System and method for nanoparticle and nanoagglomerate fluidization

a nanoparticle and fluidization technology, applied in the field of systems and methods/processes for fluidizing nanoparticles and nanoagglomerates, can solve the problems of difficult fluidization of nanoparticles, complex fluidization behavior of ultrafine particles, and geldart's classification of powders, etc., to achieve reliably and effectively fluidize a chamber or bed of nanoparticles, and facilitate substantially homogenous coating and/or treatment. , the effect of effective dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

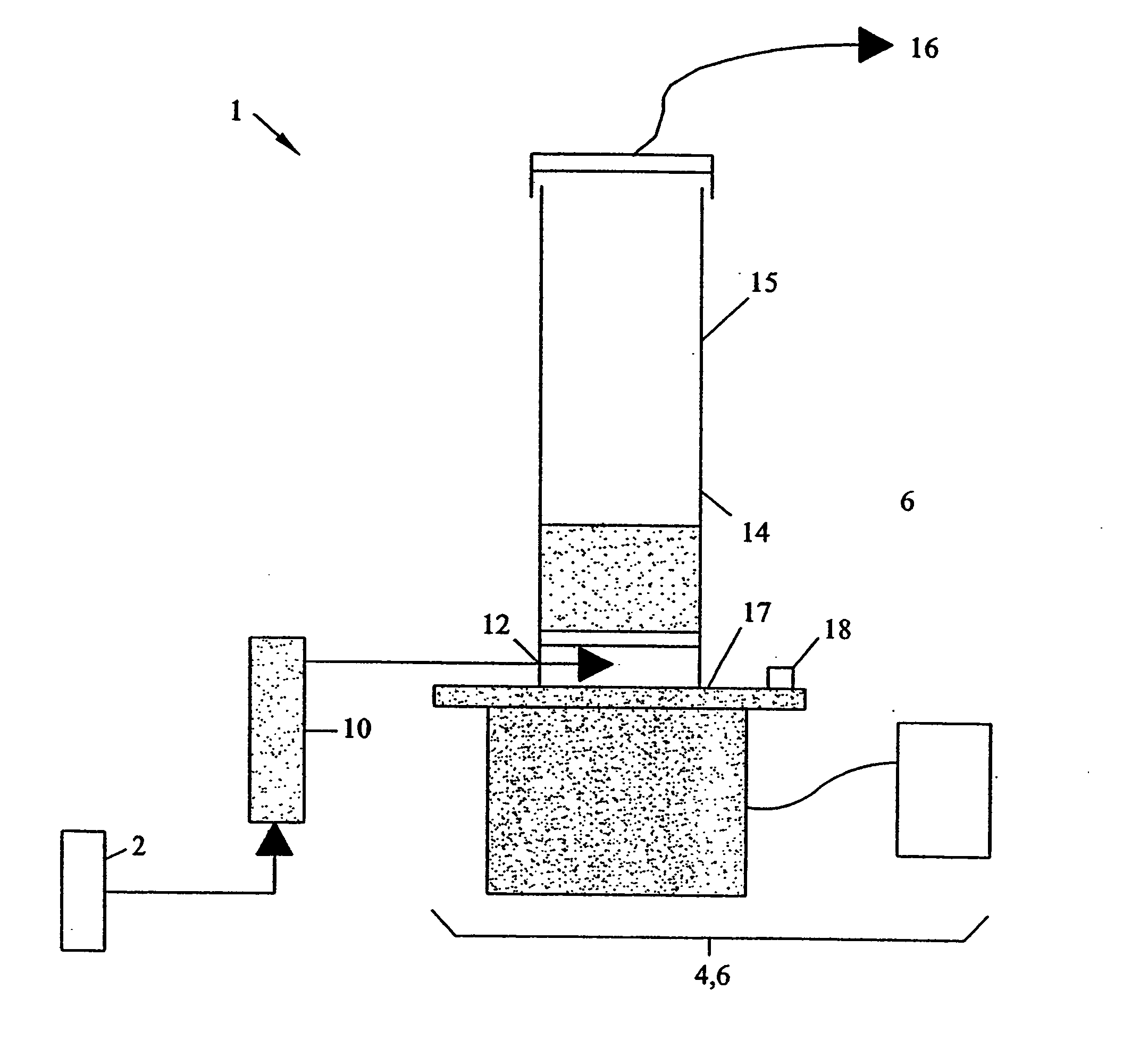

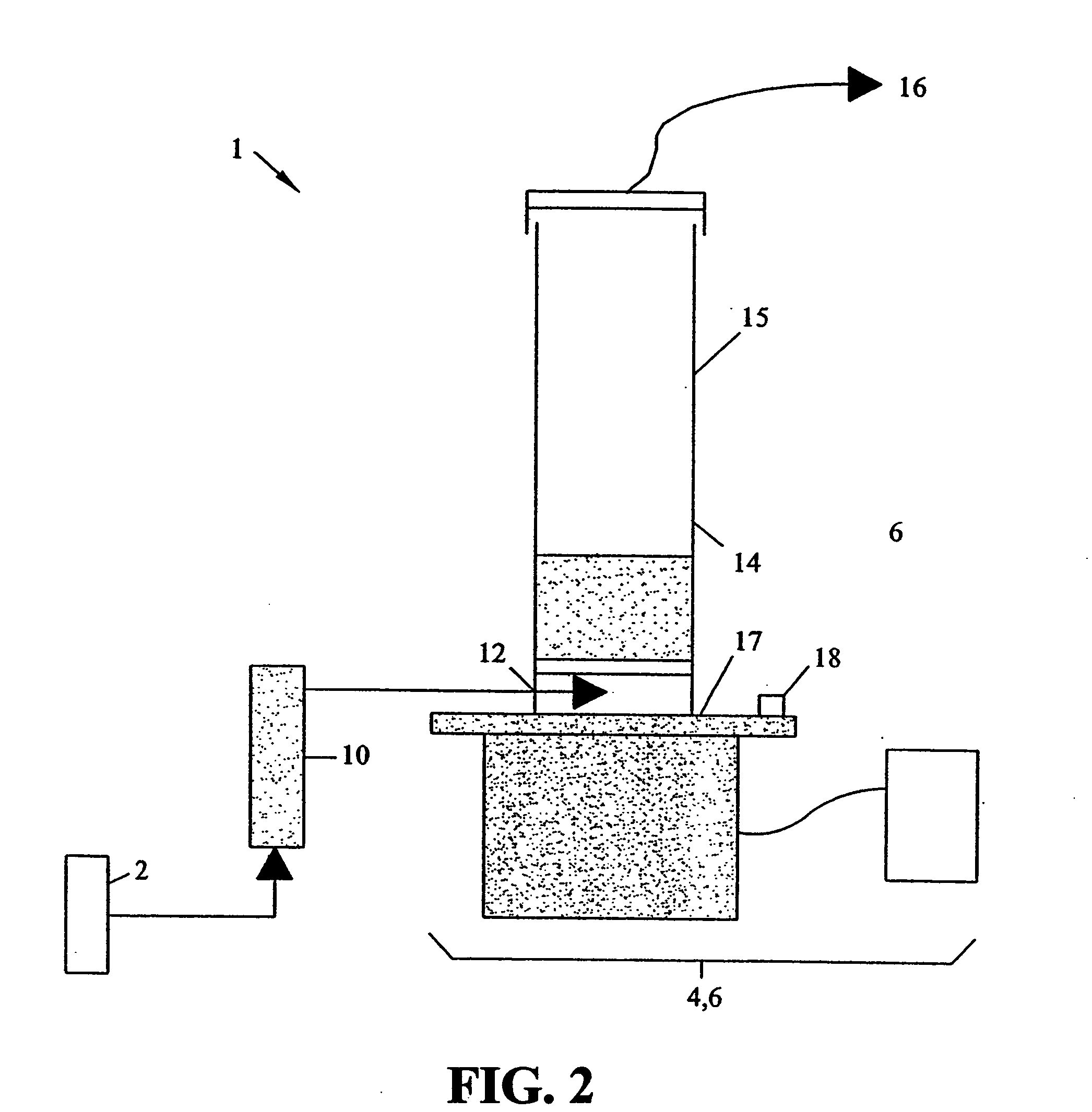

[0190] An apparatus as shown in FIG. 2 was used to fluidize nanopowders using any gas such as air or nitrogen and vibration.

[0191]FIG. 36 shows an exemplary plot of observed pressure drop and bed expansion vs. superficial air velocity. At gas velocities greater than 0.1 cm / sec and a vertical sinusoidal vibration of 5.5 g's, the bed begins to expand and continues to expand both before and after the minimum fluidization velocity, defined as the velocity at which the pressure drop across the bed is equal to the weight of the bed divided by its cross sectional area. The bed expanded to four times its initial height and appeared to be uniformly fluidized with negligible elutriation.

example 2

[0192] Using the apparatus of FIG. 2, and 12 nm silica powders with a constant flow rate and vibrational parameters of 50 Hz and 2 g's, the silica powders were fluidized.

[0193] FIGS. 37(a) and 37(b) illustratively show what may typically occur during a fluidization process. With air or vibration alone, nothing useful occurs to a conventional nanoparticle powder bed. When the two are coupled together, however, the nanoparticle size distribution is reduced / lowered and the powder bed expands with vigorous particle movement.

example 3

[0194] Using the apparatus of FIG. 2, and 12 nm silica, tracer silica dyed with methylene blue and constant flow rate of dry air and vibrational parameters of 50 Hz and 4 g's, was fluidized.

[0195]FIG. 38 shows the progression of mixing 12 nm silica with a small amount of the same nano-sized silica dyed with methylene blue. The bed was operated at a constant air velocity of 0.45 cm / see with a vertical sinusoidal vibration of 4 g's at a frequency of 50 Hz. As can be seen in the figure, as soon as the vibration was turned on the bed started to expand and uniform bubble less fluidization was observed. Within 2 minutes, the entire bed turned blue, indicating not only good fluidization, but also very good mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com