Patents

Literature

470 results about "Nanofluidics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nanofluidics is the study of the behavior, manipulation, and control of fluids that are confined to structures of nanometer (typically 1–100 nm) characteristic dimensions (1 nm = 10⁻⁹ m). Fluids confined in these structures exhibit physical behaviors not observed in larger structures, such as those of micrometer dimensions and above, because the characteristic physical scaling lengths of the fluid, (e.g. Debye length, hydrodynamic radius) very closely coincide with the dimensions of the nanostructure itself.

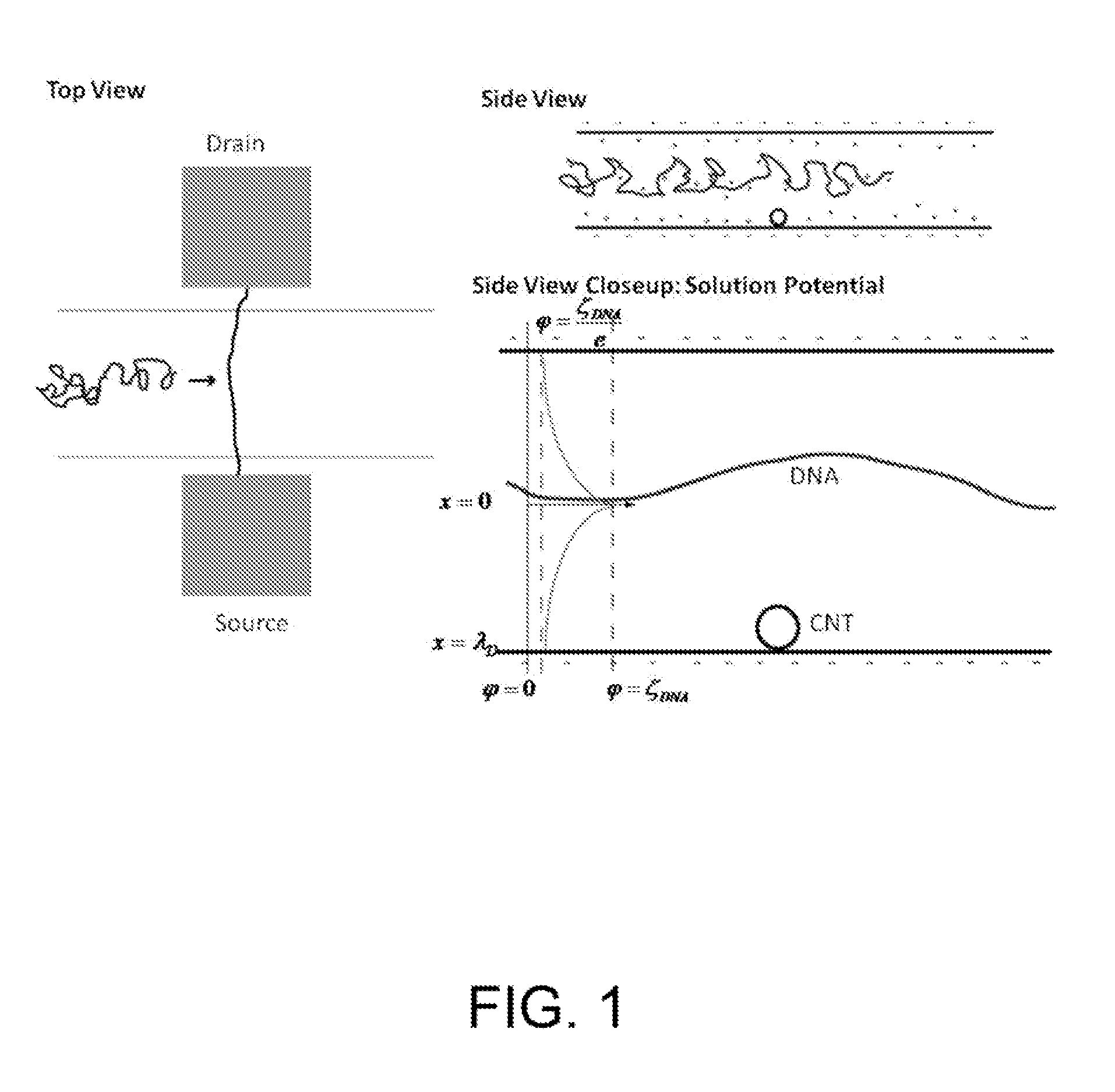

Nanofluidic channels with integrated charge sensors and methods based thereon

An electrical detector is provided that comprises a nanofluidic channel with an integrated nanoscale charge sensor. The charge sensor can be an unfunctionalized nanowire, nanotube, transistor or capacitor and can be of carbon, silicon, carbon / silicon or other semiconducting material. The nanofluidic channel depth is on the order of the Debye screening length. Methods are also provided for detecting charged molecules or biological or chemical species with the electrical detector. Charged molecules or species in solution are driven through the nanofluidic channel of the electrical detector and contact the charge sensor, thereby producing a detectable signal. Methods are also provided for detecting a local solution potential of interest. A solution flowing through the nanofluidic channel of the electrical detector contacts the charge sensor, thereby producing a detectable local solution potential signal.

Owner:CORNELL UNIVERSITY

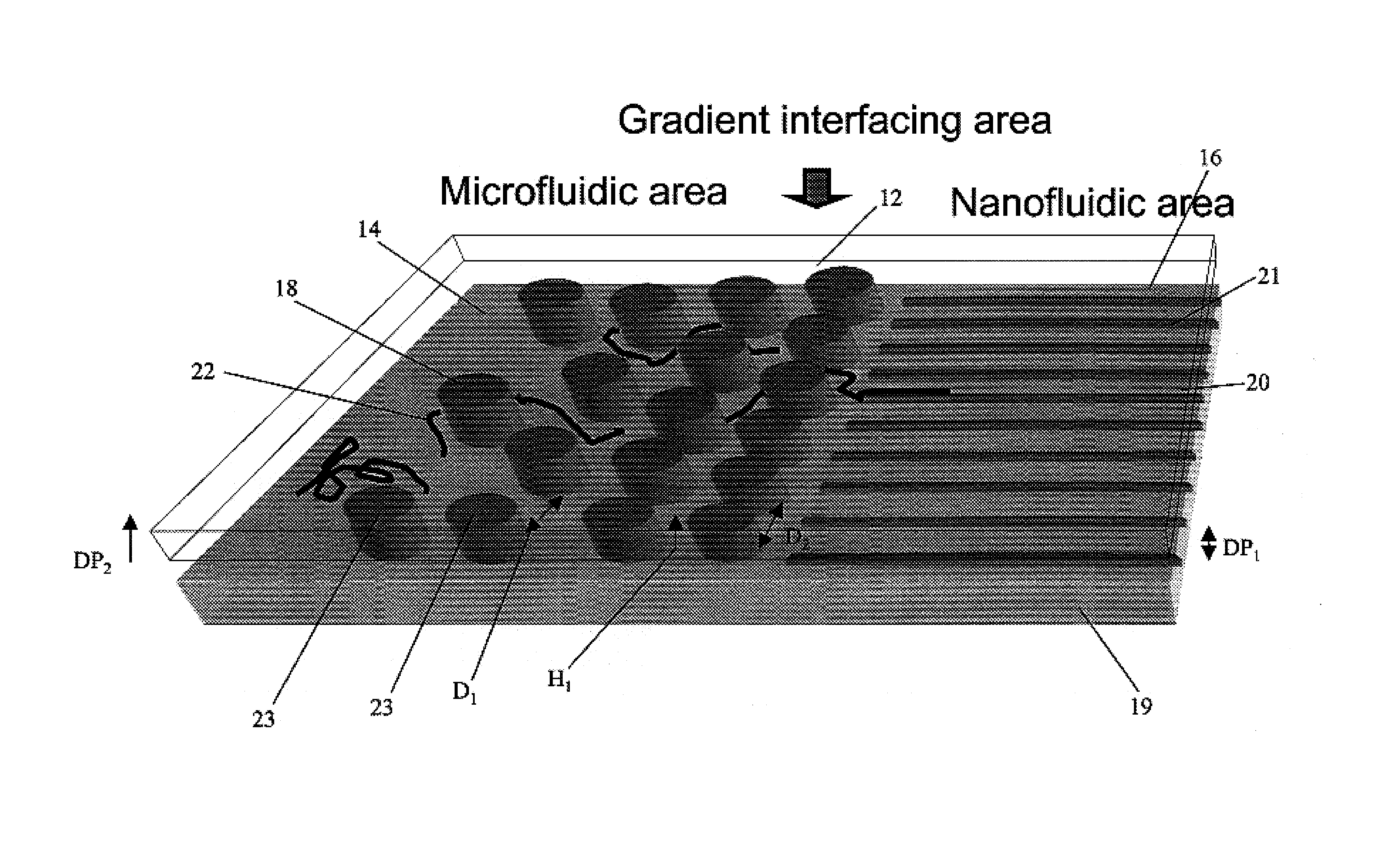

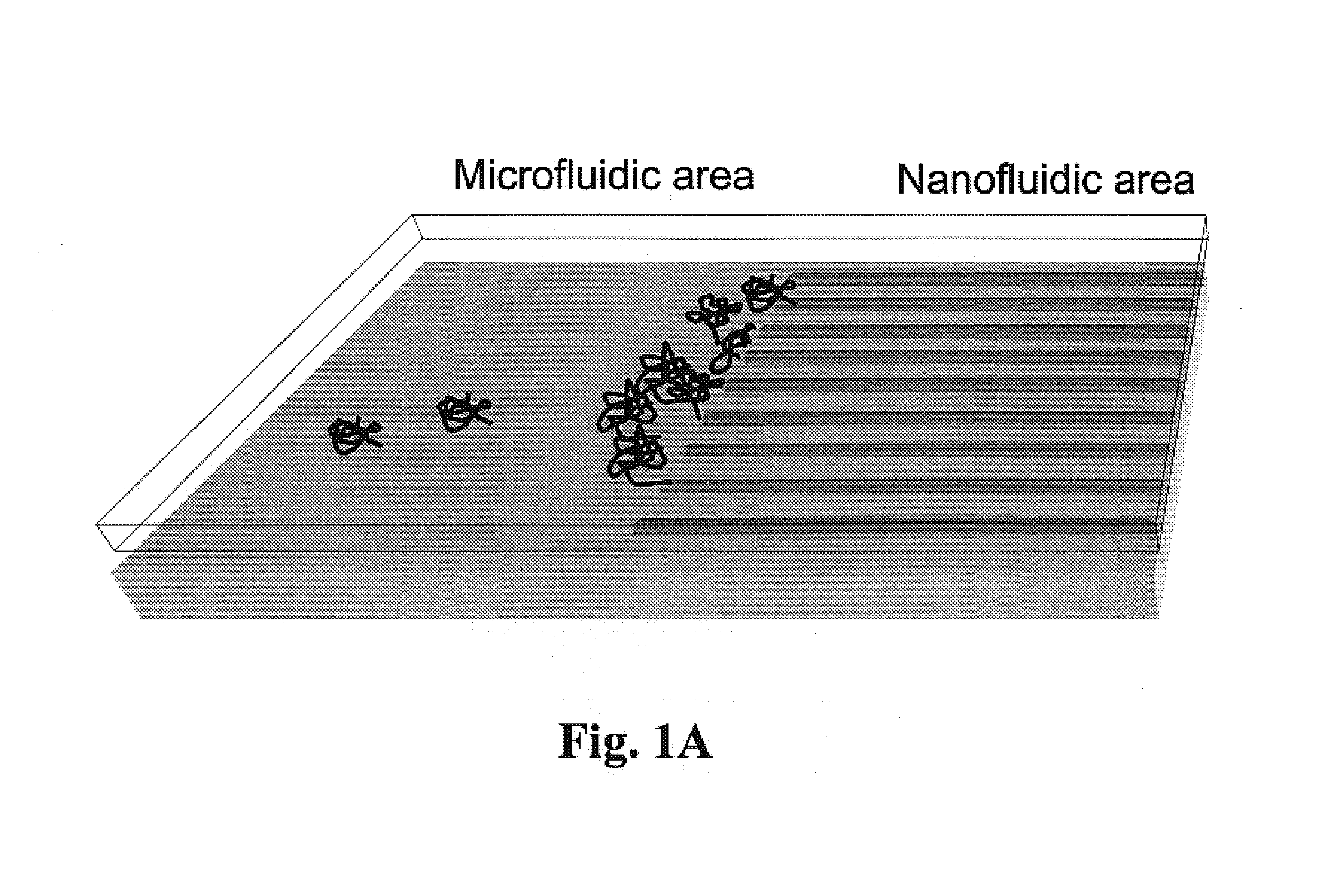

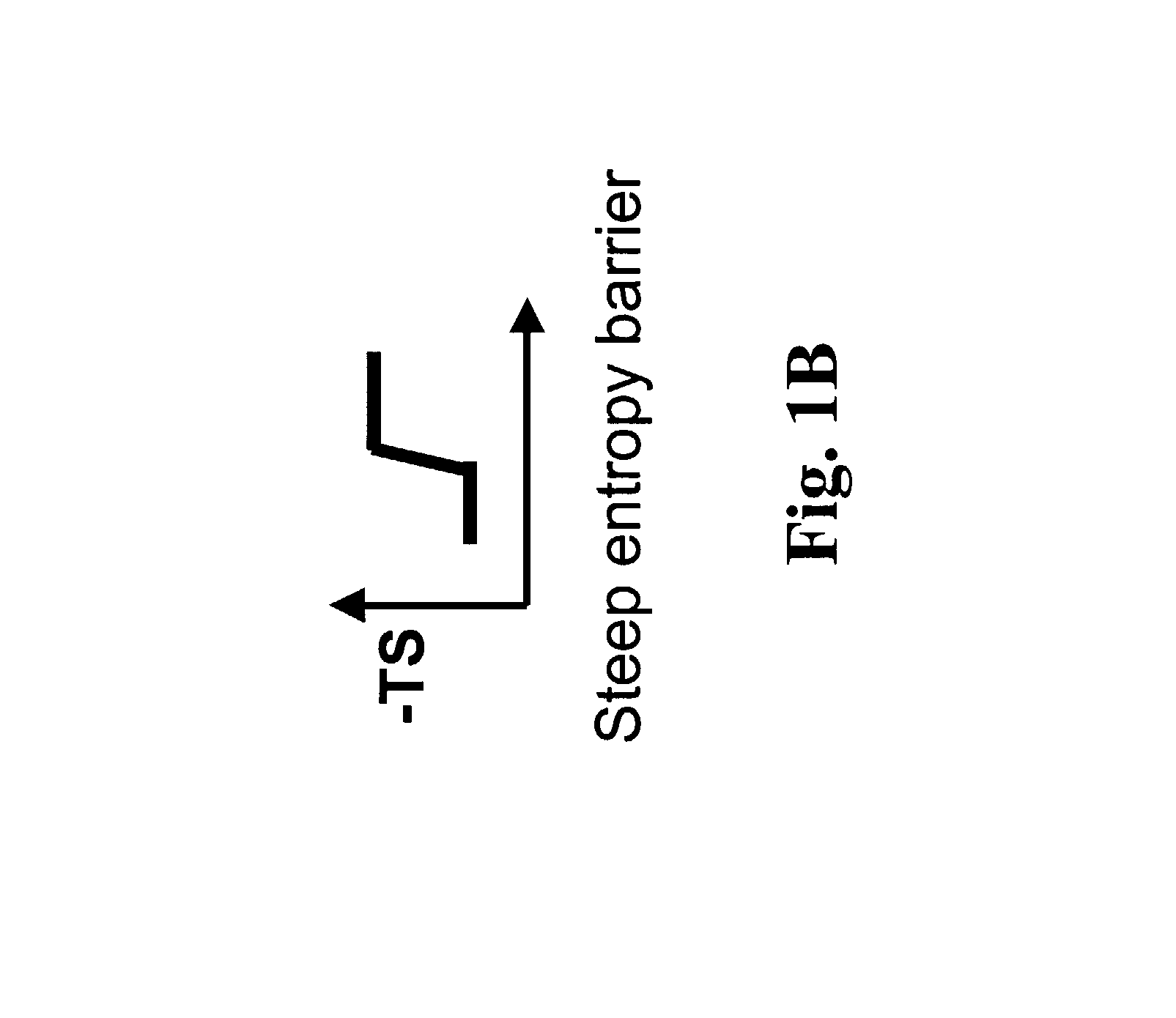

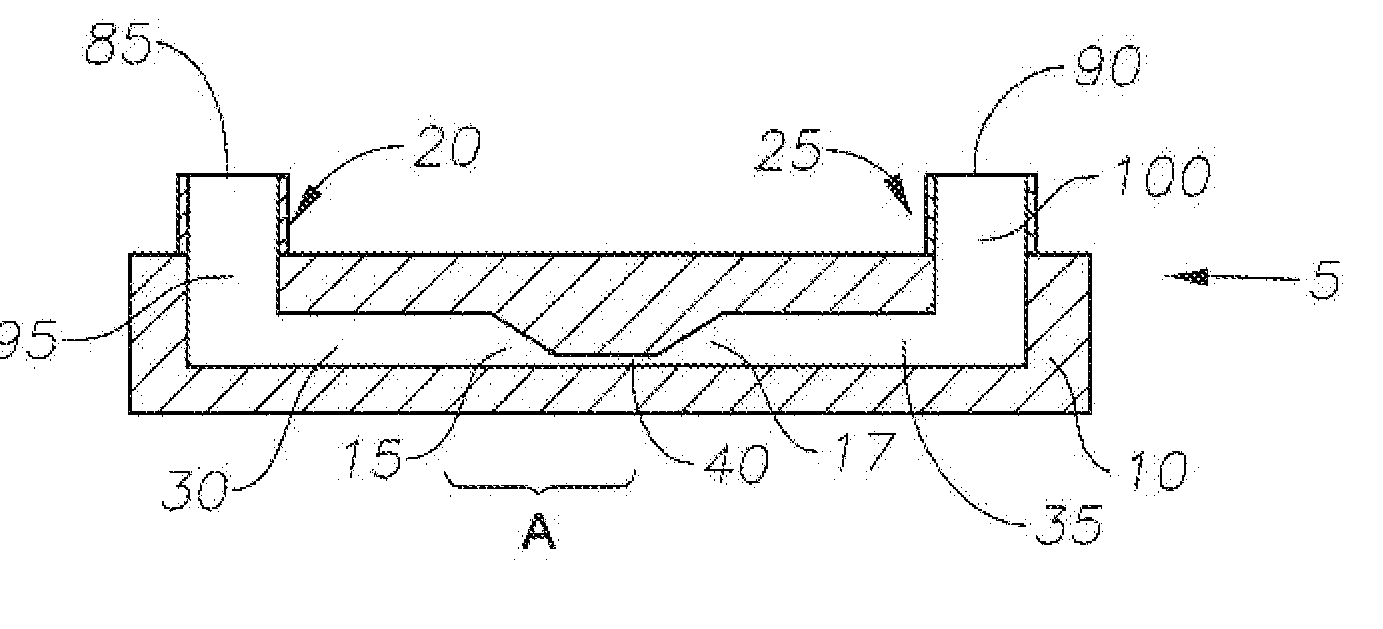

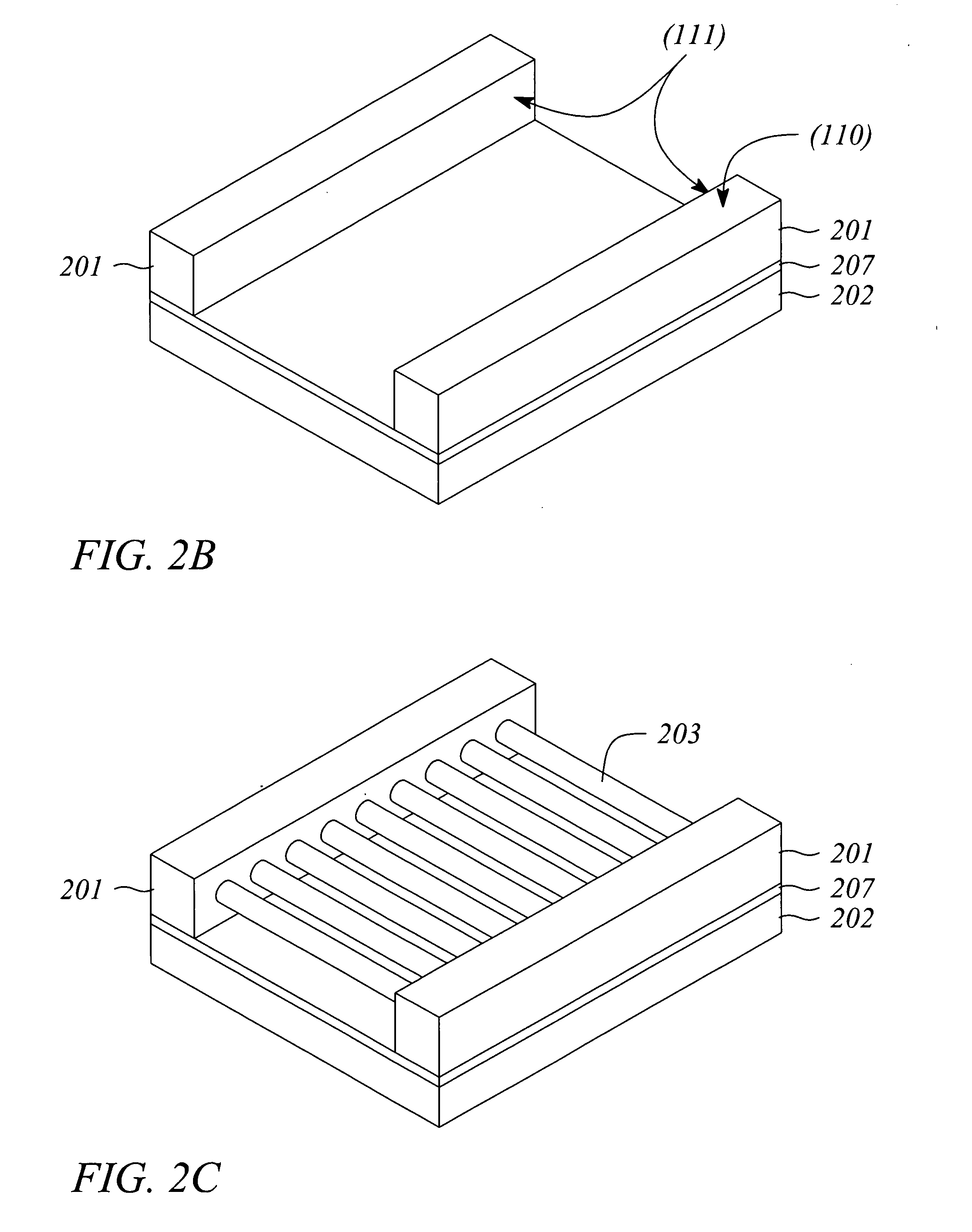

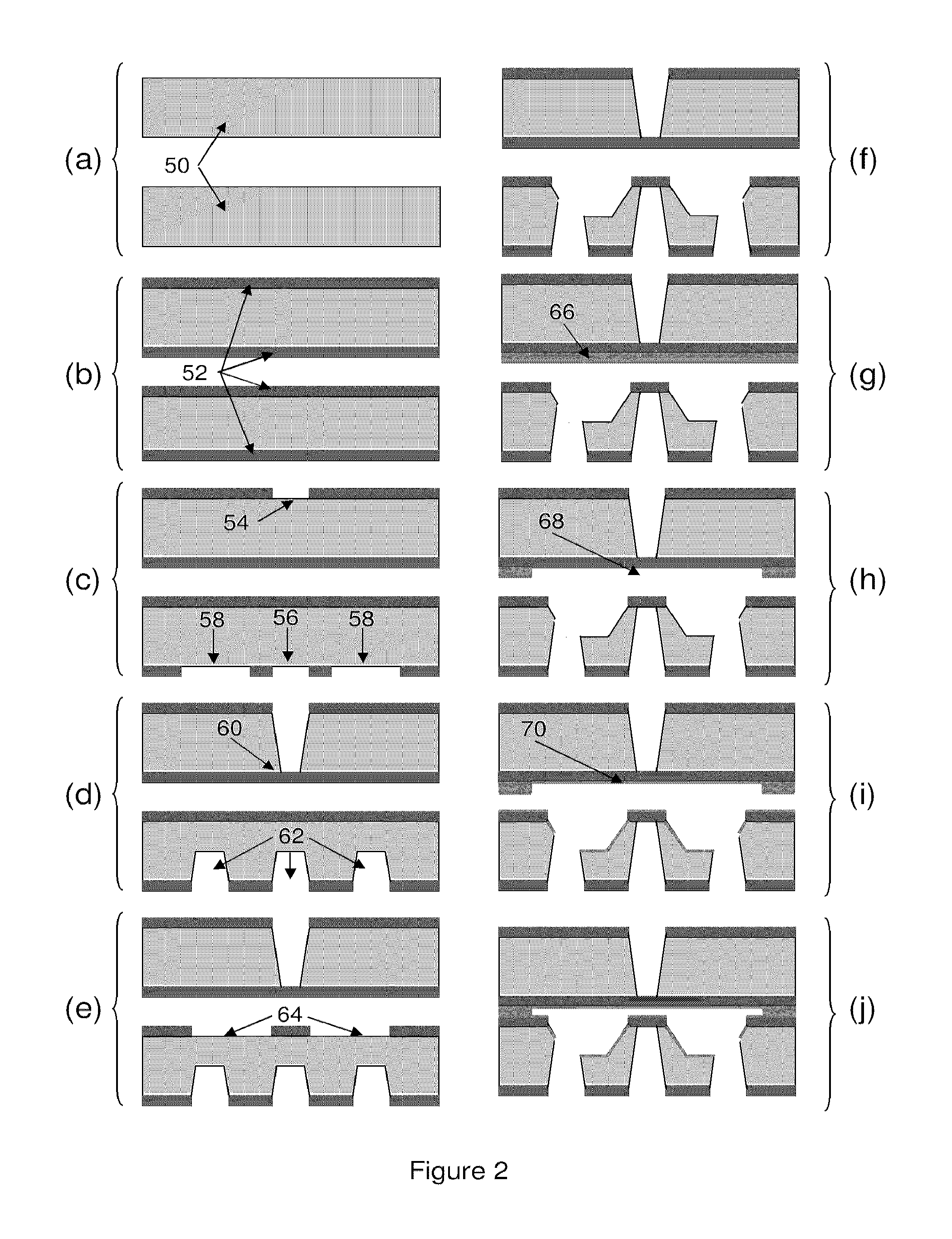

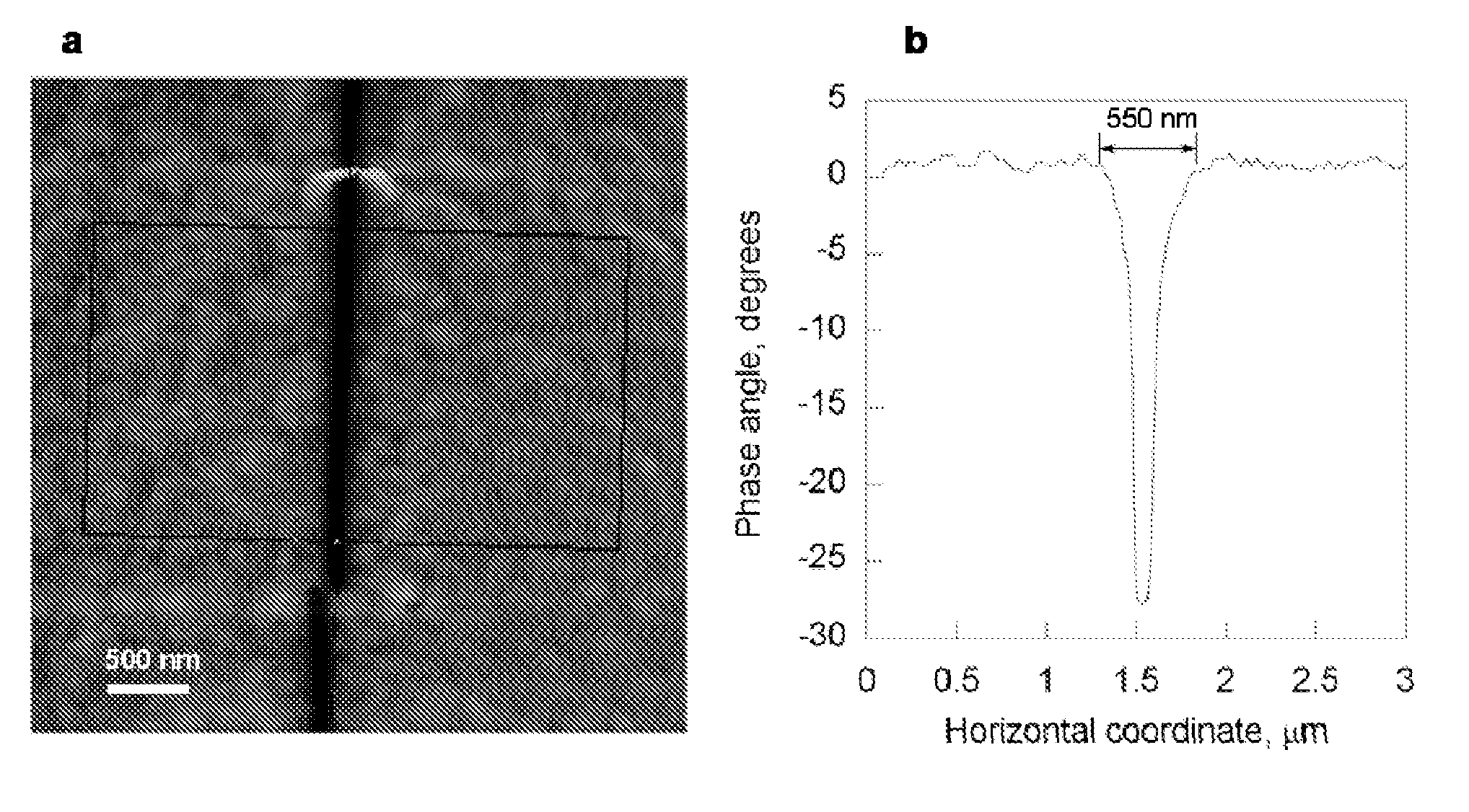

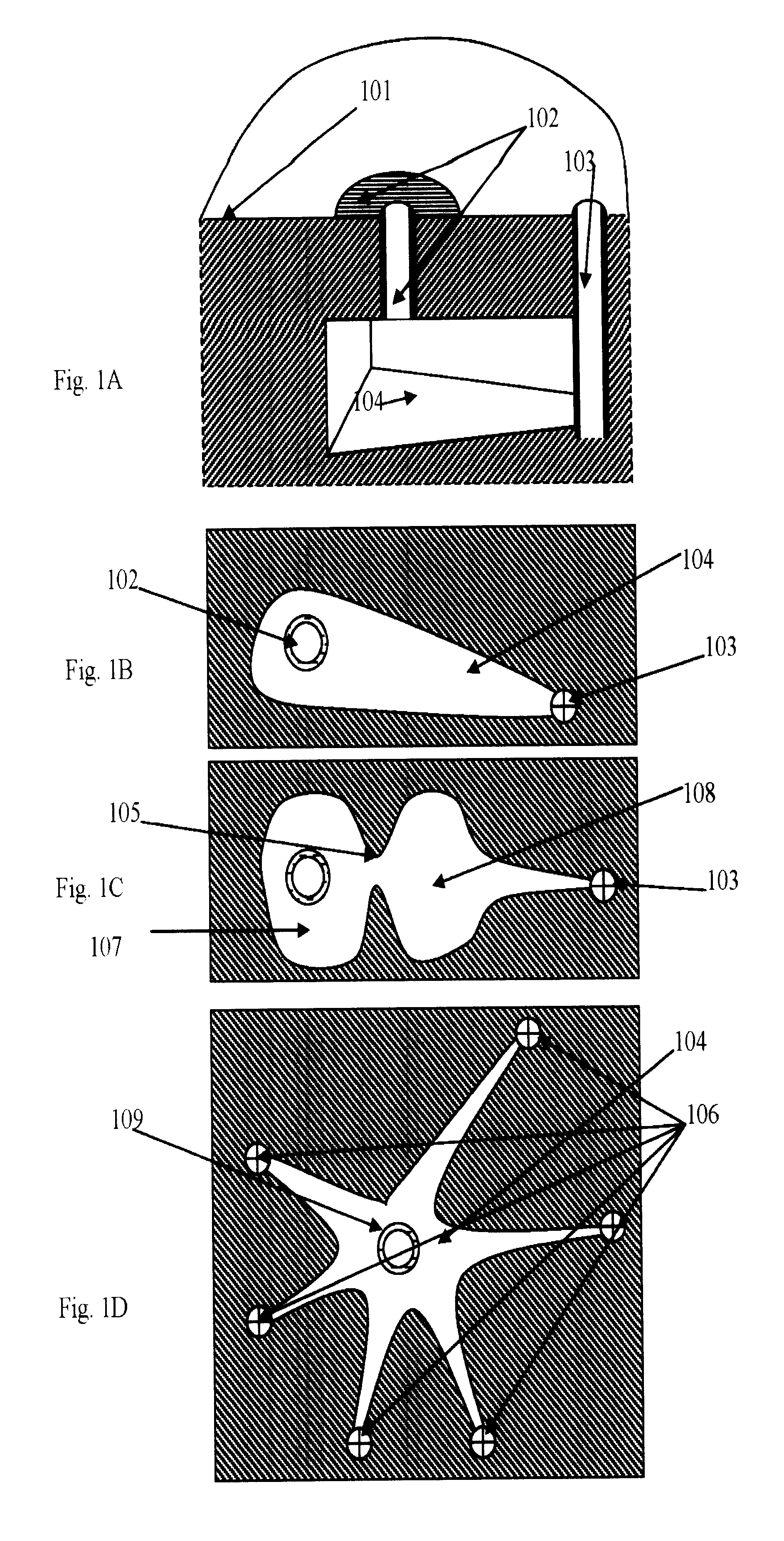

Gradient structures interfacing microfluidics and nanofluidics, methods for fabrication and uses thereof

ActiveUS7217562B2Improve throughputReduces the local entropic barrierMaterial nanotechnologyNanostructure manufactureVertical gradientMicrofluidics

The present invention relates to a device for interfacing nanofluidic and microfluidic components suitable for use in performing high throughput macromolecular analysis. Diffraction gradient lithography (DGL) is used to form a gradient interface between a microfluidic area and a nanofluidic area. The gradient interface area reduces the local entropic barrier to nanochannels formed in the nanofluidic area. In one embodiment, the gradient interface area is formed of lateral spatial gradient structures for narrowing the cross section of a value from the micron to the nanometer length scale. In another embodiment, the gradient interface area is formed of a vertical sloped gradient structure. Additionally, the gradient structure can provide both a lateral and vertical gradient.

Owner:PRINCETON UNIV

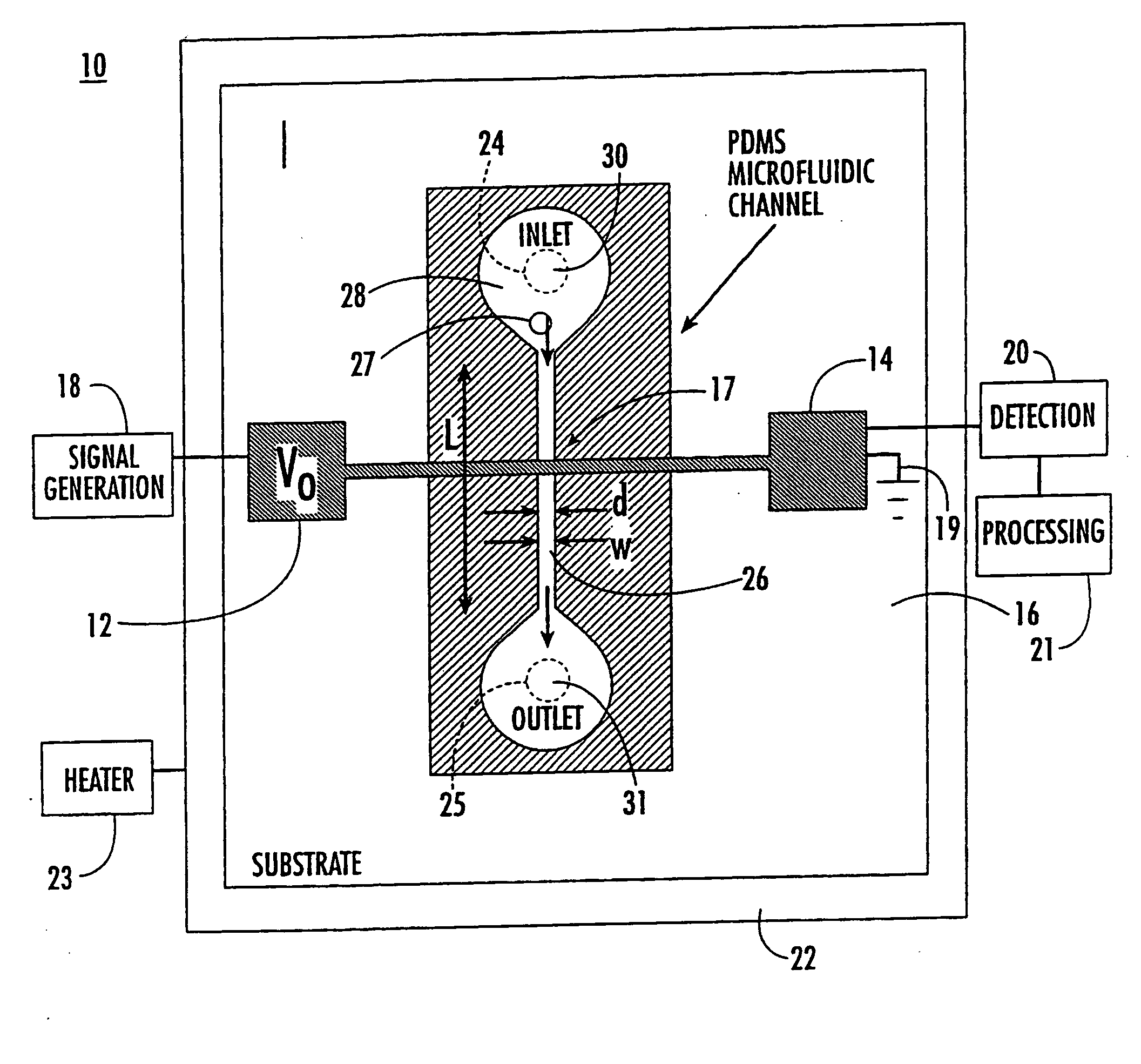

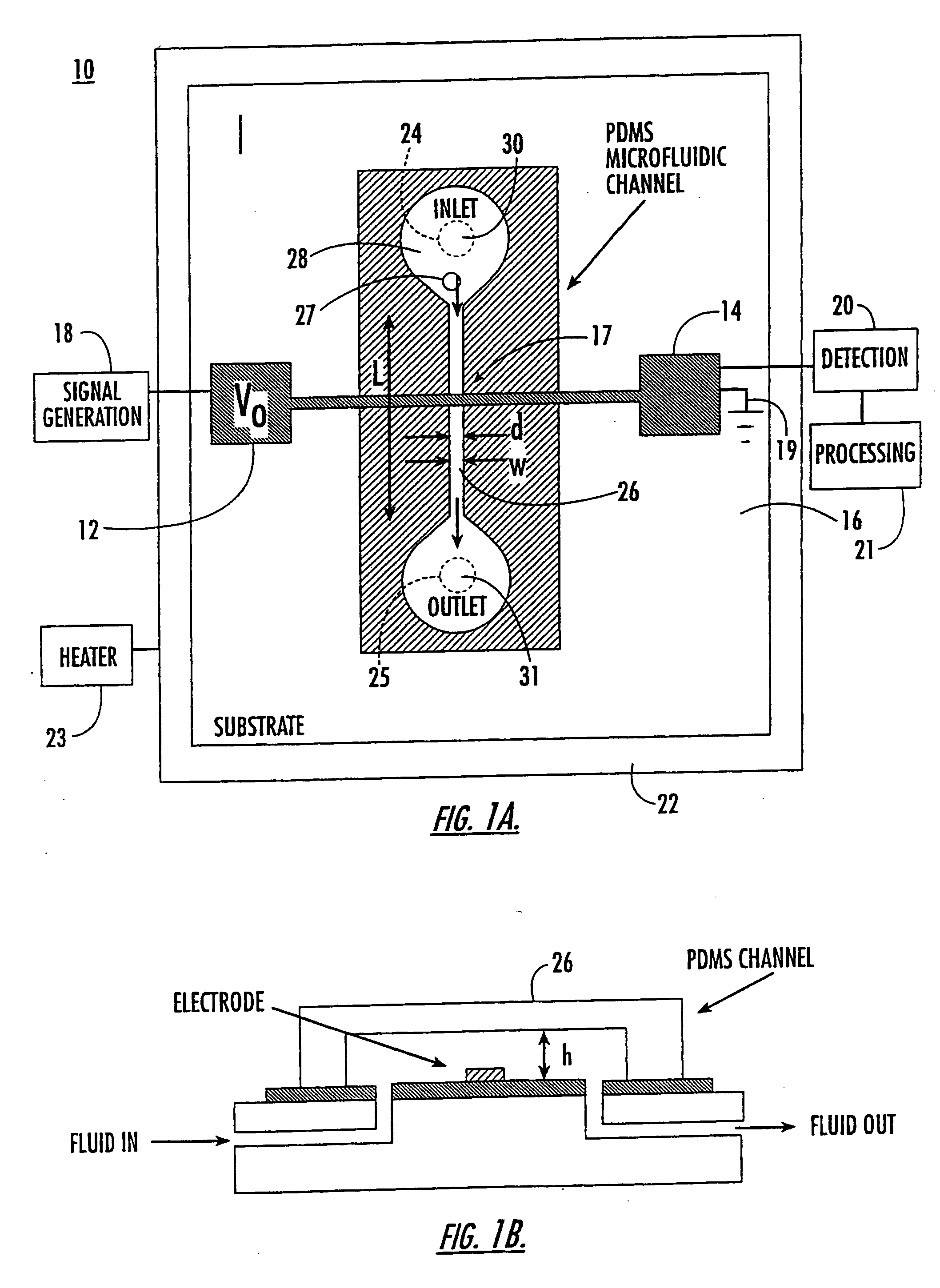

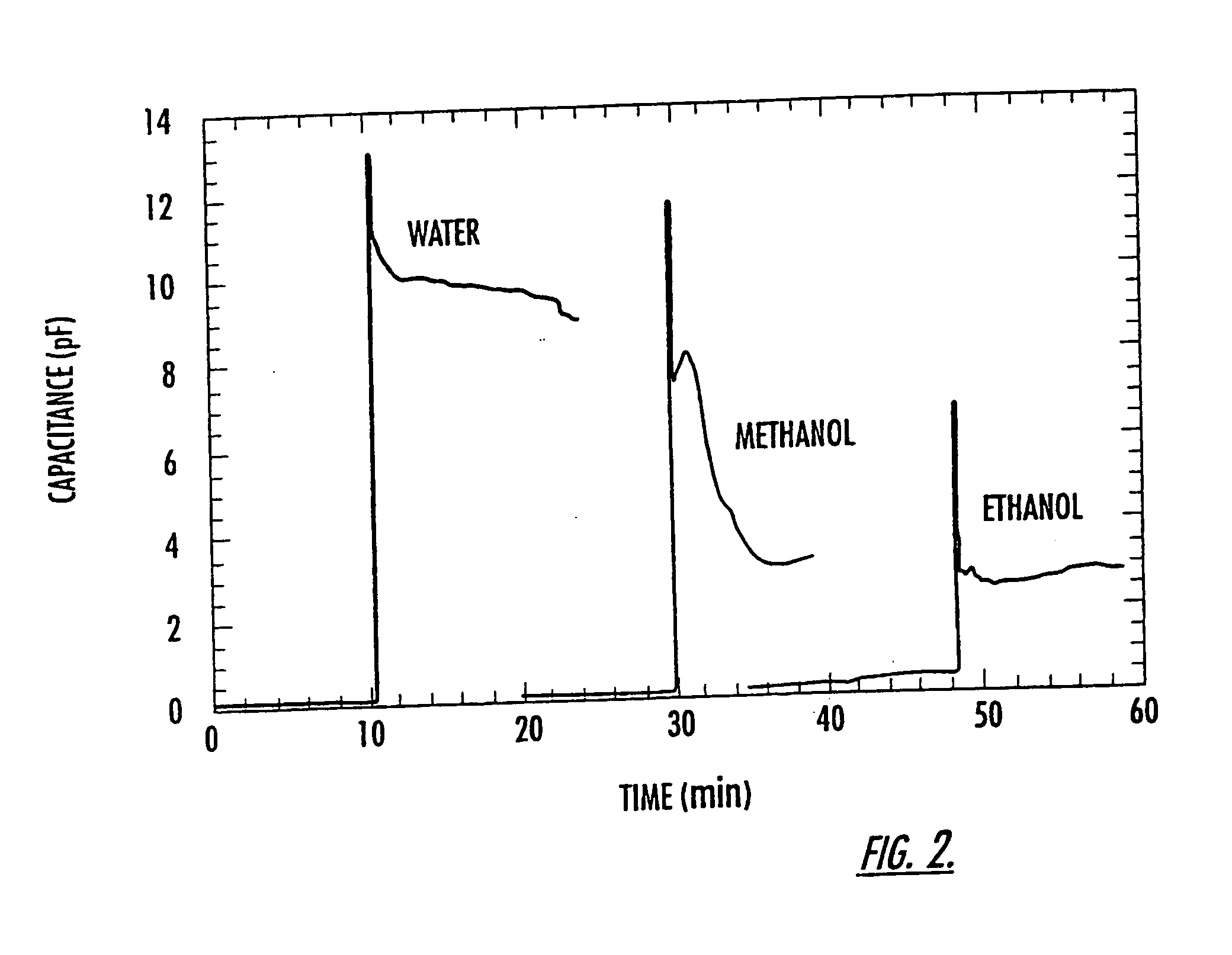

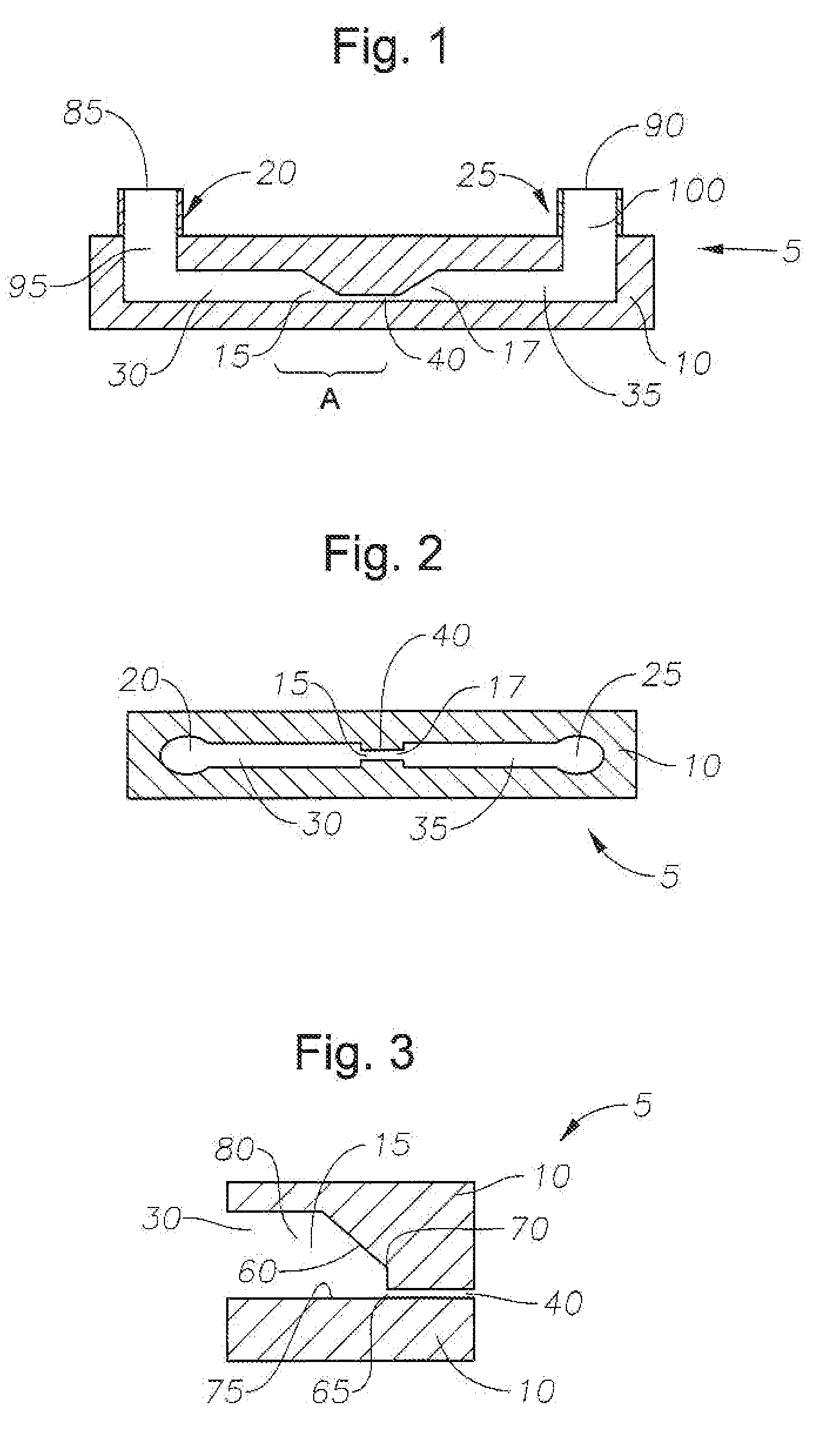

Microfluidic and nanofluidic electronic devices for detecting changes in capacitance of fluids and methods of using

InactiveUS20070238112A1Simpler and faster and less-expensiveMaterial nanotechnologyBioreactor/fermenter combinationsCapacitanceCell Cycle Kinetics

The present invention (also identified as “Capacitance cytometry”) relates to microfluidic and nanofluidic devices for detecting or measuring an electrical property of a fluid (liquid or aerosol), a single molecule, particle, or cell in fluid. In a particular embodiment, the devices detect or measure changes in capacitance of a fluid, molecule, particle or cell as it passes through the device. The invention relates to detection and measurement of single molecules, particularly biological molecules, and to methods of sequencing polynucleotide molecules (RNA or DNA) by detecting differentially labeled single nucleotides. Single molecule detection applications include DNA or RNA sequencing, detection of SNPs, protoemics, and particle sizing. The device can be used to determine cell DNA content, to analyze cell-cycle kinetics of cell populations, and to assay for abnormal changes in cell DNA content. Nano-microfluidic devices of this invention also have utility as detectors in molecular sorting systems and for detecting pathogens.

Owner:THE TRUSTEES FOR PRINCETON UNIV

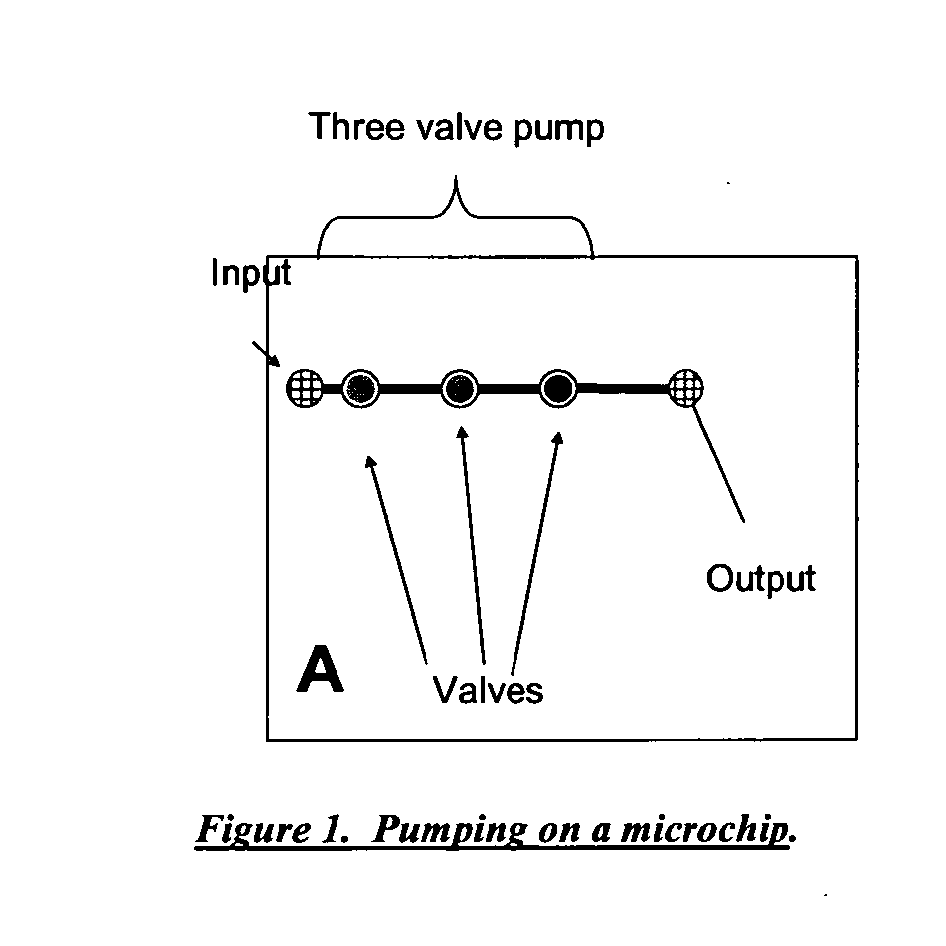

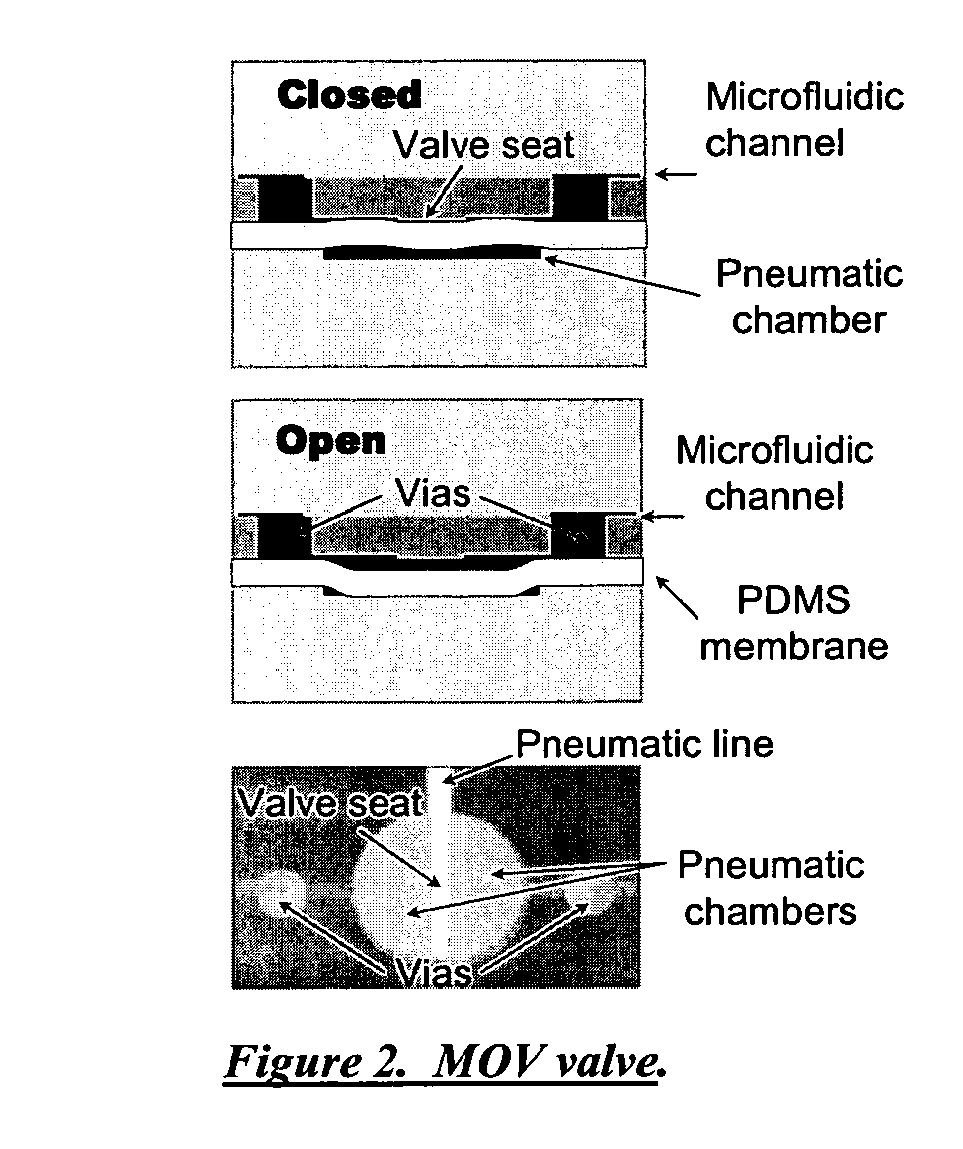

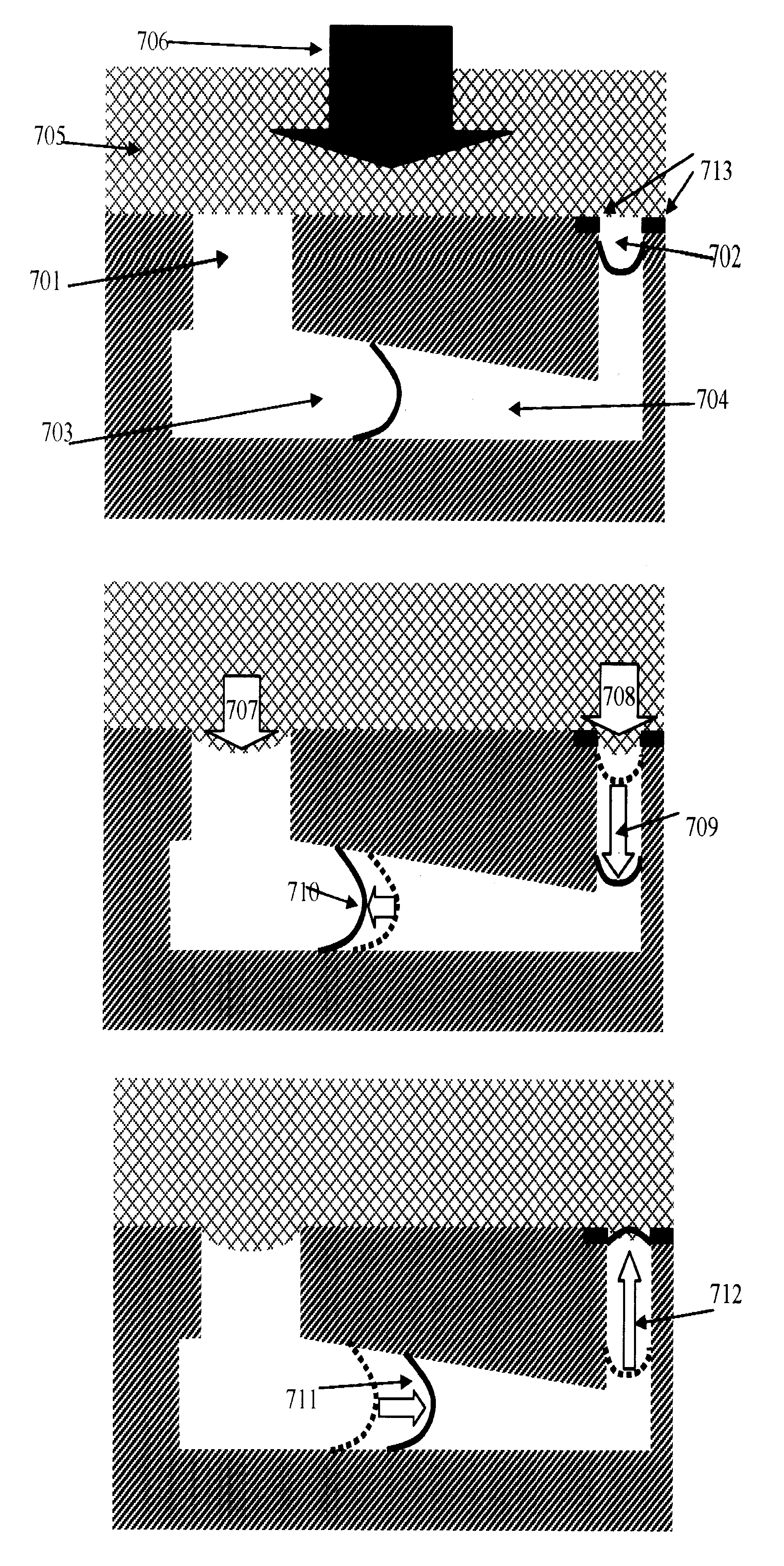

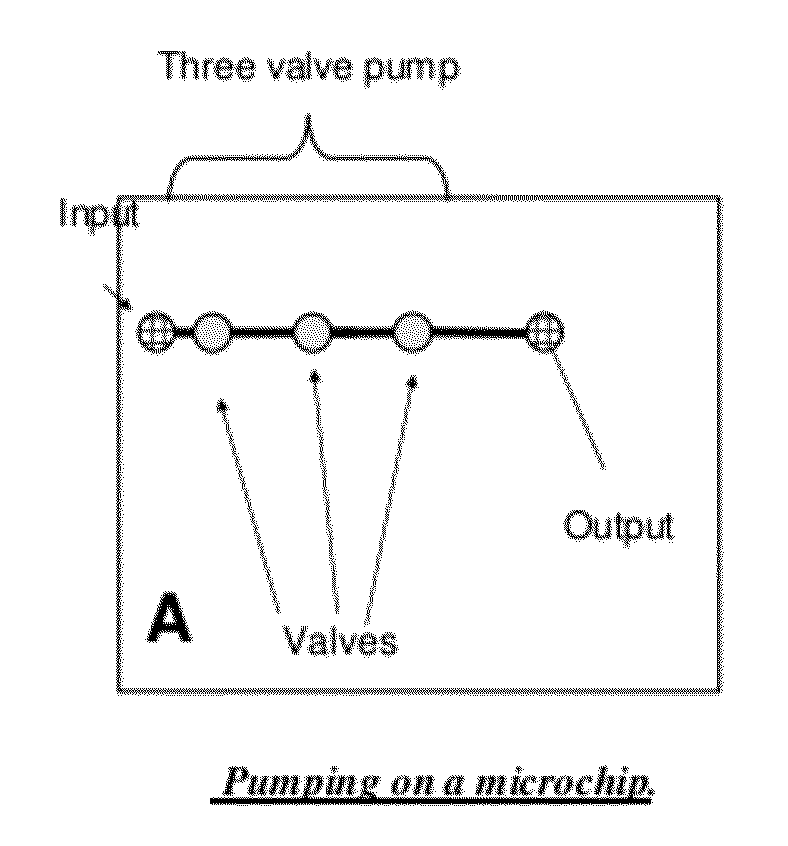

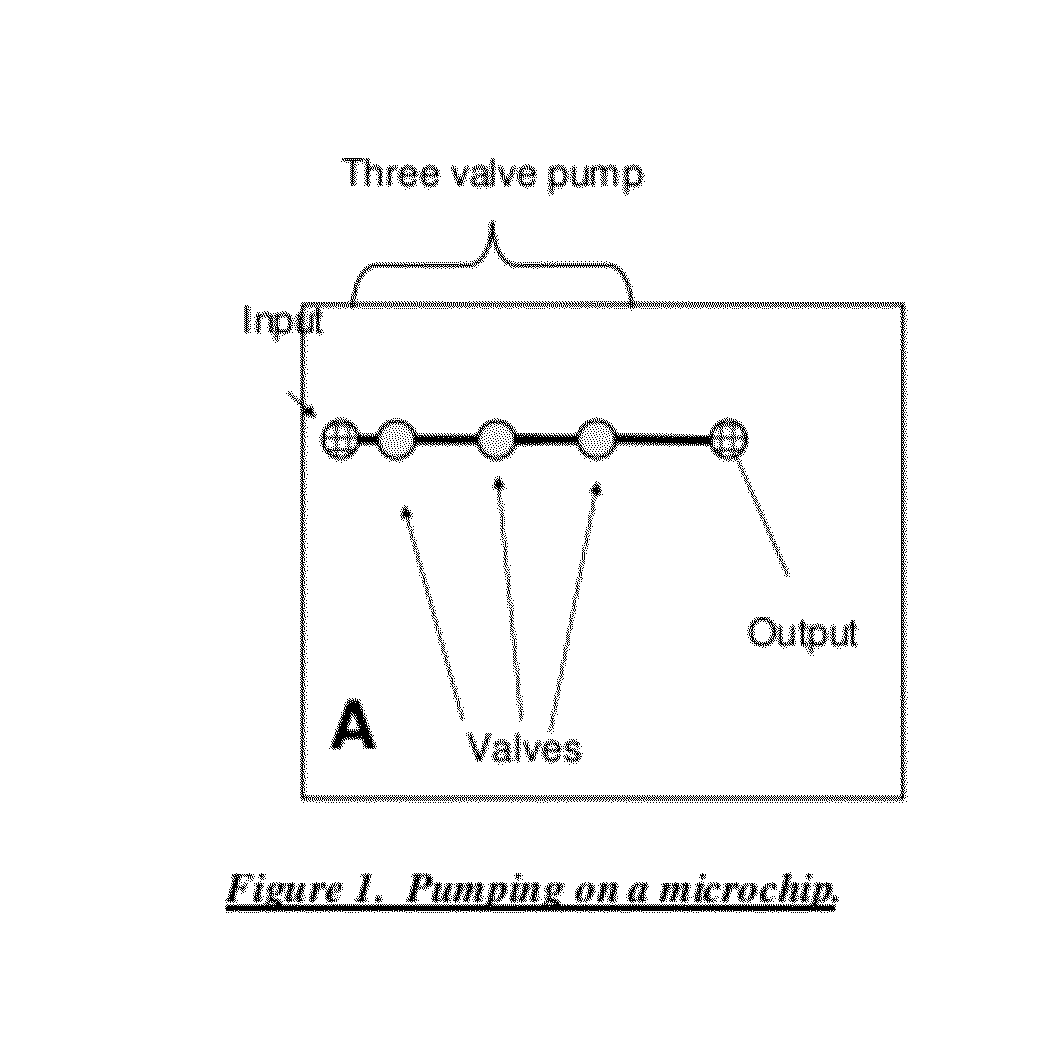

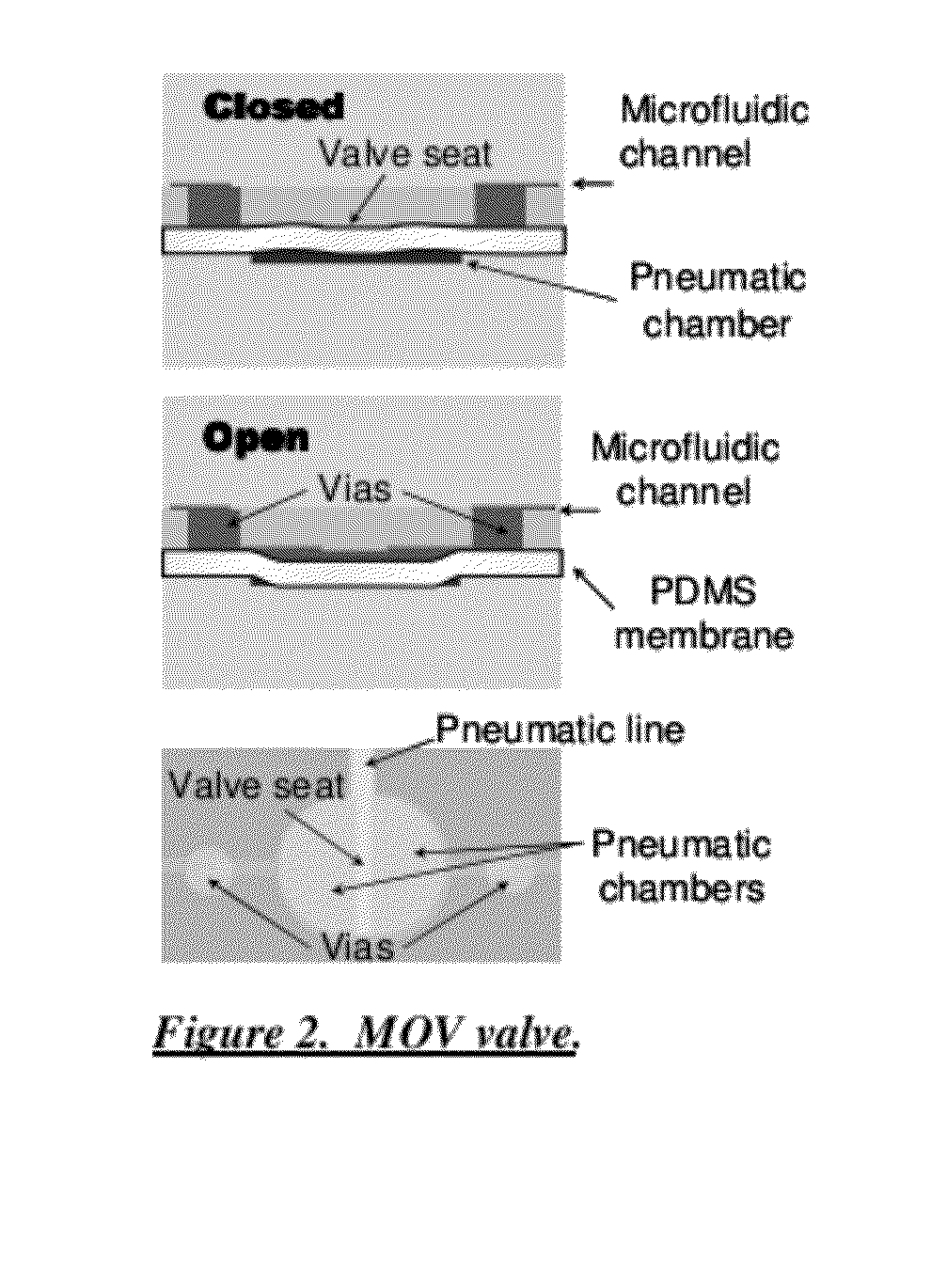

Microfluidic and nanofluidic devices, systems, and applications

InactiveUS20110039303A1Block fluid flowMaterial nanotechnologyValve arrangementsChemical reactionMicrofluidics

The present invention discloses the integration of programmable microfluidic circuits to achieve practical applications to process biochemical and chemical reactions and to integrate these reactions. In some embodiments workflows for biochemical reactions or chemical workflows are combined. Microvalves such as programmable microfluidic circuit with Y valves and flow through valves are disclosed. In some embodiments microvalves of the present invention are used for mixing fluids, which may be part of an integrated process. These processes include mixing samples and moving reactions to an edge or reservoir for modular microfluidics, use of capture regions, and injection into analytical devices on separate devices. In some embodiments star and nested star designs, or bead capture by change of cross sectional area of a channel in a microvalve are used. Movement of samples between temperature zones are further disclosed using fixed temperature and movement of the samples by micropumps.

Owner:INTEGENX

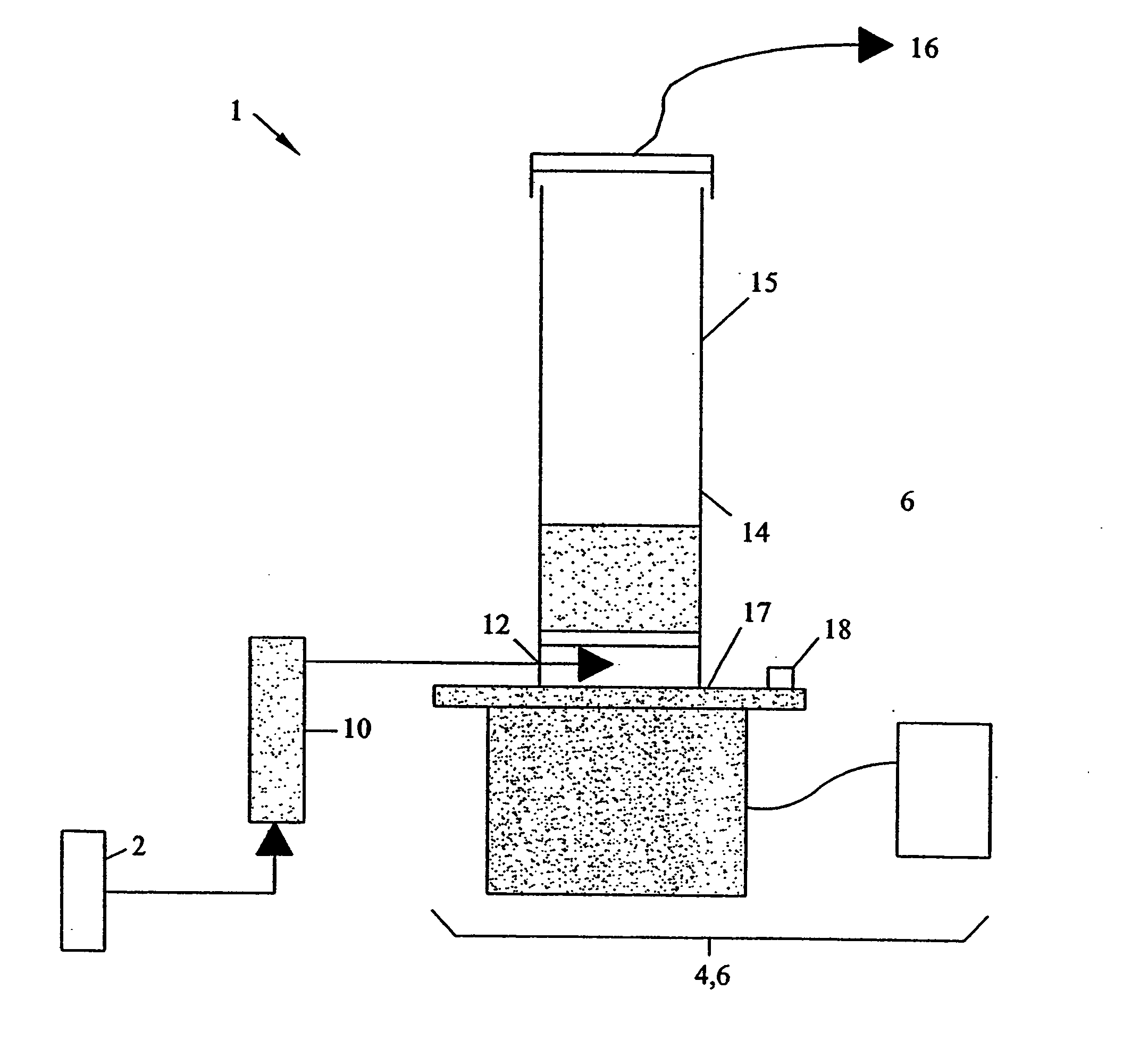

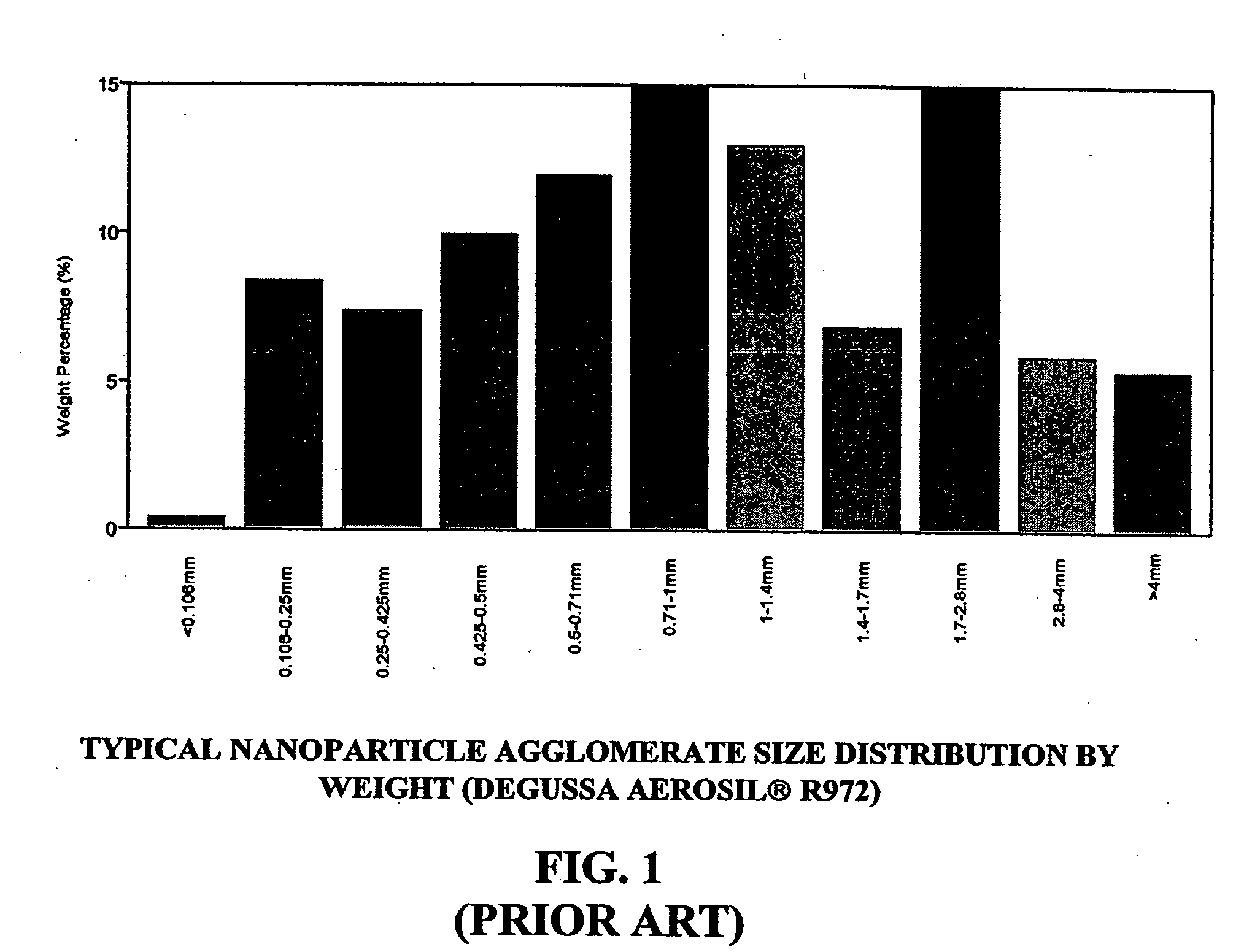

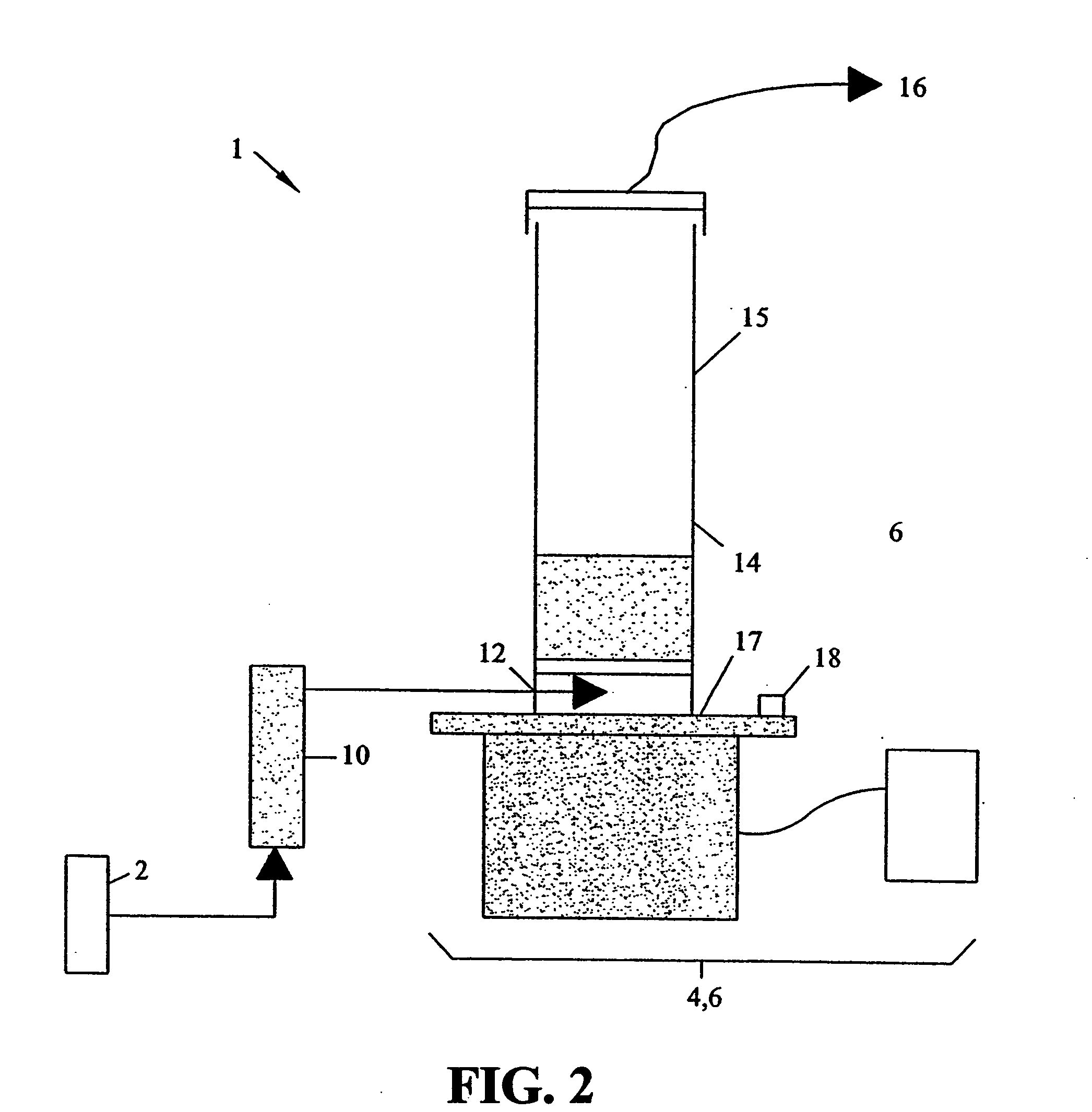

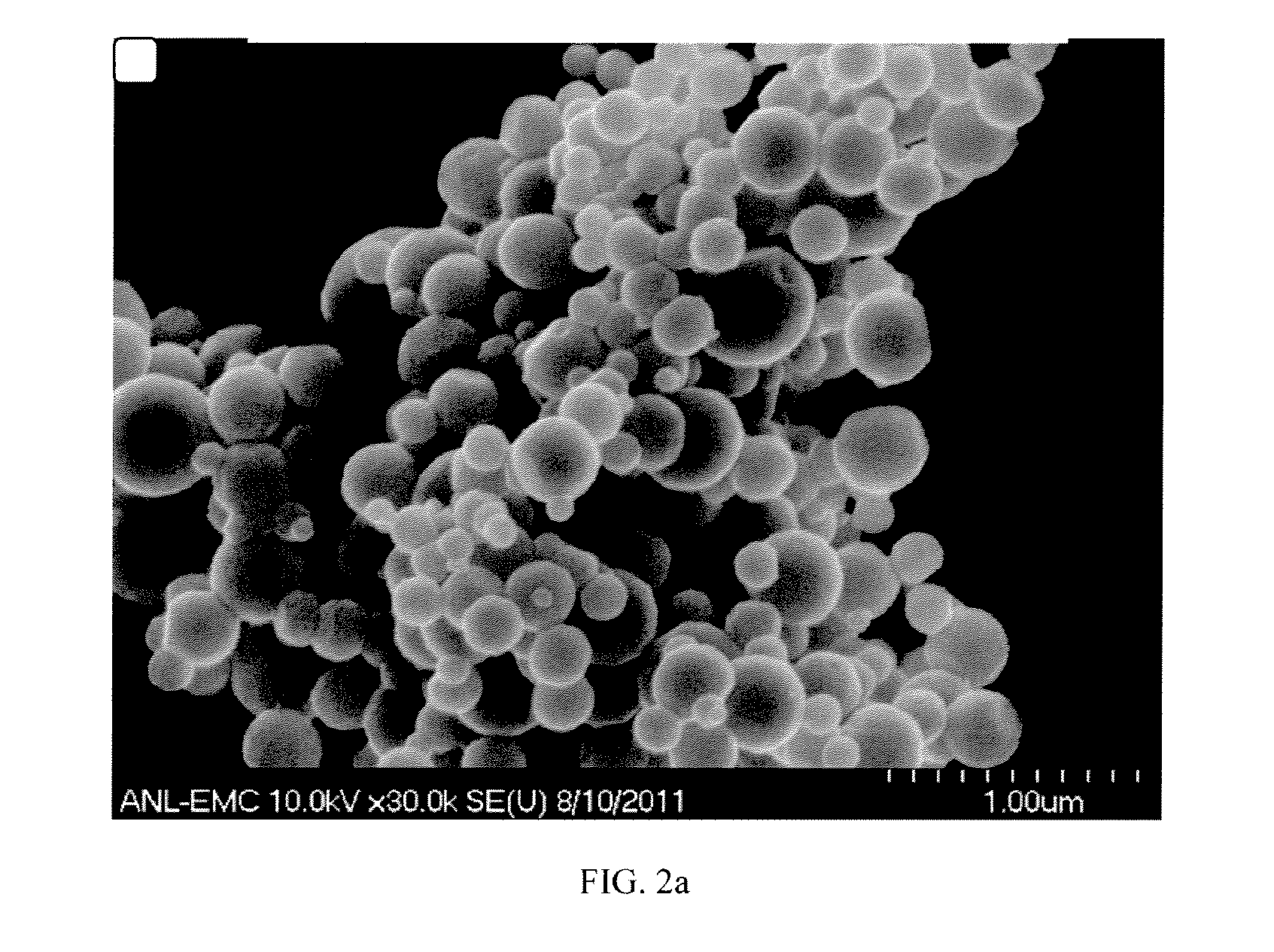

System and method for nanoparticle and nanoagglomerate fluidization

InactiveUS20060086834A1Convenient treatmentEffective dispersionShaking/oscillating/vibrating mixersElectrical apparatusEngineeringElutriation

With the coupling of an external field and aeration (or a flow of another gas), nanoparticles can be smoothly and vigorously fluidized. Multiple external fields and / or pre-treatment may be employed with the fluidizing gas: sieving, magnetic assistance, vibration, acoustic / sound or rotational / centrifugal forces. Any of these forces, either alone or in combination, when coupled with a fluidizing medium, provide excellent means for achieving homogenous nanofluidization. The additional force(s) help to break channels as well as provide enough energy to disrupt the strong interparticle forces, thereby establishing an advantageous agglomerate size distribution. Enhanced fluidization is reflected by at least one of the following performance-related attributes: reduced levels of bubbles within the fluidized system, reduced gas bypass relative to the fluidized bed, smooth fluidization behavior, reduced elutriation, a high level of bed expansion, reduced gas velocity levels to achieve desired fluidization performance, and / or enhanced control of agglomerate size / distribution. The fluidized nanoparticles may be coated, surface-treated and / or surface-modified in the fluidized state. In addition, the fluidized nanoparticles may participate in a reaction, either as a reactant or a catalyst, while in the fluidized state.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

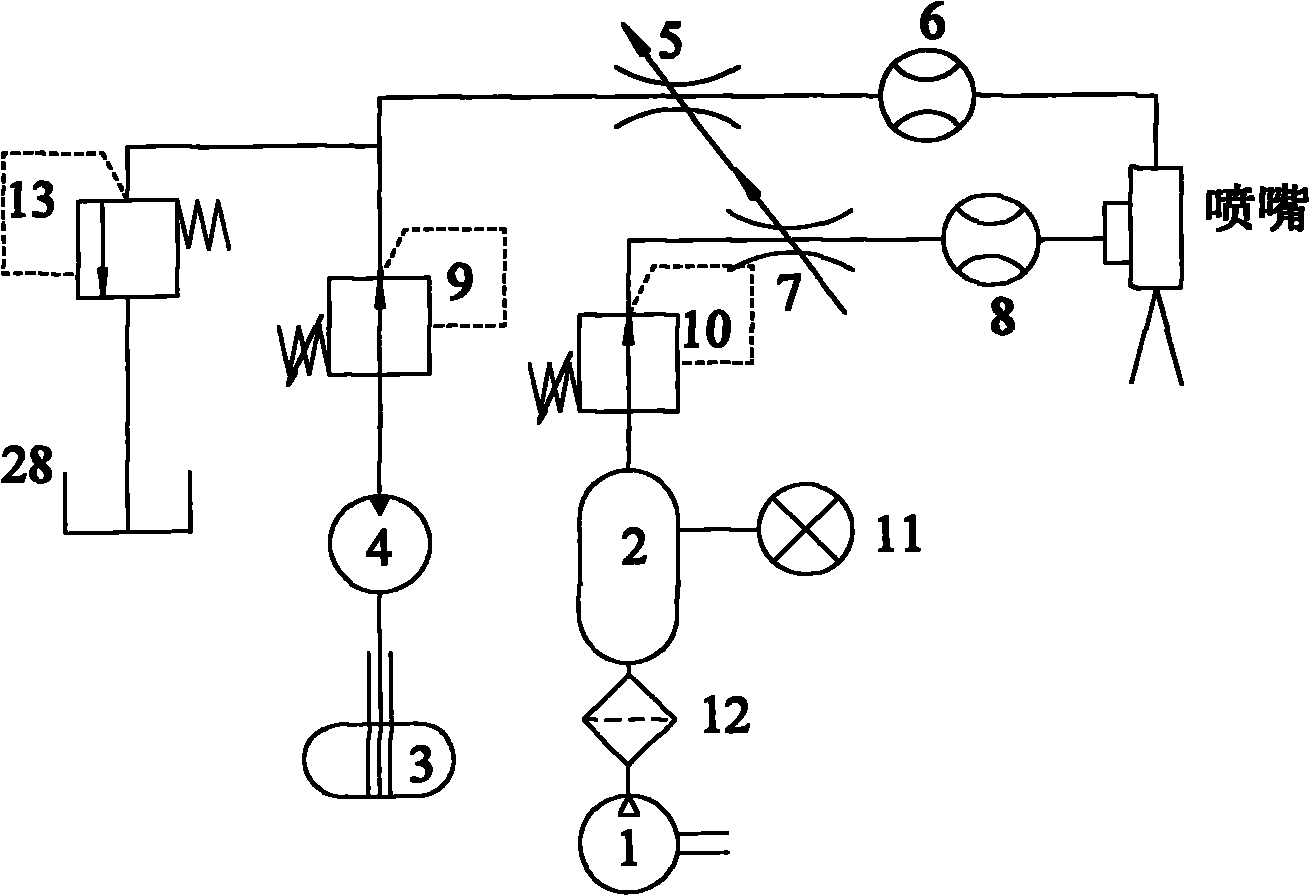

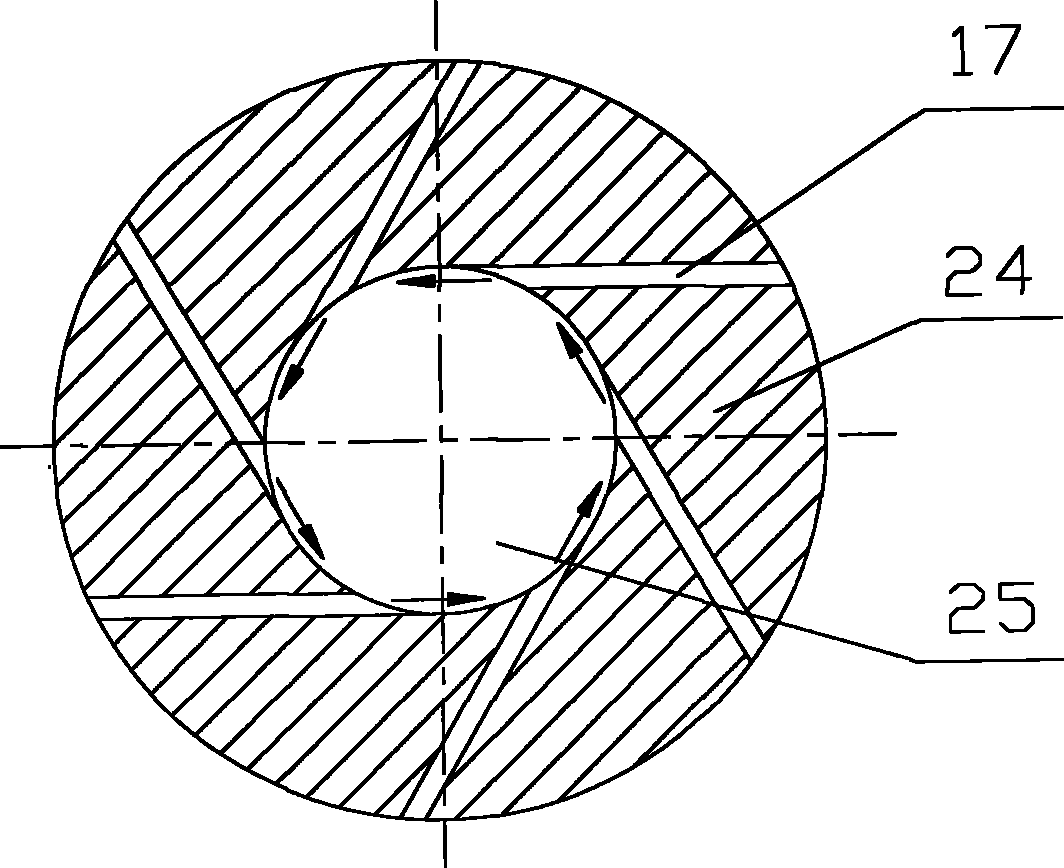

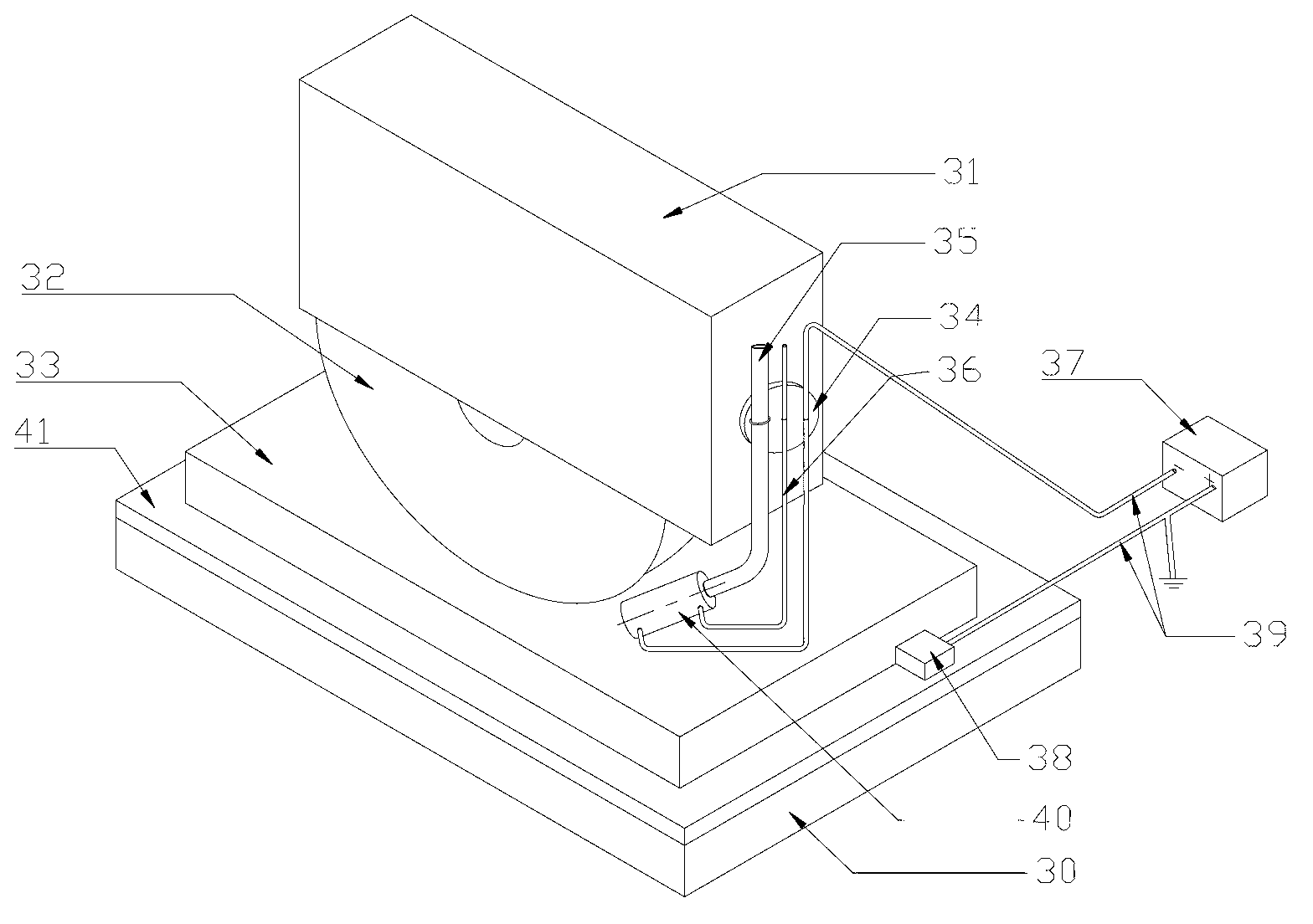

Three-phase flow supply system for nanoparticle jet micro-lubrication grinding

ActiveCN102287606AWell mixedIncrease the diameterConduits/junctionsLubrication check valvesEngineeringHigh pressure

The invention relates to the field of machining, in particular to a nano particle jet flow micro-scale lubricating and grinding three-phase flow supply system. The system is characterized in that: nano fluid is conveyed to a nozzle by a liquid path, high temperature gas enters the nozzle through a gas path at the same time, the high pressure gas and the nano fluid are fully mixed and atomized in the mixing room of the nozzle, the mixed high pressure gas and nano fluid are accelerated in an acceleration room and enter a vortex room, compressed gas enters from the vent hole of the vortex room, and a three-phase flow is further mixed and accelerated by rotating, and is jetted in the form of atomized liquid drops to a grinding area through the outlet of the nozzle. The system has the advantages that: the helical vent hole of the mixing room of the nozzle is tangent to the wall surface of the mixing room, and the nano fluid and the gas are uniformly mixed; pressure adjusting valves, throttles and flow meters are arranged in the gas path and the liquid path, and the pressure and the flow of the nano fluid and the high pressure gas can be adjusted as required so as to achieve an optimal micro-scale lubricating effect; and the problems of insufficient cooling capability in micro-scale lubricating, the large using quantity of a lubricant in pouring type grinding, high waste liquid processing cost and heavy environment pollution are solved.

Owner:青岛前瞻产业园区运营管理有限公司

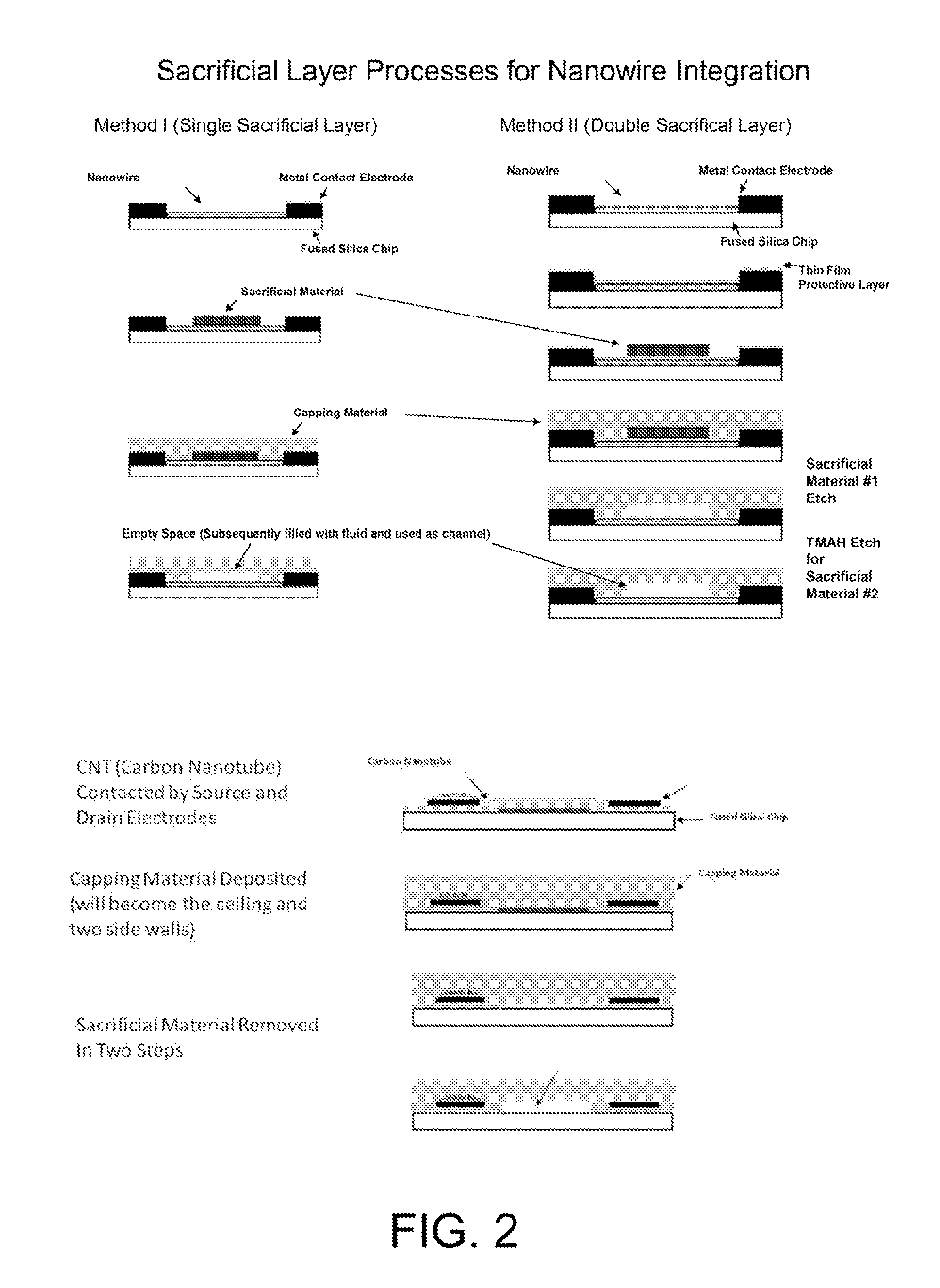

Nanofluidic channels with integrated charge sensors and methods based thereon

An electrical detector is provided that comprises a nanofluidic channel with an integrated nanoscale charge sensor. The charge sensor can be an unfunctionalized nanowire, nanotube, transistor or capacitor and can be of carbon, silicon, carbon / silicon or other semiconducting material. The nanofluidic channel depth is on the order of the Debye screening length. Methods are also provided for detecting charged molecules or biological or chemical species with the electrical detector. Charged molecules or species in solution are driven through the nanofluidic channel of the electrical detector and contact the charge sensor, thereby producing a detectable signal. Methods are also provided for detecting a local solution potential of interest.; A solution flowing through the nanofluidic channel of the electrical detector contacts the charge sensor, thereby producing a detectable local solution potential signal.

Owner:CORNELL UNIVERSITY

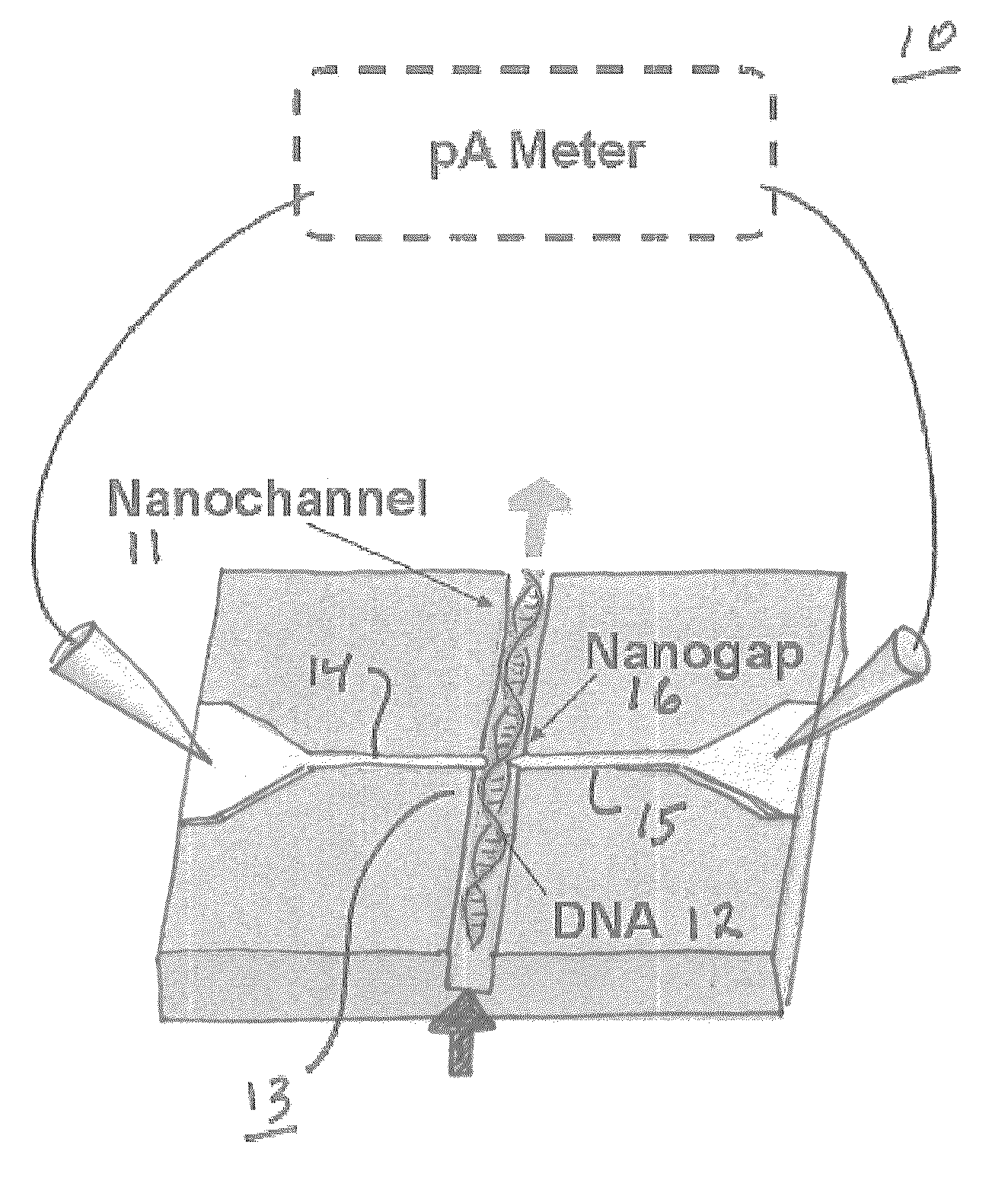

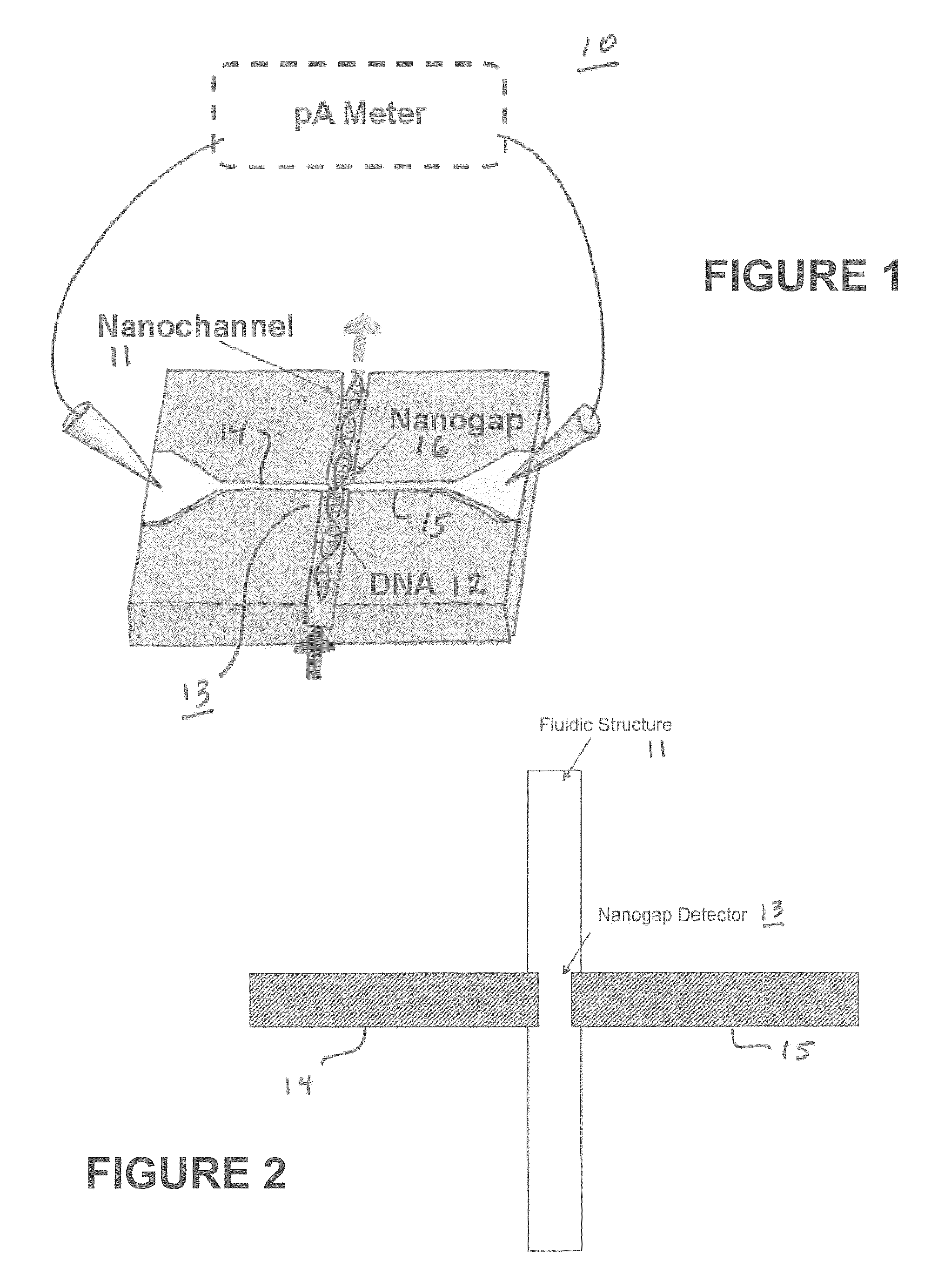

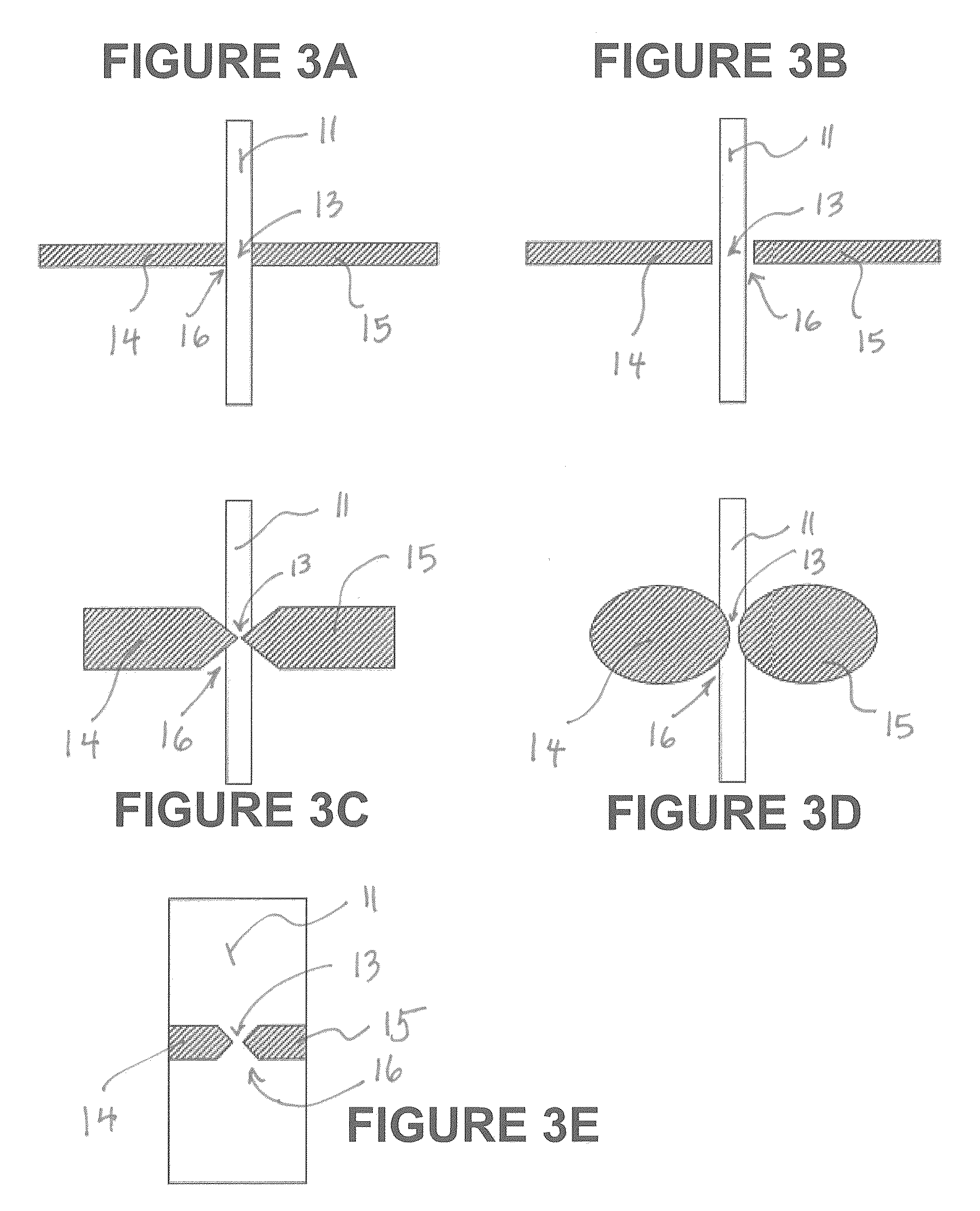

Electronic Detectors Inside Nanofluidic Channels For Detection, Analysis, and Manipulation of Molecules, Small Particles, and Small Samples of Material

ActiveUS20100267158A1Decorative surface effectsMicrobiological testing/measurementSmall sampleSmall particle

The present invention provides methods and apparatus that can manipulate, detect, and / or analyze single molecules, single small particles or single small samples of matter passing through a nanoscale gap within a nanofluidic channel of a detector.

Owner:NANONEX

Nano-fluidic Trapping Device for Surface-Enhanced Raman Spectroscopy

InactiveUS20090214392A1Radiation pyrometryAnalysis using chemical indicatorsSurface-enhanced Raman spectroscopyTrapping

A nano-fluidic trapping device and method of fabrication are disclosed. In one embodiment, a nano-fluidic trapping device for assembling a SERS-active cluster includes a substrate. The nano-fluidic trapping device further includes a SERS-active cluster compartment. The SERS-active cluster is formed in the SERS-active cluster compartment. In addition, the nano-fluidic trapping device includes a reservoir. The reservoir allows introduction of target molecules into the nano-fluidic trapping device. Moreover, the nano-fluidic trapping device includes a microchannel. The microchannel allows the target molecules to be introduced to the SERS-active cluster compartment from the reservoir. The nano-fluidic trapping device also includes a nanochannel. The SERS-active cluster compartment, the reservoir, the microchannel, and the nanochannel are disposed within the substrate.

Owner:TEXAS A&M UNIVERSITY

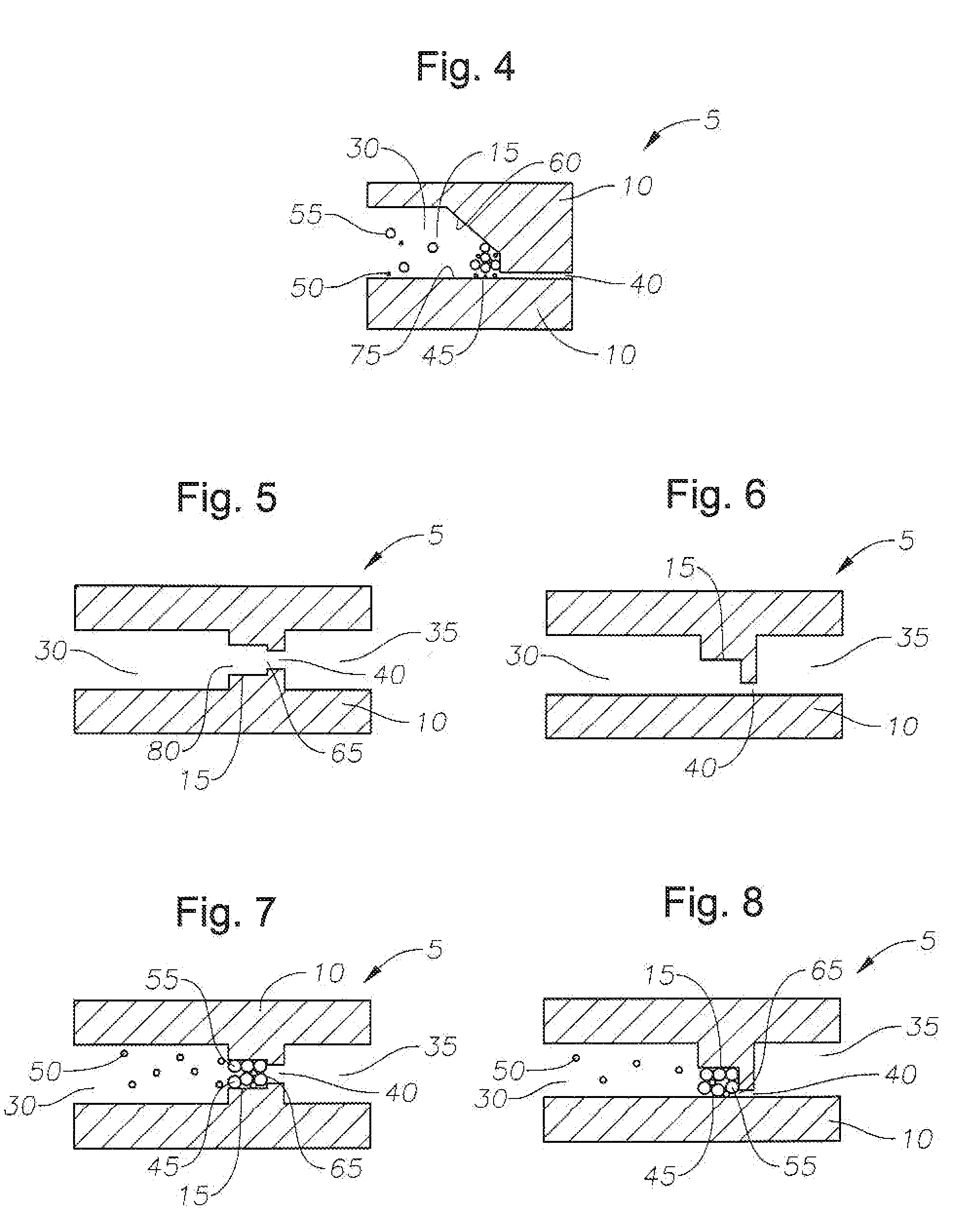

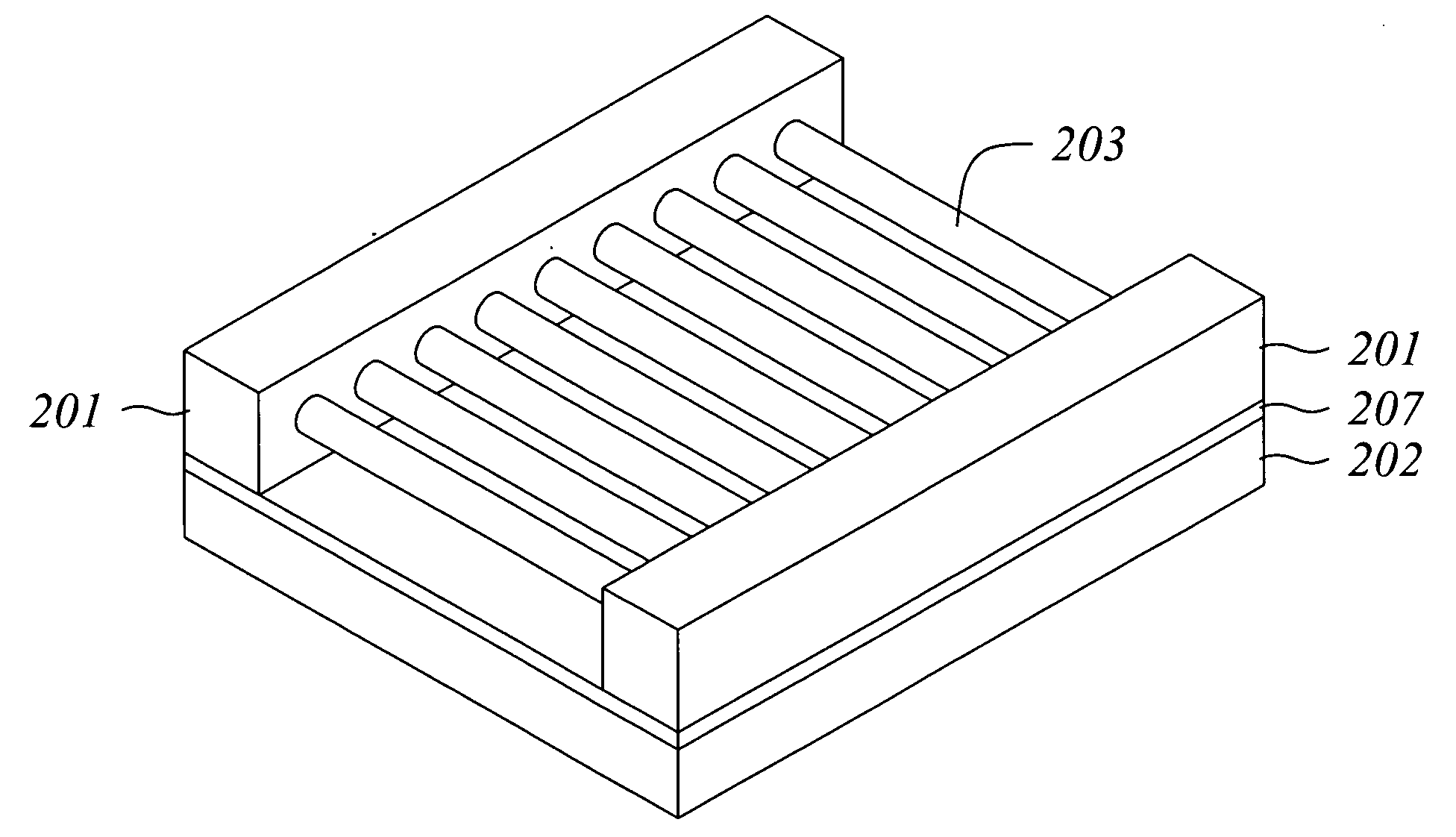

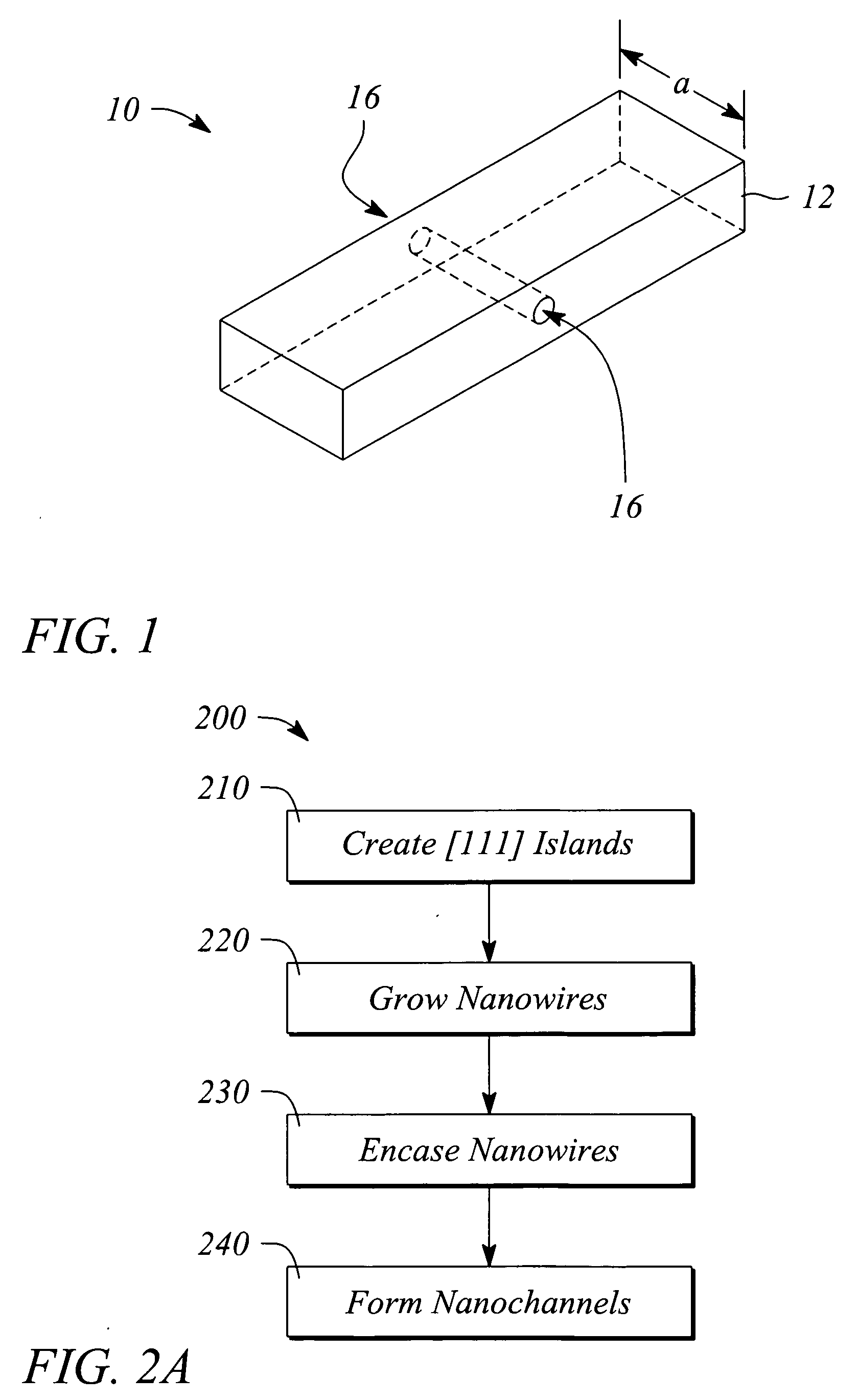

Nanochannel apparatus and method of fabricating

InactiveUS20070122313A1Easy to analyzeEasy to detectMaterial nanotechnologyAnalysis using chemical indicatorsNanowire arrayNanometre

A nanochannel apparatus and method of fabrication provide an array of nanochannels with distal open or exposed ends formed in situ through a permanent support. A nanofluidic system includes the nanochannel apparatus, a fluidic interface, and a component interfaced to the nanochannel apparatus. The method includes encasing an array of nanowires in a support, and forming the array of nanochannels in situ in locations of the nanowires, such that distal ends of the nanochannels are exposed.

Owner:HEWLETT PACKARD DEV CO LP

Nanofluidic cell

InactiveUS20120182548A1Reduced fluidic resistanceReduce resistanceMaterial analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis using wave/particle radiationMicron scaleActive feedback

A flow cell is provided for the analysis and / or microscopy of liquid or gas samples on the nanometer to micron scale. The flow cell preferably includes a thin membrane that is transparent to electrons and / or photons, thereby enabling the penetration of electrons or photons into a liquid flowing through the cell. Trenches are provided on either side of the membrane, which advantageously minimize fluidic resistance outside of the window area of the cell and also enable a faster response time in response to changes in external fluidic pressure. This feature enables active feedback using pathlength sensitive probes to stabilize the fluid flow to thin streams from nanometer to micron scale thicknesses with nanometer precision.

Owner:INSIGHT NANOFLUIDICS

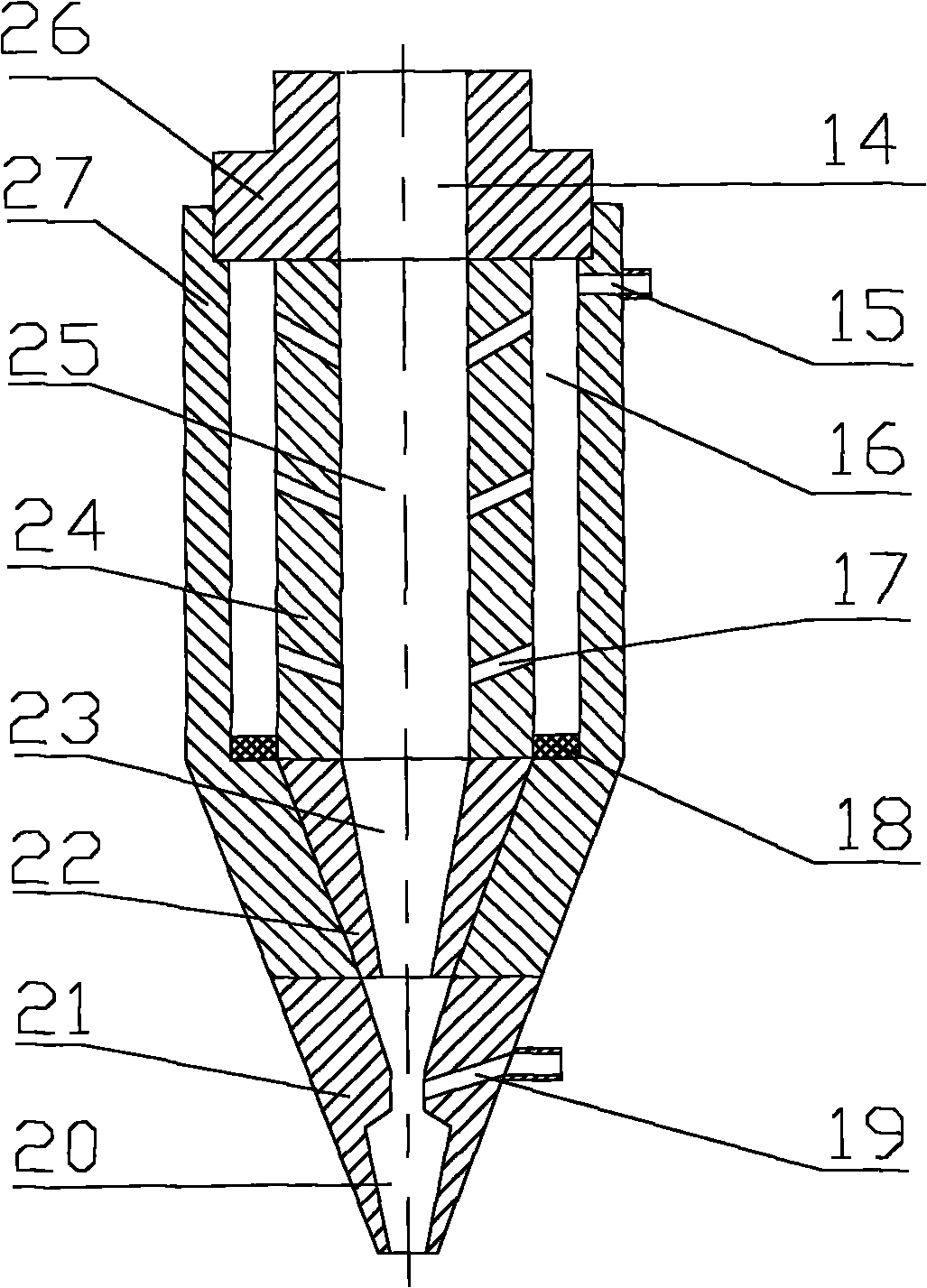

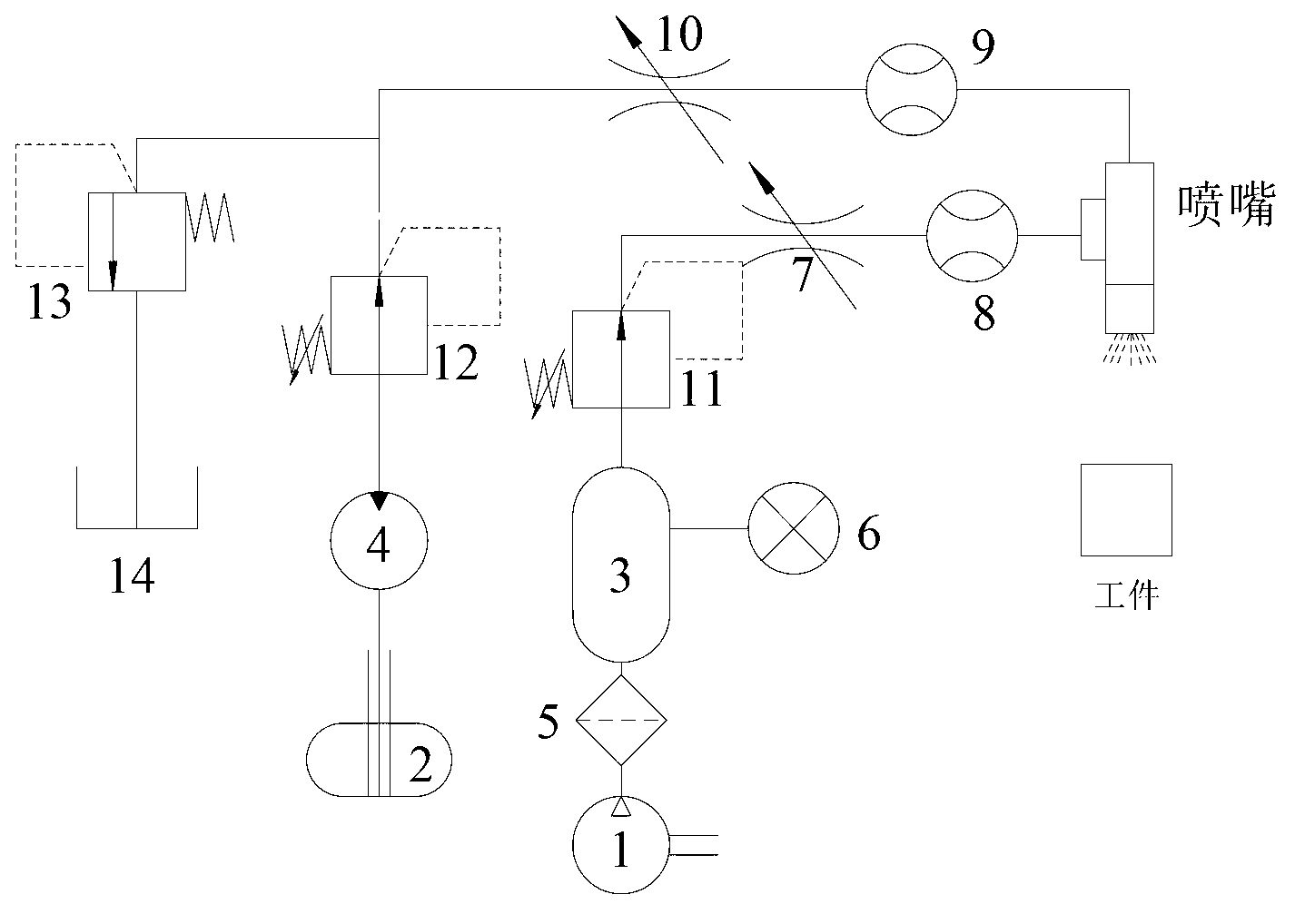

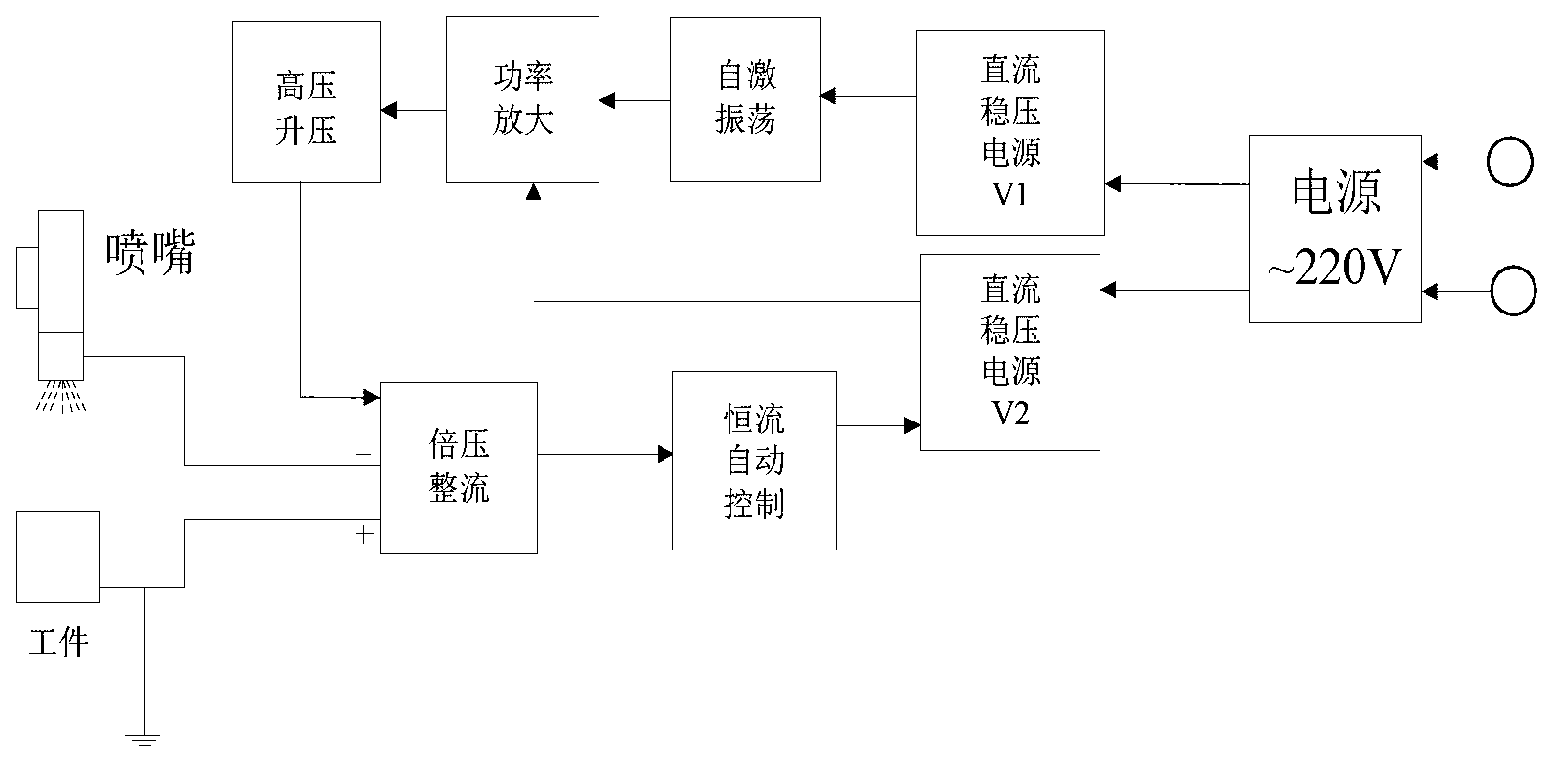

Nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system

ActiveCN103072084AReduce drift lossIncrease profitGrinding/polishing safety devicesMachined surfaceHigh-voltage direct current

The invention relates to a nano fluid electrostatic atomizing controllable jet stream minimal lubricating and grinding system. Sprayed fog drops can be controllably distributed through the electrostatic principle, so that the pollution to environment is reduced, and better health security is provided to workers. A grinding system is provided with a corona charging nozzle, wherein a nozzle body of the corona charging nozzle is connected with a liquid supply system and an air supply system; a high-voltage direct-current electrostatic generator on the lower part of the nozzle body is connected with the cathode of an adjustable high-voltage direct-current power supply; the anode of the adjustable high-voltage direct-current power supply is connected with a workpiece charging device; and the workpiece charging device is attached to the non-machined surface of a workpiece. Nano fluid grinding liquid is fed into the corona charging nozzle through the liquid supply system, meanwhile the air supply system feeds compressed air into the corona charging nozzle, the nano fluid grinding liquid is charged into controllable jet stream by the high-voltage direct-current electrostatic generator while being driven by the compressed air to be sprayed out and atomized from the nozzle body, and the controllable jet stream is controllably distributed to a grinding area of the machined workpiece under the actions of electric field force and aerodynamic force.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

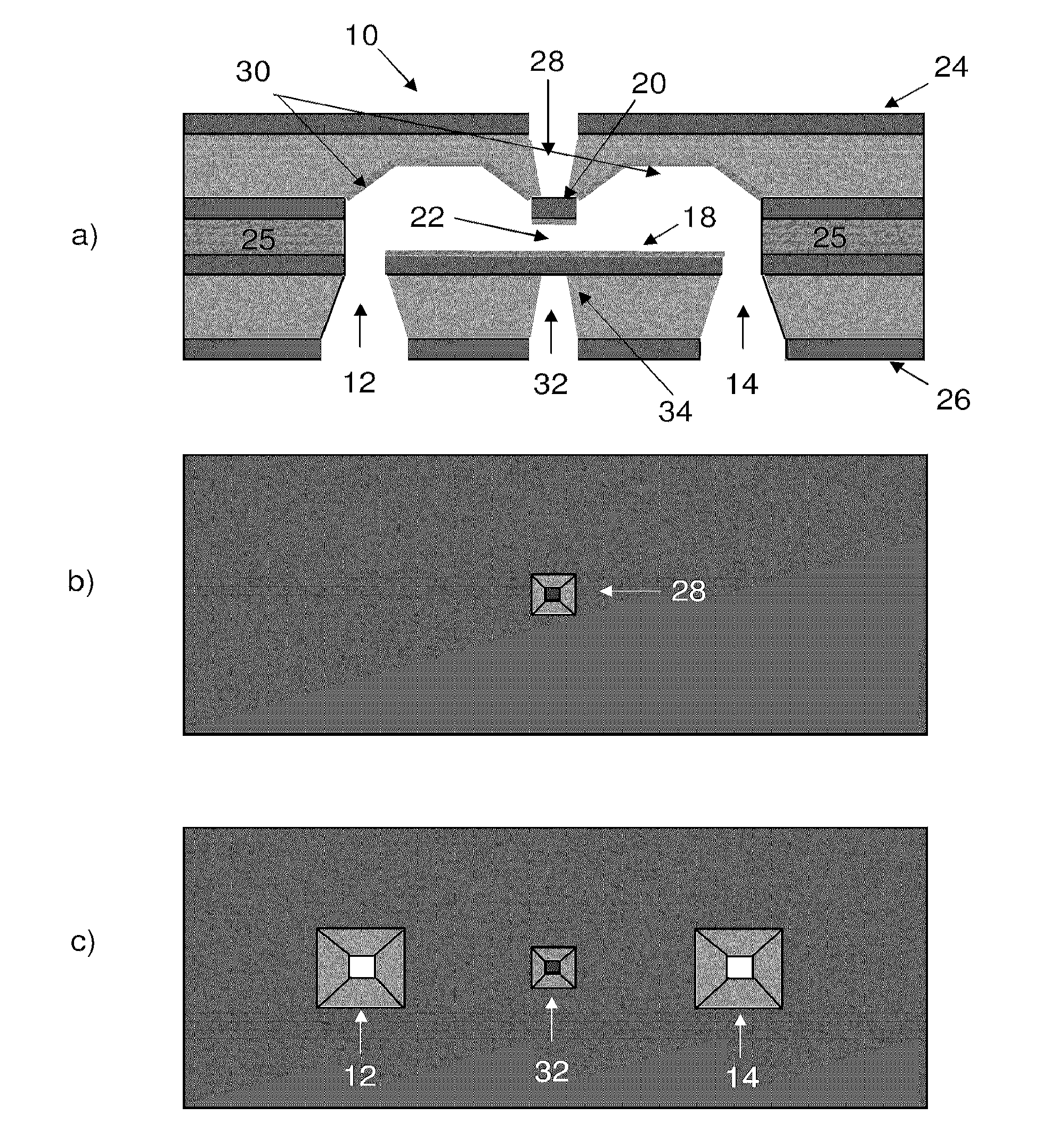

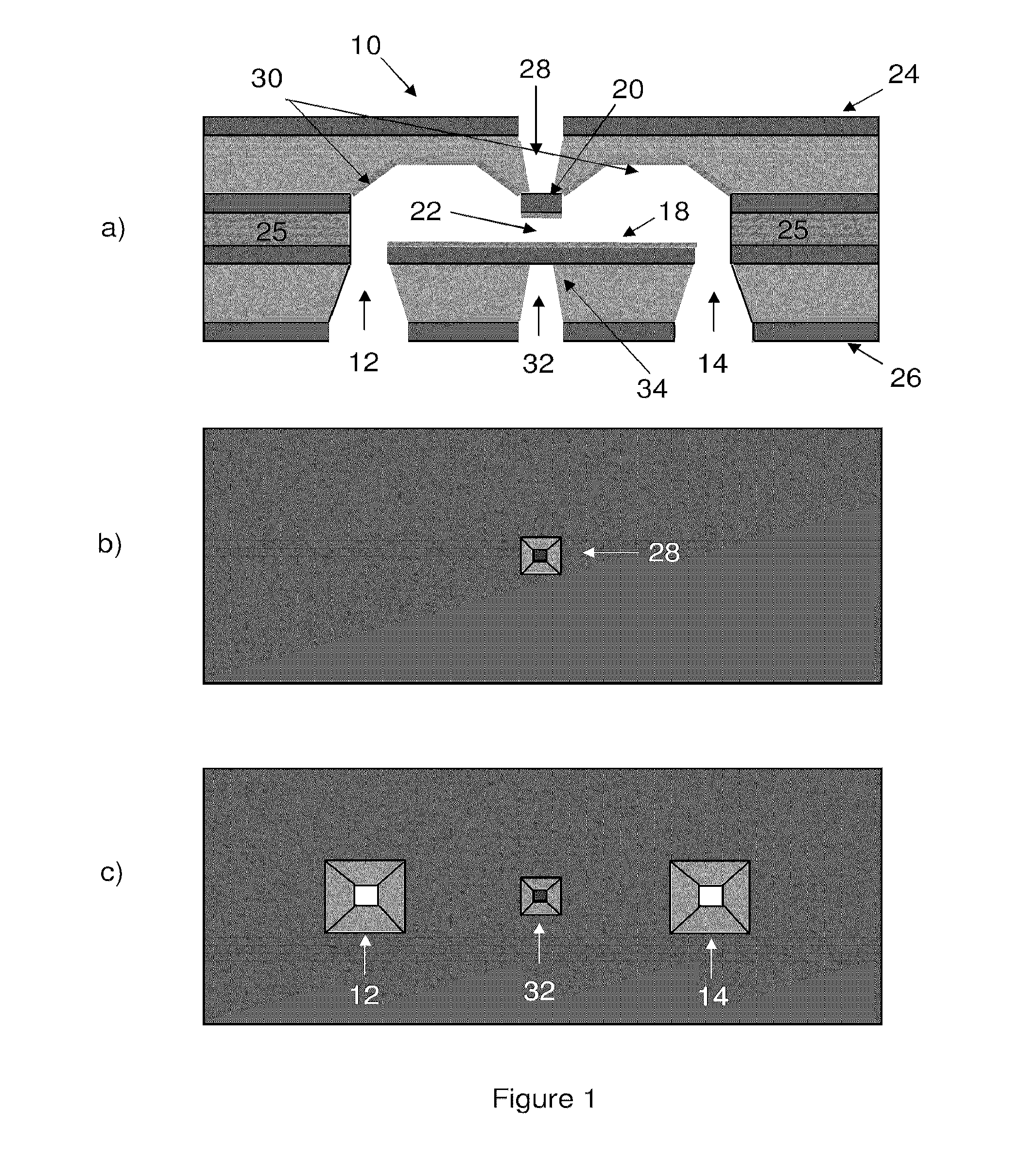

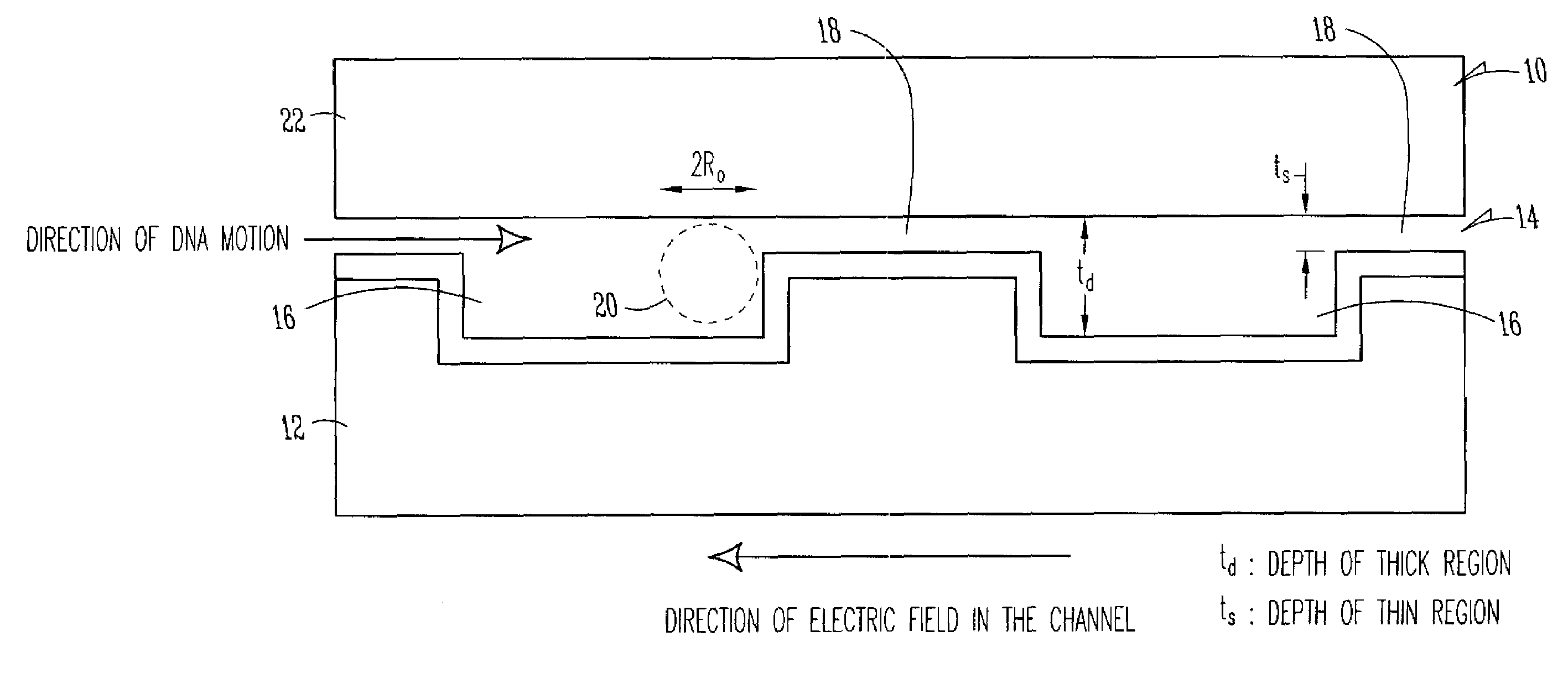

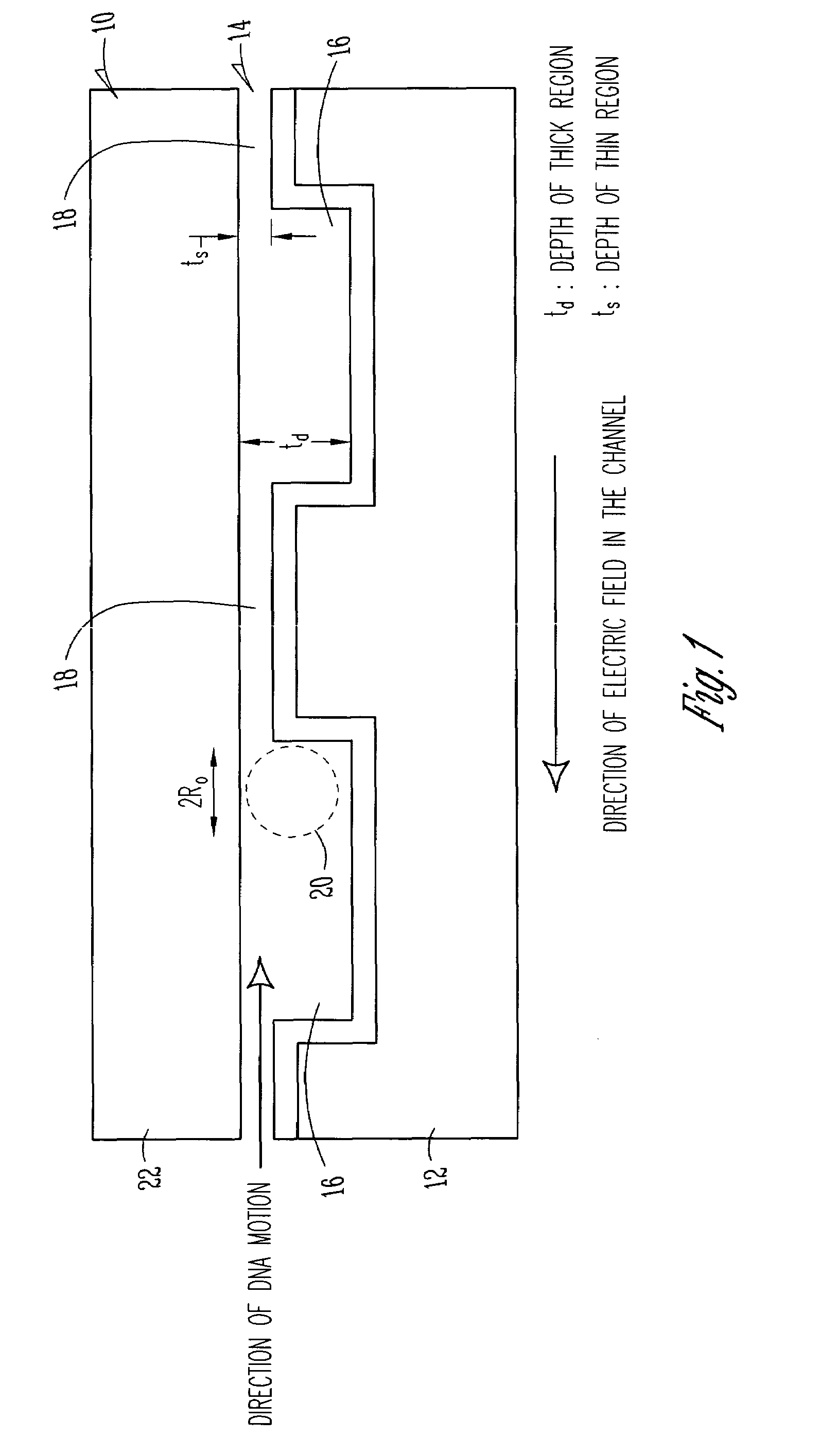

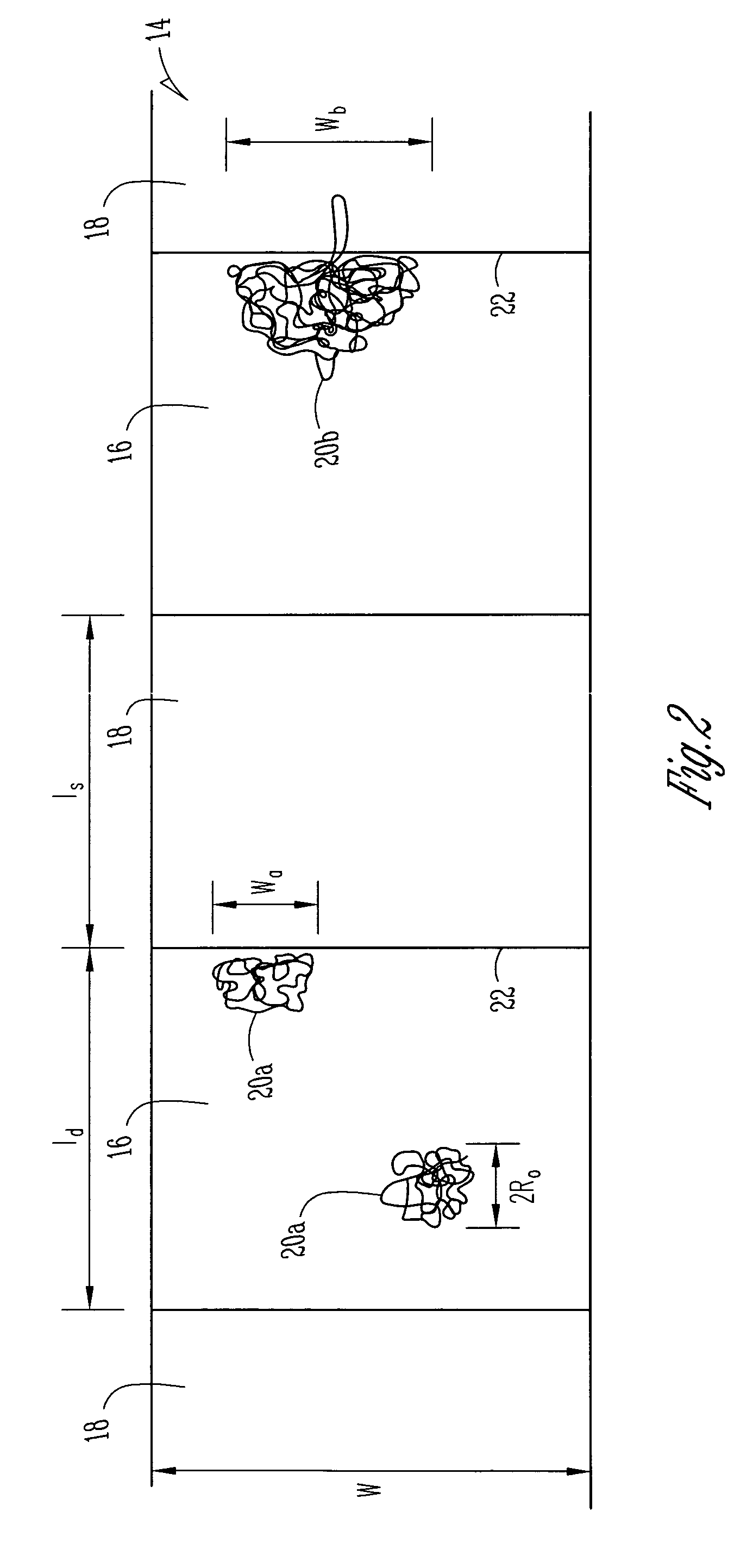

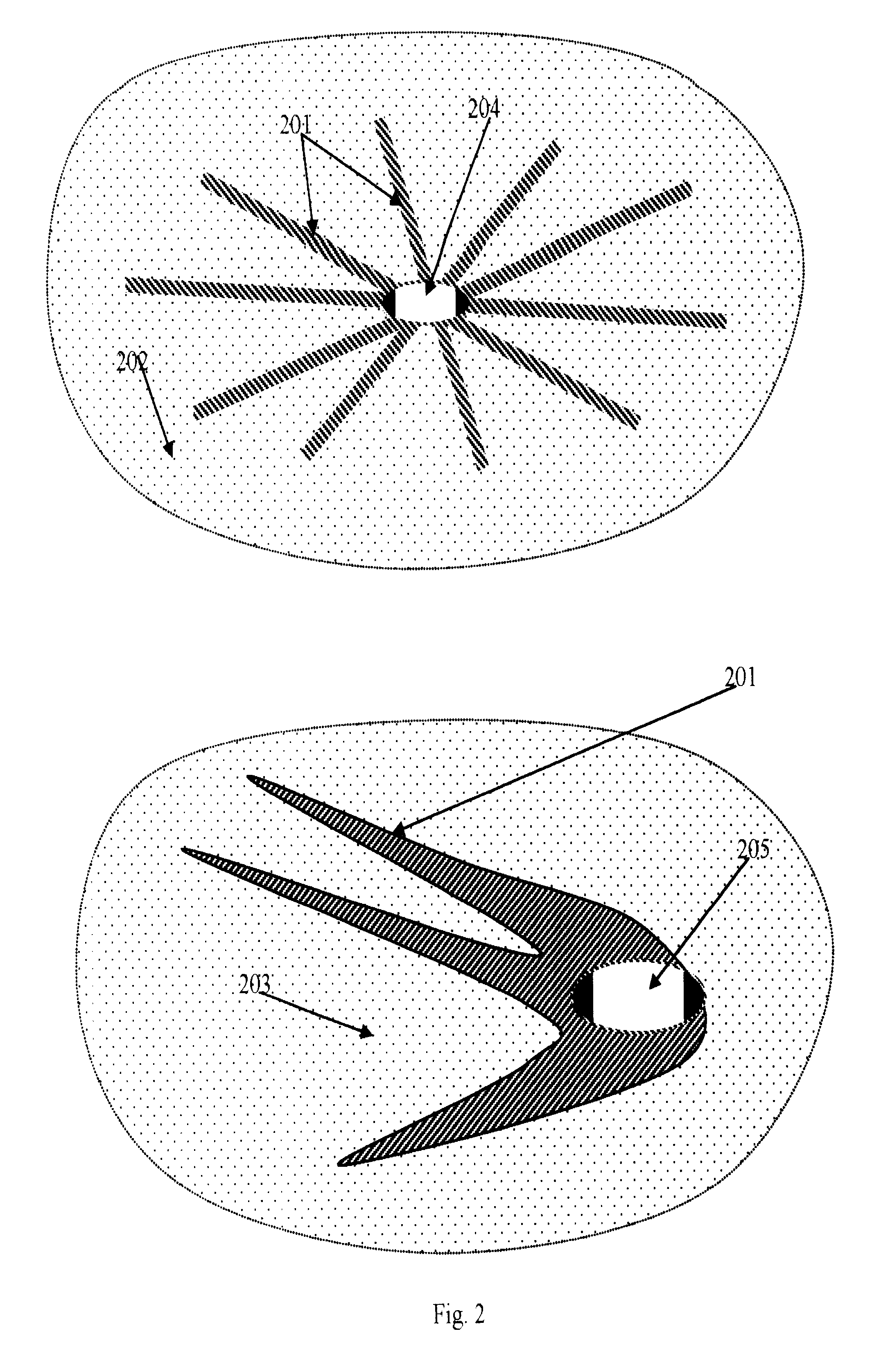

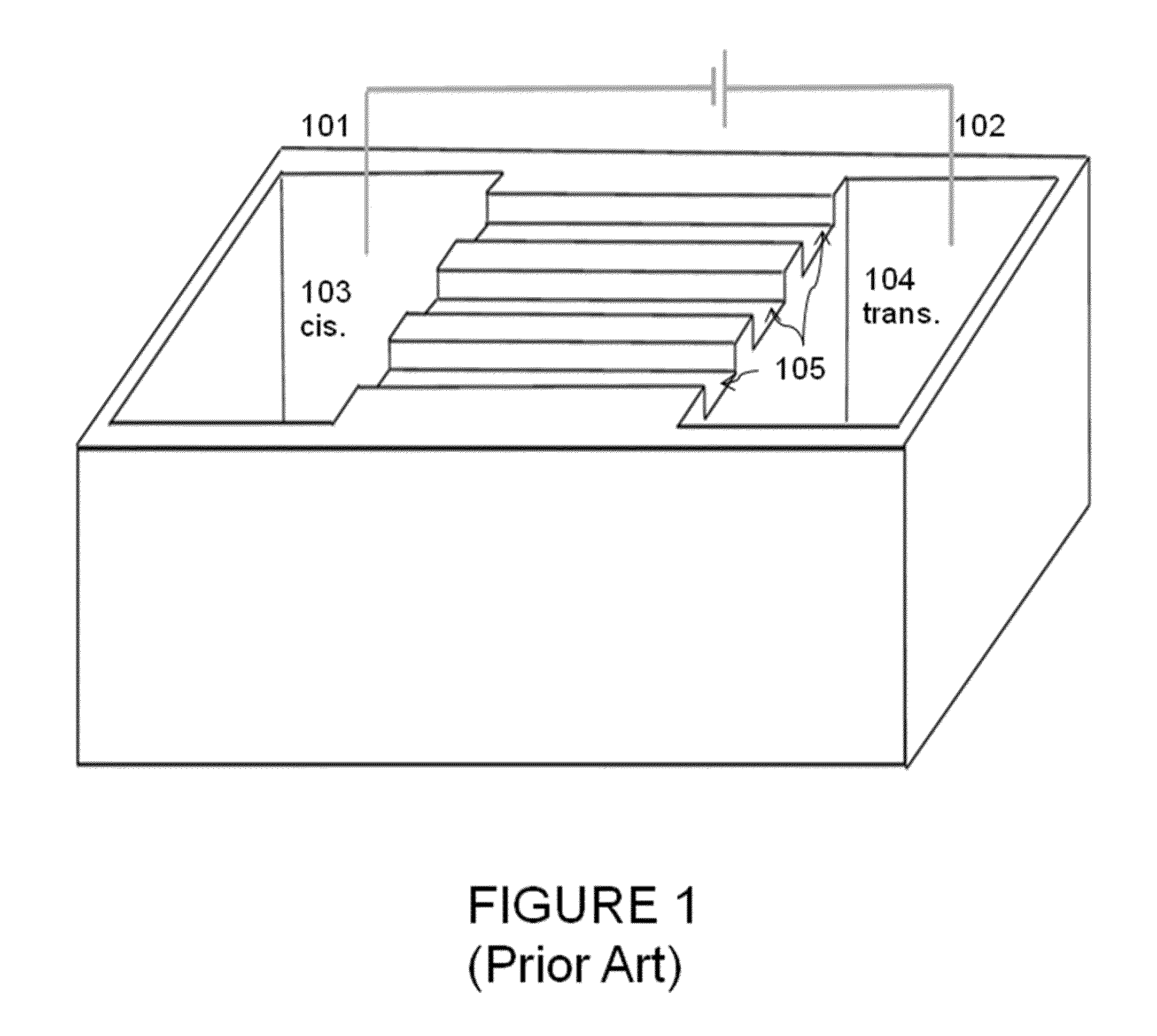

Entropic trapping and sieving of molecules

Nanofluidic entropic traps, comprising alternating thin and thick regions, sieve small molecules such as DNA or protein polymers and other molecules. The thick region is comparable or substantially larger than the molecule to be separated, while the thin region is substantially smaller than the size of the molecules to be separated. Due to the molecular size dependence of the entropic trapping effect, separation of molecules may be achieved. In addition, entropic traps are used to collect, trap and control many molecules in the nanofluidic channel. A fabrication method is disclosed to provide an efficient way to make nanofluidic constrictions in any fluidic devices.

Owner:CORNELL RES FOUNDATION INC

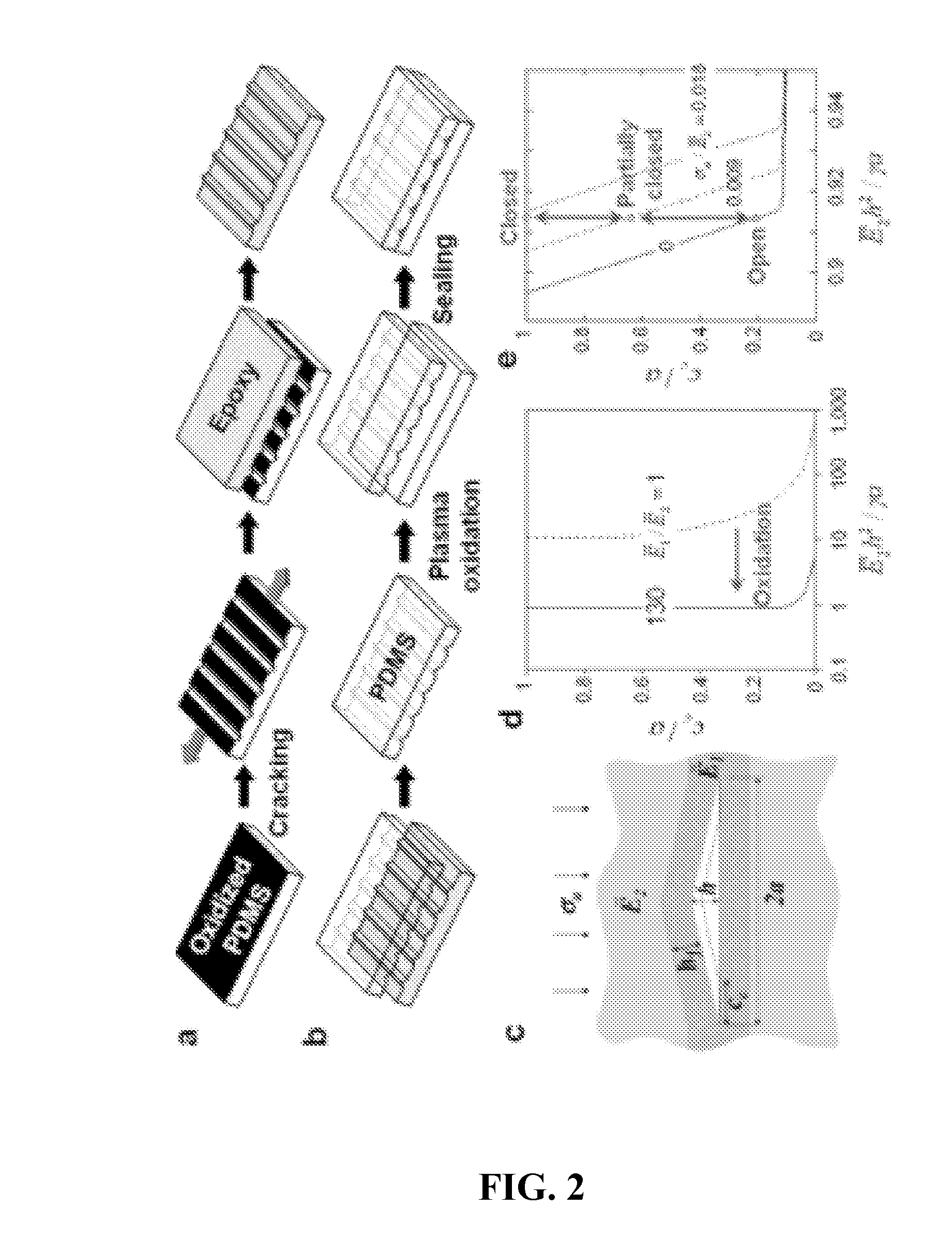

Tunable elastomeric nanochannels for nanofluidic manipulation

ActiveUS20100159462A1Bioreactor/fermenter combinationsMaterial nanotechnologyEngineeringNanofluidics

Owner:RGT UNIV OF MICHIGAN

Components for nano-scale Reactor

InactiveUS20040115830A1Compensation attenuationAvoid captureMaterial nanotechnologyFlow mixersEvaporationEngineering

Microfluidic devices and methods for operations on micro through nano-meter scales. Methods of processing, handling and analysis of yocto-liter scale volumes. Methods and devices for single-molecule transports in milli-scale dimensions. Methods of laser propulsion of individual cells and droplets. Methods of packaging and manufacturing of micro and nanofluidic devices. Method of improving dispensing accuracy. Methods of uses and manufacturing of micro-optico-fluidic devices. Bottom up processing method. Ionic particle deflector device. Smart package device and methods for high-throughput synthesis and screening. Methods and devices for controlled refills of micro stamps. Methods and devices for insitu concentration and dilution of micro volumes of solids and liquids. Methods and devices for eliminating undesirable dry outs and evaporation of microscale volumes of fluids.

Owner:TOUZOV IGOR

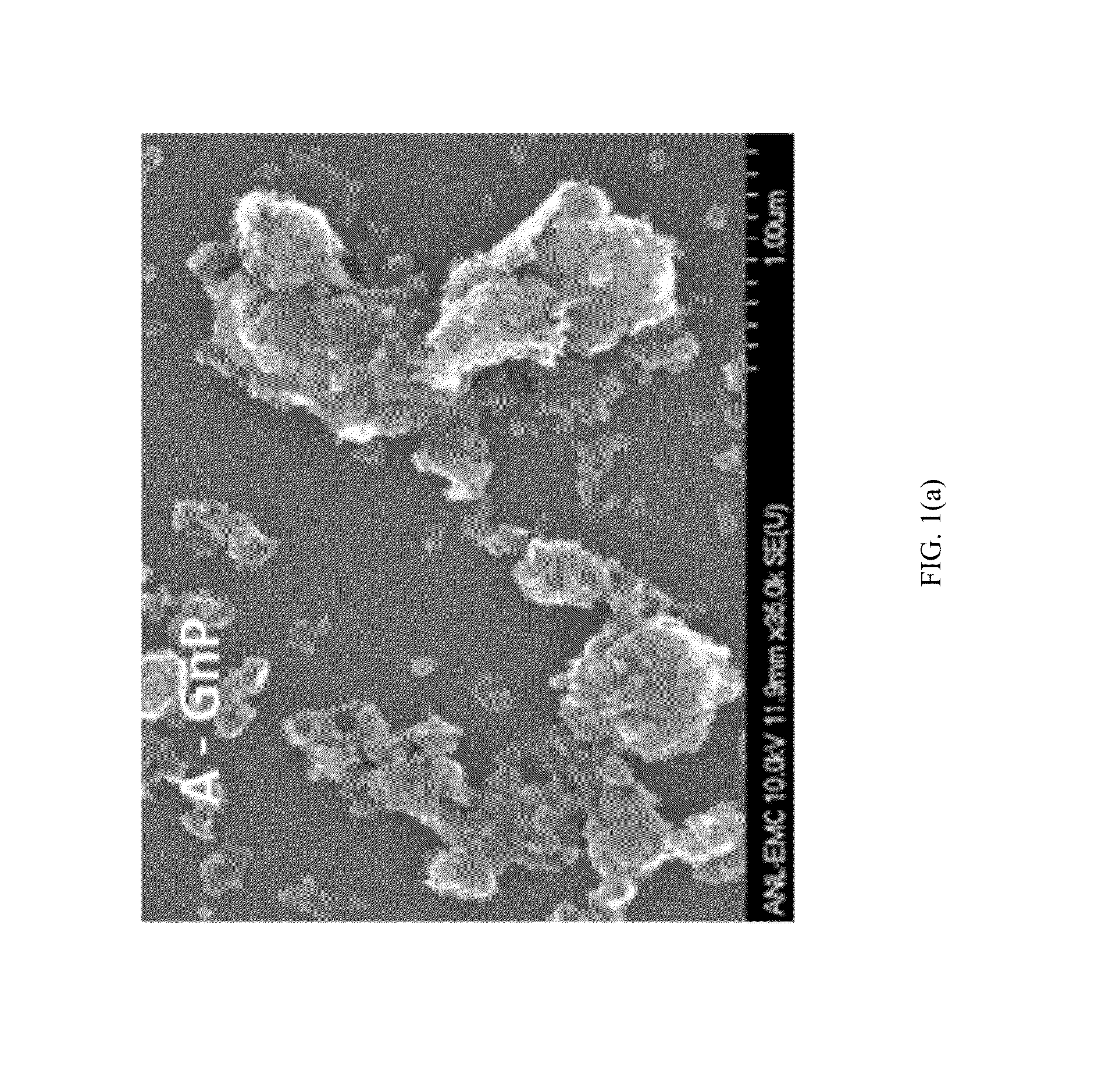

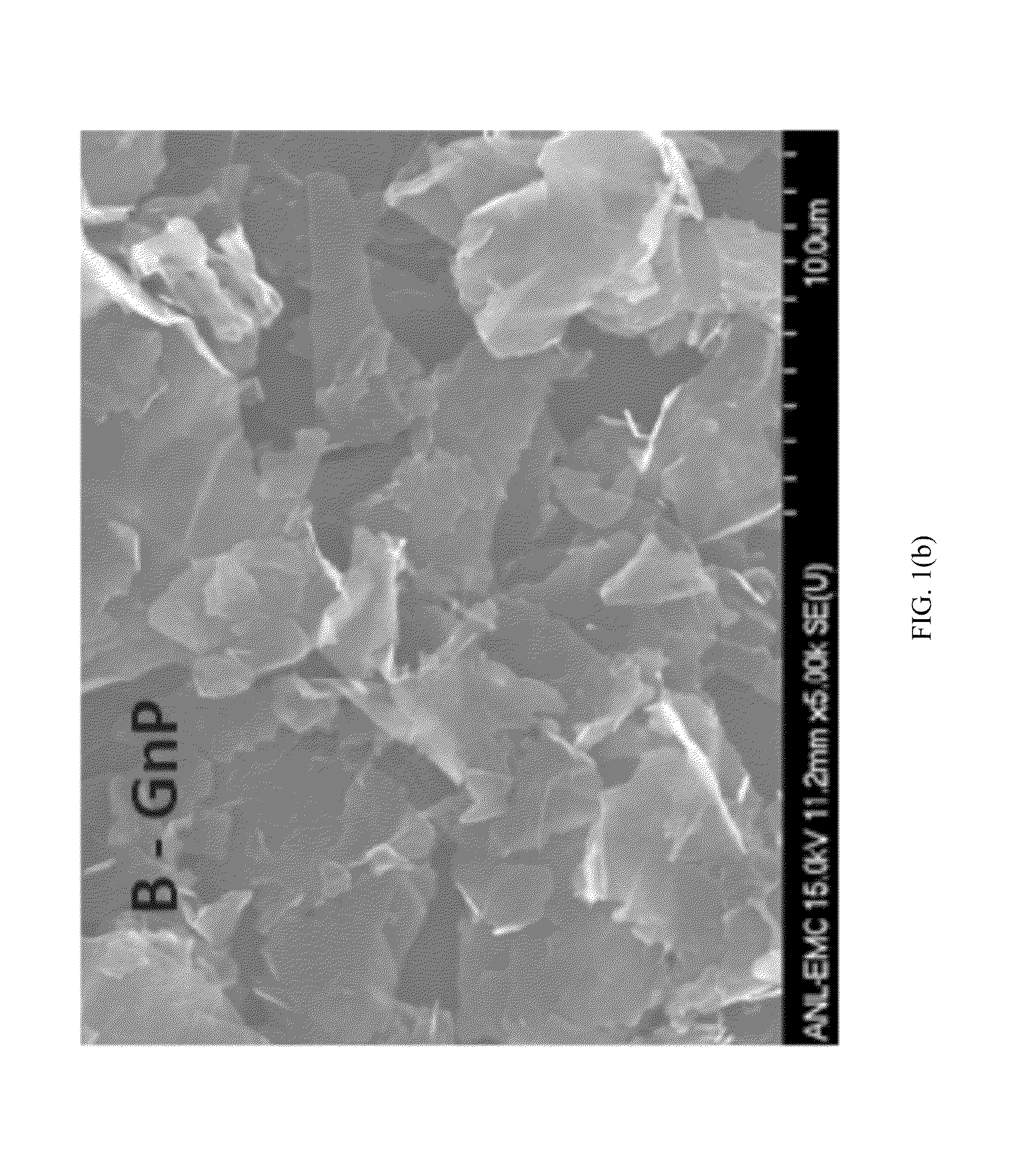

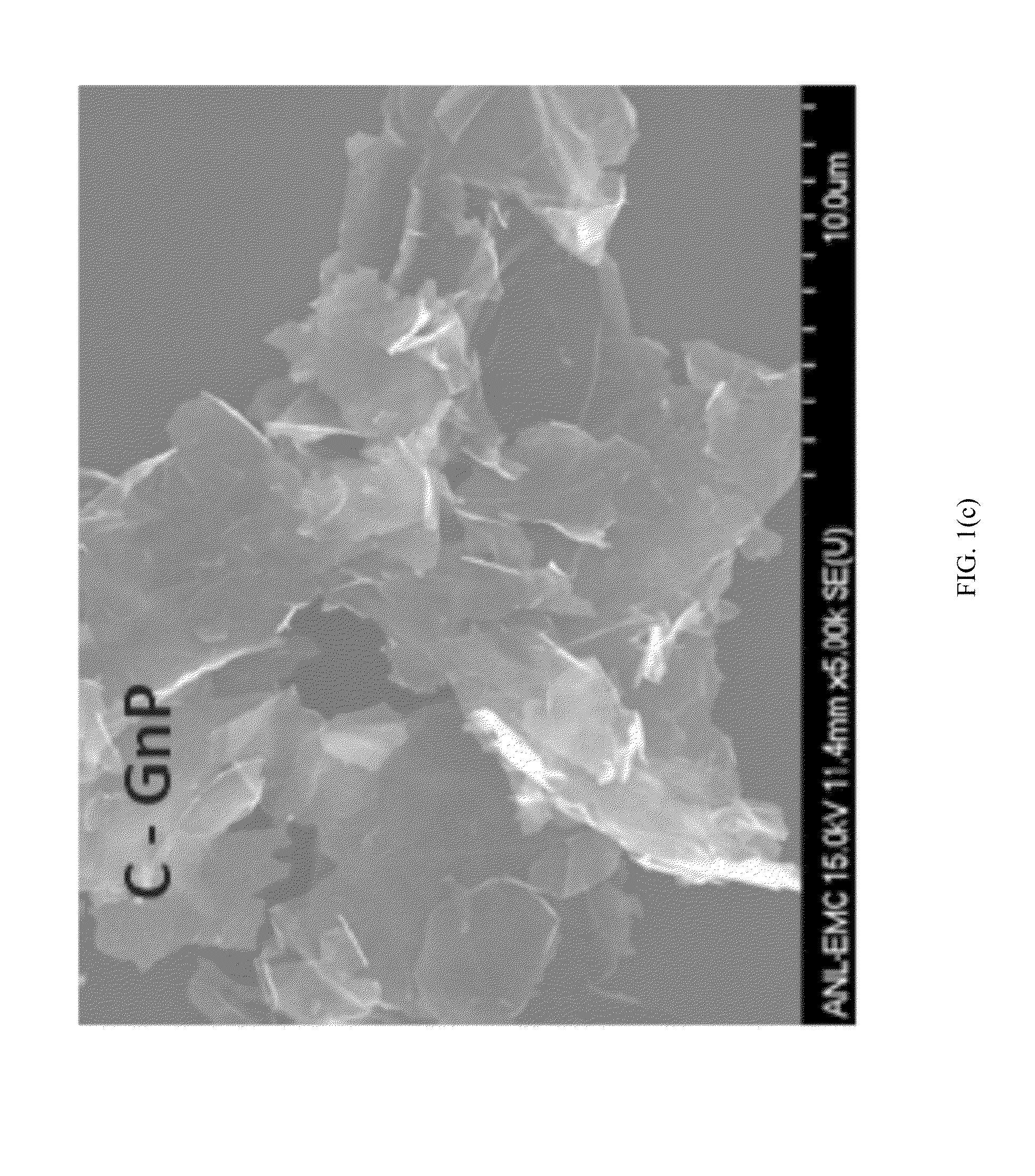

Advanced thermal properties of a suspension with graphene nano-platelets (GNPS) and custom functionalized f-gnps

InactiveUS20140312263A1Improve thermal performanceMinimal negative mechanical effectHeat-exchange elementsPower electronicsElectric power

A method for producing nanofluids with multilayered graphene nanoplatelets for providing improved heat transfer coolant fluids. A method for optimizing the concentration of nanoplatelets based on their morphology that allows achieving high thermal conductivity and low viscosity thus resulting in high heat transfer coefficient. A method is provided to functionalize as received graphene nanoplatelets by oxidaitively treating the multilayered graphene / nanothin graphite to generate highly dispensable nanoparticles for suspension in polar fluids for cooling thermal sources, such as power electronics and other heat transfer cooling applications.

Owner:UCHICAGO ARGONNE LLC

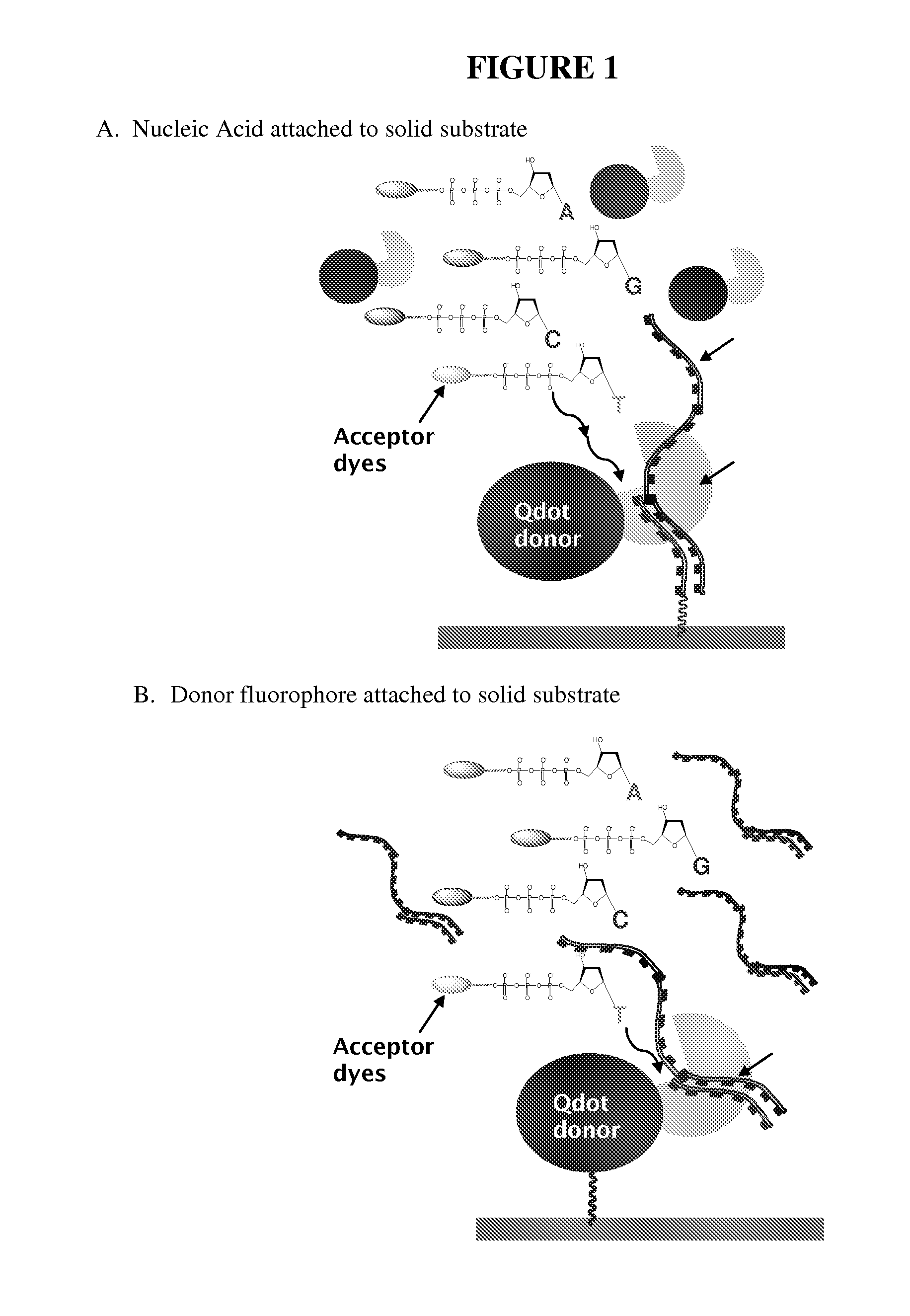

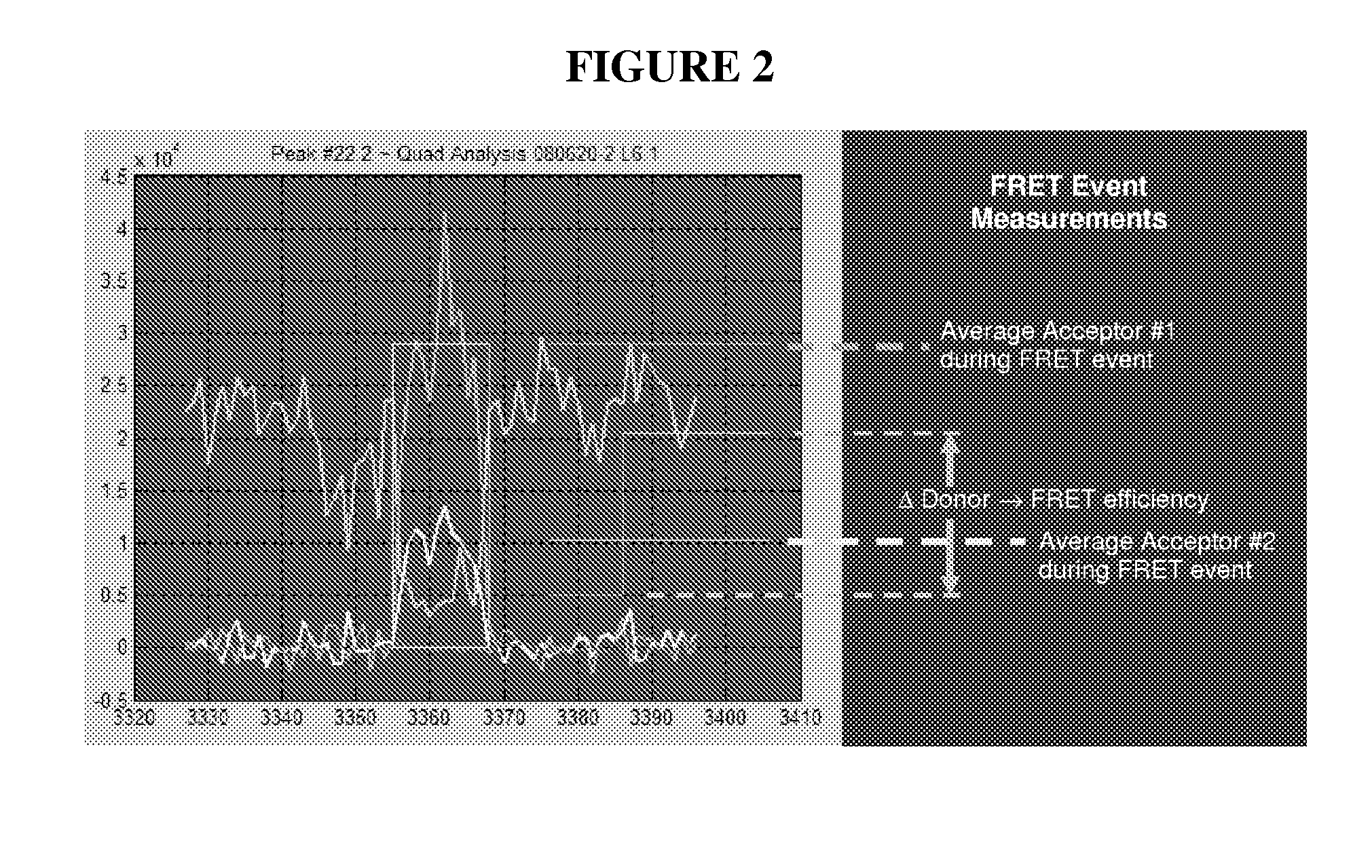

Methods for Real Time Single Molecule Sequencing

InactiveUS20110281740A1Rapid and accurate and long readFacilitate high throughput sequencingMicrobiological testing/measurementLibrary screeningPolymerase LPolynucleotide

Provided herein are methods and compositions for real time single molecule sequencing of a polymeric molecule, such as a polynucleotide, by isolating the polymeric molecule in a nanofluidic device, subjecting it in situ to a polymerase reaction wherein various components of the polymerase reaction mixture are labeled, and determining the time-sequence of incorporation of monomeric subunits during the polymerization process.

Owner:LIFE TECH CORP

Method for preparing graphite series nano fluid

InactiveCN101186808AImprove thermal conductivityNo wearHeat-exchange elementsCarbon nanotubeMaterials science

The invention discloses a process for preparing nanophrase fluid of graphite, which comprises graphitic oxidation, surface modification and deoxidization of graphitic oxidation with surface modification. The surface modification means that surfaces of achieved 100 parts by mass of graphitic oxidation are modified to prepare graphitic oxidation with surface modification by 1-20 parts by mass of surface modifying agent. Deoxidization of graphitic oxidation with surface modification means that nanophrase graphite with surface modification is achieved by deoxidizing 100 parts by mass of products with 1-100 parts by mass of deoxidization agent. Finally the nanophrase graphite is prepared into nanophrase fluid of graphite, which is dispersed in dispersive medium by ultraphonic wave. The process of the invention can produce nanophrase fluid with high thermal conductivity, and replace nanophrase fluid of diamond, carbon nanotubes, carbon 60 and the like. Further the process of the invention has the advantages of simple technique, low cost, rich raw materials supply, and stable products, which cause no abrasion to heat exchangers.

Owner:SOUTH CHINA UNIV OF TECH

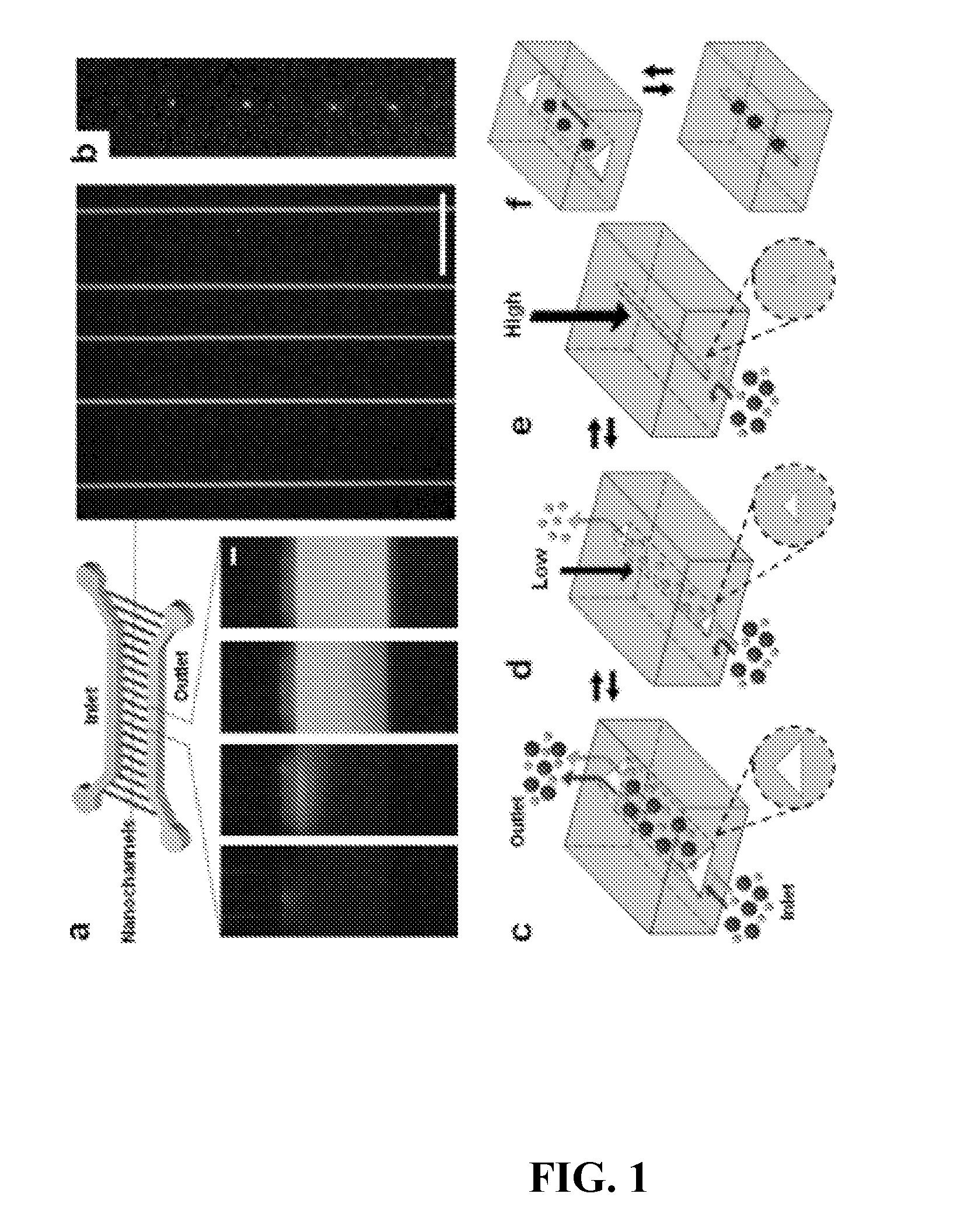

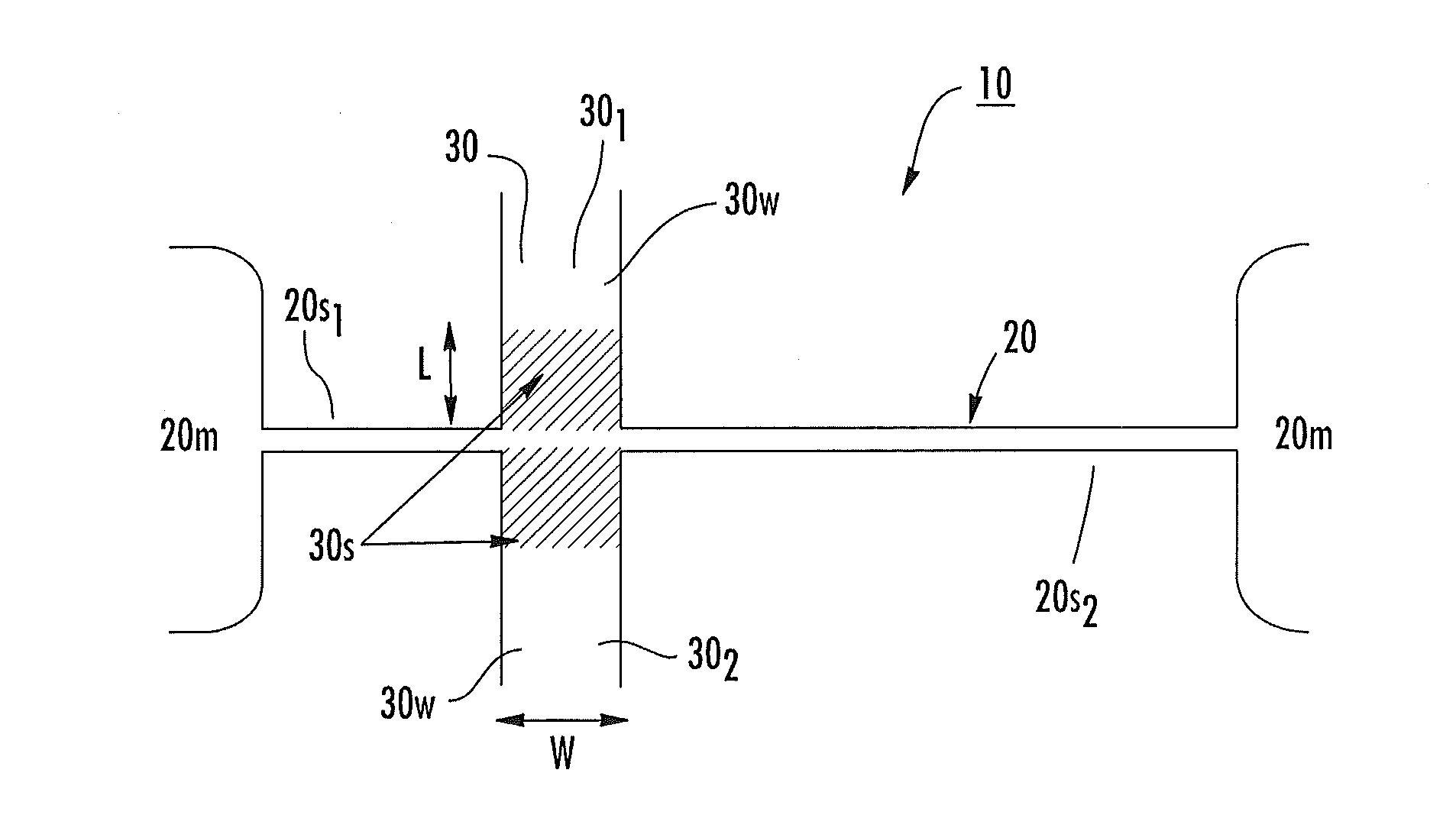

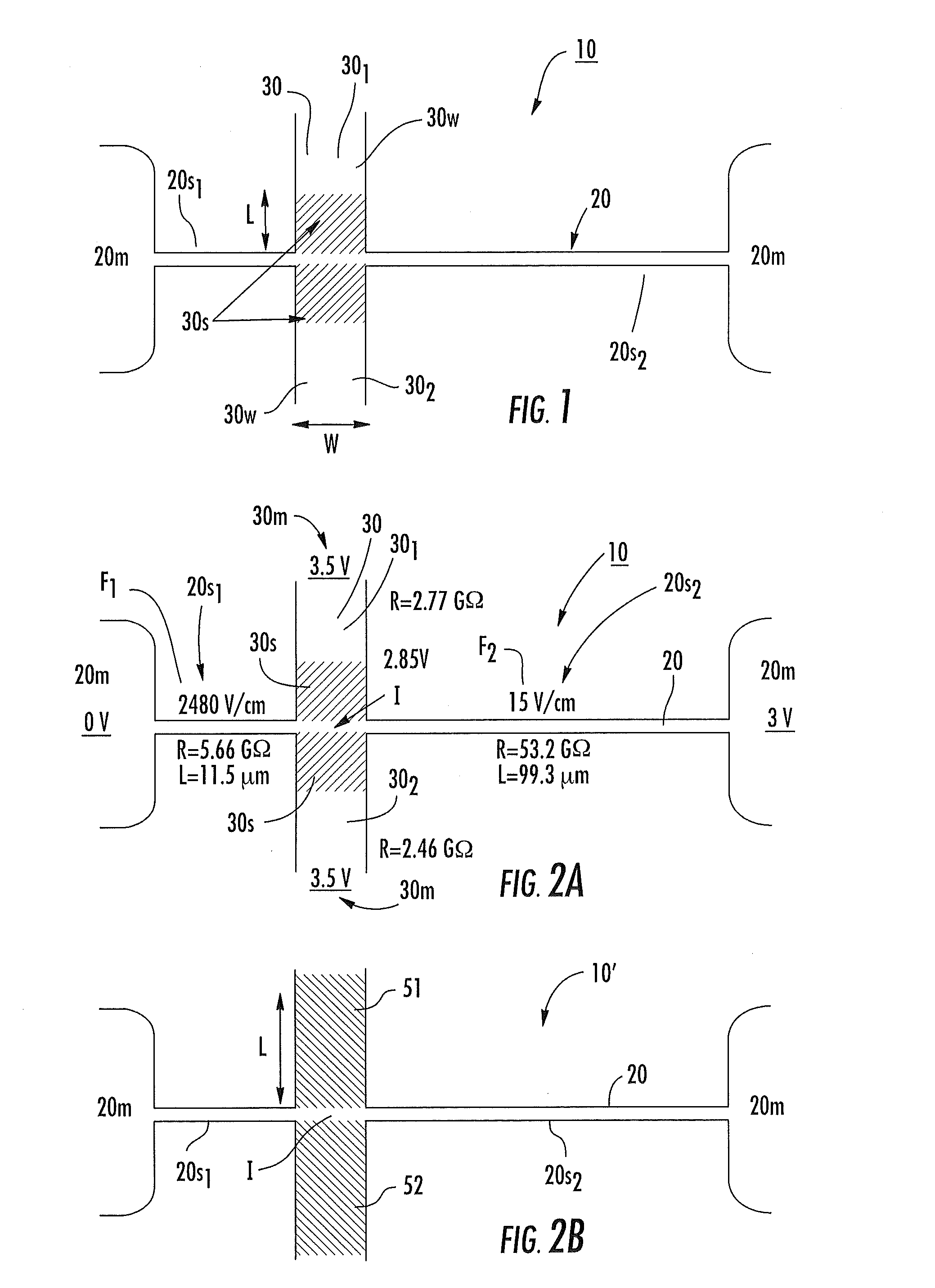

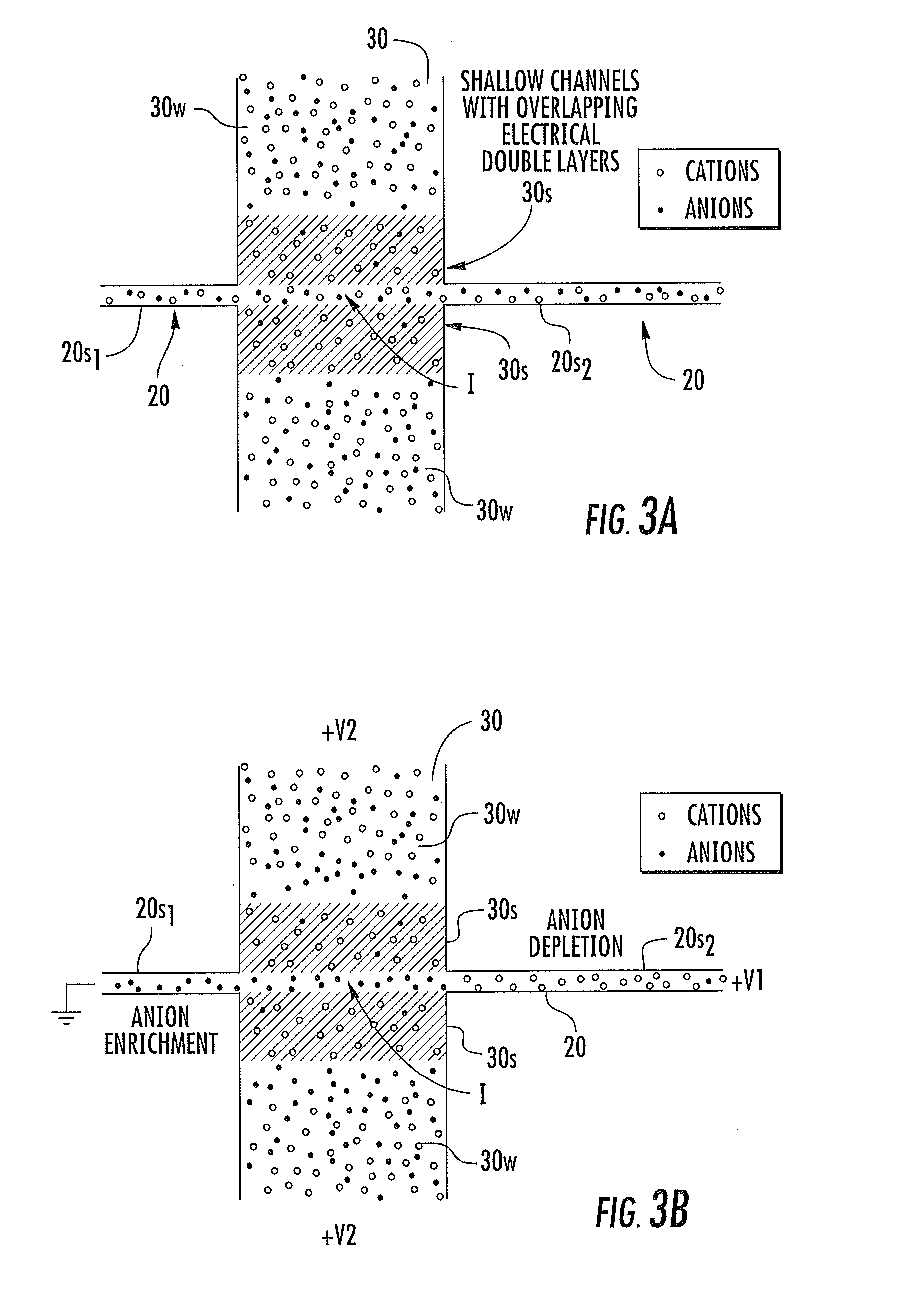

Nanofluidic devices with integrated components for the controlled capture, trapping, and transport of macromolecules and related methods of analysis

ActiveUS20140238856A1Easy to captureEasy to trapSludge treatmentVolume/mass flow measurementMolecular identificationTrapping

Devices for controlling the capture, trapping, and transport of macromolecules include at least one fluidic transport nanochannel that intersects and is in fluid communication with at least one transverse nanochannel with (shallow) regions and / or with integrated transverse electrodes that enable fine control of molecule transport dynamics and facilitates analyses of interest, e.g., molecular identification, length determination, localized (probe) mapping and the like.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

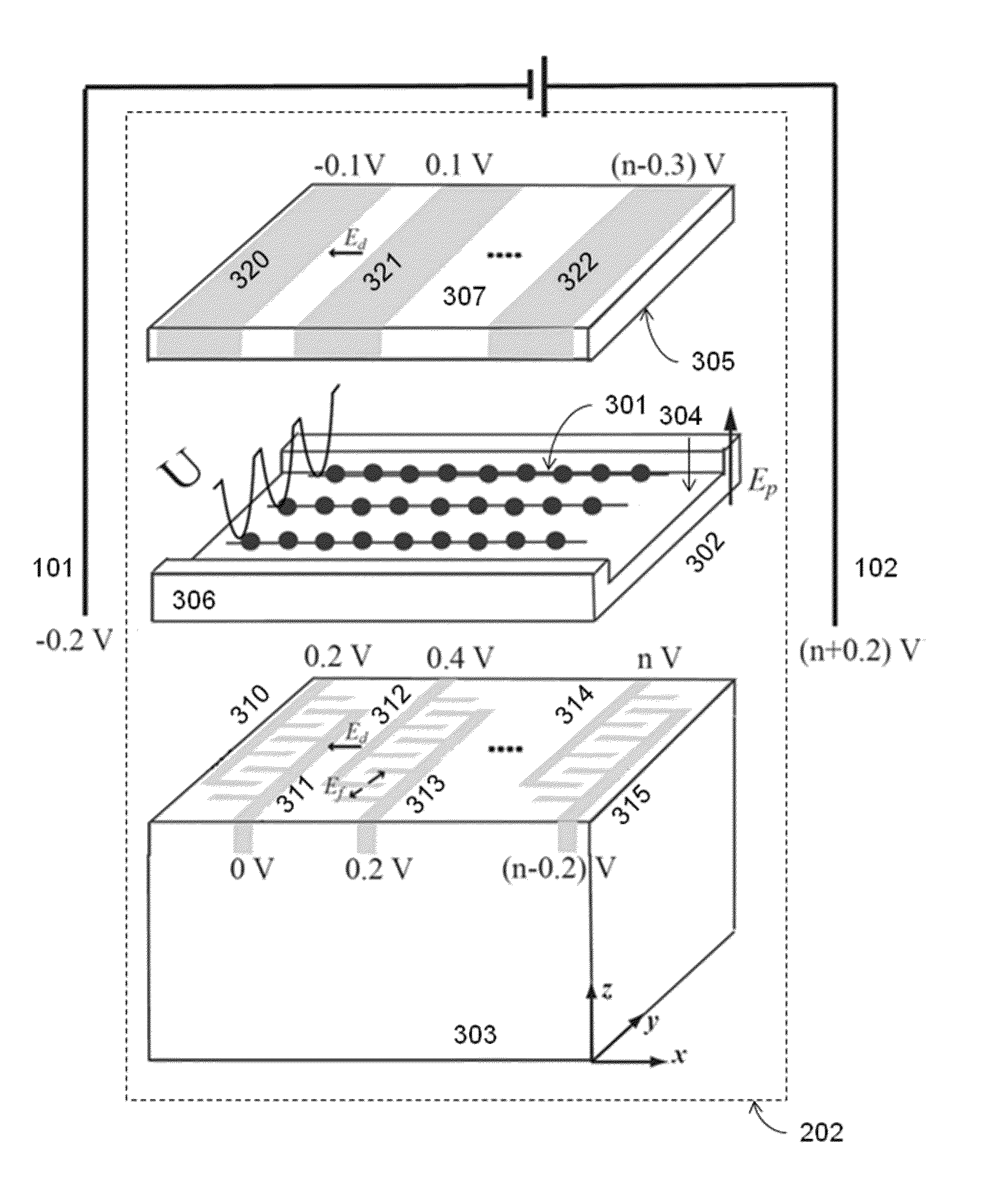

Nano-fluidic field effective device to control DNA transport through the same

The present invention provides a nano-fluidic field effective device. The device includes a channel having a first side and a second side, a first set of electrodes adjacent to the first side, a second set of electrodes adjacent to the second side, a control unit for applying electric potentials to the electrodes and a fluid within the channel containing a charge molecule. The first set of electrodes is disposed such that application of electric potentials produces a spatially varying electric field that confines a charged molecule within a predetermined area of said channel. The second set of electrodes is disposed such that application of electric potentials relative to the electric potentials applied to the first set of electrodes creates an electric field that confines the charged molecule to an area away from the second side of the channel.

Owner:IBM CORP

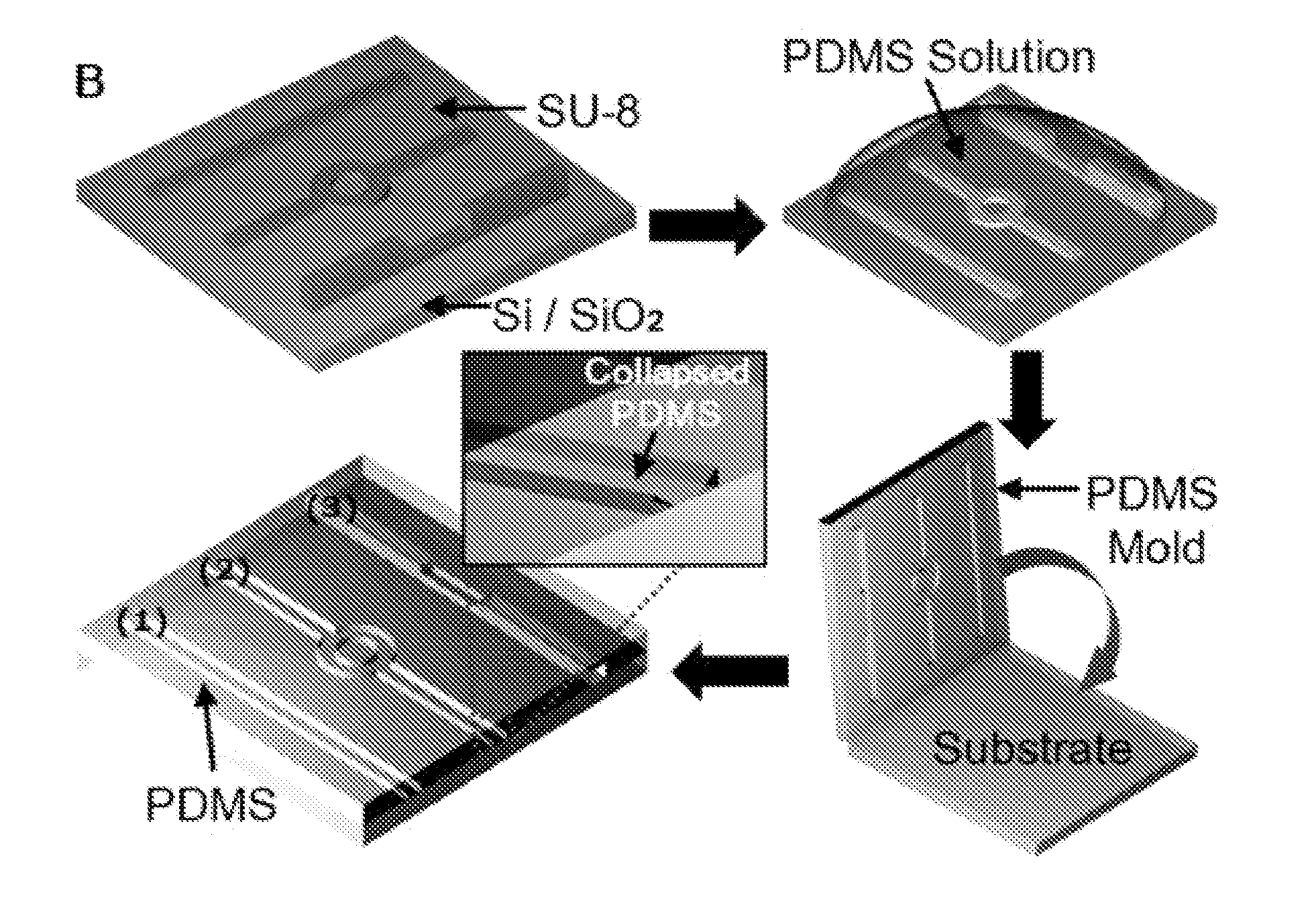

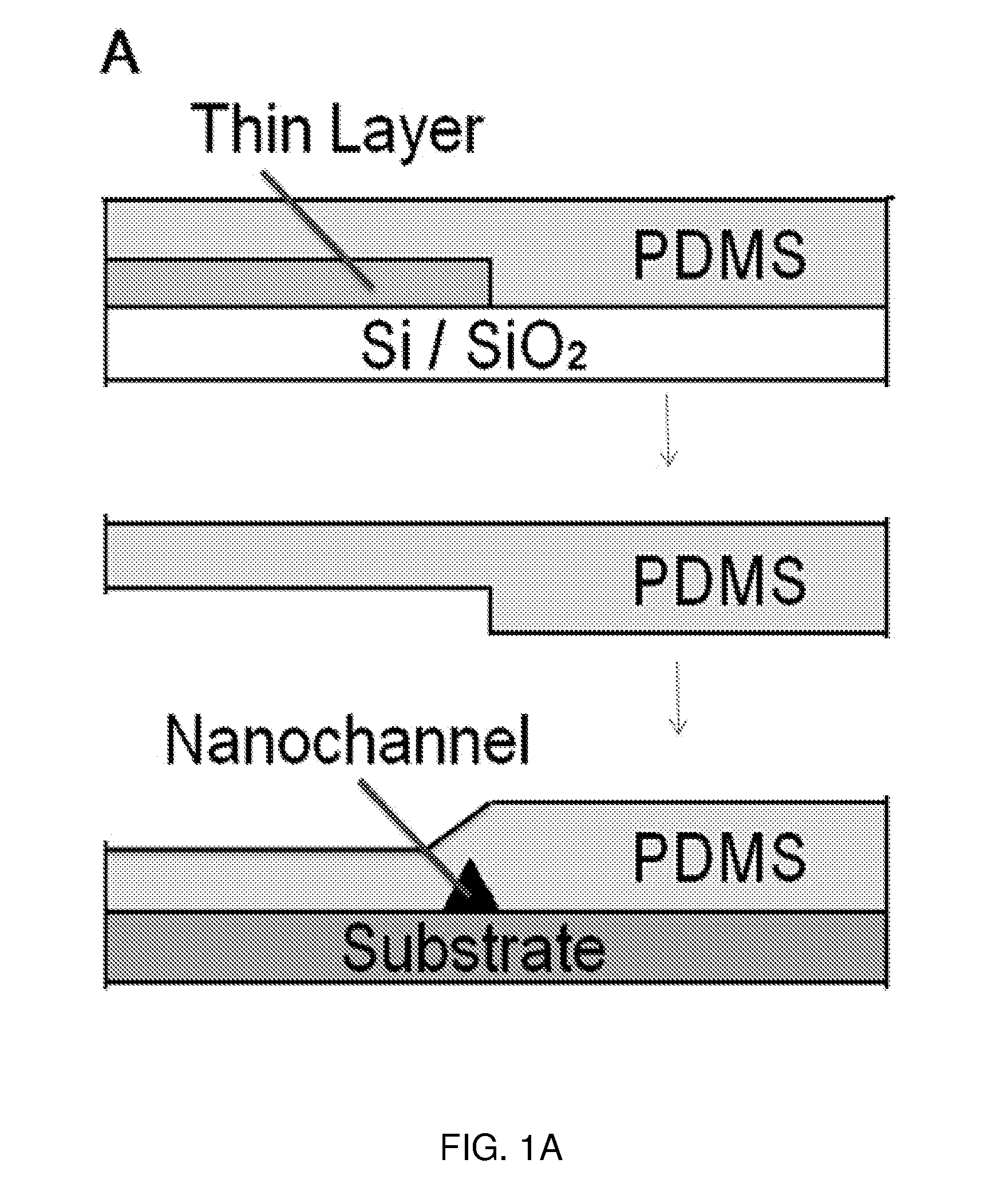

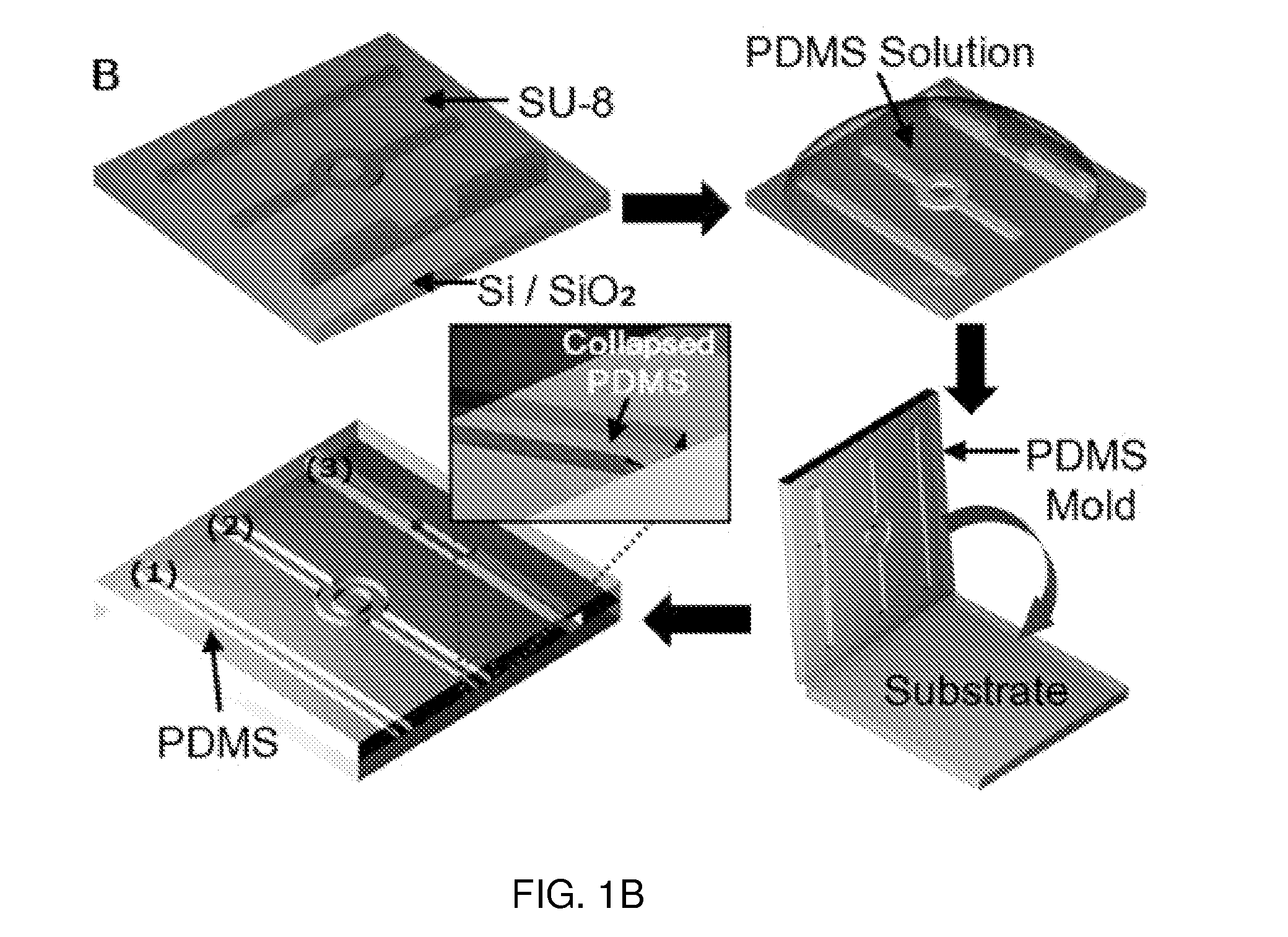

Nanofilter devices using elastomeric micro to nanochannel interfaces and methods based thereon

InactiveUS20120196376A1High frequencyOptical radiation measurementMaterial nanotechnologyElastomerEngineering

A method is provided for fabricating a nanochannel. The method comprises providing a microchannel and controlling collapse of the microchannel so that it collapses to form a nanochannel of desired dimensions. The method employs a collapsible, flexible material such as the elastomer polydimethylsiloxane (PDMS) to form the nanochannel. A master is provided that is configured to have geometric conditions that promote a desired frequency of microchannel collapse. A collapsible material having a stiffness that also promotes a desired frequency of microchannel collapse is molded on the master. The molded collapsible material is removed from the master and bonded to a base, thereby forming the microchannel, which then collapses (or is collapsed) to form the nanochannel of desired dimensions. Nanofluidic and microfluidic devices comprising complex nanochannel structures and micro to nanochannel transitions are also provided.

Owner:CORNELL UNIVERSITY

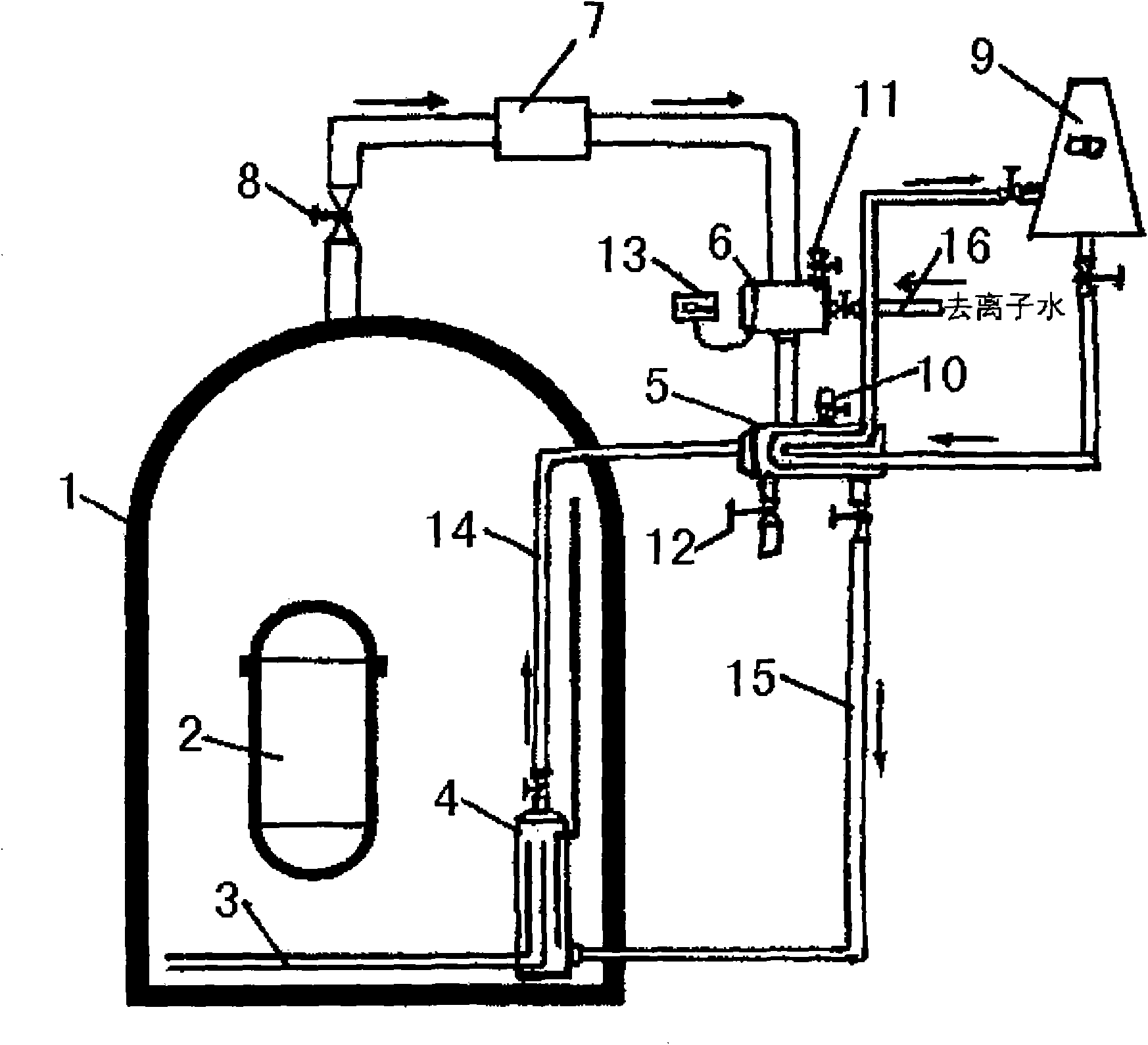

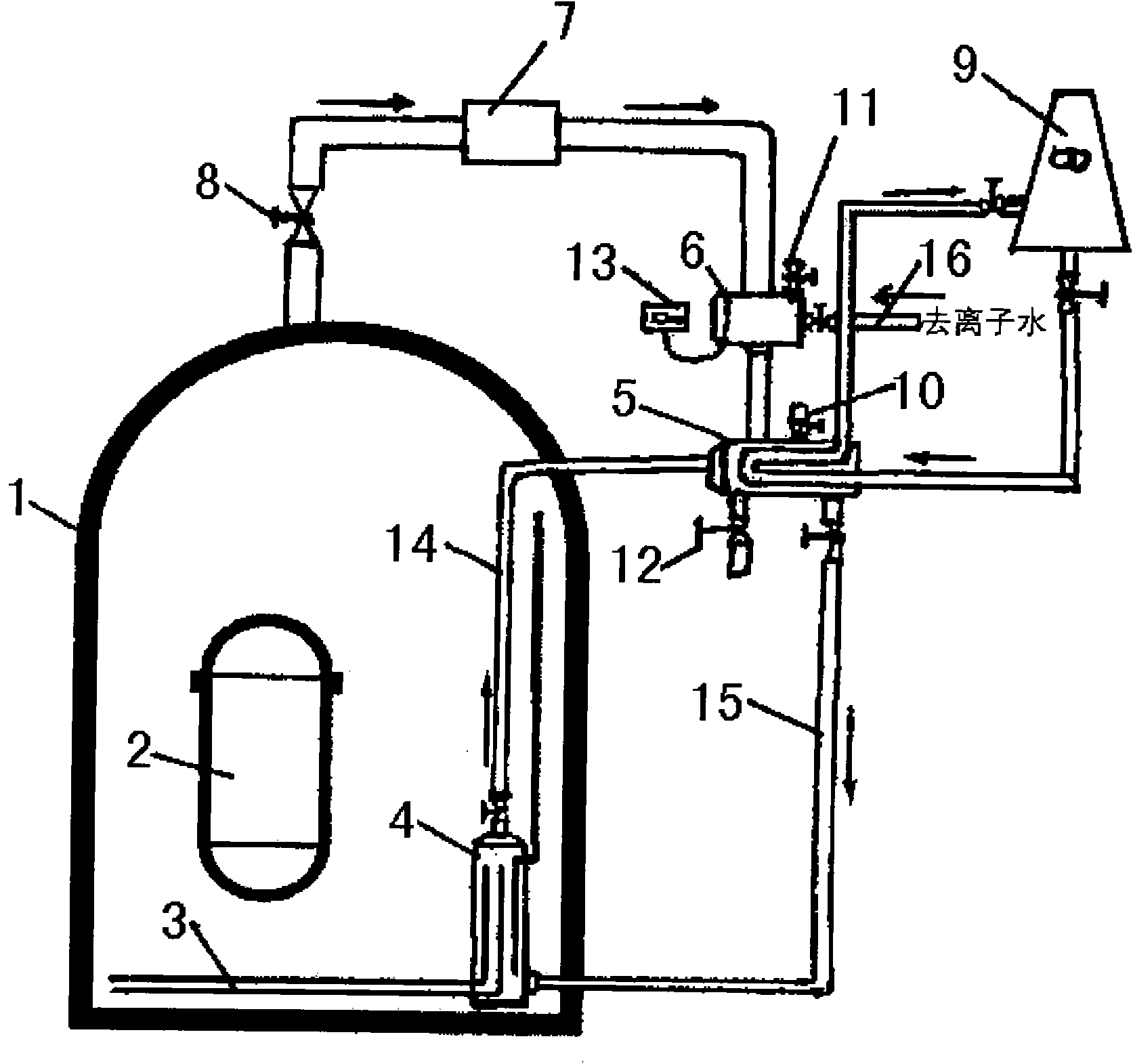

Major accident mitigation system of nuclear power station on basis of nano fluid characteristic

InactiveCN102097139AEnsure Structural IntegrityFast absorptionNuclear energy generationIndirect heat exchangersRadioactive gasCooling tower

The invention discloses a major accident mitigation system of a nuclear power station on the basis of the nano fluid characteristic, belonging to the technical field of nuclear power station equipment and safety. The system is composed of a superconductive tube, a heat exchanger, a radioactive grain removing device, a nano fluid preparation chamber, an ultrasonic oscillator, an air cooling tower and the like. The system can quickly adsorb energy in a containment under the major accident, hyperpressure in the containment can be alleviated by releasing and removing radioactive air and radioactive aerosol particles, nano particles can be obtained, and the efficient heat exchange medium nano fluid can be prepared to achieve the goal of alleviating the major accident of the reactor and protecting the integrity of the containment structure. A safety control function is performed and finished when major accidents happen. The system has the advantages of good backup safety, simple flow, stable performance and high reliability, is convenient to implement and simple to control, and treats wastes with wastes.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

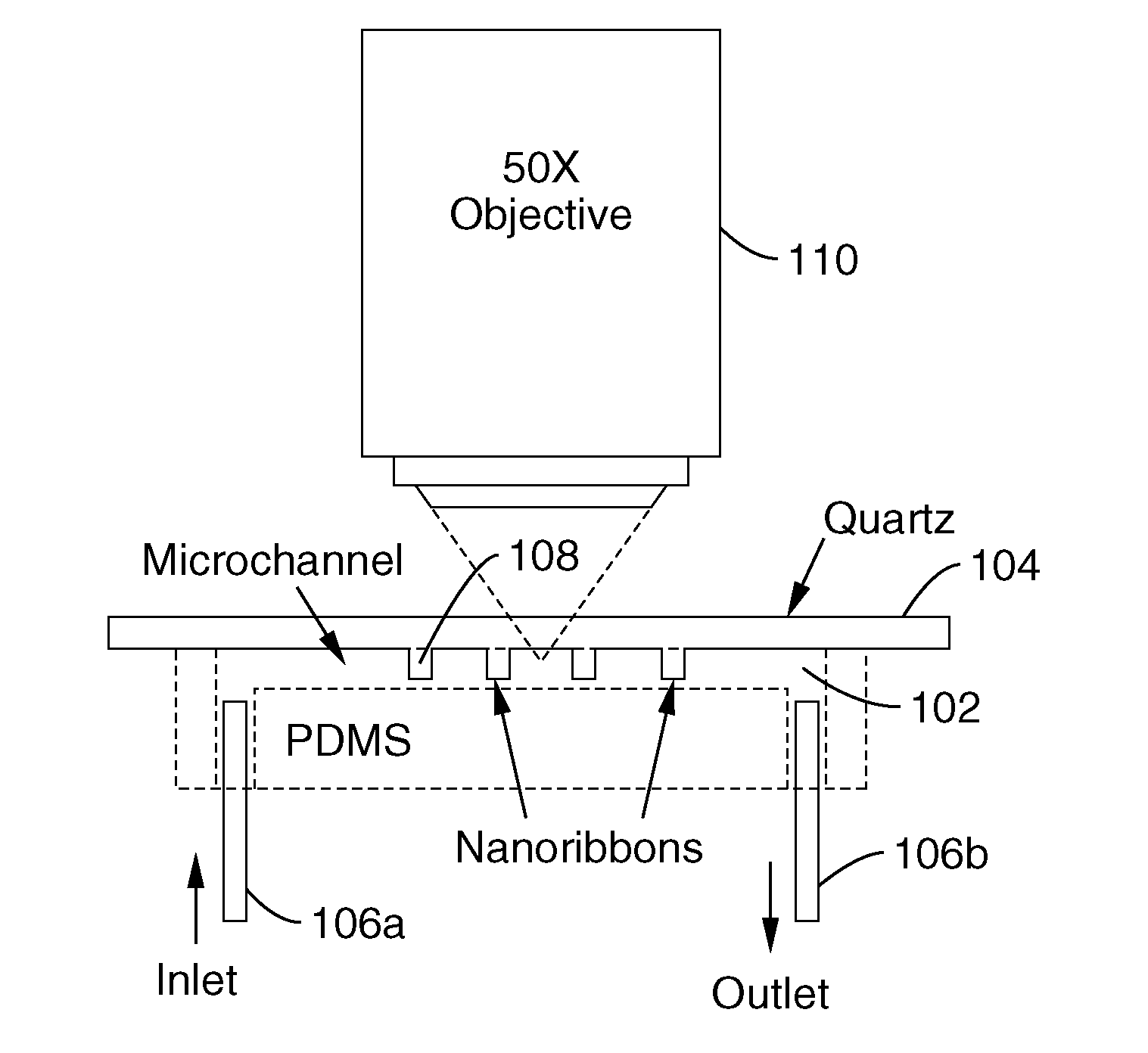

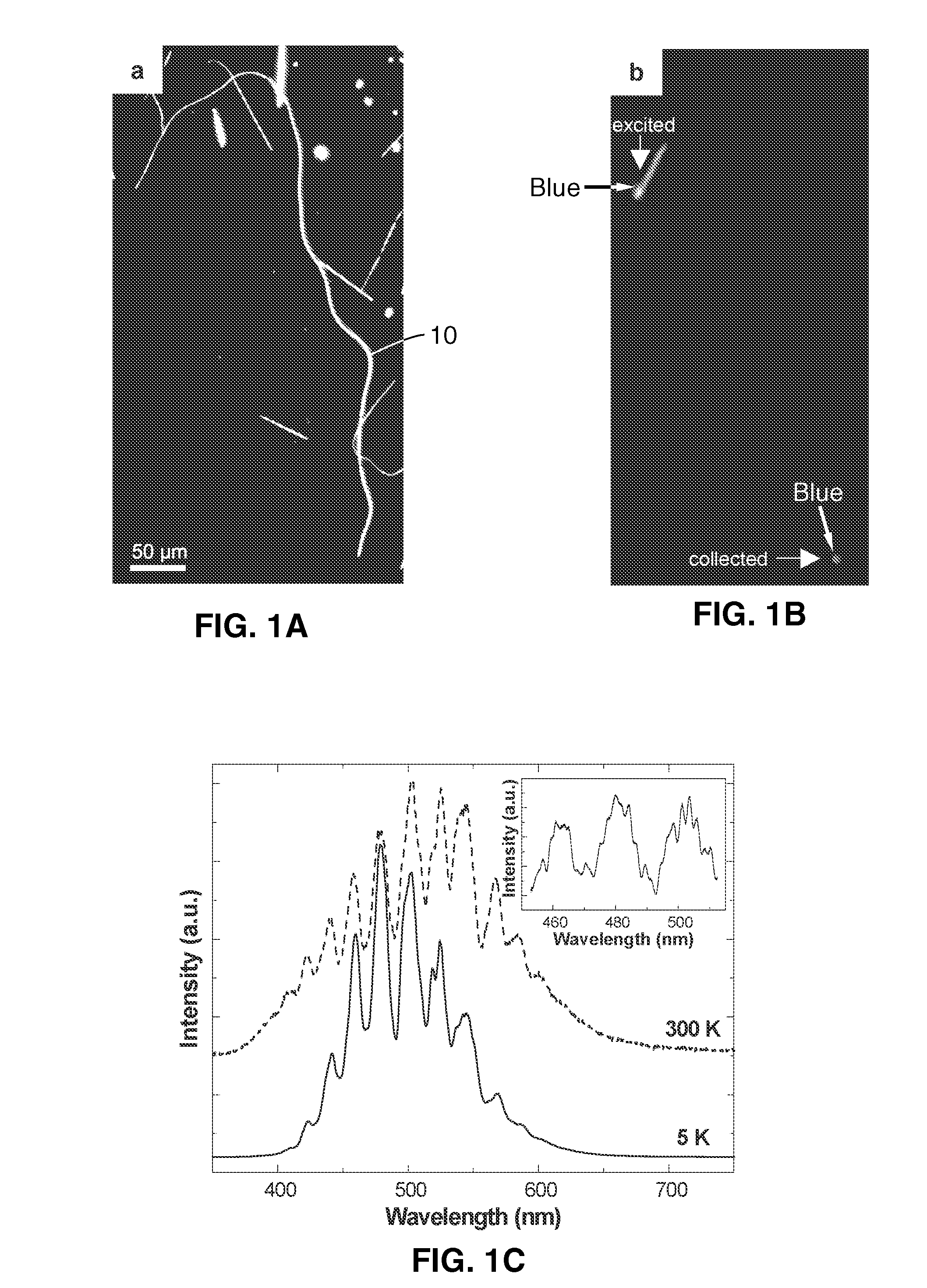

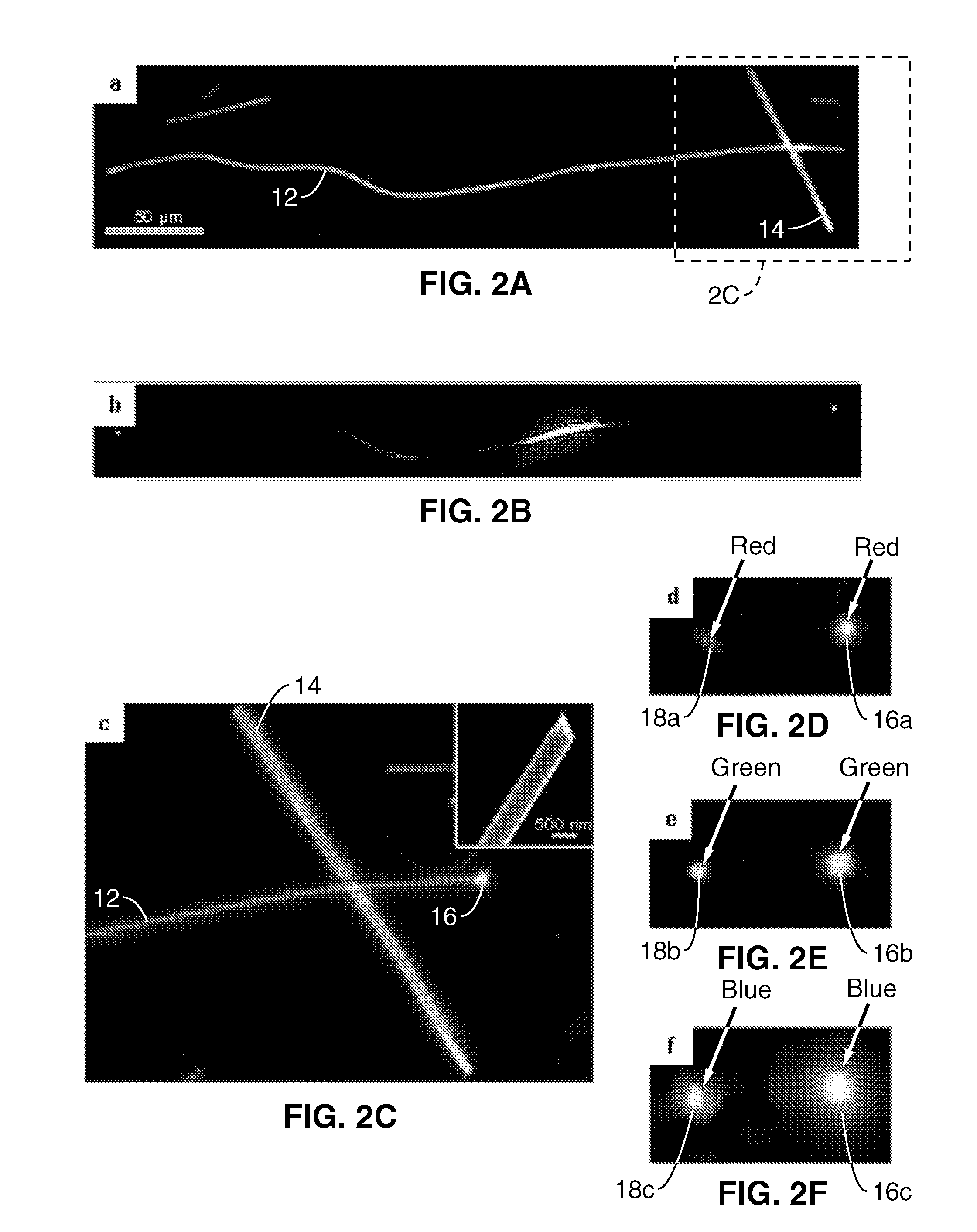

Nanowires and nanoribbons as subwavelength optical waveguides and their use as components in photonic circuits and devices

InactiveUS20090263912A1Easy constructionInherent one-dimensionalityNanoopticsLaboratory glasswaresNanowireFluorescence

A microfluidic optical sensor utilizes at least one subwavelength nanowire or nanoribbon waveguide coupled to a fluidic structure having at least one nanofluidic channel through which one or more molecular species are conveyed. In response to optical pumping (e.g., a laser source) the waveguide optically interrogates nearby molecular species retained within said fluidic structure to detect chemical species in response to optical characterization of small (on the order of sub-picoliter) volumes of solution. Characterization is performed in response to evanescent wave sensing. In one aspect, optical characterization is selected from the group of optical characterizations consisting of absorbance, fluorescence and surface enhanced Raman spectroscopy (SERS).

Owner:RGT UNIV OF CALIFORNIA

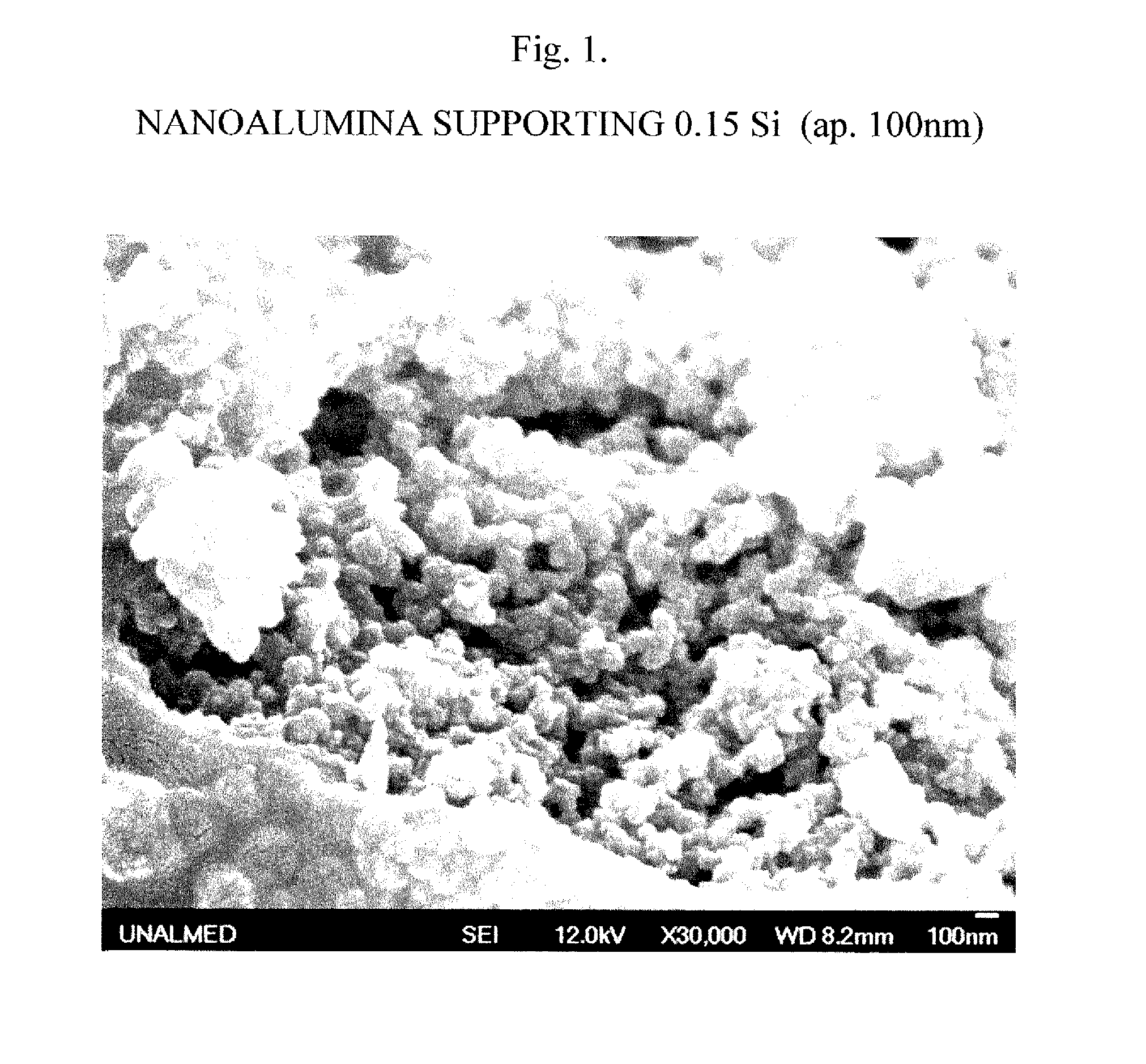

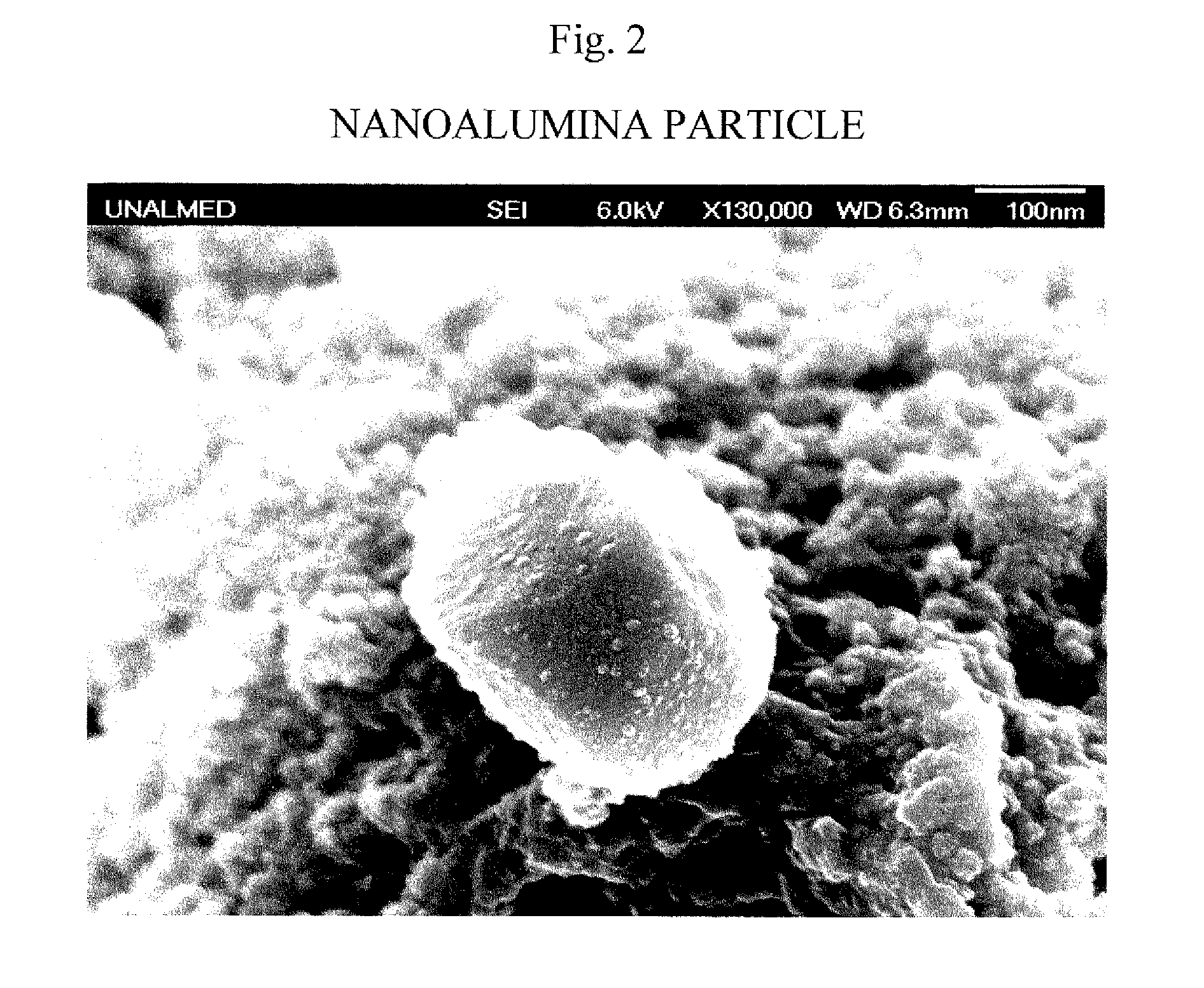

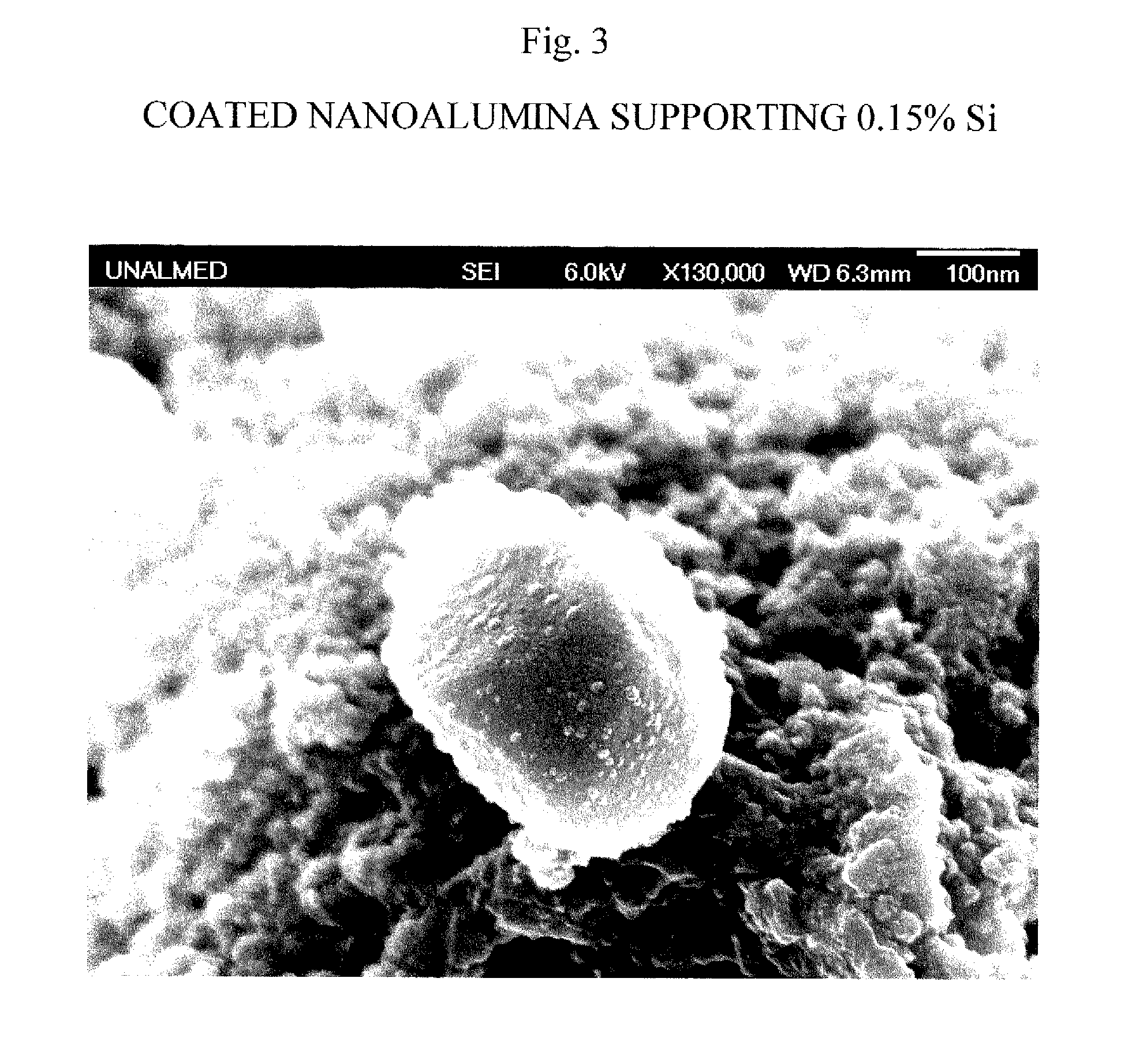

Nanofluids for oil recovery from tight light oil reservoirs and methods of their use

Novel nanoparticle catalysts comprising alumina nanoparticles doped with silicon, nanofluids containing the nanoparticle catalysts, processes for their preparation, as well as methods of their use in treating light tight oil wells having fractures and the oils produced by the wells post are disclosed. The novel nanocatalysts are useful, inter alia, improving well production, extending the time between fracturings, reducing well treatment costs associated with improving well production and or reducing equipment down time.

Owner:PETRORAZA

Carbon nanoparticle-containing hydrophilic nanofluid with enhanced thermal conductivity

Owner:SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY

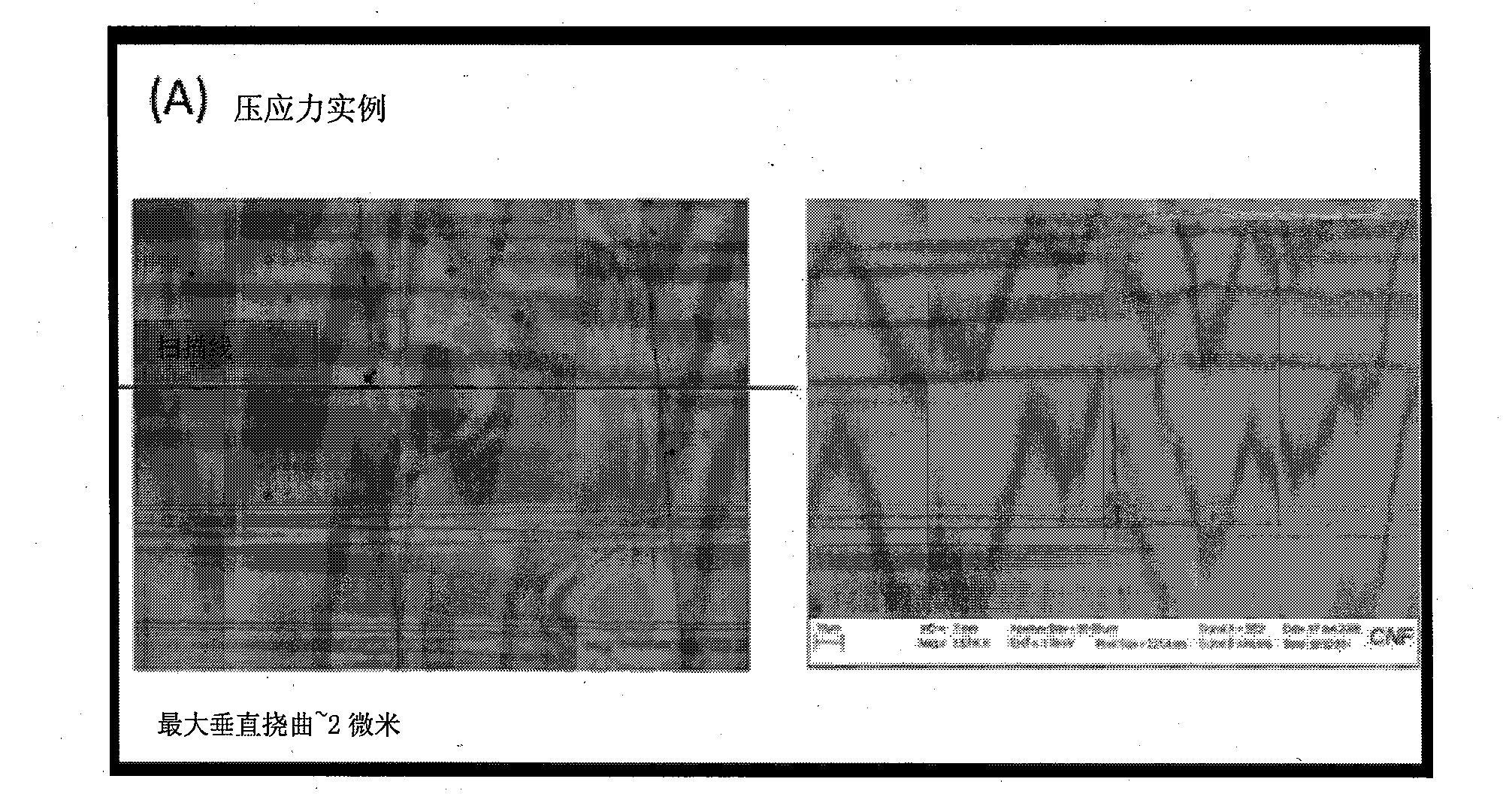

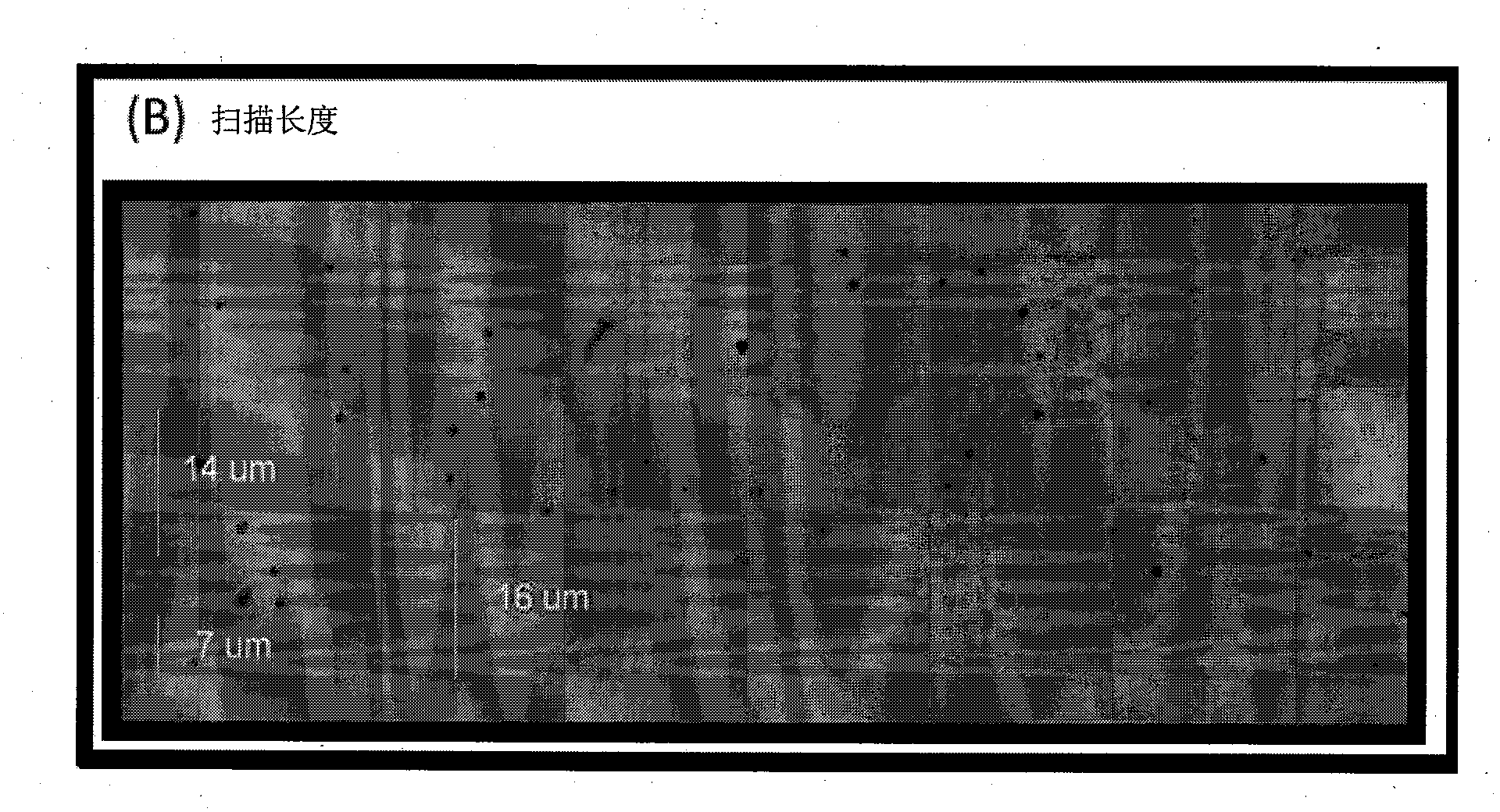

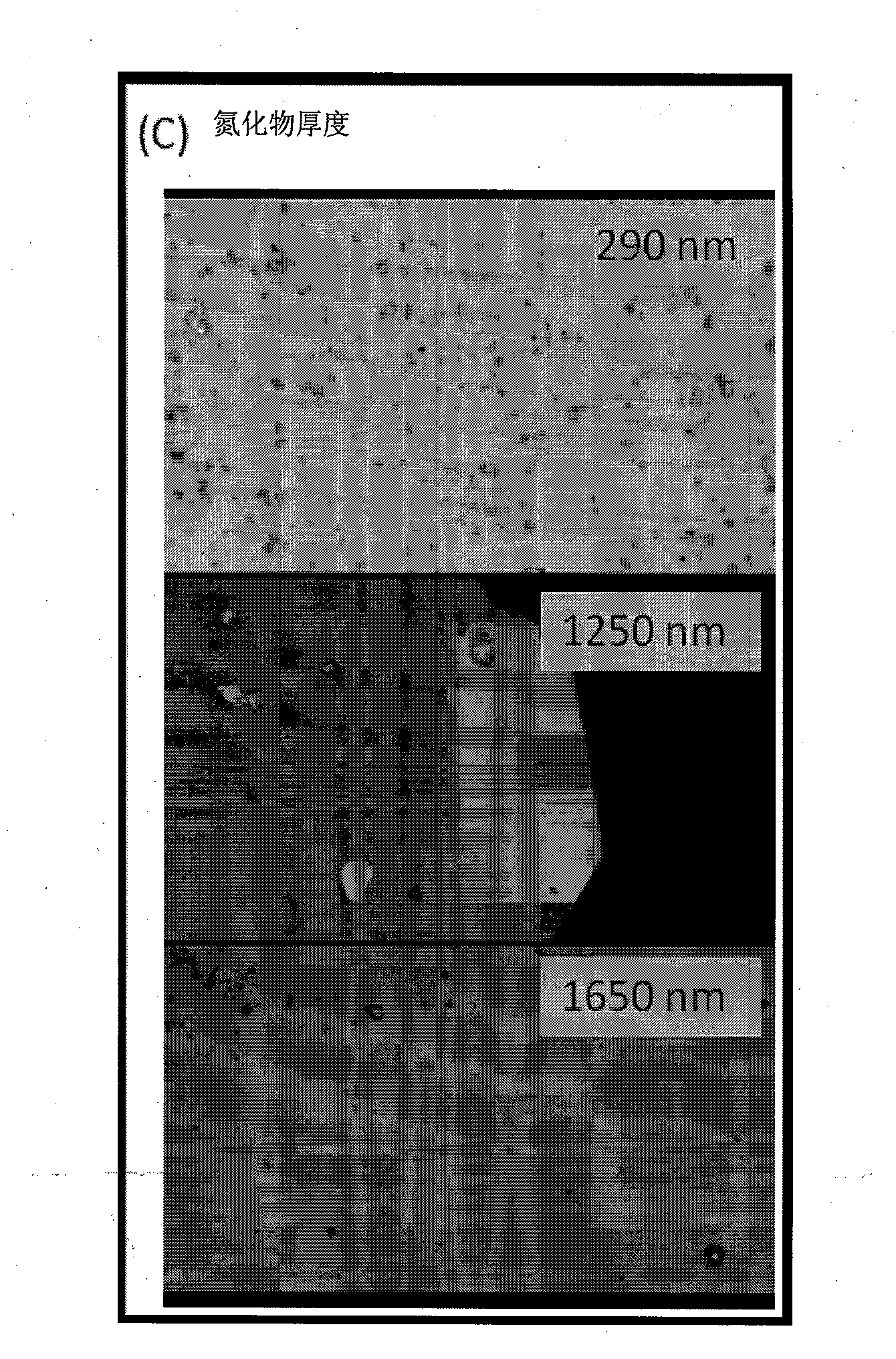

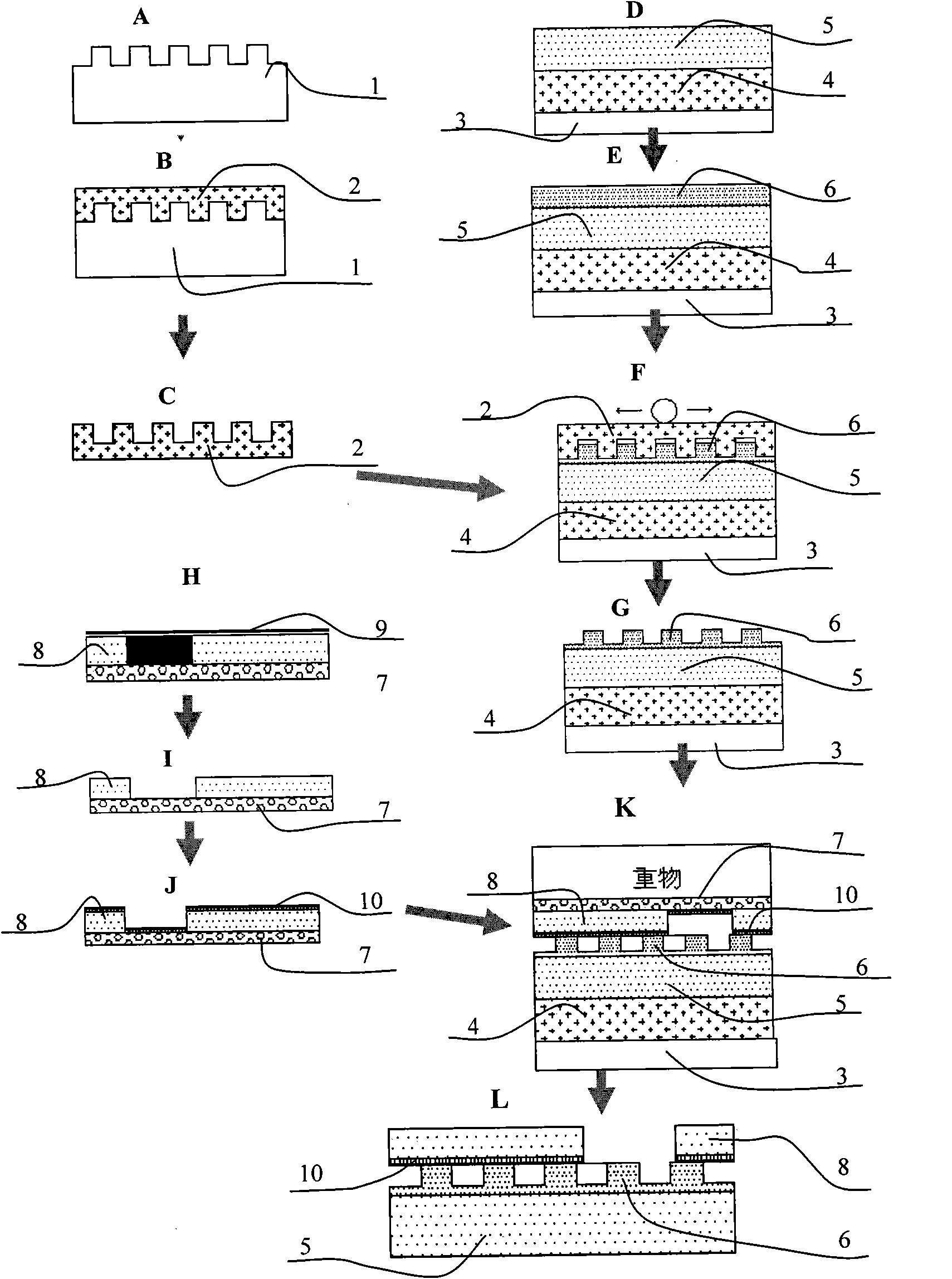

Method for making self-supporting structure of nano fluid system based on SU-8 photoresist

InactiveCN102012633AIncrease the areaLow production weekDecorative surface effectsPhotomechanical apparatusBond interfacePolyethylene terephthalate

The invention discloses a method for making a self-supporting structure of a nano fluid system based on a SU-8 photoresist, which is characterized by comprising the following steps of: firstly processing and making a PDMS (Polydimethylsiloxane) flexible template, making a SU-8 nano channel substrate by utilizing the PDMS flexible template, simultaneously making a SU-8 bonding layer comprising a sample pond by utilizing ultraviolet exposure development, realizing the bonding sealing of the SU-8 nano channel substrate and the bonding layer by utilizing a bonding technique, and finally removing PDNS and PET (Polyethylene Terephthalate) flexible substrates to obtain the self-supporting structure of the nano fluid system. The method has the advantages of simple operation, low making cost and low equipment requirement. The making result shows that the system has no delamination and blockage, the bonded interface can be hardly seen, and the outline of a channel is clear and visible so that the self-supporting structure of the nano fluid system has good quality.

Owner:HEFEI UNIV OF TECH

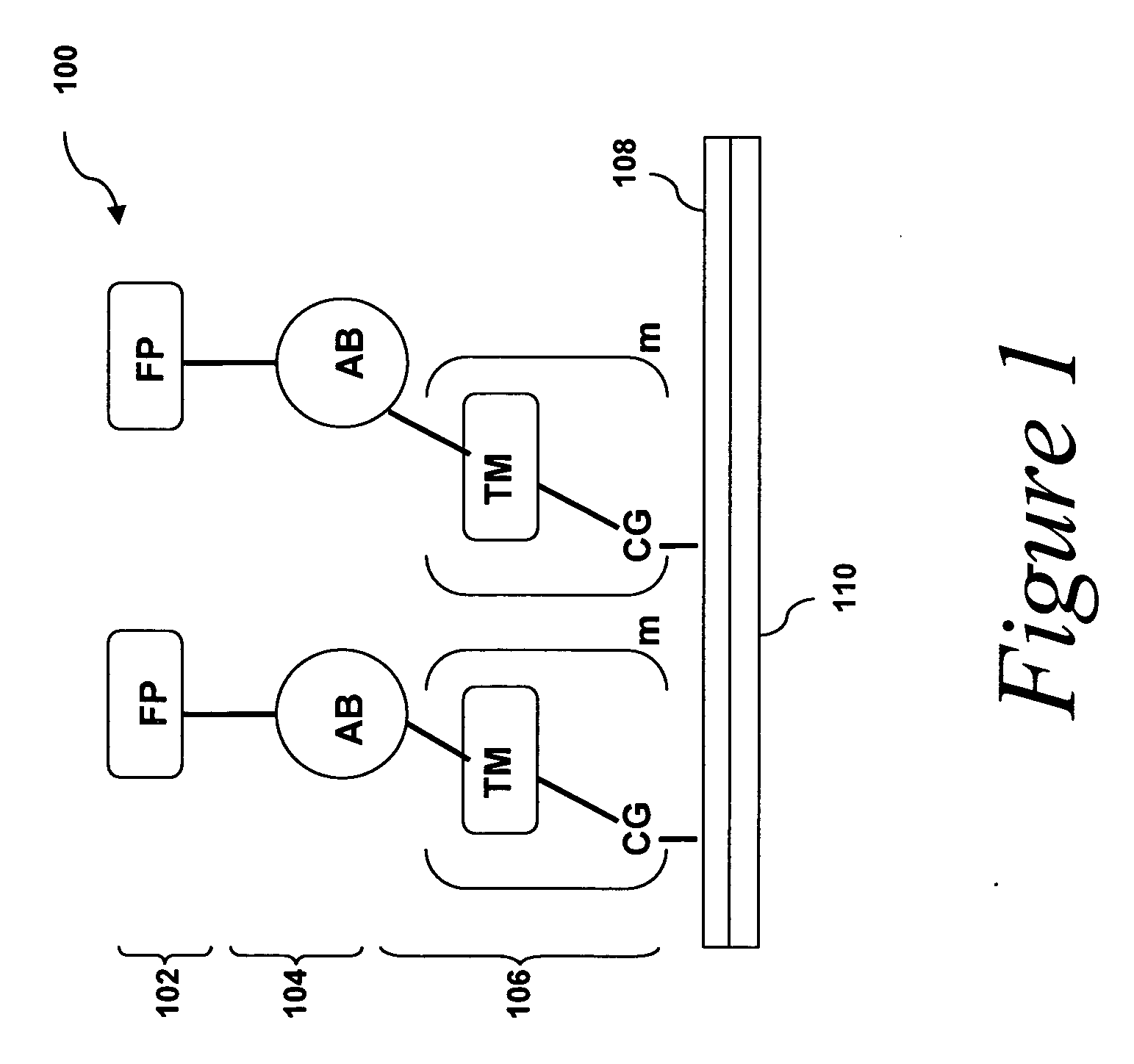

Multi-transduction mechanism based microfluidic analyte sensors

InactiveUS20070042450A1High sensitivityExtension of timeMaterial nanotechnologyBioreactor/fermenter combinationsAnalyteElectrochemistry

In various aspects are provided a microfluidic and / or nanofluidic sensor that can provide an indication of the reliability of its measurement of the presence of an analyte in a sample under investigation, an analyte concentration in the sample under investigation, or both. The provided sensors, microfluidic devices, and methods of analyte detection, utilize two transduction mechanisms from the same molecule to determine analyte presence, analyte concentration, or both. An analyte sensing molecule is used that can provide both an optical signal and electrochemical signal when an analyte is recognized by an analyte binding portion of the sensing molecule.

Owner:SIEMENS HEALTHCARE DIAGNOSTICS INC +1

Nanoparticles for heat transfer and thermal energy storage

ActiveUS20140084205A1Increased TES storageEfficient processMaterial nanotechnologyHeat-exchange elementsThermal energy storageGraphite

An article of manufacture and method of preparation thereof. The article of manufacture and method of making the article includes an eutectic salt solution suspensions and a plurality of nanocrystalline phase change material particles having a coating disposed thereon and the particles capable of undergoing the phase change which provides increase in thermal energy storage. In addition, other articles of manufacture can include a nanofluid additive comprised of nanometer-sized particles consisting of copper decorated graphene particles that provide advanced thermal conductivity to heat transfer fluids

Owner:UCHICAGO ARGONNE LLC

Microfluidic and nanofluidic devices, systems, and applications

ActiveUS20120115189A1Bioreactor/fermenter combinationsMaterial nanotechnologyChemical reactionMicrofluidics

The present invention discloses the integration of programmable microfluidic circuits to achieve practical applications to process biochemical and chemical reactions and to integrate these reactions. In some embodiments workflows for biochemical reactions or chemical workflows are combined. Microvalves such as programmable microfluidic circuit with Y valves and flow through valves are disclosed. In some embodiments microvalves of the present invention are used for mixing fluids, which may be part of an integrated process. These processes include mixing samples and moving reactions to an edge or reservoir for modular microfluidics, use of capture regions, and injection into analytical devices on separate devices. In some embodiments star and nested star designs, or bead capture by change of cross sectional area of a channel in a microvalve are used. Movement of samples between temperature zones are further disclosed using fixed temperature and movement of the samples by micropumps.

Owner:INTEGENX

Method for preparing nano fluid for heat transfer medium of solar heat exchange system

InactiveCN101735775AImprove heat collection efficiencyFast heatingHeat-exchange elementsNanoparticleSURFACTANT BLEND

The invention relates to a method for preparing nano fluid for a heat transfer medium of a solar heat exchange system, which comprises the following steps: selecting one of Al2O3, TiO2, ZnO, Ni and Cu nano grains with the grain diameter of 5 to 100 nanometers as additive, selecting water or water / ethylene glycol or water / propylene glycol mixture as base solution, adding surfactant into the solution, and strongly stirring and ultrasonically oscillating to form the nano fluid which is used for the heat transfer medium of the solar heat exchange system, wherein the Al2O3, TiO2, ZnO, Ni or Cu nano grains account for 0.1 to 3 volume percent of the volume of the nano fluid. The practical detection result for placing the solar heat exchange system on the roof shows that the nano fluid can remarkably improve the heat collecting efficiency of the solar heat exchange system, has the advantages of high heating speed, low cooling speed, low cost and simple preparation process and can remarkably improve the heat collection and heat utilization efficiencies of the existing solar heat collecting system.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com