Patents

Literature

35results about How to "Improve lubrication and cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

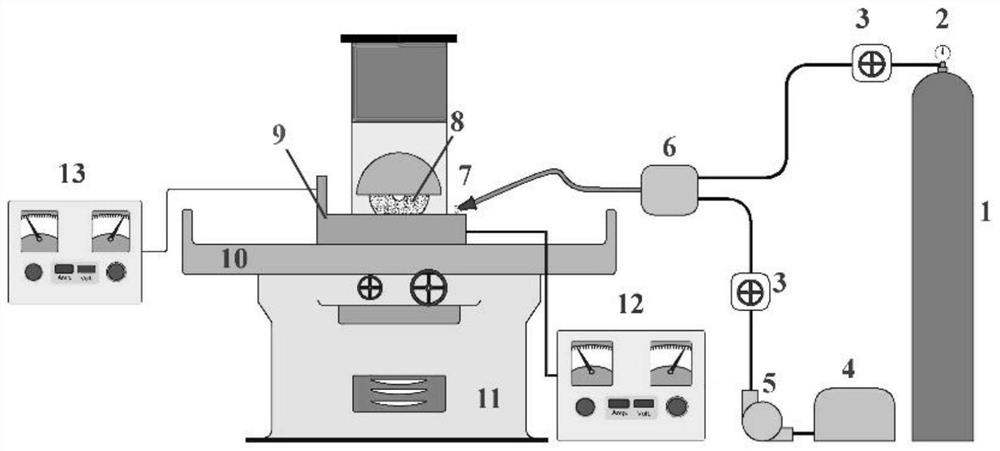

Nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system

ActiveCN103072084AReduce drift lossIncrease profitGrinding/polishing safety devicesMachined surfaceHigh-voltage direct current

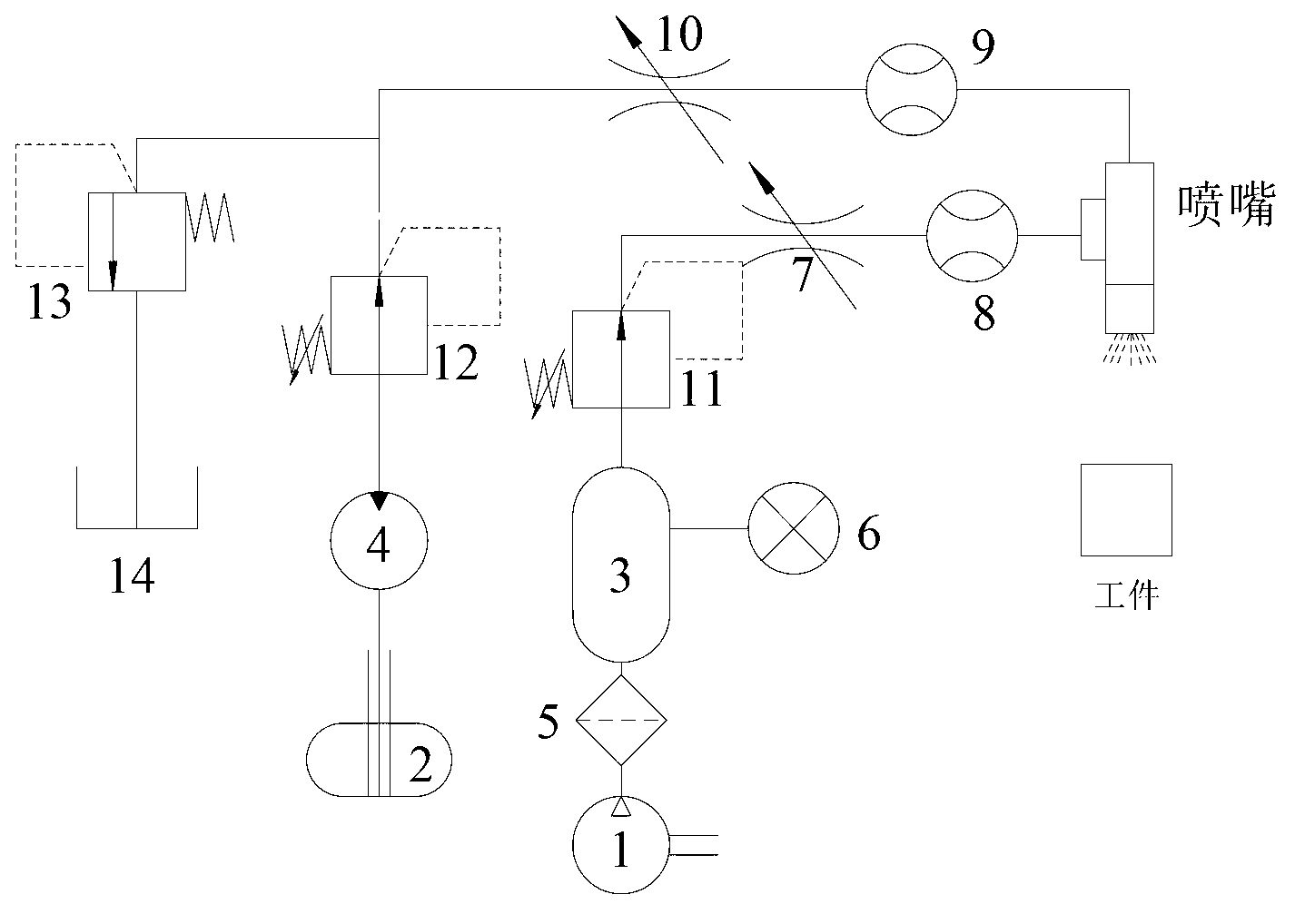

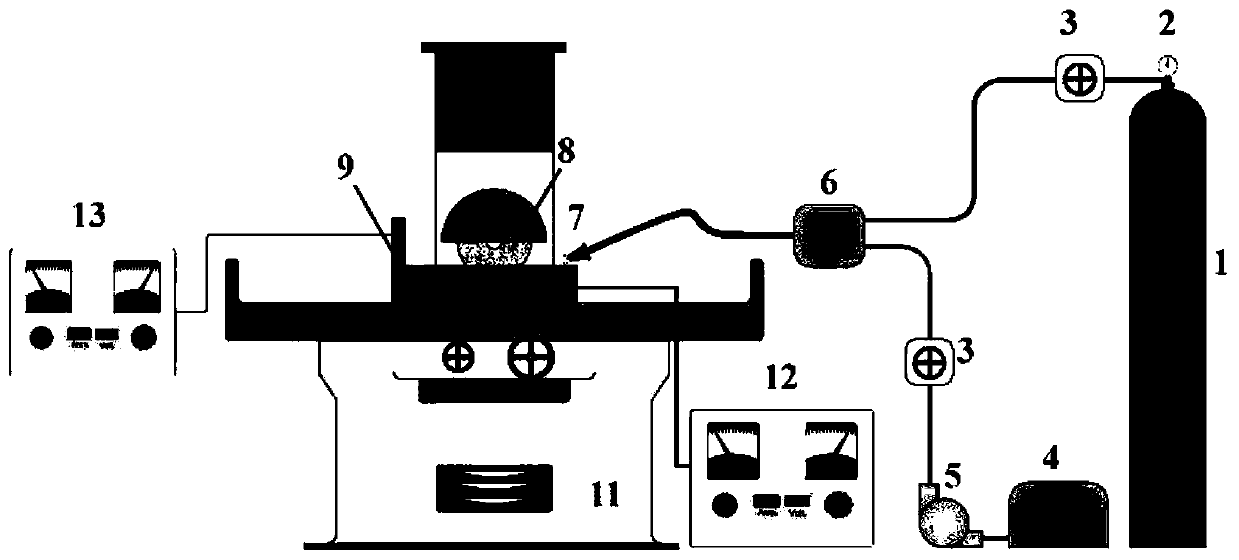

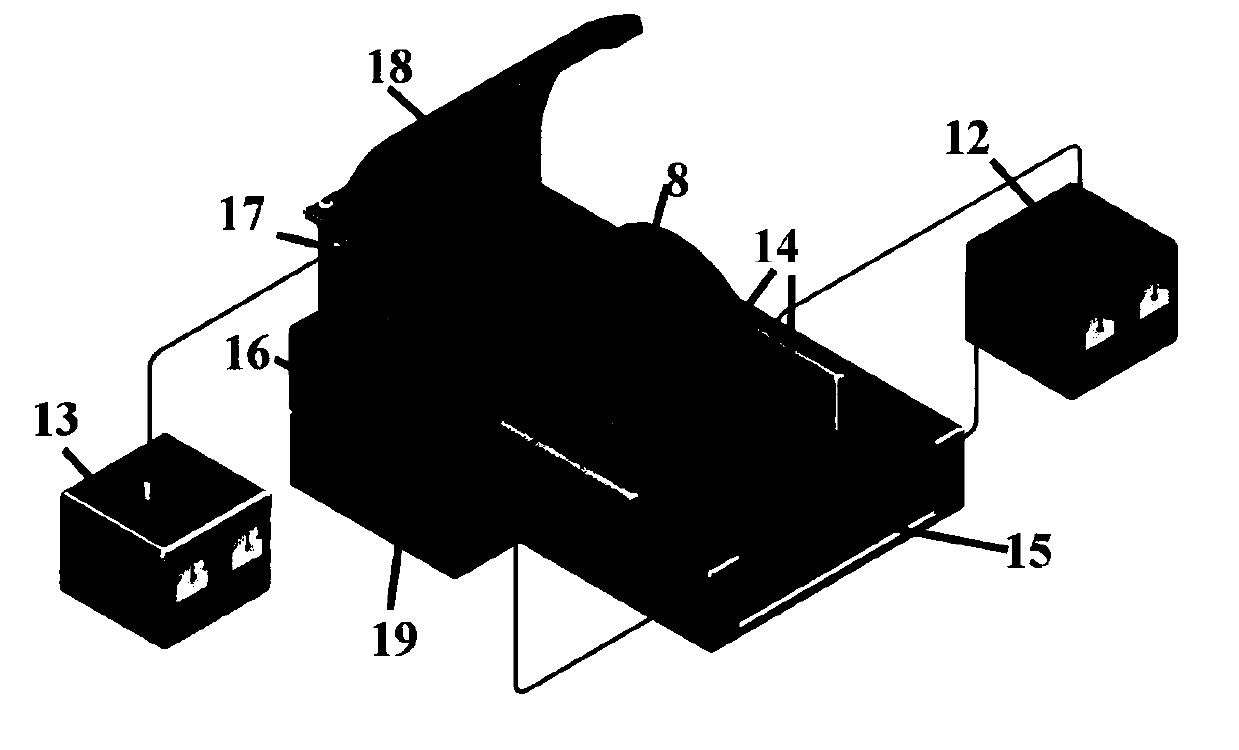

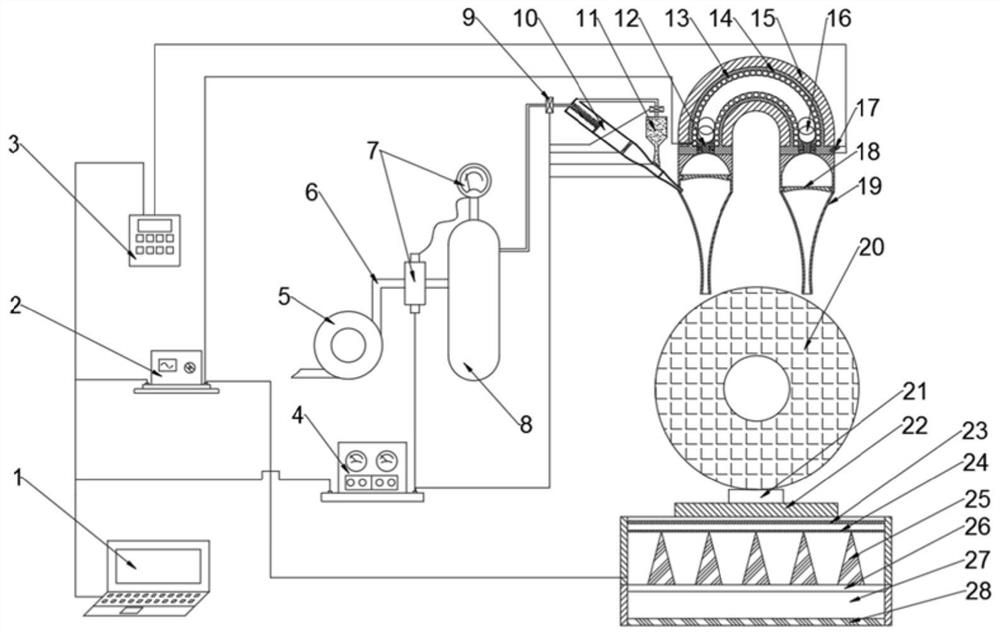

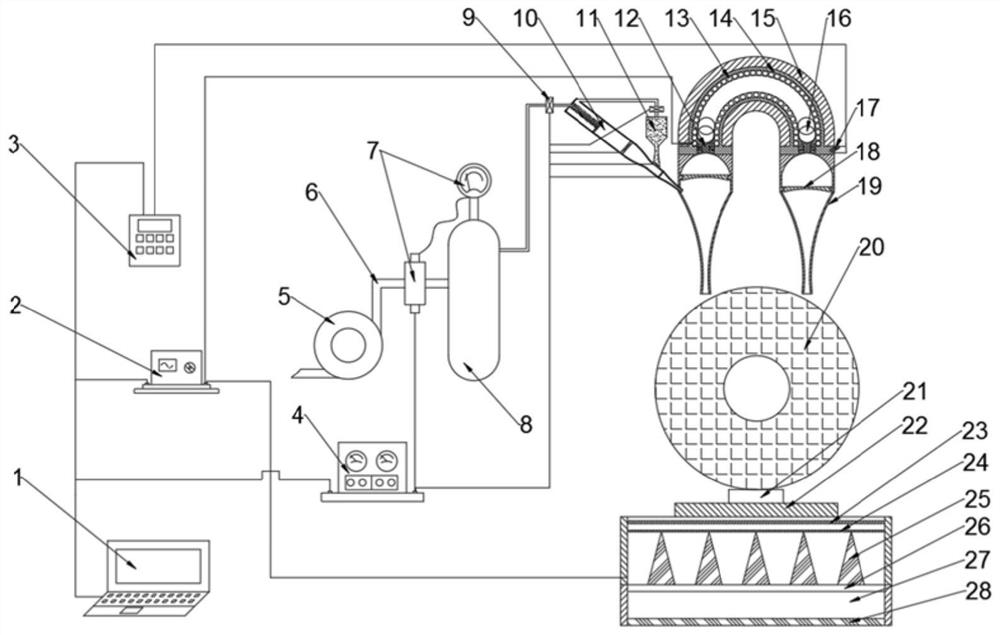

The invention relates to a nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system. Sprayed fog drops can be controllably distributed through the electrostatic principle, so that the pollution to environment is reduced, and better health security is provided to workers. A grinding system is provided with a corona charging nozzle, wherein a nozzle body of the corona charging nozzle is connected with a liquid supply system and an air supply system; a high-voltage direct-current electrostatic generator on the lower part of the nozzle body is connected with the cathode of an adjustable high-voltage direct-current power supply; the anode of the adjustable high-voltage direct-current power supply is connected with a workpiece charging device; and the workpiece charging device is attached to the non-machined surface of a workpiece. Nano fluid grinding liquid is fed into the corona charging nozzle through the liquid supply system, meanwhile the air supply system feeds compressed air into the corona charging nozzle, the nano fluid grinding liquid is charged into controllable jet stream by the high-voltage direct-current electrostatic generator while being driven by the compressed air to be sprayed out and atomized from the nozzle body, and the controllable jet stream is controllably distributed to a grinding area of the machined workpiece under the actions of electric field force and aerodynamic force.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

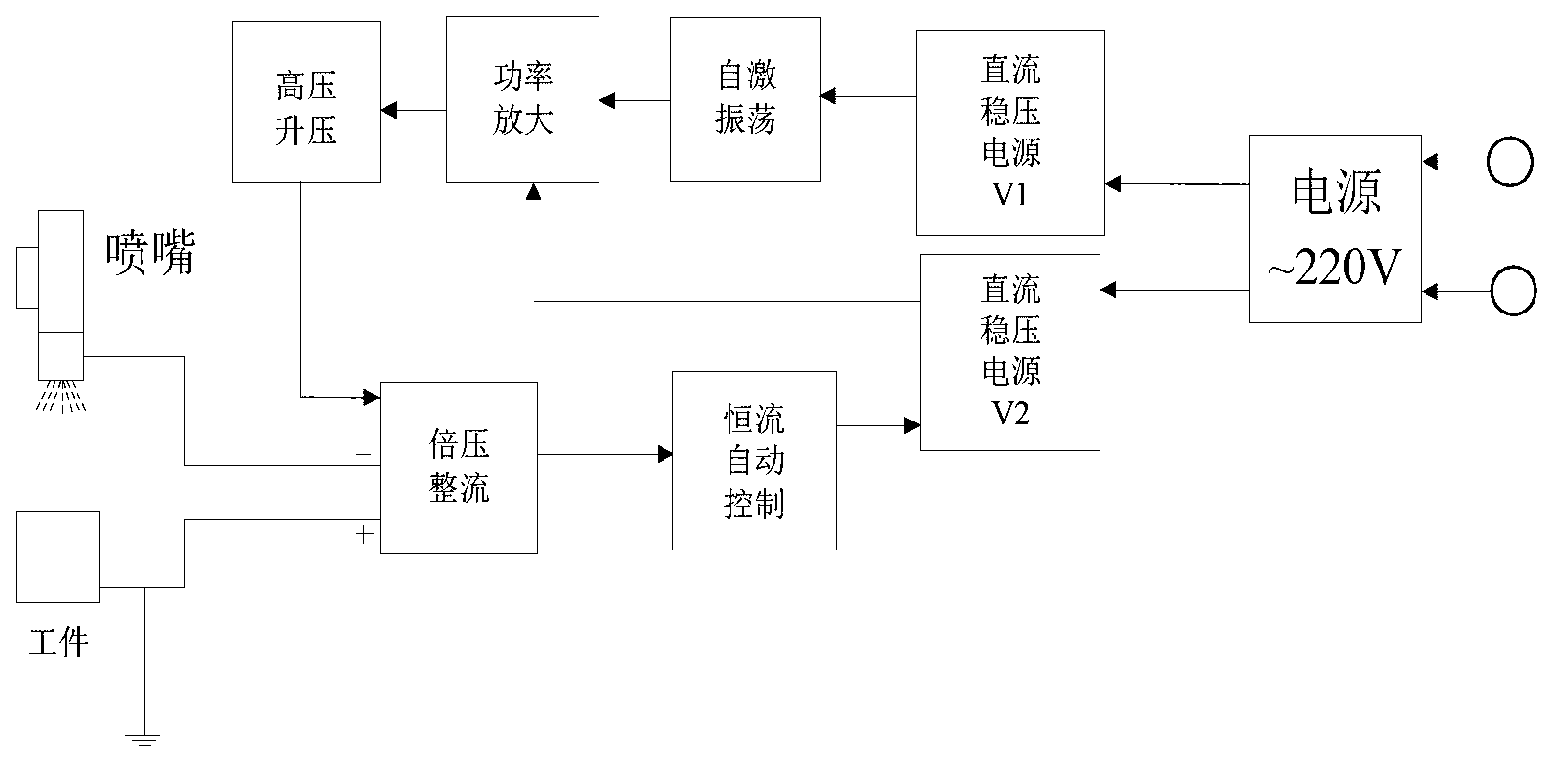

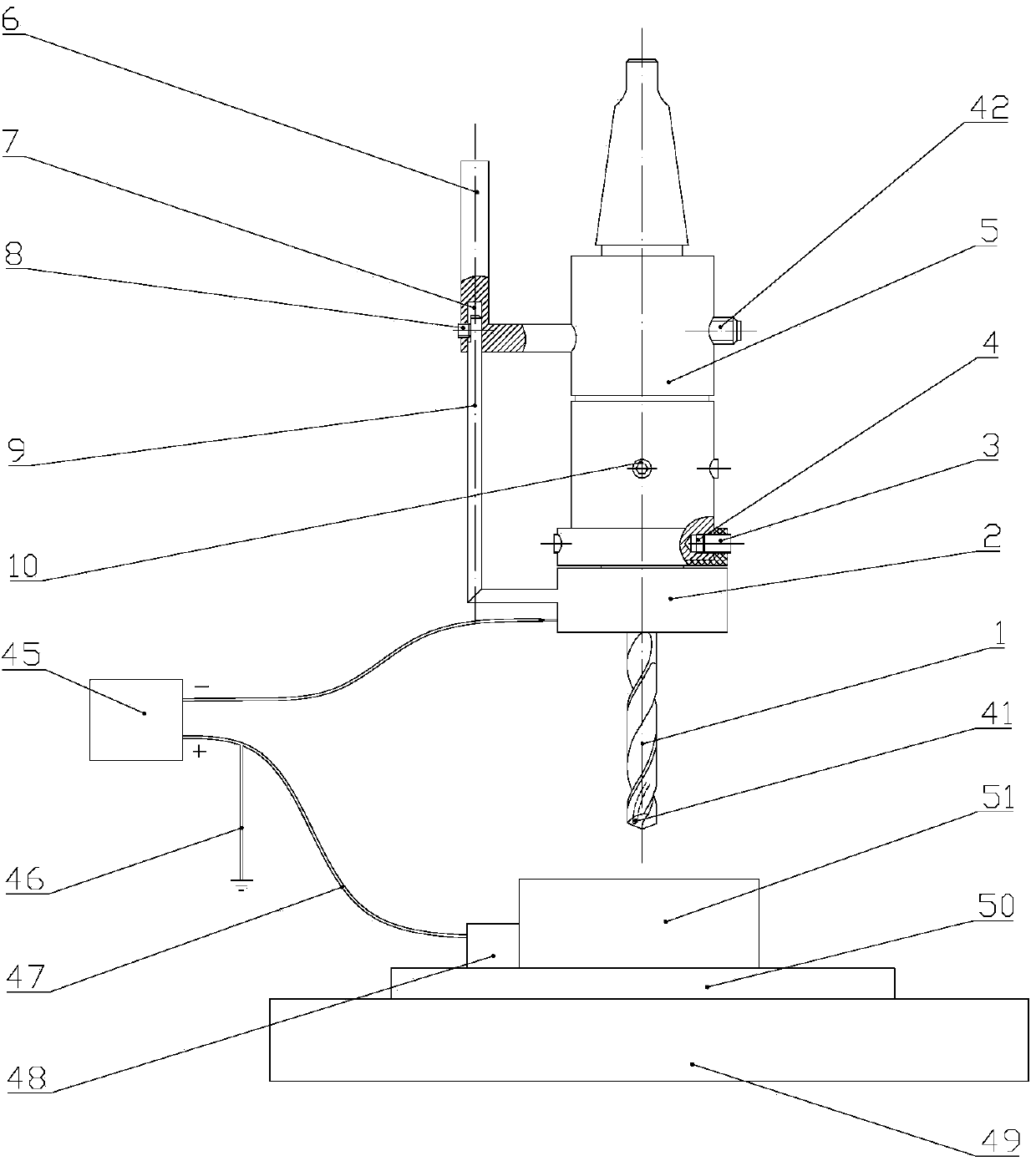

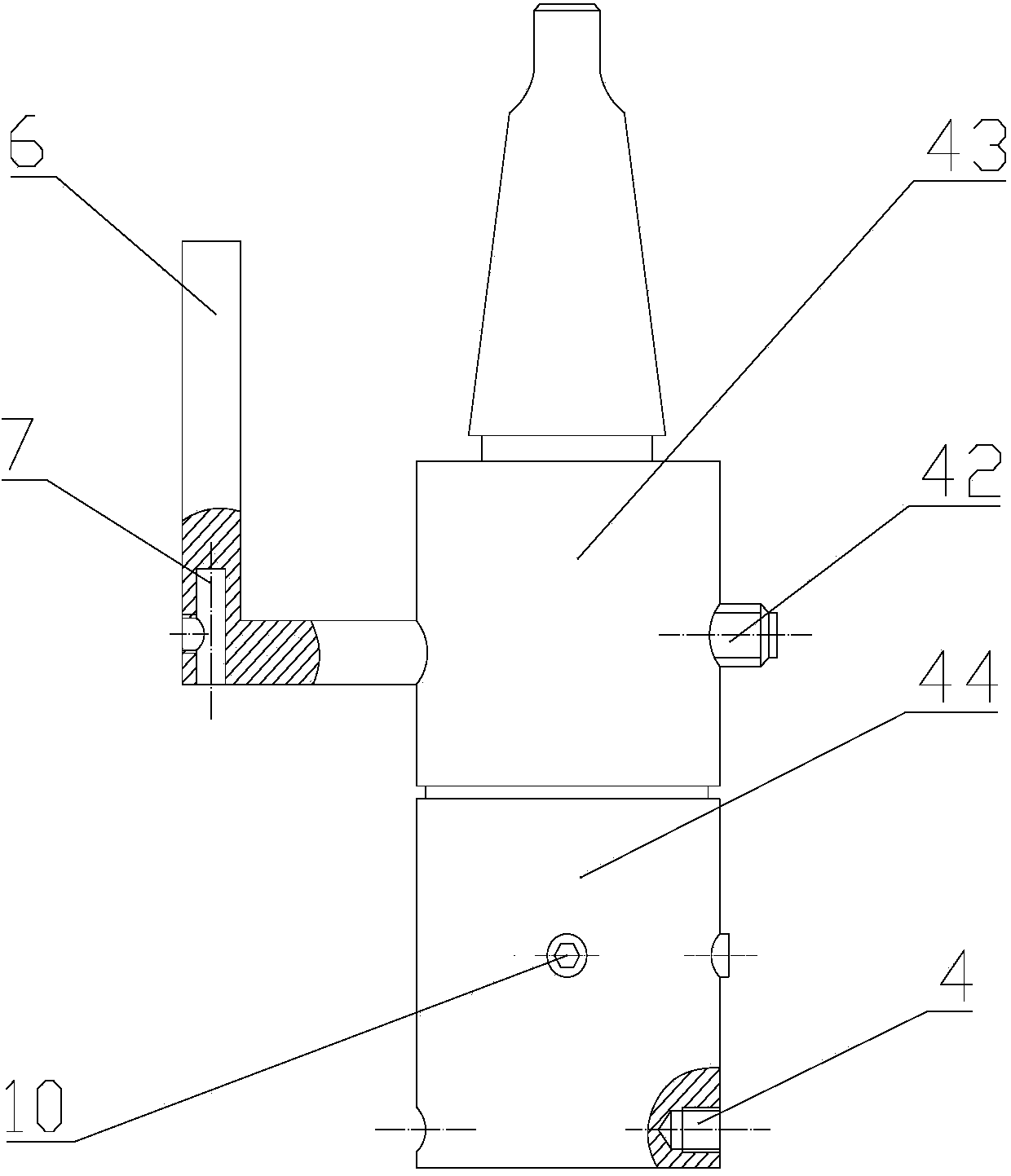

System for nanofluid minimal quantity lubrication electrostatic atomization controllable jet flow inner cooling technology

ActiveCN104191376AIncrease profitOvercome surface tensionGrinding/polishing safety devicesHigh-voltage direct currentHigh pressure

The invention relates to a system for the nanofluid minimal quantity lubrication electrostatic atomization controllable jet flow inner cooling technology. According to the system for the nanofluid minimal quantity lubrication electrostatic atomization controllable jet flow inner cooling technology, based on the electrostatic atomization principle, minimal quantity lubrication cutting fluid fog droplets can be controllably distributed during jetting, the evenness of a fog droplet spectrum can be improved, the deposition efficiency can be improved, the fluid effective utilization rate can be increased, the motion law of the fog droplets can be effectively controlled, in this way, pollution to the environment is reduced, and better health security is provided for workers. The system comprises an adjustable high-voltage direct-current power supply, an inner-cooled cutter converter, a high-voltage electricity converting device and an integrated spray nozzle. A minimal quantity lubrication system supplies minimal quantity lubrication cutting liquid to an inner-cooled drill bit through the inner-cooled cutter converter. The adjustable high-voltage direct-current power supply conducts positive electricity to a needle electrode of the integrated nozzle through the high-voltage electricity converting device, the adjustable high-voltage direct-current power supply makes negative electricity be grounded and transmits the negative electricity to a workpiece through an electromagnetic connector, and then a corona charging field is formed in the needle electrode-workpiece area; in this way, corona charging is conducted on the minimal quantity lubrication cutting fluid, and then electrostatic atomization function is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

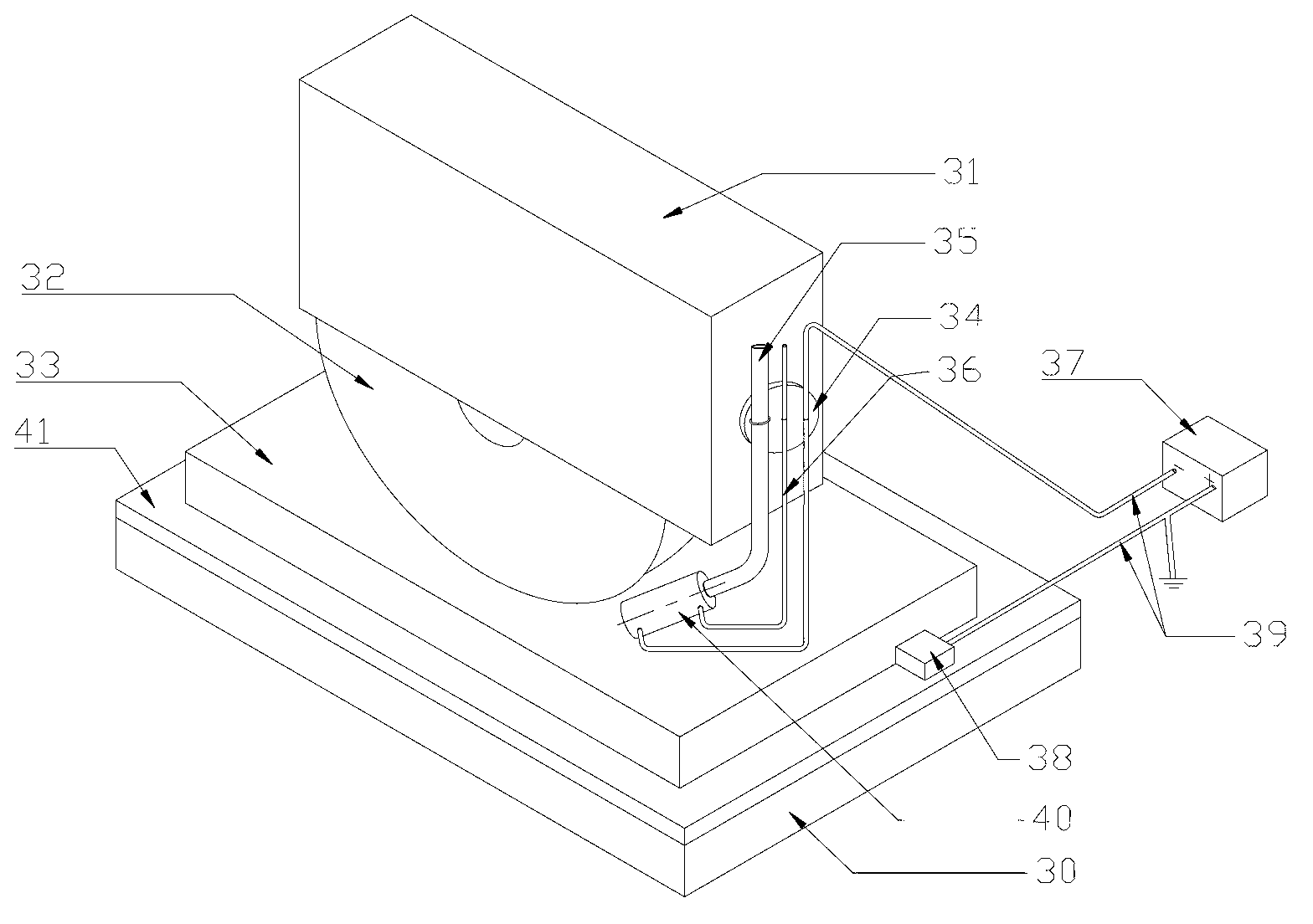

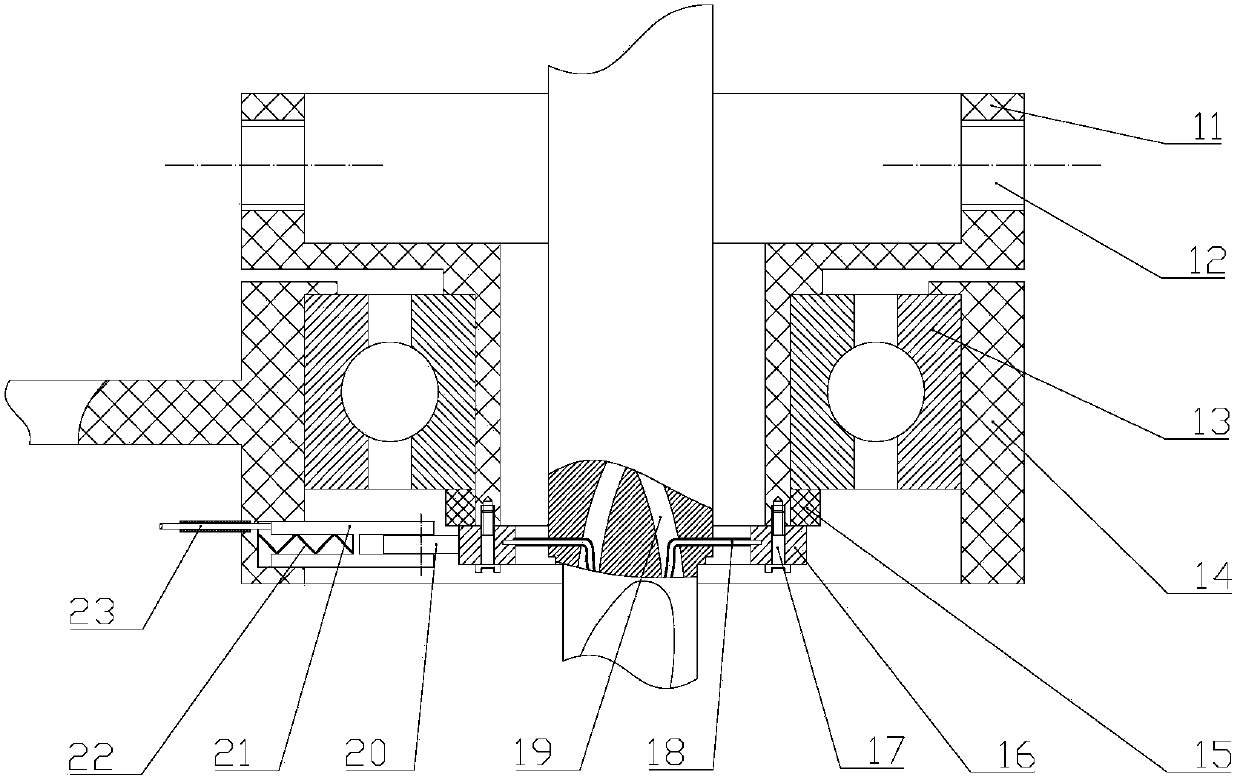

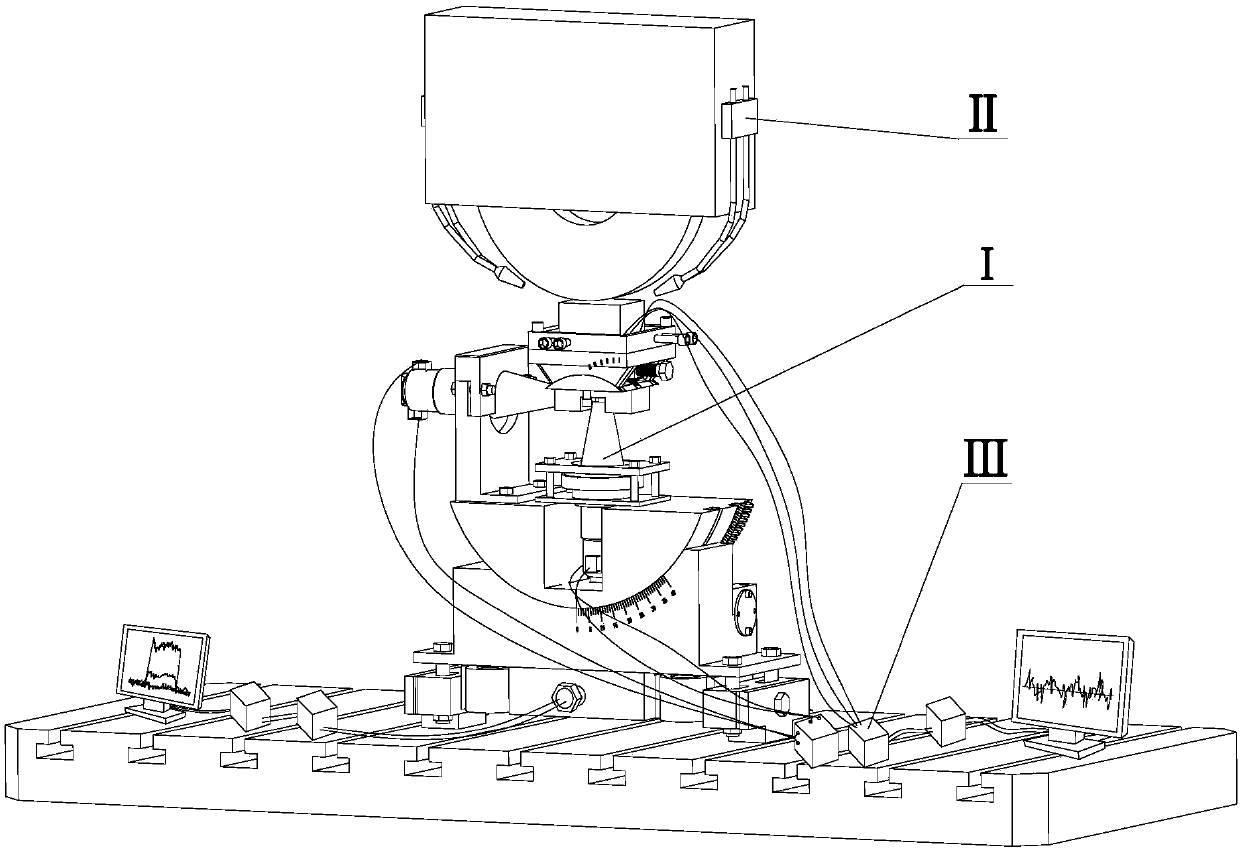

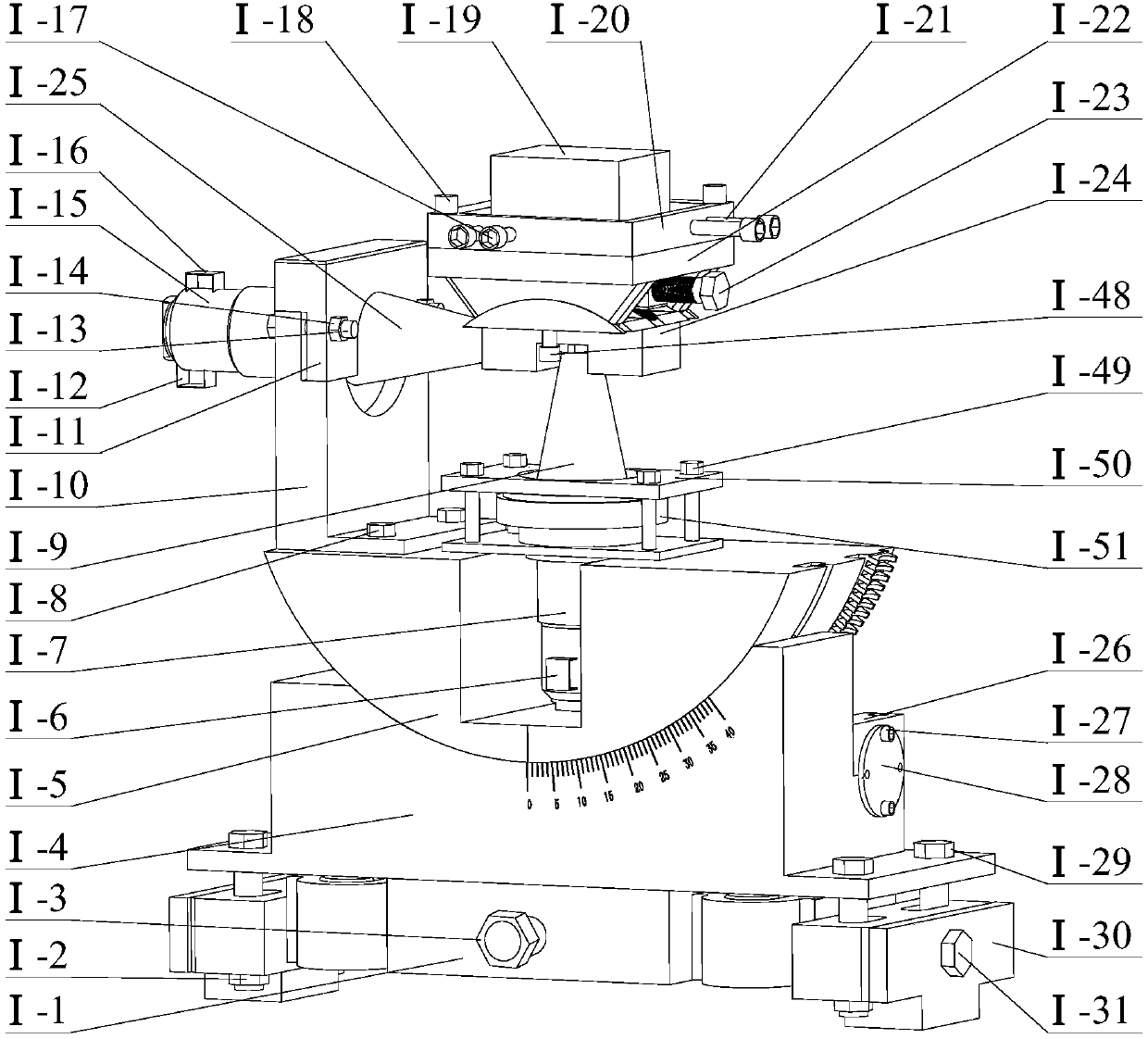

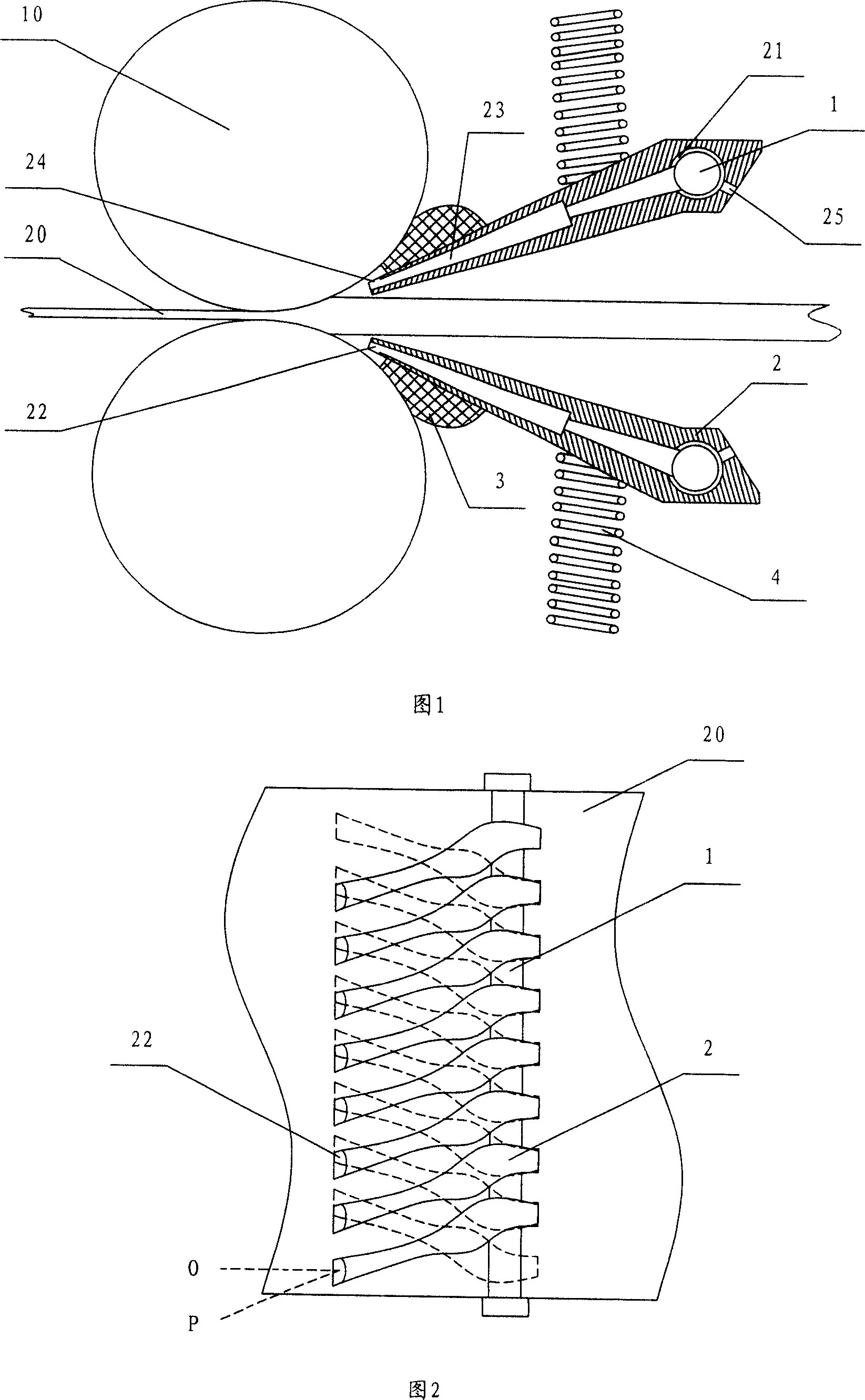

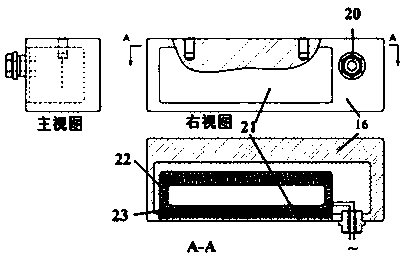

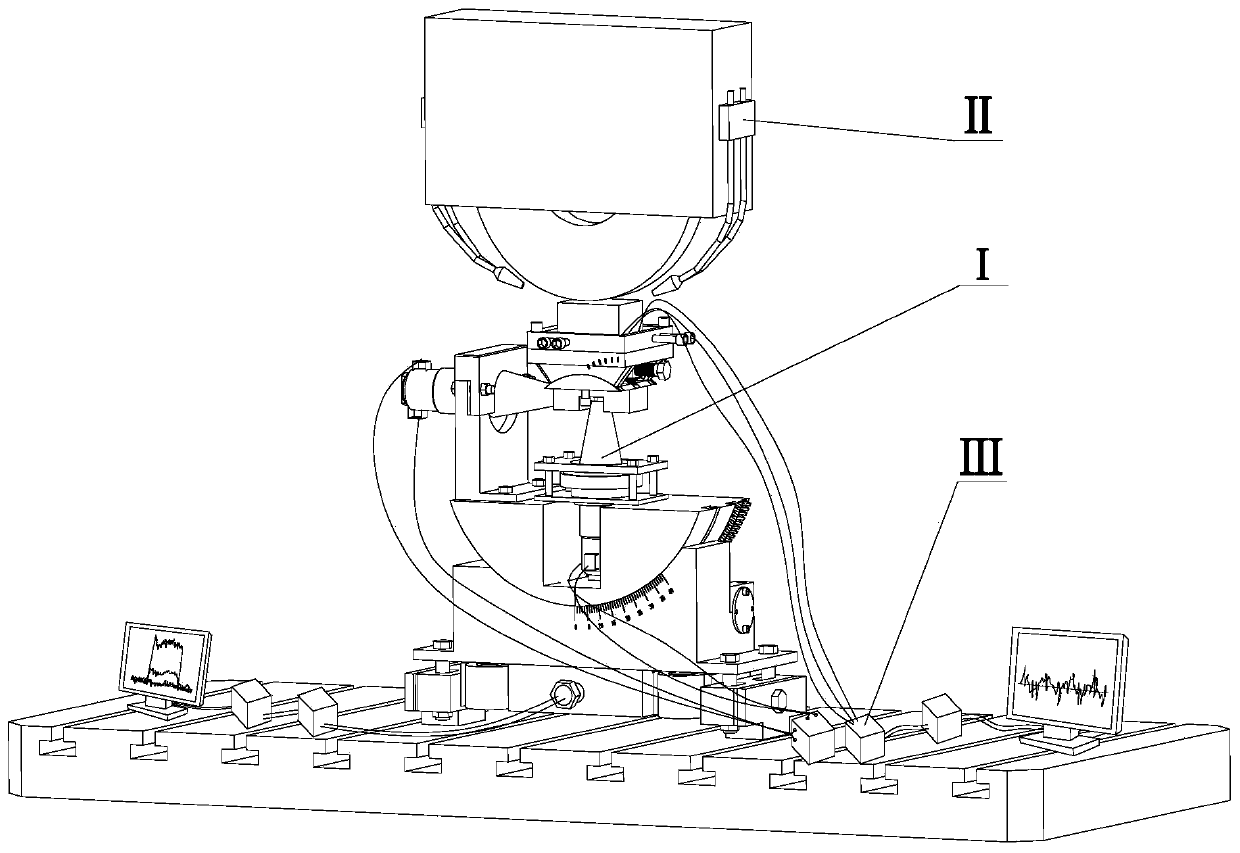

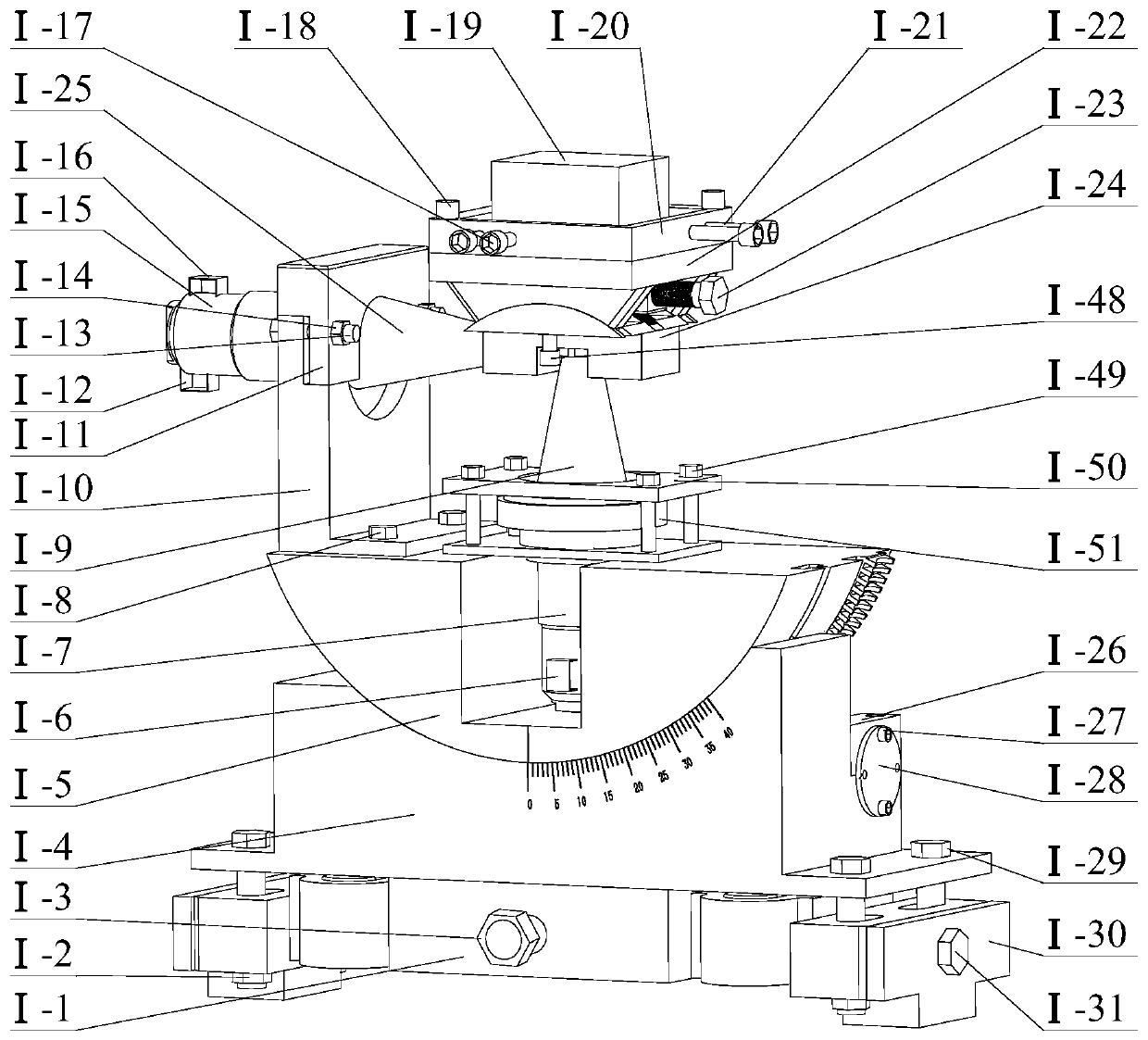

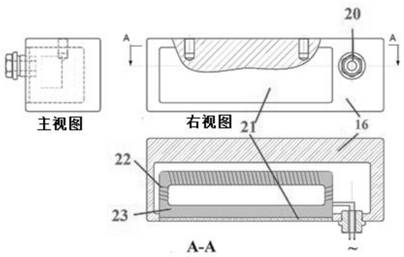

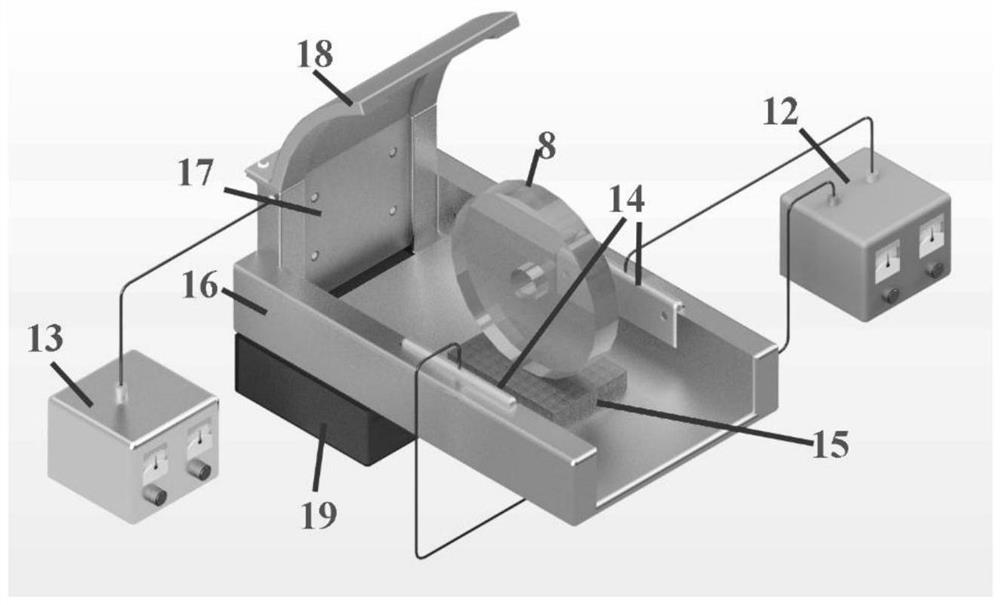

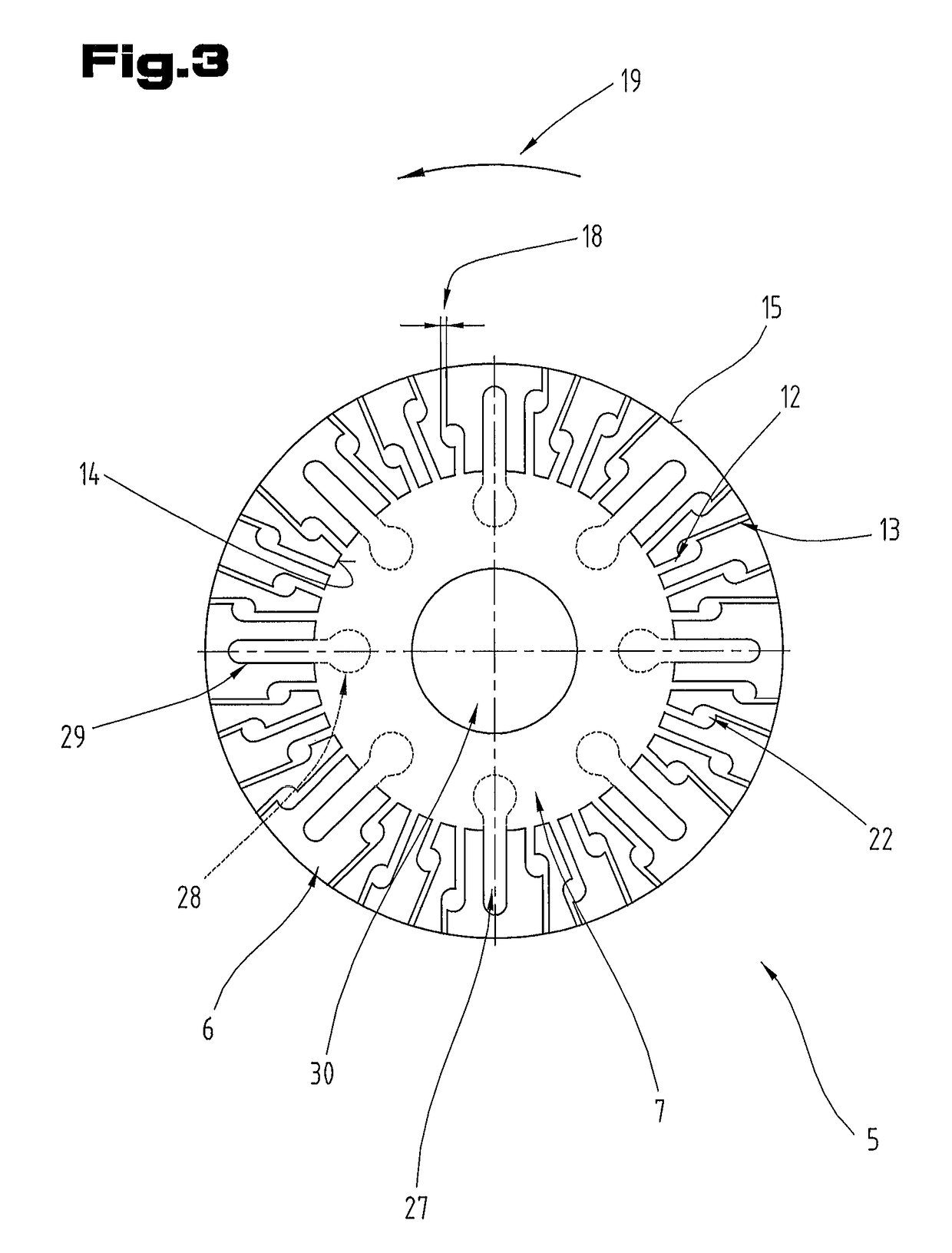

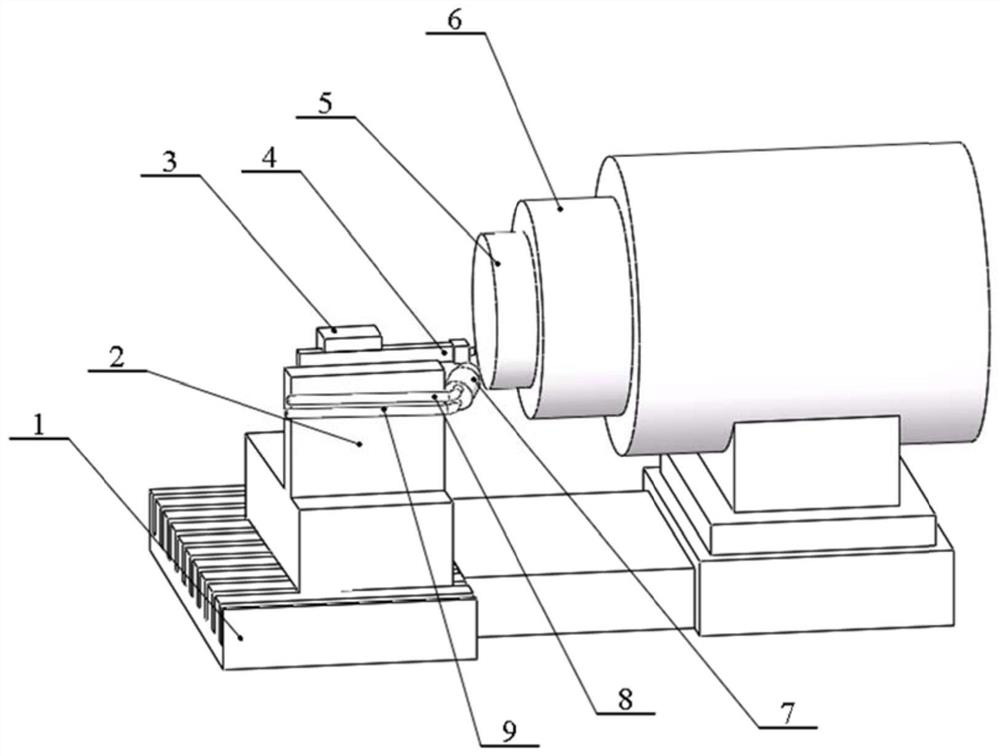

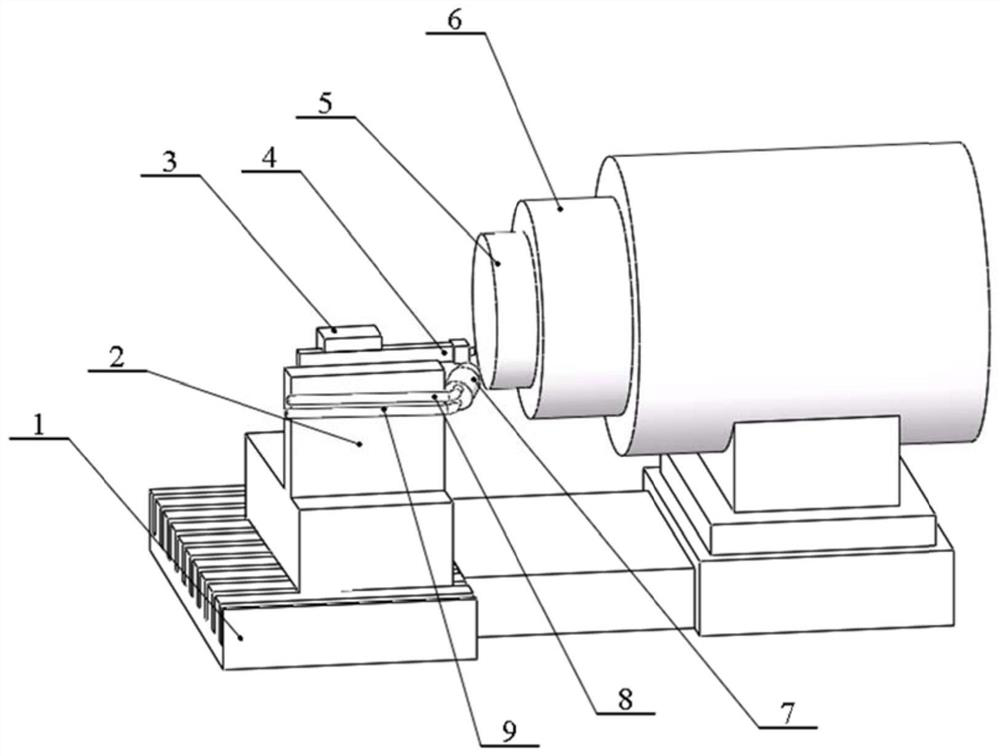

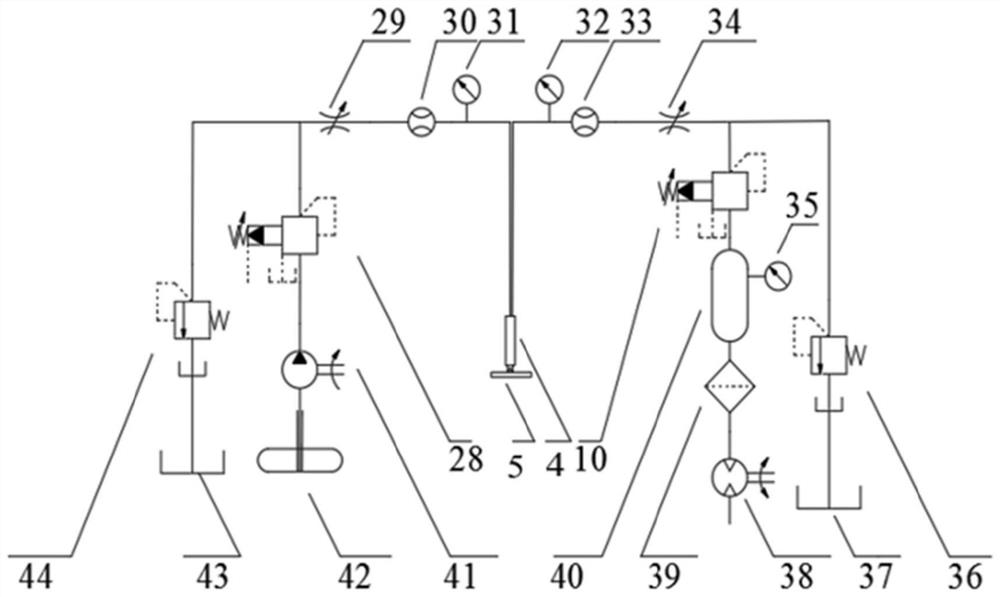

Ultrasonic vibration assisted grinding fluid microchannel infiltrated nano-fluid trace lubrication and grinding device

The invention discloses an ultrasonic vibration assisted grinding fluid microchannel infiltrated nano-fluid trace lubrication and grinding device and aims at solving the problem that undeformed abrasive dust thickness has larger influence on the grinding process in the prior art. The ultrasonic vibration assisted grinding fluid microchannel infiltrated nano-fluid trace lubrication and grinding device has the beneficial effects that the lubrication state of single abrasive grains when a material is removed in the grinding process is fully considered from microscopic, and the effect of ultrasonic vibration assisted grinding in improving the cooling and lubrication effects of nano-fluid trace lubrication is effectively realized. According to the technical scheme, the device comprises an ultrasonic vibration mechanism capable of regulating the position of an ultrasonic vibrator space, a nano-fluid trace lubrication and grinding mechanism and a grinding force measurement mechanism; the ultrasonic vibration mechanism is arranged on a workbench; the nano-fluid trace lubrication and grinding mechanism is arranged above a workpiece fixing table; the grinding force measurement mechanism comprises a dynamometer and a grinding force controller which is connected with the dynamometer; and the dynamometer is arranged at the bottom of the ultrasonic vibration mechanism.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

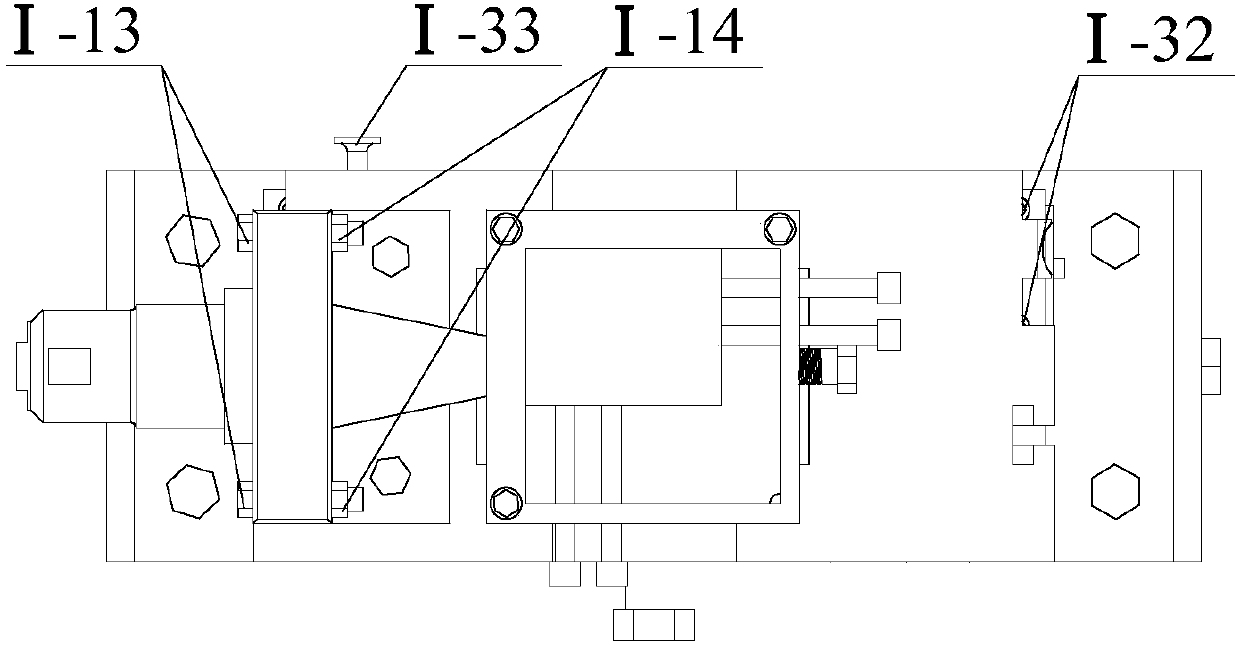

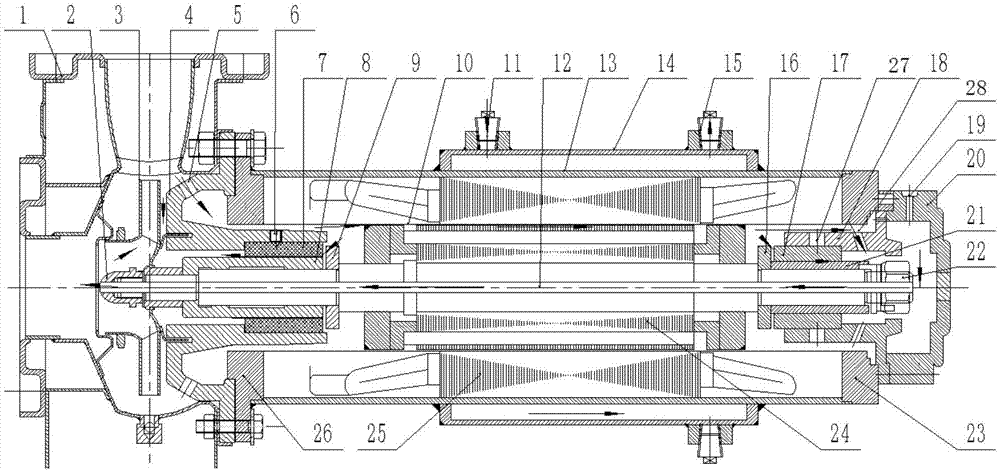

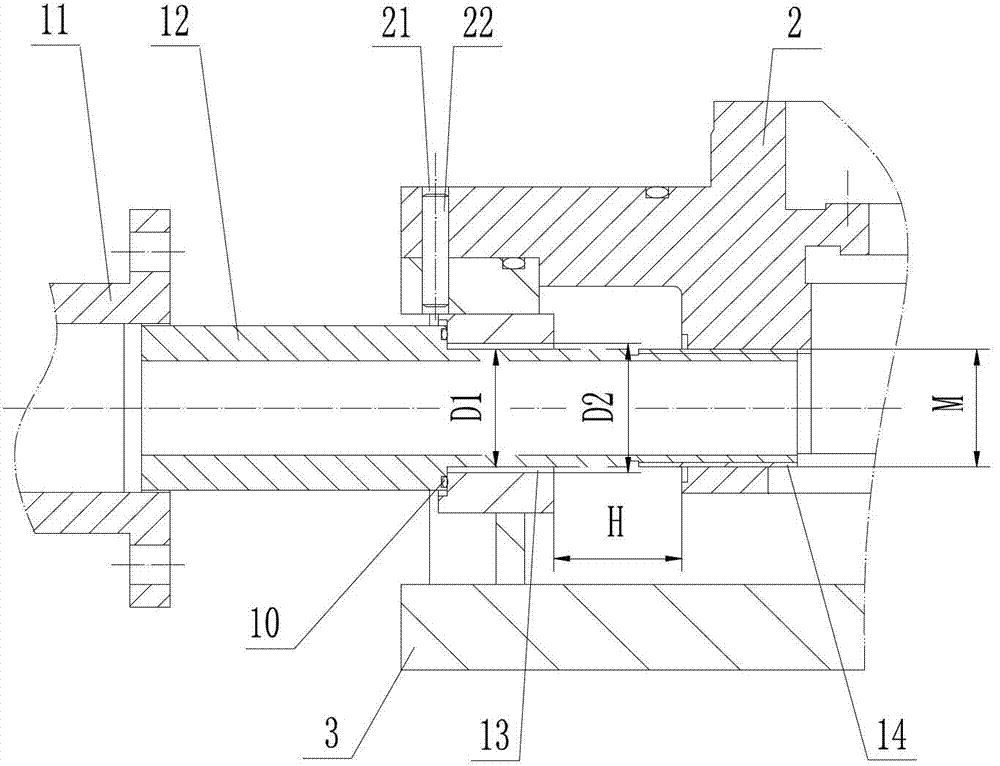

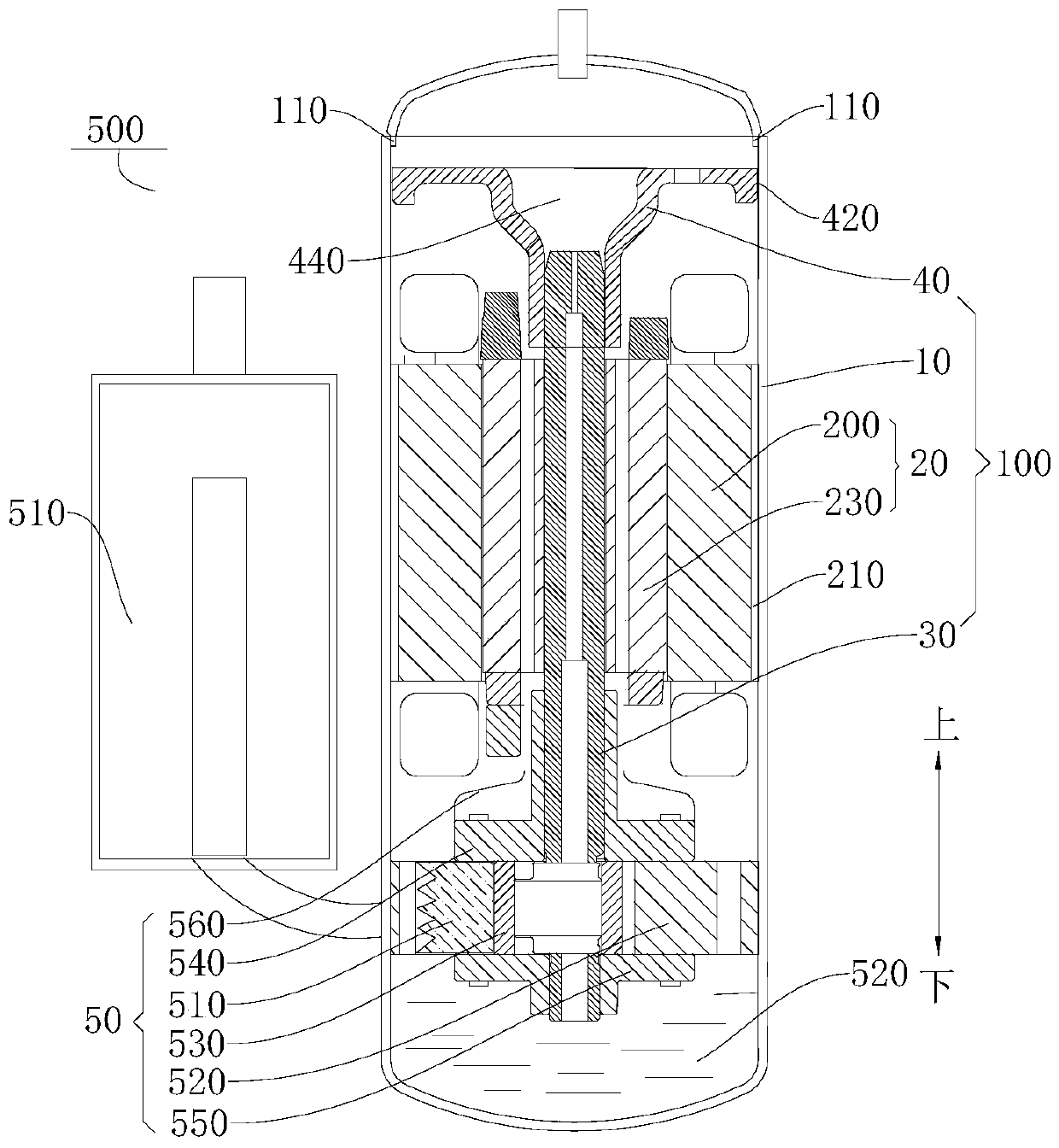

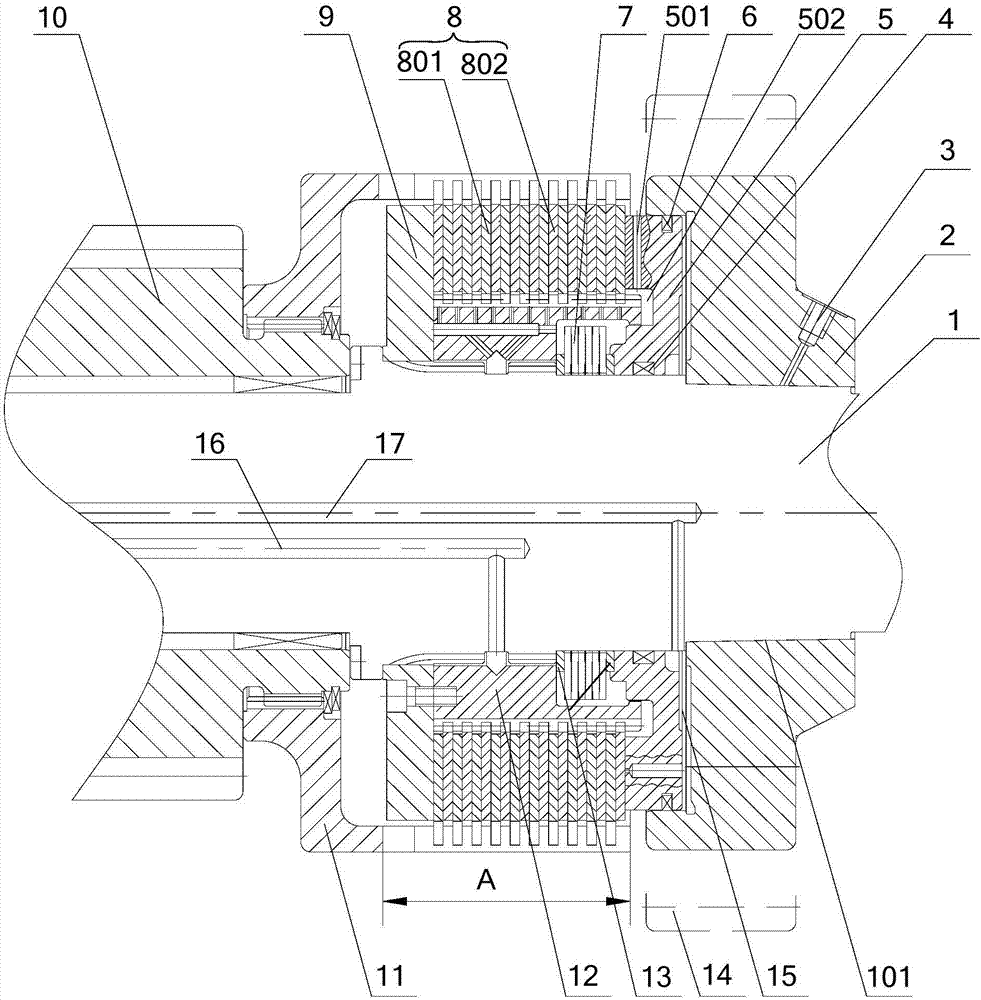

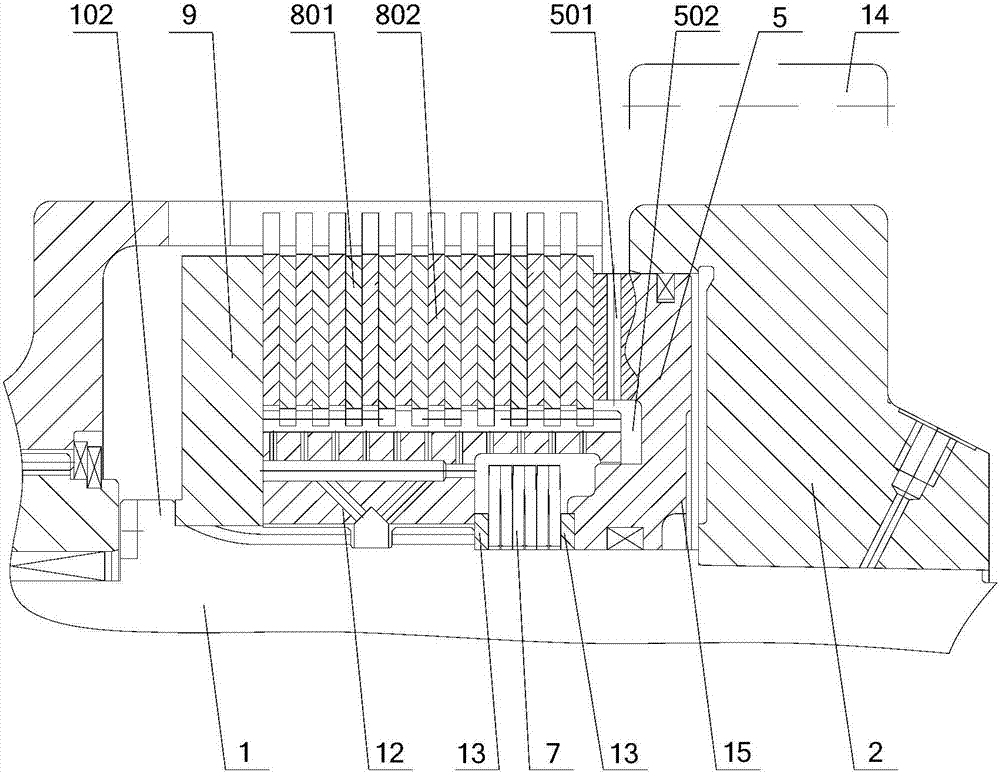

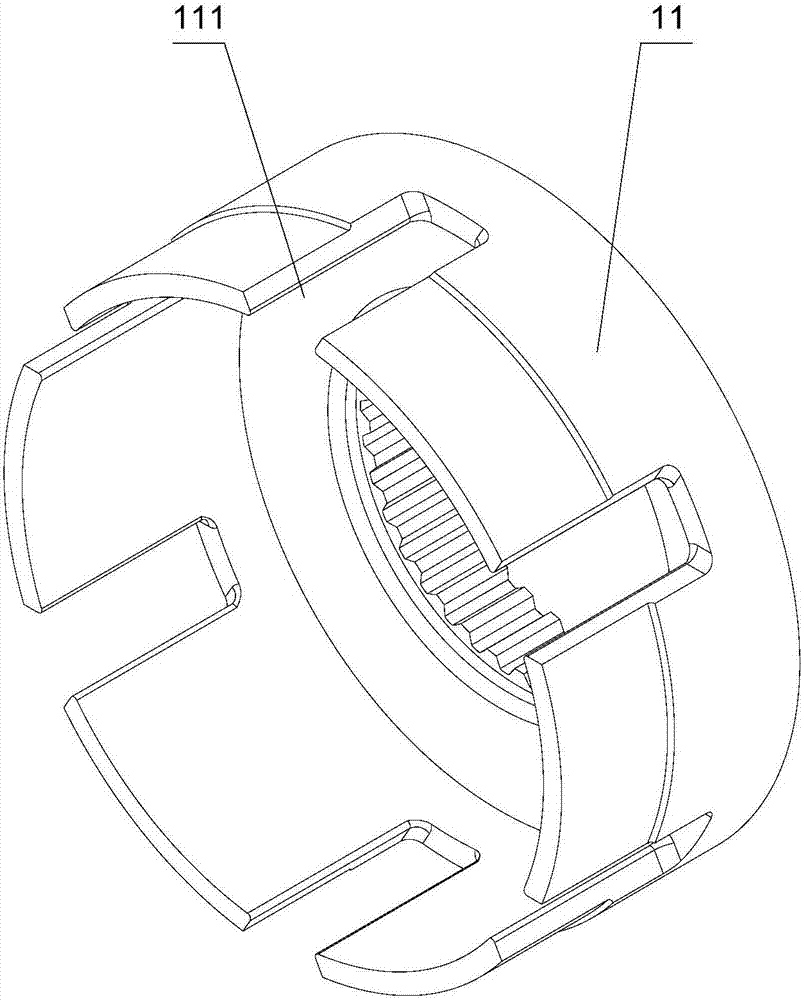

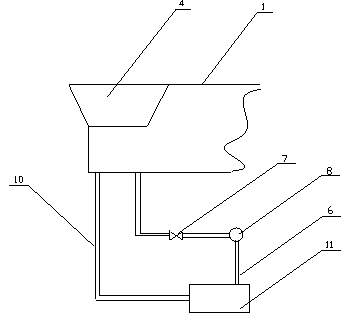

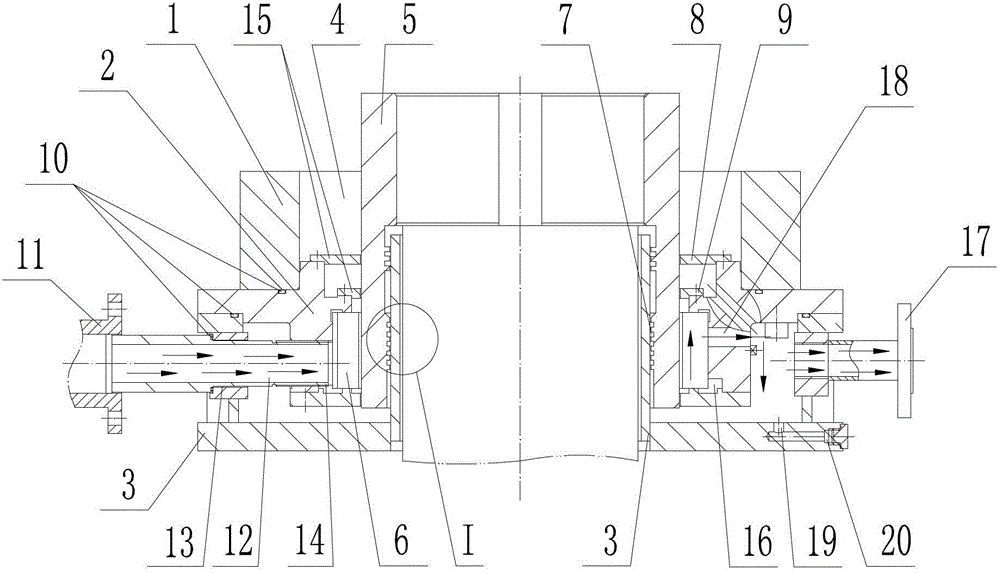

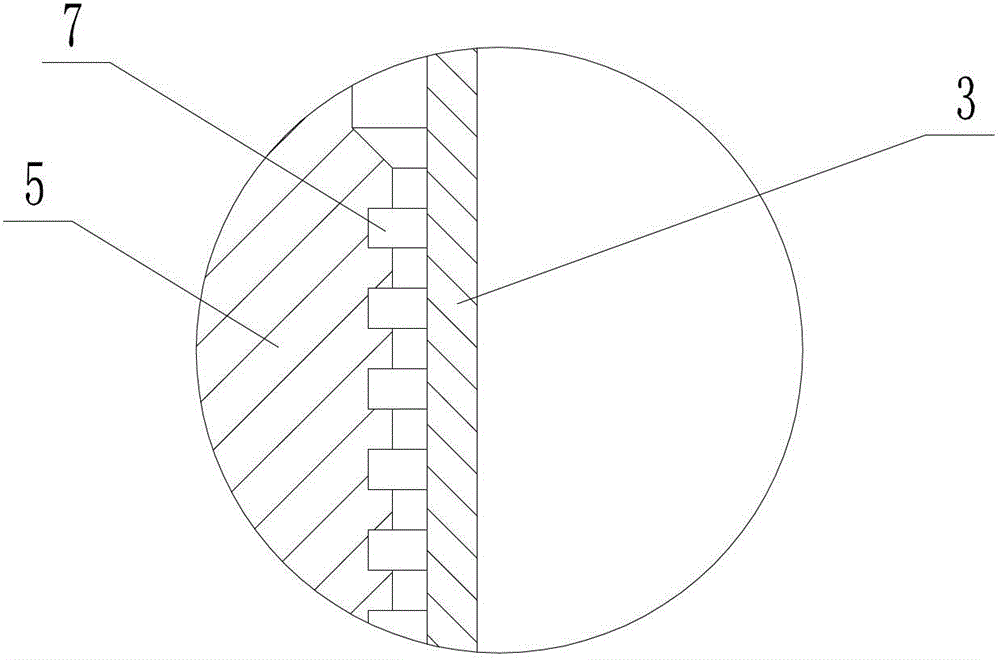

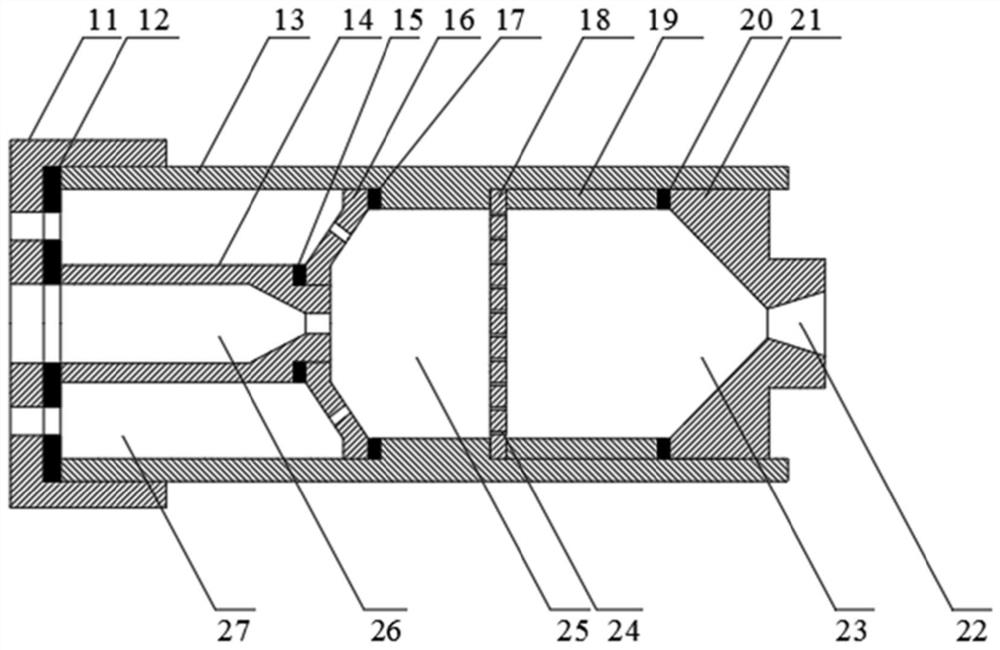

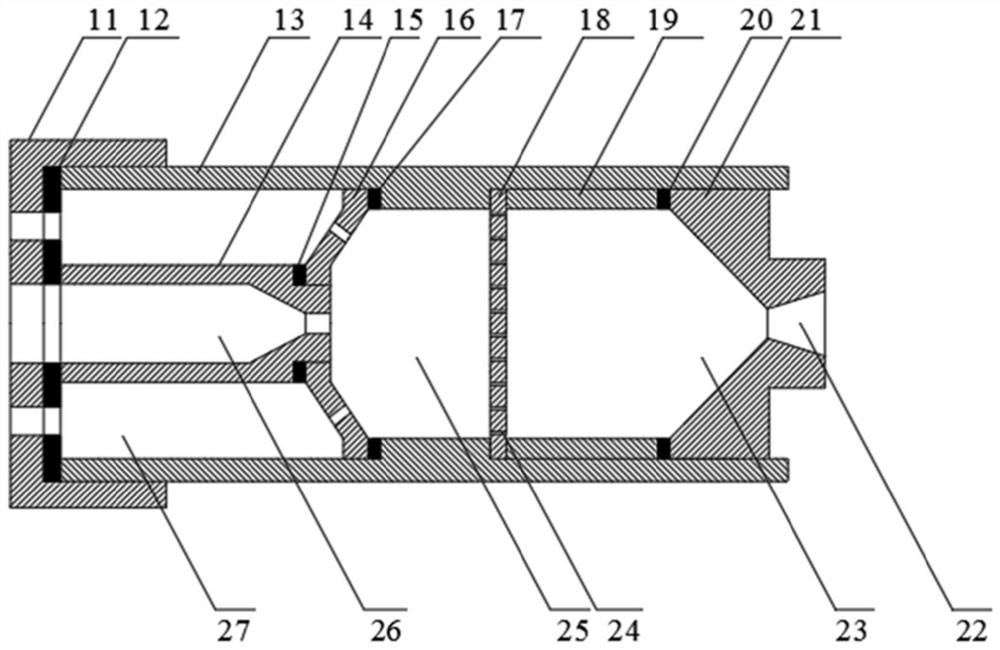

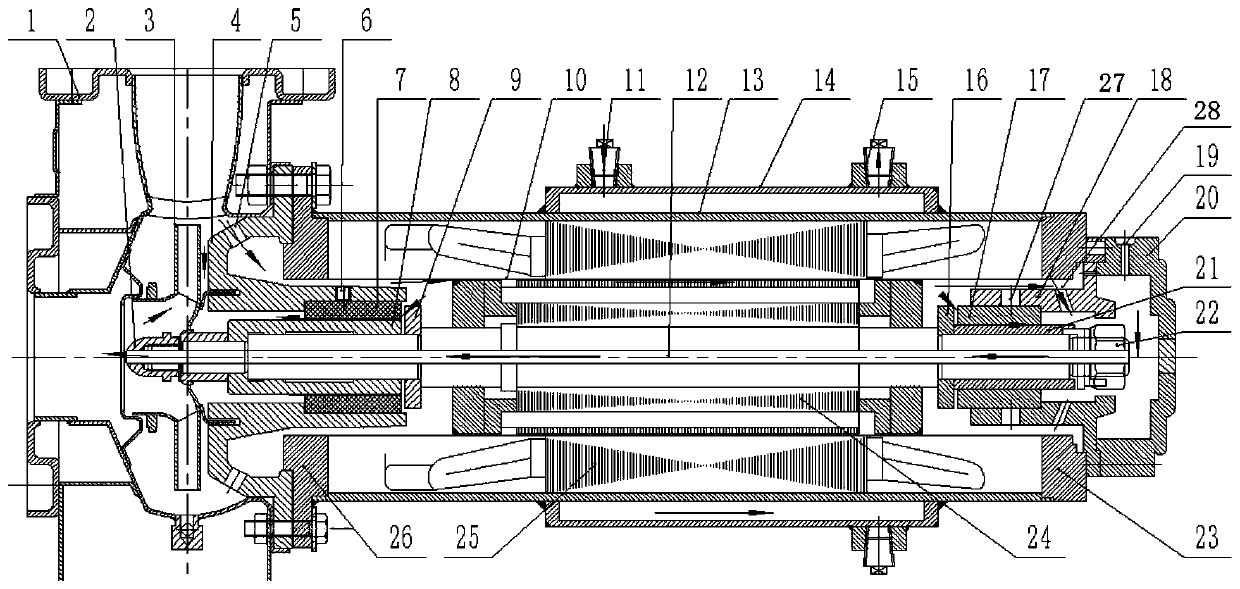

Shield pump with forced cooling and lubricating functions

ActiveCN107387424AImprove reliabilityImprove lubrication and coolingPump componentsPump installationsImpellerPlain bearing

The invention provides a shield pump with forced cooling and lubricating functions. A front bearing pedestal and a rear sliding bearing pedestal are each provided with two through holes. A gap is reserved between a front thrust disc and a front sliding bearing, and a gap is reserved between a rear thrust disc and a rear sliding bearing. The center of a shaft, the center of an impeller nut and the center of a nut are provided with through holes. Part of conveying medium from an impeller can flow past the inner side, the outer side and the end of the front sliding bearing, and then the conveying medium enters the impeller via a pressure relief opening of the impeller to form a liquid flow channel. Meanwhile, part of the conveying medium flows past the front sliding bearing pedestal, the inner side gap of a shield sleeve and the inner side, the outer side and the end of the rear sliding bearing, and then returns to an impeller inlet from the through hole in the center of the nut, the through hole in the center of the shaft and the through hole in the center of the impeller nut to form a loop. The rear sliding bearing, a second shaft sleeve and the rear thrust disc are effectively cooled and lubricated, the reliability of the shield pump is improved and the service life of the shield pump is prolonged.

Owner:JIANGSU UNIV

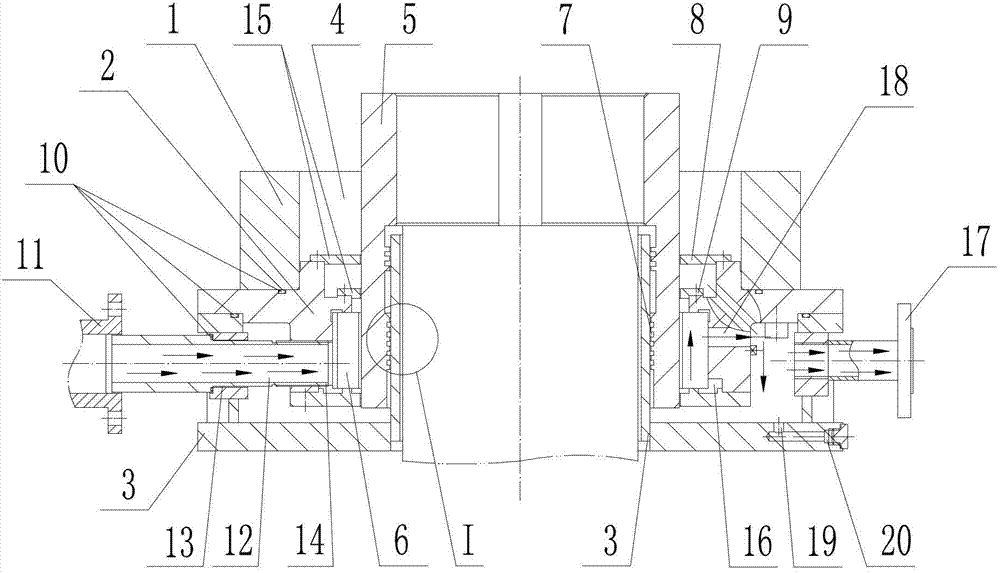

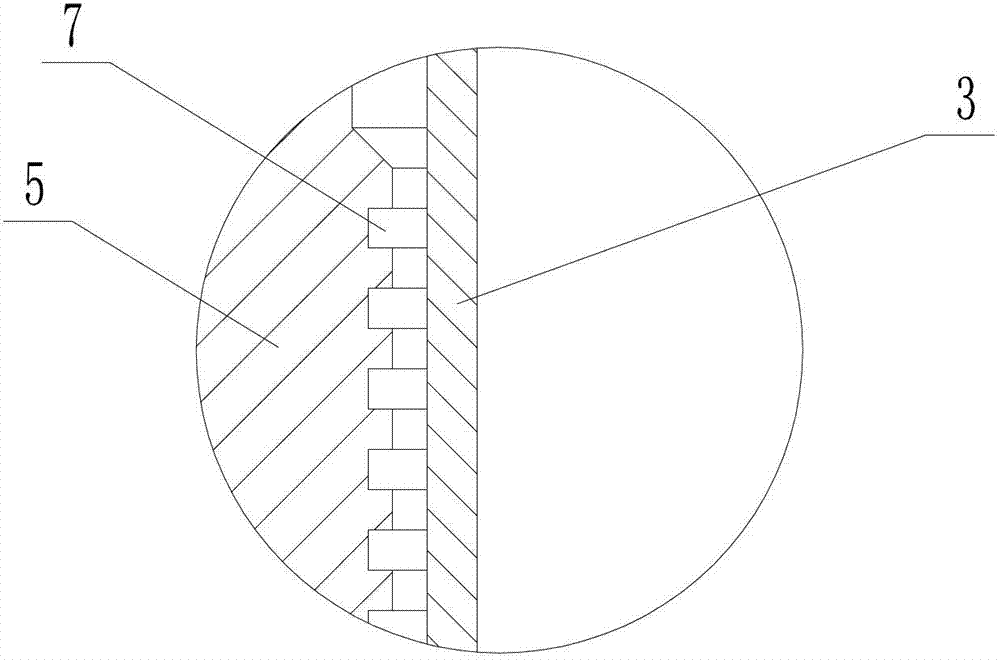

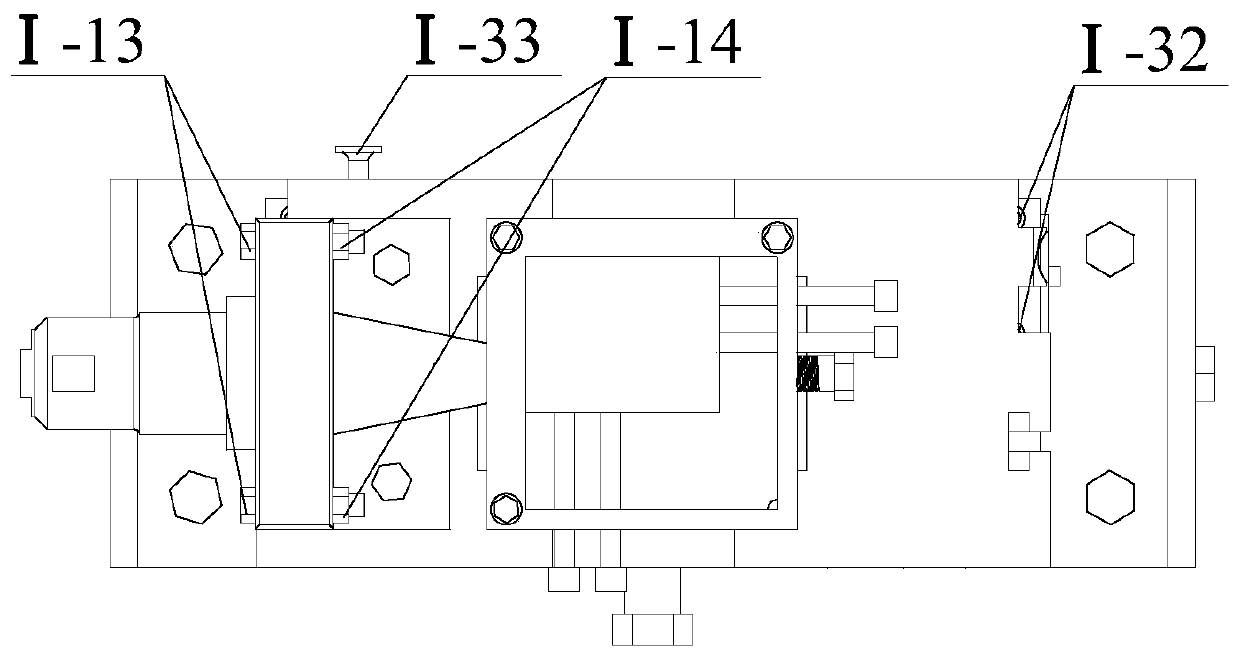

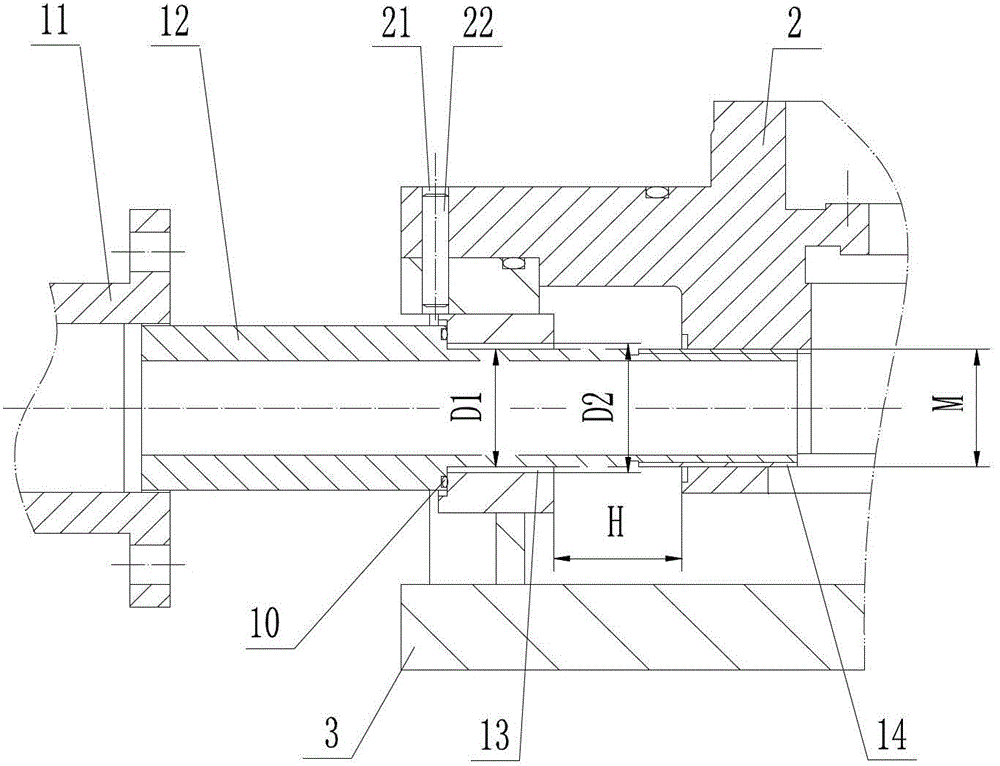

Lubricant circulating device based on sliding bearing and manufacturing process of lubricant circulating device

ActiveCN102829314AExpand the scope of applicationImprove cooling effectBearing coolingEngine lubricationPower equipmentHeavy load

The invention discloses a lubricant circulating device based on a sliding bearing, as well as a manufacturing process of the lubricant circulating device. The lubricant circulating device essentially consists of a bearing bracket, a guide base and an oil tank; an oil transportation duct which is connected to a port of a cold oil inputting pipe penetrates a duct mounting hole of the oil tank and is connected to a thread hole of the guide base, and is communicated with a cold oil storing cavity; a hot oil outputting pipe is connected to the oil tank and is communicated with an oil returning hole, thereby forming a system-cold oil-hot oil / cold oil-lubricant circulating-inputting / outputting loop; meanwhile, under the synchronous control of various corresponding equipment, the scheme of arranging the lubricant circulating inputting / outputting loop system is implemented. Through the lubricant circulating device, the sliding bearing which is matched with the motor, the water pump and other host equipment is not only compactly structured but is adaptive to the high-speed operation of the host equipment, and the sliding bearing cannot change the connecting and mounting size of the original machine and can ensure the circulation of the lubricant; the bearing bush can not generate heat; the equipment system is stable, reliable and safe in operation; the lubricant circulating device is suitable to be used as a supporting product of various power equipment, especially for as a supporting product of various heavy-load engineering machineries.

Owner:HUNAN CHONGDE IND TECH

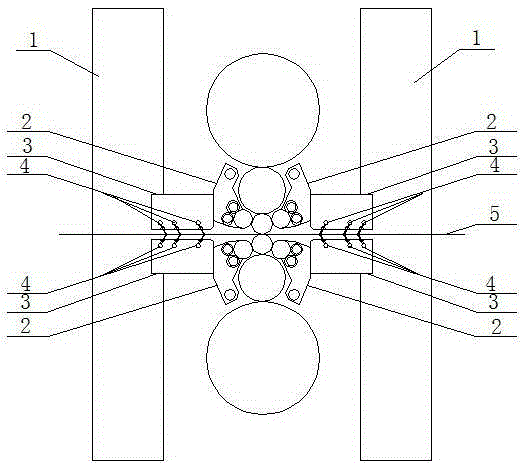

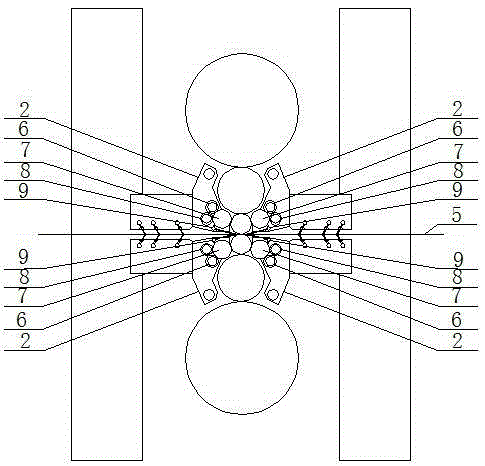

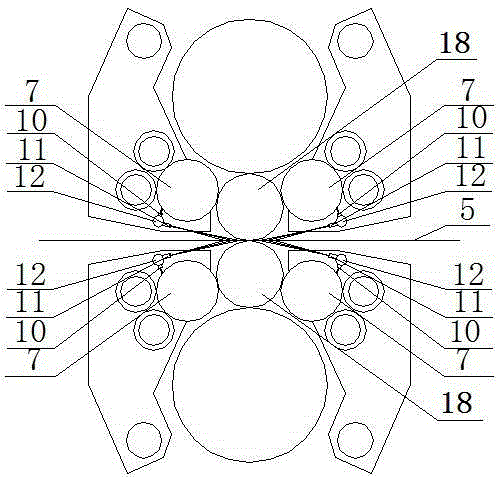

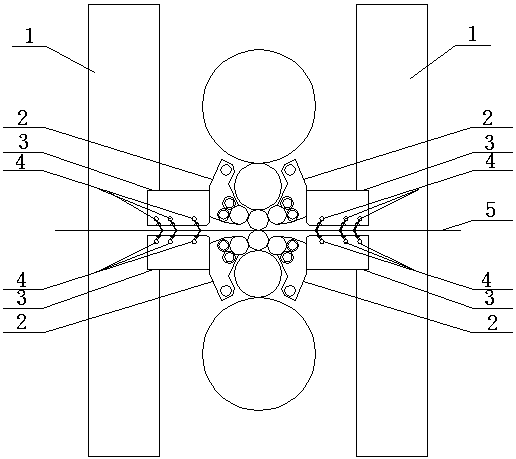

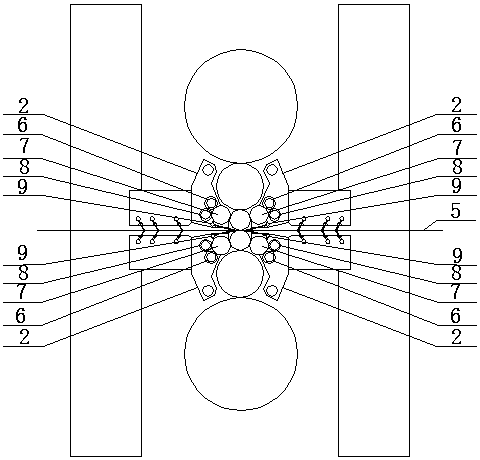

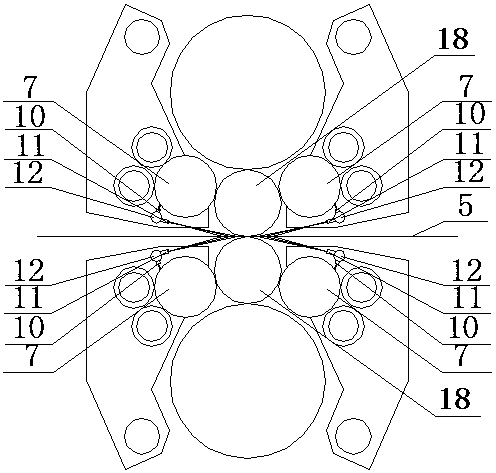

Injecting devices for emulsified liquid of eighteen-roller cold-rolling mill and application thereof

ActiveCN105382041AImprove lubrication and coolingImprove surface qualityRollsWork cooling devicesCooling effectStrip steel

The invention provides injecting devices for emulsified liquid of an eighteen-roller cold-rolling mill. The injecting devices comprise four side supporting frames. The side supporting frames are each provided with an upper backing bearing roller, a side supporting roller and a lower backing bearing roller. A second injecting device is arranged in the position, close to each side supporting roller and each lower backing bearing roller, of each side supporting frame. The second injecting devices comprise injecting beams, a plurality of first nozzles and a plurality of second nozzles, wherein the multiple first nozzles and the multiple second nozzles are installed in the length direction of the injecting beams, the first nozzles face towards the side supporting rollers, and the second nozzles face towards the roller seams of working rollers. According to the injecting devices, the second injecting devices are arranged on the side supporting frames on the basis of unchanging original first injecting devices on side supporting beams, the emulsified liquid is injected into strip steel in the position of the roller seams and the side supporting rollers simultaneously through the second injecting devices, so the lubricating cooling effect of the strip steel in the position of the roller seams is improved, and thus the rolling speed is improved, the rolling energy consumption is reduced, and the surface quality of the strip steel is improved; meanwhile, the side supporting rollers are further cooled, and hence the control precision of the strip shape of the strip steel is improved.

Owner:WISDRI ENG & RES INC LTD +1

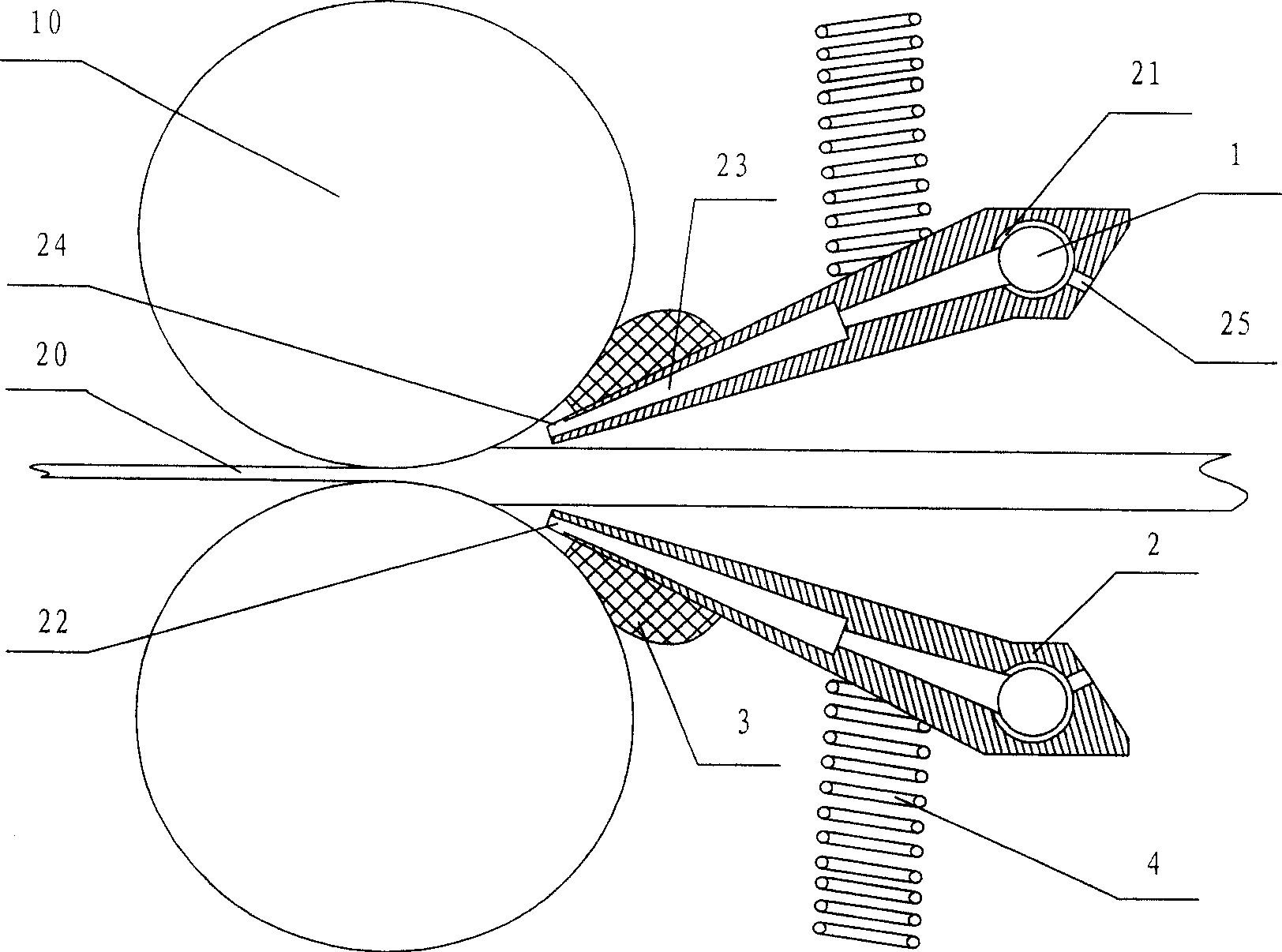

Apparatus for cleaning and lubricating roller

A cleaning and lubricating unit for rolling roller is composed of upper and lower liquid inlet tubes, upper and lower sprayers with front nozzle and back end connected to said liquid inlet tube, upper and lower springs connected between said sprayer and machine frame, and upper and lower erasers fixed to said sprayer and in contact with the surface of working roller.

Owner:郑星昱

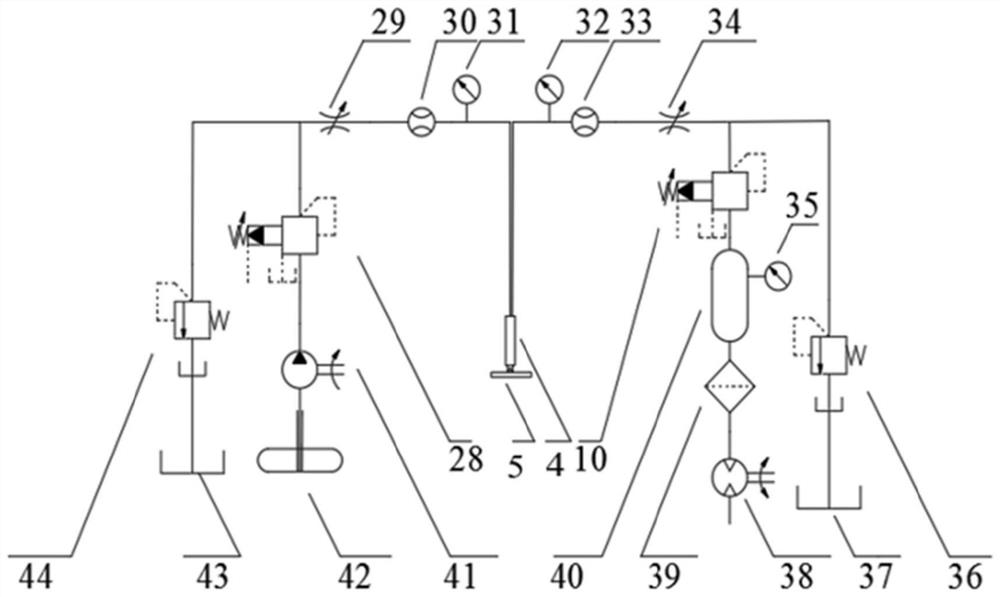

Nanofluid magnetic grinding fluid and magnetic field assisted minimal quantity lubrication system

ActiveCN111423929AReduce performanceHigh strengthLubricant compositionGrinding/polishing safety devicesMagnetic effectCooling effect

The invention discloses a nanofluid magnetic grinding fluid and a magnetic field assisted minimal quantity lubrication system. Magnetic ferroferric oxide nanoparticles in the nanofluid magnetic grinding fluid can be adsorbed on the surface of graphene to form magnetic lubricating mixed particles; the nanofluid magnetic grinding fluid forms spray under the action of the minimal quantity lubricationdevice, magnetic lubrication mixed particles in the spray are uniformly spread in a machining area of a workpiece under the action of the magnetic field auxiliary device to be lubricated and cooled,and the magnetic lubrication mixed particles are collected through the recovery container and can be reused. According to the invention, graphene is used as a lubricant, and the magnetic effect and the minimal quantity lubrication technology are combined for lubrication and cooling, so that the lubricant can be efficiently utilized, the lubrication and cooling effects are greatly improved, energyis saved, the environment is protected, and the industrial production requirements are met.

Owner:HUNAN UNIV

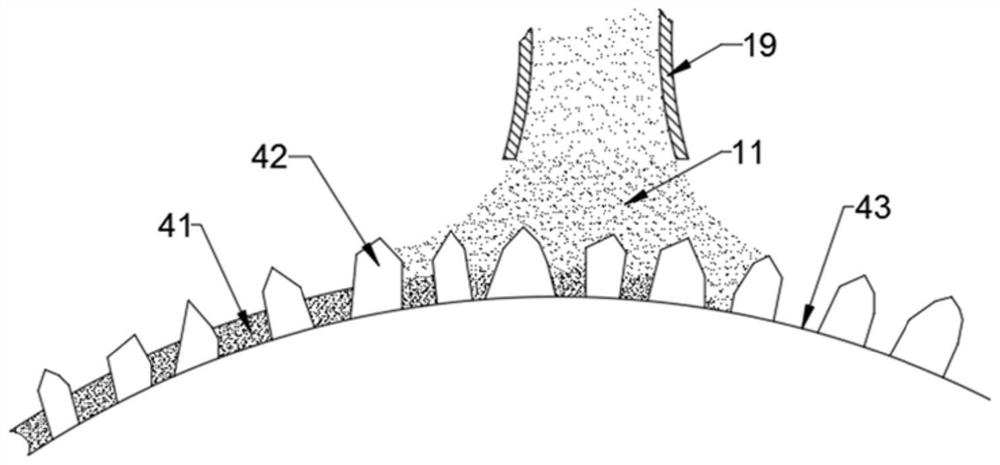

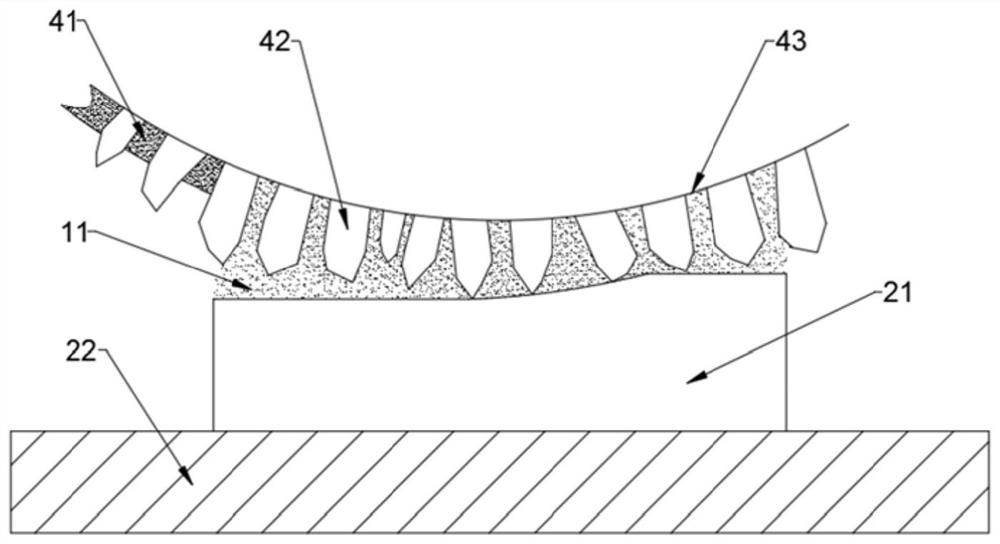

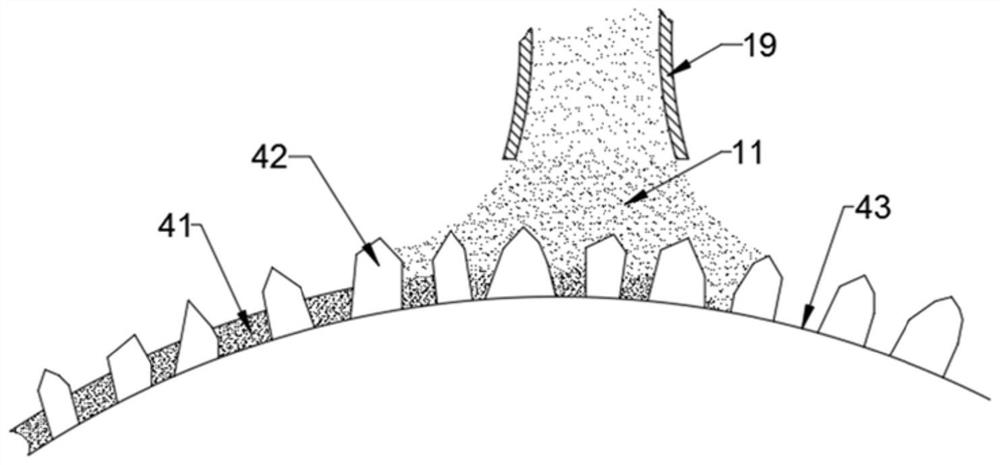

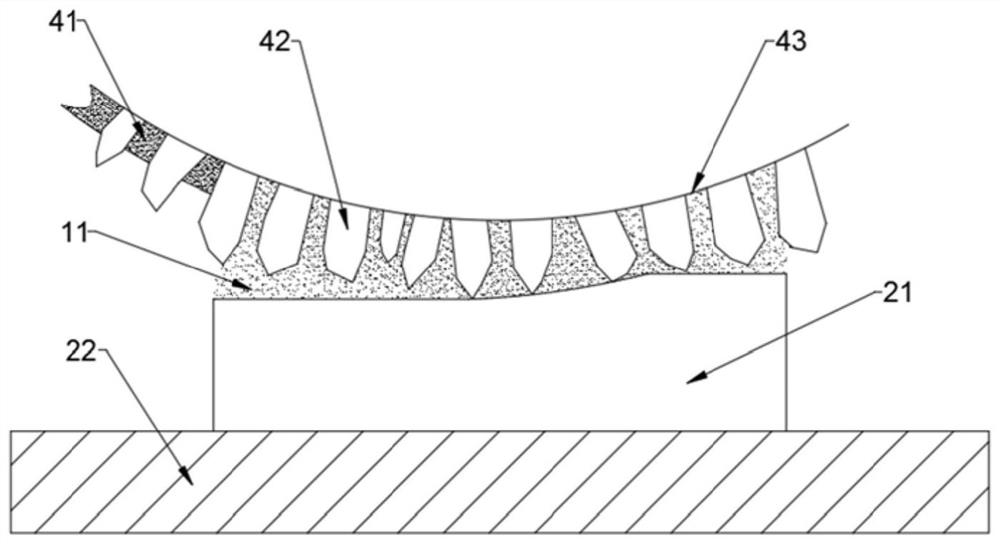

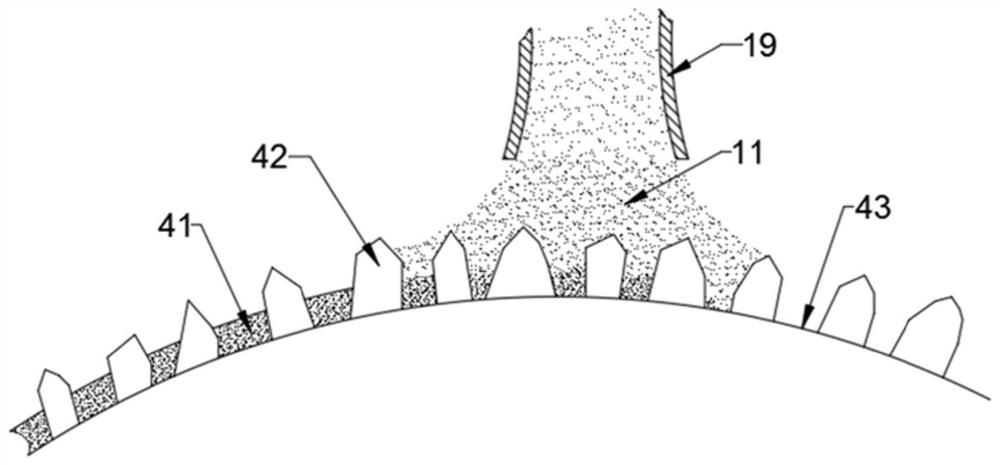

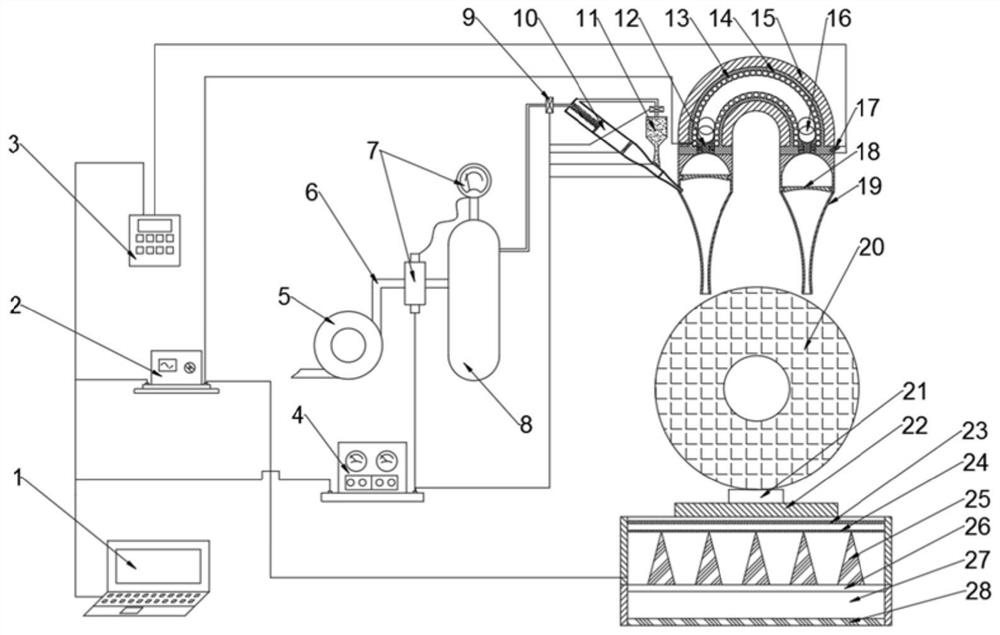

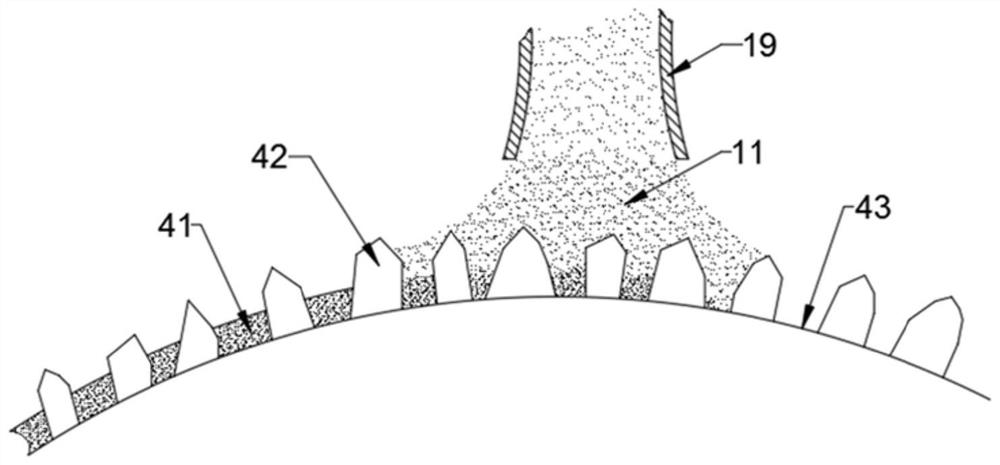

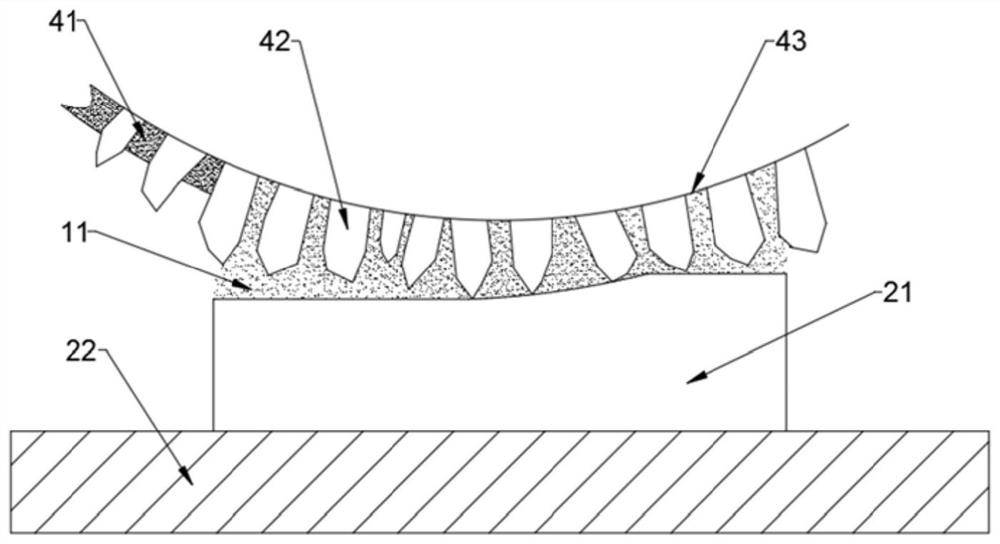

Nano layer lubrication diamond grinding wheel grinding method based on shock wave cavitation effect

ActiveCN112025554AImprove lubrication and coolingReduce grinding specific energyGrinding feed controlAbrasive surface conditioning devicesPhysicsDiamond grinding

The invention provides a nano layer lubrication diamond grinding wheel grinding method based on a shock wave cavitation effect. The method is characterized in that after an air pressure adjusting valve is opened, shock waves generated by an accelerating tube push nano particles to move forwards, and then the nano particles are accelerated by a small laval tube to obtain a high initial speed; meanwhile, a wave source of a shock wave accelerating module generates high-frequency and high-strength shock waves to impact the nano particles with the initial speed, so that the nano particles are continuously accelerated downwards in the axial direction of a large laval tube until the nano particles are embedded into the surface of a grinding wheel at the highest speed to form a nano layer; the other wave source is used for cleaning impurities on the surface of the grinding wheel; and in the machining process, the nano particles of the nano layer are autonomously released in a grinding core area, so that self-lubricating cooling in a grinding area is achieved. The method greatly enhances the lubricating cooling effect, and also conforms to the concept of green development.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

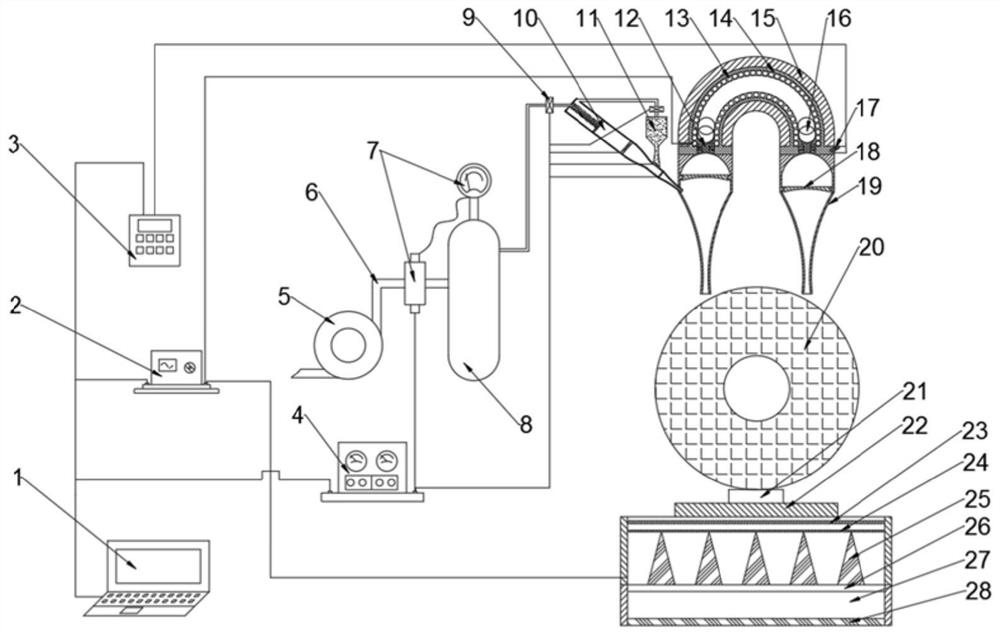

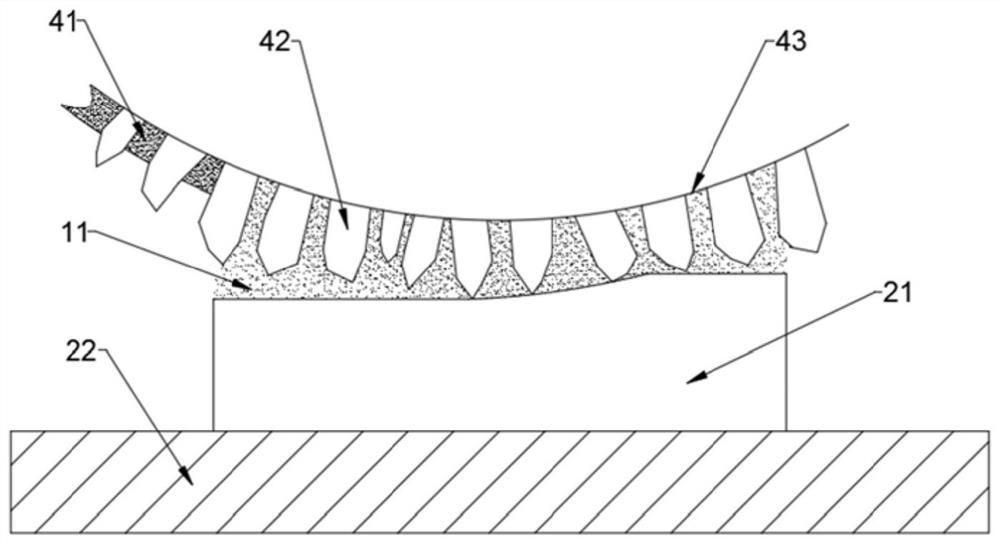

Nanolayer lubricating diamond grinding wheel grinding device based on impact wave cavitation effect

ActiveCN111993270AImprove lubrication and coolingReduce grinding specific energyAutomatic grinding controlGrinding/polishing safety devicesPhysicsDiamond grinding

The invention provides a nanolayer lubricating diamond grinding wheel grinding device based on an impact wave cavitation effect for solving the problem that a grinding solution affected by an air barrier is hard to enter a grinding core region. The device specifically comprises a control system, an accelerating module, an impact wave accelerating module, a machining module and a recovery module. The control system controls operation of the device; the accelerating module is composed of an accelerating pipe, a small La Farr pipe and the like, so that nanoparticles gain initial speeds; the impact wave accelerating module composed of an electromagnetic coil, an impact head, an impact ball, a wave collector, a large La Farr pipe and the like generates two wave sources, wherein one of the wavesources cleans impurities on the surface of the grinding wheel while the other one impacts the nanoparticles with initial speeds to the surface of the grinding wheels to form a nanolayer; in the machining process, the nanoparticles in the nanolayer are released to the grinding core region autonomously, so that the grinding region is self-lubricated and cooled; and the recovery module is used for recovering the nanoparticles to use the nanoparticles repeatedly. The nanolayer lubricating diamond grinding wheel grinding device not only improves the lubricating and cooling effect, but also meets an environmental-friendly development idea.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Nanofluid Minimal Quantity Lubrication Grinding Device

ActiveCN107855836BReduce burnIncrease profitGrinding/polishing safety devicesMetallurgyUltrasonic vibration

The invention discloses an ultrasonic vibration assisted grinding fluid microchannel infiltrated nano-fluid trace lubrication and grinding device and aims at solving the problem that undeformed abrasive dust thickness has larger influence on the grinding process in the prior art. The ultrasonic vibration assisted grinding fluid microchannel infiltrated nano-fluid trace lubrication and grinding device has the beneficial effects that the lubrication state of single abrasive grains when a material is removed in the grinding process is fully considered from microscopic, and the effect of ultrasonic vibration assisted grinding in improving the cooling and lubrication effects of nano-fluid trace lubrication is effectively realized. According to the technical scheme, the device comprises an ultrasonic vibration mechanism capable of regulating the position of an ultrasonic vibrator space, a nano-fluid trace lubrication and grinding mechanism and a grinding force measurement mechanism; the ultrasonic vibration mechanism is arranged on a workbench; the nano-fluid trace lubrication and grinding mechanism is arranged above a workpiece fixing table; the grinding force measurement mechanism comprises a dynamometer and a grinding force controller which is connected with the dynamometer; and the dynamometer is arranged at the bottom of the ultrasonic vibration mechanism.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

Lubricating oil for stamping machinery

InactiveCN107118831AImprove lubrication and coolingEliminate environmental pollutionLubricant compositionStamping processChemistry

The invention discloses lubricating oil for stamping machinery. The lubricating oil consists of the following raw materials in parts by weight: 100-300 parts of III-type basic oil, 500-800 parts of PAO (Poly Alpha Olefin) synthetic oil, 50-80 parts of mineral oil, 10-20 parts of animal and plant grease, 1-5 parts of zinc dialkylphosphorodithiloate, 5-7 parts of petroleum sulfonate, 1-6 parts of benzoic acid, 3-5 parts of an T2XX anti-oxidation preservative, 1-3 parts of polymethacrylate, 1-2 parts of a PPD (Pour Point Depressant) improver and 1-5 parts of triethyl-hexyl phosphoric acid. According to the lubricating oil for stamping machinery, the synthetic oil is adopted as basic oil, the mineral oil and the grease oil are added, the III-type basic oil is adopted as neutralizing oil, and additives are added, therefore, the volatilization time of the lubricating oil can be reasonably controlled, the lubrication and cooling effect of the stamping process can be improved, environment pollution is eliminated, and the production environments are improved.

Owner:安徽省东至县东鑫冲压件有限责任公司

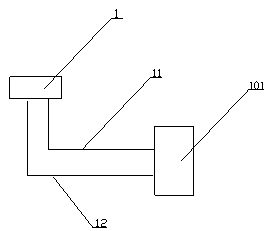

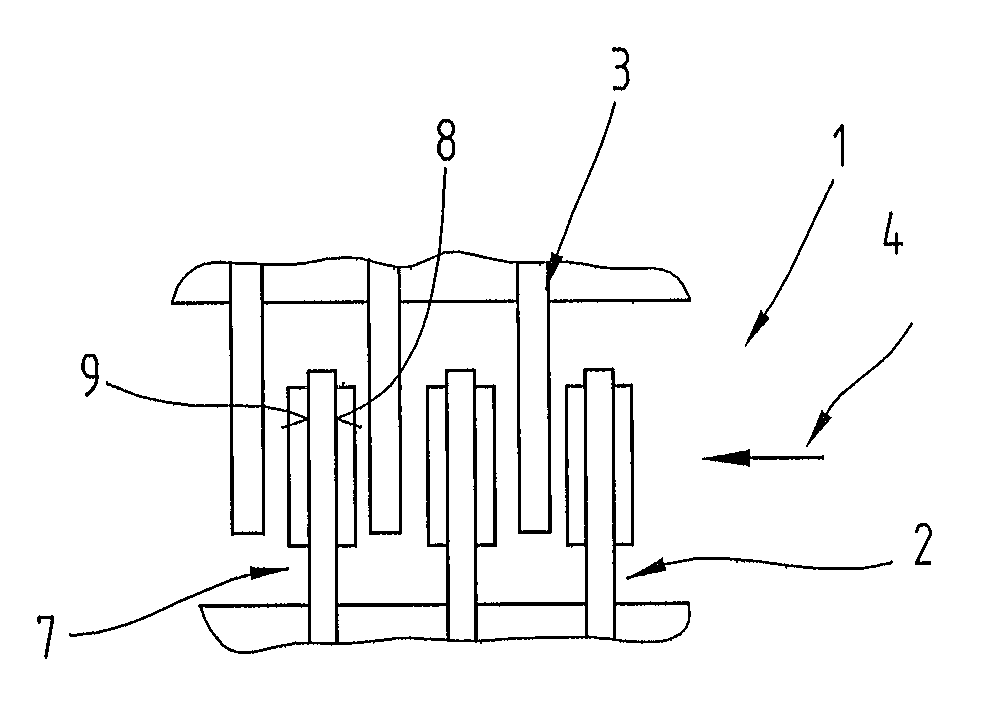

Compression mechanism and compressor

ActiveCN106989023BImprove reliabilityImprove lubrication and coolingRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsElectric machineryMotor shaft

The invention discloses a compressing mechanism and a compressor. The compressing mechanism comprises a shell, a motor assembly, a crankshaft and a motor bearing. Stopping protrusions are arranged inside the shell. At least one first exhaust channel is defined by the outer circumferential wall of the motor assembly and the inner circumferential wall of the shell. At least one second exhaust channel is defined by the motor bearing and the inner circumferential wall of the shell. One ends of the second exhaust channels correspond to the first exhaust channels, and the other ends of the exhaust channels correspond to the stopping protrusions. An oil guide channel is defined by the upper end face of the motor bearing so as to guide lubricating oil into the gap between the motor bearing and the crankshaft. According to the compressing mechanism, the lubricating oil inside the compressing mechanism can sequentially penetrate through the first exhaust channels and the second exhaust channels along with refrigerant, the lubricating oil impacts onto the stopping protrusions and is separated from the refrigerant, the lubricating oil at the positions of the stopping protrusions can drip onto the upper end face of the motor bearing and then flow into the gap between the motor bearing and the crankshaft through the oil guide channel, and accordingly the motor bearing and the crankshaft can be lubricated and cooled.

Owner:GUANGDONG MEIZHI COMPRESSOR

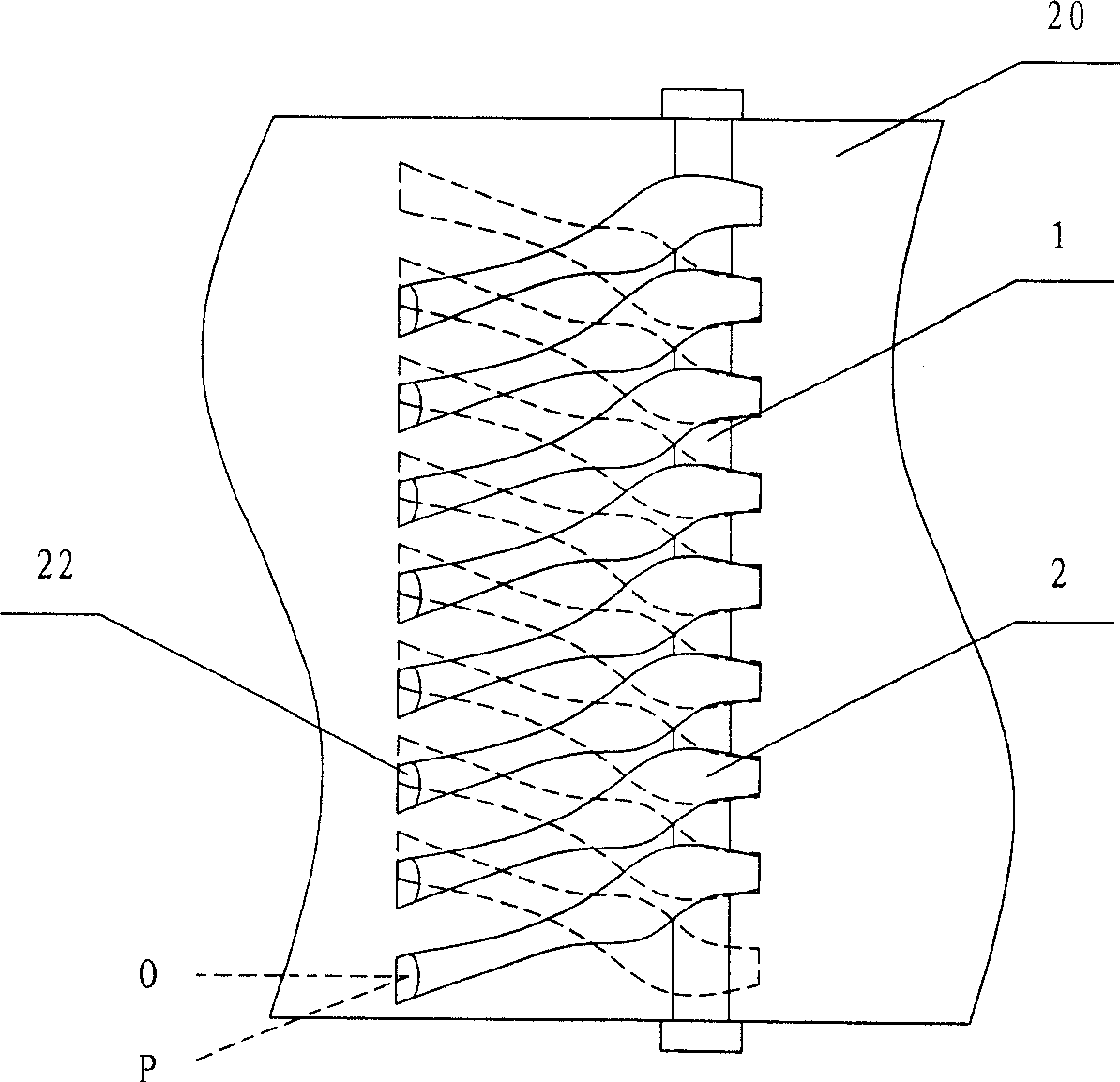

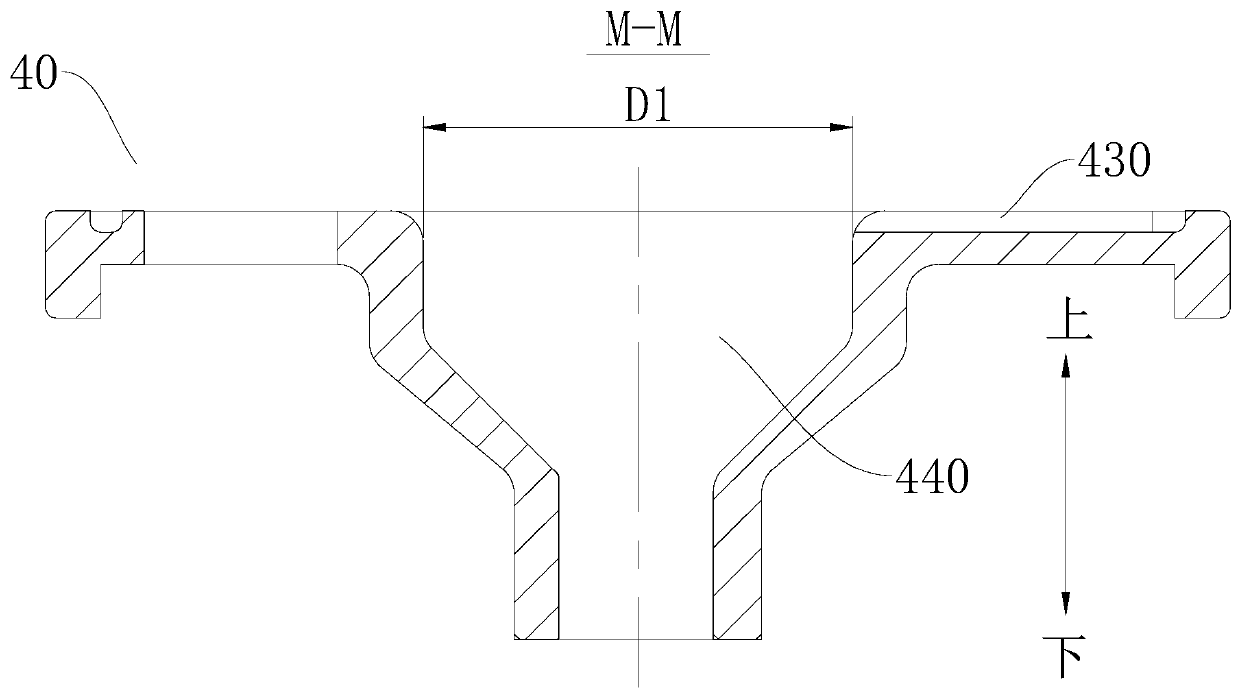

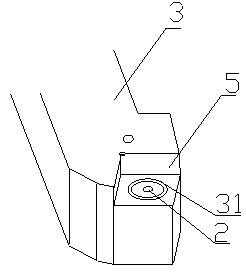

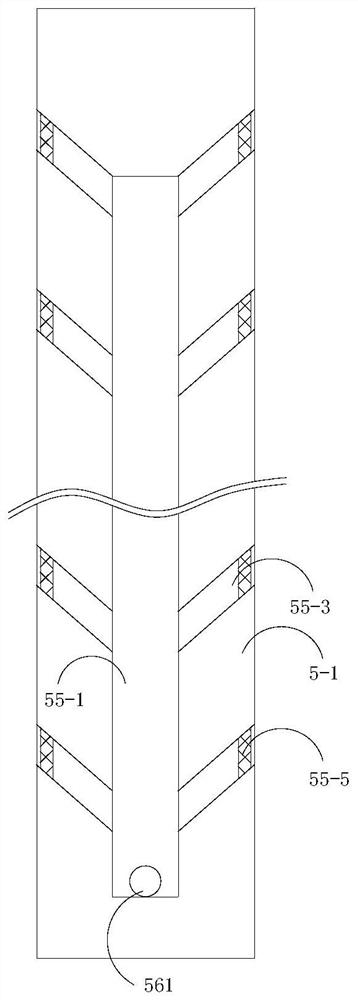

Cutting lubricating method directly acting on tool-scrap interface and cutting tool

InactiveCN108188421AReduce usageHarm reductionTurning toolsMaintainance and safety accessoriesCooling effectEngineering

The invention provides a cutting lubricating method directly acting on a tool-scrap interface and a cutting tool and relates to the technical field of machining. According to the method, a lubricant is directly conveyed to the tool-scrap interface through a passage penetrating to the tool-scrap interface from the tool and acts on tool cutting operation; the cutting tool comprises two parts of a tool body and a tool rod, the tool is internally provided with the passage penetrating to the tool-scrap interface of the tool body from the bottom face of the tool rod, and the passage is divided intoa micro passage body located in the tool body and vertical upper and lower sections a lubricating pipeline located on the tool rod; on the tool-scrap interface of the tool, a microtexture is arrangedwith an upper opening in the micro passage body as the center, and a lower opening of the lubricating pipeline is connected with a lubricant supplying system; a main cooling cavity is formed in the lower end of the micro passage body, a secondary cooling cavity is formed in the upper end of the micro passage body , and a circulating pipeline is arranged at the lower end of the secondary cooling cavity; and a lower opening of the circulating pipeline is connected with the lubricant supplying system. The cutting lubricating method has the beneficial effects that the lubricant directly acts on the tool-scrap interface, the lubricating and cooling effects are excellent, using of the lubricant is reduced, the cost is reduced, and environment protection is achieved.

Owner:QINGDAO UNIV OF SCI & TECH

Nano-layer lubricated diamond grinding wheel grinding device based on shock wave cavitation effect

ActiveCN111993270BImprove lubrication and coolingAvoid wasteful useAutomatic grinding controlGrinding/polishing safety devicesControl systemNanoparticle

The invention proposes a nano-layer lubricated diamond grinding wheel grinding device based on the shock wave cavitation effect, which is used to solve the problem that the grinding fluid is difficult to enter the grinding core area due to the influence of the gas barrier layer. Specifically, it includes the control system, acceleration module, shock wave acceleration module, processing module, and recovery module. Among them, the control system controls the operation of the device; the acceleration module is composed of an acceleration tube, a small Rafal tube, etc., which can make the nanoparticles obtain an initial velocity; it consists of an electromagnetic coil, an impact head, an impact ball, a wave condenser, and a large Lafal The shock wave speed-up module composed of equal components will generate two wave sources, one to clean the impurities on the surface of the grinding wheel, and the other to impact the nanoparticles with initial velocity to the surface of the grinding wheel to form a nano-layer; during the processing, the nanoparticles in the nano-layer are released autonomously in the grinding core area , to achieve self-lubricating cooling inside the grinding area; the recovery module is used to recover nanoparticles and realize their reuse. The device not only enhances the lubricating and cooling effect, but also complies with the concept of green development.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

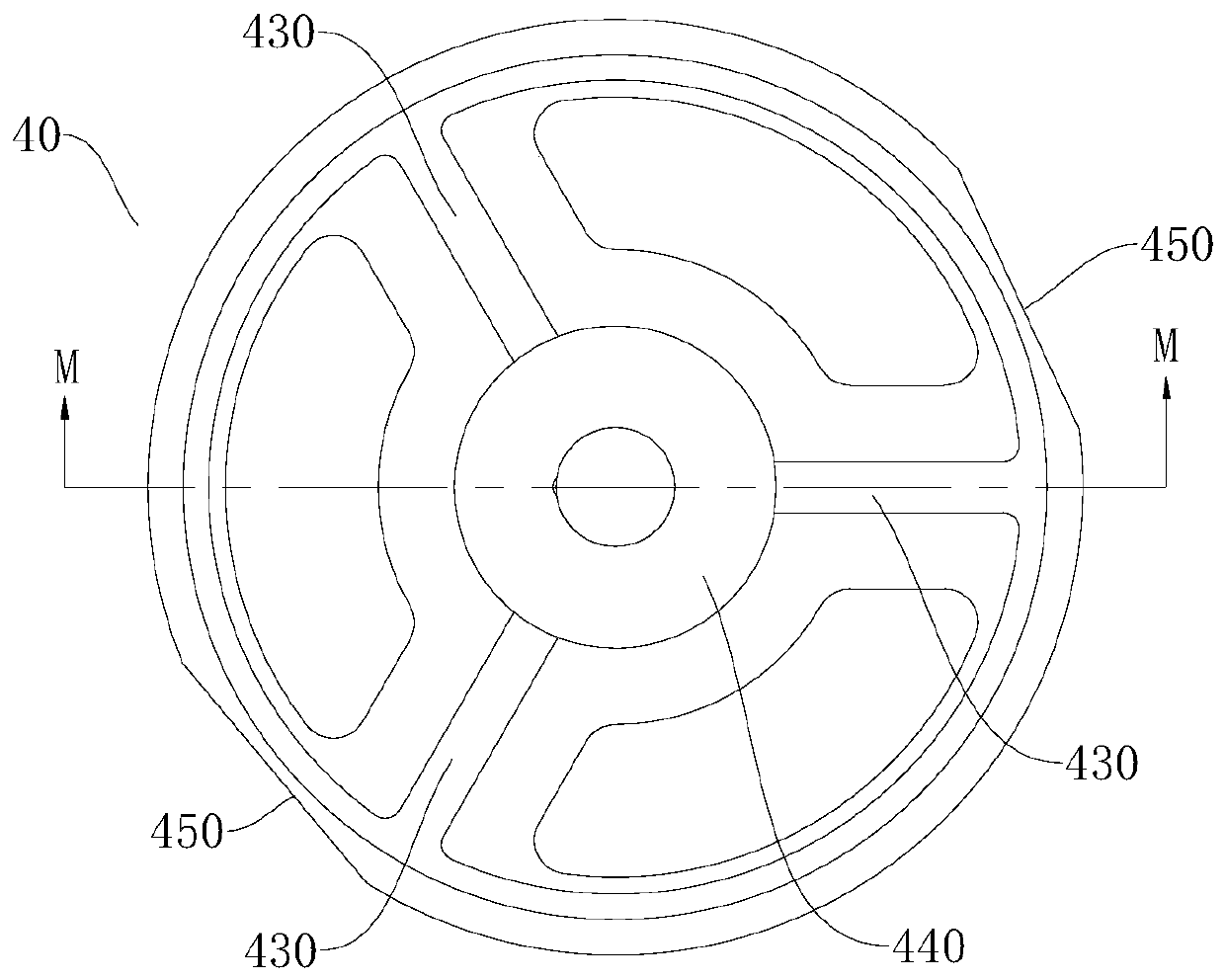

a wet clutch

Owner:CHONGQING GEARBOX

Liquid Lubrication Method and Cutting Lubrication System Acting on Tool-Swarf Interface

InactiveCN107891160BReduce the temperatureImproved fill distribution capabilityTurning toolsEnvironmental resistanceCooling chamber

The invention provides a liquid lubrication method and a cutting lubrication system directly acting on a blade-chip interface, and relates to the technical field of machining. A channel penetrating from a bottom surface of a blade to the blade-chip interface conveys a liquid lubricant to the blade-chip interface; the cutting lubrication system comprises a blade body and a blade rod which are detachably connected with each other, and is internally provided with the channel penetrating from the bottom surface to the blade-chip interface, and the channel comprises a micro-channel positioned within a range of the blade body and a lubrication pipeline positioned within a range of the blade rod; micro-texture is arranged by taking an upper opening of the micro-channel as a center; a lower opening of a lubrication channel is connected with a liquid lubricant feeding system; and the lower end of the micro-channel is provided with a primary cooling chamber, the upper end of the lubrication channel is provided with a secondary cooling chamber adapted to the primary cooling chamber, a circulating pipeline extends out from the lower end of the secondary cooling chamber, a lower opening of thecirculating pipeline is positioned on a bottom surface of the blade rod, and the circulating pipeline is detachably connected with the liquid lubricant feeding system through an output pipe. The liquid lubrication method and the cutting lubrication system provided by the invention have the beneficial effects of directly acting on the blade-chip interface, reducing the cutting cost, and being environmentally-friendly.

Owner:QINGDAO UNIV OF SCI & TECH

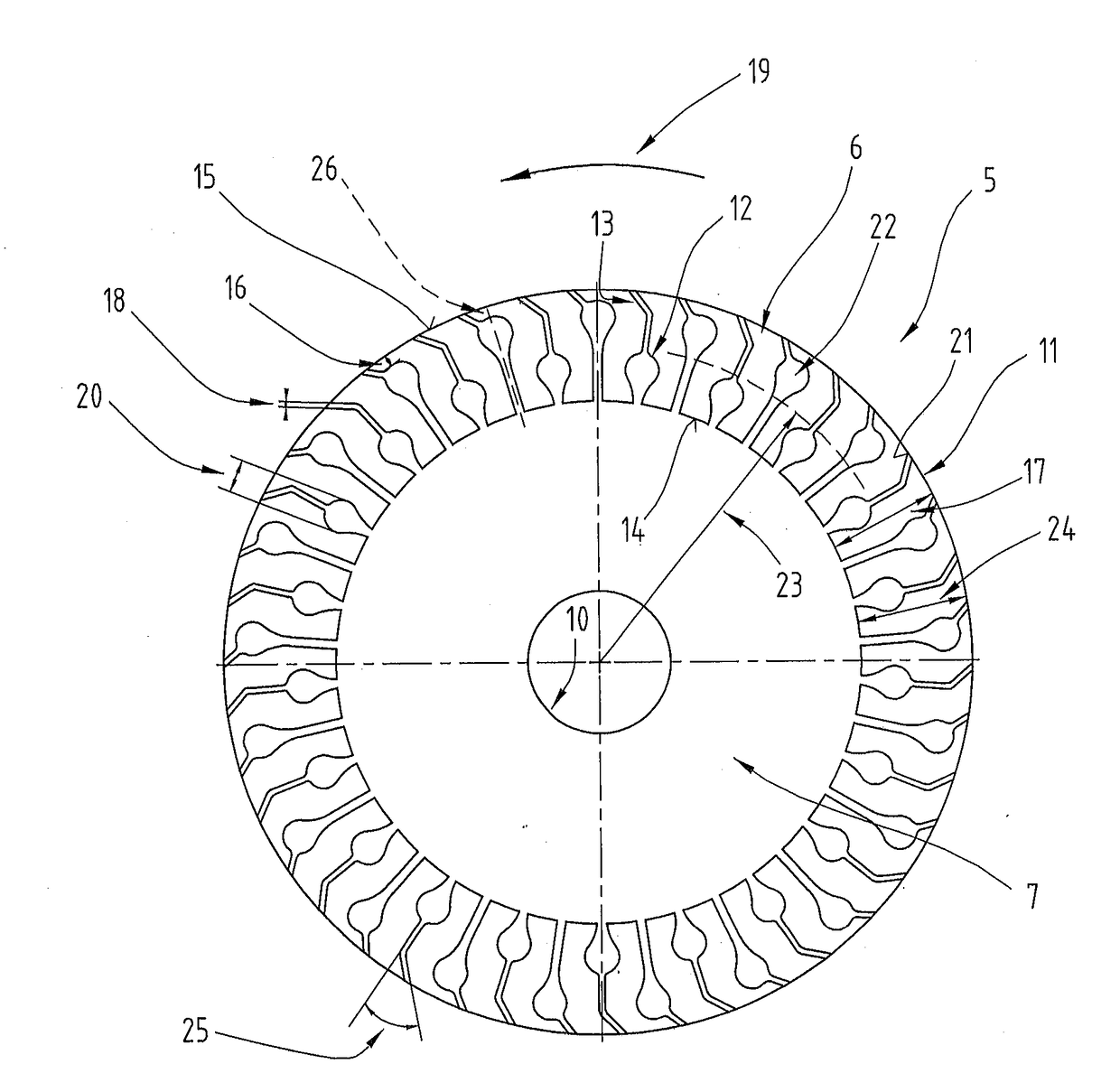

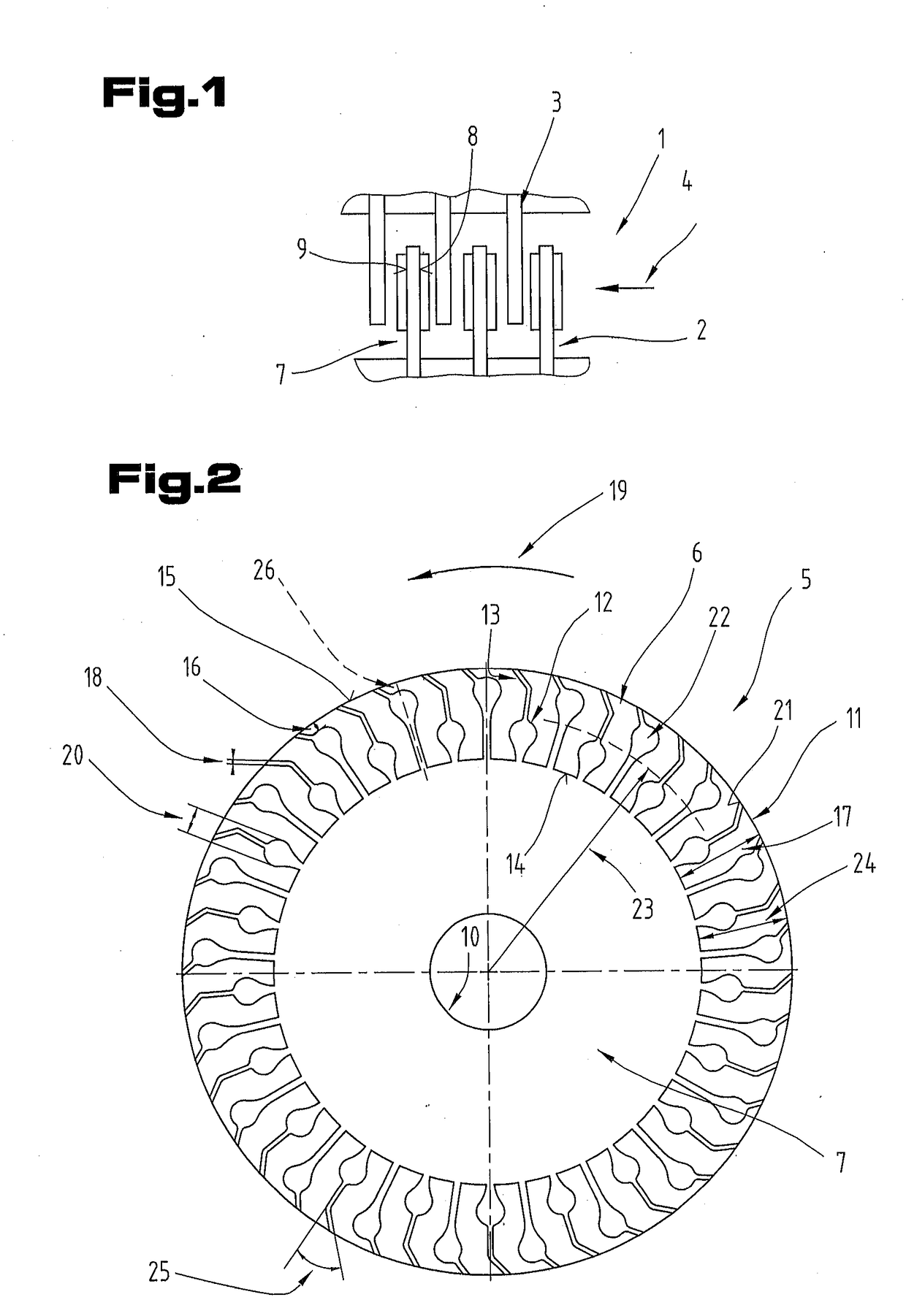

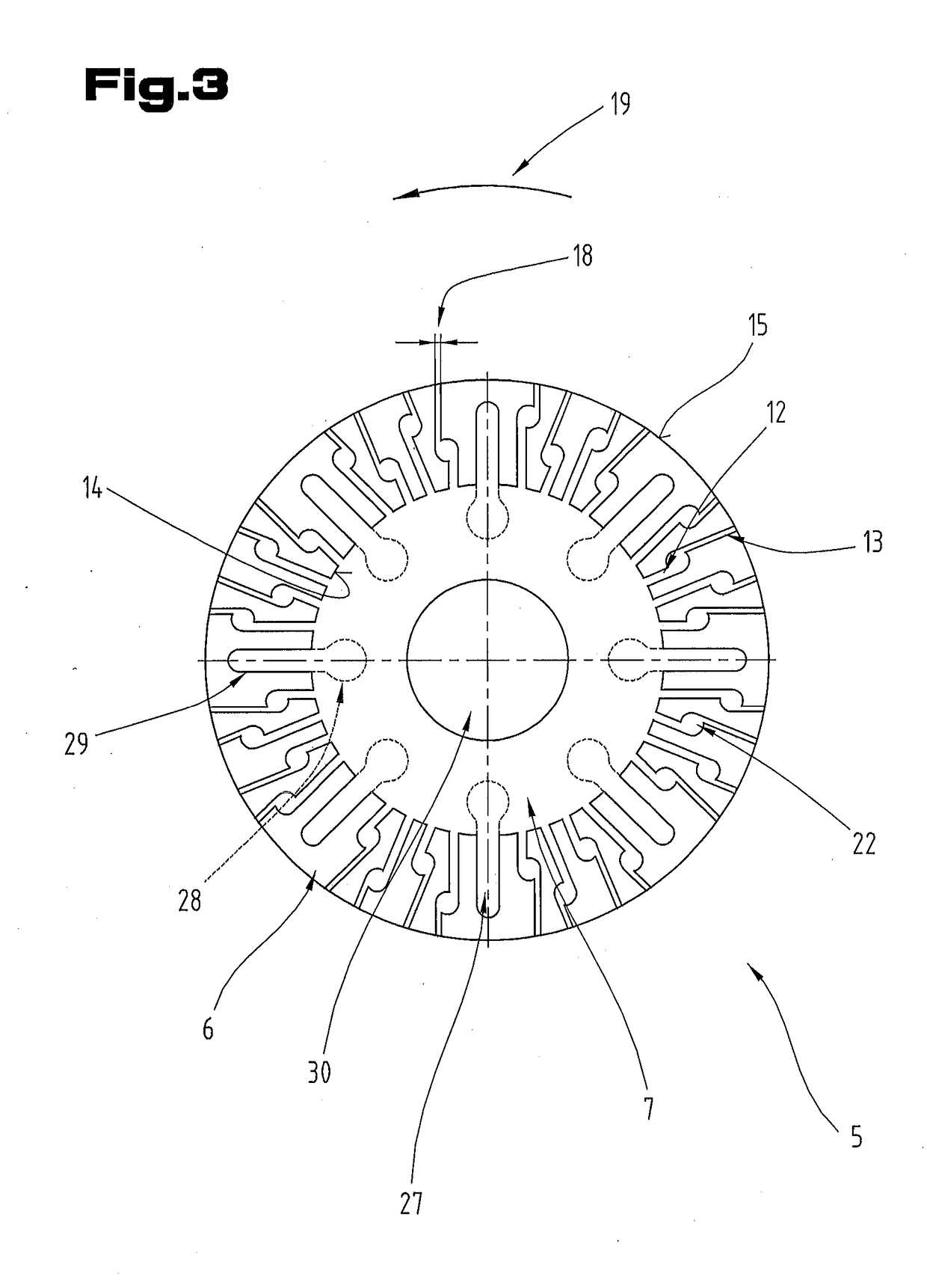

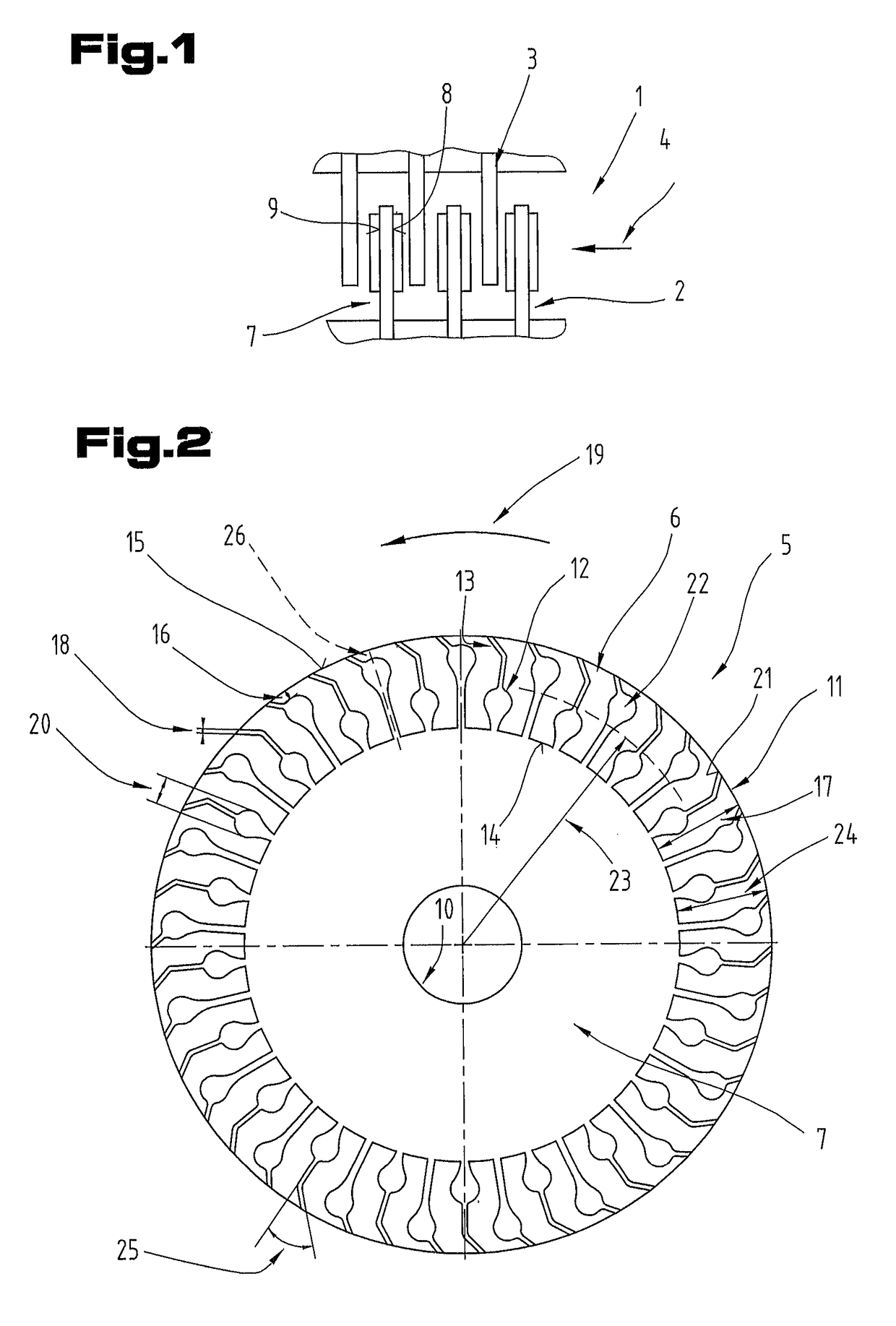

Friction plate

ActiveUS20170292573A1Raise transfer toIncrease inflowFriction clutchesFriction liningMarine engineering

Owner:MIBA FRICTEC

Grinding method of nano-layer lubricated diamond wheel based on shock wave cavitation effect

ActiveCN112025554BImprove lubrication and coolingAvoid wasteful useNon-mechanical blast generatorsGrinding feed controlCavitationNanoparticle

The invention proposes a nano-layer lubricated diamond grinding wheel grinding method based on the shock wave cavitation effect. When the air pressure regulating valve is opened, the shock wave generated by the acceleration tube pushes the nano particles forward, and then the small Rafal tube accelerates them to move forward. Obtain a higher initial velocity; at the same time, a wave source of the shock wave acceleration module generates a high-frequency and high-intensity shock wave, which impacts the nanoparticles with an initial velocity, making it continuously accelerate downward along the axial direction of the large Lafal tube until reaching the highest velocity Embedding the surface of the grinding wheel to form a nano-layer; another wave source is used to clean the surface impurities of the grinding wheel; during the processing, the nanoparticles in the nano-layer are released in the grinding core area independently, realizing self-lubricating and cooling inside the grinding area; this method not only greatly enhances the Lubricating and cooling effect, and in line with the concept of green development.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Lubricant circulating device based on sliding bearing and manufacturing process of lubricant circulating device

ActiveCN102829314BSolve the problem of high temperatureImprove lubrication and coolingBearing coolingEngine lubricationSynchronous controlSlider bearing

The invention discloses a lubricant circulating device based on a sliding bearing, as well as a manufacturing process of the lubricant circulating device. The lubricant circulating device essentially consists of a bearing bracket, a guide base and an oil tank; an oil transportation duct which is connected to a port of a cold oil inputting pipe penetrates a duct mounting hole of the oil tank and is connected to a thread hole of the guide base, and is communicated with a cold oil storing cavity; a hot oil outputting pipe is connected to the oil tank and is communicated with an oil returning hole, thereby forming a system-cold oil-hot oil / cold oil-lubricant circulating-inputting / outputting loop; meanwhile, under the synchronous control of various corresponding equipment, the scheme of arranging the lubricant circulating inputting / outputting loop system is implemented. Through the lubricant circulating device, the sliding bearing which is matched with the motor, the water pump and other host equipment is not only compactly structured but is adaptive to the high-speed operation of the host equipment, and the sliding bearing cannot change the connecting and mounting size of the original machine and can ensure the circulation of the lubricant; the bearing bush can not generate heat; the equipment system is stable, reliable and safe in operation; the lubricant circulating device is suitable to be used as a supporting product of various power equipment, especially for as a supporting product of various heavy-load engineering machineries.

Owner:HUNAN CHONGDE IND TECH

An eighteen-high cold rolling mill emulsion injection device and its application

ActiveCN105382041BImprove lubrication and coolingImprove surface qualityRollsWork cooling devicesEmulsionCooling effect

Owner:WISDRI ENG & RES INC LTD +1

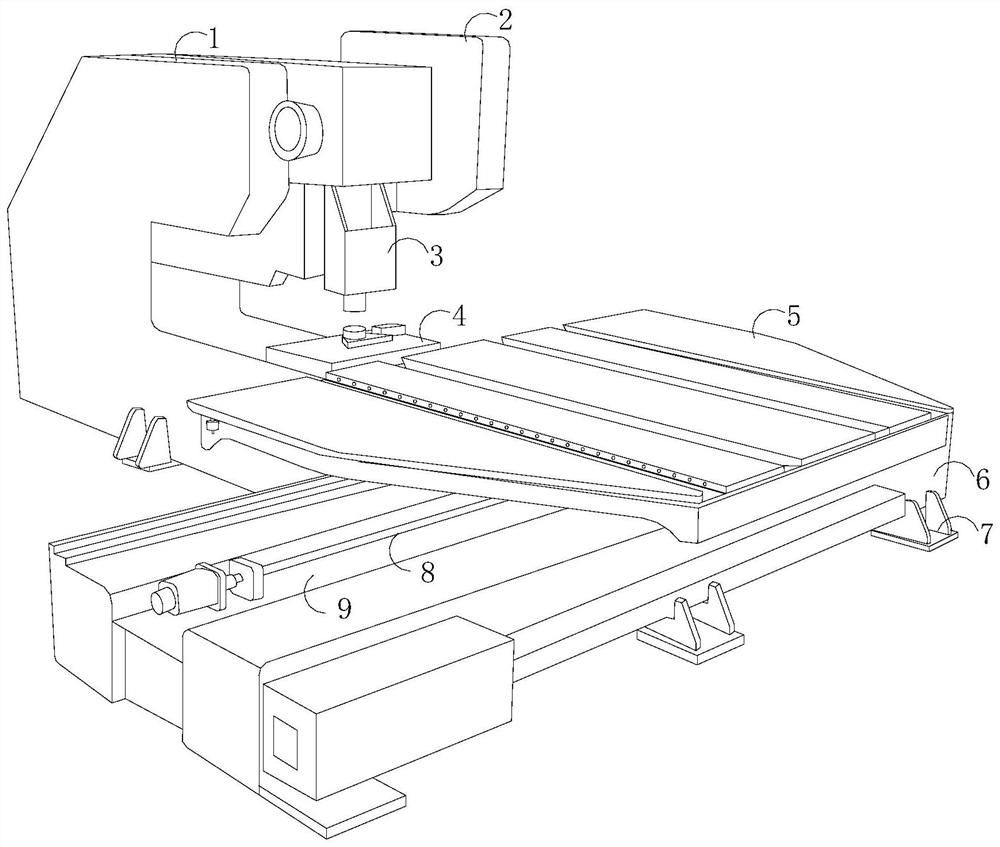

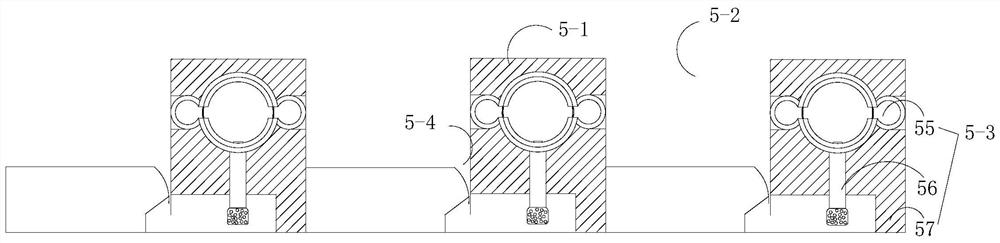

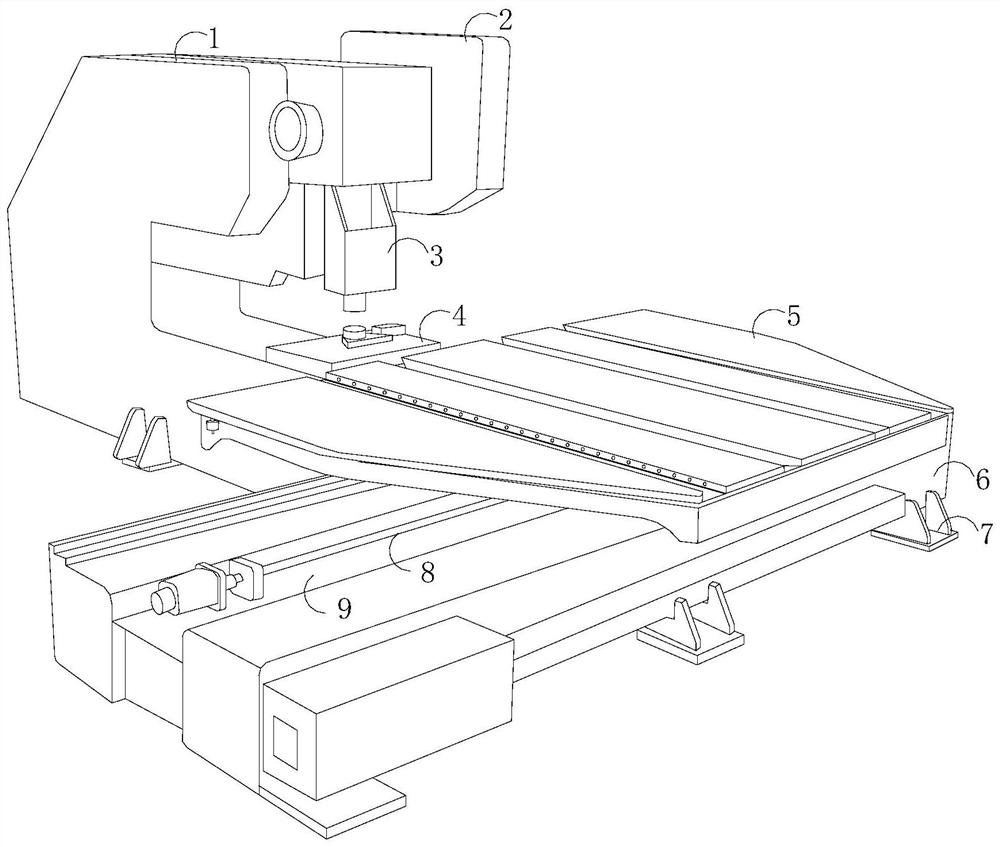

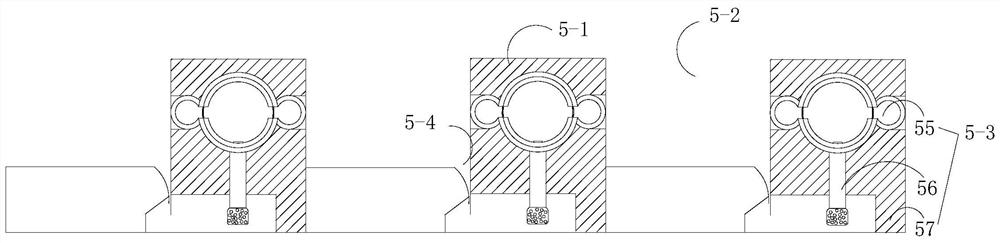

A multi-station CNC bearing rolling processing equipment

ActiveCN110743994BImprove lubrication and coolingIncrease profitBearing componentsWork cooling devicesControl engineeringProcess engineering

Owner:常荣杰

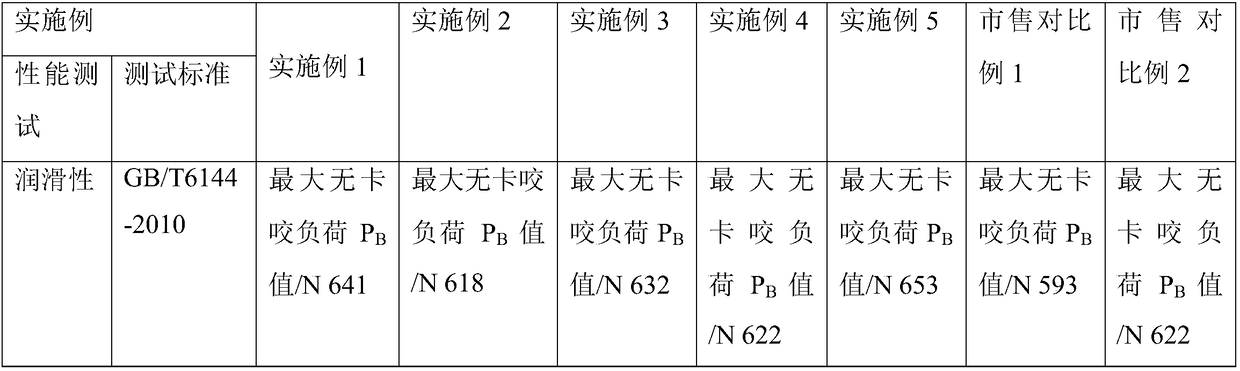

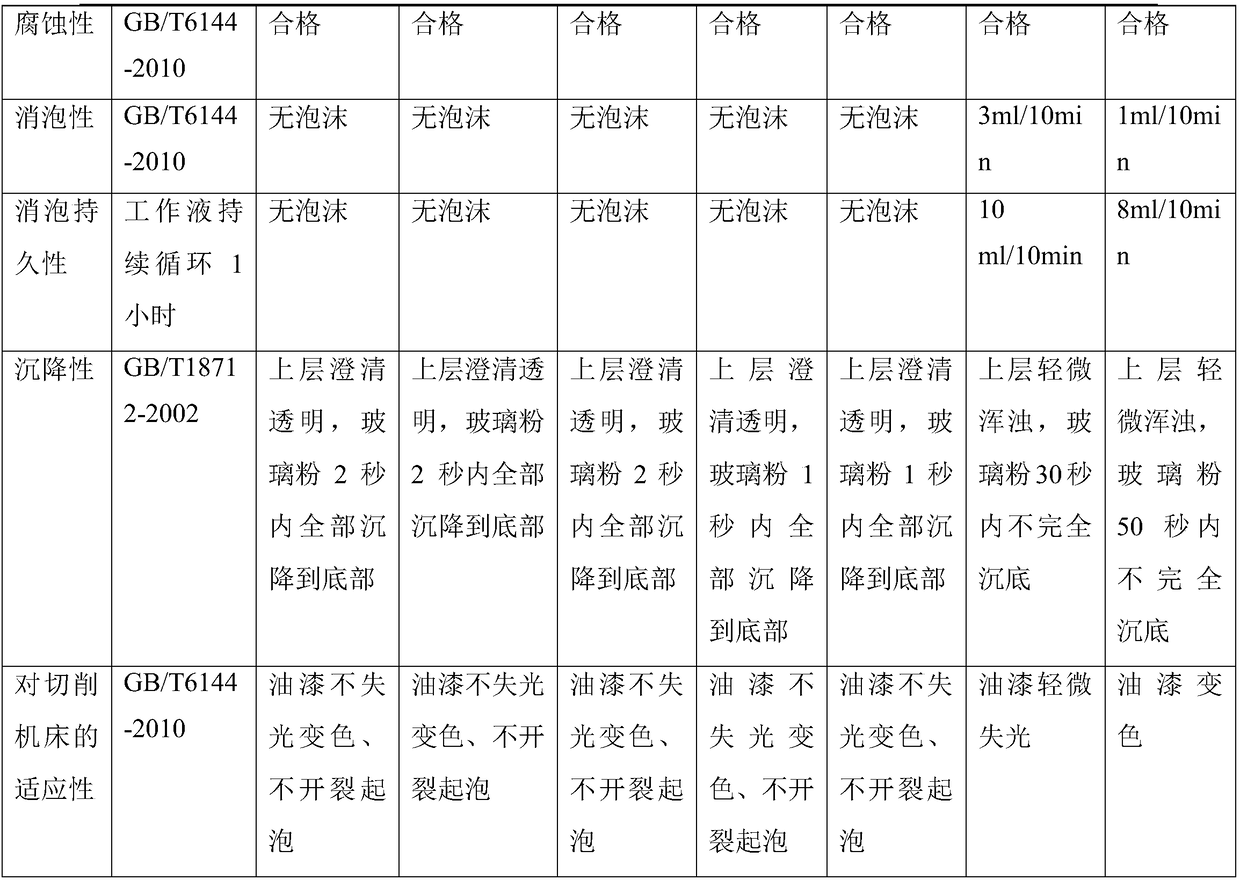

Total synthesis glass cutting fluid and preparation method thereof

ActiveCN108342246AImprove rust resistanceImprove the lubrication effectLubricant compositionWorking fluidSebacic acid

The invention discloses a total synthesis glass cutting fluid which comprises the following main components: triethanolamine borate, sebacic acid, PEG-400, polyacrylamide, ammonium polyphosphate, starcool TOR, fluorescent green and alkaline electrolyzed water. The total synthesis glass cutting fluid has good lubricity cooling performance, the whole process of circulation of a working fluid is freeof bubble, glass powder has fast sedimentation speed, operators are not allergic to the total synthesis glass cutting fluid, and the working fluid has excellent anti-rust performance. The total synthesis glass cutting fluid is mainly used for processing precision glass components such as optical glass, camera lenses, LCD glass panels and optical instruments.

Owner:CHINA THREE GORGES UNIV

A Nanofluid Magnetic Grinding Fluid and Magnetic Field Assisted Minimal Quantity Lubrication System

ActiveCN111423929BReduce performanceHigh strengthLubricant compositionGrinding/polishing safety devicesMagnetic effectCooling effect

The invention discloses a nanofluid magnetic grinding fluid and a magnetic field-assisted micro-lubrication system. Magnetic iron ferric oxide nanoparticles in the nanofluid magnetic grinding fluid will be adsorbed on the surface of graphene to form magnetic lubrication mixed particles. The nano-fluid magnetic grinding fluid forms a spray under the action of the micro-lubrication device, and the magnetic lubrication mixed particles in the spray are evenly spread on the processing area of the workpiece under the action of the magnetic field auxiliary device for lubrication and cooling. The magnetic lubrication mixed particles are collected by the recovery container , can be reused. The invention uses graphene as a lubricant, and combines magnetic effects and micro-lubrication technology to carry out lubrication and cooling, which can not only realize the efficient utilization of lubricants, greatly improve the lubrication and cooling effect, but also save energy and protect the environment, and meet the requirements of industrial production.

Owner:HUNAN UNIV

Multi-station numerical control bearing rolling machining system and method

InactiveCN112828215AImprove lubrication and coolingIncrease profitBearing componentsWork cooling devicesNumerical controlControl engineering

The invention discloses a multi-station numerical control bearing rolling machining system and method. The multi-station numerical control bearing rolling machining system structurally comprises a top frame, a control panel, a rolling head, a connecting butt plate, a station fixing structure, a sliding bottom frame, supporting feet, a hydraulic rod and a sliding groove, wherein the two or more supporting feet are arranged at the bottom of the sliding bottom frame; the sliding groove is formed in the horizontal middle of the sliding bottom frame; and the hydraulic rod is arranged at one end of the sliding groove. Through the design of a lubricating system and an oil return port, a bearing ring which is located in a groove and is about to be rolled or is rolled is overall lubricated, lubricating oil obtained after lubricating can flow back to the lubricating system along the oil return port to be reutilized, due to the fact that the lubricating system carries the lubricating oil obtained after backflow, impurities are many, two or more filtering structures are arranged, the cleanliness of the lubricating oil in the lubricating system is improved, and the friction force between the bearing ring and the groove is reduced.

Owner:常荣杰

Friction plate

ActiveUS9982724B2Heat dissipation fastAvoid overall overheatingFriction clutchesFriction liningMarine engineering

Owner:MIBA FRICTEC

Nanofluid minimal quantity lubrication and atomization cooling ultra-precision cutting medium supply system

ActiveCN113478393AReduce usageAvoid breakingGrinding/polishing safety devicesAtomizer nozzleEngineering

The invention discloses a nanofluid minimal quantity lubrication and atomization cooling ultra-precision cutting medium supply system. The system comprises a workbench, a compressed air path, a nanofluid liquid path, a cutter, a workpiece to be machined and a jet flow atomization nozzle; the cutter and the workpiece to be machined are arranged on the workbench and move in the same direction or away from each other; the jet flow atomization nozzle is arranged on one side of the cutter, and the second end of the jet flow atomization nozzle faces a cutting area, making contact with the workpiece to be machined, of the cutter; and the second end of the jet flow atomization nozzle sprays three-phase bubble flow to the cutting area at the near sound speed. By arranging the jet flow atomization nozzle, high-speed atomization of the nanofluid can be achieved through compressed air, a large number of tiny liquid drops are formed after the nanofluid is sprayed out, the tiny liquid drops are evenly attached to the cutting face of the cutting area, and therefore the technical problem existing when the existing nanofluid is directly used for cutting is effectively solved.

Owner:YUNNAN KIRO CH PHOTONICS

Nanofluid MQL and Atomization Cooling Ultra-Precision Cutting Medium Supply System

ActiveCN113478393BReduce usageAvoid breakingGrinding/polishing safety devicesJet flowAtomizer nozzle

The present application discloses a nanofluid micro-lubrication and atomization cooling ultra-precision cutting medium supply system, comprising: a workbench, a compressed air path, a nanofluid liquid path, a tool, a workpiece to be processed, and a jet atomization nozzle; The workpiece to be processed is set on the worktable, and moves toward or away from each other; the jet atomization nozzle is arranged on one side of the tool, and the second end of the jet atomization nozzle is arranged towards the cutting area where the tool contacts the workpiece to be processed; the jet atomization nozzle The second end of the jet sprays a three-phase bubble-like flow to the cutting area at a near-sonic speed. By setting the jet atomization nozzle, the high-speed atomization of the nano-fluid can be realized by using compressed air, so that a large number of tiny droplets are formed after spraying, which are evenly attached to the cutting surface of the cutting area, thereby effectively solving the problem of direct nano-fluid directly. Technical problems when used for cutting.

Owner:YUNNAN KIRO CH PHOTONICS

A Canned Pump with Forced Cooling and Lubricating Function

ActiveCN107387424BImprove reliabilityImprove lubrication and coolingPump componentsPump installationsImpellerSlider bearing

The invention provides a shield pump with forced cooling and lubricating functions. A front bearing pedestal and a rear sliding bearing pedestal are each provided with two through holes. A gap is reserved between a front thrust disc and a front sliding bearing, and a gap is reserved between a rear thrust disc and a rear sliding bearing. The center of a shaft, the center of an impeller nut and the center of a nut are provided with through holes. Part of conveying medium from an impeller can flow past the inner side, the outer side and the end of the front sliding bearing, and then the conveying medium enters the impeller via a pressure relief opening of the impeller to form a liquid flow channel. Meanwhile, part of the conveying medium flows past the front sliding bearing pedestal, the inner side gap of a shield sleeve and the inner side, the outer side and the end of the rear sliding bearing, and then returns to an impeller inlet from the through hole in the center of the nut, the through hole in the center of the shaft and the through hole in the center of the impeller nut to form a loop. The rear sliding bearing, a second shaft sleeve and the rear thrust disc are effectively cooled and lubricated, the reliability of the shield pump is improved and the service life of the shield pump is prolonged.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com