Pressure release type backflow preventer

A technology of backflow preventer and pressure relief, which is applied in the direction of valve details, control valves, function valve types, etc., can solve the problems of ineffective prevention of pressure water backflow pollution, unsuccinct valve core structure, and difficult diaphragm processing, etc., to achieve The design calculation is convenient, the processing difficulty is overcome, and the processing is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

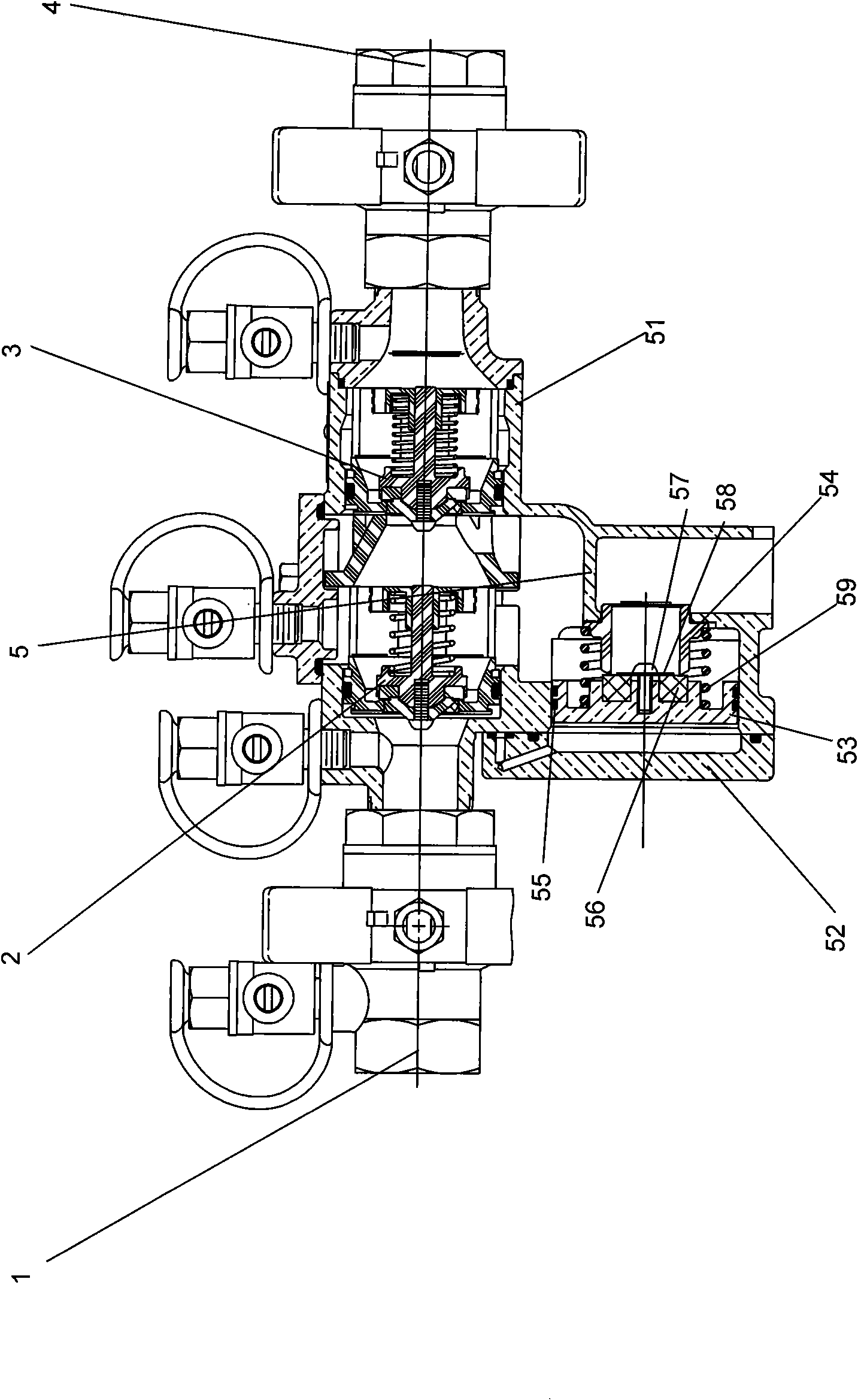

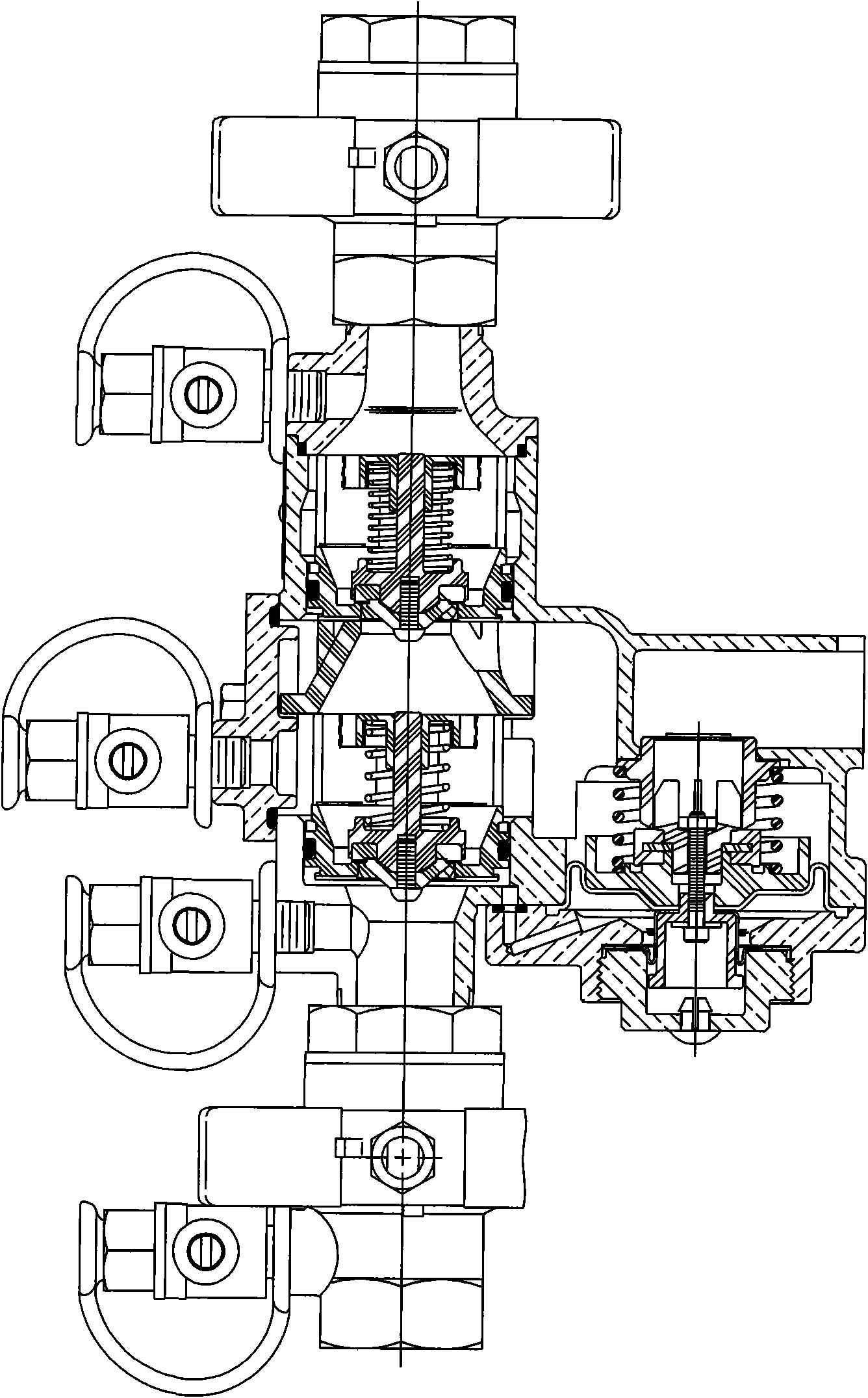

[0013] like figure 1 As shown, a pressure relief type backflow preventer, which includes a water inlet ball valve 1, a primary check valve 2, a secondary check valve 3, a water outlet ball valve 4, and a bypassed water relief valve 5 are installed in sequence. Between the primary check valve 2 and the secondary check valve 3, the drain relief valve 5 is divided into a valve cover 52 of the drain relief valve and a valve body 51 of the drain relief valve, a piston body that can move left and right 53 is arranged in the inner cavity of the water relief valve to divide it into a left chamber and a right chamber. The piston body 53 can be made of anti-corrosion plastic. The water inlet is connected, and the right chamber communicates the water inlet and the water outlet of the water relief valve through the annular seat 54. There are two annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com