. The wallpaper disclosed by the invention has a good imitated gold stamping effect, is high in glossiness, low in raw material cost and environmental friendly.

Owner:GUANGDONG YULAN GRP

Method for preparing acrylic resin emulsion and paper coating emulsion

InactiveCN102864682ASimple manufacturing processLow equipment requirementsPaper coatingCoatingsEmulsionMetallic aluminum

The invention provides a method for preparing an acrylic resin emulsion and a paper coating emulsion. The paper coating emulsion consists of the acrylic resin emulsion and an isocyanate curing agent. Compared with vacuum aluminizing liner paper in the prior art, the paper coating emulsion has the advantage that the isocyanate curing agent and the acrylic resin emulsion are subjected to chemical crosslinking reaction, so that a network structure is formed on the surface of paper. By the network structure formed by the paper coating emulsion, water vapor inside and outside the paper can be isolated from air, so that the vacuum aluminizing liner paper has the functions of keeping the drying and smell of cigarettes; metallic aluminum is not contained in the emulsion, so that resources are saved, and the emulsion can also be used for food-grade packaging materials; and a process for preparing the paper coating emulsion is convenient, the requirement on equipment is low, and an aluminum layer is not contained, so that a printing process is simple.

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

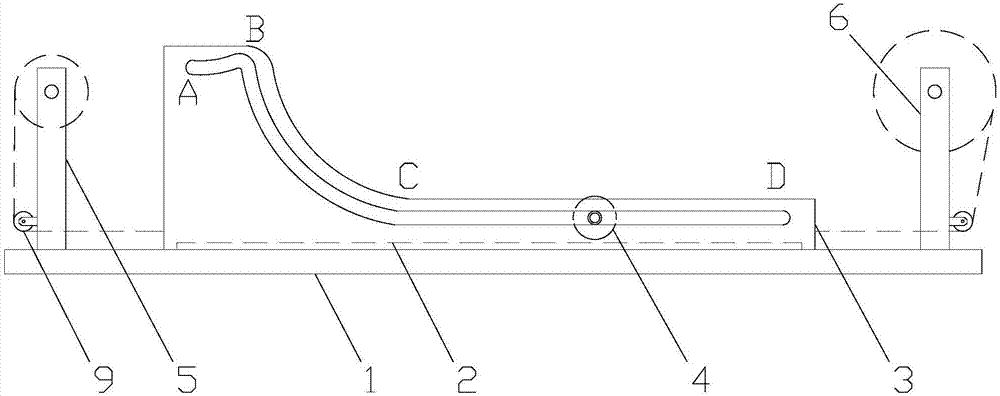

Semi-automatic textile printing equipment

ActiveCN107471816ASimple printing processEfficient printing processTransfer printingTextile printerSemi automatic

The invention discloses semi-automatic textile printing equipment. The semi-automatic textile printing equipment comprises a bottom plate, a printing table is movably mounted on the bottom plate, and can be fixed to a waiting position and a working position, two first supports arranged symmetrically are mounted on the two sides of the working position, a guide rail is arranged on each first support, a slide block is mounted in each guide rail, the two ends of a hot pressing roller are mounted in the slide blocks arranged on the two sides of the hot pressing roller, a second support and a third support are arranged on the bottom plate, and a discharging roller and a feeding roller are rotatably mounted on the second support and the third support correspondingly. The semi-automatic textile printing equipment utilizes a simple mechanical transmission structure to make the printing technology of textile fabrics to be simpler and more efficient, has good operability, and has a good price advantage at the same time.

Owner:安徽双盈纺织有限公司

One-step forming reflective silk screen printing ink and production method thereof

The invention provides a one-step forming reflective silk screen printing ink and a production method thereof, relating to the technical field of ink and silk screen printing. The production method comprises the following steps: mixing resin with solid content of 100%, a plasticizer, an anti-sedimentation agent, transparent pigment, an organic solvent and aluminum powder paste, and grinding until a mixed material with fineness less than 25 mu m and viscosity large than or equal to 140 S is obtained; and adding reflective microspheres with fineness above 350 meshes, and evenly stirring, wherein in the mixing process, the masses of the resin with solid content of 100%, the plasticizer, the anti-sedimentation agent, the transparent pigment, the organic solvent, the aluminum powder paste and the reflective microspheres respectively account for 15-45%, 0.5-4%, 1-4%, 2-8%, 10-36%, 1-20% and 30-70% of the total mass of the ink. The operation is simple, and the method is especially suitable for large-scale production of reflective signs with the same pattern; the ink can be applied to the surfaces of materials such as plastics, metals, clothes and the like; and when being irradiated by lamplight at night, the bright reflective signs can be provided, thereby effectively reducing the loss of life and property.

Owner:庄晓明

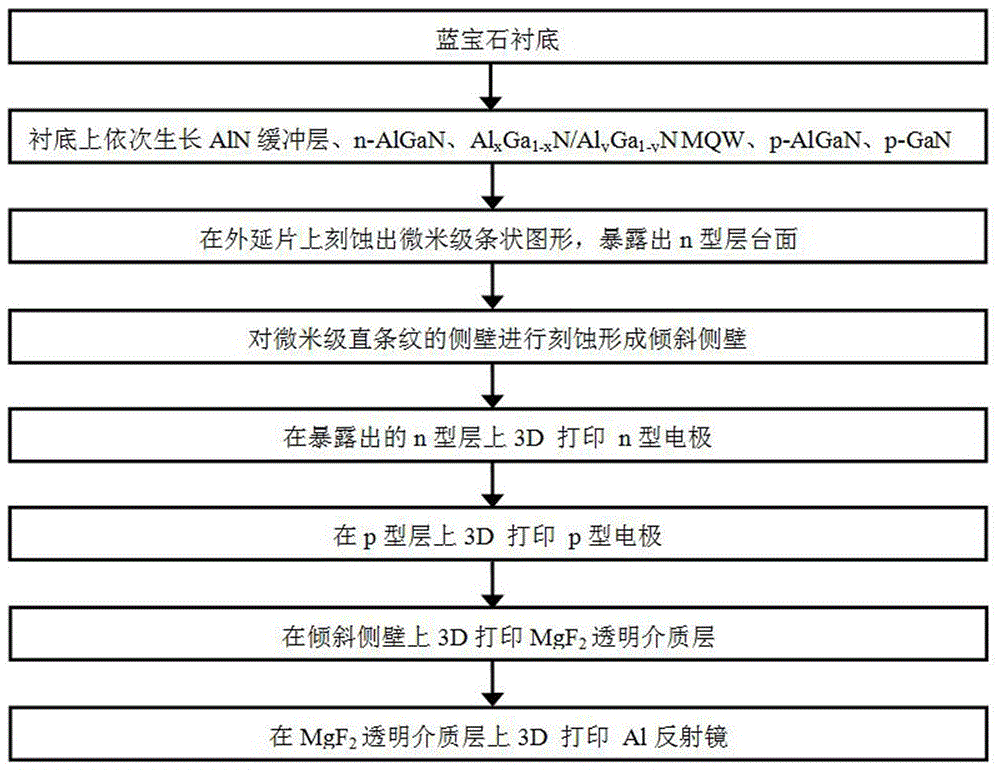

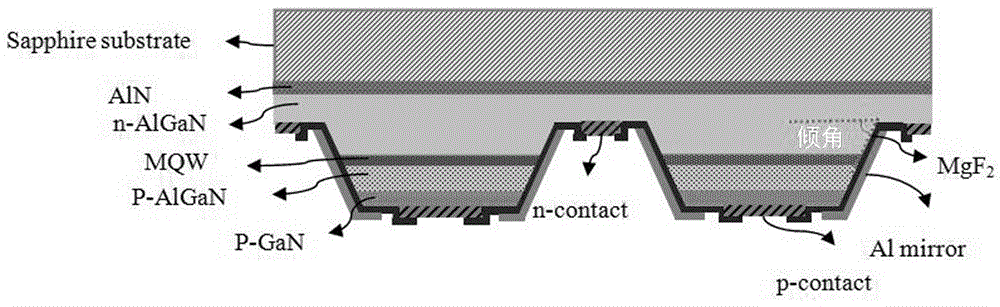

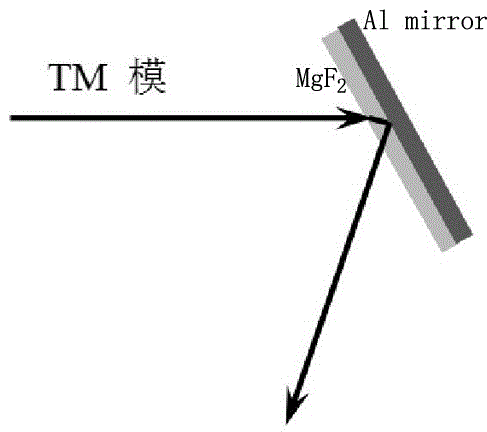

Preparation of sidewall reflector DUV LED based on3D printing

ActiveCN105914290AImprove luminous efficiencyImprove light extraction efficiencySemiconductor devicesElectricityContact layer

The invention belongs to the field of photoelectronic devices, in particular to preparation of a sidewall reflector DUV LED based on3D printing. The preparation comprises the steps of: providing an epitaxial wafer which is generated by MOCVD or MBE and comprises an AlN buffer layer, an n-AlGaN layer, a multi-period Al<x>Ga<1-x>N / Al<y>Ga<1-y>N active layer (where x<y), a p-AlGaN layer and a p-GaN contact layer; etching the epitaxial layer to form micron-grade straight stripes with inclined side walls; taking the epitaxial layer as a substrate; and printing electrodes, a UV light transmission medium layer and a reflector reflective layer in a 3D manner. The UV light transmission medium layer serves as an electric insulating layer between the active layer and a metal reflector and serves as an electric passivation layer of the side walls, and the UV light transmission medium layer and the reflector reflective layer are combined together to form an omni-directional reflector which can reflect TM mode lateral reflected light to the substrate, thereby increasing light emitting efficiency. In addition, the 3D printing production process is simple, and production efficiency can be effectively increased.

Owner:TAIYUAN UNIV OF TECH

Black carbon powder and method for preparing same

The invention relates to a yellow carbon powder and its manufacturing method. It is made by mixing 75-98 parts resin, 1-10 parts polyacrylic wax or polyethylene wax, 1-20 yellow pigment, 0.5-10 electric charge regulator, 0.1-1 part earth silicon, through extruding, coarse crushing and fine crushing. Matching yellow carbon powders with black, red and blue ones, it can simplify printing process, improve working efficiency, and reduce printing cost, applicable for long time preservation of archives.

Owner:王建新

Inkjet printing technology for cotton and linen fiber fabric

InactiveCN106436349AImprove dark tone of dyeingEnhanced wash resistance and sorptionDry-cleaning apparatus for textilesDyeing processHot blastDyeing

The invention discloses an inkjet printing technology for a cotton and linen fiber fabric. The technological processes of low-temperature plasma modified pretreatment, sizing pretreatment, drying, inkjet printing, steaming fixation, after-treatment and washing and drying are adopted, low-temperature plasma modified pretreatment is performed at first before sizing pretreatment, modified treatment is performed on cotton and linen fiber, and then preshrinking technological treatment is performed; on one hand, the defect that the dyeing keynote of the cotton and linen fiber fabric is dark is overcome; on the other hand, the phenomenon that printing is irregular due to the fact that the cotton and linen fiber fabric is shrunk in the inkjet printing technology is effectively avoided; in addition, the special inkjet printing pigment ink is adopted for jet printing, the washing technology adopts warm water washing and hot-blast air drying, chemical tolerance of pigment is stimulated, and the wash resistance is enhanced and the absorption rate is increased; the technology has the advantages of being smooth in printing, bright in color, suitable for coloring depth, not prone to color fading, simple and the like.

Owner:苏州市恒信针织印染有限责任公司

Method for producing thermal-formation products of plastic sheet material

A thermally shaping method for preparing the product from plastic sheet includes such steps as printing patterns and locating marker on transparent plastic film, attaching the plastic film onto surface of a plastic sheet, heating the plastic sheet for softening it, moving it into a moulding cavity, applying pressure to make it close to the inner surface of moulding cavity, cooling, demoulding and punch shearing.

Owner:广东日烽吸塑包装实业有限公司

Electronic equipment and manufacturing method for single-layered multipoint capacitive touch screen and touch layer

InactiveCN103761017AImprove accuracyExpand the range of speciesInput/output processes for data processingEngineeringTouchscreen

The invention discloses electronic equipment and a manufacturing method for a single-layered multipoint capacitive touch screen and a touch layer thereof. The single-layered multipoint capacitive touch screen comprises a panel and a screen module, wherein a transparent optical adhesive layer is arranged between the panel and the screen module; a BM (basement membrane) frame layer is arranged on the frame of the panel; the screen module comprises an upper polaroid, an upper glass substrate, a lower glass substrate, a lower polaroid and a backlight plate which are sequentially arranged in a stacked manner from top to bottom and are adhered to one another; a metal conductive ink circuit layer is arranged between the panel and the screen module or in the screen module and comprises a plurality of touch units which are arranged in parallel; and each touch unit is independently provided with a lead connected with a processor. The single-layered multipoint capacitive touch screen is sensitive in touch, high in accuracy and wide in application range; the manufacturing method for the touch layer of the single-layered multipoint capacitive touch screen is simple; the touch layer is low in cost, and is energy-saving and environment-friendly; and the using convenience and the reliability of the electronic equipment with the touch screen are improved.

Owner:SHENZHEN SUCCESS ELECTRONICS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com