Bearing device

A bearing device and ball bearing technology, applied in the field of bearing devices, can solve the problems of large outer diameter, high processing cost, high material cost, and many cutting parts, etc., and achieve the effect of reducing the outer diameter, reducing the material cost, and improving the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

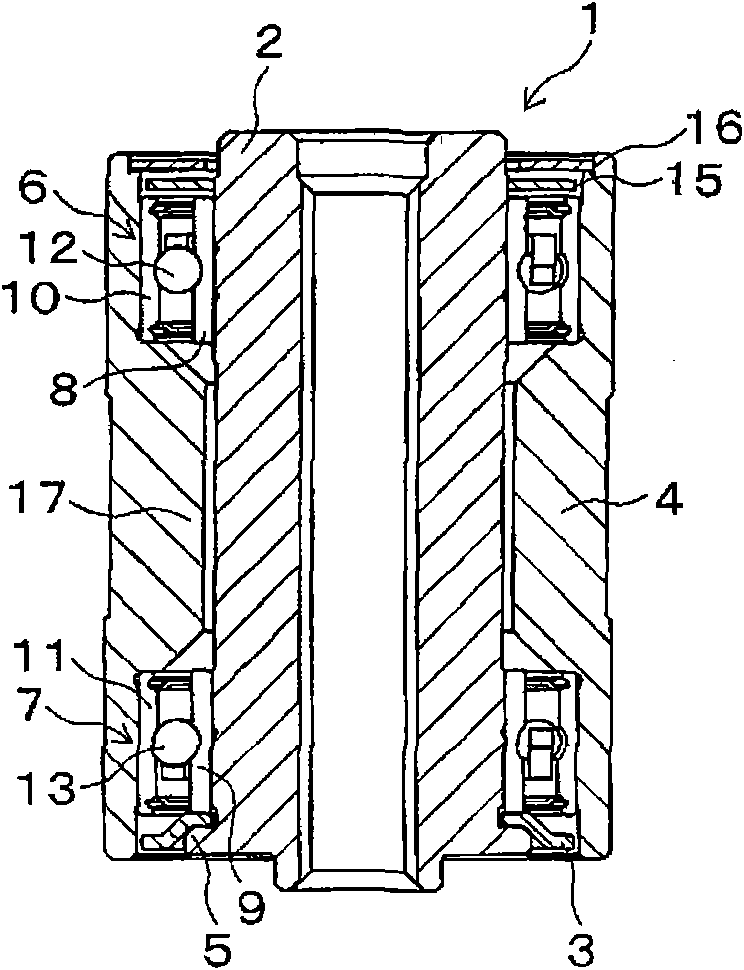

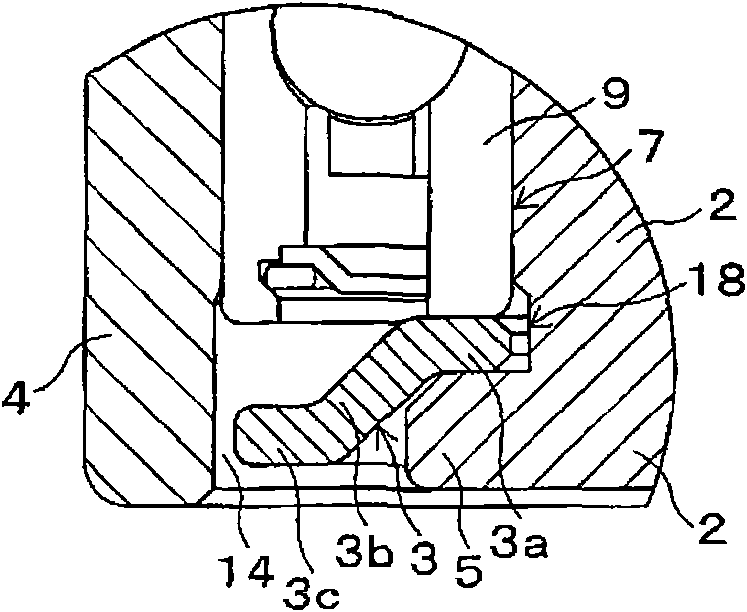

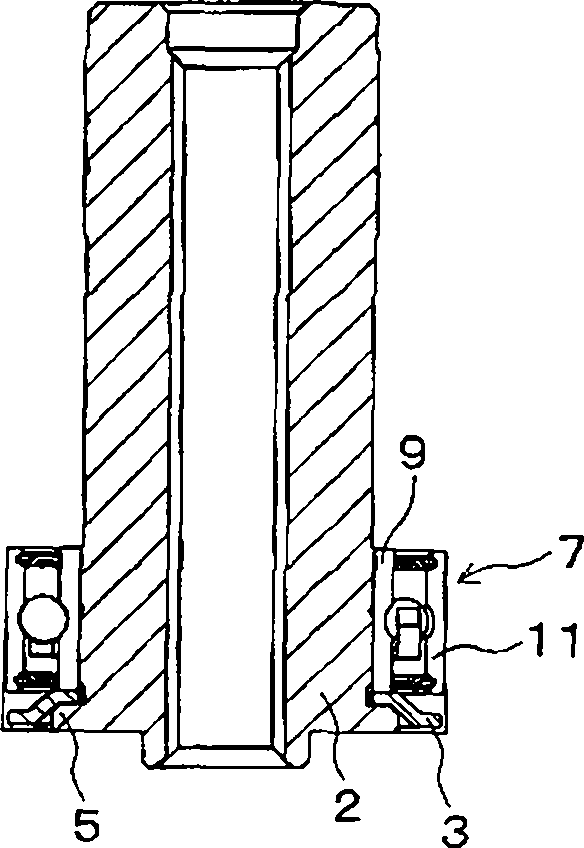

[0022] (structure)

[0023] Figure 1A and Figure 1B Shown is a pivot assembly bearing device 1 as a bearing device according to an embodiment. The pivot assembly bearing device 1 is used for swingably supporting a rocker arm mounted with a magnetic head for reading and writing information in a hard disk drive. The pivot unit bearing device 1 is used by being fitted into a through hole of a not-shown rocker block (E block).

[0024] The pivot unit bearing device 1 includes a shaft 2 . The shaft 2 is rotatably held by a pair of ball bearings 6 and 7 . That is, the ball bearing 6 holds the rolling elements 12 between the inner ring 8 and the outer ring 10 , and the ball bearing 7 holds the rolling elements 13 between the inner ring 9 and the outer ring 11 . Furthermore, the inner rings 8 and 9 are fixed to the outer periphery of the shaft 2, and the outer rings 10 and 11 are fixed to the inner side of the sleeve 4 which is a cylindrical structure. Lubricants such as grease...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com