Radiographic inspection compensation method

A technology of radiography and compensation method, which is applied in the direction of using radiation for material analysis, using wave/particle radiation for material analysis, and measuring devices, etc., which can solve the problems of relatively high environmental requirements on the detection site, low production efficiency, and high equipment costs. To achieve the effect of ensuring image quality and sensitivity, low equipment cost, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

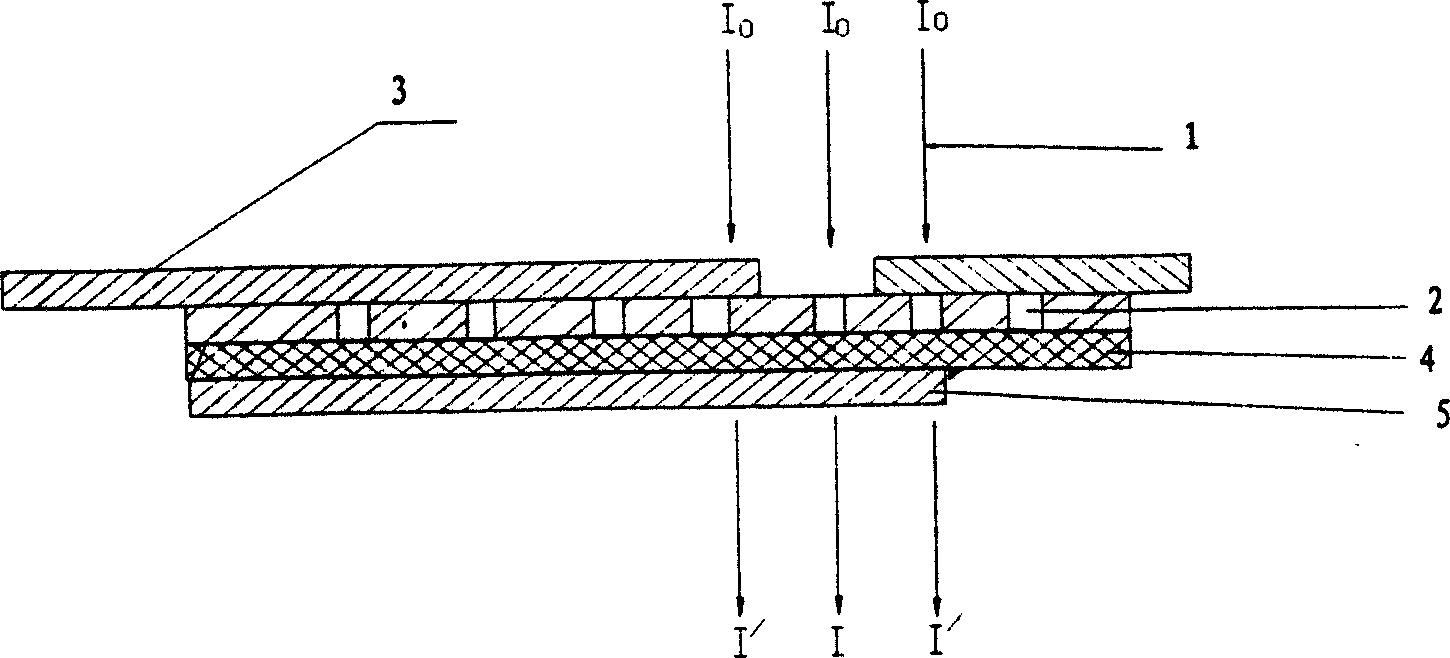

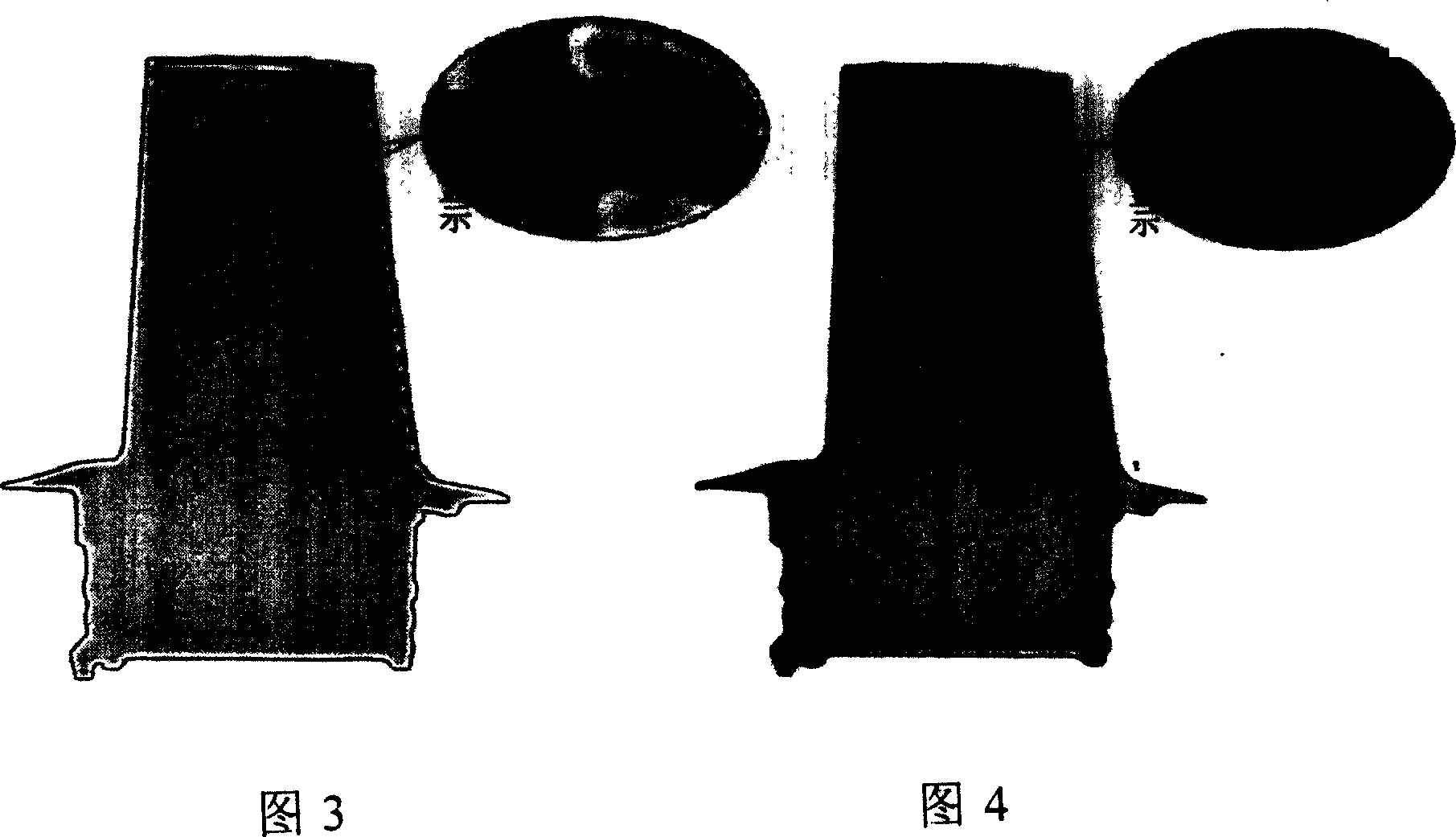

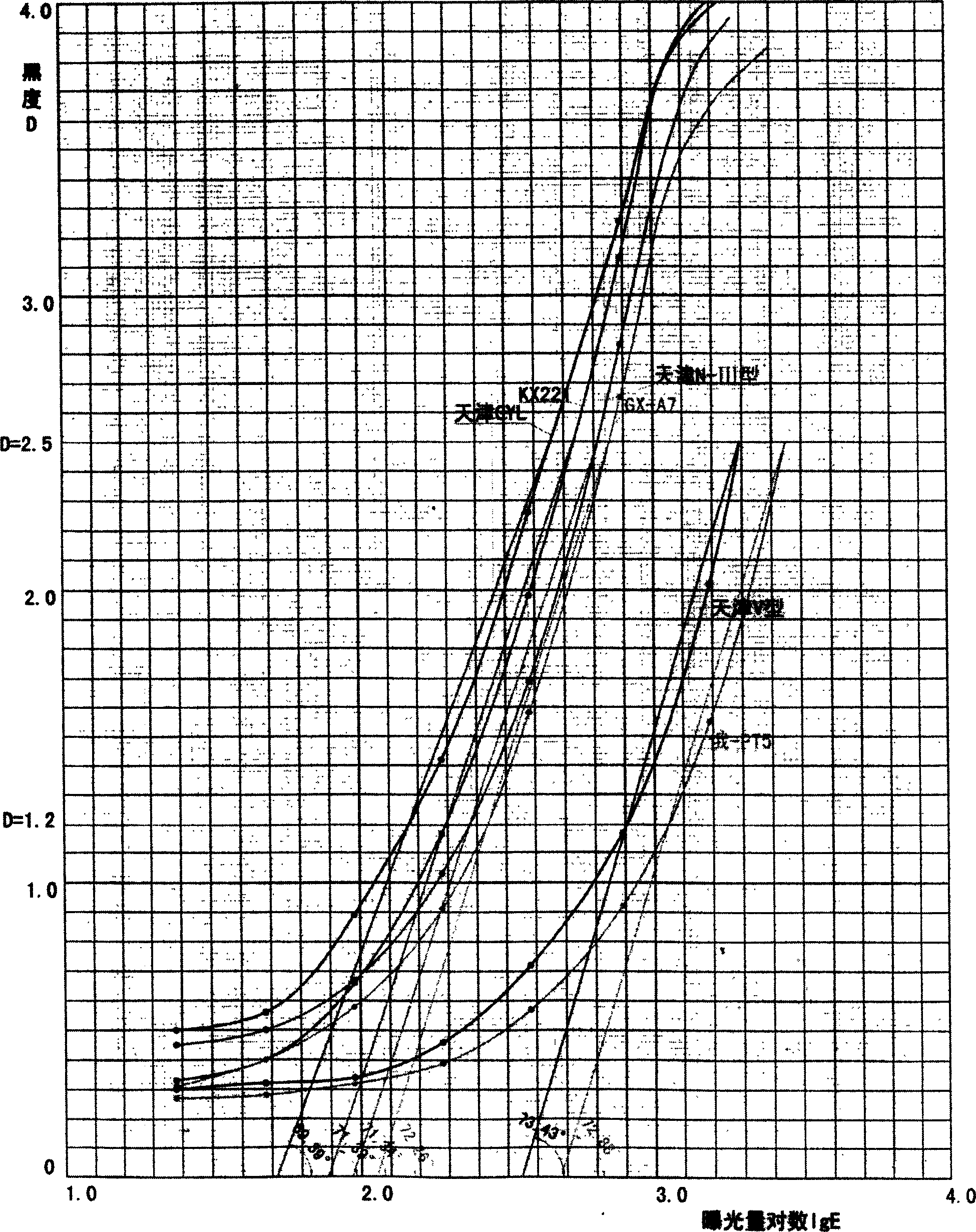

[0019] The selected aero-engine turbine blade is a cast grid cavity structure, the purpose is to check the cleanliness of the inner cavity to prevent foreign matter from blocking the airflow channel and ensure the cooling effect of the blade. First, use the comparative measurement method to analyze and select the film characteristics; take an X-ray film of length × width (11 inches × 1.5 inches) and wrap it with black paper, and cover it with a lead plate. The thickness must be sufficient to prevent the film from being affected by X-rays. There are holes with a diameter of 15 mm on the lead plate. During exposure, the lead plate is gradually moved, and the X-rays pass through the small holes to expose the film in sections, such as figure 1 shown. In this example, SEIFERT ISOVOT320 / 13 fixed X-ray machine is selected, the basic transillumination parameters are tube voltage 95KV, tube current 3mA, focal length 1800mm, and each exposure time is 8, 16, 32, 94, 128, 256, 512 second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com