Split drainage waterproof system

A technology of split type and draining parts, which is applied in the direction of roof insulation materials, roofing, building components, etc., can solve the problems of difficult construction, waterproof technology and not long waterproof period, and achieve long waterproof period, reduce construction difficulty and reduce production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] It makes full use of the principle that water flow can absorb, infiltrate and flow well in hydrophilic substances or on the surface, but it is difficult to absorb, infiltrate and flow in hydrophobic substances or on the surface. The waterproof parts with hydrophobic surface are elevated and spliced together tightly. Install hydrophilic drainage parts between the drainage interfaces of waterproof parts, and process or install drainage ditch below the hydrophilic drainage parts lower than the back water surface of waterproof parts. , the seepage water flow from the hydrophilic drainage member is discharged into the drainage system by the drainage ditch.

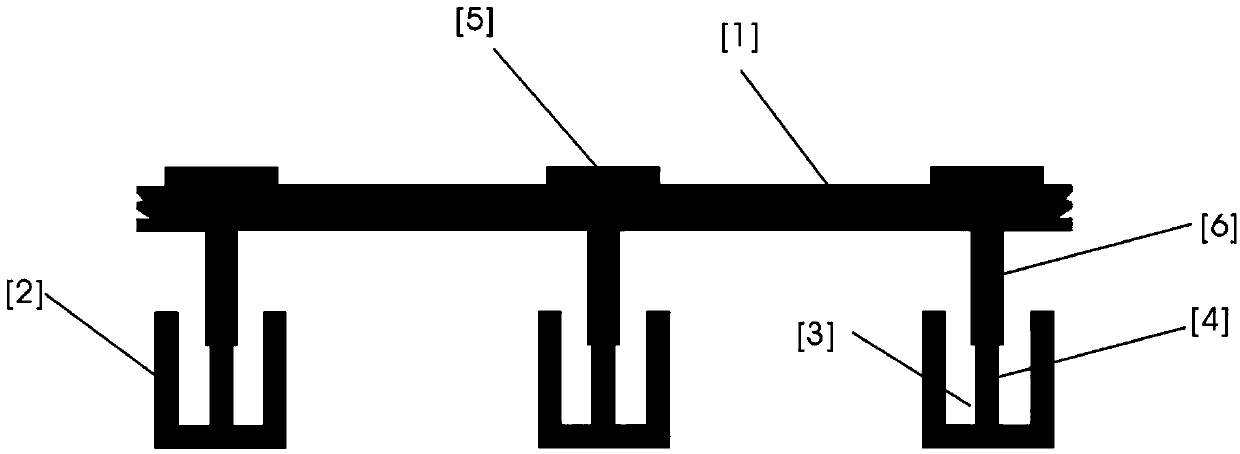

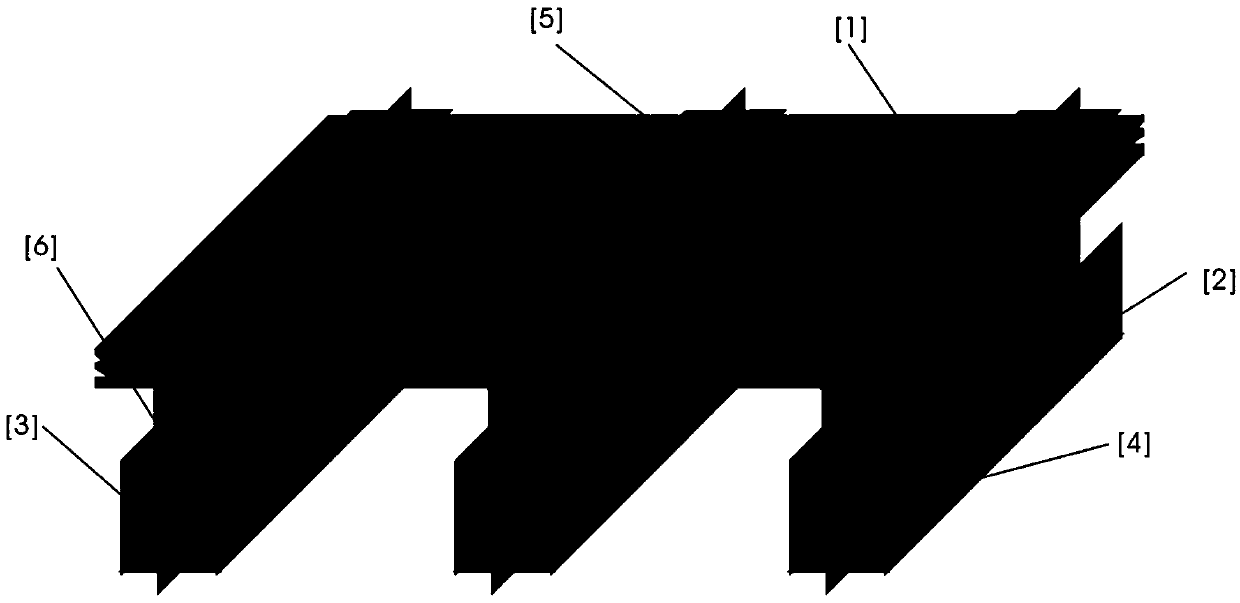

[0036] Specifically, combine figure 1 , figure 2 , Figure 4 , which is to process the backside surface of the waterproof board 1 with good waterproof performance into a hydrophobic surface, use pillars or walls to elevate it and splice it together, and the hydrophilic drainage member 2 with the flat plate 5 and the...

Embodiment 2

[0052] On the basis of Example 1, the hydrophilic surface 6 in Example 1 is replaced by the hydrophilic flow guide 2 in this example, and the structure is as follows:

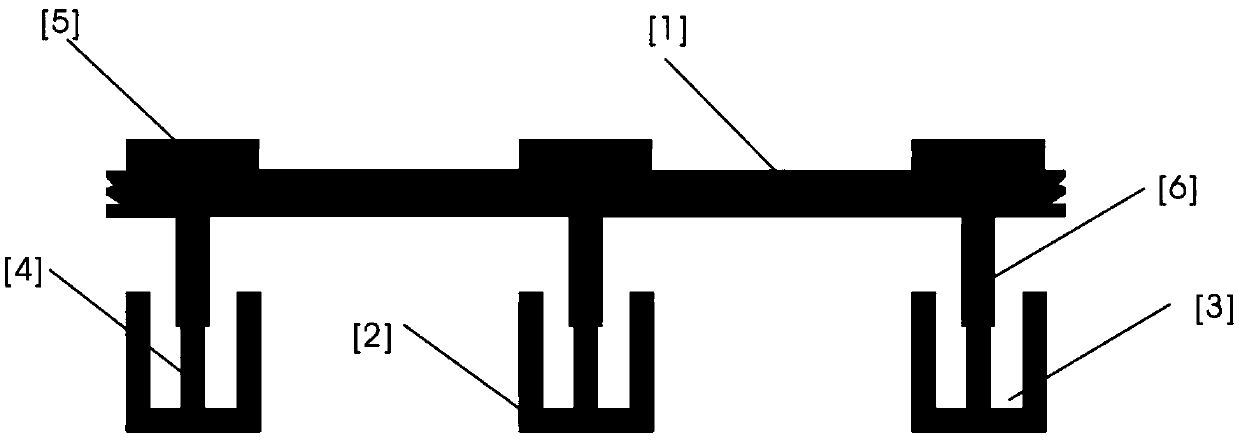

[0053] combine Figure 7 , Figure 8 , Figure 9 , which is to process the back surface of the water outlet of the waterproof board 1 with good waterproof performance into a hydrophobic surface, and use pillars or walls to elevate it and then tightly splice them together, and make the hydrophilicity of the curved surface 7 between the two ends The flow guide 2 is tightly installed between the interfaces of the waterproof board 1, the narrowest part of the hydrophilic guide 2 should be greater than the thickness of the waterproof board 1, and the hydrophilic guide 2 is anchored or closely attached to the upper plate 5 The upper surface of the waterproof board 1 prevents the hydrophilic flow guide 2 from falling off and prevents water leakage to a certain extent, and installs a drainage ditch or a drain pipe di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com