Microfluidic and nanofluidic devices, systems, and applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

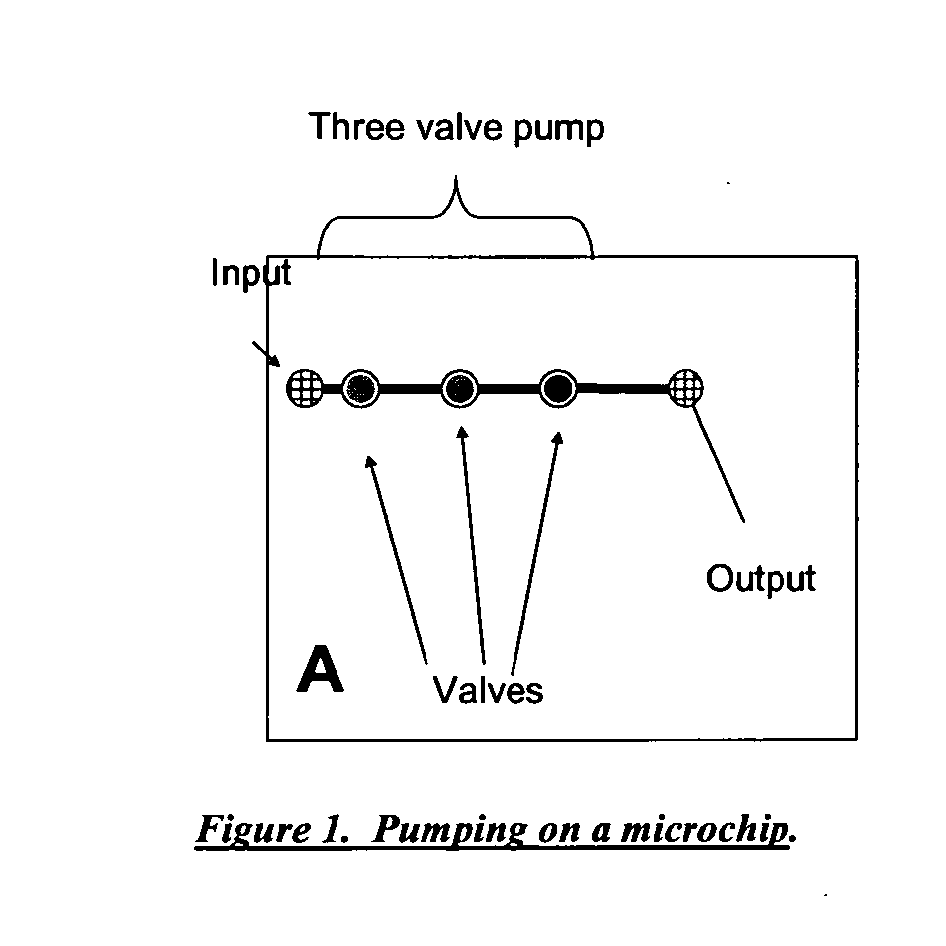

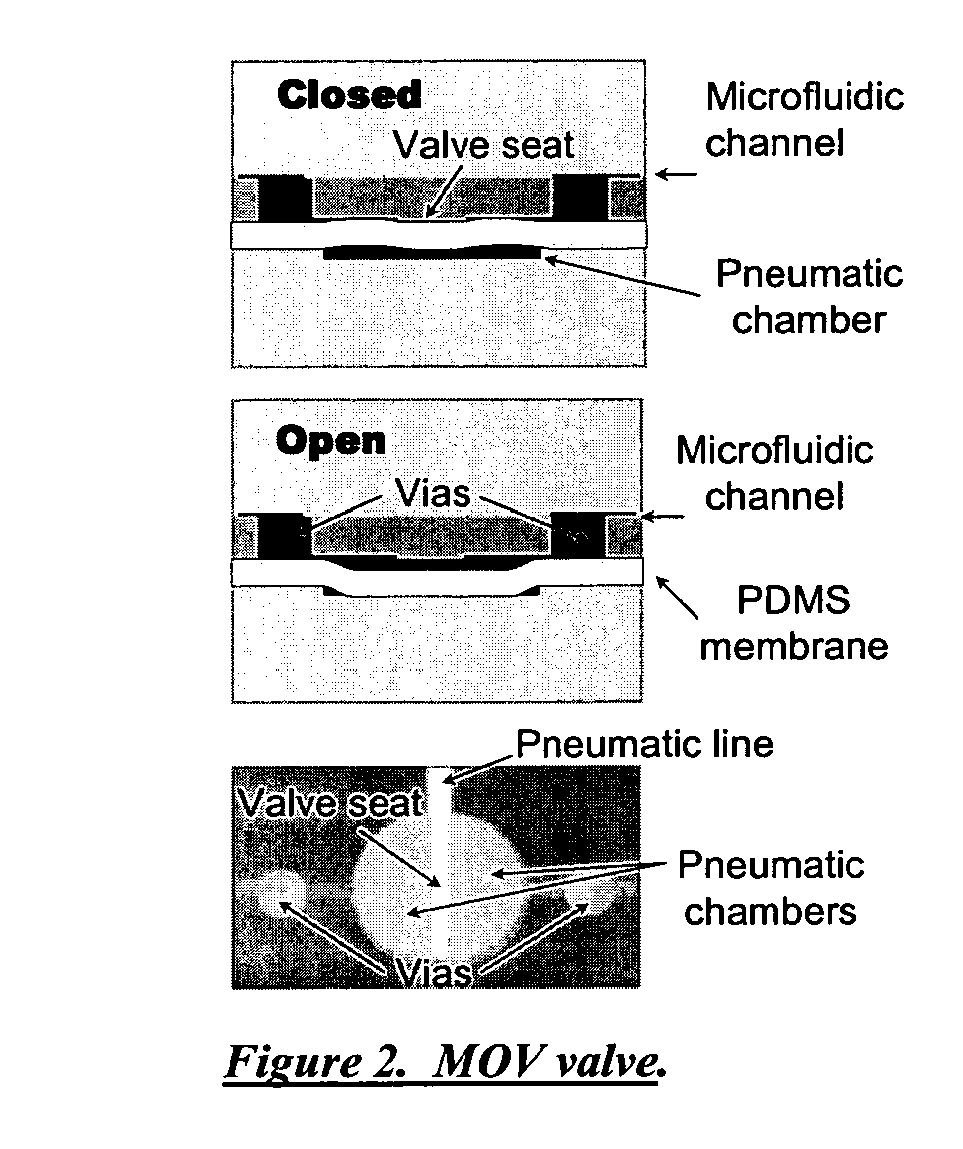

[0090]In one aspect this invention provides guidance on the use of programmable microfluidic circuits and devices to process biochemical or chemical samples. In some embodiments microfluidic processes are connected with inputs or sample volumes of milliliter or centiliter scale. Further chemical and biochemical processes and the integration of multiple processes are disclosed. In some embodiments, microfabrication of microvalves with different designs are taught.

[0091]In certain embodiments the microfluidic devices of this invention comprise a microfluidic layer, an actuation layer and an elastomeric membrane sandwiched therebetween. The fluidics layer comprises fluidic channels adapted to allow the flow of liquid. In certain embodiments, the fluidics channels are located on the surface of the microfluidics layer that touches the elastomeric membrane. In this embodiment, an open channel, furrow or groove can be etched into the surface of the layer. In other embodiments, the channel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com