Water stop section for crossing floor layer installation of building drainage pipeline and installation method of water stop section

A technology for building drainage and water-stopping, which is applied in the direction of pipes, pipes/pipe joints/pipes, mechanical equipment, etc. It can solve problems such as affecting the water flow pattern and drainage performance of the drainage riser, increasing the risk of leakage, and affecting the service life. , to achieve good sealing and water-stop function, improve the efficiency of installation and construction, and avoid the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

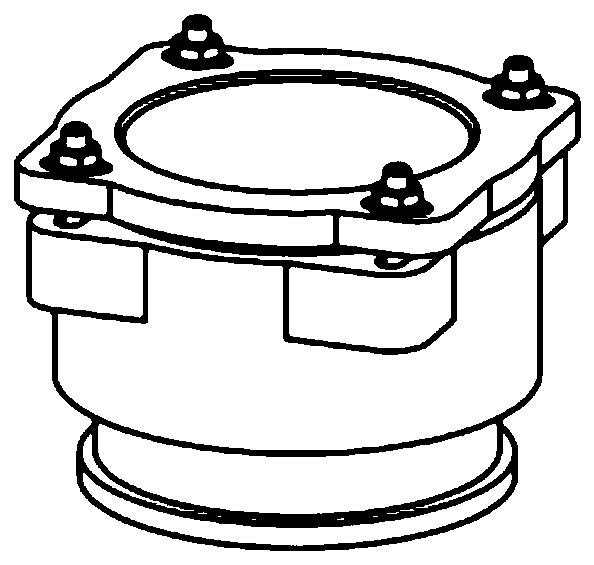

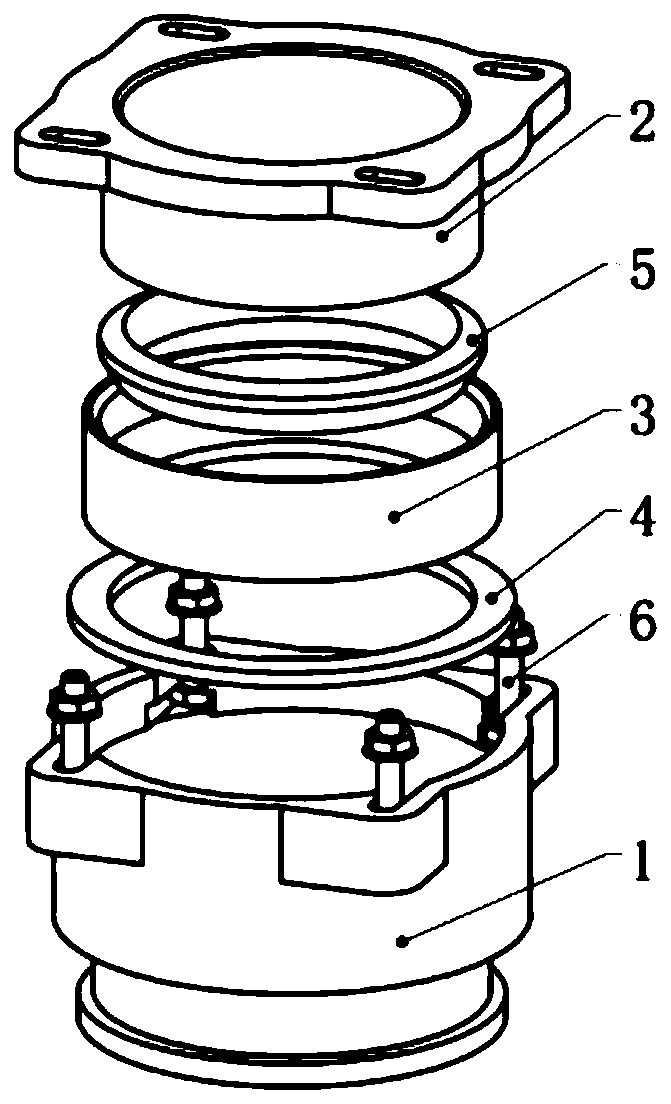

[0054] Such as Figure 1-2 , used for the water-stop section installed by building drainage pipes passing through the floor layer, including the water-stop section body 1, the flange gland 2, the sealing ring sleeve 3, the sealing rubber pad 4, the sealing rubber ring 5 and the fastening bolt 6, the water-stopping The section body 1 and the flange gland 2 are fastened and assembled by fastening bolts 6, and the inner cavity of the waterstop section body 1 is sealed and connected with the sealing ring 3 through the sealing rubber ring 5, and the sealing ring 3 and the flange gland 2 They are sealed and connected by the sealing rubber pad 4 inside the sealing ring sleeve 3 to ensure the tightness of the joint. The water stop section body 1 and the flange gland 2 are set on the drainage riser 7, and the water stop section body 1 is embedded in the floor Layer 8.

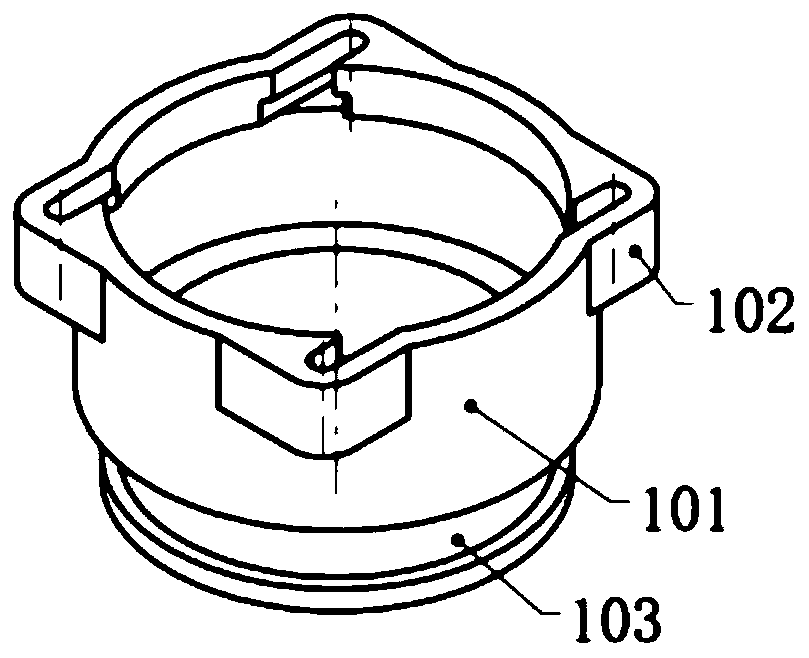

[0055] Water stop festival body 1 (such as Figure 3-4 ) consists of three sections of water-stop pipe body 101 wit...

Embodiment 2

[0069] The water stop section of the present invention is pre-cast in the reinforced concrete floor layer 8. In order to ensure the accuracy of the installation position of the drainage riser 7, before the floor layer 8 is poured, the plane of the water stop section body 1 in the floor layer 8 needs to be fixed. Location. The building drainage riser has a single drainage riser 7 to install, and also has multiple drainage risers 7 to install, all need to be positioned according to the installation dimension requirement of design drawing during installation. as Figure 10 The positioning and installation of the three drainage standpipes 7 is taken as an example, and the positioning and fixing methods are as follows:

[0070] Such as Image 6 According to the size of the installation position on the design drawings, the positioning plate 10 is fixed on the aluminum formwork 9 before pouring with bolts 14 . Set the water stop body 1 on the outer ring of the positioning plate 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com