Apparatus for cleaning and lubricating roller

A lubricating device and cleaning technology, applied to rolls, keeping roll equipment in an effective state, metal rolling, etc., can solve the problems of inconvenient installation and adjustment, complex structure, etc., achieve convenient adjustment, improve product quality, and improve lubrication and cooling effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

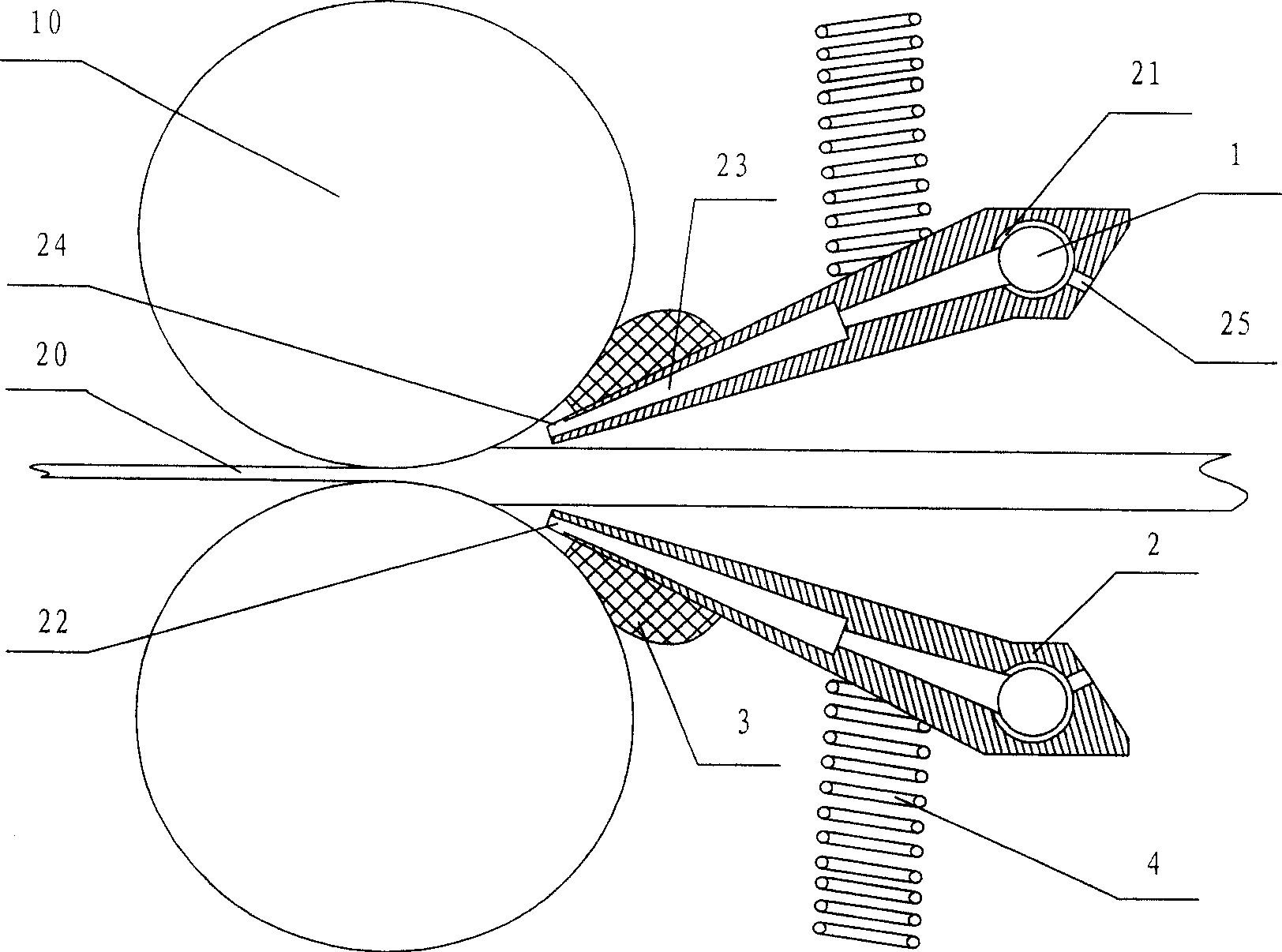

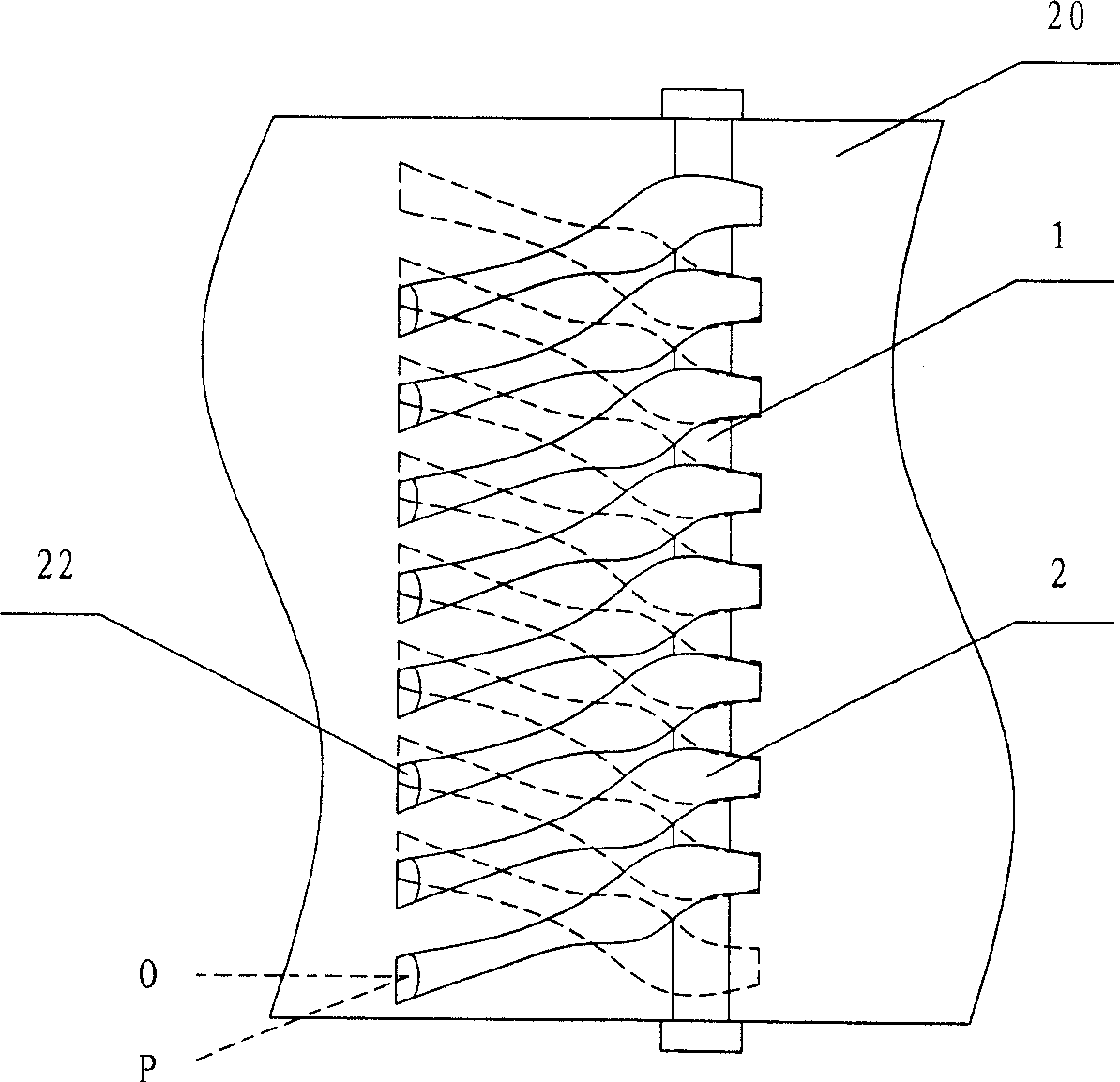

[0016] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a schematic diagram of the layout of the present invention. Such as figure 1 , figure 2 As shown, the roll cleaning and lubricating device of the present invention is arranged on the plate entry side of the work roll 10, and is respectively located above and below the plate strip 20, and can also be symmetrically arranged on the plate entry side and the plate exit side of the work roll 10. The roll cleaning and lubricating device includes two liquid inlet pipes 1 respectively located above and below the plate and strip 20, several injectors 2 respectively socketed with the two liquid inlet pipes 1, and each injector 2 is fixedly connected with an erasing device 3 and spring 4. Specifically, one end of the injector 2 is provided with a radial through hole 21, and the through hole 21 is sleeved on the liquid inlet pipe 1, so that the injector 2 can be deflected with the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com