System for nanofluid minimal quantity lubrication electrostatic atomization controllable jet flow inner cooling technology

A micro-lubrication and electrostatic atomization technology, which is used in manufacturing tools, metal processing equipment, grinding/polishing safety devices, etc., and can solve problems such as the inability to generally adapt to mechanical processing, the large size of electrostatic atomization nozzles, and the inability to use machine tools. , to achieve the effect of improving lubrication and cooling effect, reducing particle spreading pollution and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention is described below in conjunction with accompanying drawing.

[0065] The first embodiment of the present invention is Figures 1 to 12 As shown, it is about the technological method and equipment of nanofluid micro-lubrication electrostatic atomization controllable jet internal cooling.

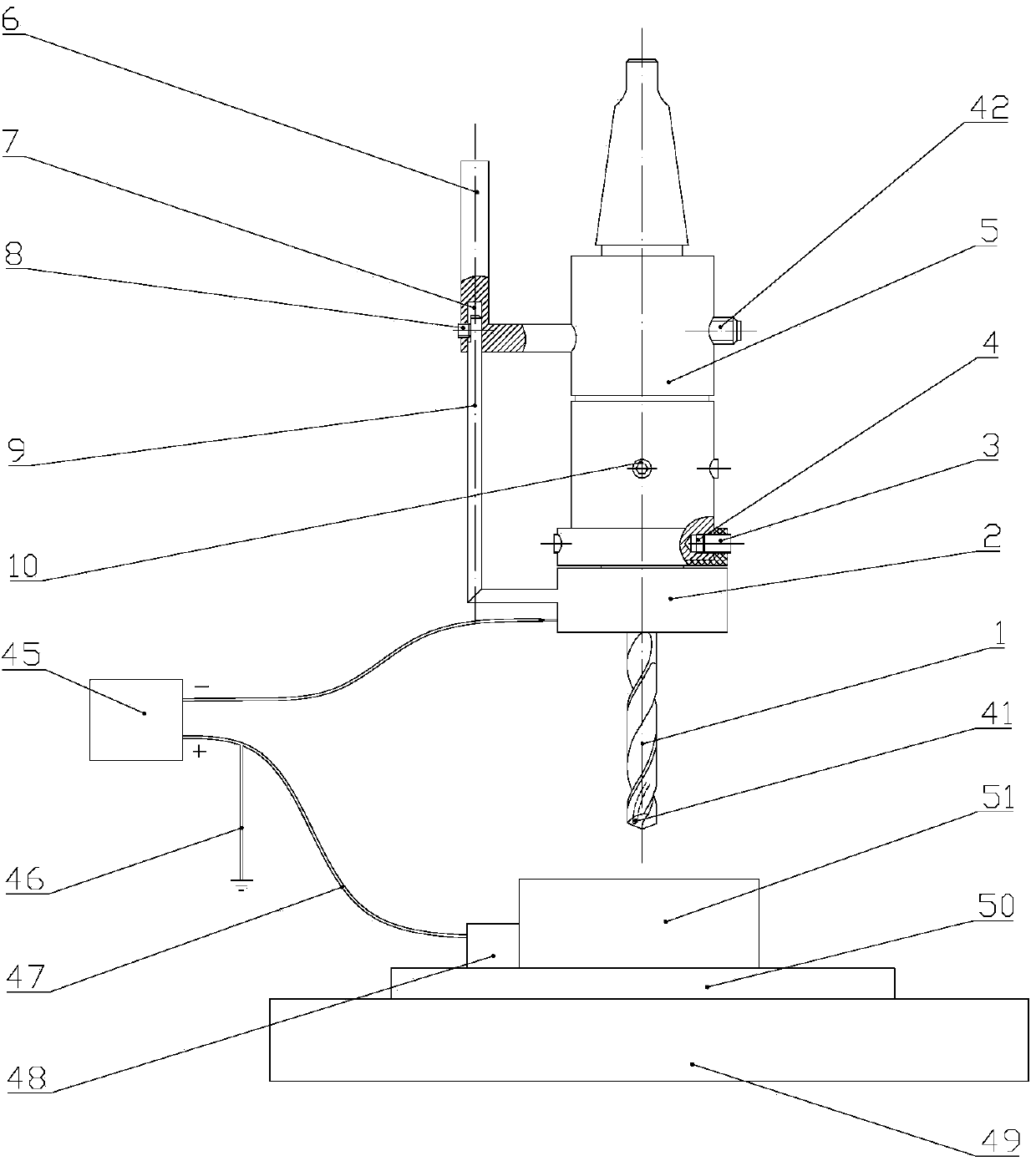

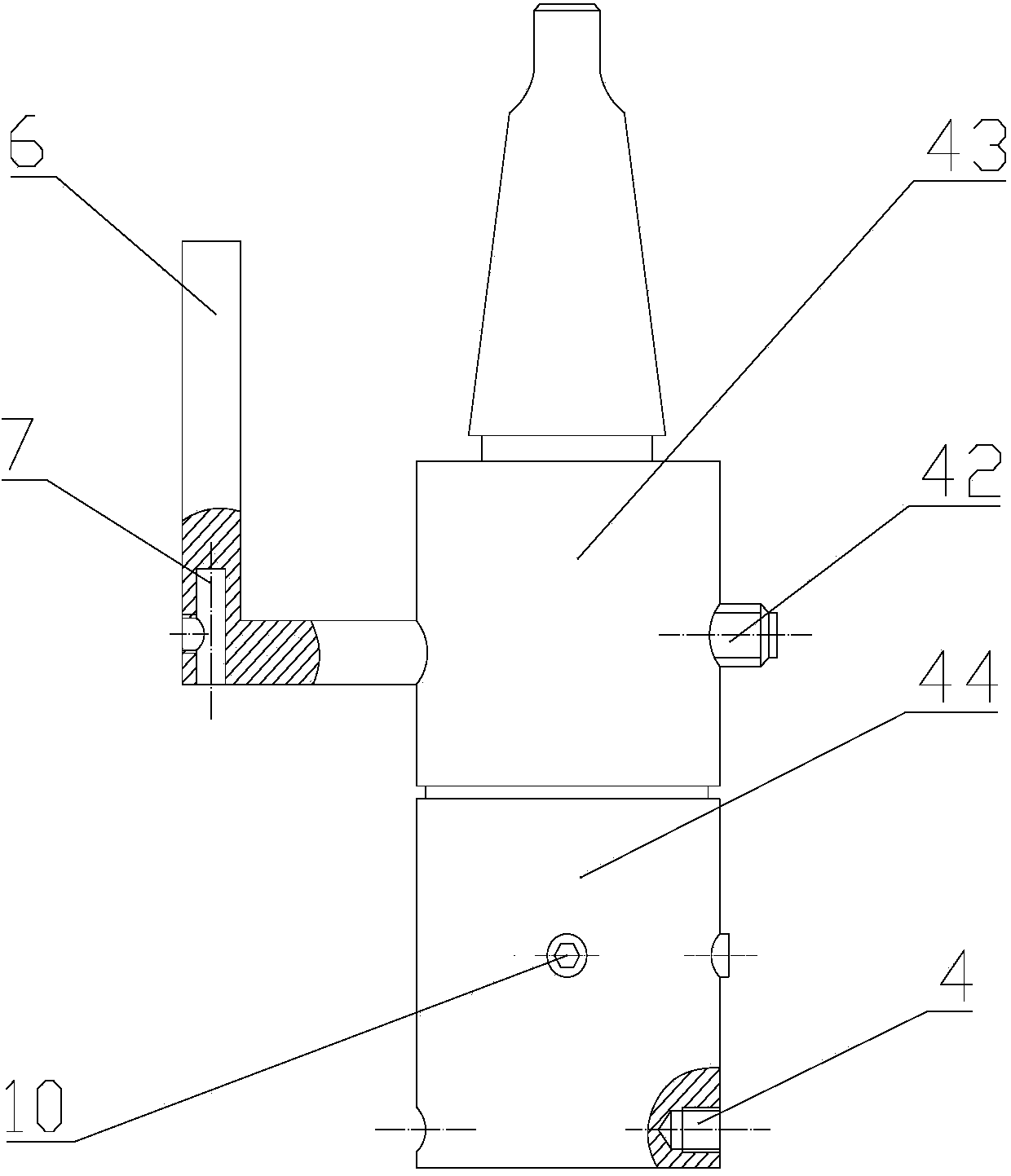

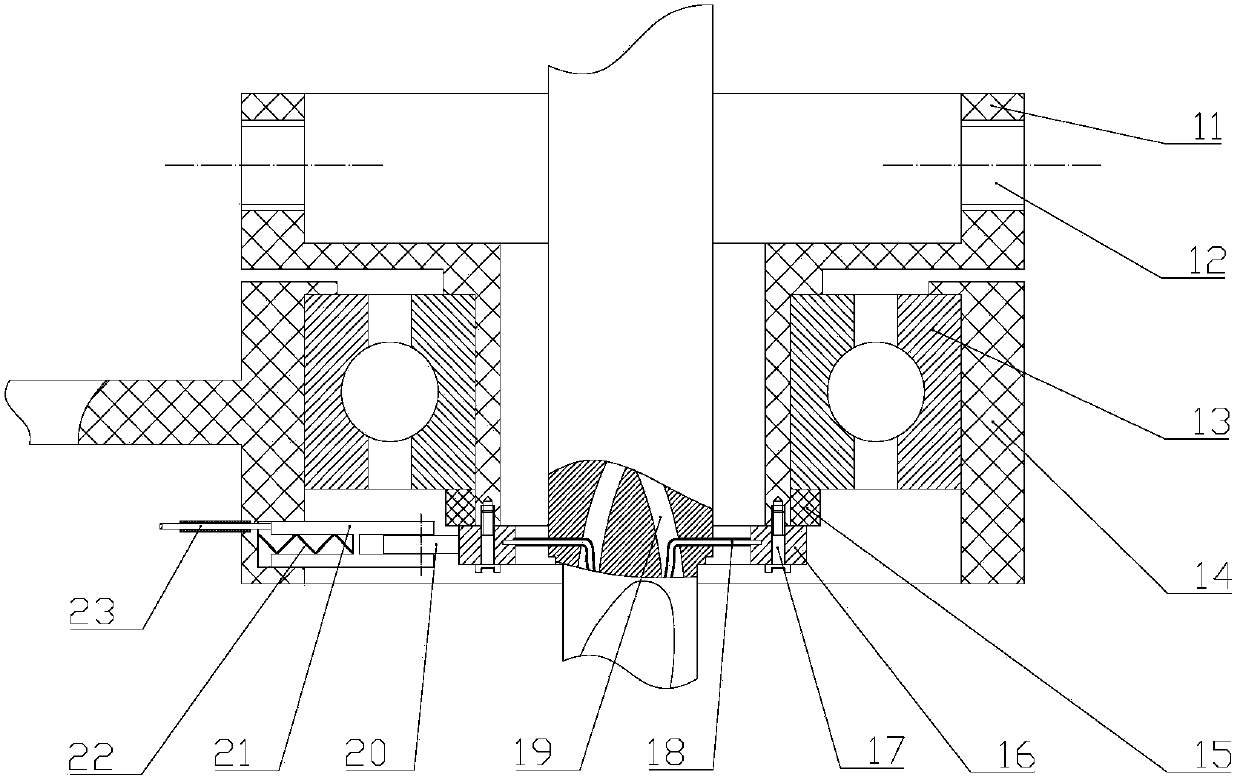

[0066] Such as figure 1 As shown, the internal cooling drill bit 1 is clamped by the internal cooling tool converter 5, and the internal cooling drill bit 1 is positioned and clamped by two hexagon socket head screws III 10 to the rotating part of the internal cooling tool converter 5; the internal cooling tool converter 5 The fixed part of the internal cooling tool converter is connected to the positioning hole of the machine tool by the positioning shaft 6 of the internal cooling tool converter to realize the positioning of the fixed part of the internal cooling tool converter 5; the minimum quantity lubrication system is connected to the fixed part of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com