Total synthesis glass cutting fluid and preparation method thereof

A cutting fluid, fully synthetic technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of difficult to meet glass powder settling, harmful to operators, low paraffin oil lightning, etc., to achieve excellent anti-rust effect, reduce effective Loss of ingredients, improvement of lubricating cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

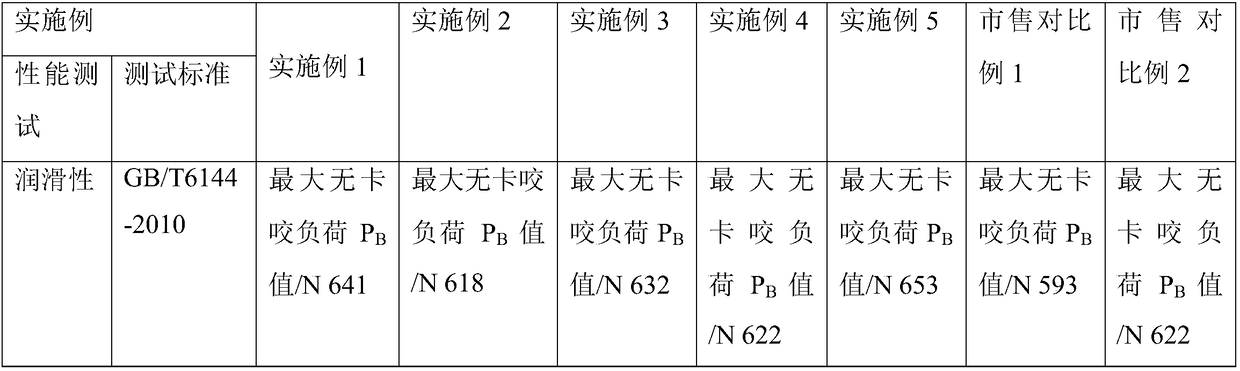

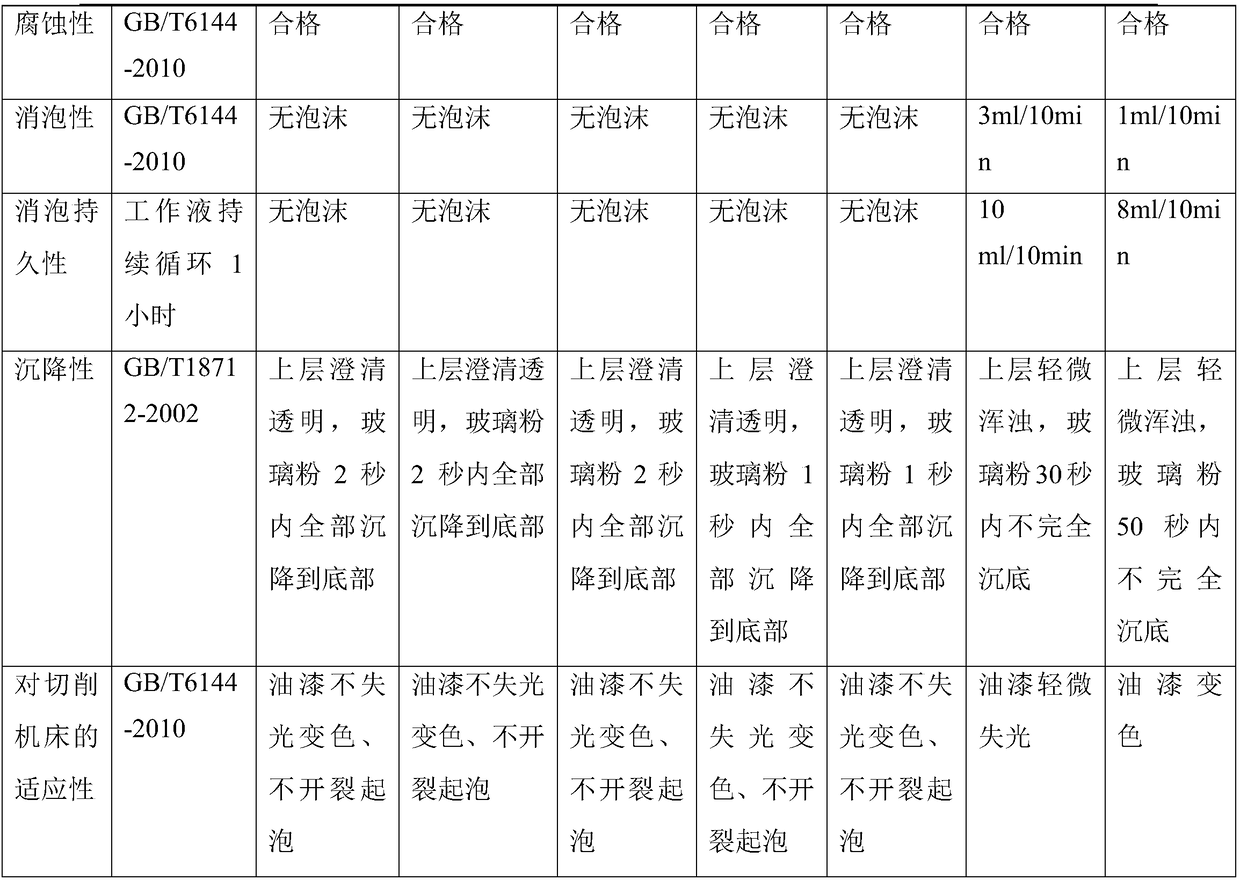

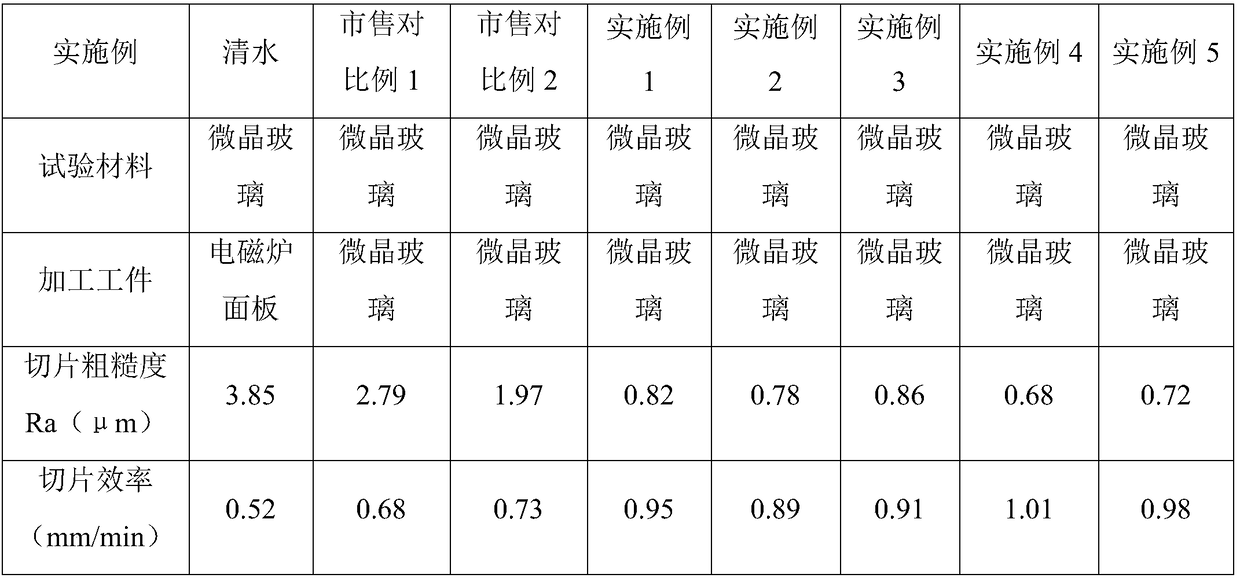

Examples

Embodiment 1

[0034] This glass cutting fluid comprises the following components by mass percentage:

[0035] 10 parts of triethanolamine borate, 2 parts of sebacic acid, 4 parts of PEG-400, 0.001 part of polyacrylamide, 3 parts of ammonium polyphosphate, 0.2 part of starcool TOR, 0.001 part of fluorescent green, 80 parts of alkaline electrolyzed water.

[0036] In this embodiment, anionic polyacrylamide with a molecular weight of 13 million to 15 million is used, and the ammonium polyphosphate is a water-soluble ammonium polyphosphate with a degree of polymerization of 5-8.

[0037] The preparation method of above-mentioned embodiment:

[0038] 1) Add 2 kg of sebacic acid to 40 kg of alkaline electrolyzed water required for 1 / 2 amount, fully stir to dissolve the sebacic acid, and obtain a transparent solution.

[0039]2) Fully stir and dissolve 1 g of polyacrylamide with the remaining 1 / 2 amount of 40 kg of alkaline electrolyzed water to obtain a solution for later use.

[0040] 3) Add 1...

Embodiment 2

[0045] This glass cutting fluid comprises the following components by mass percentage:

[0046] 5 parts of triethanolamine borate, 3 parts of sebacic acid, 5 parts of PEG-400, 0.003 parts of polyacrylamide, 3 parts of ammonium polyphosphate, 0.2 parts of starcool TOR, 0.001 part of fluorescent green, 84 parts of alkaline electrolyzed water.

[0047] In this embodiment, non-ionic polyacrylamide with a molecular weight of 12 million to 18 million is used, and the ammonium polyphosphate is a water-soluble ammonium polyphosphate with a degree of polymerization of 10-15.

[0048] The preparation method of above-mentioned embodiment:

[0049] 1) Add 3 kg of sebacic acid to 42 kg of alkaline electrolyzed water required for 1 / 2 amount, fully stir to dissolve the sebacic acid, and obtain a transparent solution.

[0050] 2) Fully stir and dissolve 3 g of polyacrylamide with the remaining 1 / 2 amount of 42 kg of alkaline electrolyzed water to obtain a solution for later use.

[0051] 3)...

Embodiment 3

[0056] This glass cutting fluid comprises the following components by mass percentage:

[0057] 15 parts of triethanolamine borate, 1 part of sebacic acid, 2 parts of PEG-400, 0.002 parts of polyacrylamide, 4 parts of ammonium polyphosphate, 0.5 parts of starcool TOR, 0.002 parts of fluorescent green, 78 parts of alkaline electrolyzed water.

[0058] In this embodiment, a cationic polyacrylamide with a molecular weight of 12 million to 20 million is used, and the ammonium polyphosphate is a water-soluble ammonium polyphosphate with a degree of polymerization of 5-20.

[0059] The preparation method of above-mentioned embodiment:

[0060] 1) Add 1 kg of sebacic acid to 39 kg of alkaline electrolyzed water required for 1 / 2 amount, fully stir to dissolve the sebacic acid, and obtain a transparent solution.

[0061] 2) Fully stir and dissolve 2 g of polyacrylamide with the remaining 1 / 2 amount of 39 kg of alkaline electrolyzed water to obtain a solution for later use.

[0062] 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com