Method for making self-supporting structure of nano fluid system based on SU-8 photoresist

A self-supporting structure, SU-8 technology, used in nanotechnology, microstructure technology, microstructure devices, etc., can solve problems such as increasing process complexity and manufacturing cost, and nanoimprinting technology cannot process micro-nano composite structures at the same time. , to achieve the effect of low production cost, simple and controllable method, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

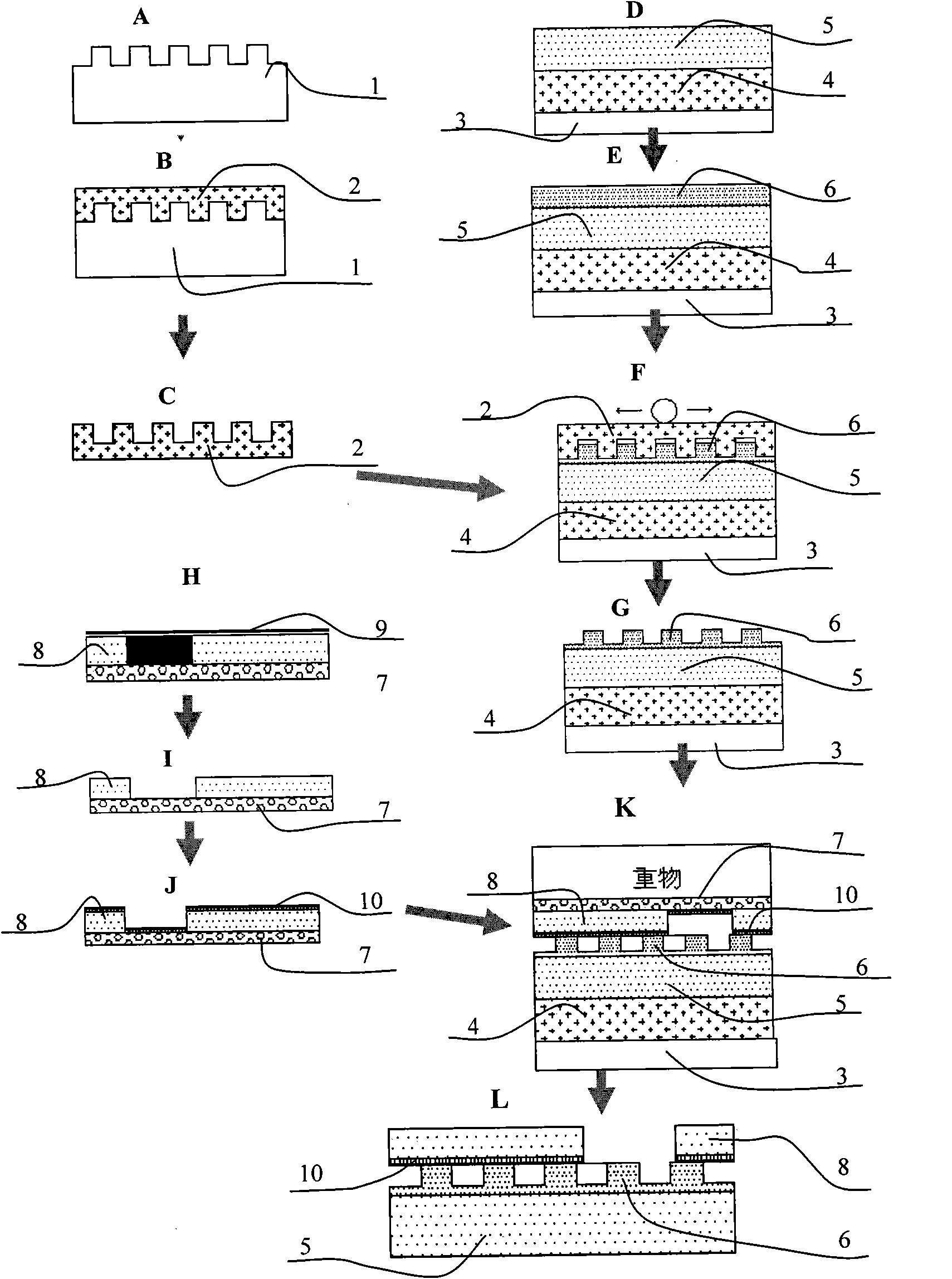

[0025] The manufacturing method of the self-supporting structure of the nanofluid system based on SU-8 photoresist in this embodiment operates as follows:

[0026] 1. Make PDMS soft template:

[0027] Clean the holographic grating 1, see figure 1 A. Configure the PDMS viscous liquid. After stirring, the PDMS viscous liquid will form a lot of bubbles, and the bubbles will disappear slowly after standing for about 30 minutes. Cast the configured PDMS viscous liquid 2 on the holographic grating 1 and use heat Stage bake to cure PDMS 2, the bake temperature is 90℃, the time is 60 minutes, see figure 1 B. Finally, use tweezers to remove the cured PDMS seal 2. At this time, the PDMS 2 has copied the micro-nano structure of the holographic grating, see figure 1 C.

[0028] 2. Production of fluid channel substrate:

[0029] Firstly, the glass substrate 3 is cleaned and treated, the glass substrate 3 is ultrasonically treated with acetone for 5 minutes, then rinsed with deionized water and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com