Patents

Literature

208results about How to "Improve sealing function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

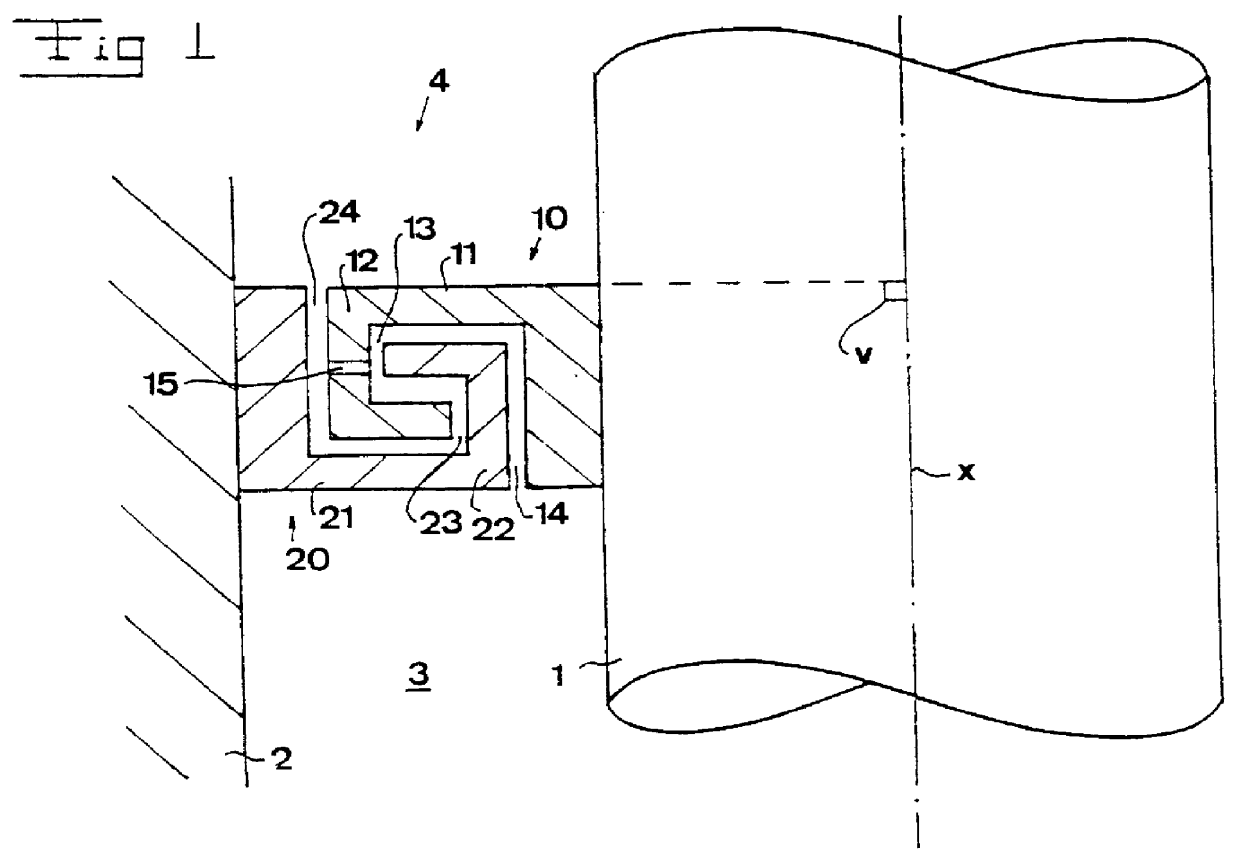

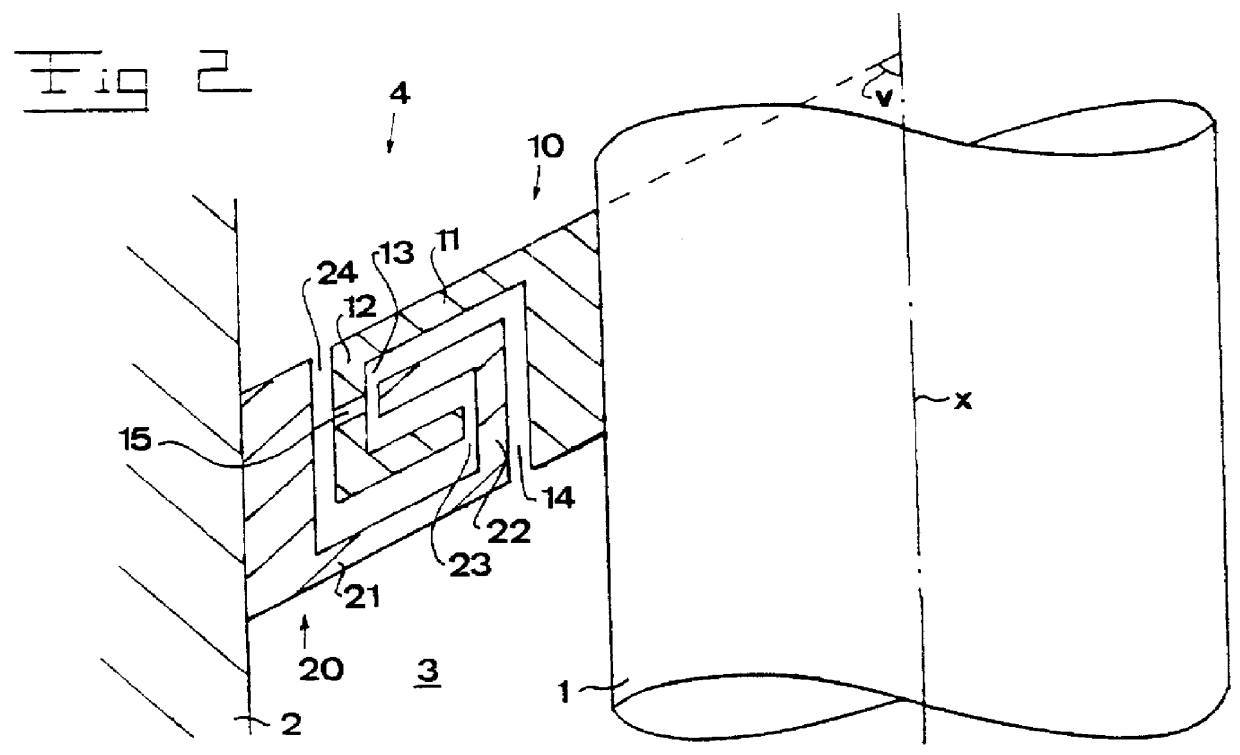

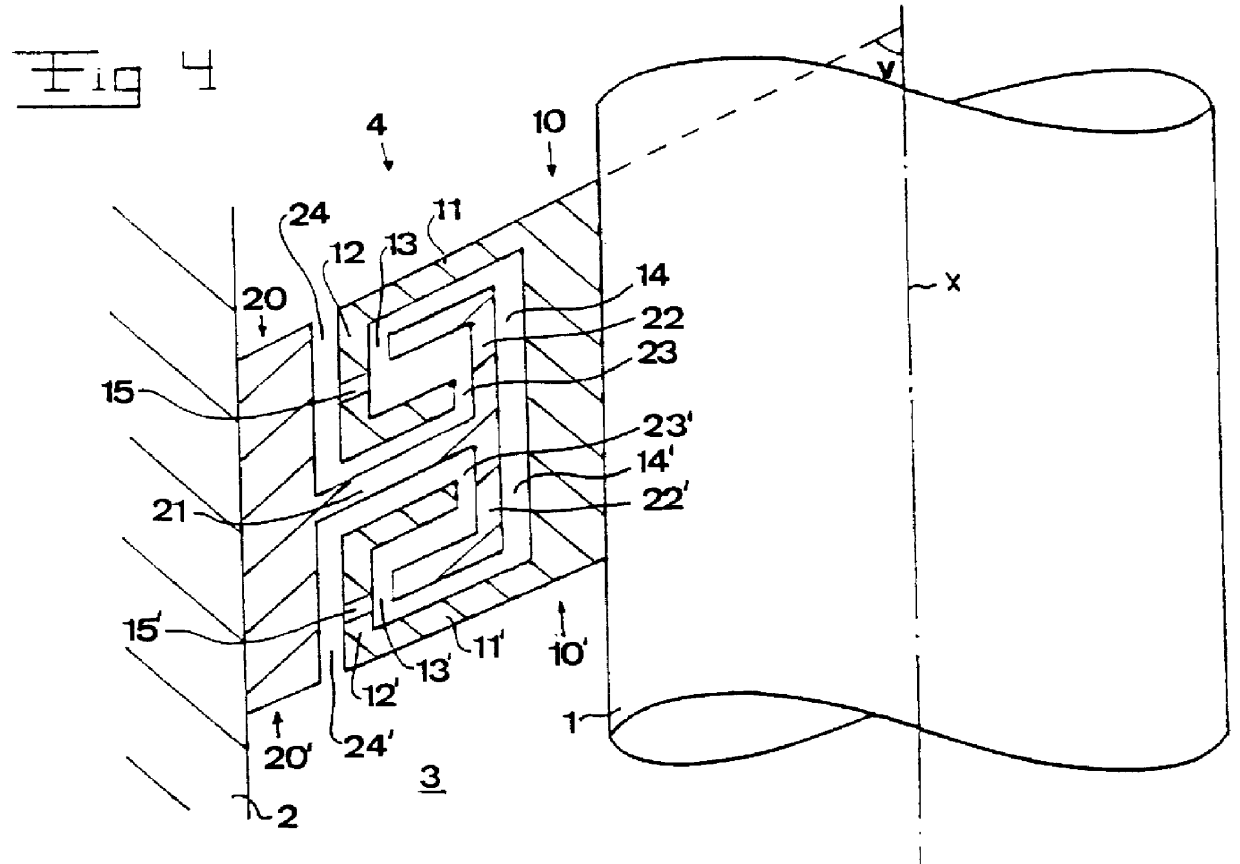

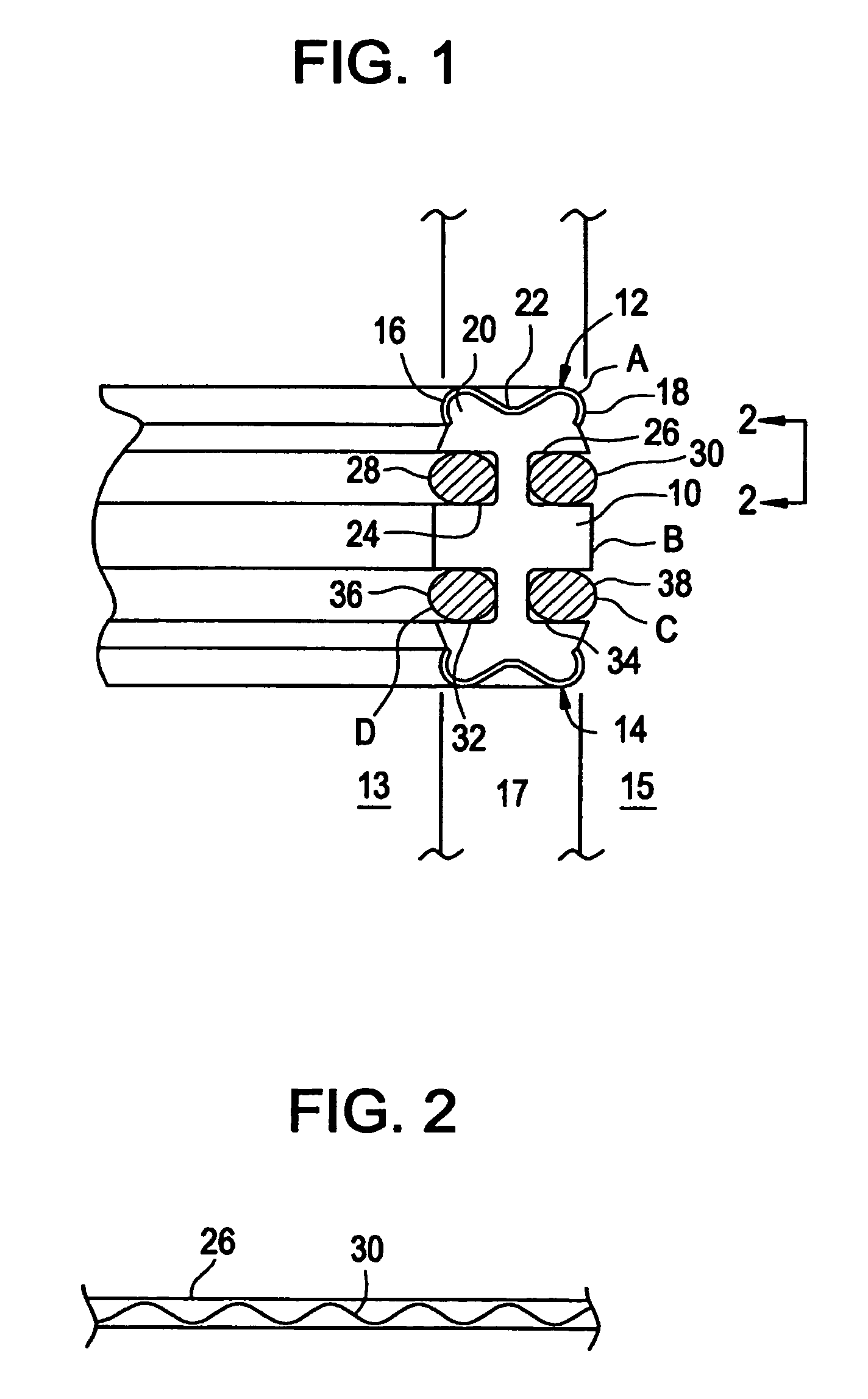

Sealing device

A sealing device (4) is provided for sealing between a first member (1) and a second member (2) and comprises a first sealing element (10), provided on the first member and extending thereabout towards the second member, and a second sealing element (20), provided on the second member and extending towards the first member without direct contact with the first sealing element (10). The first sealing element (10) comprises a first flange member (12) extending towards the first member (1) forming a first chamber (13) and the second sealing element (20) comprises a second flange member (22) extending towards the second member (2) and forming a second chamber (23). The flange members (12, 22) are provided overlapping each other in such a manner that the first flange member (12) extends in the second chamber (23) and the second flange member (22) extends in the first chamber (13).

Owner:ALFA LAVAL AB

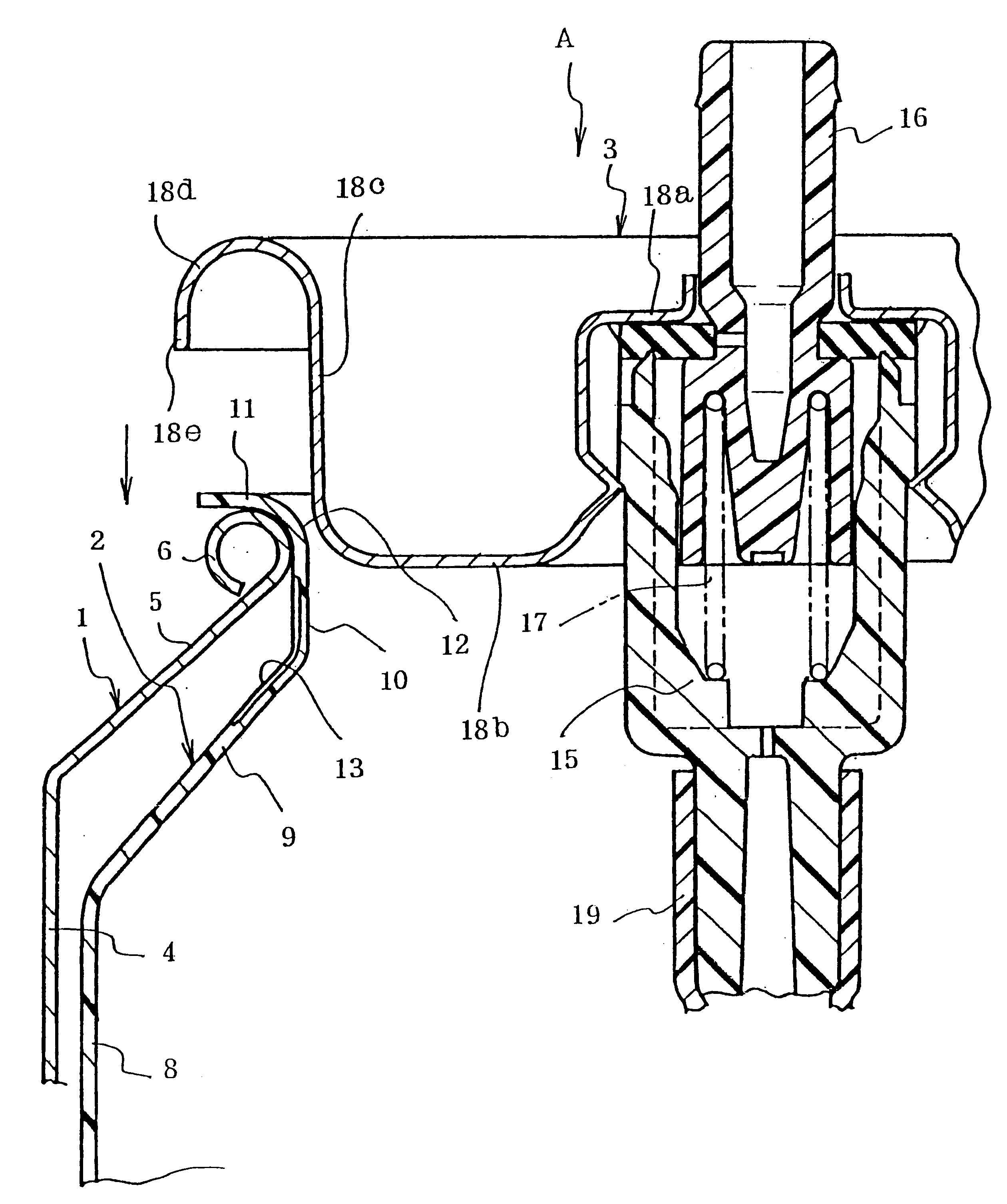

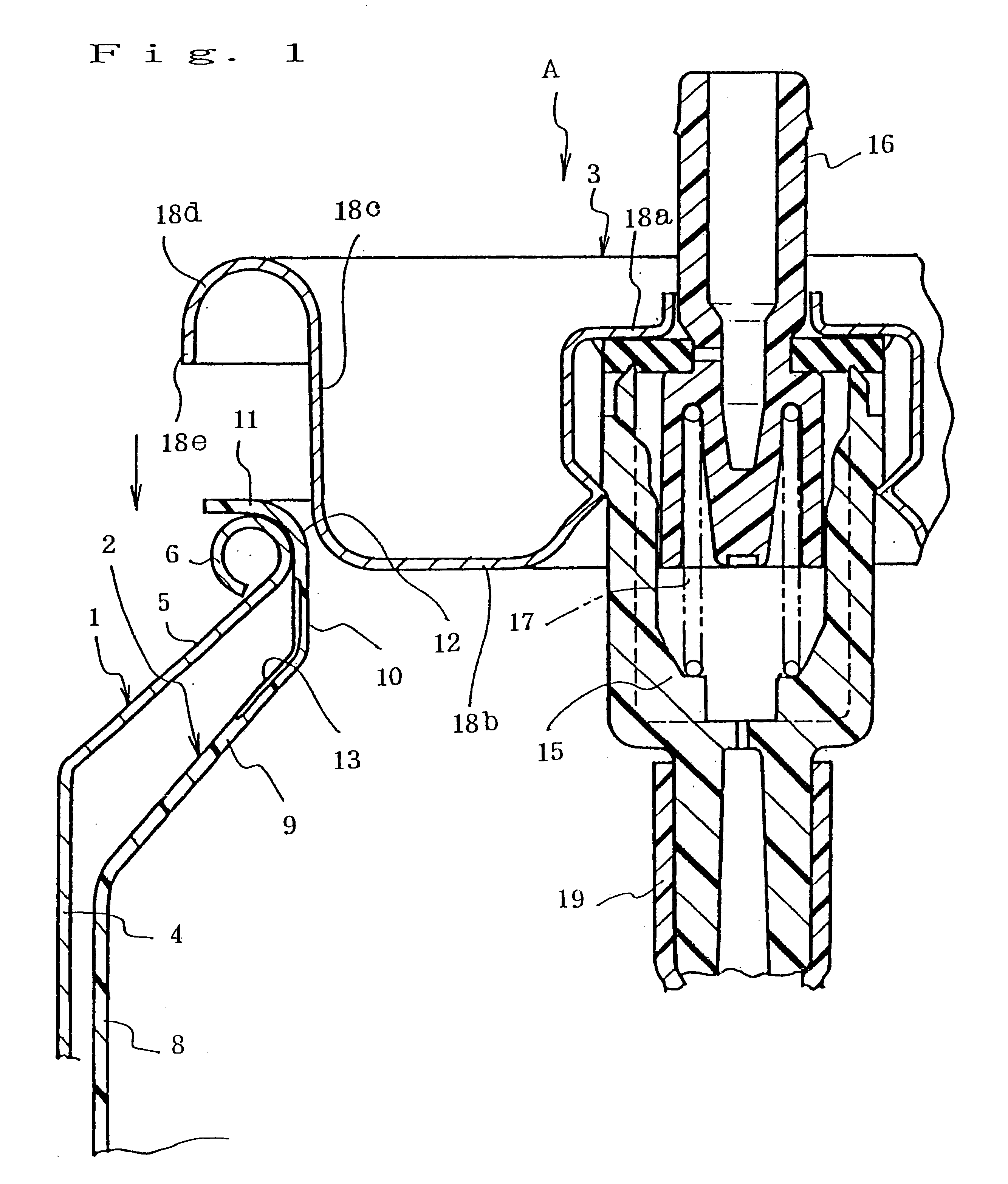

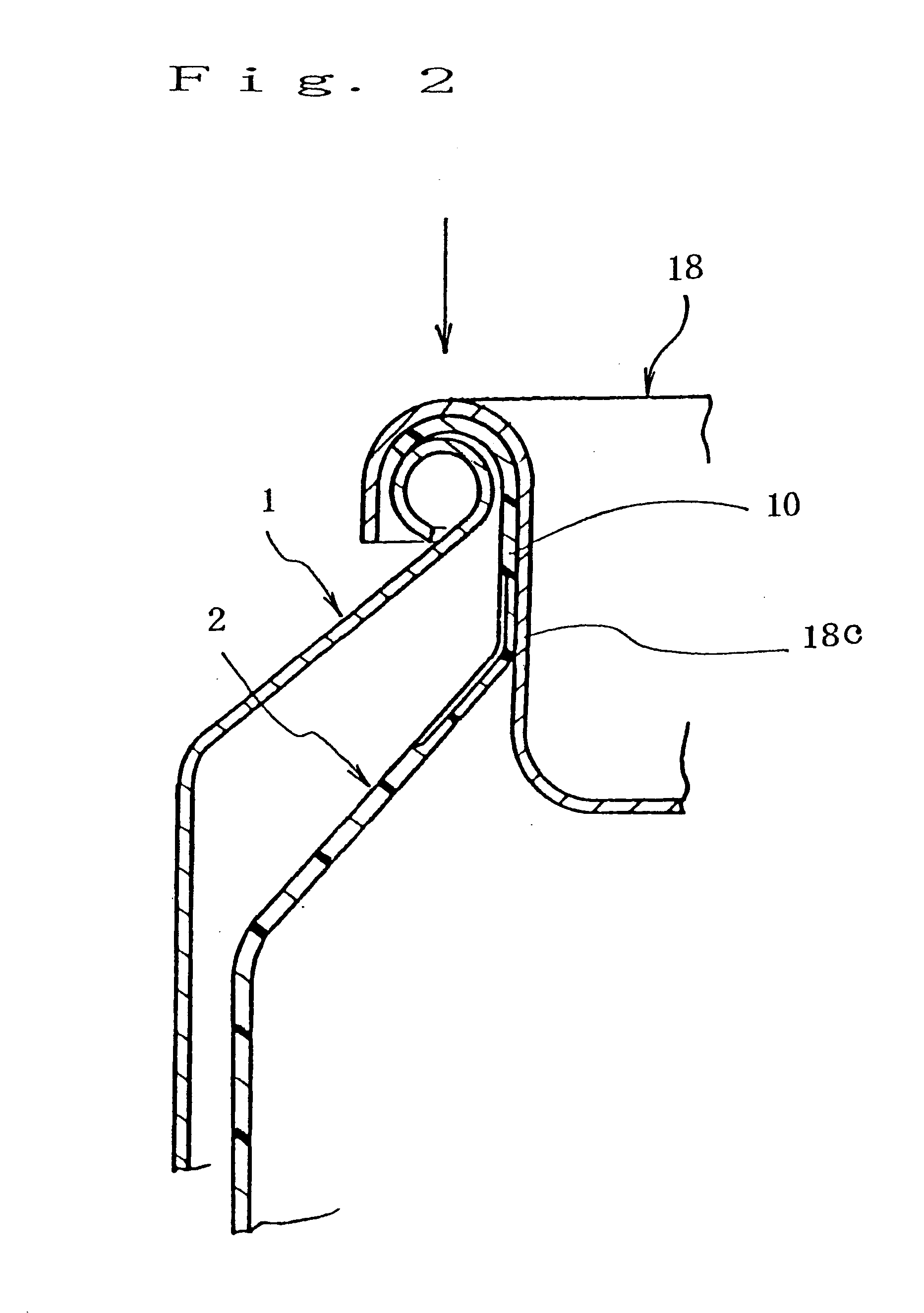

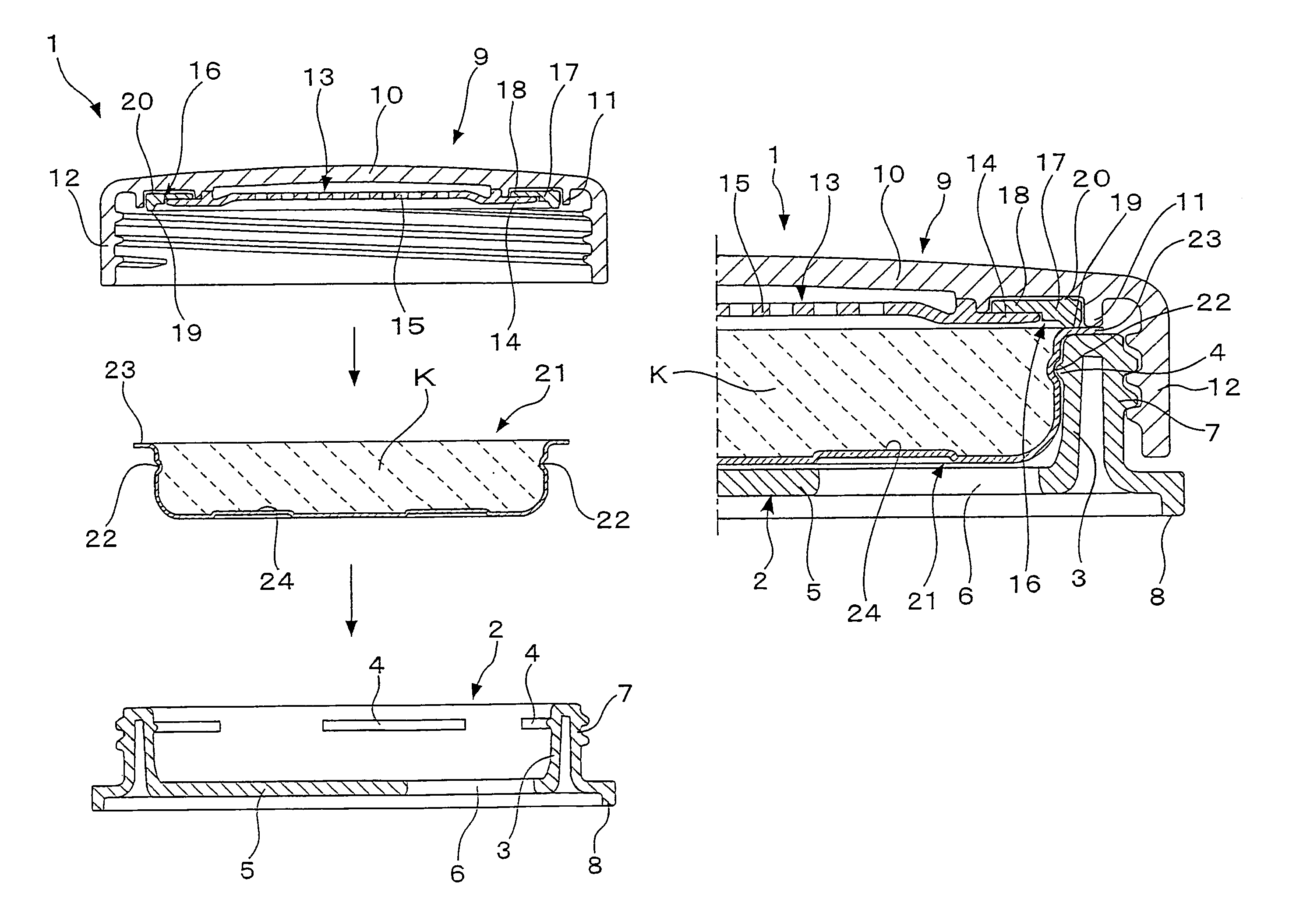

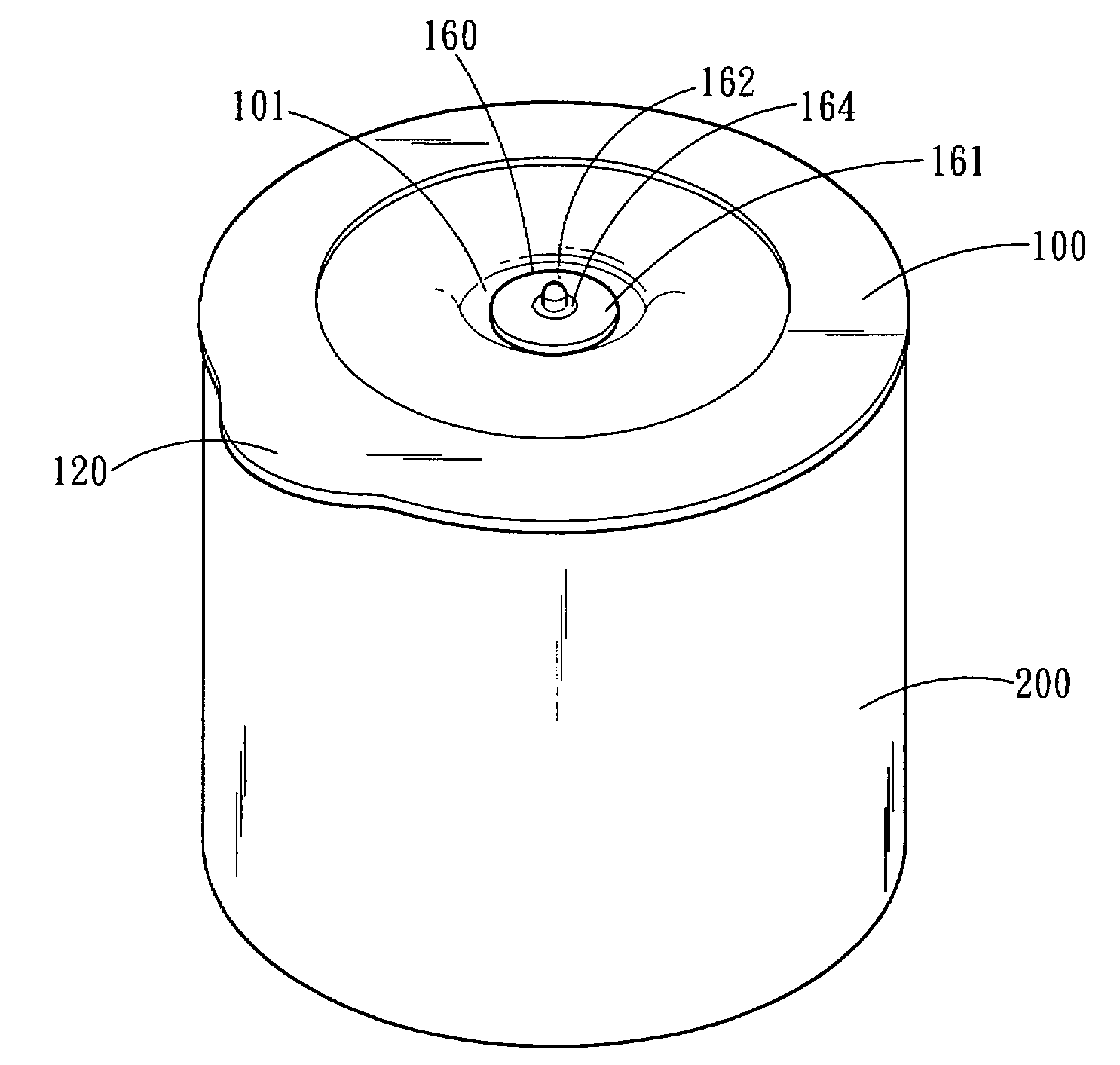

Double pressurized container for charging undercup and double pressurized products using the container

InactiveUS6651847B2Improve sealing functionLittle riskPackaging under special atmospheric conditionsLiquid dispensingEngineeringFlange

A pressurized container A for under-cup charging which comprises a container main body 1 equipped with a bead portion 6 at a periphery of an opening at its upper end, a mounting cup 18 having a curved flange 18d which engages with the bead portion 6, a flexible inner bag which is interposed between the container main body 1 and the mounting cup 18. The inner bag 2 is equipped with a neck portion which abuts tightly against an outer peripheral surface of a rising wall of the mounting cup with predetermined fitting strength and a flange portion 11 which is disposed at the upper end of the neck portion and clamped between the curved flange and the bead portion. The flange portion 11 exhibits a sealing function when pressed to the inner surface of the curved flange 18d with a charging pressure at the time of under-cup charging and also when clamped between the curved flange 18d and the bead portion 6 after assembly.

Owner:THAI DAIZO AEROSOL

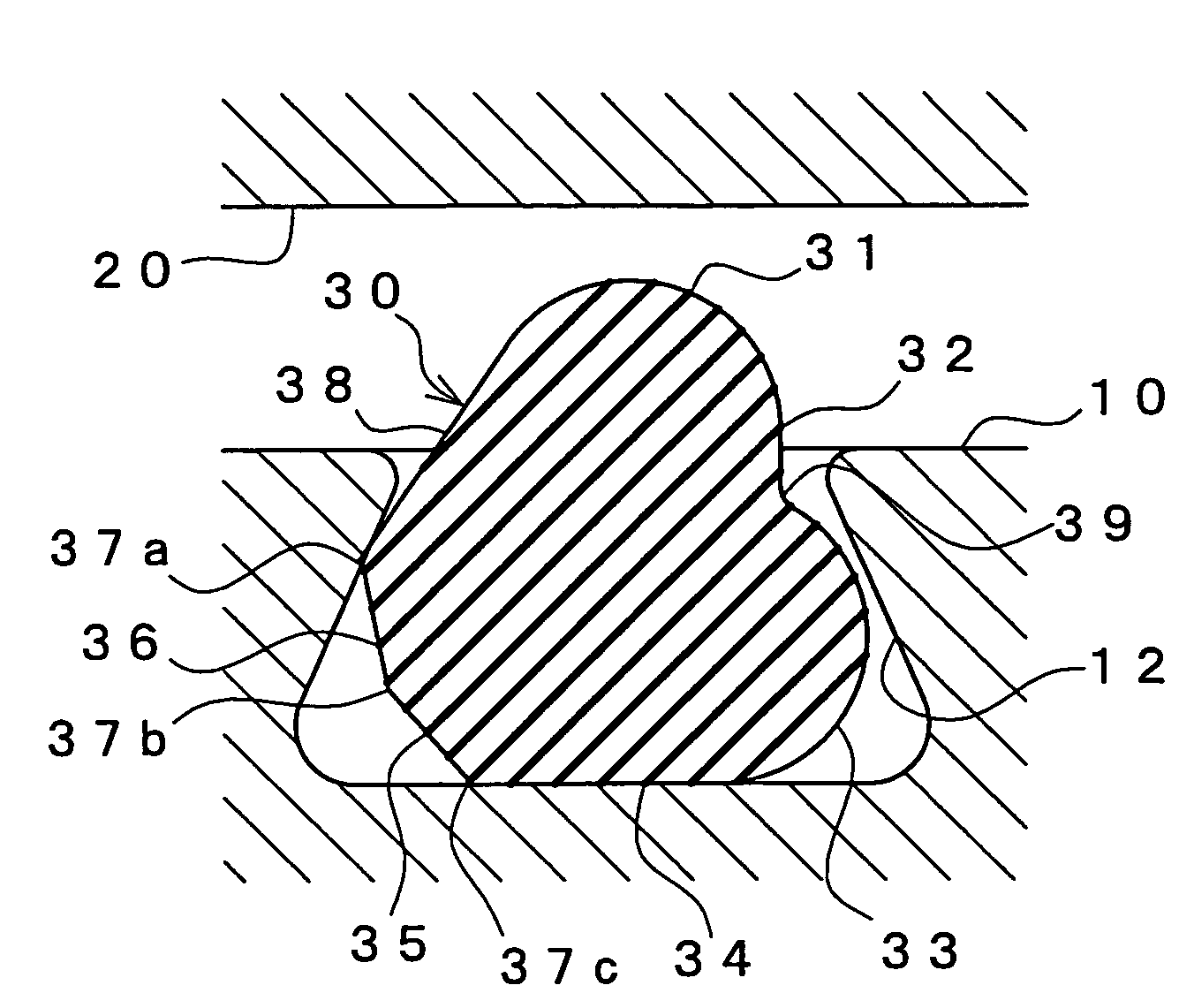

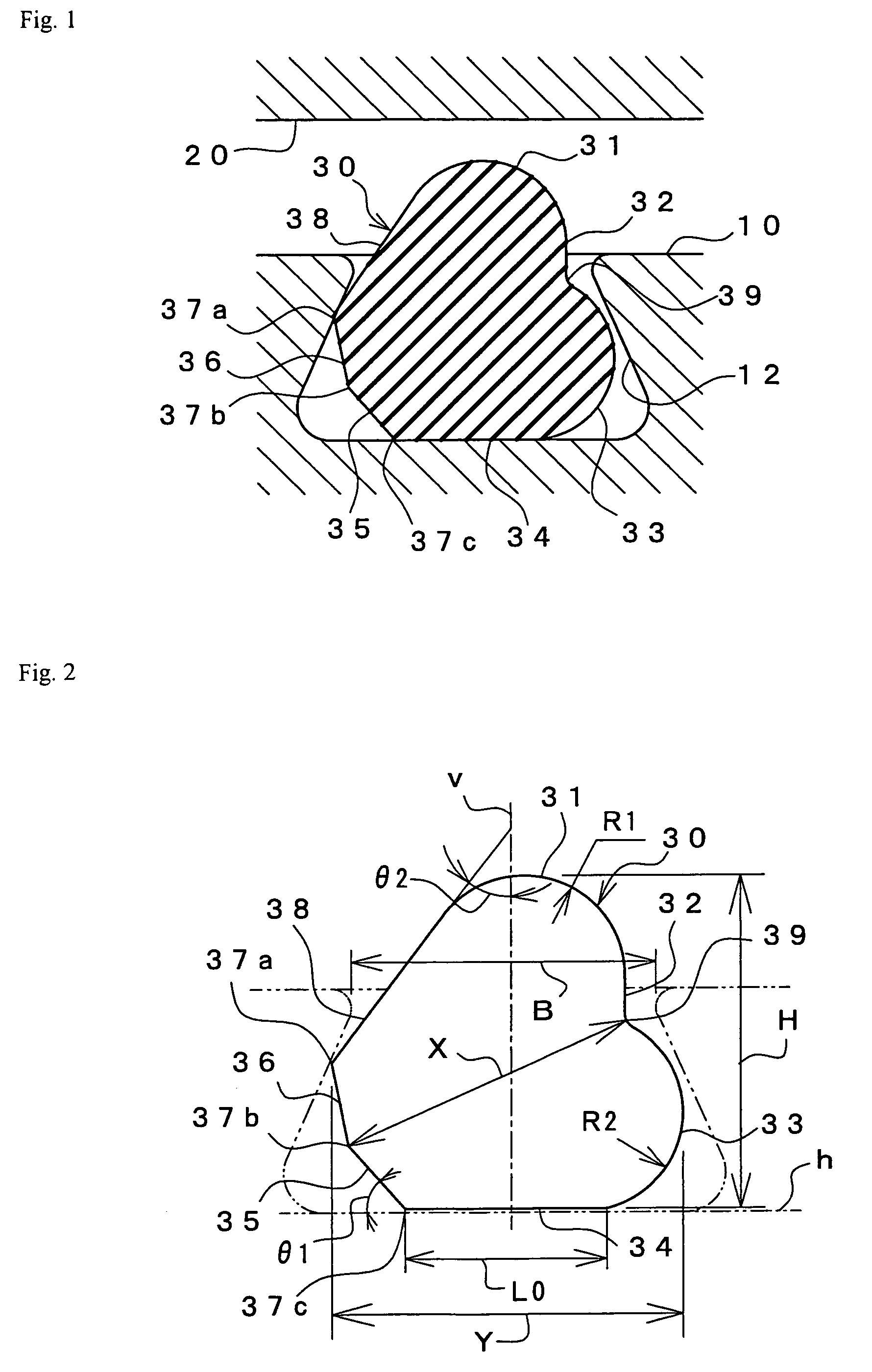

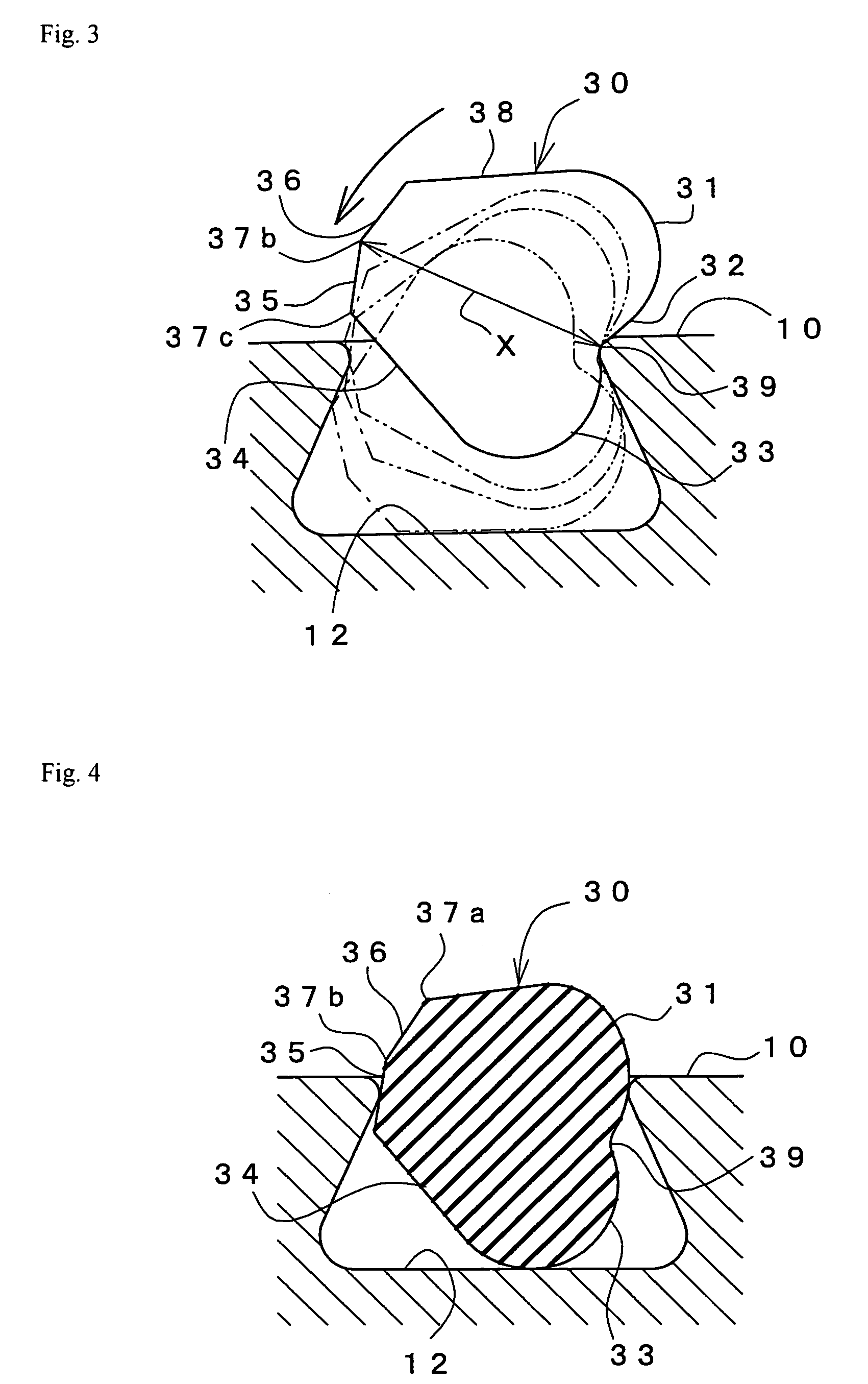

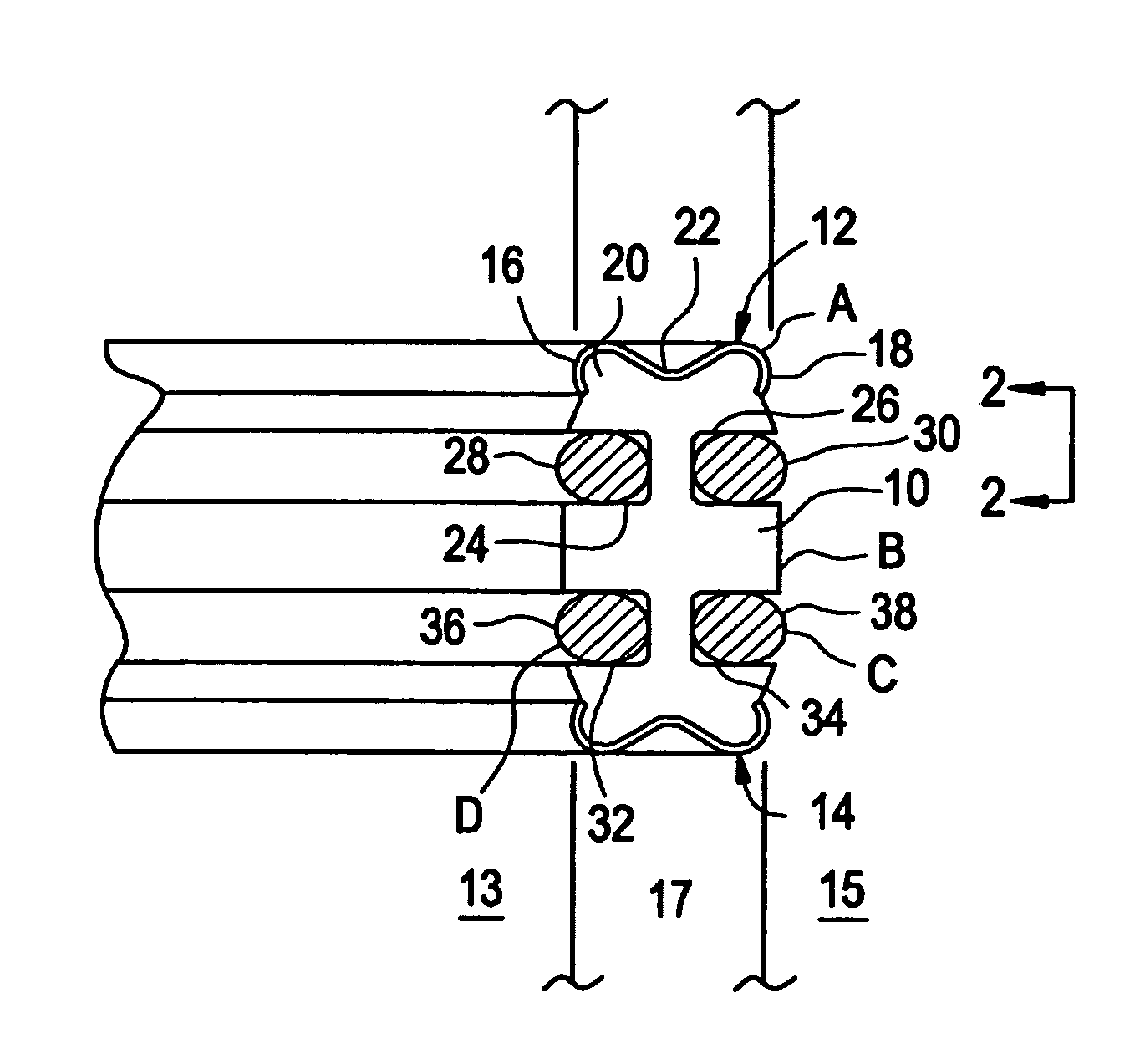

Sealing material for ant groove

ActiveUS7306237B2Easy to installImprove sealing functionEngine sealsEngineeringMechanical engineering

There is disclosed a sealing material for an ant groove, wherein the sealing material is easy to fit to the ant groove and little involves a phenomenon such that the sealing material unfavorably slips out of the ant groove in the form of remaining fixing to the opposite member when the sealed place is opened, and wherein the sealing material can exercise the good sealing function. The sectional shape of the sealing material has: a straight bottom edge 34 which is disposed on a bottom face of the ant groove 12; an arched convex edge 31 which contacts with the other member 20; a first projecting edge 33 which projects outside; a concave inlet portion 39; a second projecting edge which is composed of straight lines 35, 36 that project outside; a straight sloping edge 38; and at least one corner portion 37a-c which is constituted in the range of from the straight bottom edge 34 via the second projecting edge 35, 36 to the sloping edge 38.

Owner:VALQUA LTD

Refill case

ActiveUS7451877B2Utilize an expensive compact case more effectivelyEfficient use ofCapsClosure capsBiomedical engineeringGasket

A refill case that includes a middle plate, the middle plate has a bottomed short cylinder shape that contains a cosmetic item and an outward brim along the periphery, a case body that accepts and keeps the middle plate, and a cap that is fitted around the case body detachably in screw engagement. The refill case also includes a ring-shaped gasket made of a soft, elastic material used to seal the middle plate through tight contact of the brim, and a butting wall disposed on either one of the case body or the cap to butt against the other one at a position in which screw engagement of the cap is complete and in which soft contact deformation of the gasket is controlled within a range of elastic deformation. The gasket is fitted to the cap in an undetachable manner but having play relative to the roof.

Owner:YOSHINO KOGYOSHO CO LTD +1

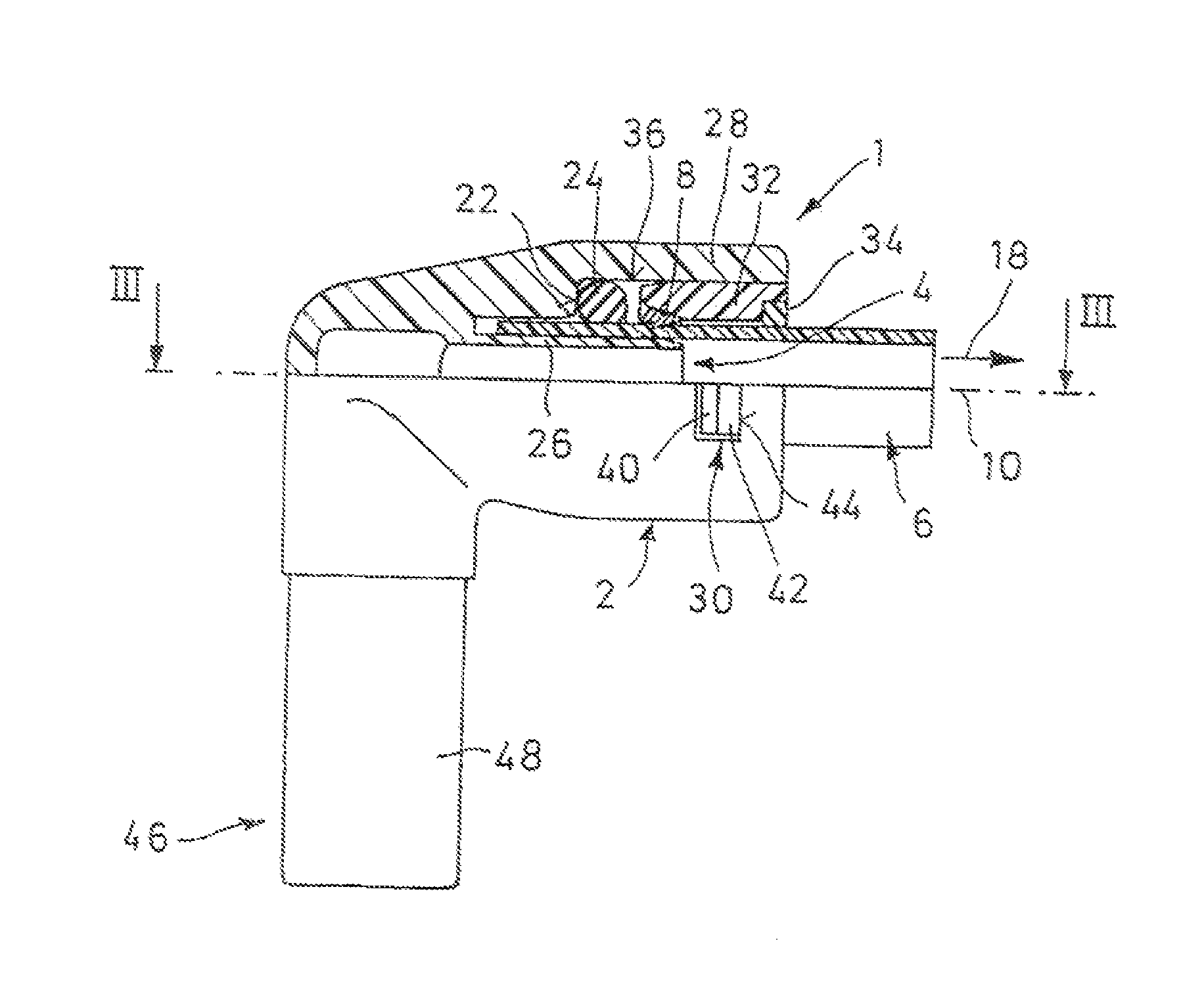

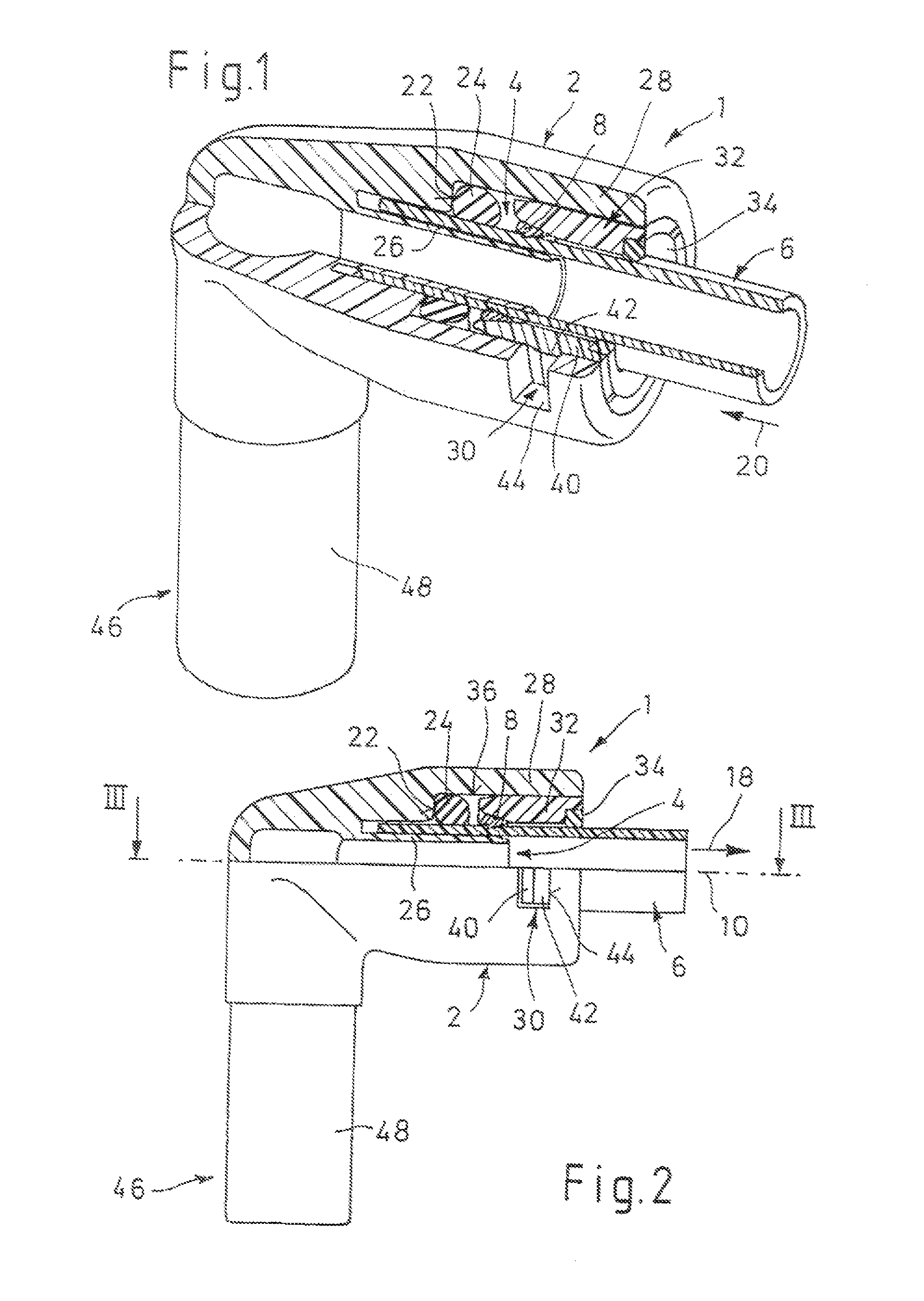

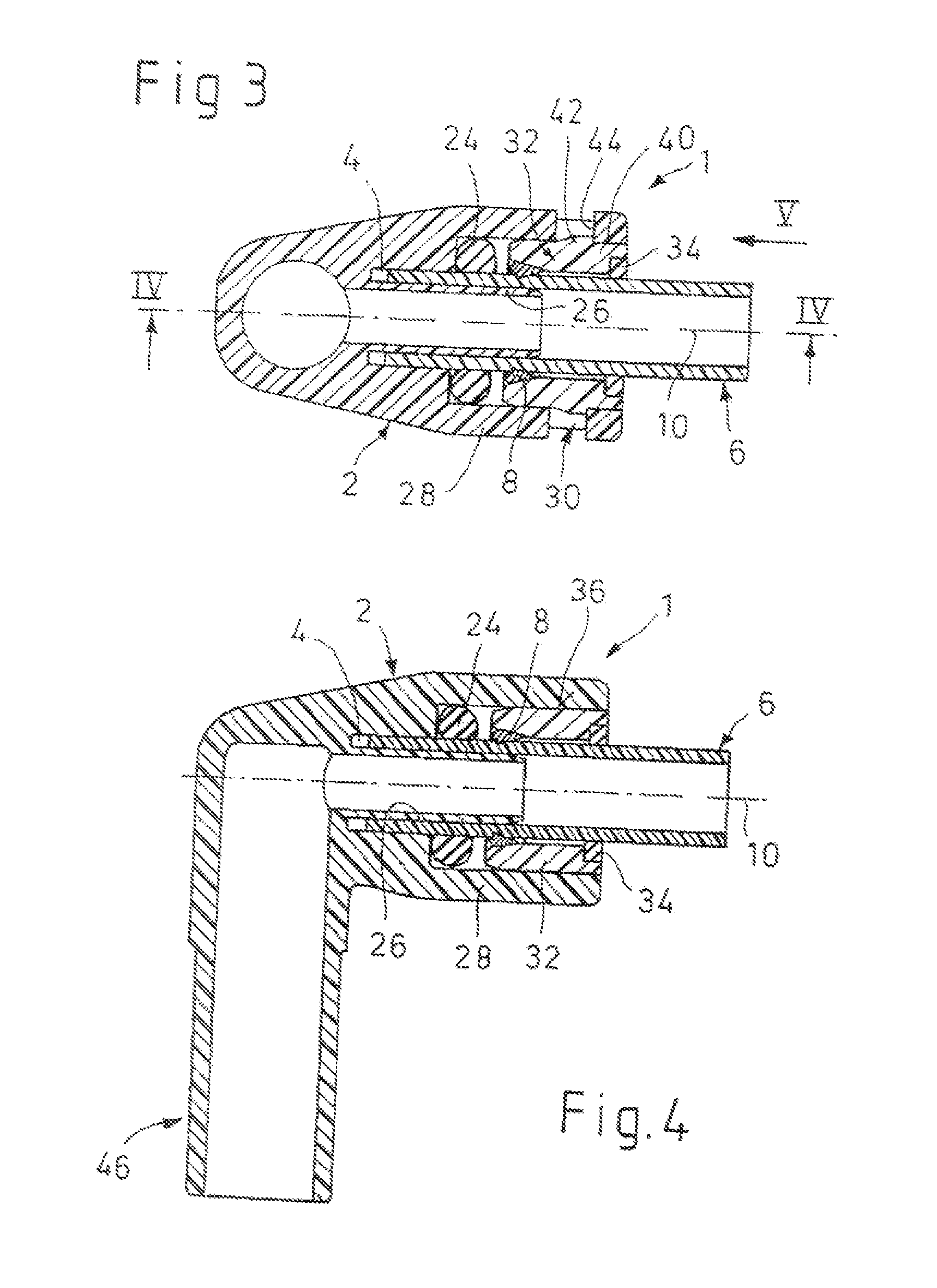

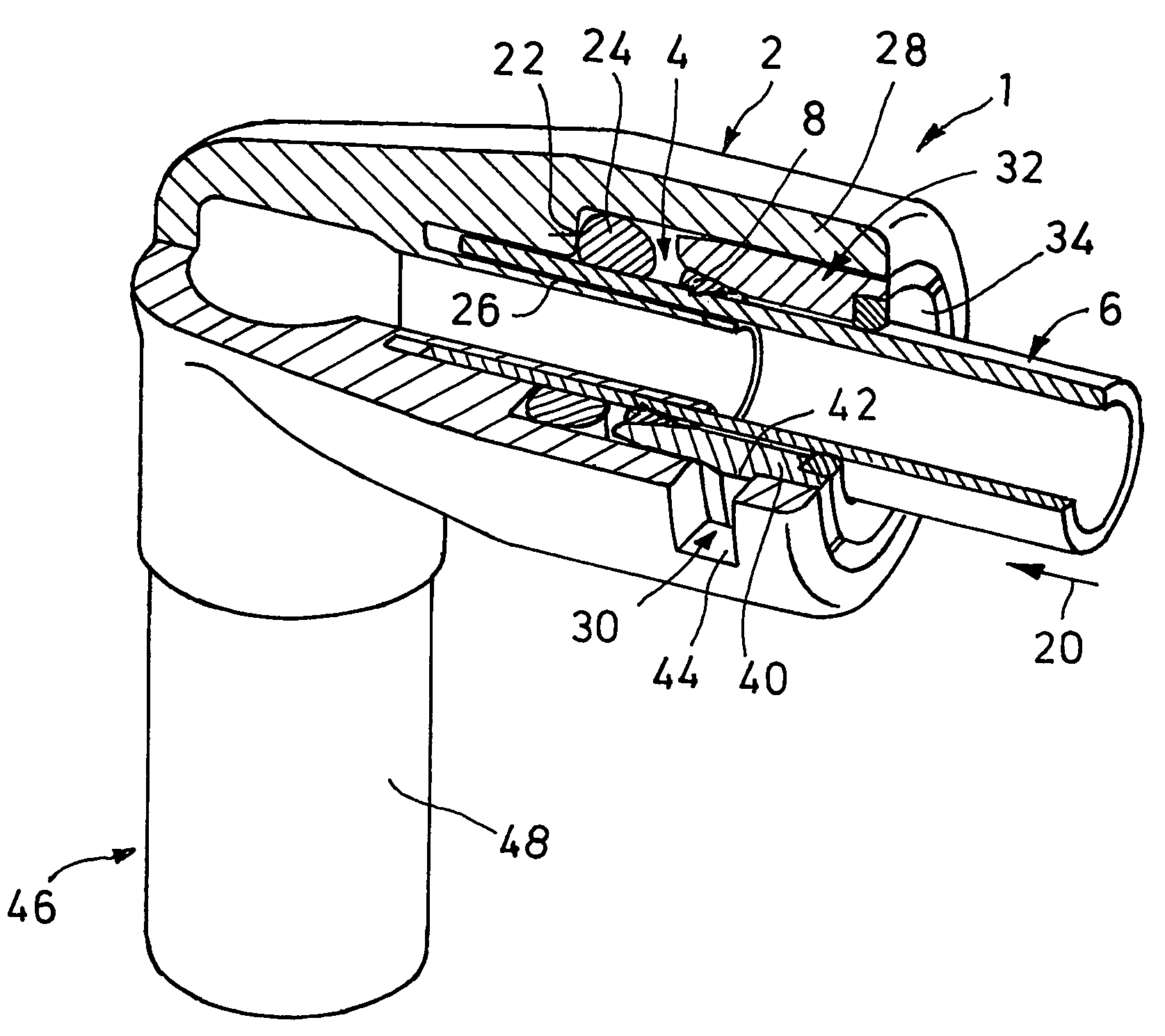

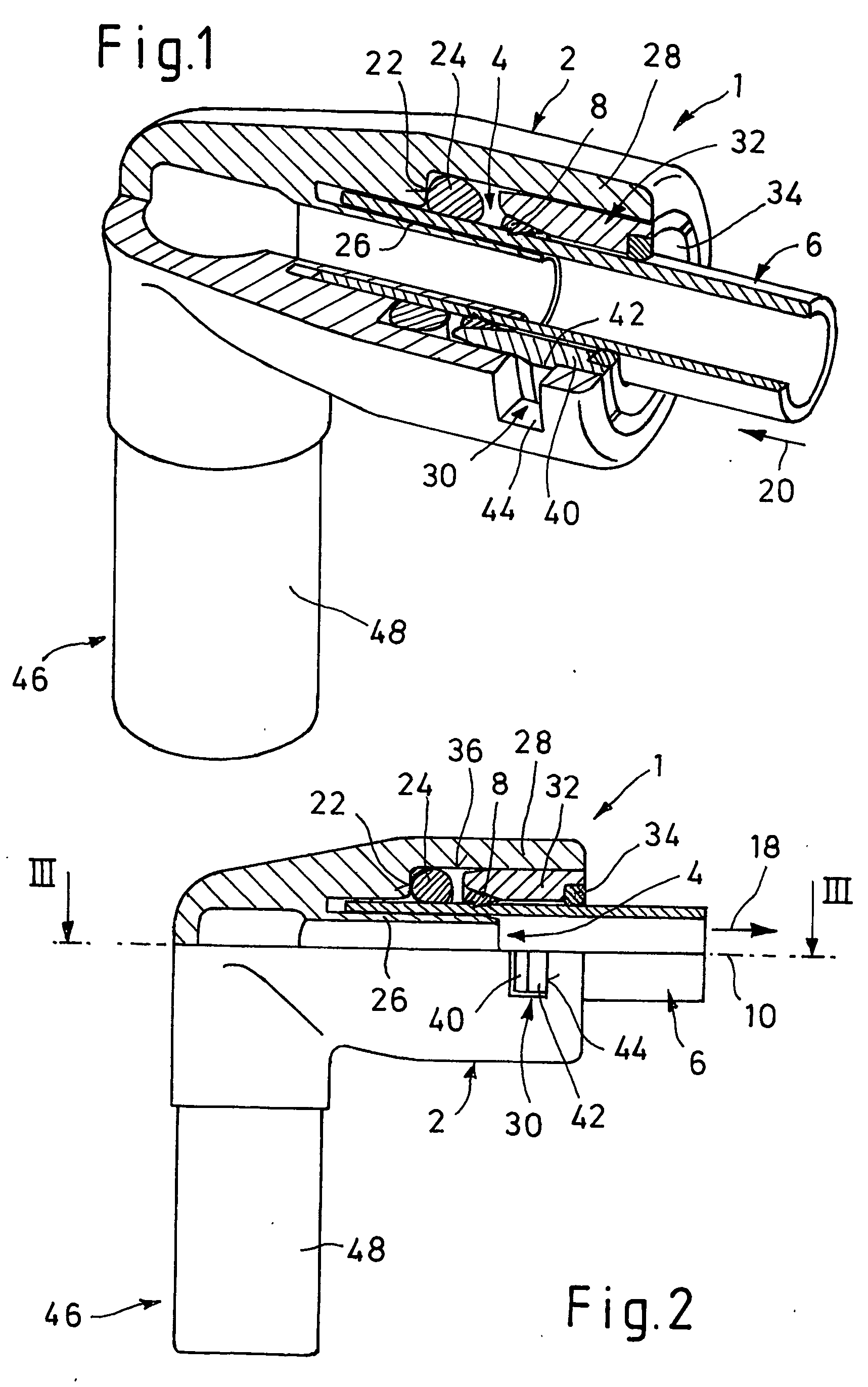

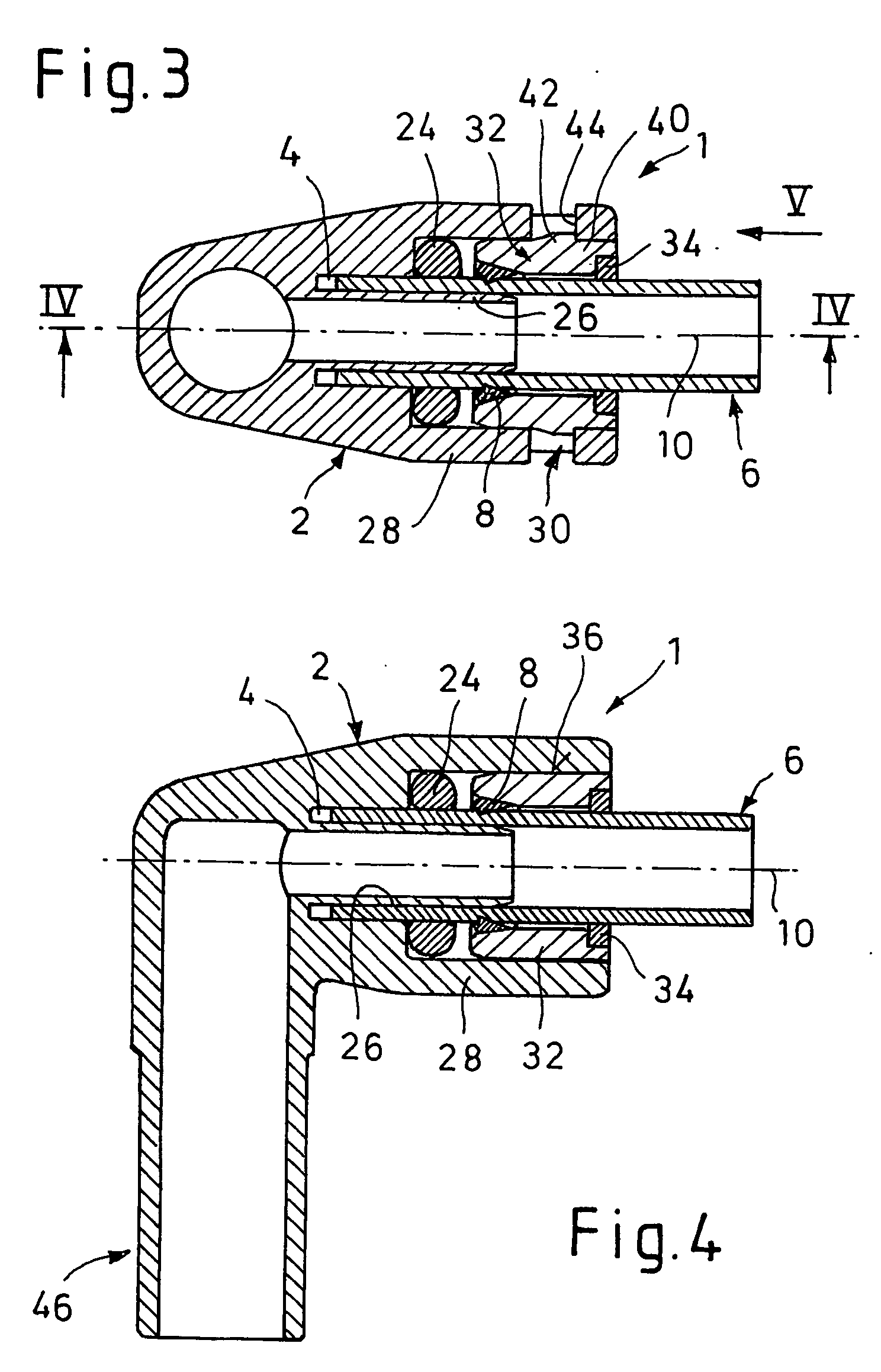

Connector device for pipes

InactiveUS7581763B2Improve sealing functionGood body shapeSleeve/socket jointsFluid pressure sealed jointsMating connectionPlastic materials

A connecting device for a plug-in connection of at least one pipeline having a housing part having at least one receiving opening for the insertion of the pipeline. A clamping ring is arranged in the receiving opening and, in order to lock the pipeline in place, interacts with an inner cone of the housing part. The housing part is made in two parts including a base part and an insert part, which is connected to the base part via a snap-in action forming-fitting connection. The insert part has a direct seal for resting on the circumference of the inserted pipeline. The insert part is formed of a first relatively hard and dimensionally stable plastic material, and has a dirt seal which consists of a second, relatively soft and elastic plastic material and is molded directly into the first material as a single piece with a cohesive material joint therebetween.

Owner:VOSS AUTOMOTIVE

Annular seal

ActiveUS7740248B2Avoid squeezingImprove sealing functionSleeve/socket jointsPipe supportsStored energyEngineering

A seal assembly capable of low temperature service is disclosed. It features upper and lower metallic backup rings that are specially shaped to act as a spring to keep the sidewalls of such rings in contact with the inside and outside surfaces to be sealed to prevent extrusion of the seal material even in low temperature situations. Inner and outer grooves are provided. O-ring seals, used for the ID of the seal, are manufactured to have a slightly greater diameter than the groove into which they will be installed. The greater length provides stored energy to promote sealing functionality in cold temperature situations. The O-rings used for the OD of the seal are manufactured to have a slightly smaller diameter than the groove into which they will be installed. The shorter length provides stored energy to promote sealing functionality in cold temperature situations.

Owner:SCHLUMBERGER TECH CORP

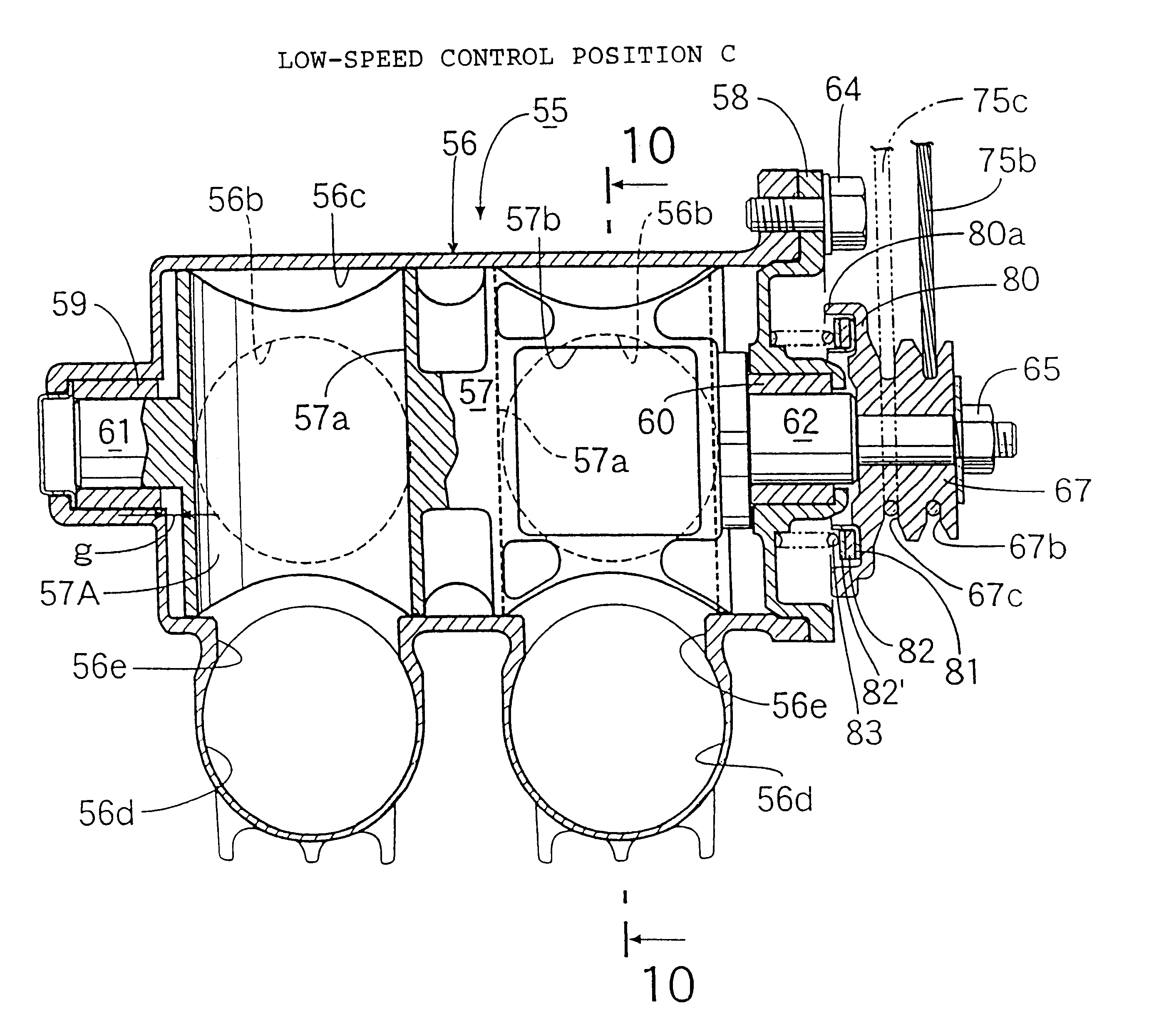

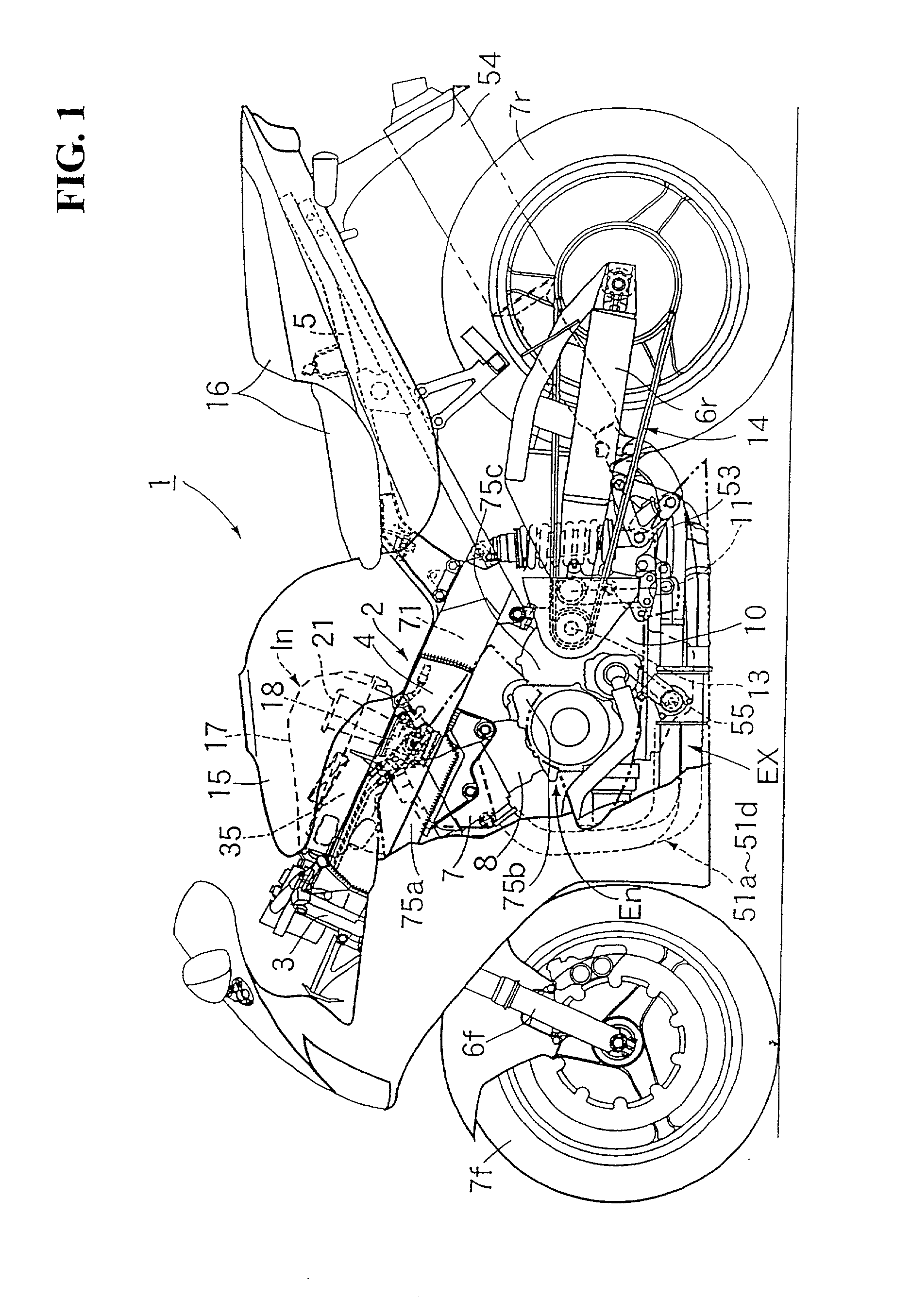

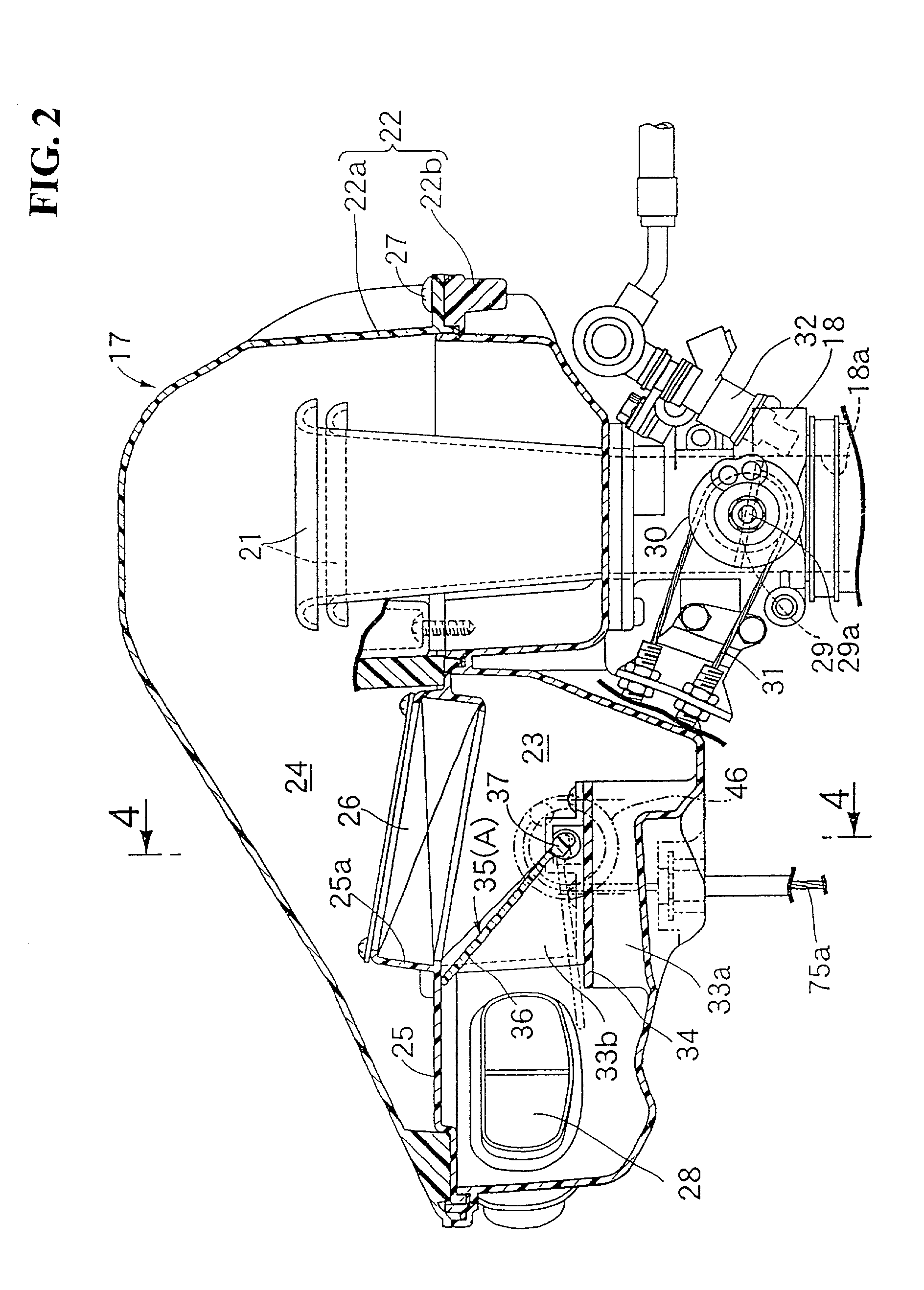

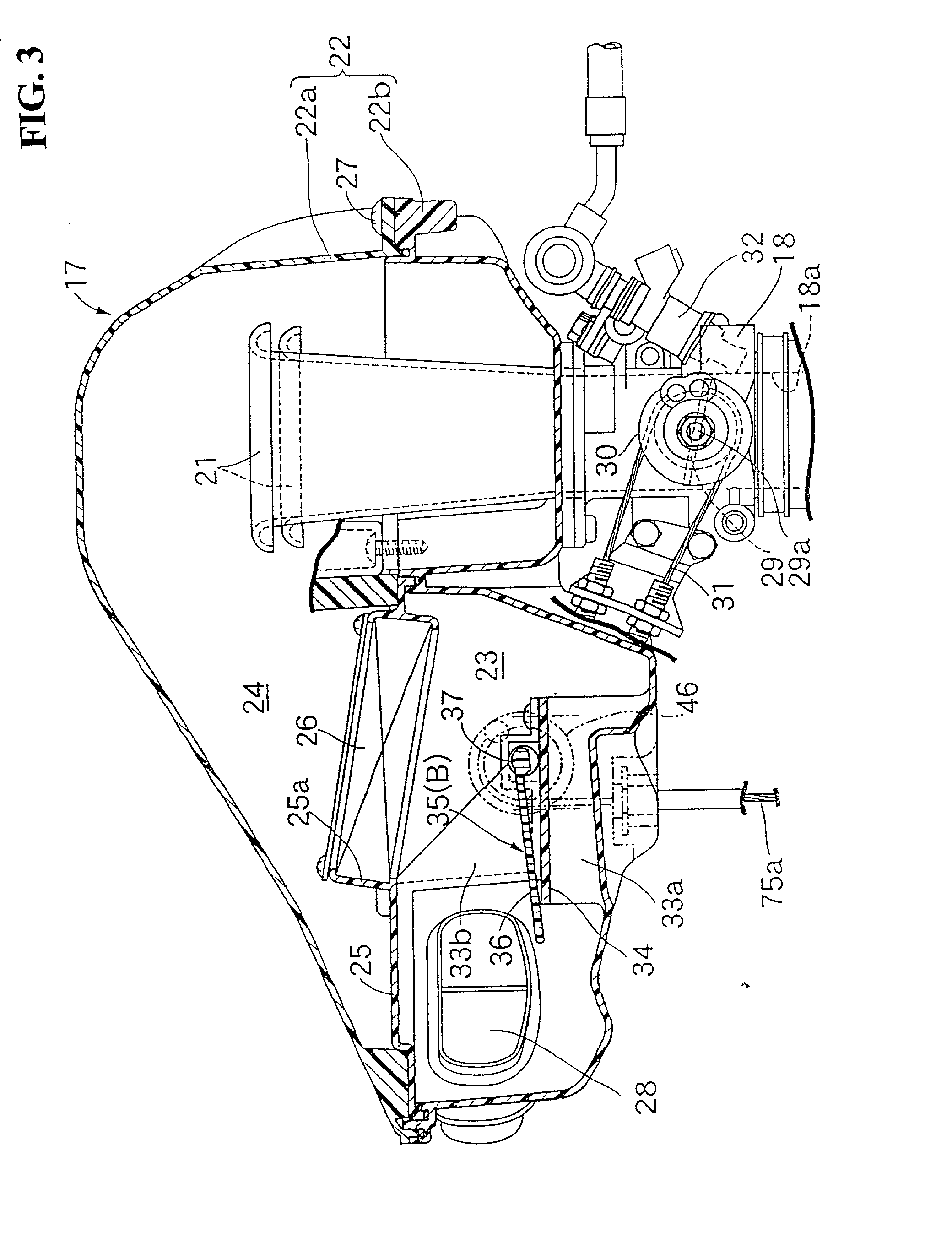

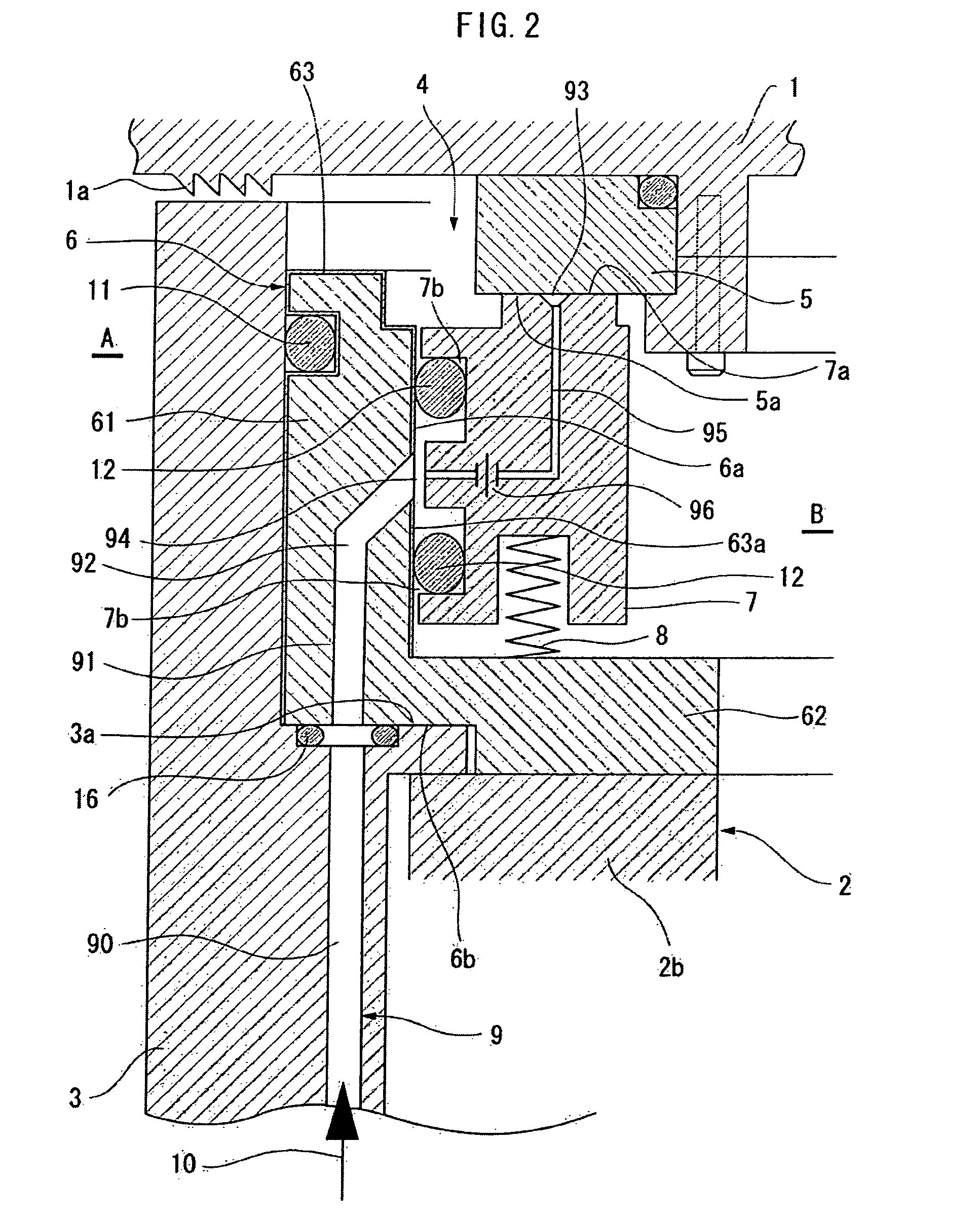

Exhaust control valve

InactiveUS6609367B2Leakage of exhaust gas from the vicinity of a valve shaft can be preventedLow costPlug valvesOperating means/releasing devices for valvesEngineeringControl valves

In an exhaust control valve having a valve housing and a valve body rotatably contained in the valve housing, a transmission member is fitted to an outer end of the valve shaft and protrudes from the outside of the valve housing. A bearing bushing for rotatably bearing an external circumferential surface of the valve shaft by its internal circumferential surface and rotatably bearing an end face of the valve body by its end face is mounted in the valve housing. The valve body is urged by load from a thrust spring for achieving a pressure contact seal condition between the opposed end faces of the bearing bush and the valve body.

Owner:HONDA MOTOR CO LTD

Exhaust control valve

InactiveUS20010035009A1Leakage of exhaust gas from the vicinity of a valve shaft can be preventedLow costPlug valvesOperating means/releasing devices for valvesEngineeringControl valves

In an exhaust control valve having a valve housing and a valve body rotatably contained in the valve housing, a transmission member is fitted to an outer end of the valve shaft and protrudes from the outside of the valve housing. A bearing bushing for rotatably bearing an external circumferential surface of the valve shaft by its internal circumferential surface and rotatably bearing an end face of the valve body by its end face is mounted in the valve housing. The valve body is urged by load from a thrust spring for achieving a pressure contact seal condition between the opposed end faces of the bearing bush and the valve body.

Owner:HONDA MOTOR CO LTD

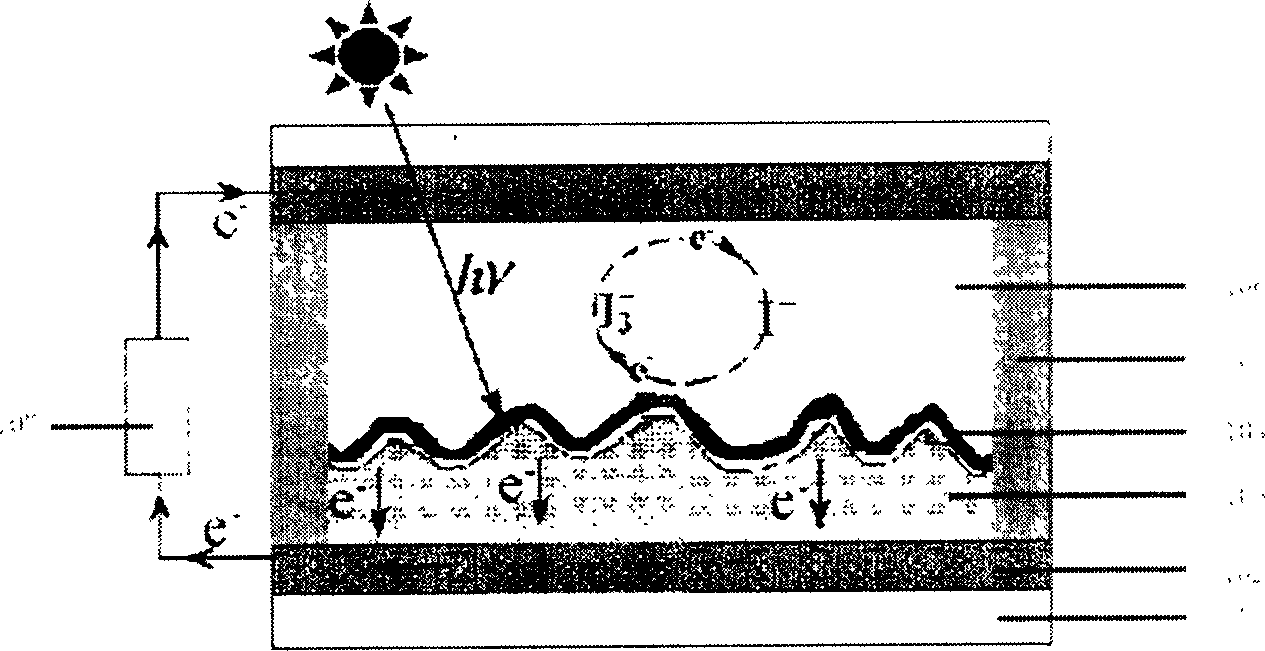

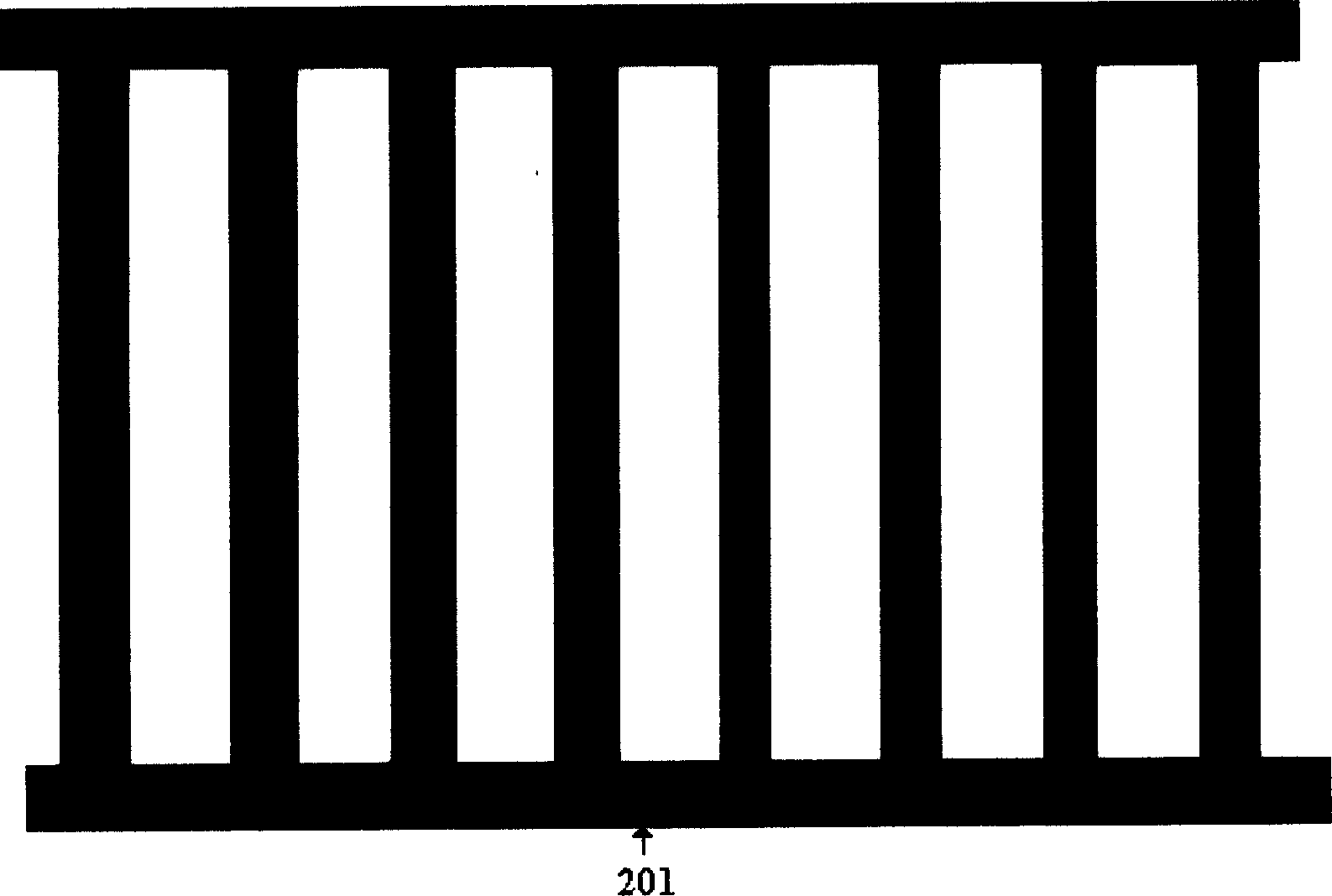

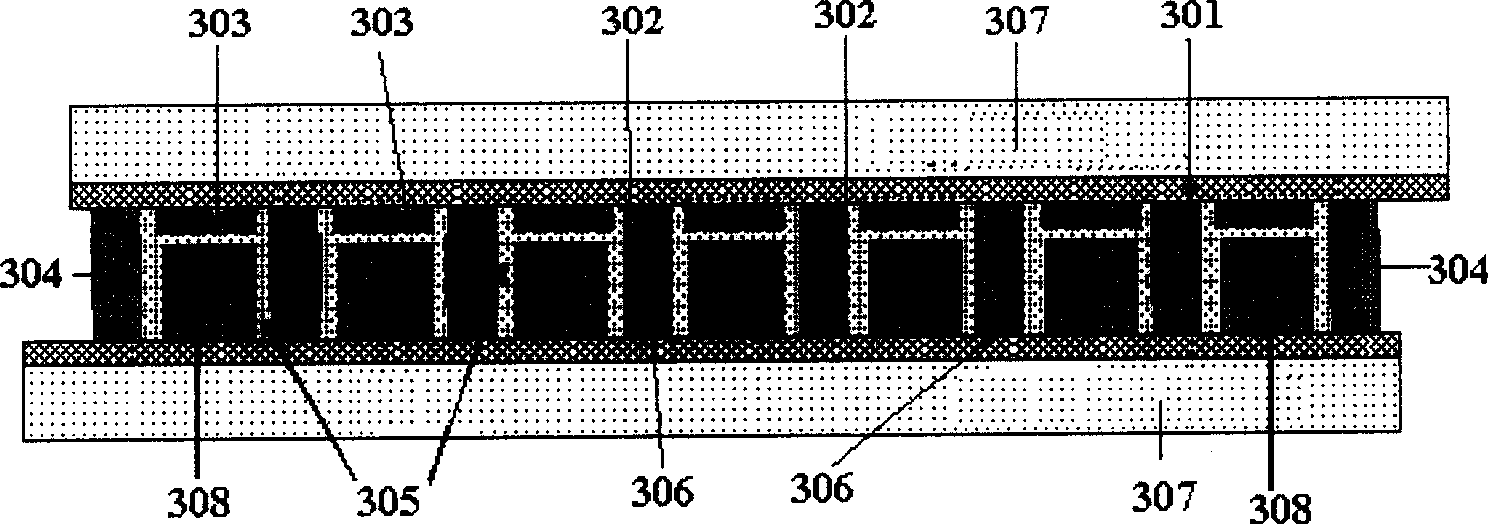

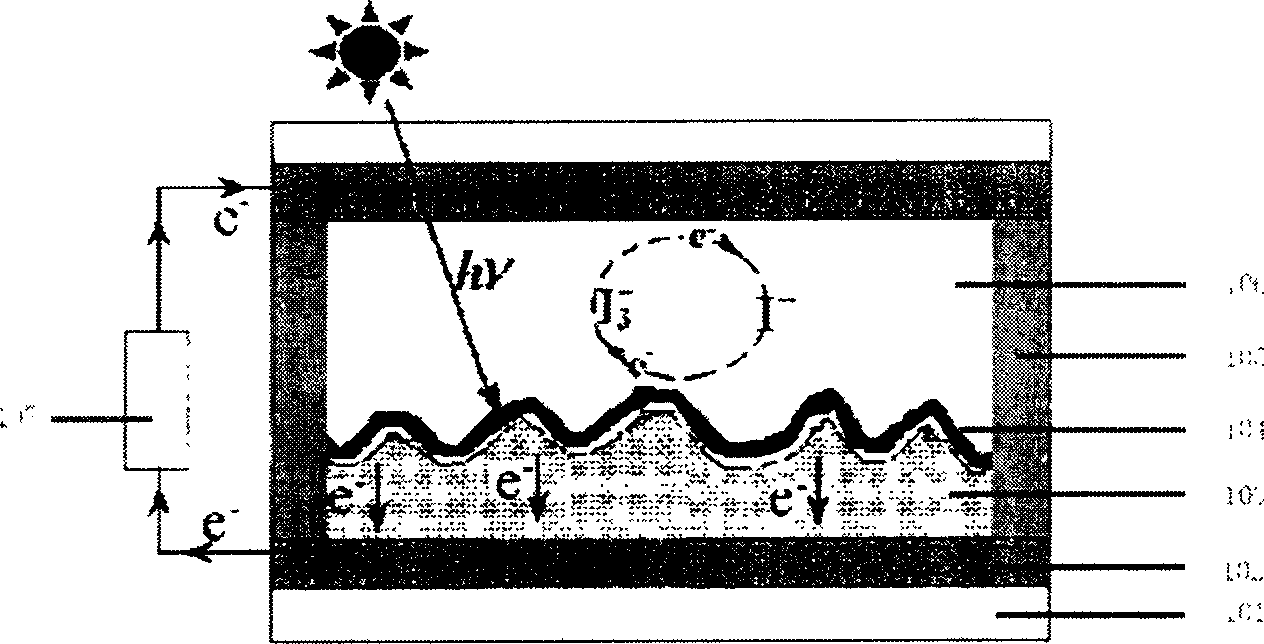

Large area internal series dye sensitization nano-thin film solar cell and producing method thereof

InactiveCN1674303AOvercome technical difficultiesOvercoming selectivityPhotovoltaic energy generationSemiconductor devicesSemiconductor materialsTransparent conducting film

A film solar cell comprises top and bottom transparent baseboards. It is prepared by arranging conduction electrode and catalyst layer in interval on one transparent conduction film of substrate as well as arranging conduction electrode and nanomutihole semiconductor material block in interval on another one, soaking dyestuff in said nanomaterial, overlapping two transparent baseboards and sealing periphery of them to form cavity with electrolyte. The internal parallel electrode is also prepared for obtaining output current of solar cell.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

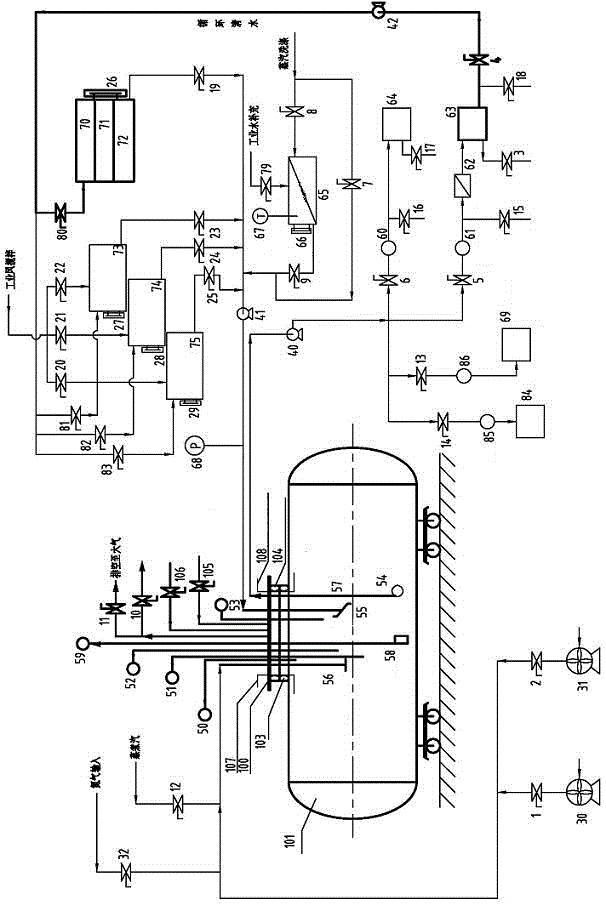

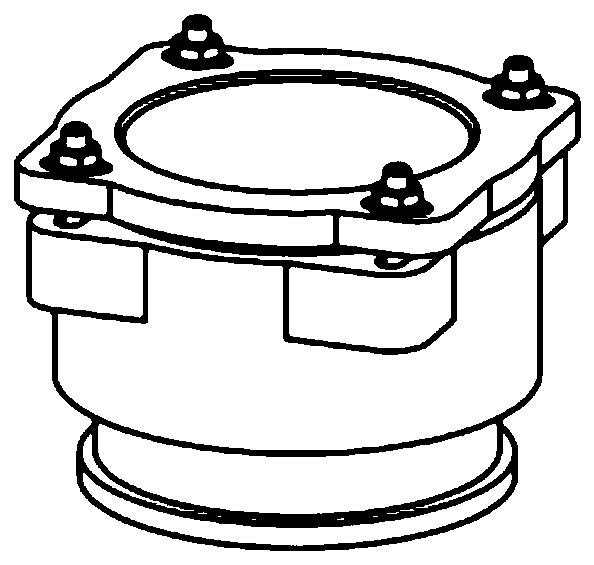

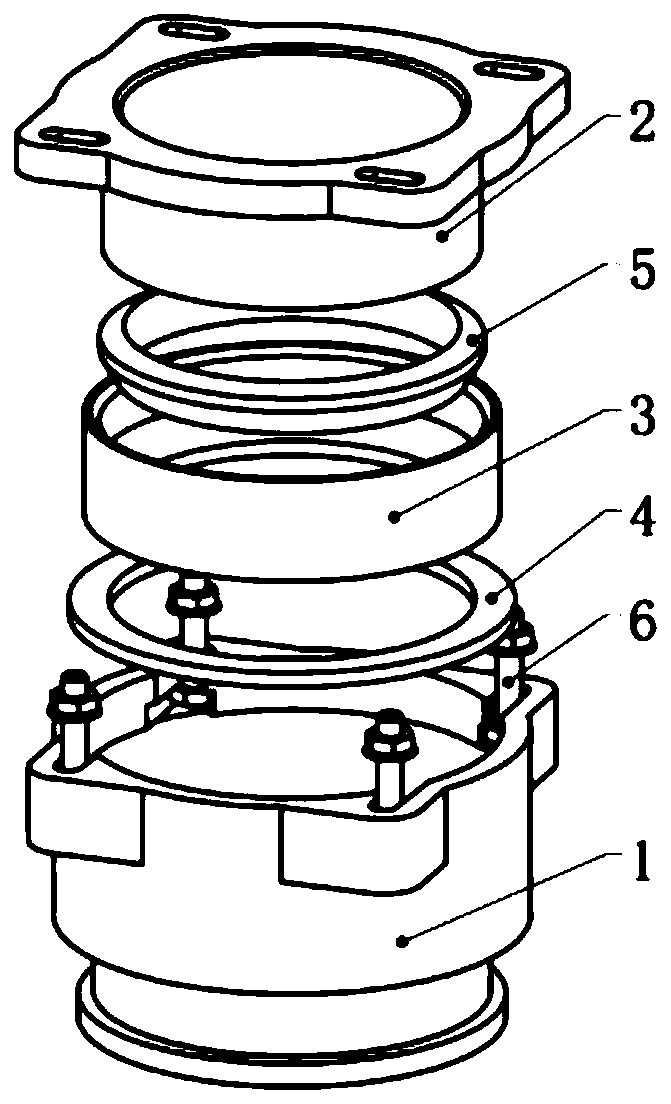

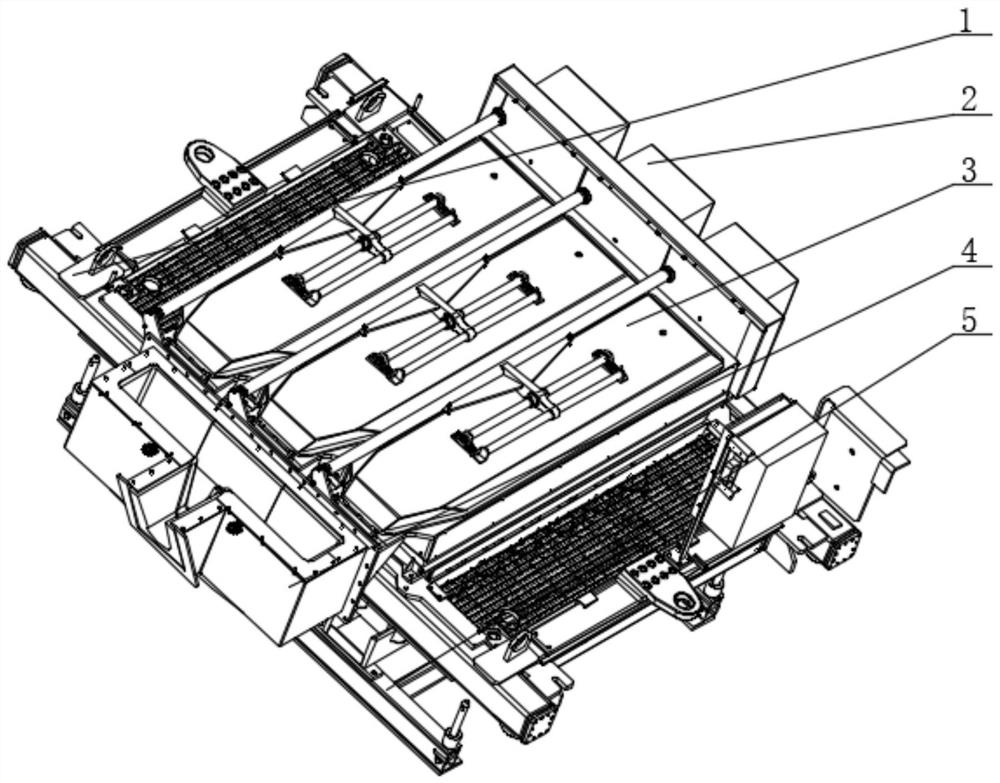

Closed energy-saving and environment-friendly tank truck cleaning device and cleaning method thereof

ActiveCN106140751AFree height adjustmentImprove sealing functionHollow article cleaningTank truckHigh pressure water

The invention relates to a closed energy-saving and environment-friendly tank truck cleaning device which comprises a tank truck and an air bag type closing cover plate, wherein the air bag type closing cover plate is connected with a nitrogen input pipe, a cooking steam input pipe, an exhaust fan and a drying fan respectively, and is also connected with an alkali liquid washing basin, a detergent washing basin, a chemical agent washing basin, a high-pressure water washing basin, a low-pressure water washing basin, a water washing basin and a heat exchanger respectively; the heat exchanger is connected with a steam washing pipeline and an industrial water supplementation pipeline respectively; the air bag type closing cover plate is connected with a residual liquid basin, an oil-water separator, a wastewater sedimentation treatment basin, a residual acid basin and a lime reaction sedimentation basin in sequence; the wastewater sedimentation treatment basin is connected with the alkali liquid washing basin, the detergent washing basin, the chemical agent washing basin, the high-pressure water washing basin, the low-pressure water washing basin and the water washing basin respectively; and an industrial air stirring device is connected with the alkali liquid washing basin and the chemical agent washing basin. Meanwhile, the invention further discloses a cleaning method for the device. The closed energy-saving and environment-friendly tank truck cleaning device and the cleaning method thereof are safe and convenient to use, and good in cleaning effect.

Owner:LANZHOU LEIDE INSTR +2

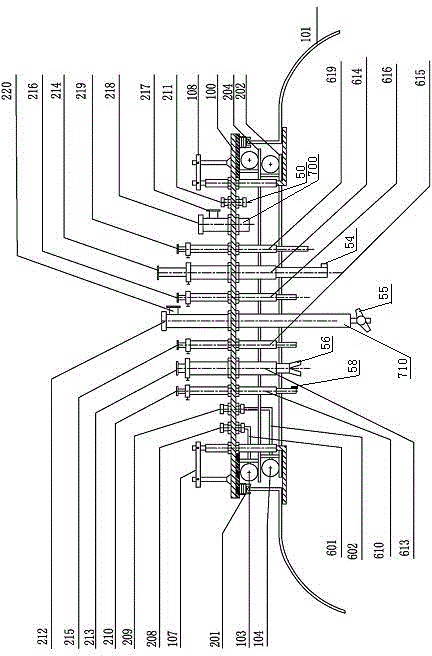

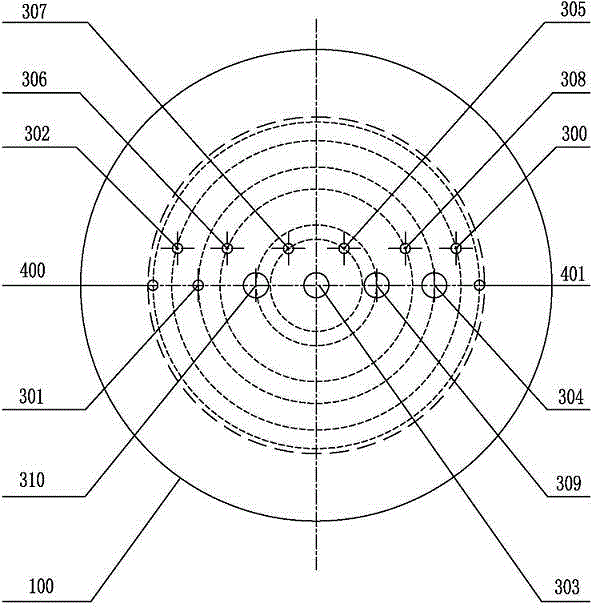

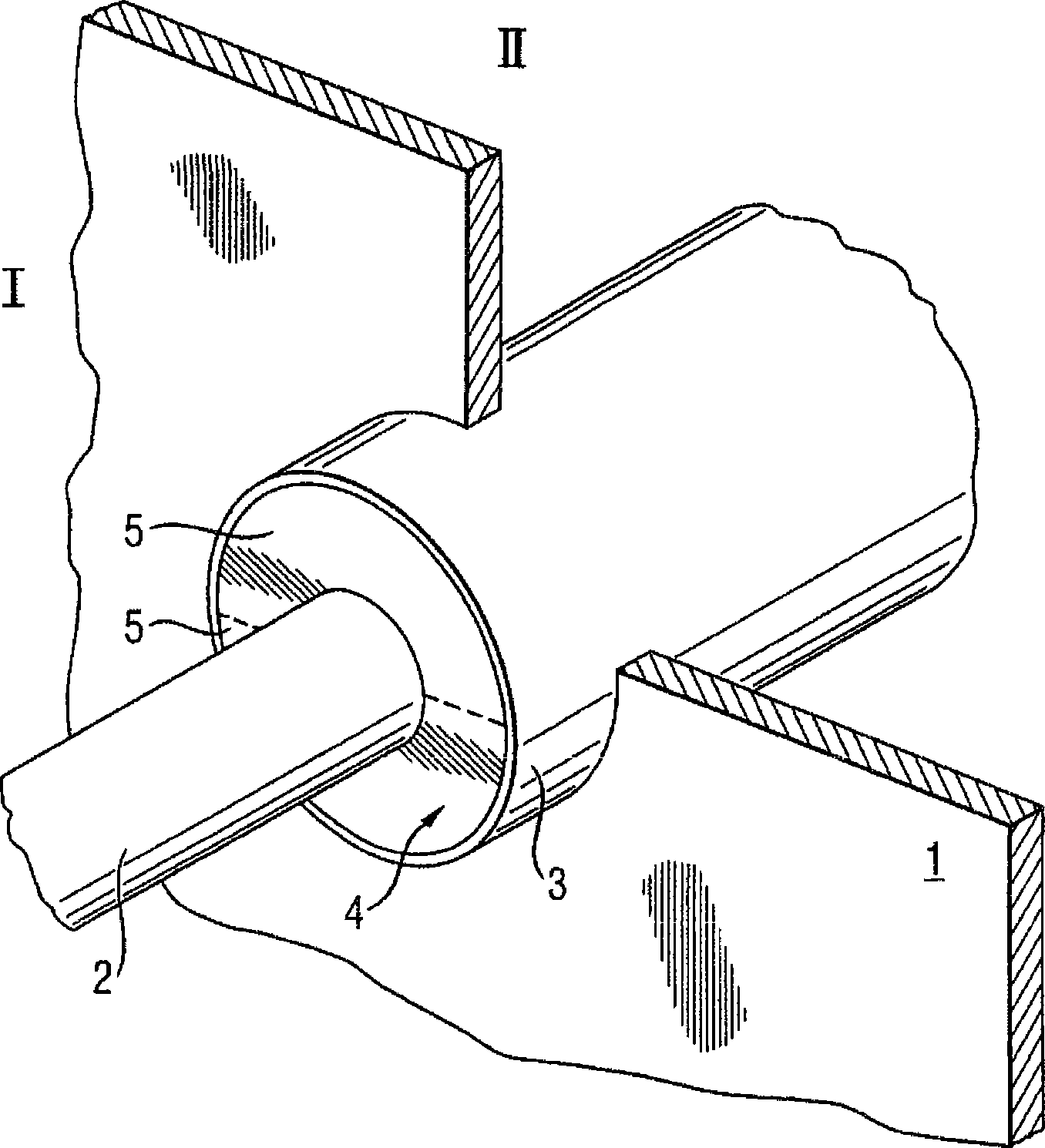

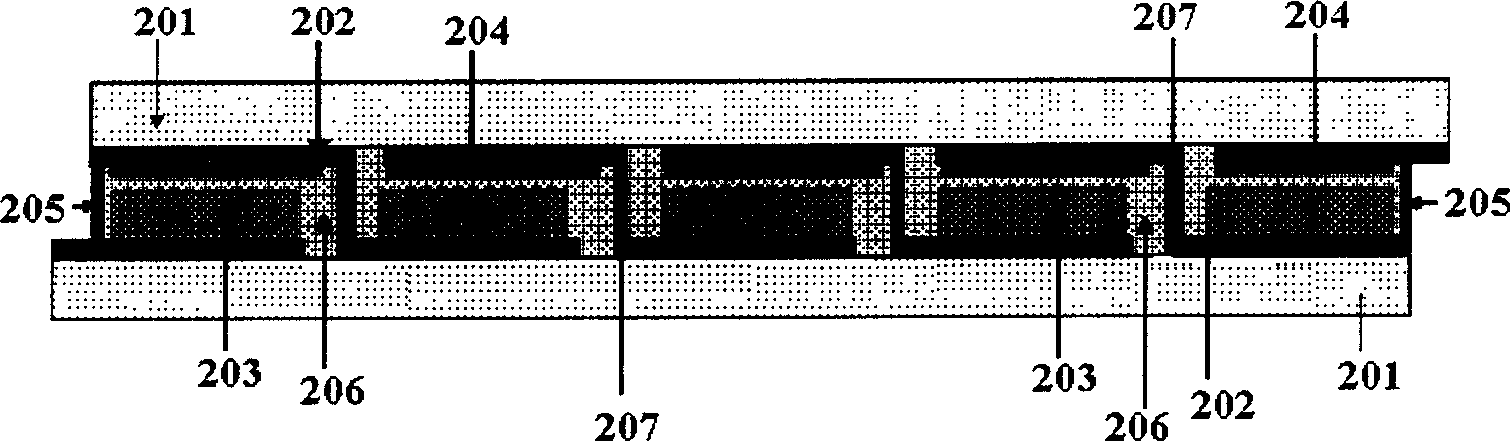

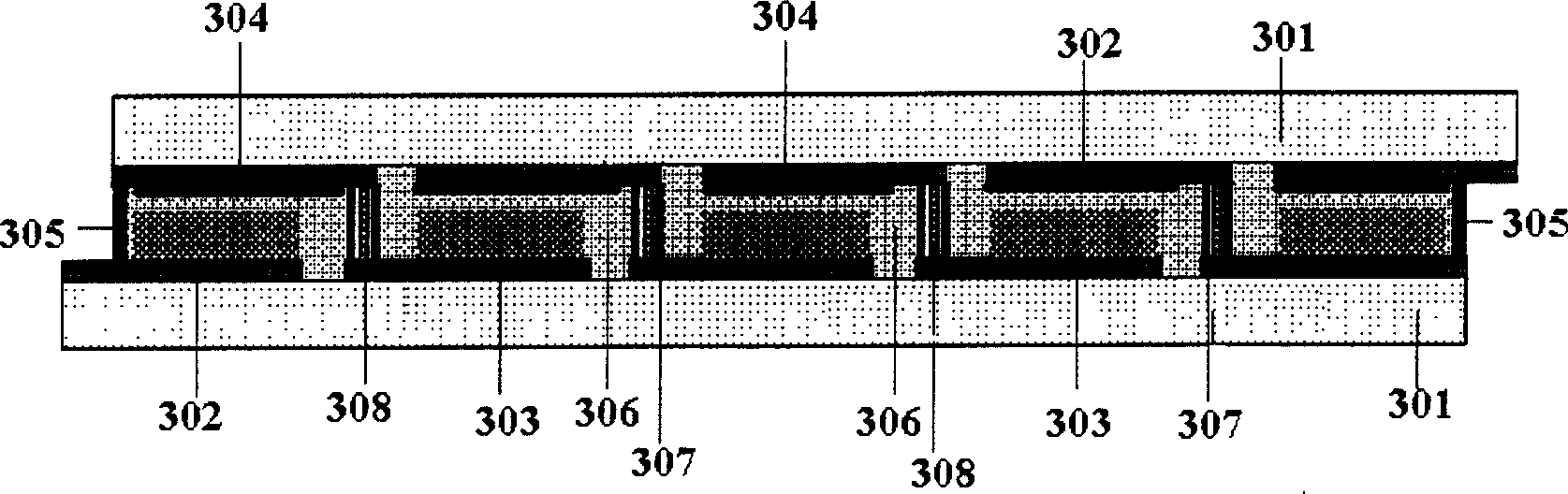

System for dynamically sealing at least one conduit through which a pipe or cable extends

ActiveCN101506565AImprove sealingImprove sealing functionElectrical apparatusPipesBiomedical engineering

A system for providing a sealed transit for a situation wherein one or a plurality of cables, pipes or ducts (2) extend through the transit, wherein the system comprises a frame (100) which is sealingly fixed or fixable into or onto an opening, wherein the frame (100) comprises one or a plurality of conduits (203) which are each suitable for receiving at least one of the plurality of cables, pipes or ducts (2) and for receiving an elastically deformable plug (4) for sealingly filling space between an inner circumferential wall of the conduits (203) and the at least one of the plurality of cables, pipes or ducts (2), wherein the system further comprises at least one blocking element (37) for hindering in each conduit (203) movement of one end of a plug (4) which is inserted in that conduit (203).

Owner:BEELE ENG

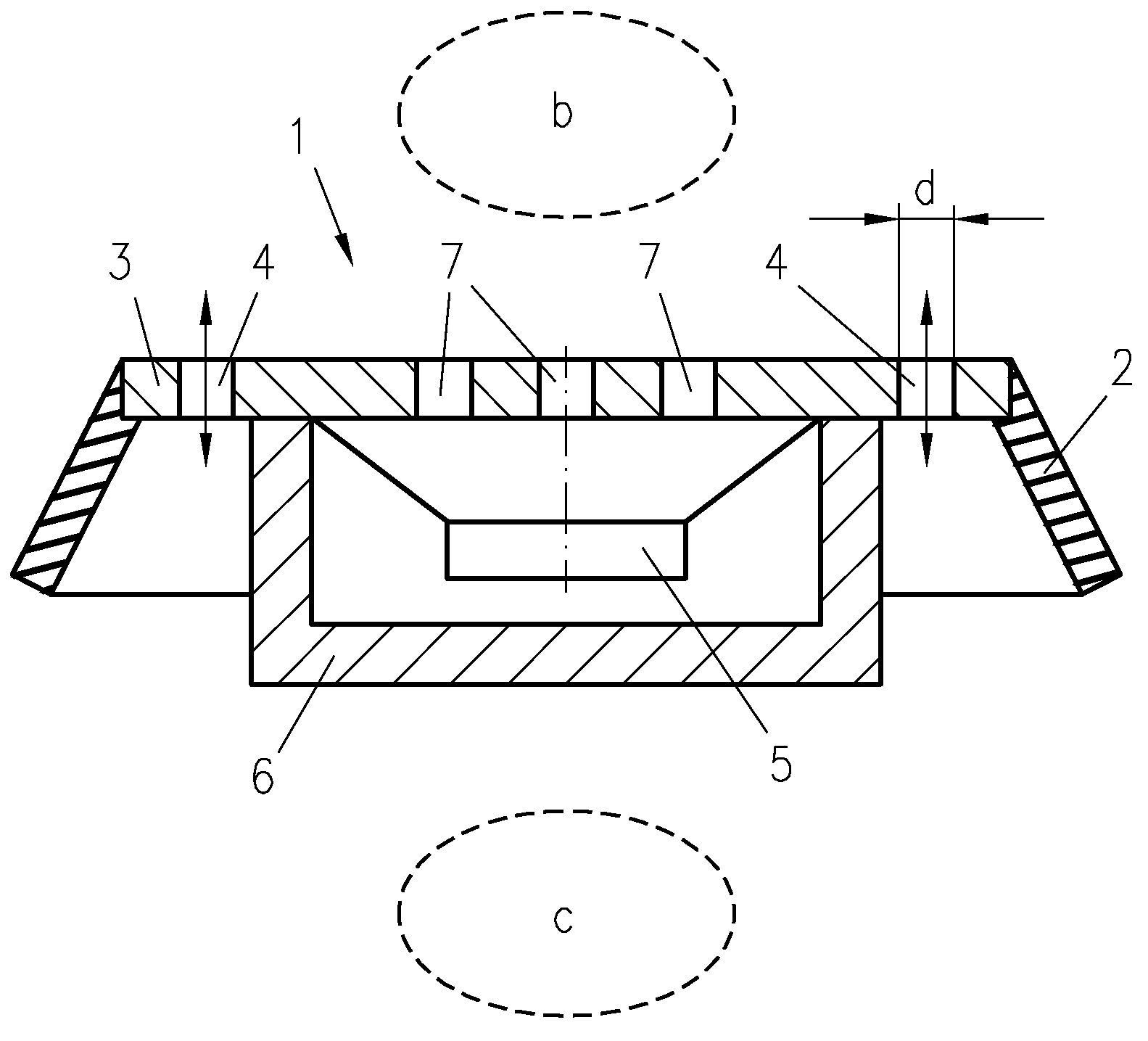

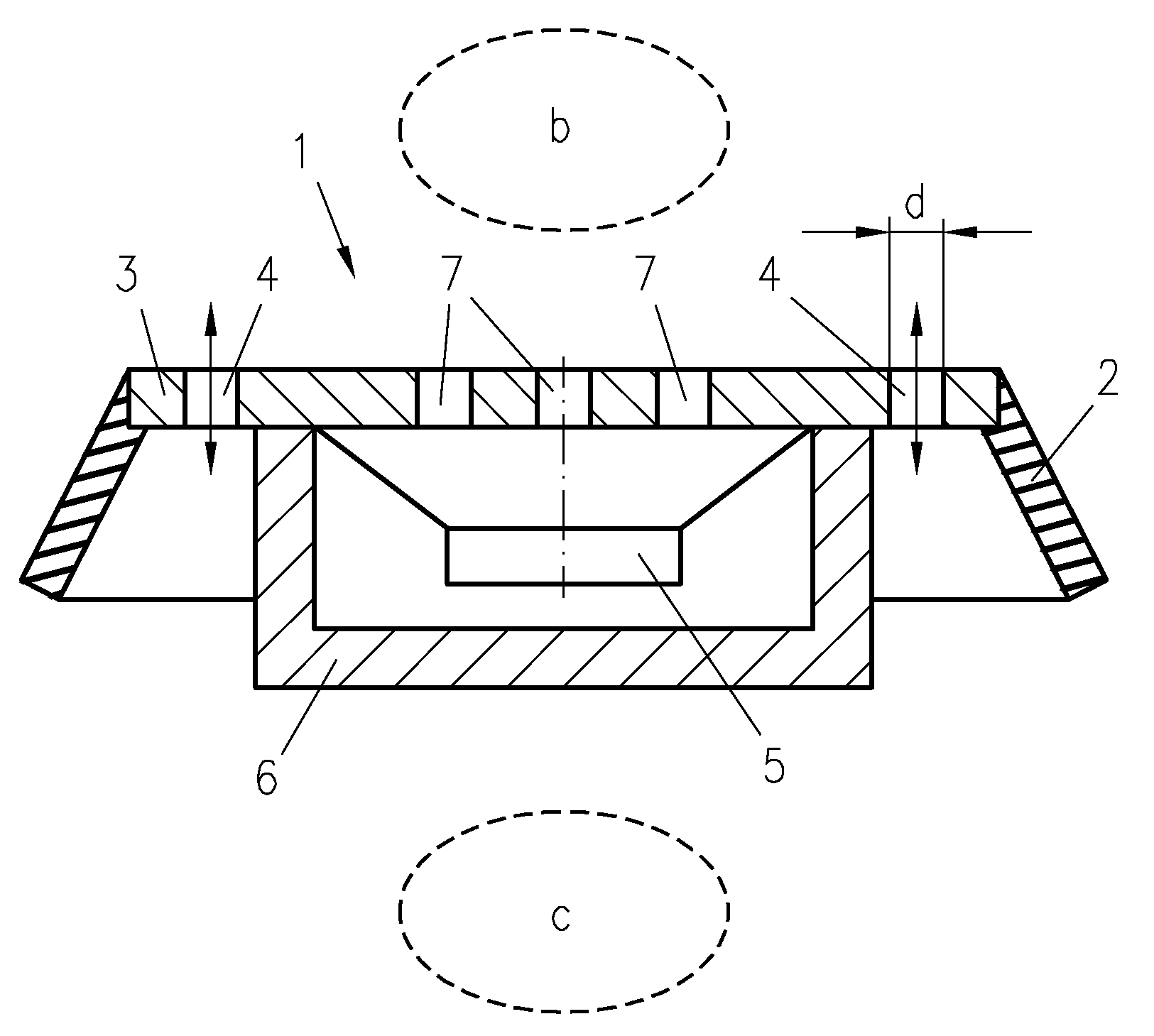

In-Ear Headphone

InactiveUS20080095393A1Good sound reproductionEasy to produceHearing aid ventsIntra aural earpiecesEngineeringHeadphones

An in-ear headphone (1) comprising an elastic sealing part (2) and a solid sealing part (3) for sealing an ear cavity (b) against an outside region (c) is disclosed, wherein said solid sealing part (3) comprises at least one damping vent (4) interconnecting the ear cavity (b) and the outside region (c), and wherein said damping vent (4) forms an acoustic friction.

Owner:NXP BV

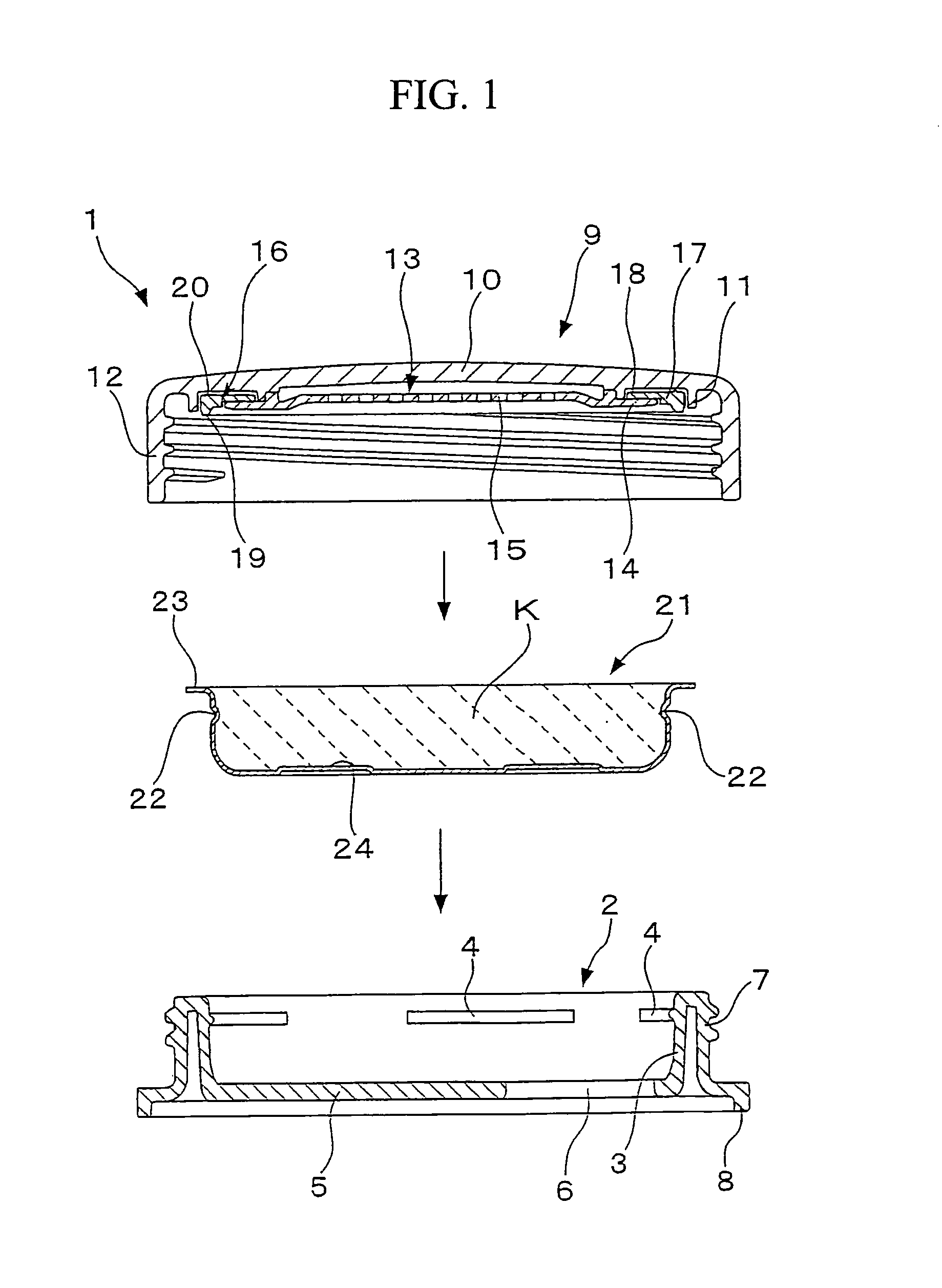

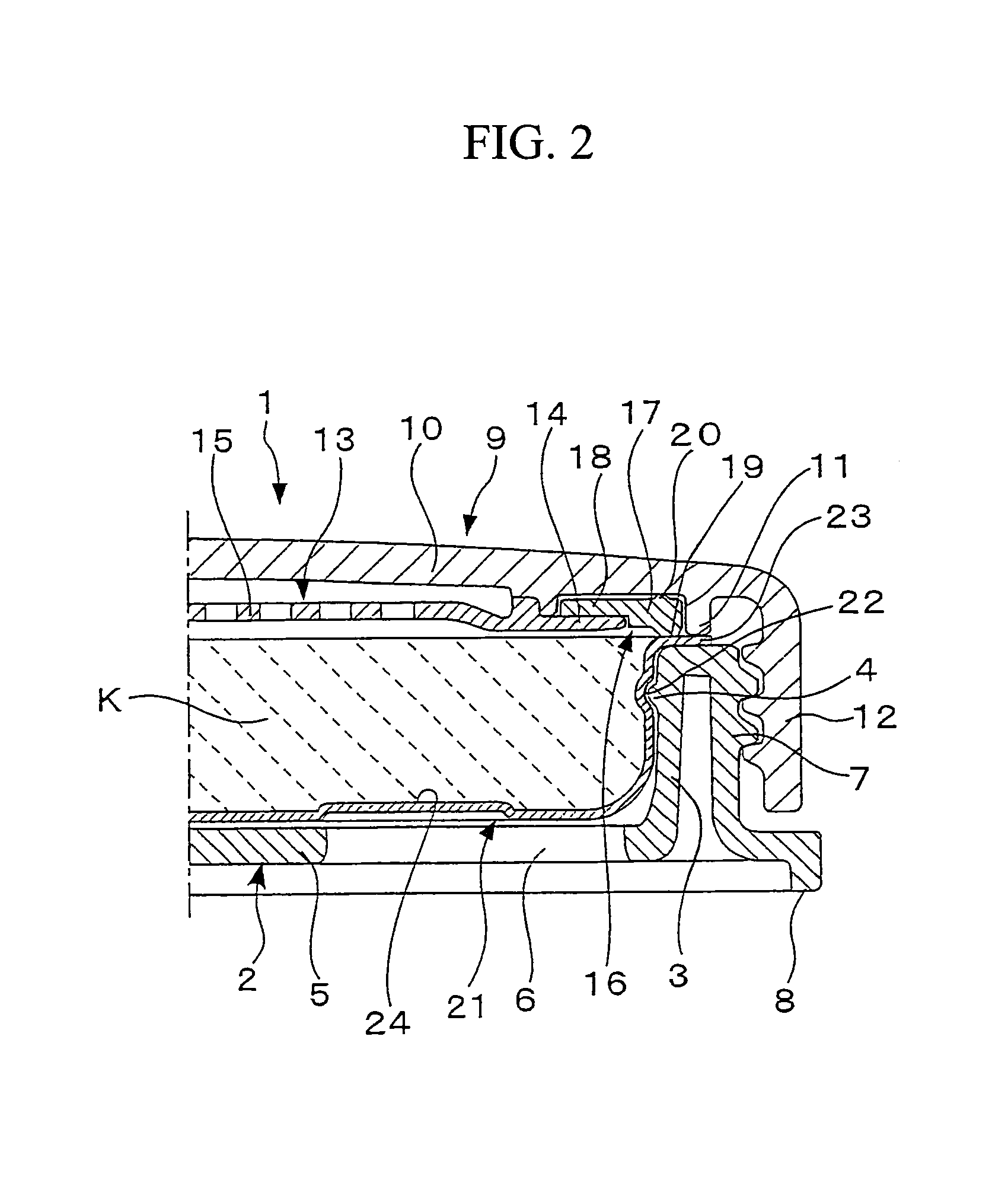

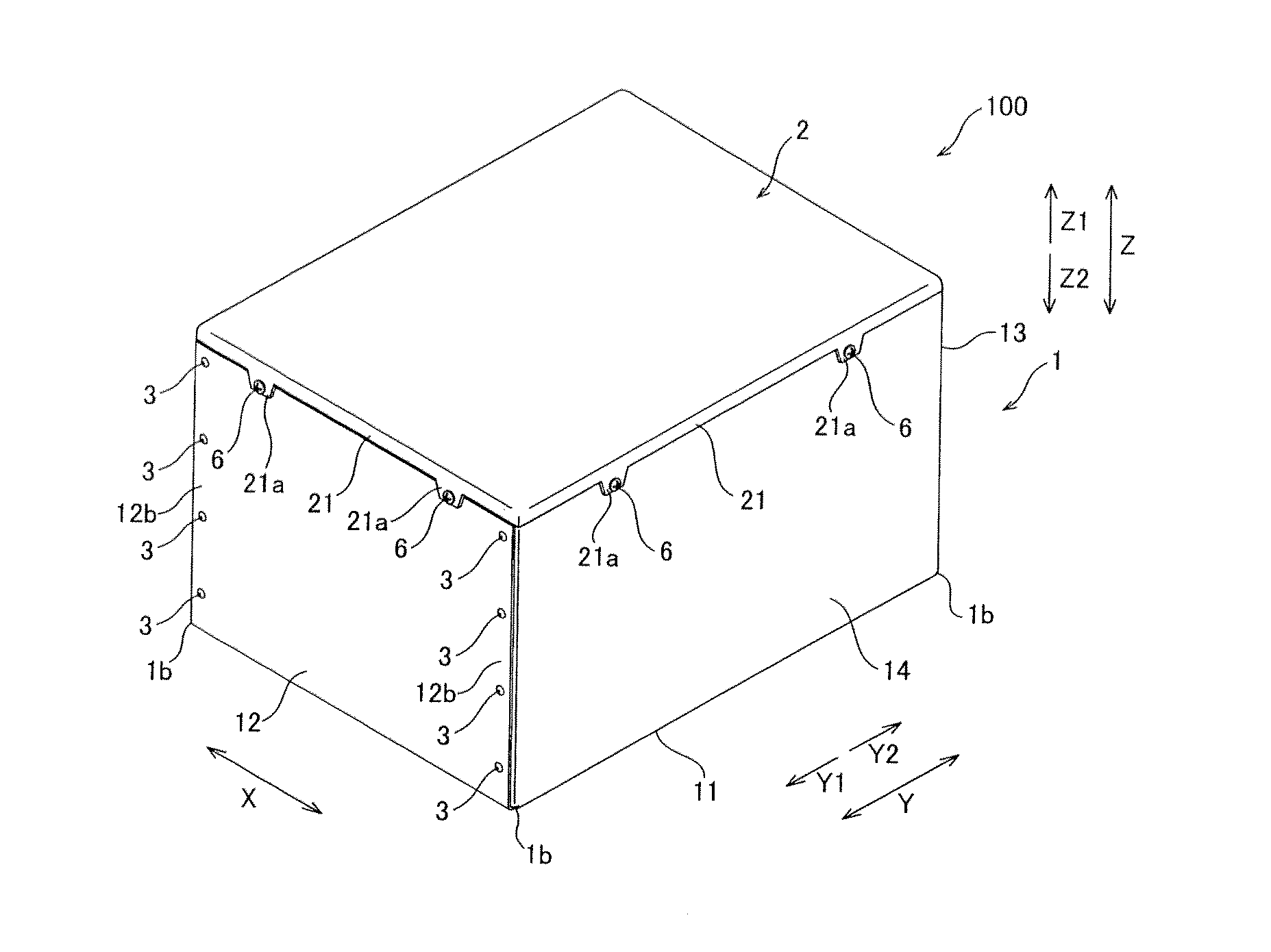

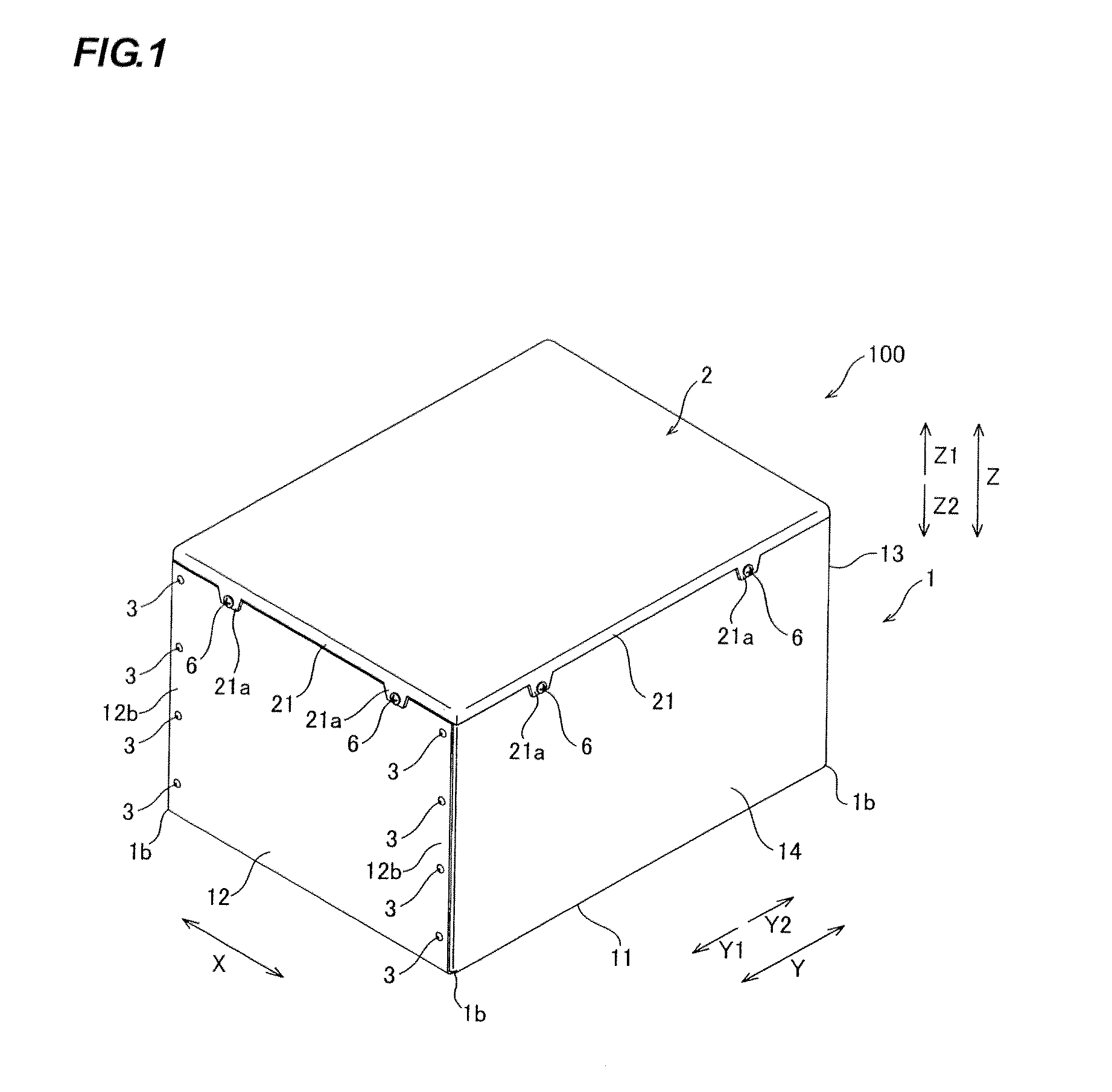

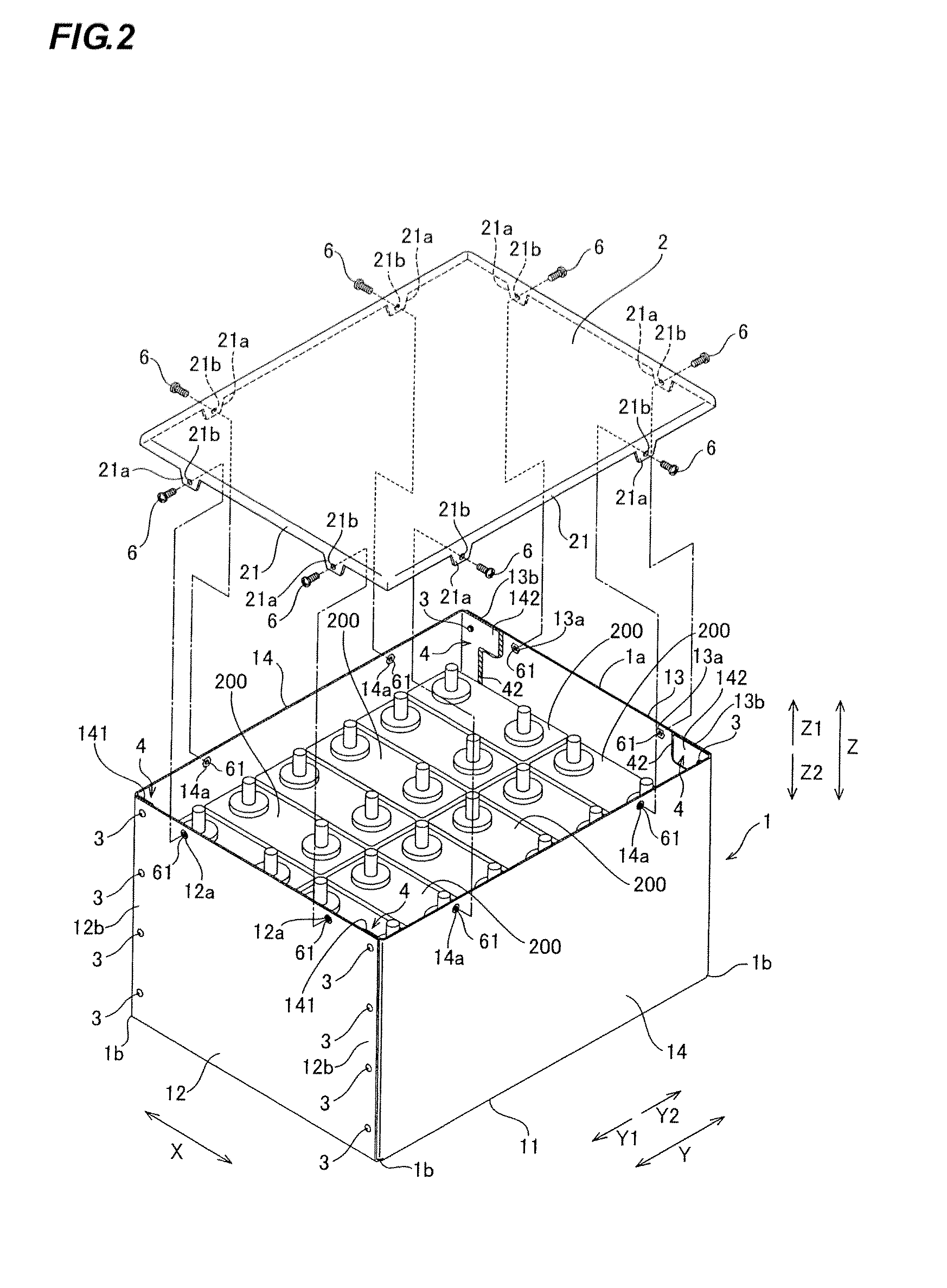

Battery case

ActiveUS20120244422A1Improve sealing functionSuppress leakageBattery isolationLi-accumulatorsElectrical batteryEngineering

Owner:GS YUASA INT LTD

Airbag for a motor vehicle

InactiveUS20090322062A1Increase loadImprove sealing functionPedestrian/occupant safety arrangementMobile vehicleMotor vehicle part

In an airbag for a motor vehicle, with a flow passage via which two pressure chambers are connected to one another, a flow medium, in particular gas, flows from one pressure chamber through the flow passage into the other pressure chamber in a passage direction. To increase the suitability of the airbag for, for example, side impact loads, the flow passage includes a backflow safeguard that allows the flow medium to flow in the passage direction, whereas the flow of the flow medium in a blocking direction opposite to the passage direction is largely prevented.

Owner:DAIMLER AG

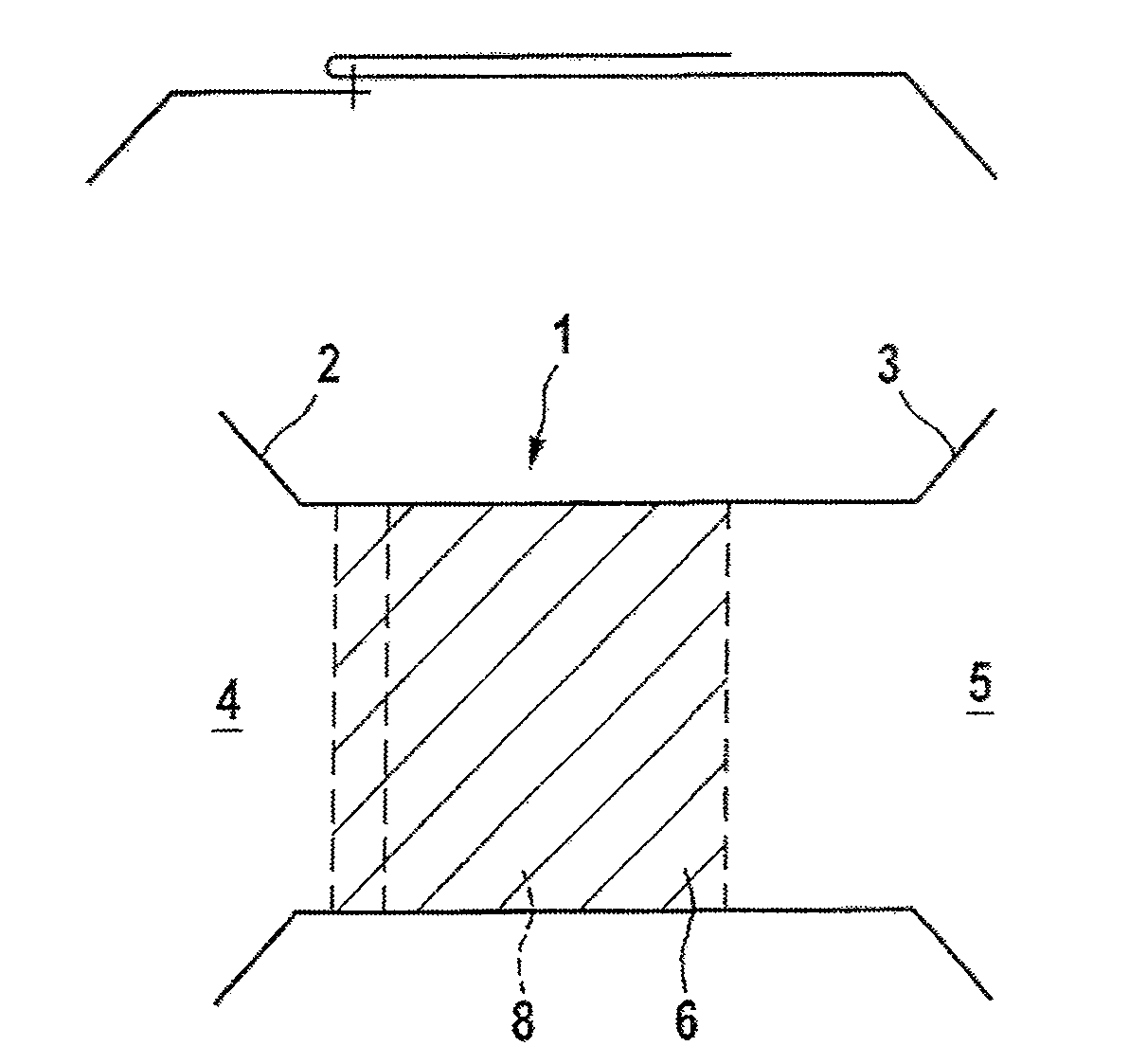

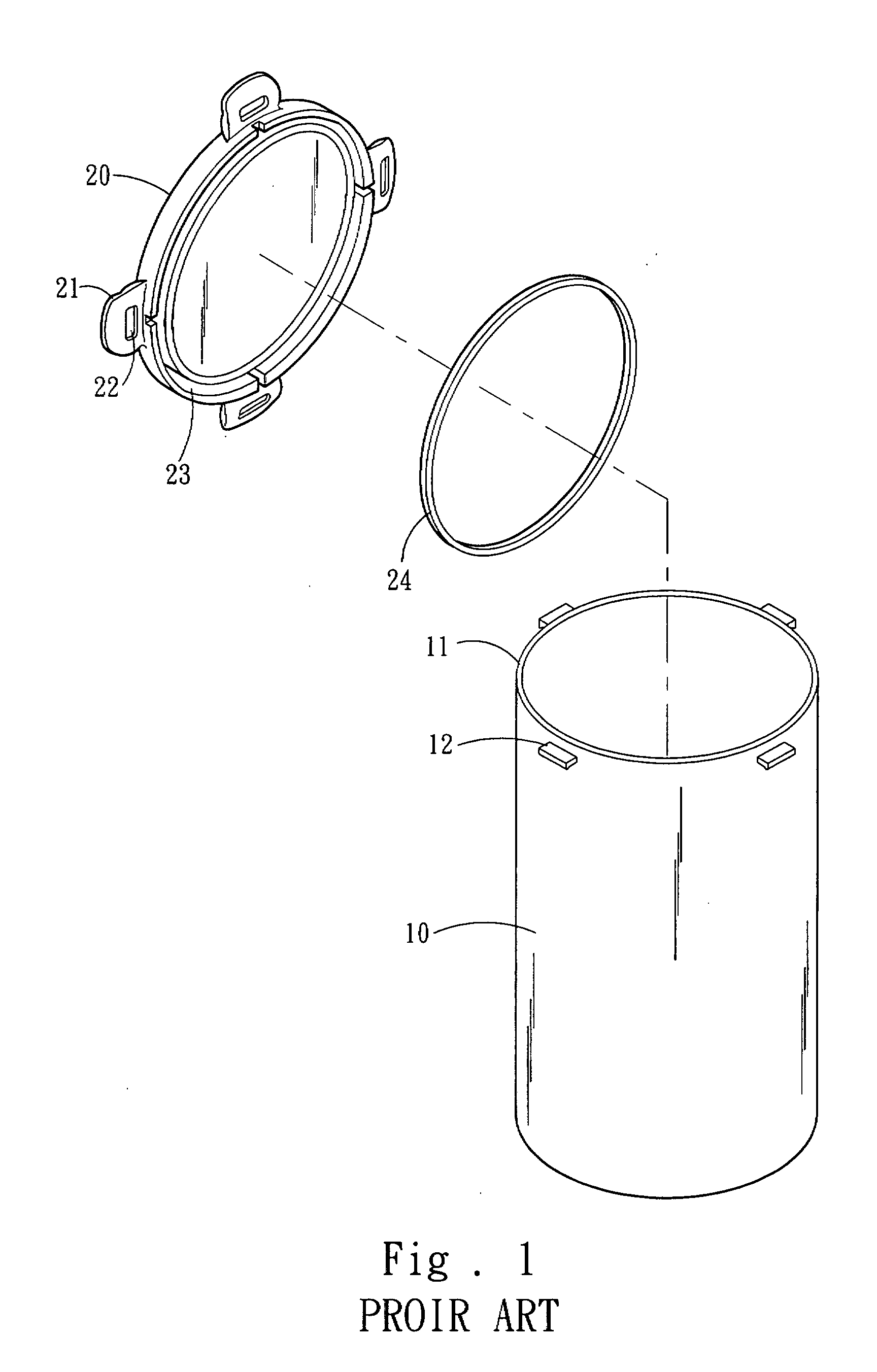

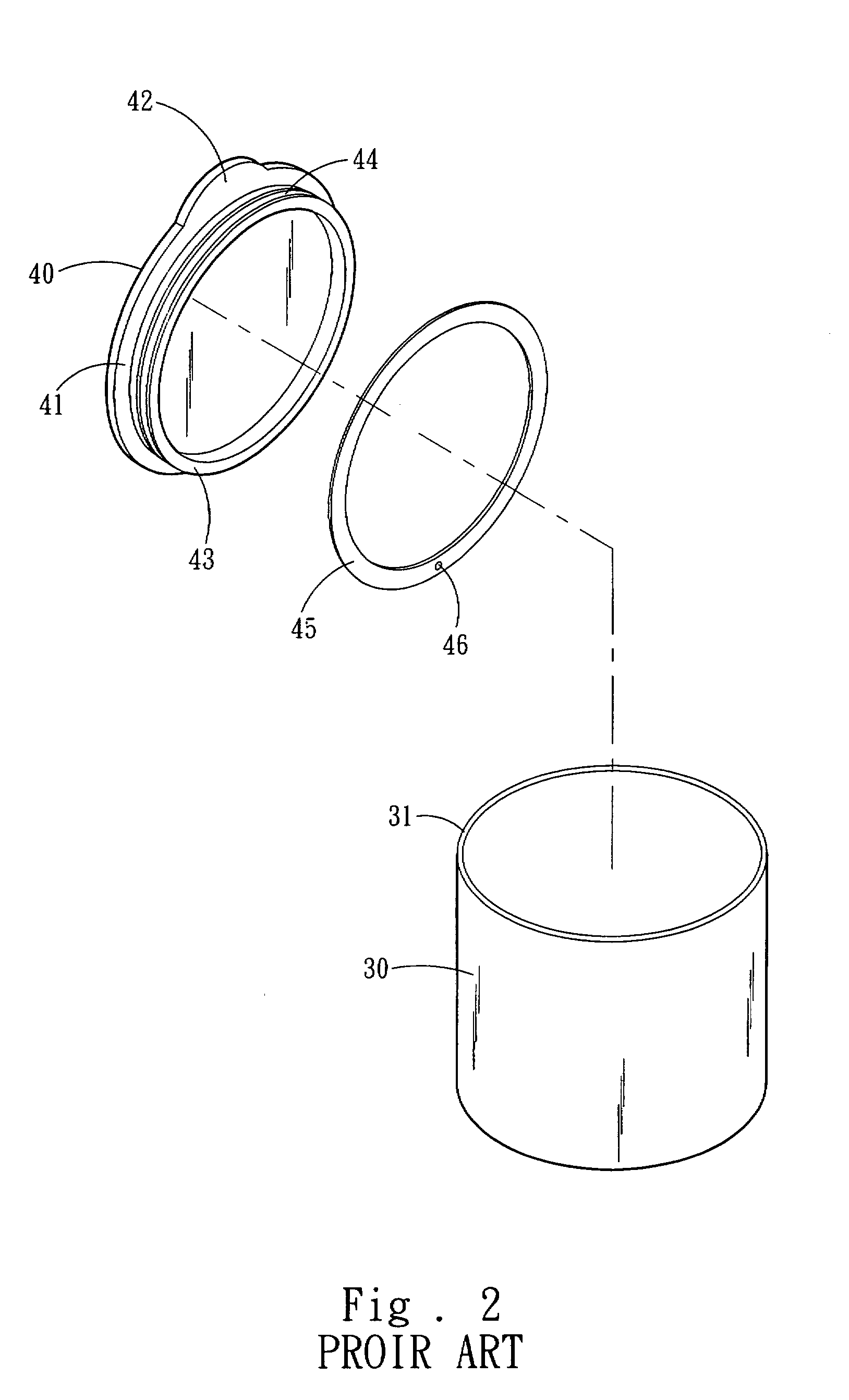

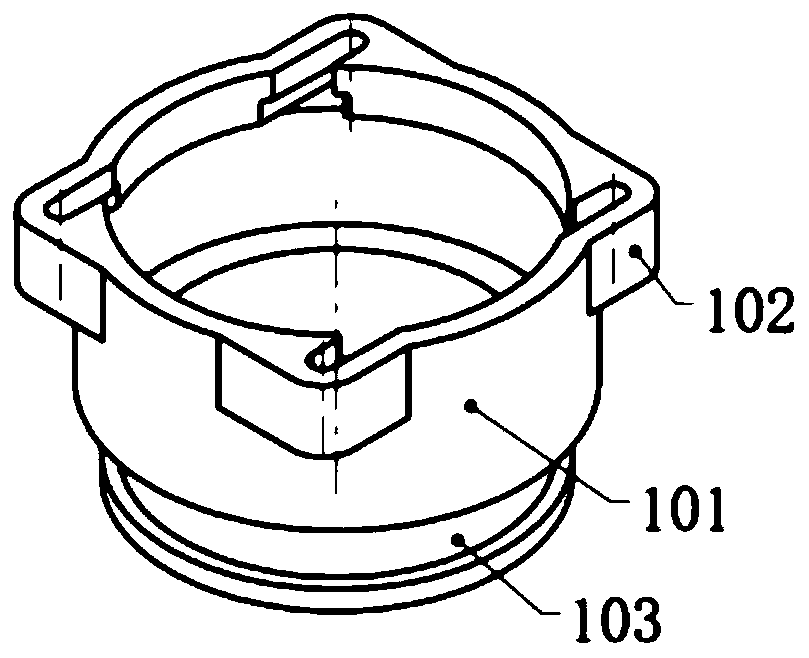

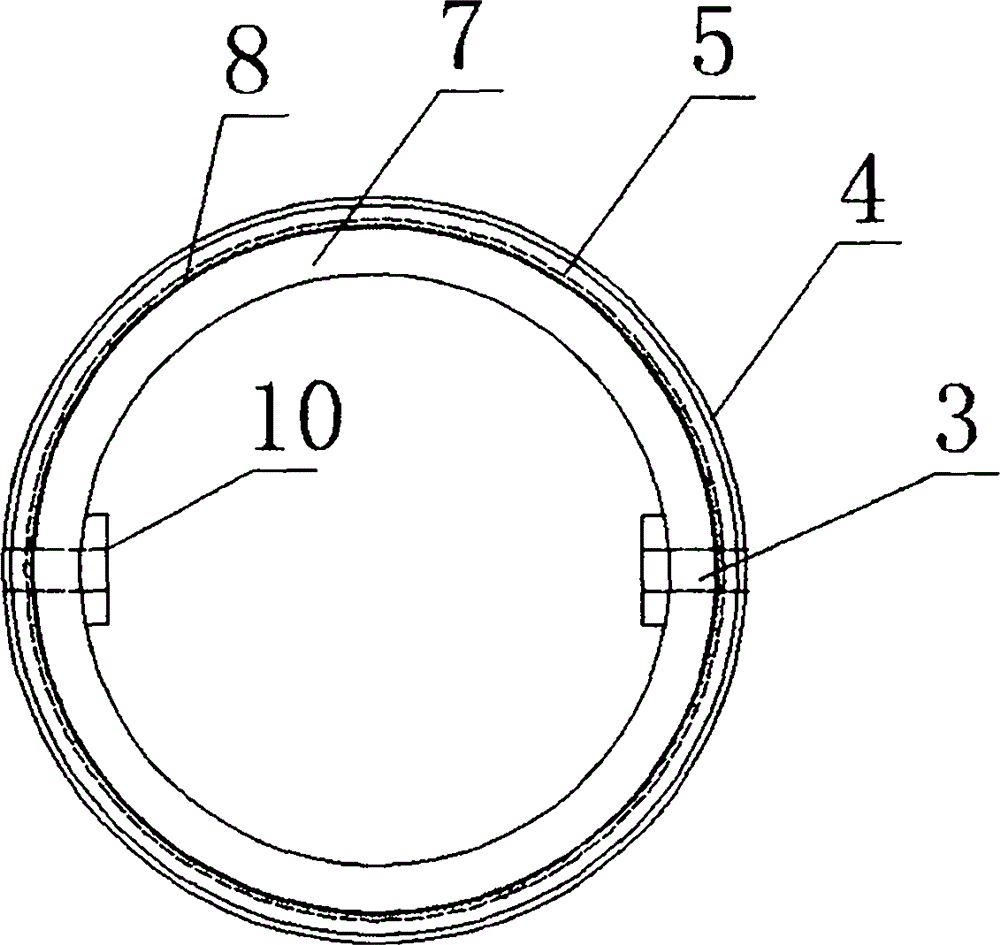

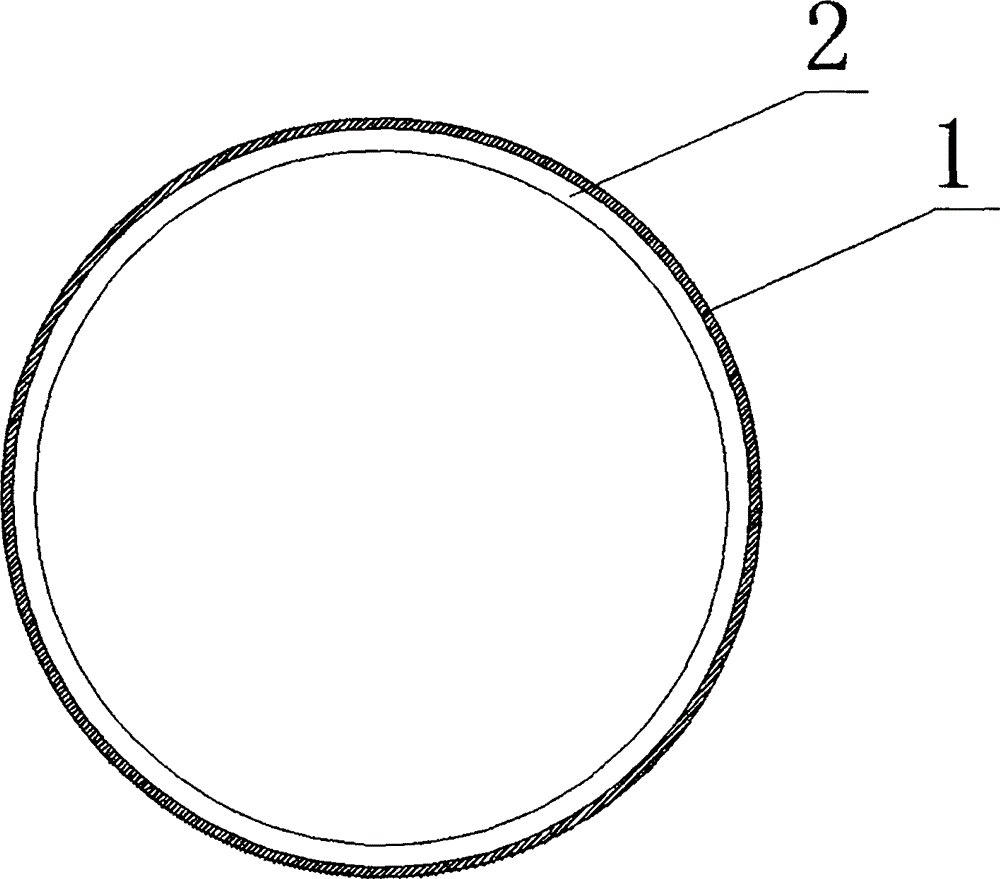

Vacuum seal cover of circular container

InactiveUS20080217335A1Expiration date can be extendedEasy to fixClosuresMechanical engineeringEngineering

Owner:CHEN YU HSIN

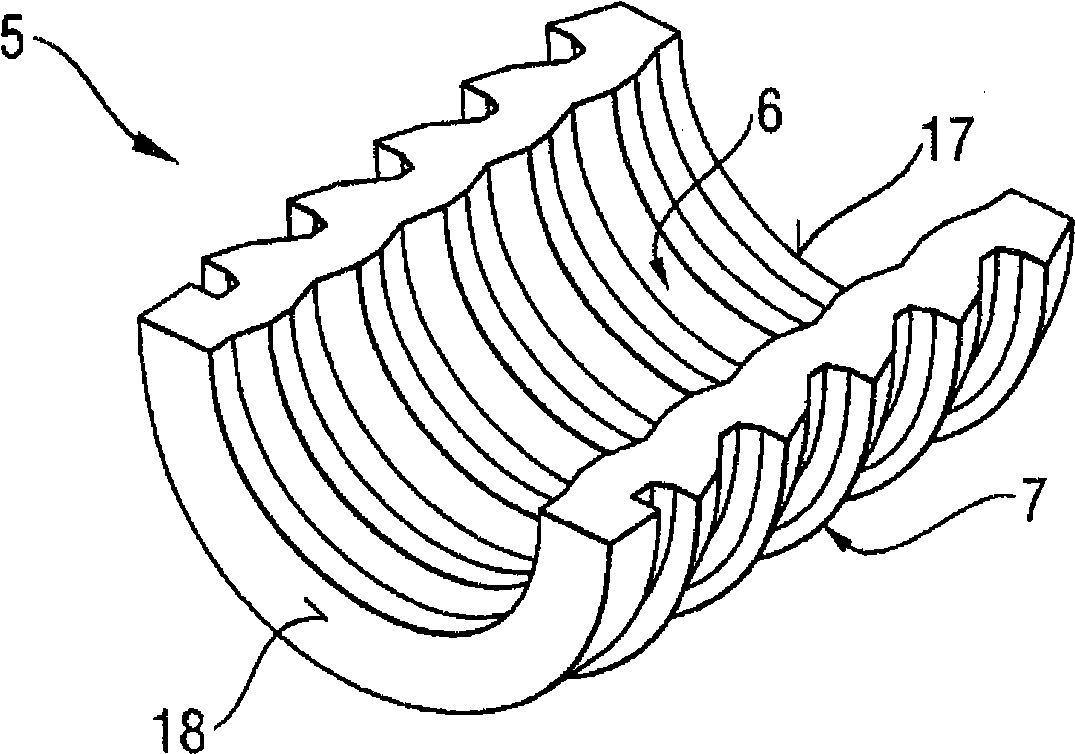

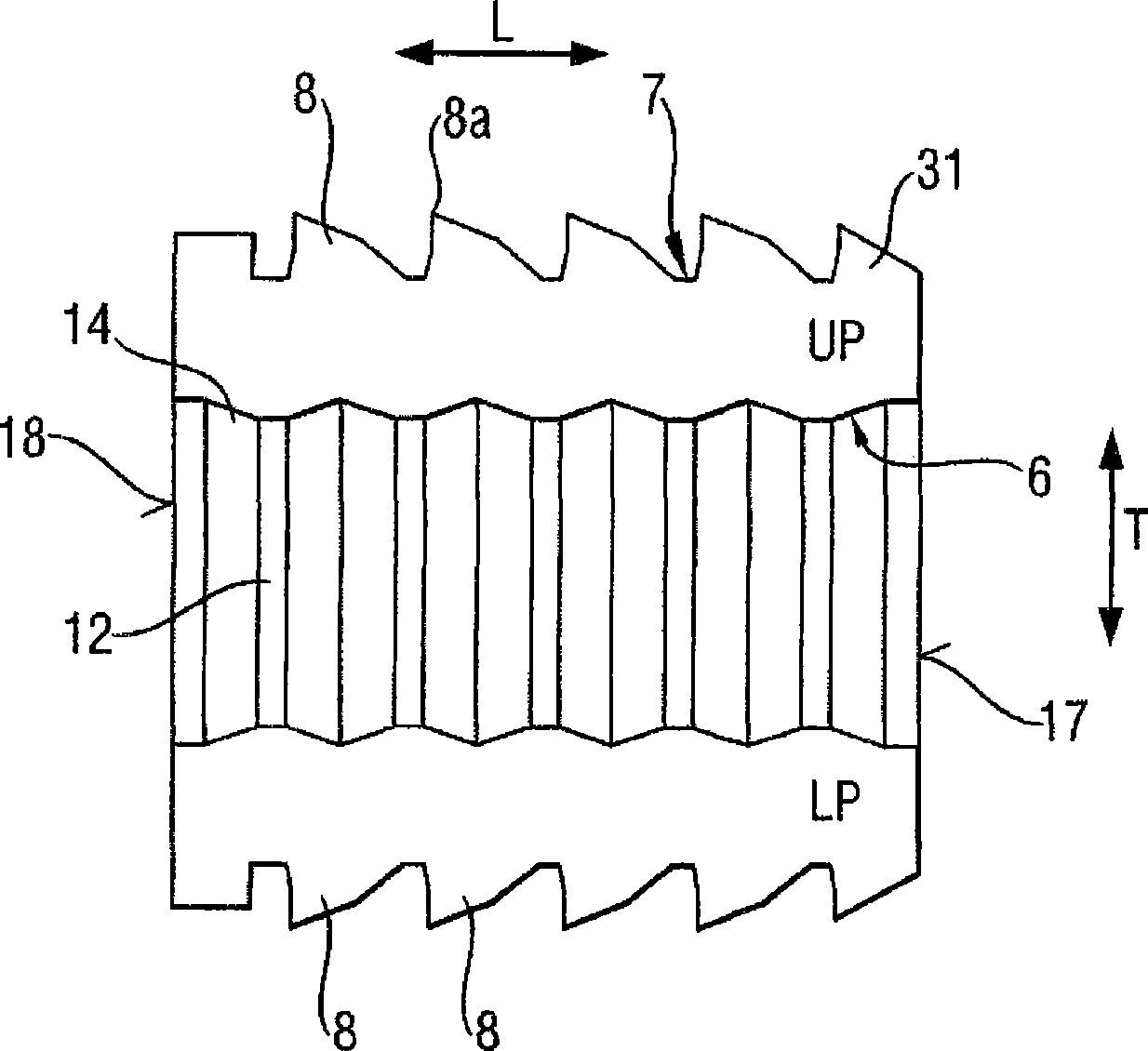

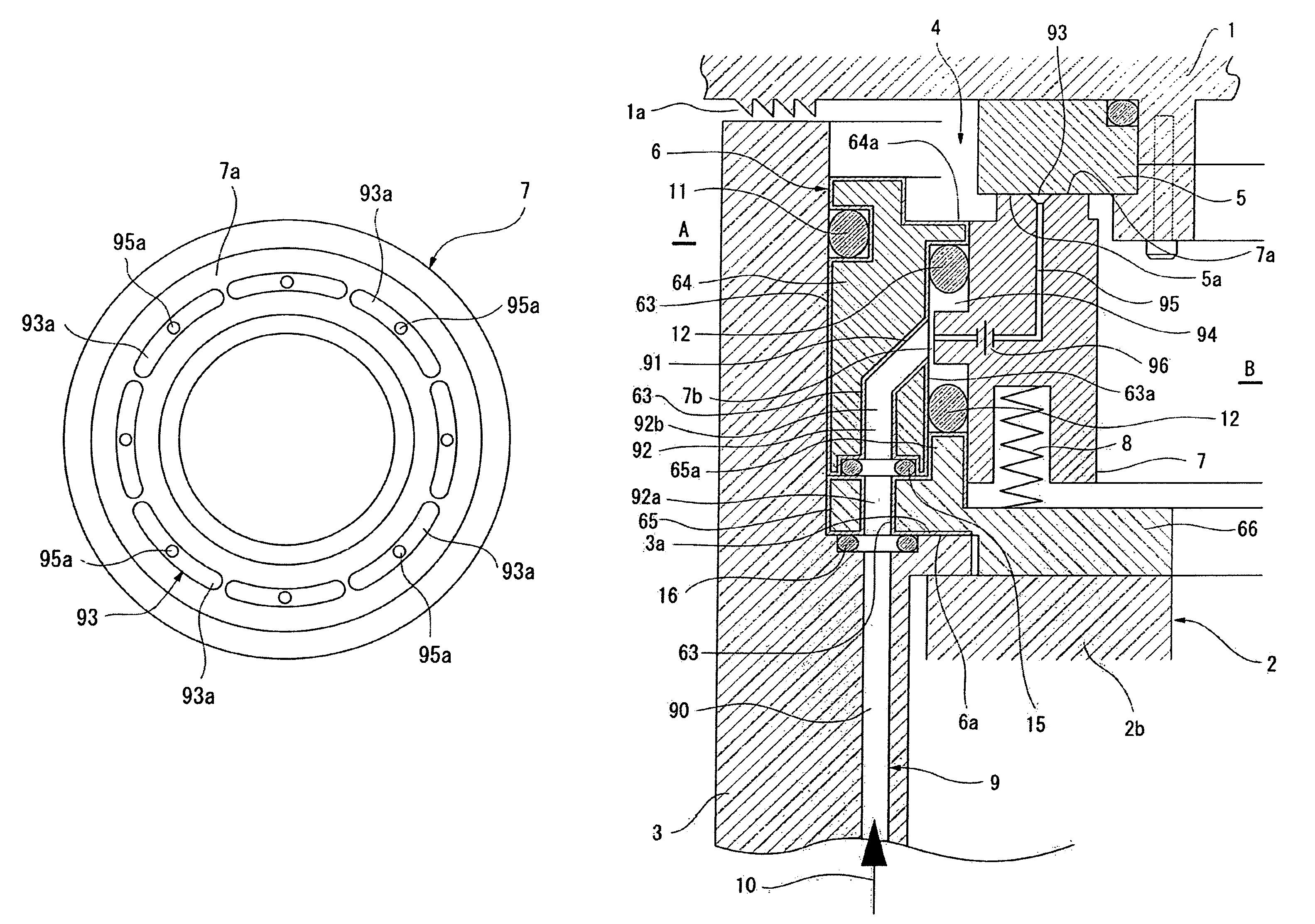

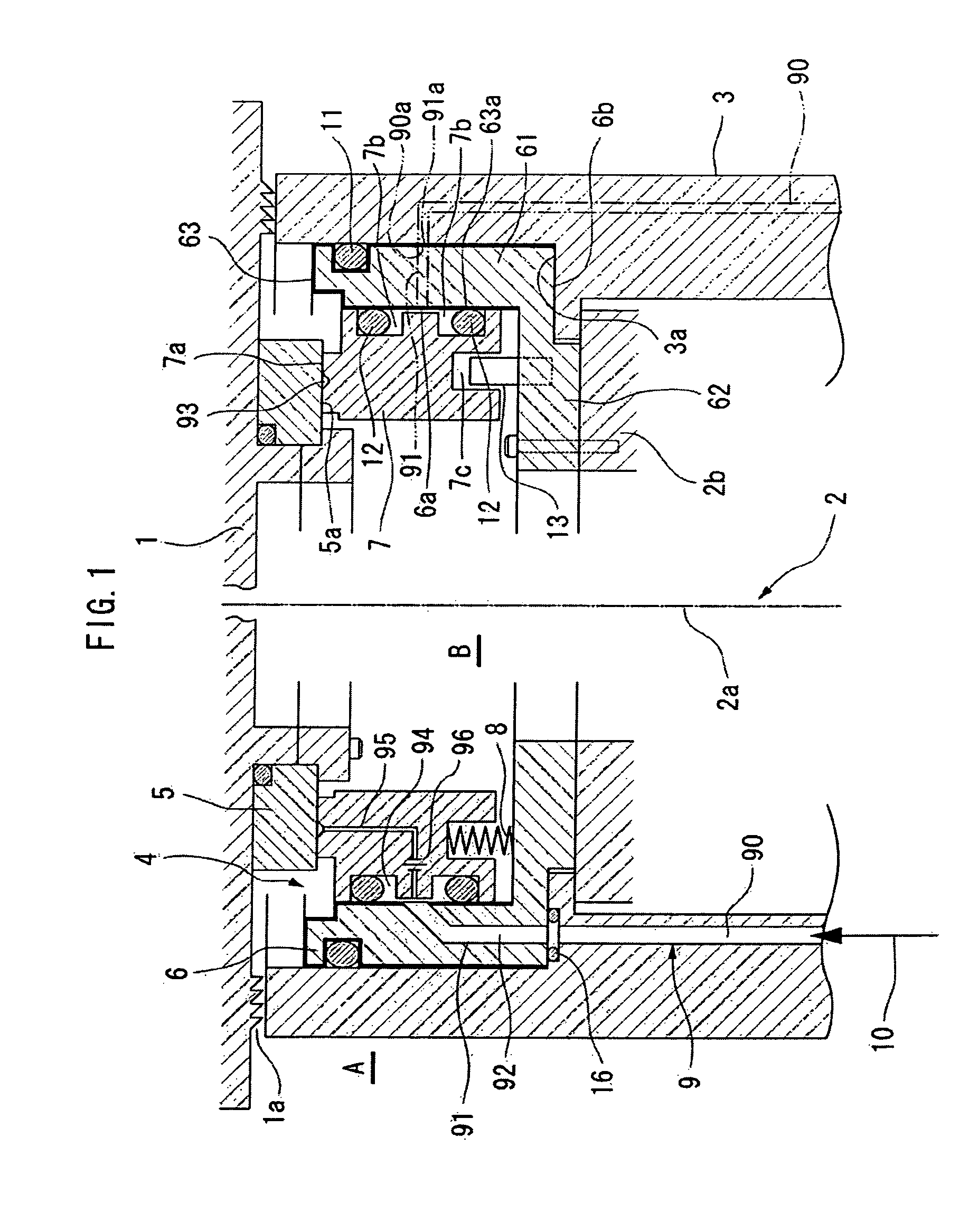

Mechanical seal

ActiveUS7883093B2Improve sealingImprove sealing functionEngine sealsLeakage preventionResin coatingMechanical engineering

A mechanical non-contact gas seal including a rotary scaling ring and a stationary sealing ring that is engaged and held in an inner periphery of a seal case by means of O-rings so as to move in an axial direction thereof. The O-rings engage with the outer periphery of the stationary sealing ring and come in press contact with the inner periphery of the seal case to seal a gap between the stationary sealing ring and the seal case while allowing the stationary sealing ring to move in an axial direction. A resin coating of a thickness in the range of 5 to 100 μm is formed on the inner periphery of the seal case at least within a range in which the O-rings relatively move with the movement of the stationary sealing ring.

Owner:NIPPON PILLAR PACKING CO LTD

Connector device for pipes

InactiveUS20050258645A1Improve sealing functionImprove sealingSleeve/socket jointsFluid pressure sealed jointsPlastic materialsMechanical engineering

A connecting device for a plug-in connection of at least one pipeline having a housing part having at least one receiving opening for the insertion of the pipeline. A clamping ring is arranged in the receiving opening and, in order to lock the pipeline in place, interacts with an inner one of the housing part. The housing part is made in two parts including a base part and an insert part, which is connected to the base part via a snap-in action forming-fitting connection. The insert part has a direct seal for resting on the circumference of the inserted pipeline. The insert part is formed of a first relatively hard and dimensionally stable plastic material, and has a dirt seal consists of a second, relatively soft and elastic plastic material and is molded directly into the first material as a single piece with a cohesive material joint therebetween.

Owner:VOSS AUTOMOTIVE

Large area internal series dye sensitization nano thin film solar cell and producing method thereof

InactiveCN1674302AOvercoming technical difficulties and material selection difficultiesIncrease the output voltagePhotovoltaic energy generationSemiconductor devicesElectrically conductiveNanometre

A film solar cell comprises top and bottom transparent baseboards. It is prepared by sealing baseboard periphery to form cavity with electrolyte, arranging transparent conduction film in interval on substrate, making conduction film on one substrate have catalyst layer and conduction film on another one have nanomultihole semiconductor material block, soaking dyestuff in said nanomaterial and connecting two staggered transparent conduction films by series electrodes. The internal series electrode is also prepared for obtaining output current of solar cell.

Owner:铜陵中科聚鑫太阳能有限责任公司

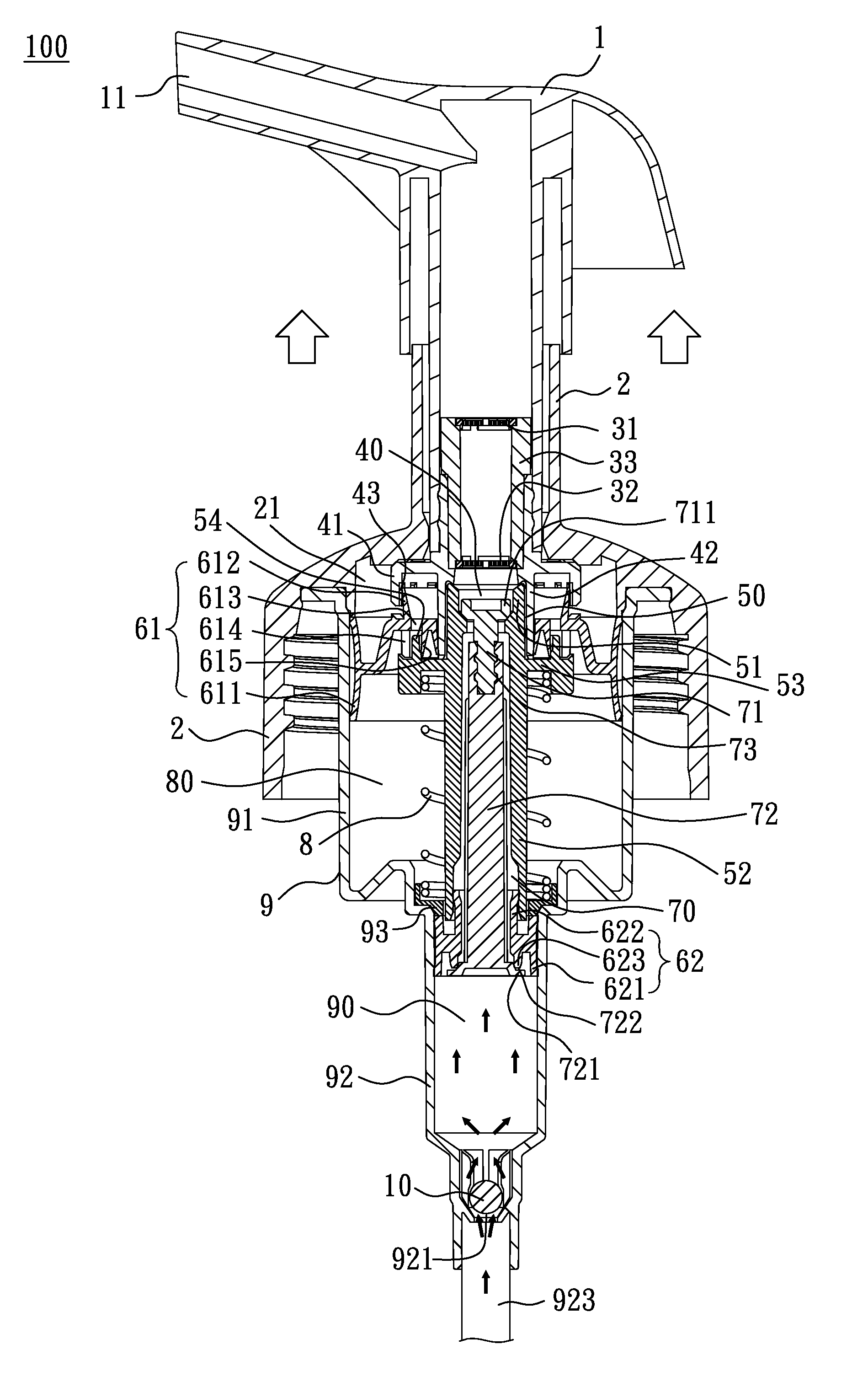

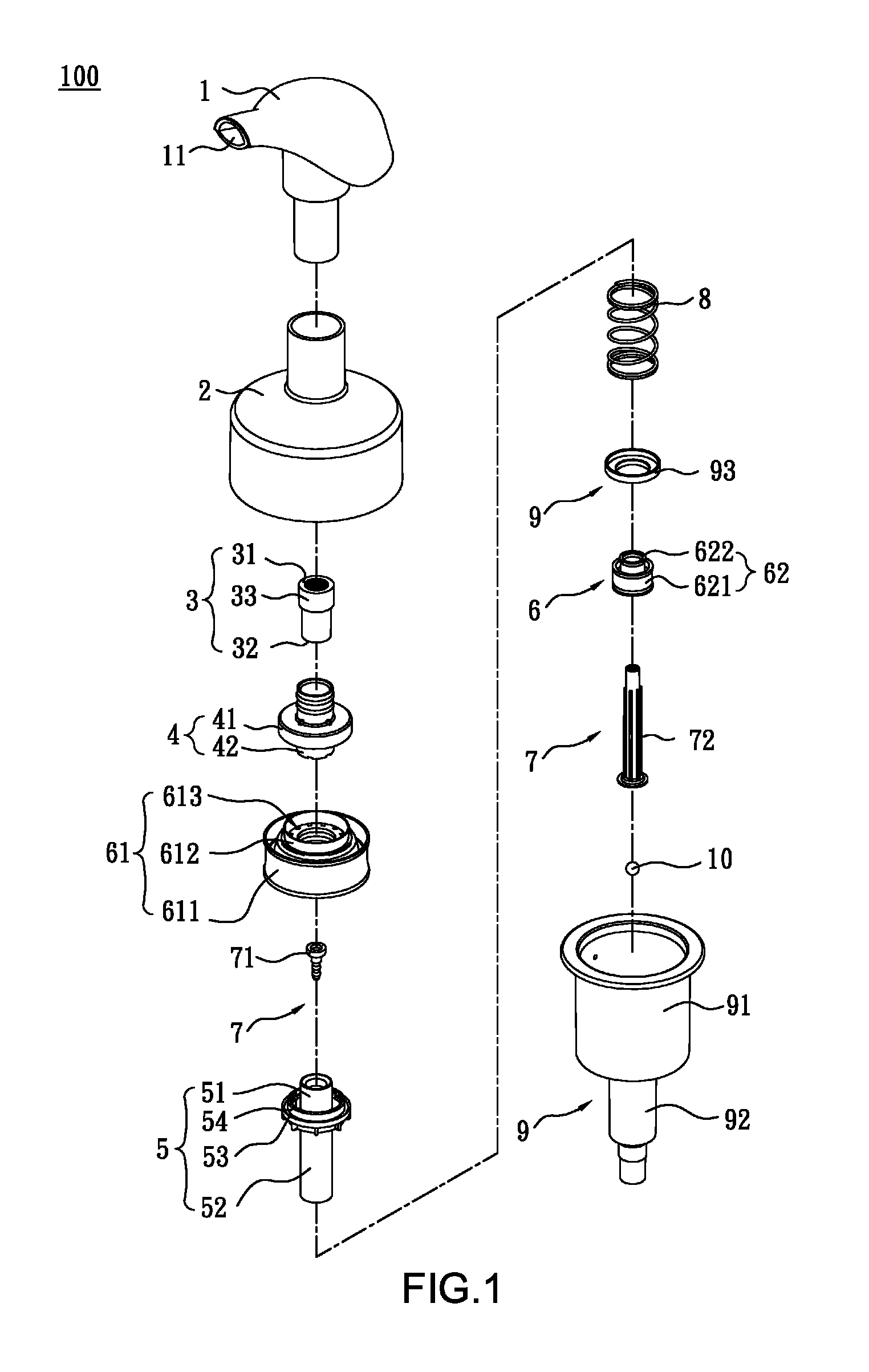

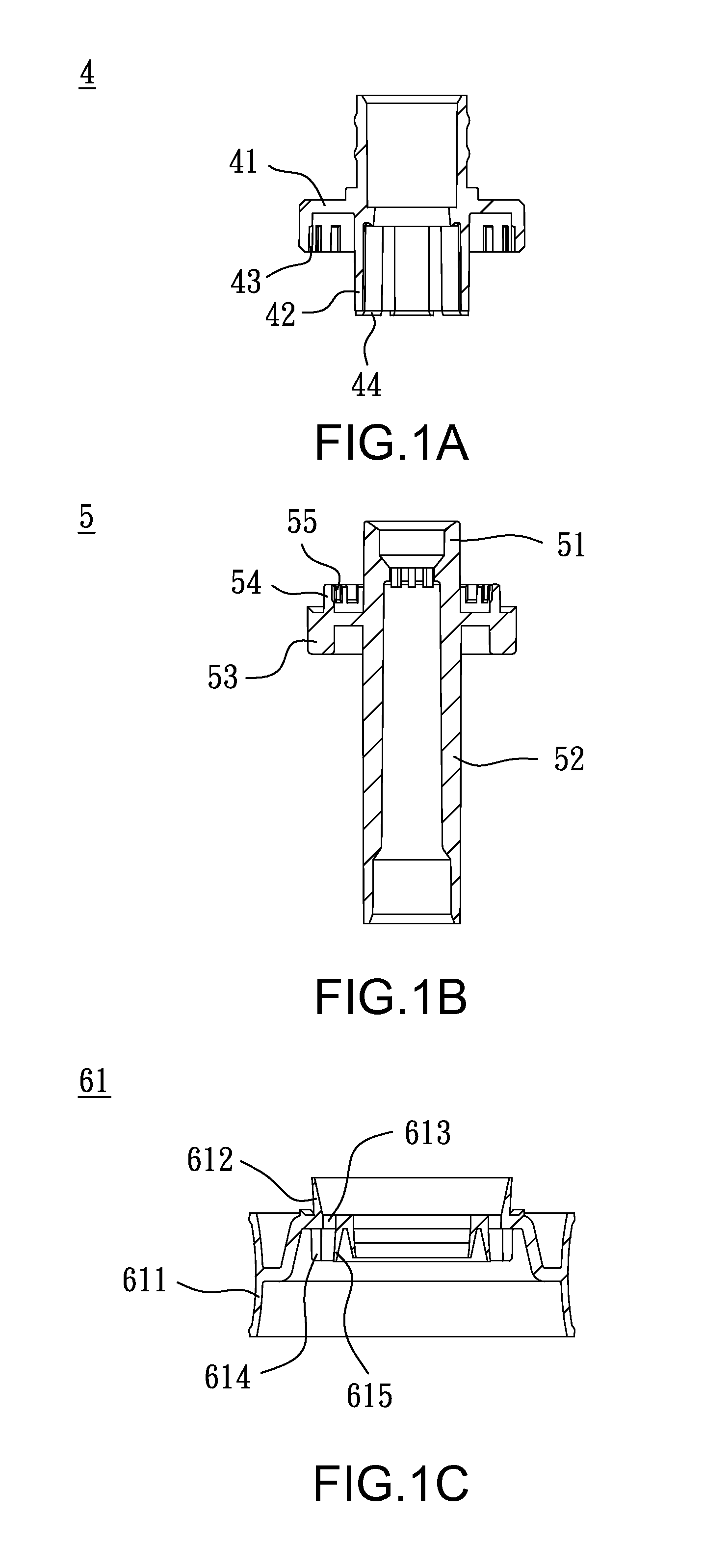

Foam spray head assembly

ActiveUS8678241B2Improve sealing functionSensitive and reliableLarge containersLiquid transferring devicesEngineeringPiston

A foam spray head assembly includes a press head connected to a cap, a netted tube, a valve member, a main tube, a piston unit, a link unit, a resilient member, a cylinder unit and a valve. The netted tube is connected to the valve member. An outlet is defined between the first link of the link unit and the first tube. An inlet is defined between the second link of the link unit and the protrusion of the piston unit. The resilient member is mounted to the second tube and contacts the flange of the second tube. The first piston of the cylinder unit is movable in the first cylinder to form a sealed second chamber. The second piston of the cylinder unit is movable in the second cylinder to form a sealed third chamber. The valve is located in the passage of the second cylinder.

Owner:DERJIN (JIANGSU) PLASTIC PACKAGING CO LTD

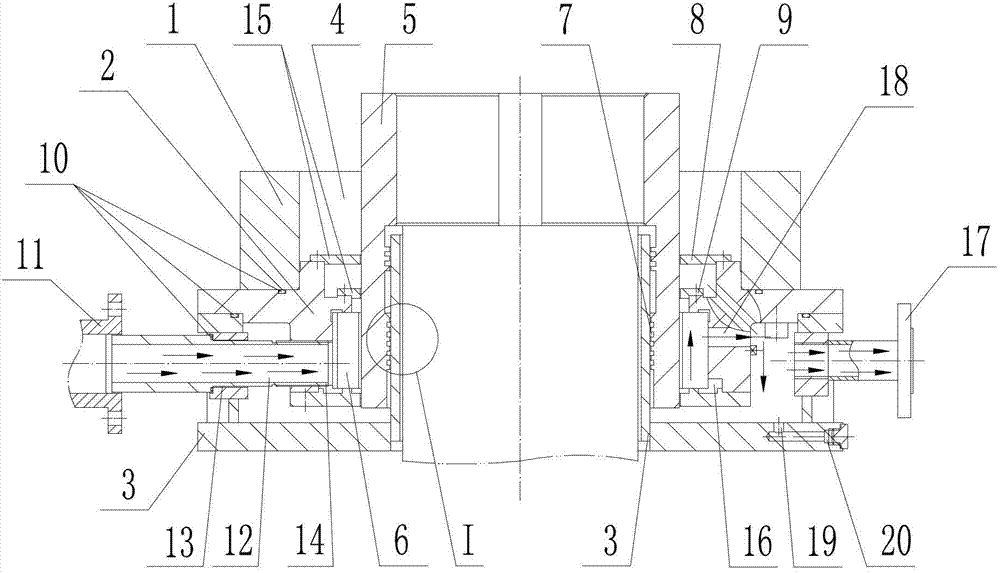

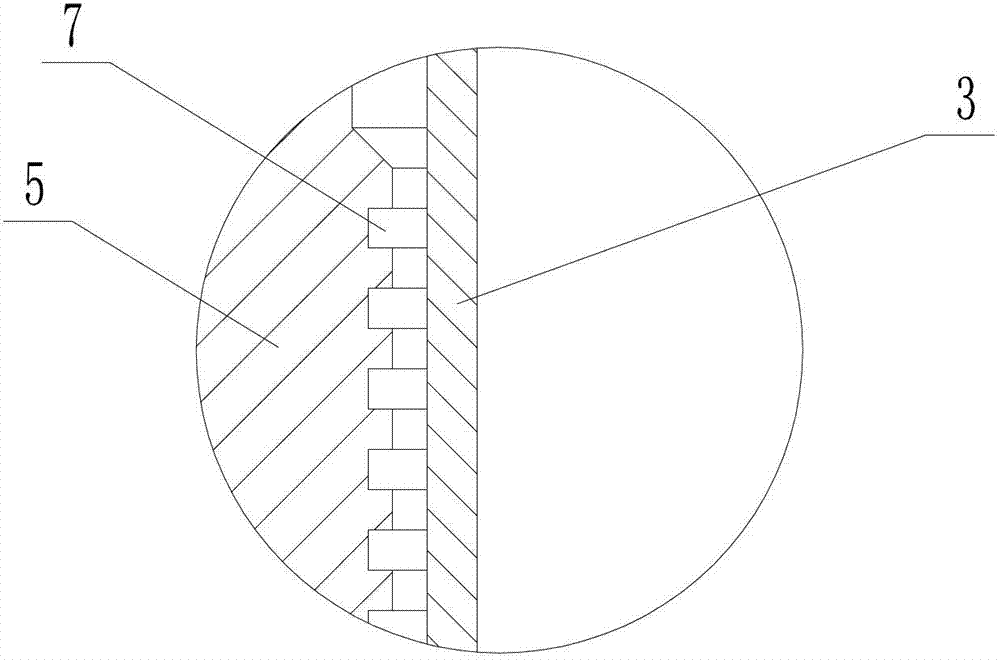

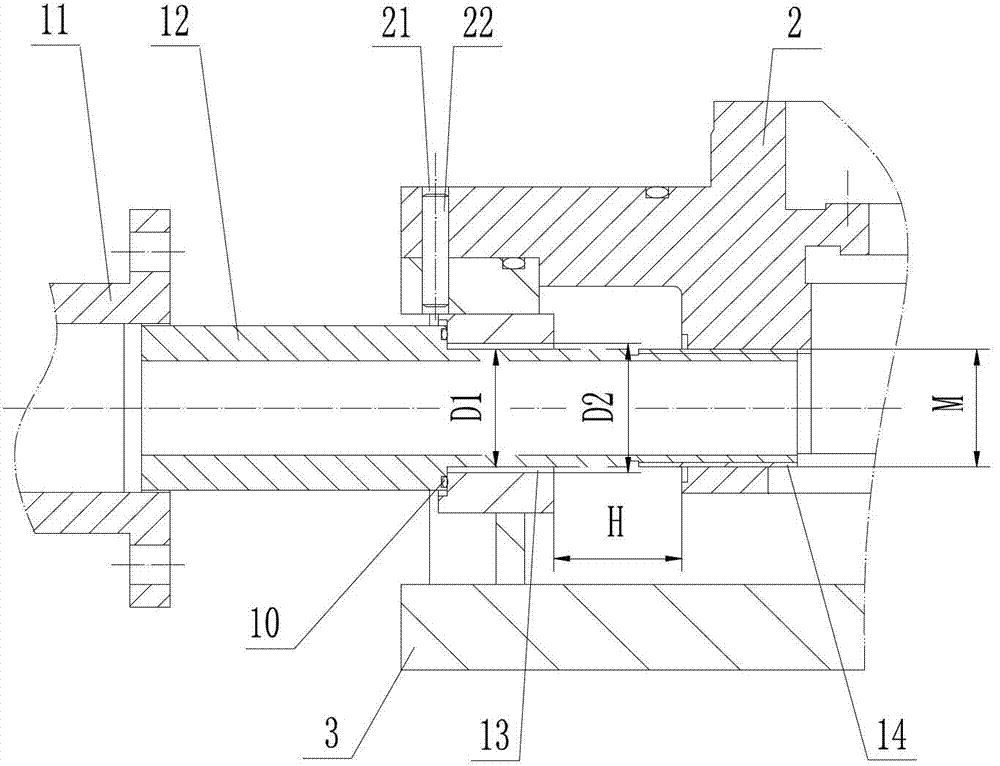

Lubricant circulating device based on sliding bearing and manufacturing process of lubricant circulating device

ActiveCN102829314AExpand the scope of applicationImprove cooling effectBearing coolingEngine lubricationPower equipmentHeavy load

The invention discloses a lubricant circulating device based on a sliding bearing, as well as a manufacturing process of the lubricant circulating device. The lubricant circulating device essentially consists of a bearing bracket, a guide base and an oil tank; an oil transportation duct which is connected to a port of a cold oil inputting pipe penetrates a duct mounting hole of the oil tank and is connected to a thread hole of the guide base, and is communicated with a cold oil storing cavity; a hot oil outputting pipe is connected to the oil tank and is communicated with an oil returning hole, thereby forming a system-cold oil-hot oil / cold oil-lubricant circulating-inputting / outputting loop; meanwhile, under the synchronous control of various corresponding equipment, the scheme of arranging the lubricant circulating inputting / outputting loop system is implemented. Through the lubricant circulating device, the sliding bearing which is matched with the motor, the water pump and other host equipment is not only compactly structured but is adaptive to the high-speed operation of the host equipment, and the sliding bearing cannot change the connecting and mounting size of the original machine and can ensure the circulation of the lubricant; the bearing bush can not generate heat; the equipment system is stable, reliable and safe in operation; the lubricant circulating device is suitable to be used as a supporting product of various power equipment, especially for as a supporting product of various heavy-load engineering machineries.

Owner:HUNAN CHONGDE IND TECH

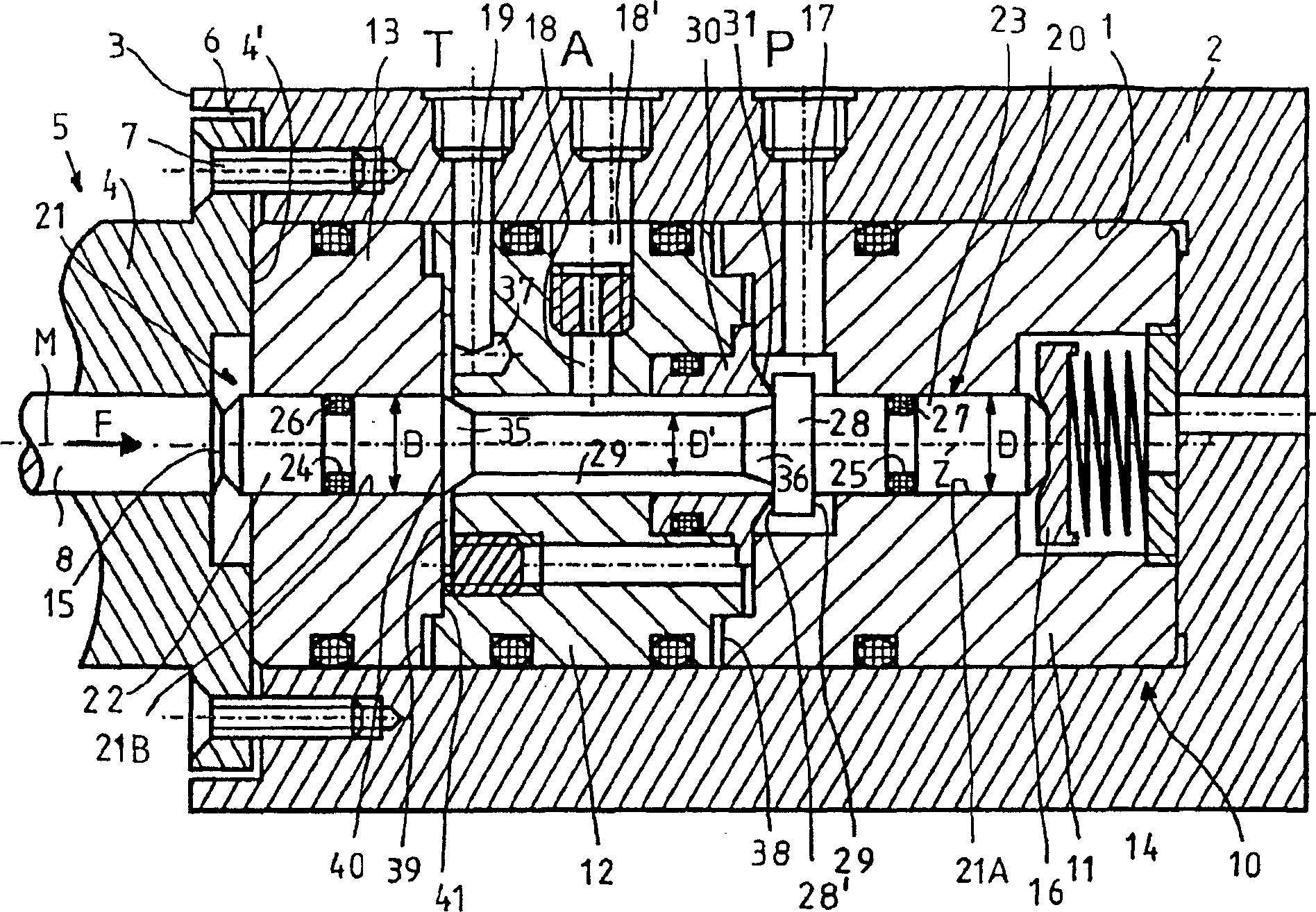

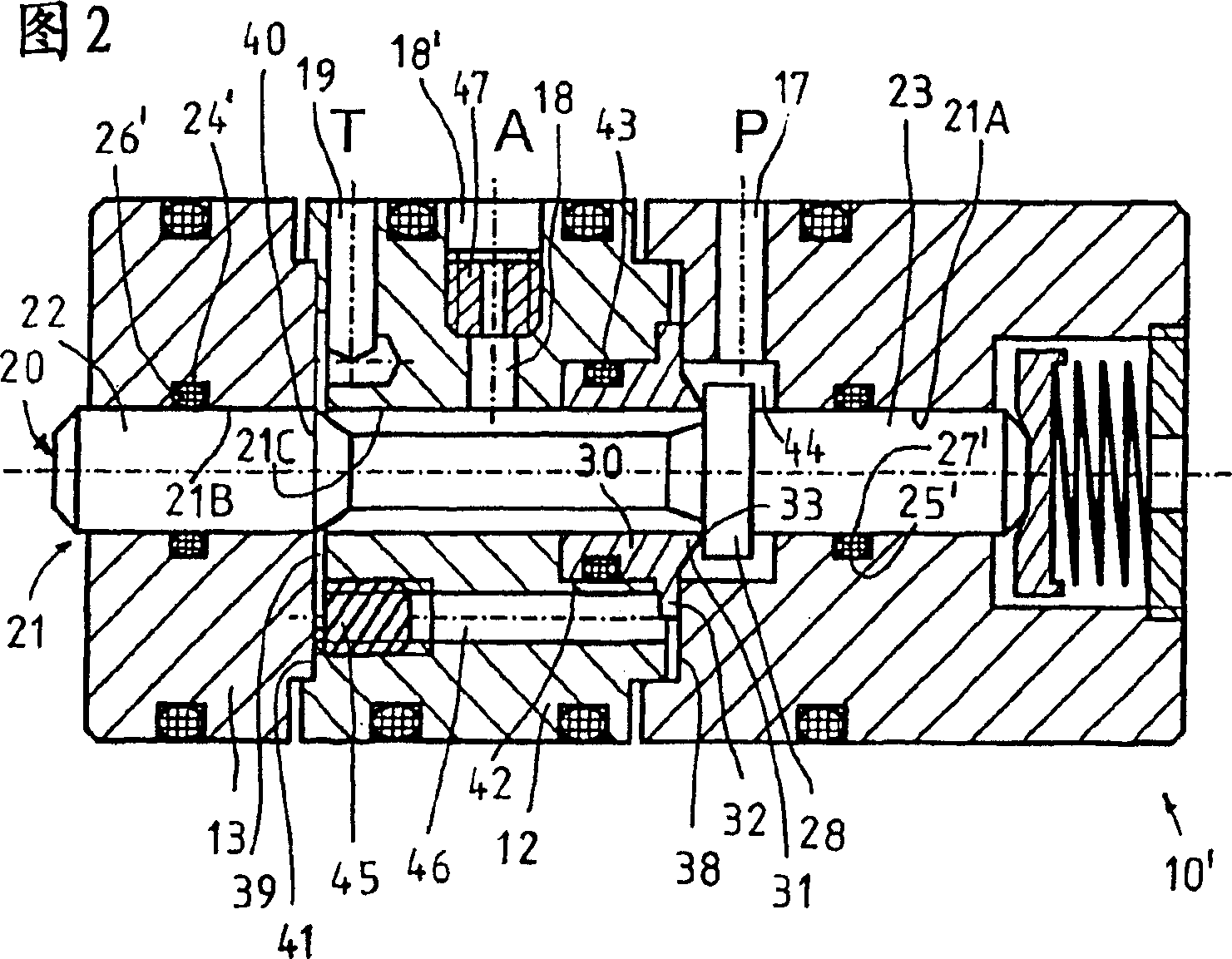

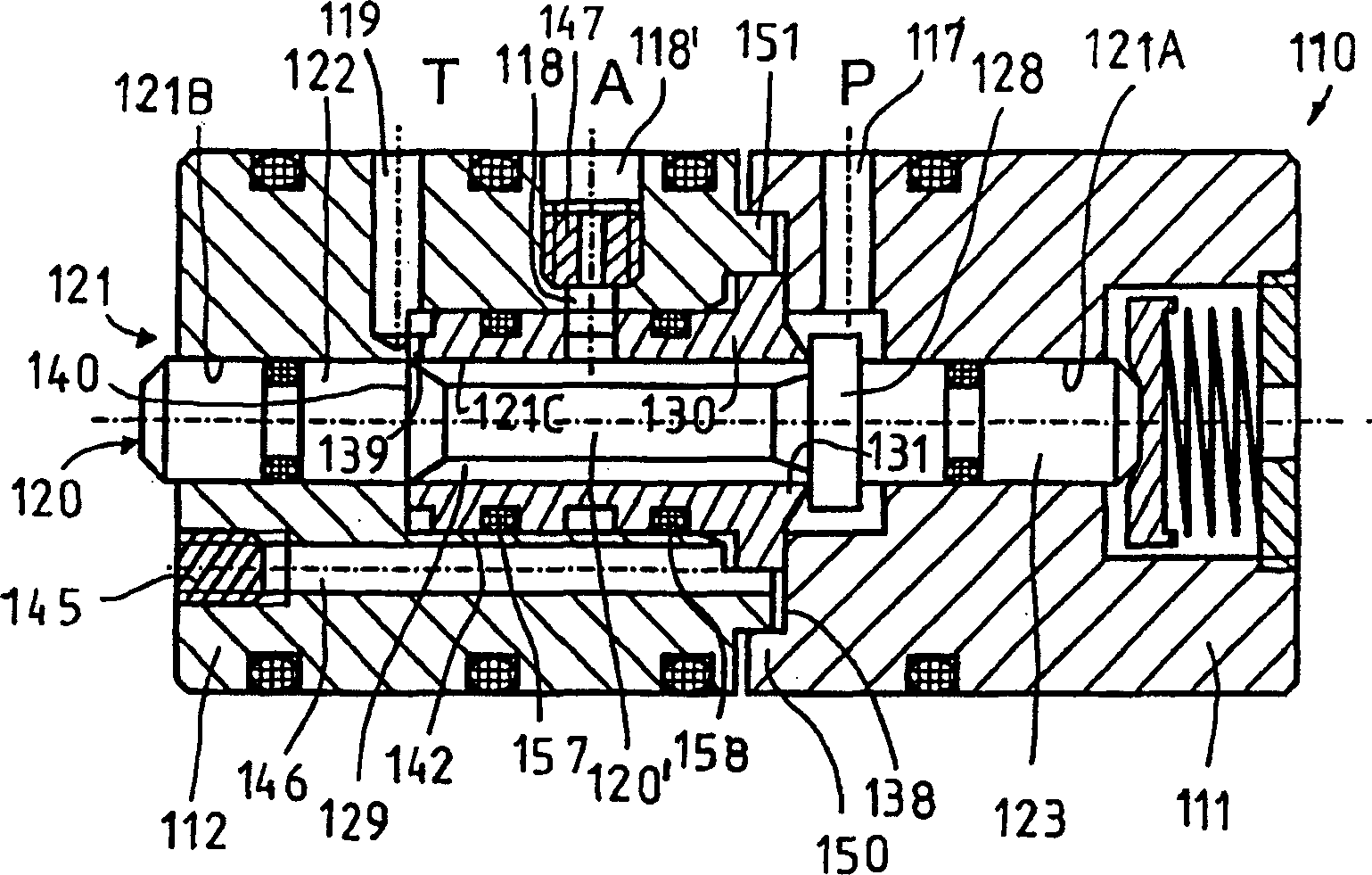

Pilot-actuated valve

InactiveCN1435577AReduce manufacturing costShort switch strokeServomotor componentsMultiple way valvesStructural engineeringHydraulic equipment

The present invention relates to a pilot control valve, especially for use in mining hydraulics. The valve has a valve insert constructed as a valve cartridge, whose single or multipart valve housing has an input entry for pressure fluid, a connection opening for a load connection, an output opening, opening into the return flow and an axial boring to accept a valve closing body provided with a closing surface, which can be lifted from a valve sealing seat arranged between the entry opening and the connection opening by means of an electro-magnetic or piezo-electric switching device which can be fastened onto the valve housing. With the lifting movement of the valve closing body from the valve sealing seat is coupled an at least two part closing mechanism for their separation arranged between the connection opening and the output opening. In accordance with the present invention a single part valve closing body is provided, having the sealing surface in the form of a collar and the moving part of the closing mechanism in the form of a shaft section, whereby the shaft section enters into a boring section of the axial boring during the lifting movement, closing a radial opening. The valve sealing seat can be exchanged with a valve sleeve and the nominal bore of the pilot control valve can be changed by means of a throttle.

Owner:CATERPILLER GLOBAL MINING EURO GMBH

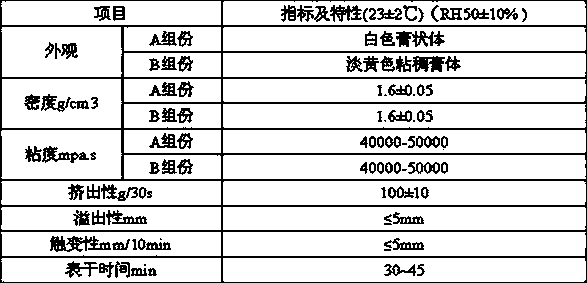

Environment-friendly polyurethane two-component corner-crimping glue

ActiveCN104327790AHigh hardnessImprove toughnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAlcoholPolyol

The invention discloses environment-friendly polyurethane two-component corner-crimping glue. The corner-crimping glue consists of a component I and a component II, wherein a weight ratio of the component I to the component II is 10:1 to 1:10, the component I comprises the following components: 41-52 percent of polyhydric alcohol A, 30-40 percent of filler A, 8-15 percent of filler B, 6-12 percent of modifier, 0.05-0.1 percent of catalyst, 1-2 percent of surfactant A, 2-5 percent of plasticizer A and 5-10 percent of plasticizer B; and the component II comprises the following components: 50-60 percent of isocyanate, 15-25 percent of MDI prepolymer, 10-16 percent of filler C, 2-6 percent of polyhydric alcohol B, 1-2 percent of surfactant B and 10-15 percent of plasticizer C. The comprehensive strength of the corner-crimping glue is greatly superior to that of polyurethane single-component corner-crimping glue, and the corner-crimping glue is high in stability and high in curing speed; and the corner-crimping glue has excellent joint filling capacity and is suitable for corner-crimping insertion of aluminum alloy doors and windows and curtain walls and overall corner cementing adhesion-sealing.

Owner:大连固瑞聚氨酯股份有限公司

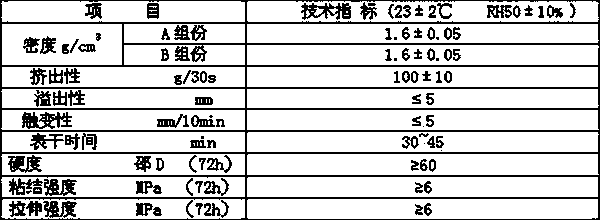

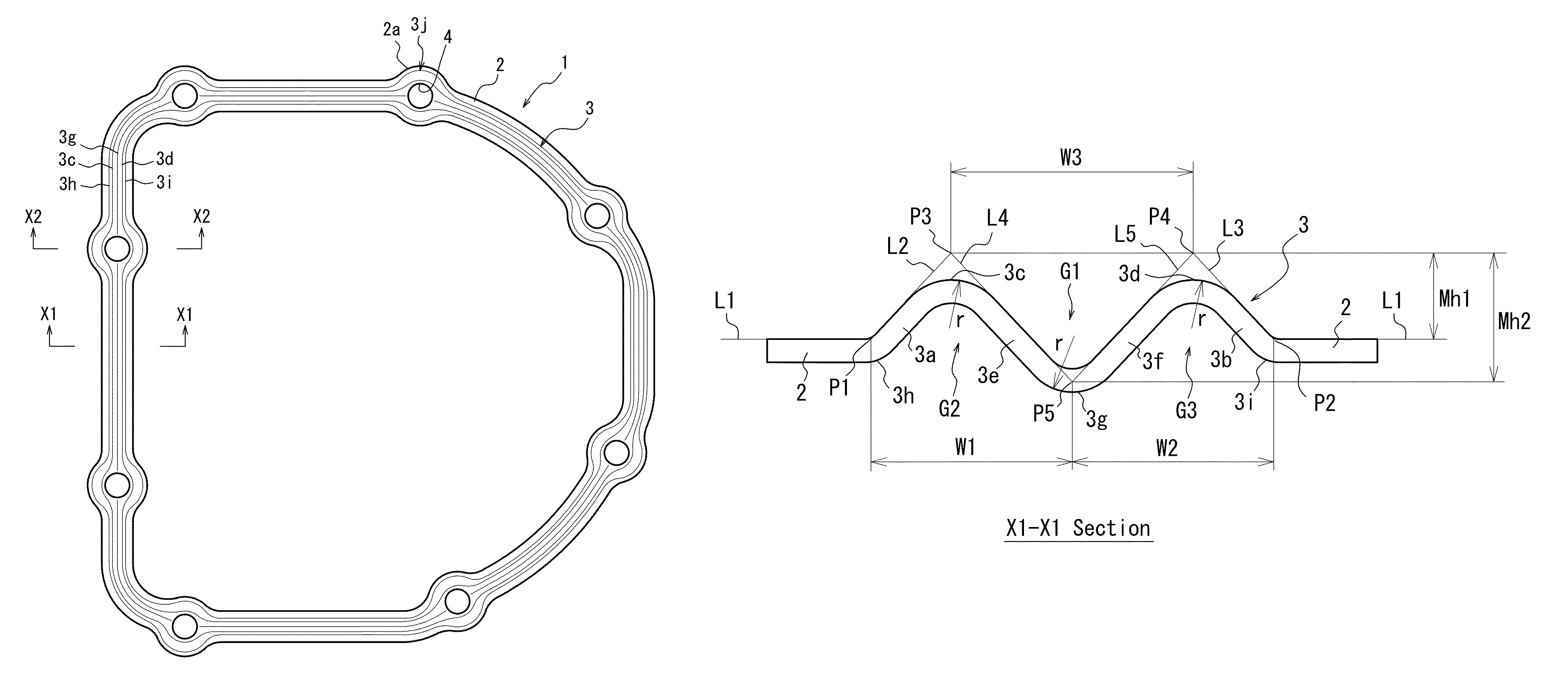

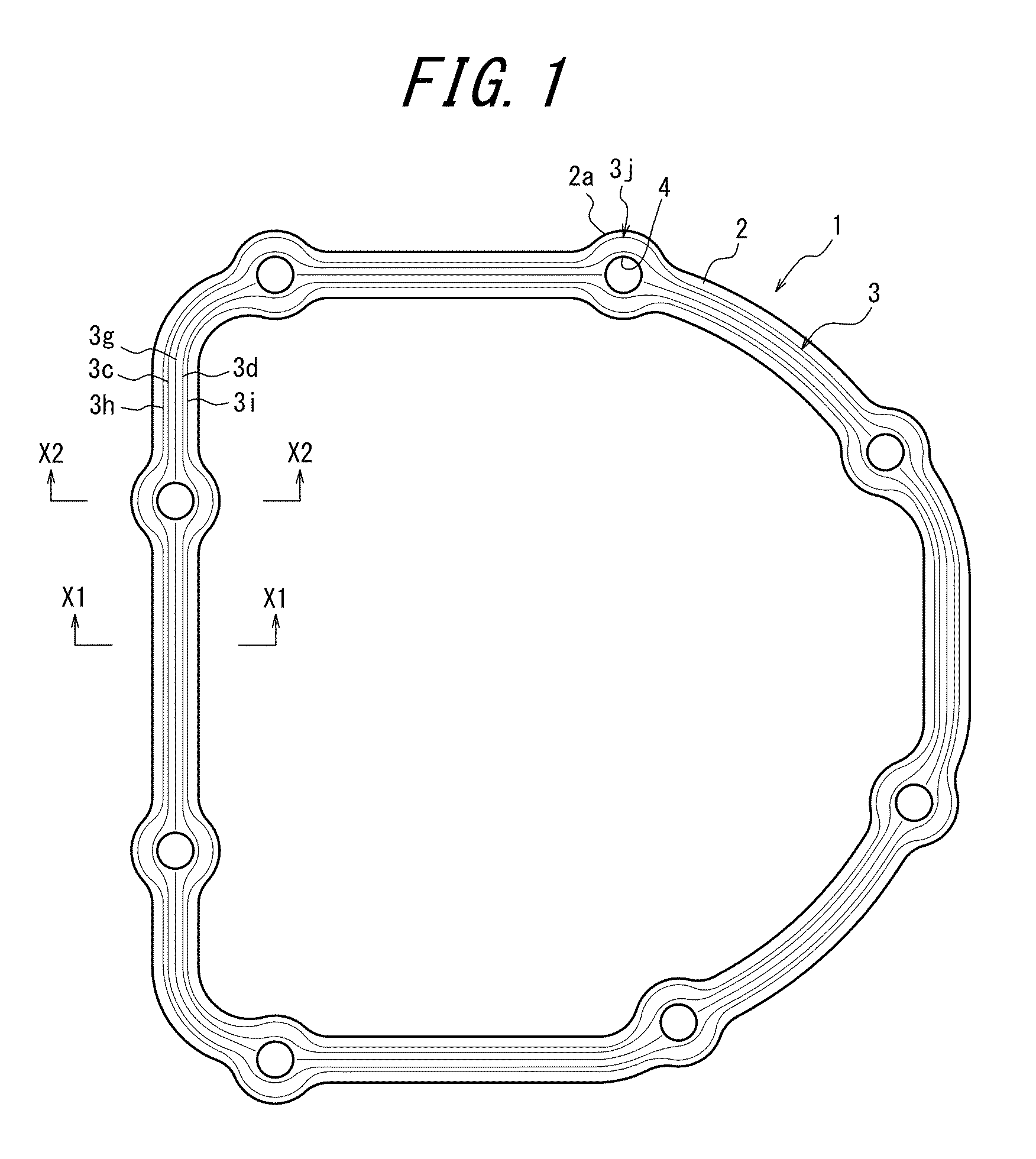

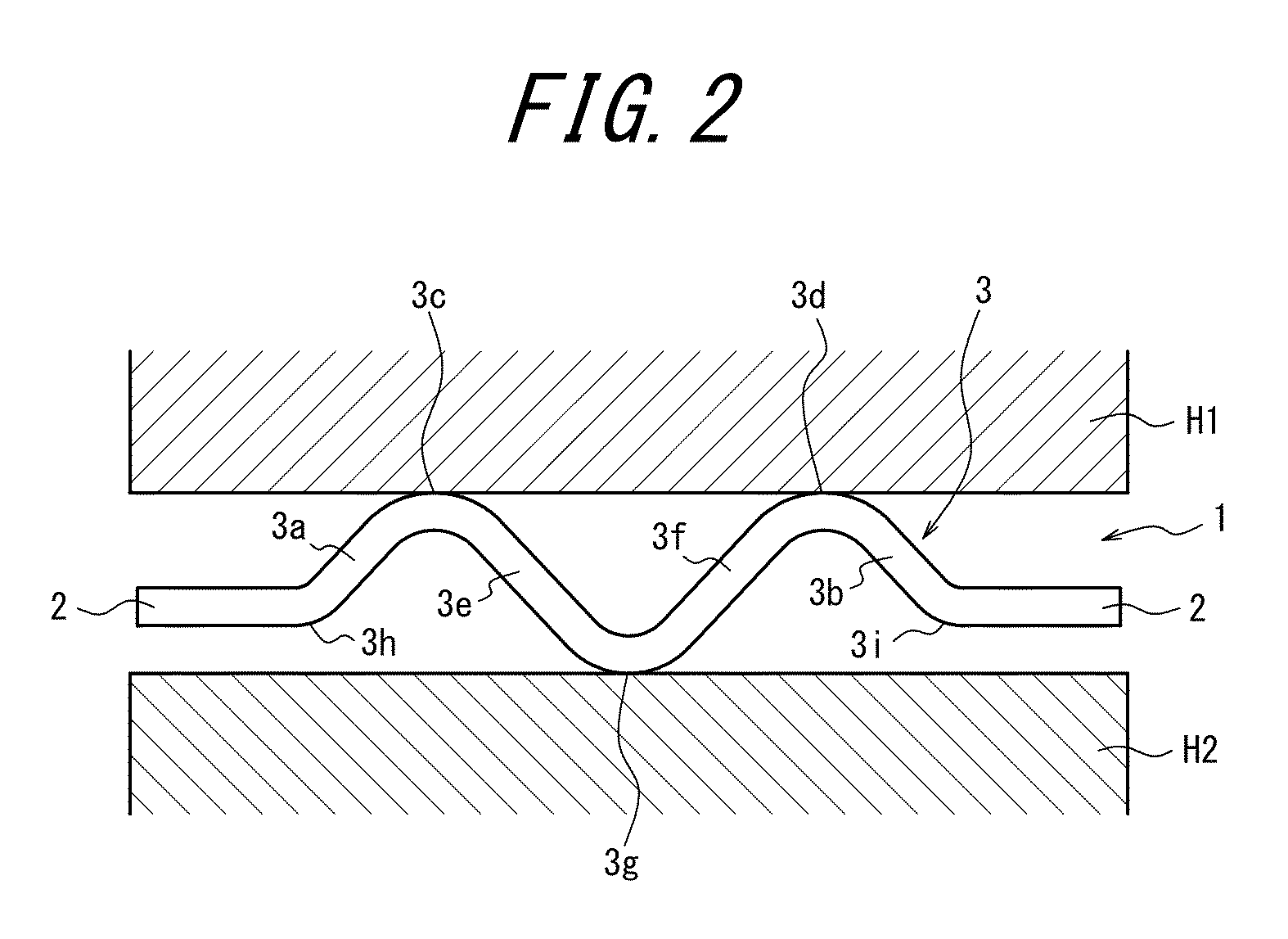

Metal gasket

ActiveUS9121489B1Reduced external diameterAvoid failureEngine sealsGearing detailsMetalElectrical and Electronics engineering

There is provided a metal gasket that is less susceptible to lift and thrust phenomenon of housings and can effectively function as a sealing at a blowhole. The metal gasket includes an embossment portion provided with a pair of outer inclined portions and a pair of inner inclined portions. The metal gasket and satisfies the following relationships: Mh2 / Mh1=1.10−1.81, W3>W1, and W3>W2, where Mh1 and Mh2 are vertical lengths, and W1, W2 and W3 are horizontal lengths. When the gasket is sandwiched in between two housings, tip ends abut on the housing to form two seal lines, and root ends, and another tip end abut on the housing H2 to form three seal lines.

Owner:NIPPON LEAKLESS IND CO LTD +1

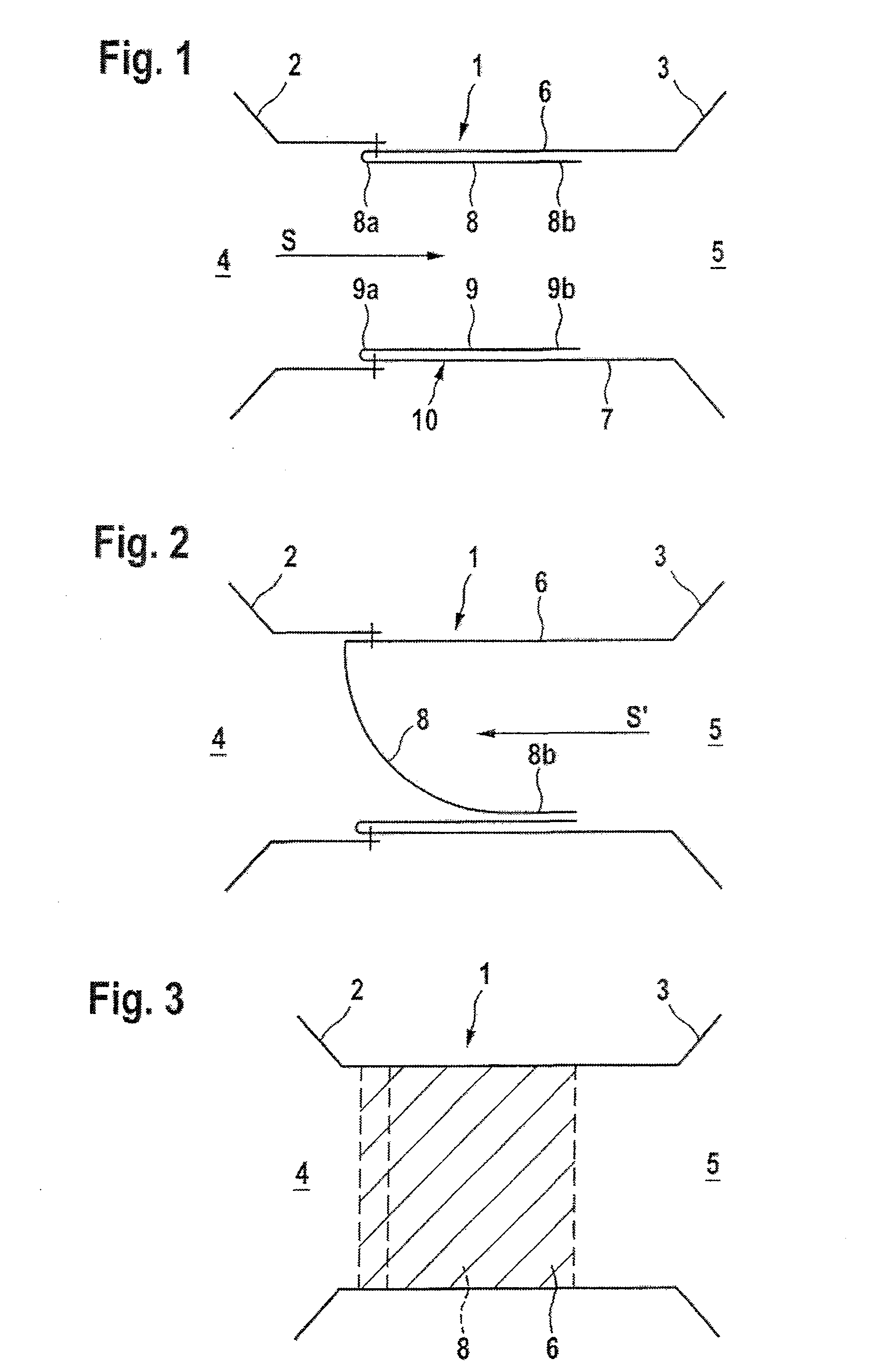

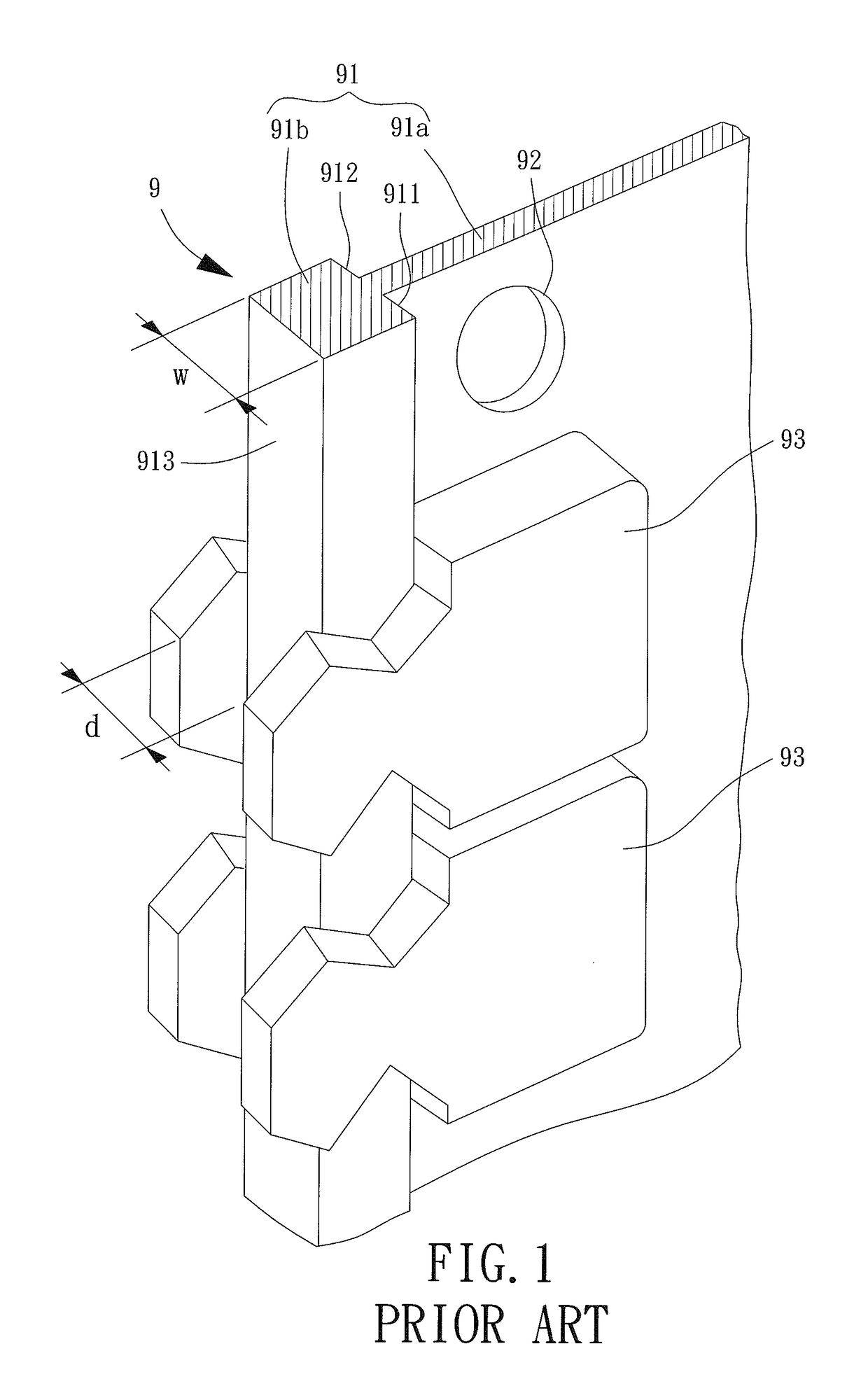

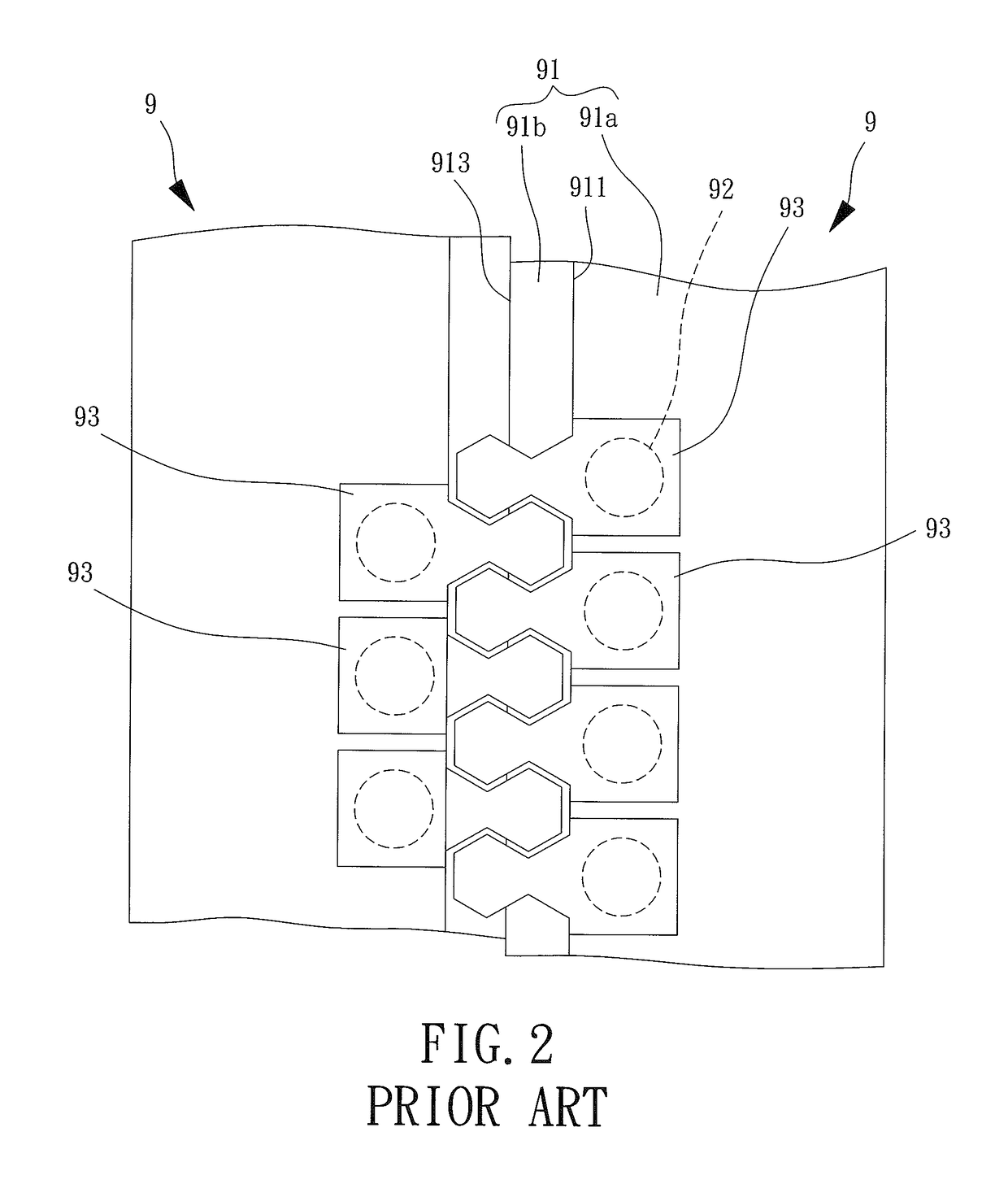

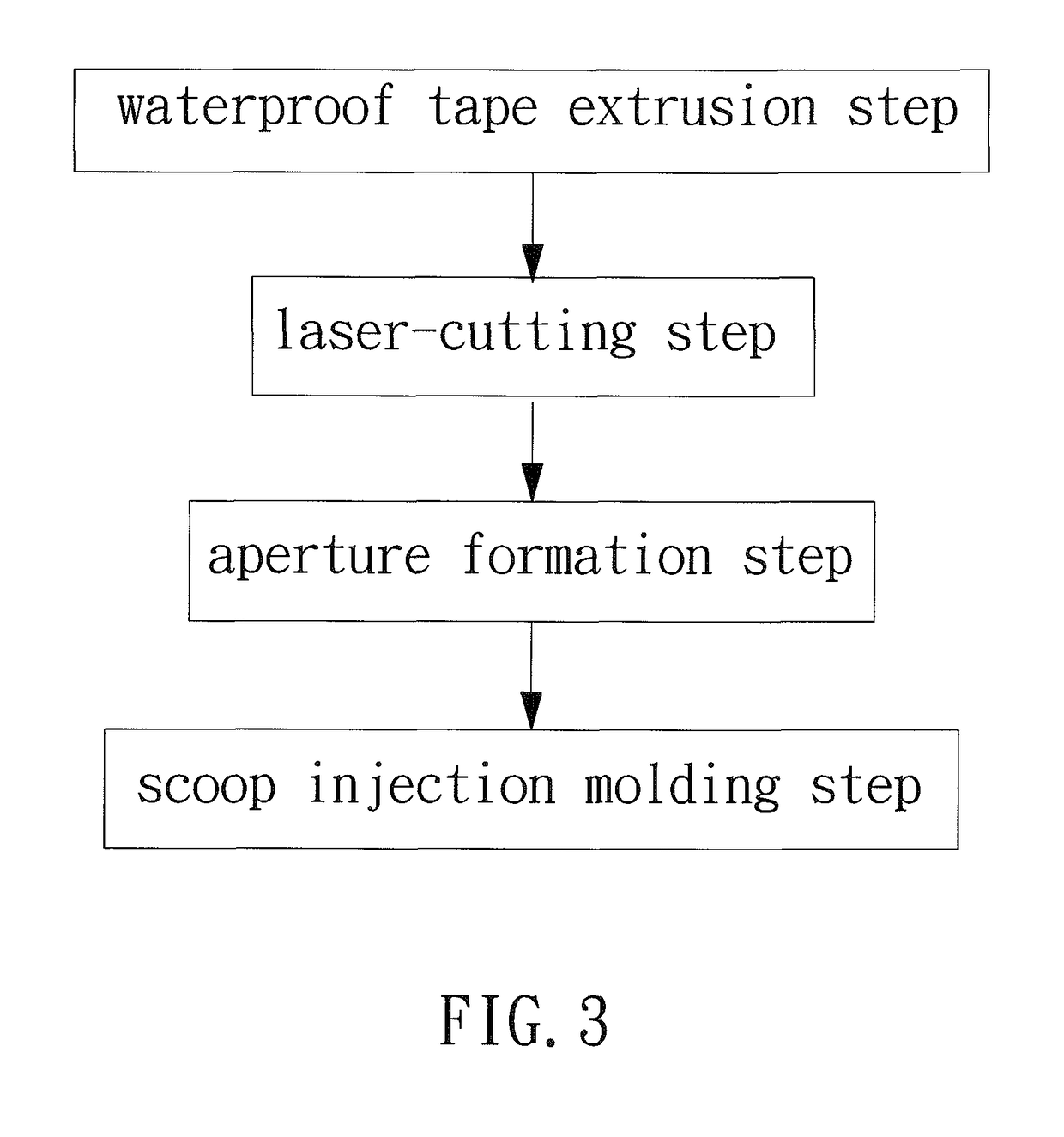

Method for manufacturing a watertight zipper

ActiveUS10144160B2Uneven thicknessImprove sealing functionSlide fastenersDomestic slide fastenersEngineeringMechanical engineering

A method for manufacturing a watertight zipper includes forming a waterproof tape by extruding a polymeric material in a melted state wrapping around a cloth tape, cutting a side of the waterproof tape that is covered by the thick waterproof layer to form a side surface of the thick waterproof layer as an abutting surface, forming a plurality of apertures in the waterproof tape that extends through the cloth tape and the thick waterproof layer, and forming a plurality of scoops spaced from the thin waterproof layer and corresponding to the apertures. The waterproof tape includes a thick waterproof layer and a thin waterproof layer both formed by the polymeric material. The thick waterproof layer covers an upper surface, a lower surface and an edge of the cloth tape. The thin waterproof layer connects with the thick waterproof layer. An end of each scoop extends beyond the abutting surface.

Owner:TAIWAN UNITED OUTDOOR GRP INC

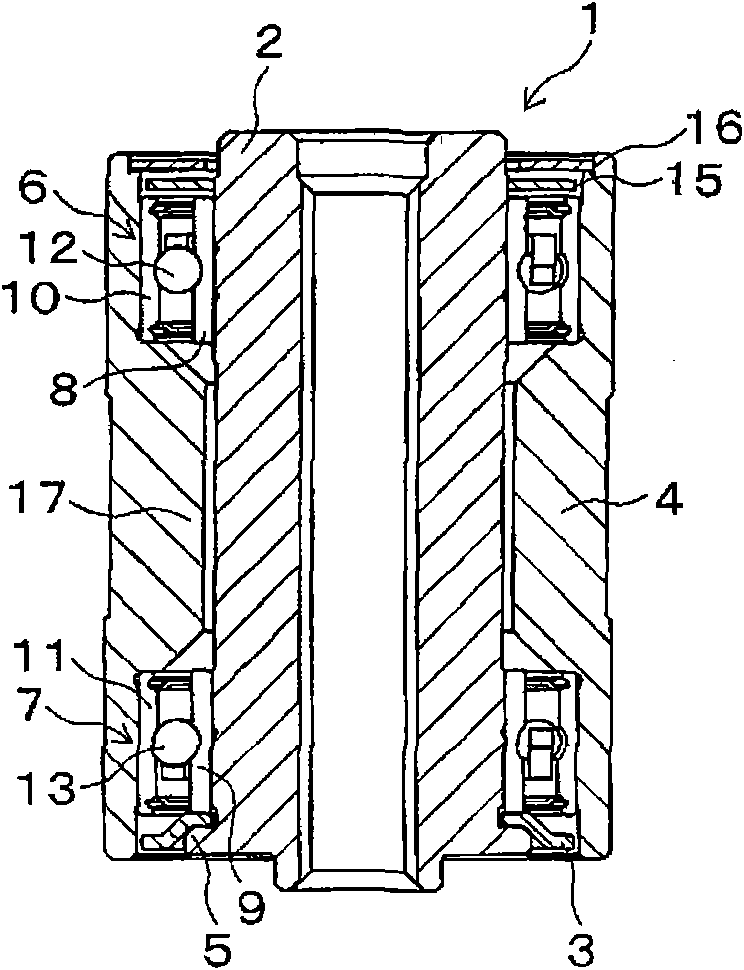

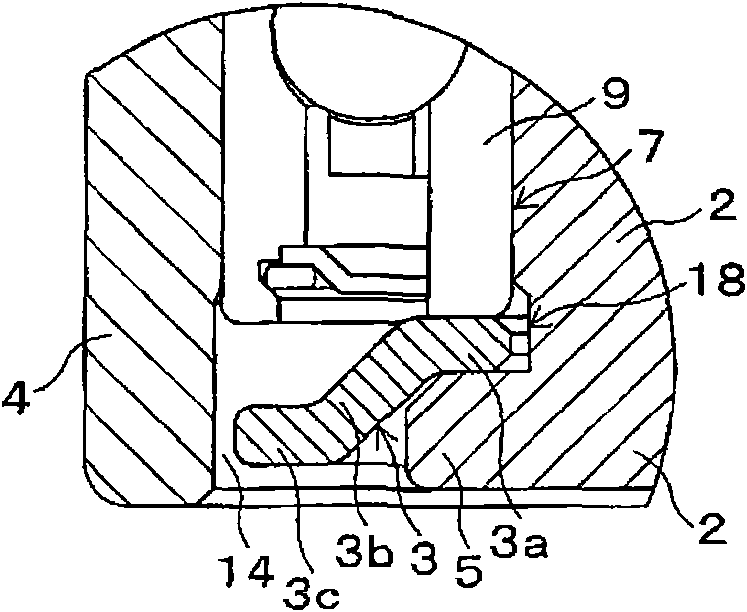

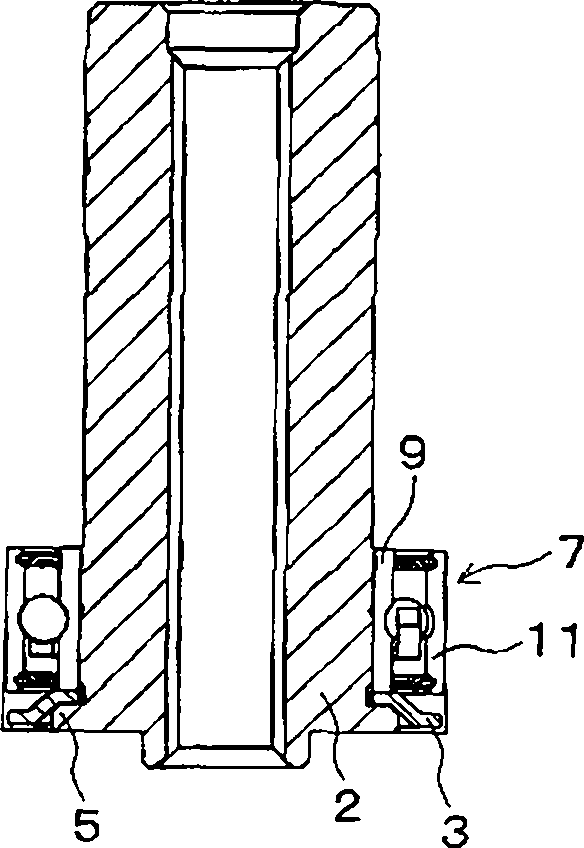

Bearing device

The present invention relates to a bearing device, in which one end part of a shaft (2) is provided with a flange (5), and an annular sealing plate (3) is held between the flange (5) and an inner ring (9) of a ball bearing (7). Leakage of lubricant is prevented by forming a labyrinth seal between the sealing plate (3) and a sleeve (4). An external diameter of the flange is reduced by the sealing plat (3), such that cost of material is reduced.

Owner:MINEBEA CO LTD

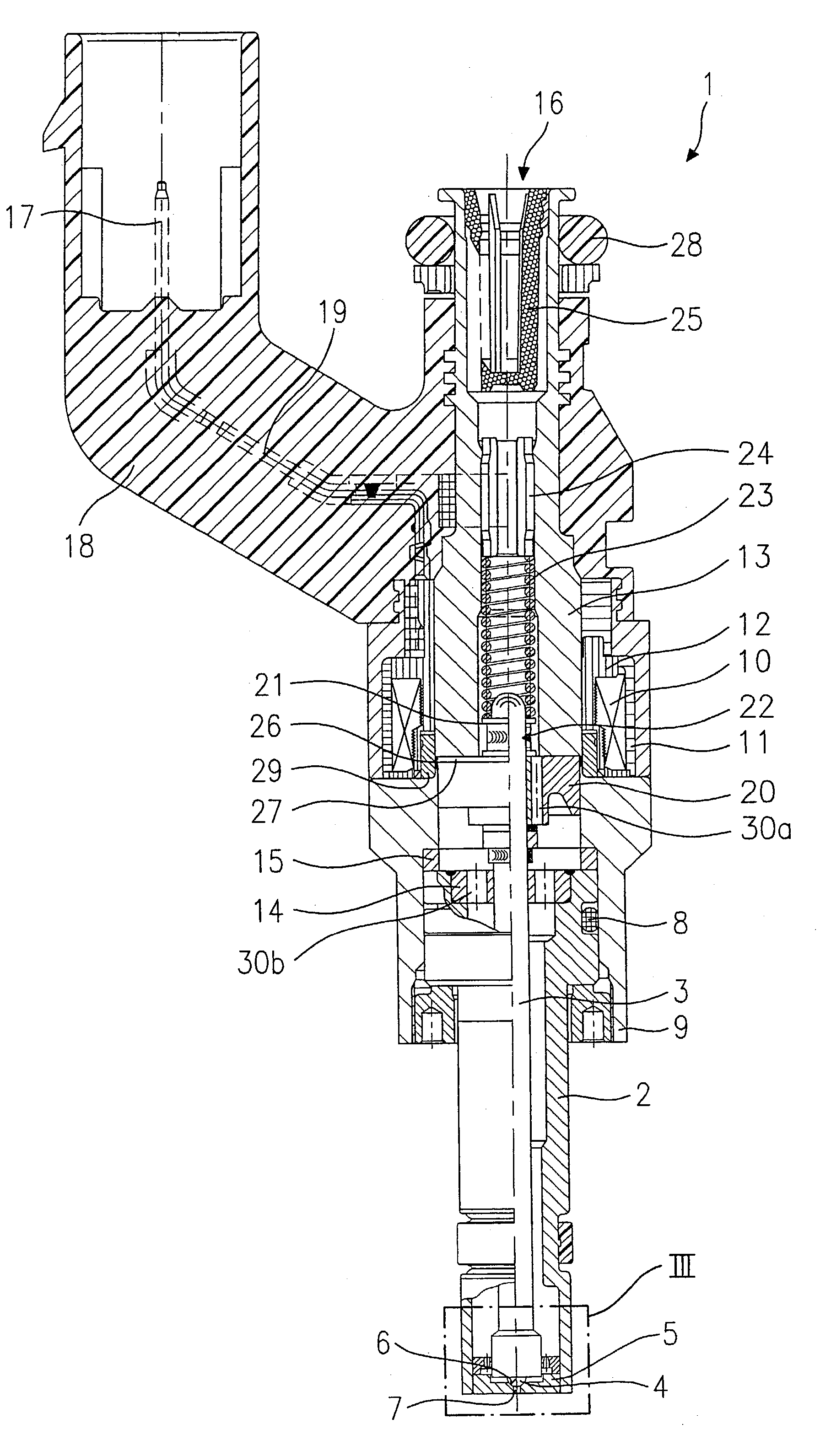

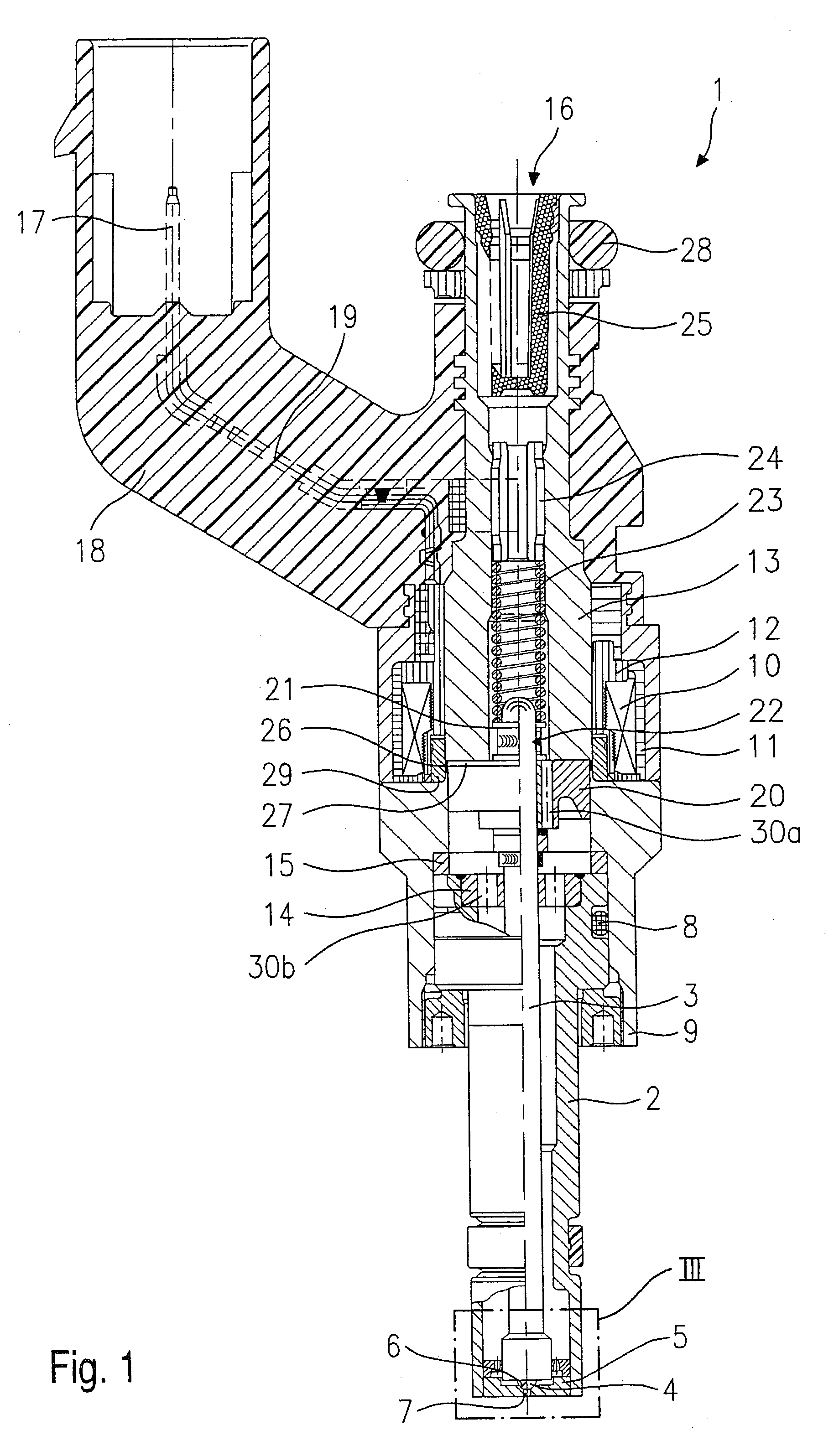

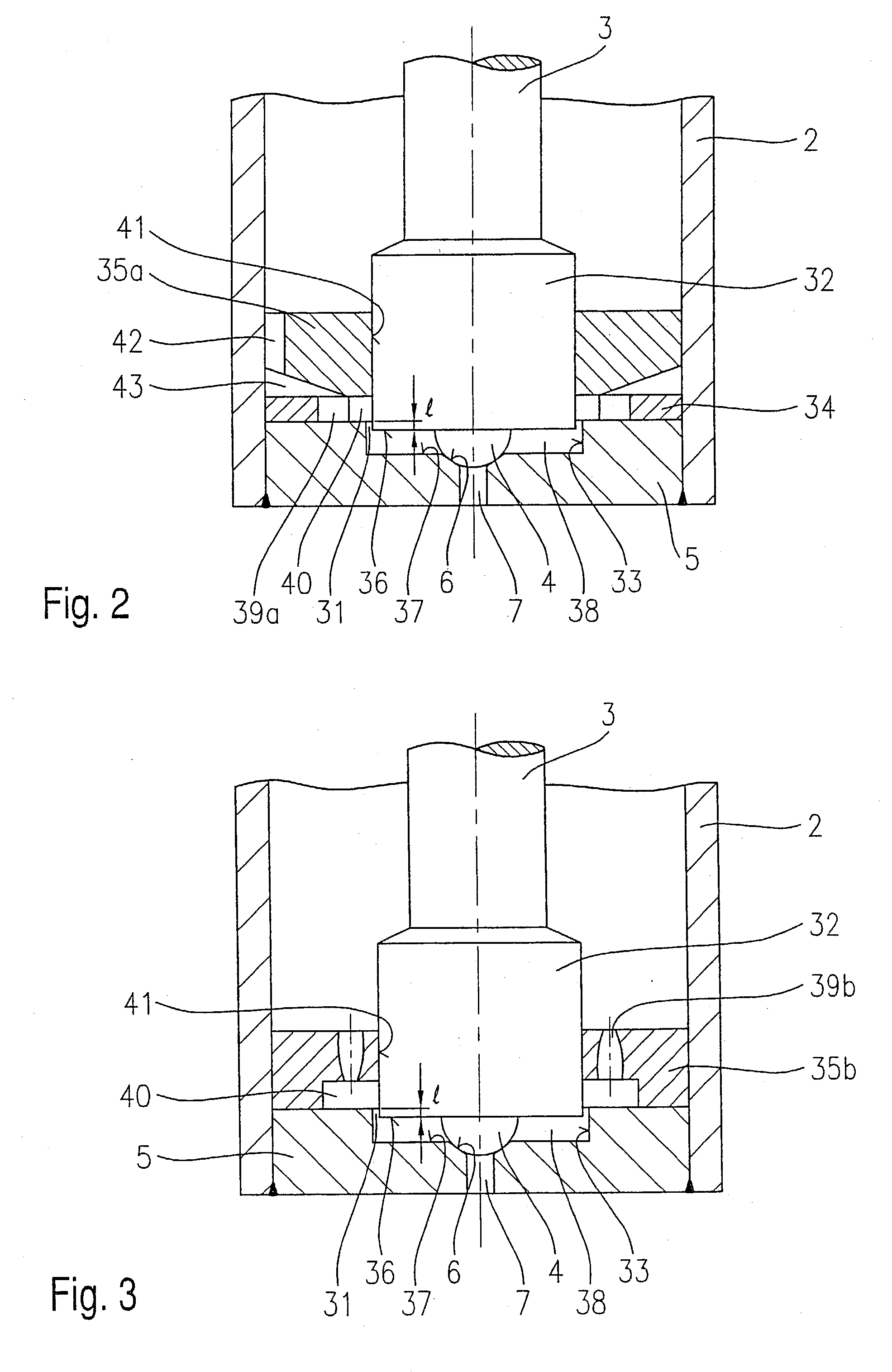

Fuel injector

InactiveUS20030136381A1Easy to adjustIntuitive adjustmentLow pressure fuel injectionMachines/enginesInjectorEngineering

A fuel injector for fuel injection systems of internal combustion engines includes a valve-seat member (5), in which a valve-seat surface (6) is introduced, which cooperates with a valve-closure member (4), mechanically linked to a valve needle (3), to form a sealing seat, and at least one spray-discharge orifice (7); in the idle state of the fuel injector (1) a gap (31), whose length (1) is smaller than the opening lift of the fuel injector (1), is situated between a downstream part of valve needle (3) and a recess (33) introduced in valve-seat member (5) on its upstream side.

Owner:ROBERT BOSCH GMBH

Water stop section for crossing floor layer installation of building drainage pipeline and installation method of water stop section

The invention discloses a water stop section for the crossing floor layer installation of a building drainage pipeline and an installation method of the water stop section. The water stop section includes a water stop section body, a flange gland, a sealing ring sleeve, a sealing rubber pad, a sealing rubber ring and a fastening bolt, the water stop section body and the flange gland are assembledin a fastened mode by the fastening bolt, the inner cavity of the water stop section body is connected with the sealing ring sleeve by the sealing rubber ring in a sealed mode, and the sealing ring sleeve and the flange gland are connected in a sealed mode through the sealing rubber pad inside of the sealing ring sleeve. The risk that water leakage is prone to occurring at openings in the two endsof an embedded connecting pipe or a center-adjustable embedded connecting pipe structure is avoided, a bolt connection fastening method of a T-shaped groove formed in the water stop section body witha cross groove of a flange pressure plate long bolt hole is adopted, when the position of the water stop section poured on a reinforced concrete floor is deviated, the installation position of the pipeline can be conveniently adjusted in any horizontal direction by displacing adjustment to ensure the verticality of the vertical pipe installation, the product structure is simplified, the manufacturing cost is reduced, and the efficiency of installation and construction are improved.

Owner:广州观景文化科技有限公司

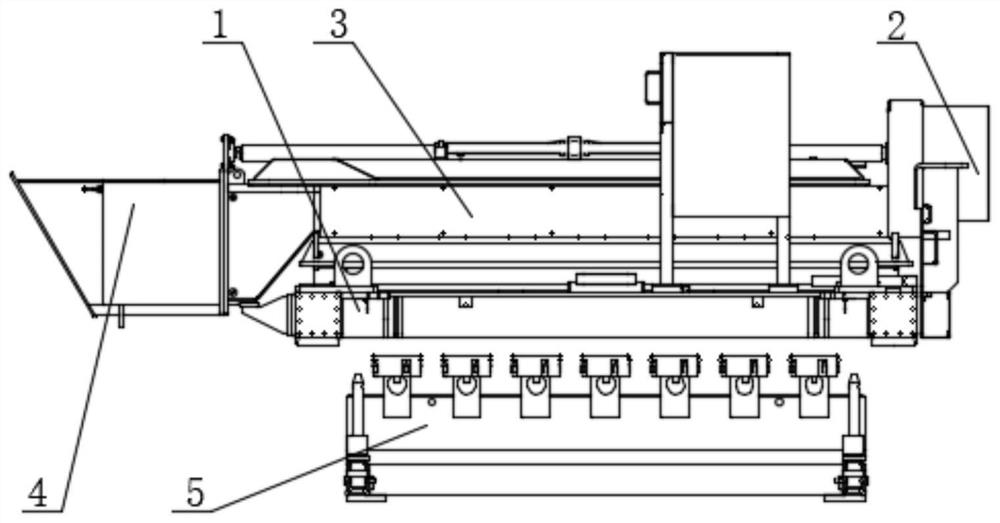

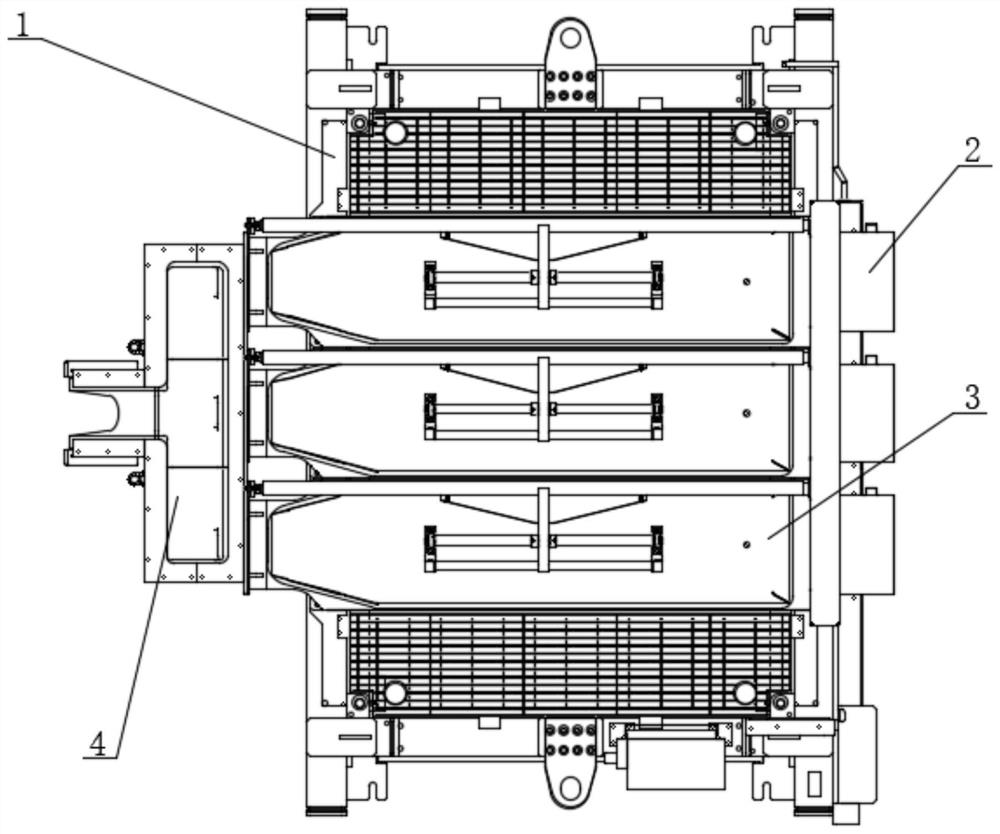

Aluminum bar casting forming equipment and processing technology thereof

The invention relates to aluminum bar casting forming equipment and a processing technology thereof. The equipment comprises a fixed frame, wherein a plurality of adjacent die plate units are mountedabove the fixed frame, a plurality of distributed crystal heads are arranged below each die plate unit, molten aluminum introduced by the die plate units is injected into the crystal heads, a ventilating valve is arranged next to each crystal head, a dummy bar head lifting platform is mounted at the bottom of the fixed frame, a plurality of dummy bar heads are mounted on the dummy bar head liftingplatform, each dummy bar head corresponds to each crystal head one by one, a lifting oil cylinder is arranged at the bottom of the dummy bar head lifting platform, and when the dummy bar head liftingplatform ascends, each dummy bar head stretches into each crystal head. In the crystallizing process, a cooling measure is applied, and the dummy bar head lifting platform is controlled to descend slowly to form an aluminum bar. A control box is mounted on the fixed frame and the die plate units, so that the aluminum bar casting forming equipment is high in work efficiency and good in forming effect.

Owner:SUNYO S&T CO LTD

Sanitary butterfly valve

InactiveCN106151542AThe overall structure is compactEasy to install and disassembleLift valveHinge angleInternal rotation

The invention relates to the technical field of valves, discloses a butterfly valve, and particularly provides a sanitary butterfly valve. The sanitary butterfly valve comprises a flange connected to a pipeline. The flange is provided with connecting holes. A valve seat is arranged on the connecting holes. A valve element which is capable of rotating in the valve seat through hinge shafts and can be sealed with the valve seat is arranged in the valve seat. The section of the valve seat is in a circle shape. An annular boss is arranged on the inner face of the valve seat. A valve bush capable of being matched with the valve element is further arranged in the valve seat. The sanitary butterfly valve has the advantages that the annular boss is arranged on the inner face of the valve seat, the valve bush capable of being matched with the valve element is further arranged in the valve seat, and thus the better sealing function can be achieved; the overall structure is more compact through matching of the valve bush and the boss, and meanwhile mounting and dismounting are convenient; the effect that connection of first sealing bodies and second connecting end faces can still achieve the good sealing function after long-time use can be achieved; and meanwhile, the quality of water can be prevented from being affected under any condition through a material adopted by the valve bush.

Owner:德清三盛氟塑科技有限公司

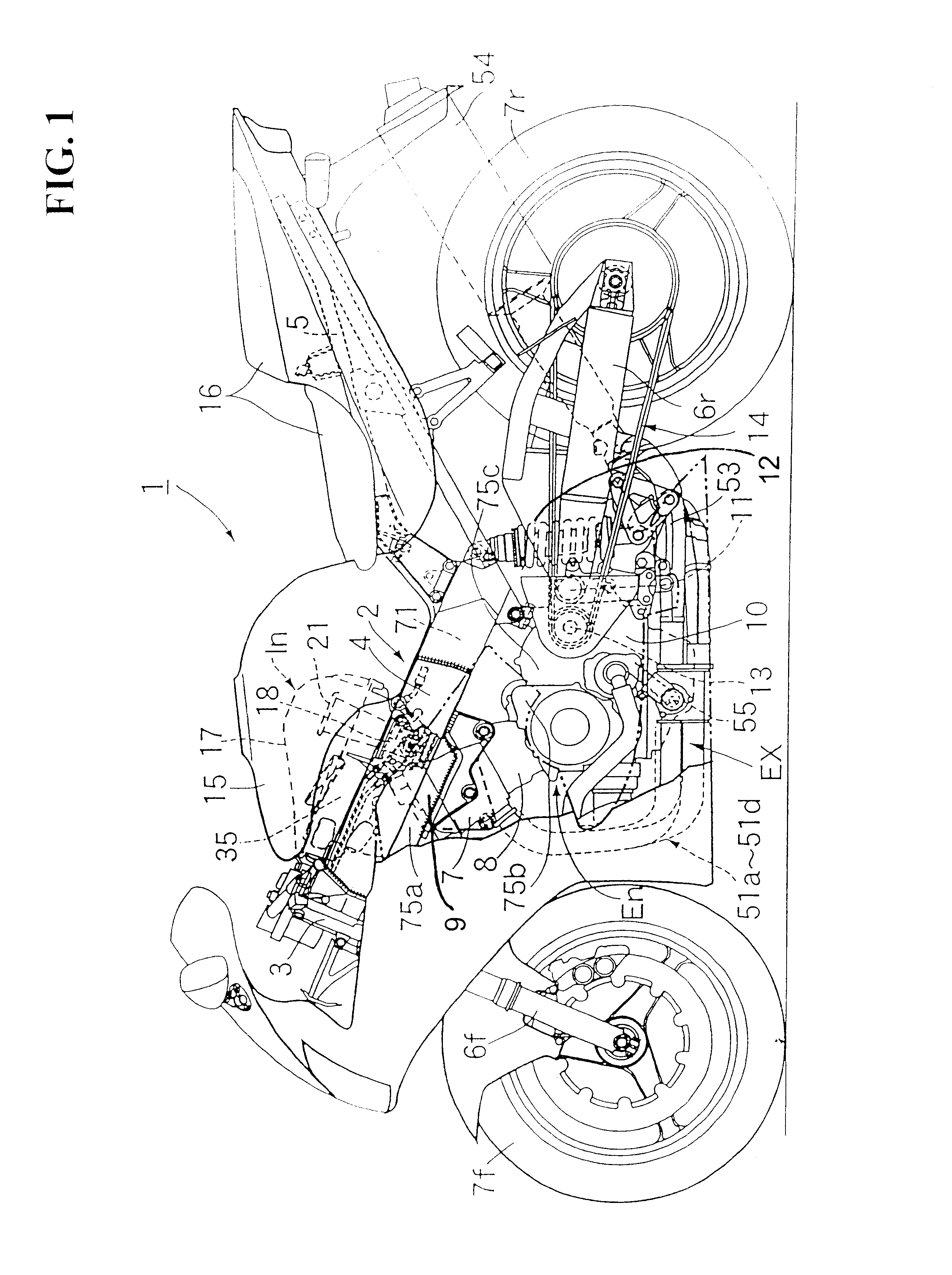

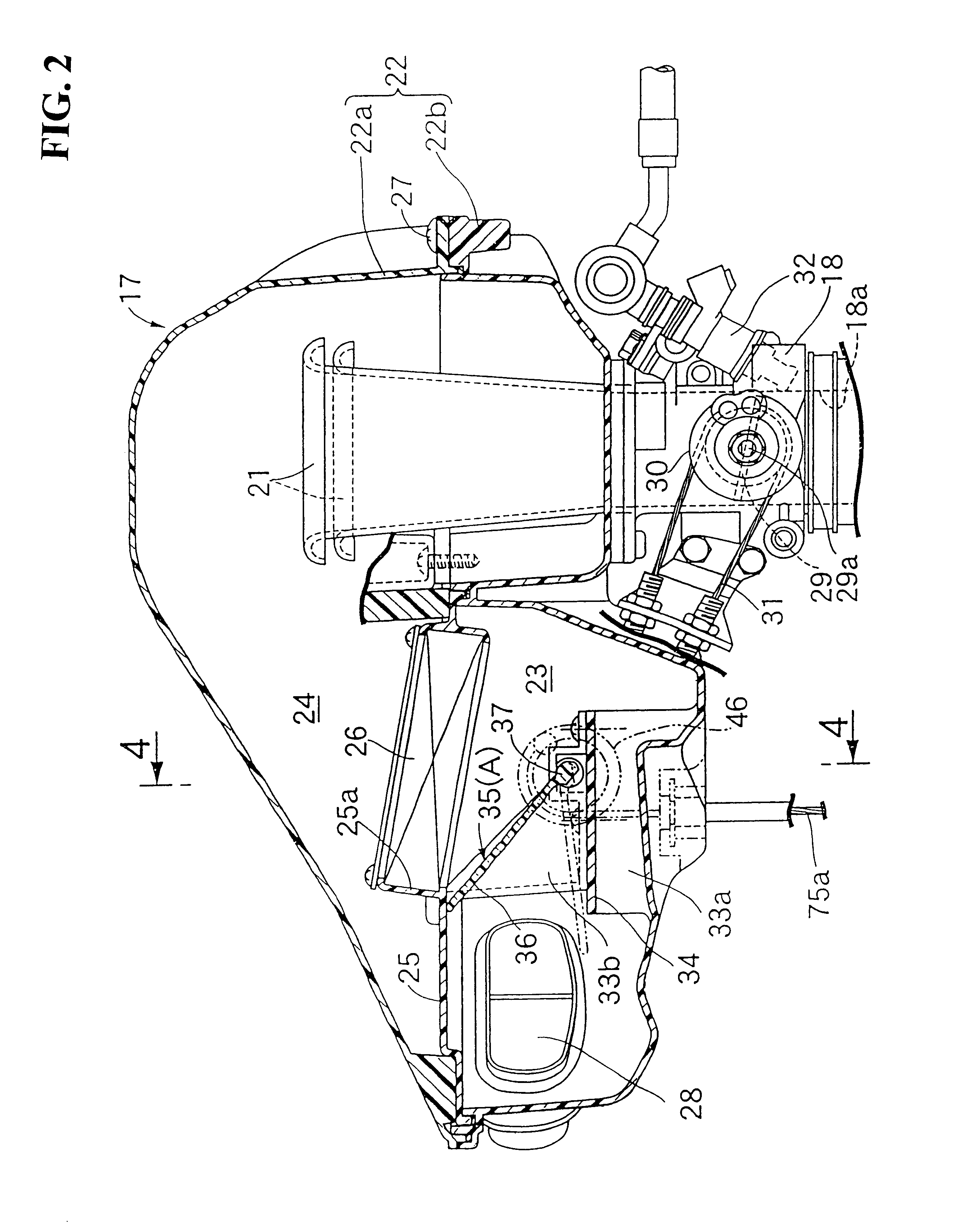

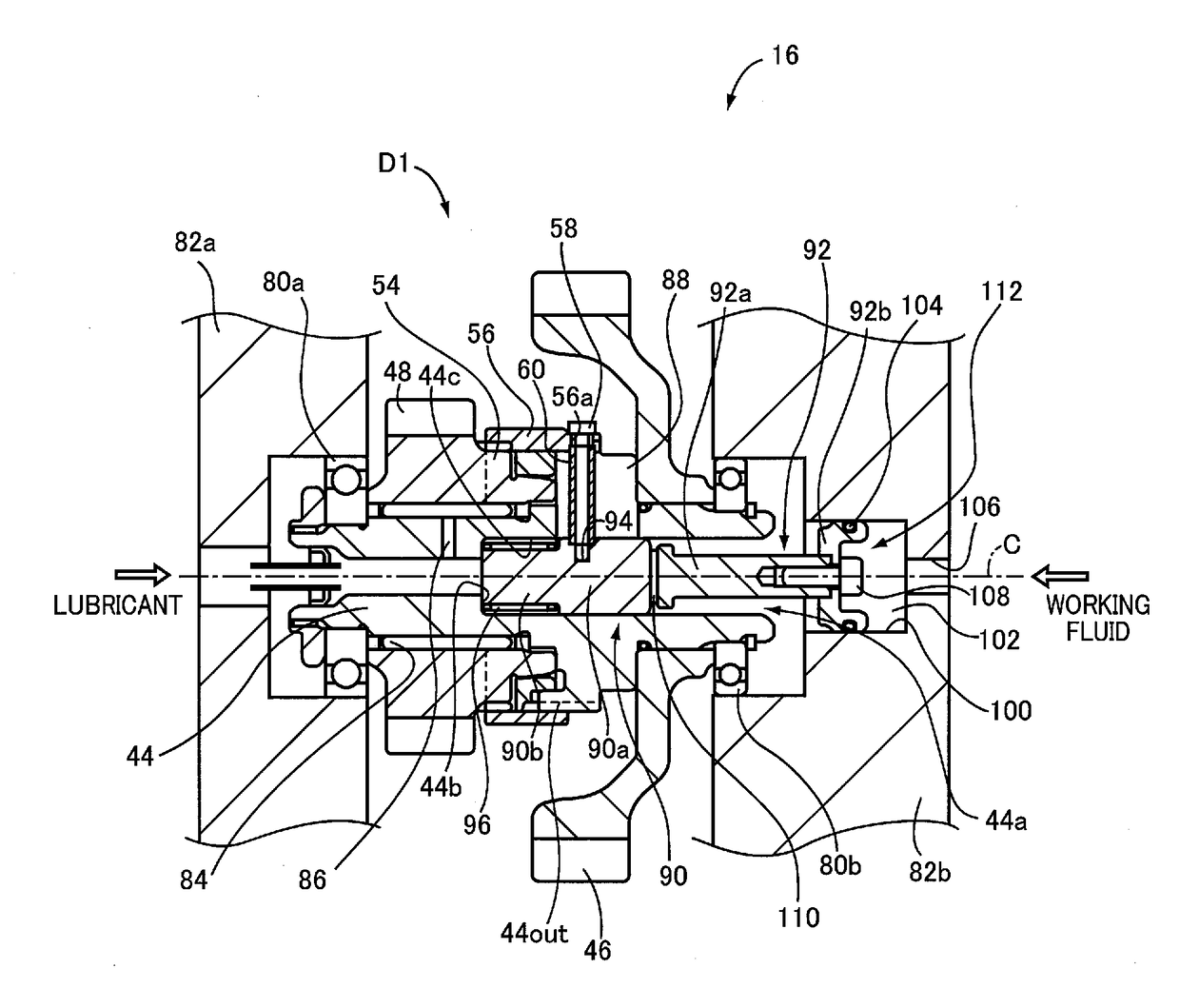

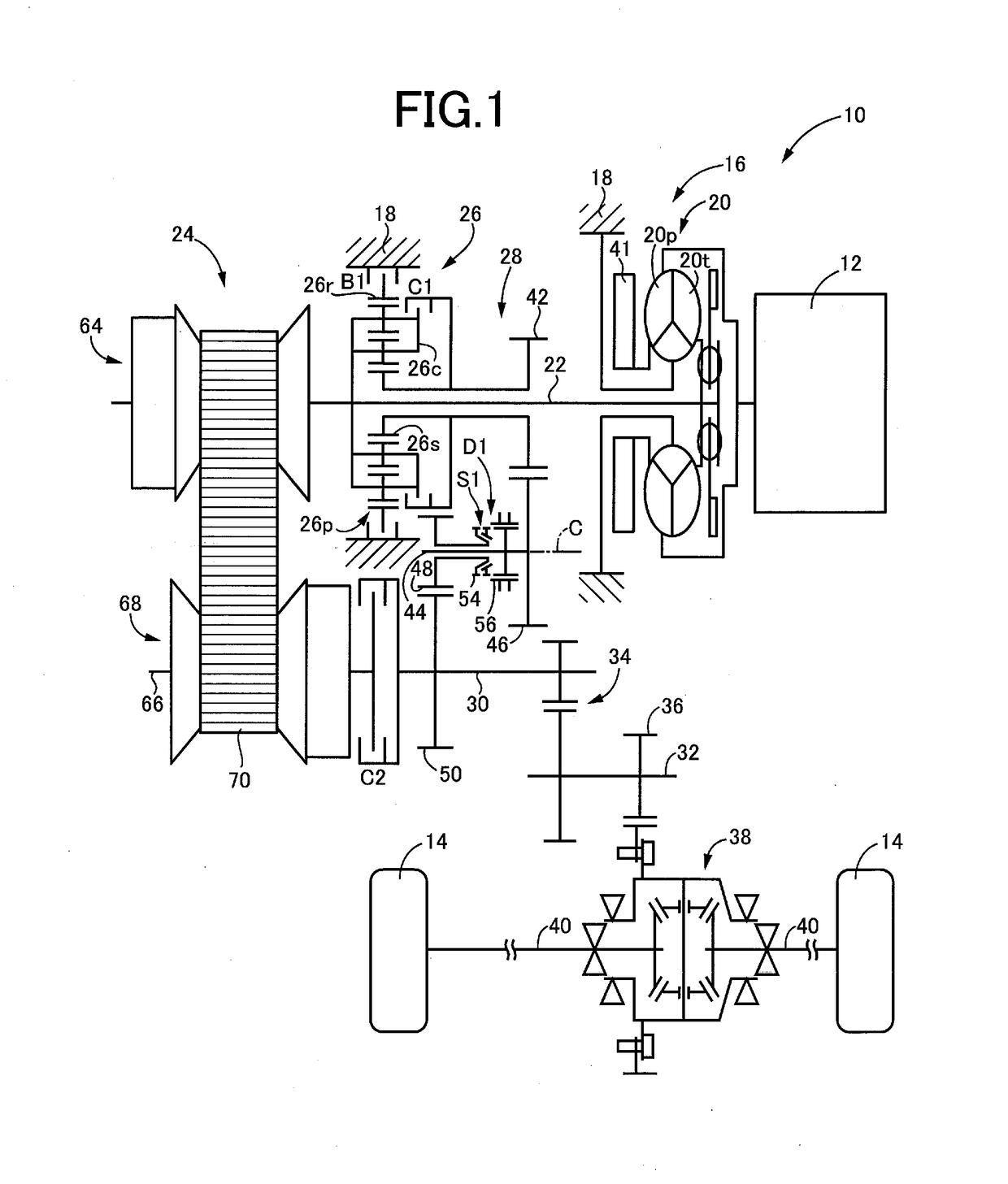

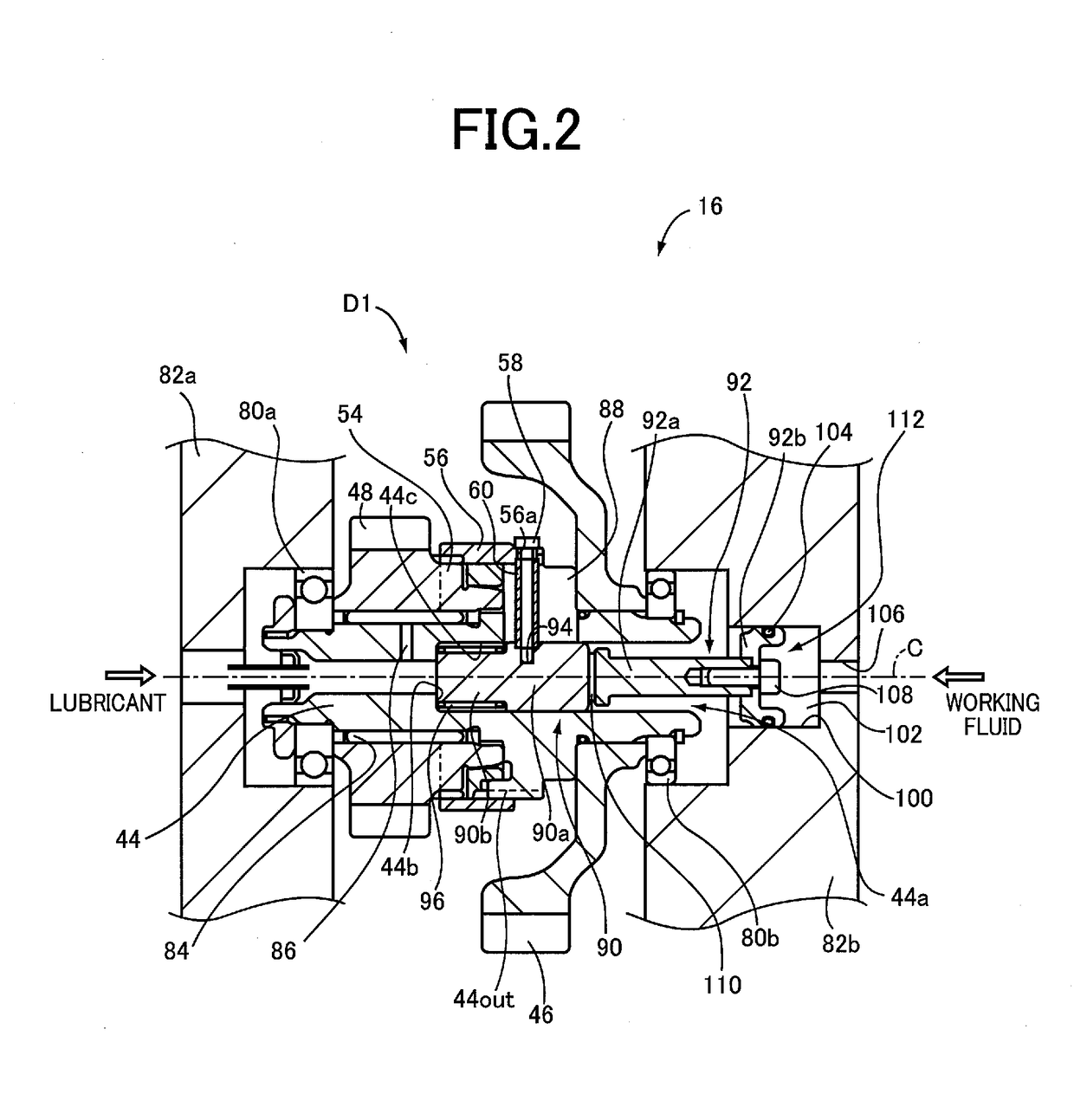

Vehicular power transmitting system

ActiveUS20180245641A1Improve stabilityImprove operational reliabilityGearingFluid actuated clutchesReciprocating motionEngineering

A power transmitting system including: a first piston disposed within a center bore formed through the rotary shaft such that the first piston is axially reciprocable; a sleeve connected to the first piston and having internal teeth meshing with the external teeth of the rotary shaft so that the sleeve is rotated with the rotary shaft, and such that the sleeve is axially reciprocable together with the first piston according to axial movements of the first piston; a synchronizer ring supported in sliding contact with an outer circumferential tapered surface of the clutch gear such that the synchronizer ring is rotatable relative to the clutch gear; and an actuator including a second piston to axially advance the first piston for thereby bringing the sleeve's internal teeth into meshing engagement with the clutch gear through the synchronizer ring. The first piston and second piston are disposed coaxially with the rotary shaft.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com