Three-phase flow supply system for nanoparticle jet micro-lubrication grinding

A technology of micro-lubrication and nano-particles, which is applied in the direction of lubricating parts, lubricating oil control valves, and engine lubrication. It can solve the problems of poor fluidity of solid materials, difficult grinding process, and difficulty in taking away heat. , wide range of dispersion, solve the effect of insufficient cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

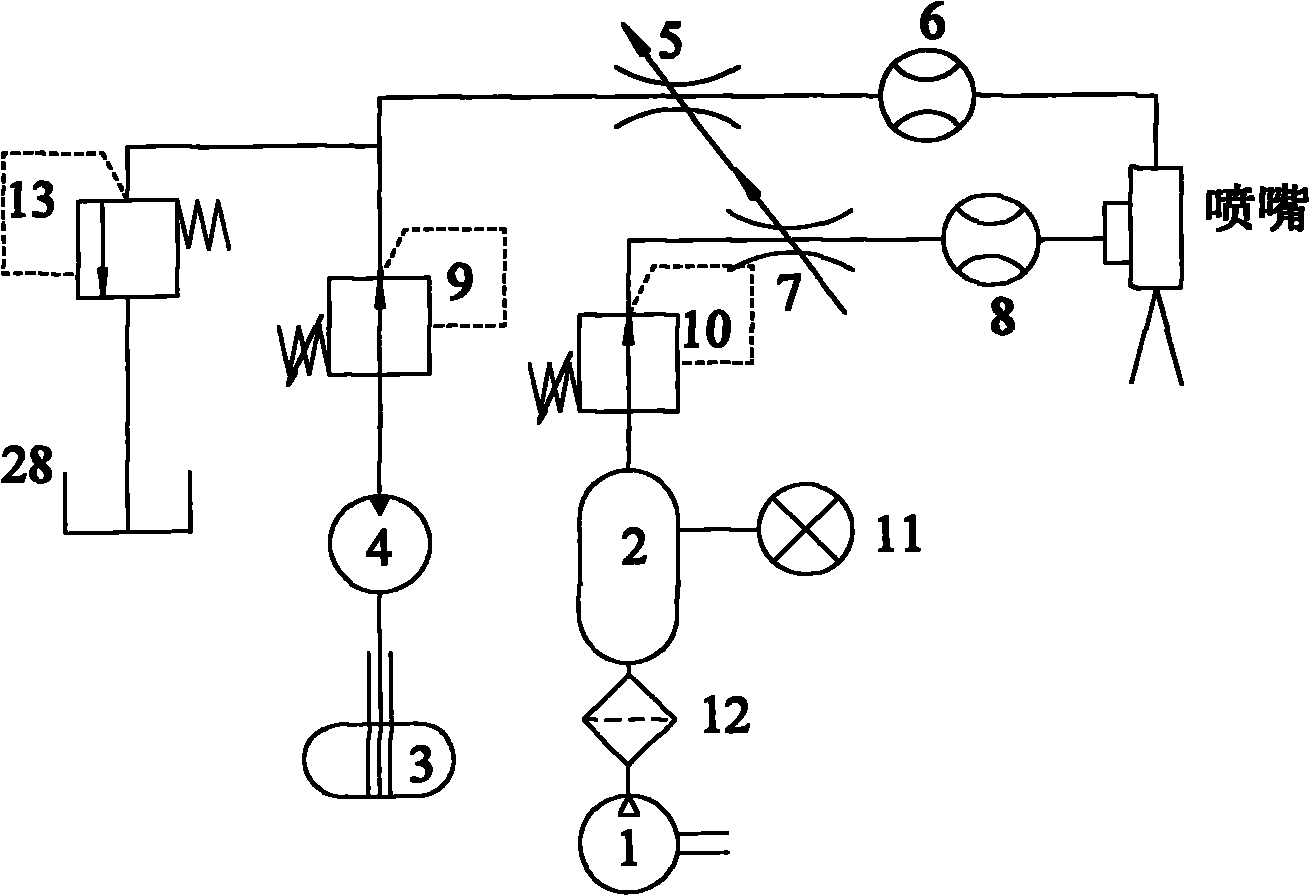

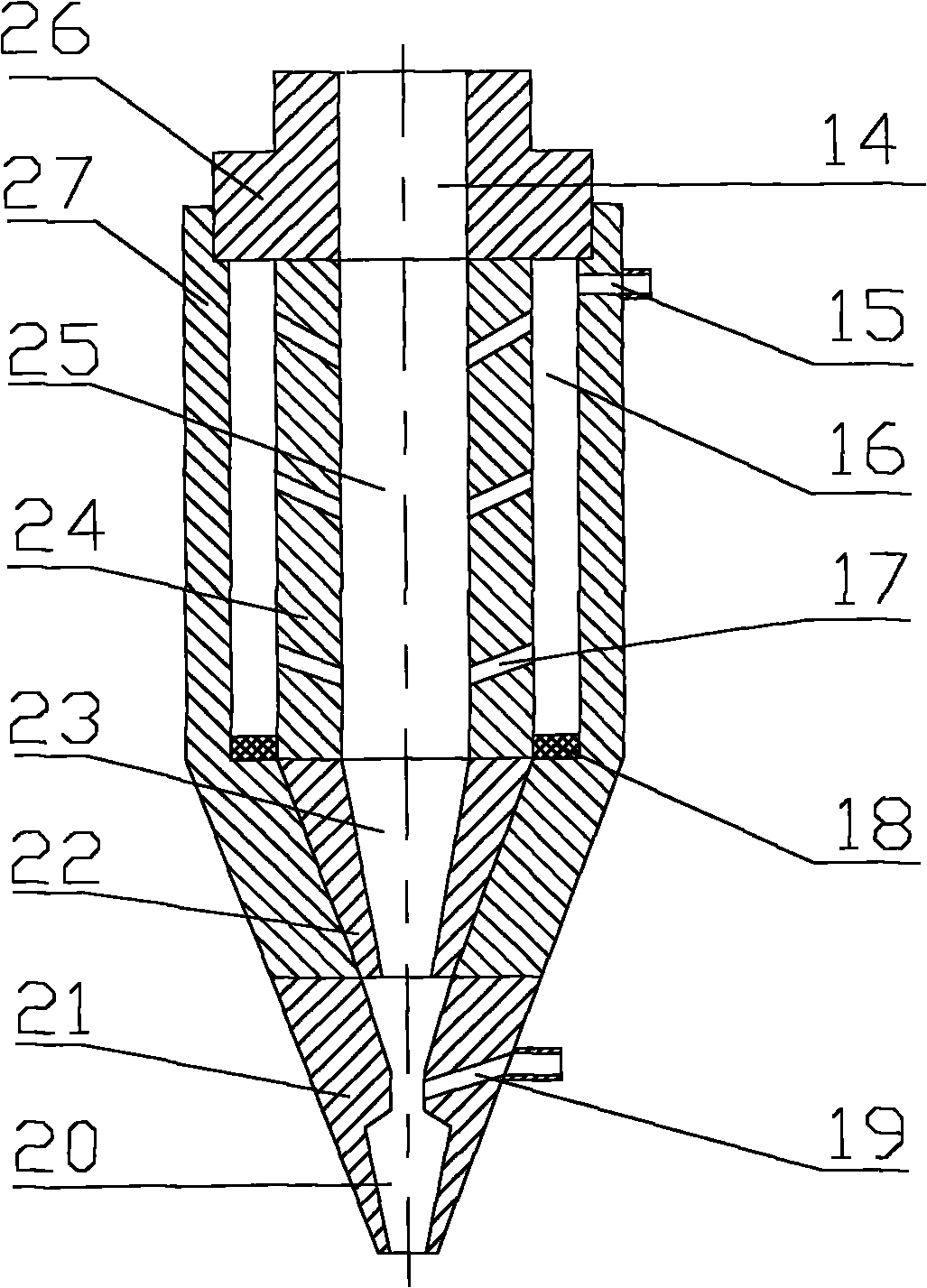

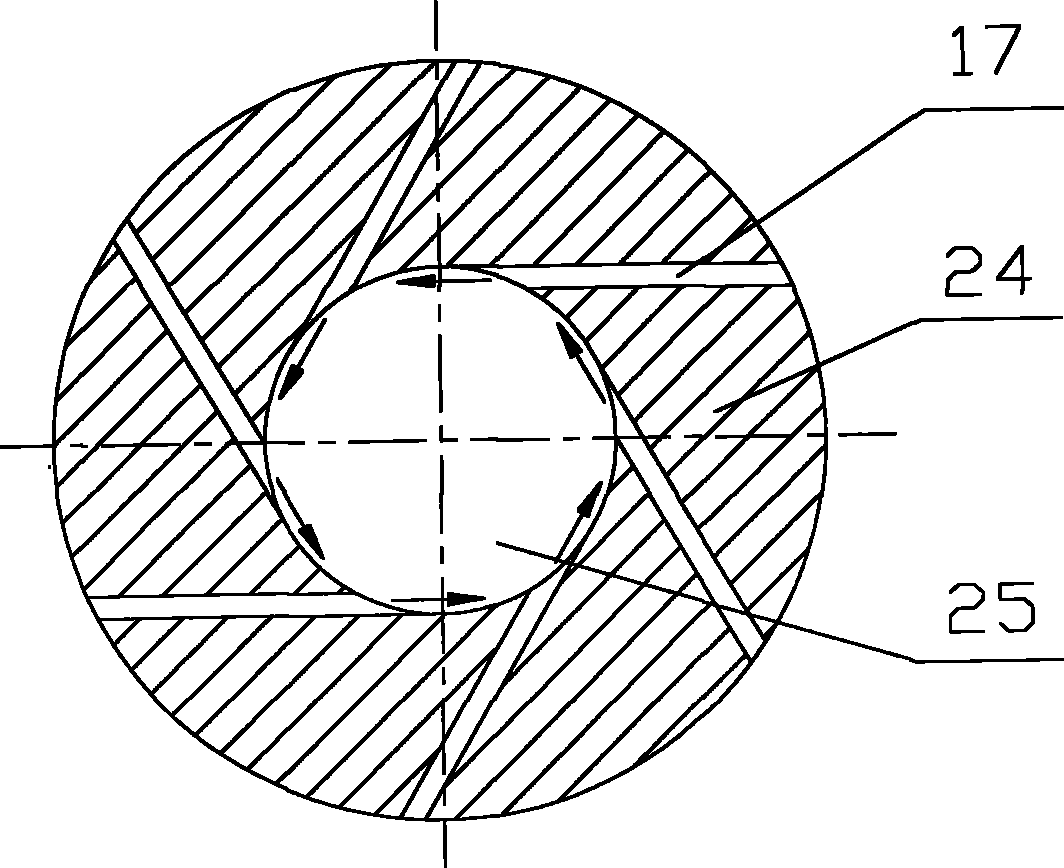

[0025] The general idea of the present invention is to transport the nanofluid (nanoparticles and lubricant) to the nanofluid channel in the nozzle through the liquid path, and at the same time, the high-pressure gas enters the vent hole in the nozzle through the gas path, and the high-pressure gas in the high-pressure gas channel is vortexed. Enter the mixing chamber from the vent hole, fully mix and atomize the nanofluid from the nanofluid channel in the nozzle mixing chamber, and enter the vortex chamber after being accelerated by the acceleration chamber. At the same time, the high-pressure gas enters through the vent hole of the vortex chamber, making the three-phase flow further Rotational mixing and acceleration, the three-phase flow is then sprayed into the grinding zone in the form of atomized droplets through the nozzle outlet. Due to the high thermal conductivity of nanoparticles, when the nanofluid passes through the high-temperature area, it will take away a larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com