Patents

Literature

43results about How to "Excellent following" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

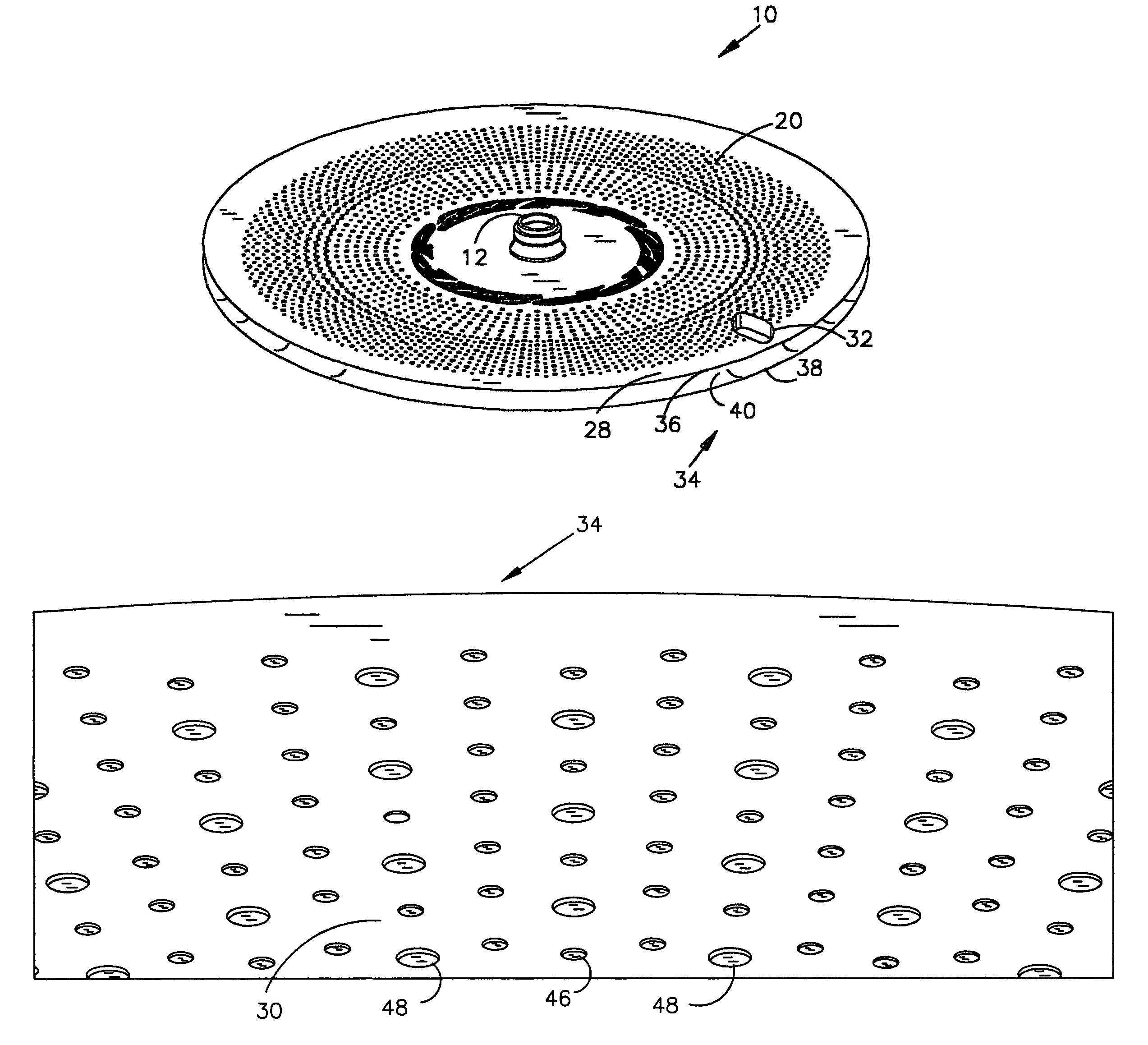

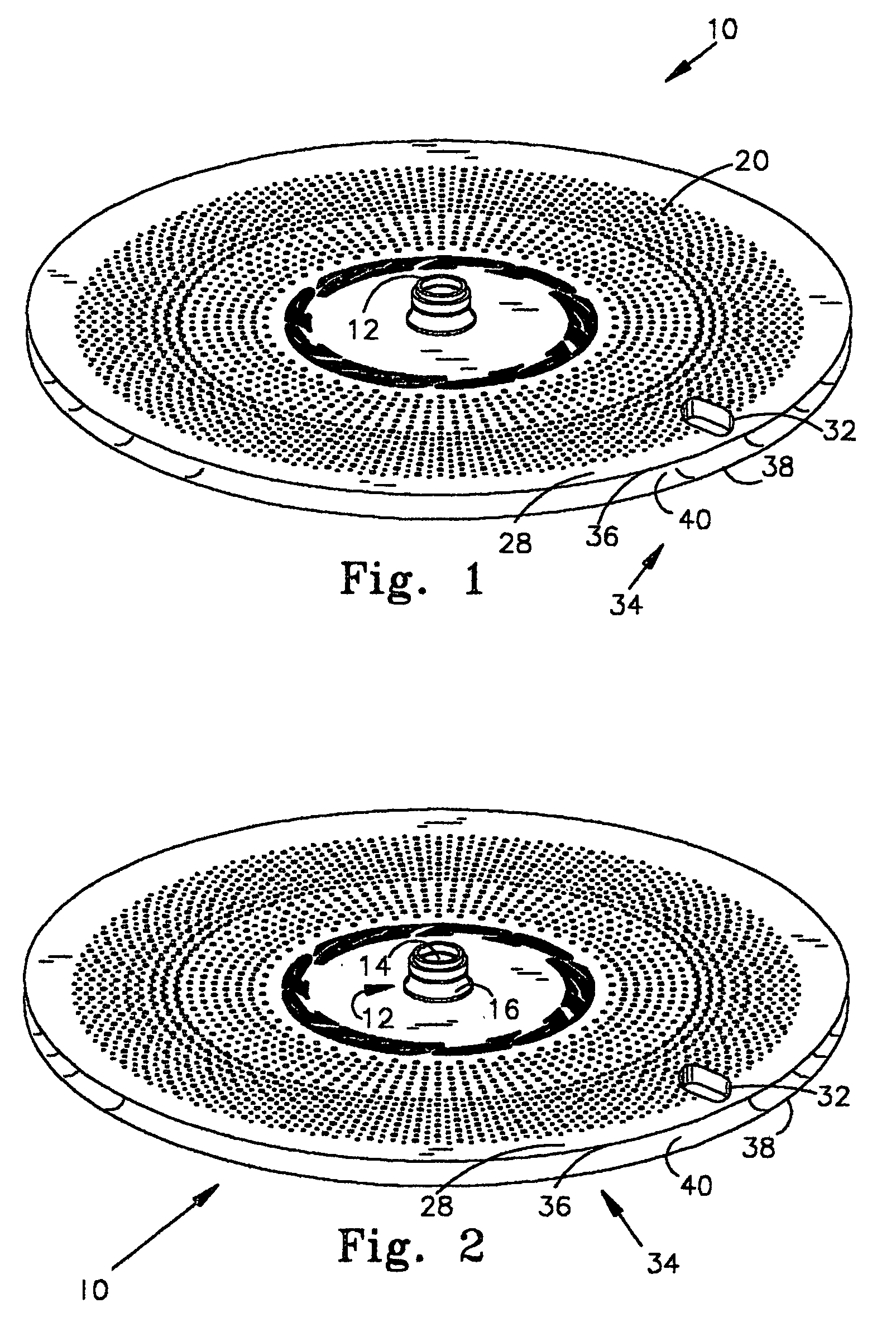

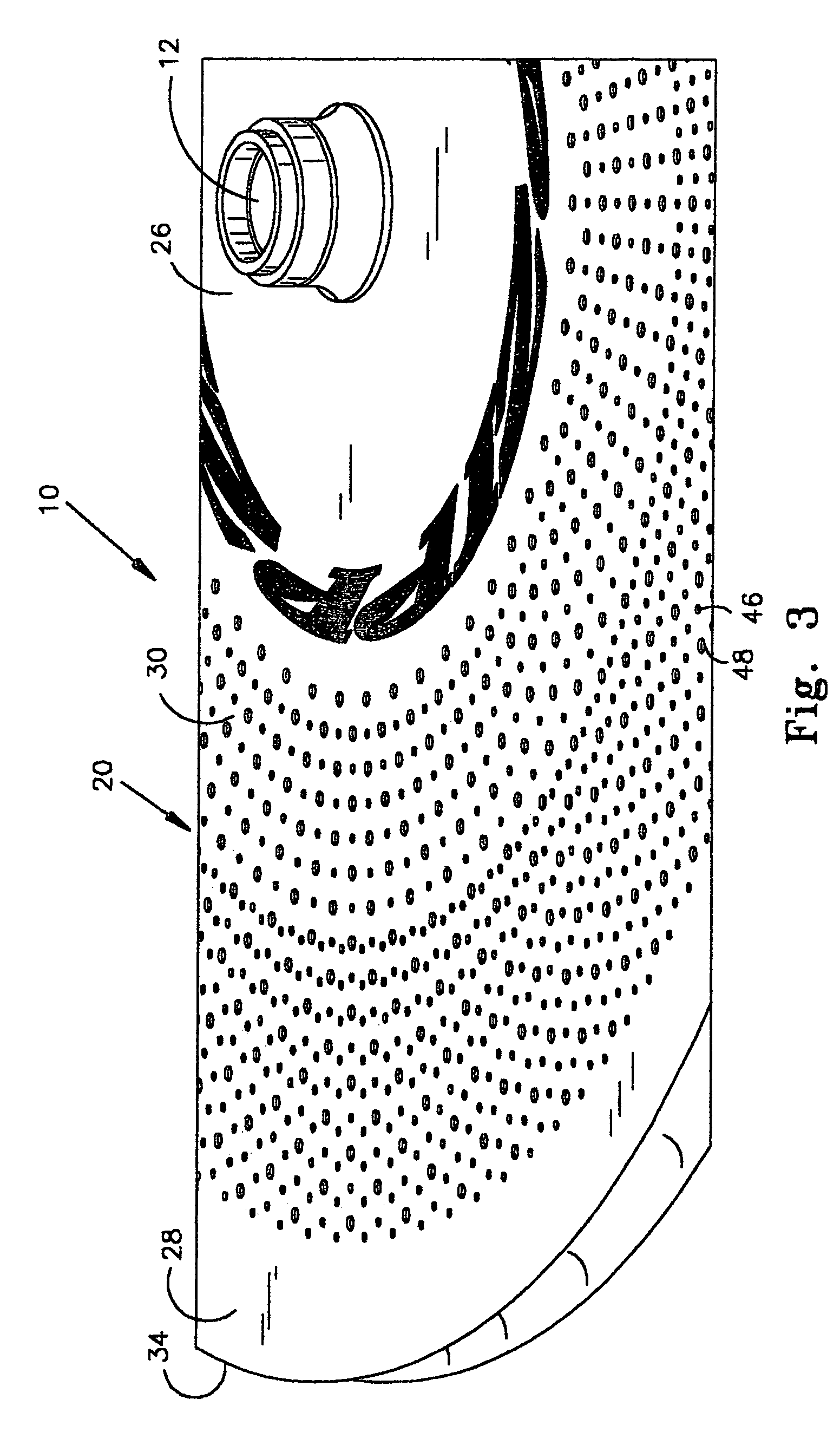

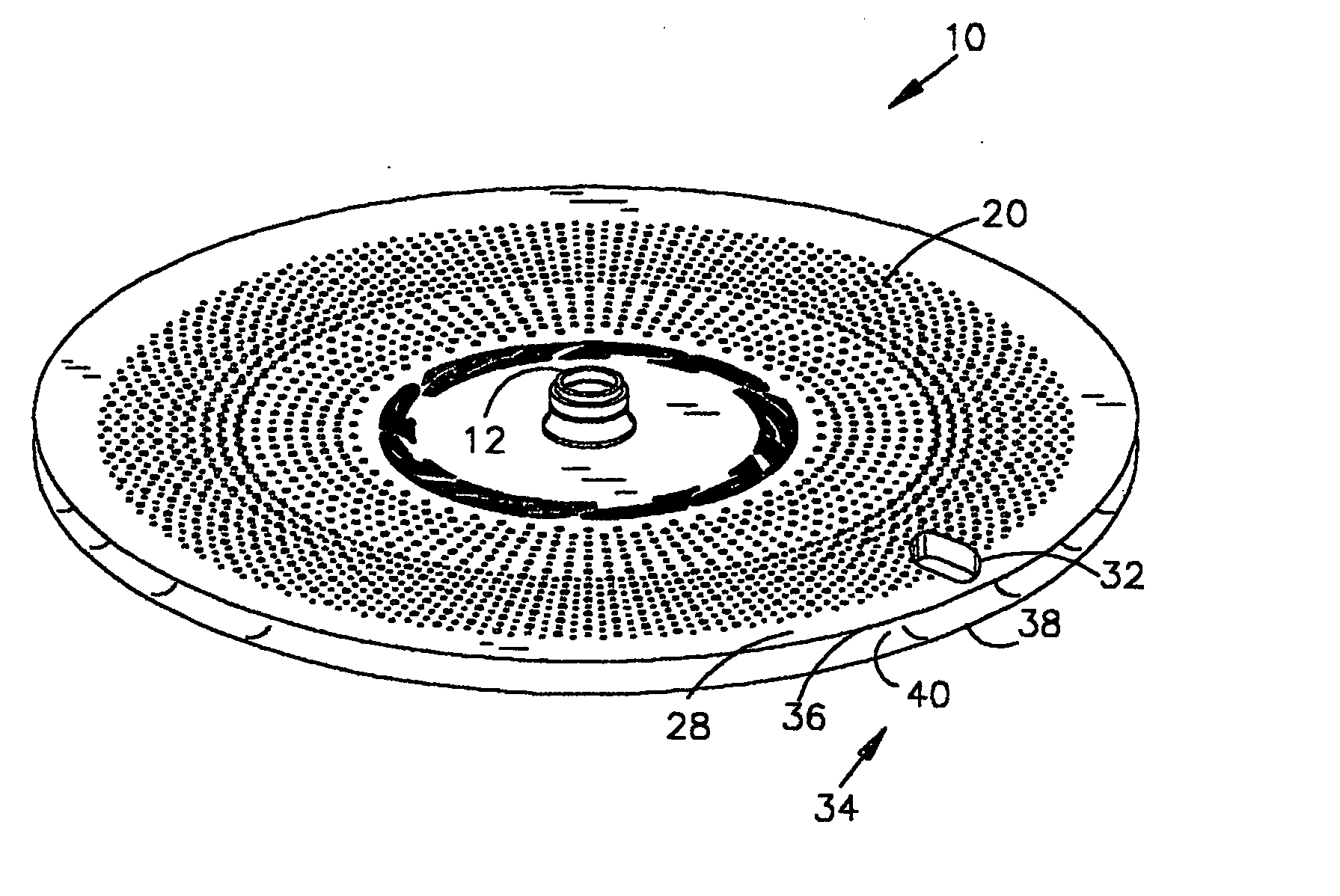

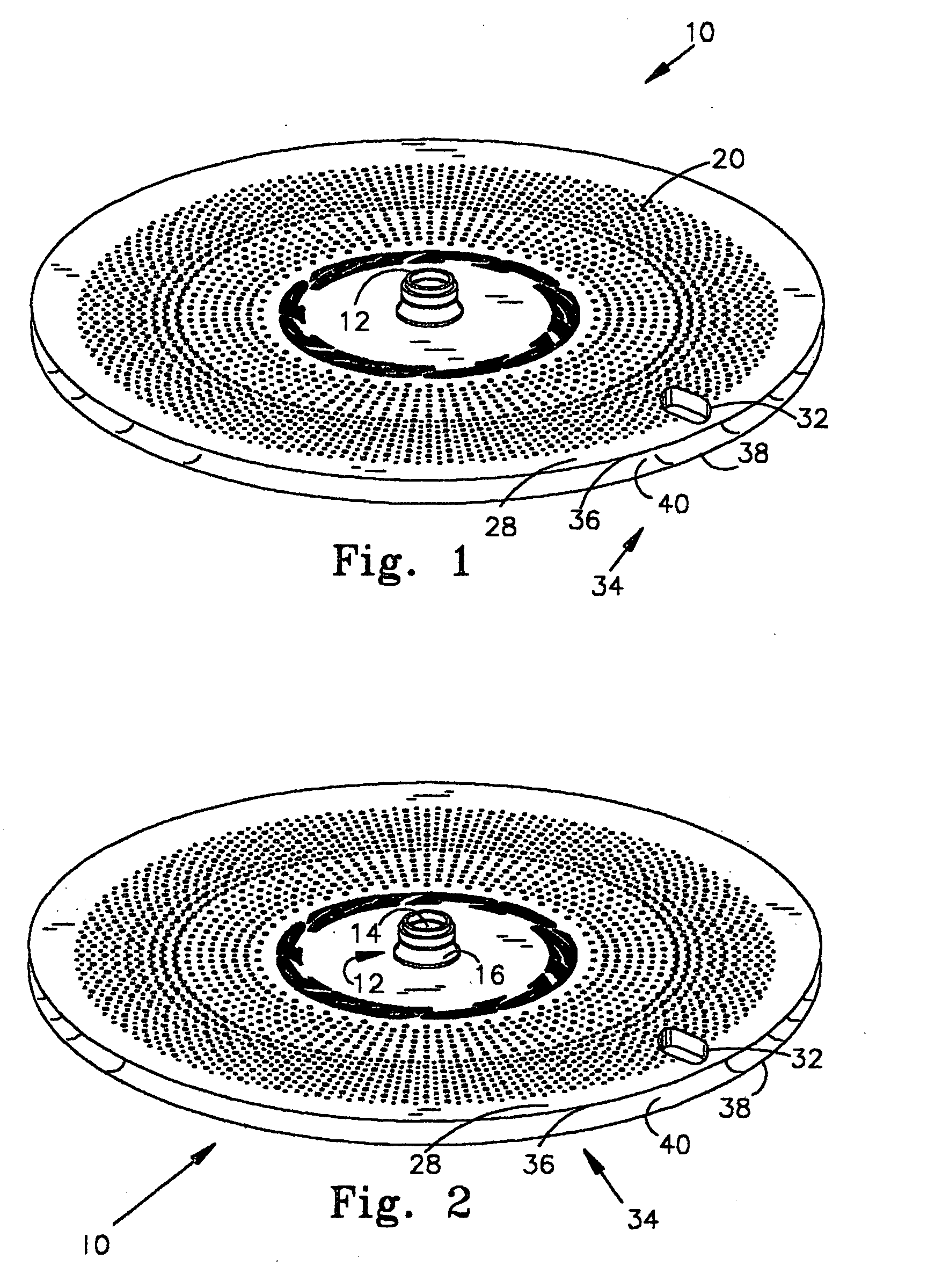

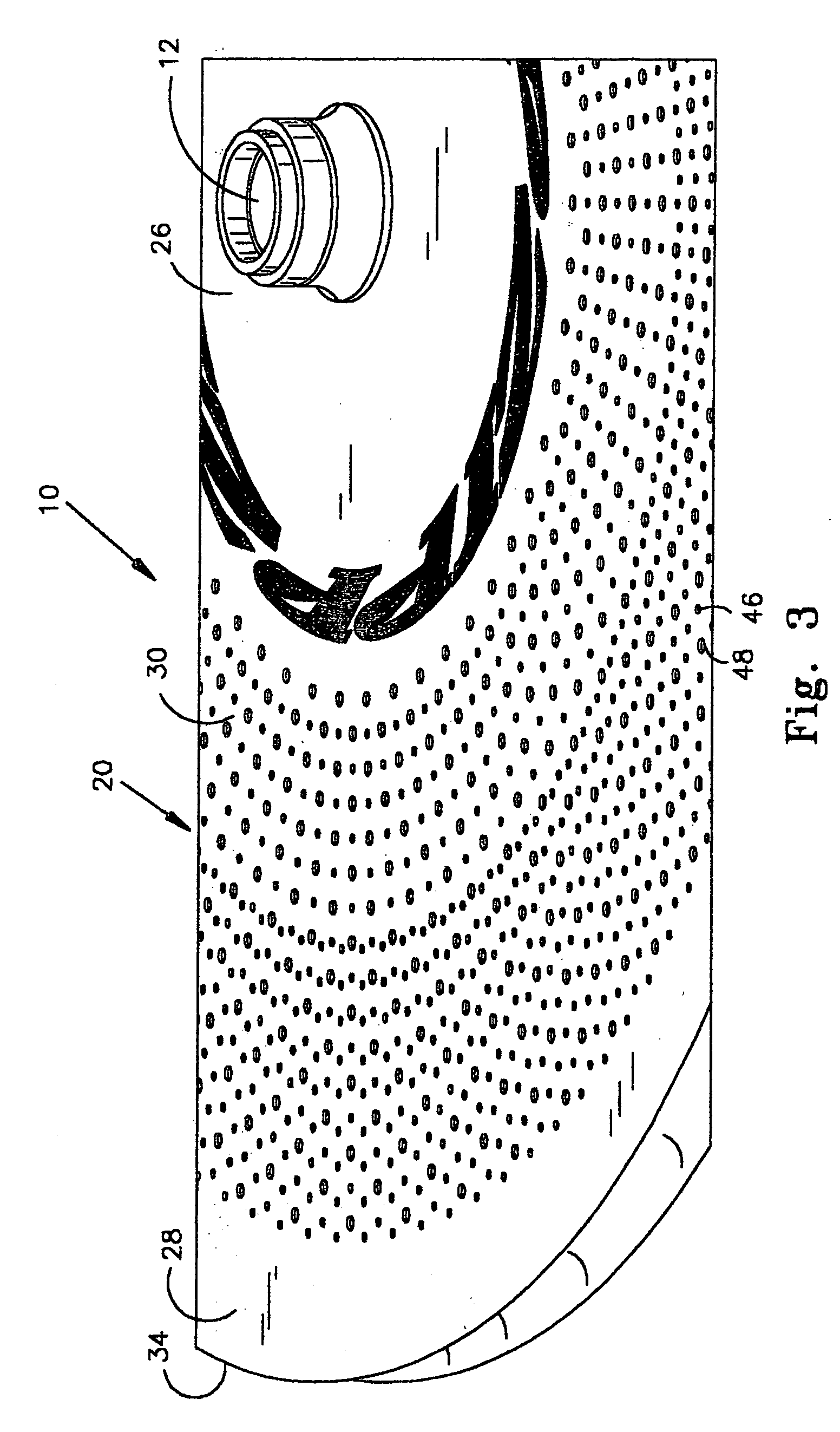

Aerodynamic surfaced bicycle wheel

InactiveUS7114785B2Reduce air resistanceHigh speedNon-metallic wheel bodyWheel protectionAerodynamic dragEngineering

A bicycle wheel includes a tire engaging portion located at the outward perimeter of the wheel, an inner portion located radially inward from the tire engaging portion A pair of air engaging side surfaces extend radially between the inner portion and the tire engaging portion forming the sides of the wheel. The air engaging side surfaces contain a plurality of surface features designed to create a turbulent boundary layer when the wheel travels through air to reduce aerodynamic drag on the wheel.

Owner:COMPOSITECH

Meltable ink for an inkjet printer and a method of selecting such an ink

InactiveUS6923853B2Specific visco-elastic propertyEffect print qualityMeasurement apparatus componentsDuplicating/marking methodsRoom temperatureEngineering

A meltable ink which is solid at room temperature, which ink is suitable for use in an indirect printing process, in which printing process the ink is transferred, by the use of an inkjet printhead, to a transfer element, whereafter the ink is transferred to a receiving material under pressure from the transfer element, the ink having a composition such that it is pressure-transferable at a temperature between a bottom temperature limit and a top temperature limit, wherein the ink has a deformation energy of less than 20×105 Pa.s at a temperature equal to said top temperature limit.

Owner:OCE TECH

Header

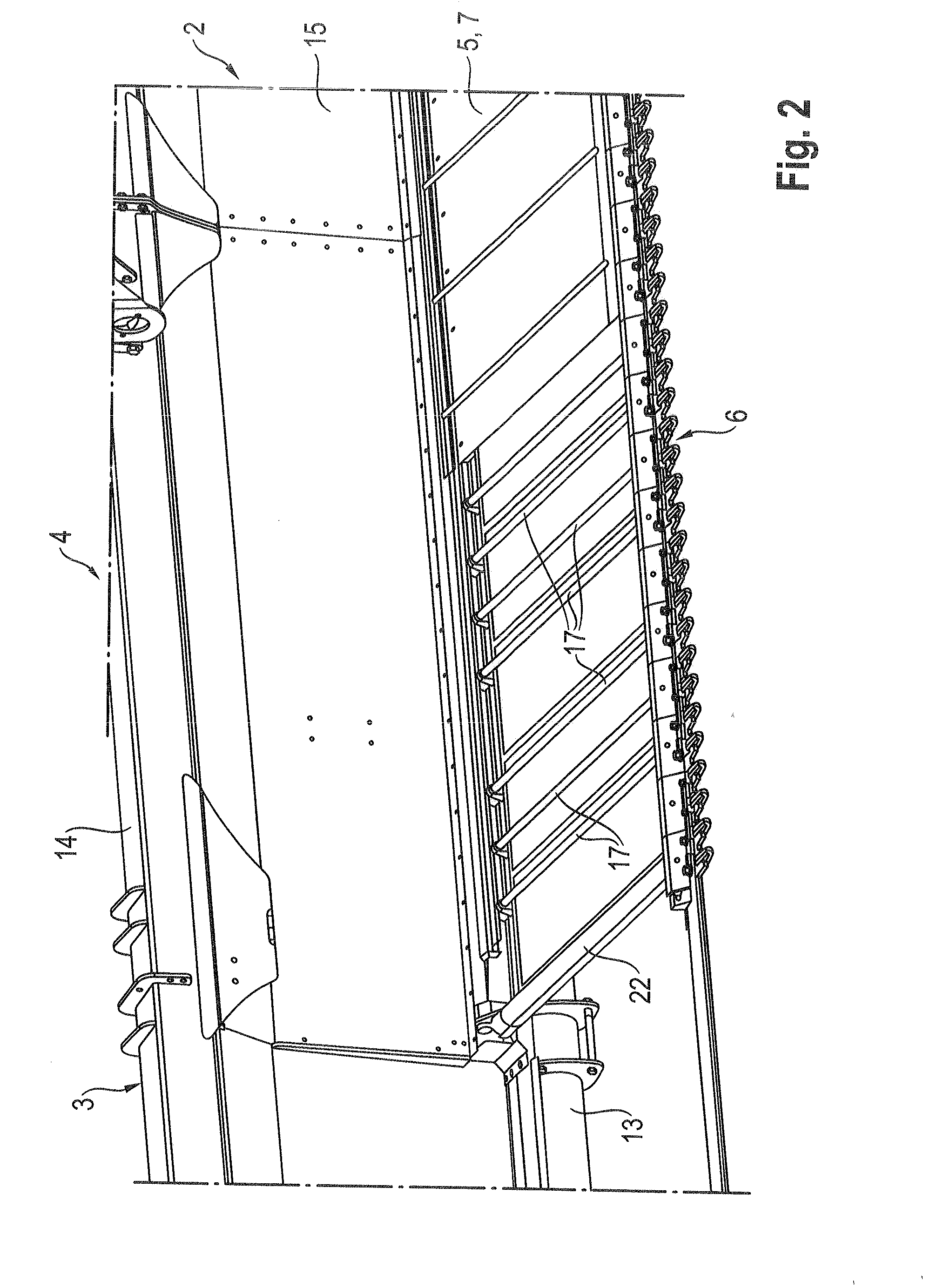

A header has a middle section disposed on a main frame, at least two side sections adjacent to the middle section, a rear panel extending perpendicularly to the main frame, a flexible finger bar extending across a width of the header and a conveyor device disposed behind the finger bar. The conveyer device is designed on the side sections as a continuous conveyor belt disposed adjacent to the middle section in order to transport crop cut by the finger bar laterally in the direction of the middle section. The side sections are formed as a plurality of supporting arms swivellably disposed on the main frame that support the finger bar. Each side section has a plurality of supporting elements for supporting the conveyor belt. Each of the supporting elements is supported in a bearing point to be displaceable in the axial direction relative to the main frame.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

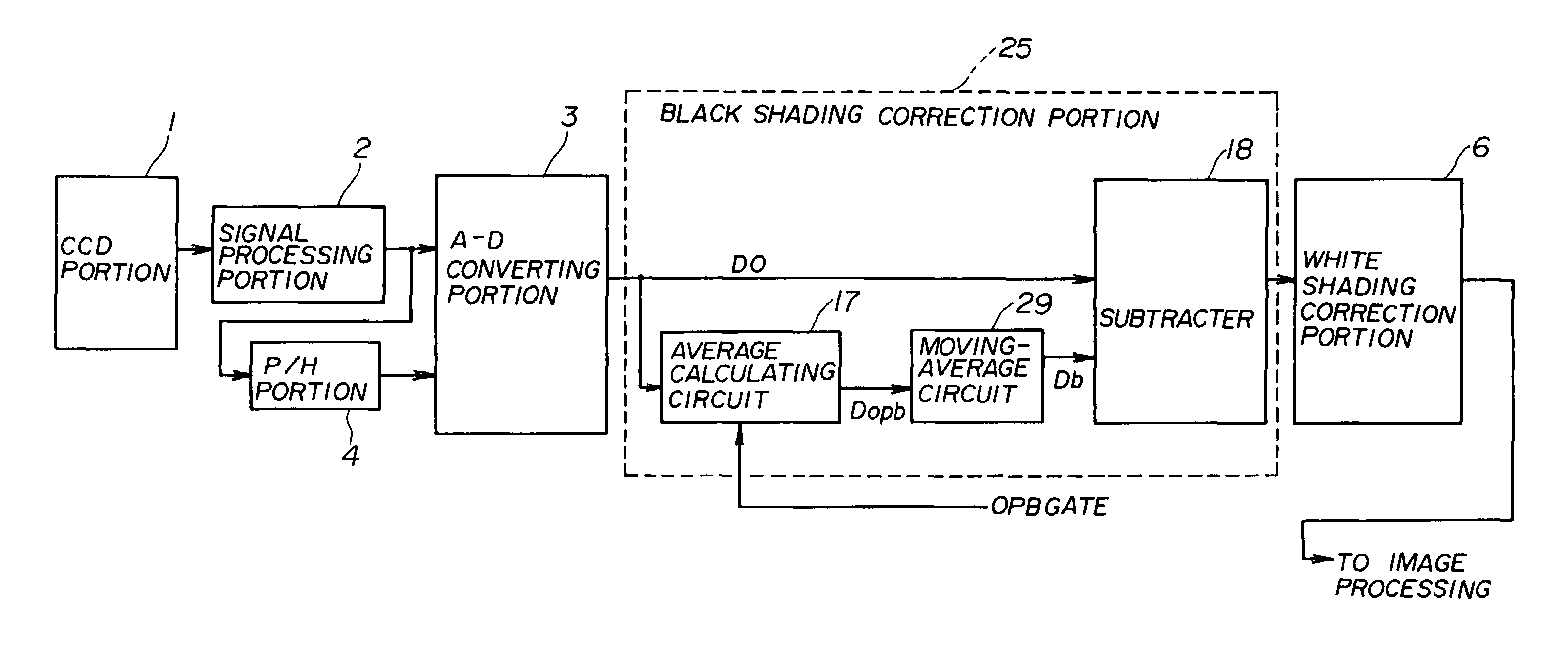

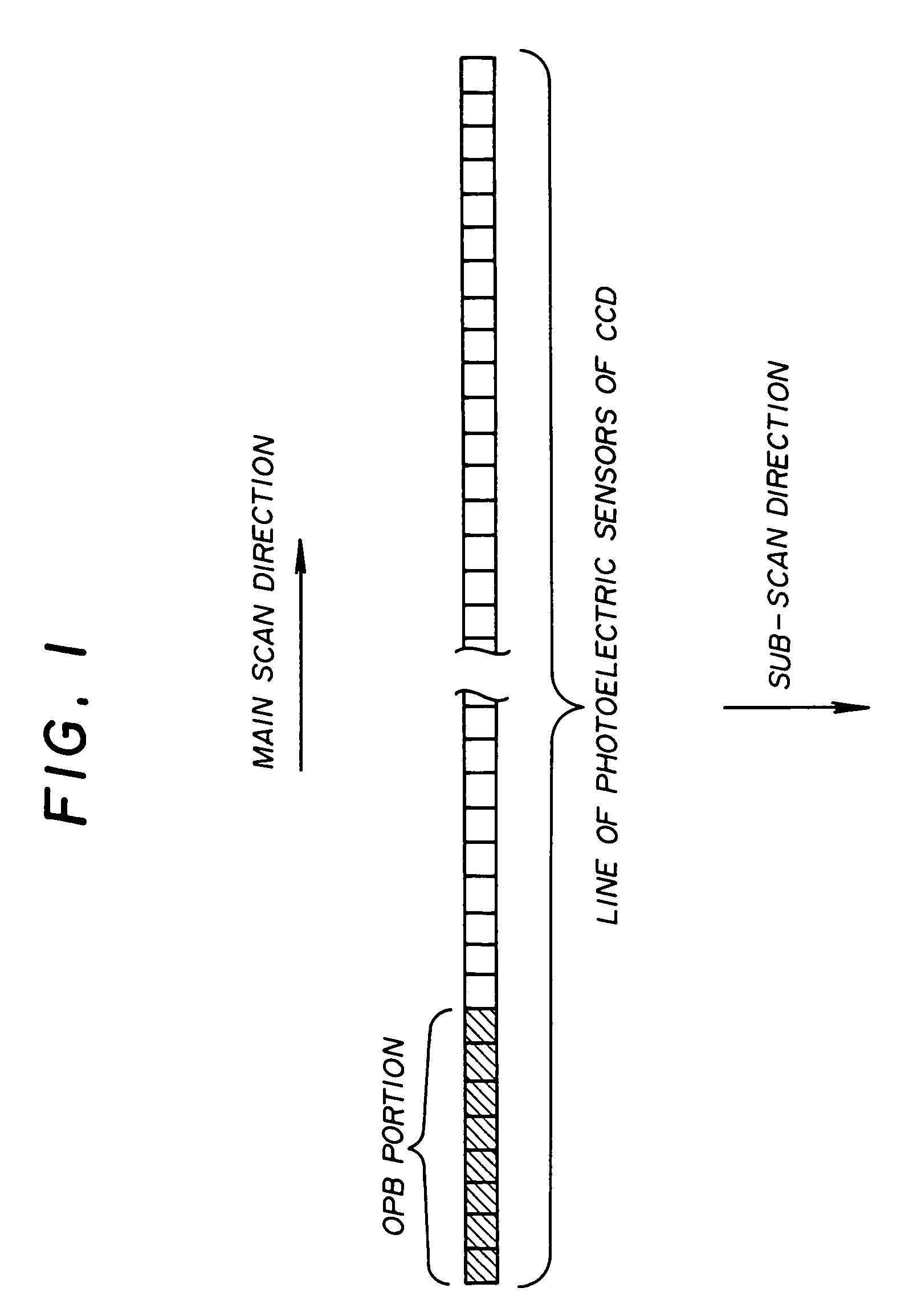

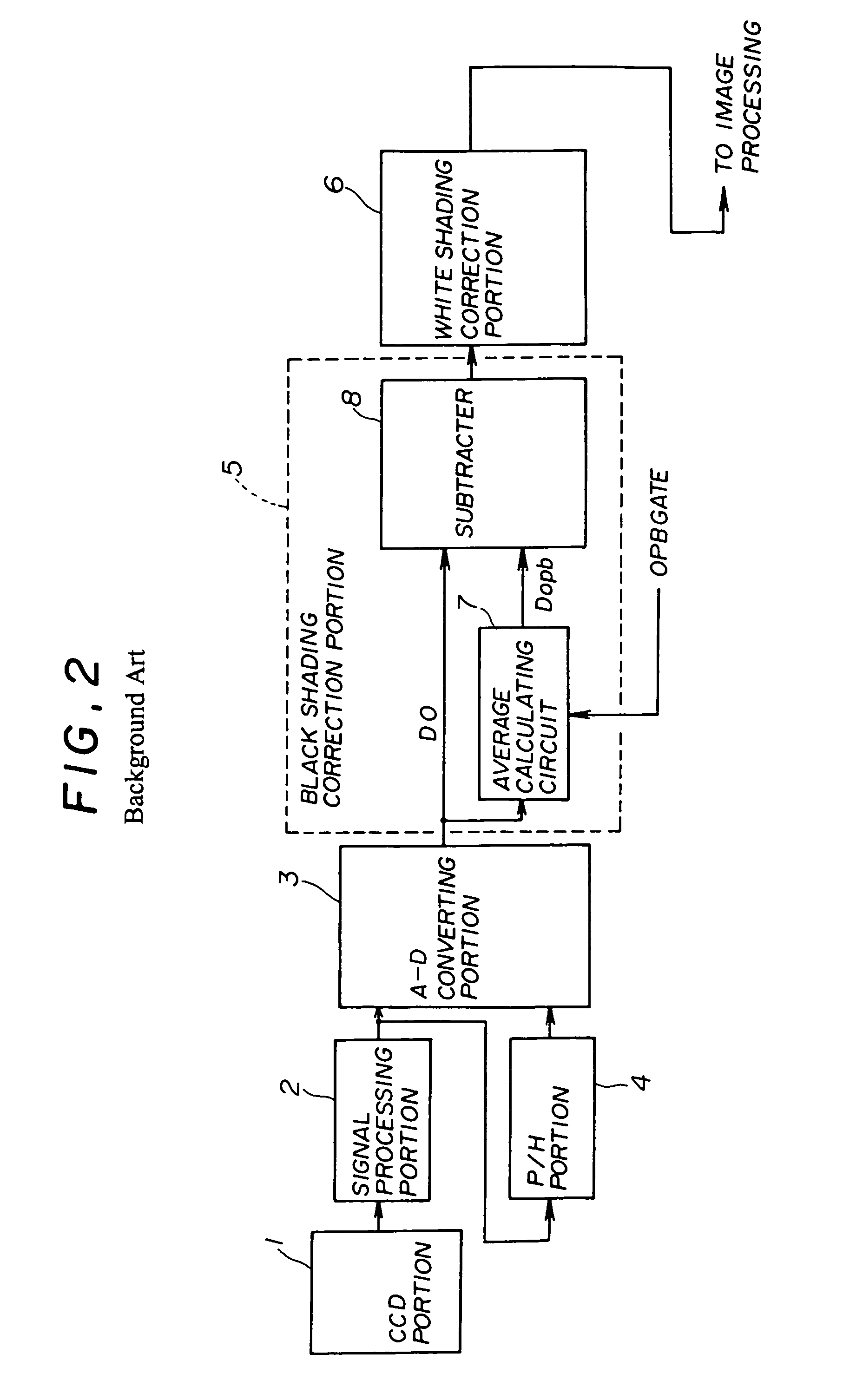

Image reading apparatus

InactiveUS7161626B1Suppresses output variationSuppress mutationTelevision system detailsColor signal processing circuitsComputer scienceImage signal

A CCD photoelectrically converts image information obtained from optically reading an original image, line by line, and outputs an image signal. Several of the photoelectric sensors of a CCD of the CCD portion form an optical black portion. A black shading correcting portion corrects the image signal using a black reference level. The black reference level is obtained from the optical black portion of the CCD for each line during an operation of the reading of the original image. The black reference level used by said black shading correcting portion for each line is obtained using black reference values, each of the black reference values being data of the optical black portion for a respective one of a plurality of lines.

Owner:RICOH KK

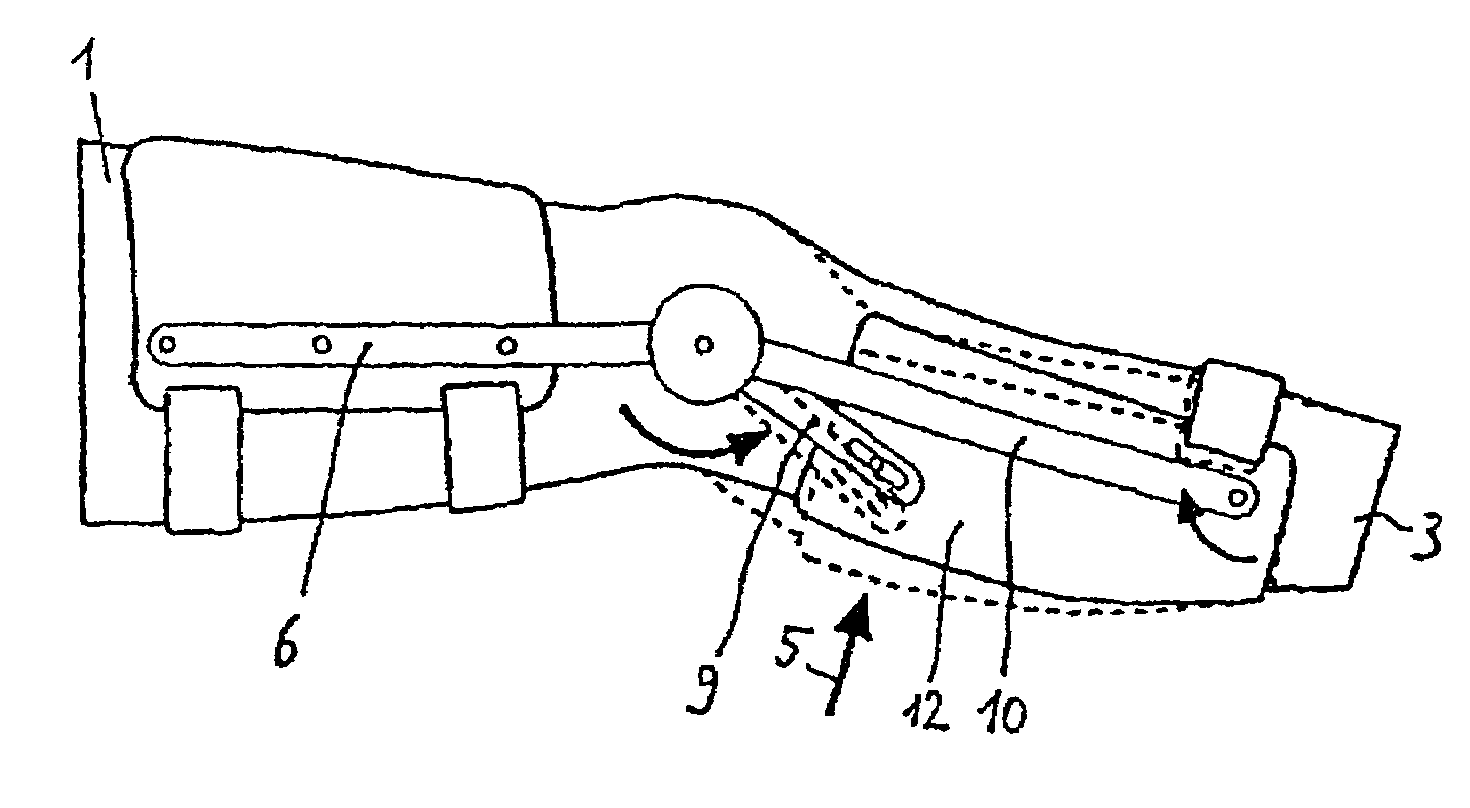

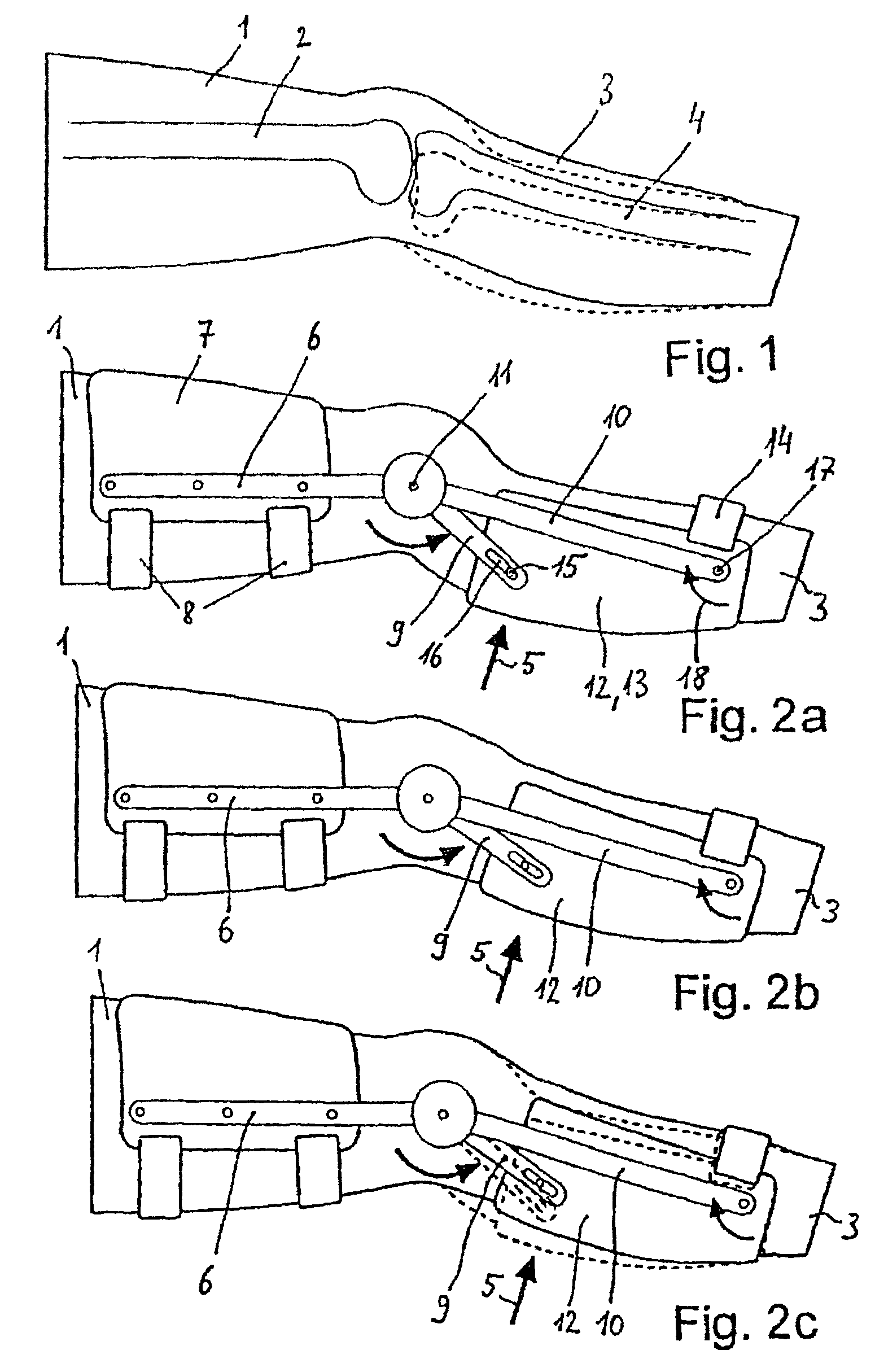

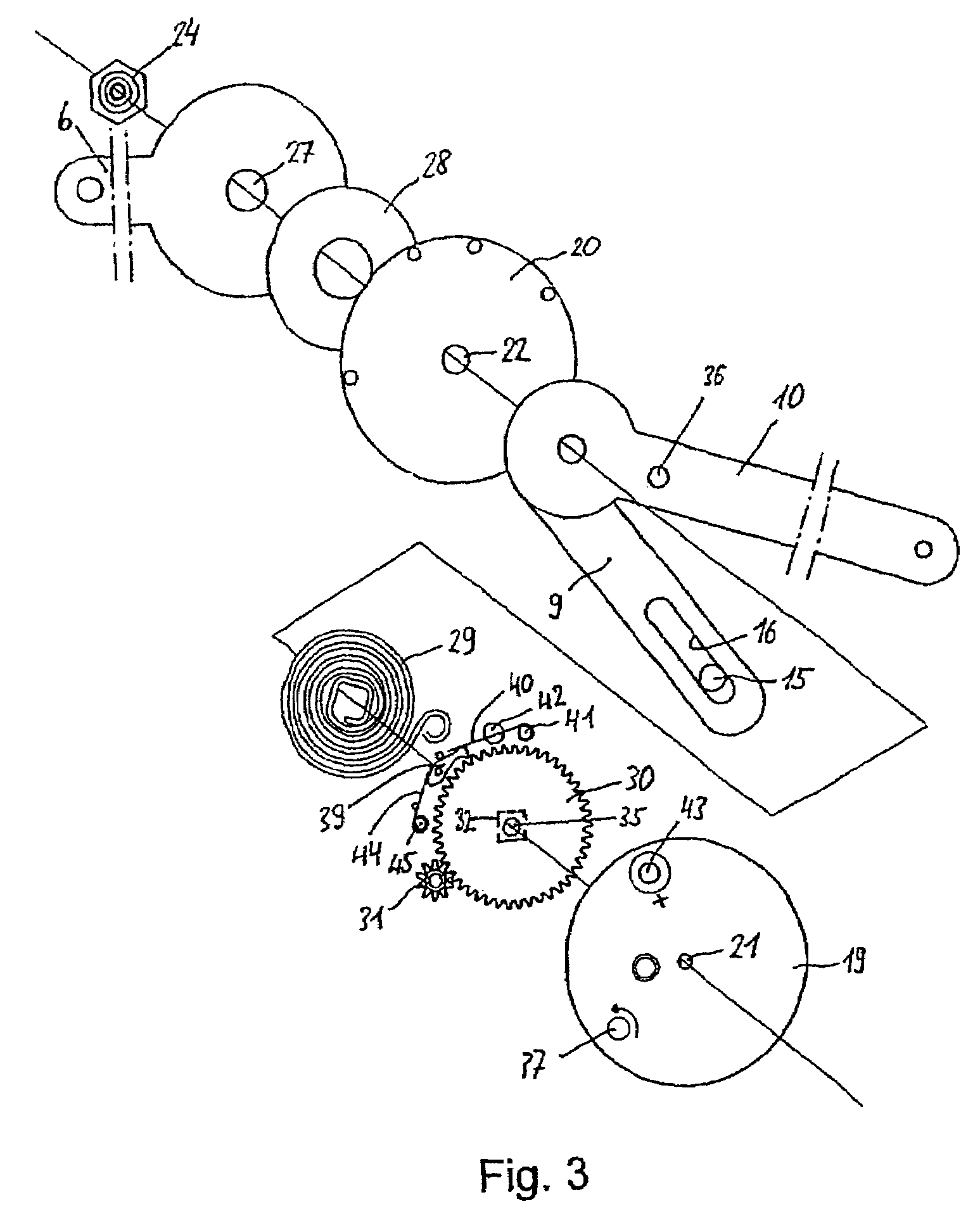

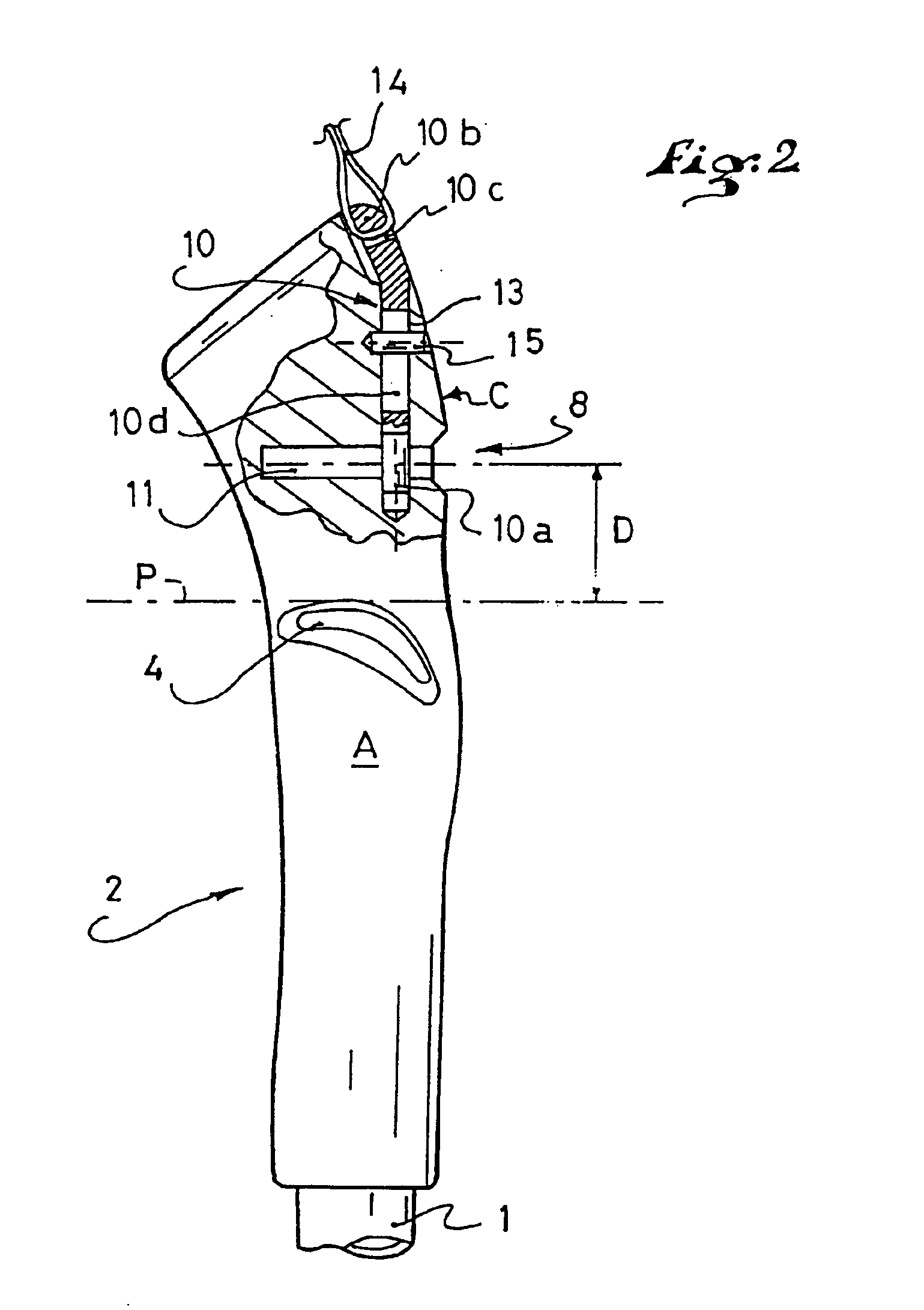

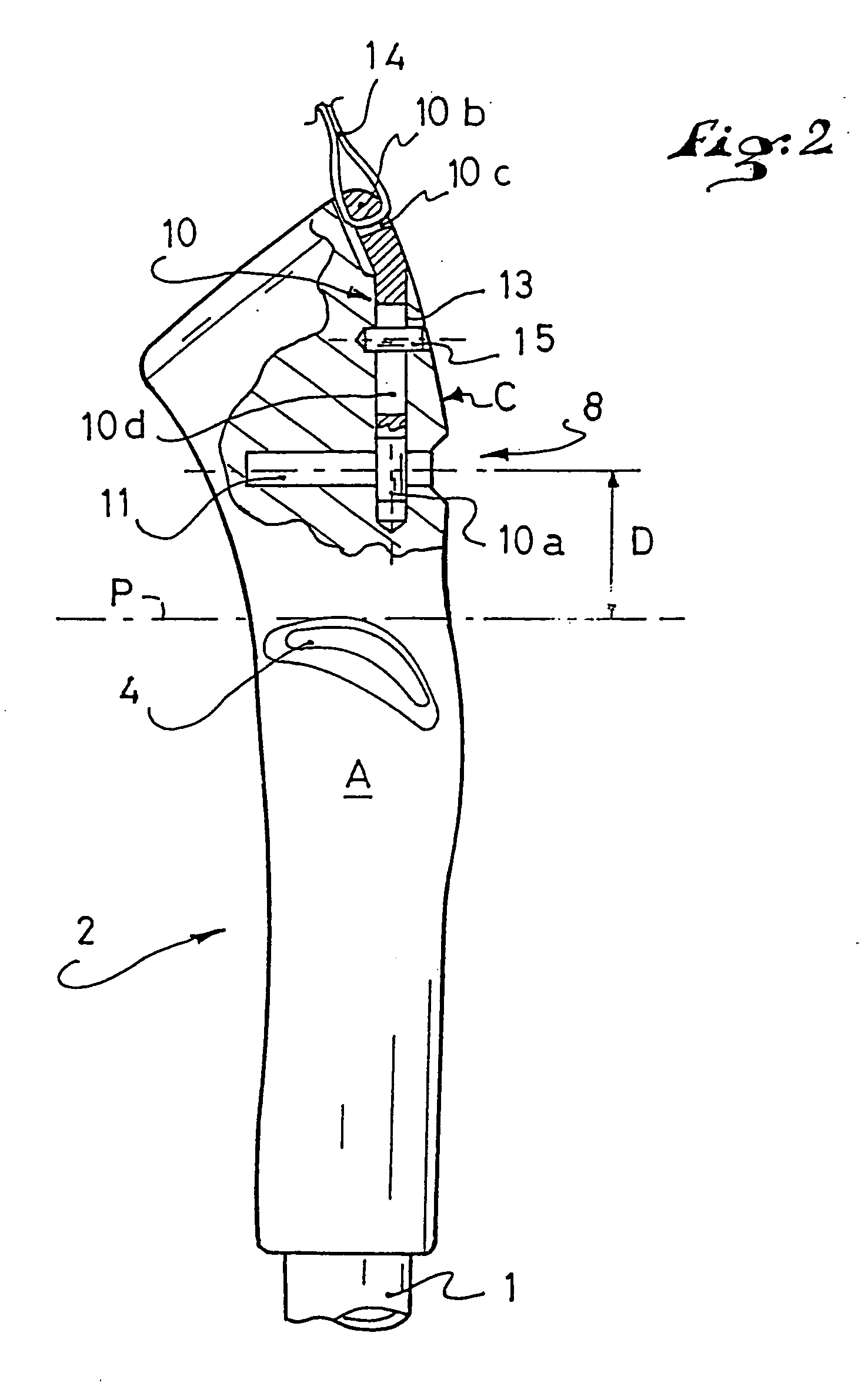

Device for applying a ventrally or dorsally directed translatory force in the area of a knee joint

ActiveUS7309322B2Avoid accidental displacementPermit free mobilityRestraining devicesNon-surgical orthopedic devicesThighKnee Joint

A device for applying a ventrally or dorsally directed translatory force onto a lower leg in the area of the knee joint includes a thigh bar and a lower leg bar device having a shorter and a longer bar arm. Both bar arms can be freely swiveled relative to the thigh bar. The two bar arms are disposed in such a manner that they can be swiveled relative to each other. A pretension of a spring device between the shorter and the longer bar arm has the effect that the bar arms are urged to carry out a swiveling motion relative to each other, thereby applying a ventrally or dorsally directed translatory force onto a lower leg fixation device in an area close to the knee.

Owner:ALBRECHT

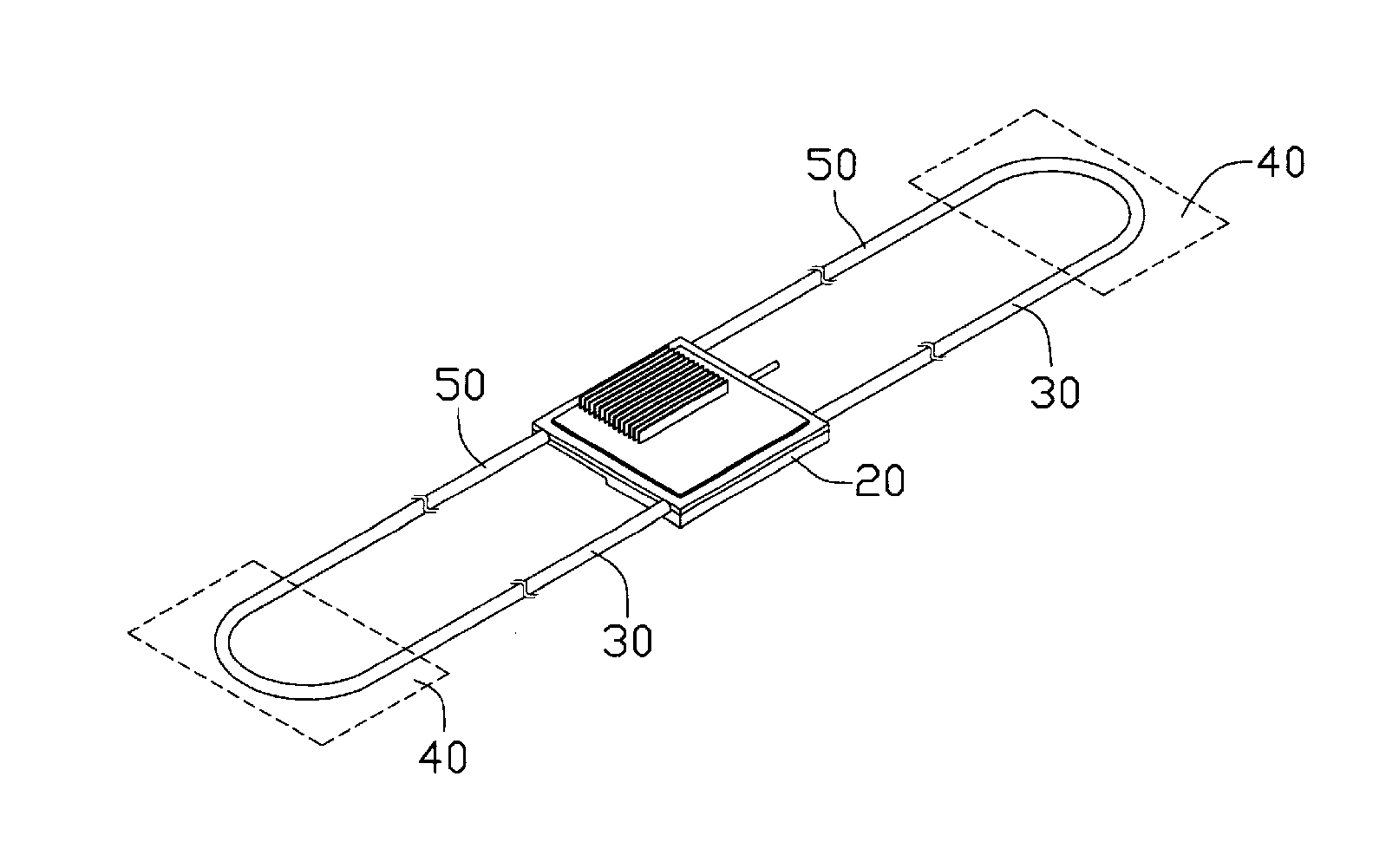

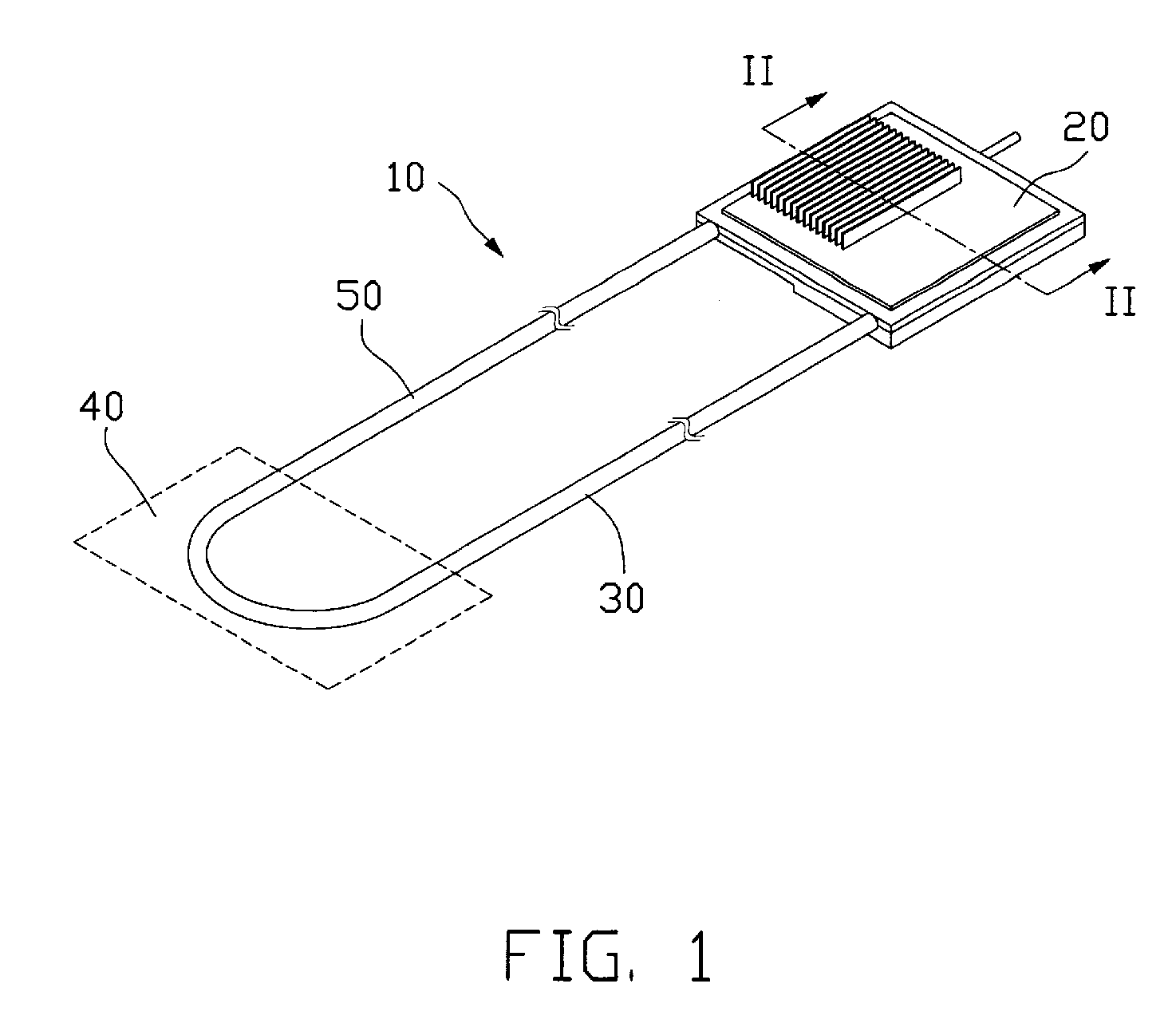

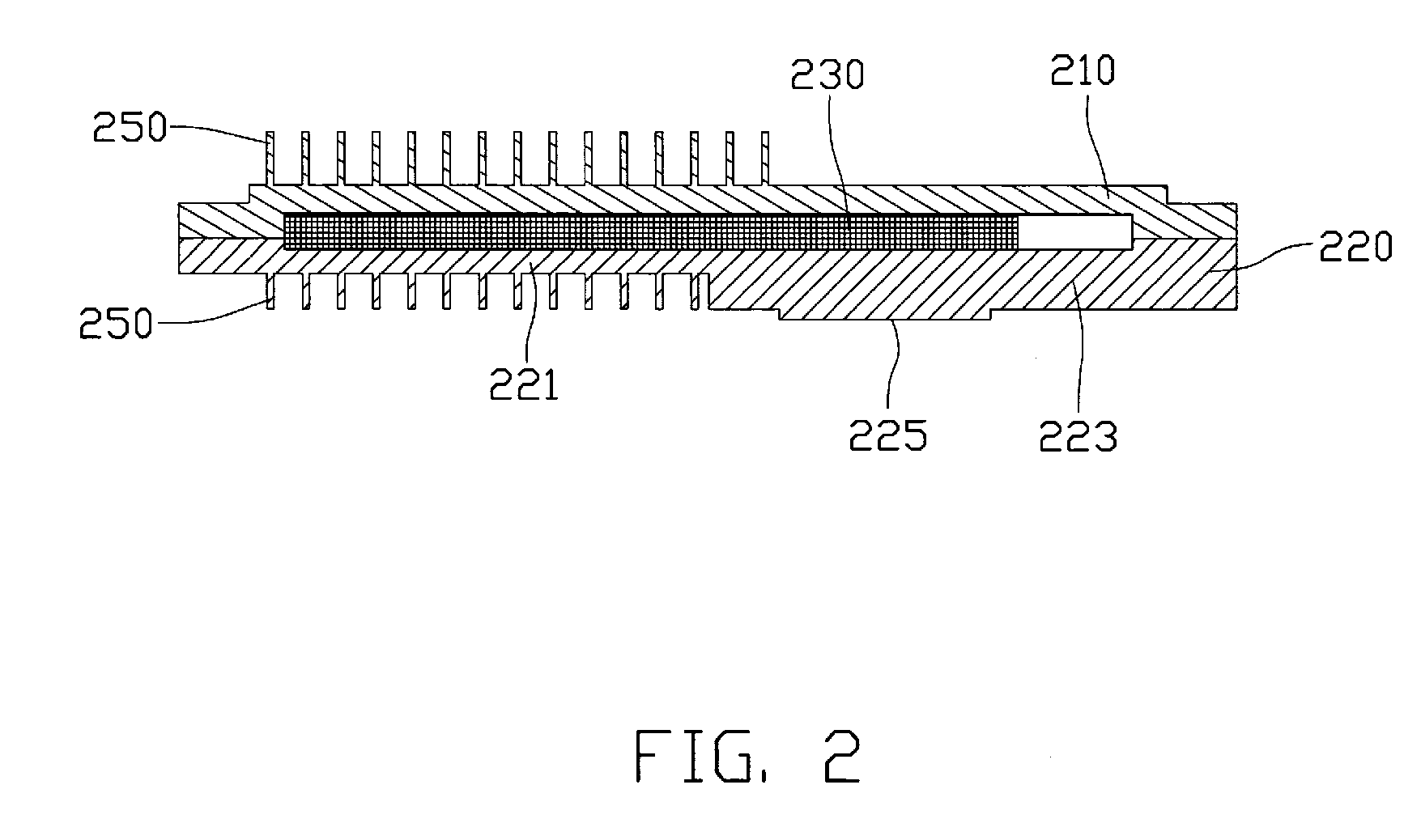

Loop-type heat exchange device

InactiveUS20070006994A1Reduce the amount requiredReduce the temperatureSolid-state devicesIndirect heat exchangersWorking fluidEvaporation

A loop-type heat exchange device (10) is disclosed, which includes an evaporator (20), a condenser (40), a vapor conduit (30) and a liquid conduit (50). The evaporator defines therein a chamber for containing a working fluid. The chamber is divided into an evaporating region and a micro-channel region. The working fluid in the evaporator evaporates into vapor after absorbing heat at the evaporating region, and the generated vapor flows, via the vapor conduit, to the condenser where the vapor releases its latent heat of evaporation and is condensed into condensate. The condensate then returns back, via the liquid conduit, to the evaporator to thereby form a heat transfer loop. The evaporator is configured in such a manner that an amount of vapor to be formed and accumulated in the micro-channel region can be minimized.

Owner:HON HAI PRECISION IND CO LTD

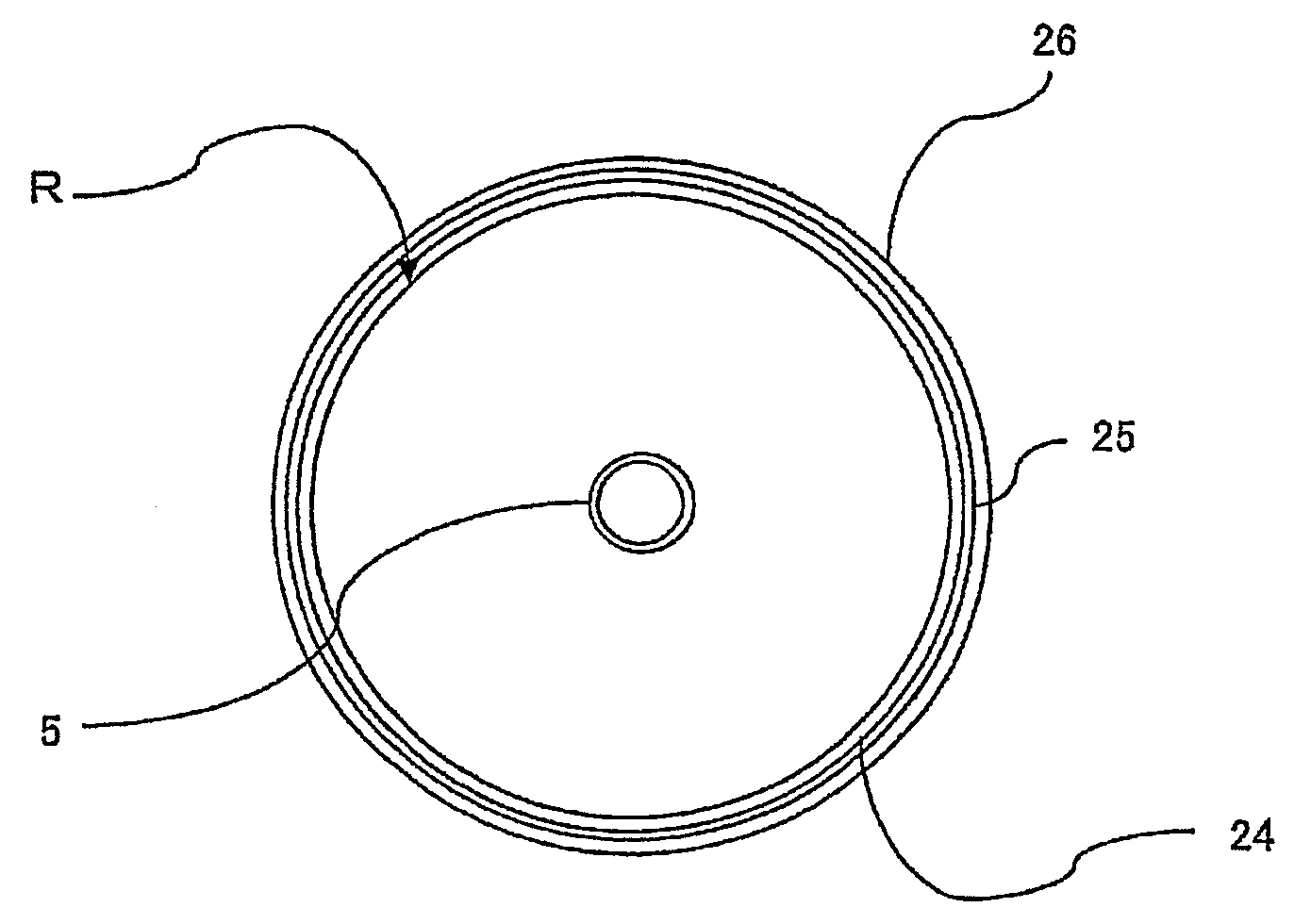

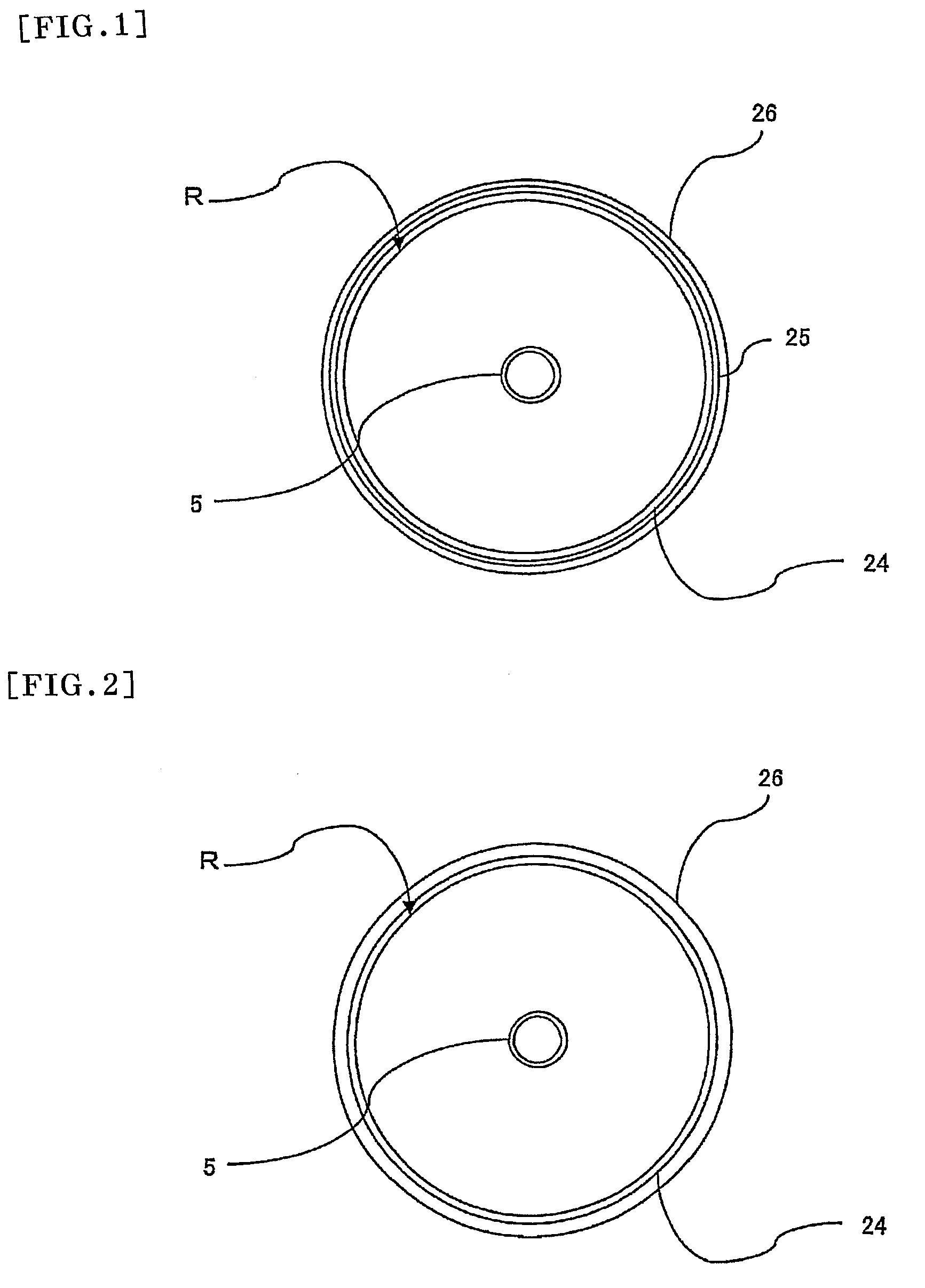

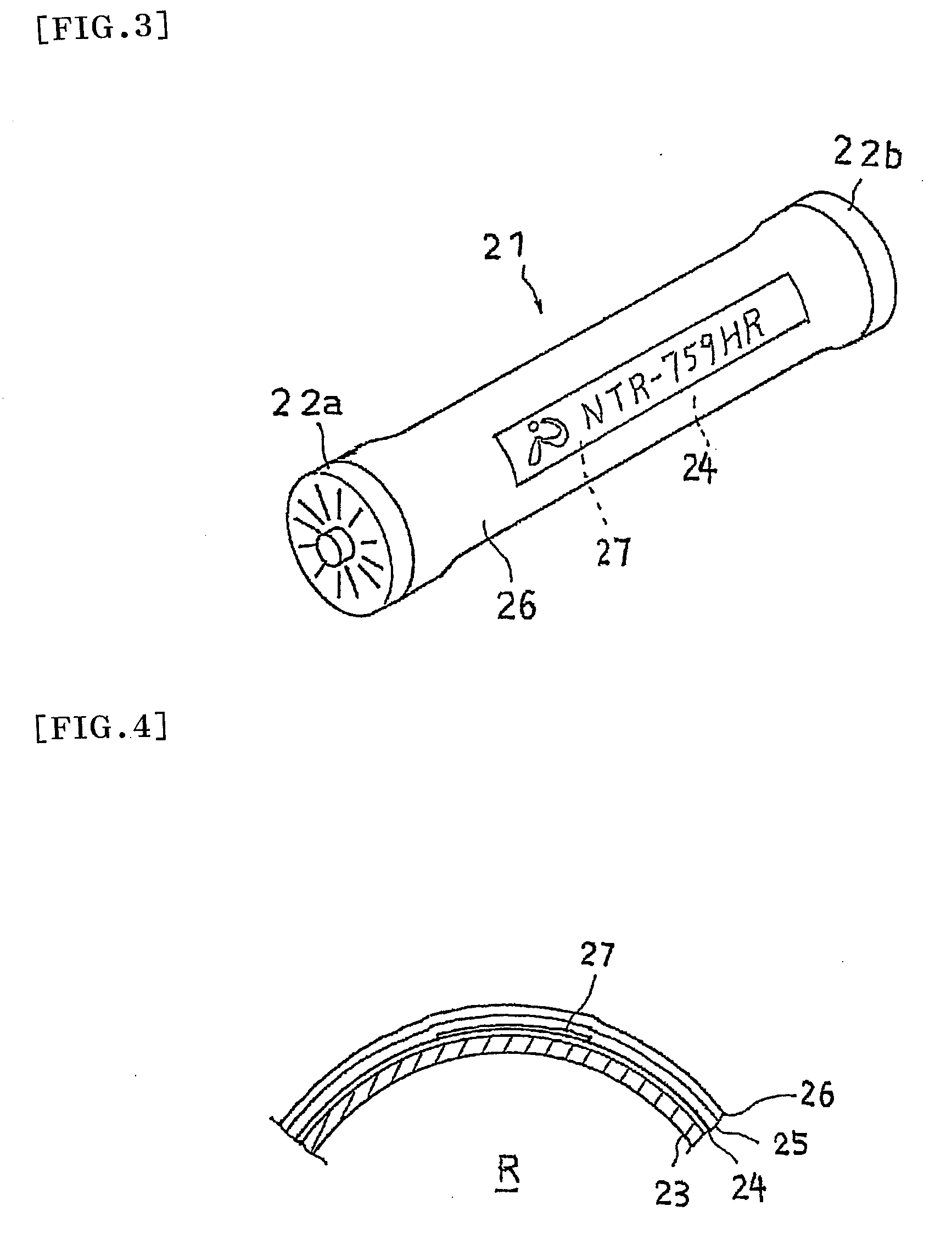

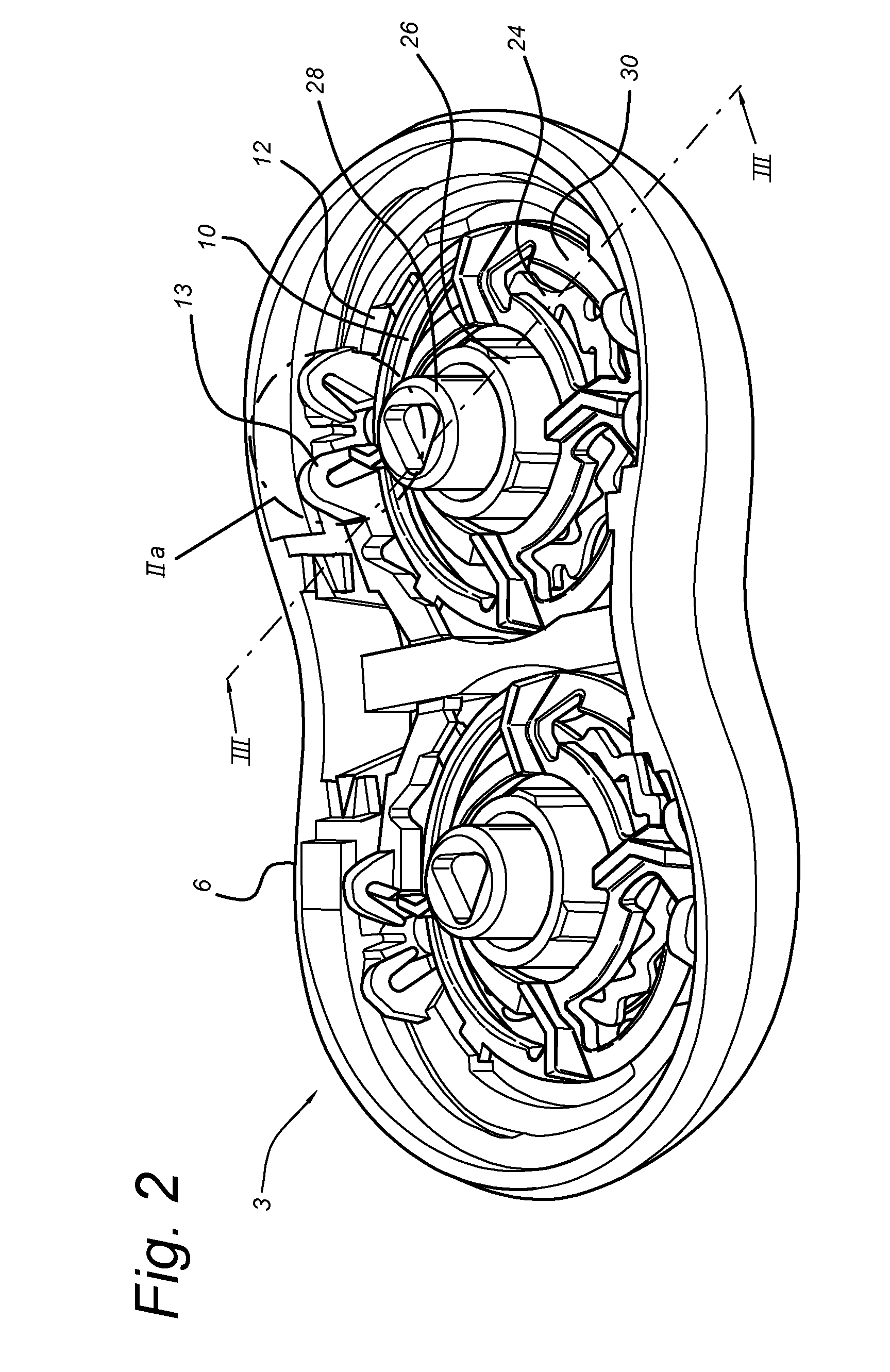

Spiral membrane element

InactiveUS20090065426A1Improve barrier propertiesAvoid crackingSemi-permeable membranesLaminationEngineeringMechanical engineering

An object of the present invention is to provide a spiral membrane element that can improve the barrier property of a fiber reinforced plastic layer having a fiber roll as a reinforcing phase and that can effectively prevent occurrence of cracks. The spiral membrane element of the present invention is a spiral membrane element containing a cylindrical roll R in which a separation membrane, a feed-side flow passageway member, and a permeate-side flow passageway member are spirally wound in a laminate state around a perforated center tube 5 and in which a sealing part for preventing mixing of feed-side fluid and permeate-side fluid is disposed, wherein a fiber reinforced plastic layer 26 having a fiber roll as a reinforcing phase is formed on the outer circumferential side of said cylindrical roll R, and a plastic layer 24 is disposed in the inner part or on the inner side of the fiber reinforced plastic layer 26 approximately over the entire length and approximately over the entire circumference of the fiber reinforced plastic layer 26.

Owner:NITTO DENKO CORP

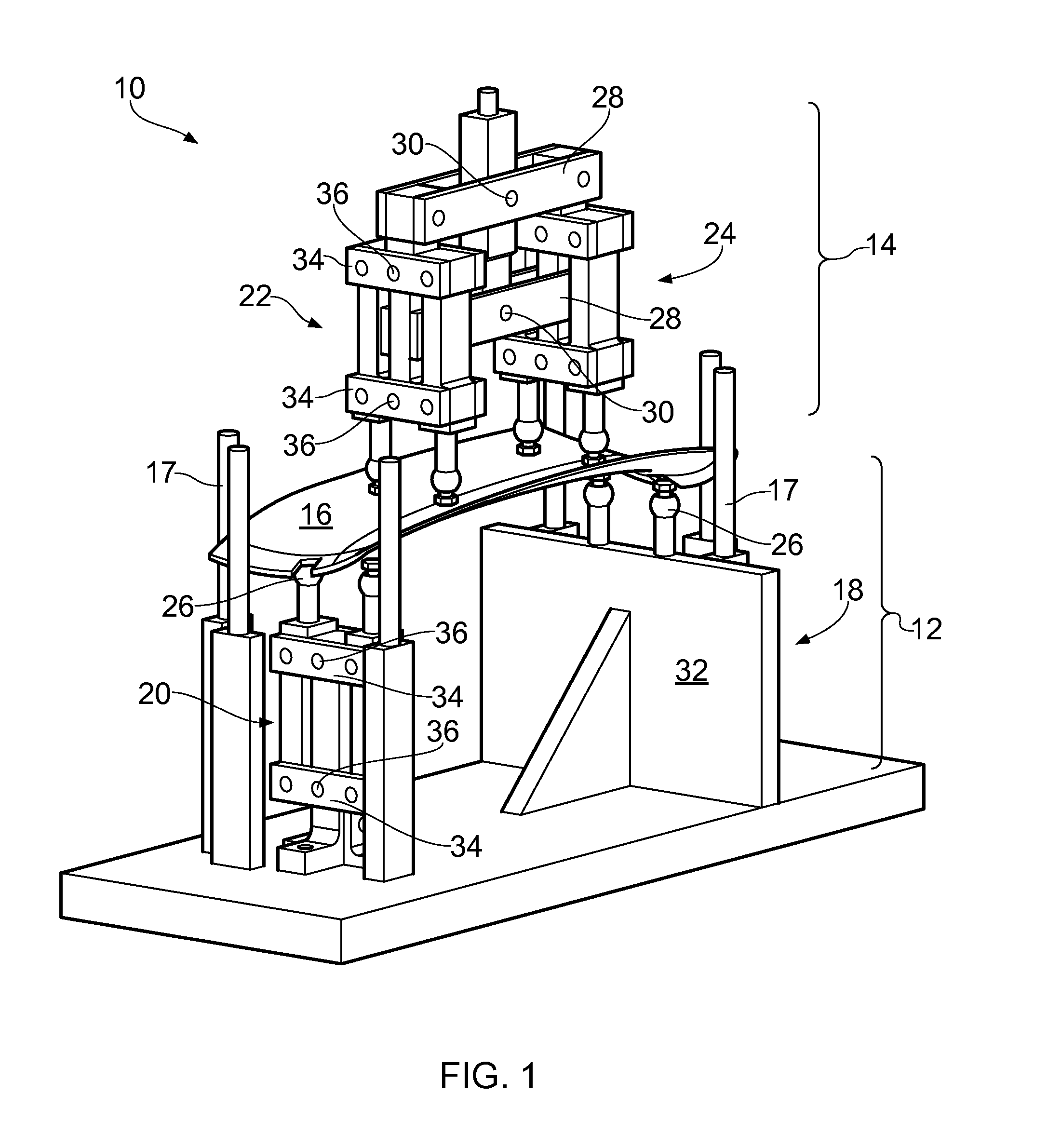

Testing rig

ActiveUS20150268144A1Improve supportUniform applicationMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesEngineeringMechanical engineering

Owner:ROLLS ROYCE PLC

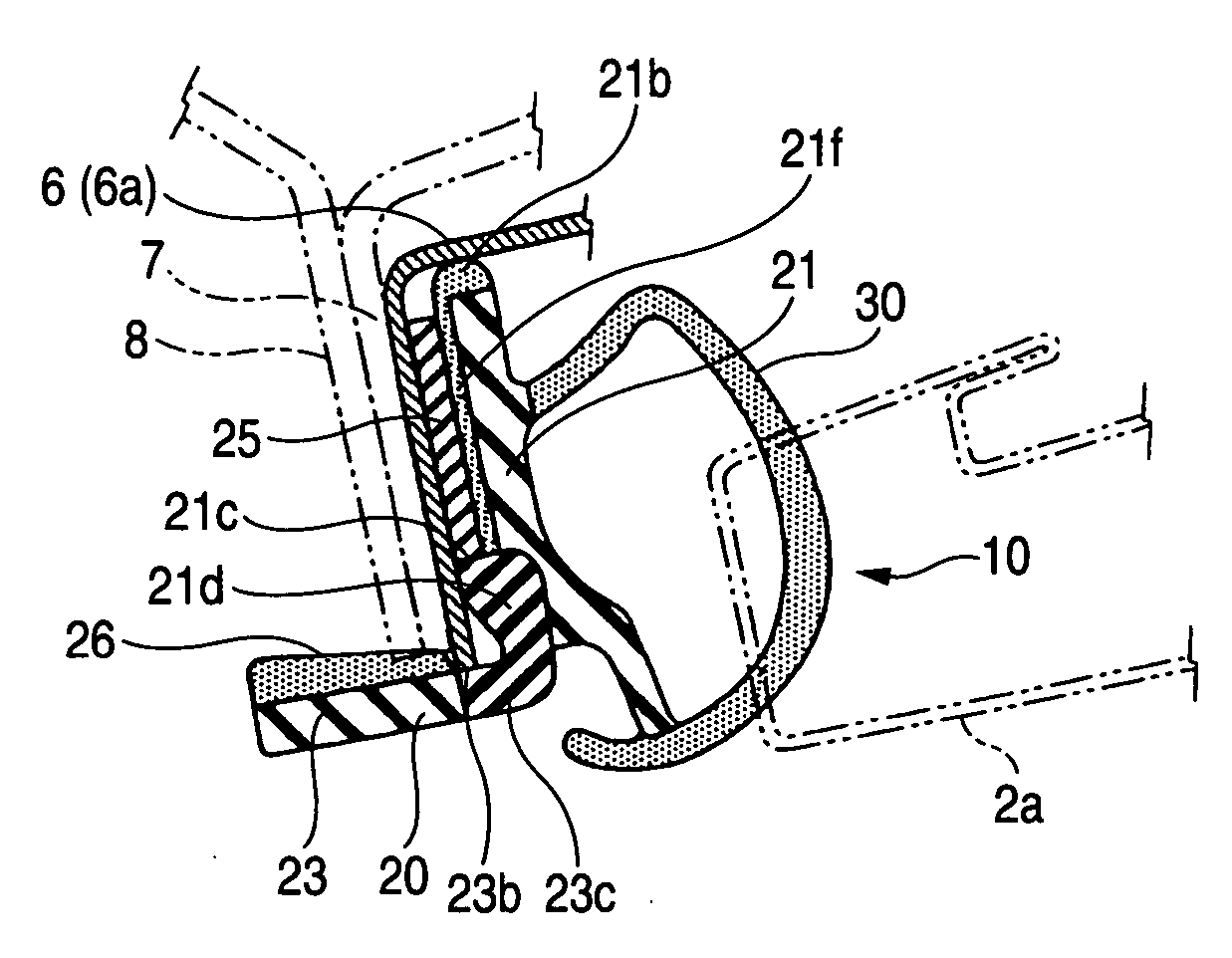

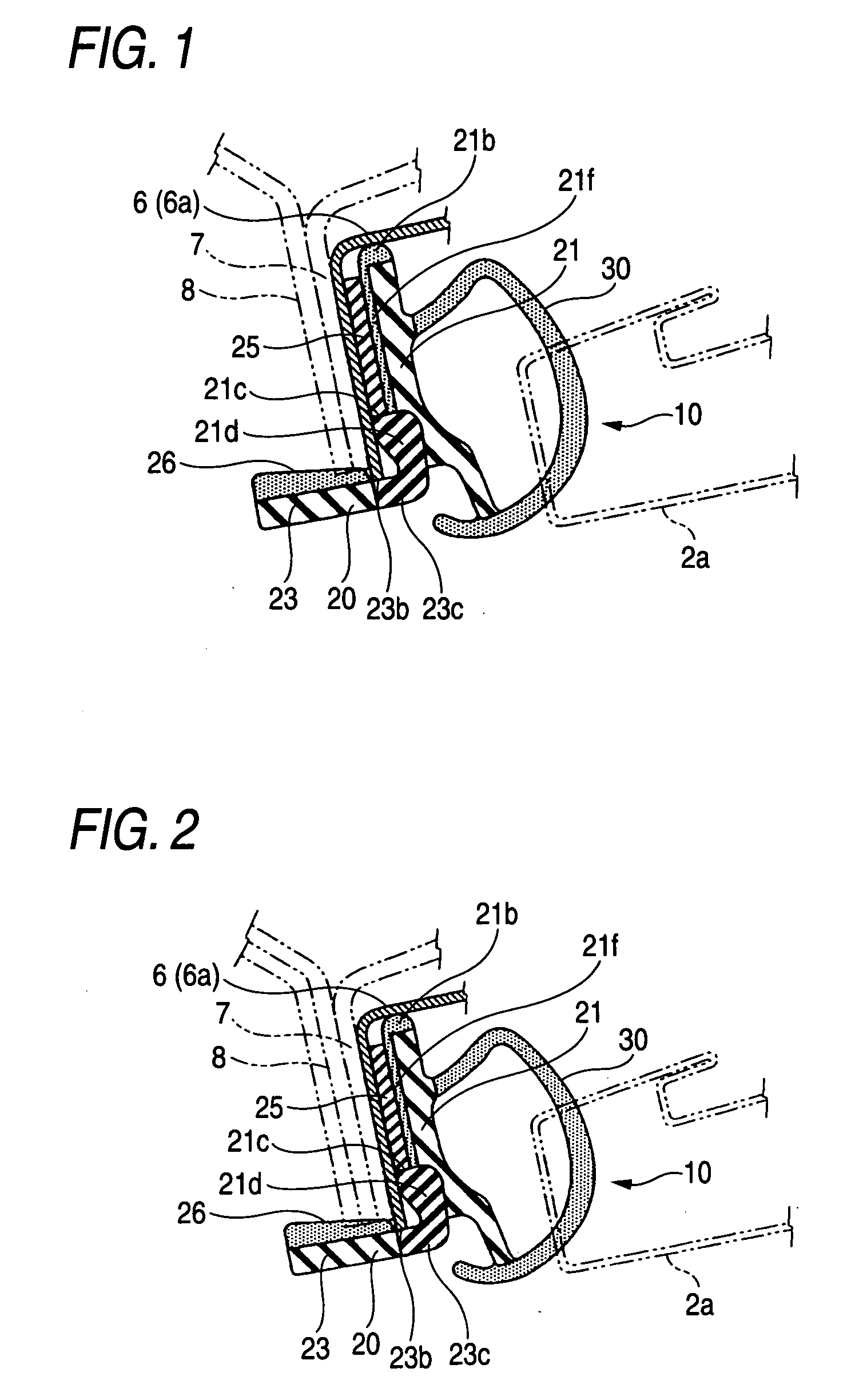

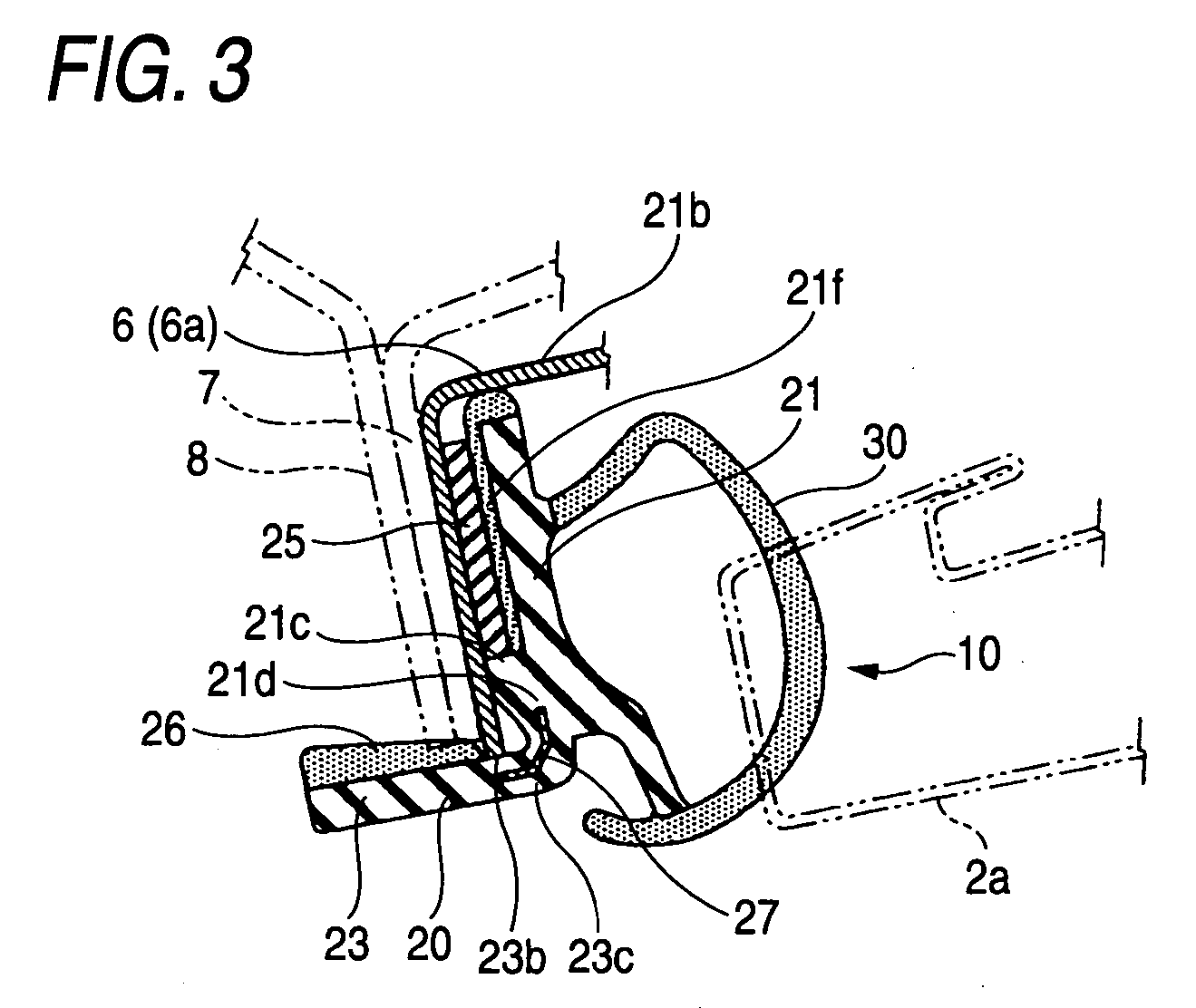

Weather strip

InactiveUS20070024084A1Easy to installPrevent intrusionEngine sealsSealing arrangementsEngineeringFlange

A weather strip has a mounting base portion which is mounted on a flange and a seal portion which is integrally provided on the mounting base portion, so as to seal a gap between a vehicle body opening open / close member and a vehicle body opening peripheral part. The mounting base portion is provided with at least an exterior side wall and a bottom wall, and a connecting portion between the exterior side wall and the bottom wall is formed more rigid than the other portions of the mounting base portion, a pressure sensitive adhesive double sided tape being bonded to an interior side surface of the exterior side wall. A flange contact portion which holds a distal end of the flange is formed on an inner surface of the bottom wall at a position in the vicinity of the connecting portion with the exterior side wall, while a caulking member which seals the distal end of the flange is mounted on the inner surface of the bottom wall except for the portion where the flange contact portion is formed.

Owner:TOYODA GOSEI CO LTD

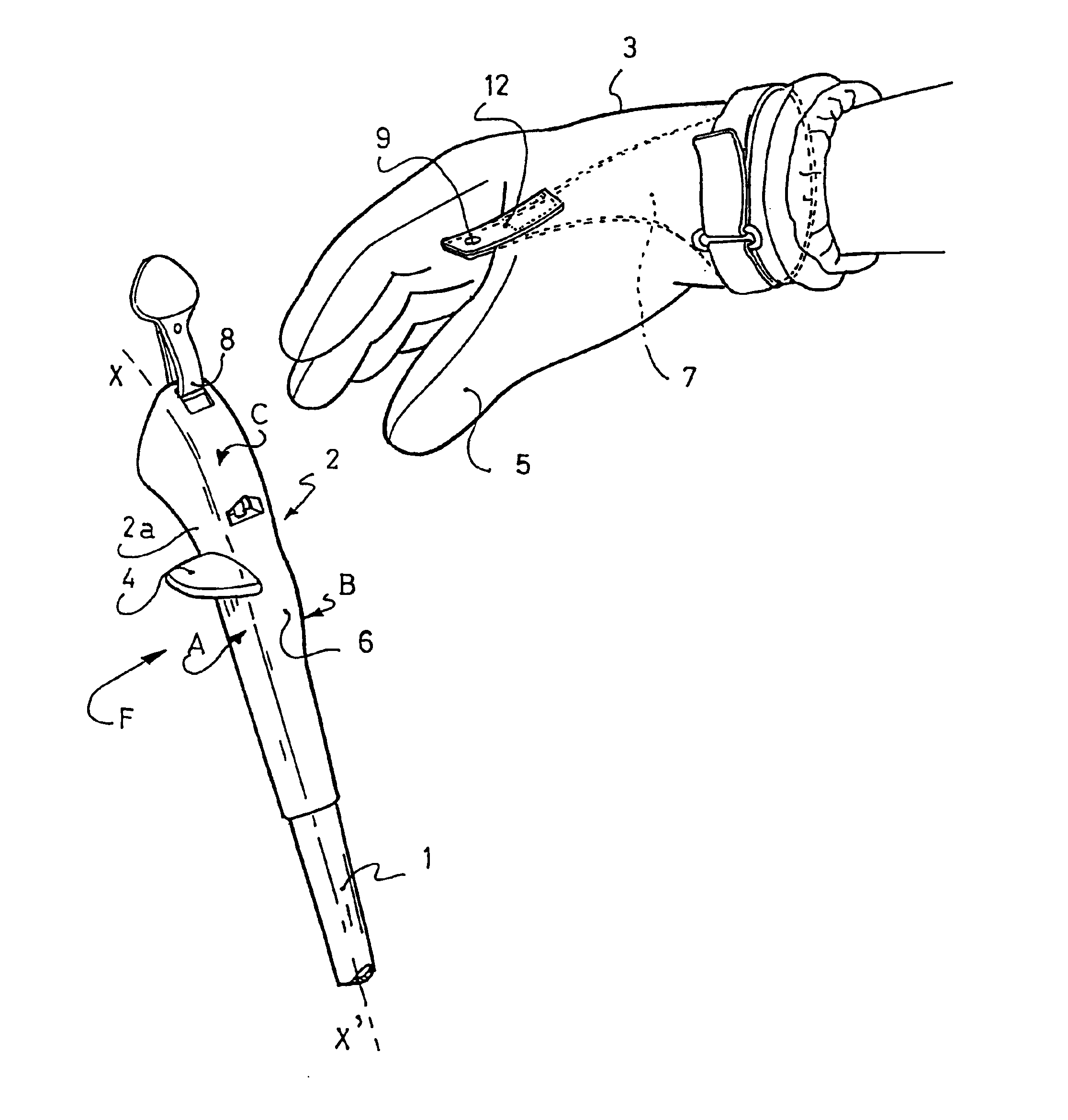

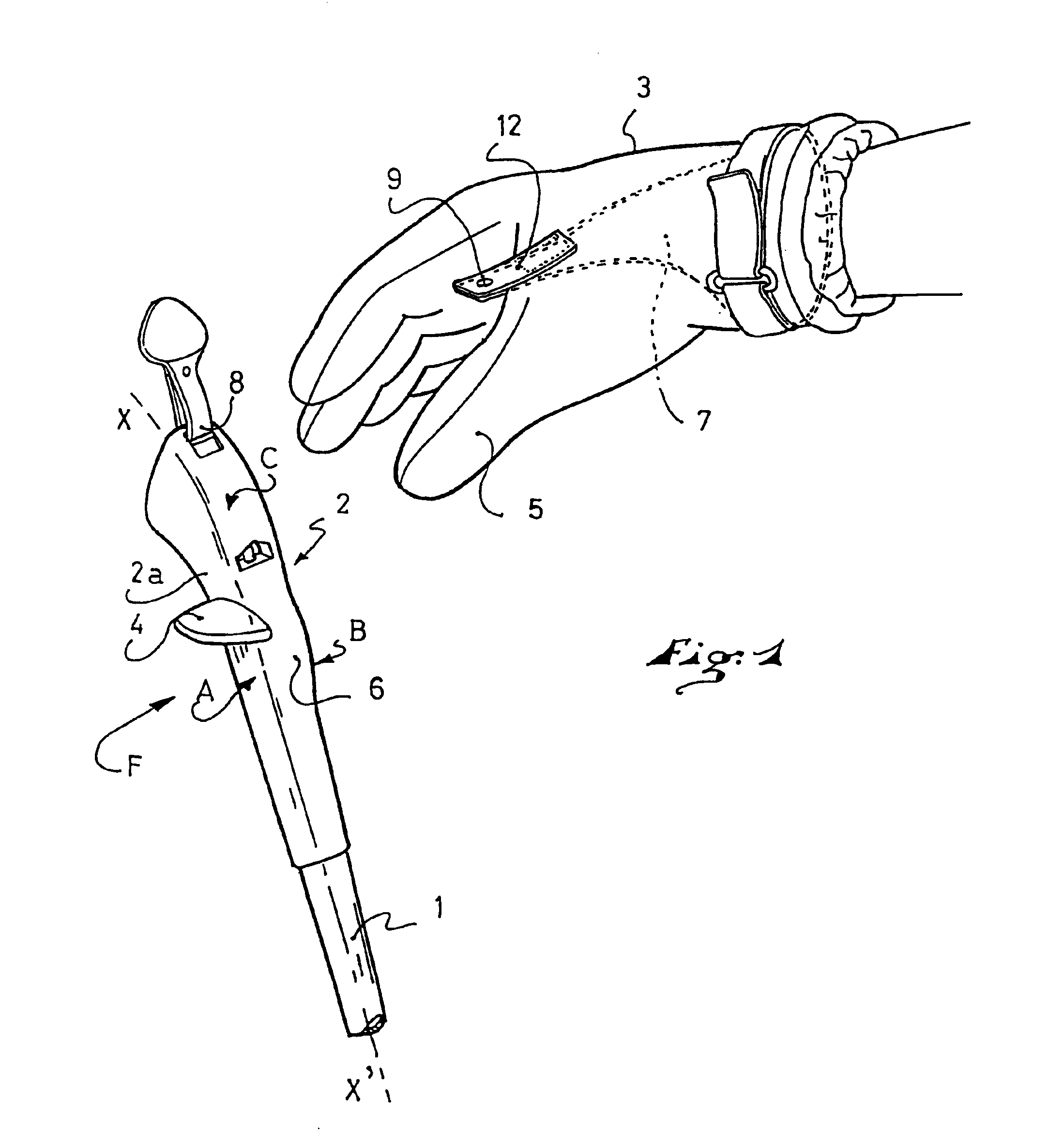

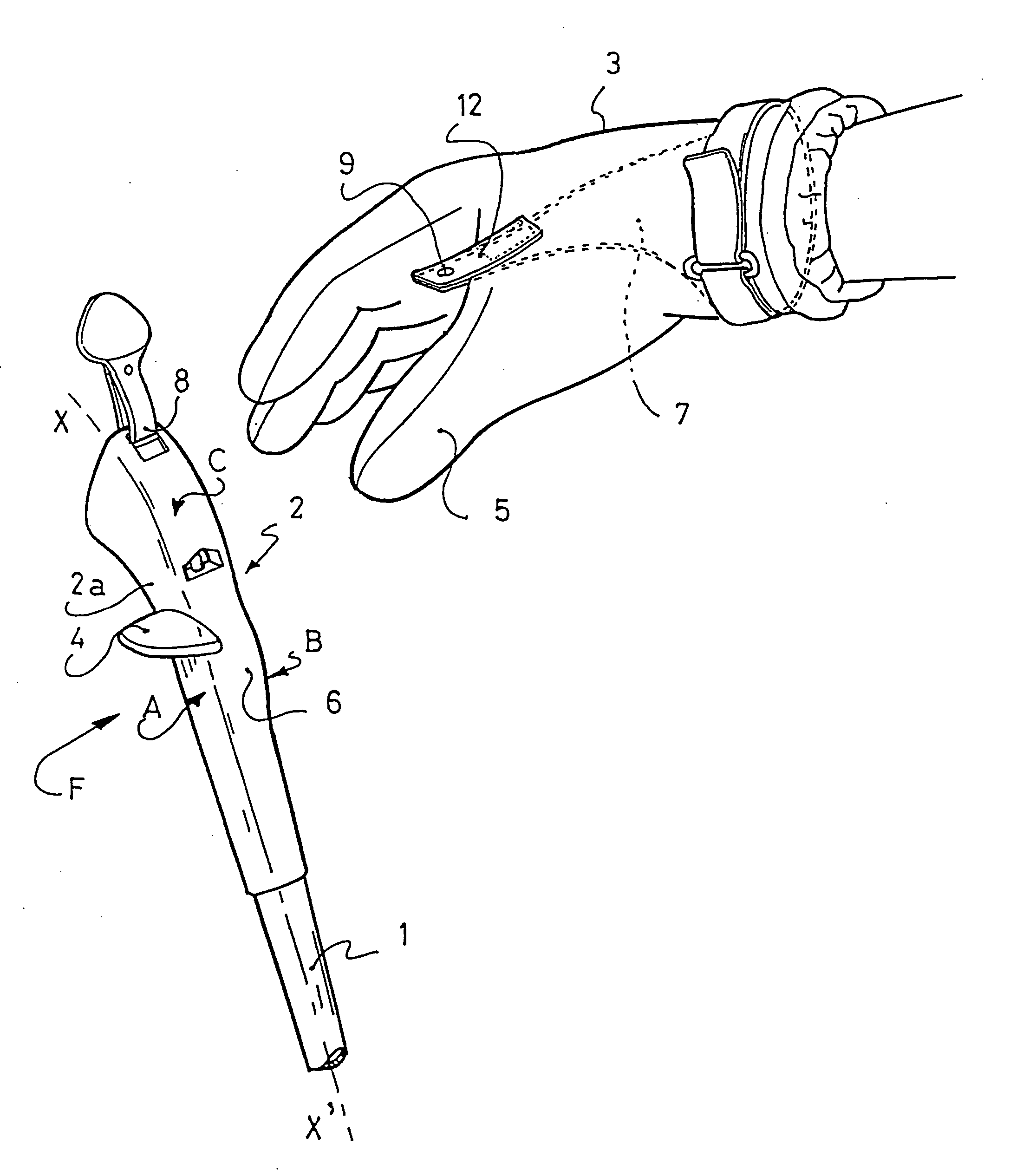

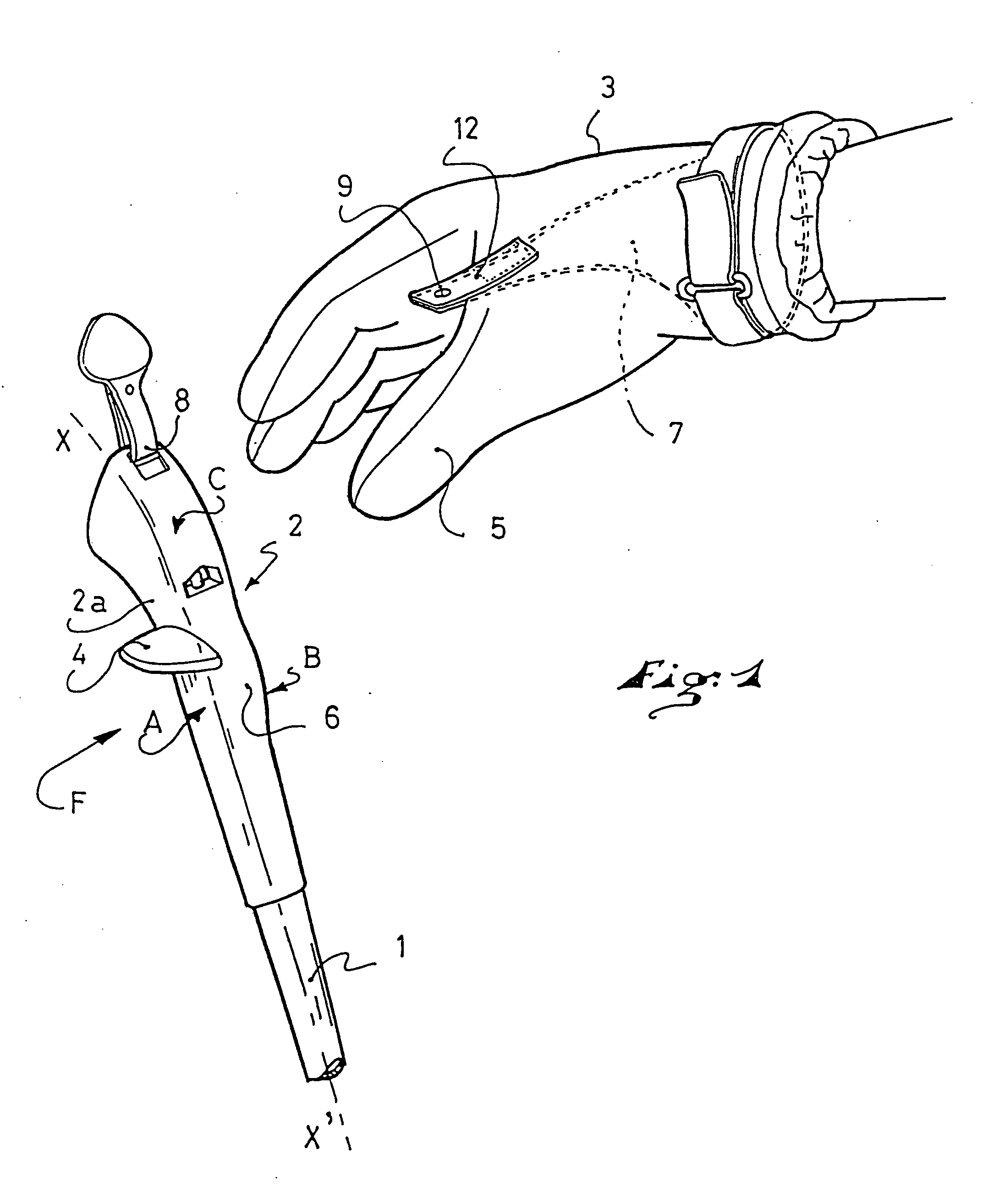

Grip for a sports pole, and a sports pole having such grip

InactiveUS6988745B2Improved force transmissionImproving grip and contactSnowboard bindingsGlovesEngineeringAxial transmission

A pole, for use in skiing or other sport, of the type that includes a grip handle at its upper end, wherein the handle includes a support extending from its side wall and adapted to cooperate with the thumb of a user, so as to constitute an additional mechanism for the axial transmission of forces, by the thumb, when the hand is closed on the handle of the pole.

Owner:SALOMON SA

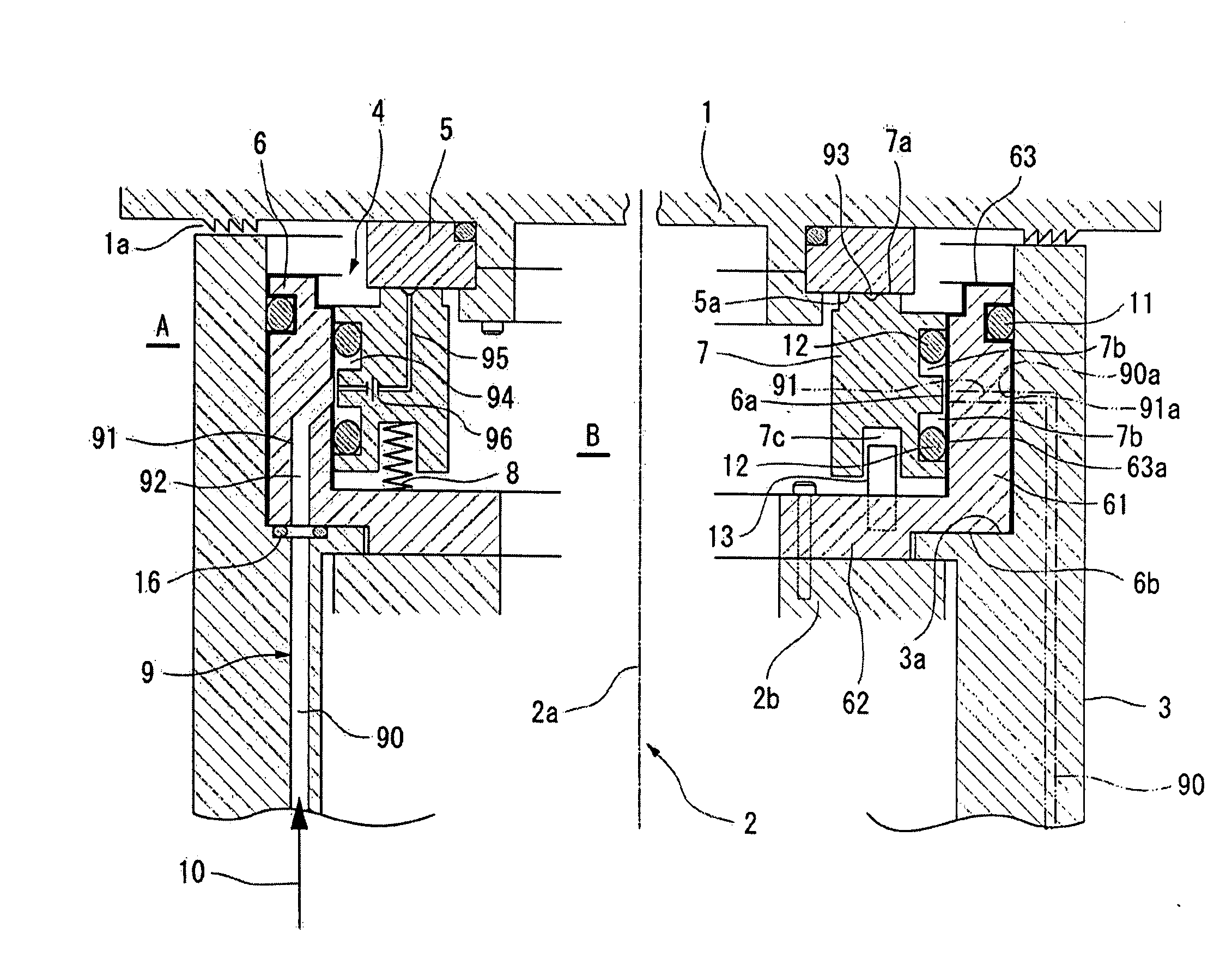

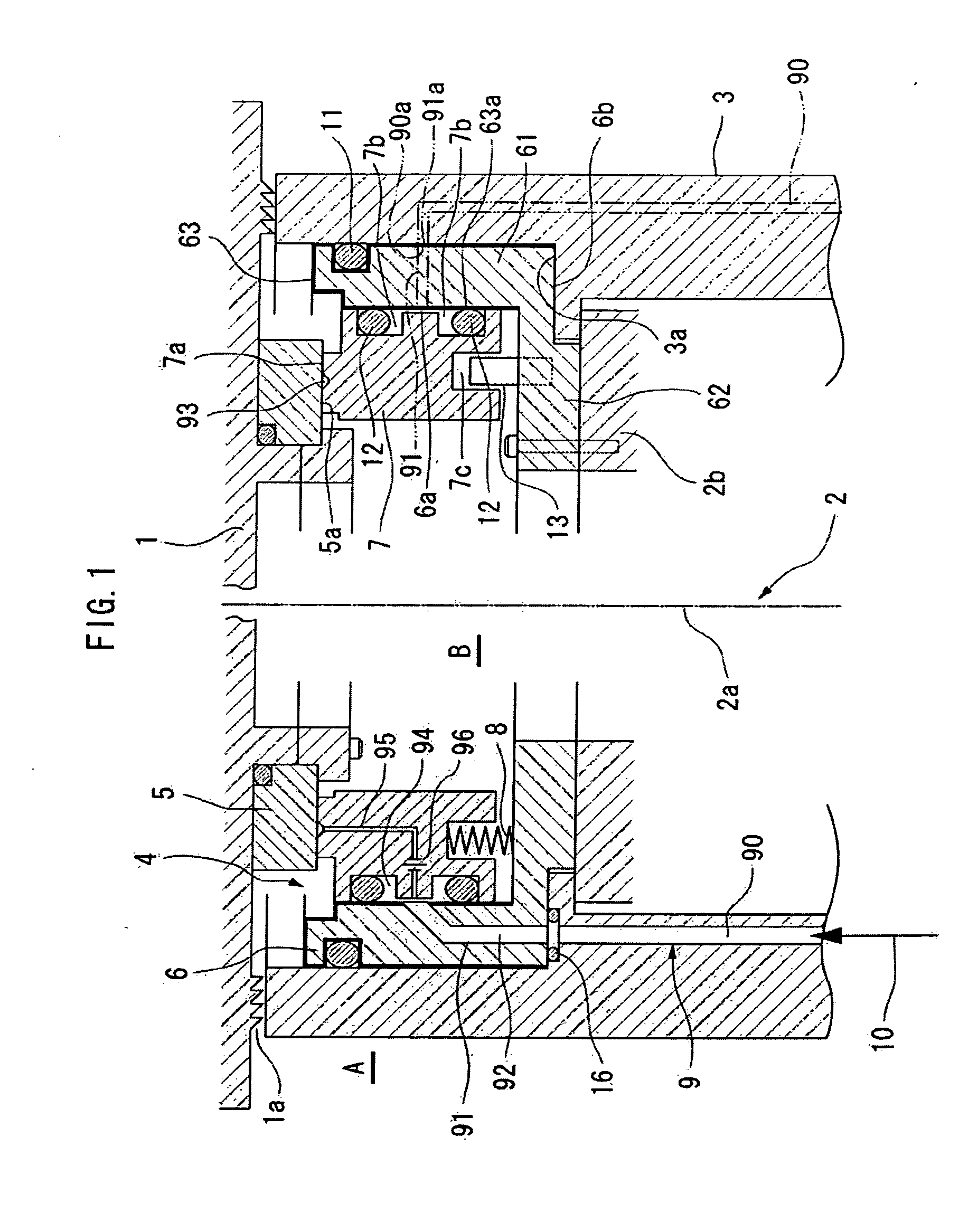

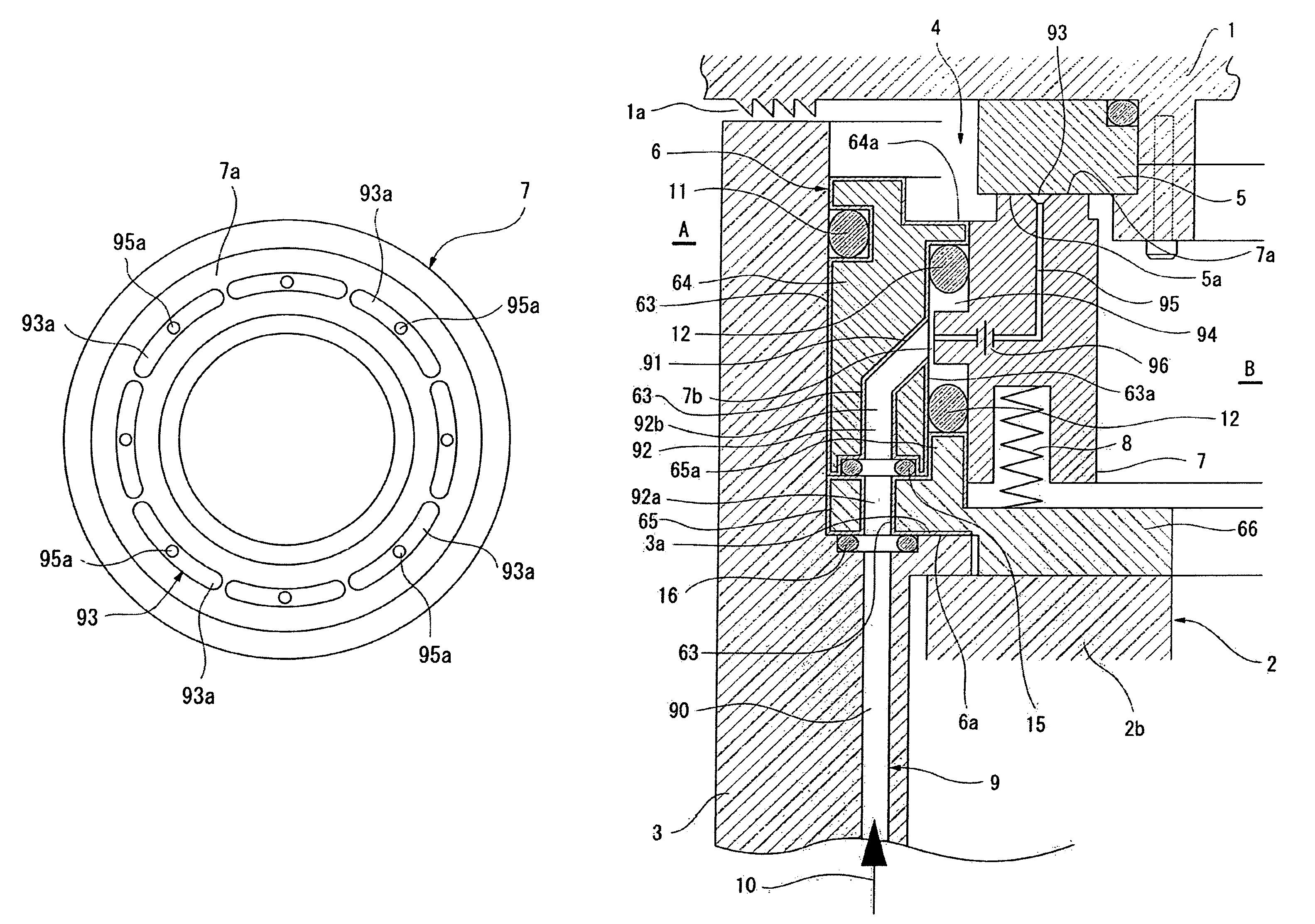

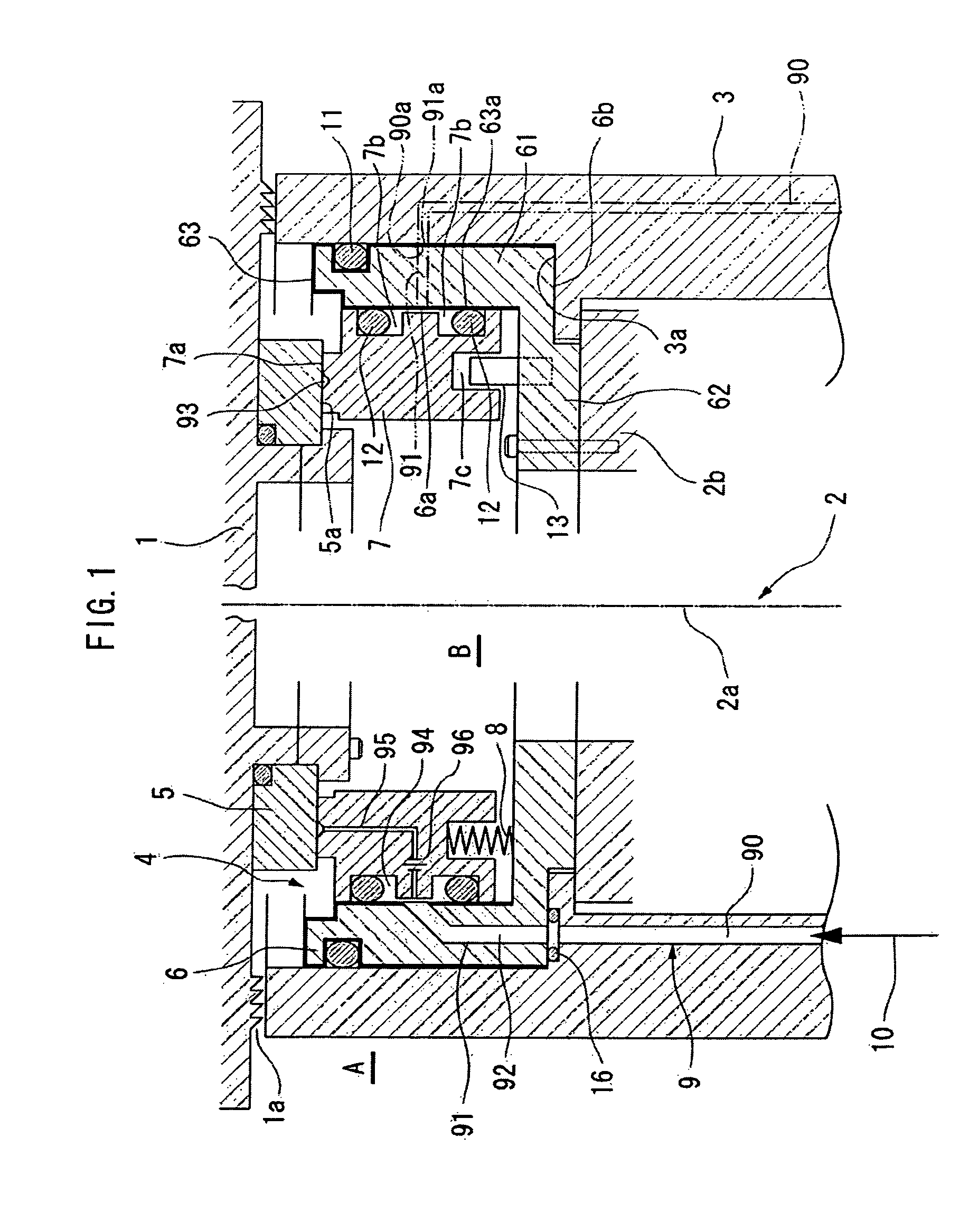

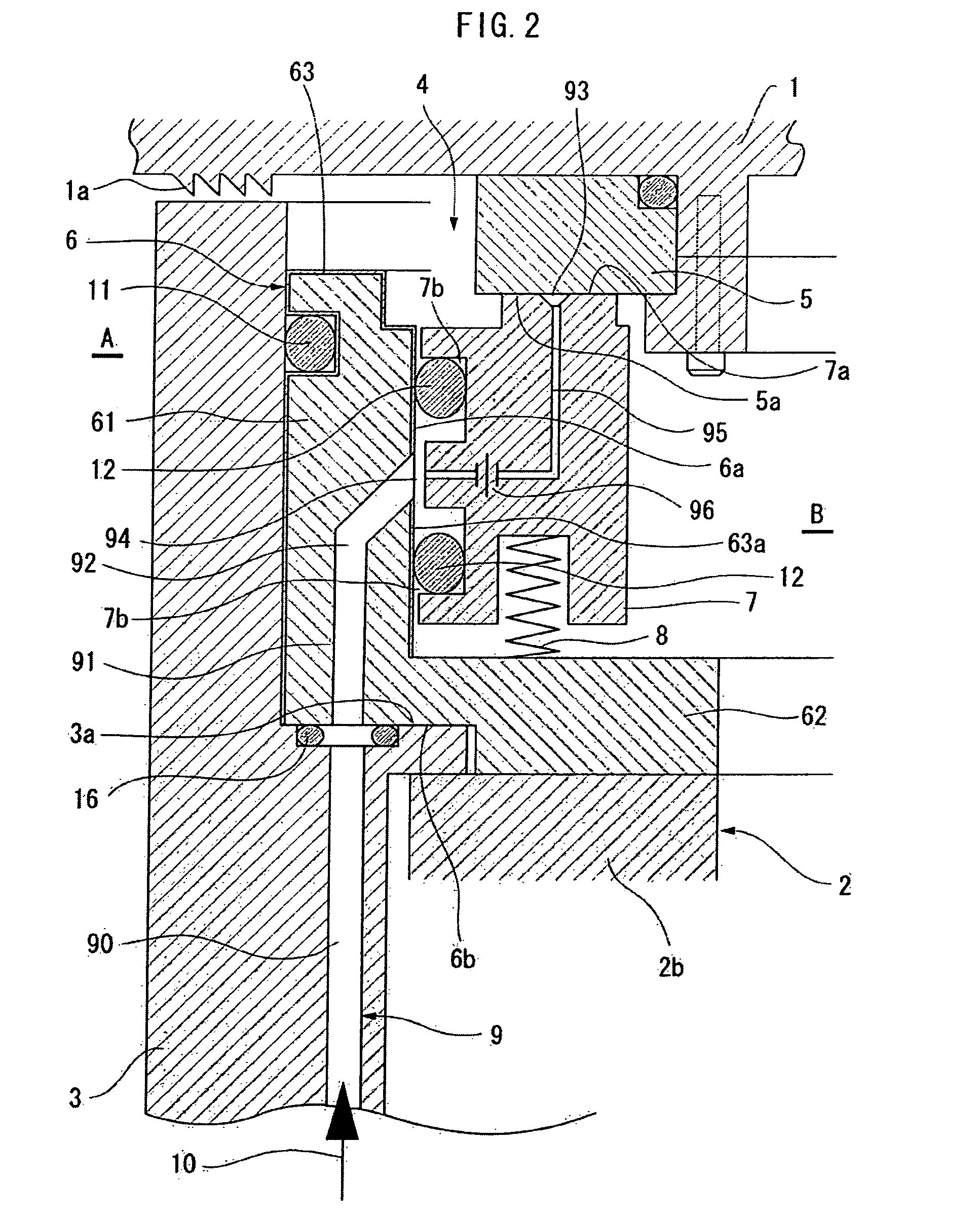

Mechanical seal

ActiveUS20090189355A1Improve sealing functionImprove sealingEngine sealsLeakage preventionEngineeringMechanical engineering

A mechanical seal 4 is a static pressure type non-contact gas seal, including a rotary sealing ring 5 that is fixed to a rotating shaft, and a stationary sealing ring 7 that is engaged and held in an inner periphery of a seal case 6 made of a metal by means of O-rings 12 so as to move in an axial direction thereof. The O-rings 12 are held engaging with the outer periphery of the stationary sealing ring 7, and come in press contact with the inner periphery of the seal case 6 so as to give a secondary seal to a gap between the stationary sealing ring 7 and the seal case 6, while allowing the stationary sealing ring 7 to move ih ng a thickness in the range of 5 to 100 μm is formed on the inner periphery of the seal case 6 at least within a range in which the O-rings 12 relatively move in accordance with the movement of the stationary sealing ring 7 in the axial direction.

Owner:NIPPON PILLAR PACKING CO LTD

Mechanical seal

ActiveUS7883093B2Improve sealingImprove sealing functionEngine sealsLeakage preventionResin coatingMechanical engineering

A mechanical non-contact gas seal including a rotary scaling ring and a stationary sealing ring that is engaged and held in an inner periphery of a seal case by means of O-rings so as to move in an axial direction thereof. The O-rings engage with the outer periphery of the stationary sealing ring and come in press contact with the inner periphery of the seal case to seal a gap between the stationary sealing ring and the seal case while allowing the stationary sealing ring to move in an axial direction. A resin coating of a thickness in the range of 5 to 100 μm is formed on the inner periphery of the seal case at least within a range in which the O-rings relatively move with the movement of the stationary sealing ring.

Owner:NIPPON PILLAR PACKING CO LTD

Aerodynamic surfaced bicycle wheel

ActiveUS20040135424A1Reduce air resistanceHigh speedNon-metallic wheel bodyWheel protectionAerodynamic dragMechanical engineering

A bicycle wheel includes a tire engaging portion located at the outward perimeter of the wheel, an inner portion located radially inward from the tire engaging portion A pair of air engaging side surfaces extend radially between the inner portion and the tire engaging portion forming the sides of the wheel. The air engaging side surfaces contain a plurality of surface features designed to create a turbulent boundary layer when the wheel travels through air to reduce aerodynamic drag on the wheel

Owner:COMPOSITECH

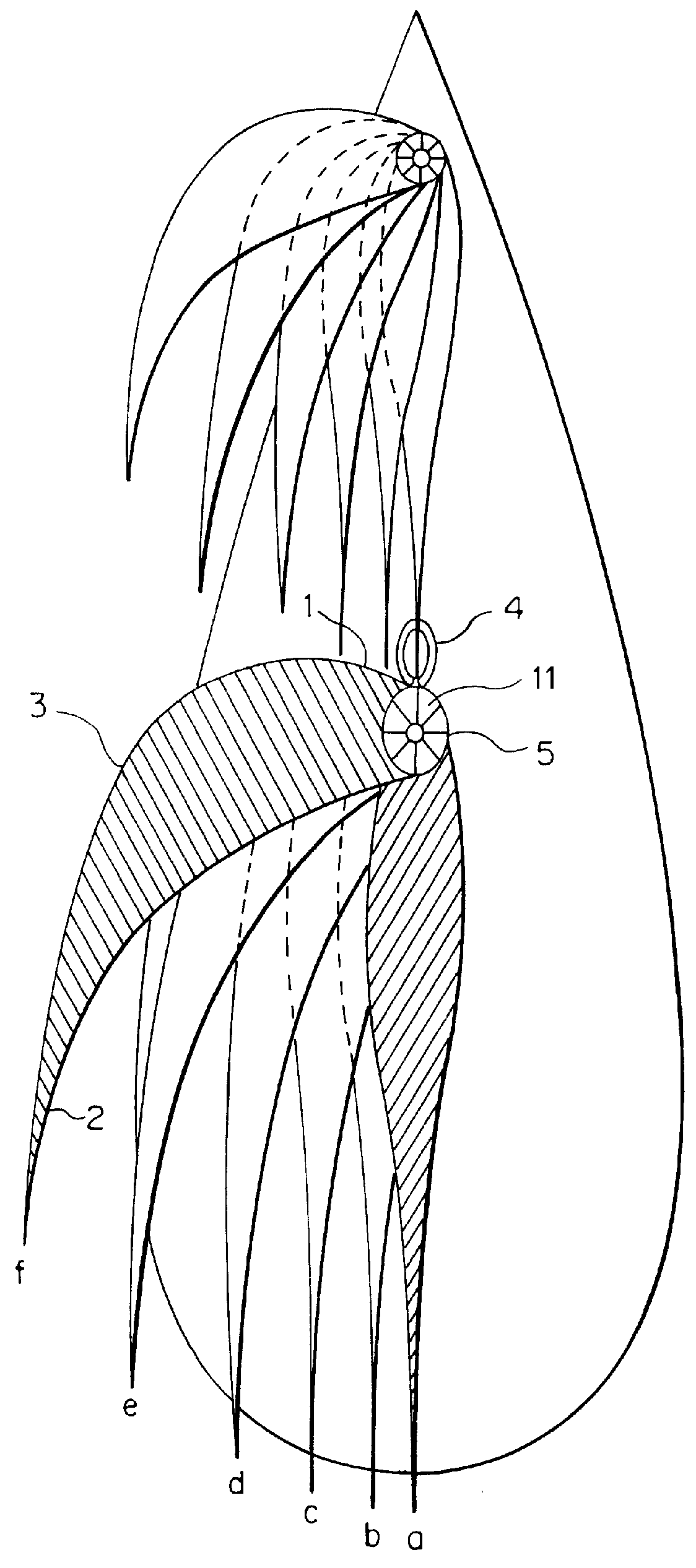

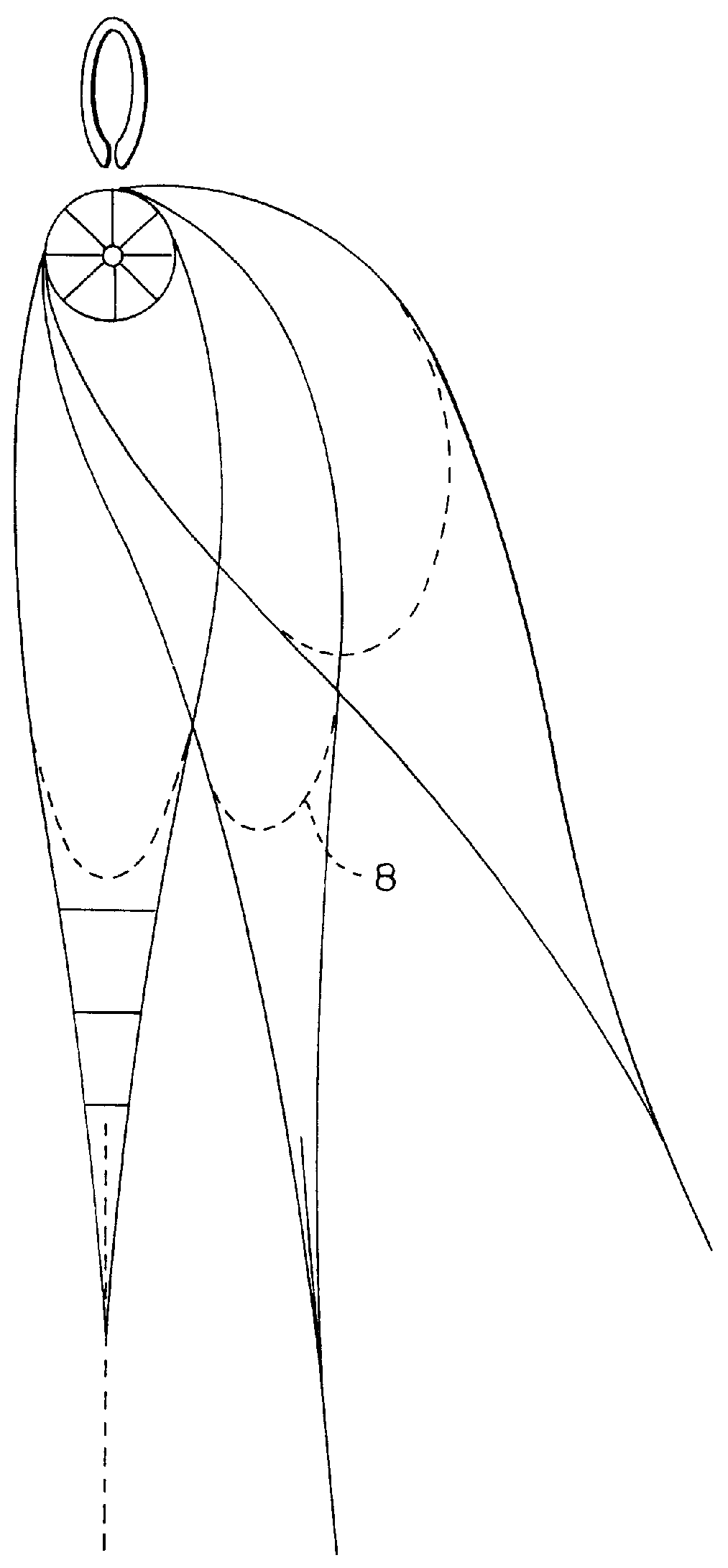

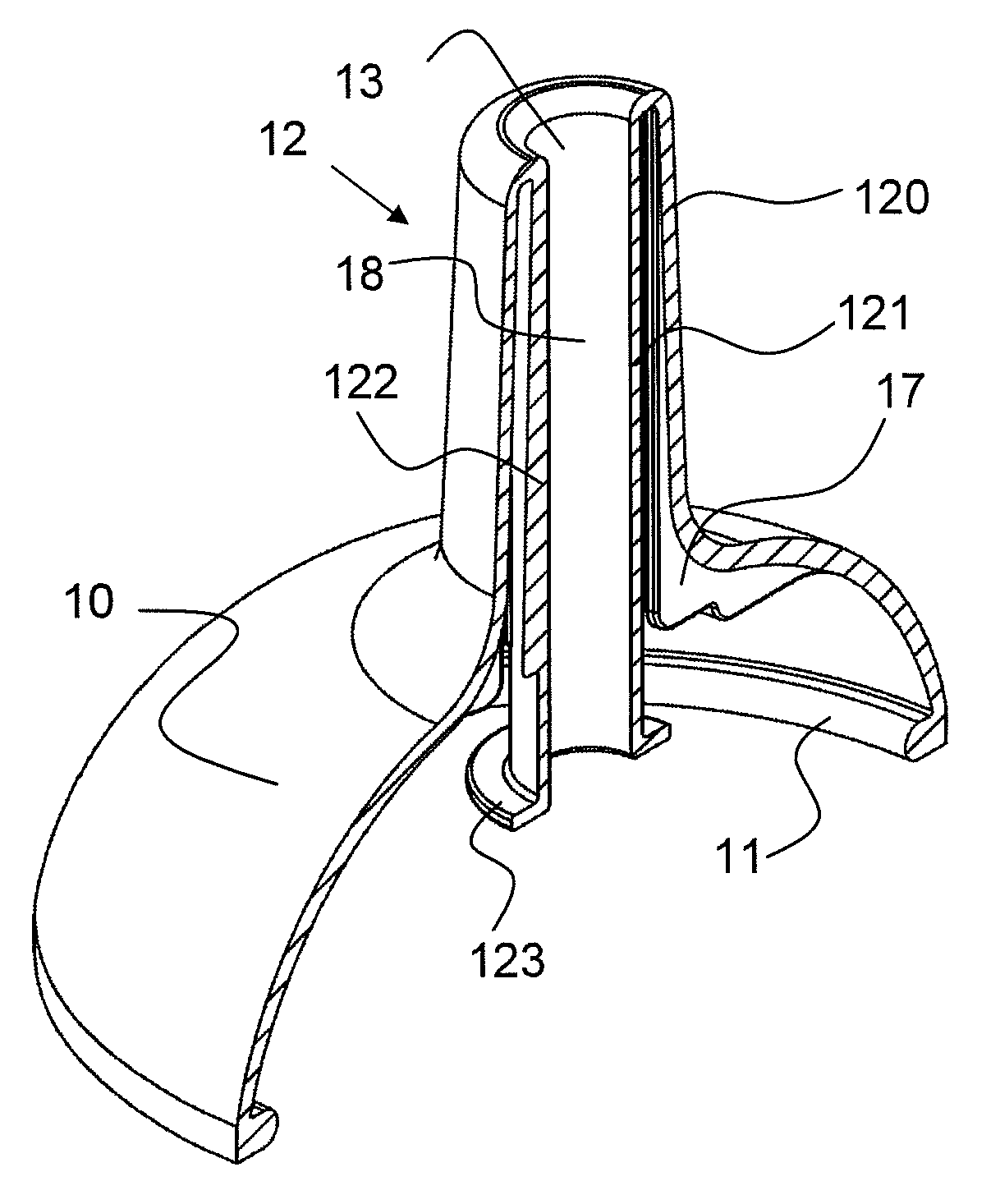

Wing profile sail

InactiveUS6141809AEnhance the imageSimple designFloating buildingsWind acting propulsive elementsState formMechanical engineering

PCT No. PCT / NO97 / 00337 Sec. 371 Date Aug. 11, 1999 Sec. 102(e) Date Aug. 11, 1999 PCT Filed Dec. 15, 1997 PCT Pub. No. WO98 / 26982 PCT Pub. Date Jun. 25, 1998A wing profile sail is in the form of a sailcloth which defines an airfoil-shaped space, which is filled with air through openings or one-way closing mechanisms. At the sail's luff (1) there is provided a bag / lung-shaped body which can be filled with air and which is extendable in the height direction and which in an extended state forms an upwardly tapering conical, cylindrical body (11). The sail's outer cloth (2, 3) extends from this body (11) and is transferred on each side from this body (11) and is attached at a distance from the after leech (7), the sail's after part (7) being composed of one sailcloth surface. From the outer sailcloth's (2, 3) attachment area, in the inner spaces of the sail there is provided an intermediate sailcloth, which at least covers the area of the openings for air supply. The outer sailcloths (2, 3) are connected in the sail's bottom area in order to form the inner spaces in such a manner that the outer sailcloths are movable in relation to each other.

Owner:LYNGHOLM TORE

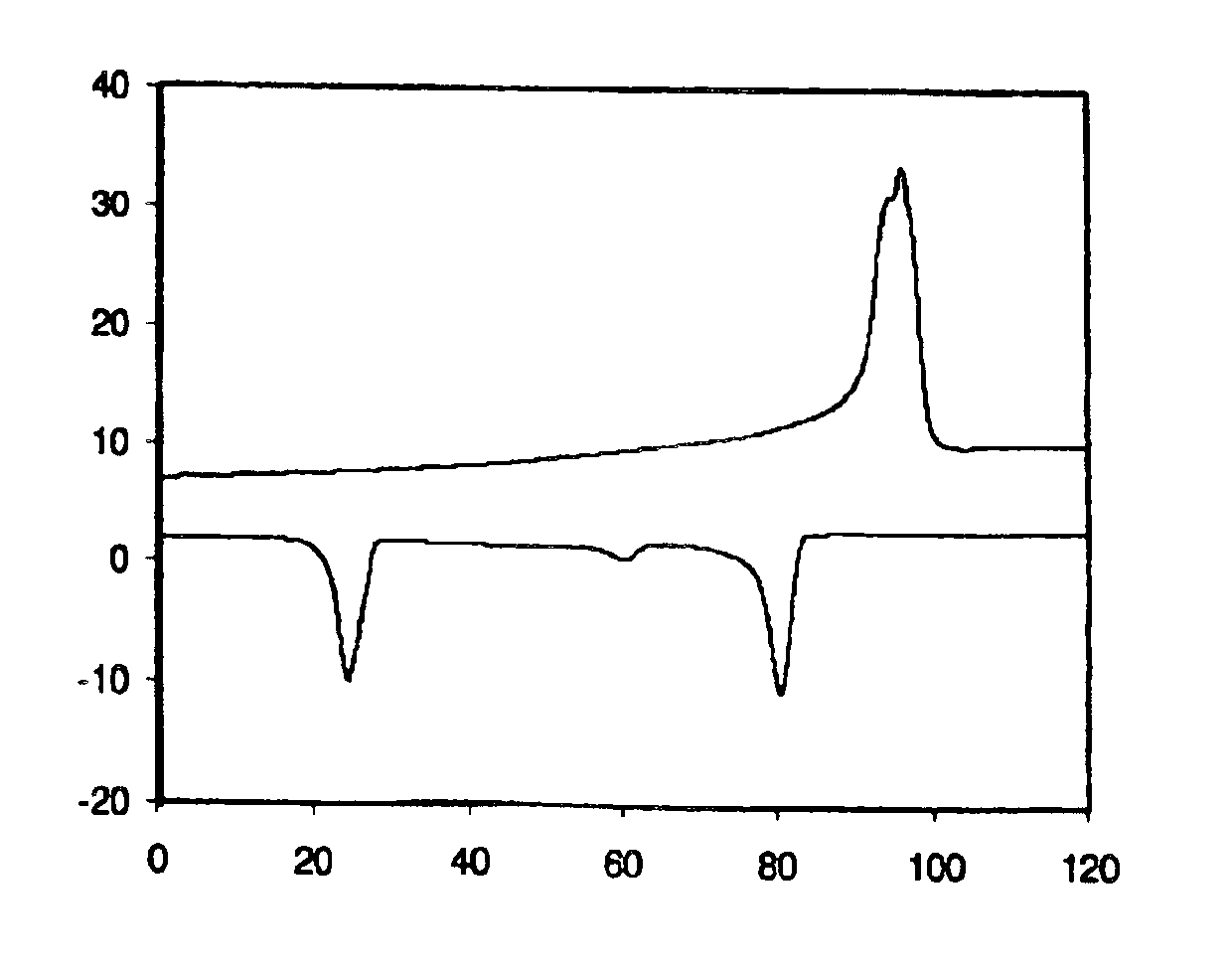

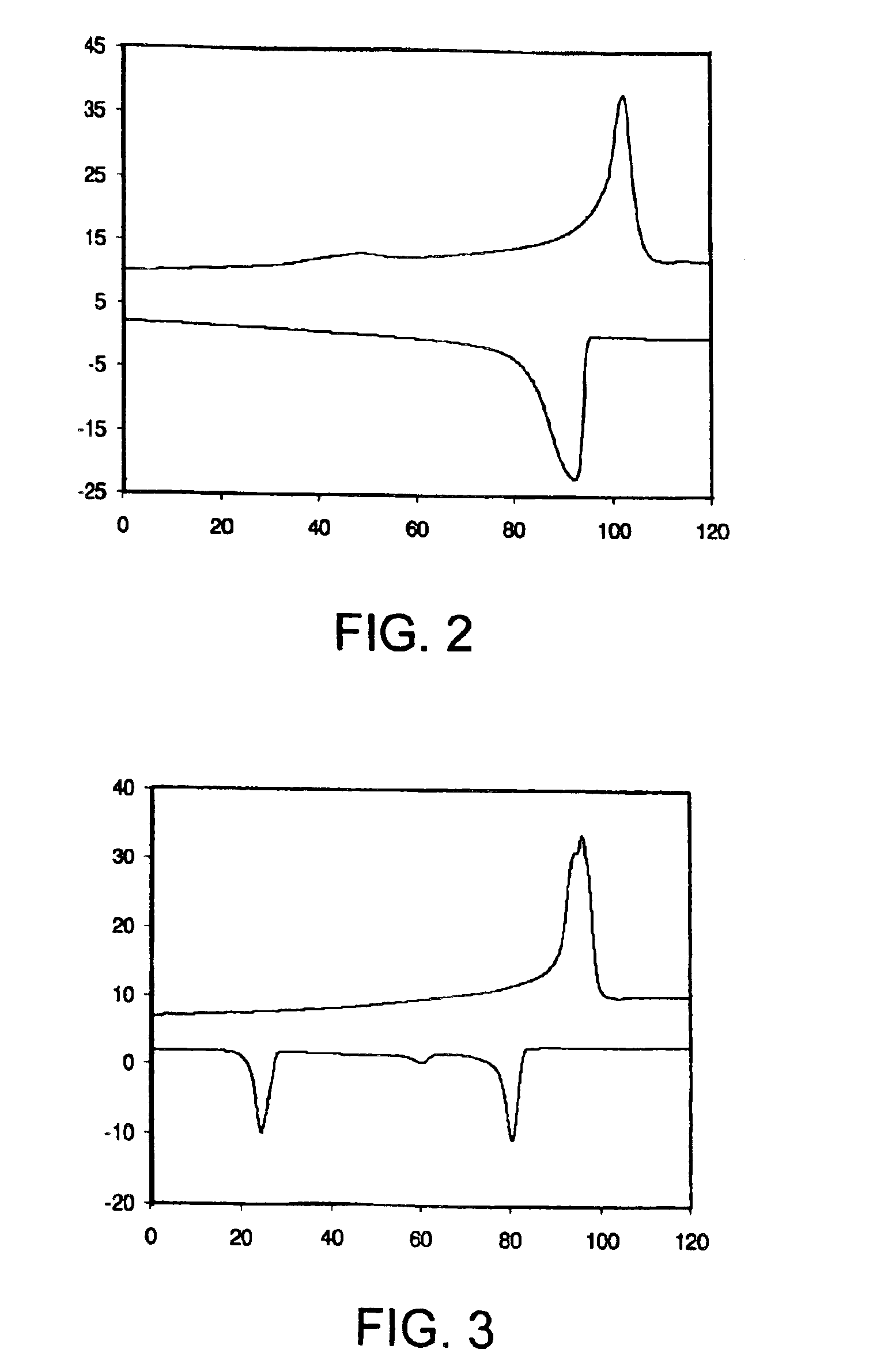

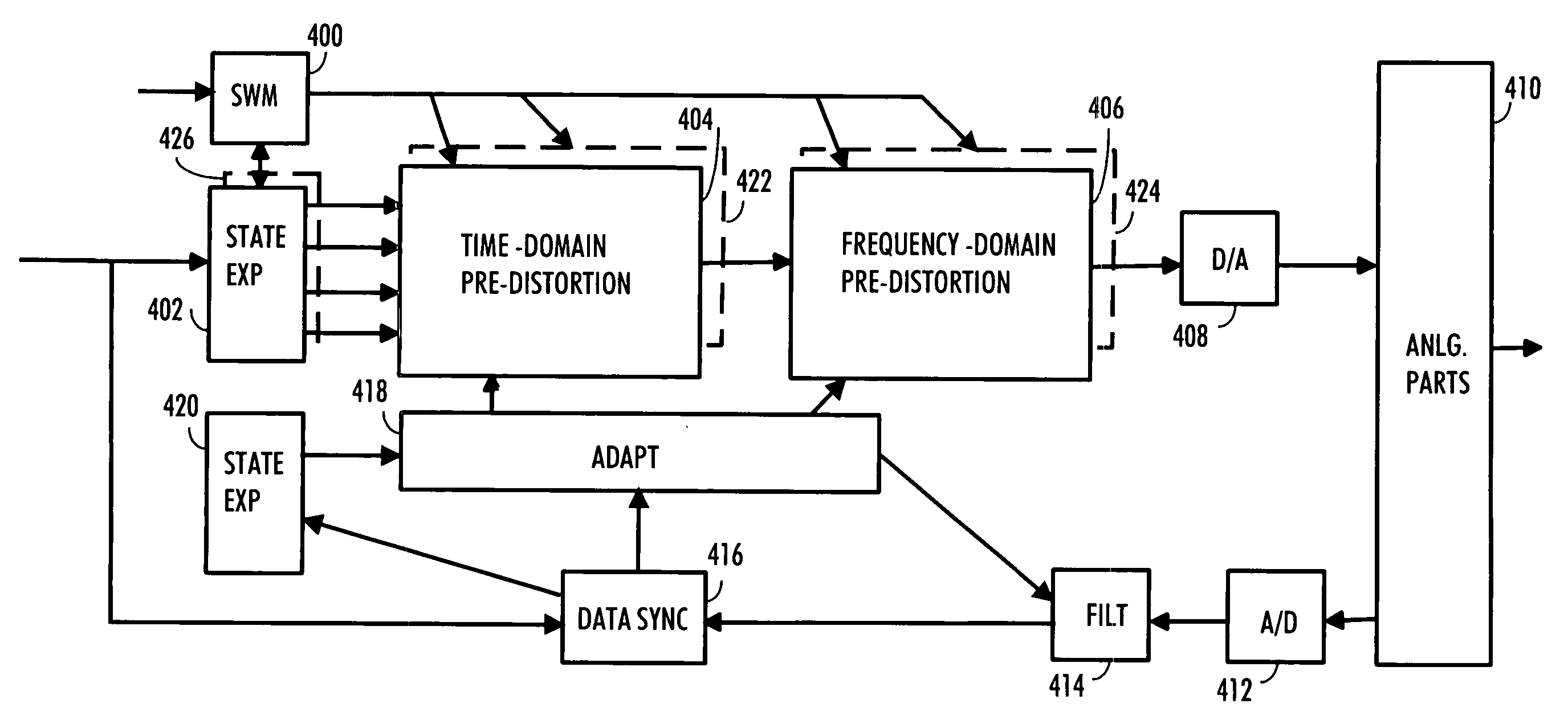

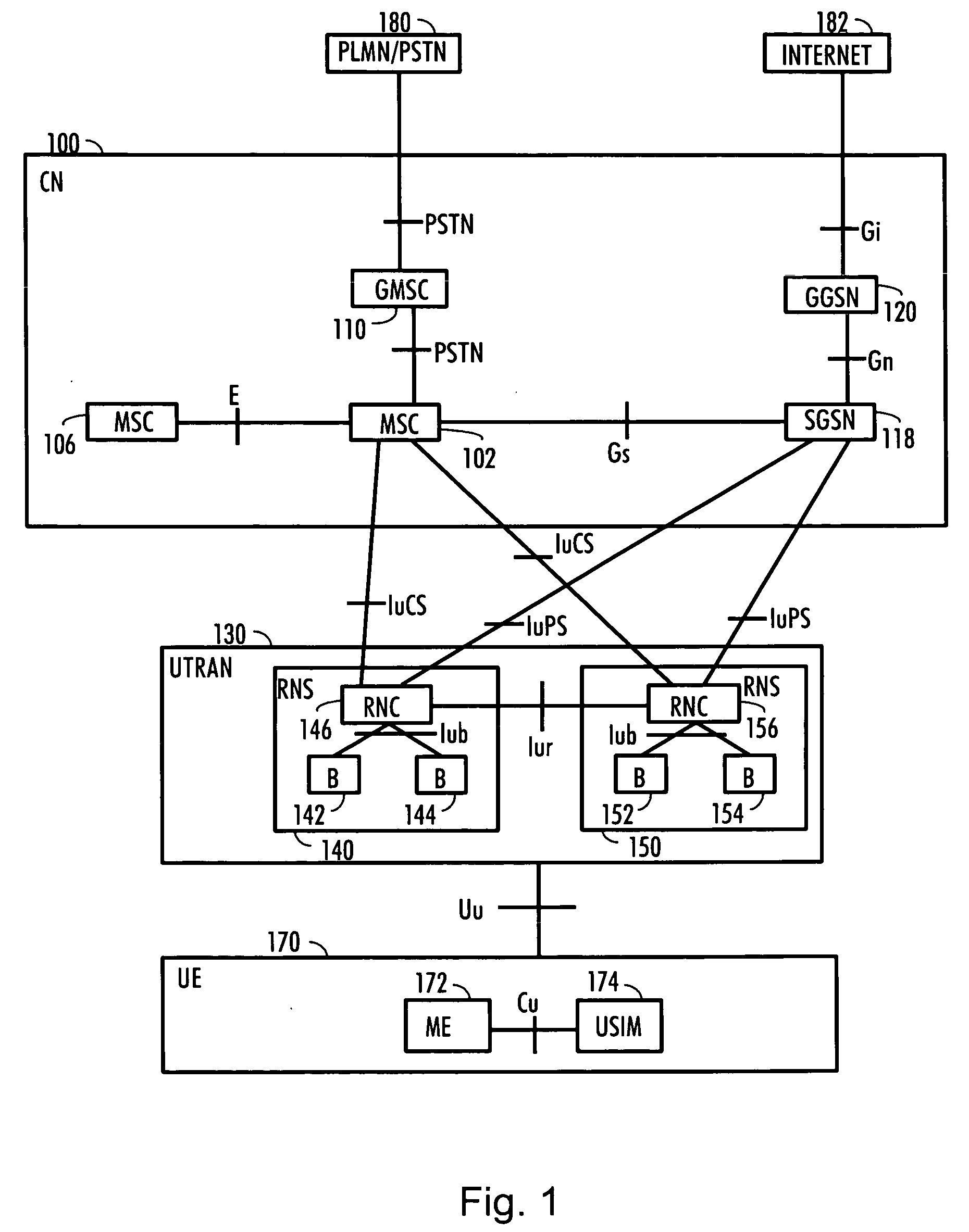

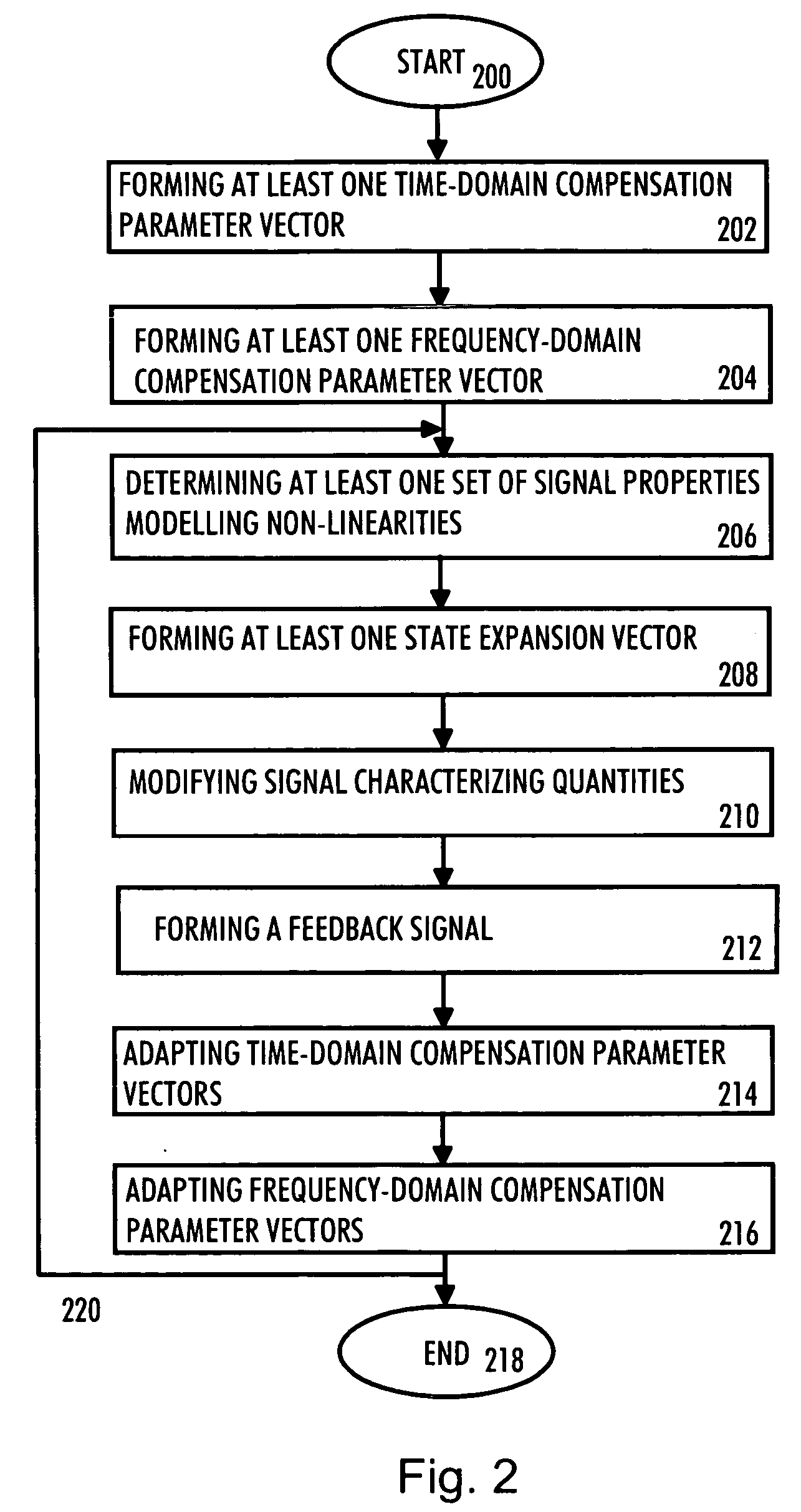

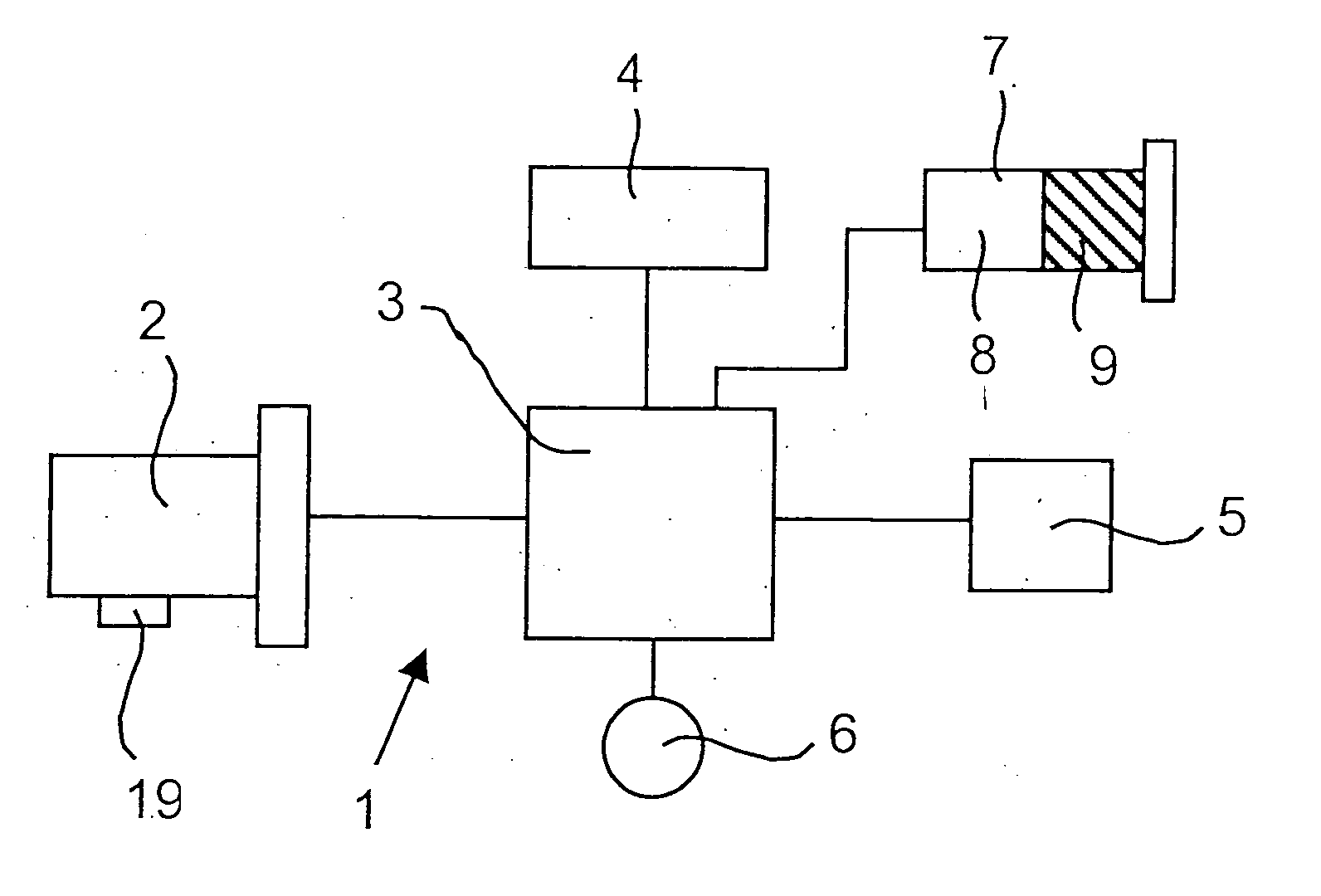

Data transmission method, base station and transmitter for compensating for non-linearities in a transmission chain

InactiveUS20060141955A1Reduce the numberExcellent followingCode division multiplexTransmissionTime domainData transmission

A transmitter compensates for the non-linearities within a transmission chain. The transmitter includes, for instance, a first forming device for forming, on the basis of at least one set of signal properties, at least one state expansion vector comprising quantities characterizing a signal. The transmitter includes a modifier for modifying the signal characterizing quantities of at least one state expansion vector with the at least one time-domain compensation parameter vector and with the at least one frequency-domain compensation parameter vector to form a pre-distorted signal. The transmitter includes a second forming device for forming a feedback signal from an output signal of a transmission chain. The transmitter includes an adapter for adapting at least one time-domain compensation parameter vector for adapting at least one frequency-domain compensation parameter vector based on a residual error between a transmit signal and the feedback signal.

Owner:NOKIA SOLUTIONS & NETWORKS OY

Rotor blade for a compressor or a gas turbine

ActiveUS20070292271A1Relieve pressureExtended service lifeEngine fuctionsBlade accessoriesLeading edgeEngineering

Rotor blade for a compressor or a gas turbine, in particular for a turbojet engine, comprising a suction side and a pressure side, which are joined at their upstream ends by a leading edge and at their downstream ends by a trailing edge for the gases, a platform connecting the suction side and the pressure side to a blade root, and a stiffener formed beneath the downstream part of the platform and including at least one notch or a cut-away in line with the trailing edge, in order to reduce the stresses in the joint region between the aerofoil and the platform.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Teat

ActiveUS20090314737A1Avoidance of closure of the milk channelEasy to fillFeeding-bottlesTeatsEngineeringPacifier

A teat has a main body, a mouthpiece with a suction opening, and at least one milk channel extending from the main body to the suction opening. During use, the mouthpiece has an upper side directed towards a palate of a baby, and a lower side directed towards the baby's tongue. It is designed, on its upper side, with at least two walls, and with at least one air space arranged between said walls. The at least one air space extends separately from the at least one milk channel. The mouthpiece is designed on the upper side in such a way that this at least one air space inflates in the presence of an underpressure. This allows the palate, tongue and teat to interact in a manner that imitates breastfeeding.

Owner:MEDELA HLDG AG

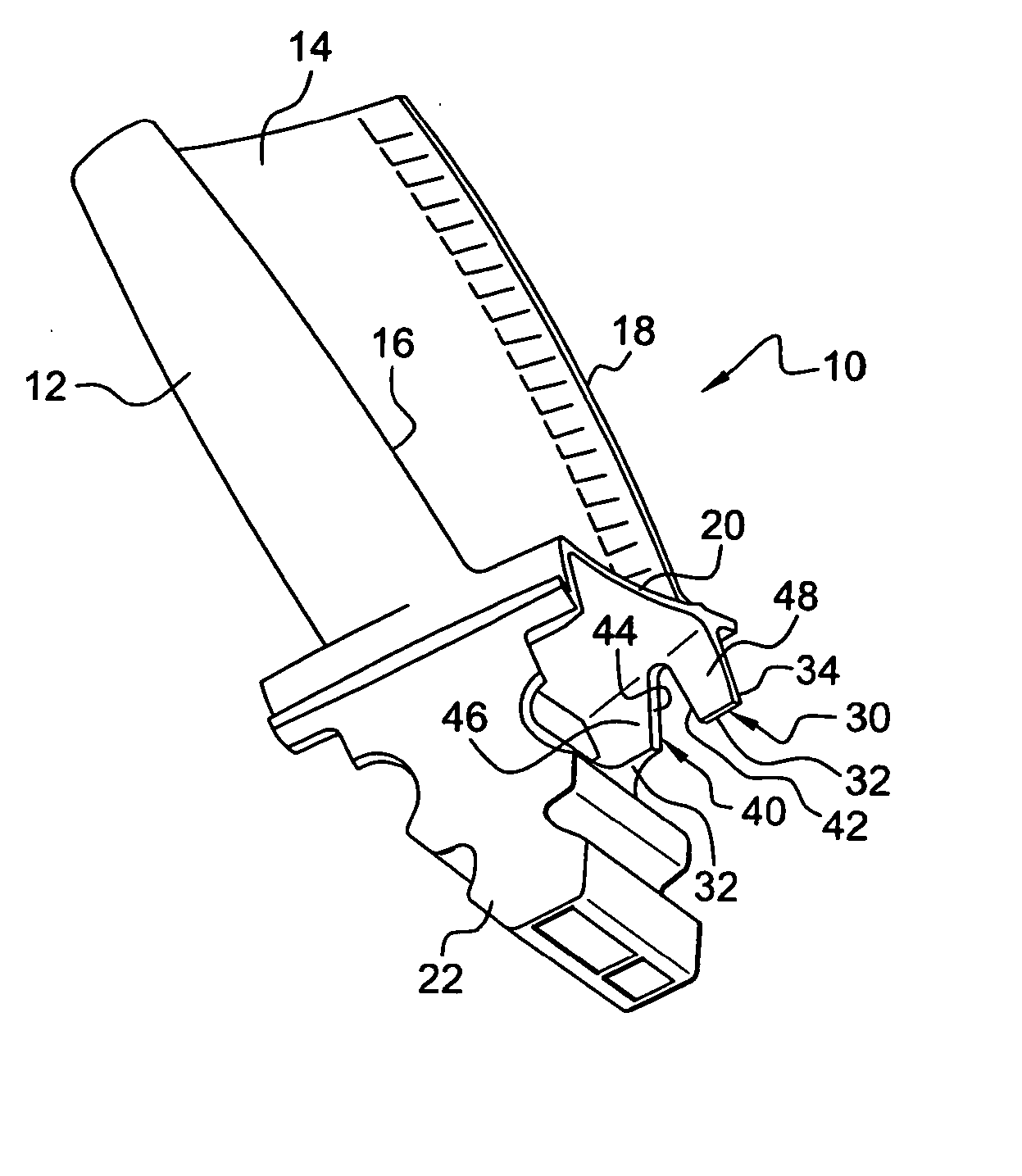

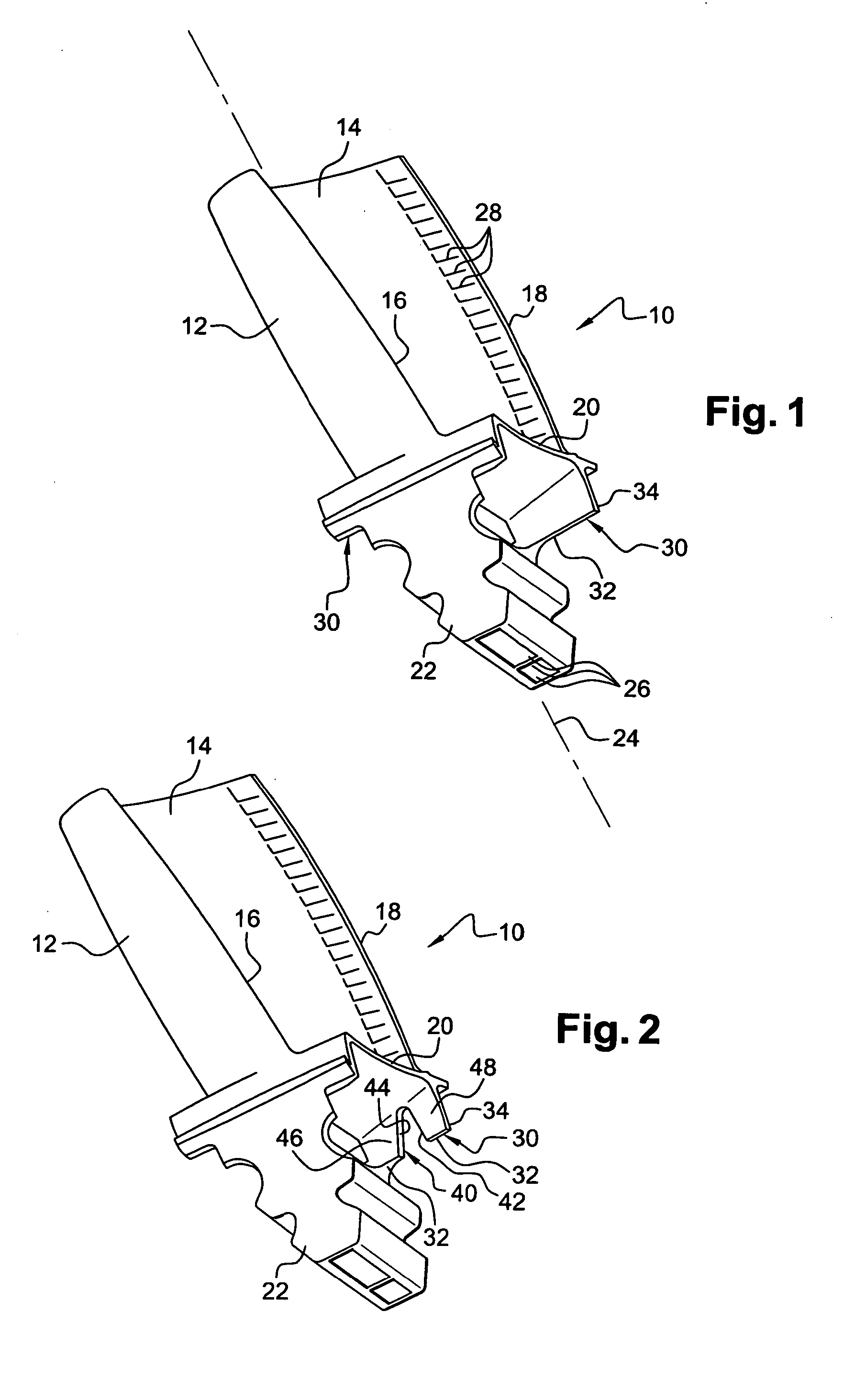

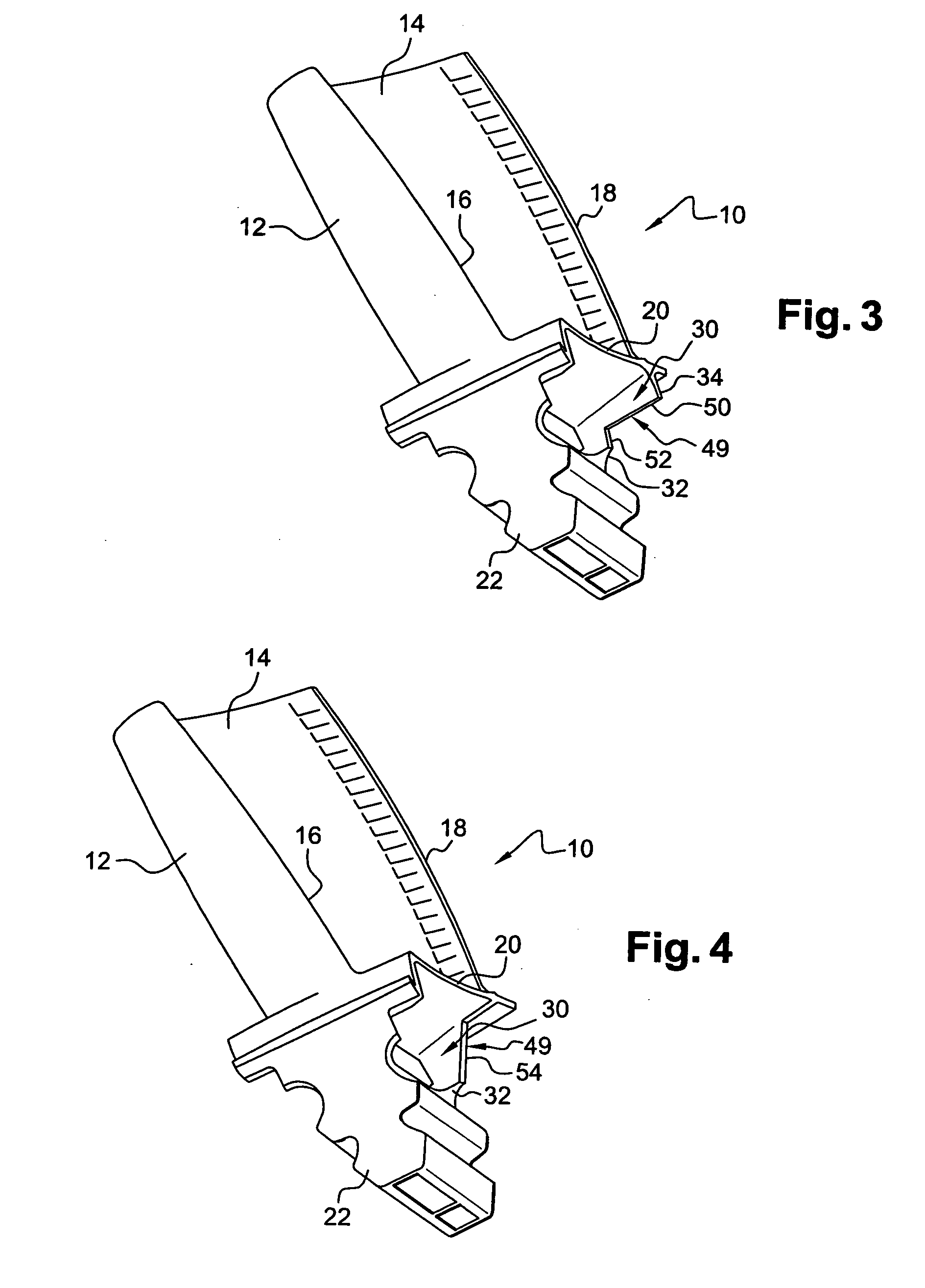

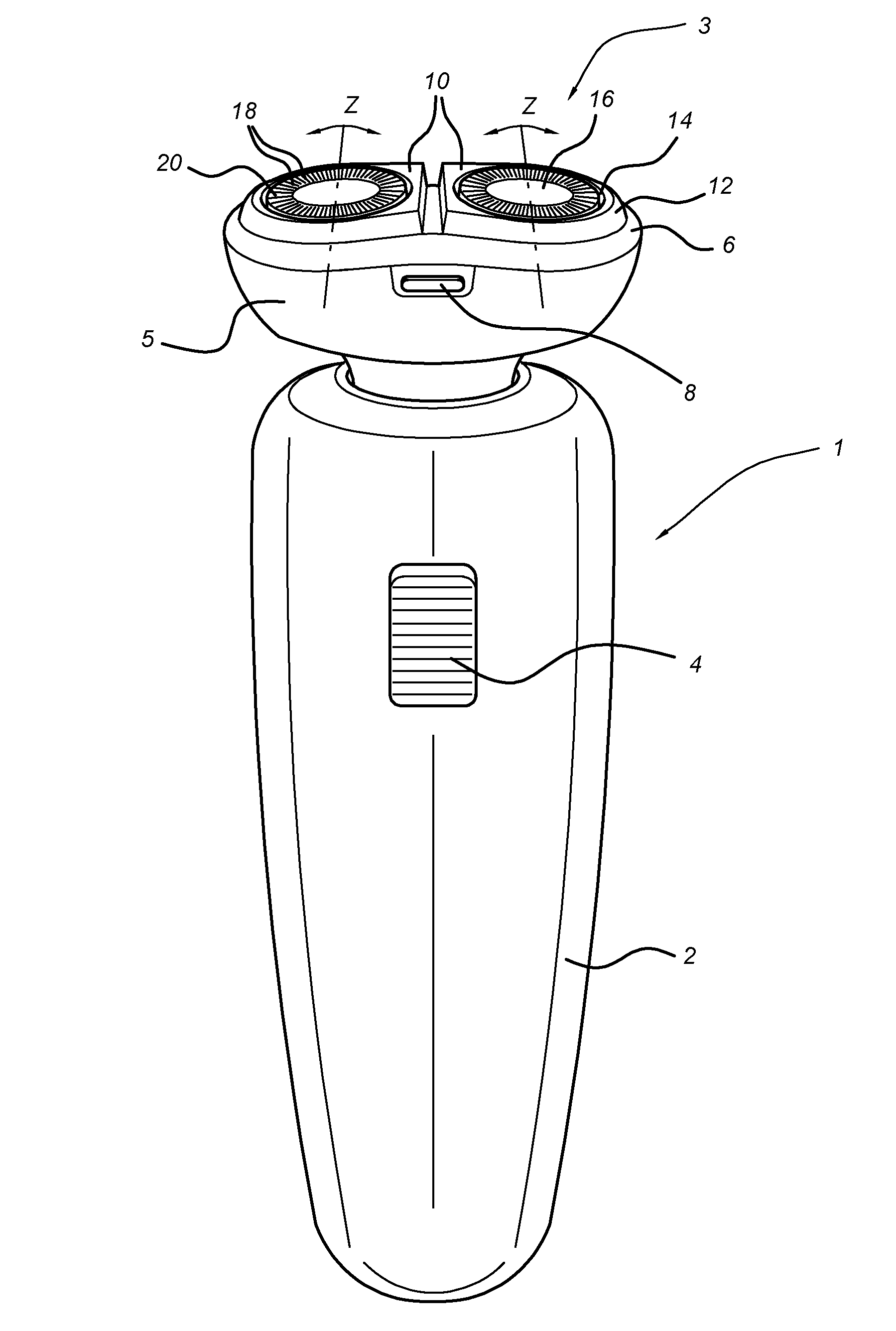

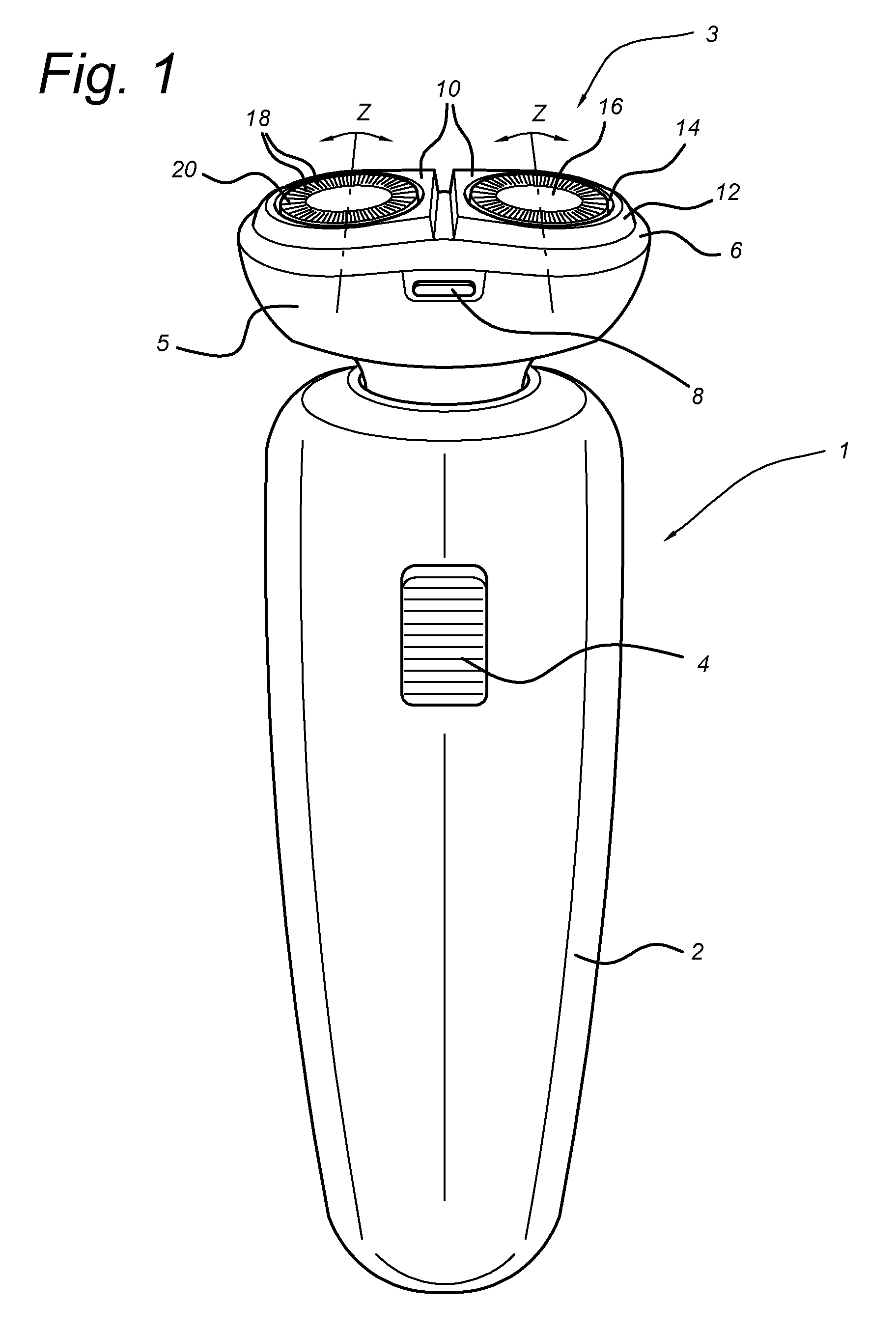

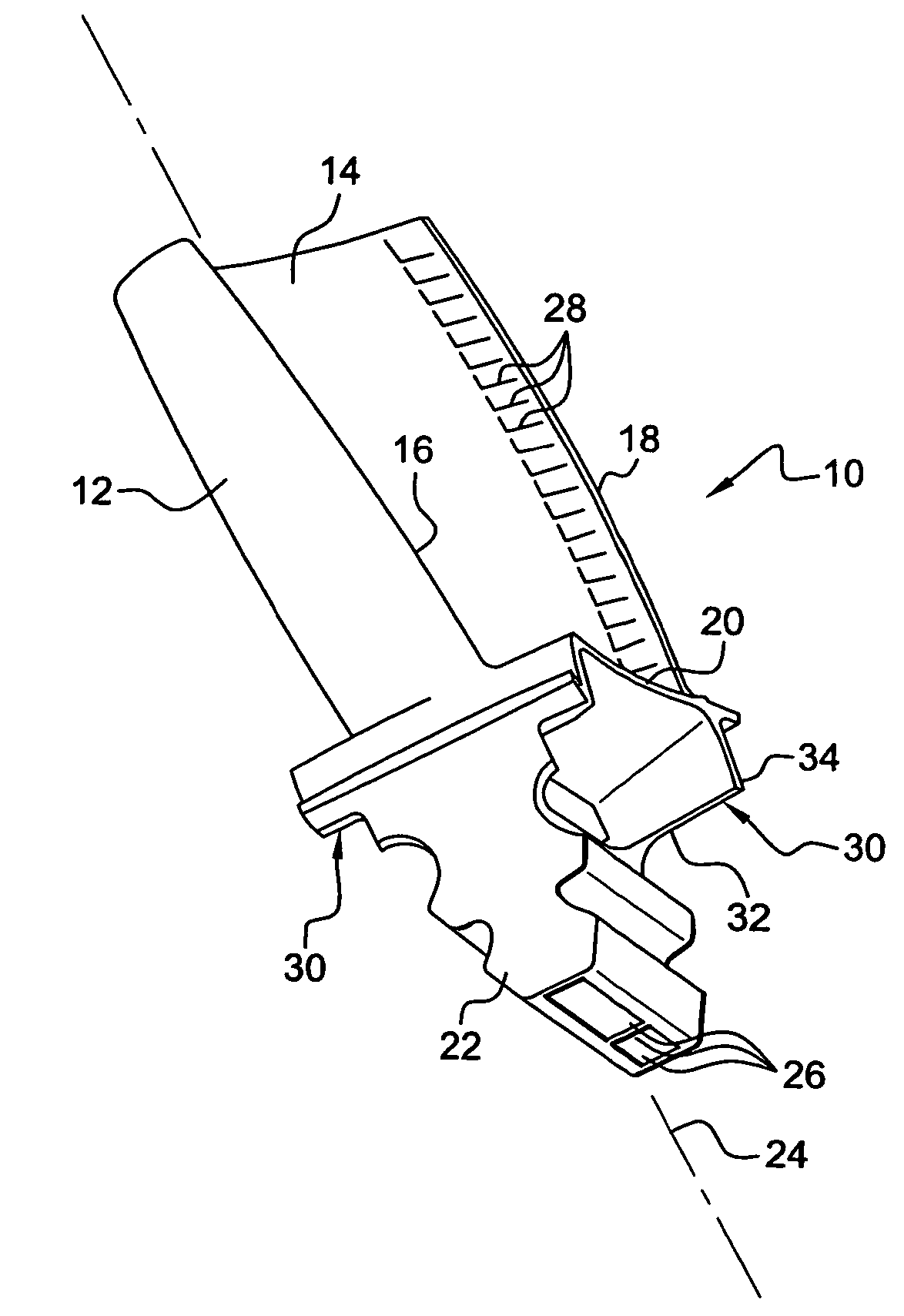

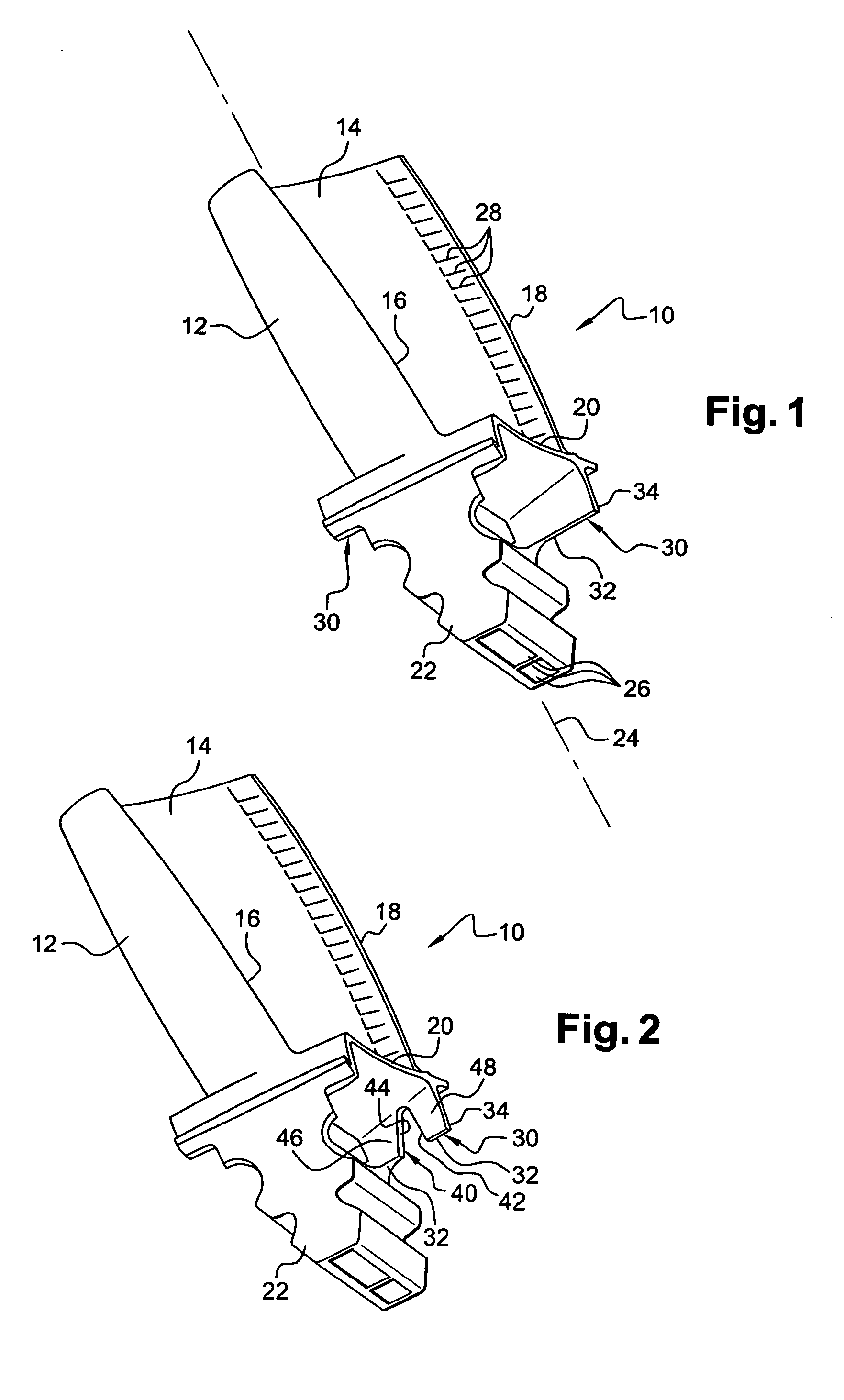

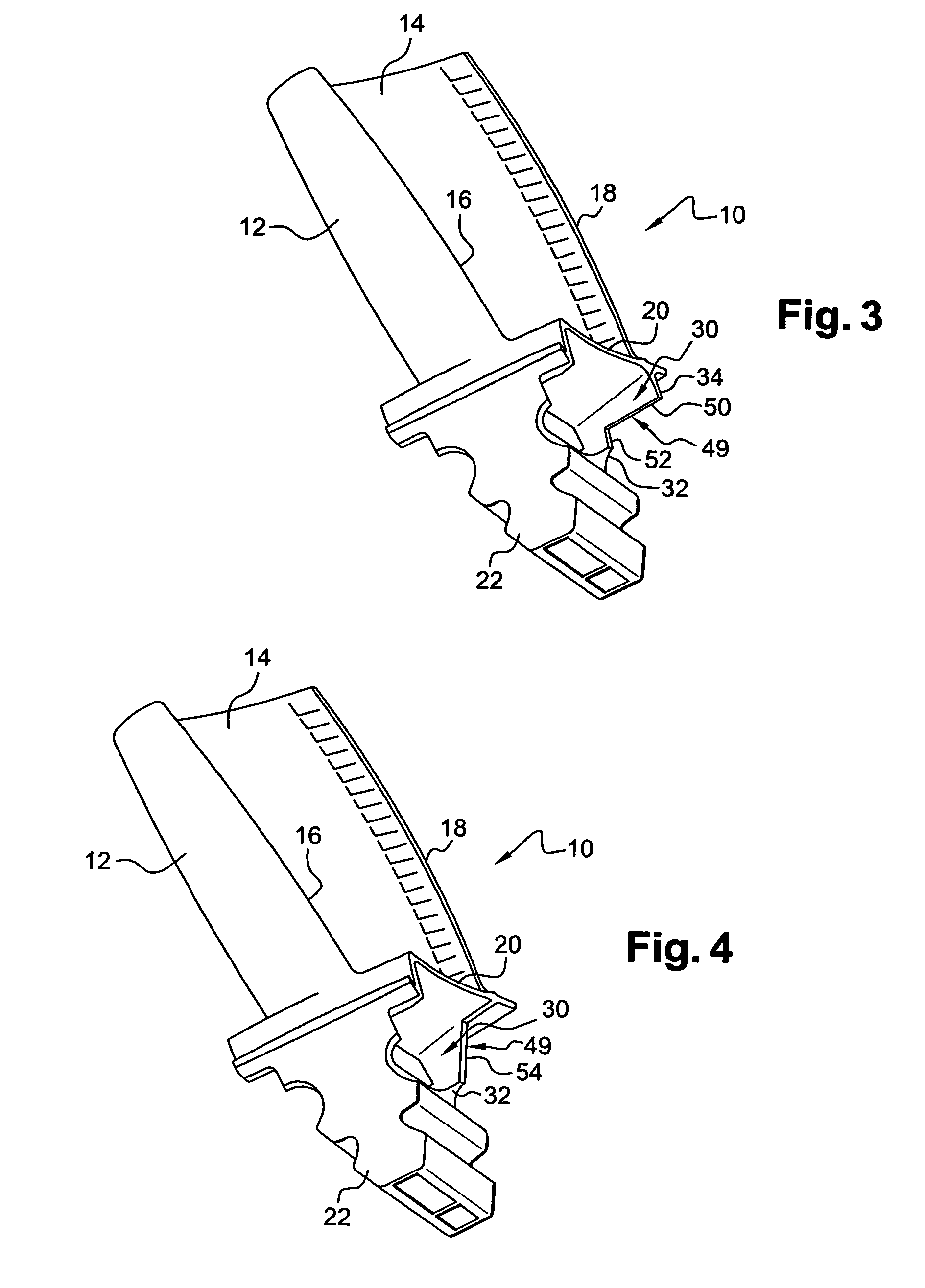

Rotary shaving head having a locking retainer

InactiveUS20150224654A1Easy maintenanceEasy accessMetal working apparatusEngineeringMechanical engineering

A rotary shaving head 3 has at least one cutter unit 10, each cutter unit comprising a cap 16 having an external surface 20 with hair-entry openings 18 for engaging the skin of a user; and a rotary cutter 24 having cutting elements 32 supported by a carrier 26, the rotary cutter being locatable within and rotatable with respect to the cap. The shaving head further comprises: a support member 12 for supporting the cutter unit; and a retainer 30, arranged to engage and lock with the support member by relative rotation therewith and retain the cap and the rotary cutter therebetween, wherein the retainer comprises an annular body 36, 38 defining a drive opening 42, the annular body being provided with one or more holes 40 allowing cut hairs to pass through. The holes are shaped as directional indicators indicating a direction of rotation of the retainer with respect to the support. As a result of the pro posed design, a user can identify the retainer as being a rotational component even though it is located within the support member. In an alternative embodiment, the retainer is provided with gripping formations which are formed as directional indicators.

Owner:KONINKLJIJKE PHILIPS NV

Grip for a sports pole, and a sports pole having such a grip

InactiveUS20060001255A1Improved force transmissionImprove gripSnowboard bindingsSkisAxial transmissionMechanical engineering

A pole, for use in skiing or other sport, of the type that includes a grip handle at its upper end, the handle including a support extending from its side wall and adapted to cooperate with the thumb of a user, so as to constitute an additional mechanism for the axial transmission of forces, by the thumb, when the hand is closed on the handle of the pole.

Owner:SALOMON SA

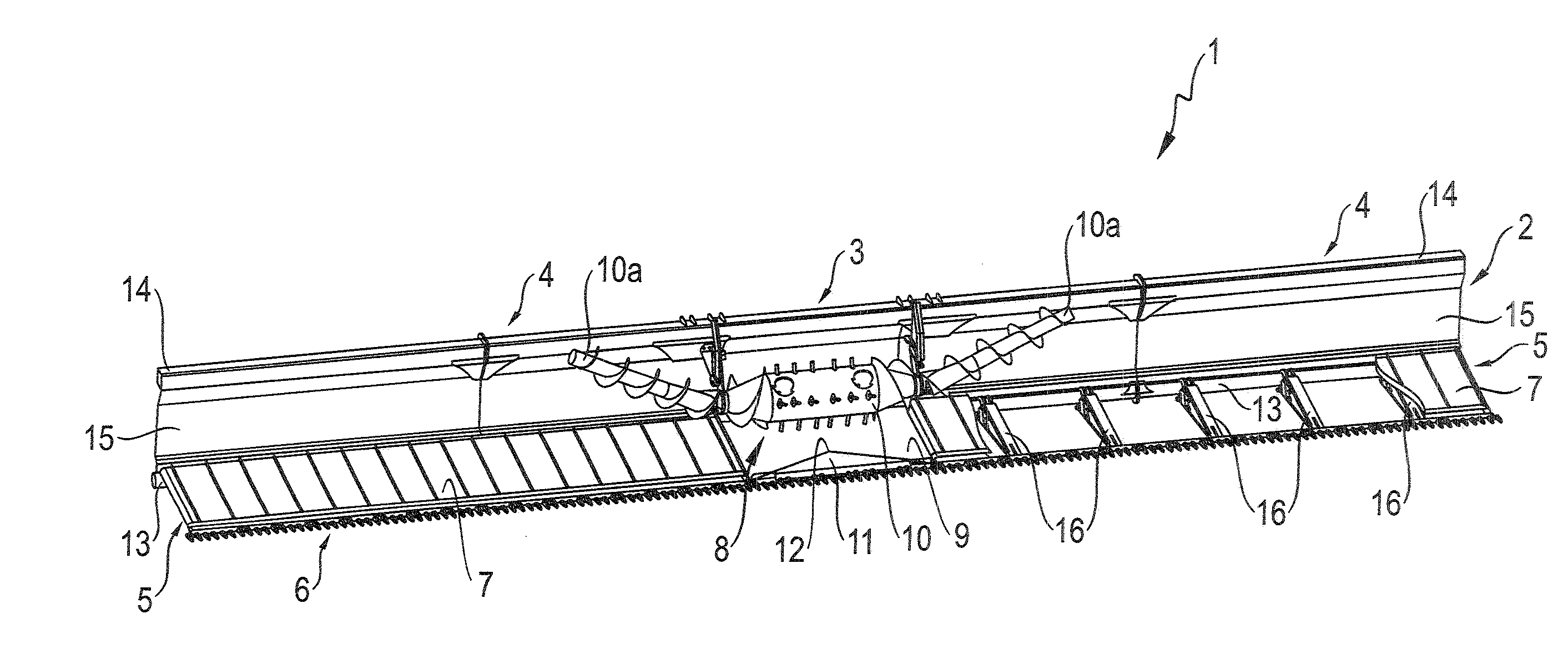

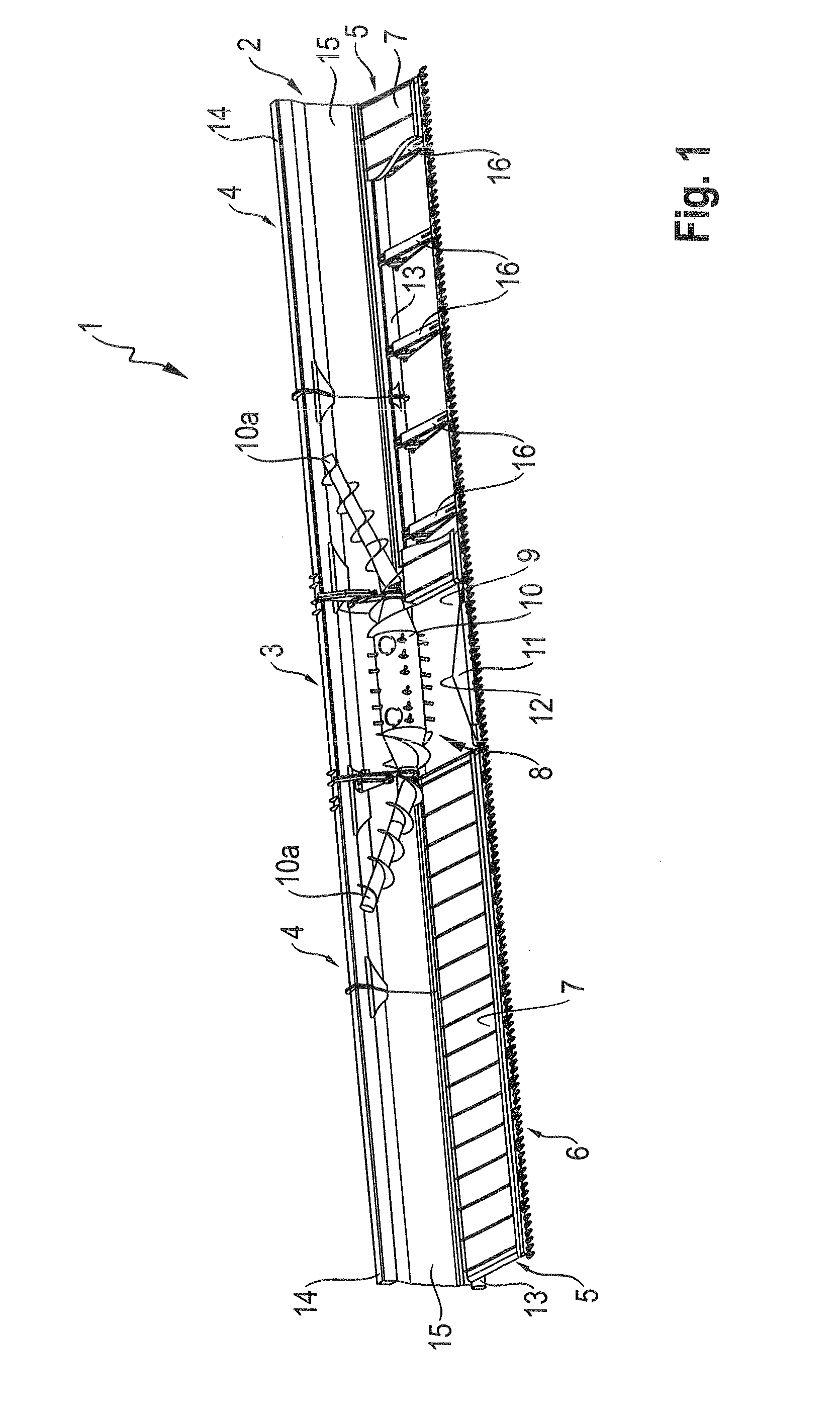

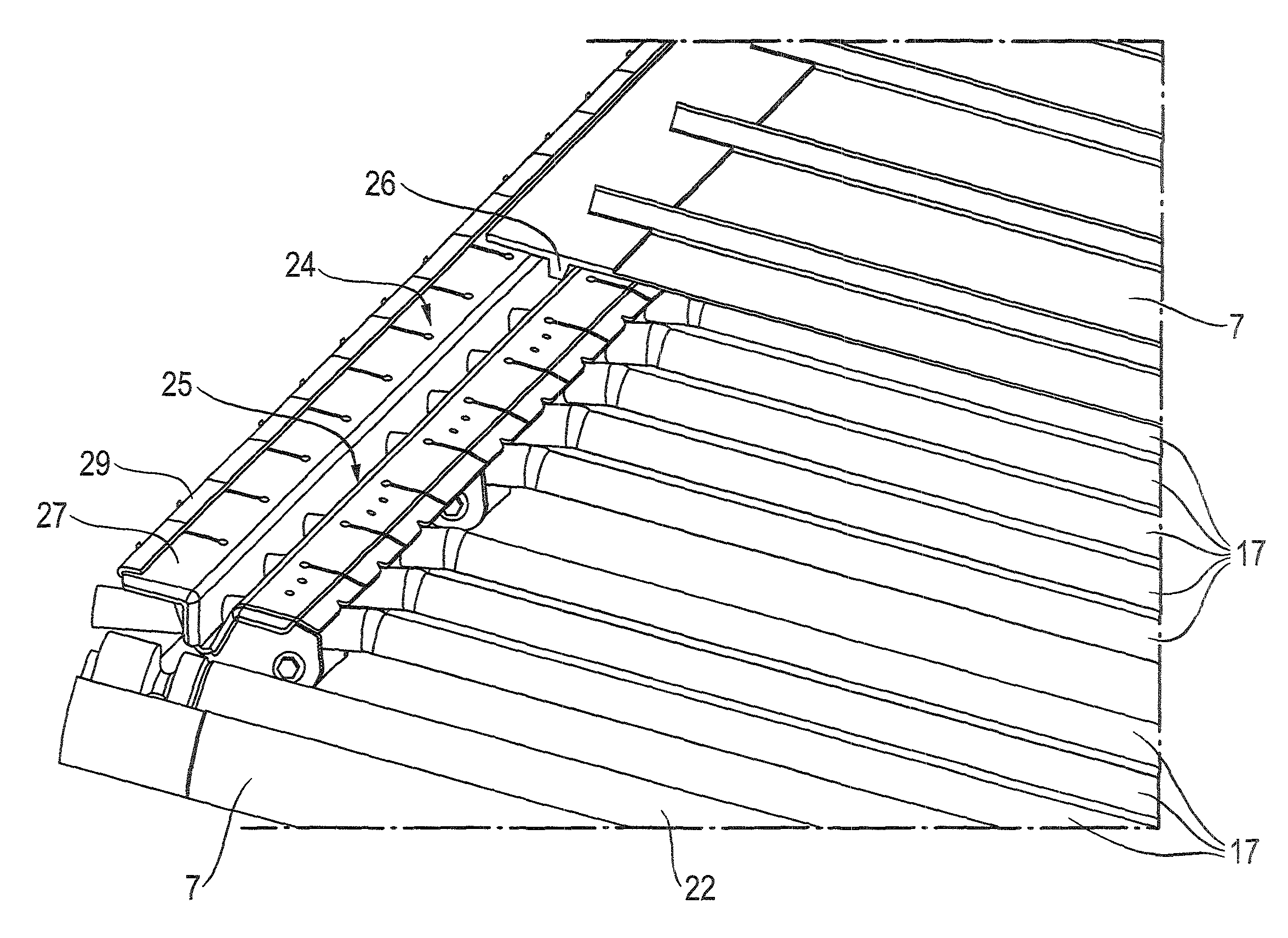

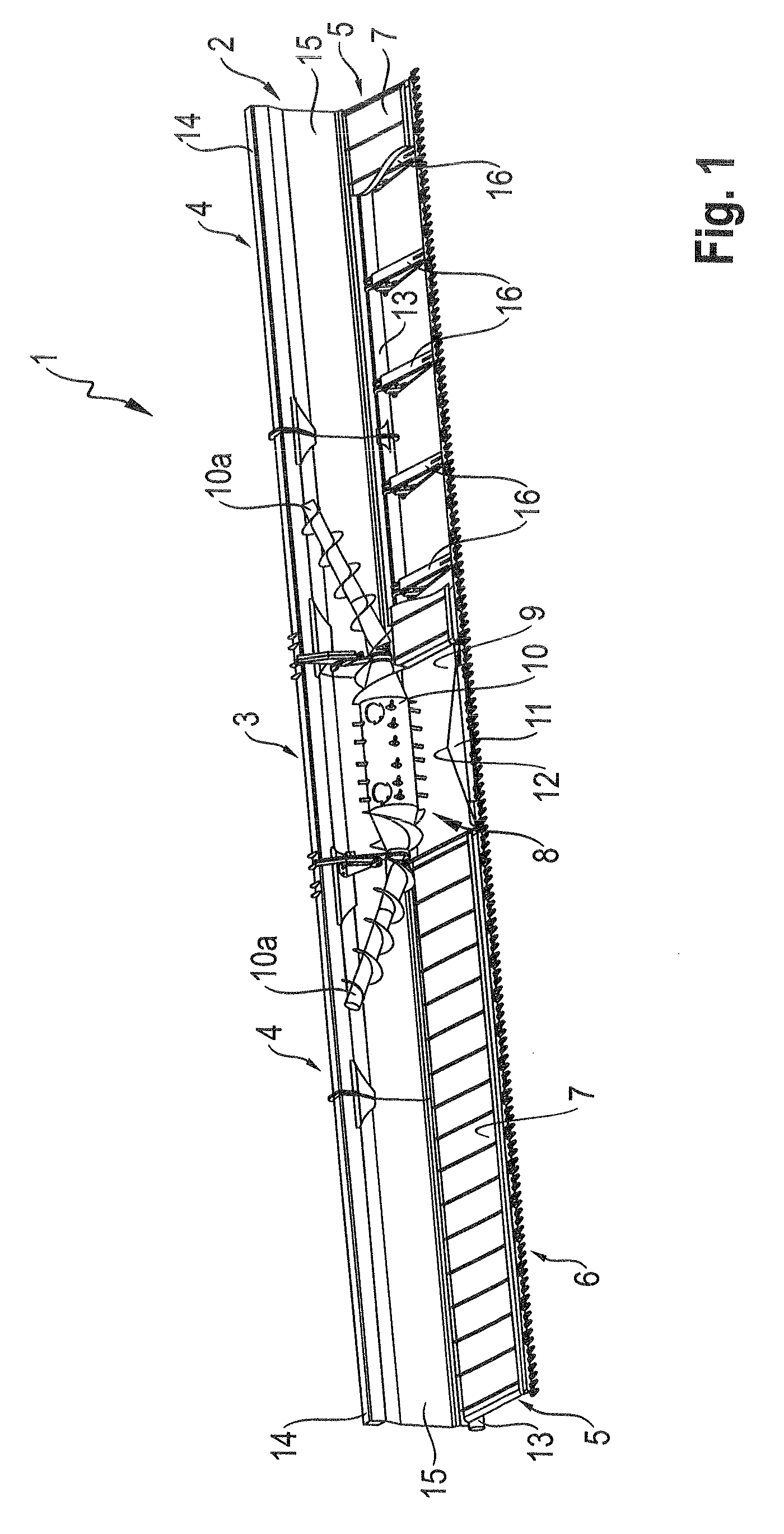

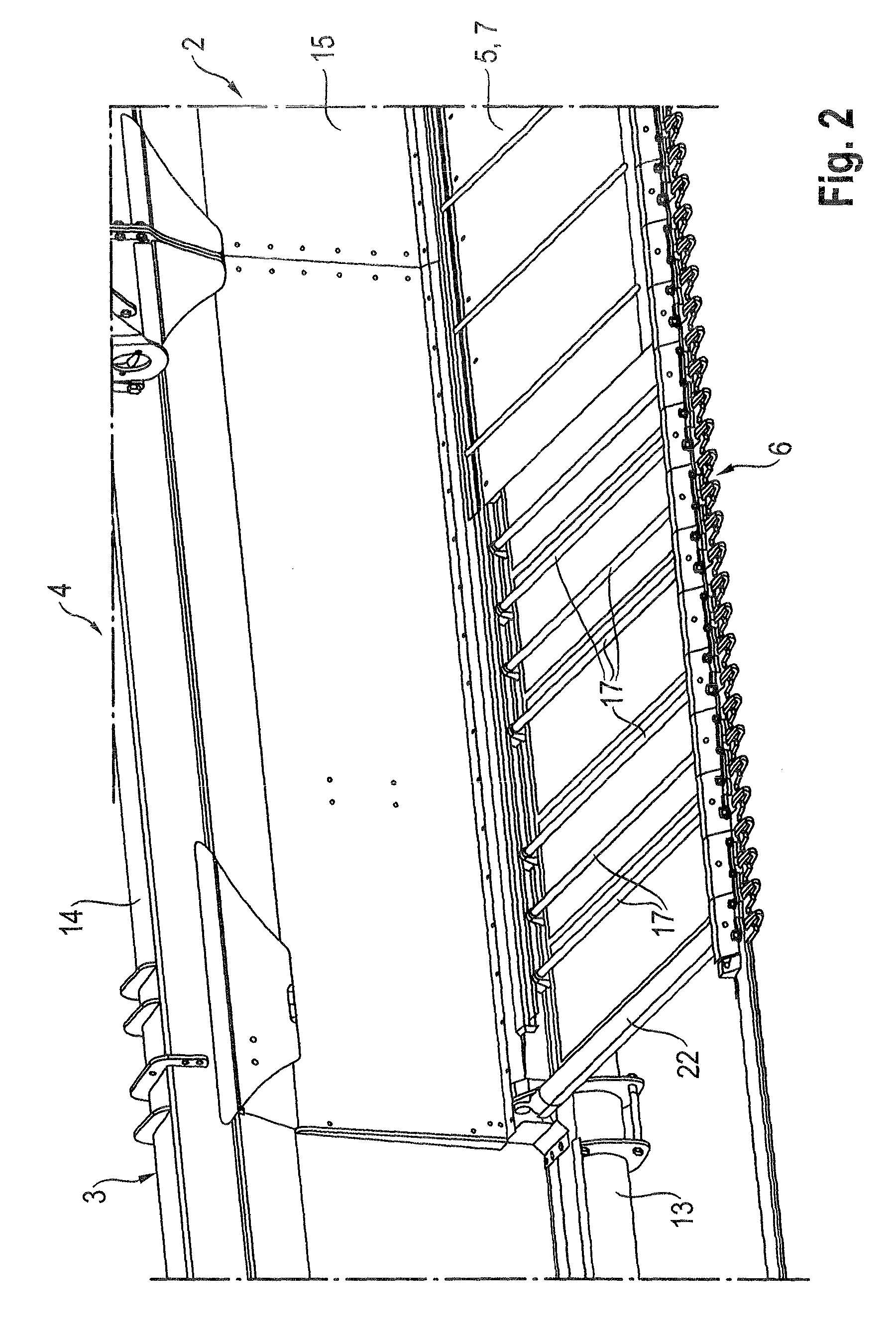

Header with a conveyor belt having conveyor belt supports configured for improved sealability

A header has a middle section disposed on a main frame, at least two side sections adjacent to the middle section, a rear panel extending perpendicularly to the main frame, a flexible finger bar extending across a width of the header and a conveyor device disposed behind the finger bar. The conveyer device is designed on the side sections as a continuous conveyor belt disposed adjacent to the middle section in order to transport crop cut by the finger bar laterally in the direction of the middle section. The side sections are formed as a plurality of supporting arms swivellably disposed on the main frame that support the finger bar. Each side section has a plurality of supporting elements for supporting the conveyor belt. Each of the supporting elements is supported in a bearing point to be displaceable in the axial direction relative to the main frame.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

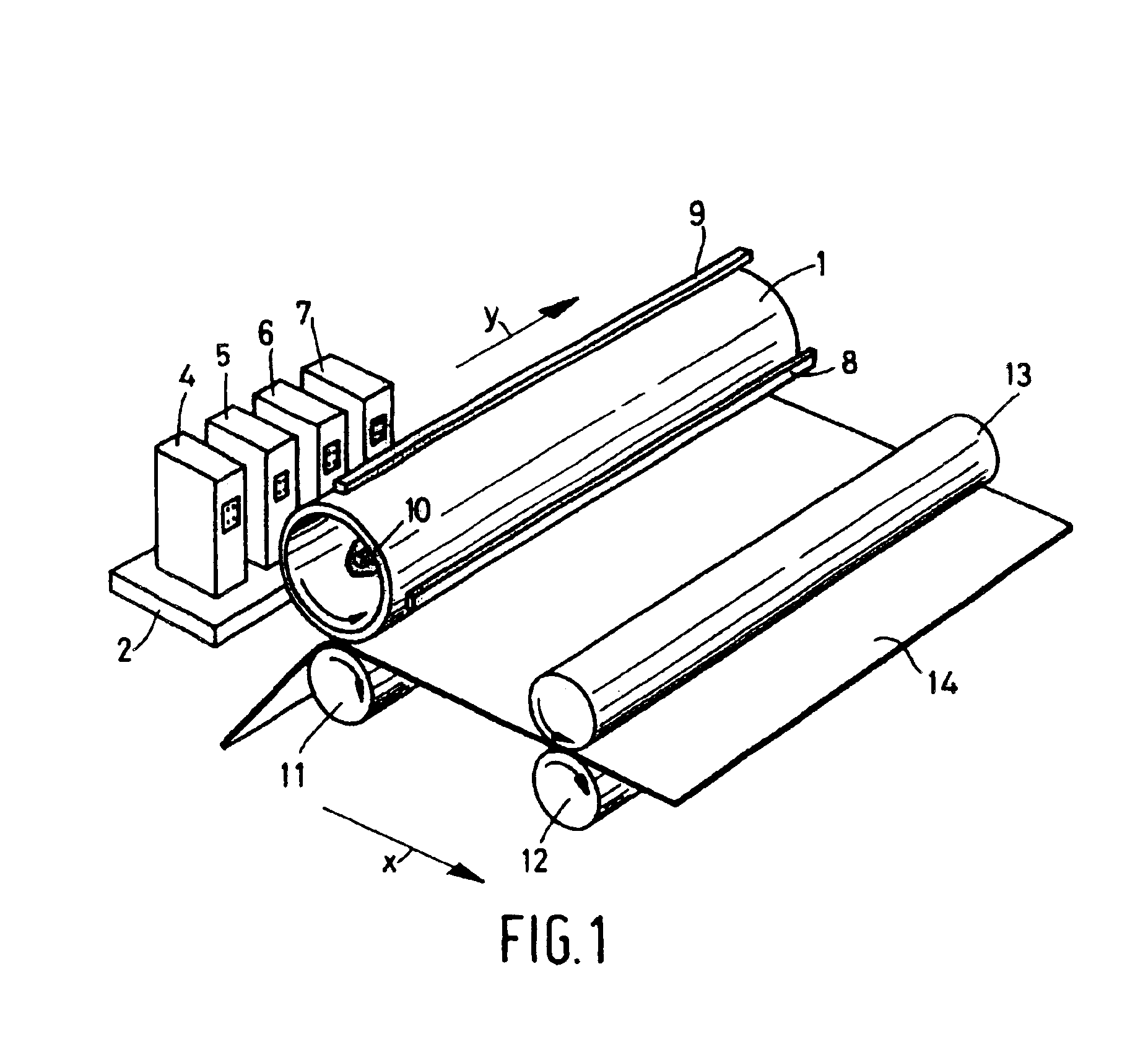

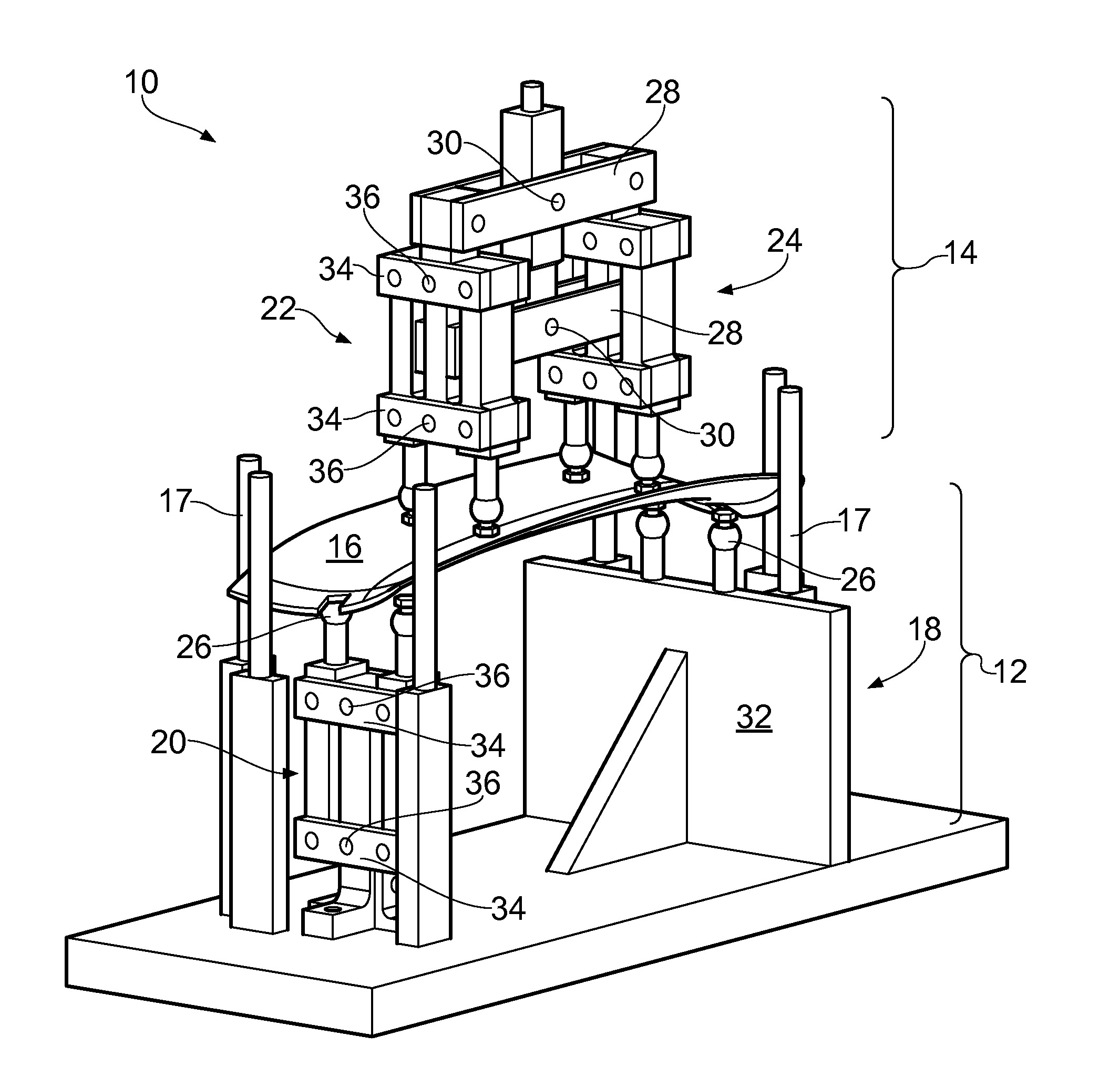

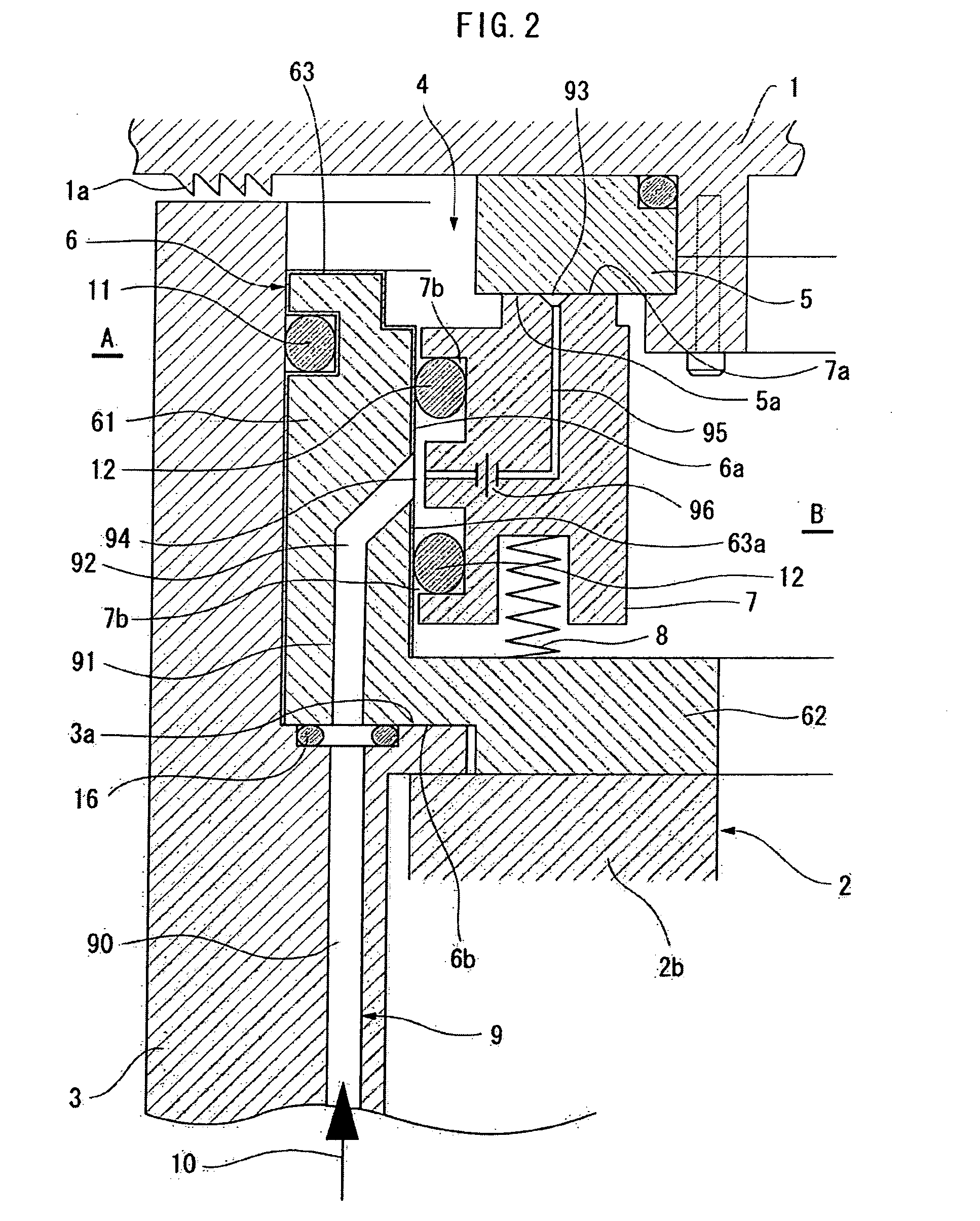

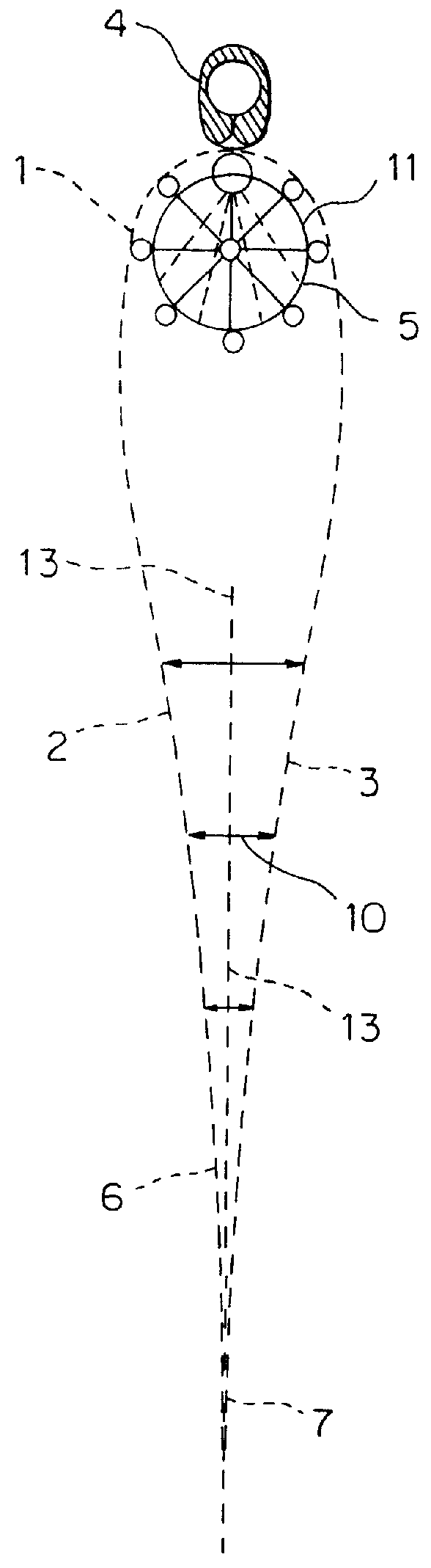

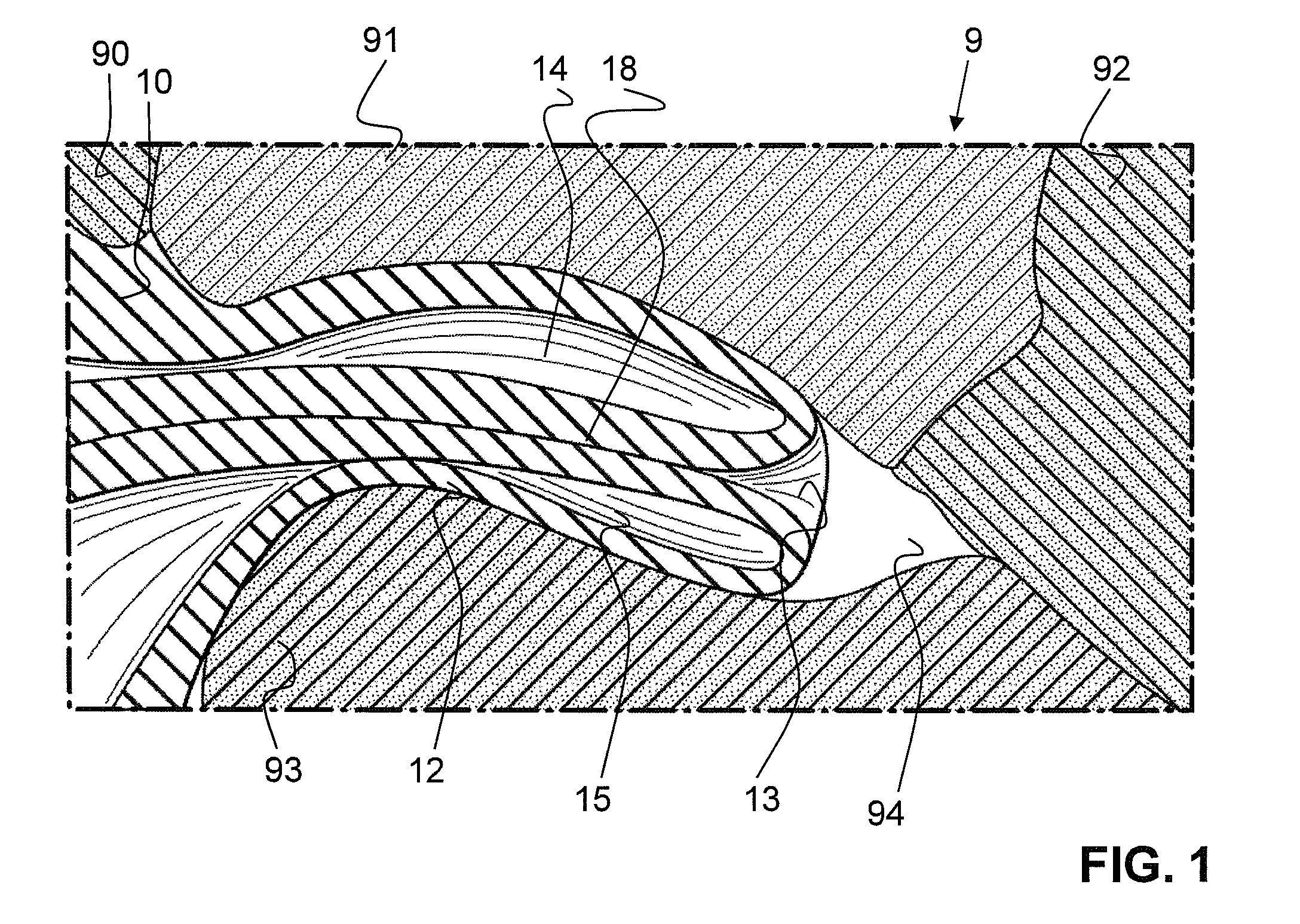

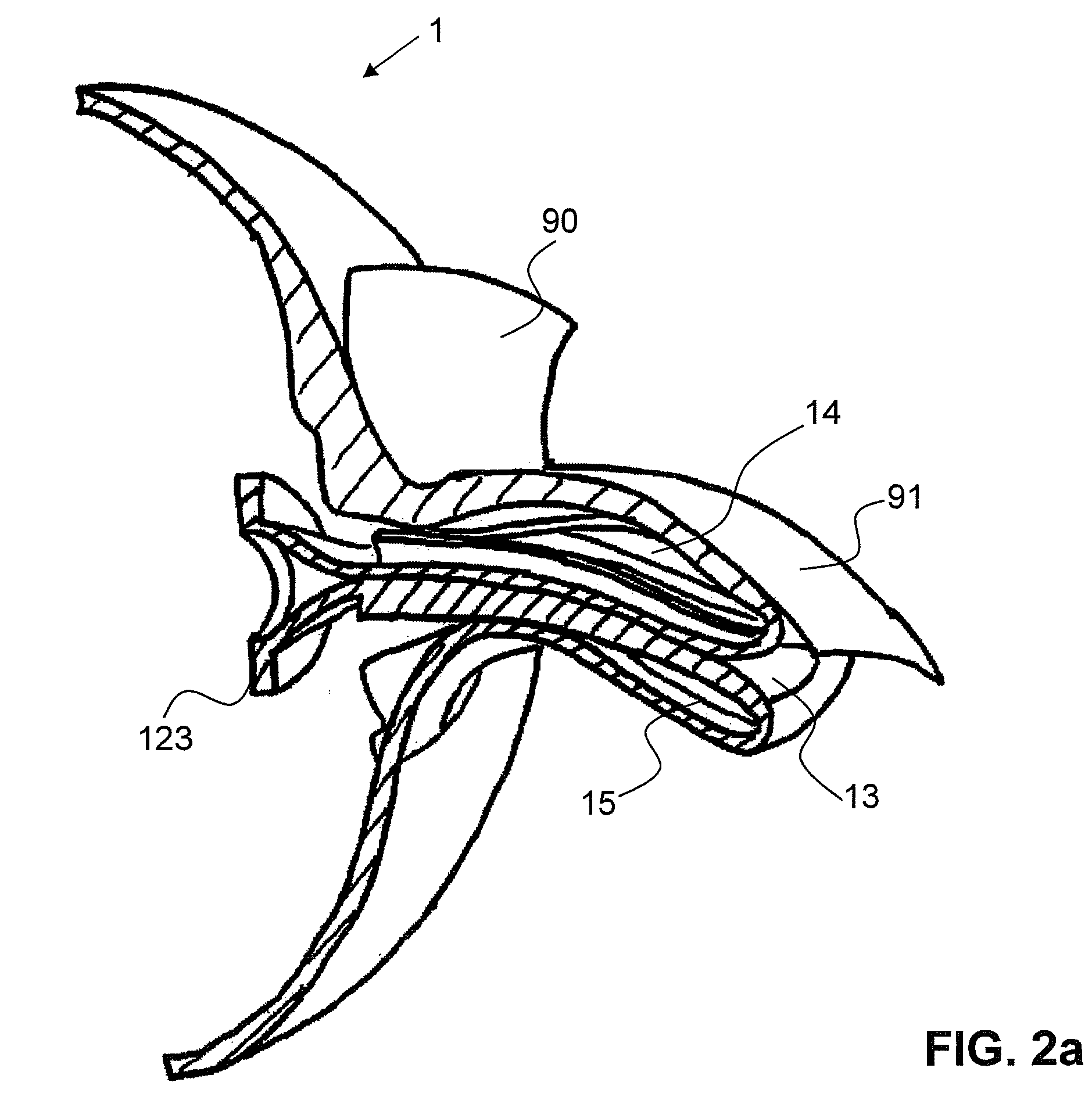

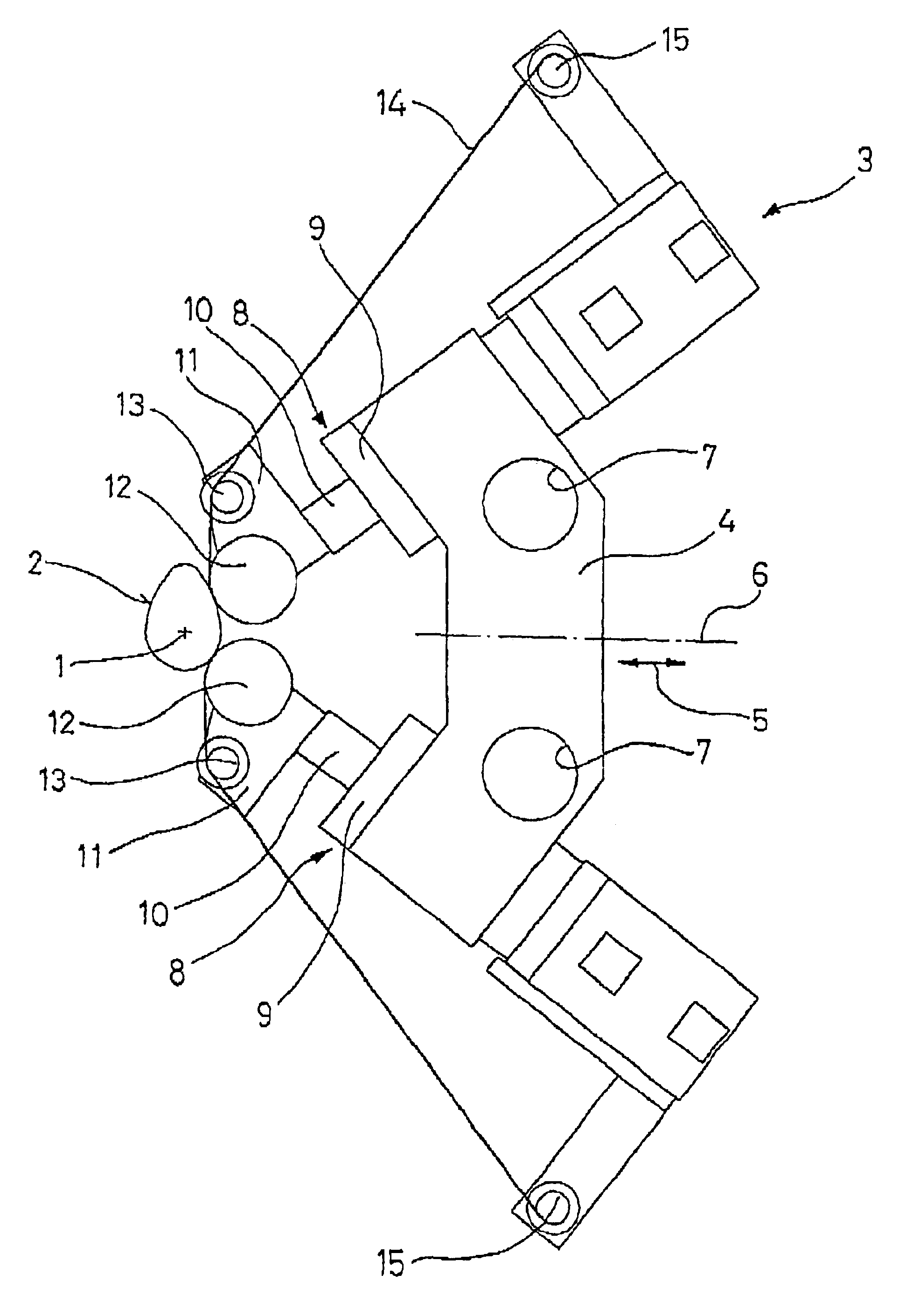

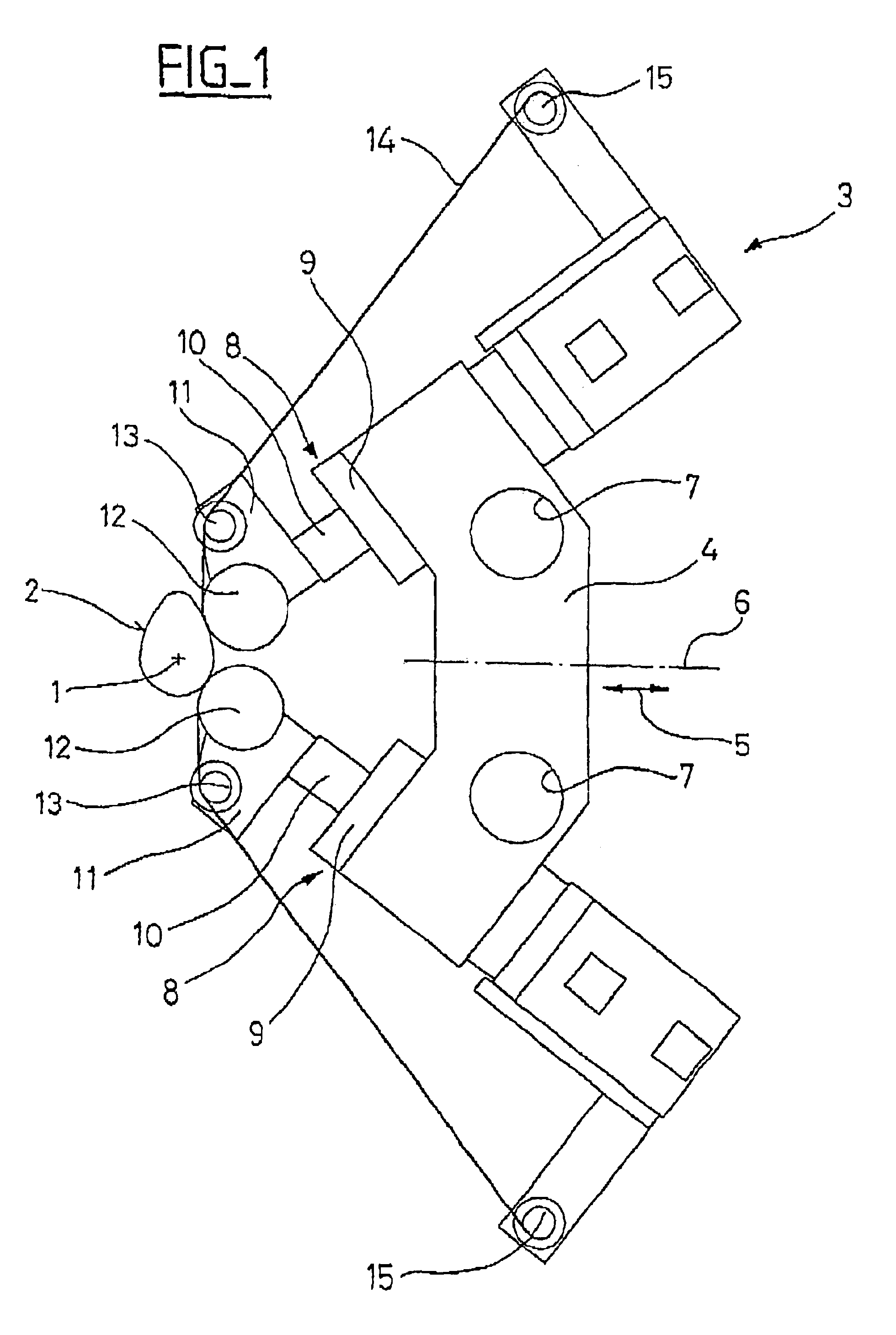

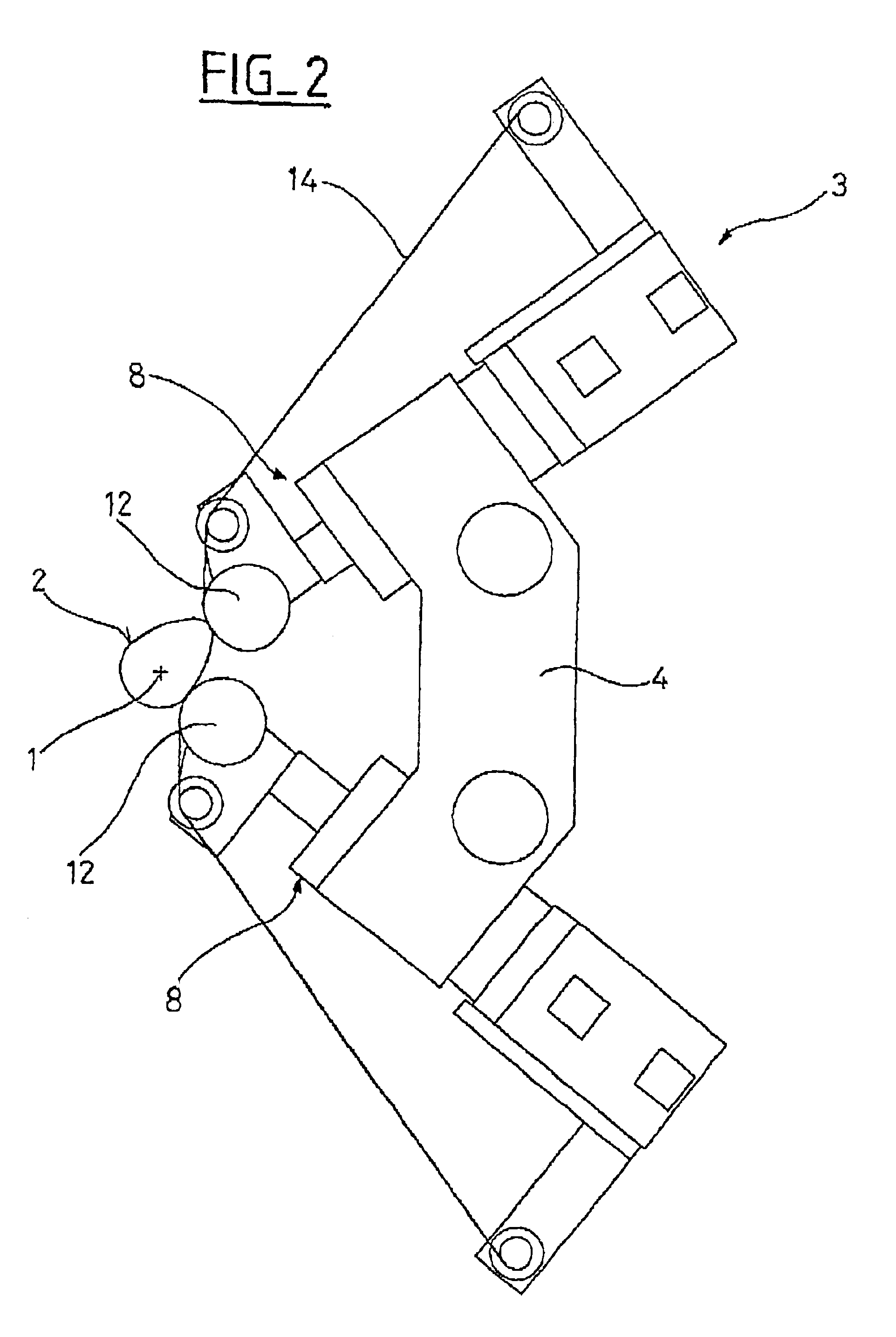

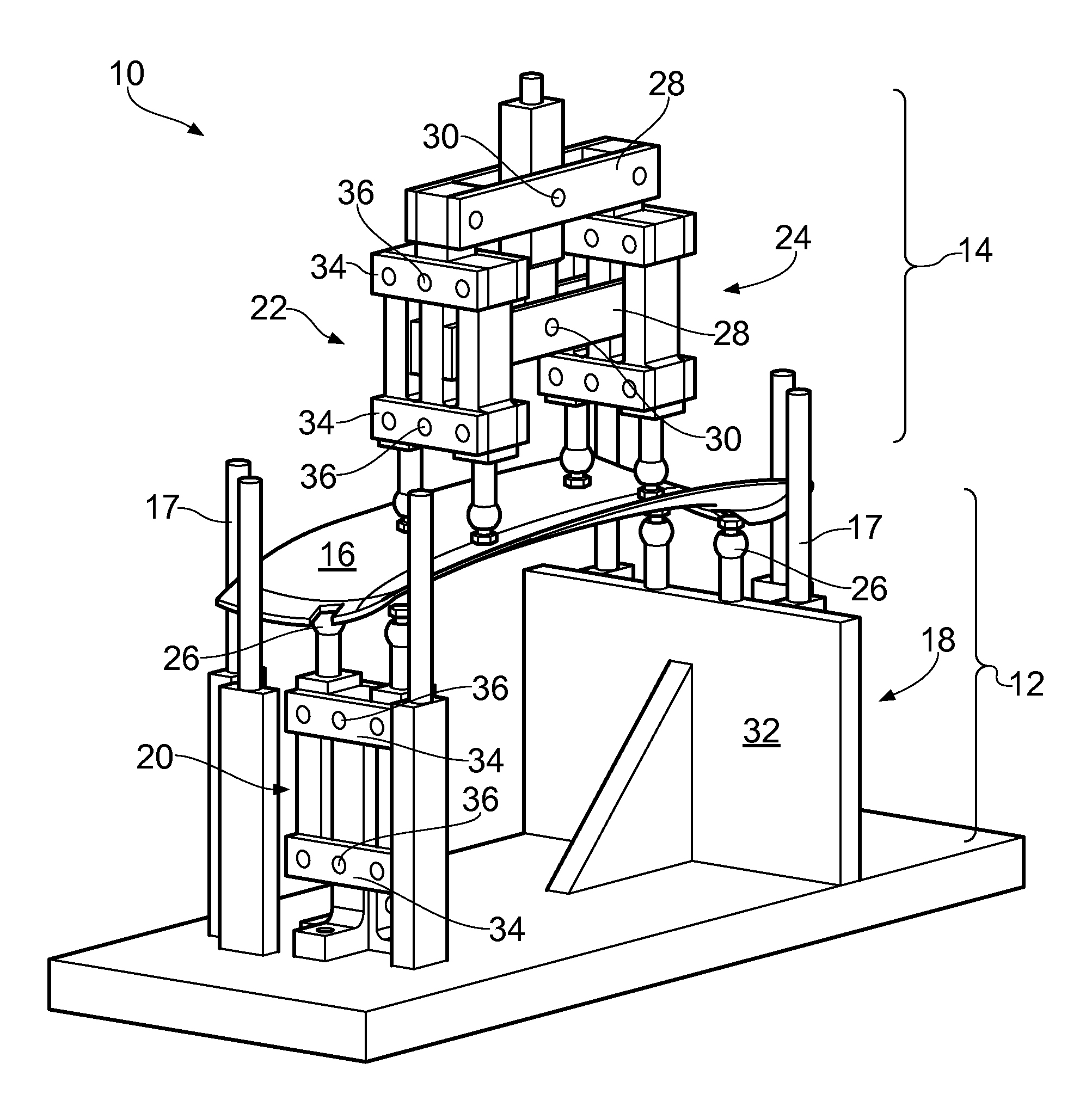

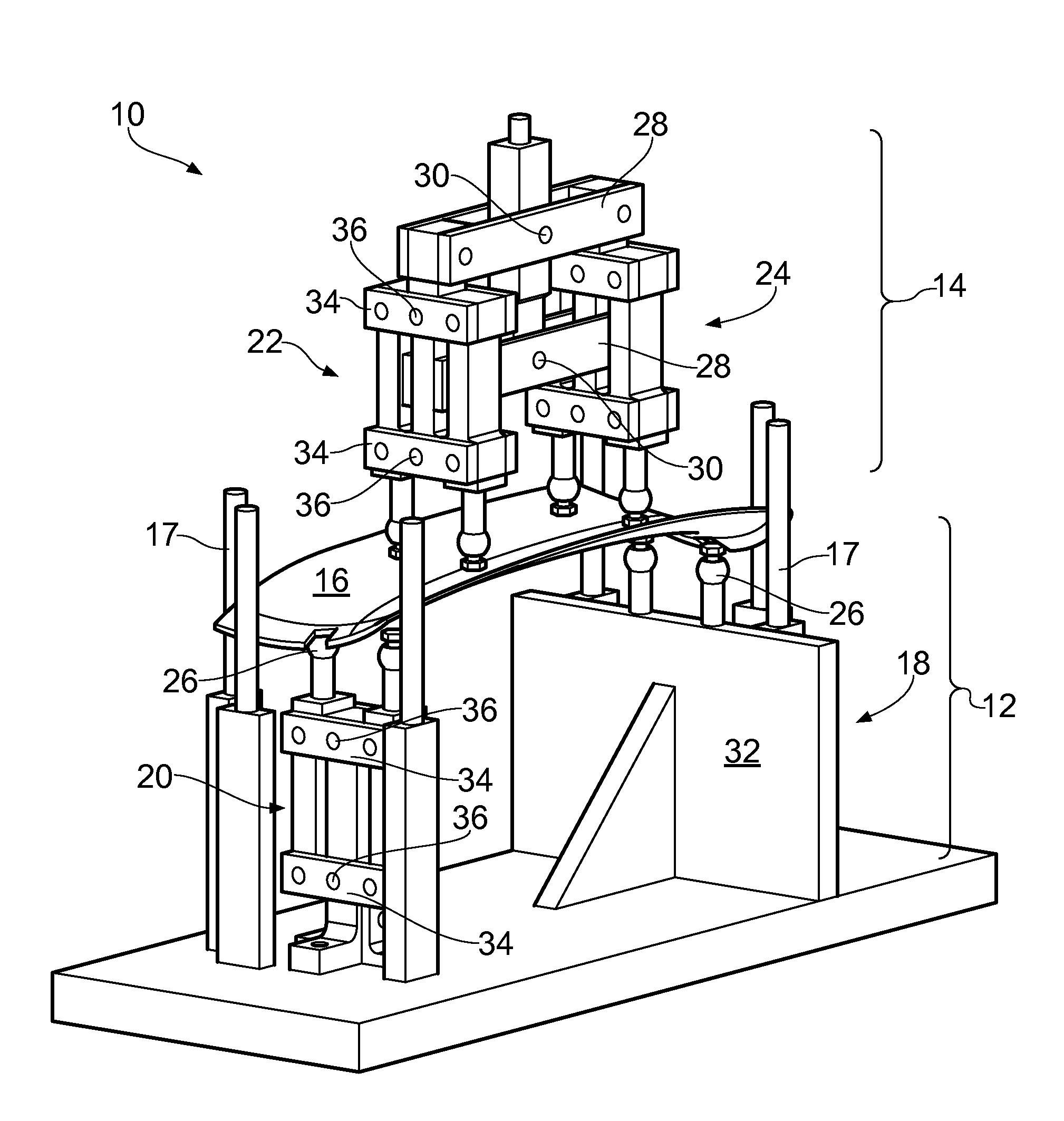

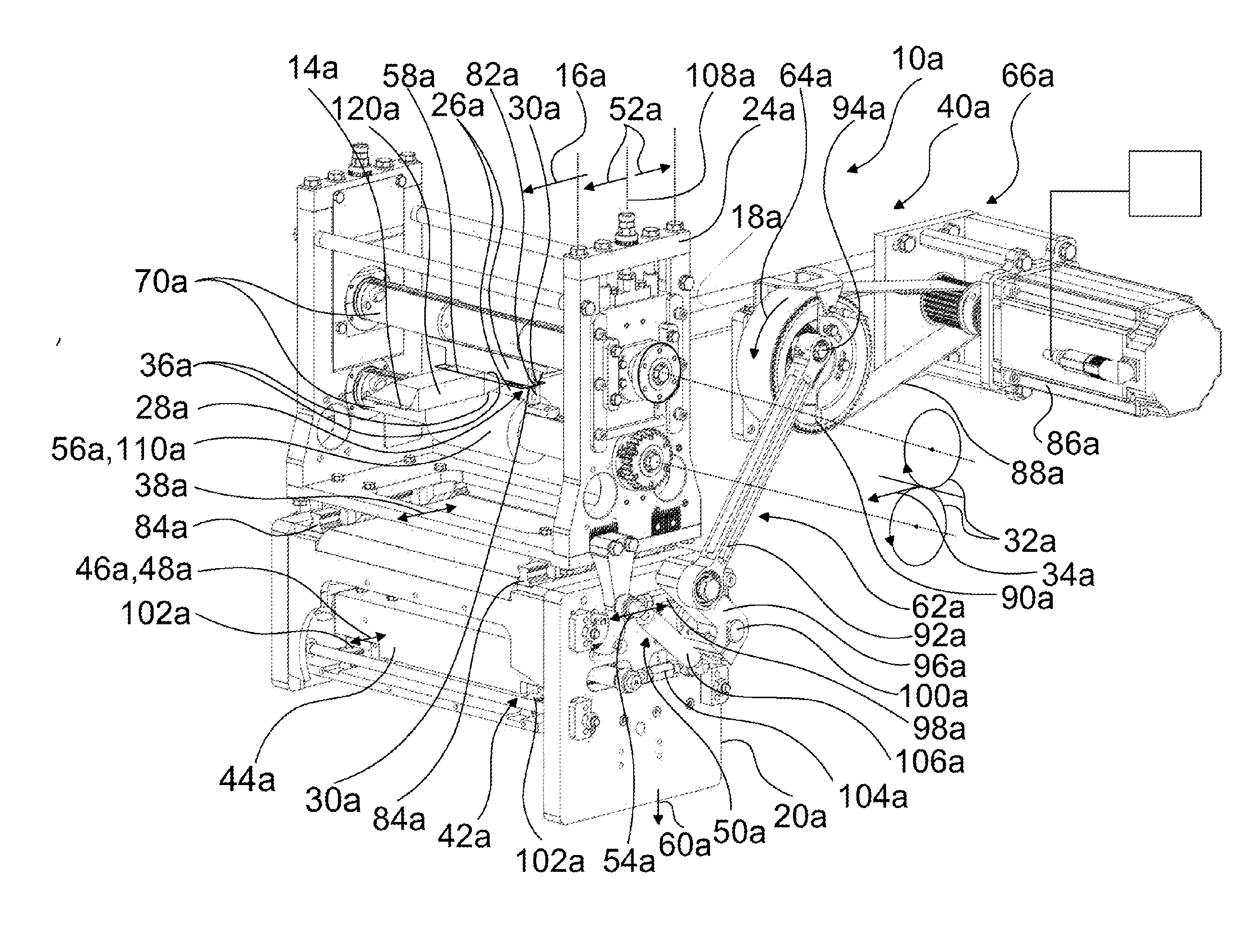

Abrasive belt and machining process associated therewith

InactiveUS6916230B2Excellent followingImprovement speed and quality and consistencyEdge grinding machinesRevolution surface grinding machinesEngineeringBearing surface

A process and device for machining by abrasive belt, on a part 1 with an axis of rotation, of a non-cylindrical bearing surface 2, two portions of the same running abrasive belt 14, which are spaced apart from each other in the longitudinal direction of the belt, using two independent support components 12, preferably activated by two jacks 8 mounted on a common carrier 4, along two contact zones spaced apart angularly around the axis of rotation of the part, are applied against the bearing surface 2. The application is particularly suited for cam surfaces of cam shafts.

Owner:SOC DES PROCEDES & MACHINES SPECIALES

Rotor blade for a compressor or a gas turbine

ActiveUS7399163B2Relieve pressureExtended service lifeEngine fuctionsBlade accessoriesLeading edgeEngineering

Rotor blade for a compressor or a gas turbine, in particular for a turbojet engine, including a suction side and a pressure side, which are joined at their upstream ends by a leading edge and at their downstream ends by a trailing edge for the gases, a platform connecting the suction side and the pressure side to a blade root, and a stiffener formed beneath the downstream part of the platform and including at least one notch or a cut-away in line with the trailing edge, in order to reduce the stresses in the joint region between the aerofoil and the platform.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Apparatus for four-point bend testing

ActiveUS9354151B2Uniform applicationConveniently balancedMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesFour point flexural testEngineering

Owner:ROLLS ROYCE PLC

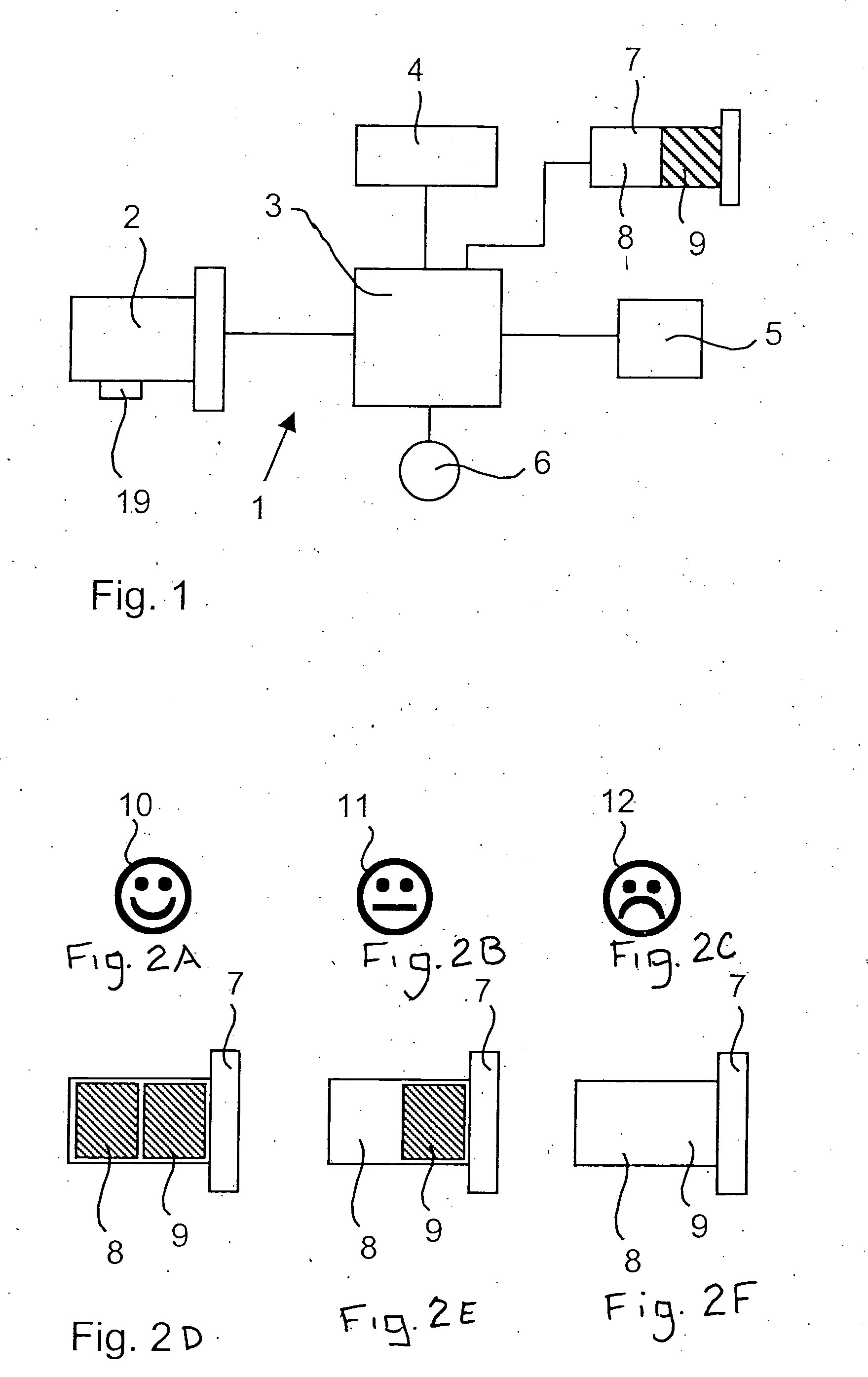

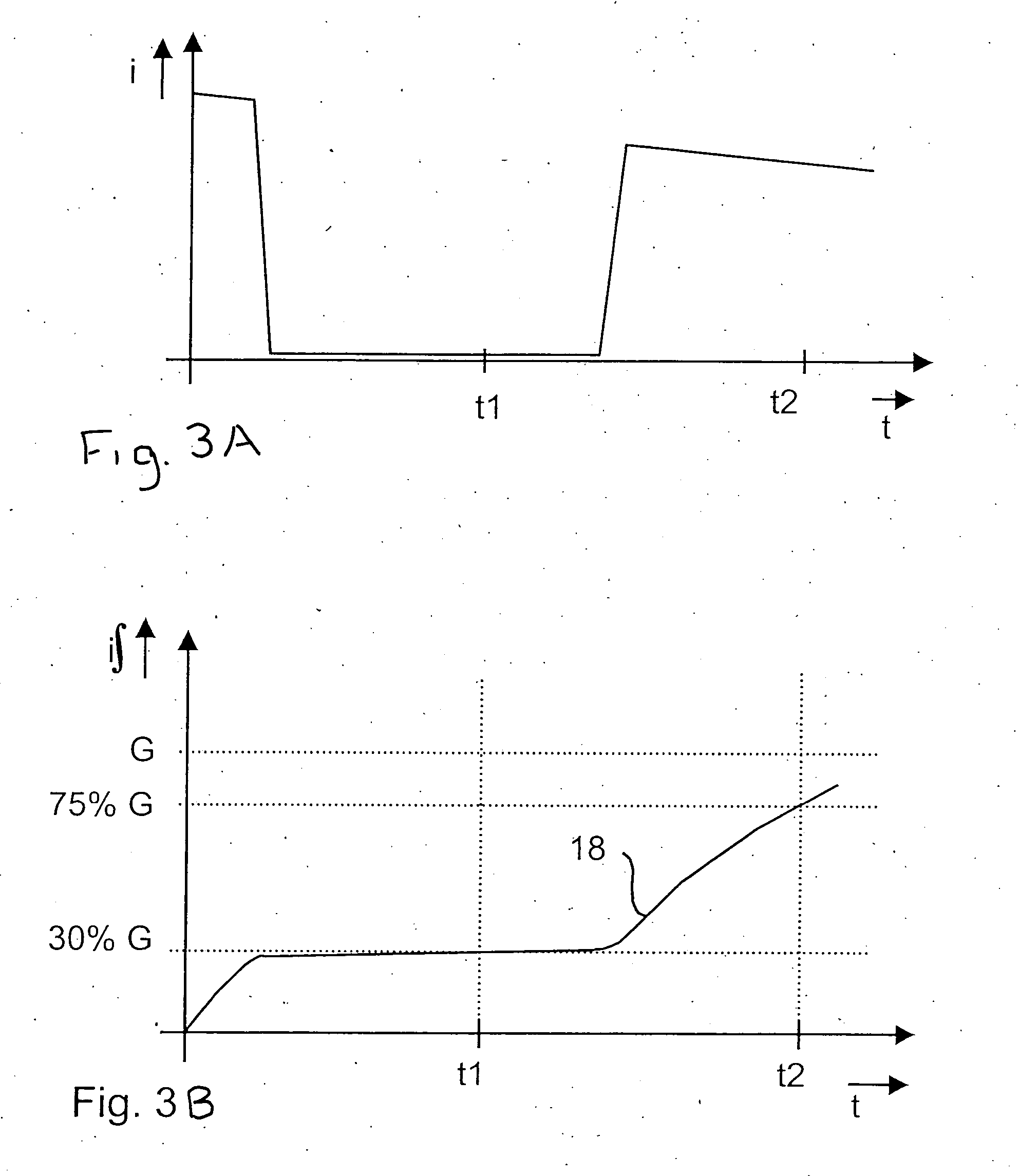

Gas-measuring device with an electrochemical sensor

ActiveUS20050155406A1Optimize timingExcellent followingMaterial analysis by optical meansMaterial resistanceMeasurement deviceEngineering

Owner:DRAGER SAFETY

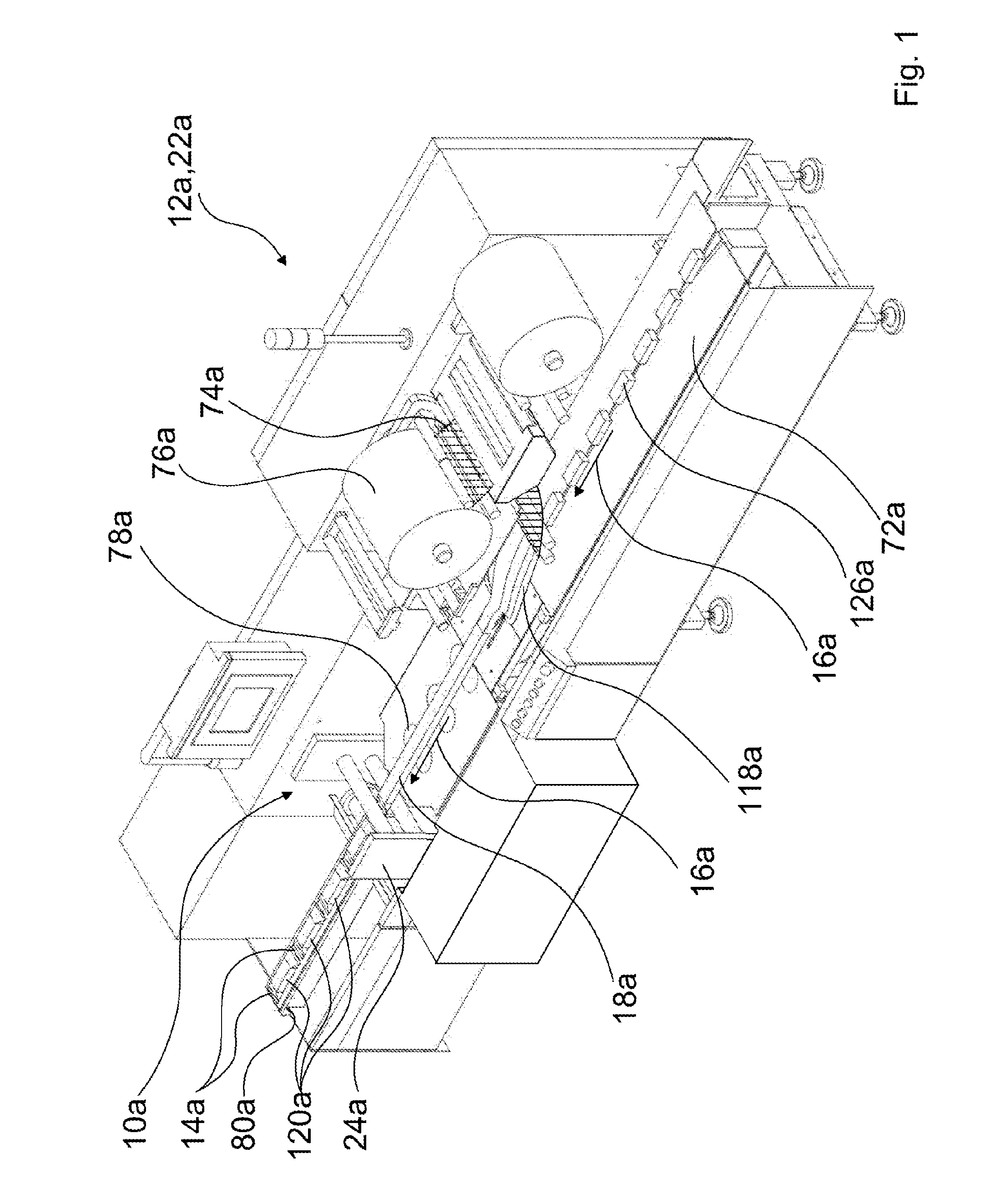

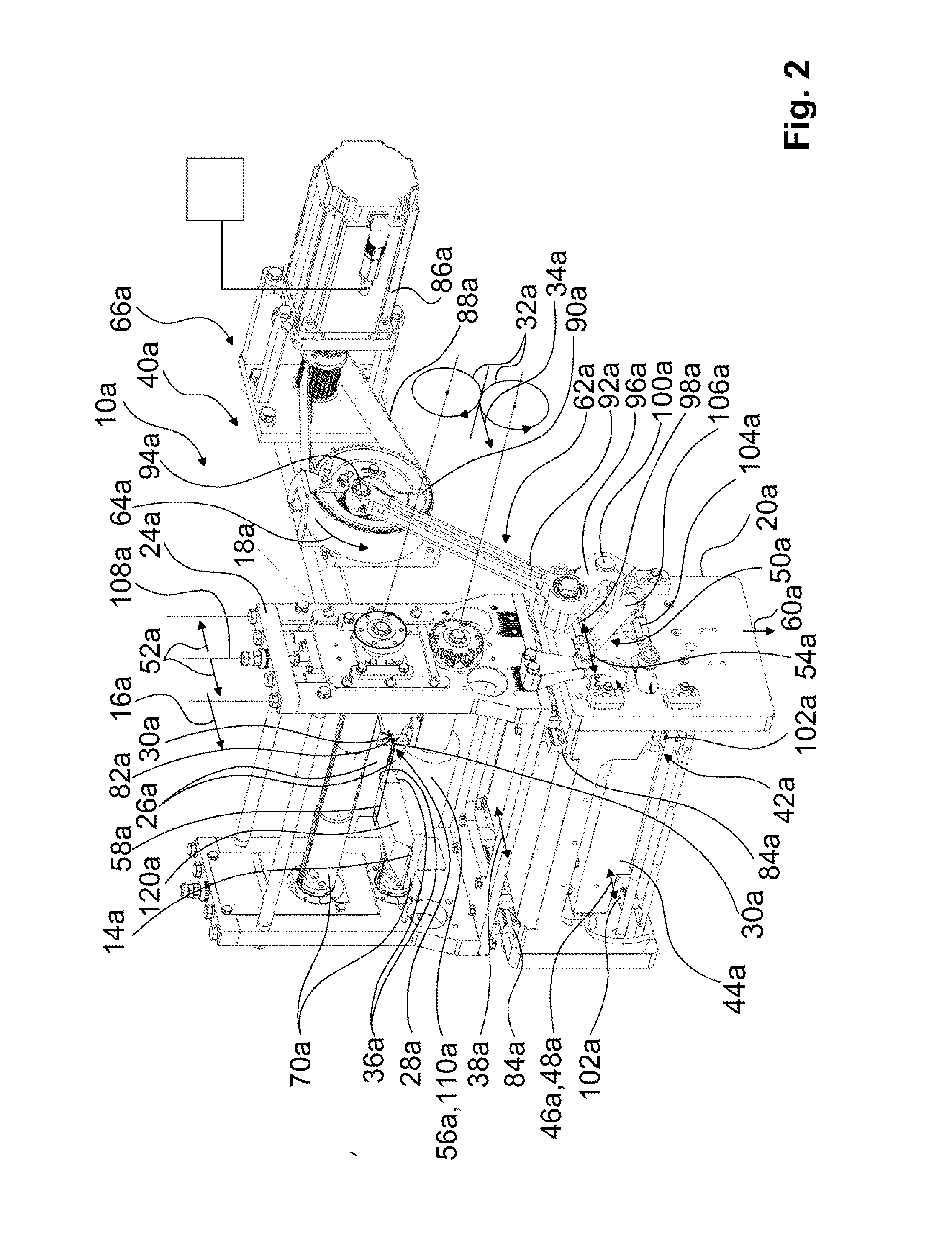

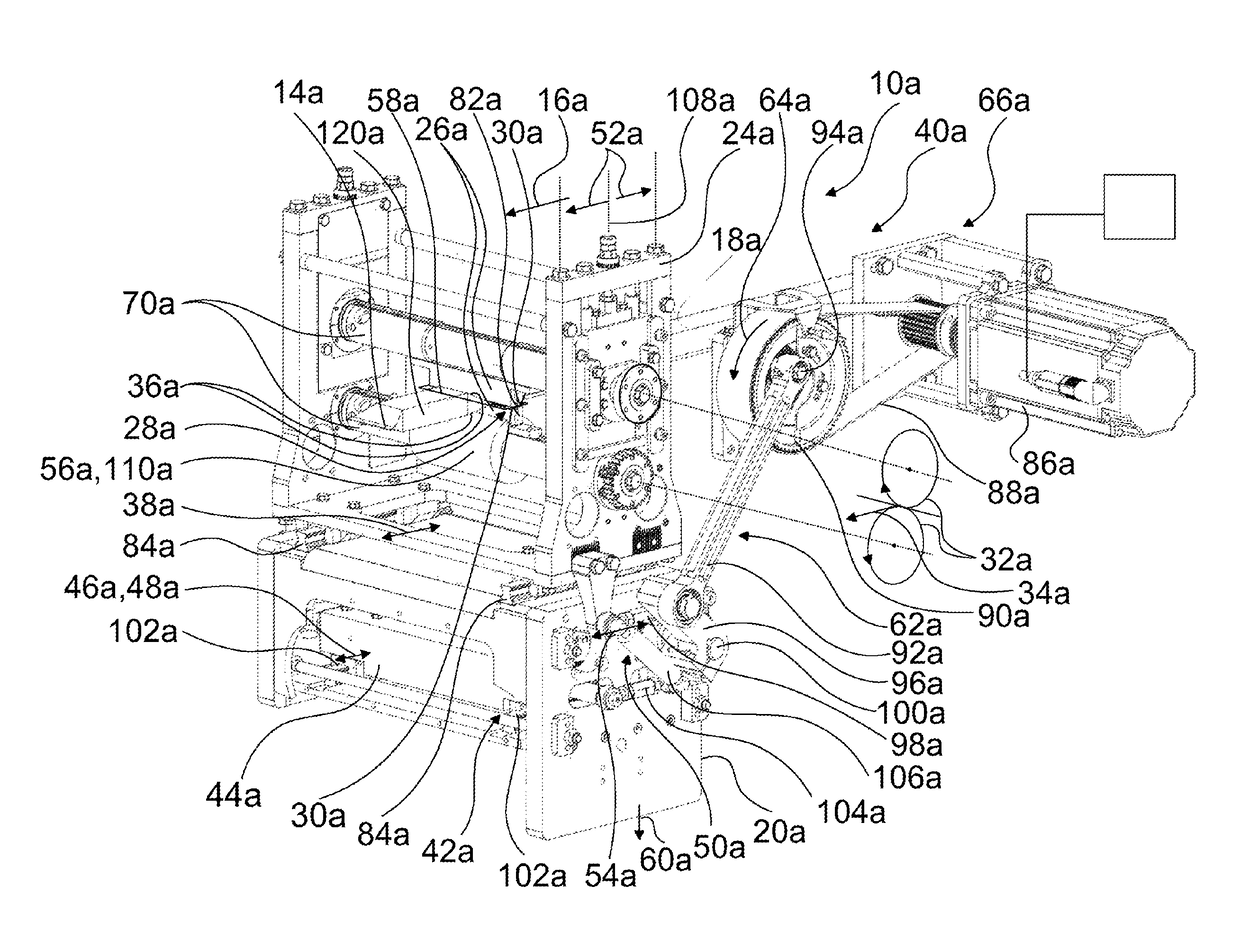

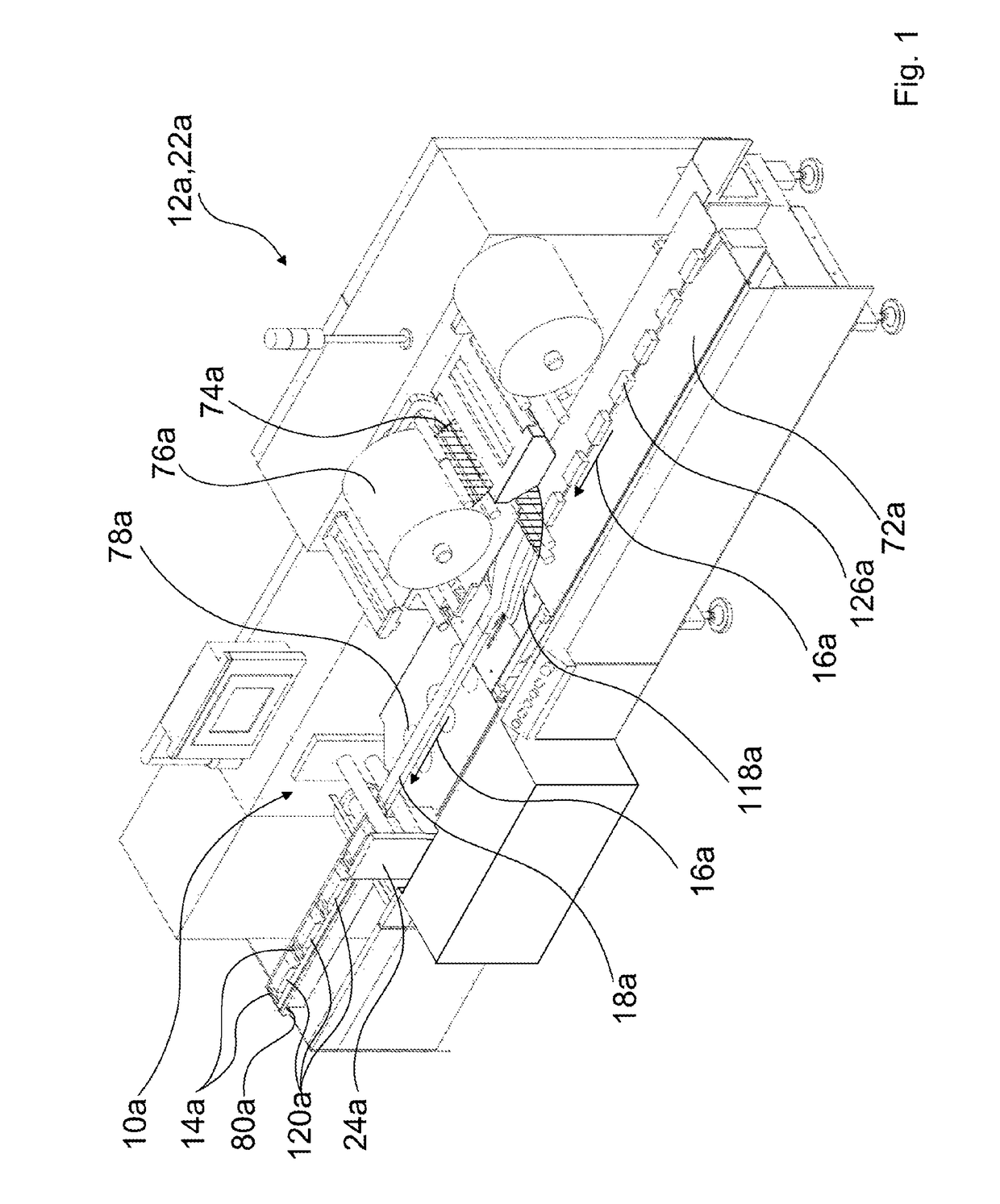

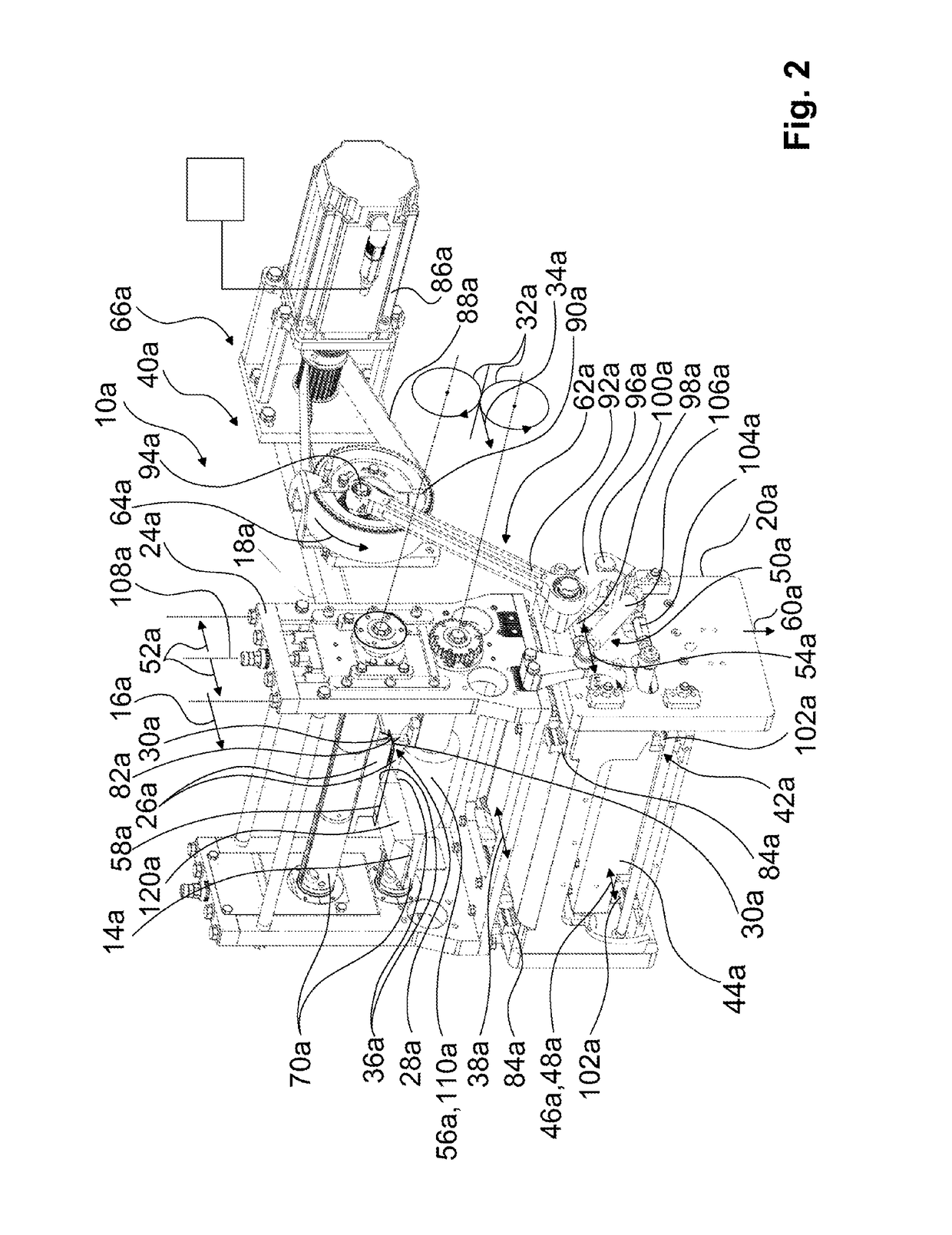

Horizontal transverse sealing station

ActiveUS20160193783A1Increase speedReduce the average velocityControlling laminationLaminationEngineeringMechanical engineering

The invention relates to a horizontal transverse sealing station (10a-b), in particular for a horizontal tubular bag machine (12a-b), for producing transverse sealing seams (14a-b) on at least one film tube (18a-b) transported in a continuous, at least essentially horizontal transport direction (16a-b), comprising a transverse sealing station base (20a-b) fixedly connected to a packing machine (22a-b), a transverse sealing unit (24a-b), and at least one sealing jaw pair (28a-b) movably mounted on the transverse sealing unit (24a-b) and formed by two sealing jaws (26a-b), the sealing surfaces (30a-b) of which come closer to each other during a sealing process in a sealing movement (32a-b), which relative to the transverse sealing unit (24a-b) is provided with at least one movement component (34a-b) in the transport direction (16a-b), in order to seal material layers (36a-b) of the film tube (18a-b) between the sealing surfaces (30a-b) by way of heating and / or applying pressure, and to remove again at the end of the sealing process. According to the invention the transverse sealing unit (24a-b) is driveably mounted on the transverse sealing station base (20a-b) in a displacement movement (38a-b) that is at least substantially parallel to the transport direction (16a-b).

Owner:SYNTEGON PACKAGING SYST AG

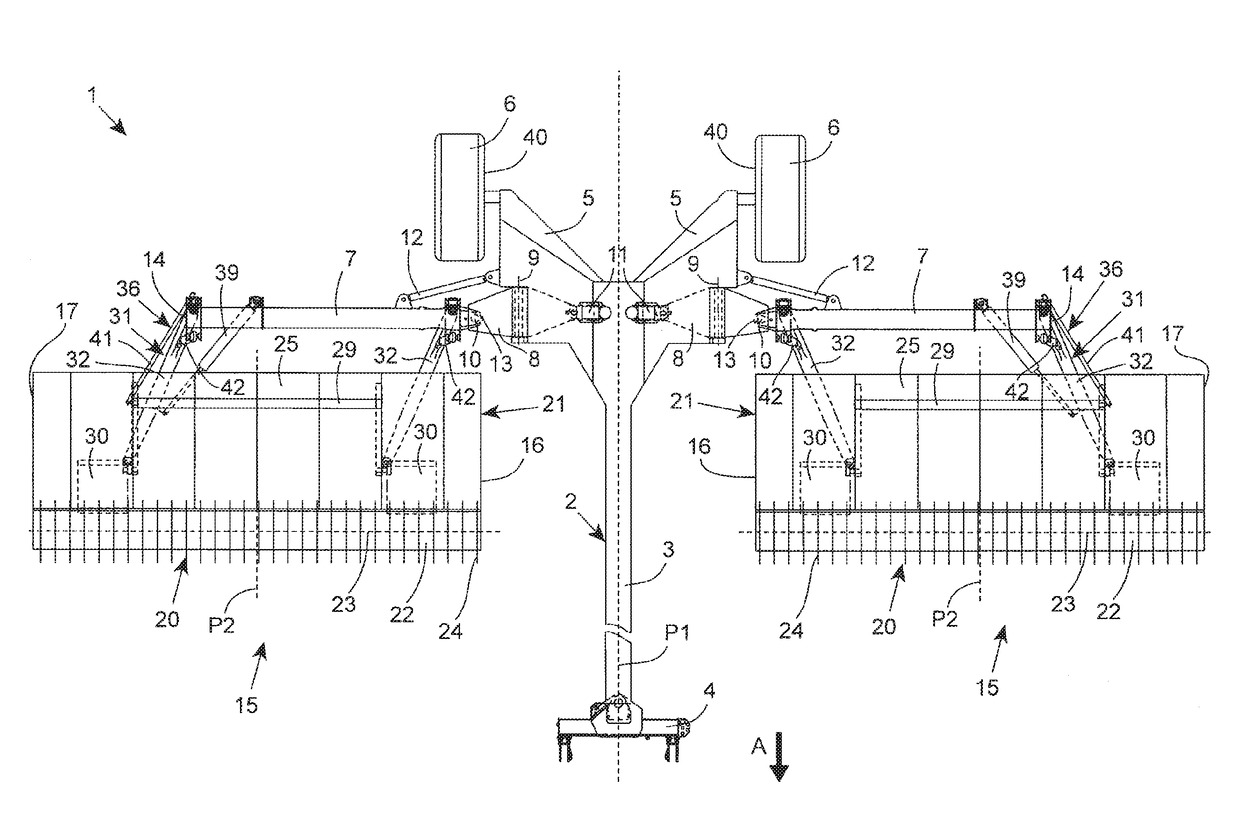

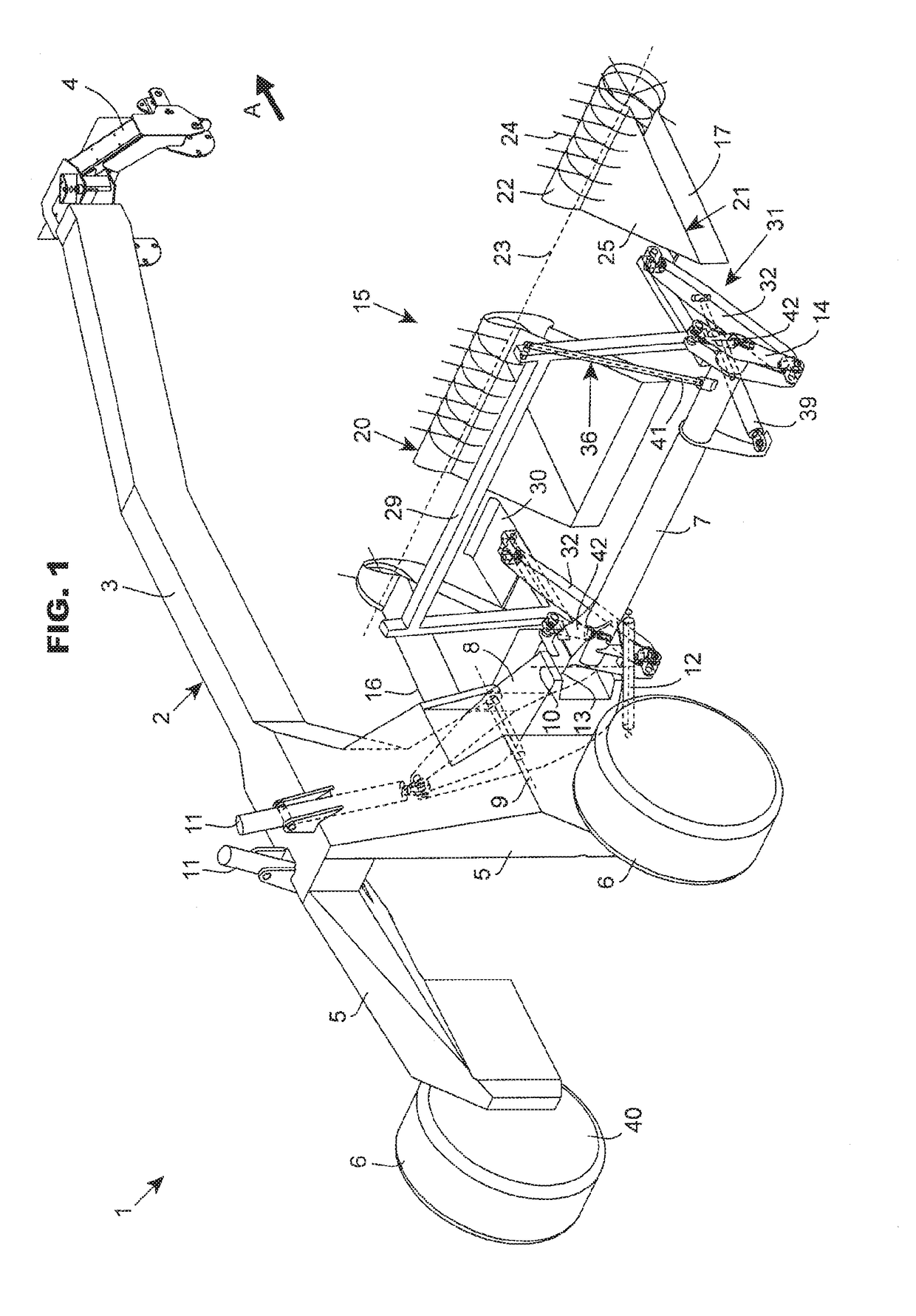

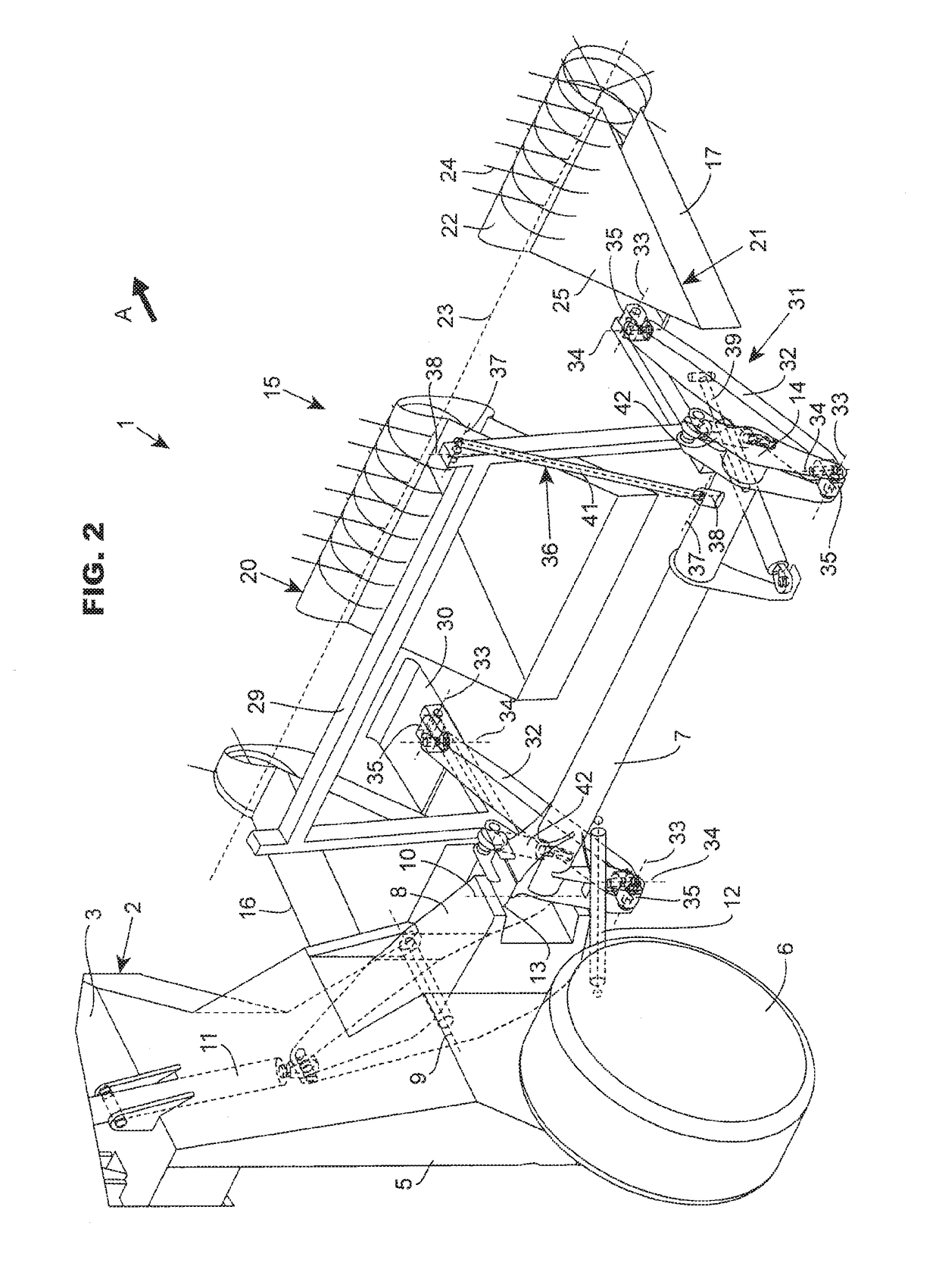

Machine for harvesting fodder

ActiveUS10076071B2Readily resist longitudinal forceIncreased durabilityAgricultural machinesLoadersHorizontal axisEngineering

A machine for the harvesting of plants comprises an arm movable between work and transport configuration, a tool comprising lateral ends and being able to occupy a work position and another position, a connecting device via which the tool is connected to the arm and enabling a first movement of the tool relative to the arm, during which the lateral ends move vertically relative to the arm in the same vertical direction relative thereto, the connecting device can operate a second transverse and horizontal movement of the tool relative to the arm and making it possible to operate this second movement independently of the first movement. The connecting device comprises an arm articulated on the support arm about a first transverse and horizontal axis when the support arm is in the work configuration, and this arm can, by pivoting about the first axis, moved vertically relative to the support arm.

Owner:KUHN SA

Horizontal transverse sealing station

ActiveUS9649810B2Increase speedCompensation differenceLaminationLamination apparatusMechanical engineeringEngineering

The invention relates to a horizontal transverse sealing station (10a-b), in particular for a horizontal tubular bag machine (12a-b), for producing transverse sealing seams (14a-b) on at least one film tube (18a-b) transported in a continuous, at least essentially horizontal transport direction (16a-b), comprising a transverse sealing station base (20a-b) fixedly connected to a packing machine (22a-b), a transverse sealing unit (24a-b), and at least one sealing jaw pair (28a-b) movably mounted on the transverse sealing unit (24a-b) and formed by two sealing jaws (26a-b), the sealing surfaces (30a-b) of which come closer to each other during a sealing process in a sealing movement (32a-b), which relative to the transverse sealing unit (24a-b) is provided with at least one movement component (34a-b) in the transport direction (16a-b), in order to seal material layers (36a-b) of the film tube (18a-b) between the sealing surfaces (30a-b) by way of heating and / or applying pressure, and to remove again at the end of the sealing process. According to the invention the transverse sealing unit (24a-b) is driveably mounted on the transverse sealing station base (20a-b) in a displacement movement (38a-b) that is at least substantially parallel to the transport direction (16a-b).

Owner:SYNTEGON PACKAGING SYST AG

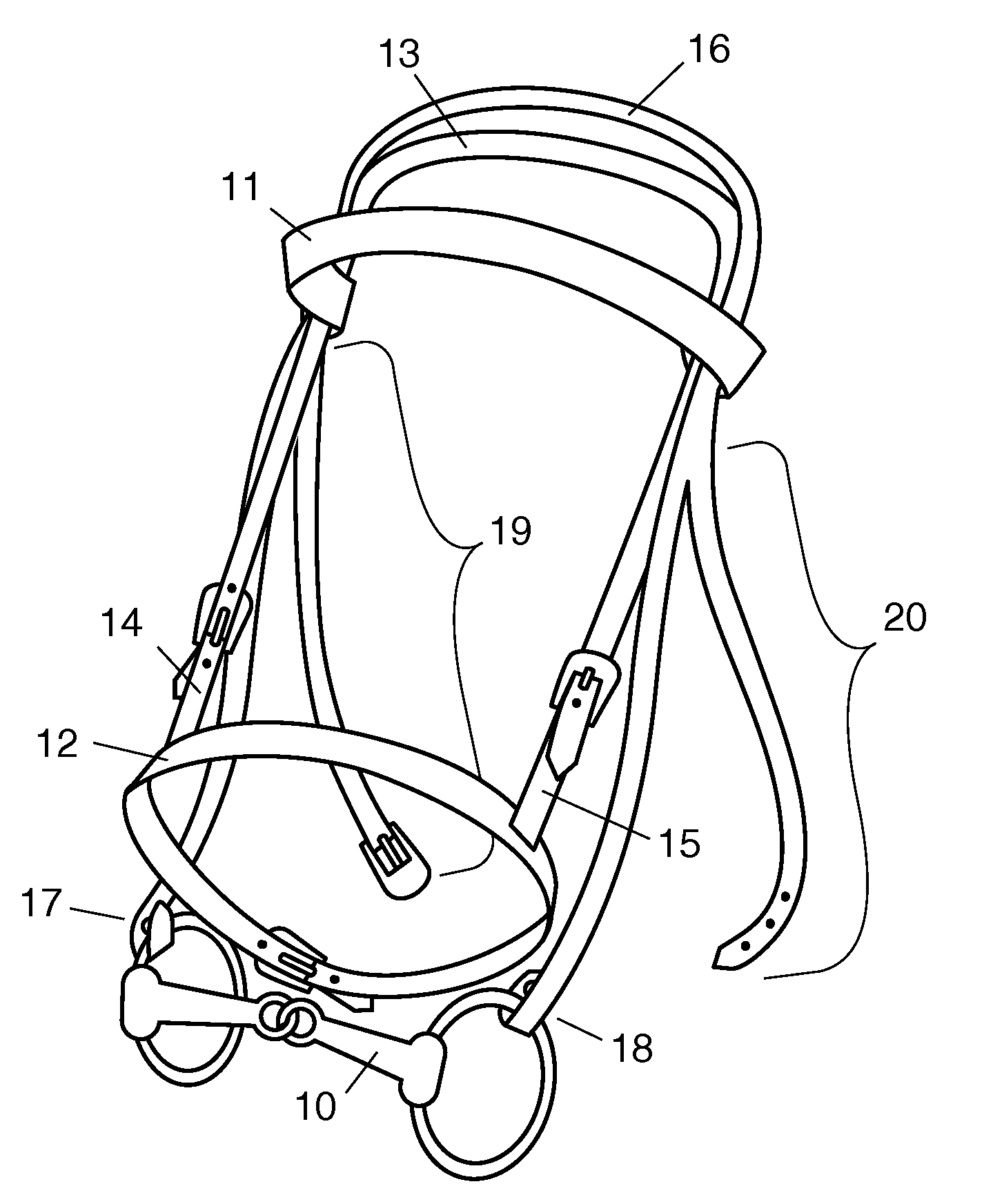

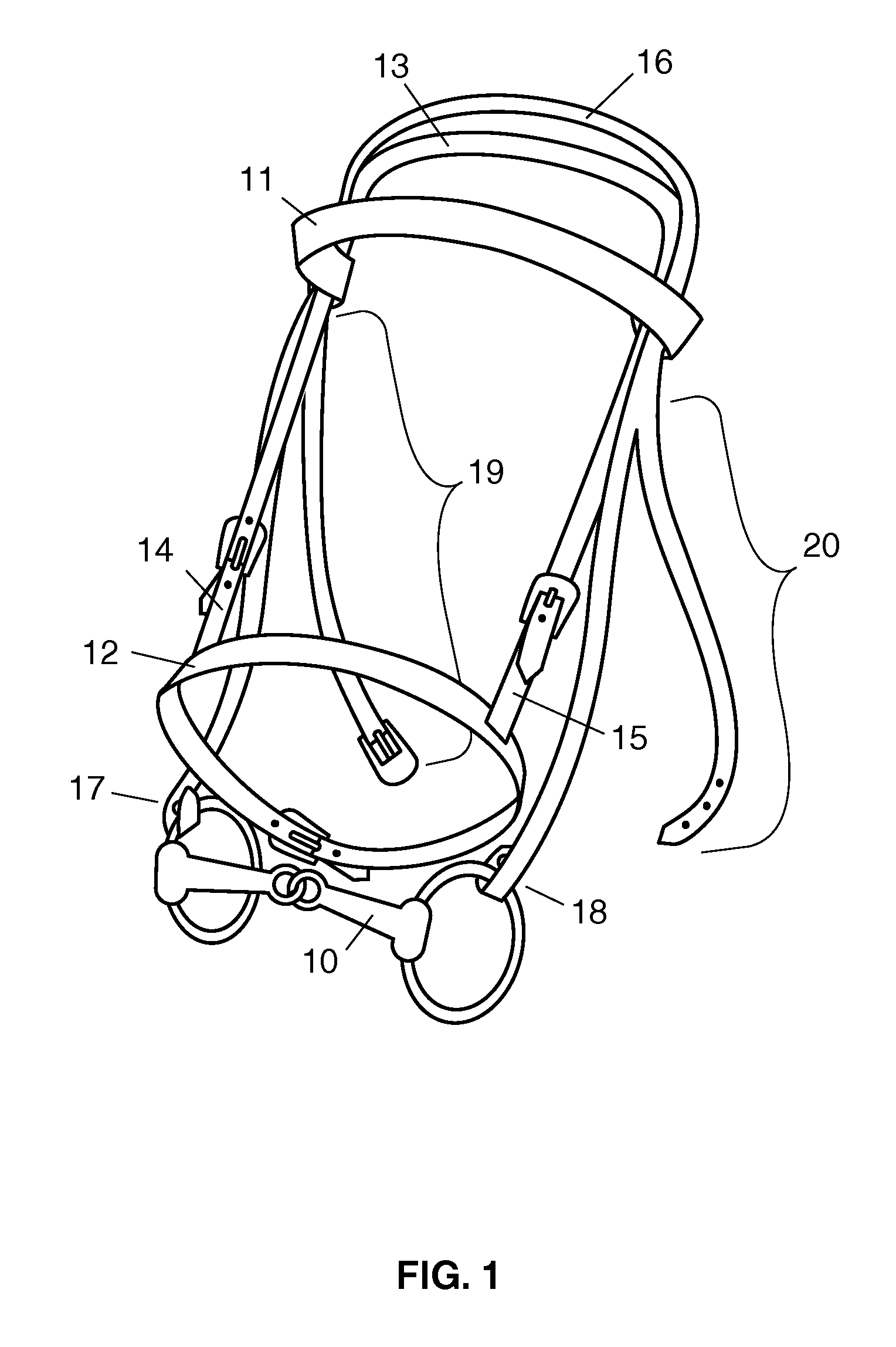

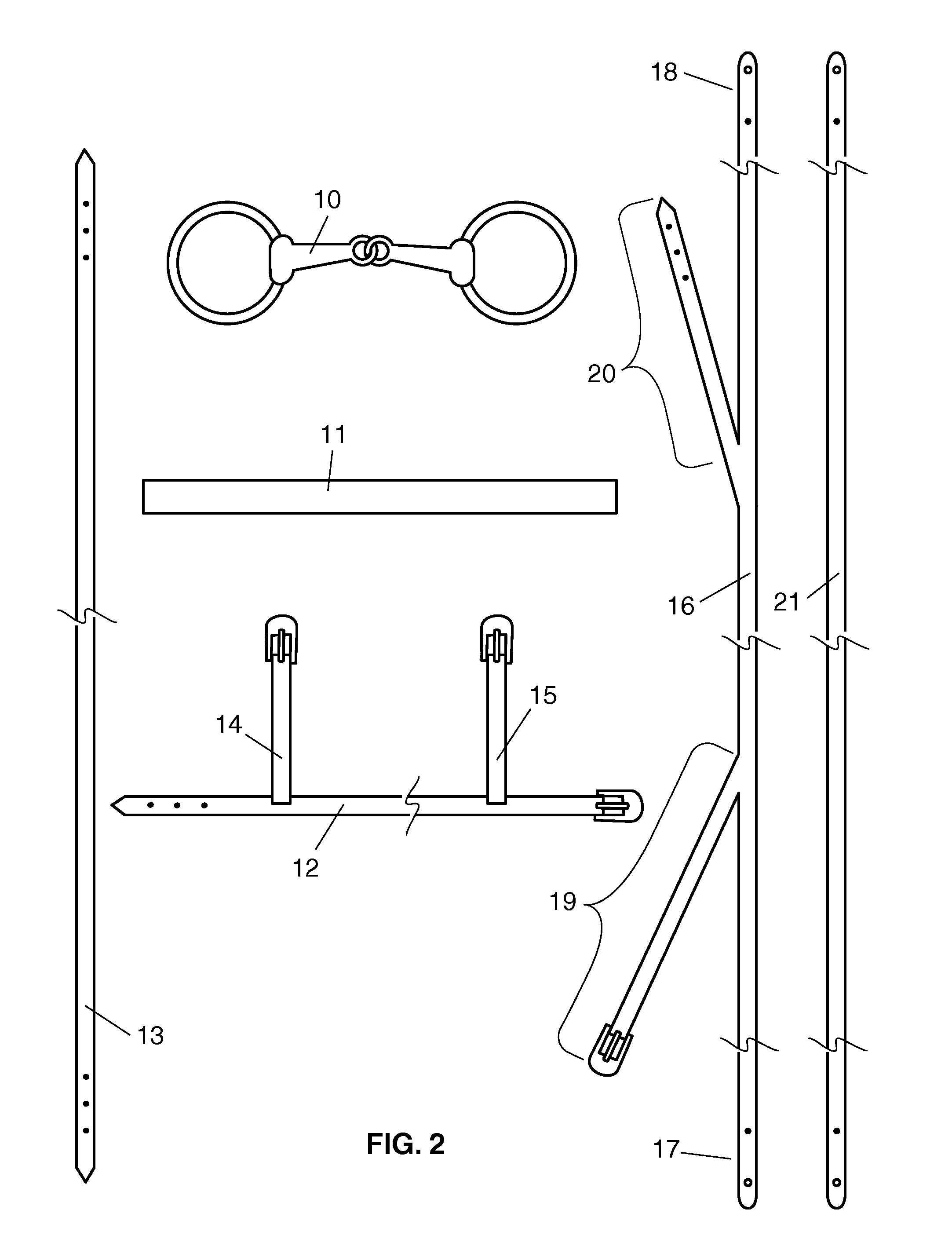

Contoured construction for improved fit in horse bridles

A bridle for horses which alleviates the problem of poor fit often encountered in conventional bridles. This invention shows a way in which bridles may be constructed so that their fit is improved, taking into account the various curvatures, dimensions and features of a horse's head and removing a potential source of irritation or distraction to the animal. The invention enhances the comfort of the horse and thus the safety of the rider.

Owner:SANDOR EVA CHARLENE

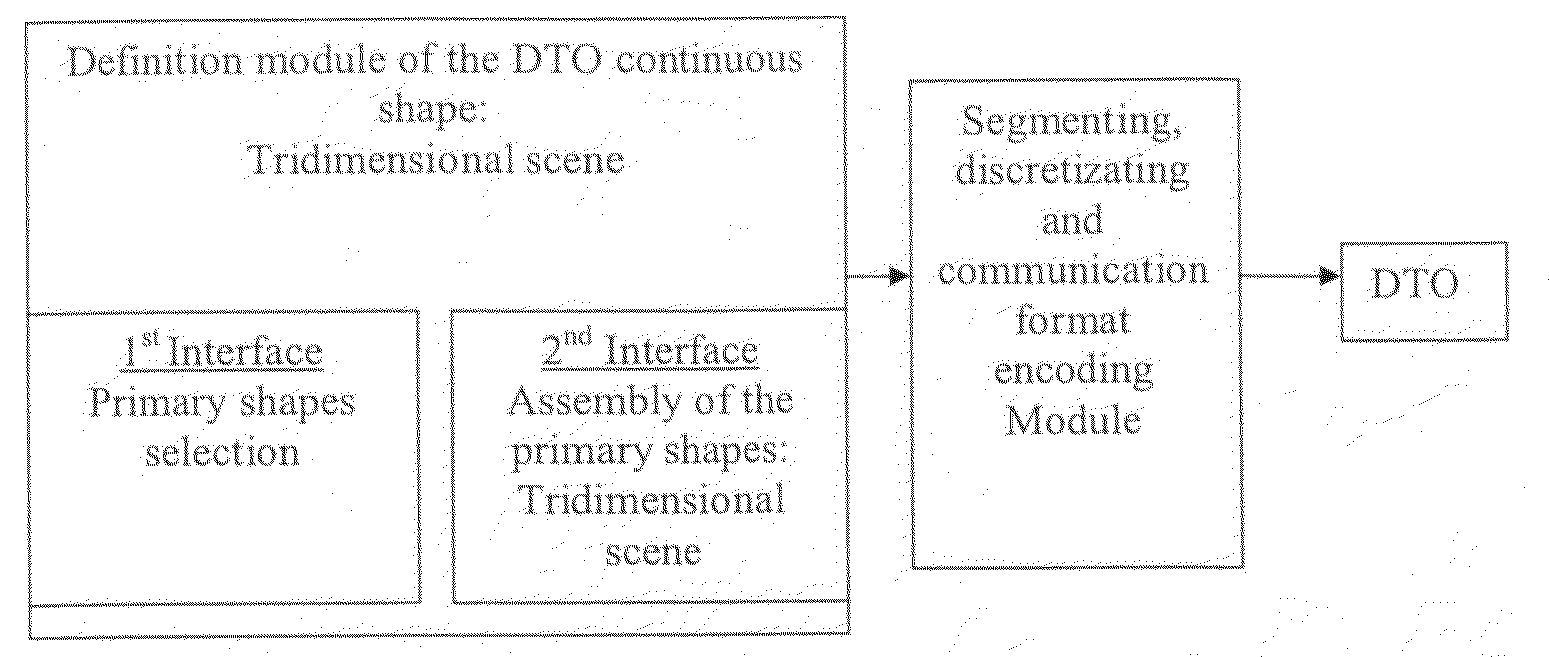

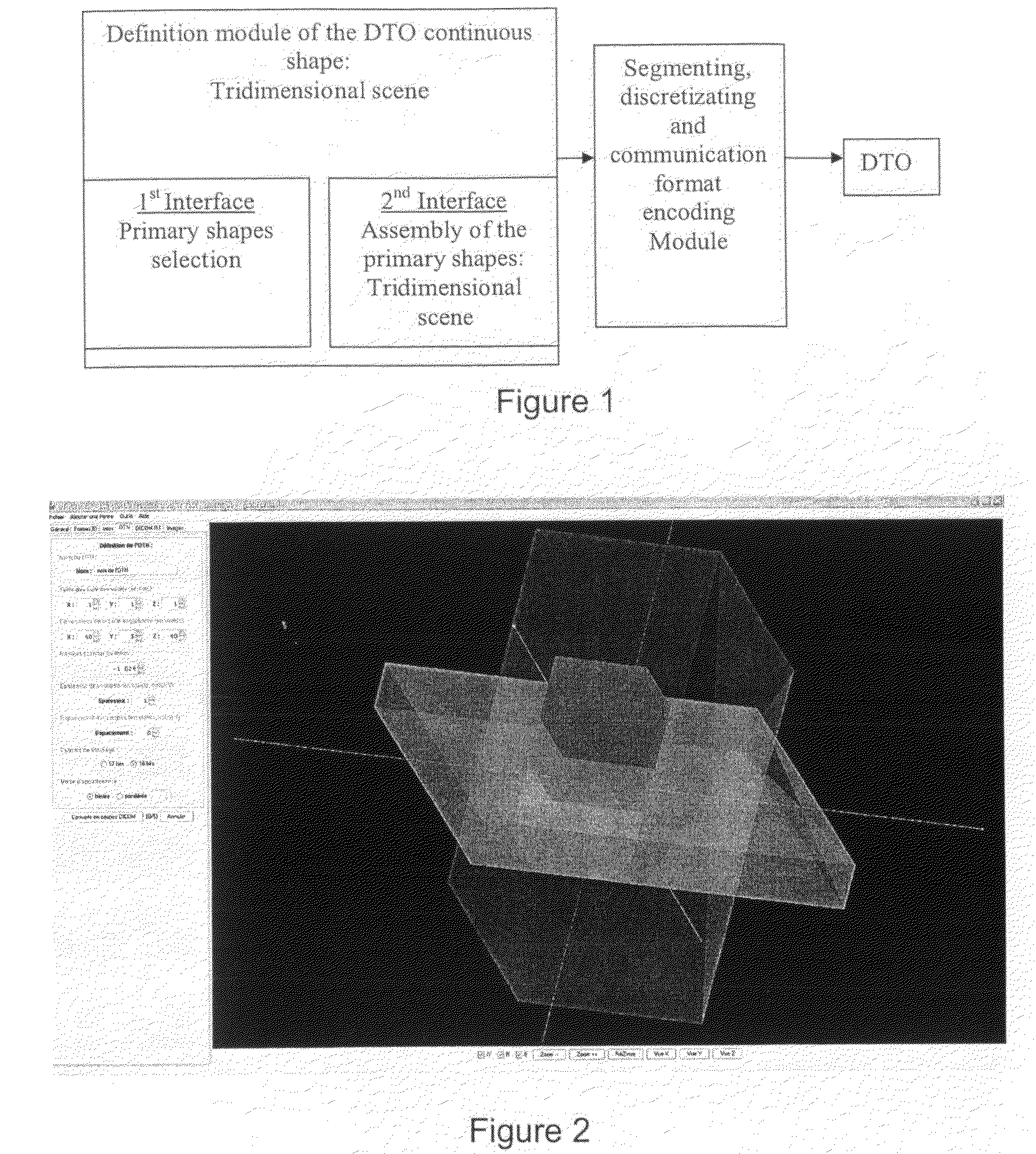

Method for generating digital test objects

ActiveUS20090110250A1Excellent followingCharacter and pattern recognition3D-image renderingVoxelAlgorithm

The object of the present invention is a computer-implemented method for generating digital images encoded into a format readable by medical imaging apparatus, characterized in that it comprises the steps of:defining, in a tridimensional continuous space, a tridimensional scene comprising a tridimensional continuous shape and an encompassing medium, said tridimensional shape being constituted from basic primary shapes by rotation, translation, overlapping or gathering of one or several basic primary shapes;discretizing the tridimensional scene obtained at the previous step into volume elements (voxels) using a weighting mechanism;segmenting the discretized tridimensional scene into voxels by creating bidimensional cross-sections of the tridimensional scene; andencoding the information describing the obtained bidimensional cross-sections of the tridimensional scene into a format readable by medical imaging apparatus.

Owner:QUALIFORMED +1

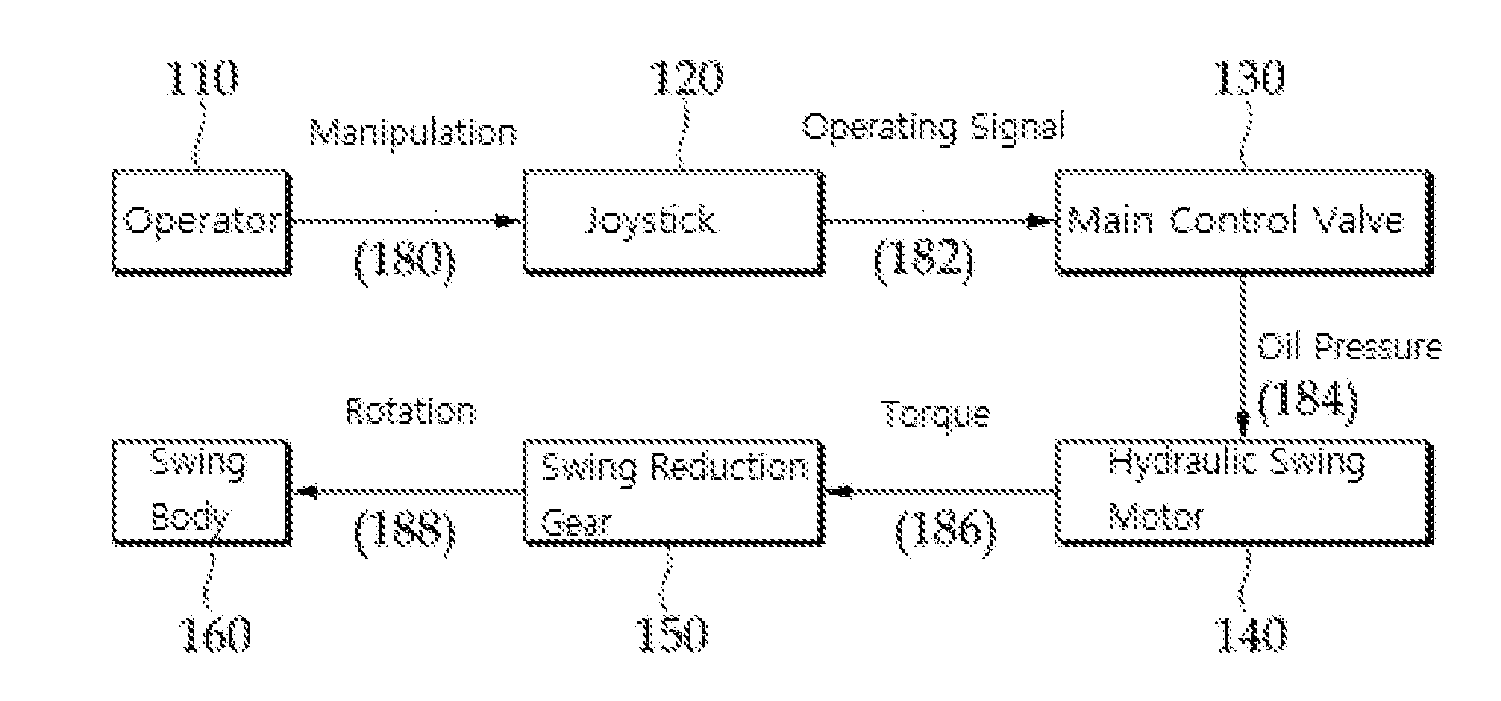

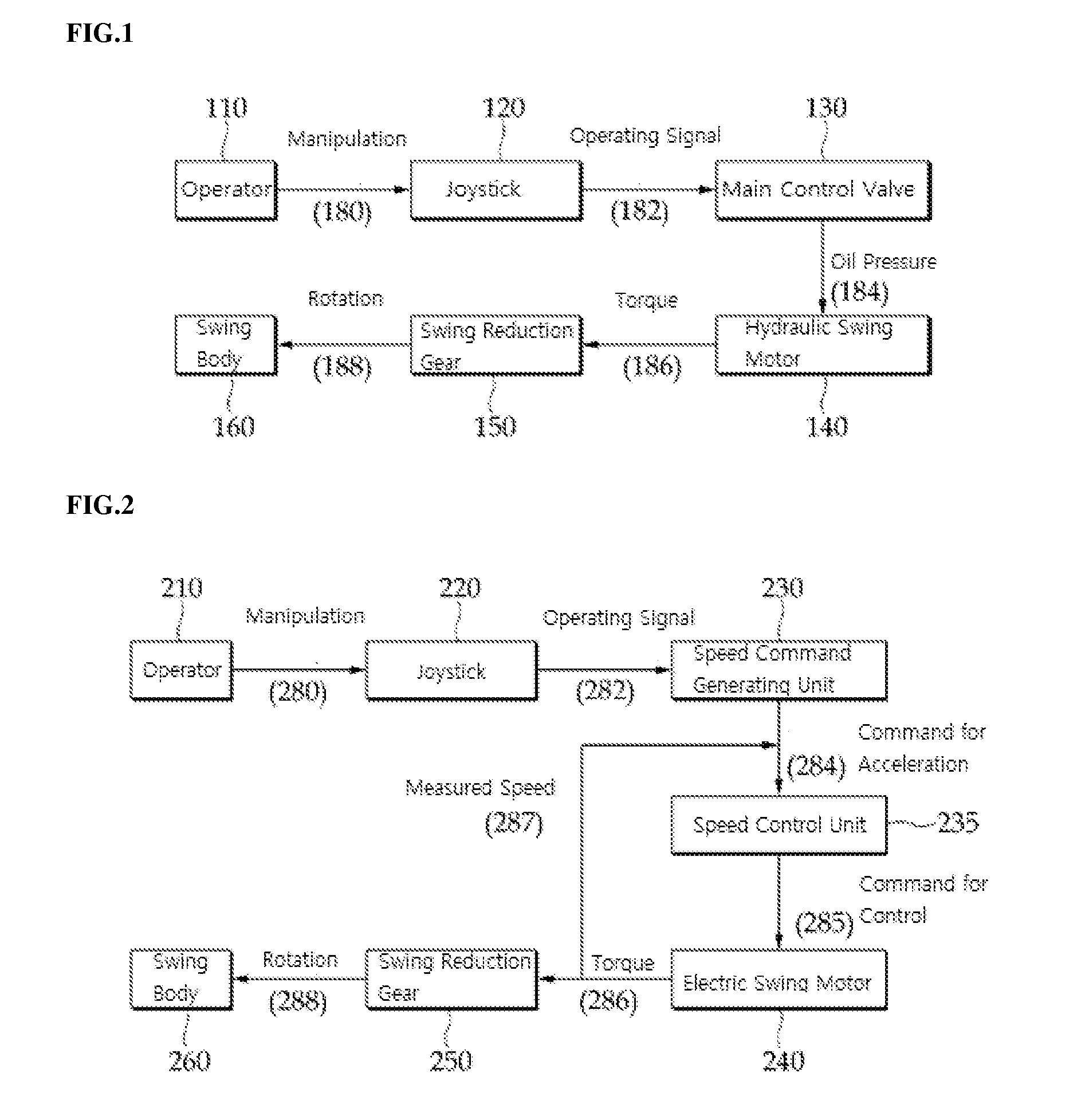

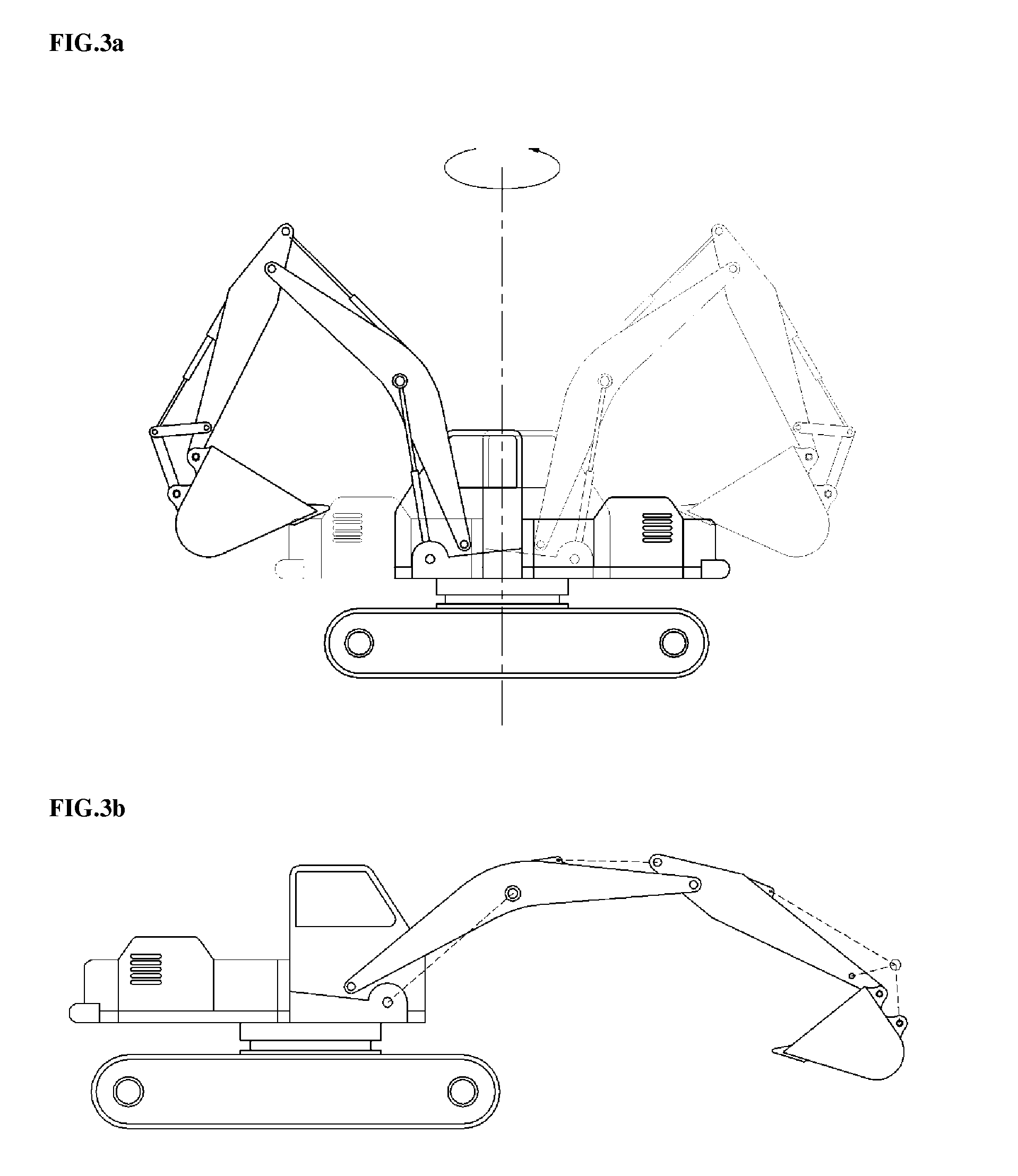

Method and apparatus for controlling swing body of construction equipment

ActiveUS20150240449A1Easy to handleExcellent followingAnalogue computers for trafficServomotorsRotation velocityControl theory

Exemplary embodiments relate to controlling a swing body of construction equipment. Disclosed methods may include selecting a representative signal vs. speed curve, receiving an operating signal value from the operating input device, obtaining a reference speed value by applying said operating signal value to the selected curve, transmitting a command for rotational speed equivalent to said reference speed to the swing motor making the swing body rotate, obtaining rotational speed of said motor, determining whether a value obtained by subtracting rotational speed from reference speed exceeds the maximum permissible errors, obtaining a new signal vs. speed curve equivalent to rotational speed when a value obtained by subtracting rotational speed from reference speed exceeds the maximum permissible errors, obtaining a new reference speed value from an operating signal value using said new curve, and transmitting a new command for rotational speed equivalent to said new reference speed to said motor.

Owner:DOOSAN INFRACORE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com