A Canned Pump with Forced Cooling and Lubricating Function

A technology of forced cooling and shielded pumps, which is applied to parts, pumps, and pump components of elastic fluid pumping devices, and can solve the problems of easy wear of friction pairs, high heat generation, and easy burning of motor windings, etc. The life of the pump, the improvement of reliability, and the effect of enhancing the lubrication and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

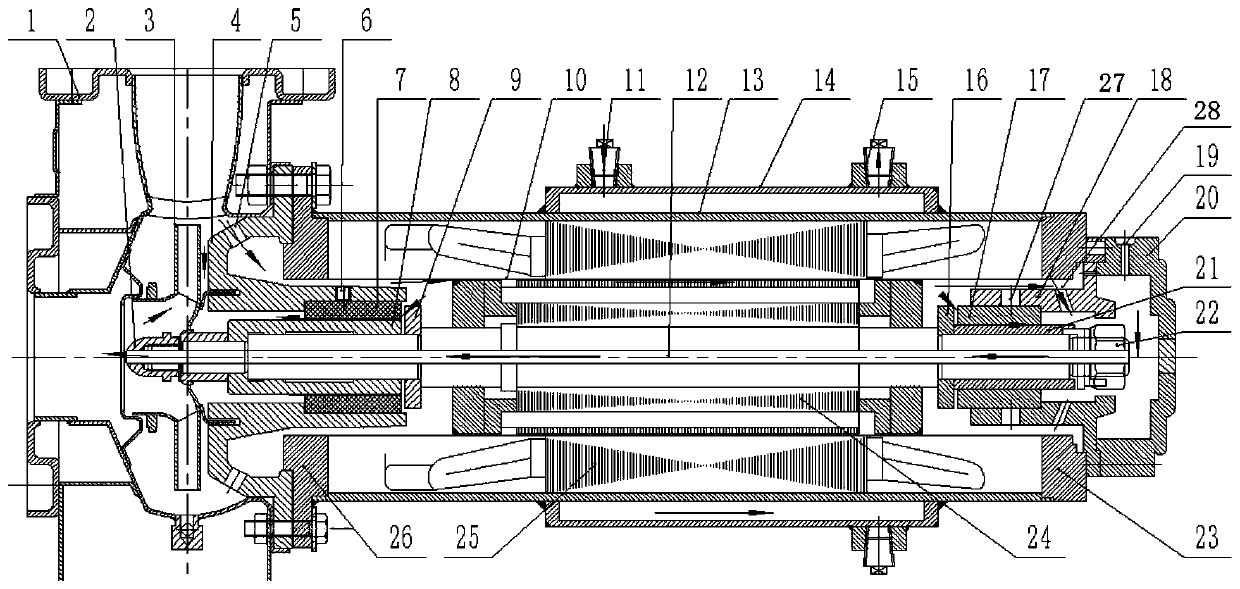

[0018] Such as figure 1 As shown, the canned pump with forced cooling and lubricating function of the present invention includes a pump body 1, an impeller nut 2, an impeller 4, a front bearing seat 4, a front sliding bearing 7, a shaft sleeve 8, a front thrust plate 9, a shielding Sleeve 10, shaft 12, motor housing 13, jacket 14, rear thrust plate 16, rear sliding bearing 17, rear bearing seat 18, motor rear cover plate 20, shaft sleeve 2 21, nut 22, motor rear end cover 23, Motor rotor winding 24, motor stator winding 25, motor front end cover 26, the impeller 3 is located inside the pump body 1 and fixed on one end of the shaft 12 through the impeller nut 2, the front bearing seat is located on the far pump side of the impeller , the shaft sleeve 1 8, the front slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com