Method for rapidly predicting 28-day colloidal mortar compression strength of cement

A technology of compressive strength and prediction method, applied in the fields of water conservancy engineering, civil engineering, and construction industry, can solve the problems of different strength development laws, large prediction deviation, low correlation coefficient, etc., and achieve high homotropic correlation coefficient and high accuracy. , the effect of small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

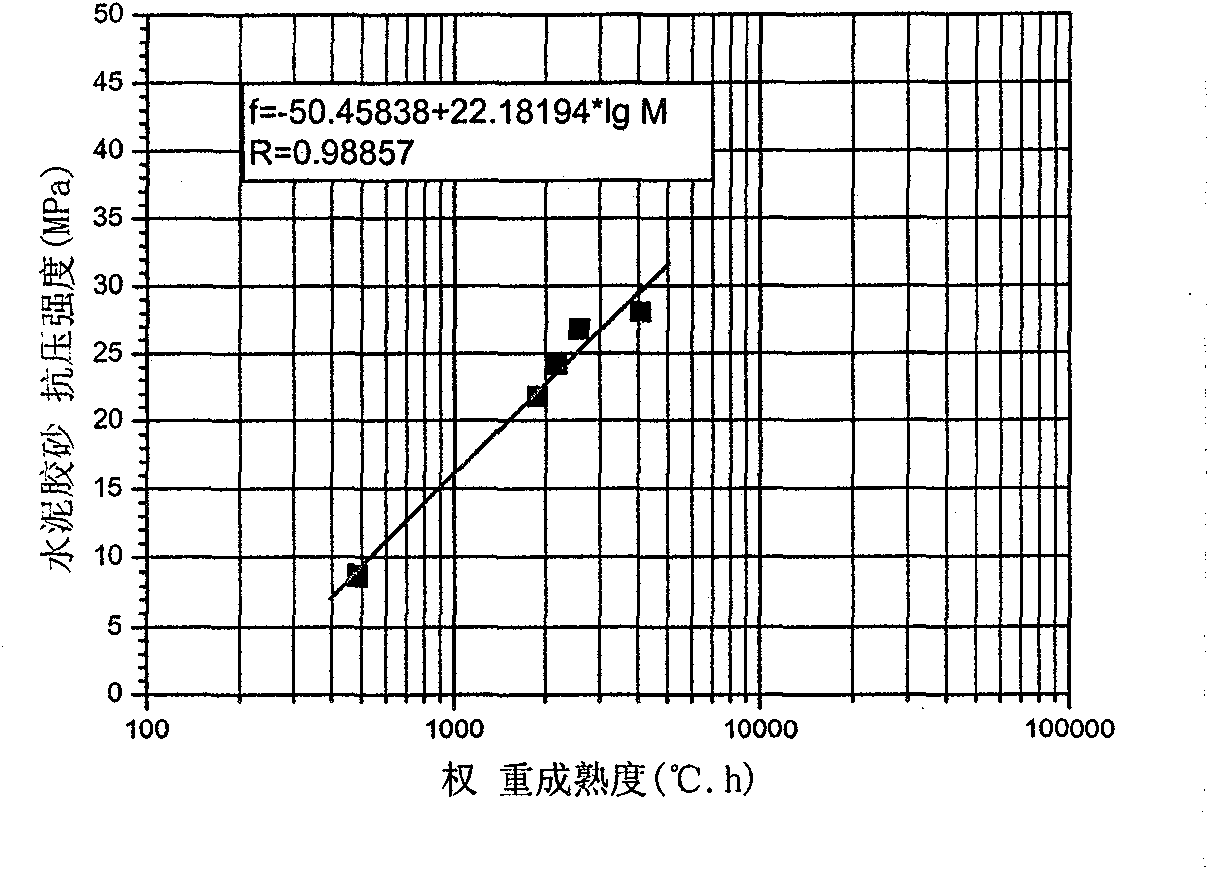

Embodiment 1

[0082] Check "General Portland Cement" GB 175-2007, it can be seen that the percentage of Portland cement in the total mass of cement is ≥80% and <95%, and then according to the reference material of cement C value (when it is greater than 65%, the C value is 1.3, When 50%-64%, the C value is 1.4, when 35%-49%, the C value is 1.5, and when 35%-49%, the C value is 1.5), and the C value of the cement is determined to be 1.3.

[0083] When placed in the humid heat curing box, the temperature is 24°C, and the results of calculating the weight maturity and strength are as follows:

[0084] Age 4h:

[0085] Age 5.5h:: 1.5h is from 24°C to 55°C, this part is calculated according to the average temperature

[0086]

[0087] Age 9h: Demoulding 0.5h ahead of time and taking out the test piece, this part is calculated based on the laboratory temperature of 20°C, and the constant temperature time of 55°C is 9h-0.5h-5.5h=3h

[0088] M 9 ...

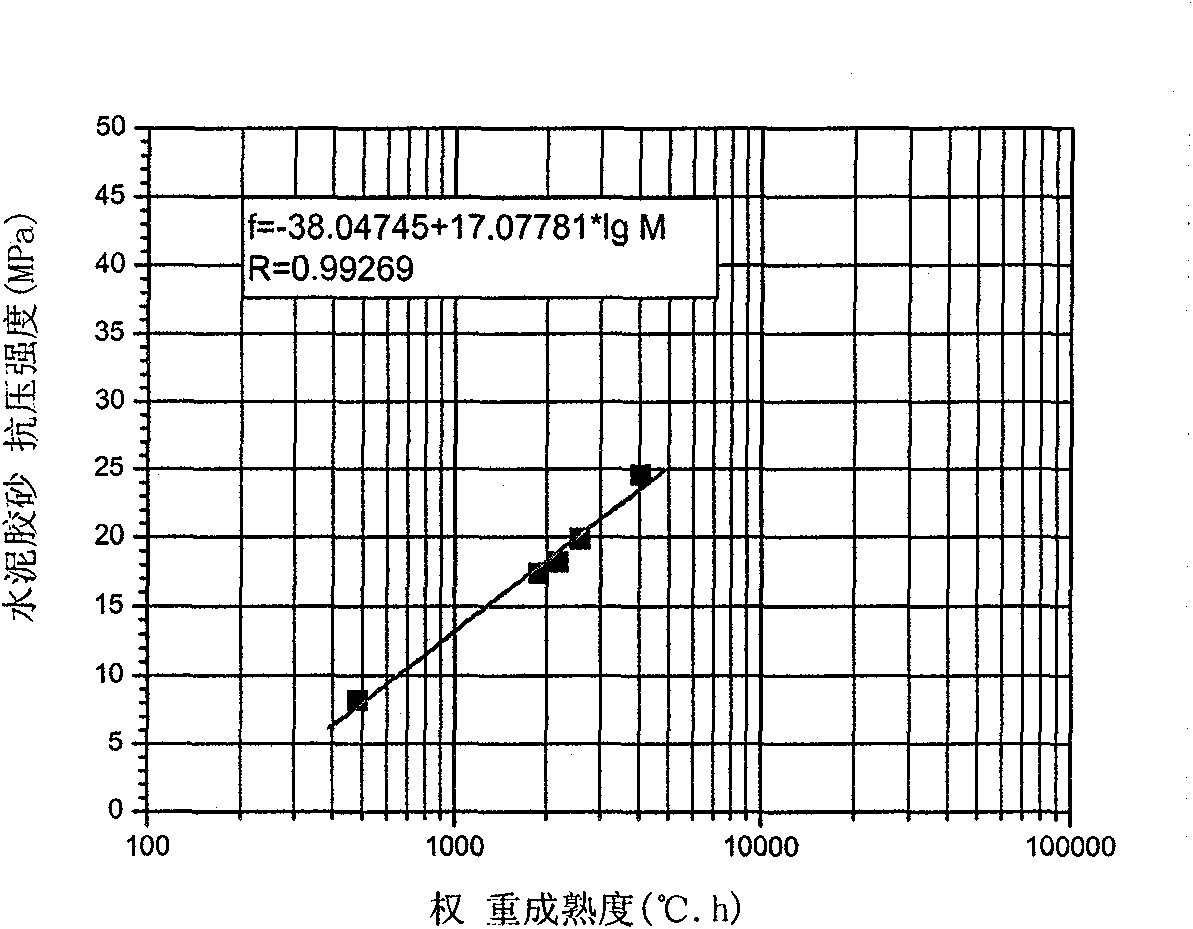

Embodiment 2

[0108] Check "General Portland Cement" GB 175-2007, it can be seen that the percentage of Portland cement in the total mass of cement is ≥80% and <95%, and then according to the reference material of cement C value (when it is greater than 65%, the C value is 1.3, When 50%-64%, the C value is 1.4, when 35%-49%, the C value is 1.5, and when 35%-49%, the C value is 1.5), and the C value of the cement is determined to be 1.3.

[0109] The temperature in the humid heat curing box is 22°C, and the results of calculating the weight maturity and strength are as follows:

[0110] Table 5. Test results of weight maturity and compressive strength of a certain brand P.O32.5R

[0111] Age (h)

Maturity M(℃.h)

lm w

Compressive strength (MPa)

9

481.2

2.68

8.2

24

1874.9

3.27

17.4

27.5

2173.2

3.34

18.2

32

2566.9

3.41

19.9

48

4055.8

3.61

24.6

[0112] C...

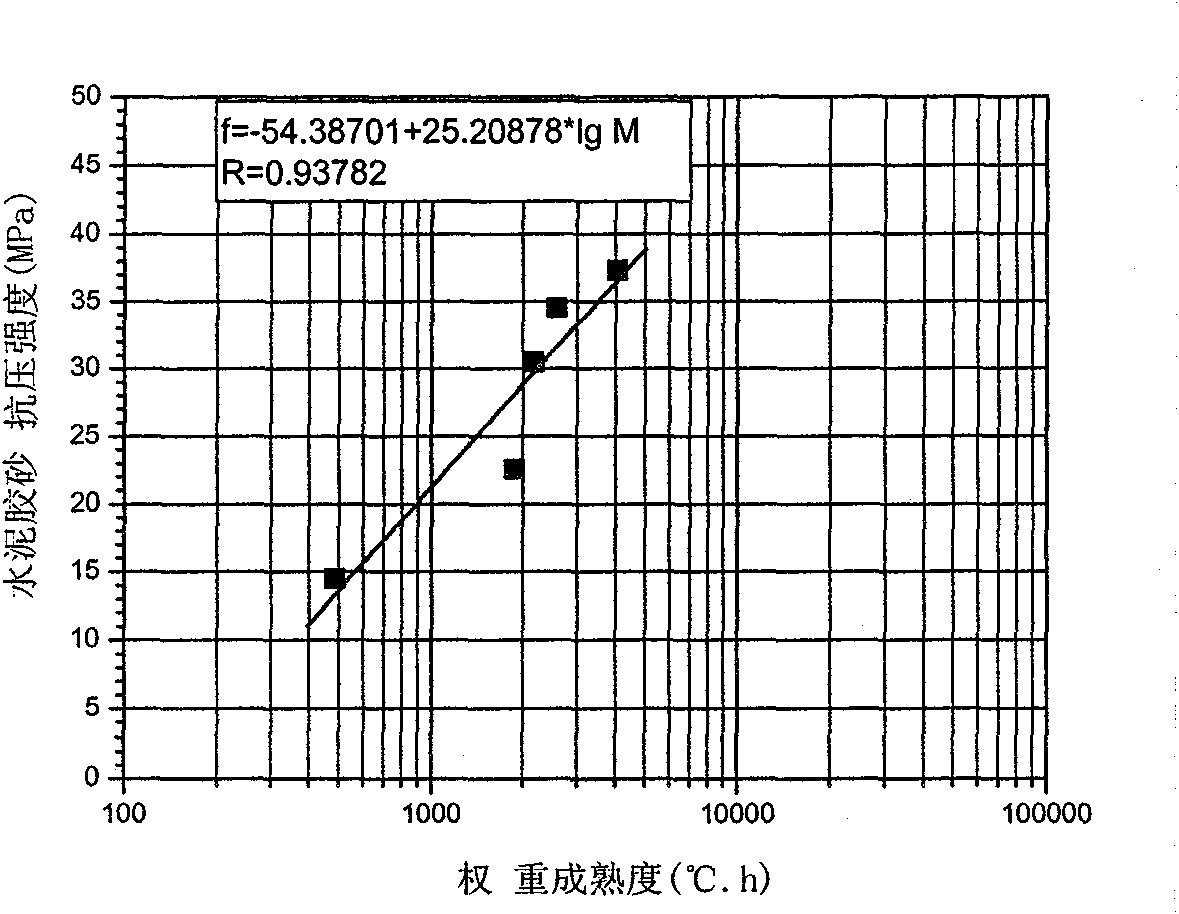

Embodiment 3

[0118] Check "General Portland Cement" GB 175-2007, it can be seen that the percentage of Portland cement in the total mass of cement is ≥80% and <95%, and then according to the reference material of cement C value (when it is greater than 65%, the C value is 1.3, When 50%-64%, the C value is 1.4, when 35%-49%, the C value is 1.5, and when 35%-49%, the C value is 1.5), and the C value of the cement is determined to be 1.3.

[0119] The temperature in the humid heat curing box is 25°C, and the results of calculating the weight maturity and strength are as follows:

[0120] Table 7. Test results of weight maturity and compressive strength of a certain brand of P.O42.5R

[0121] Age (h)

Maturity M(℃.h)

lm w

Compressive strength (MPa)

9

485.7

2.69

14.5

24

1879.4

3.27

22.6

27.5

2177.8

3.34

30.5

32

2571.4

3.41

34.5

48

4060.3

3.61

37.3

[012...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com