Large area internal series dye sensitization nano thin film solar cell and producing method thereof

A technology of internal series connection and solar cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve stability problems, difficult material selection and other problems, achieve high output voltage, overcome technical difficulties and material selection difficulties, and avoid stability Problems and Effects of Industrialization Technology Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

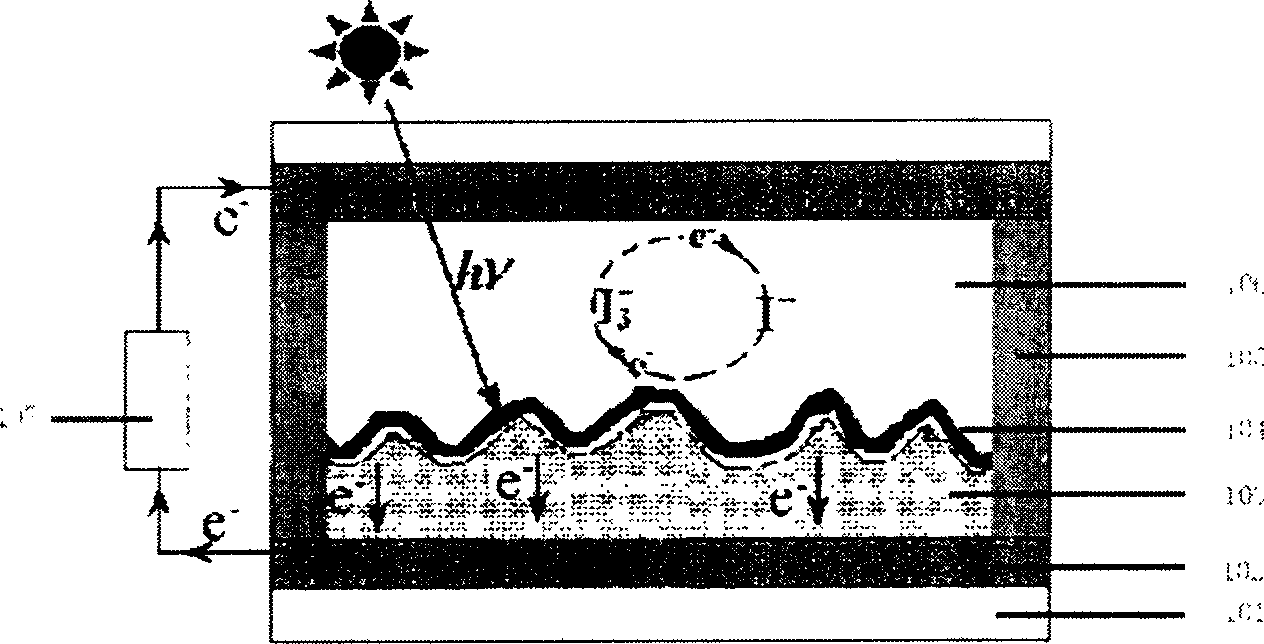

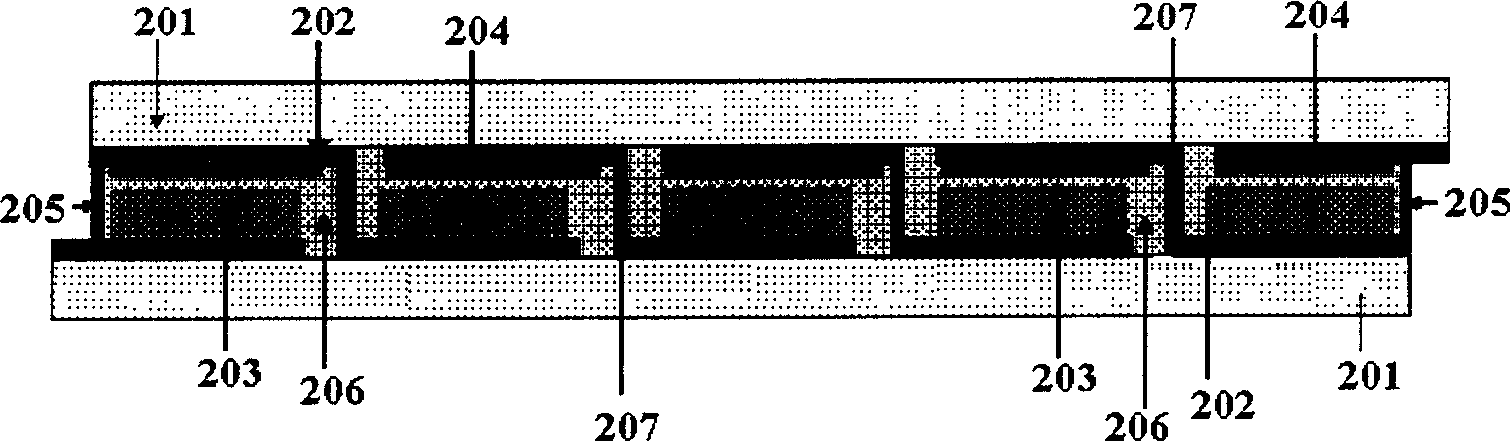

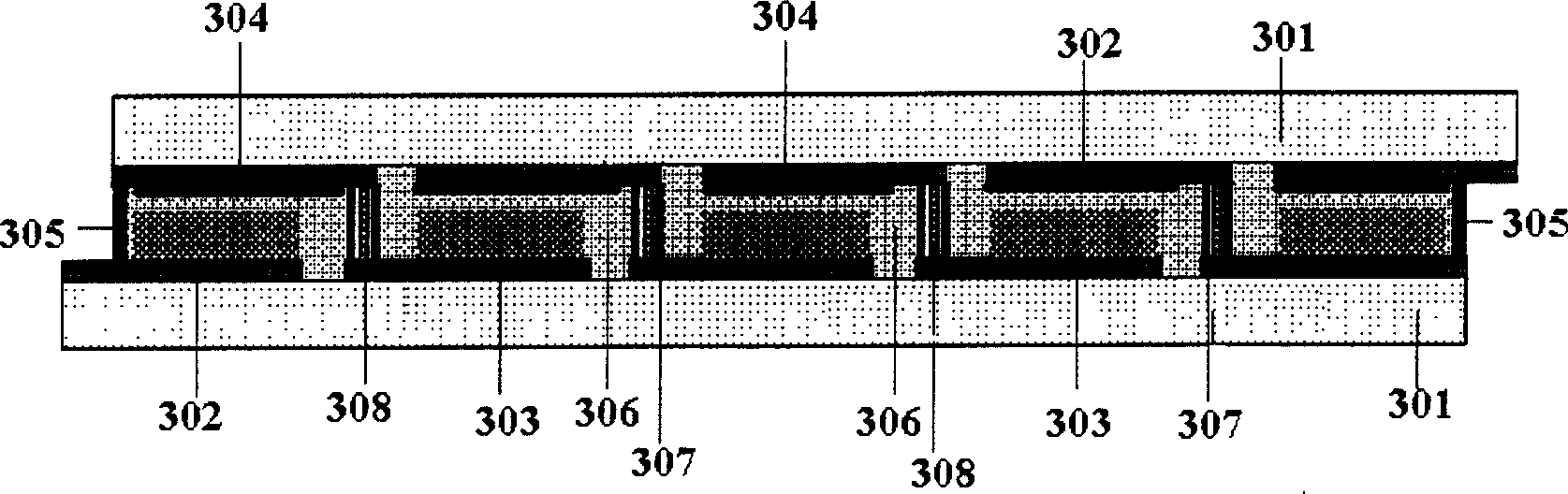

[0038] see figure 1 , image 3 .

[0039] 1. Preparation of transparent conductive electrode material: Put a transparent substrate 301, such as: transparent conductive glass, or conductive plastic, or transparent conductive polymer material, on it to cover a layer of conductive film 302, use laser marking, or other mechanical engraving Divide the conductive film 302 on the conductive glass into certain sizes according to design requirements by scratching or high-pressure water marking, and clean it for later use.

[0040] 2. Preparation of photoanode (negative electrode): On conductive glass 301, methods such as printing, or spraying, or sputtering prepare nanometer (or porous) film 303 (such as nanometer TiO 2 Porous film, or nano ZnO porous film), the thickness of the film can be between 0.1 micron and 1 mm, and it is sintered and processed according to the characteristics of the material itself (such as: to prepare a battery with a transparent conductive glass as a substr...

Embodiment 2

[0046] see figure 2 . Put the photoanode printed with nanoporous film into the dye solution for more than one hour, so that the dye can be evenly adsorbed in the porous semiconductor film, and you can choose to use a specific solution to wash it, so that there is no dye adsorption in the place where there is no film. Take 100 grams of 200-mesh titanium powder, 30 grams of silica gel and 0.1 grams of Platium-Divinyltetramethyl-Disiloxrane Complex, mix them evenly as electrode materials, and print sealing paste outside the electrode materials. The rest are the same as example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com