Vacuum seal cover of circular container

a seal cover and container technology, applied in the direction of closures, packaging, transportation and packaging, etc., can solve the problems of easy torn or cracked hinges, difficult for users to latch or open locking tabs, and users' inability to operate locking tabs, etc., to achieve the effect of prolonging the expiration date of contents stored in the container

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention will now be described in more detail hereinafter with reference to the accompanying drawings that show various embodiments of the invention.

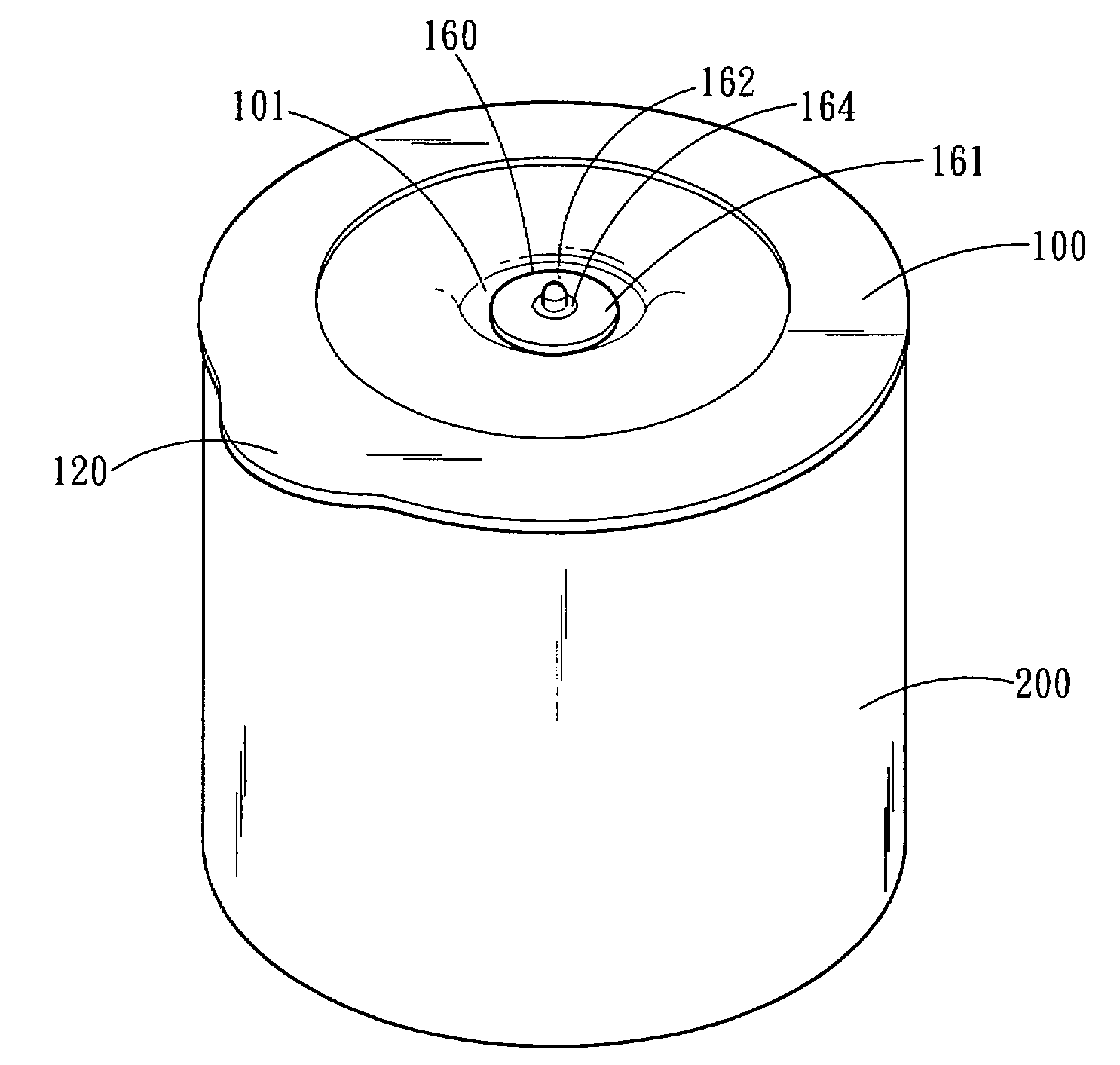

[0023]Referring to FIGS. 3 and 4 for a perspective view and an exploded view of a circular container and a vacuum seal cover of the present invention, the vacuum seal cover is applied as a cover 100 of a container 200 with a circular opening 220, and the cover 100 comprises: a protruding circular wall 130 disposed at the bottom of the cover 100 and sheathed to an opening 220 of the container 200, and an external side of the circular wall 130 forming a circular top connecting portion 110, and a pulling portion 120 extended and expanded from an appropriate position of the top connecting portion 110, such that a user can lift and turn the pulling portion 120 to separate the cover 100 from the opening 220 of the container 200.

[0024]A groove 140 is disposed around the external sidewall of the circular wall 130, and a circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com