Hydrophilic polyolefin-based composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and olefin-based membrane technology, which is applied in the field of hydrophilic polyolefin-based composite nanofiltration membrane and its preparation, can solve the problems of poor membrane uniformity, cumbersome operation steps, and long time required to achieve flux retention time Long, wide application range, simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

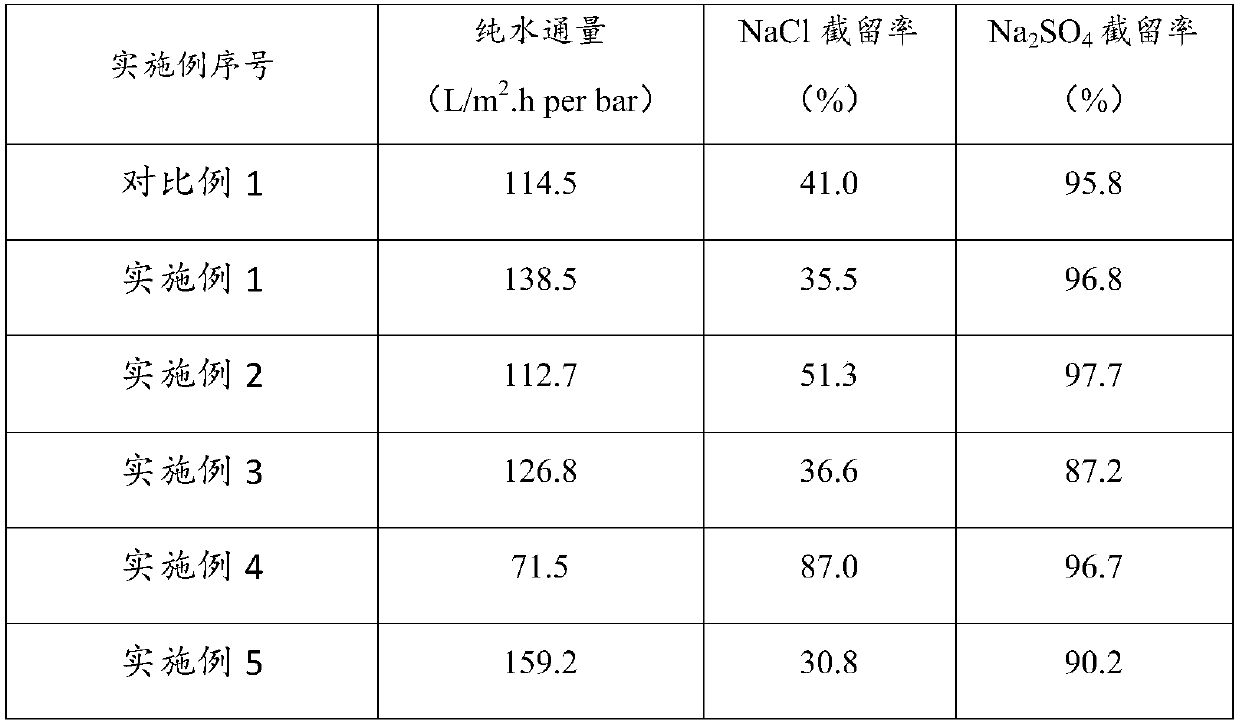

Embodiment 1

[0059] Polyethylene (Mn=3×10 6 ) Microporous membrane (average pore diameter 0.058 micron, porosity 47%, thickness 20 micron) cleans and dries with isopropanol, then immerses in 2wt% polyvinyl alcohol (alcoholysis degree 98%, molecular weight 110000) solution, with 0.5wt% For glutaraldehyde crosslinking, the content of surfactant SDBS in the hydrophilic agent is 10wt%, and after standing for 10 minutes, transfer to an oven to heat, and crosslink at 70°C for 10 minutes. After completion, take it out and put it into 40wt% ethanol aqueous solution to remove excess hydrophilic agent to obtain a hydrophilic polyethylene microporous membrane.

[0060] Pour the aqueous phase solution containing 2wt% of piperazine into the hydrophilic polyethylene membrane frame, the content of ethylenediamine in the solution is 1wt%, the content of precipitated silica is 0.5wt%, take it out after 5min, and extrude it with a polyurethane roller Excess liquid on the surface; finally pour n-hexane cont...

Embodiment 2

[0064] Polyethylene (Mn=6×10 6 ) Microporous membrane (average pore diameter 0.043 micron, porosity 35.4%, thickness 16 micron) cleans and dries with isopropanol, then immerses in 8wt% polyvinyl alcohol (alcoholysis degree 98%, molecular weight 110000) solution, with 0.5wt% Maleic anhydride is cross-linked, and the content of surfactant sodium polystyrene sulfonate in the hydrophilic agent is 10 wt%. After standing for 10 minutes, transfer to an oven to heat, and cross-link at 70° C. for 20 minutes. After completion, take it out and put it into 40wt% ethanol aqueous solution to remove excess hydrophilic agent to obtain a hydrophilic polyethylene microporous membrane.

[0065] Pour the aqueous phase solution containing 2wt% of piperazine into the hydrophilic polyethylene membrane frame, the content of ethylenediamine in the solution is 1wt%, the content of precipitated silica is 0.5wt%, take it out after 5min, and extrude it with a polyurethane roller Excess liquid on the surf...

Embodiment 3

[0069] Adjust the amount of precipitated silica, increase its content to 5wt%, ultrasonic 10min, increase the interfacial polymerization time to 120s, other conditions are the same as Example 2.

[0070] Example 3 is tested, and the pure water flux reaches 126.8L / m2.h per bar, showing that increasing the amount of precipitated silica has a certain effect on improving the flux, but the retention rate of sodium chloride is reduced to 36.6%, and sodium sulfate It was reduced to 87.2%, indicating that the formed polyamide skin layer had a larger pore size and formed defects, resulting in a general decrease in the rejection rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com