A Nanofluid Magnetic Grinding Fluid and Magnetic Field Assisted Minimal Quantity Lubrication System

A micro-lubrication, magnetic field-assisted technology, applied in lubricating compositions, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of poor lubrication and cooling effect of grinding fluid, large potential safety hazards, and harmful pollution, etc. Achieve the effect of improving lubrication and cooling effect, reducing grinding specific energy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

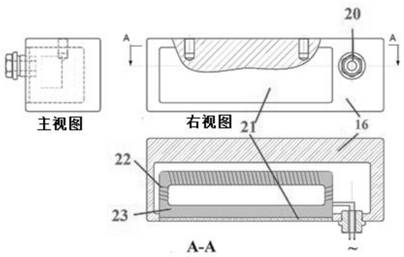

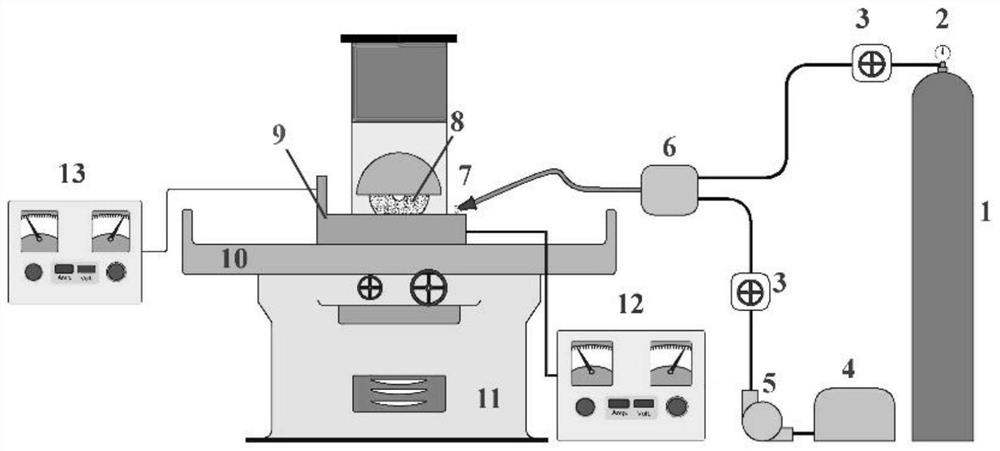

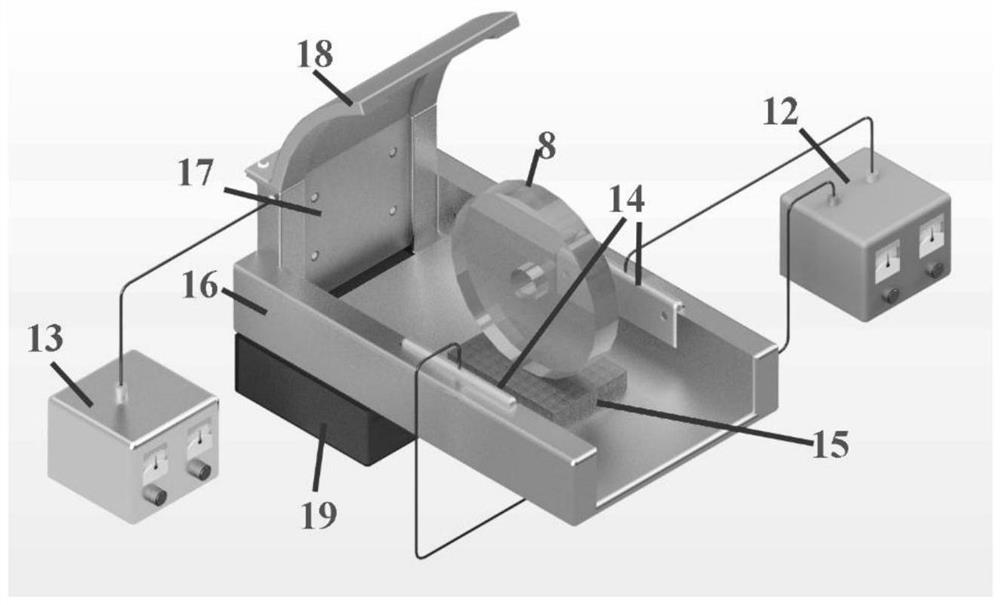

[0024] In order to facilitate the understanding of those skilled in the art, the following in conjunction with the attached Figure 1-3 The present invention will be described in detail.

[0025] The present invention proposes a nanofluid magnetic grinding fluid, which is composed of distilled water, sodium deoxycholate (0.3-1.0wt.%), ethylene glycol (1.0-5.0wt.%), ferric oxide (Fe 3 o 4 ) nanoparticles, graphene powder configuration, the configuration of the grinding fluid has a magnetic Fe 3 o 4 Nanoparticles will be adsorbed on the surface of graphene to form magnetic lubricating mixed particles, and other additives such as sodium deoxycholate and ethylene glycol will promote the uniform dispersion of magnetic lubricating mixed particles in the grinding fluid. Distilled water in the nanofluid magnetic grinding fluid It can also be replaced with biodegradable oils such as palm oil. Graphene has excellent mechanical properties such as strength and toughness. It is used as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com