Pilot-actuated valve

A pilot valve and valve technology, applied in the field of pilot valves, can solve the problem of high production cost of valve closing components and connecting rods, and achieve the effect of reducing flow force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

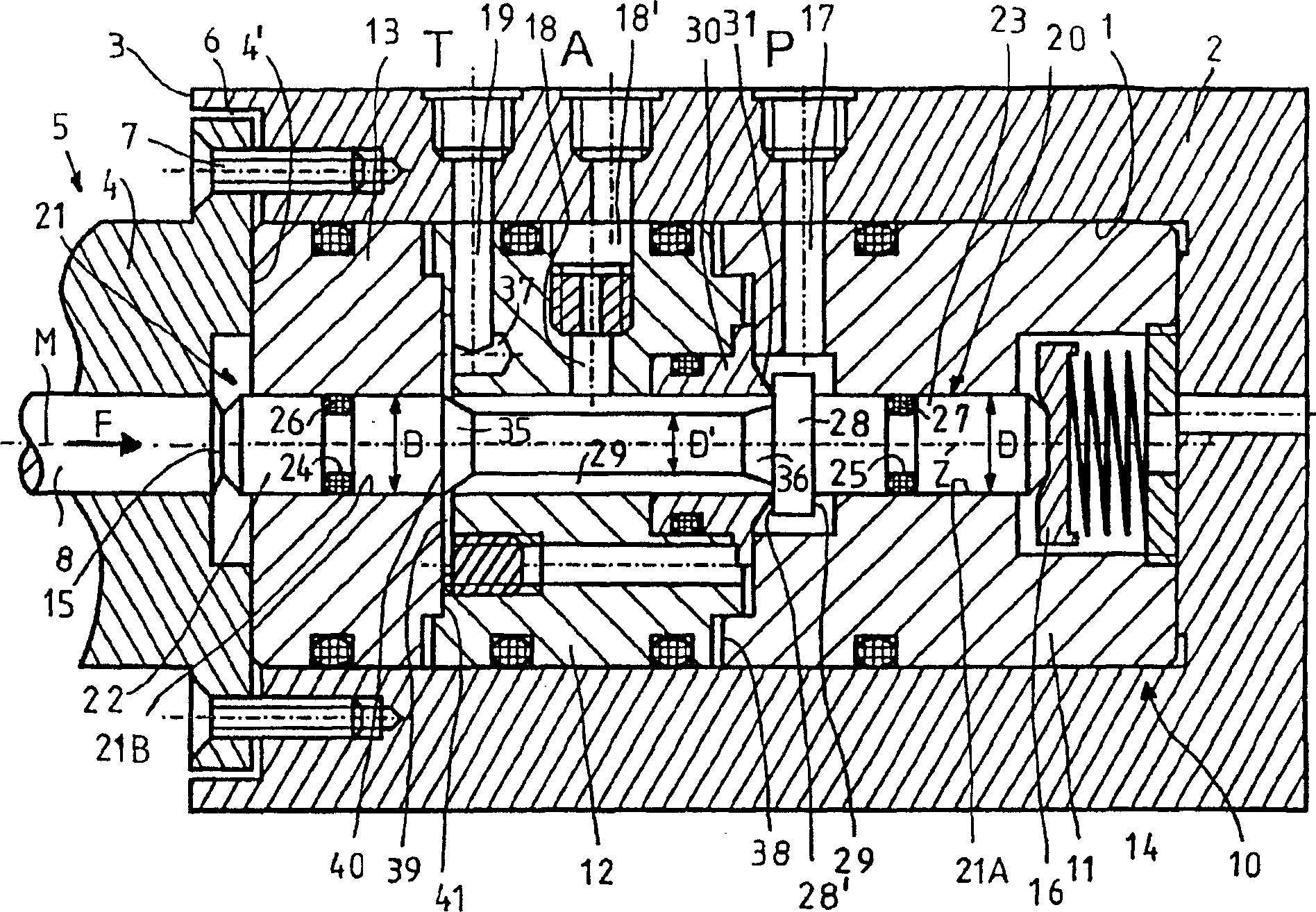

[0024] figure 1 It shows a vertical section through a valve opening 1 of a valve block 2 with possibly several valve openings arranged side by side and superimposed on one another. The valve mounting hole 1 is designed as a blind hole, into which the pilot valve 10 designed as a sleeve-like valve insert according to the first embodiment is inserted from the direction of the end side 3 of the valve block 2 . The valve insert constituting the pilot valve 10 has a valve housing divided into three parts, comprising a first valve housing part 11, a second valve housing part 12 and a third valve housing part 13, which pass through each other at their interface 38 or 41 respectively. They are screwed together and fixed together in the valve mounting hole 1 by means of the housing 4 of the switching device 5 which is only schematically indicated. The housing bottom 4 ′ of the switching device 5 is seated in a countersink 6 on the end side 3 , and its fastening flange protrudes beyond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com