Split plugging waterproof system

A split-type, waterproof board technology, which is applied to roof insulation materials, roofing, building components, etc., can solve the problems of difficult construction and the short waterproof life of the overall waterproof technology, so as to achieve a long waterproof period, reduce construction difficulty, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

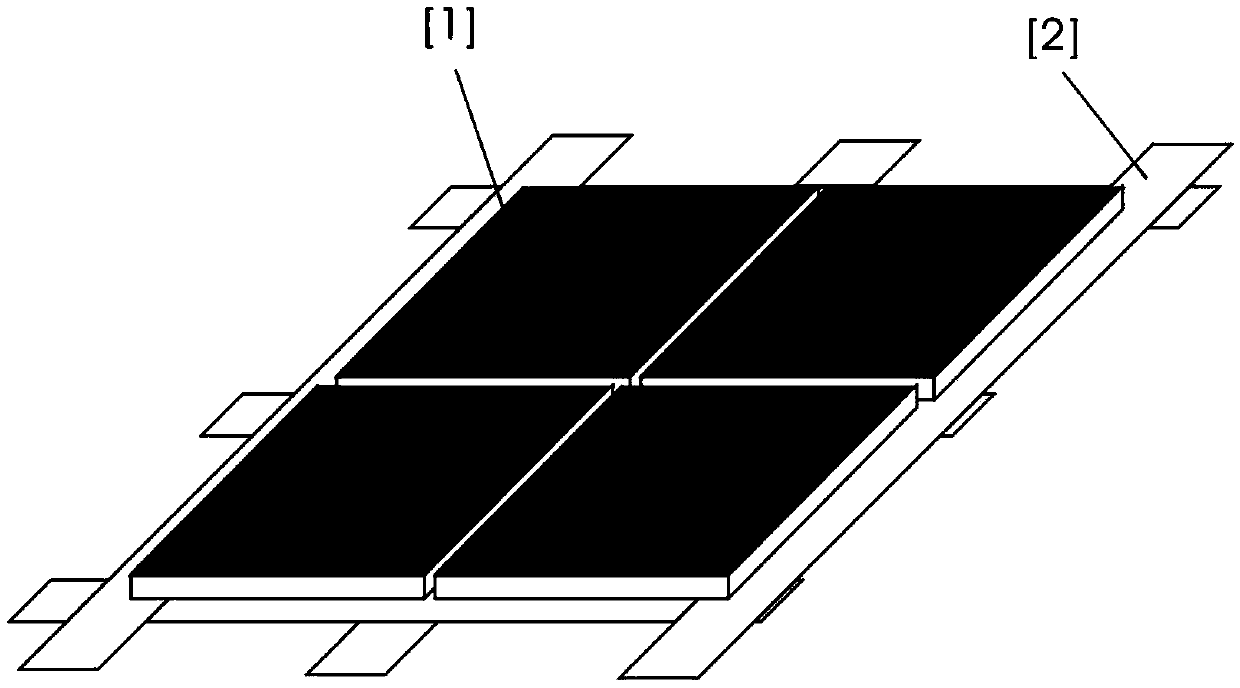

[0027] Example 1: Combining figure 1 , which is to process the back water surface of the waterproof board 1 with good waterproof performance to be sealed and waterproof to a hydrophobic surface, and spread the sealed waterproof sheet 2 with a hydrophobic surface on the load-bearing wall or load-bearing wall. On the board, the placement of the sealing waterproof sheet 2 should ensure that it can fully overlap or overlap with each hydrophobic sealing and waterproof surface of the back water surface of the waterproof board 1, so that the hydrophobic back water surface of the waterproof board 1 Press on the hydrophobic surface of the sealing waterproof sheet 2, and make the sealing waterproof sheet 2 and the hydrophobic sealing waterproof surface of the back surface of the waterproof plate 1 tightly fit together, preventing the water from flowing between the sealing waterproof sheet 2 and the waterproof surface. The hydrophobicity of the back surface of the board 1 blocks the infi...

Embodiment 2

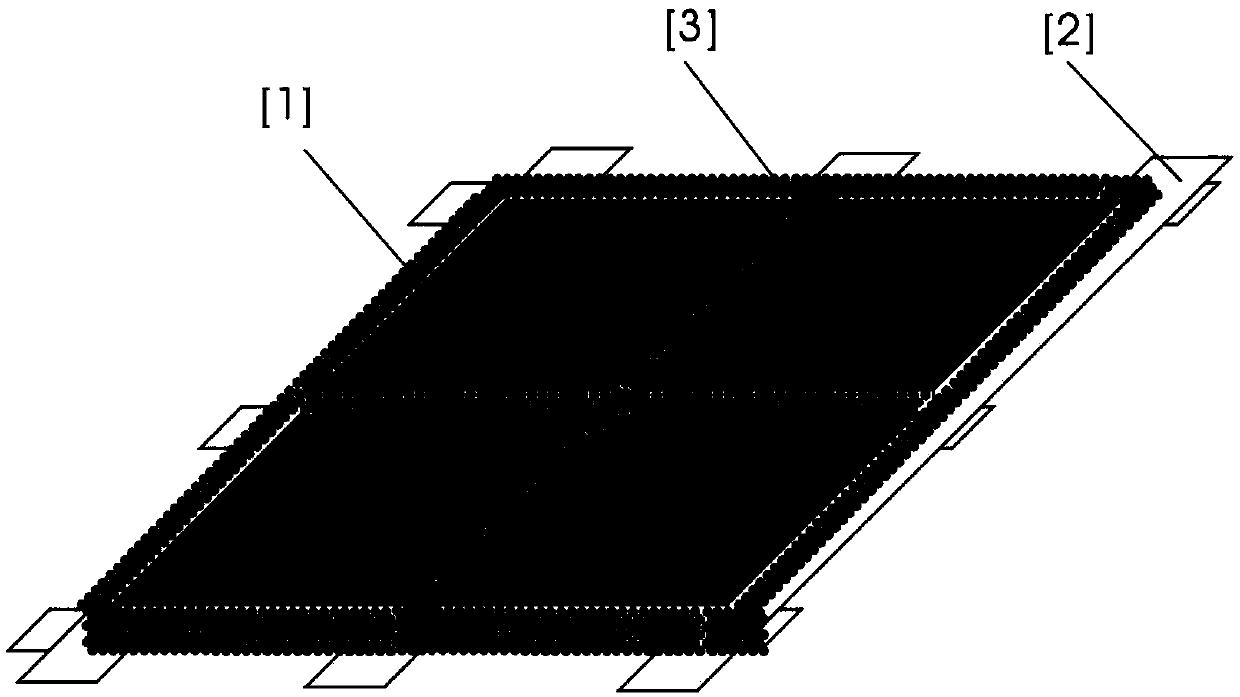

[0032] Example 2: Combining figure 2 , it is on the basis of embodiment 1, each waterproof board 1 needs to be sealed and processed into a hydrophobic surface on the side of the waterproof side, and before the upper surface of the waterproof board 1 is sealed with concrete or other suitable sealing materials, each waterproof The hydrophobic side of the board 1 that needs to be sealed and waterproof is fully densely filled with hydrophobic material 3, or the hydrophobic side that can be closely fitted is directly bonded together to further prevent water leakage.

[0033] In this embodiment, when the hydrophobic surface on the side of the waterproof board 1 can well complete the waterproof task, the hydrophobic waterproof construction work on the back surface can be omitted.

[0034] In this embodiment, the hydrophobic material 3 can be a flexible material with a hydrophobic surface, uniform texture and easy deformation under force, such as fine sand, dust, fiber products, hydr...

Embodiment 3

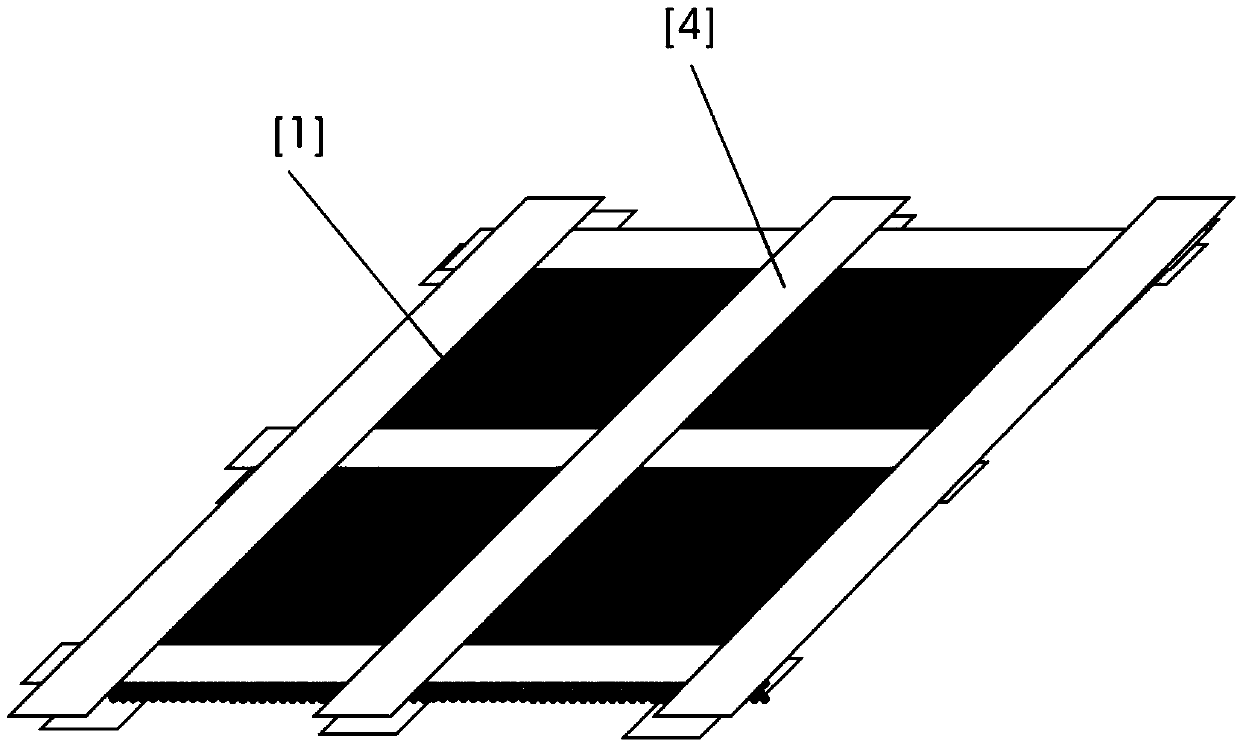

[0035] Example 3: Binding image 3 , it is on the basis of embodiment 2, in order to prevent the hydrophobic material 3 filled between the side interfaces of the two waterproof boards 1 from overflowing upwards in the future, a thin sheet 4 can be covered or pasted on the side interface of the two waterproof boards 1, and the thin sheet 4. It is suitable for flexibility, good waterproof and anti-aging performance, and good mechanical properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com