Liquid Lubrication Method and Cutting Lubrication System Acting on Tool-Swarf Interface

A lubricating system and liquid technology, applied in the direction of tools used in lathes, accessories of tool holders, turning equipment, etc., can solve the problems of short tool life, difficult for lubricant to enter the chip interface, environmental pollution, etc., and achieve the lubrication effect. Good, reduce the temperature of the cutter body, reduce the effect of harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

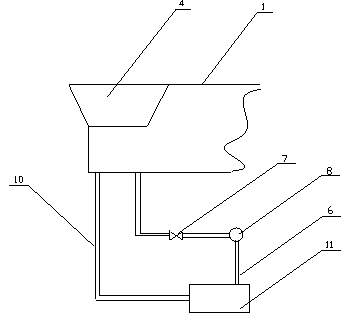

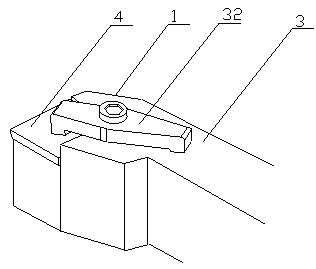

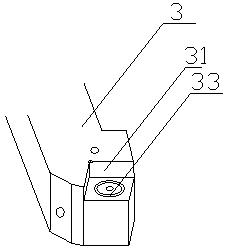

[0028] refer to figure 1 , figure 2 and image 3 , a cutting lubrication system including a cutting tool and a liquid lubricant supply system. Cutter 1 comprises cutter body 4 and cutter bar 3, and cutter bar 3 front end is provided with the knife groove 31 that can place cutter body 4, and cutter bar 3 upper surface is provided with thread fastening hole, and the center of pressing plate 32 is provided with the screw hole that runs through up and down, and pressing plate 32 is screwed into the screw hole and the threaded fastening hole to be connected with the cutter bar 3 by a bolt, and when the pressing plate 32 is fixed on the cutter bar 3 by the bolt, the bottom surface of the pressing plate 32 close to the end of the cutter body 4 is in close contact with the upper surface of the cutter body 4; Inside the tool 1, there is a channel penetrating from the bottom surface of the tool 1 to the tool-chip interface of the tool 1. The upper opening of the channel is located at...

Embodiment 2

[0034] refer to figure 1 , figure 2 and image 3 , a cutting lubrication system including a cutting tool and a liquid lubricant supply system. Cutter 1 comprises cutter body 4 and cutter bar 3, and cutter bar 3 front end is provided with the knife groove 31 that can place cutter body 4, and cutter bar 3 upper surface is provided with thread fastening hole, and the center of pressing plate 32 is provided with the screw hole that runs through up and down, and pressing plate 32 is screwed into the screw hole by a bolt and connected with the threaded fastening hole with the knife bar 3, and when the pressing plate 32 is fixed on the knife bar 3 by the bolt, the bottom surface of the pressing plate 32 close to the end of the knife body 4 is in close contact with the knife body 4;

[0035] Inside the tool 1, there is a channel penetrating from the bottom surface of the tool 1 to the tool-chip interface of the tool 1. The upper opening of the channel is located at the tool-chip in...

Embodiment 3

[0041] refer to figure 1 , figure 2 and image 3 , a cutting lubrication system including a cutting tool and a liquid lubricant supply system. Cutter 1 comprises cutter body 4 and cutter bar 3, and cutter bar 3 front end is provided with the knife groove 31 that can place cutter body 4, and cutter bar 3 upper surface is provided with thread fastening hole, and the center of pressing plate 32 is provided with the screw hole that runs through up and down, and pressing plate 32 is screwed into the screw hole by a bolt and connected with the threaded fastening hole with the knife bar 3, and when the pressing plate 32 is fixed on the knife bar 3 by the bolt, the bottom surface of the pressing plate 32 close to the end of the knife body 4 is in close contact with the knife body 4;

[0042] Inside the tool 1, there is a channel penetrating from the bottom surface of the tool 1 to the tool-chip interface of the tool 1. The upper opening of the channel is located at the tool-chip in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com