Patents

Literature

70results about How to "Overcome technical difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

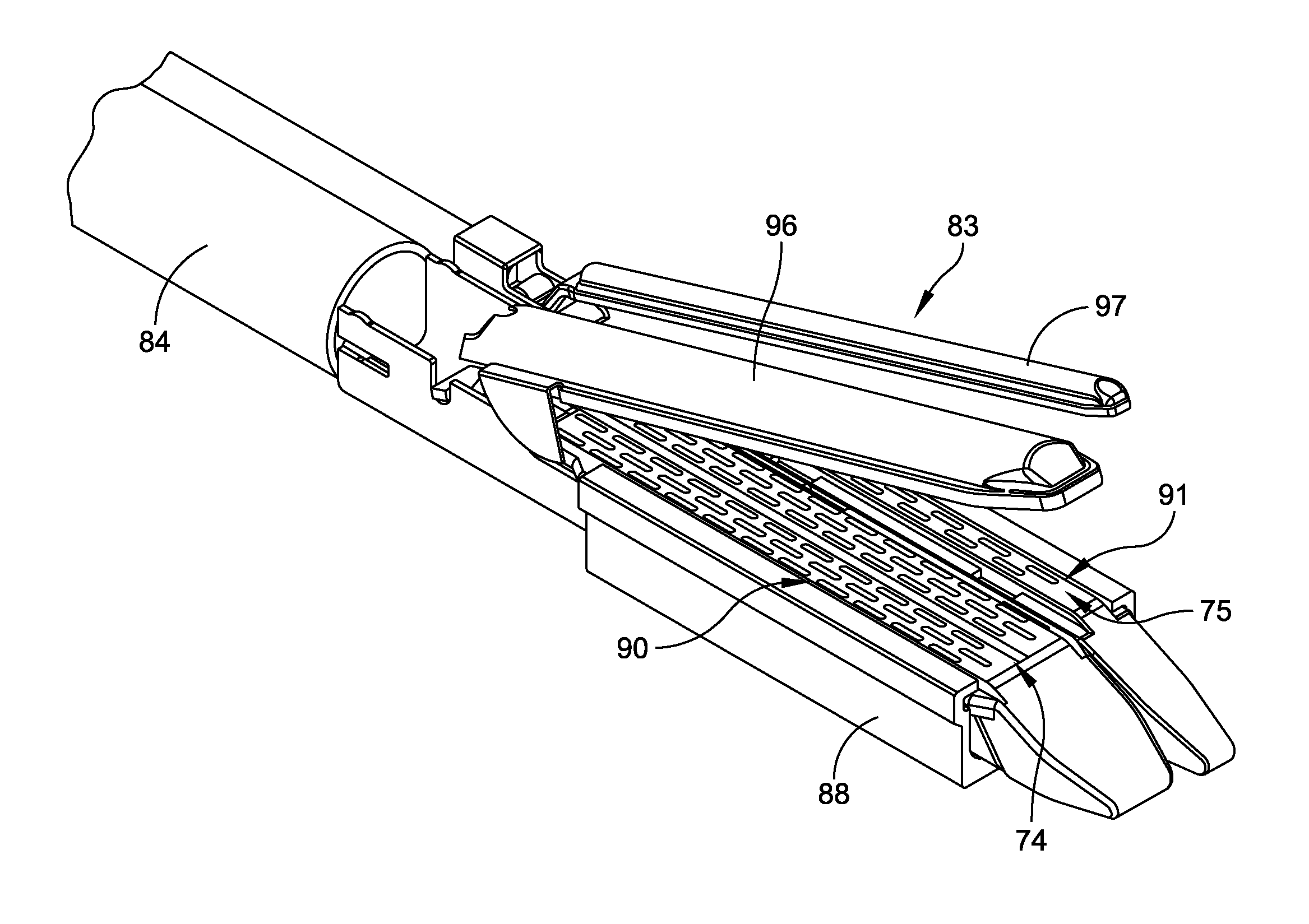

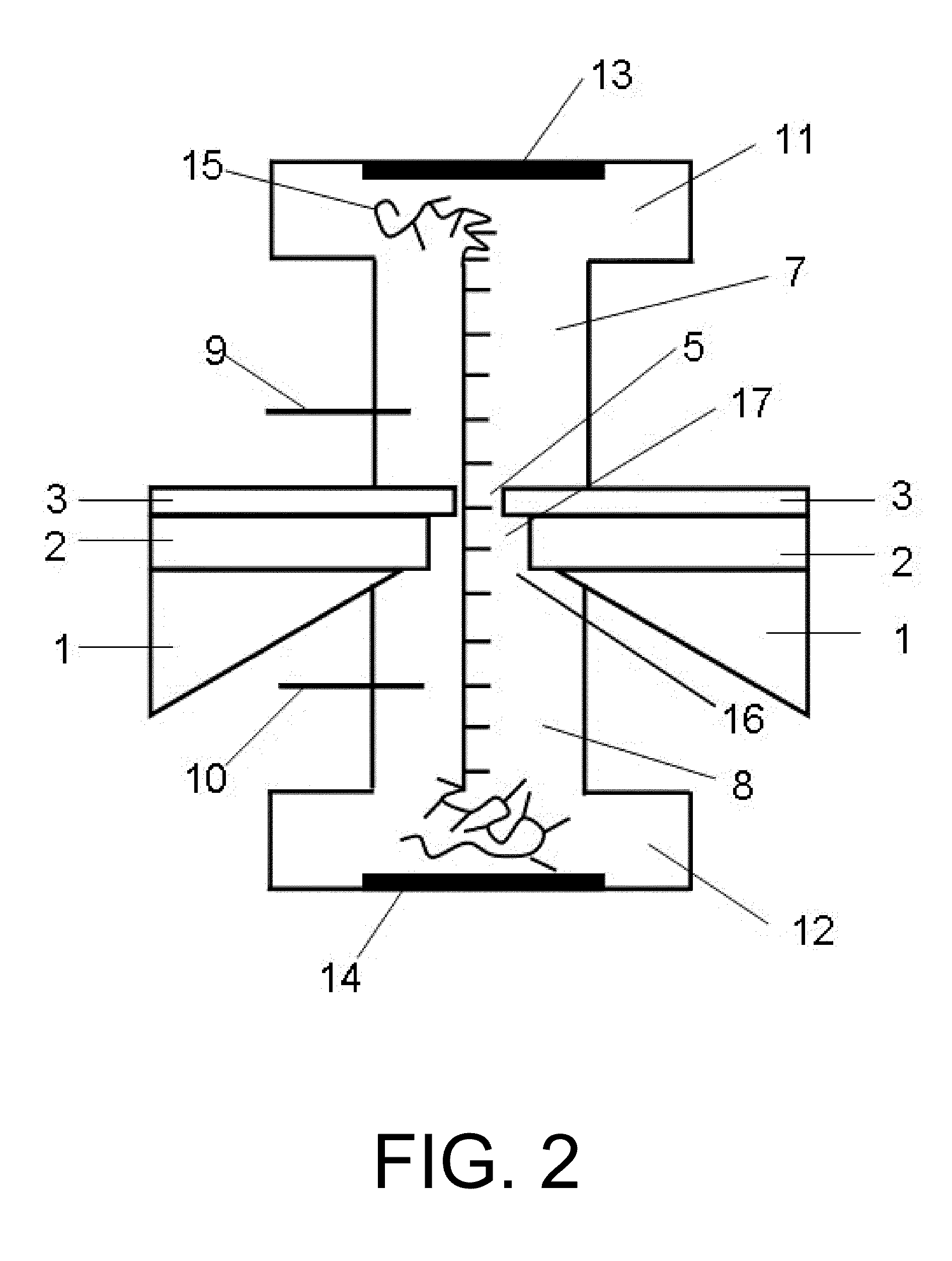

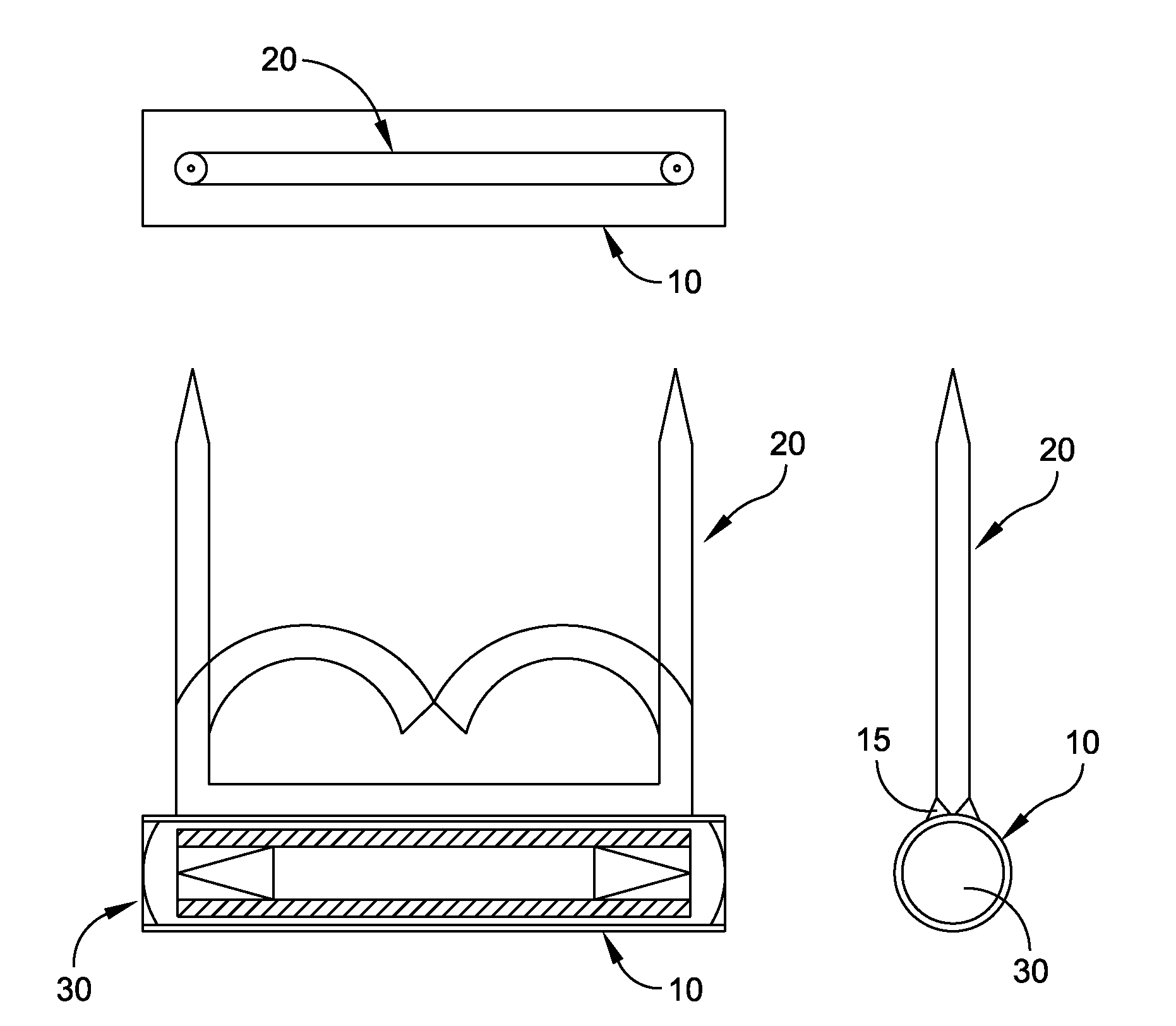

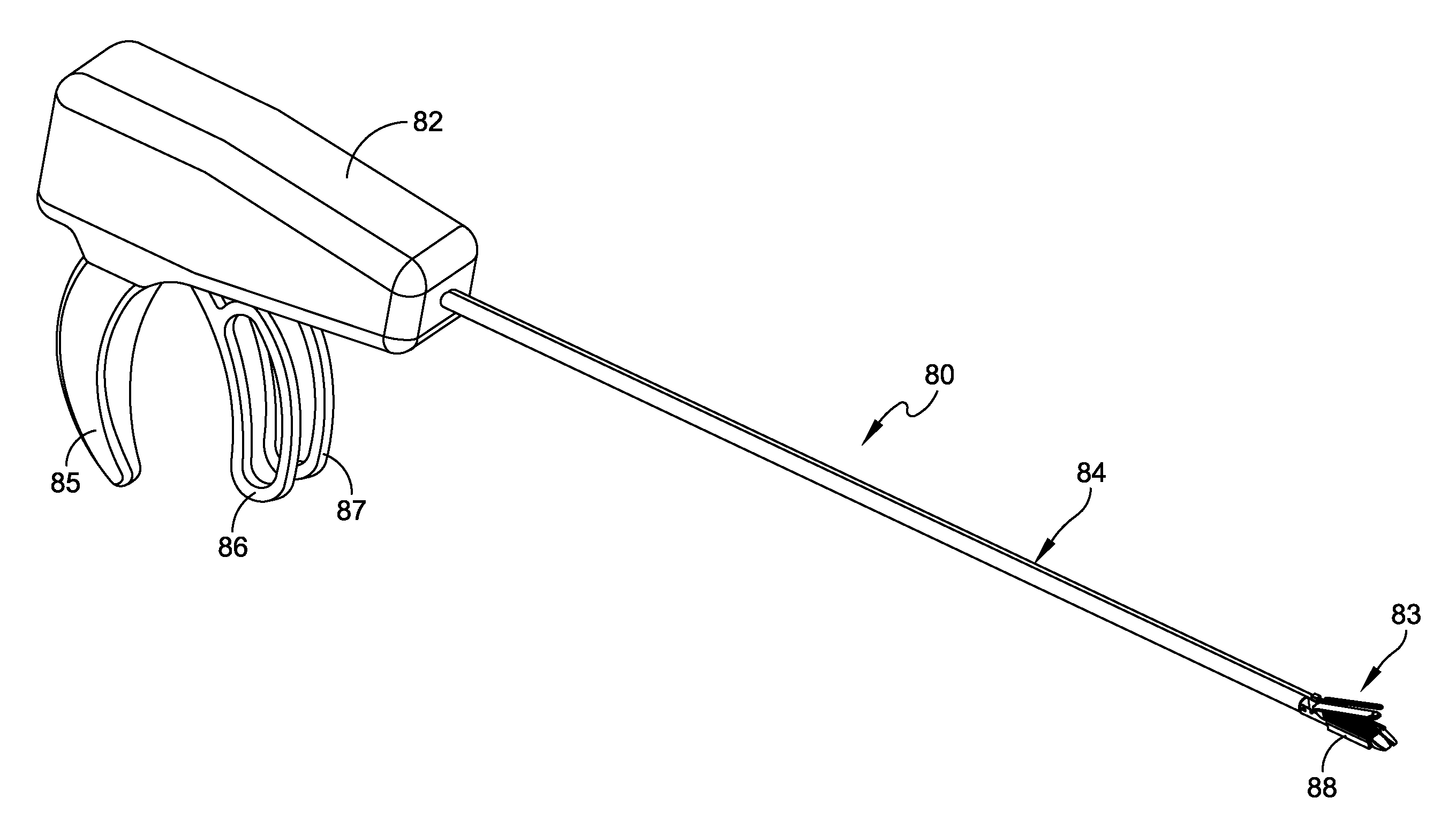

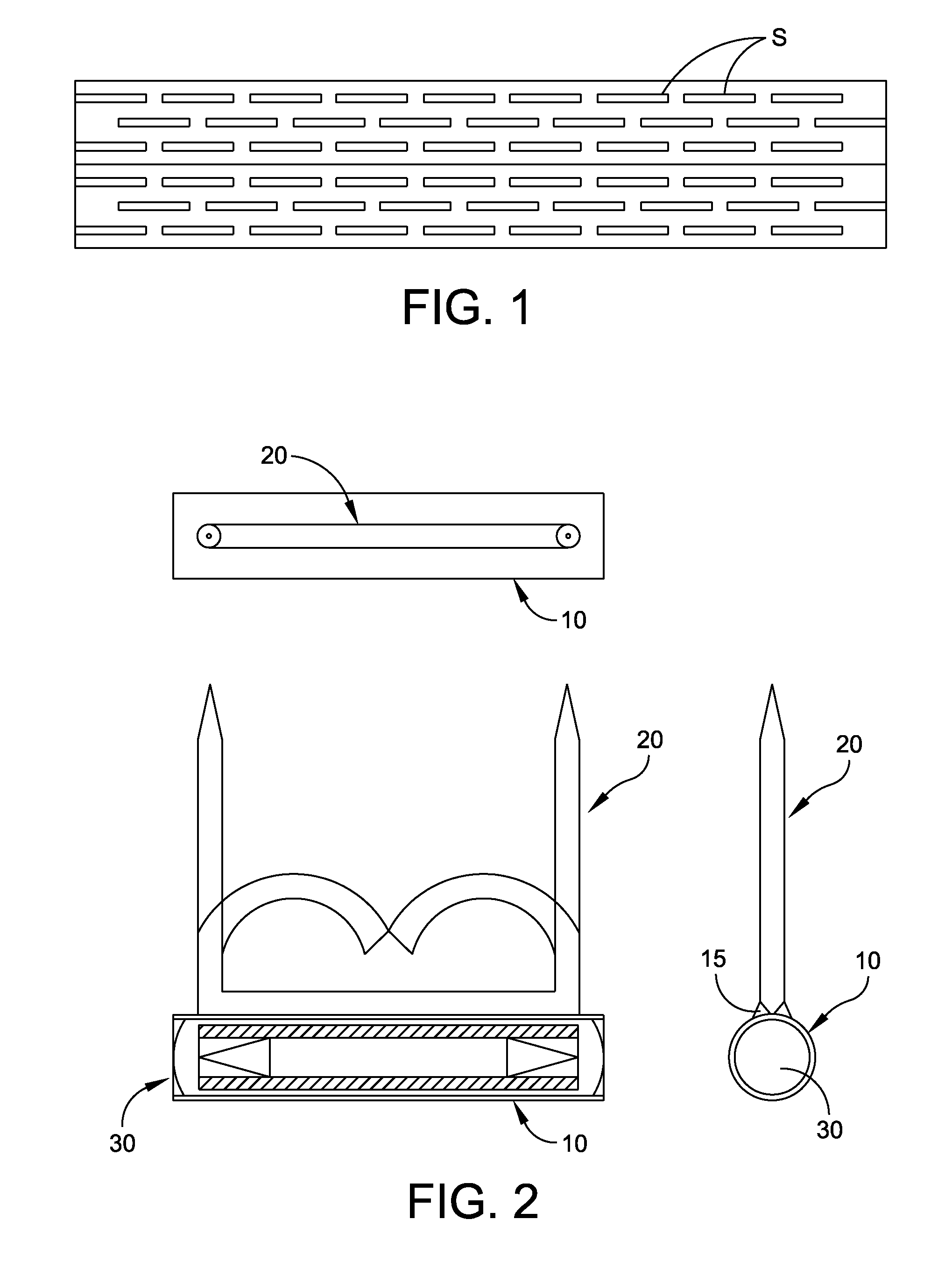

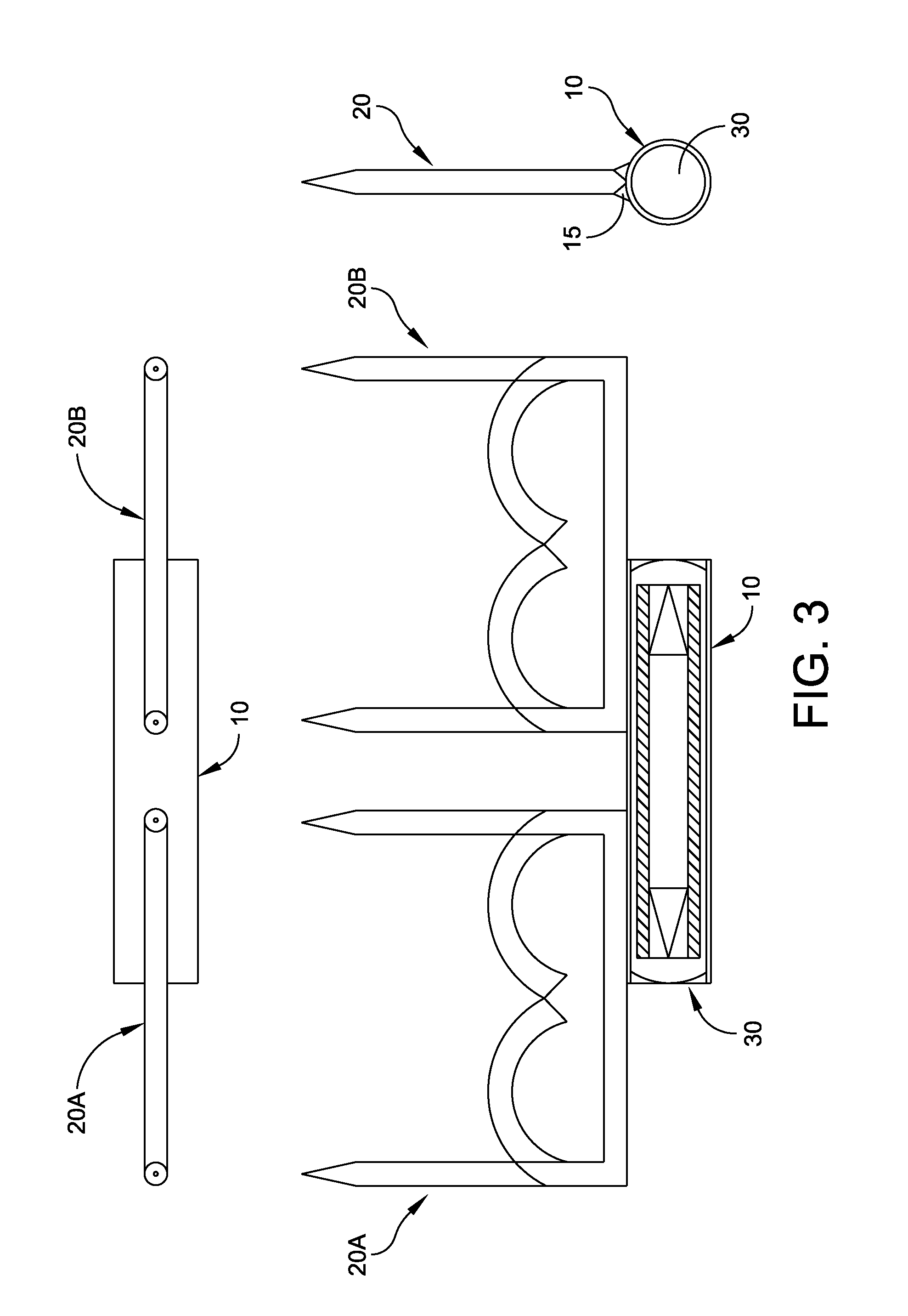

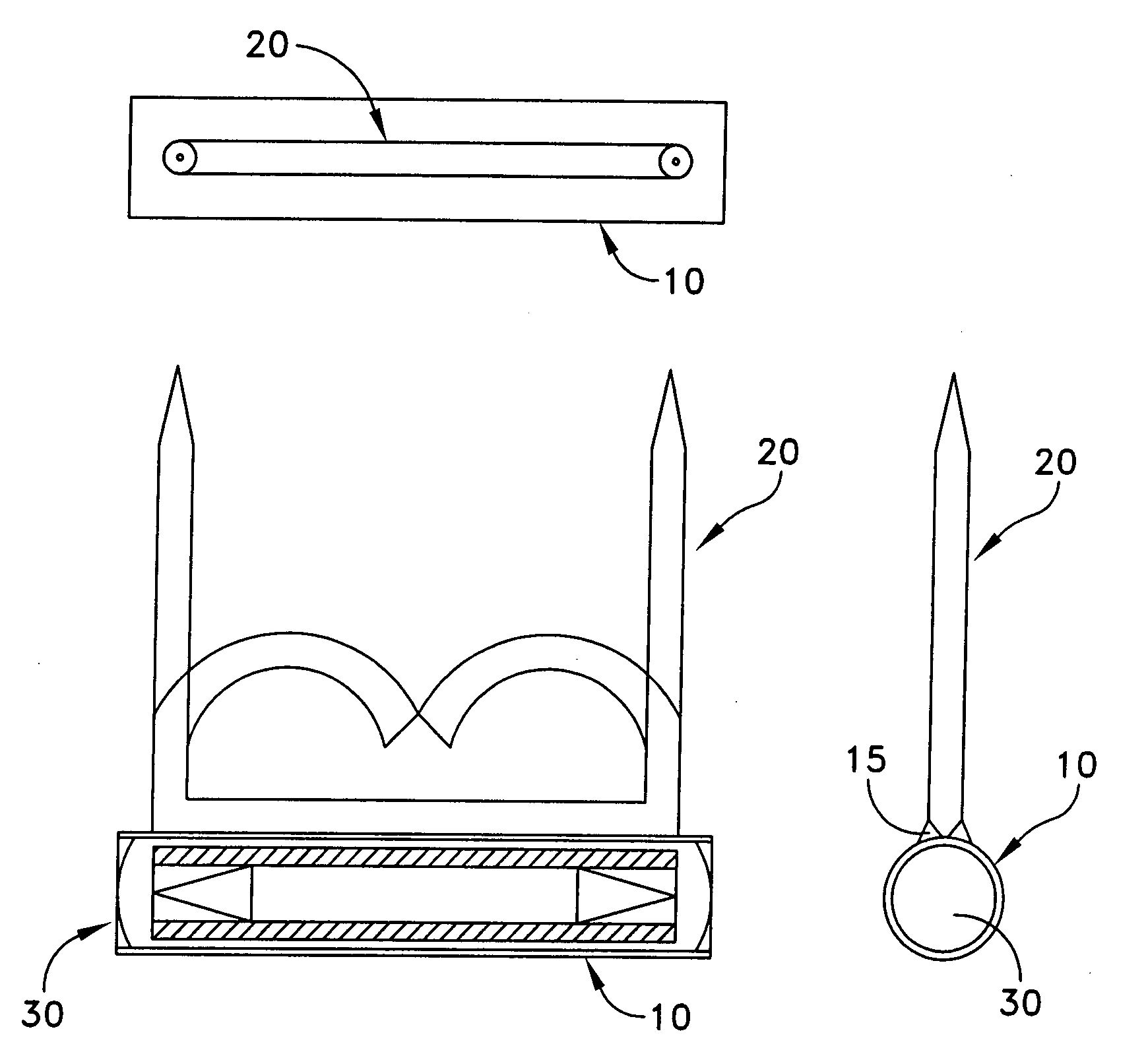

Radioactive therapeutic fastening instrument

ActiveUS8267849B2For accurate placementReduce doseSuture equipmentsStapling toolsBrachytherapyEngineering

An instrument used for brachytherapy delivery in the treatment of cancer by radiation therapy including a handle having first and second handle actuators; an end effector; and an instrument shaft that connects the handle with the end effector. The end effector has first and second adjacent disposed staple mechanisms that each retain a set of staples. The first mechanism is for holding standard staples in a first array, and dispensing the standard staples under control of the corresponding first handle actuator. The second mechanism is for holding radioactive source staples in a second array, and dispensing said radioactive source staples under control of the corresponding second handle actuator. A holder is for receiving the first and second mechanisms in a substantially parallel array so that the standard staples close the incision at a surgical margin while the source staples are secured adjacent thereto.

Owner:POINT SOURCE TECH

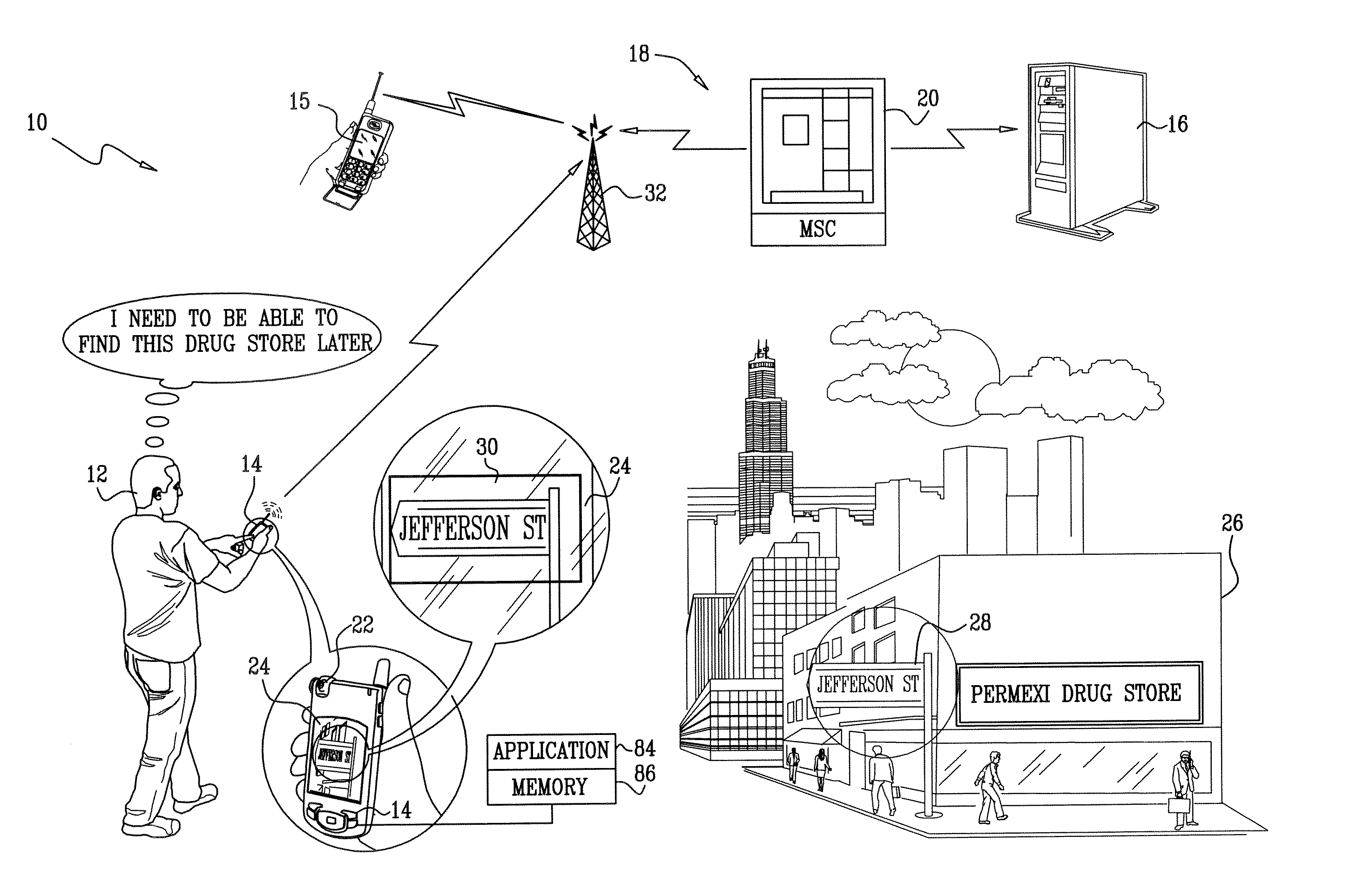

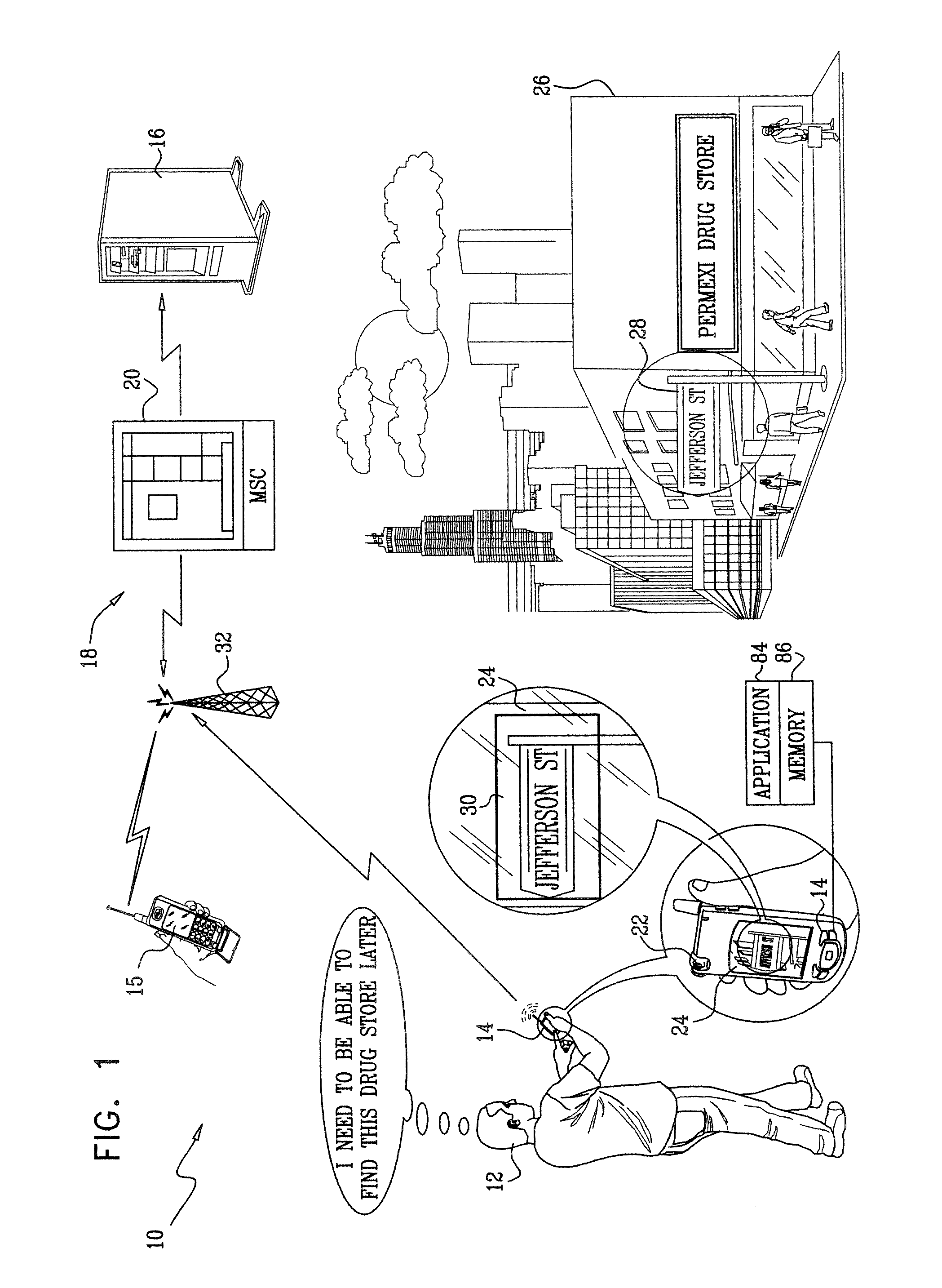

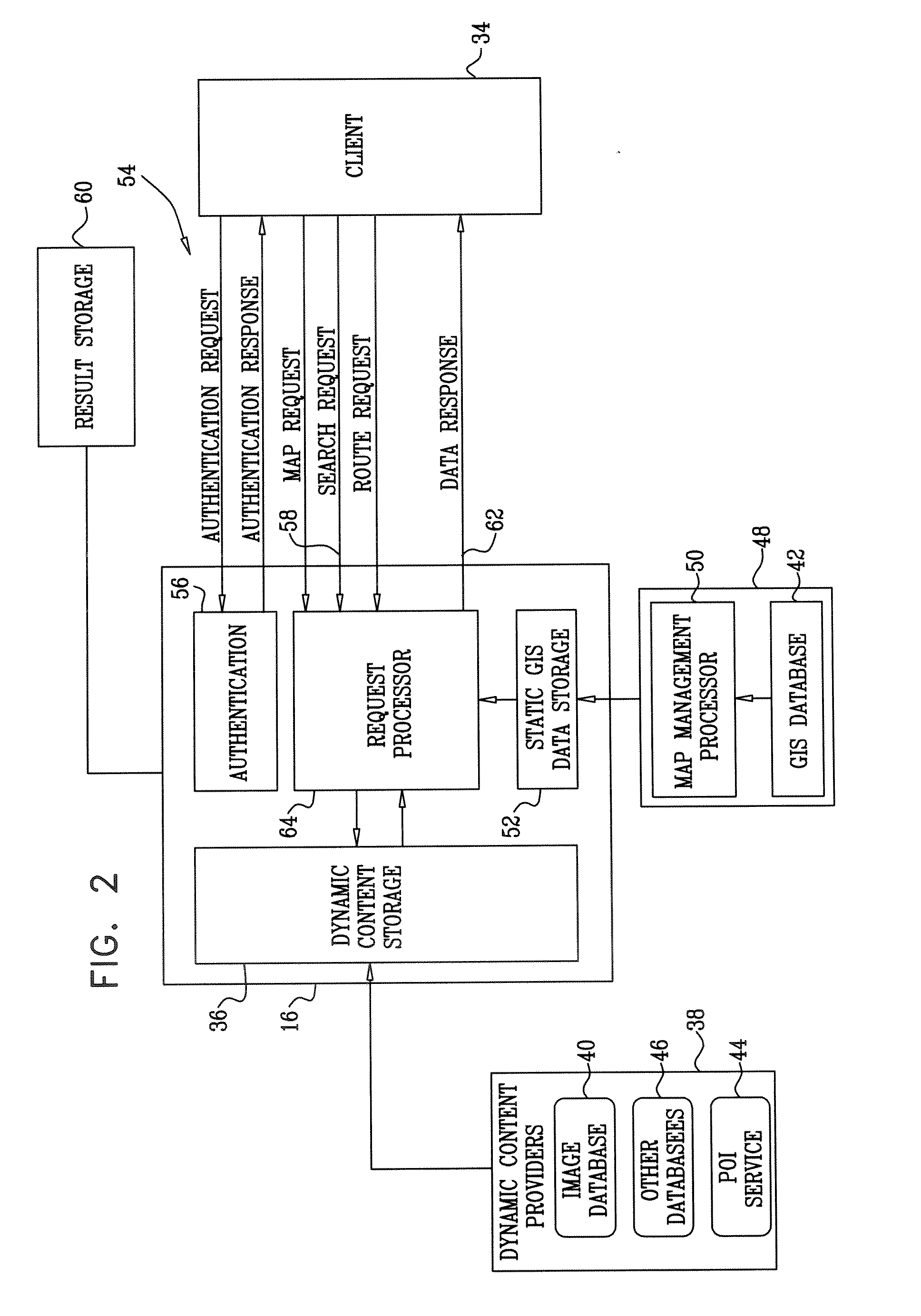

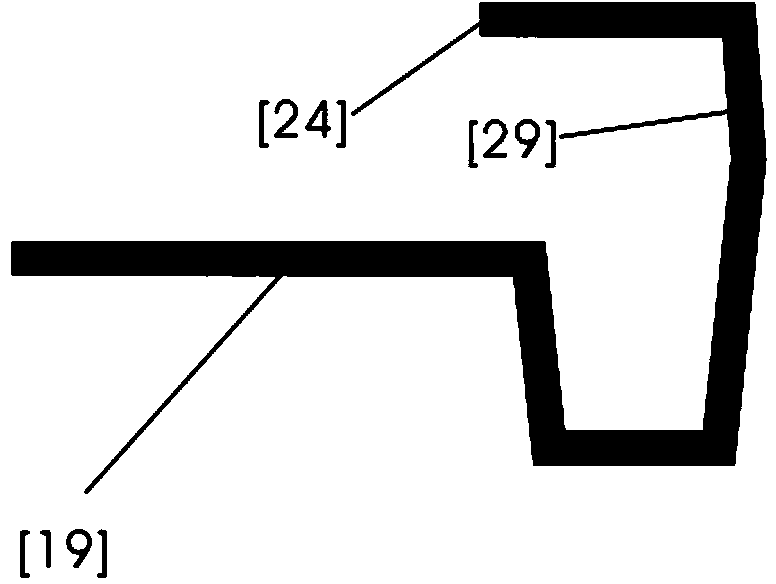

Visual inputs for navigation

InactiveUS20080039120A1Improve performanceOvercome technical difficultiesNavigational calculation instrumentsWireless communicationMobile navigationNavigation system

An interface is provided to a mobile navigation system in which an optical image of a point-of-interest acquired by cellular telephone devices is an input to the system. Textual and optionally other location information is extracted from the image, and used by the navigation system to identify coordinates and vectors relating to the point-of-interest. The results are stored and may be subsequently recalled to provide mapping and routing information to the cellular telephone device, whose position relative to the point-of-interest may have changed. Optical images may be uploaded from telephone device to the navigation system automatically or interactively, and can be processed remotely, generally without further user interaction.

Owner:INTEL CORP

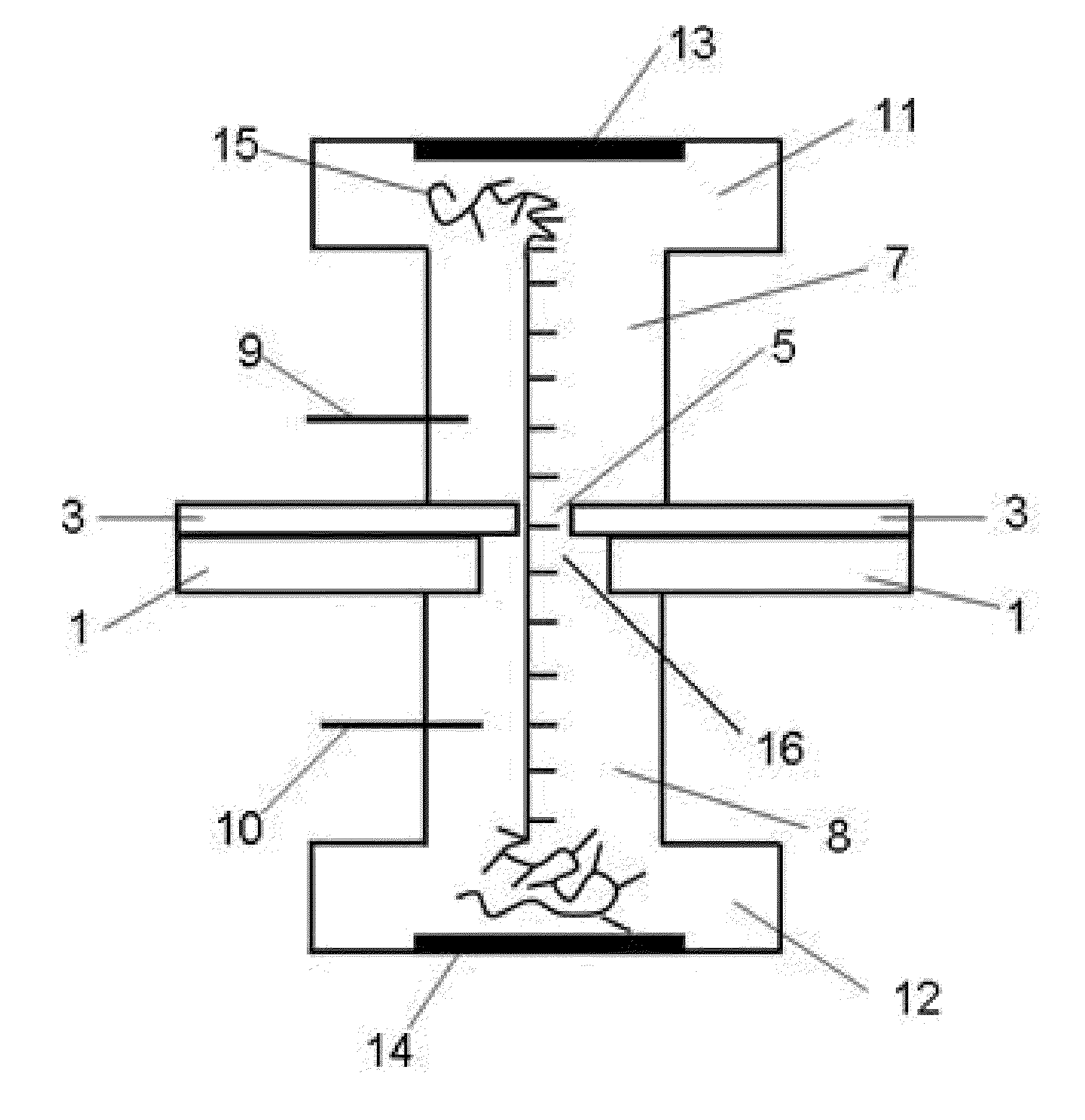

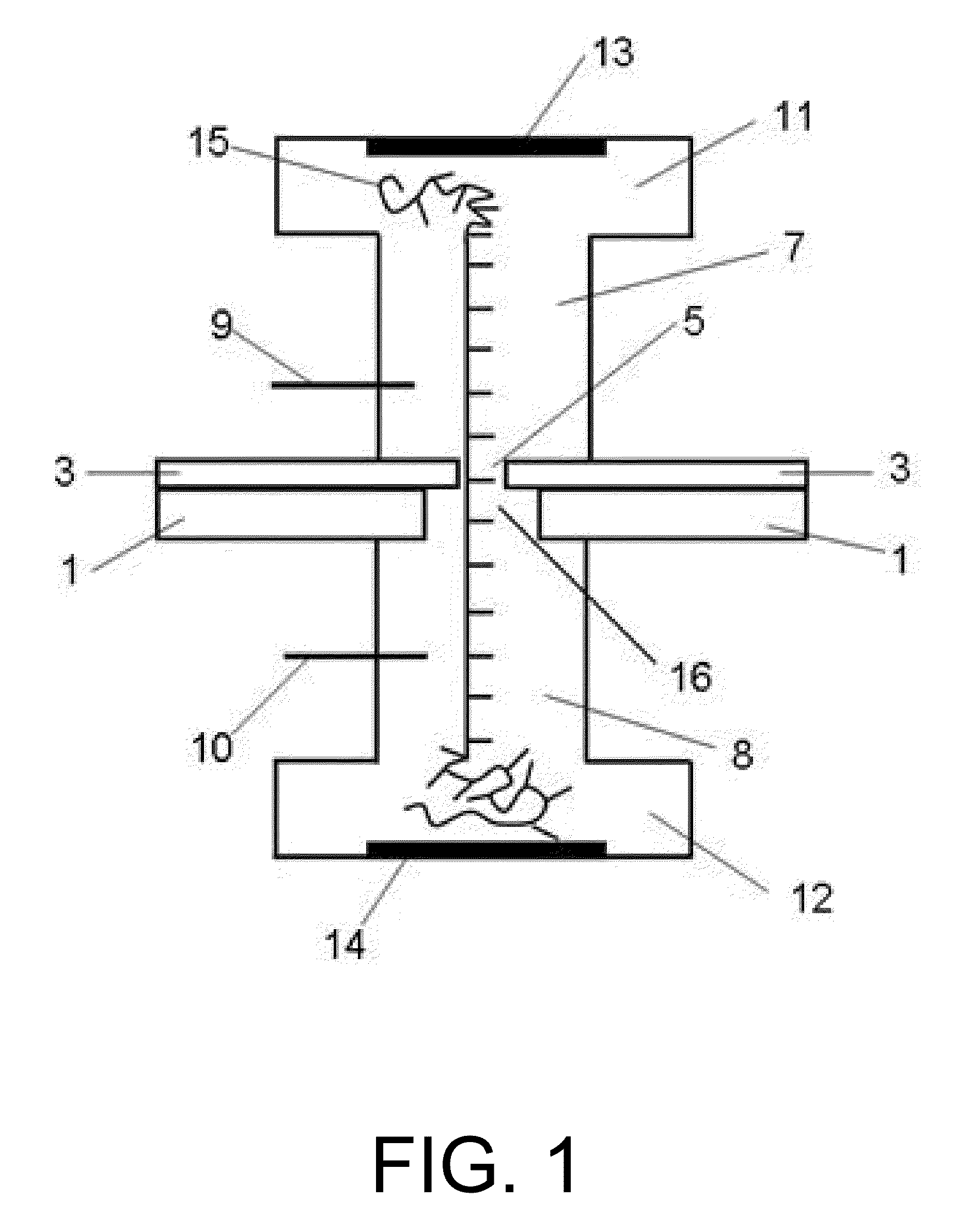

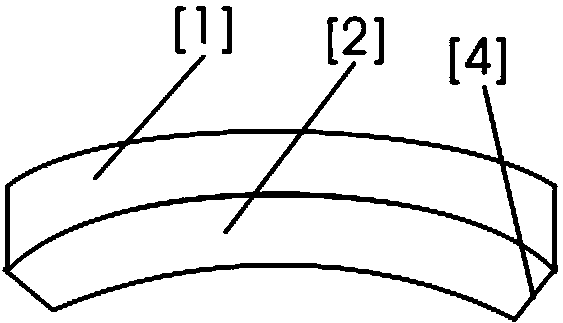

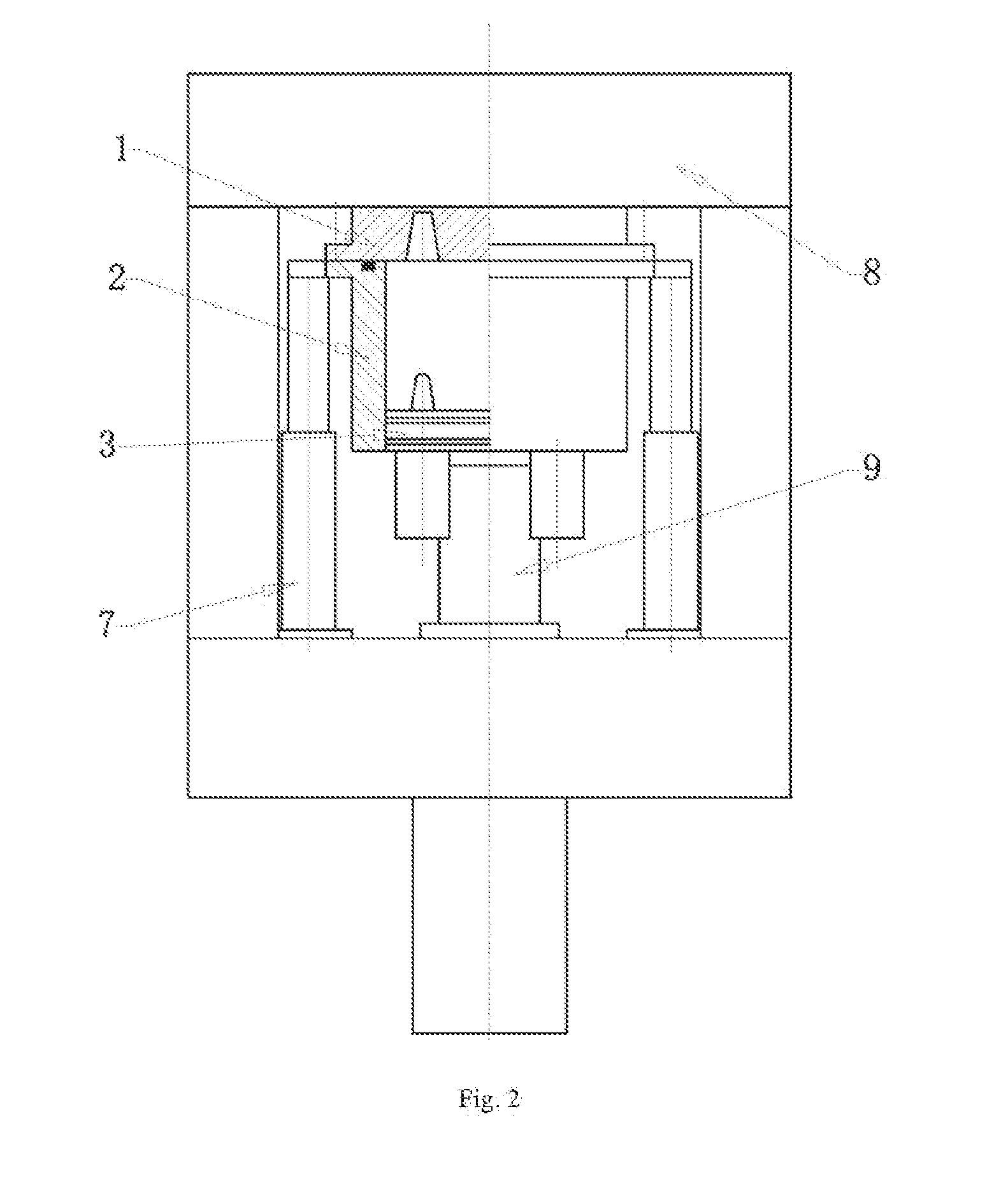

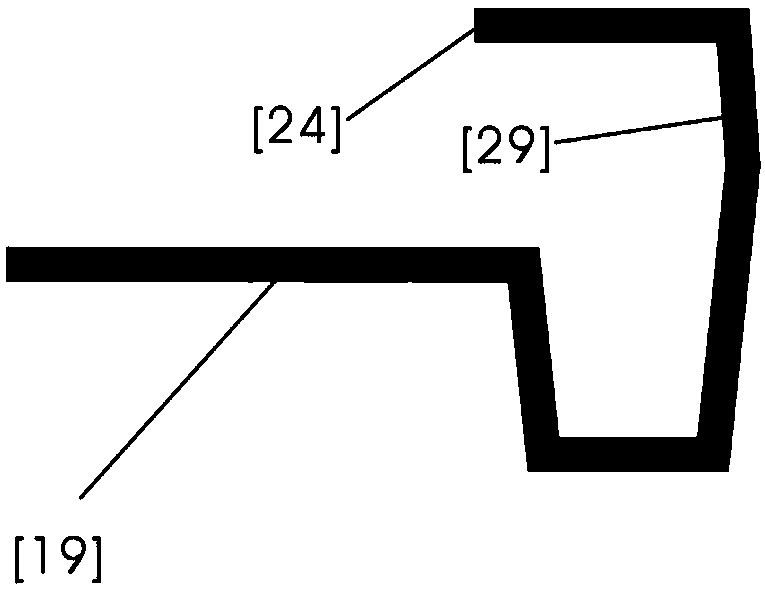

Nanopore Sensor Comprising A Sub-Nanometer-Thick Layer

A nanopore sensor comprises second electrophoresis electrode or micropump, second fluidic reservoir, second micro-nanometer separation channel, substrate, sub-nanometer-thick functional layer, first micro-nanometer separation channel, first electrophoresis electrode or micropump, and electrophoresis electrode or micropump that are sequentially assembled. An opening and a nanopore are provided through the substrate and the sub-nanometer-thick functional layer, respectively. A first electrode for measuring ionic current is provided in the first micro-nanometer separation channel, and a second electrode for measuring ionic current is provide in the second micro-nanometer separation channel. The present invention provides a simple method to prepare a sub-nanometer functional layer having a nanopore extending through the sub-nanometer-thick functional layer. The pore size is comparable to the spacing between two adjacent bases in a DNA strand required for single-base resolution sequencing. The shape of nanopore overcomes nucleotide conformation effect on the identification as bases translocate through the nanopore.

Owner:ZHEJIANG UNIV

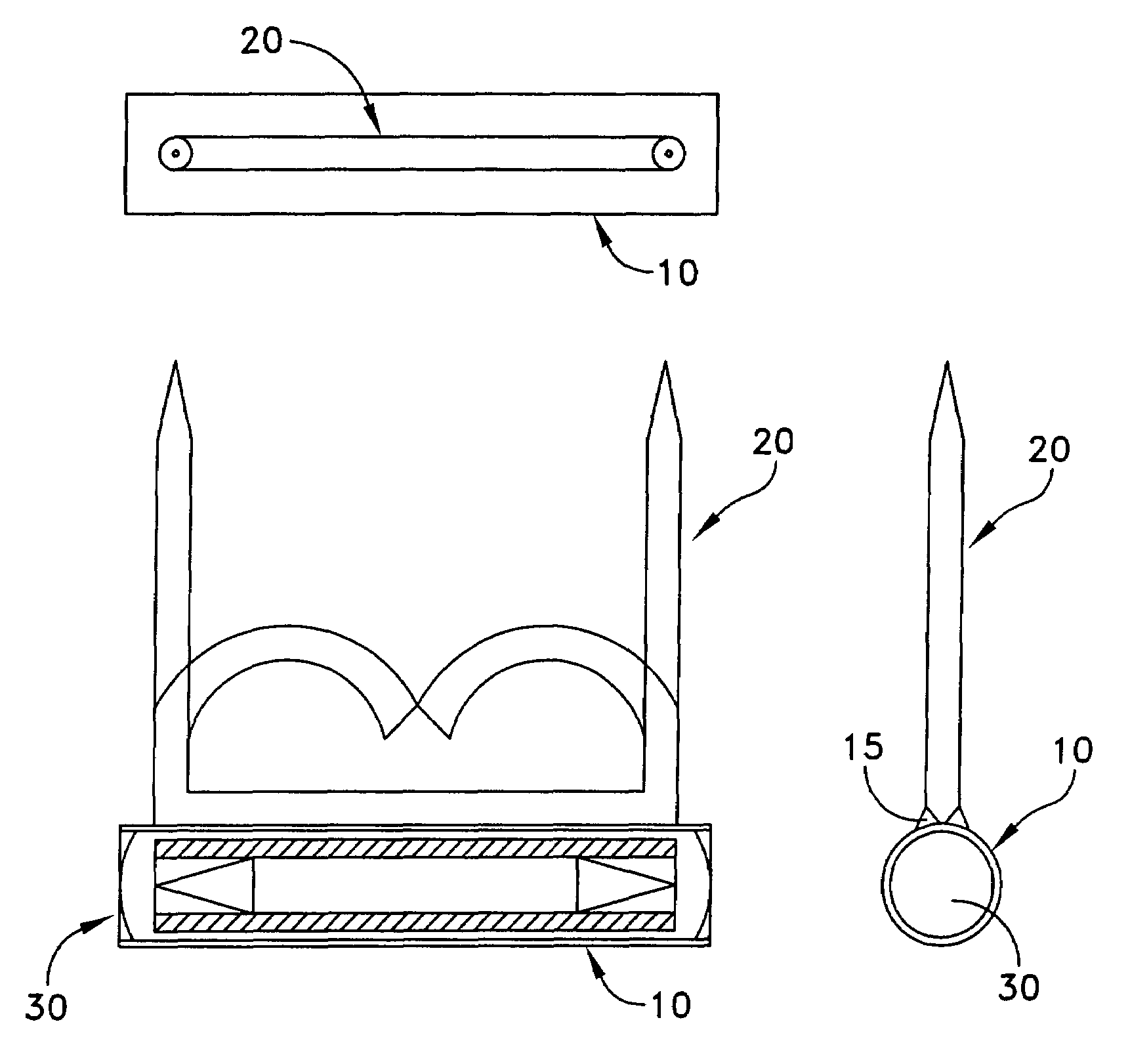

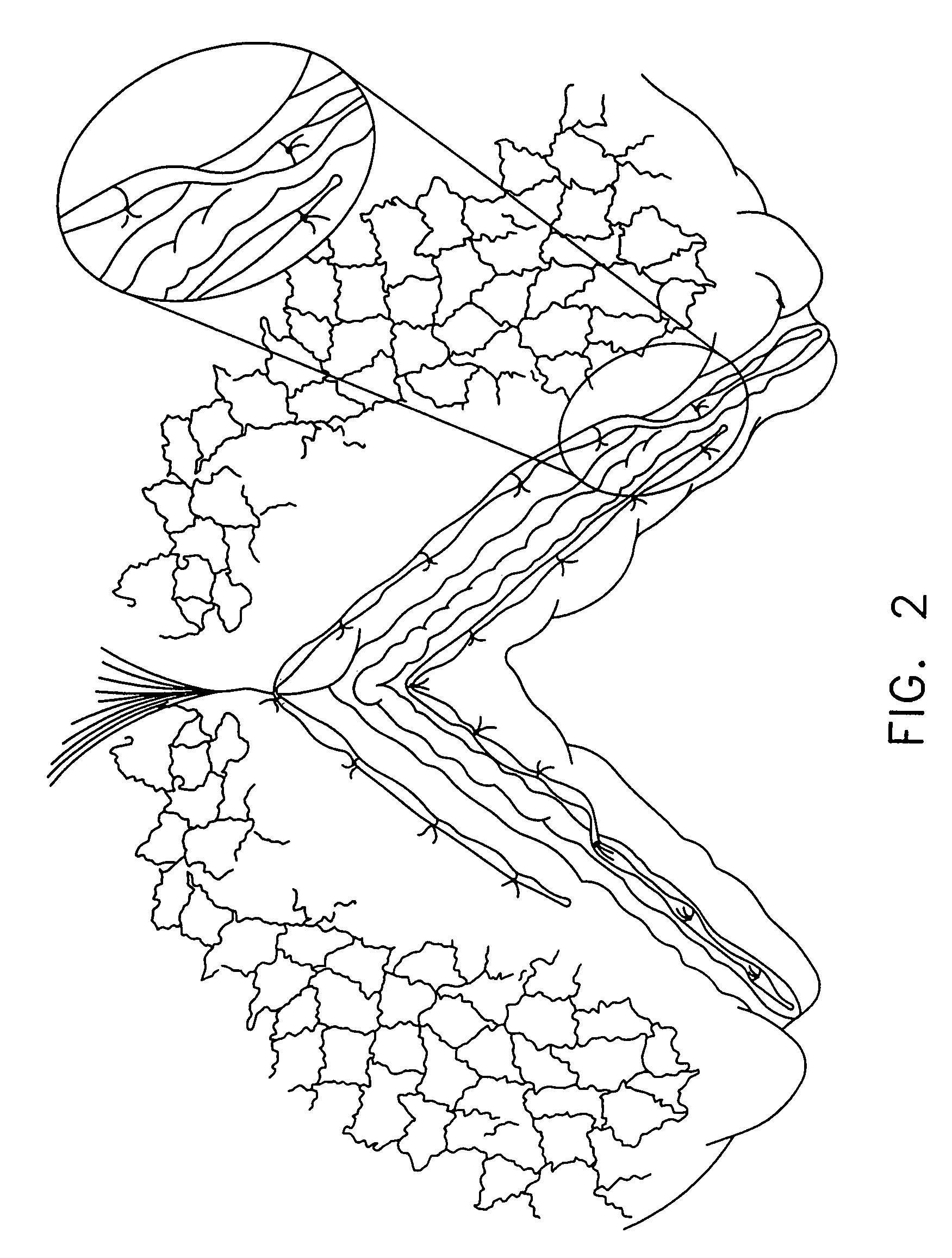

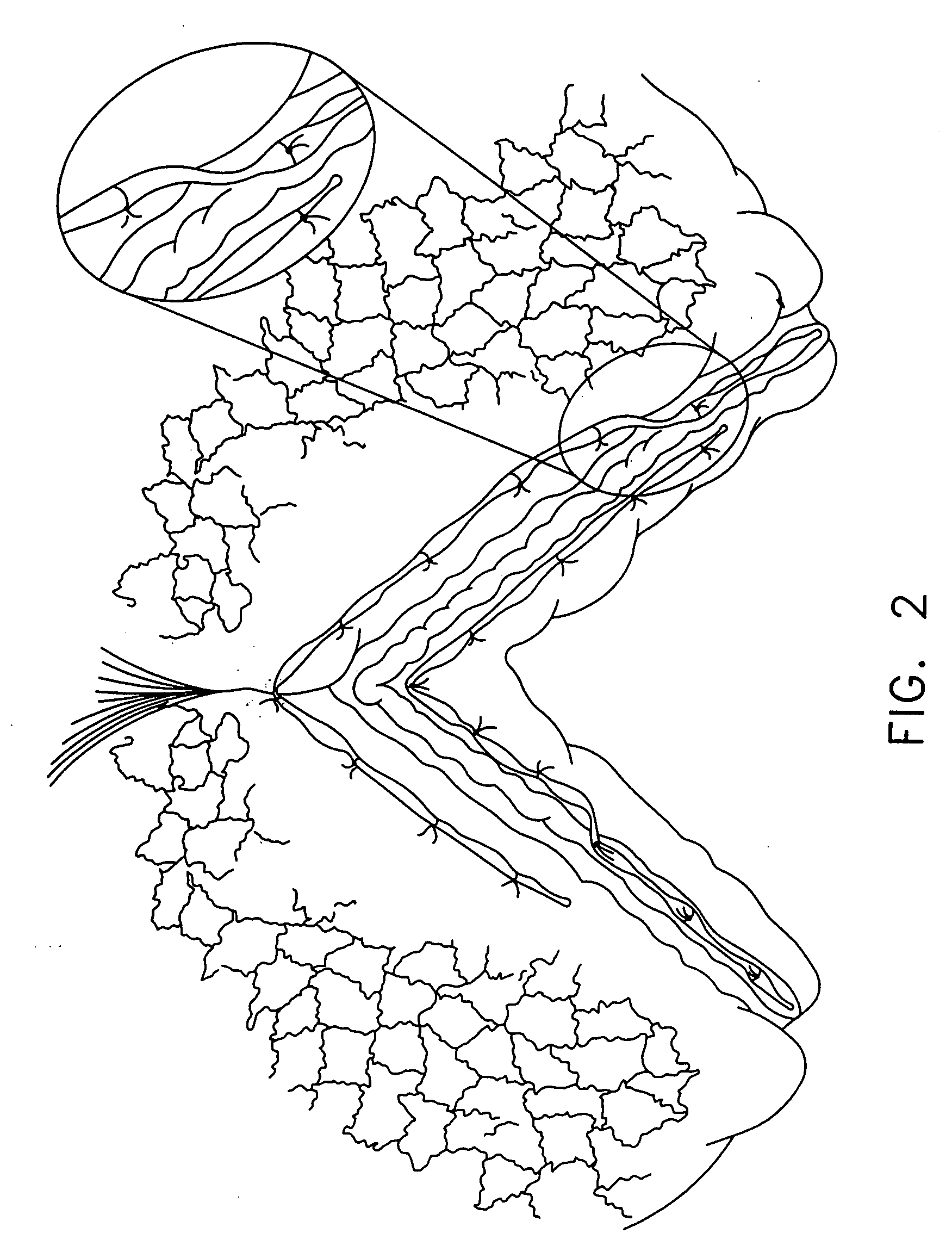

Radioactive therapeutic fastening instrument

ActiveUS20110245578A1For accurate placementReduce radiation doseSuture equipmentsStapling toolsBrachytherapyEngineering

An instrument used for brachytherapy delivery in the treatment of cancer by radiation therapy including a handle having first and second handle actuators; an end effector; and an instrument shaft that connects the handle with the end effector. The end effector has first and second adjacent disposed staple mechanisms that each retain a set of staples. The first mechanism is for holding standard staples in a first array, and dispensing the standard staples under control of the corresponding first handle actuator. The second mechanism is for holding radioactive source staples in a second array, and dispensing said radioactive source staples under control of the corresponding second handle actuator. A holder is for receiving the first and second mechanisms in a substantially parallel array so that the standard staples close the incision at a surgical margin while the source staples are secured adjacent thereto.

Owner:POINT SOURCE TECH

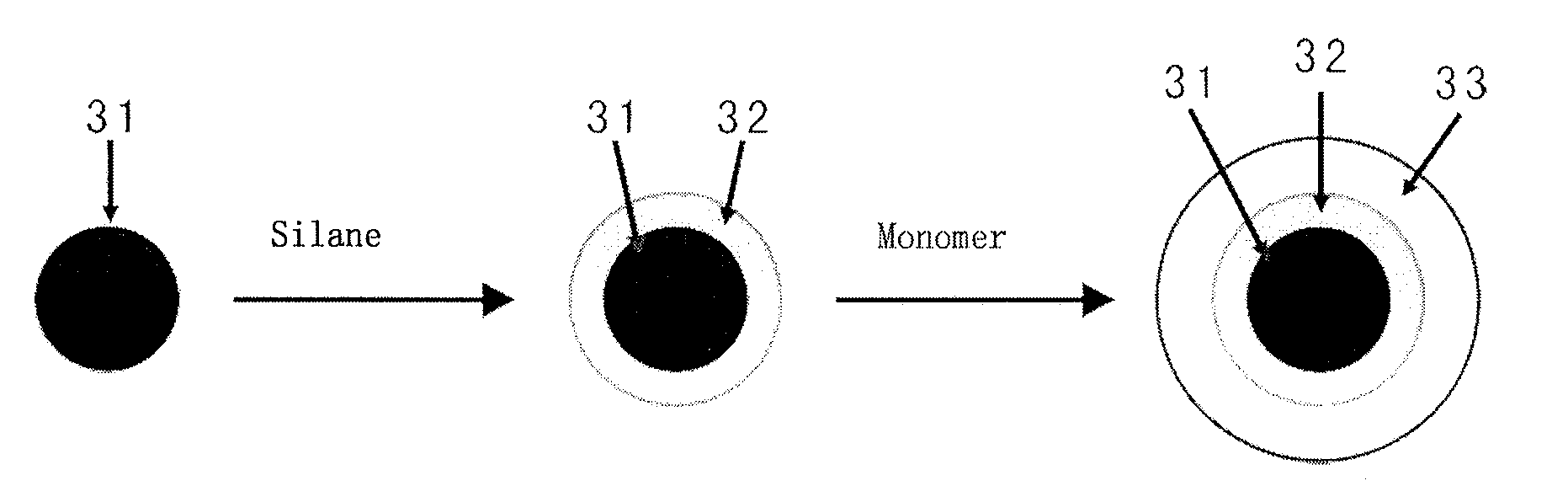

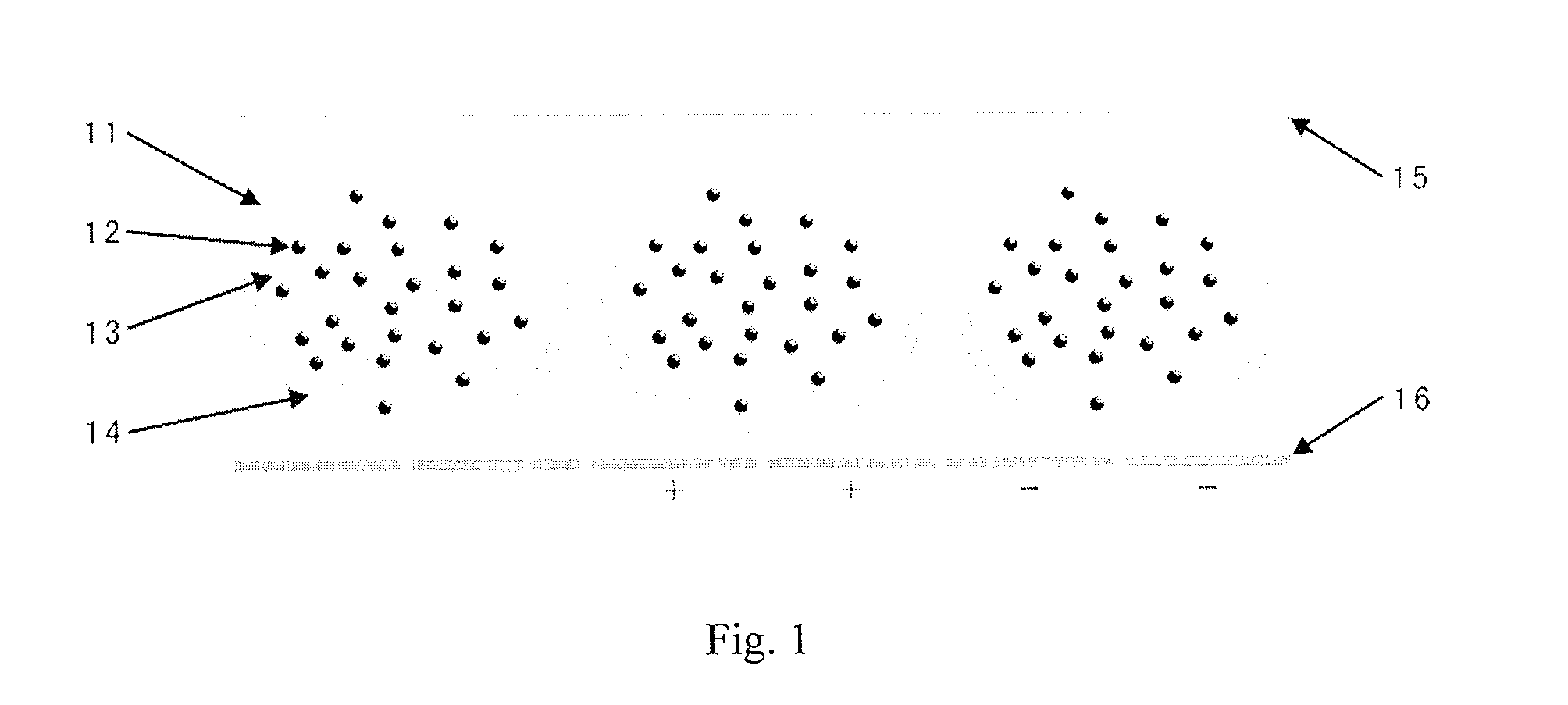

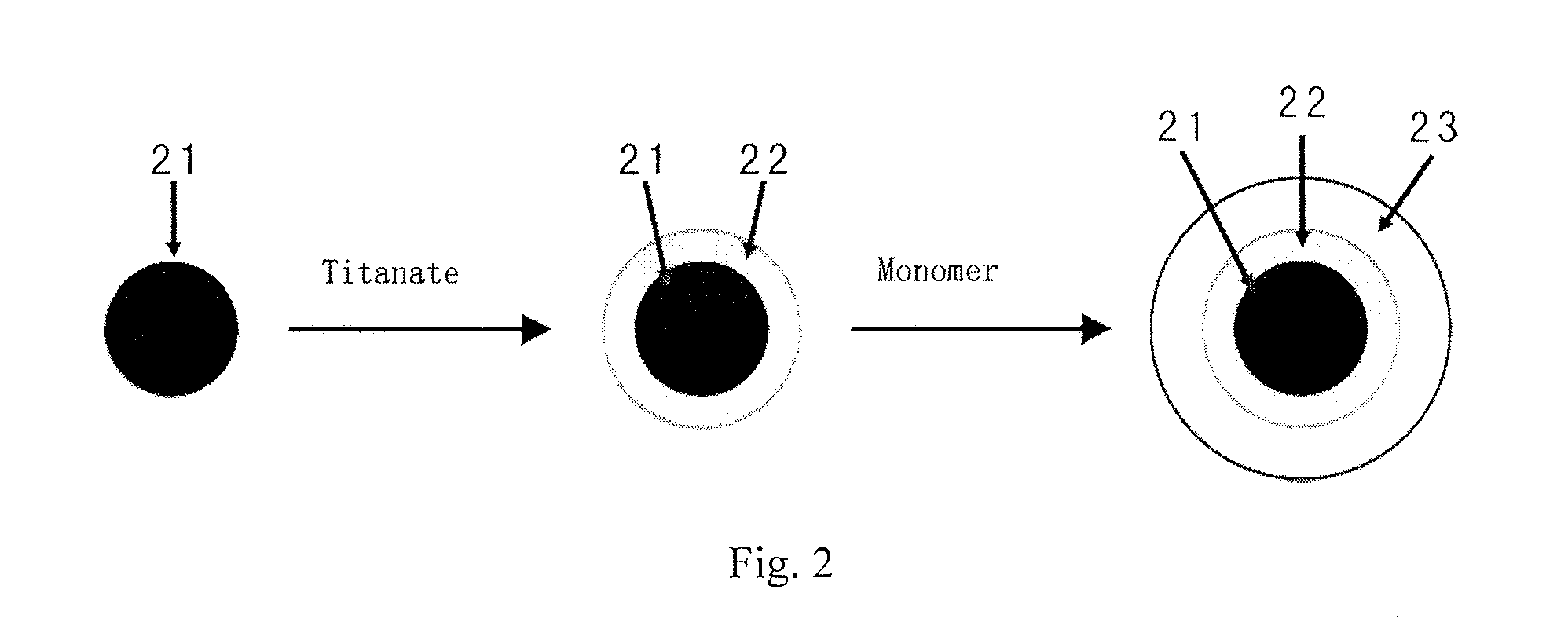

Electrophoretic display medium and preparing method thereof

ActiveUS20120229885A1Improve performanceOvercome technical difficultiesElectrographic processes using photoelectrophoresisElectrographic process apparatusInorganic saltsElectrophoresis

An electrophoretic display medium and preparing method thereof. The electrophoretic display medium comprises: negatively or positively-charged pigment particles; neutral pigment particles with colors different from the charged pigment particles; and low-polar and / or non-polar dispersing solvent. The method of preparing the electrophoretic display medium comprises: synthesizing neutral pigment particles; synthesizing charged pigment particles; and preparing electrophoretic display medium. The method of synthesizing the neutral pigment particles comprises: mixing together pigment particles, macromonomers, coupling-agents and chain-initiators for polymeric reaction in the solvent, and reacting at a temperature of 30-120° C. for 4-48 hours. The method is applied to many kinds of inorganic oxides, inorganic salts and complex inorganic salt pigments. This method fundamentally avoids agglomeration caused by attraction of positively and negatively-charged electrophoretic particles, greatly enhancing display performance. The steps of synthesizing particles are simple and the preparing procedure of the electrophoretic medium is simplified, making the whole process simple and highly efficient.

Owner:GUANGZHOU OED TECH INC

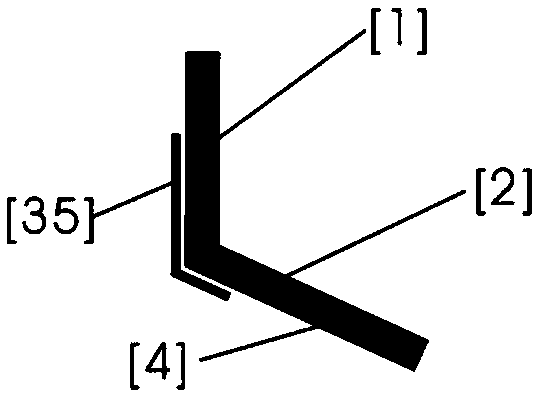

Radioactive therapeutic fastening instrument

ActiveUS20120318846A1Reduce doseReduce radiation doseSuture equipmentsStapling toolsBrachytherapyRadical radiotherapy

An instrument used for brachytherapy delivery in the treatment of cancer by radiation therapy including a handle having first and second handle actuators; an end effector; and an instrument shaft that connects the handle with the end effector. The end effector has first and second adjacent disposed staple mechanisms that each retain a set of staples. The first mechanism is for holding standard staples in a first array, and dispensing the standard staples under control of the corresponding first handle actuator. The second mechanism is for holding radioactive source staples in a second array, and dispensing said radioactive source staples under control of the corresponding second handle actuator. A holder is for receiving the first and second mechanisms in a substantially parallel array so that the standard staples close the incision at a surgical margin while the source staples are secured adjacent thereto.

Owner:POINT SOURCE TECH

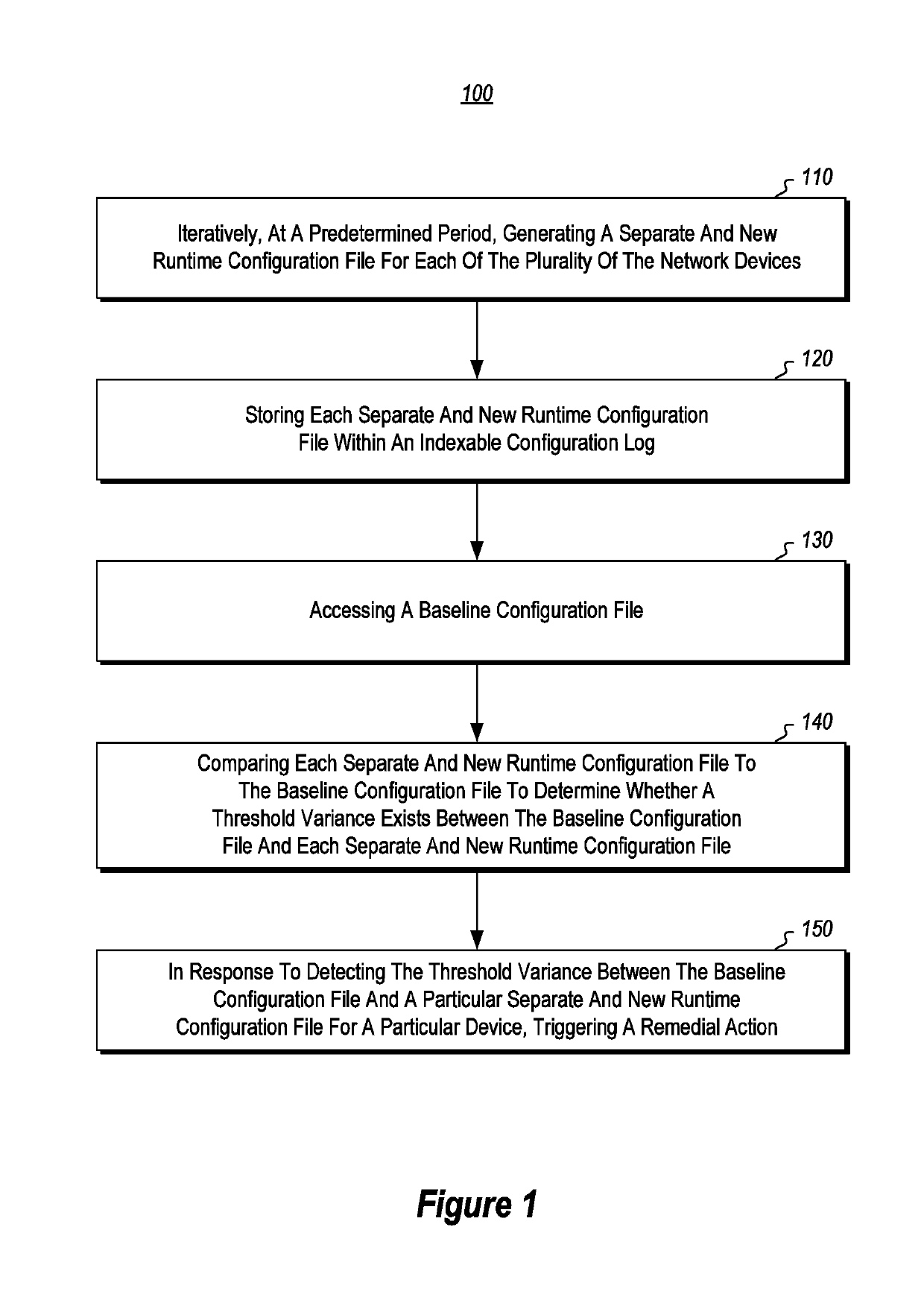

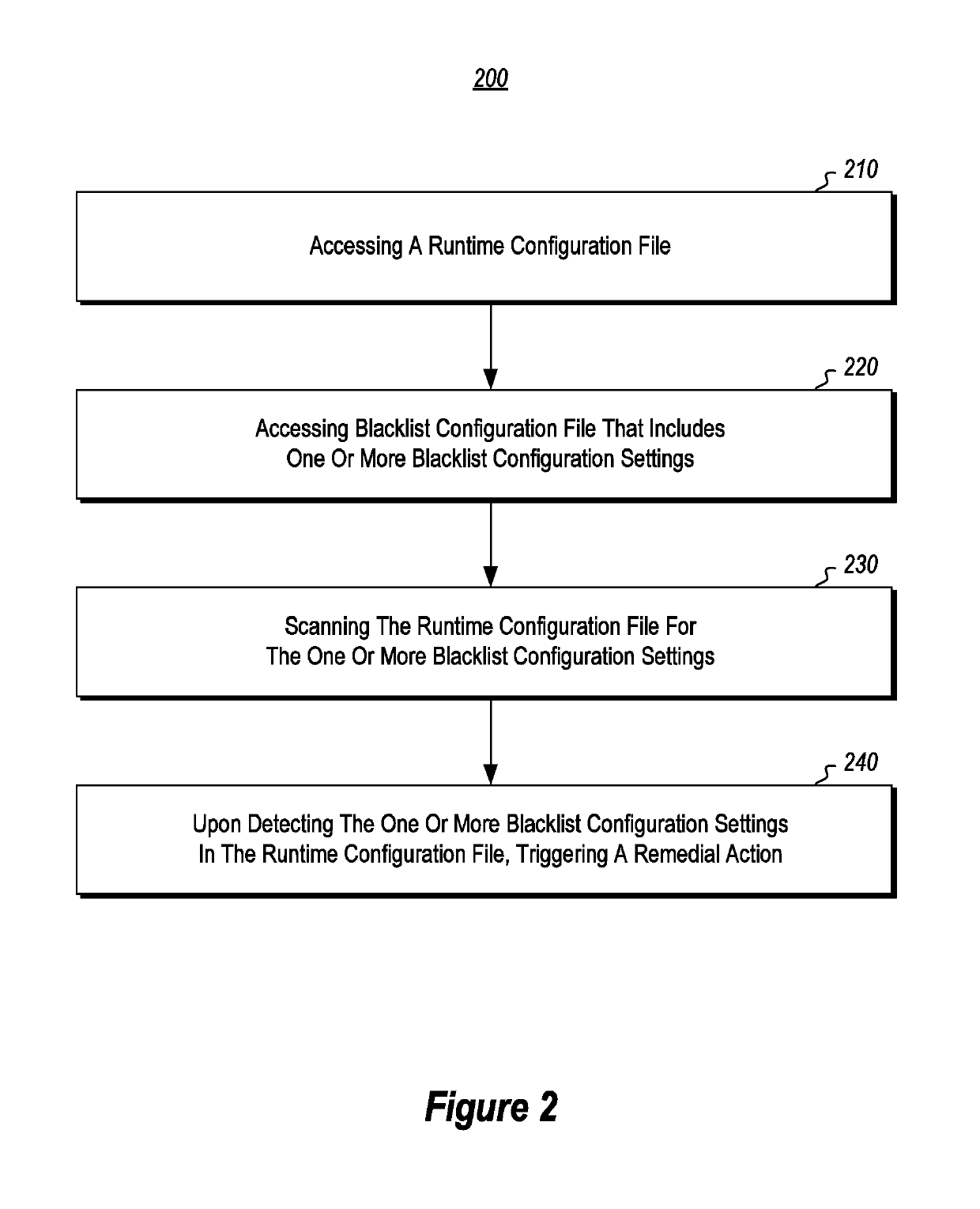

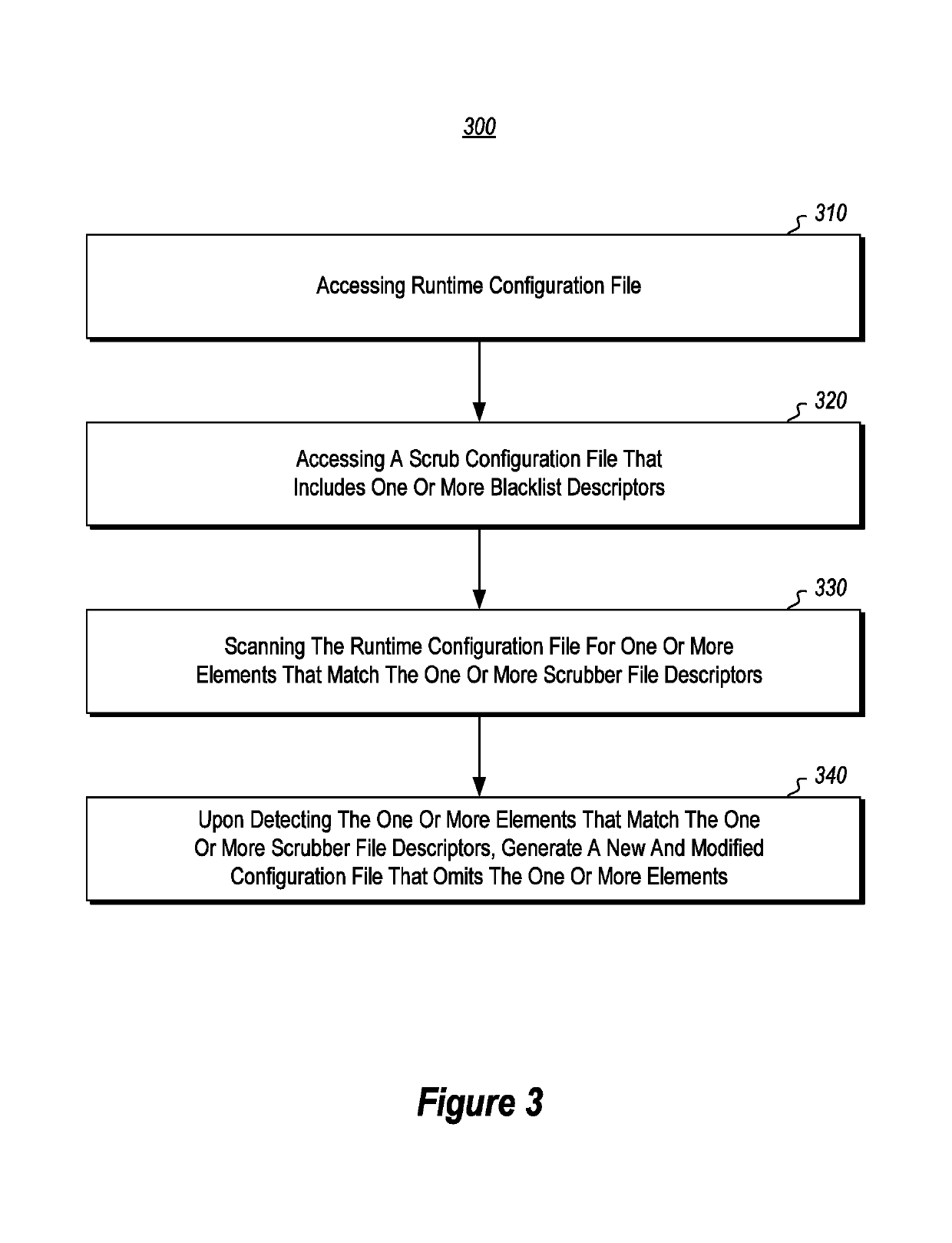

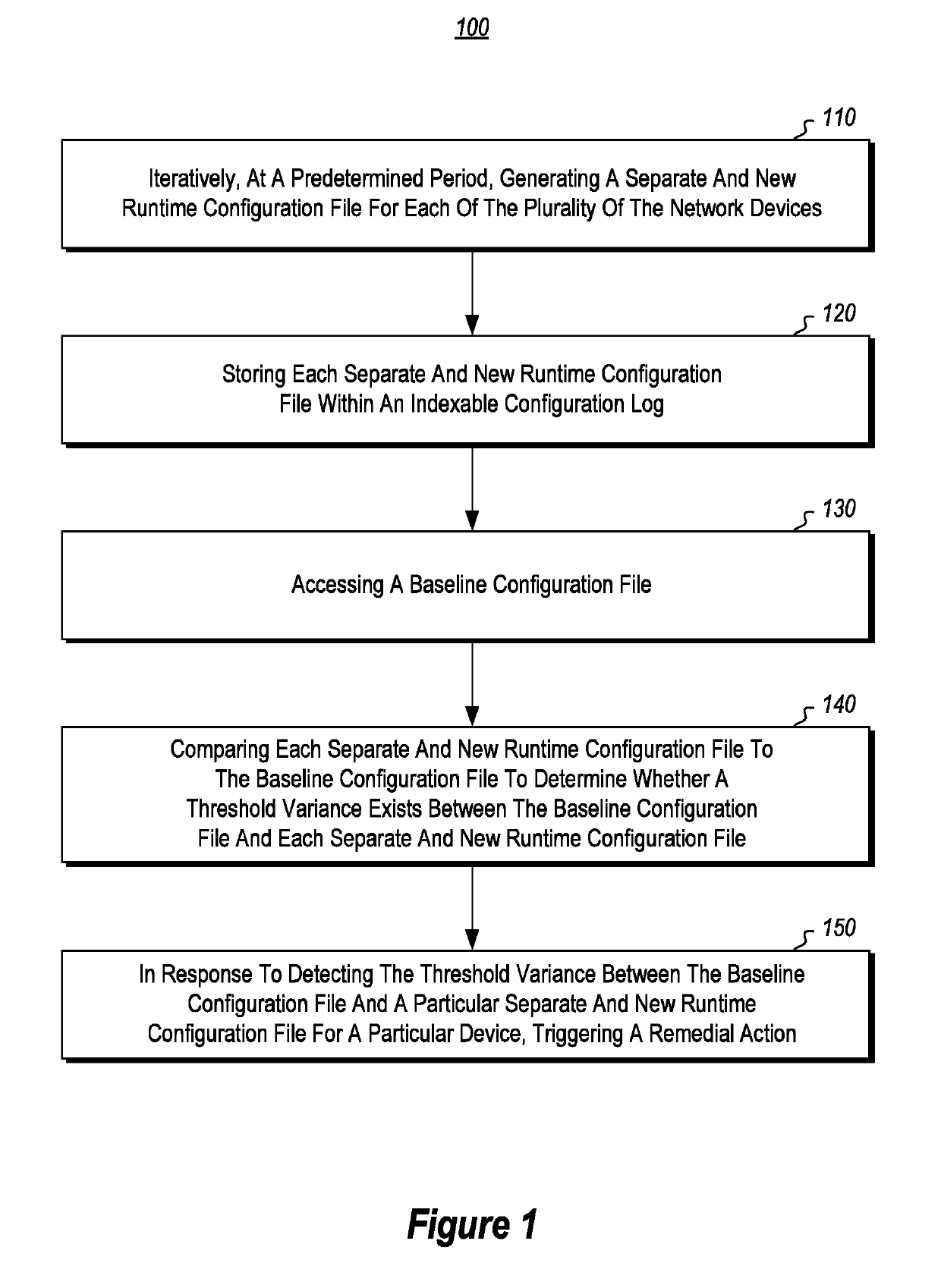

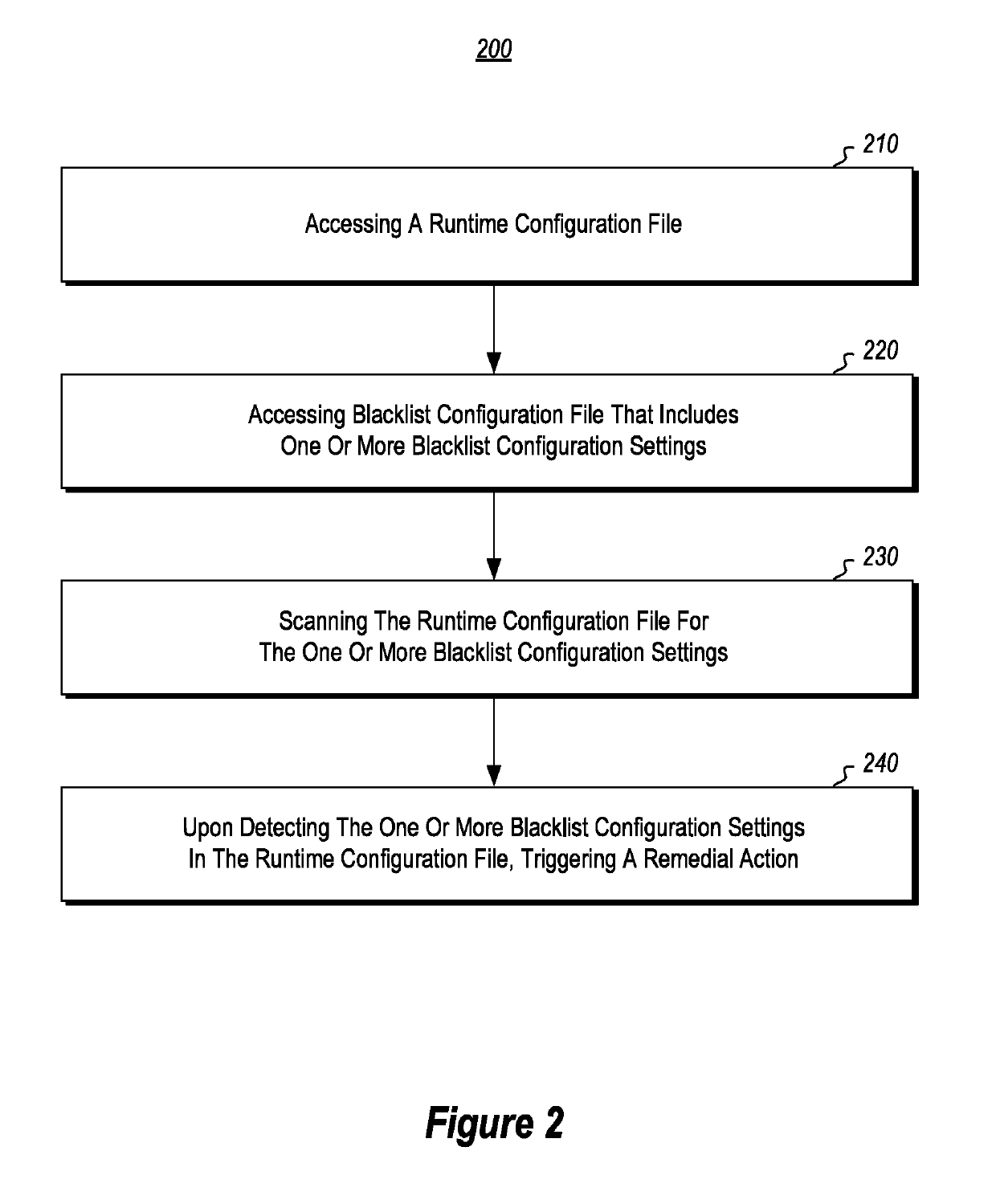

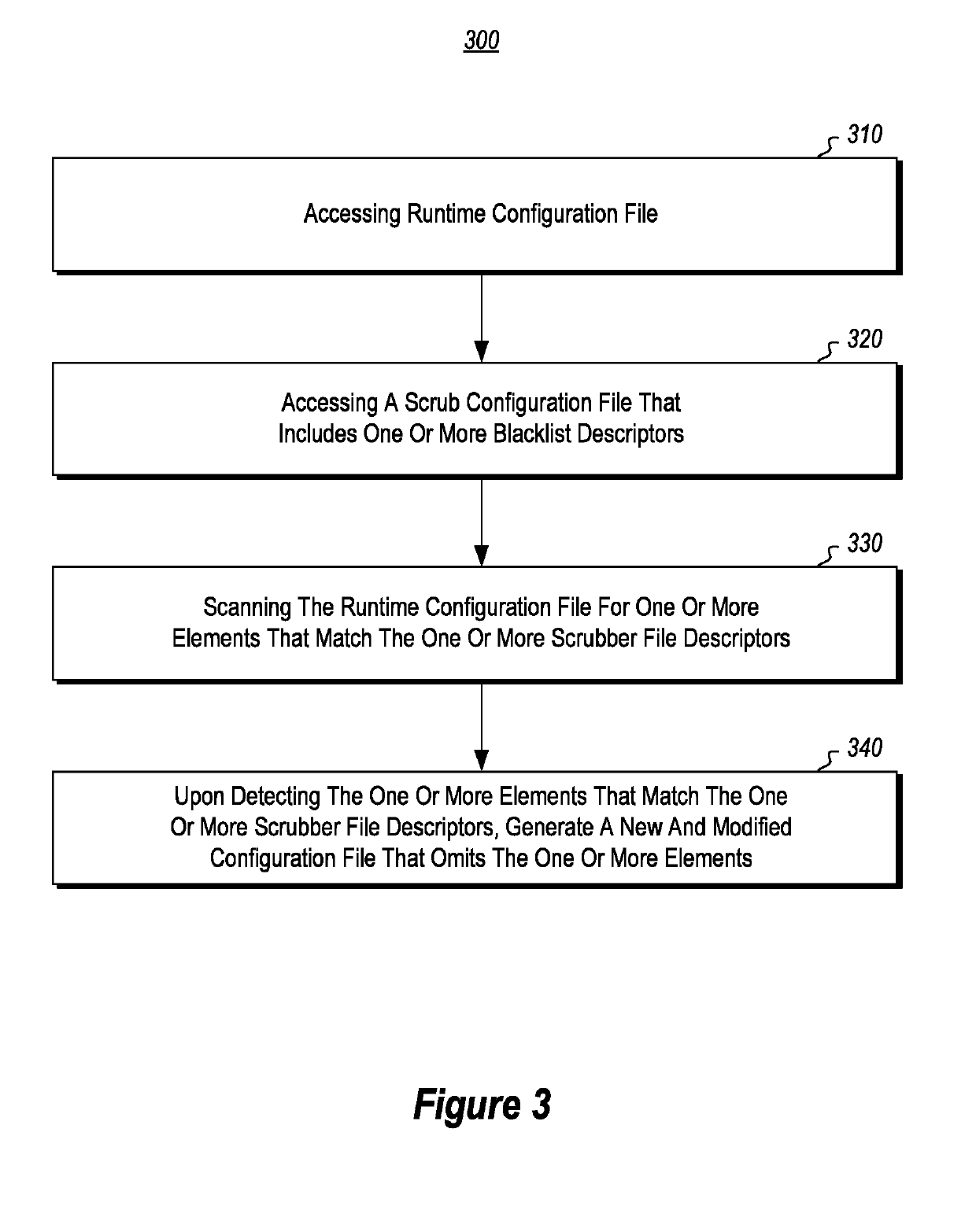

Automated compliance with security, audit and network configuration policies

InactiveUS20190342296A1Facilitate automated complianceExtension of timeData switching networksRemedial actionBlack list

Systems and methods are provided for facilitating automated compliance with security, audit and network configuration policies. In some instances, new runtime configuration files are iteratively generated and compared to a baseline configuration file to determine whether a threshold variance exists between the baseline configuration file and each separate and new runtime configuration file. If the threshold variance exists, remedial actions are triggered. In some instances, runtime configuration files are scanned for blacklist configuration settings. When blacklist configuration settings are found, remedial actions can also be triggered. In some instances, configuration files are scrubbed by omitting detected blacklist items from the configuration files. In some instances, changes are only made to configuration files when they match changes on an approved change list and are absent from an open incident list.

Owner:MICROSOFT TECH LICENSING LLC

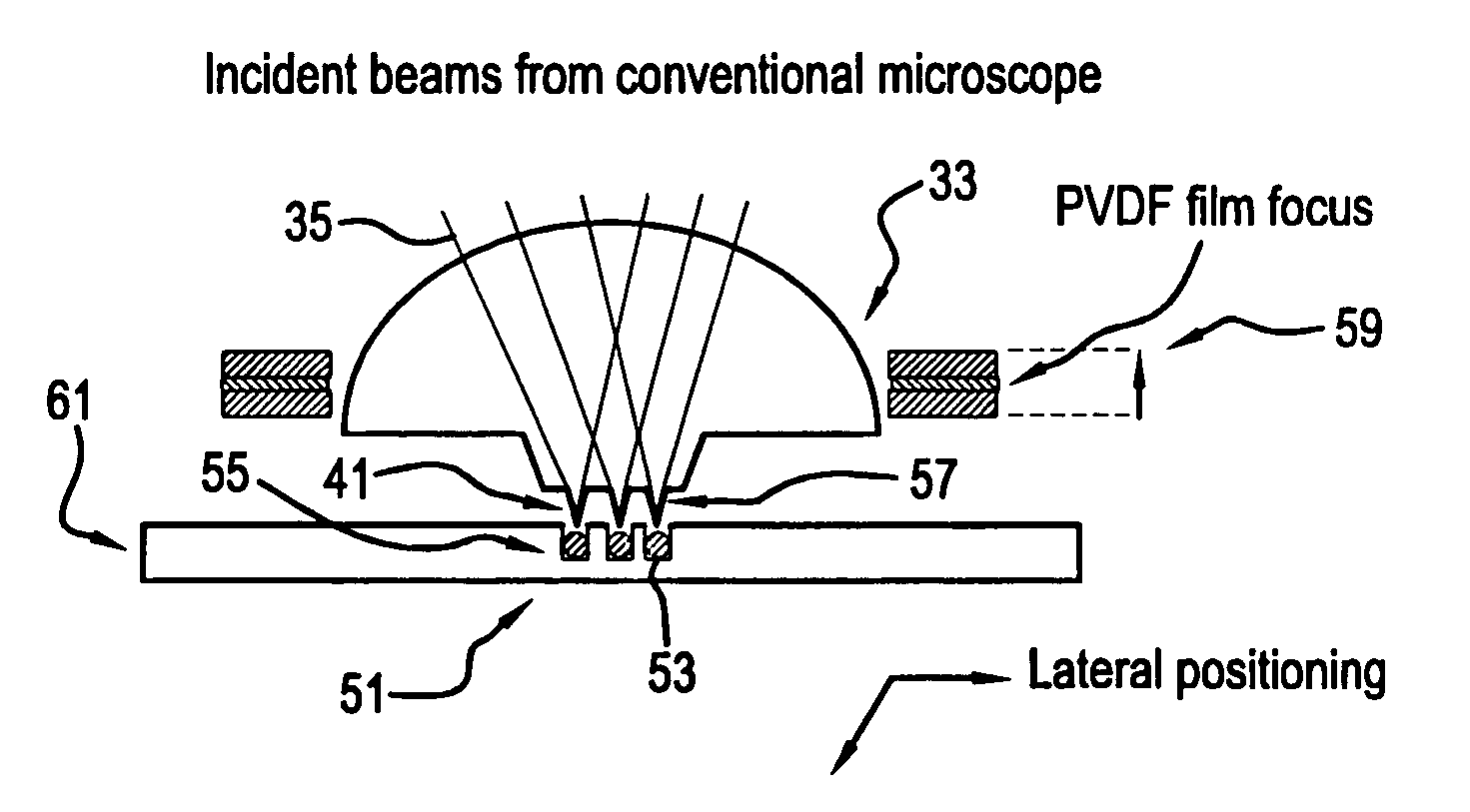

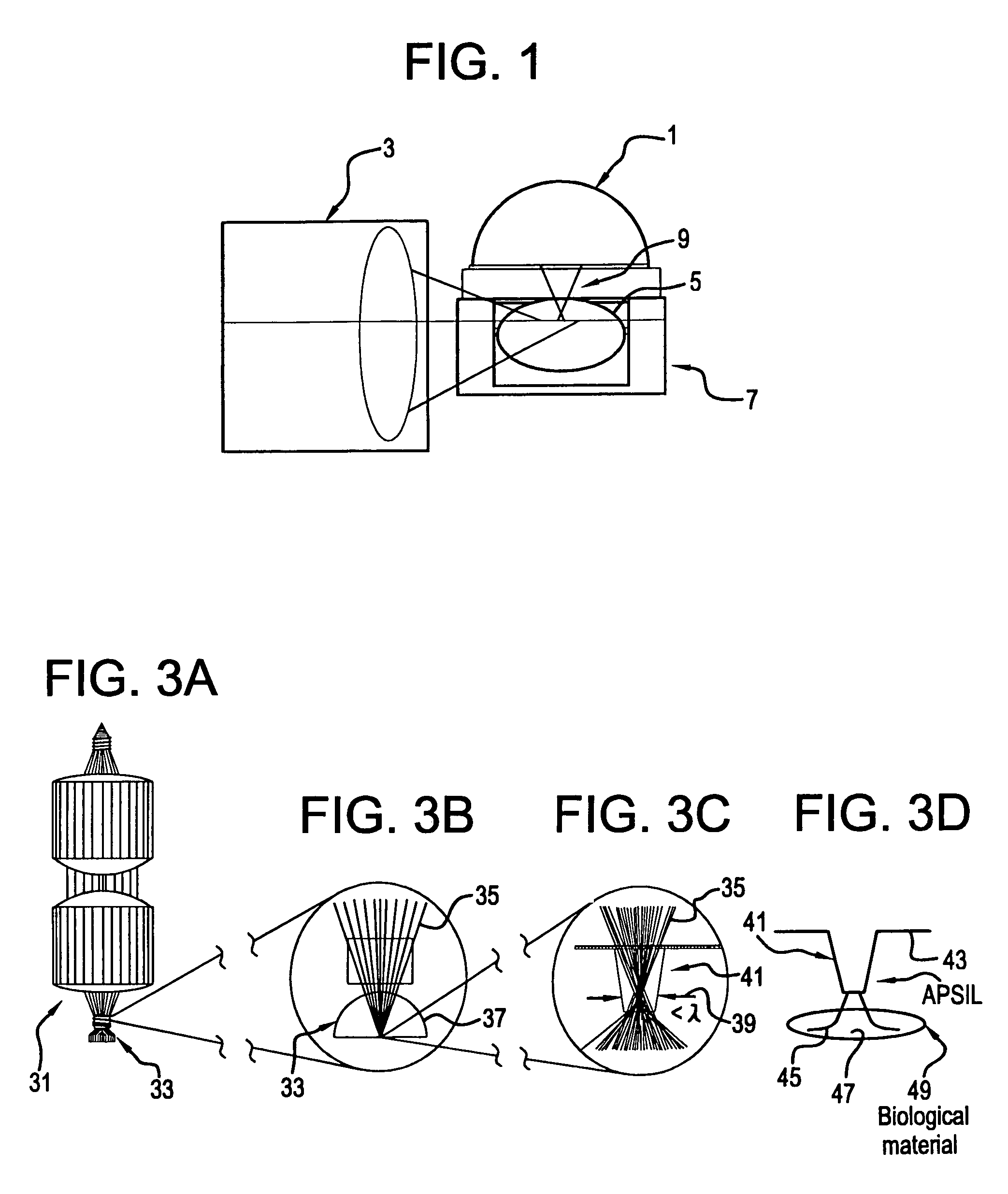

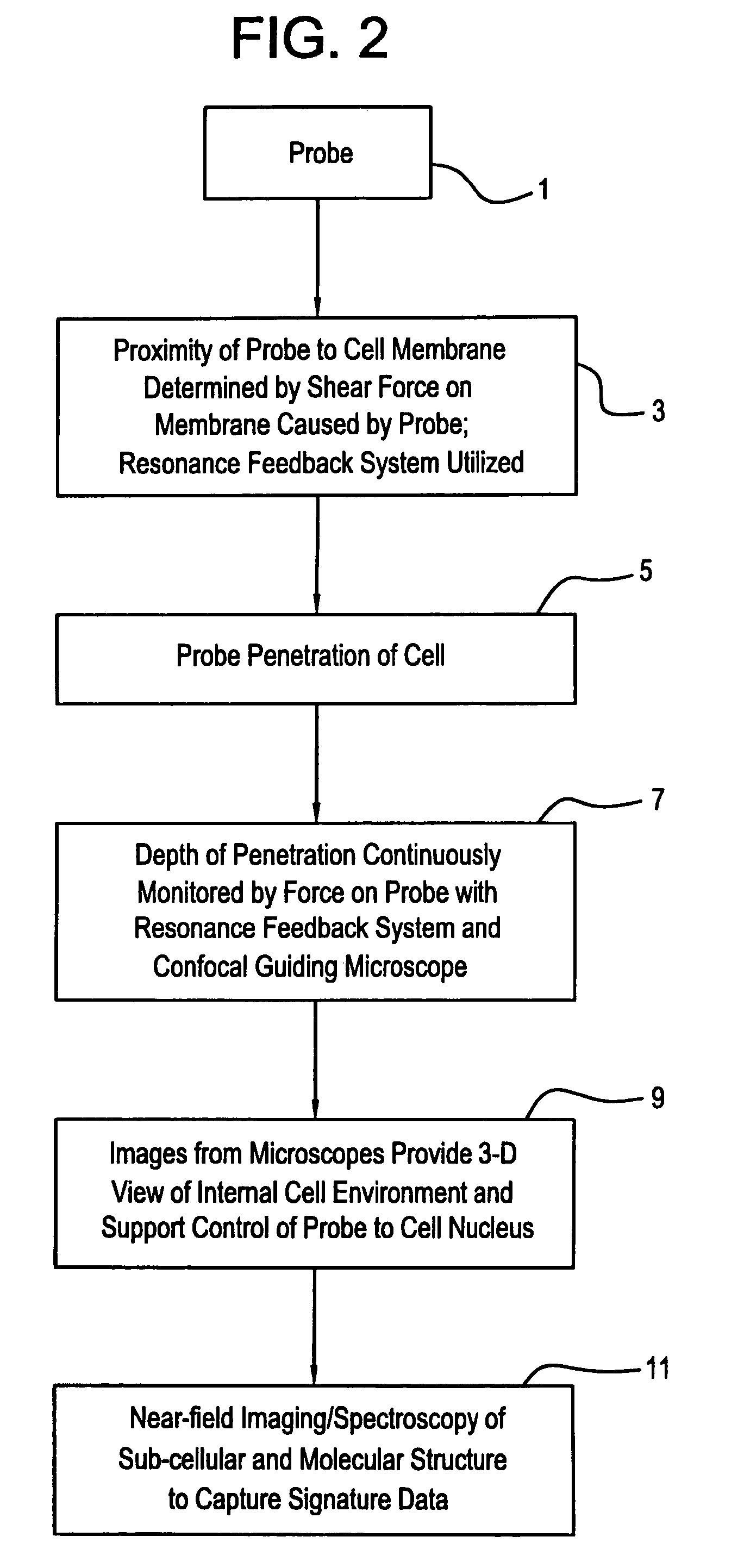

Precision optical intracellular near field imaging/spectroscopy technology

InactiveUS7129454B2Facilitates molecular analysisMore powerSolid-state devicesMaterial analysis by optical meansDiseaseMolecular analysis

A Precision Optical Intracellular Near Field Imaging / Spectroscopy Technology (POINT / NANOPOINT) is a high-resolution instrument for analyzing and comparing molecular characteristics of cells. A nanosensor array is provided which is capable of imaging inner regions of living cells without destroying its natural environment and providing new information about molecular makeup of cells. The POINT probe collects data from high-resolution imagery, providing an imaging tool for investigating cells at sub-cellular and molecular levels. Data are then incorporated into a signature facilitating molecular analysis of diseases. The POINT probe non-invasively penetrates cell membranes to image insides of intact cells allowing the POINT probe to collect data without destroying cell structures. The probe provides cellular imaging to enable the viewing of both imaging and spectroscopy of internal regions of cells. The POINT system may be attached to existing microscopes to achieve a very high resolution.

Owner:NANOPOINTS

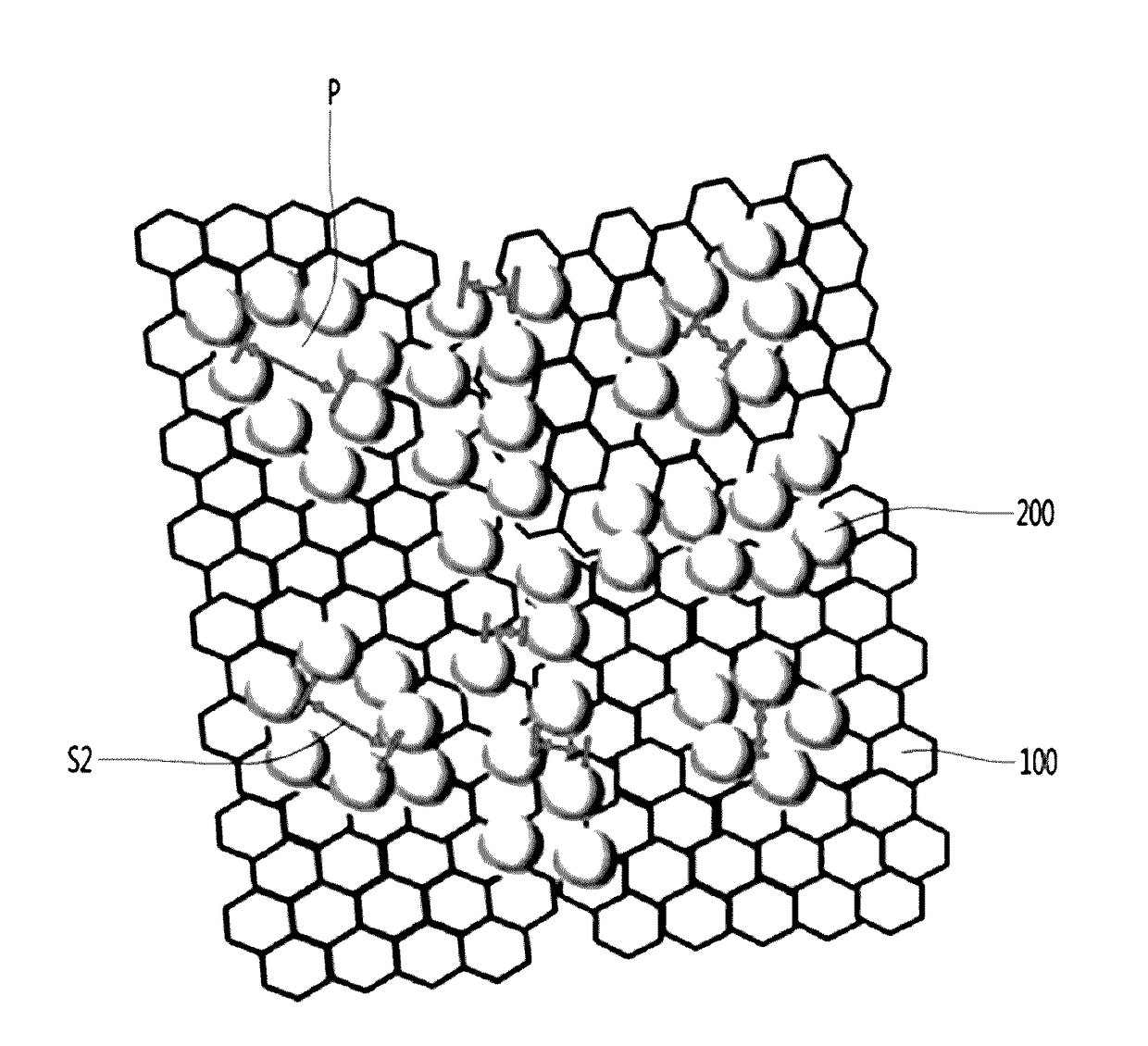

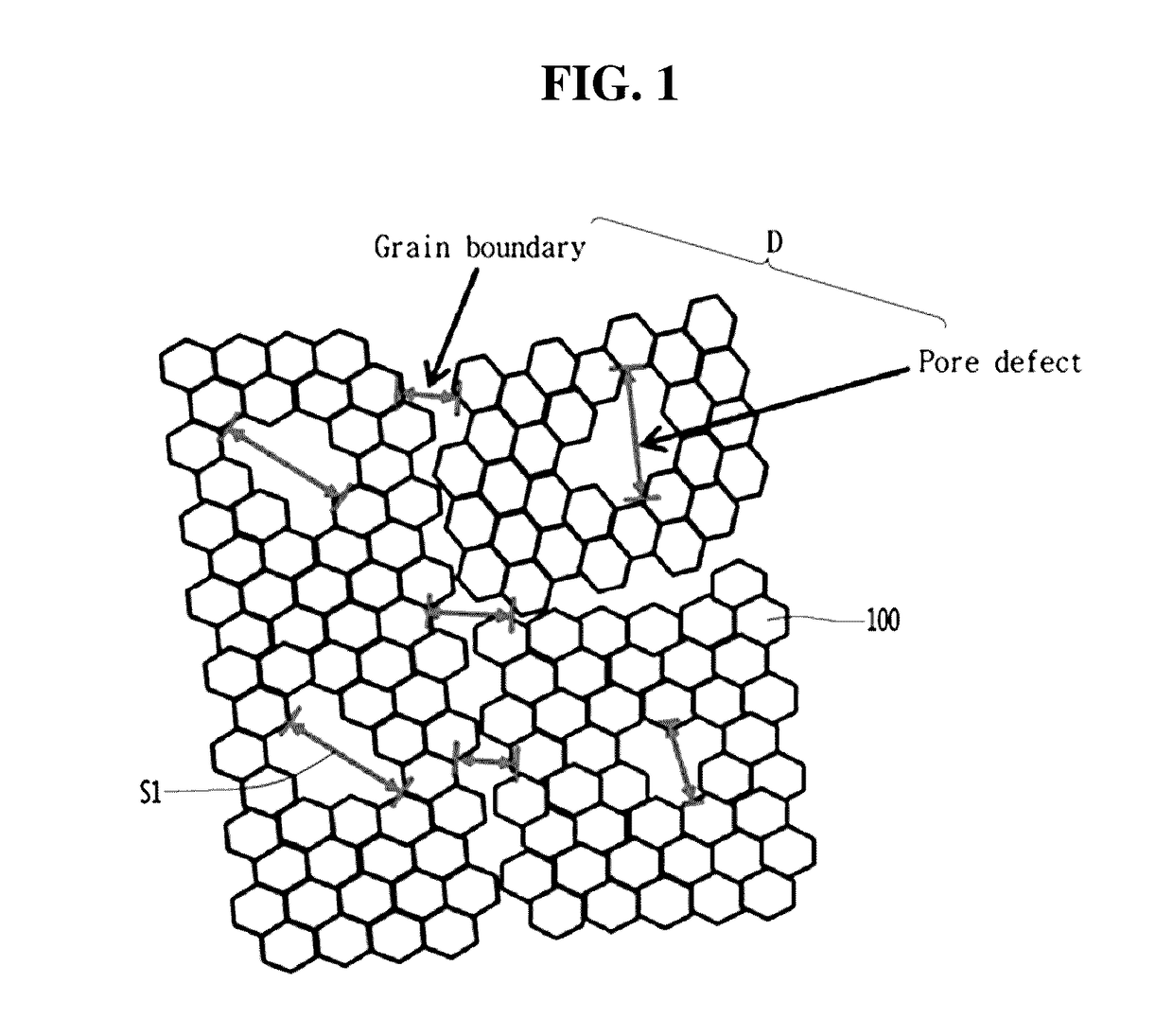

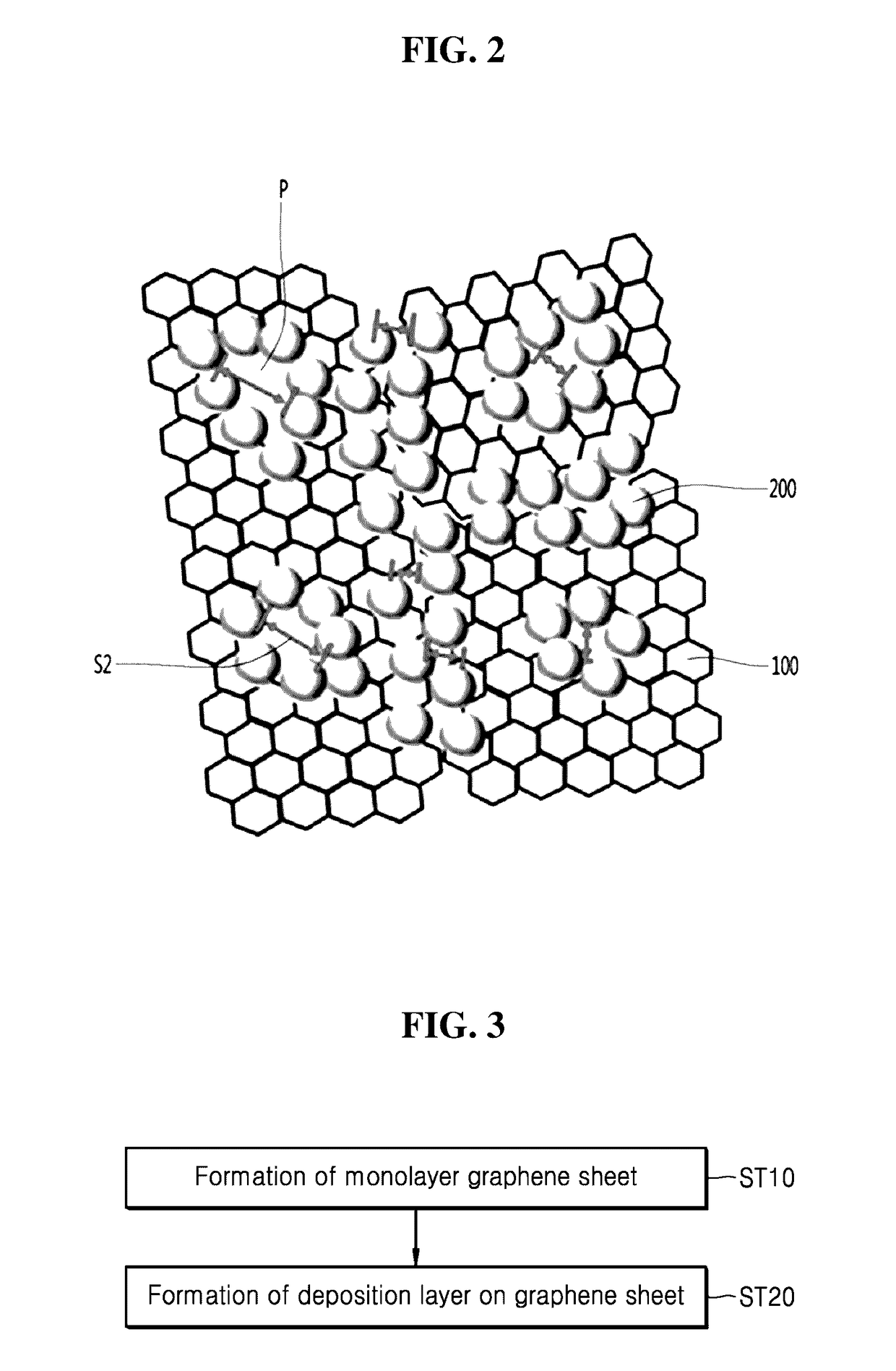

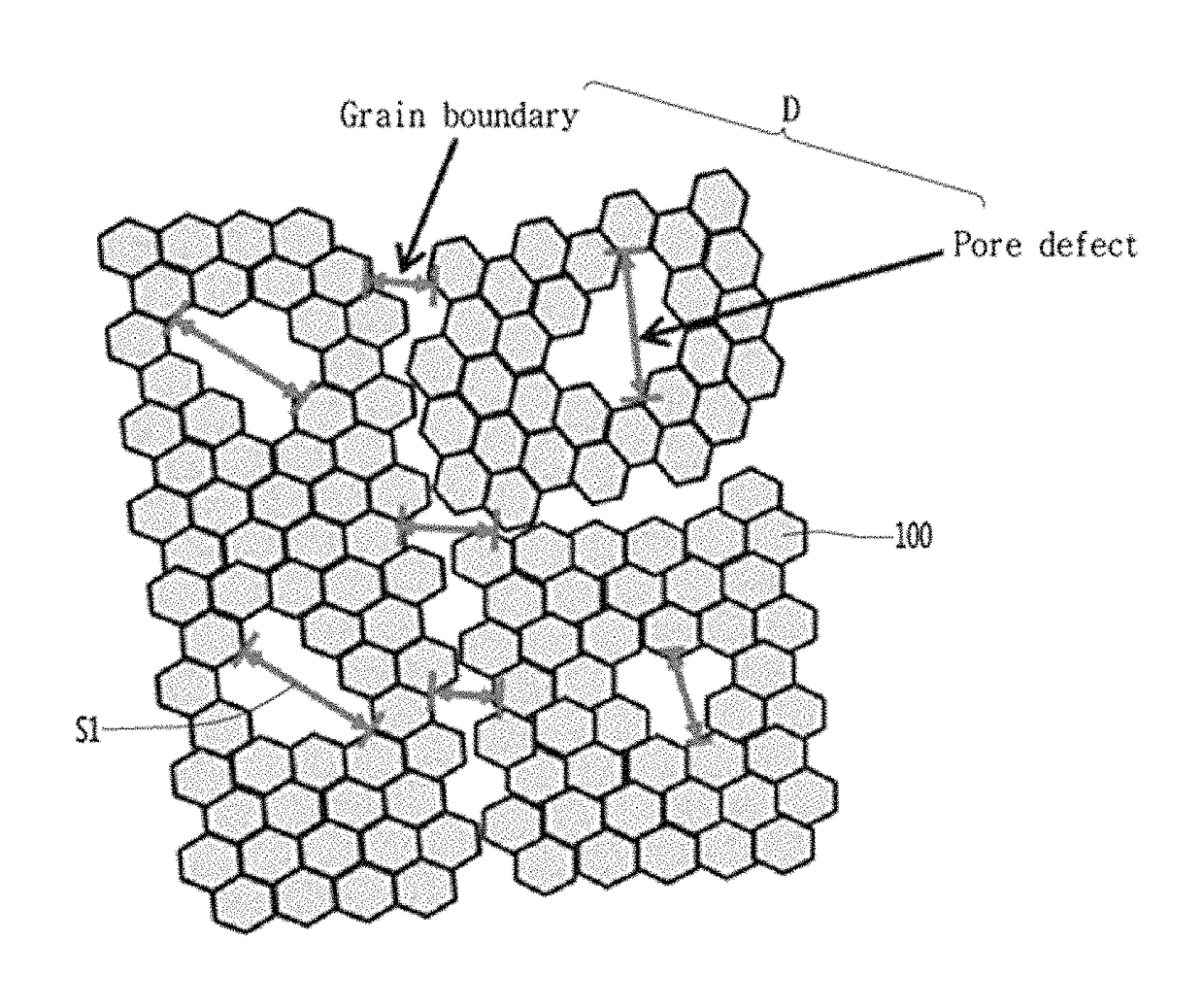

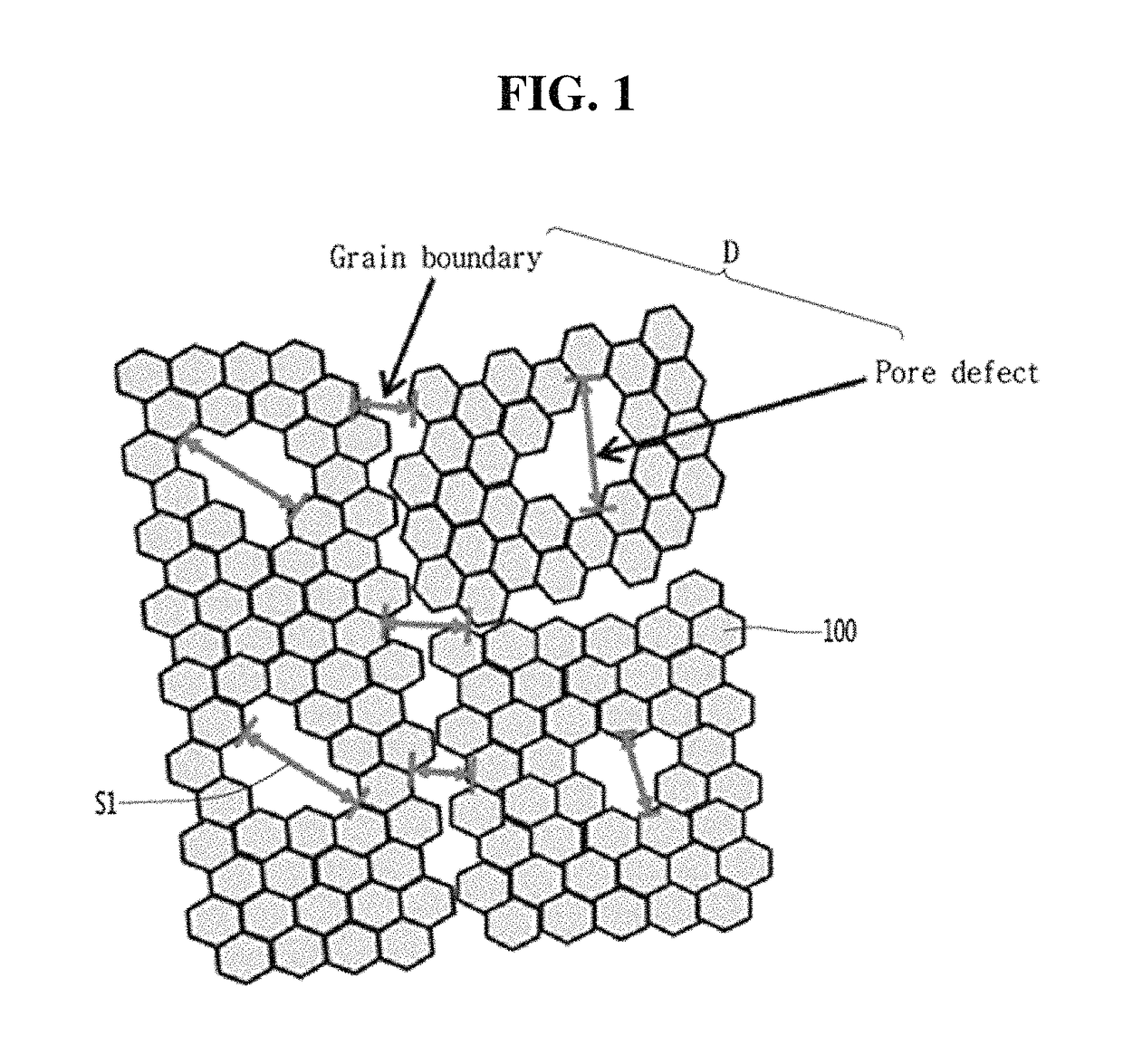

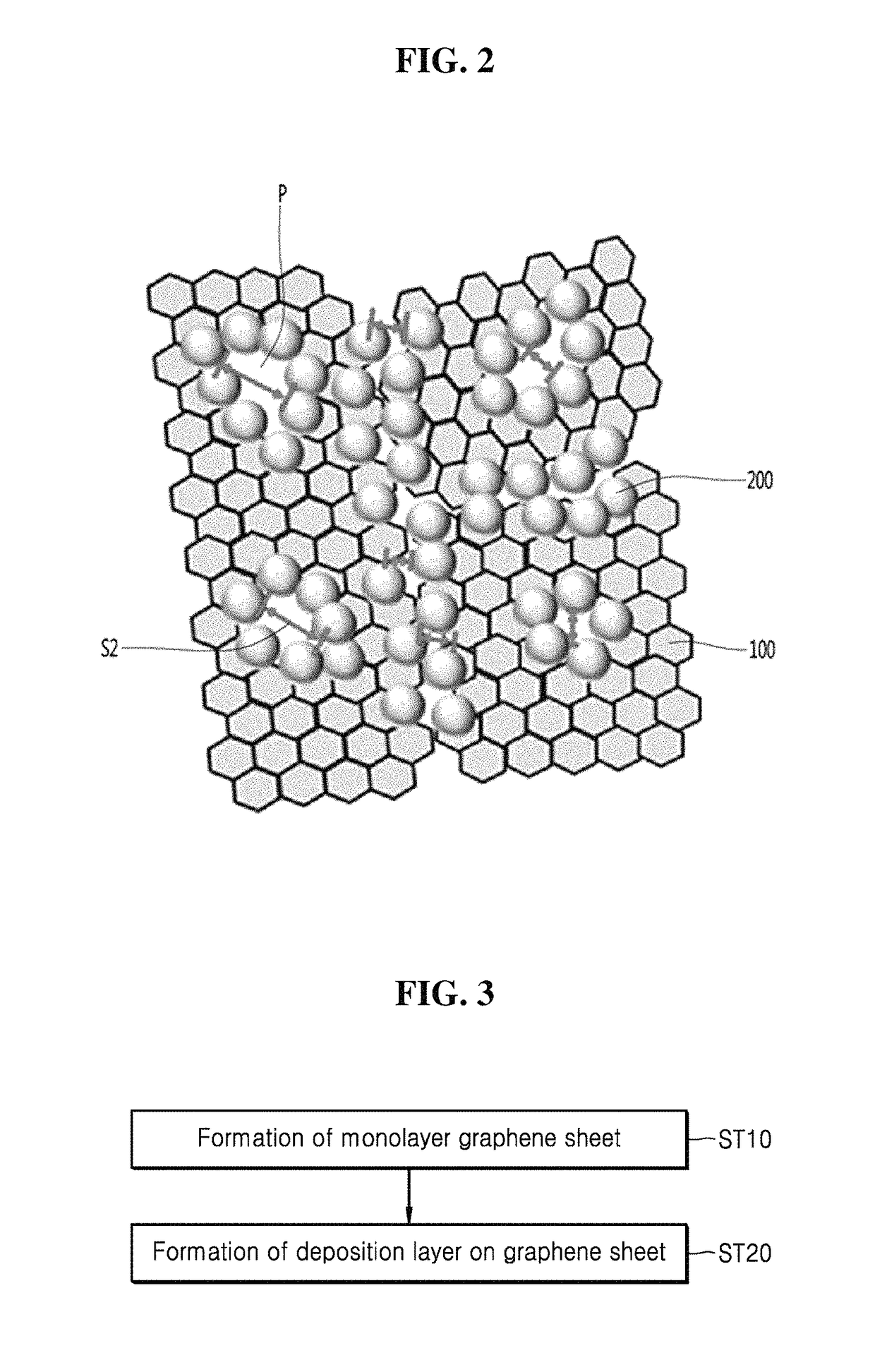

Membrane based on graphene and method of manufacturing same

ActiveUS20170065939A1Increase physical strengthIncrease the number ofMembranesSeawater treatmentMonolayer grapheneCvd graphene

Disclosed herein are a graphene-based membrane and a method of manufacturing the same. The graphene-based membrane includes: monolayer graphene containing defects; a deposition layer disposed on the defects; and nanopores surrounded by the deposition layer. The method of manufacturing a graphene-based membrane includes forming a monolayer graphene sheet and partially forming a deposition layer on the graphene sheet.

Owner:GWANGJU INST OF SCI & TECH

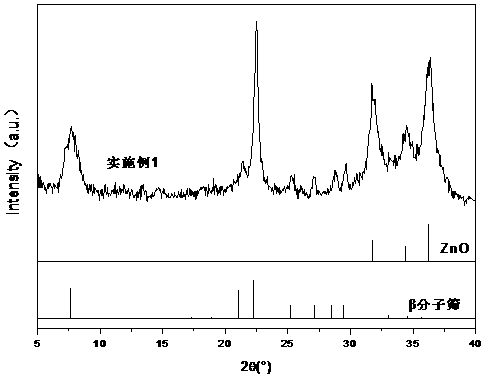

Core-shell type catalyst for directional catalytic conversion of biomass synthesis gas, and preparation of core-shell type catalyst

PendingCN108906070AImprove conversion rateAvoid churnMolecular sieve catalystsHeterogenous catalyst chemical elementsCatalytic transformationFreeze-drying

The invention provides a core-shell structure catalyst for directional catalytic conversion of biomass synthesis gas, and also provides a preparation method and application of the core-shell structurecatalyst. The core-shell structure catalyst comprises a core layer and a shell layer, wherein the core layer is prepared from small-grain composite metal oxide, and the shell layer is prepared from porous solid acid; the small-grain composite metal oxide is a solid solution or mixture of two or more oxides of ZnO, ZrO2, Co3O4, Fe2O3, In2O3, Ga2O3, CuO, Mn2O3, NiO, Cr2O3, La2O3 and CeO2. The core-shell catalyst adopts the solid solution or mixture of the small-grain composite metal oxide having a synergistic effect on hydrogenation of CO and CO2 as the core layer, and uses the solid acid having a microporous, mesoporous or multi-stage pore structure as the shell layer. The catalyst is prepared into a core-shell structure by means of a freeze-drying method, so that not only is the problem of lower hydrogenation conversion rate of CO2 in the biomass synthesis gas at present solved, but the conversion rate of CO hydrogenation is also further improved.

Owner:QINGDAO UNIV

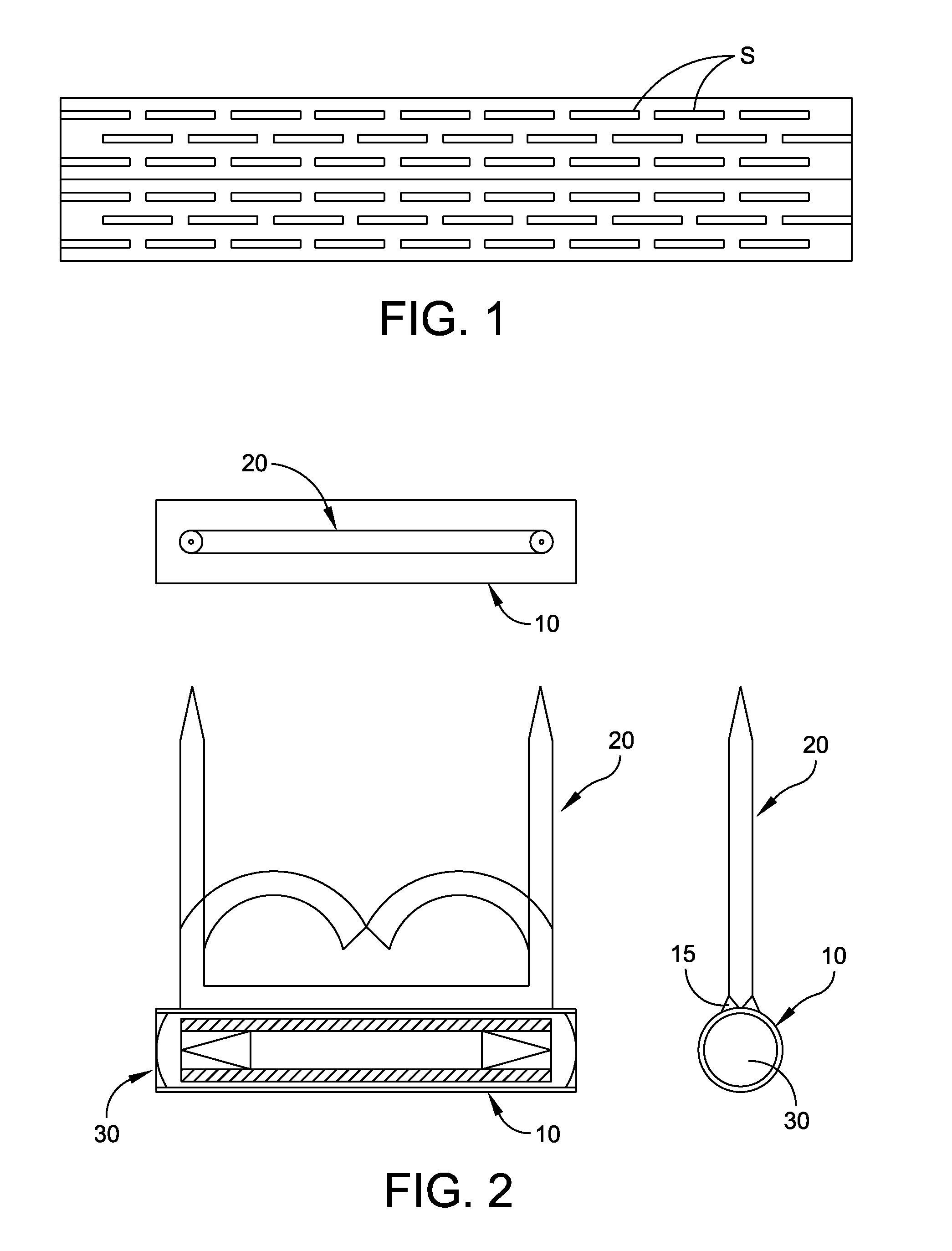

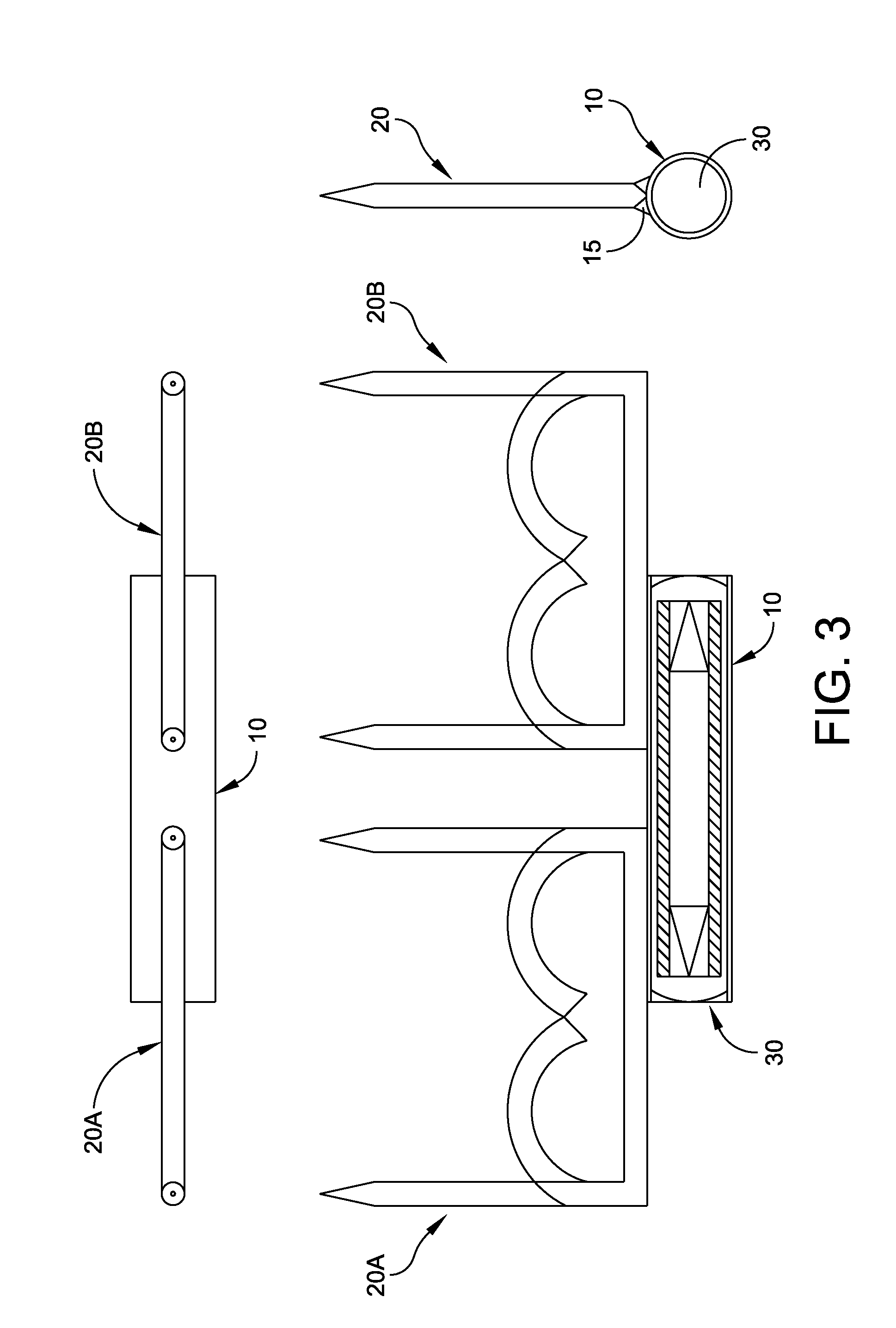

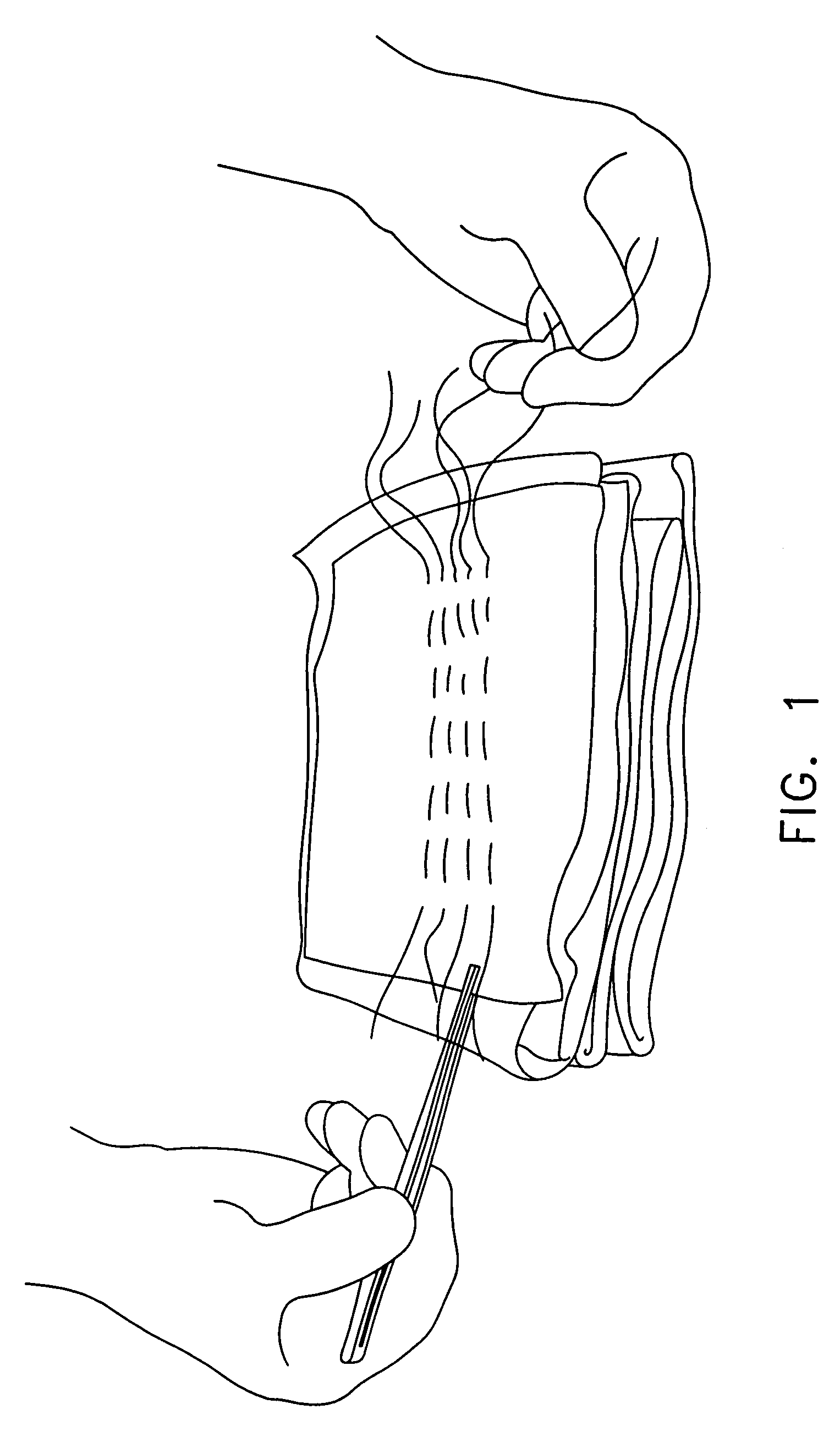

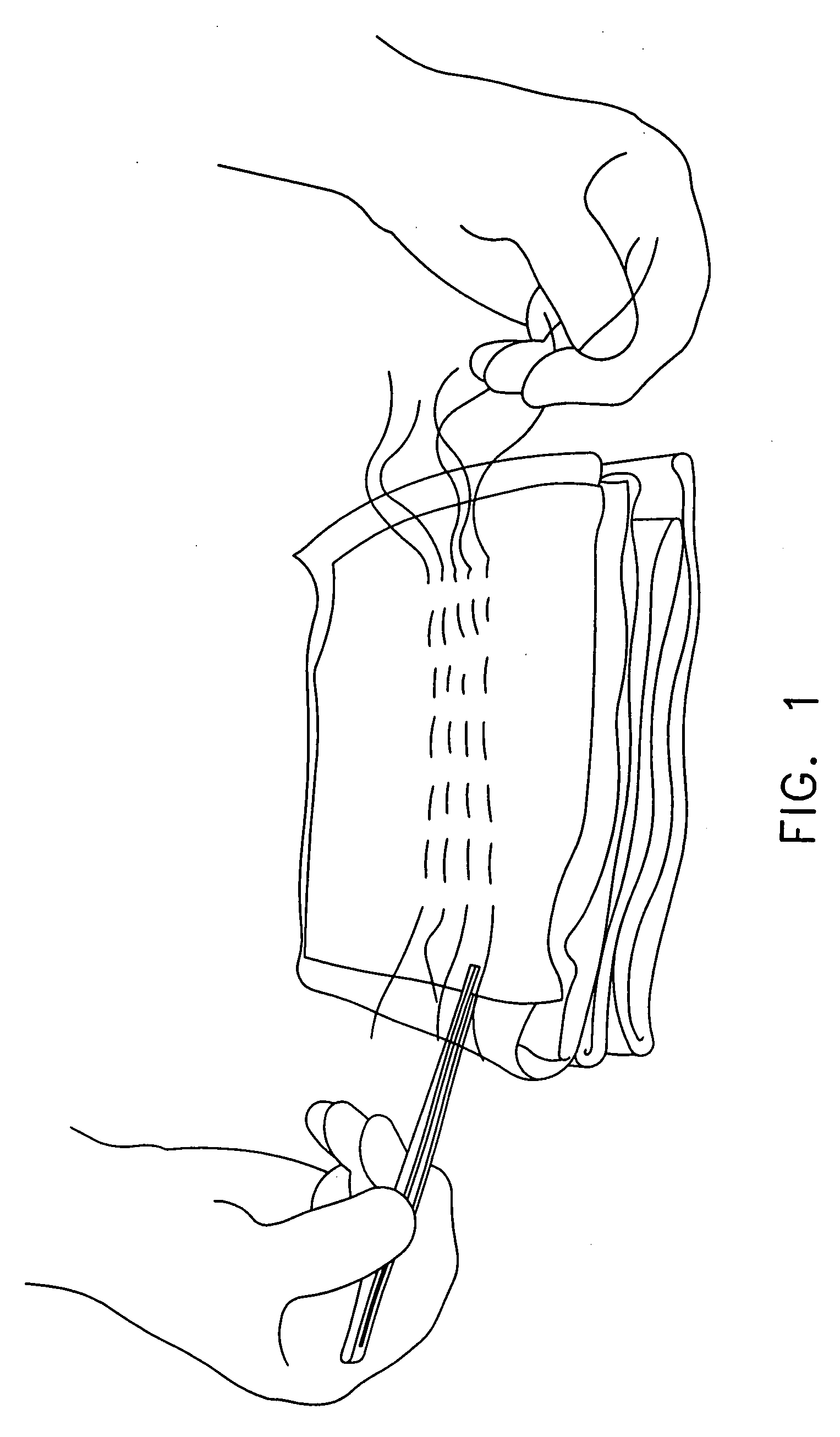

Radioactive therapeutic apparatus

ActiveUS7604586B2For accurate placementReduce doseRadiation therapySurgical staplesSurgical stapleSurgical incision

A method and device for applying a radioactive source to a tissue site is disclosed. The device facilitates the precise placement of, for example, 125Iodine seeds relative to the surgical margin, assures the seeds remain fixed in their precise position for the duration of the treatment, overcomes the technical difficulties of manipulating the seeds through the narrow surgical incision, and reduces the radiation dose to the clinicians. The device incorporates the radioactive seeds into a fastening means, preferably surgical staples, used in the surgical procedure. In this way, the seeds are concurrently secured in position directly adjacent to the surgical resection and remain immobile.

Owner:POINT SOURCE TECH

Radioactive therapeutic apparatus

ActiveUS20070244351A1For accurate placementReduce doseRadiation therapySurgical staplesSurgical stapleSurgical incision

A method and device for applying a radioactive source to a tissue site is disclosed. The device facilitates the precise placement of, for example, 125Iodine seeds relative to the surgical margin, assures the seeds remain fixed in their precise position for the duration of the treatment, overcomes the technical difficulties of manipulating the seeds through the narrow surgical incision, and reduces the radiation dose to the clinicians. The device incorporates the radioactive seeds into a fastening means, preferably surgical staples, used in the surgical procedure. In this way, the seeds are concurrently secured in position directly adjacent to the surgical resection and remain immobile.

Owner:POINT SOURCE TECH

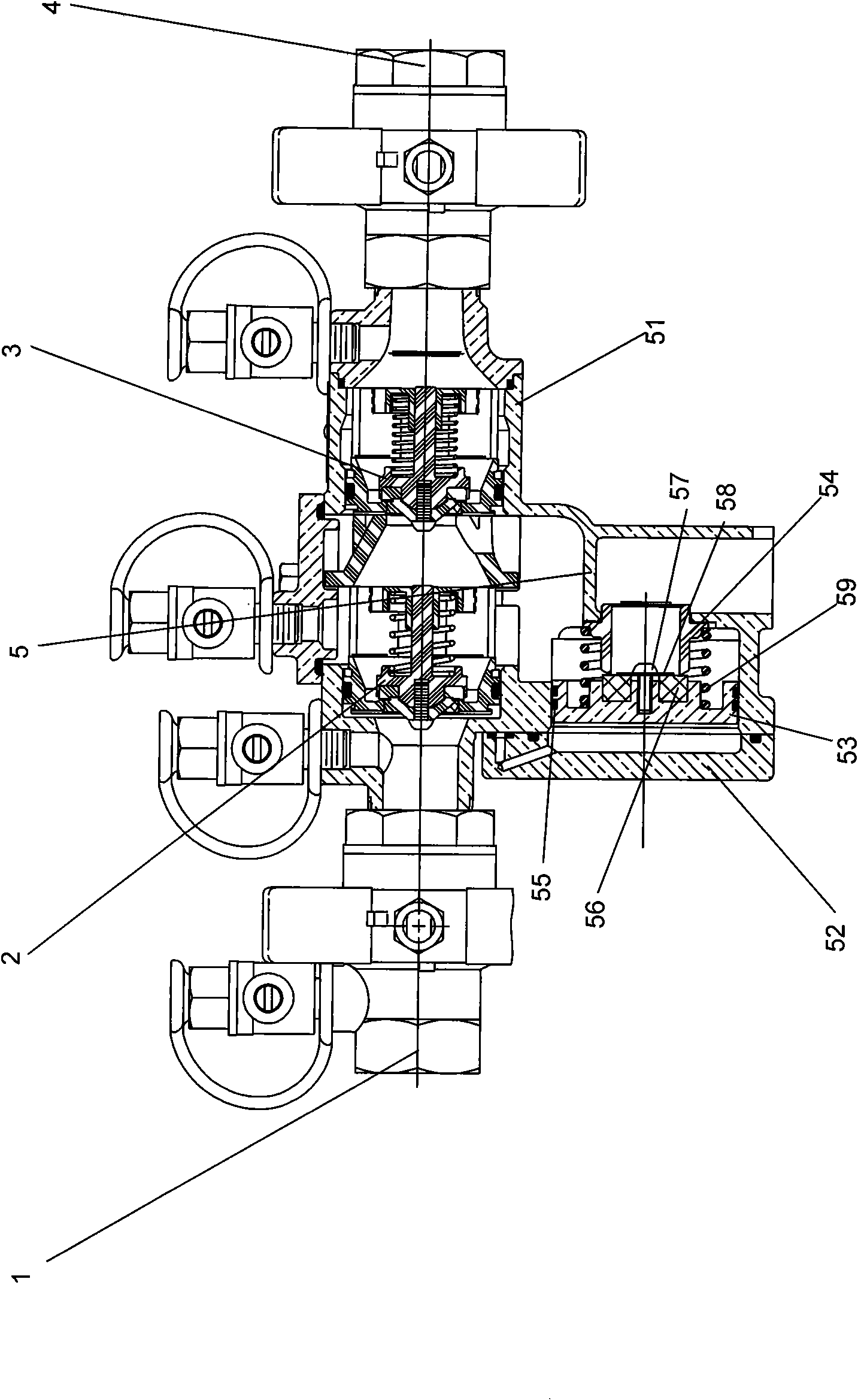

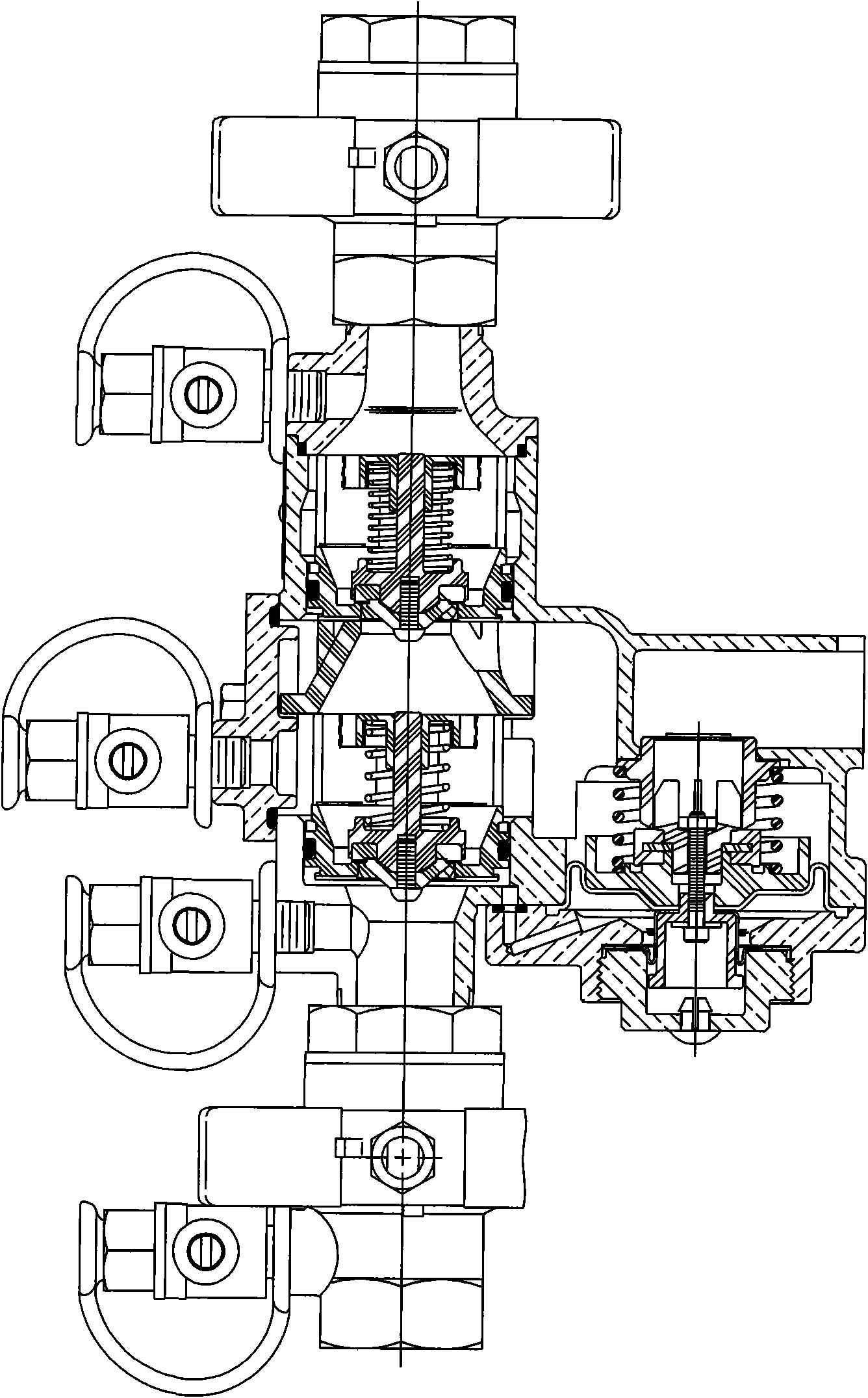

Pressure release type backflow preventer

InactiveCN101676590AEasy to processOvercome difficultyOperating means/releasing devices for valvesCheck valvesEngineeringCheck valve

The invention relates to a pressure release type backflow preventer which comprises a water inlet ball valve, a first-stage check valve, a second-stage check valve and a water outlet ball valve, wherein a bypass draining pressure reducing valve is installed between the first-stage check valve and the second-stage check valve and comprises a valve cover and a valve body. The backflow preventer is characterized in that a piston body which can move left and right is distributed inside an inner cavity of the draining pressure reducing valve and divides the inner cavity into a left cavity and a right cavity, wherein the left cavity is communicated with a master water inlet by a channel arranged on the valve cover of the draining pressure reducing valve, and the right cavity leads a water inletto be communicated with a water outlet of the draining pressure reducing valve by a ring-shaped seat; the circumferential surface of the piston body is distributed with a ring-shaped sealing ring which is used for realizing sliding seal with the wall surface of the inner cavity, and the right side of the piston body is provided with a gasket which is matched and sealed with the ring-shaped seat; and a spring is supported between the piston body and the ring-shaped seat. Therefore, the pressure release type backflow preventer has simple and reasonable structure, and is easy to produce and assemble.

Owner:NINGBO HUACHENG VALVE

Method for preparing foam concrete foaming agent by sludge protein

InactiveCN101709002AReduce secondary pollutionOvercome technical difficultiesSludge treatmentSolid waste managementProtein solutionFoam concrete

The invention provides a method for producing a protein foam concrete foaming agent by sludge, which comprises the following steps of: adding 5-6 percent of lime into sludge containing protein; carrying out high-temperature hydrolysis for 1-2 hours in a reactor; filtering and removing slag to obtain a protein solution mixture; concentrating, and then adding 0.1-0.2 percent of protective agent and adding 3.0-3.6 percent of xanthan gum to prepare the sludge protein foam concrete foaming agent. The foaming agent has the expansion rate of foam more than 50 and the stable time more than four hours and achieves the production requirement. After foaming, the foaming agent is added with No. 42.5 cement, perlite, pulverized fuel ash and water to be uniformly mixed and can be directly used as heat insulation materials of a roof, an inner wall and an outer wall and a filling material in construction or after foaming by an air tank, the sludge protein foam concrete foaming agent is uniformly mixed with rapid-hardening sulphoaluminate, the pulverized fuel ash, a fiber and water; and a sludge protein foam concrete energy-saving plate or a sandwich plate and a sound insulating material used for a high-rise building wall or a high-noise environment can be prepared in the processes of casting and maintenance.

Owner:HUBEI UNIV

Split plugging waterproof system

ActiveCN109577494AOvercome technical difficultiesReduce the difficulty of engineering constructionRoof covering insulationsBuilding insulationsEngineeringHydrophobic surfaces

The invention discloses a split plugging waterproof system. According to the system, the surface of a joint needing plugging water prevention of a waterproof plate with good water resistance is processed into a hydrophobic surface, the waterproof plate is separately used or assembled with a waterproof sheet with a hydrophobic surface, two hydrophobic surfaces are closely fitted together face to face, or space between the hydrophobic surfaces is sufficiently and compactly filled with surface hydrophobic substances or filled with materials which are uniform in texture and easily deformed under stress, infiltration or flow of water solution between the closely fitted hydrophobic surfaces is prevented, and a waterproof task is completed. The split plugging waterproof system plugs and preventsleakage water by the aid of material surface properties and solves the problems that an existing overall waterproof technique is not long in waterproof service life, difficult in construction and thelike.

Owner:怀化沃普环保科技有限公司

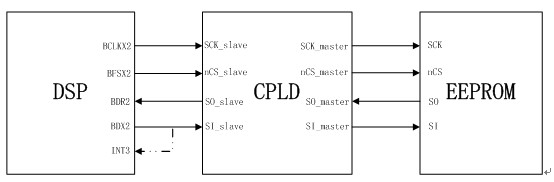

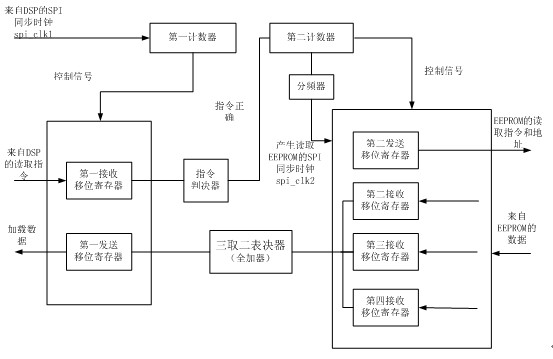

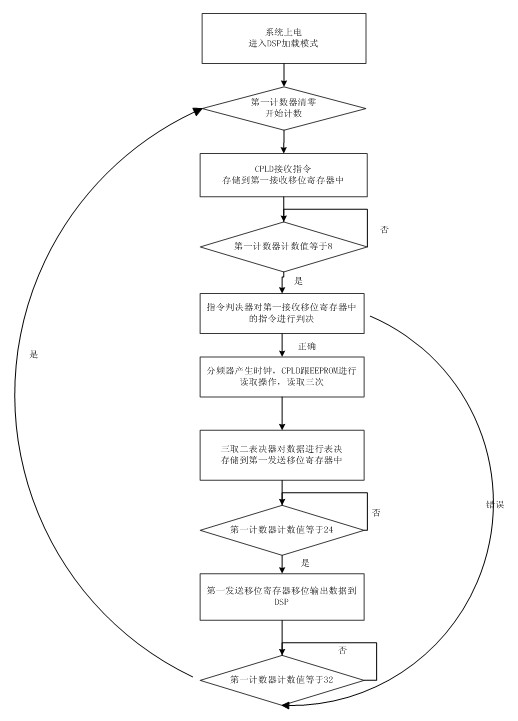

Method for improving satellite borne DSP (Digital Signal Processing) loading guiding reliability

InactiveCN102043754AOvercome technical difficultiesImprove reliabilityDigital computer detailsElectric digital data processingSatelliteAddress space

The invention discloses a method for improving satellite borne DSP (Digital Signal Processing) loading guiding reliability. The guiding loading mode adopted by DSP (Digital Signal Processing) is 8-bit serial EEPROM (Electrically Erasable Programmable Read-Only Memory) loading mode, CPLD (Complex Programmable Logic Device) is adopted to carry out two-from-three voting for the loading data, and the satellite borne DSP loading reliability is improved. Identical loading data stored in three stages of address space, i.e. 00_0000H-00_FFFFH, 01_0000H-01_FFFFH and 10_0000H-10_FFFFH of EEPROM, CPLD is communicated with DSP and EEPROM by realizing SPI (Single Program Initiation) communication protocol, and carries out two-from-three voting for the data on the three stages of different addresses in the EEPROM, and the reliability loading of DSP is realized. After the DSP loading is finished, the CPLD can realize numerical switch function, so that the DSP pin can be extended for other usages, and the utilization rate of satellite borne resource is improved.

Owner:ZHEJIANG UNIV

Flow guiding or flow leading type automatic drainage waterproof system

ActiveCN103967226AReduce construction difficultyReduce manufacturing costRoof coveringCondensed water drain-offEngineeringWater level

The invention discloses a flow guiding type or flow leading type automatic drainage waterproof system. According to the flow guiding type or flow leading type automatic drainage waterproof system, the surface properties, including the hydrophilicity and the hydrophobicity, of objects are fully utilized, water flow on a vertical wall surface with low hydrophobicity or hydrophilicity or accumulated water in a drainage ditch can be separated through leading and guiding or discharged through leading, or of each joint or the portion around each joint of the vertical wall surface and the inner side of the outer side wall and the upper edge of the inner side of the outer side wall of the drainage ditch are processed into the surfaces with hydrophilicity, water flow is prevented from being leaked into the joints, when the water level is slightly higher than the side wall of the drainage ditch, water is prevented from overflowing out of the side wall of the drainage ditch, and therefore the drainage performance of the vertical wall surface and the drainage performance of the drainage ditch are improved. By the adoption of the flow guiding type or flow leading type automatic drainage waterproof system, the technical problems that an existing flashing technology has high requirements for a construction technology, weather and the quality of a sealing material, the waterproof period is short, and guiding of accumulated water in the middle of the drainage ditch cannot be achieved are solved, and all products can be made of standard sections or prefabricated parts.

Owner:怀化沃普环保科技有限公司

Automated compliance with security, audit and network configuration policies

InactiveUS20190342338A1Facilitate automated complianceExtension of timeProgram loading/initiatingTransmissionRemedial actionOperating system

Systems and methods are provided for facilitating automated compliance with security, audit and network configuration policies. In some instances, new runtime configuration files are iteratively generated and compared to a baseline configuration file to determine whether a threshold variance exists between the baseline configuration file and each separate and new runtime configuration file. If the threshold variance exists, remedial actions are triggered. In some instances, runtime configuration files are scanned for blacklist configuration settings. When blacklist configuration settings are found, remedial actions can also be triggered. In some instances, configuration files are scrubbed by omitting detected blacklist items from the configuration files. In some instances, changes are only made to configuration files when they match changes on an approved change list and are absent from an open incident list.

Owner:MICROSOFT TECH LICENSING LLC

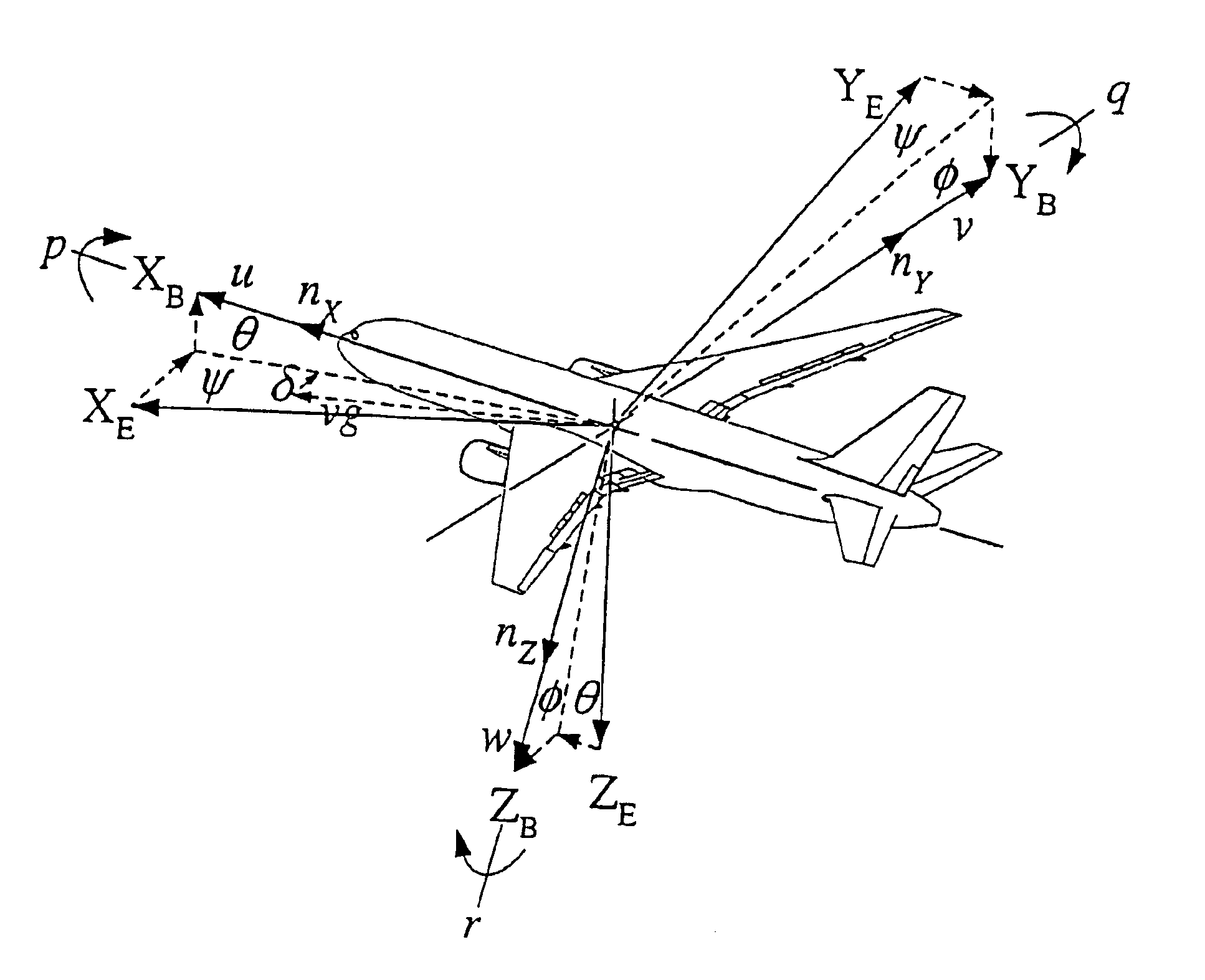

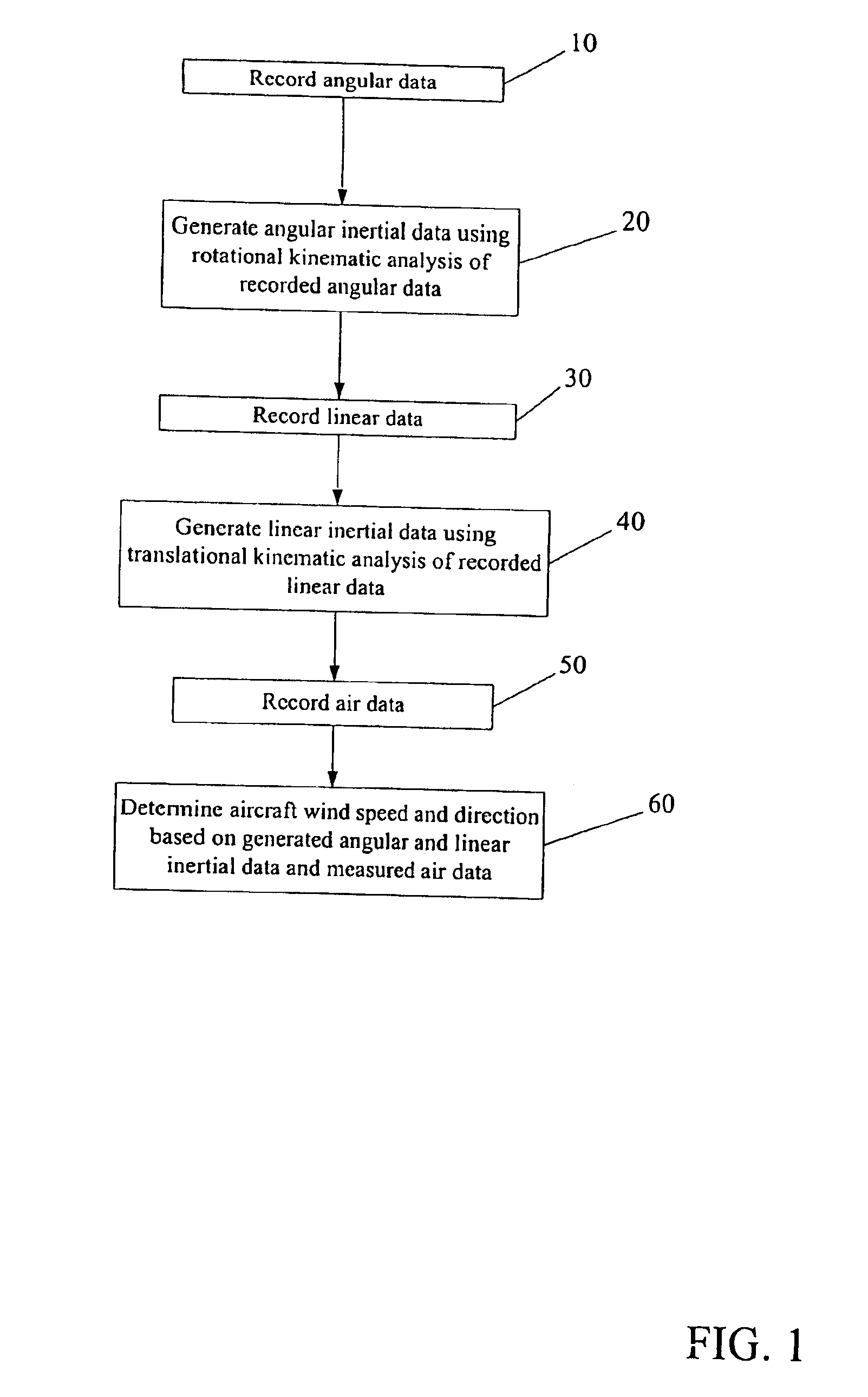

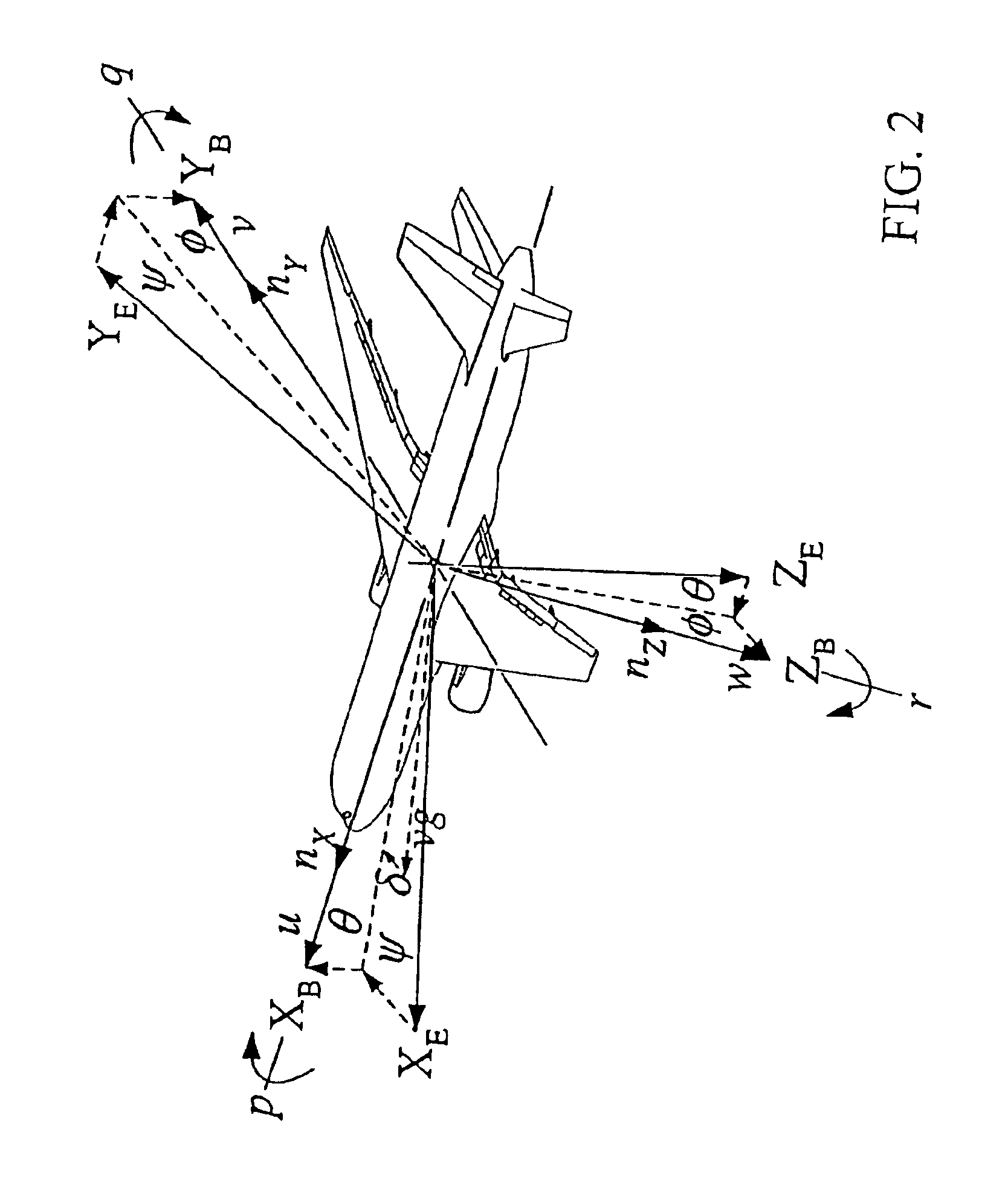

System and method for kinematic consistency processing

InactiveUS6922618B2Improve accuracy and reliabilityConfidenceDigital data processing detailsAutomatic initiationsOptimal controlEuler angles

A system, method, and computer program product for analyzing flight test and FDR data that overcomes technical difficulties associated with traditional flight data analysis methods. The method includes inputting angular, linear data and recorded air data, where angular data may include Euler angles or angular rates and linear data may include altitude, ground speed, airspeed, drift angle, runway excursion or load factors. The method generates first inertial data using optimal control to minimize the objective function associated with the angular data and second inertial data using optimal control to minimize the objective function associated with the linear data. The method determines wind speed and direction based on the first and second generated inertial data and the air data.

Owner:THE BOEING CO

Split drainage waterproof system

ActiveCN109577570AOvercome technical difficultiesReduce the difficulty of engineering constructionRoof covering insulationsBuilding insulationsArchitectural engineeringEnvironmentally friendly

The invention discloses a split drainage waterproof system which solves the technical problems of an existing waterproof engineering. The waterproof engineering is developed towards a plugging and draining combined mode from a past strict and completely closed waterproof mode, construction difficulty and production cost are greatly reduced, requirements for places, processes and weather are not high, waterproof deadline is long, harmful substances in the construction process are omitted, the waterproof system is environmentally friendly and meet requirements of environmental protection, and the waterproof system can be produced by existing material standard profiles or prefabricated parts and used for various engineering needing waterproof treatment.

Owner:怀化沃普环保科技有限公司

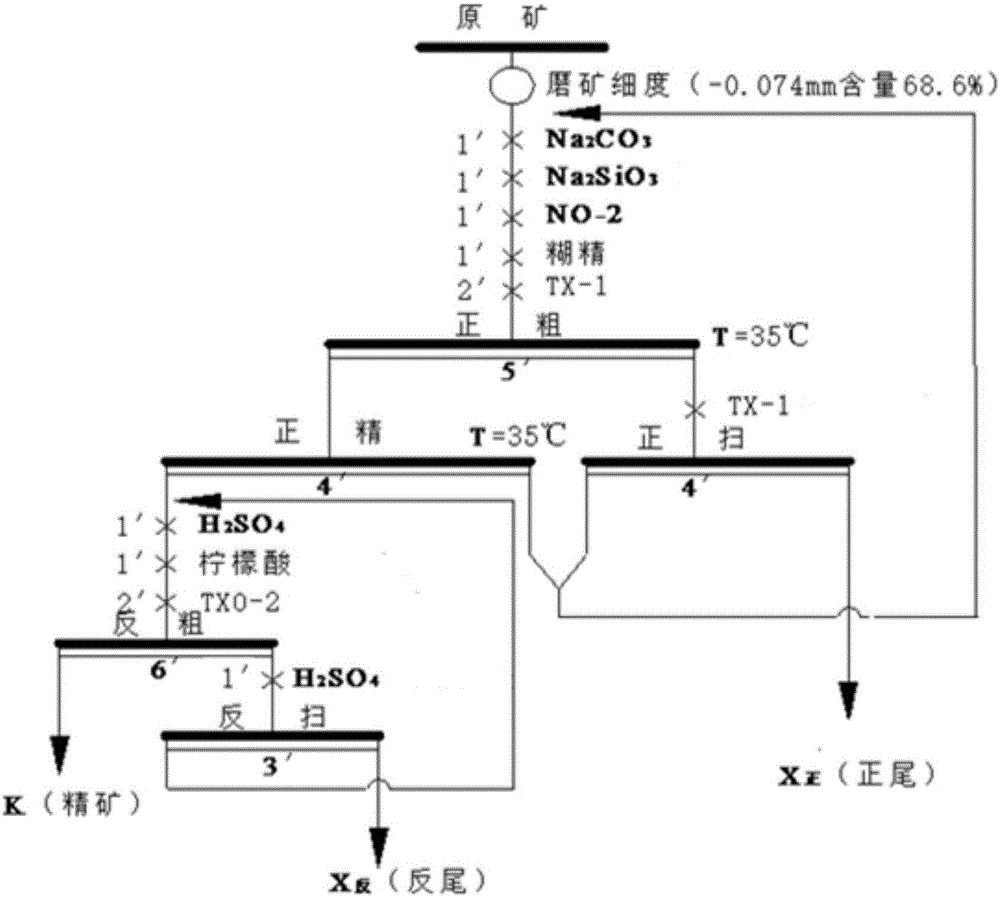

Demanganizing direct-reverse flotation process for manganese low-grade phosphate ores

The invention discloses a demanganizing direct-reverse flotation process for manganese low-grade phosphate ores. The demanganizing direct-reverse flotation process is characterized in that after manganese and magnesium low-grade phosphate ores are subjected to ore crushing and ore grinding, manganese minerals, phosphate minerals and other minerals are subjected to monomer separation, then sodium carbonate, a direct flotation inhibitor and a direct flotation collector are added, stirring is performed for size mixing, the obtained ore slurry enters the direct flotation technological process for flotation, and the obtained in-tank product is direct flotation tailings; and the obtained foam product is conveyed to the reverse flotation process, the pH is adjusted, a reverse flotation inhibitor (citric acid) and a reverse flotation demanganizing anionic collector are added, stirring is performed for size mixing, the ore slurry obtained after size mixing enters the reverse flotation technological process for further reverse flotation, the obtained foam product is reverse flotation tailings, the final in-tank product is phosphate concentrate with low contents of MnO2, MgO and SiO2, and concentration, filtering and drying are performed to obtain the end phosphate concentrate. The demanganizing direct-reverse flotation process can successfully realize mineral processing enrichment of manganese low-grade phosphate ores and improves the utilization ratio of phosphorus resources.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +2

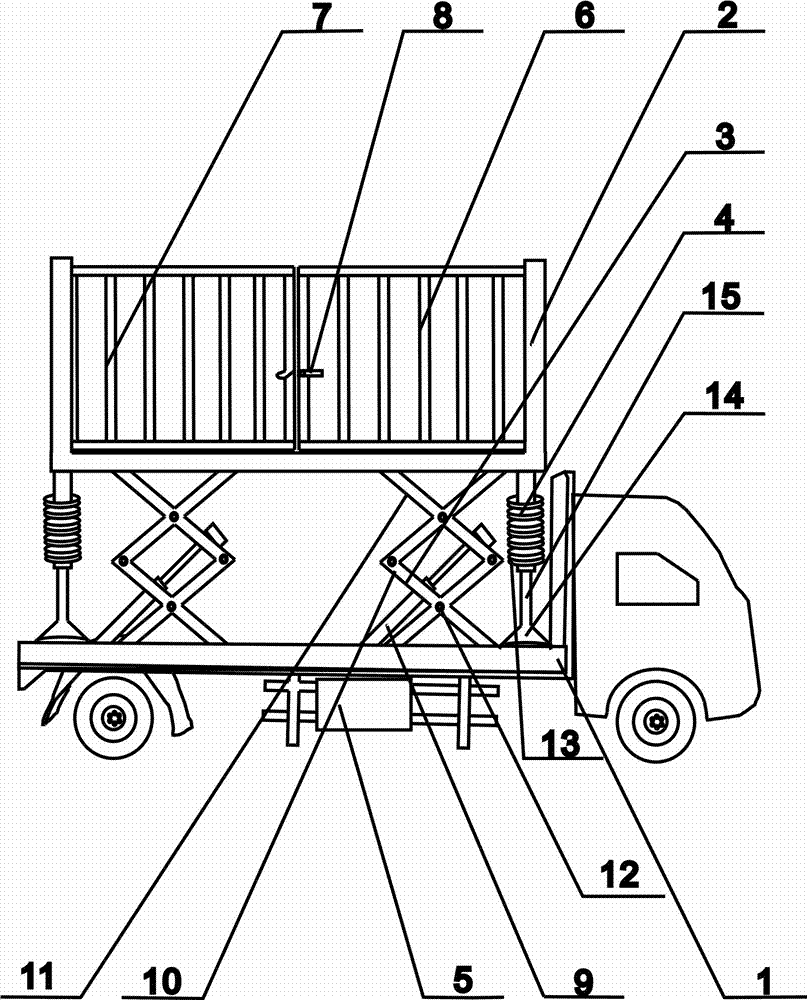

Live pig loading vehicle

PendingCN106891797AOvercome environmental problemsOvercome technical difficultiesAnimal transportationVehicle with parallel load movementMulti linkAutomotive engineering

The invention discloses a hog loading vehicle, which comprises a vehicle body, a lifting platform, a lifting device, and a shock-absorbing support device; A shock-absorbing support device for lifting, and four sets of lifting devices for lifting are fixedly arranged at the four corners of the box plate of the car body, and the lifting device and the shock-absorbing support device are fixed on the box plate of the car body superior. This kind of hog loading vehicle can solve the problem of complex and inefficient transshipment of hogs, and consumes too much energy of hogs in the process of multi-link back and forth transshipment, which affects the reduction of the total weight of hogs, and greatly improves the efficiency of hog transshipment Efficiency and improved breeding benefits.

Owner:河南省春天农牧科技有限公司

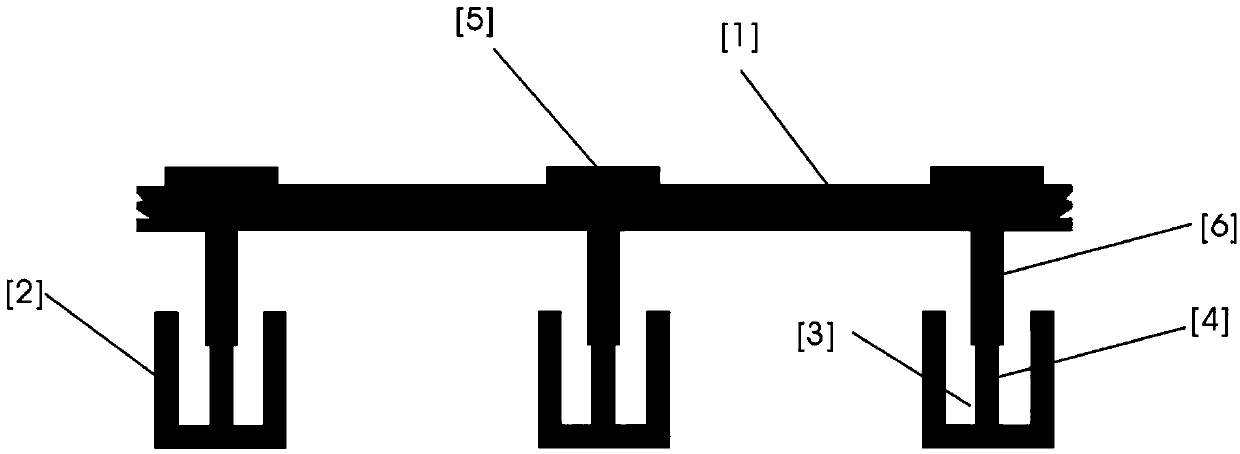

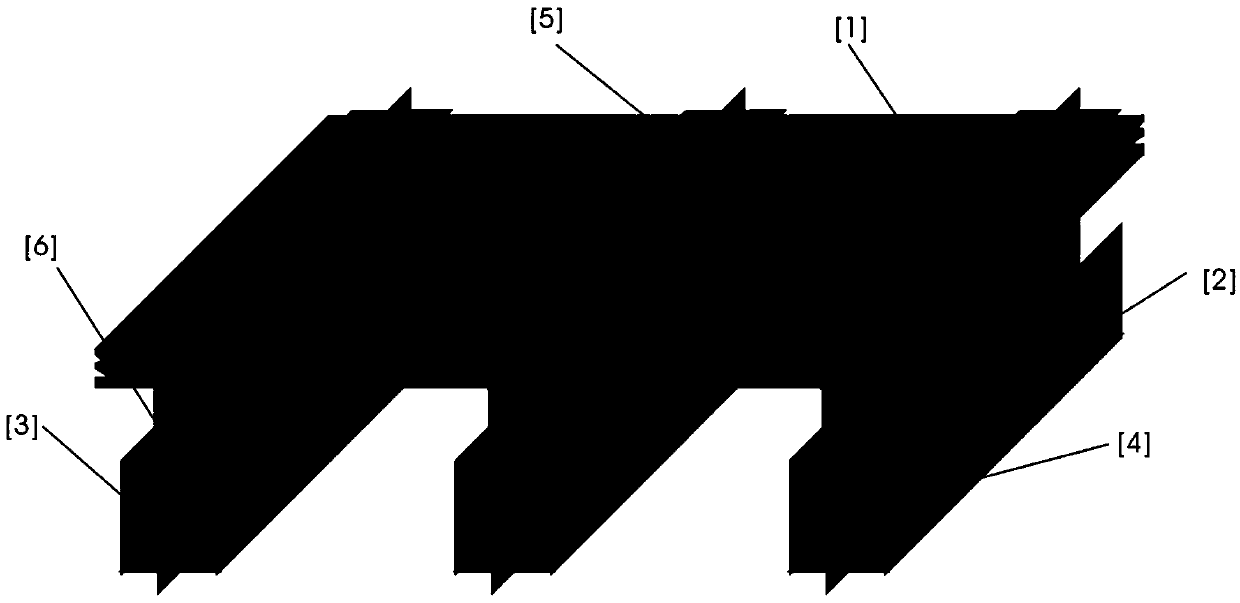

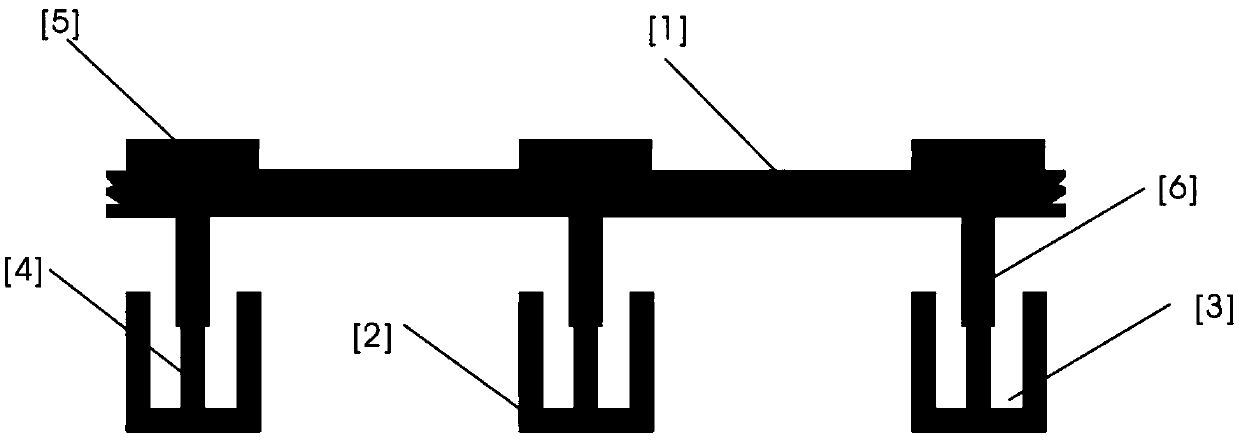

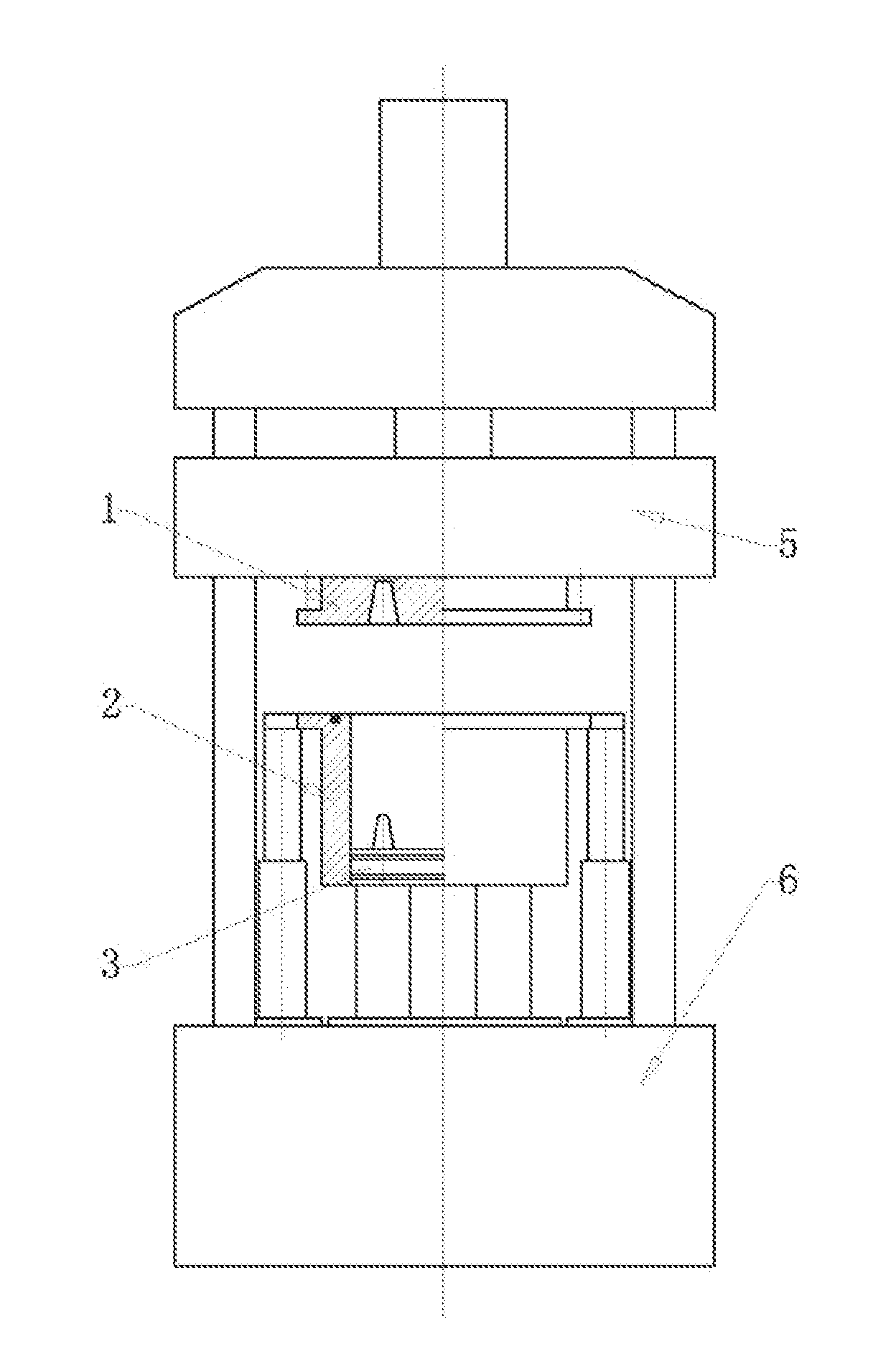

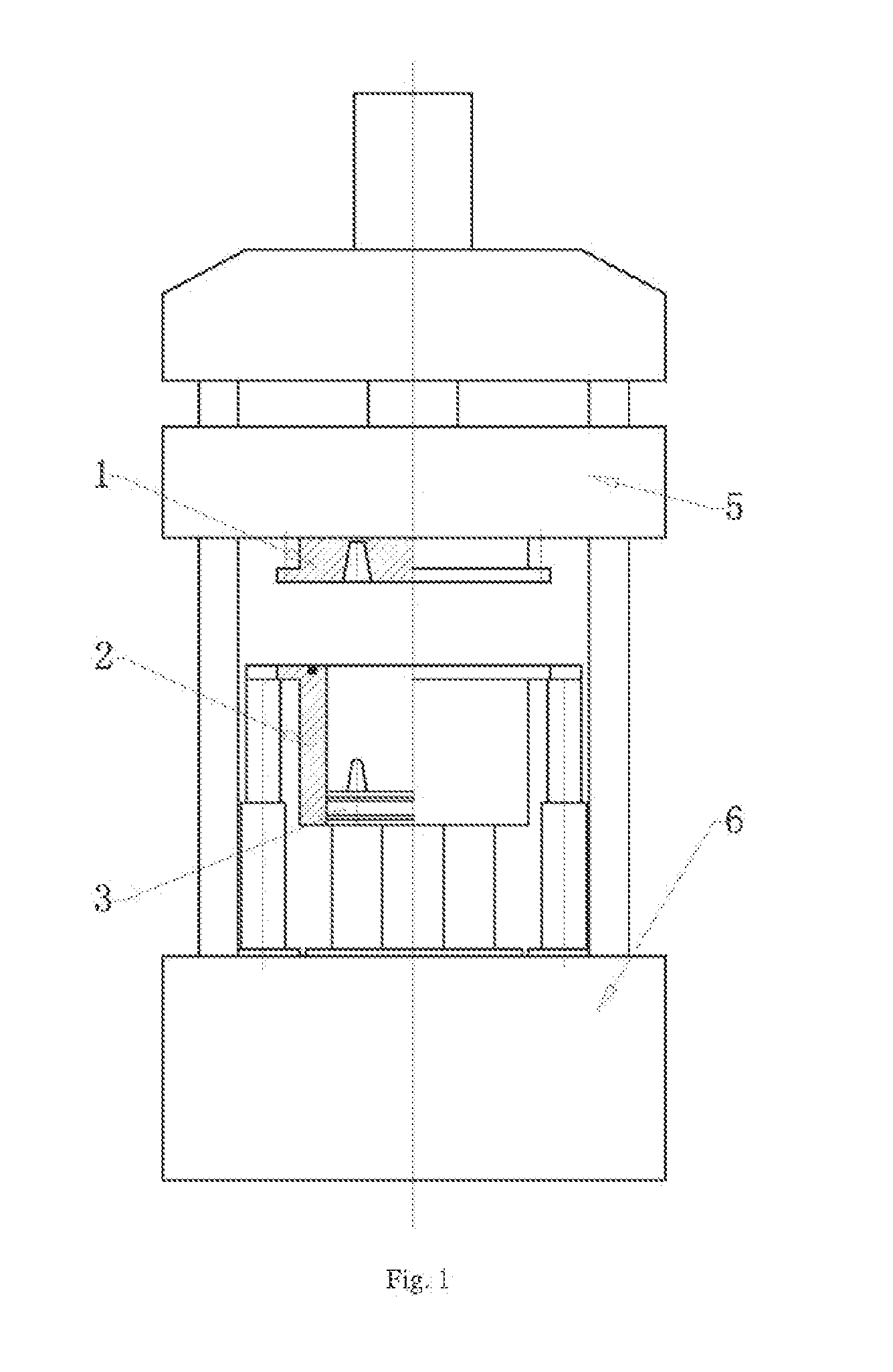

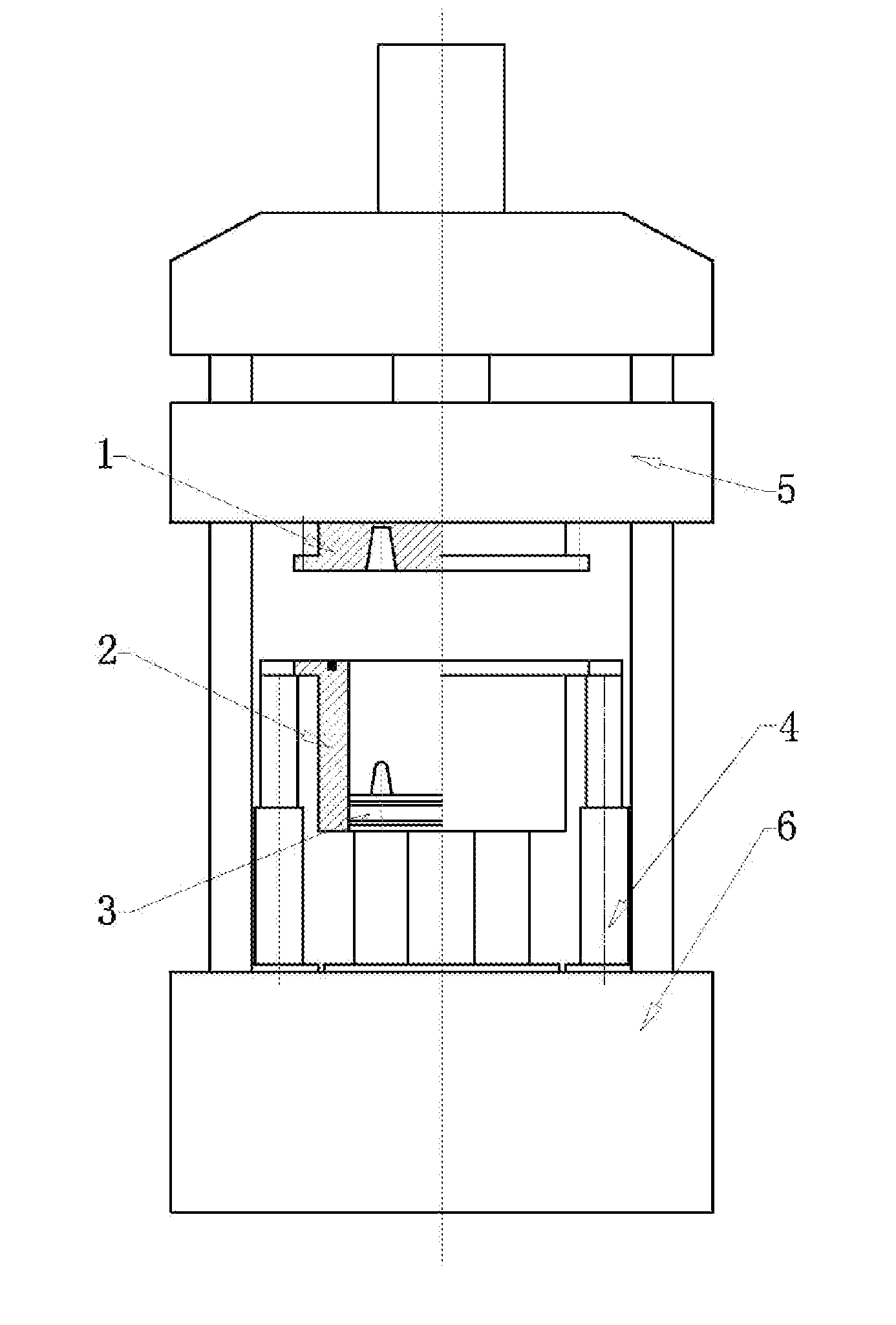

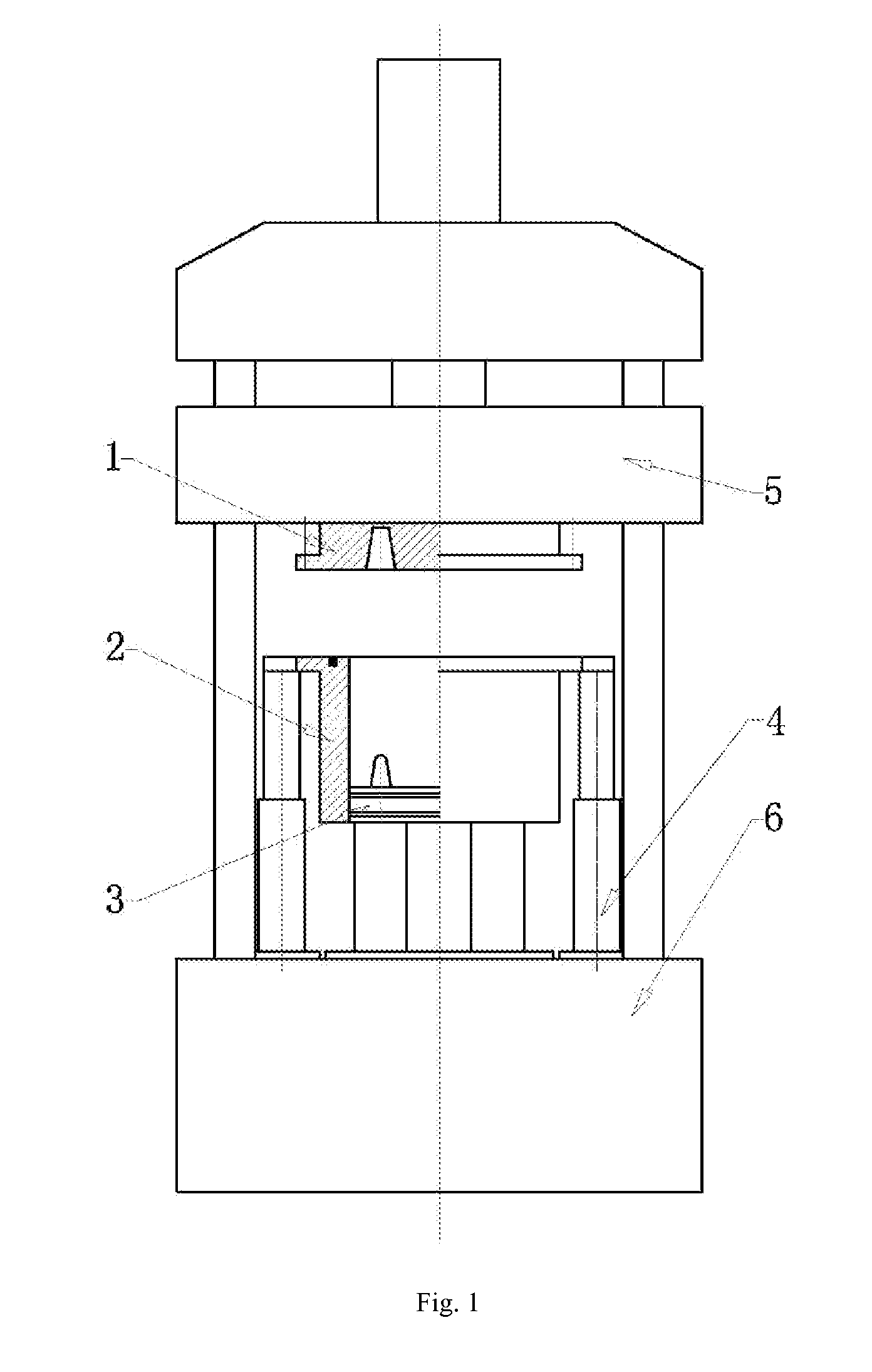

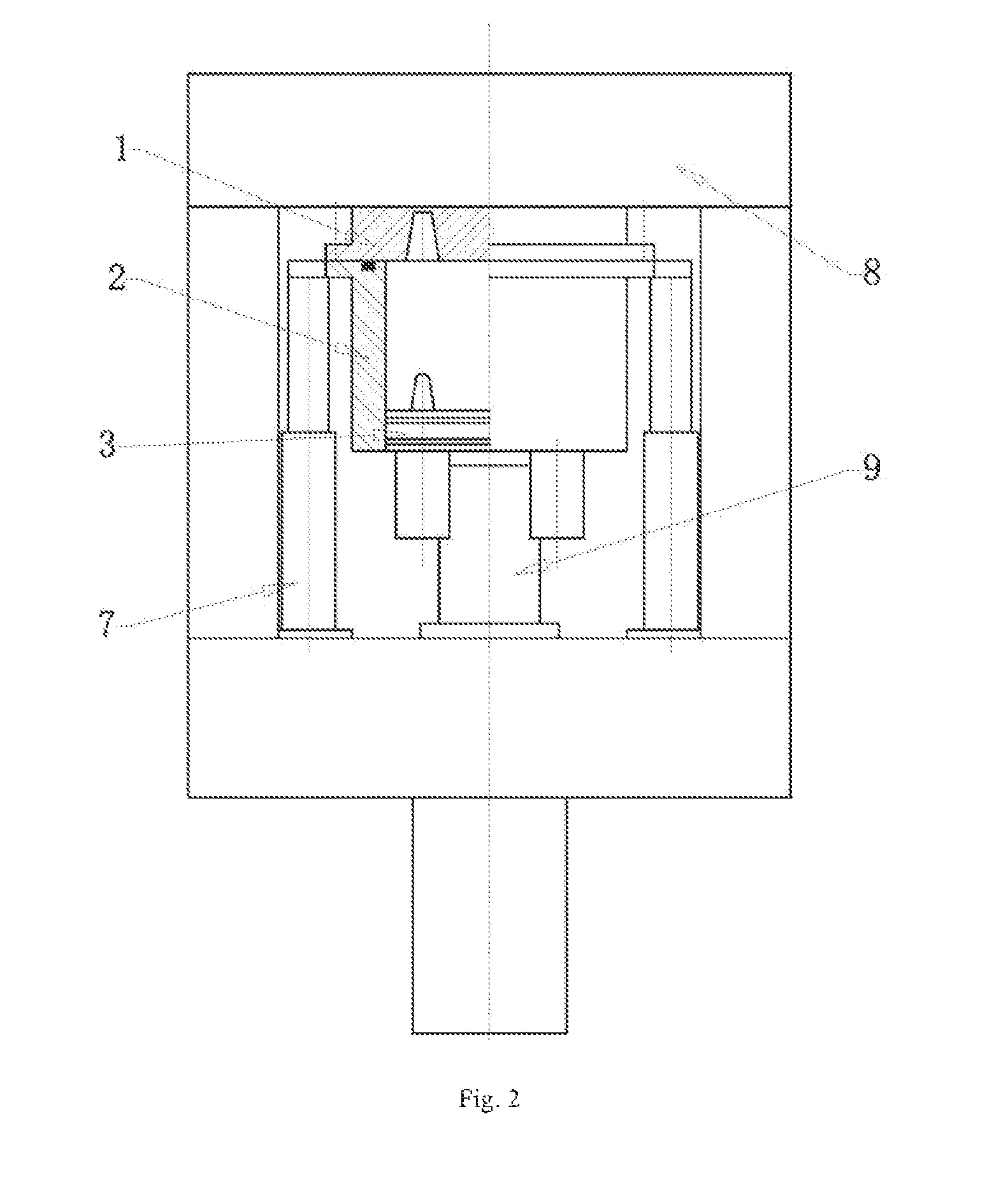

Pulp moulded plate and preparation apparatus thereof

Owner:LANG QI

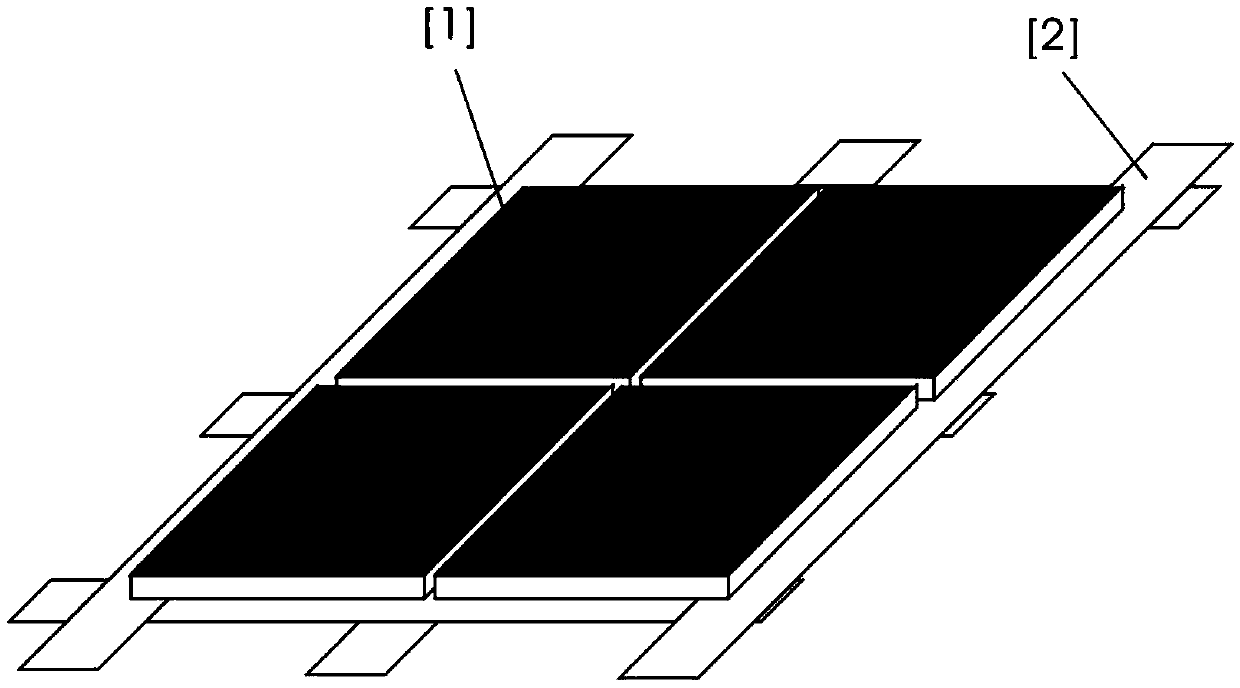

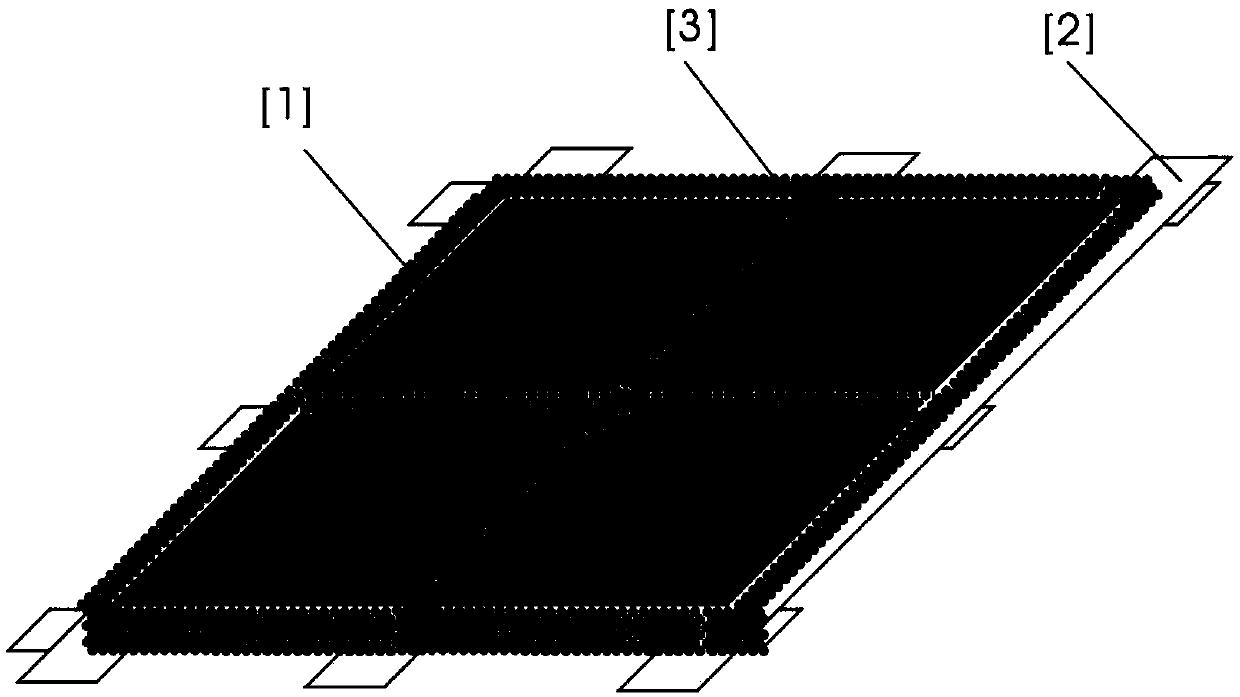

Membrane based on graphene and method of manufacturing same

ActiveUS10124299B2Increase physical strengthIncrease the number ofMembranesSeawater treatmentMonolayer grapheneCvd graphene

Disclosed herein are a graphene-based membrane and a method of manufacturing the same. The graphene-based membrane includes: monolayer graphene containing defects; a deposition layer disposed on the defects; and nanopores surrounded by the deposition layer. The method of manufacturing a graphene-based membrane includes forming a monolayer graphene sheet and partially forming a deposition layer on the graphene sheet.

Owner:GWANGJU INST OF SCI & TECH

Pulp moulded plate and preparation apparatus thereof

InactiveUS8795474B2Low costIncrease production capacityCalendersCeramic shaping apparatusEngineeringMachine press

Owner:LANG QI

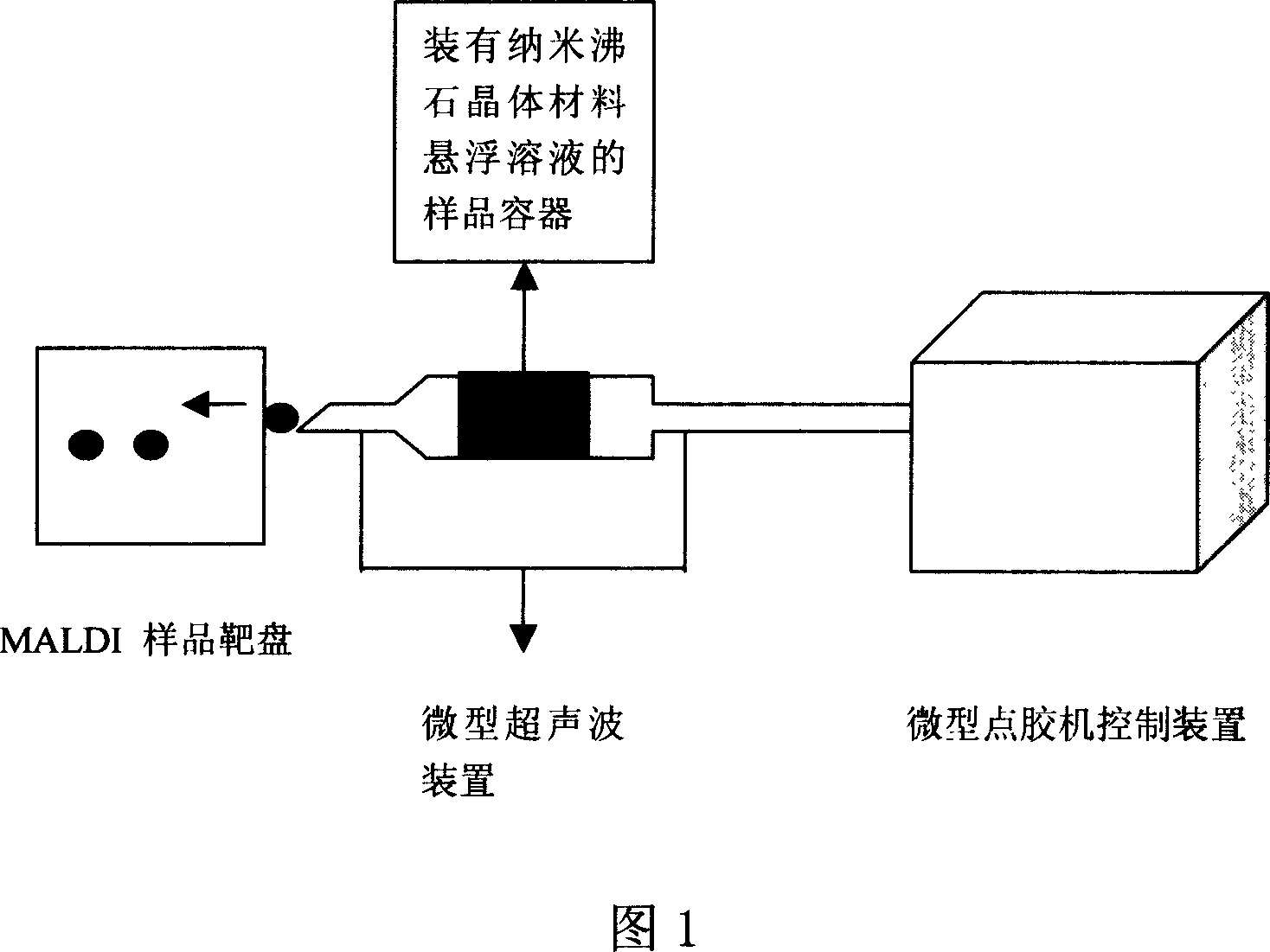

Method for preparing functional target disk of mass spectrum sample de-absorbed by ground substance assistant laser

InactiveCN101004408AOvercome technical difficultiesCompletely innovativeIon-exchange process apparatusComponent separationCooking & bakingEthyl acetate

A method for preparing mass spectrum sample function target plate of base material auxiliary laser deabsorption includes fixing nanozeolite molecular sieve doped with heteroatom in bodyframe structure, dipping mass spectrum stainless steel sample target plate of base material auxiliary laser deasorption in titanate coupler, placing dipped target plate in anhydrous ethyl acetate to let heteroatom nanozeolite crystal material suspension liquid be sufficiently dispersed then adding said liquid in sample-set hole of said sample target plate and baking said sample target plate.

Owner:SHANGHAI JIAO TONG UNIV

Chinese herbal medicine compound preparation for treating pullorum disease

ActiveCN104324120AImprove \"blackImprove big and rough”Antibacterial agentsPowder deliveryMedicinal herbsWolfiporia extensa

The invention provides a Chinese herbal medicine compound preparation for treating pullorum disease with an obvious effect. The preparation is prepared from the following raw materials in parts by weight: 15-25 parts of astragalus, 35-45 parts of scutellaria baicalensis, 25-35 parts of golden cypress, 25-35 parts of the root of Chinese pulsatilla, 25-35 parts of fructus forsythiae, 15-25 parts of cape jasmine, 25-35 parts of radix paeoniae alba, 15-25 parts of pericarpium citri reticulatae, 55-65 parts of rhizome atractylodis, 10-20 parts of smoked pulm, 15-25 parts of herba portulacae, 25-35 parts of folium isatidis, 5-15 parts of radix sophorae flacescentis, 15-25 parts of the bark of ash, 25-35 parts of wolfiporia extensa. The preparation is prepared by carrying out superfine grinding on the raw medicinal materials until the particle size is 30-90 microns, weighing in a mixture ratio and uniformly mixing. The Chinese herbal medicine compound preparation provided by the invention has the efficacies of removing heat for detoxication and eliminating dampness for preventing dysentery, and mainly acts on endoretention of damp heat and pullorum disease; a micronization technology is adopted, so that medicine waste is reduced, energy is saved, and environment is protected; and dosage is reduced, and treatment cost is reduced.

Owner:山西省医药与生命科学研究院

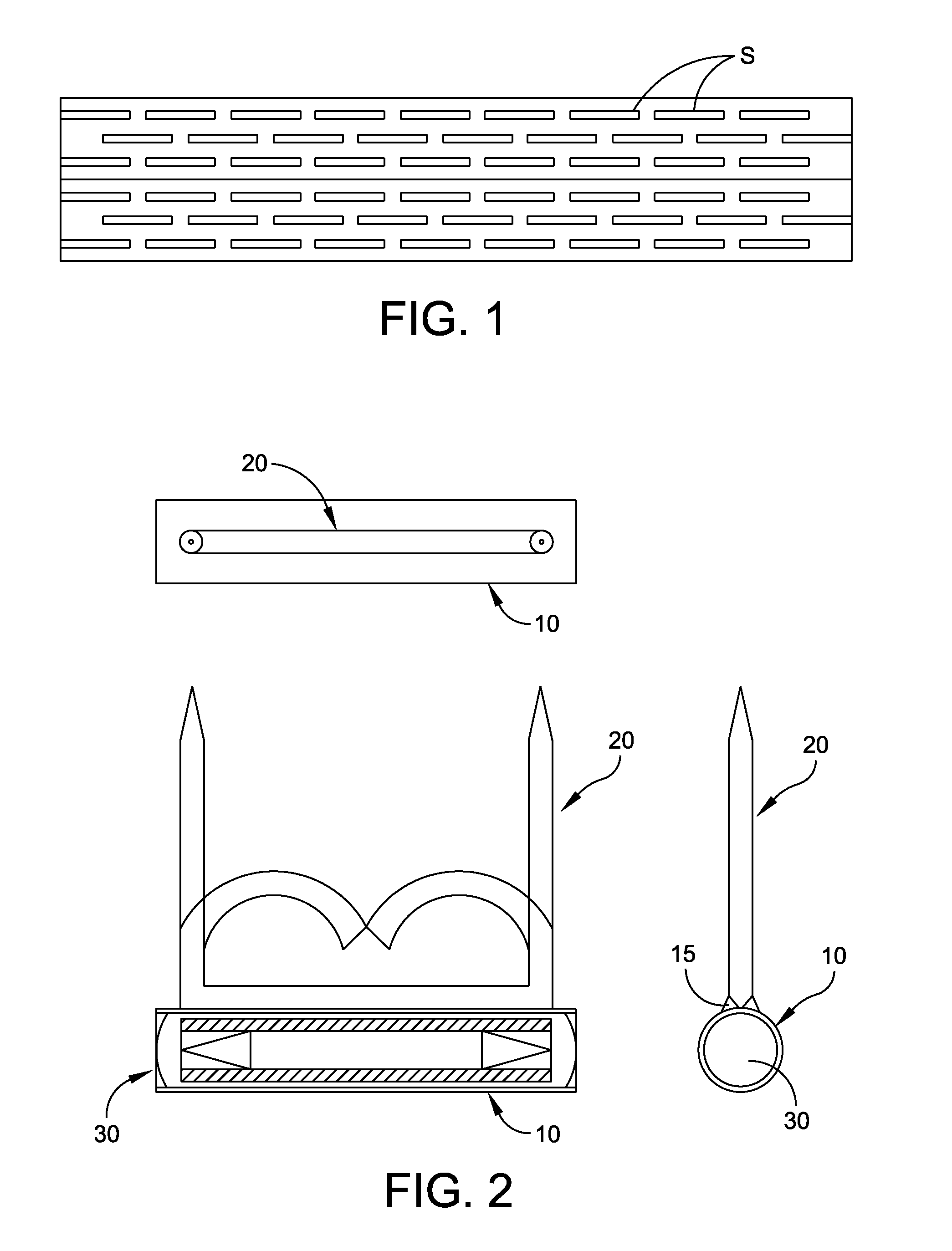

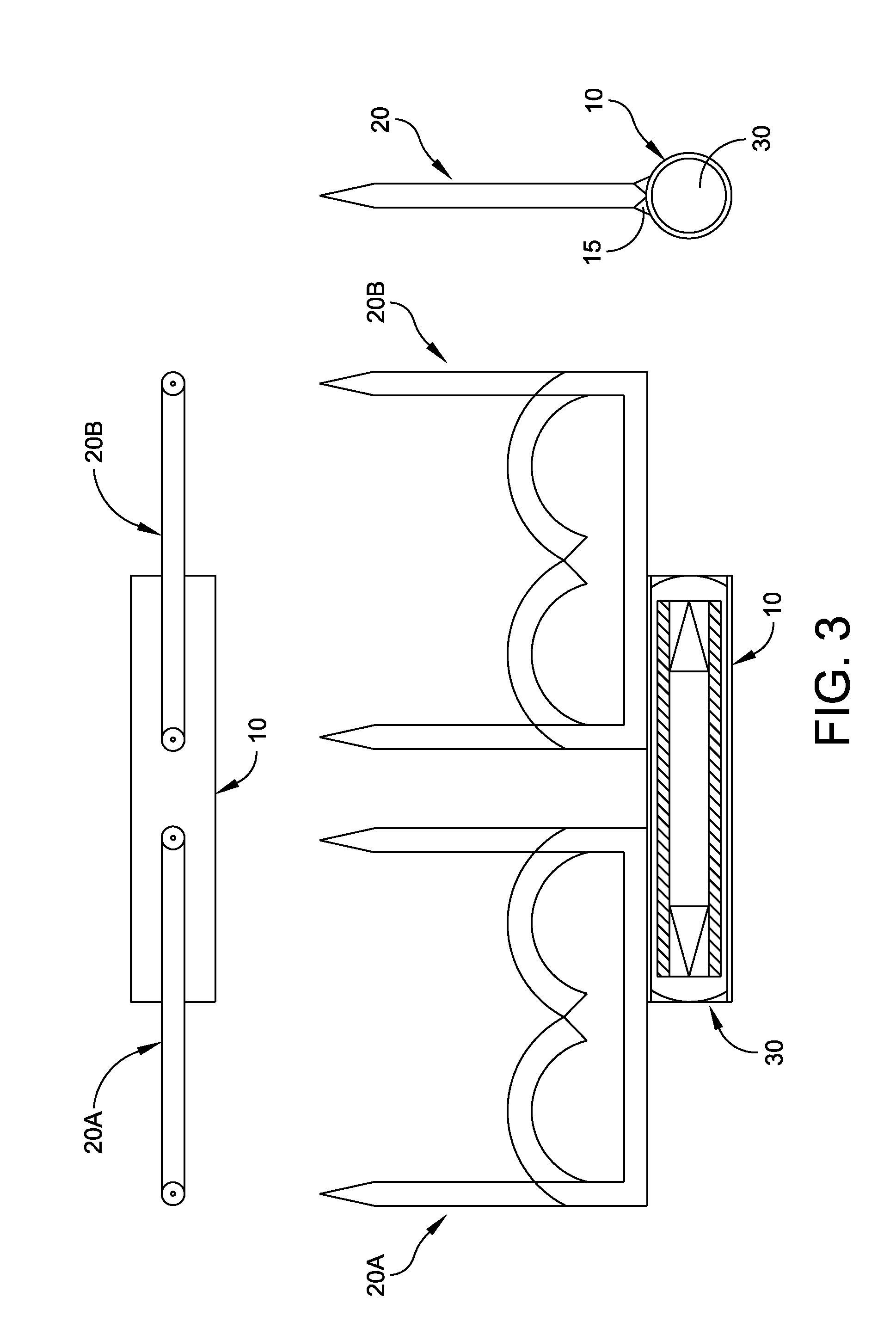

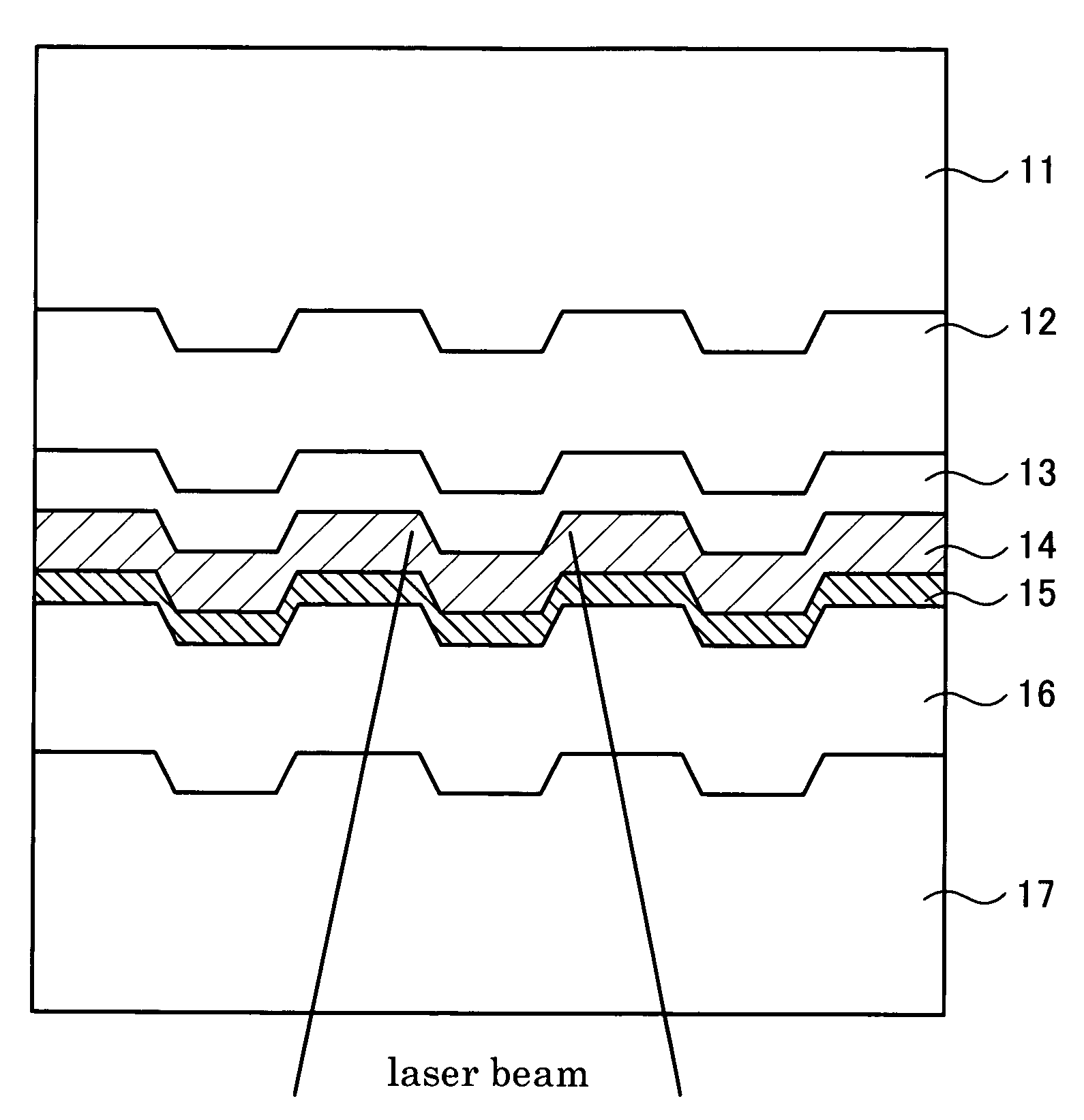

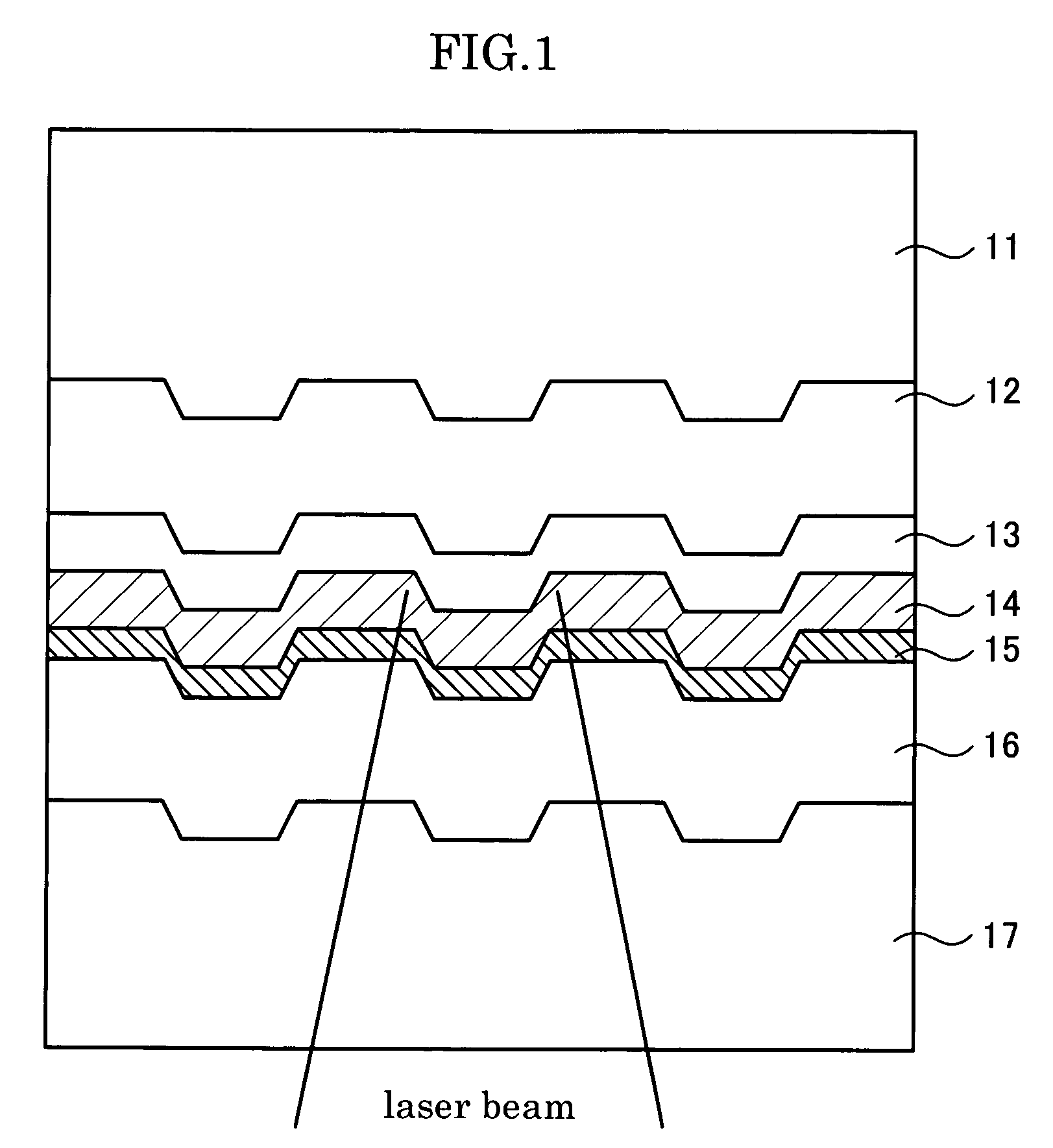

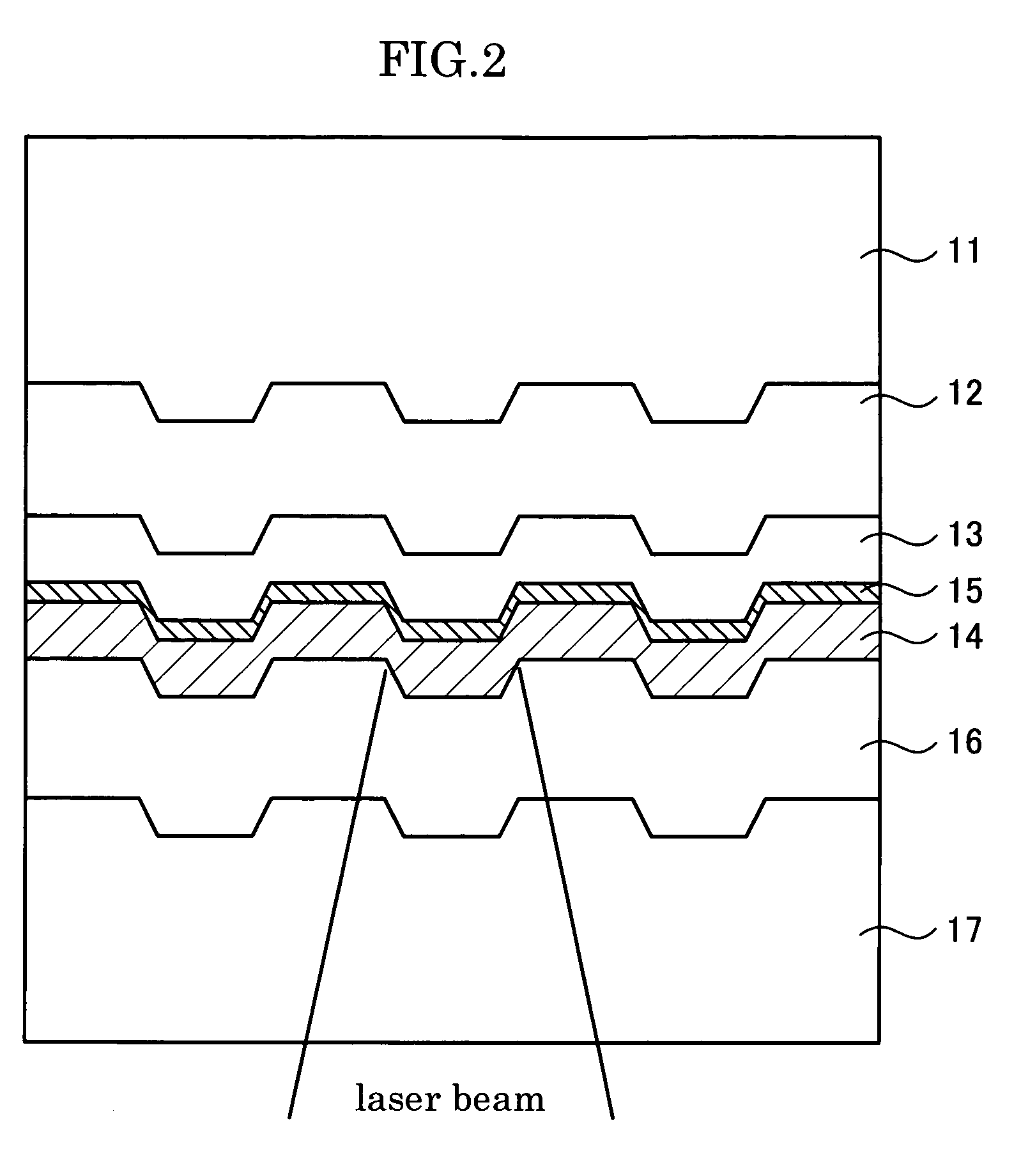

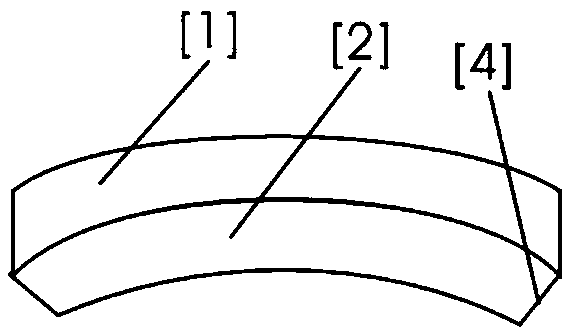

Optical information recording medium and method of recording and reproducing information on and from optical information recording medium

InactiveUS7033659B2Improve transfer rateOvercome technical difficultiesLayered productsPhotomechanical apparatusRecording layerProtection layer

A write-once optical information recording medium is provided that is capable of realizing a high transfer rate and a method of recording and reproducing information on and from the optical information recording medium. The optical information recording medium is constructed by stacking a reflective layer 12, a first dielectric layer 13, a recording layer 14, a write-protect layer 15, a second dielectric layer 16 and a transparent cover layer 17 on a polycarbonate substrate 11. The recording layer 14 is made of a phase-change material, and the cover layer 17 is made of UV curing resin. The recording layer 14 is irradiated with a laser beam with a wavelength of 500 nm or less to change from a crystalline phase to an amorphous phase. The write-protect layer 15 prevents the recording layer 14 from changing back to the crystalline phase from the amorphous phase, formed by the phase change.

Owner:HITACHT MAXELL LTD

Method for manufacturing encapsulated superhard material

ActiveUS20120009345A1Cost efficientOvercome technical difficultiesLiquid surface applicatorsCoatingsSuperhard materialFluidized bed

The invention relates to a process for the formation of pellets containing an ultra hard (superhard) core coated with an encapsulating material, the process including the process including the steps of utilising a shovel rotor in combination with a rotating pan and / or a fluidised bed apparatus in sequence.The invention teaches the steps of providing a source of superhard material, providing a mixture comprising an appropriate binder, a solvent or fluid medium and the intended coating or encapsulating layer, combining the superhard material and the mixture in a shovel rotor, rotating the rotor at an appropriate velocity such that the superhard material is encapsulated by the mixture to form pellets, introducing the pellets into a rotating vessel or fluidised bed granulating apparatus, and contacting the pellets with encapsulating material to form pellets of greater mass than the pellets introduced into the vessel.

Owner:ELEMENT SIX LTD

Drainage type waterproof system

ActiveCN109577495AOvercome technical difficultiesReduce the difficulty of engineering constructionRoof drainageRoof covering insulationsPondingWater flow

The invention discloses a drainage type waterproof system, which fully utilizes the surface performance of hydrophilicity and hydrophobicity of substances to drain, guide and separate water flow on avertical wall surface or accumulated water in a drainage ditch which has weak hydrophobicity and hydrophilicity with hydrophilic substances, or process each interface or the vicinity of each interfaceof the vertical wall surface and the inner side of the outer side wall or the upper edge of the inner side of the outer side wall of the drainage ditch into a hydrophobic surface, so as to prevent water flow from leaking into the interface or prevent the water surface slightly higher than the side wall of the drainage ditch from overflowing from the side wall of the drainage ditch, so that the drainage performance of the vertical wall surface and the drainage ditch is improved, the technical problems of the existing flooding technology, such as high quality requirements for construction technology, meteorology and sealing materials, short waterproof life and drainage of accumulated water in the middle of the drainage ditch are successfully solved, and all products can be produced with standardized profiles or prefabricated components.

Owner:怀化沃普环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com