Lubricant circulating device based on sliding bearing and manufacturing process of lubricant circulating device

A circulation device and sliding bearing technology, which is applied in the direction of engine lubrication, bearing components, bearing cooling, etc., can solve the problems of equipment system loss, burning tiles, and rise in input oil temperature, so as to improve the cooling effect and expand the application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

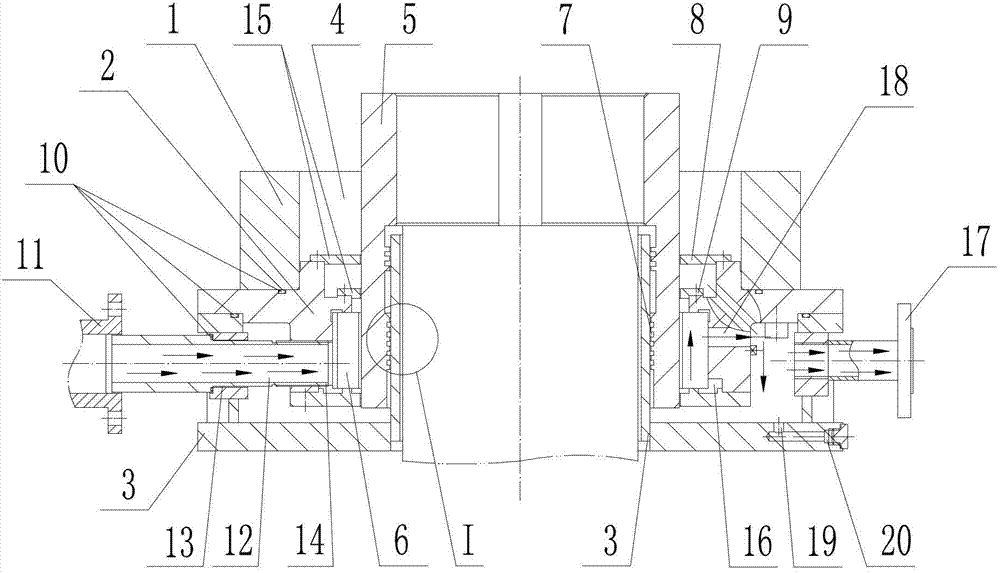

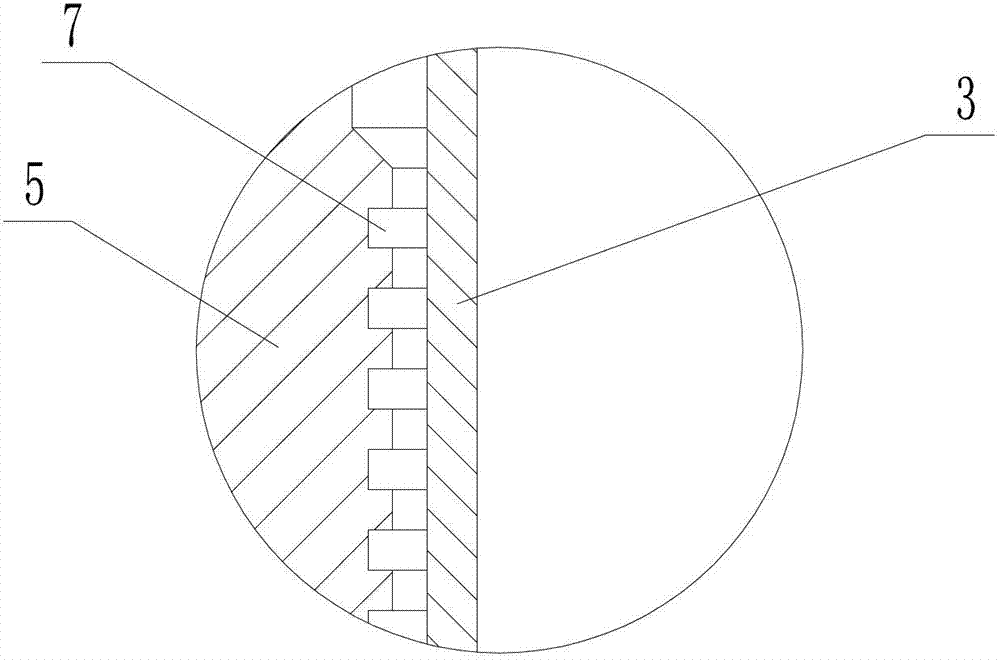

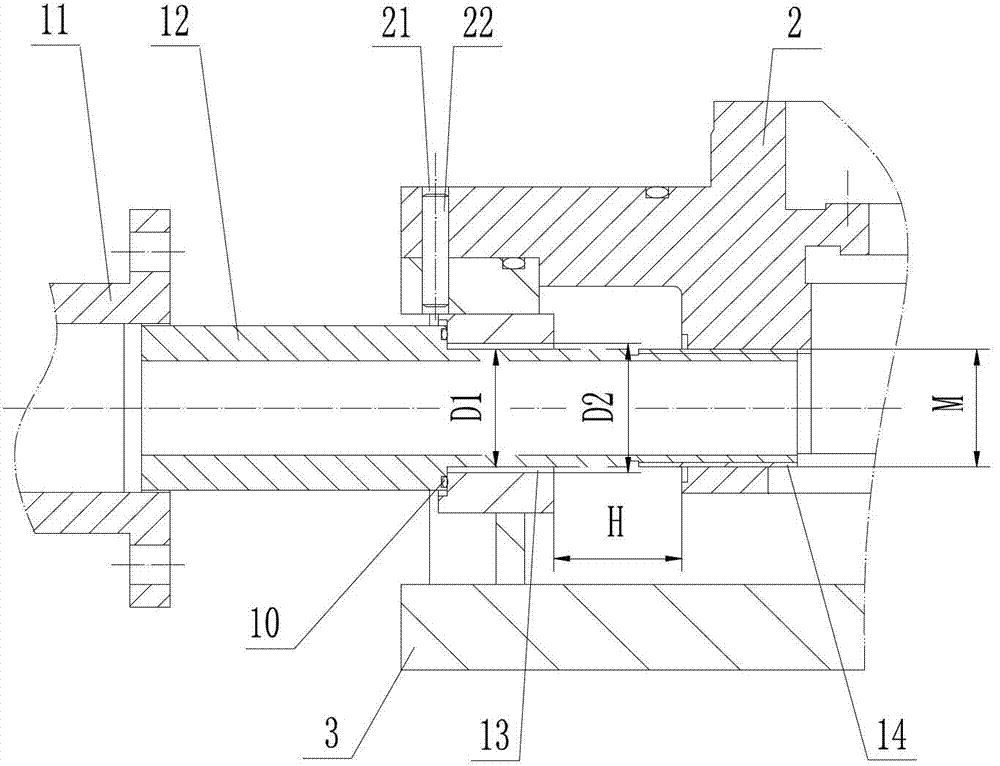

[0045] As shown in the figure, a lubricating oil circulation device based on a sliding bearing mainly includes a guide seat 2 fixed to the bearing bracket 1, an oil tank 3 connected to the guide seat 2, and a vertical shaft hole 4 is provided in the center of the guide seat 2 , The shaft hole 4 is provided with a shaft sleeve 5 and a bearing bush 6. In order to enhance the sealing effect, at least 6 radial labyrinth-shaped shaft sleeve sealing ring grooves 7 are provided in the shaft sleeve 5, and a large sealing pressure plate 8 is provided outside the shaft sleeve 5 , Small sealing pressure plate 9, large and small sealing pressure plates are collectively referred to as pressure plates, oil tank 3 and guide seat 2, guide seat 2 and bearing bracket 1, oil pipe 12, hot oil output pipe 17 and oil tank 3 are all equipped with O type The sealing ring 10, an oil pipe 12 connected to the interface of the cold oil input pipe 11 passes through the pipe mounting hole 13 of the oil tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com