Patents

Literature

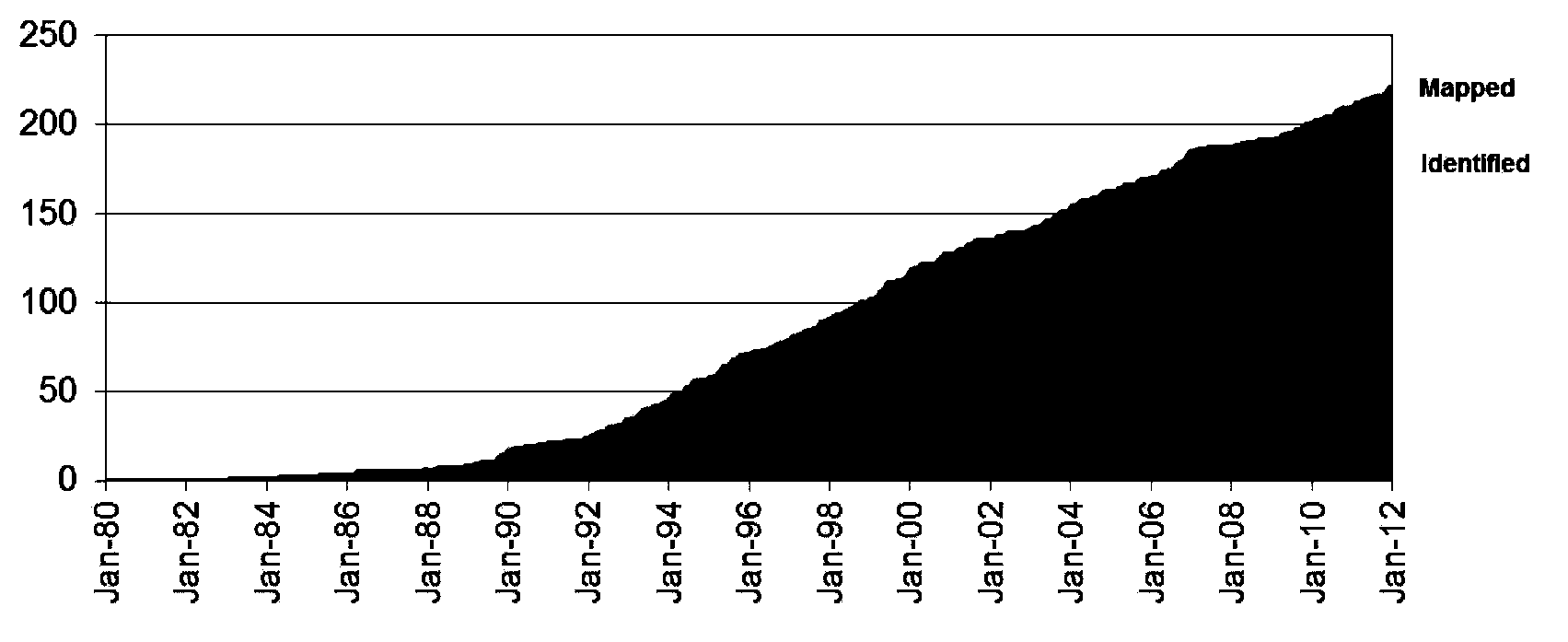

98results about How to "Change function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

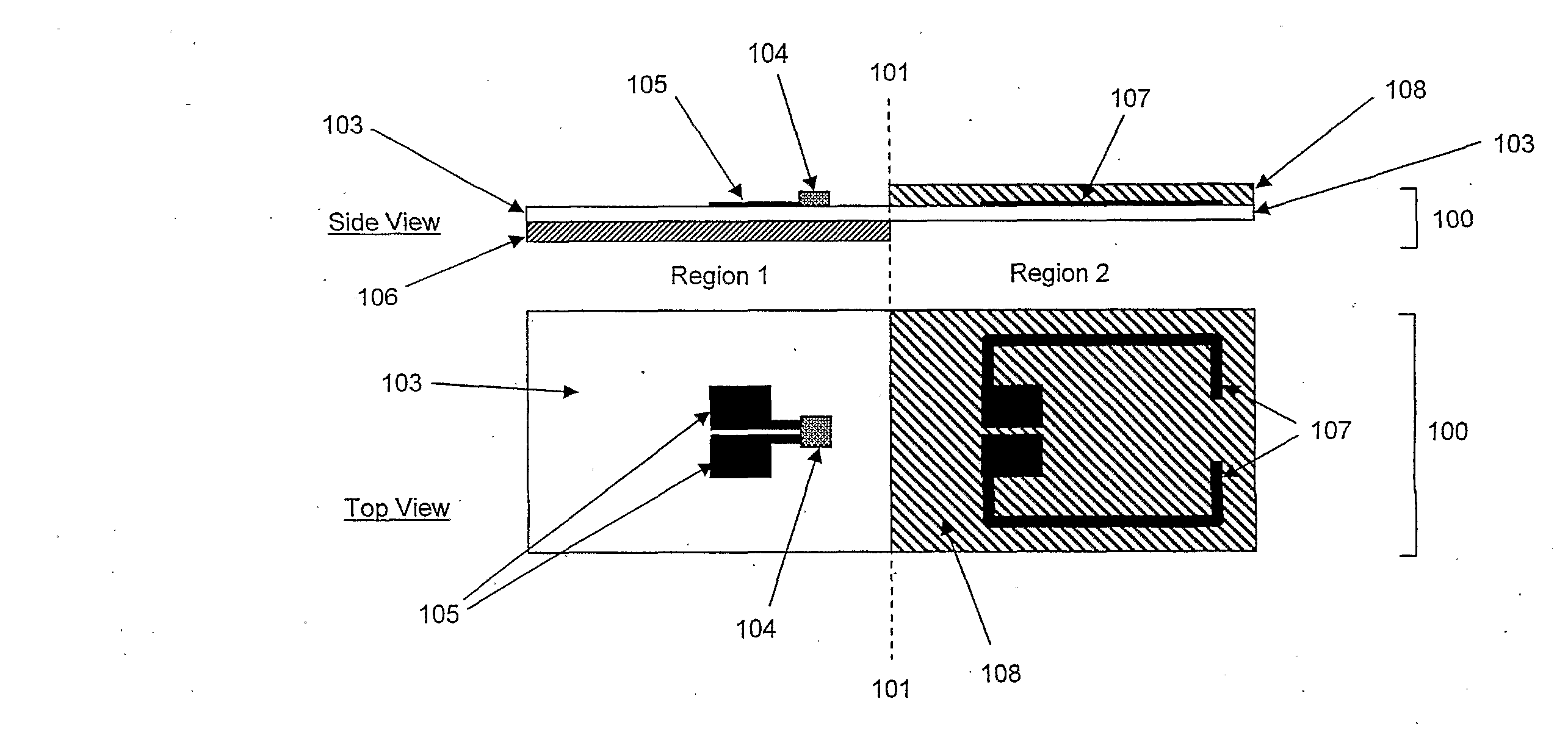

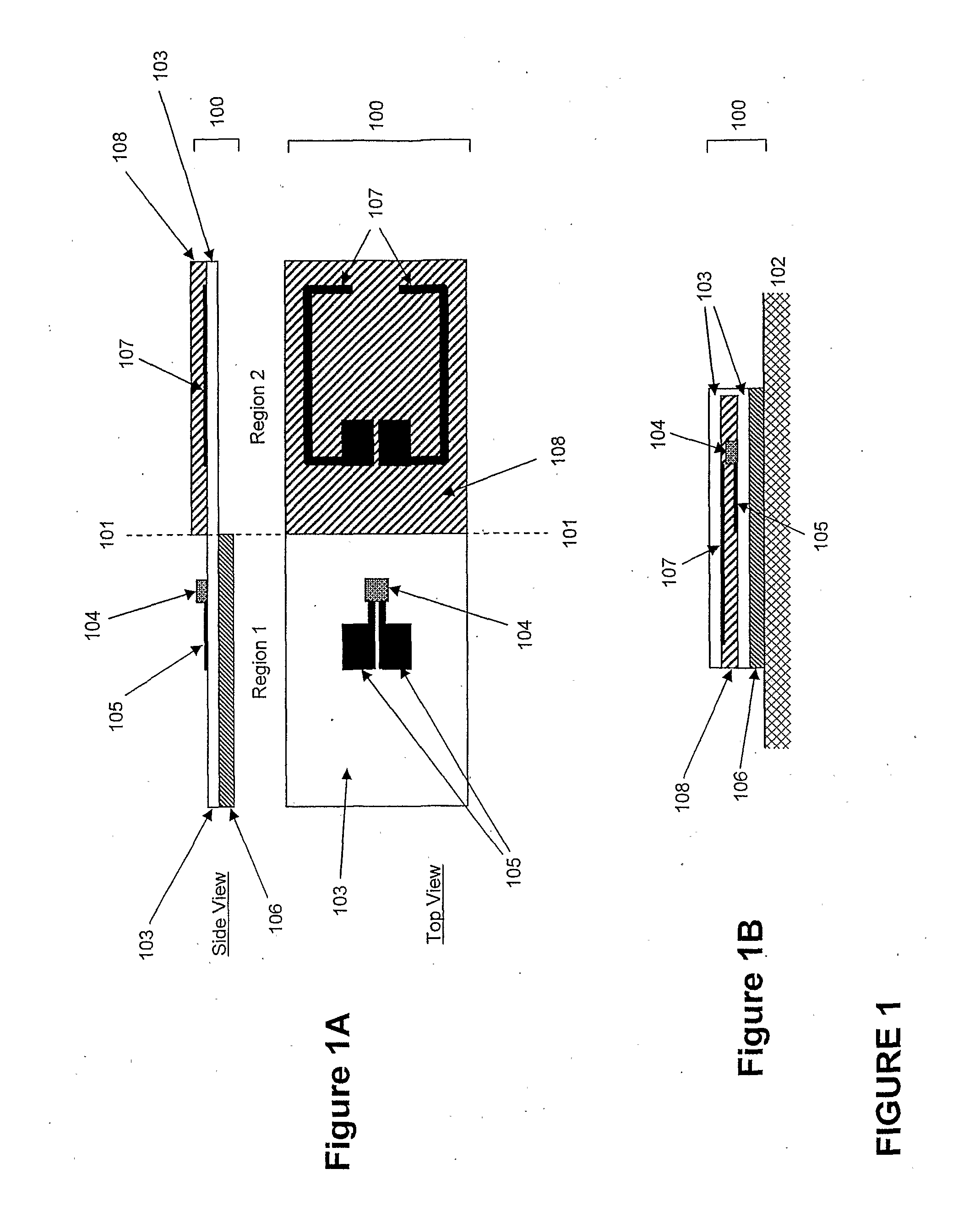

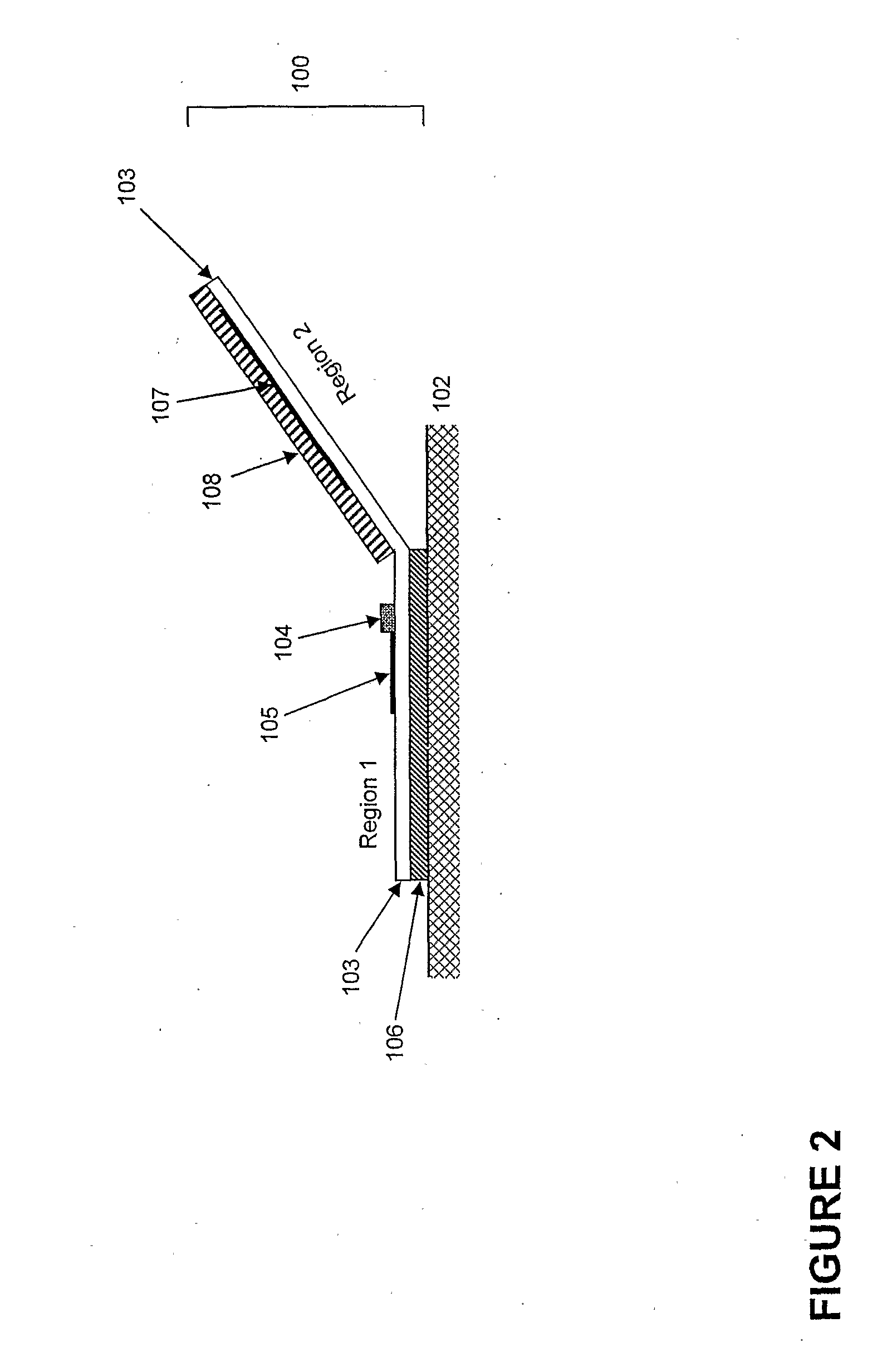

Radio frequency identification tag with privacy and security capabilities

InactiveUS20100230498A1Change functionSensing record carriersRecord carriers used with machinesEngineeringConductive materials

An RFID tag that is foldable about a generally transverse fold line. The line divides the tag into two regions. One region has an RFID integrated circuit and areas of electrically conductive material. The other region has conductive areas that provide an efficient RFID antenna. In a folded configuration the areas are operatively associated with the integrated circuit while in the open configuration the areas are not functionally associated with the integrated circuit. Accordingly in the open configuration the tag is disabled or its RFID performance substantially degraded. The tag can be reversibly altered between the open and folded configurations.

Owner:MAJKOKH CORP

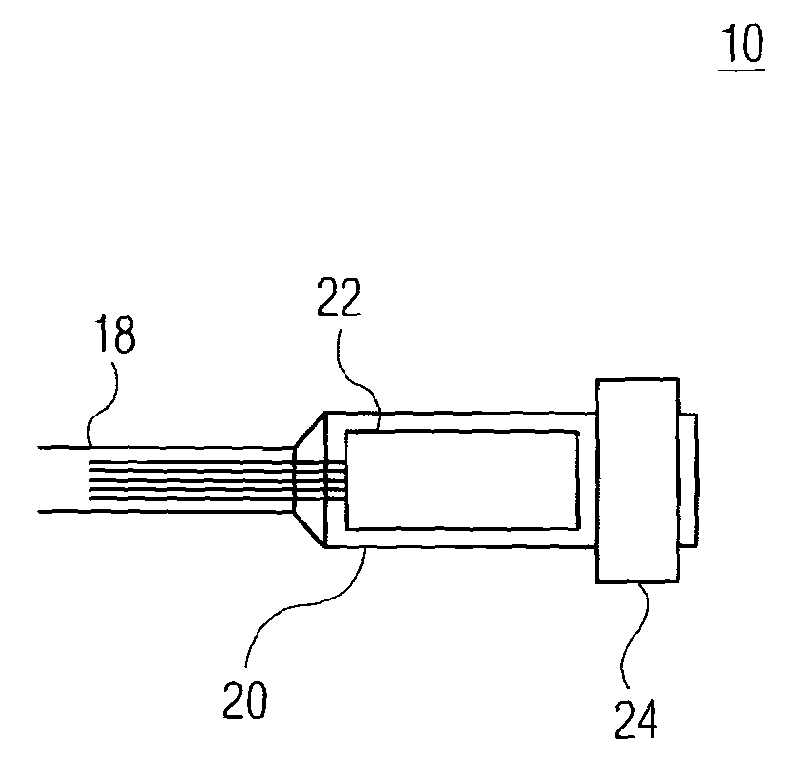

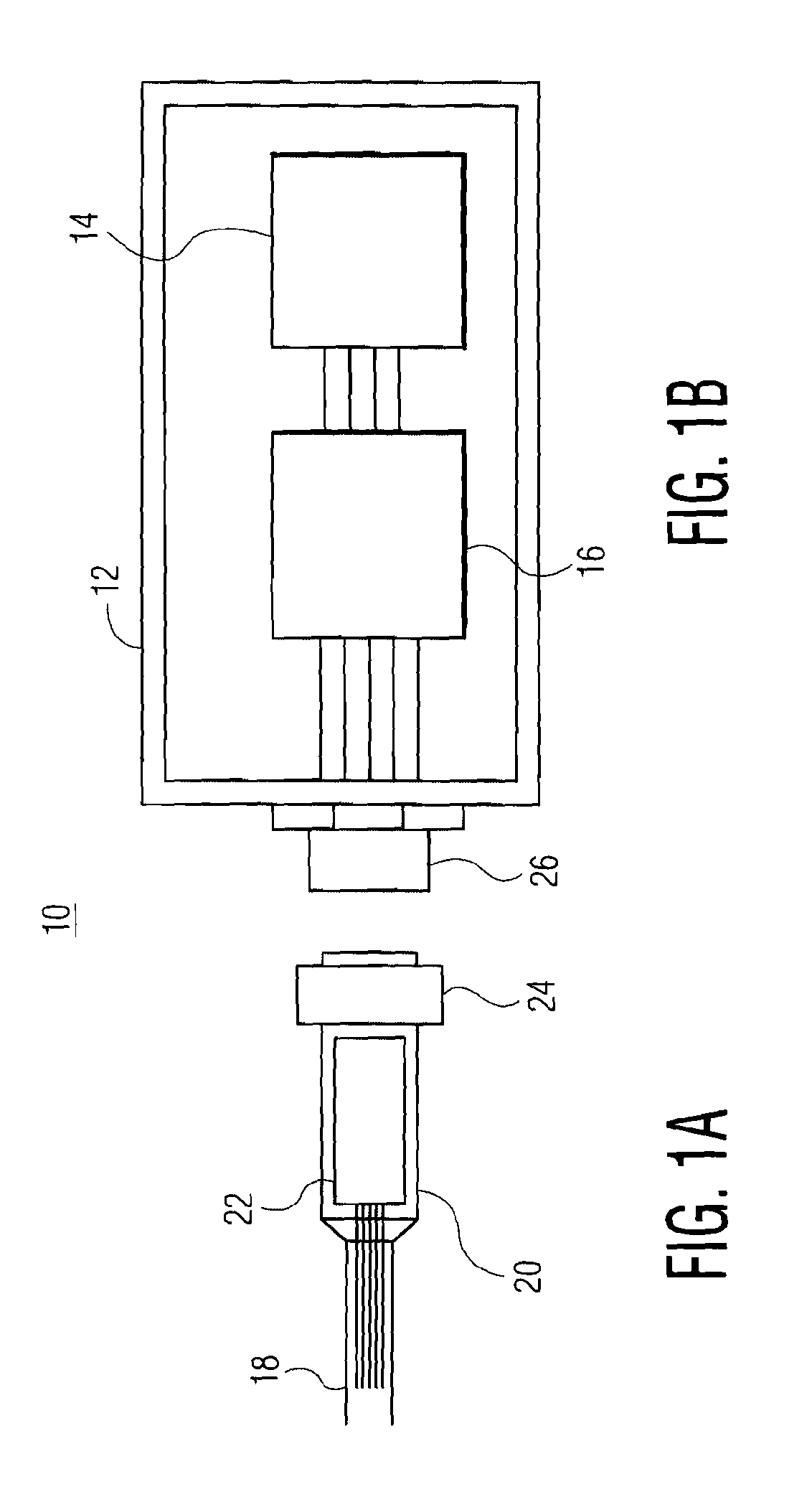

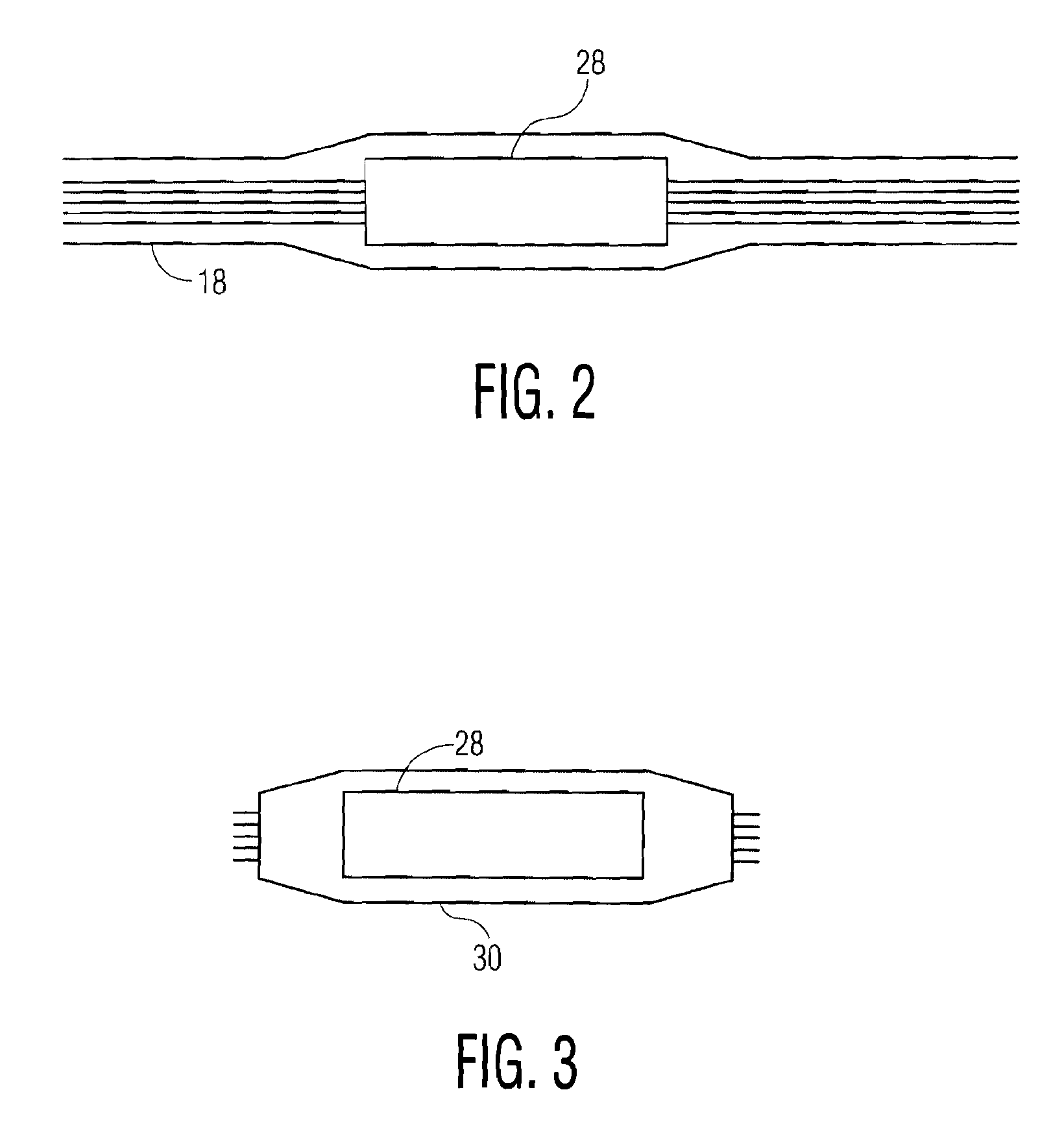

External microcontroller for LED lighting fixture, LED lighting fixture with internal controller, and LED lighting system

InactiveUS20100060194A1Avoid the possibility of damageSimple designElectrical apparatusElectroluminescent light sourcesMicrocontrollerPower cable

An LED lighting system (10) includes an LED lighting fixture (12) having at least one LED (14) and an external microcontroller (22, 28) for converting incoming lighting control data formatted according to the DMX512 standard to pulse-width modulated lighting control signals for input to the LED (14). The external microcontroller (22, 28) is preferably located inside a cable connector (20) adapted for releasably connecting a power cable (18) to the LED lighting fixture (12).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

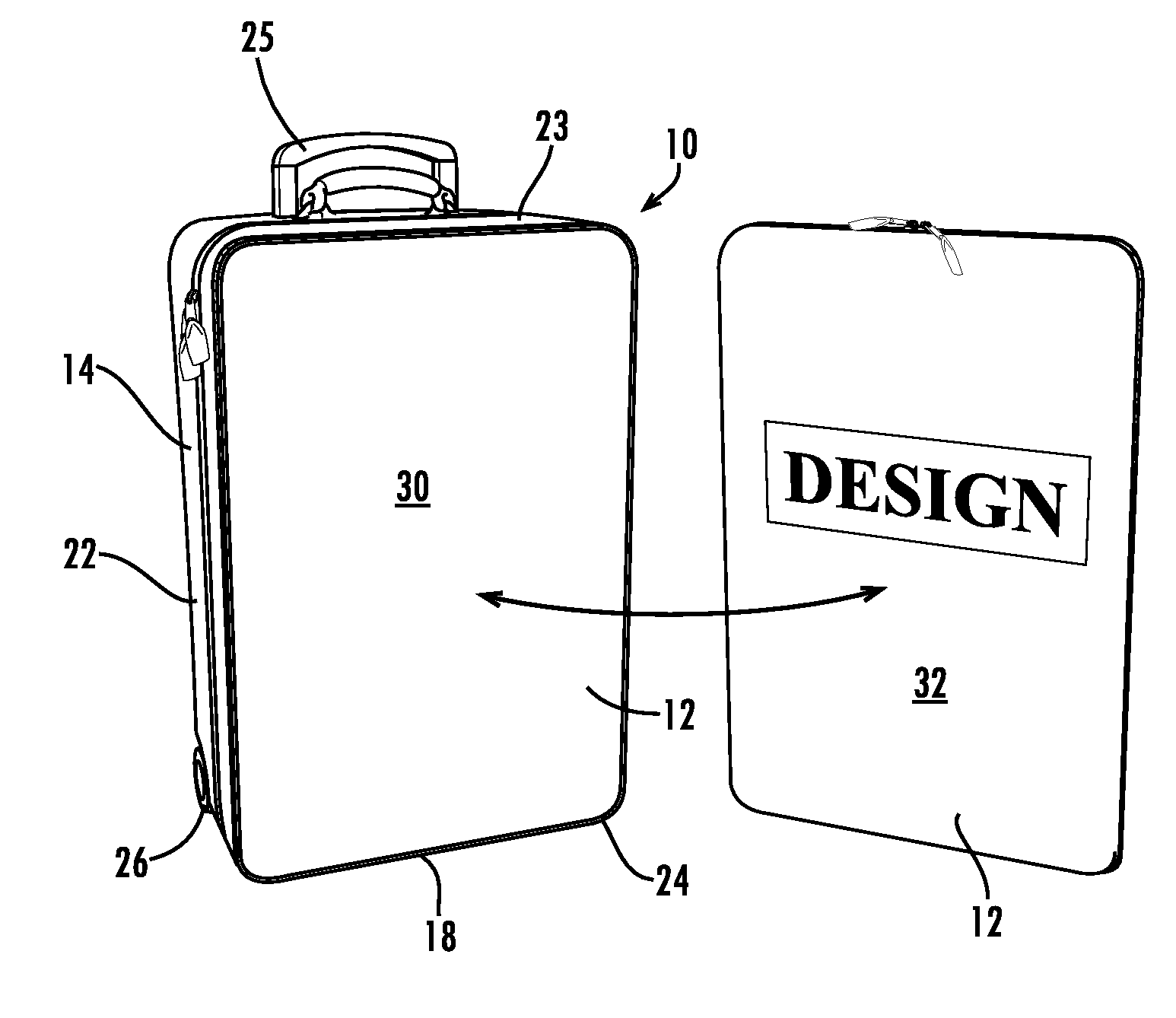

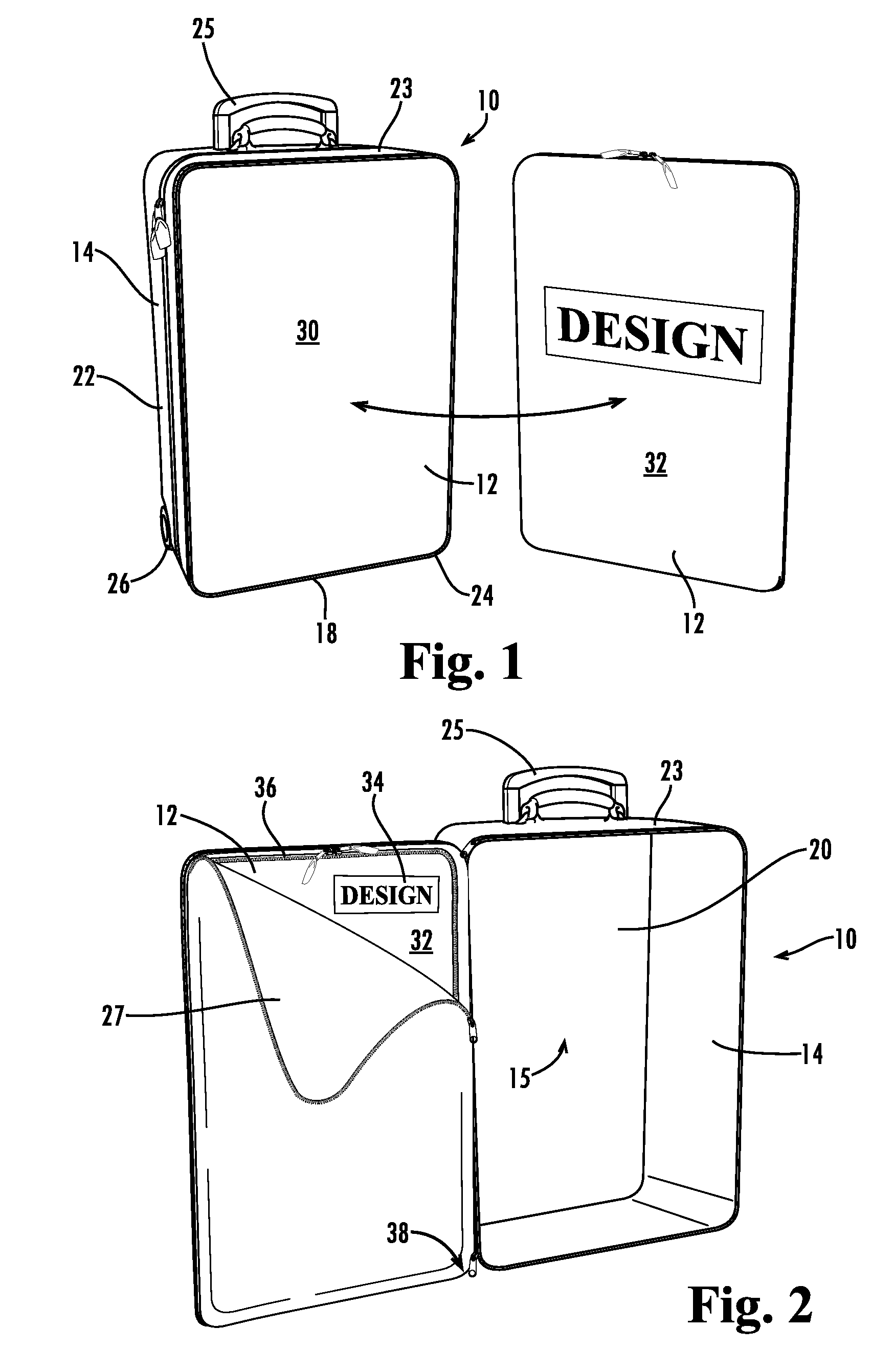

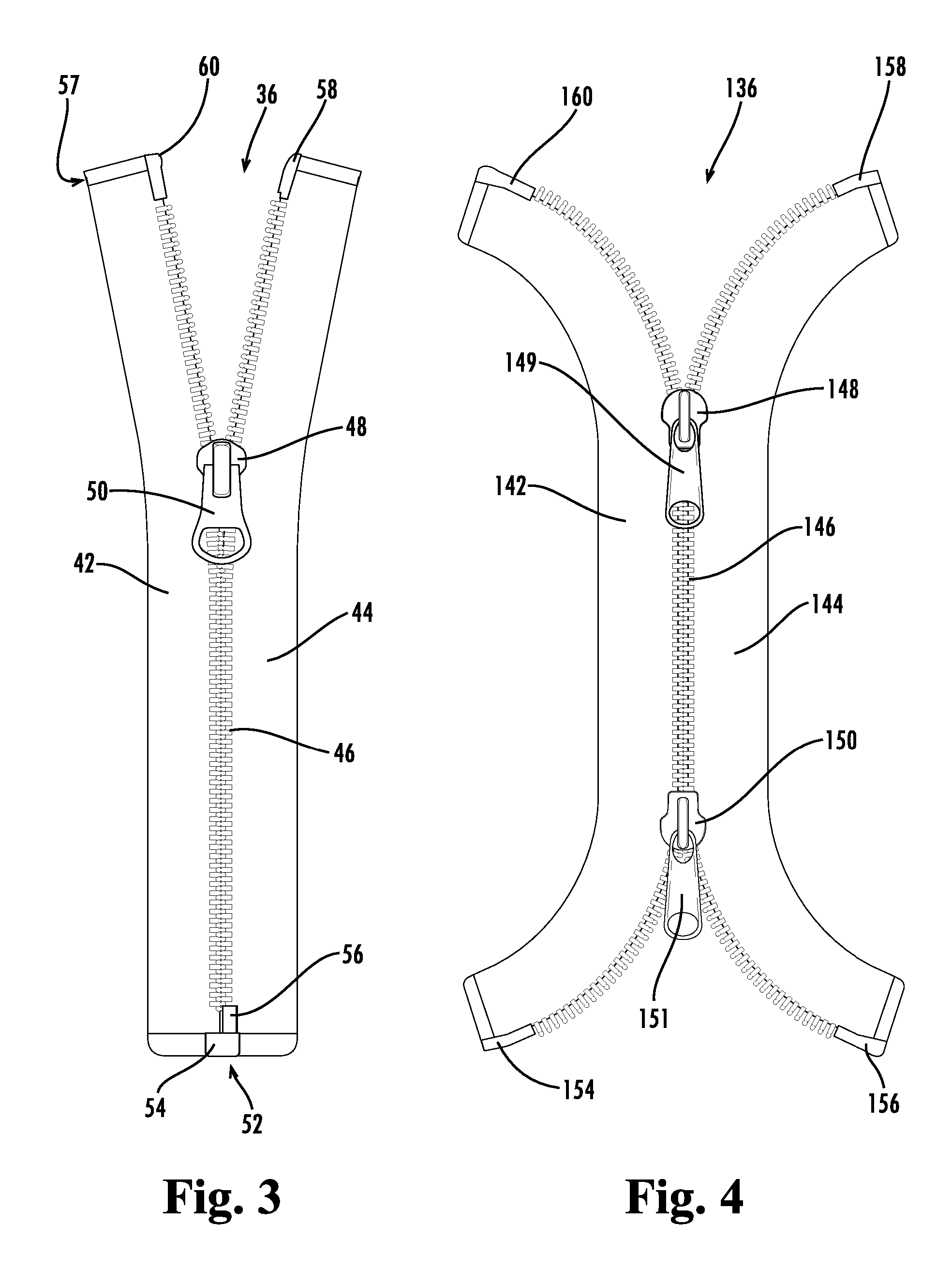

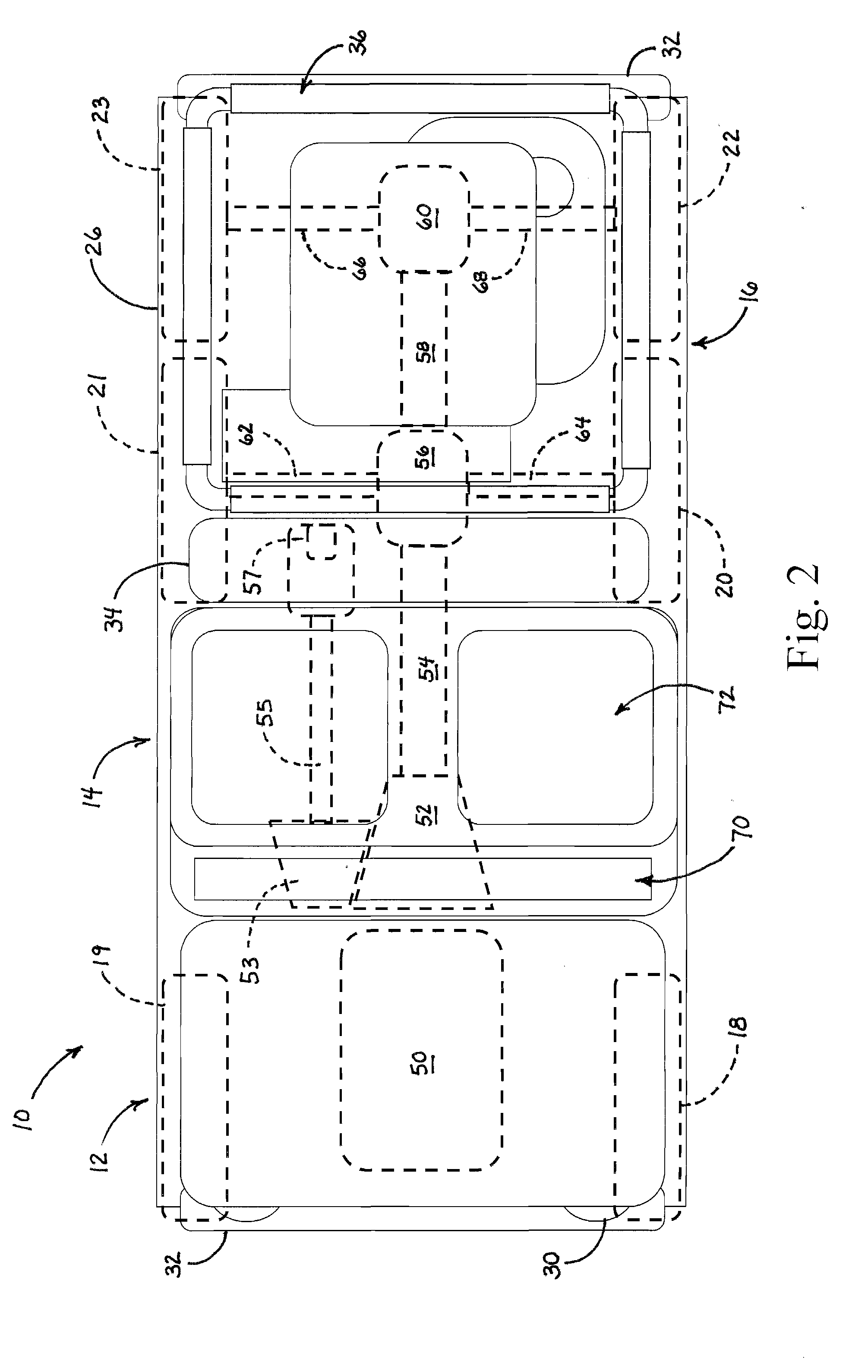

Convertible luggage and a reversible panel therefor

InactiveUS20070137959A1Gain of functionChange functionHandbagsLuggageBiomedical engineeringFace sheet

Convertible luggage, such as a suitcase, purse, briefcase, backpack, etc. includes a body and a detachable and reversible panel having a first face and a second face having a different appearance than the first face. The detachable and reversible panel can be securely attached to at least a portion of the body such that in at least a first configuration with the first face facing out and in at least a second configuration with the first face facing in and the second face facing out. Moreover, the detachable and reversible panel can create a pocket for housing items therein.

Owner:ZAUDERER KAREN B

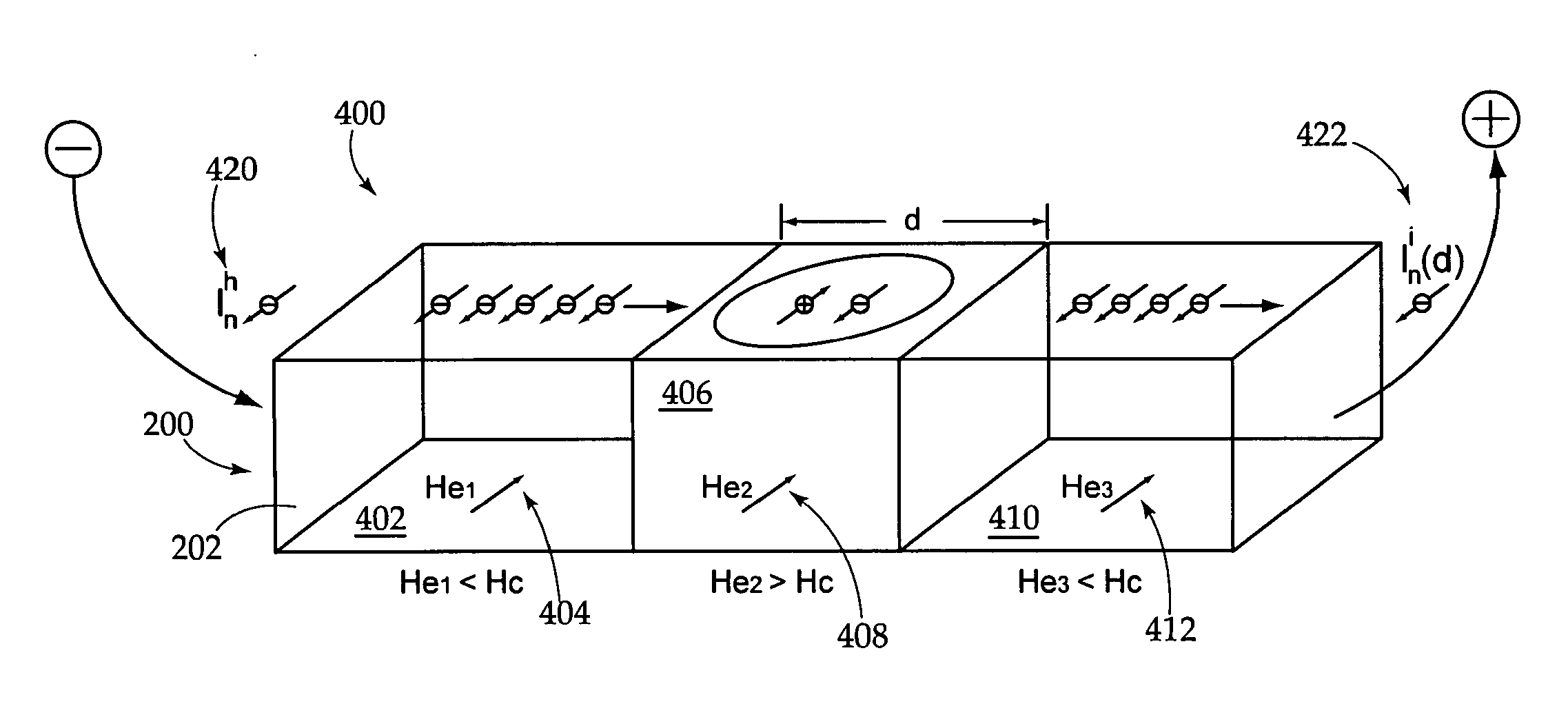

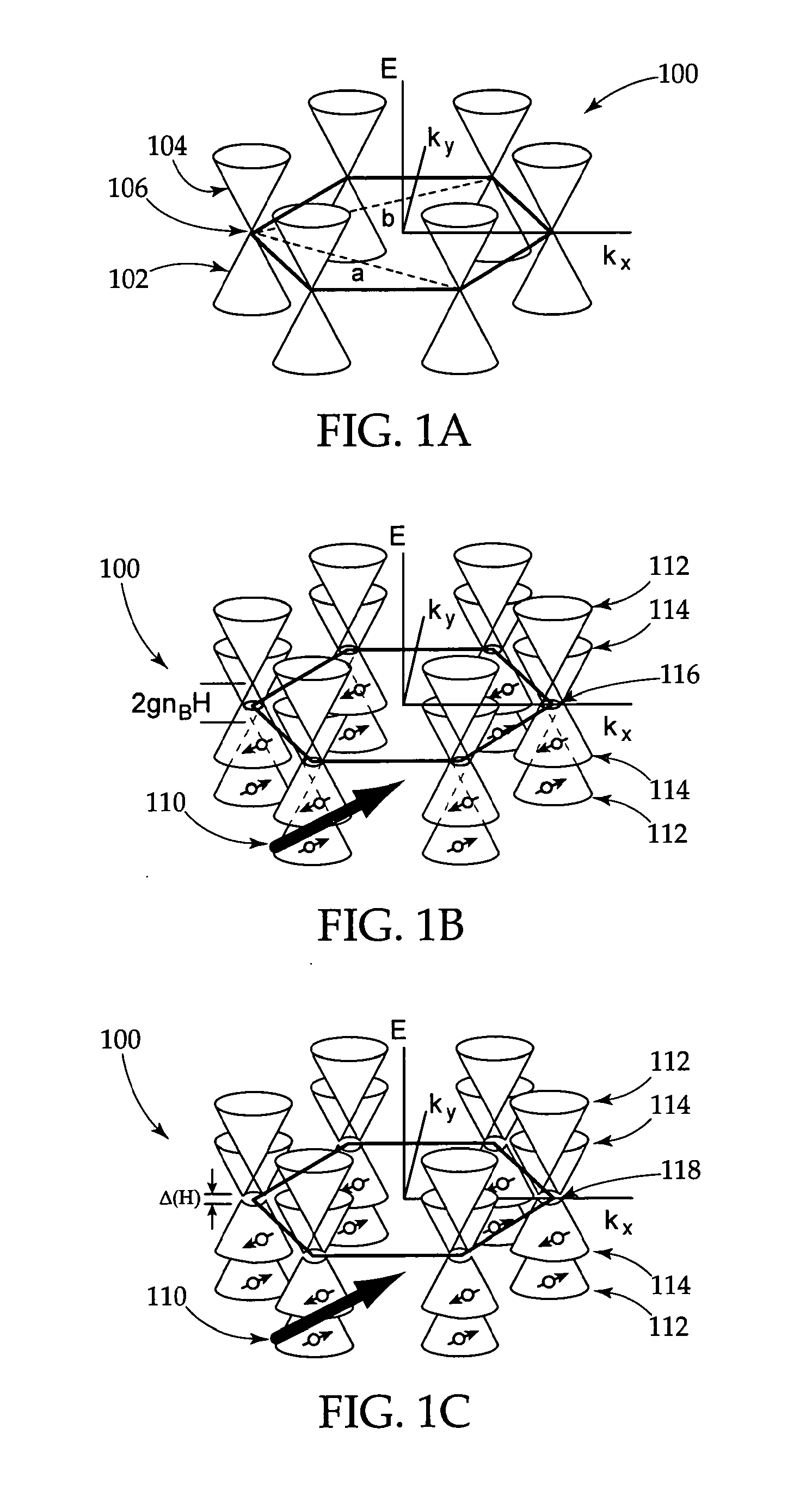

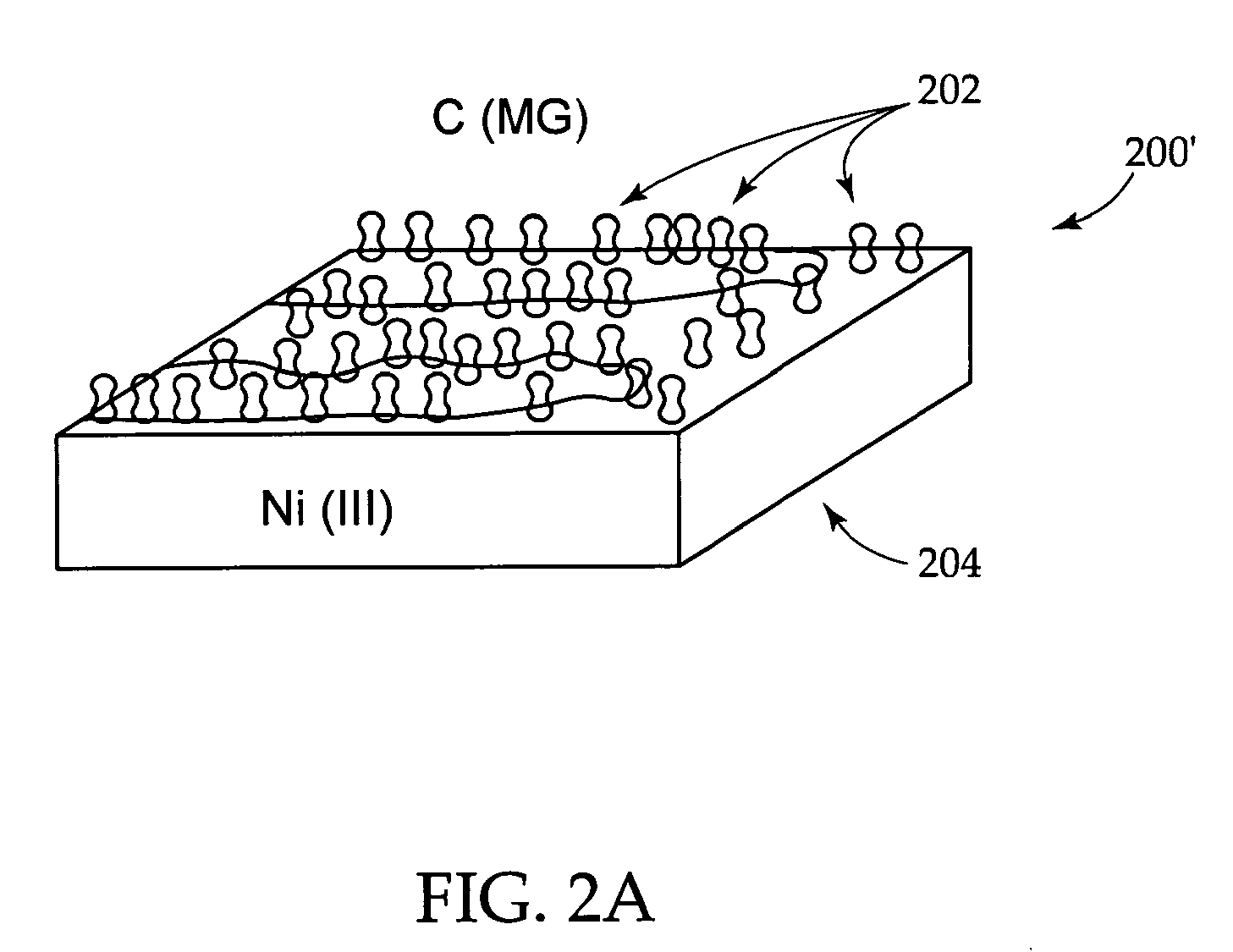

Nanodevices for Spintronics and Methods of Using Same

Graphene magnet multilayers (GMMs) are employed to facilitate development of spintronic devices. The GMMs can include a sheet of monolayer (ML) or few-layer (FL) graphene in contact with a magnetic material, such as a ferromagnetic (FM) or an antiferromagnetic material. Electrode terminals can be disposed on the GMMs to be in electrical contact with the graphene. A magnetic field effect is induced in the graphene sheet based on an exchange magnetic field resulting from a magnetization of the magnetic material which is in contact with graphene. Electrical characteristics of the graphene can be manipulated based on the magnetization of the magnetic material in the GMM.

Owner:BROOKHAVEN SCI ASSOCS

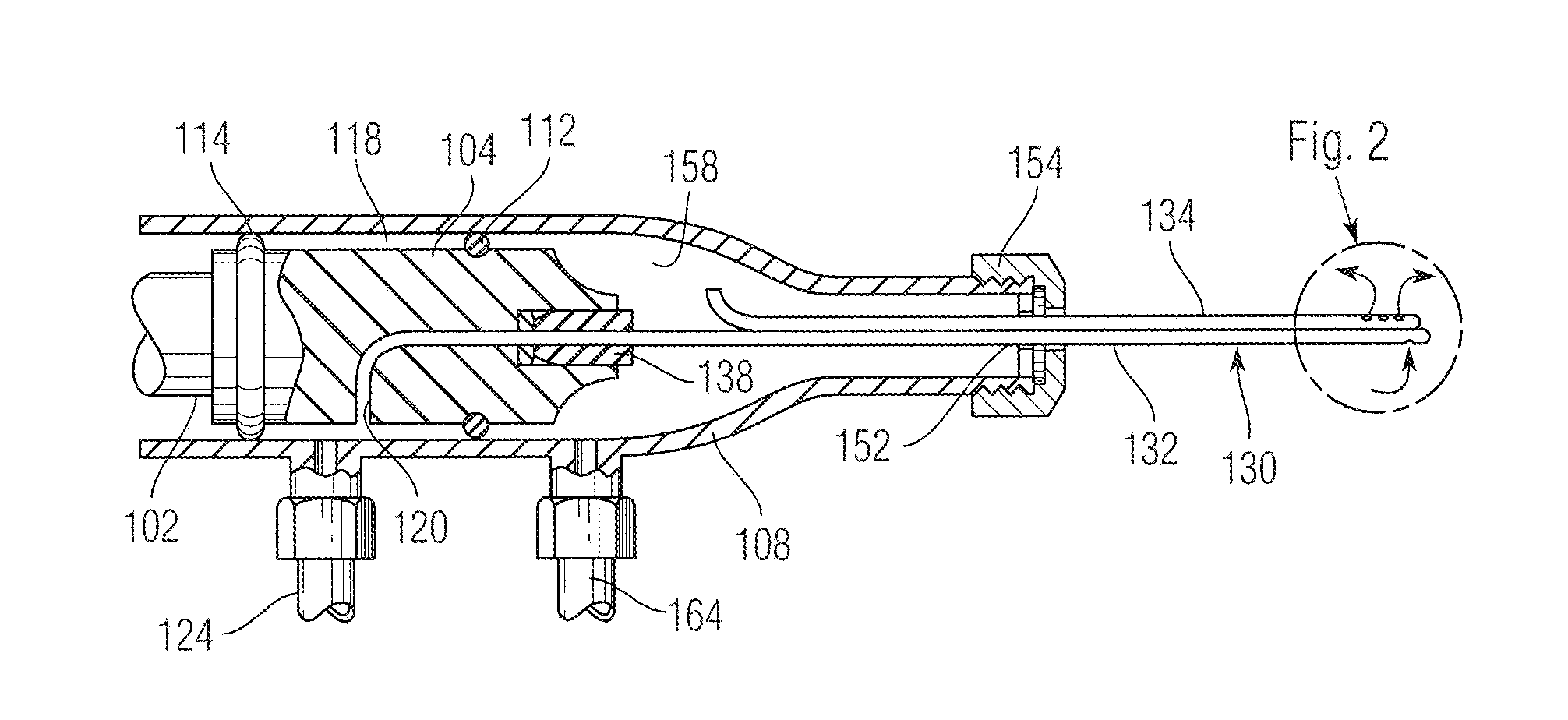

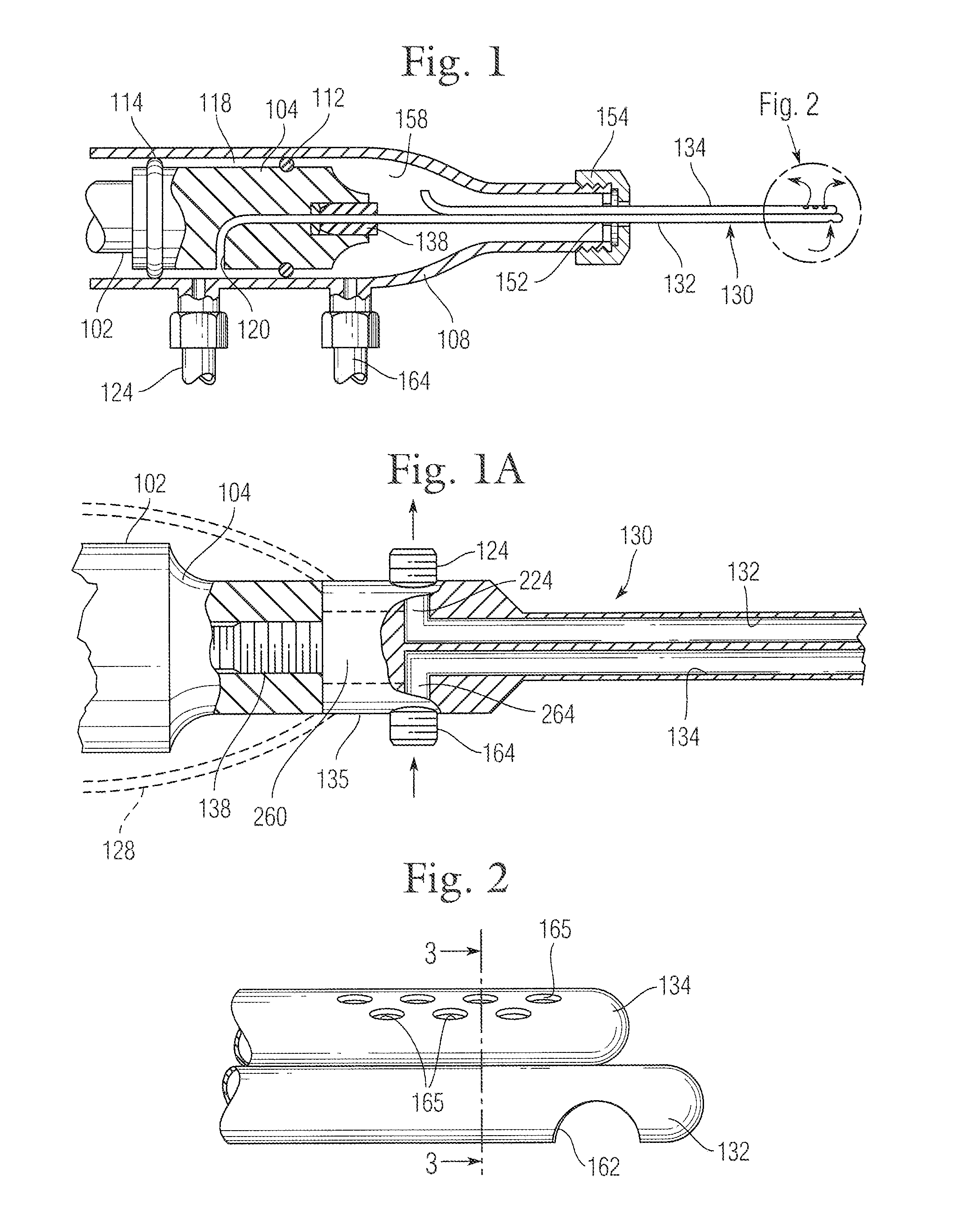

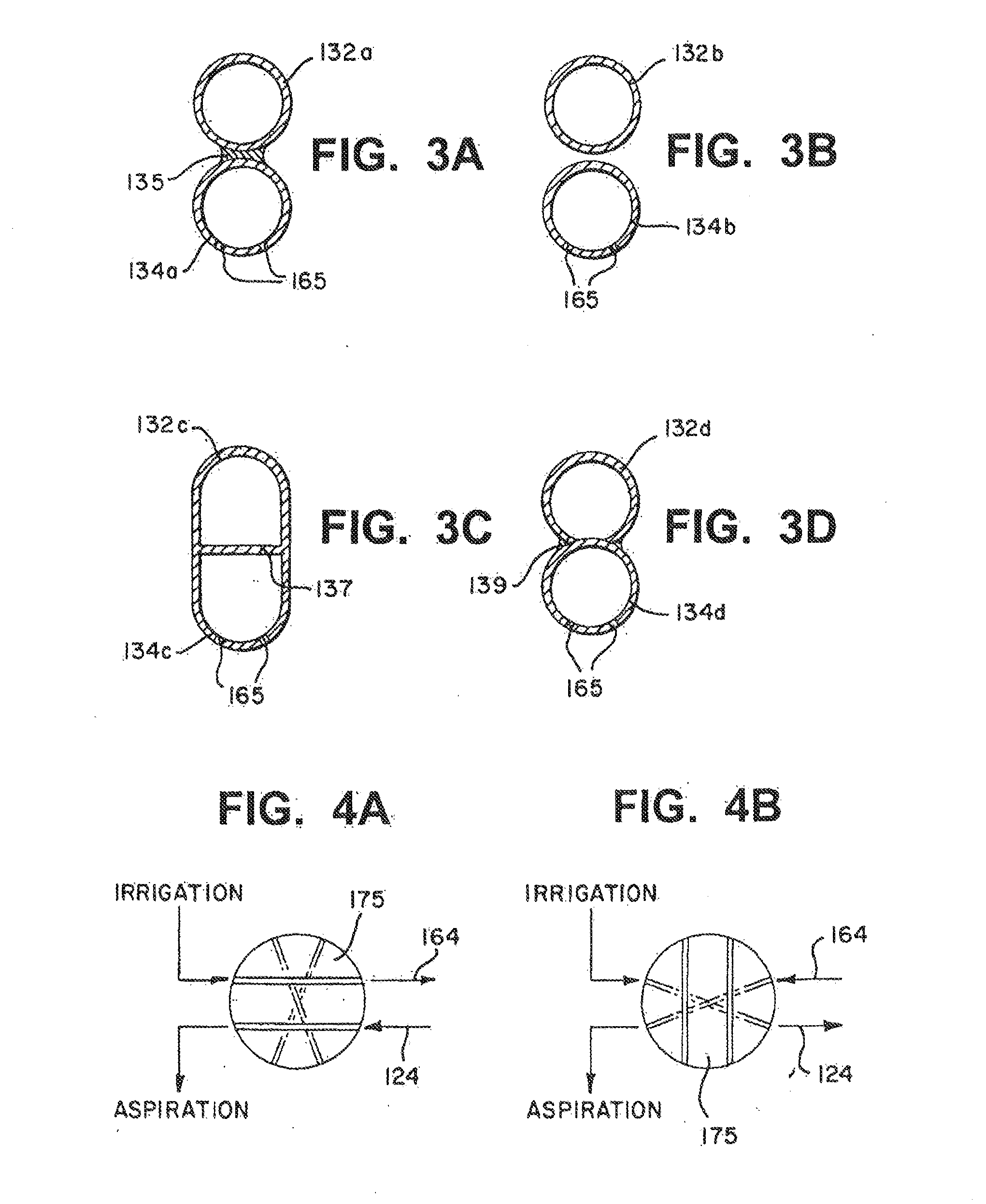

Surgical hand piece with rotatable dual lumen work tip

A surgical hand piece has a connecting body having first and second passages detachably connected to first and second lumens which are used in the eye for phacoemulsification procedures and / or cleanup of the eye capsule after the procedure. The lumens receive or discharge fluid from first and second fluid sources. A work tip supporting the first and second tubes can be rotated so as to change the function of the first and second tubes from aspiration to irrigation and vice versa. As an alternative, a sleeve holding the fluid sources can be rotated so as to change the function of the first and second tubes from aspiration to irrigation and vice versa.

Owner:SURGICAL DESIGN

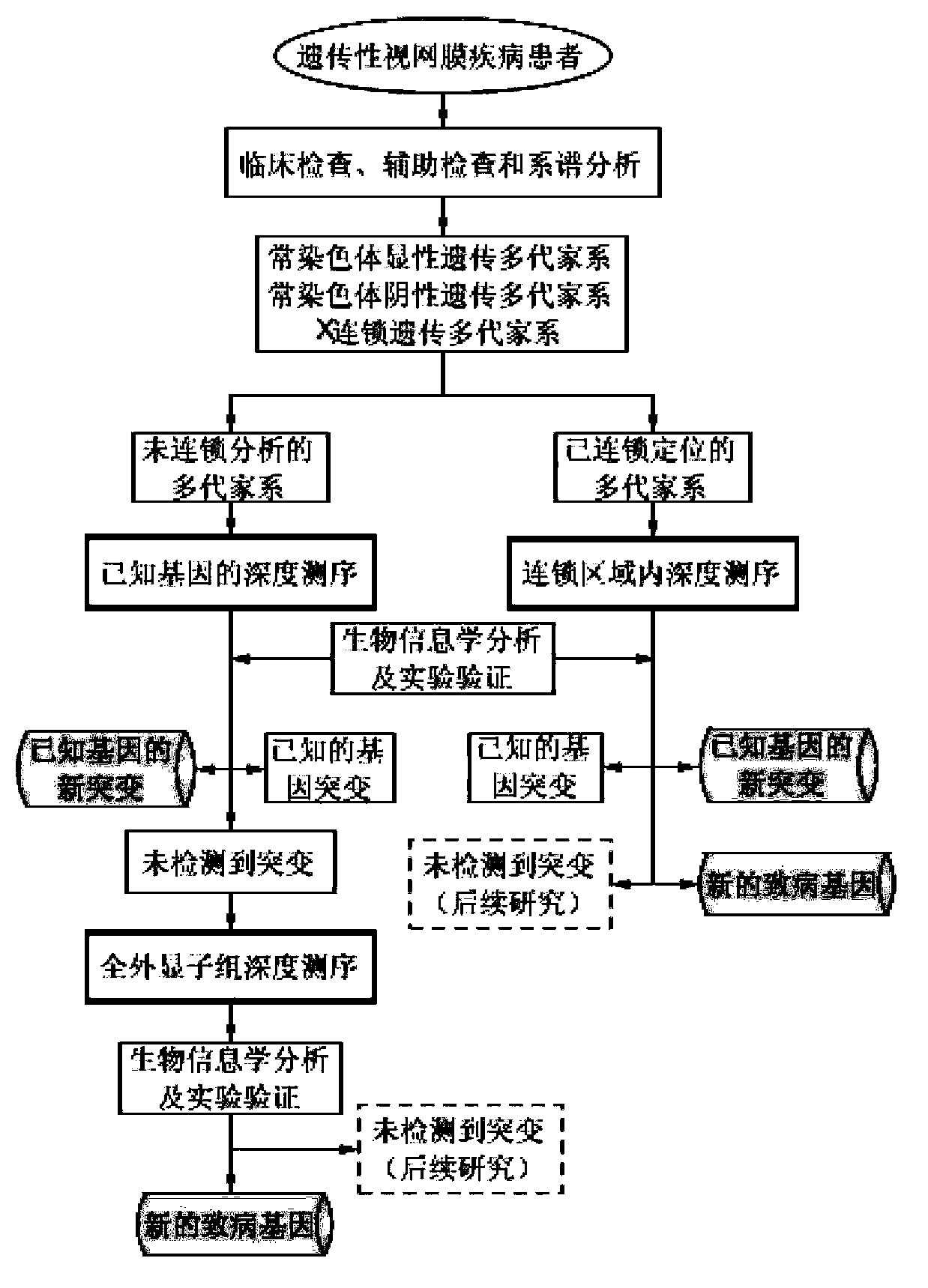

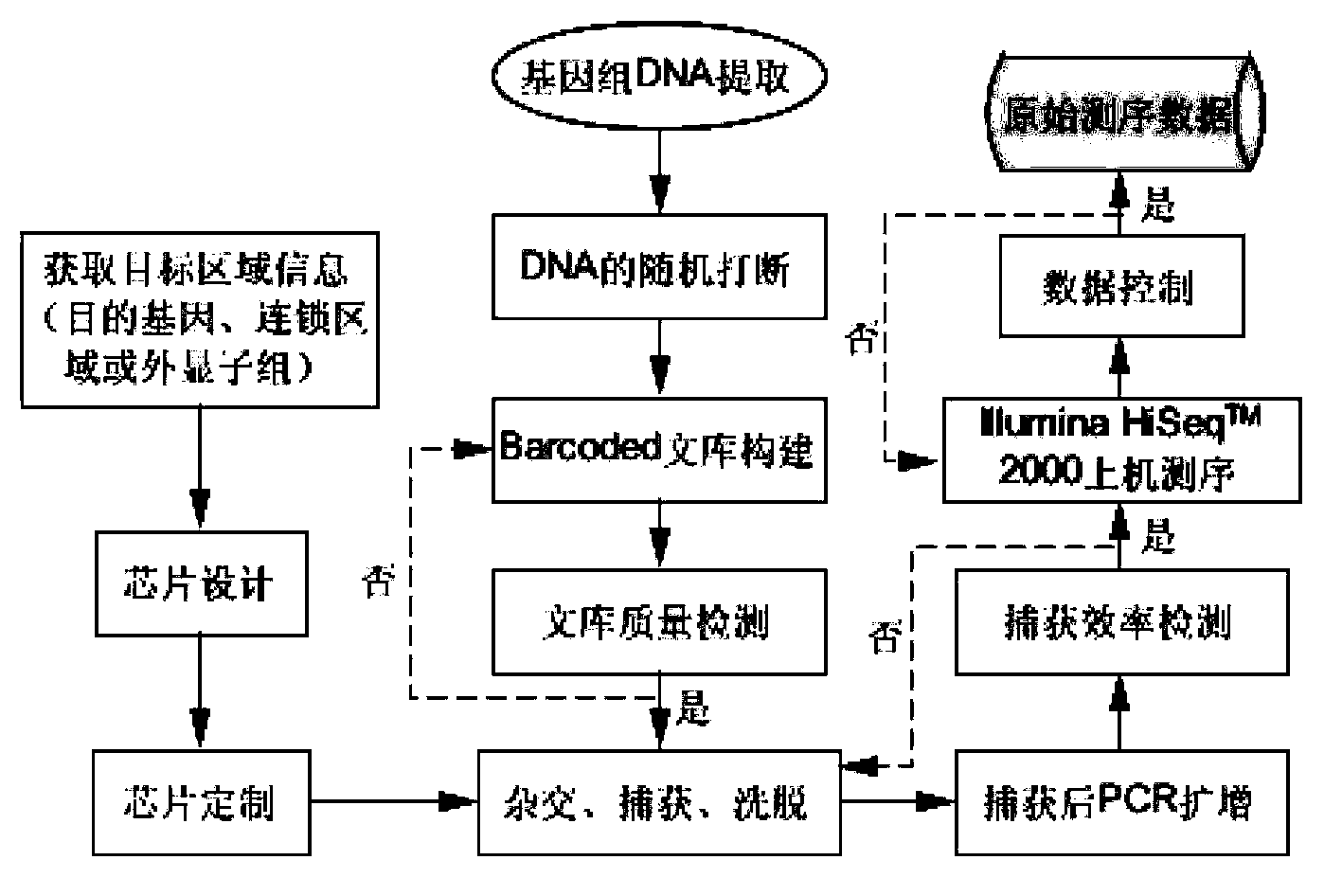

Method for screening HRDs disease-causing mutation and gene chip hybridization probe designing method involved in same

ActiveCN103667438AClear relationshipScreening benefits are highMicrobiological testing/measurementDNA preparationDiseaseHybridization probe

The invention belongs to the field of biological medicines, and relates to a method for screening HRDs disease-causing mutation and a gene chip hybridization probe designing method involved in the same. The method for screening the HRDs disease-causing mutation comprises the steps of (1) establishing an HRDs genetic resource repository; (2) designing and synthesizing a gene chip hybridization probe of an HRDs disease-causing gene, and integrating the gene chip hybridization probe onto a gene chip; (3) capturing a target area by utilizing the prepared gene chip and executing the depth sequencing; (4) analyzing the sequencing data on the aspect of bioinformatics, and screening the candidate disease-causing gene; (5) functionally predicting a newly-discovered splicing gene mutation site. By establishing the high-efficient HRDs target gene capturing technology, adopting the depth sequencing as a means and confirming the efficiency of the HRDs capturing chip, a high-efficient credible biological information analysis model is established.

Owner:赵晨

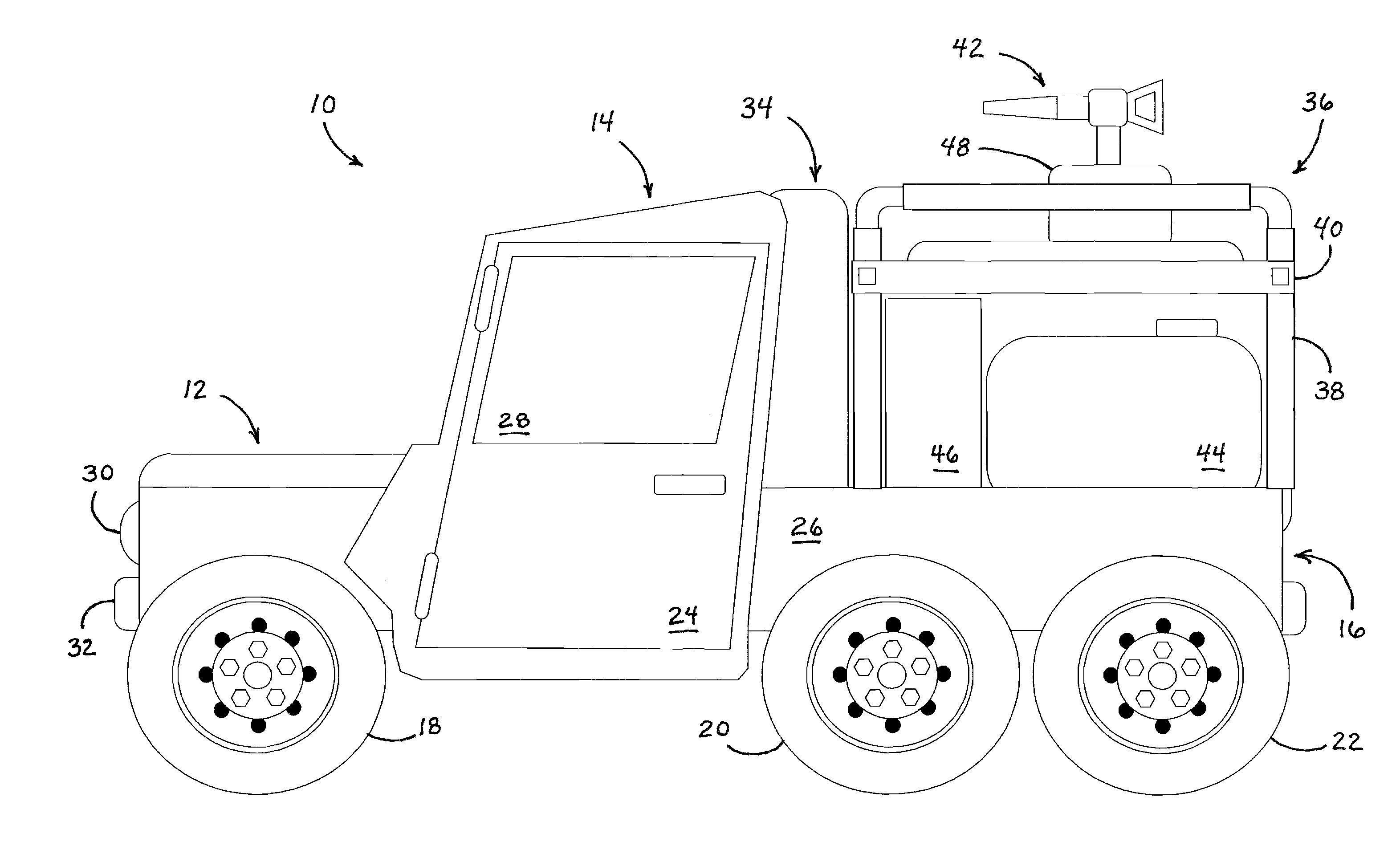

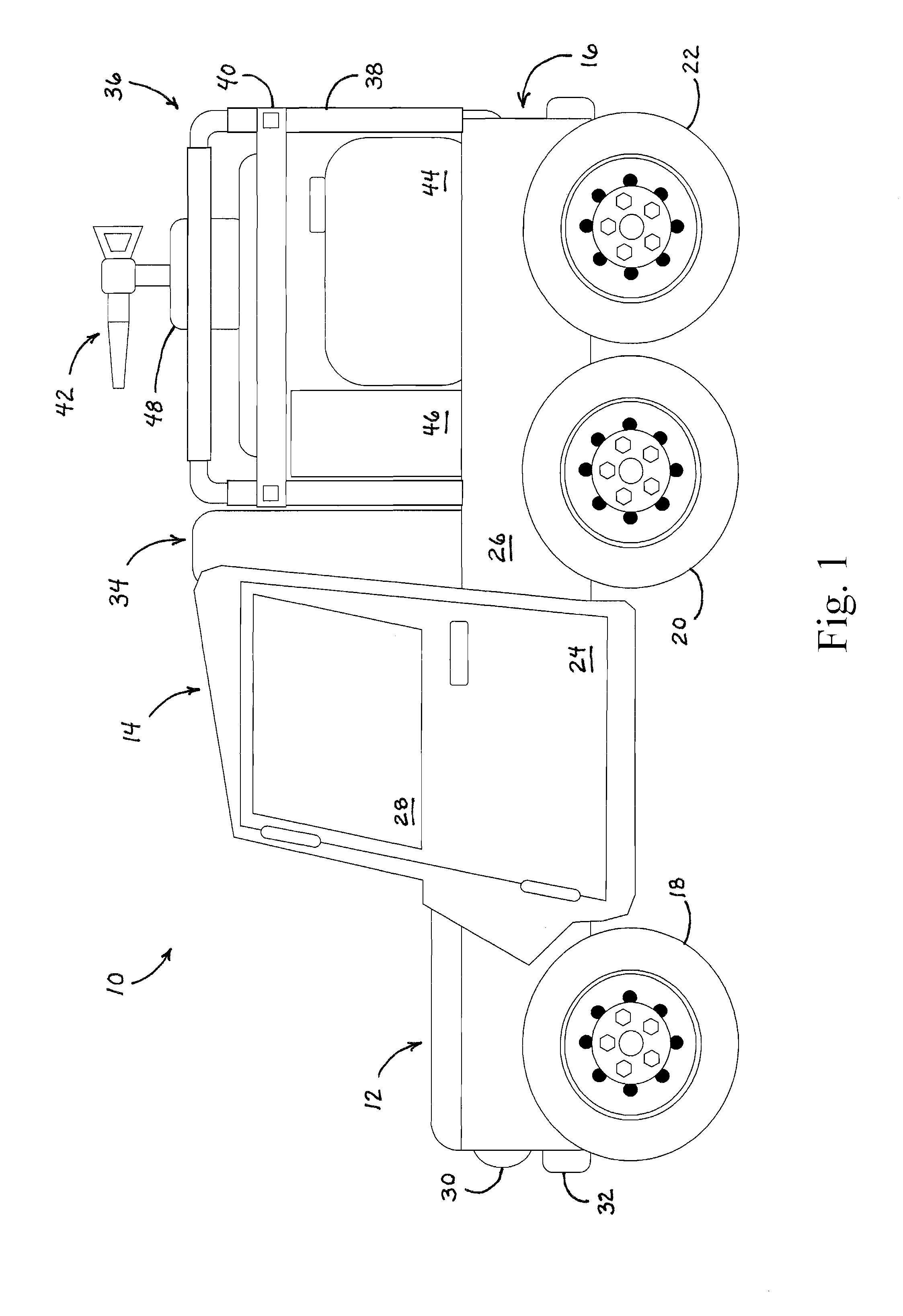

Vehicle for Fire Control and Fire Rescue Operations in Extreme Wildlands

A mid-sized firefighting and fire rescue vehicle capable of accessing a range of off-road wildland environments that is also “street legal” for rapid on-road transportation. The vehicle is configured to be outfitted as needed with any of a variety of different firefighting or fire rescue systems packaged as removable modules, fixed in place in the bed of the vehicle. The vehicle achieves stability and ruggedness through the use of three military type axles, two of which (the rear axles) are both drive axles. The vehicle is further configured with an open bed structured to receive, position, and retain an integrated, modularly structured, firefighting or fire rescue system in such a manner as may be switched out with alternate systems as required for the type of service into which the vehicle is called. The vehicle has a narrow gauge (width) that allows it to access remote and obstructed areas but is still large enough to adequately carry personnel and equipment safely to and from most wildland fire environments. The bed of the vehicle utilizes a quick load and unload system that includes either rails or alignment guide posts in a manner that allows the user to quickly change the vehicle's primary function.

Owner:WILSON ROBERT H

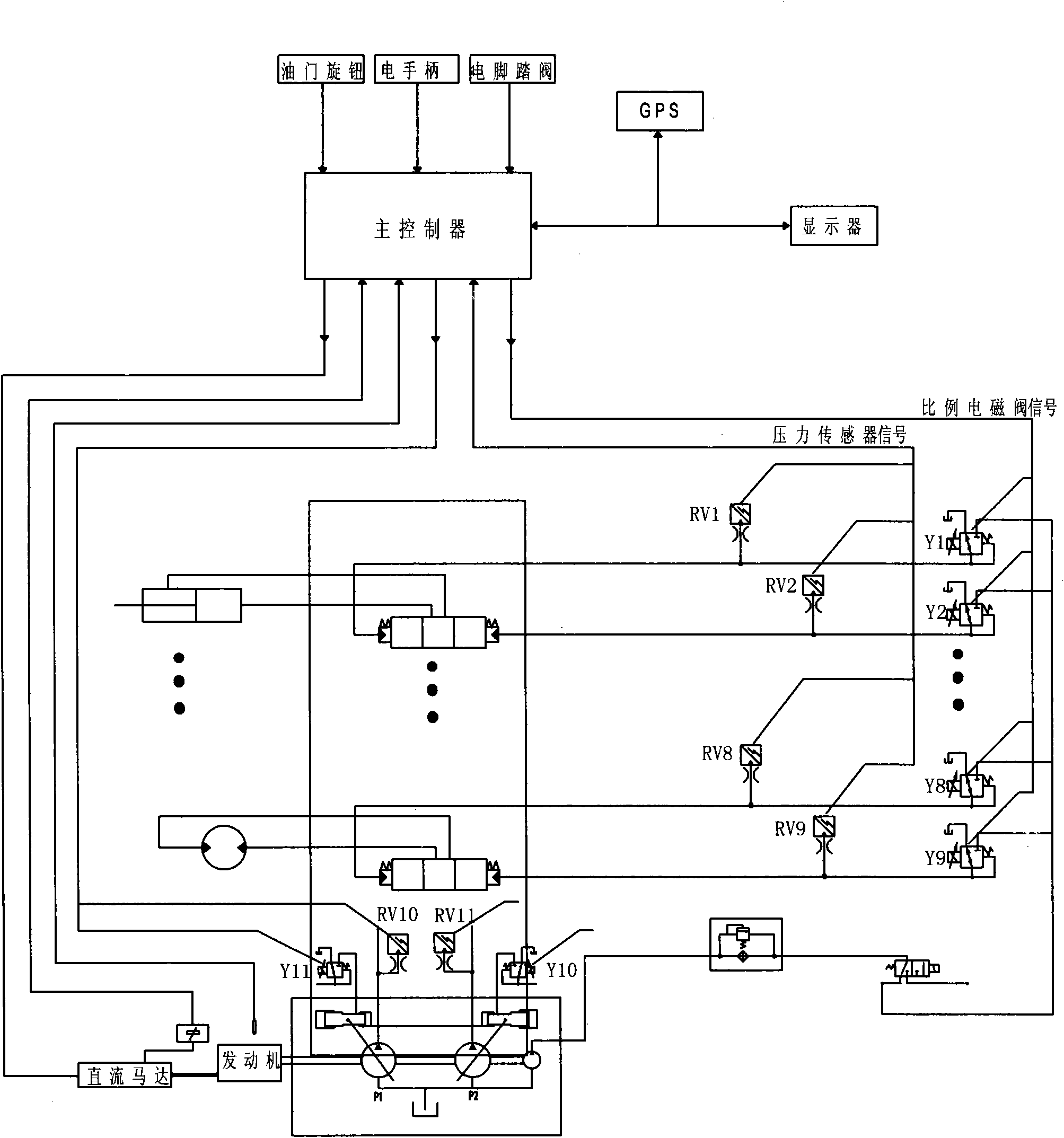

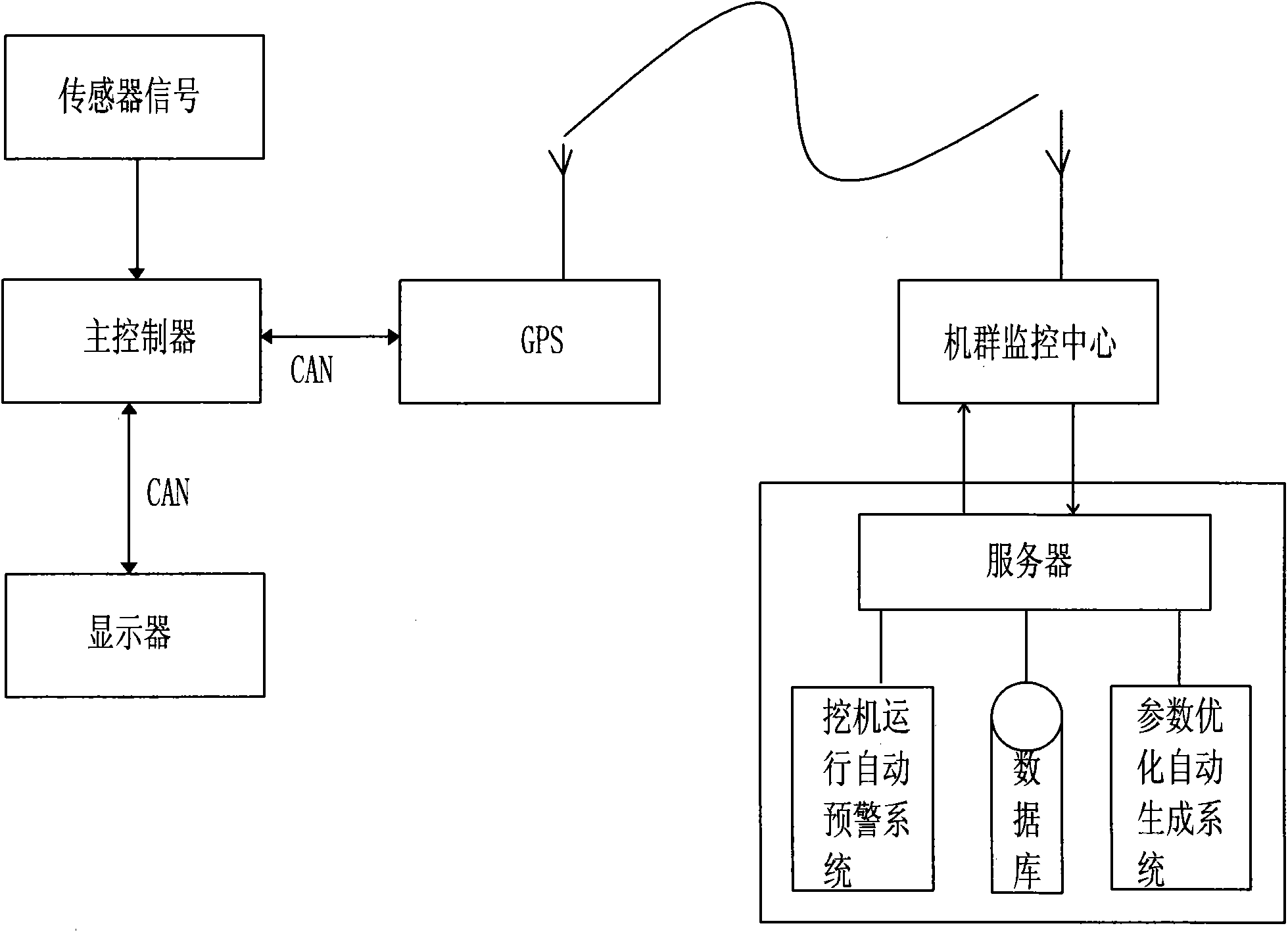

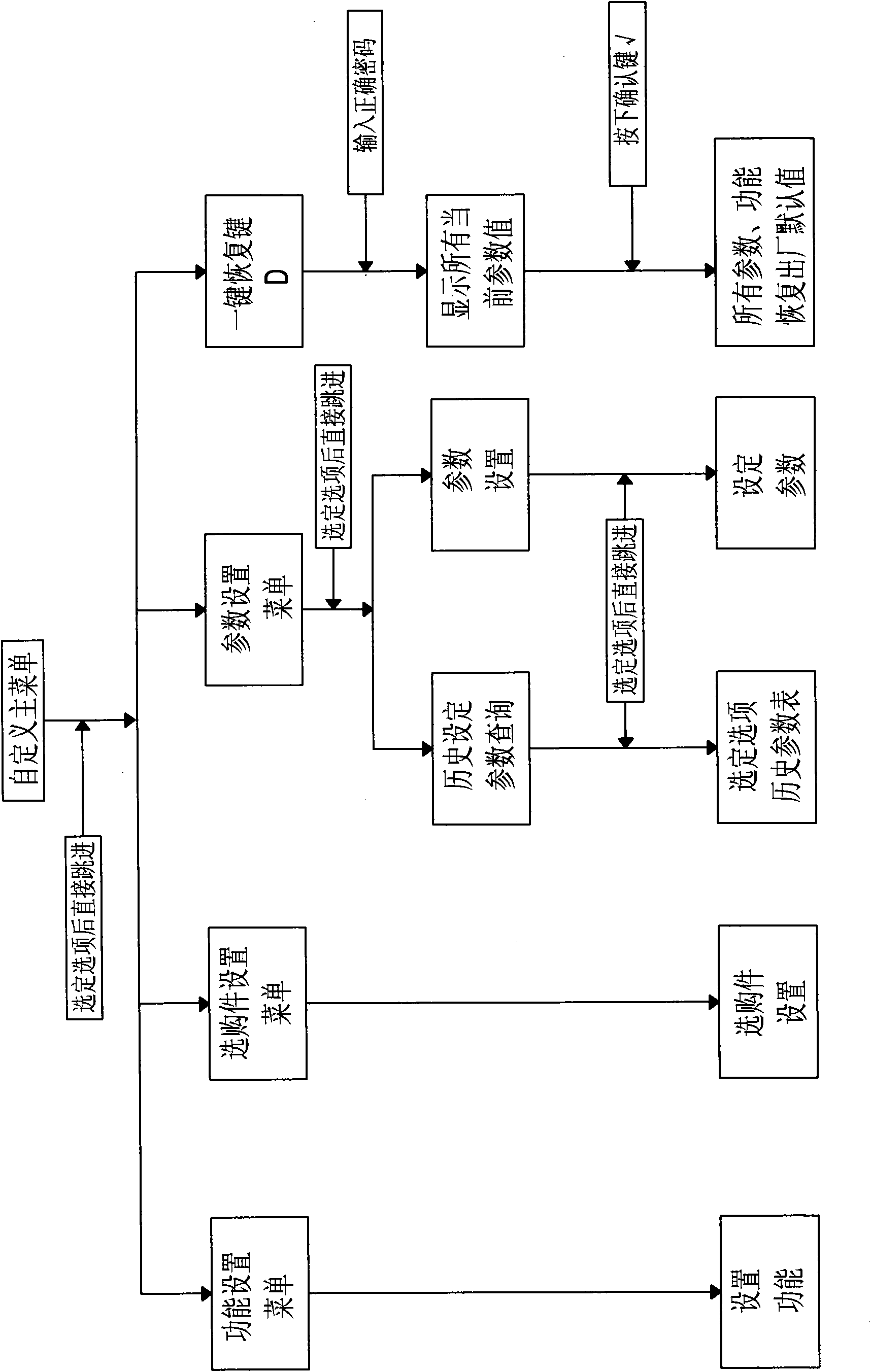

Intelligent control method for hydraulic excavator

InactiveCN101864780AImprove handlingImprove workabilityProgramme controlMechanical machines/dredgersLogical operationsEngineering

The invention discloses an intelligent control method for a hydraulic excavator. The method is characterized in that: a database set in a main controller is divided into a setting area and a recovery area; and the main controller is connected with a display modification interface through a CAN bus, wherein the operation method of the main controller comprises the following steps of: a. data modification, namely (1) the main controller detects data and obtains regulating ranges of excavator control parameters and engine output power by a logical operation; (2) an operator sets the excavator control parameters and the engine output power in the regulating ranges; and (3) modified self-defining data is stored in the setting area through a CAN bus and an excavator operates according to the data; and b. data recovery, namely the main controller calls the data in a recovery area and covers the self-defining data in the setting area. In the intelligent control method for the hydraulic excavator, data regulating ranges are given according to detected data; and the operator can modify according to implementing working conditions and habits so as to meet the requirements on site environment and user control and contribute to improving the operating performance of the excavator.

Owner:SANY HEAVY MACHINERY

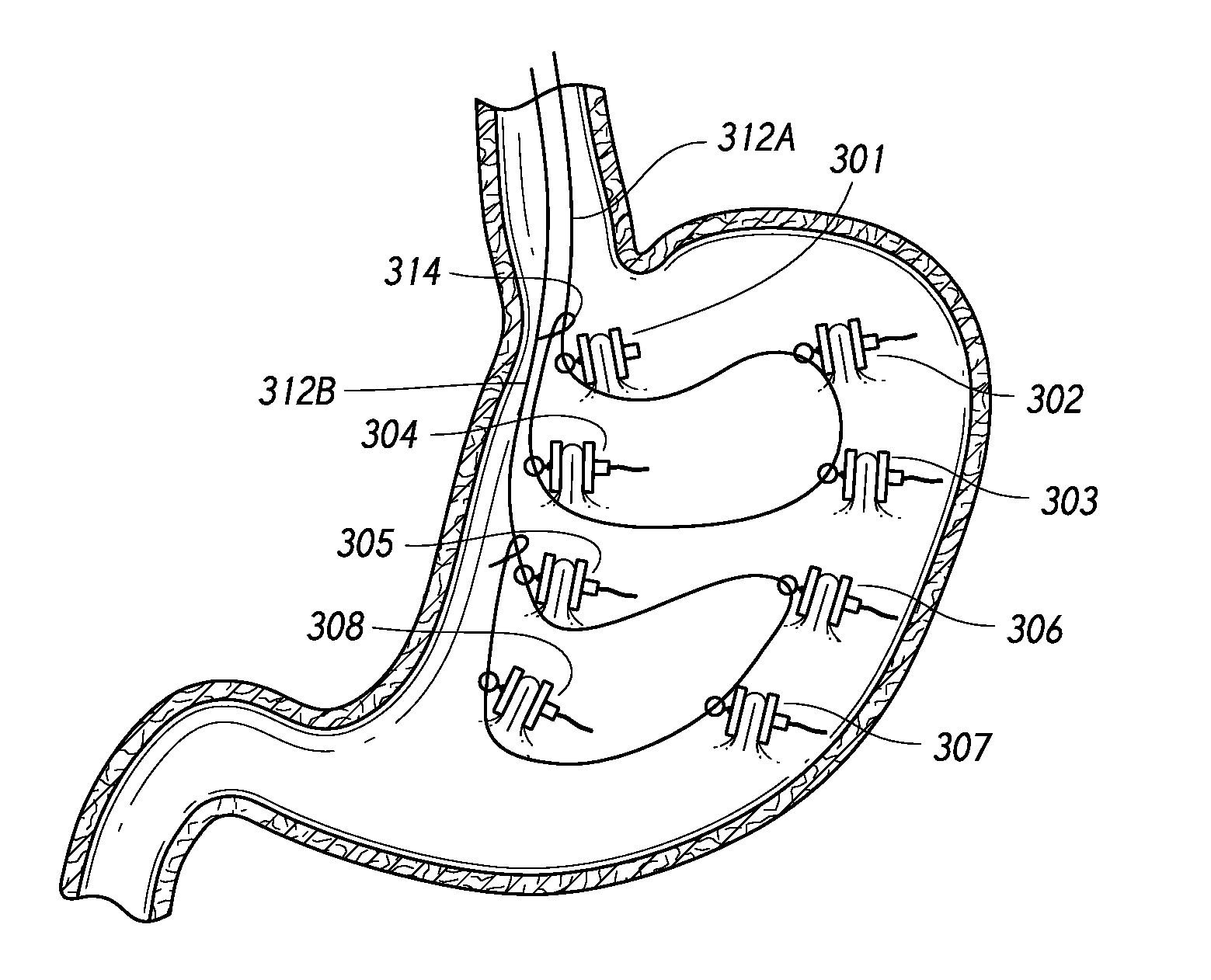

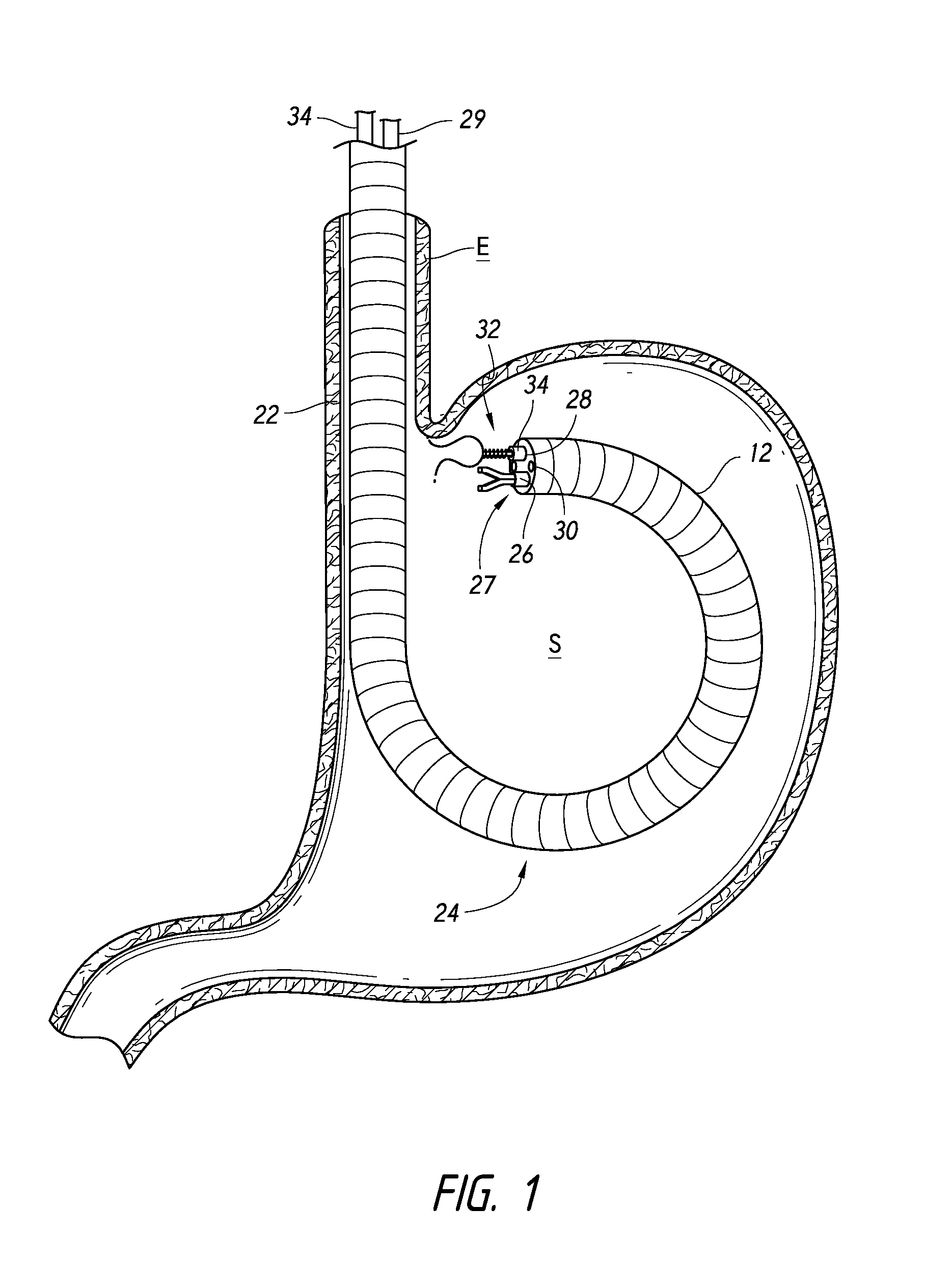

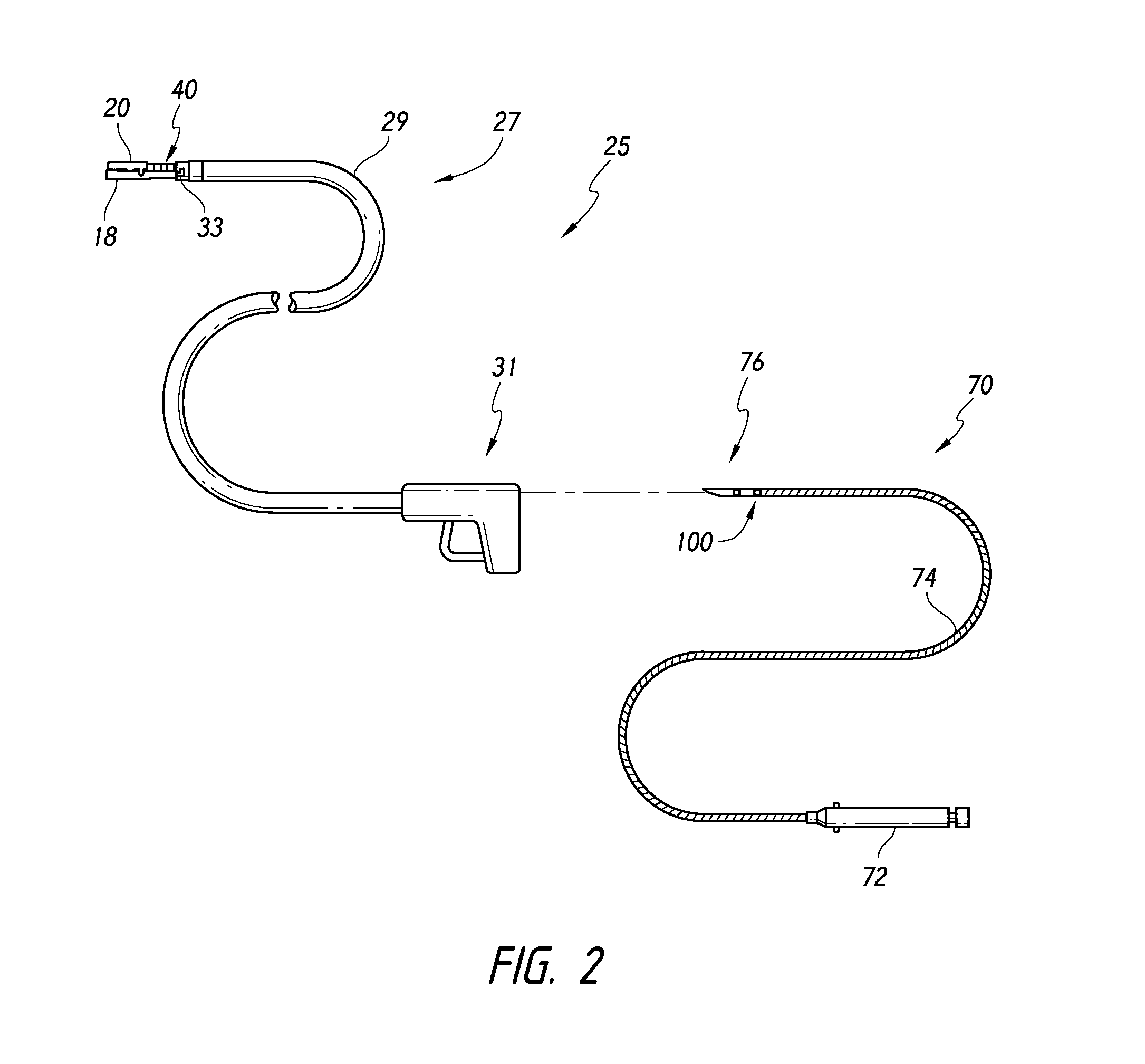

Devices and methods for the endolumenal treatment of obesity

InactiveUS20130217957A1Reducing stomach volumeSimple methodSuture equipmentsObesity treatmentObesitySurgical methods

A surgical method for treating obesity by reducing the size and / or function of the stomach includes forming at least two plications or tissue folds in tissue of a patient using anchor assemblies having a loop. The plications are then optionally allowed to heal. A loop suture or wire is threaded through the loops. The loop suture is then tensioned to draw the plications towards each other. The loop suture is then secured via a knot or a cinch. When the method is performed in the stomach for treatment of obesity, forming the plications reduces the volume of the stomach. Drawing the plications together creates a contracted tissue area which further reduces the volume of the stomach. Additional plications may also be formed and drawn together with the same loop suture, or with a different loop suture.

Owner:USGI MEDICAL

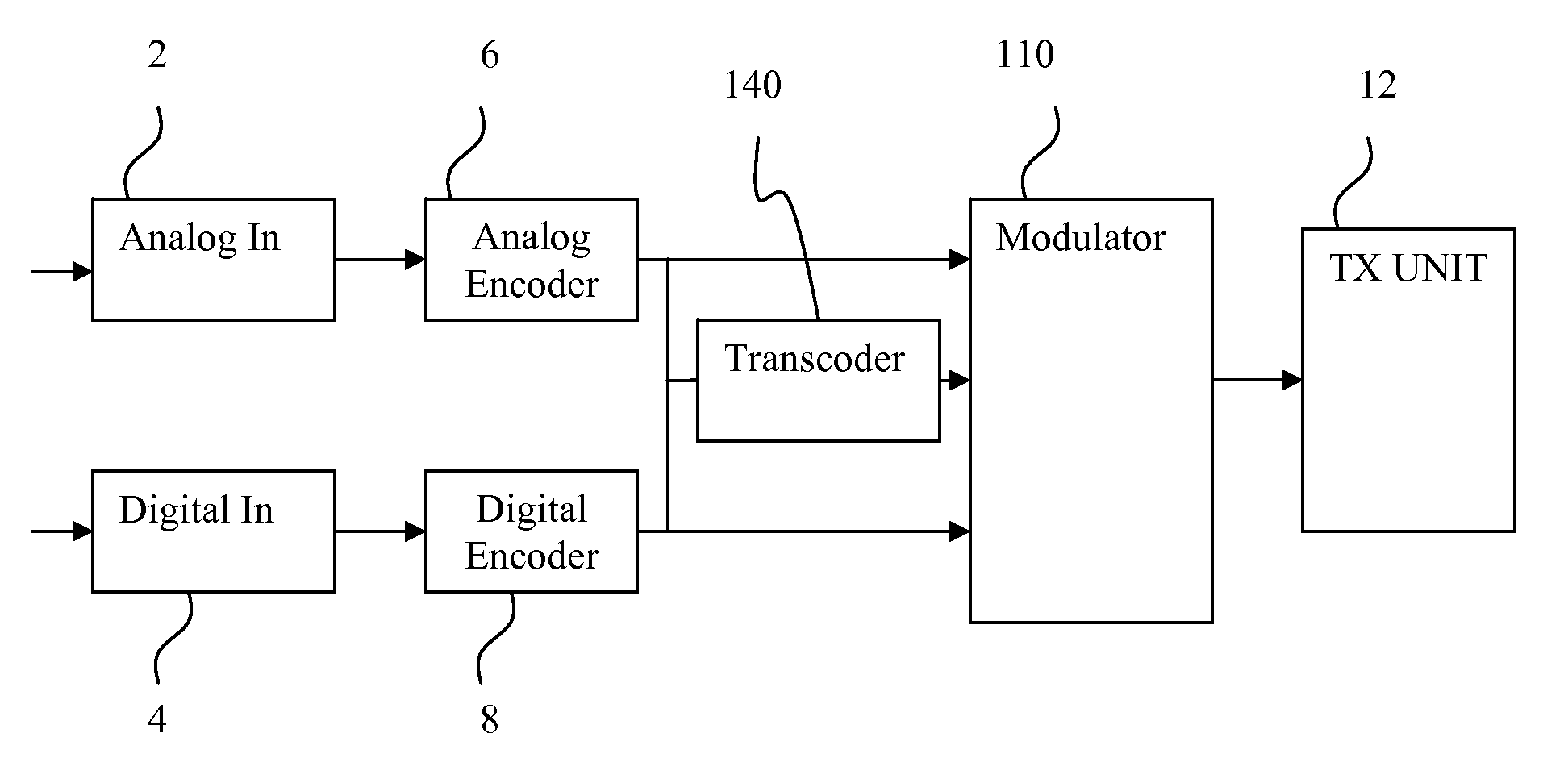

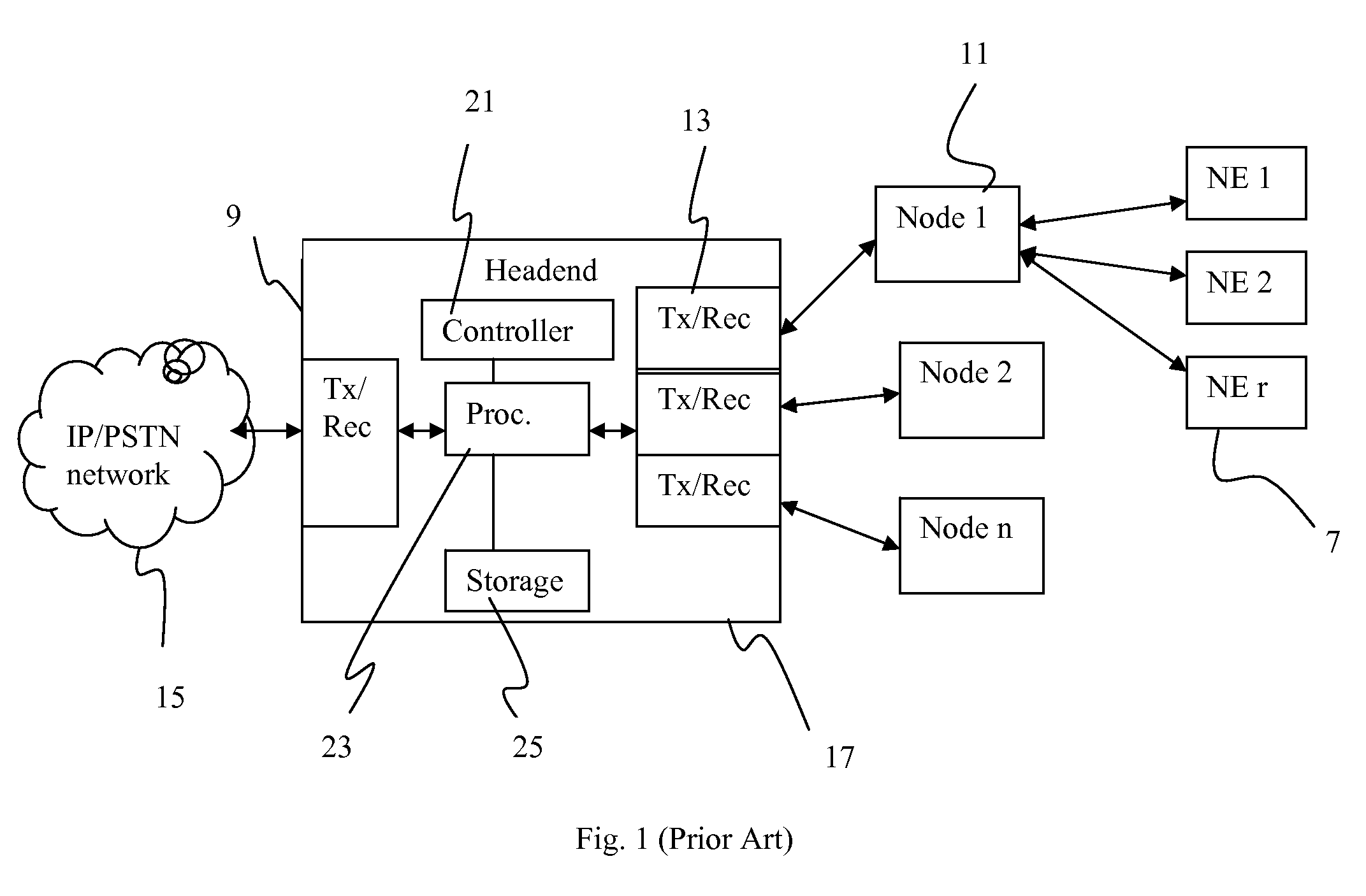

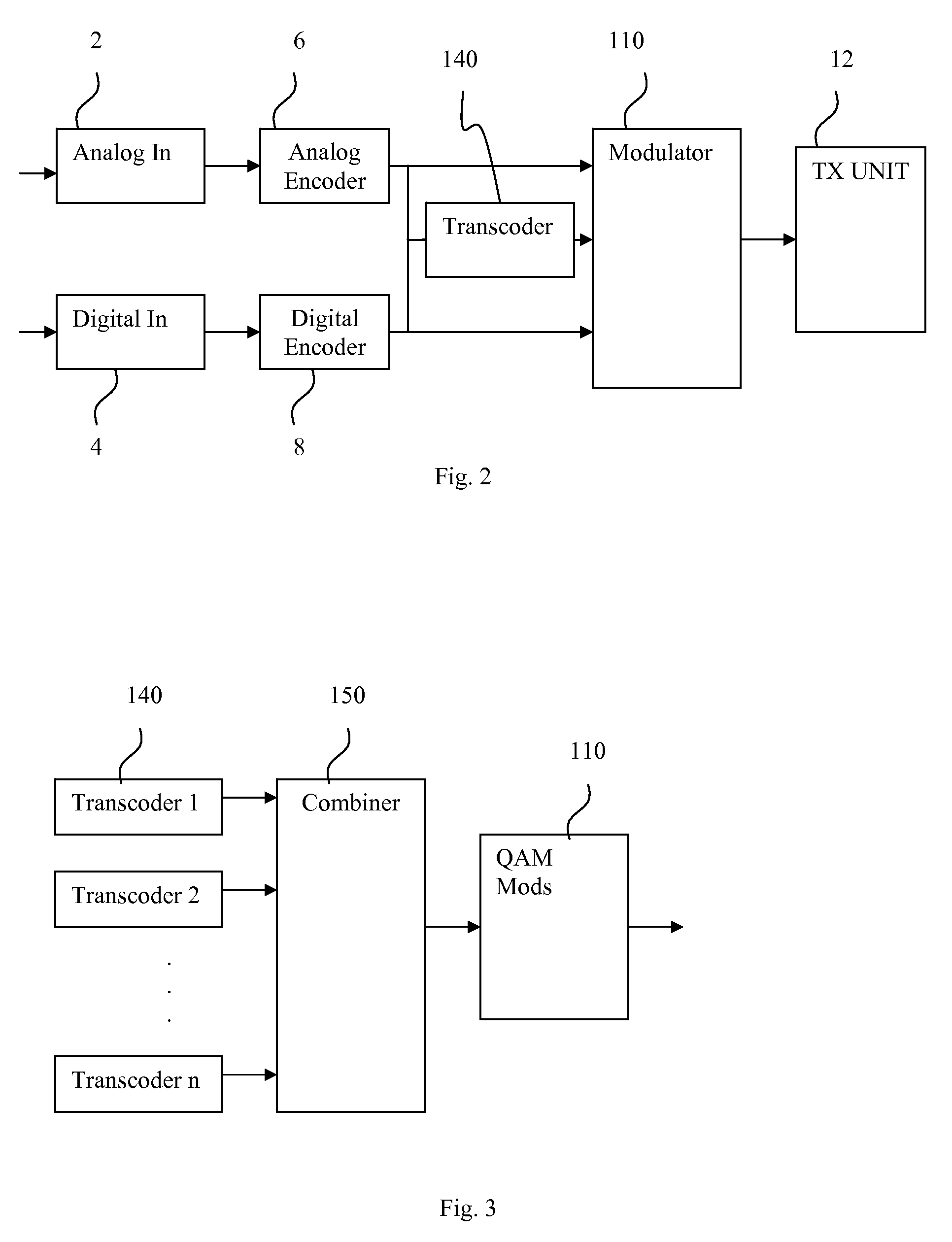

Method and apparatus for providing low resolution images in a broadcast system

ActiveUS8752092B2Change performanceImprove experienceTelevision system detailsPulse modulation television signal transmissionComputer networkImage resolution

Low resolution information streams are combined in a broadcast carrier and broadcast along with full resolution information streams down a television broadcast network. The low resolution streams may be decoded and displayed in mosaic display with multiple images from separate low resolution streams simultaneously displayed. When a user selects a particular channel to be displayed, a low resolution stream associated with the selected channel is displayed (video and audio) while the full resolution stream is processed for display. Once the full resolution stream is available for display, it replaces the low resolution stream. The user perceives a much lower channel change time by viewing the low resolution stream during the channel change delay. The low resolution stream may also be provided directly to a portable media player (PMP) in a low resolution format required for display by the PMP.

Owner:ARRIS ENTERPRISES LLC

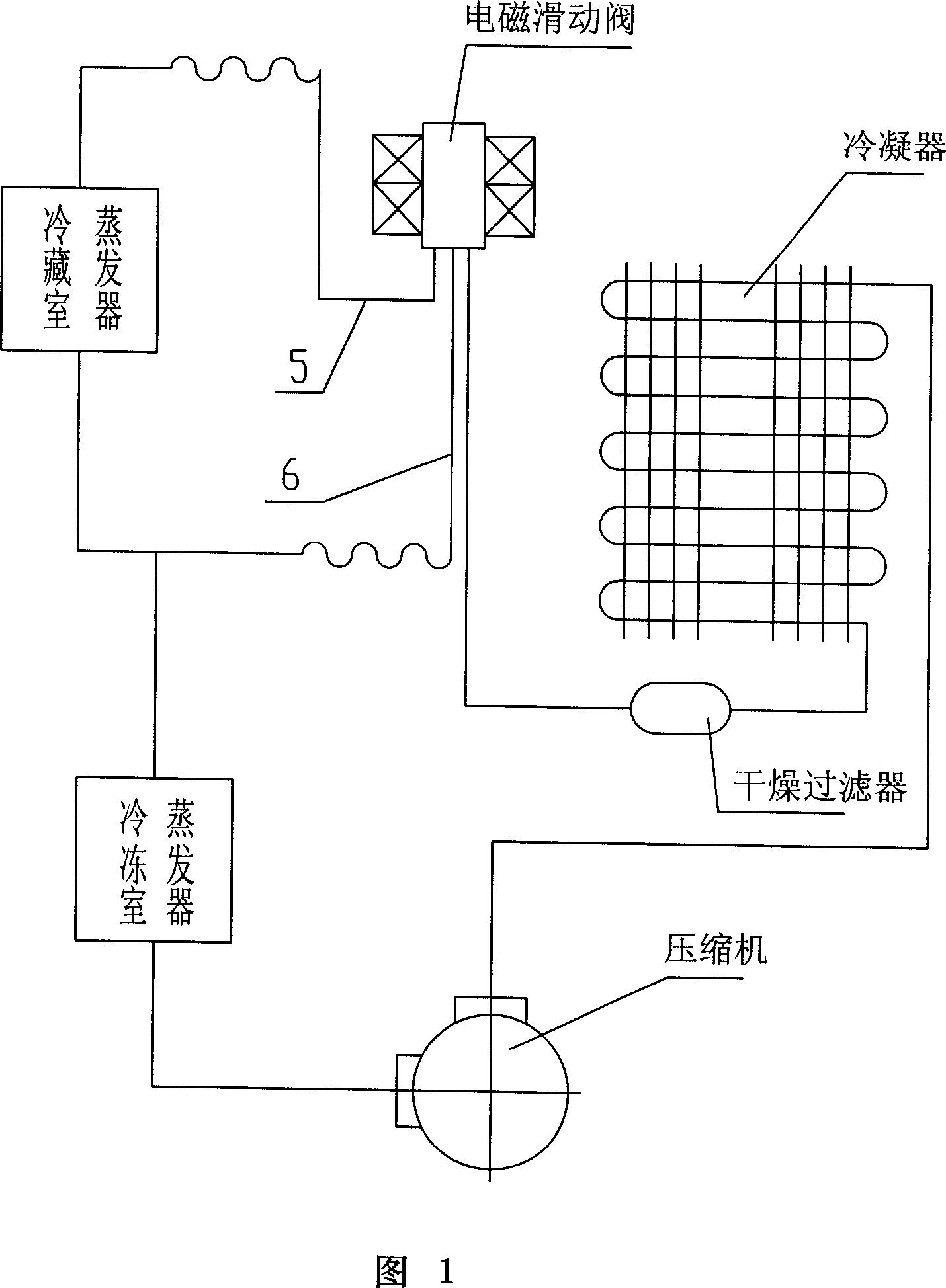

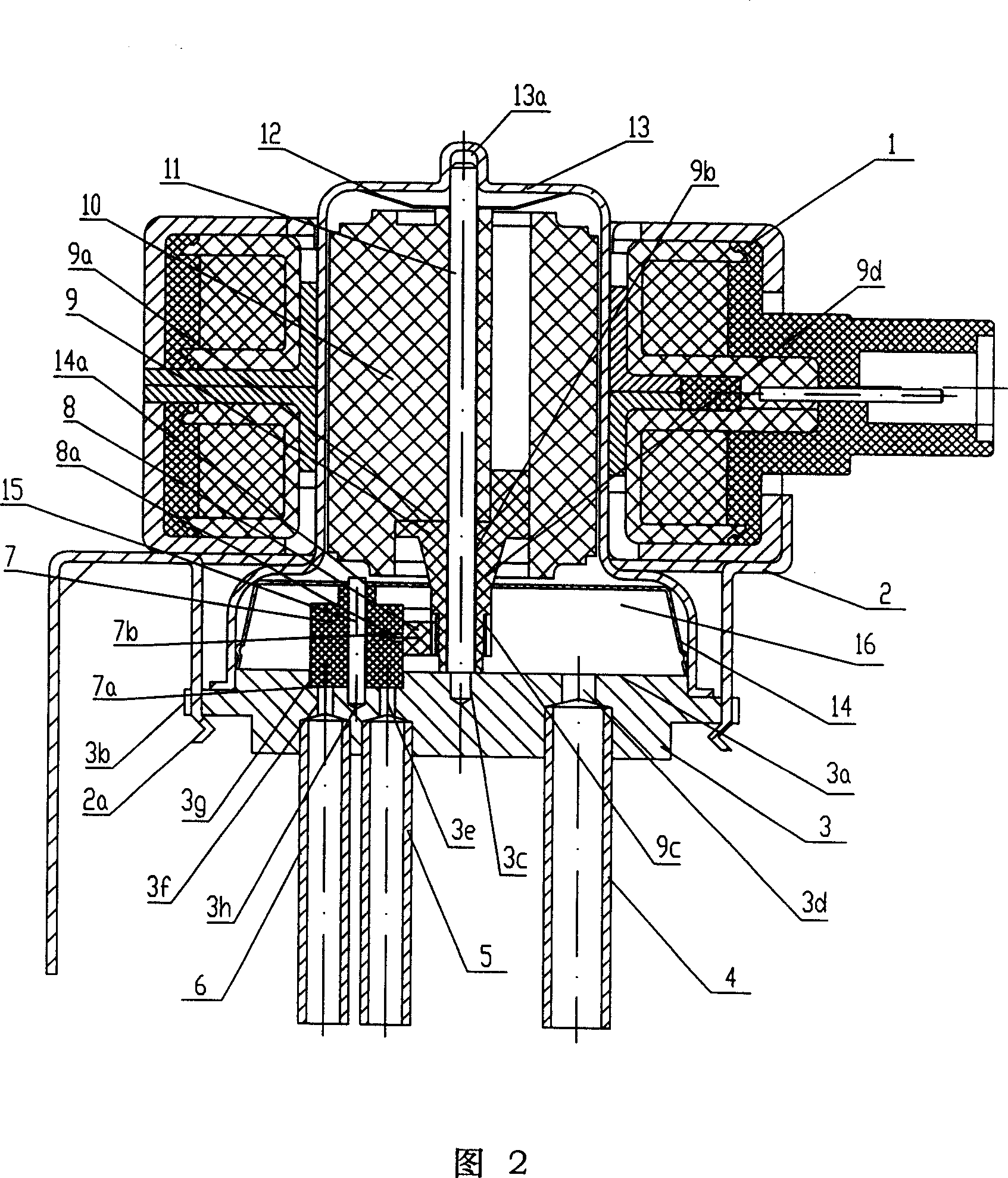

Electromagnetic sliding valve

ActiveCN1952453AReduce noiseReduce vibrationOperating means/releasing devices for valvesMultiple way valvesEngineeringRefrigeration

The invention relates to an electromagnetic sliding valve for frozen and cold storage refrigeration system so as to improve the performance, comprising valve body, valve cavity, one inlet port connected with said valve cavity and two outlet ports set on the flat sealing face of said valve cavity, a stepper motor comprised by stator on the outer shell and rotor in said valve cavity, sliding block for changing the opening-closing status of outlet port, which is driven to move on the said flat sealing face by said rotor. It is characterized in that power is transmitted to said sliding block to move straight so as to change the opening-closing status of outlet by said rotor through rack and pinion mechanism, said sliding block is pretension to said flat sealing face so as to ensure the sealing between sliding block and sealing face by encouragement method. The moving and driving method of sliding block is changed and it is suitable for machining and assembling parts. It is provided with enough designing space for opening design of electromagnetic valve and there is no vibration and noise basically.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Rare earth and carbon co-infiltration method in continuous furnace for automobile gearbox gear

InactiveCN1654700AChange other functionsOsmoticSolid state diffusion coatingHigh concentrationCarbon potential

The continuous micro deformation RE-carbon co-penetrating process for gear of automobile gear box is realized via making the pre-treated workpiece enter the different regions with RE co-penetrant in continuous carbonizing furnace at 840-890 deg.c. The workpiece is made to enter successively region-I for preheating and pre-penetrating; region-II and region-III with carbon potential of 1.15-1.25 % for carbonizing; region-IV with carbon potential of 0.8-1.05 % for diffusion treatment; and region-V with carbon potential of 0.8-1.05 % for waiting for discharging and quenching. The present invention is one controllable low temperature RE high concentration gas carbonizing process capable of resulting in optimal metallurgical structure, and has the advantages of high carbonizing rate, high efficiency and low power consumption.

Owner:HARBIN INST OF TECH

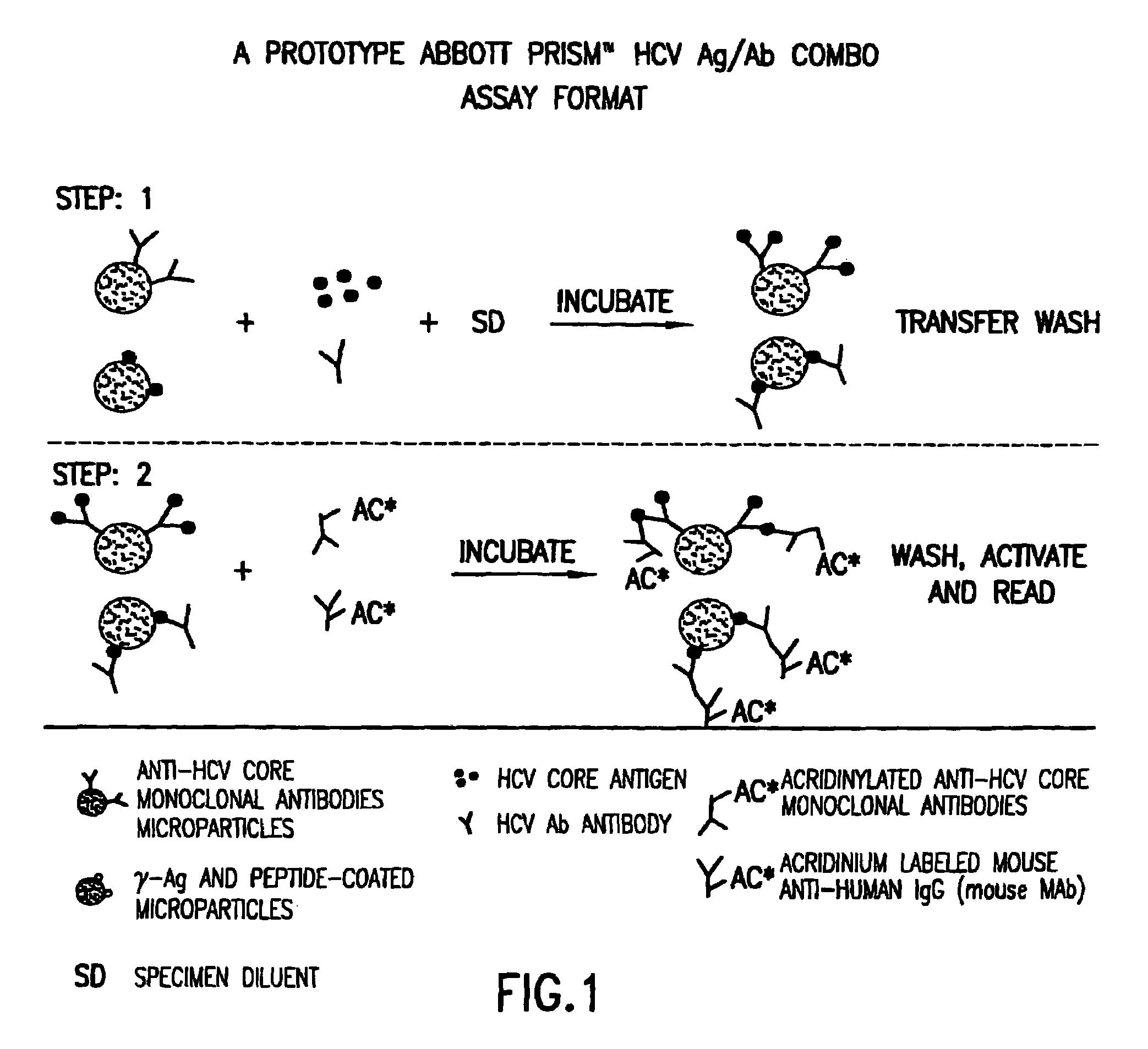

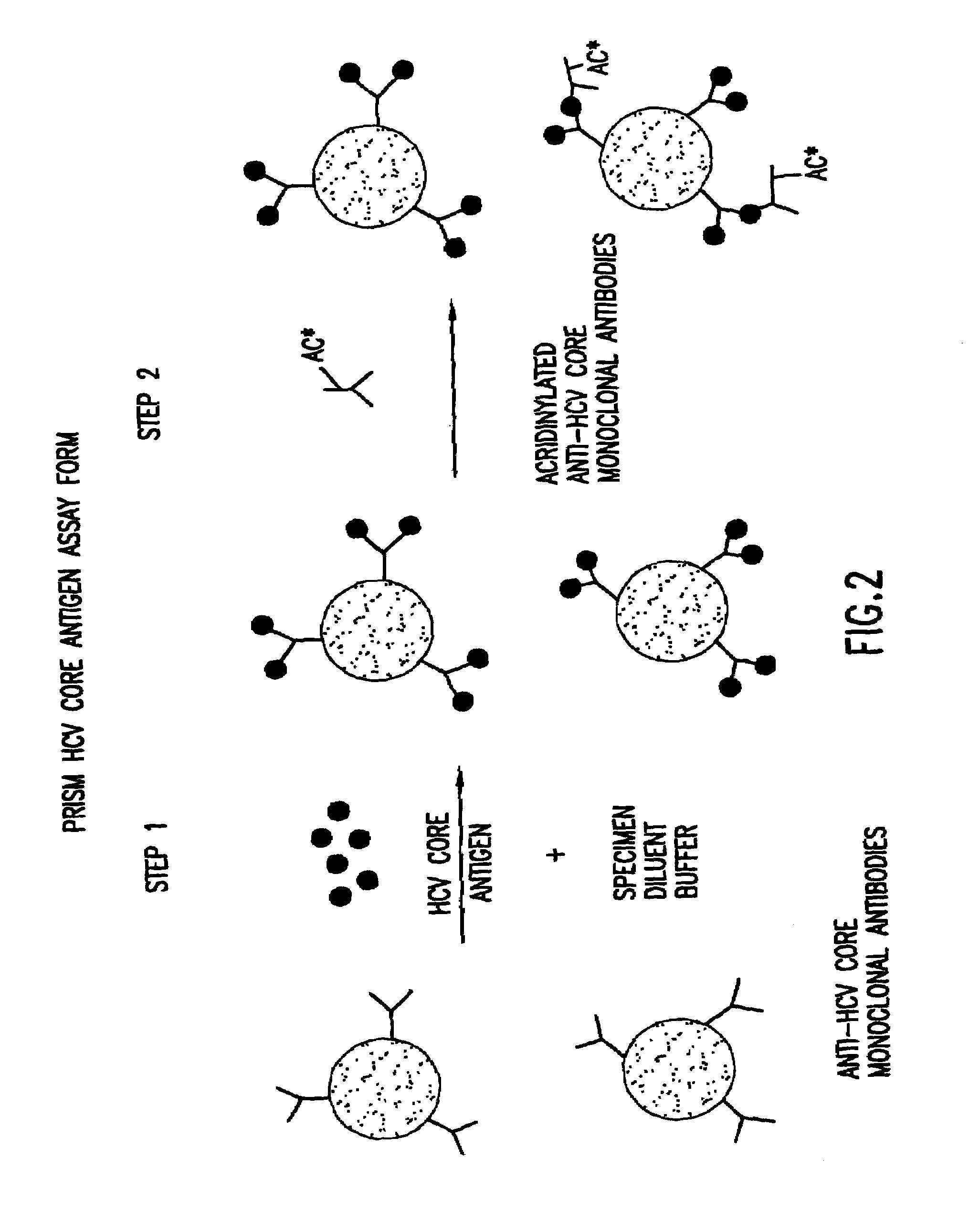

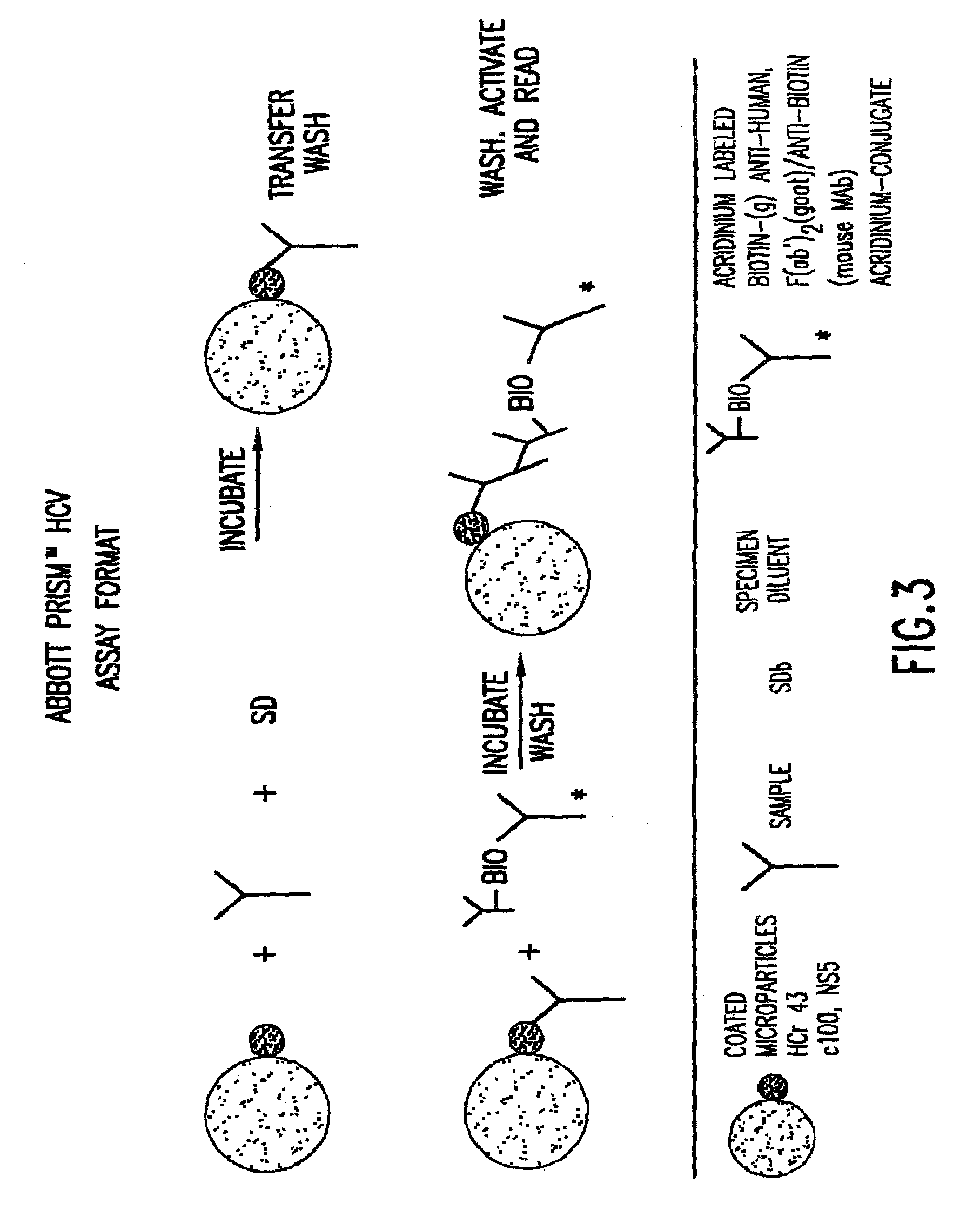

Methods for the simultaneous detection of HCV antigens and HCV antibodies

The subject invention relates to methods for the simultaneous detection of Hepatitis C Virus (HCV) antigens as well as antibodies produced in response to HCV antigens. Furthermore, the subject invention allows one to detect antigens in the early, acute stage of infection, even prior to the development of antibodies, thereby allowing for early detection of infected blood and blood products, thus improving the safety of the blood supply.

Owner:ABBOTT LAB INC

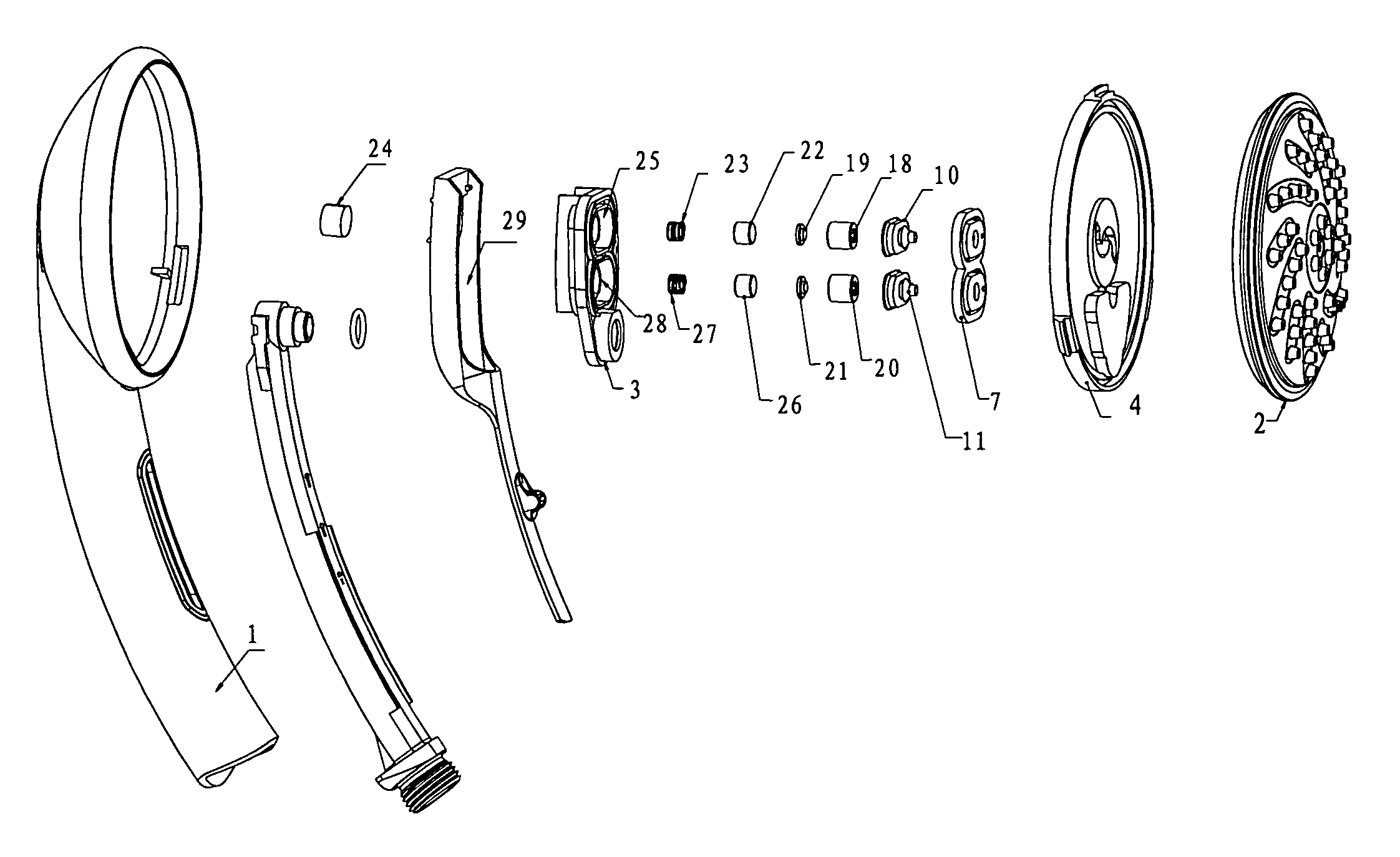

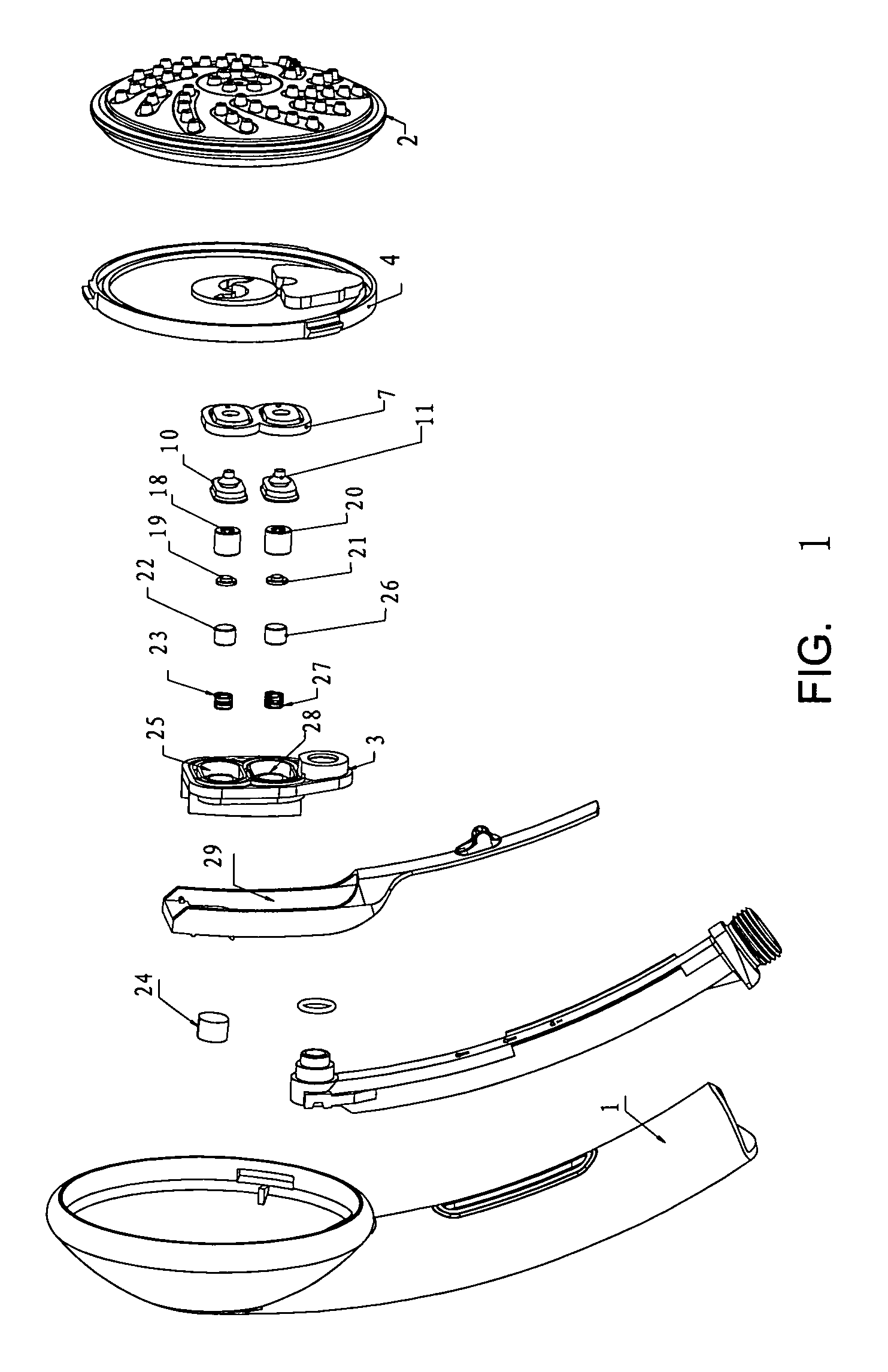

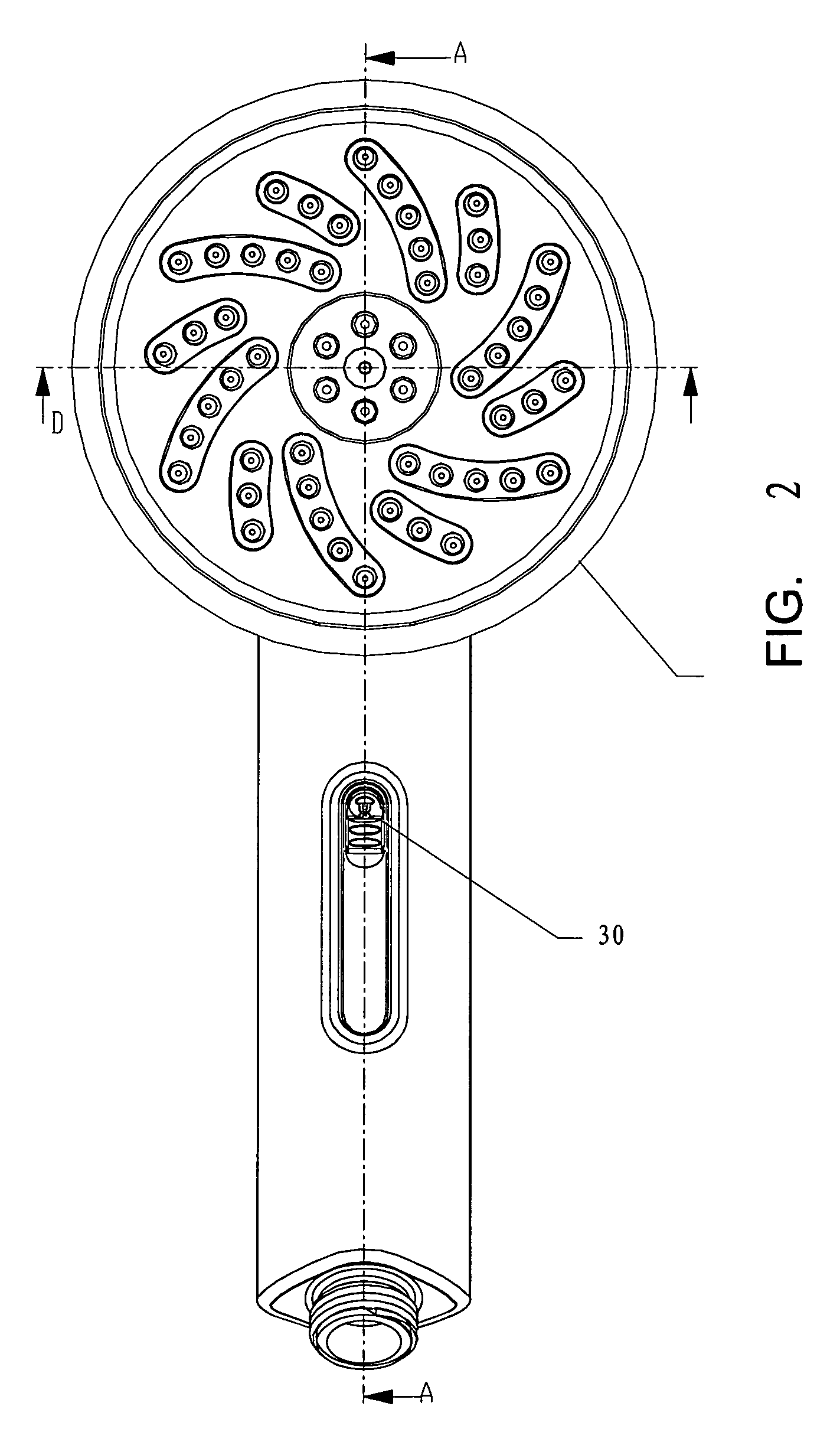

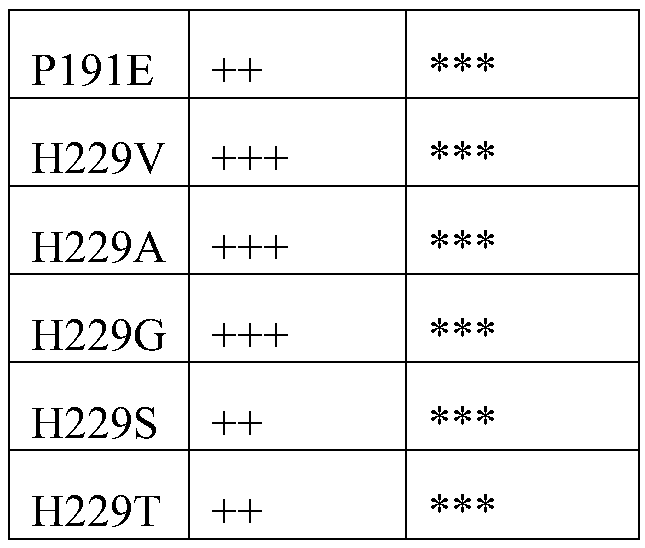

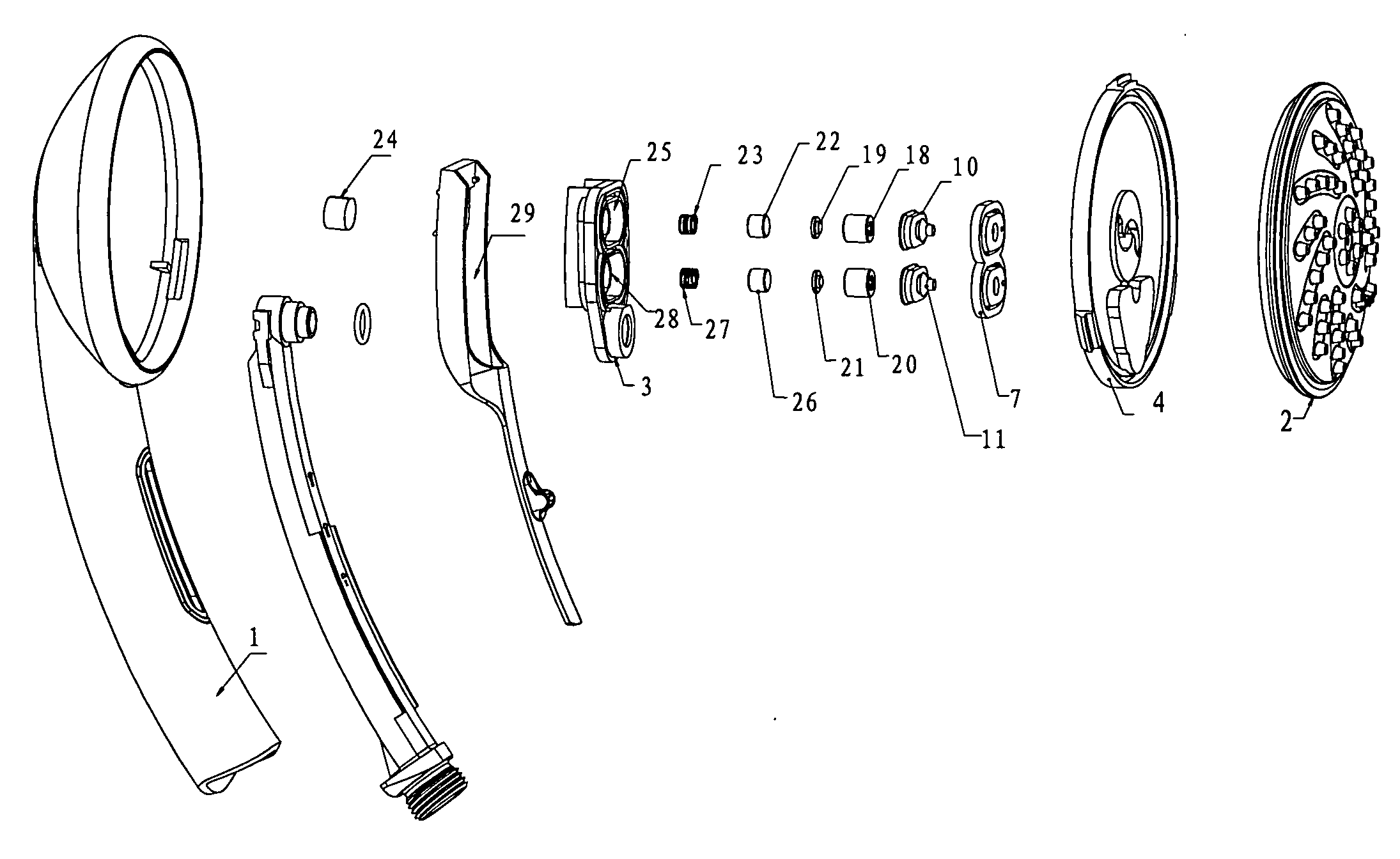

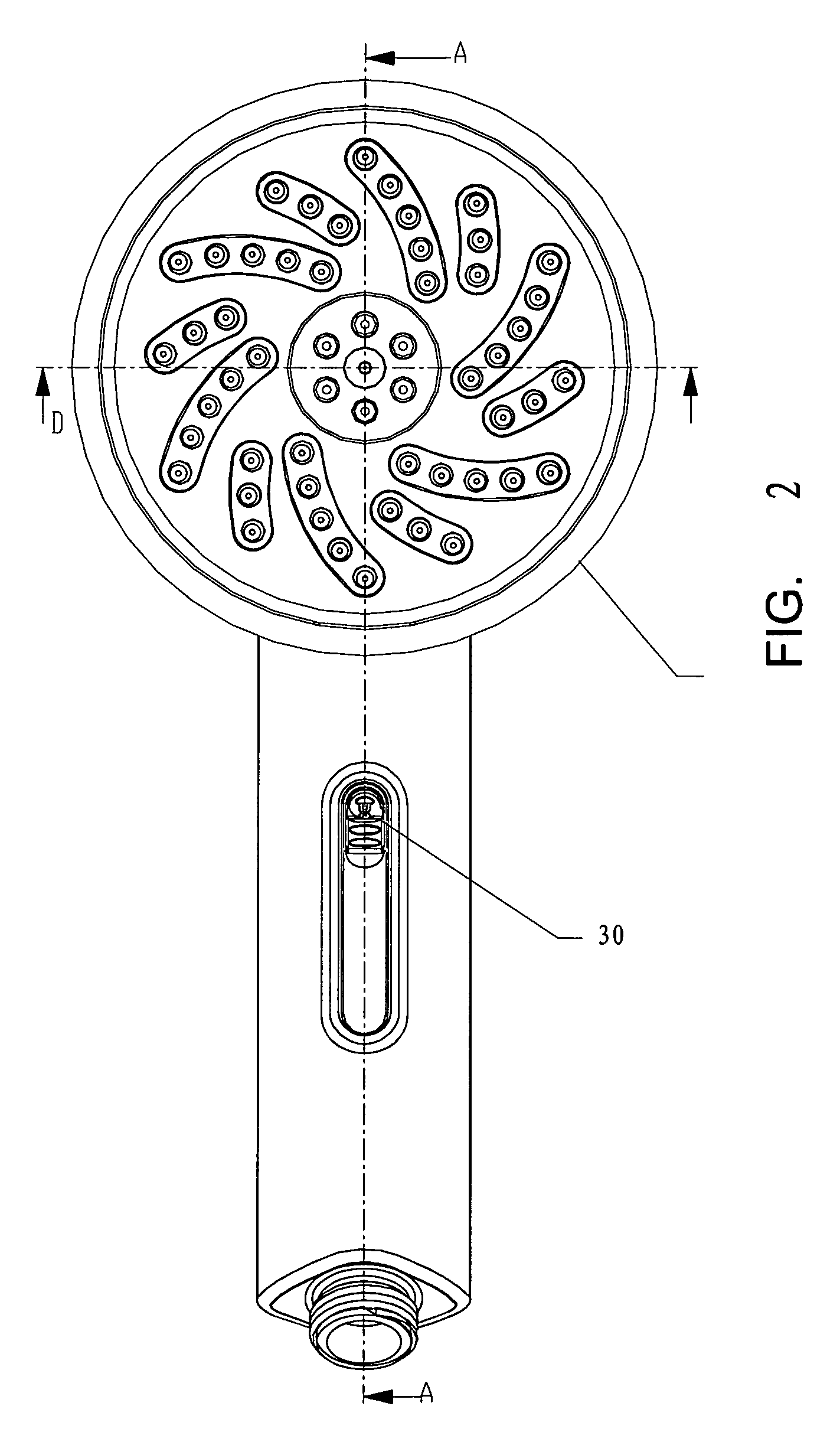

Water outlet control device of shower spray nozzle

InactiveUS7992807B2Low maneuverabilityEasy to operateOperating means/releasing devices for valvesBathsWater flowSpray nozzle

A mechanism of controlling water outflow of shower is provided in the casing of shower. The water outlet of the mechanism is aligned with the water outlet of shower. The mechanism of controlling water outflow comprises inner sealing shell, outer sealing shell, and an intermediate cavity defined between the inner sealing shell and the outer sealing shell. A water outflow cavity is formed between outer sealing shell and water outflow disc. The intermediate cavity communicates with intake channel of shower. The mechanism of controlling water outlet also comprises separating sealing pad inside the intermediate cavity, with one side sticked to the water outflow disc of outer sealing shell and the other side sticked to valve elements. The intermediate cavity comprises the inner cavity and outer cavity. The inner cavity communicates with water outflow cavity through the first small hole and with outer cavity through a through-hole. The intake channel communicates with outer cavity. The small hole matches with a mobile sealing pad that connects the button kit that controls the sealing pad to separate or contact the small hole. This invention can realize different effects of water outflow, easy operation handle and longer service life.

Owner:PAN YAOZHAO

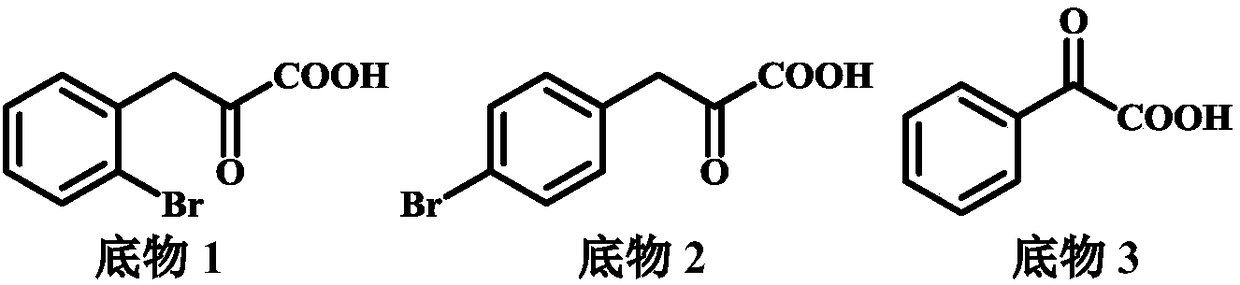

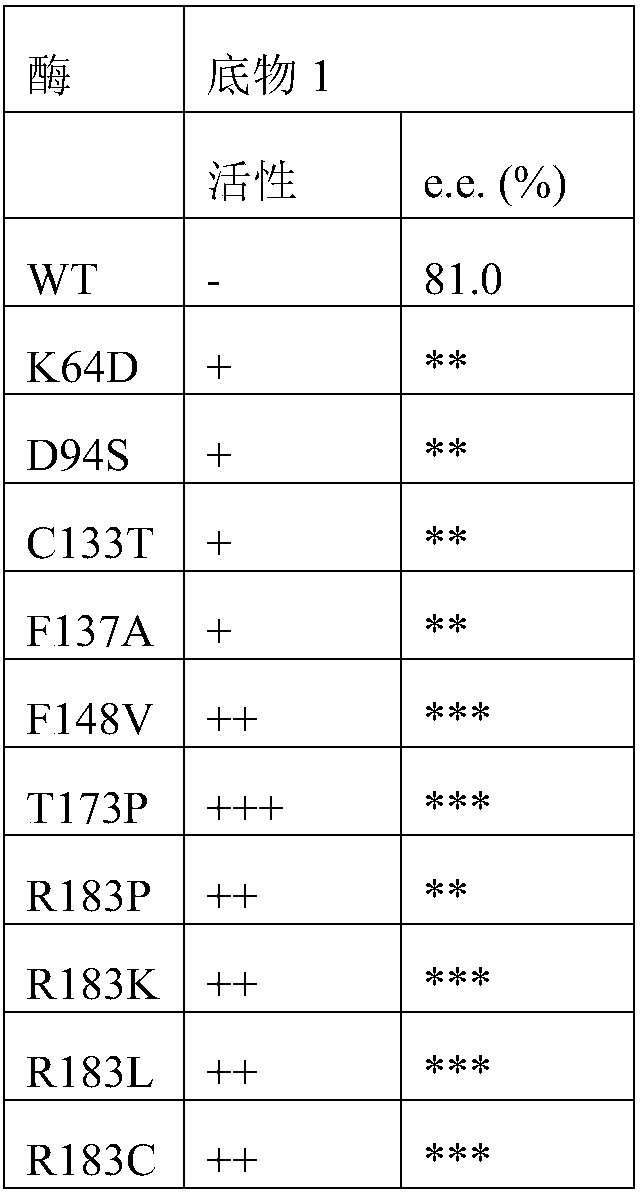

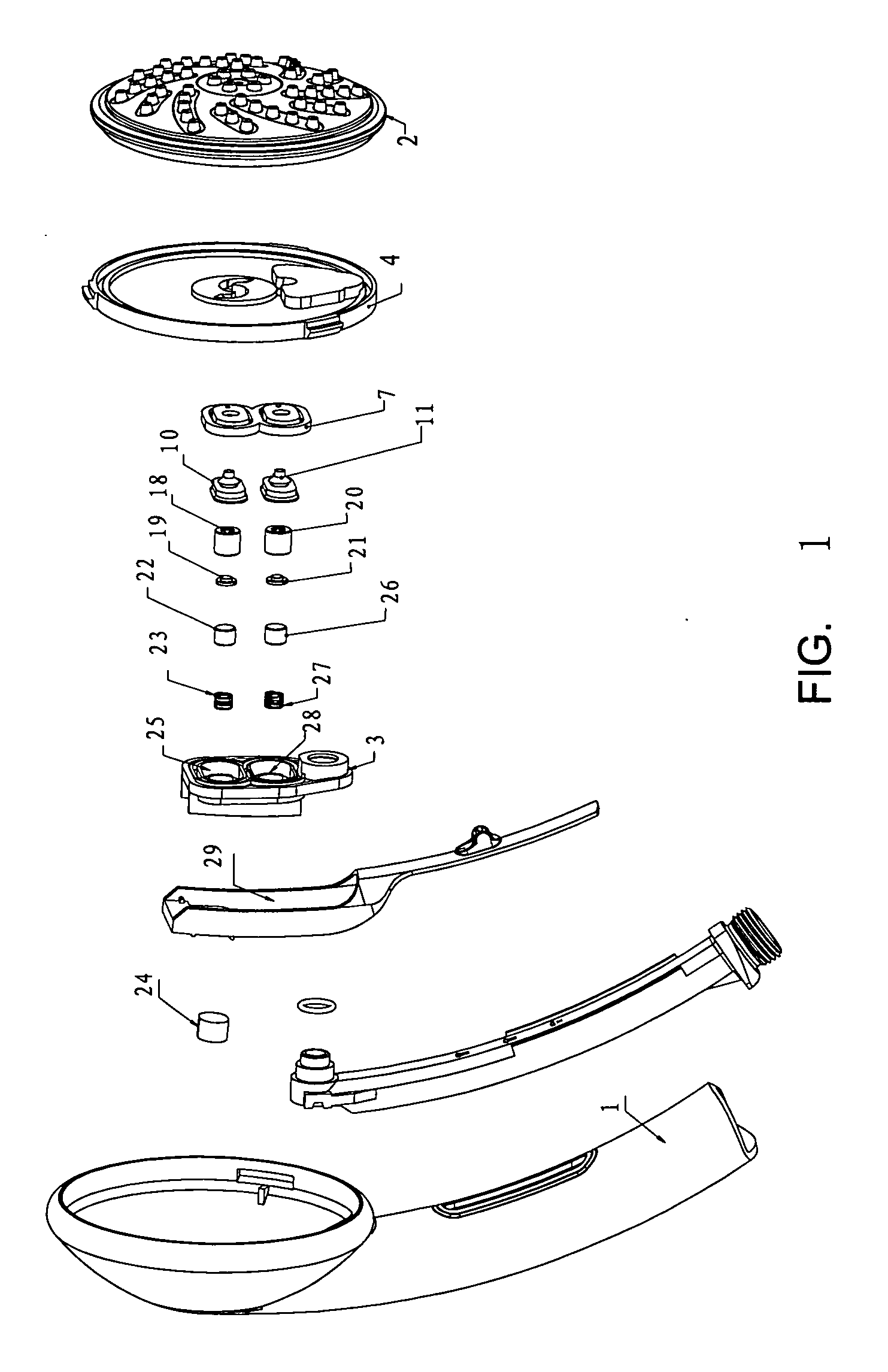

Amino acid dehydrogenase mutant and application thereof

The invention discloses an amino acid dehydrogenase mutant and an application thereof. The amino acid sequence of the amino acid dehydrogenase mutant is an amino acid sequence obtained by mutating anamino acid sequence represented by SEQ ID NO:1, and the mutation includes at least one of the following mutation sites: the 64thmutation site, the 94thmutation site, the 133rd mutation site, the 137thmutation site, the 148th mutation site, the 168th mutation site, the 173rd mutation site, the 183rd mutation site, the 191st mutation site, the 207th mutation site, the 229th mutation site, the 248thmutation site, the 255th mutation site and the 282nd mutation site; or the amino acid sequence of the amino acid dehydrogenase mutant is an amino acid sequence having the mutation sites in the mutated amino acid sequence and having a 80% or more homology with the mutated amino acid sequence. The amino acid dehydrogenase mutant has greatly improved enzyme activity, the enzyme activity is above 50times higher than that of a wild amino acid dehydrogenase, and the enzyme specificity is also correspondingly improved.

Owner:天津凯诺医药科技发展有限公司

Coke oven coking method for improving ratio of long flame coal for chemical coke

ActiveCN104087328AHigh yieldMeet the requirements of chemical cokeSpecial form destructive distillationChemical industryAdhesive

The invention relates to a coke oven coking method for improving a ratio of long flame coal for chemical coke. The method comprises the following steps: a, performing secondary crushing on long flame coal, and mixing the long flame coal with an adhesive in a storage warehouse; b, performing pre-grinding on the long flame coal mixed with the adhesive, feeding the coal into a coal blending chamber, improving a ratio of the long flame coal mixed with the adhesive to 80 percent, adjusting a gas-fat coal ratio with high adhesiveness to 20 percent, and feeding the coal into a crusher for crushing after mixing; c, performing primary water injection on the prepared mixed coal, crushing the coal in a crusher chamber, performing secondary water injection on the crushed mixed coal, feeding coking coal into a charging car for tamping, so that the coking coal is smashed into a dense coal cake, and feeding the coal into a carbonization chamber for performing high-temperature dry distillation; and d, performing high-temperature dry distillation on the coking coal, performing coke quenching by adopting a dry method, and finally naturally cooling to obtain the chemical coke product. According to the method, low-cost smelting and chemical industry carbon materials can be produced, and the gap that smelting and chemical industry carbon materials are deficient is overcome.

Owner:新疆新鑫新能源化工有限公司

Water Outlet Control Device of Shower Spray Nozzle

InactiveUS20100301141A1Handle for easy operationEasy to operateOperating means/releasing devices for valvesBathsSpray nozzleWater flow

A mechanism of controlling water outflow of shower is provided in the casing of shower. The water outlet of the mechanism is aligned with the water outlet of shower. The mechanism of controlling water outflow comprises inner sealing shell, outer sealing shell, and an intermediate cavity defined between the inner sealing shell and the outer sealing shell. A water outflow cavity is formed between outer sealing shell and water outflow disc. The intermediate cavity communicates with intake channel of shower. The mechanism of controlling water outlet also comprises separating sealing pad inside the intermediate cavity, with one side sticked to the water outflow disc of outer sealing shell and the other side sticked to valve elements. The intermediate cavity comprises the inner cavity and outer cavity. The inner cavity communicates with water outflow cavity through the first small hole and with outer cavity through a through-hole. The intake channel communicates with outer cavity. The small hole matches with a mobile sealing pad that connects the button kit that controls the sealing pad to separate or contact the small hole. This invention can realize different effects of water outflow, easy operation handle and longer service life.

Owner:PAN YAOZHAO

Preparation method of fish skin collagen jelly

The invention discloses a preparation method of fish skin collagen jelly. The preparation method of the fish skin collagen jelly mainly comprises the steps that after unfreezing and pretreatment are conducted on fish skin, water, seasoning and spices are added for decoction, a compound of transglutaminase and sodium caseinate, hydrophilic colloid and preservative are added for blending, obtained skin frozen liquid is filled into jelly cups, and after vacuum sealing, high temperature sterilization and cooling shaping are conducted sequentially, products are obtained. According to the preparation method of the fish skin collagen jelly, the prepared fish jelly is long in quality guarantee period and can be preserved for six months at normal temperature; the nutritive value is high, the gel mouthfeel and elasticity are enhanced, and the shaped jelly is crystal clear, standardization control of the production technology is convenient, novel jelly cups are adopted for packing, and eating is convenient.

Owner:SICHUAN UNIV

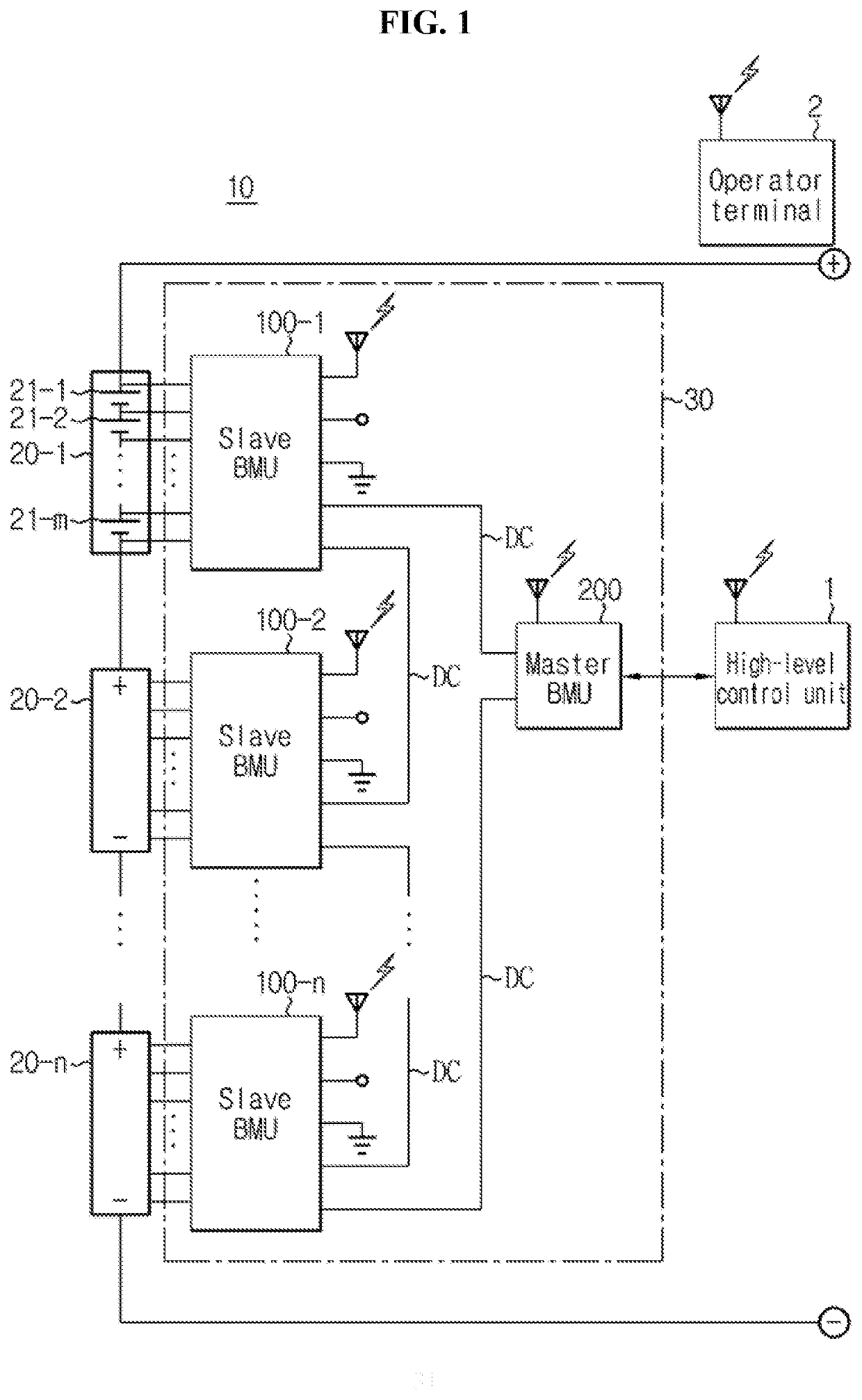

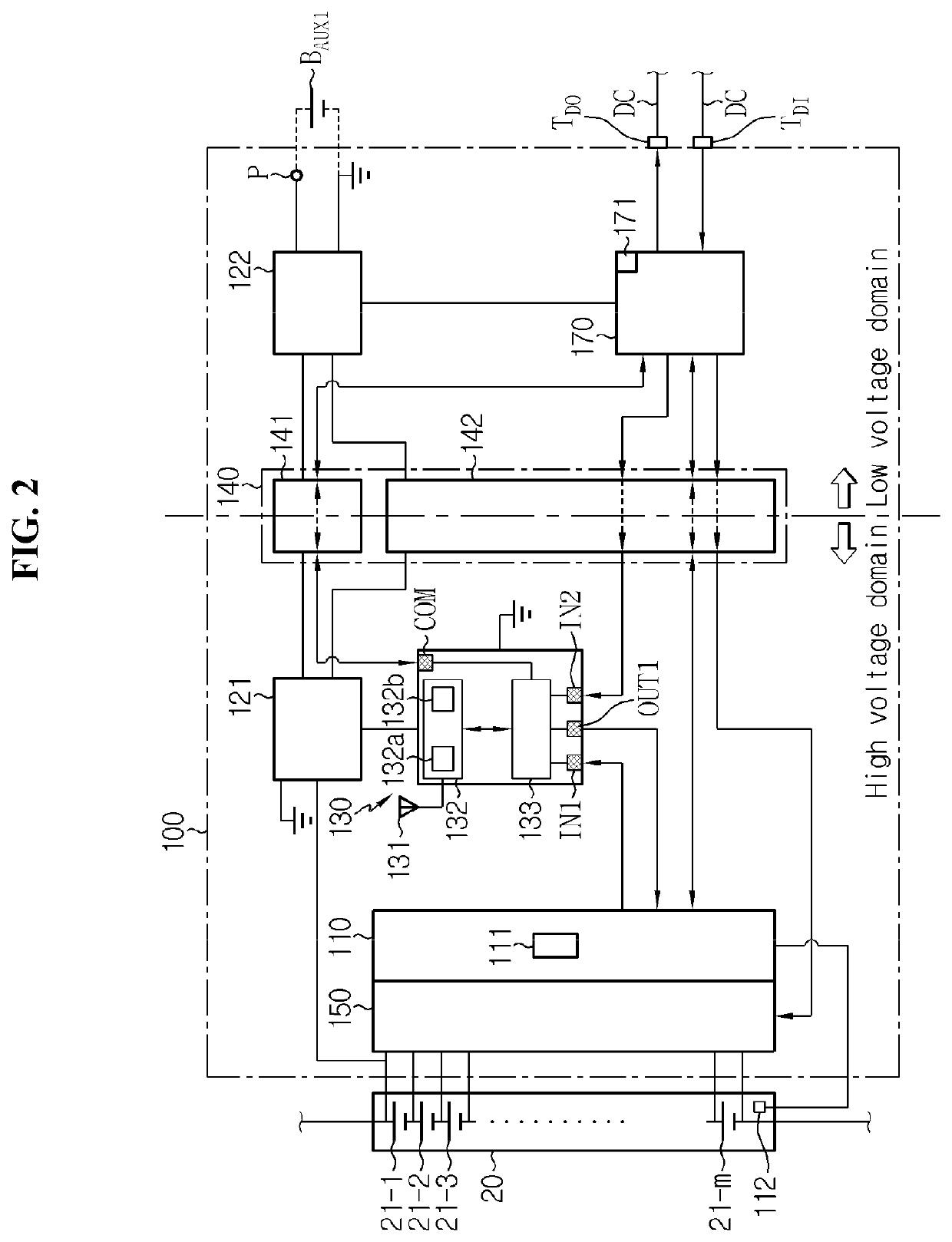

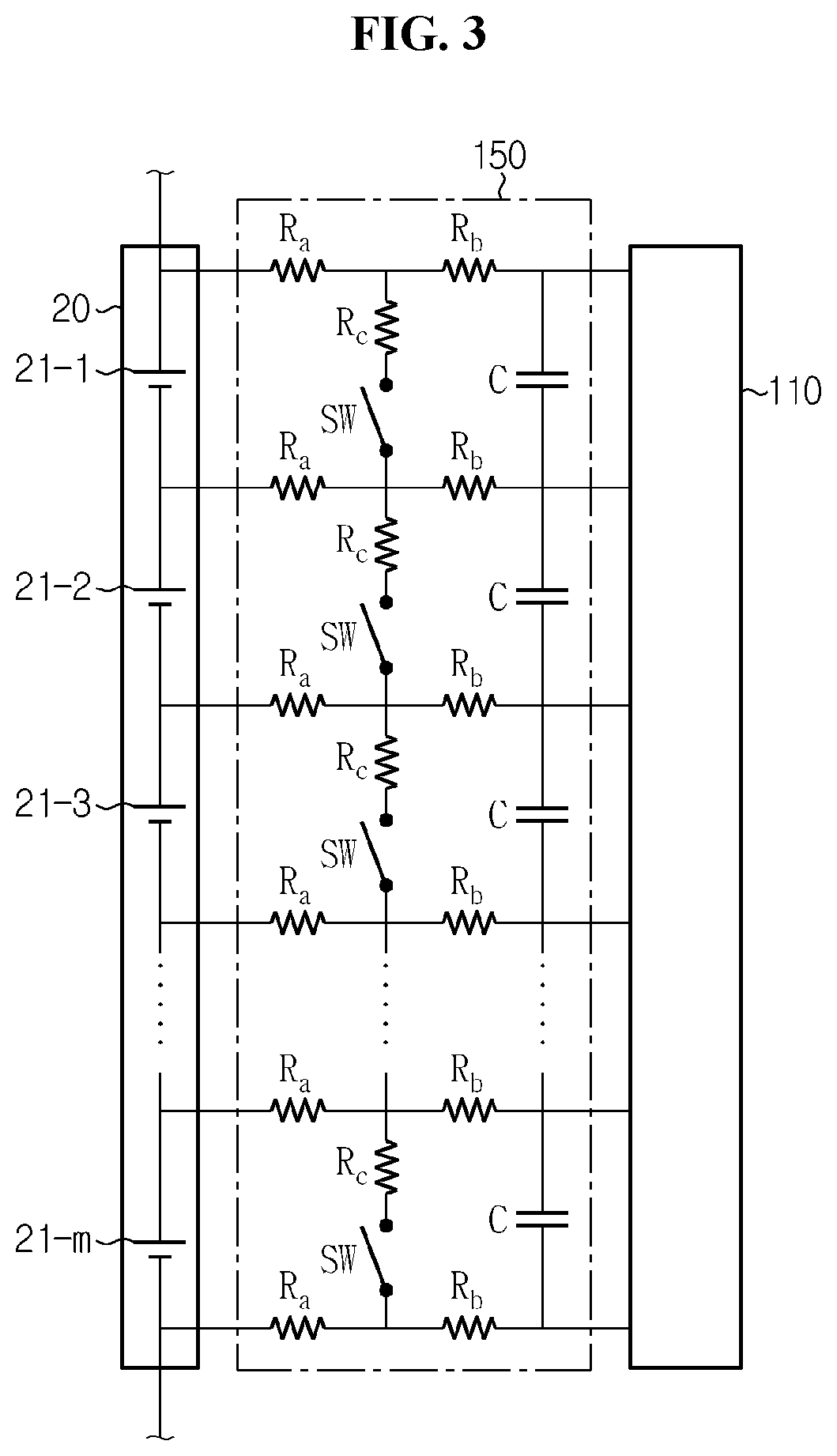

Battery management unit and battery pack including same

ActiveUS20190356143A1Change functionLimited effectIndicating/monitoring circuitsElectrical testingVIT signalsElectricity

A battery management unit including a sensing unit electrically connected to a plurality of battery cells, the sensing unit detecting voltage of each of the plurality of battery cells and outputting a detection signal including voltage information representing the detected voltage, a first power supply unit generating a first operating voltage using a module voltage of the battery module, and a communication unit which operates using the first operating voltage, the communication unit including an antenna, a wireless communication circuit and a first input port, the communication unit receiving the detection signal from the sensing unit through the first input port, testing at least one preset item based on the detection signal, and outputting a RF signal representing a result of the test through the antenna and the wireless communication circuit.

Owner:LG ENERGY SOLUTION LTD

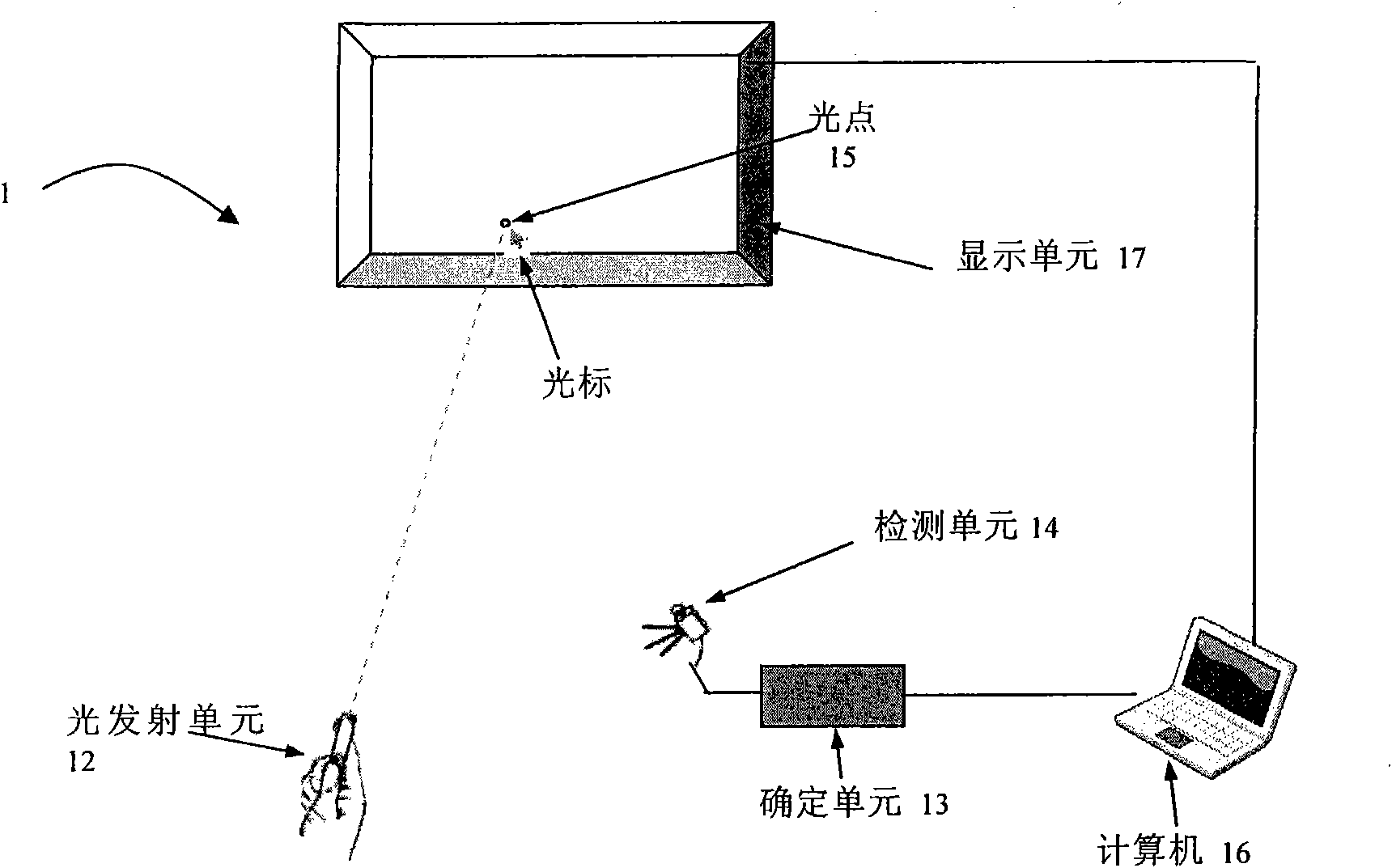

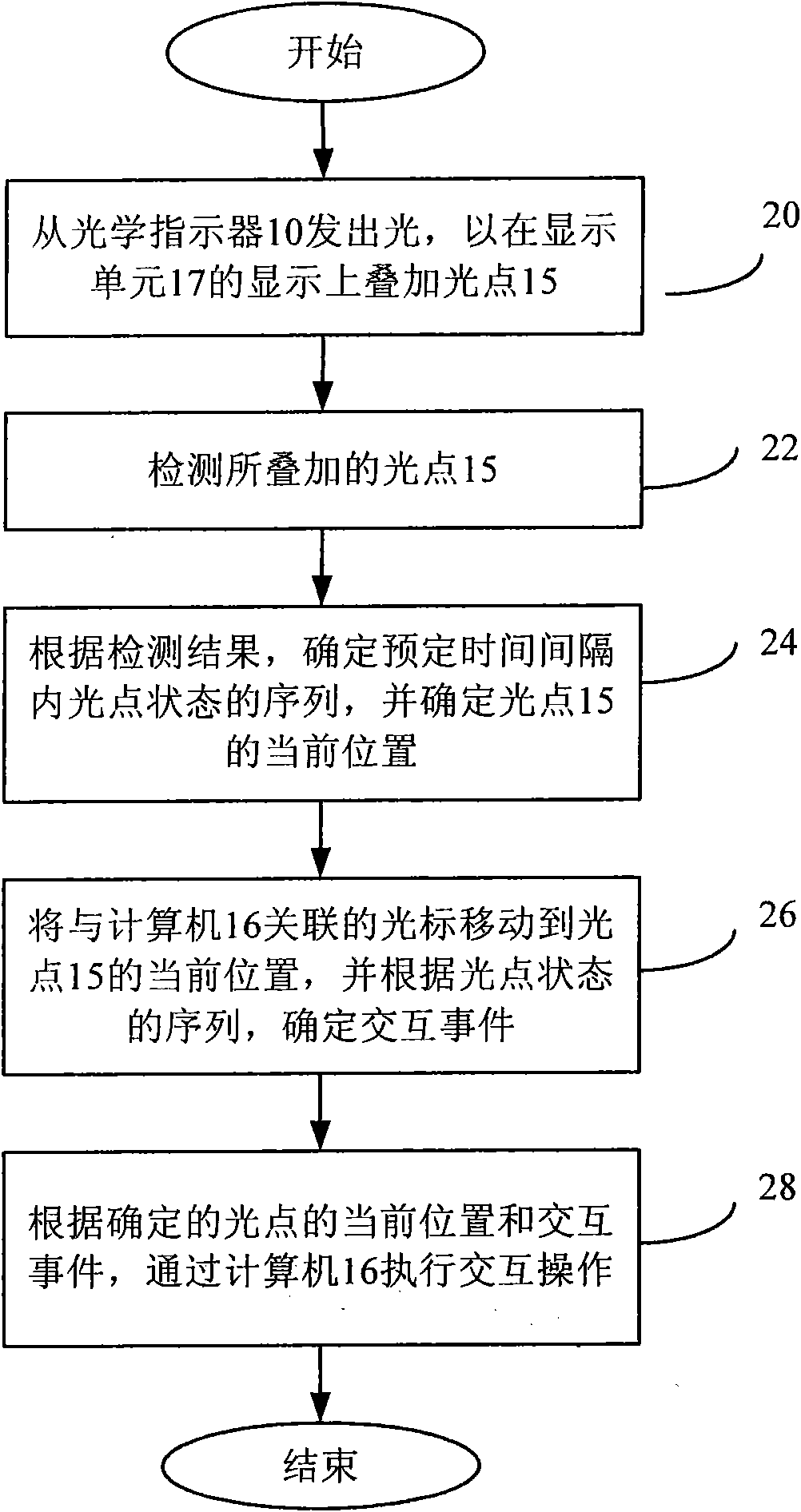

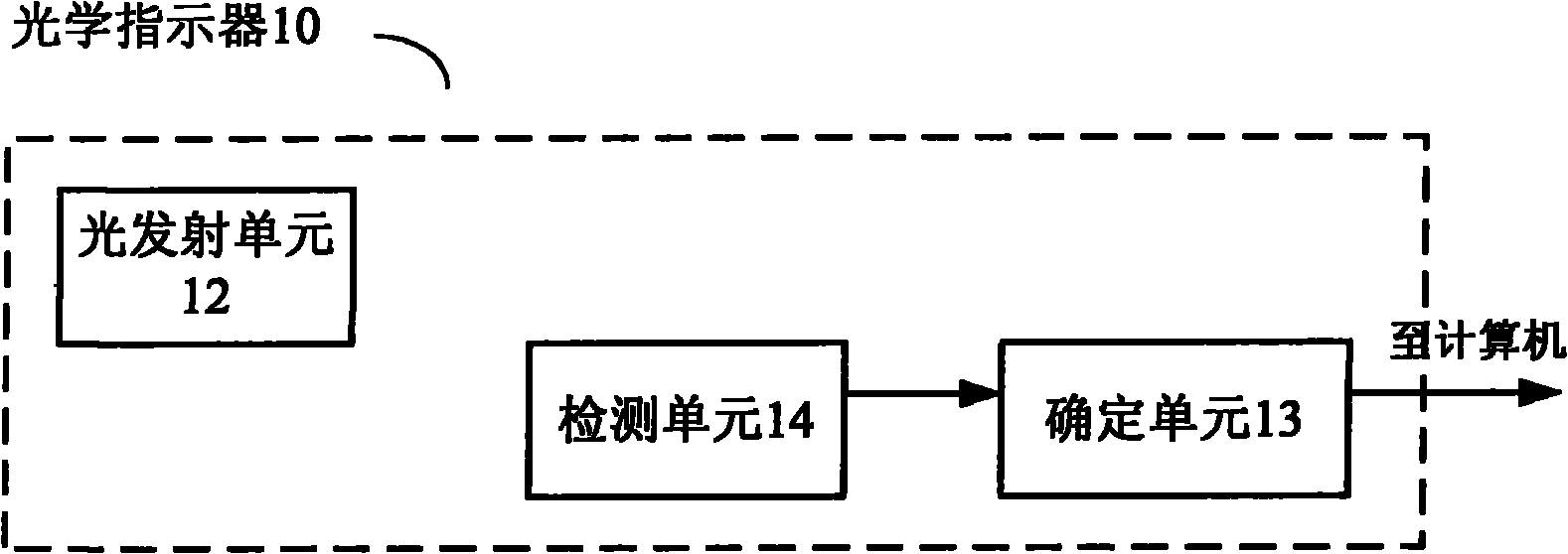

Method for interacting by adopting optical indicator, optical indicator as well as presentation method and system

InactiveCN102375564ASimple detectionImprove detection accuracy and reliabilityInput/output processes for data processingComputer scienceLight spot

The embodiment of the invention relates to a method for interacting with equipment by utilizing an optical indicator, the optical indicator as well as a presentation method and system adopting the optical indicator. The method for interacting comprises the following steps of: detecting a light spot generated by the optical indicator; determining a sequence of the state of the light spot in a preset time interval according to the detection result; and determining an interaction event according to the sequence of the light spot so as to interact with the equipment. According to the embodiment of the invention, more than one light spot is utilized, and the light spot is mapped to different interaction events according to the sequence of the state of the light spot in the preset time interval, thus more interaction events can be presented. The light spot is easier and simpler to detect, and a detection method can be used for improving the accuracy and the reliability of detection, thus the sequence of the state of the light spot can be mapped into a mouse event and a corresponding mouse signal is generated, so that interaction with a computer is realized.

Owner:SHARP KK

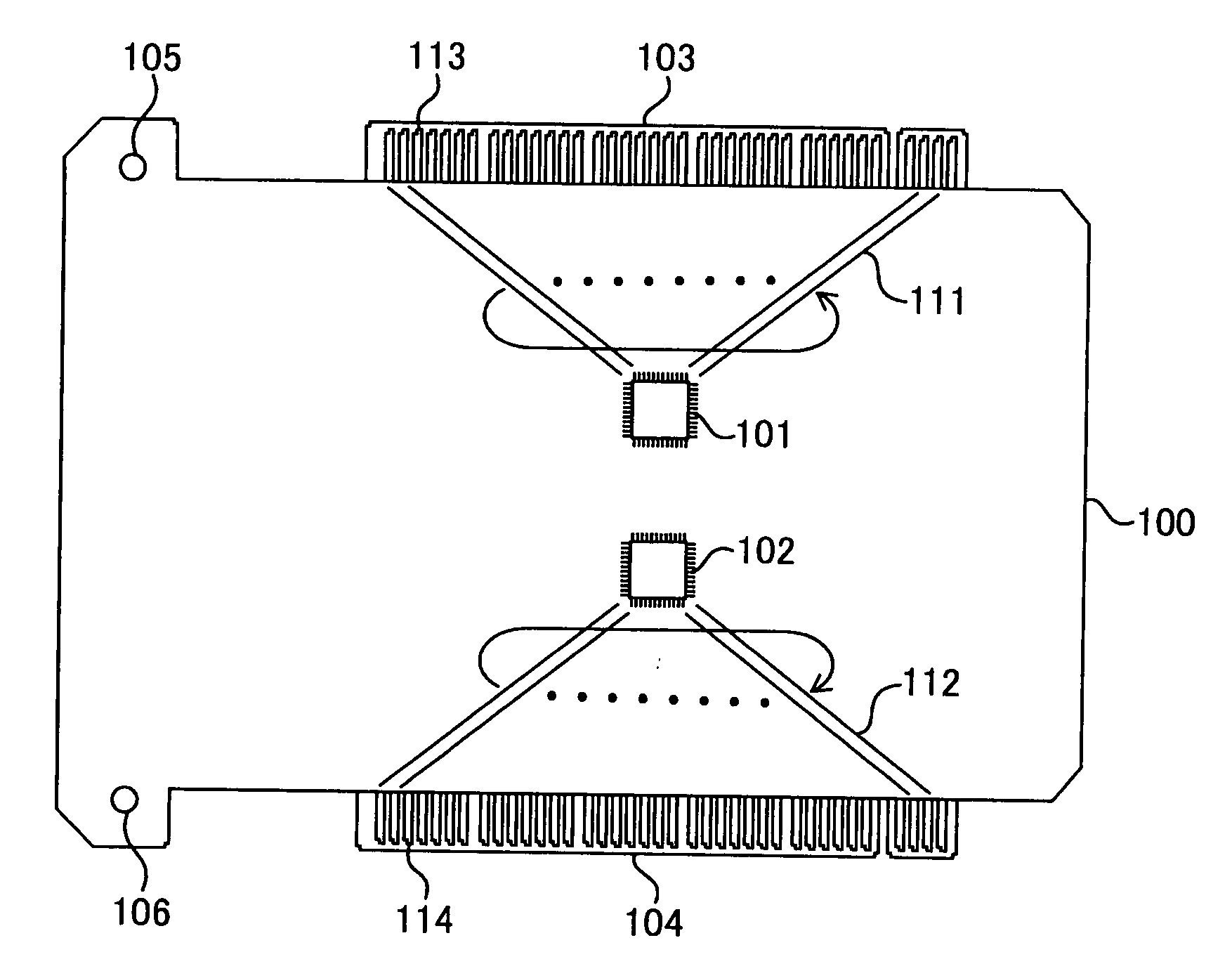

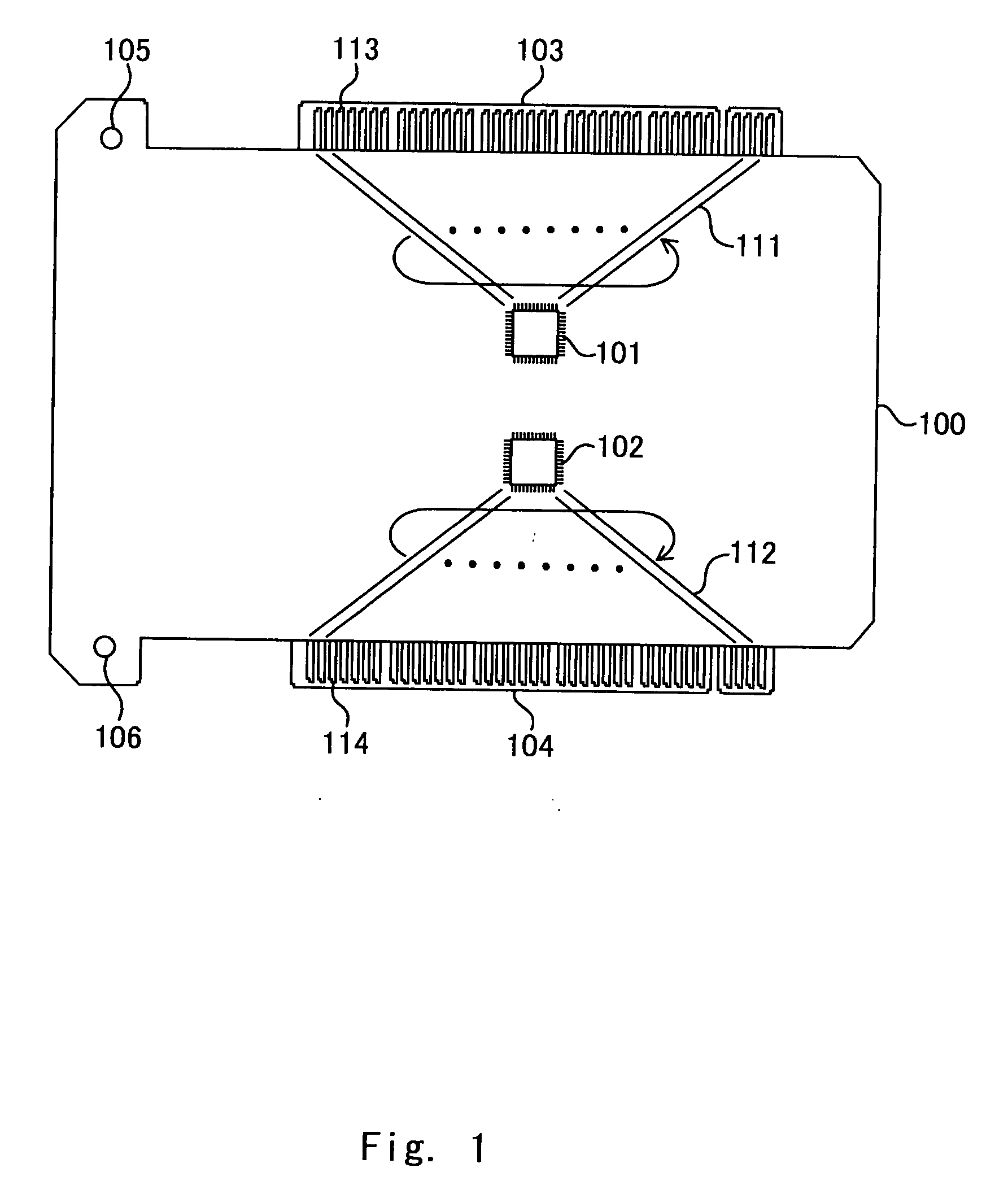

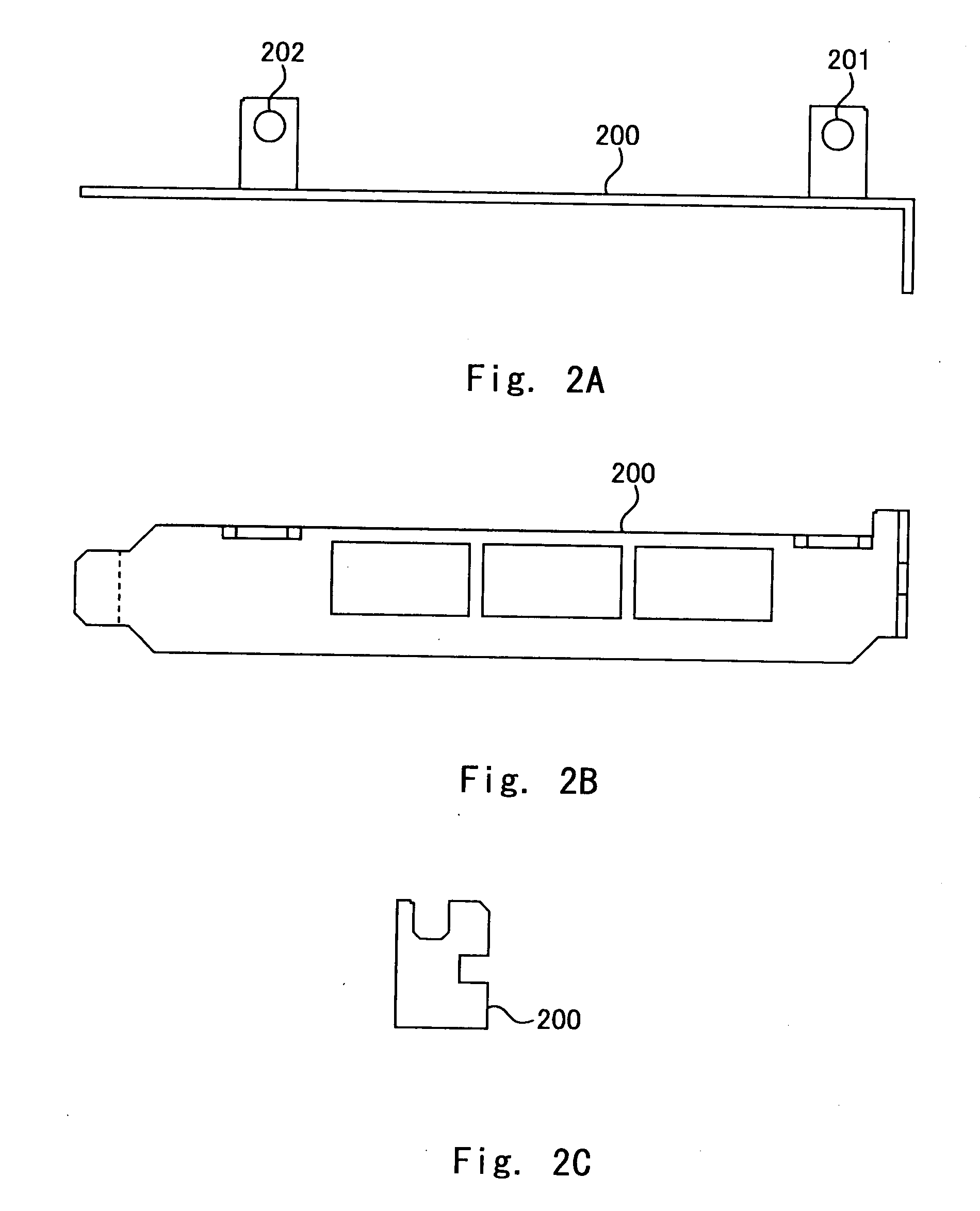

Circuit board

InactiveUS20070275577A1Easily select functionChange functionDigital data processing detailsPrinted circuit aspectsEngineeringExpansion joint

An adapter card for extending functions of a computer includes a first male connector mounted to a female connector of an expansion slot provided to the computer in a way the first male connector can be inserted / removed into / from the female connector and a second male connector that corresponds to a bus architecture same as the first male connector in a way the second male connector can be inserted / removed into / from the female connector.

Owner:NEC ELECTRONICS CORP

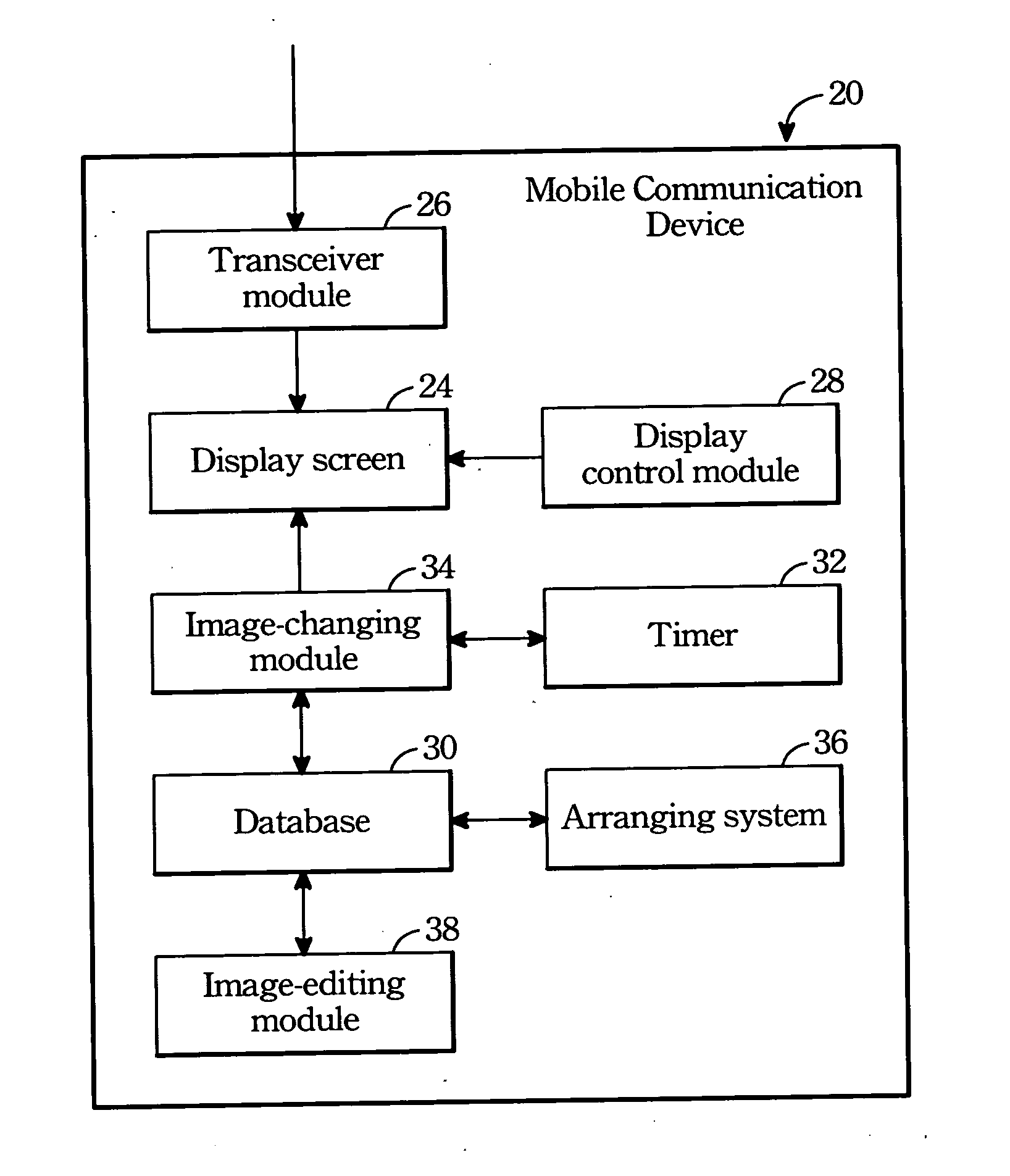

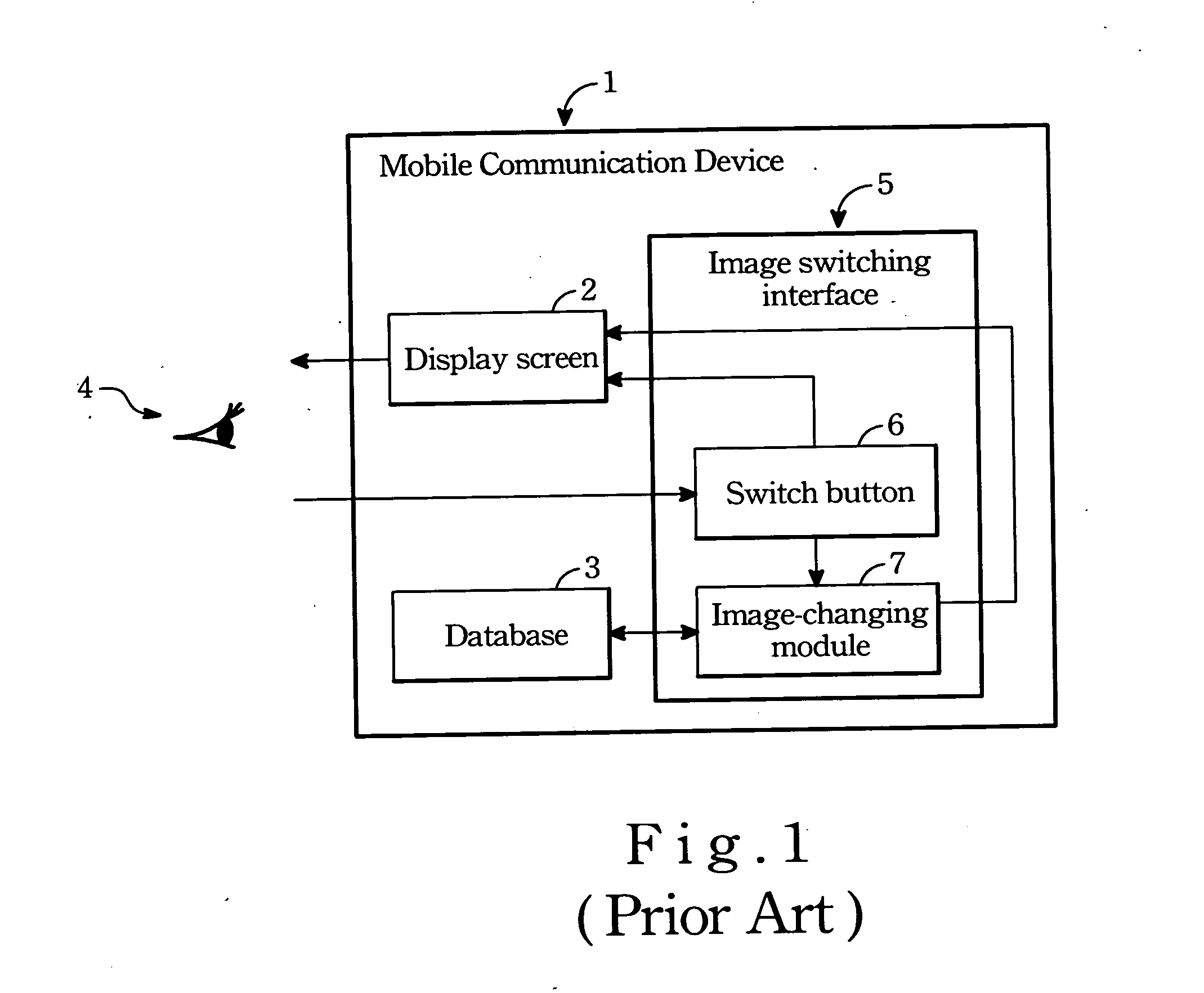

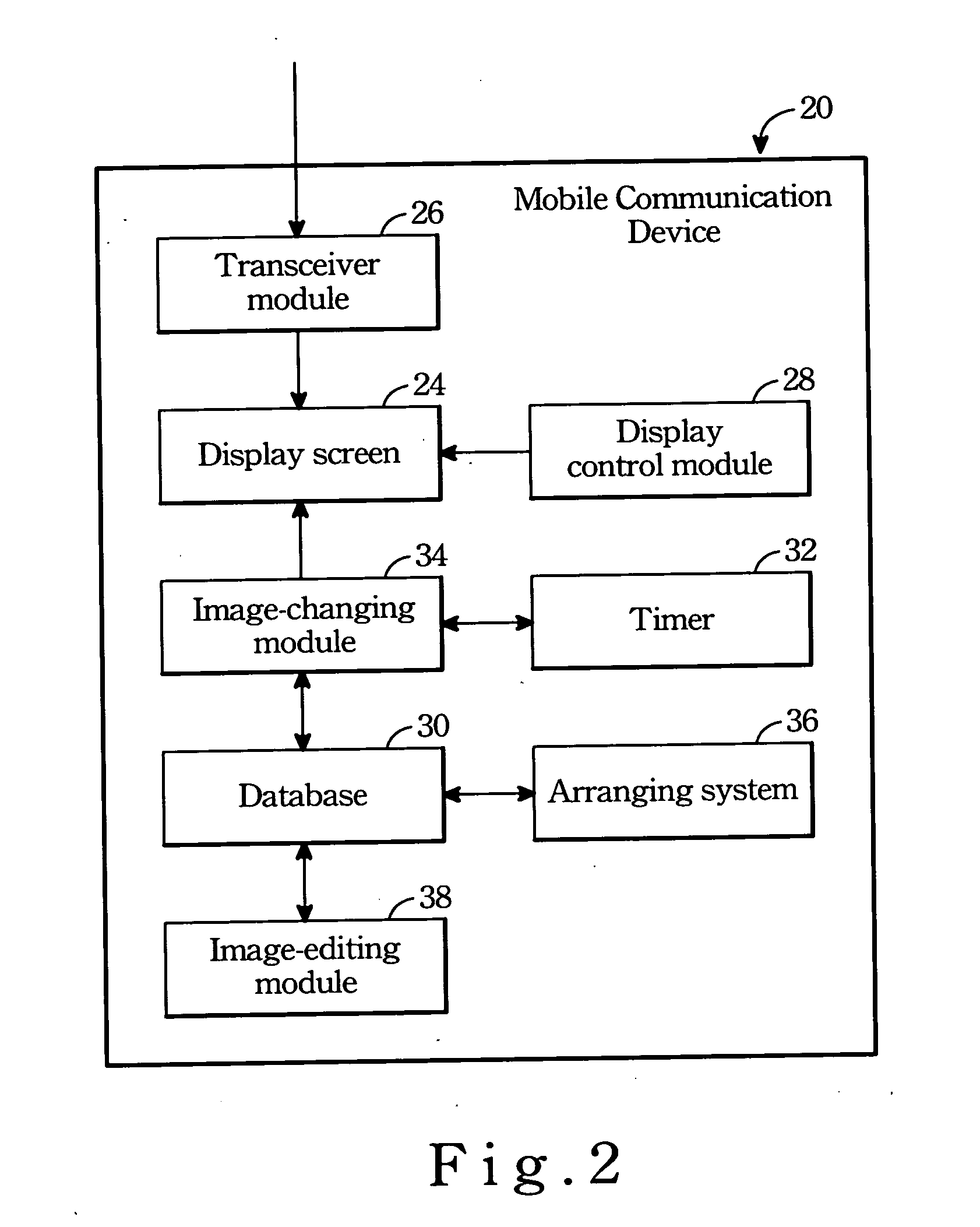

Mobile communication device with automatic image-changing functions

InactiveUS20070262950A1Increase valueChange functionCathode-ray tube indicatorsSubstation equipmentBackground imageComputer science

This invention is relative to a mobile communication device with automatic image-changing functions. Users can use these automatic image-changing functions to choose their favorite background images from a database, and set it to appear, right away or on scheduled time, randomly or in a pre-specified serial order, on the display screen of the mobile communication device. When a built-in timer detects a set time for changing images, the device then selects the image specified to be displayed at that time interval from the database through an image-changing module, and then sends it to the display screen. Also, the image-changing module allows the user to change the images at random or let the module automatically change them in pre-specified serial order.

Owner:INVENTEC APPLIANCES CORP

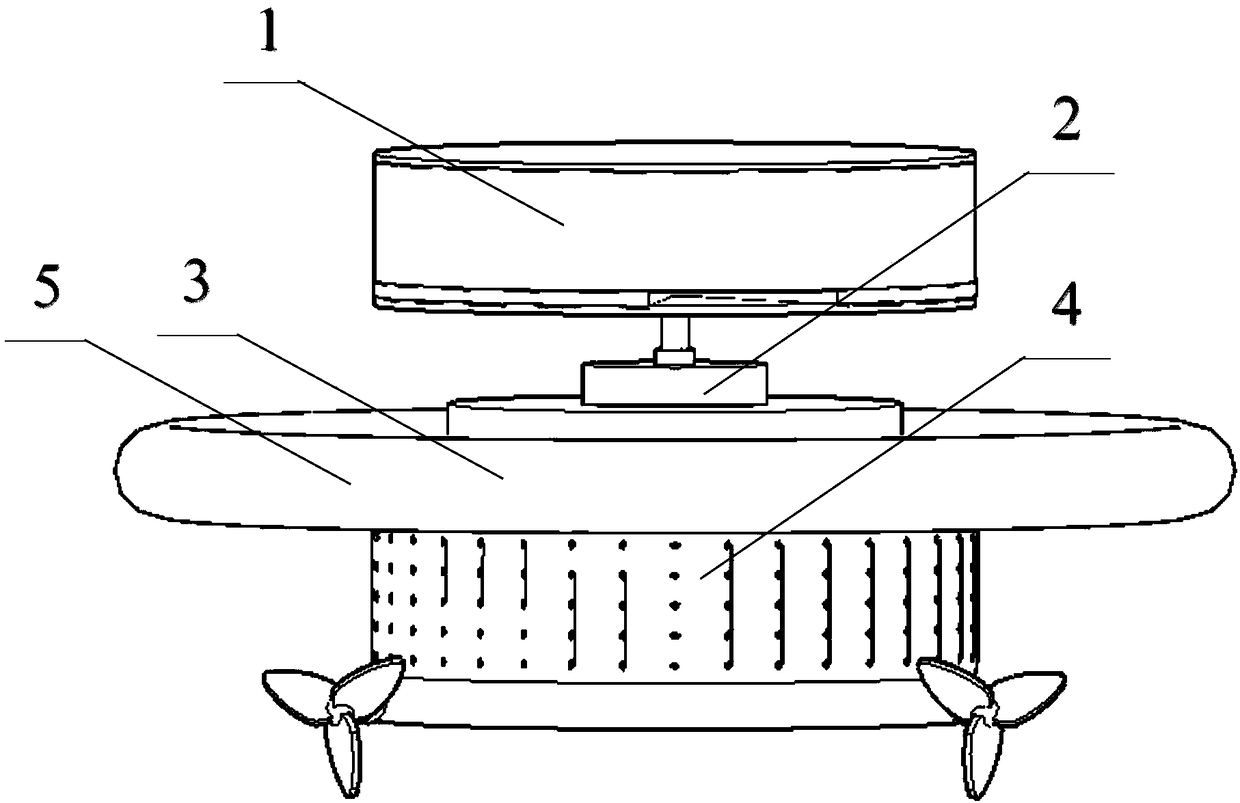

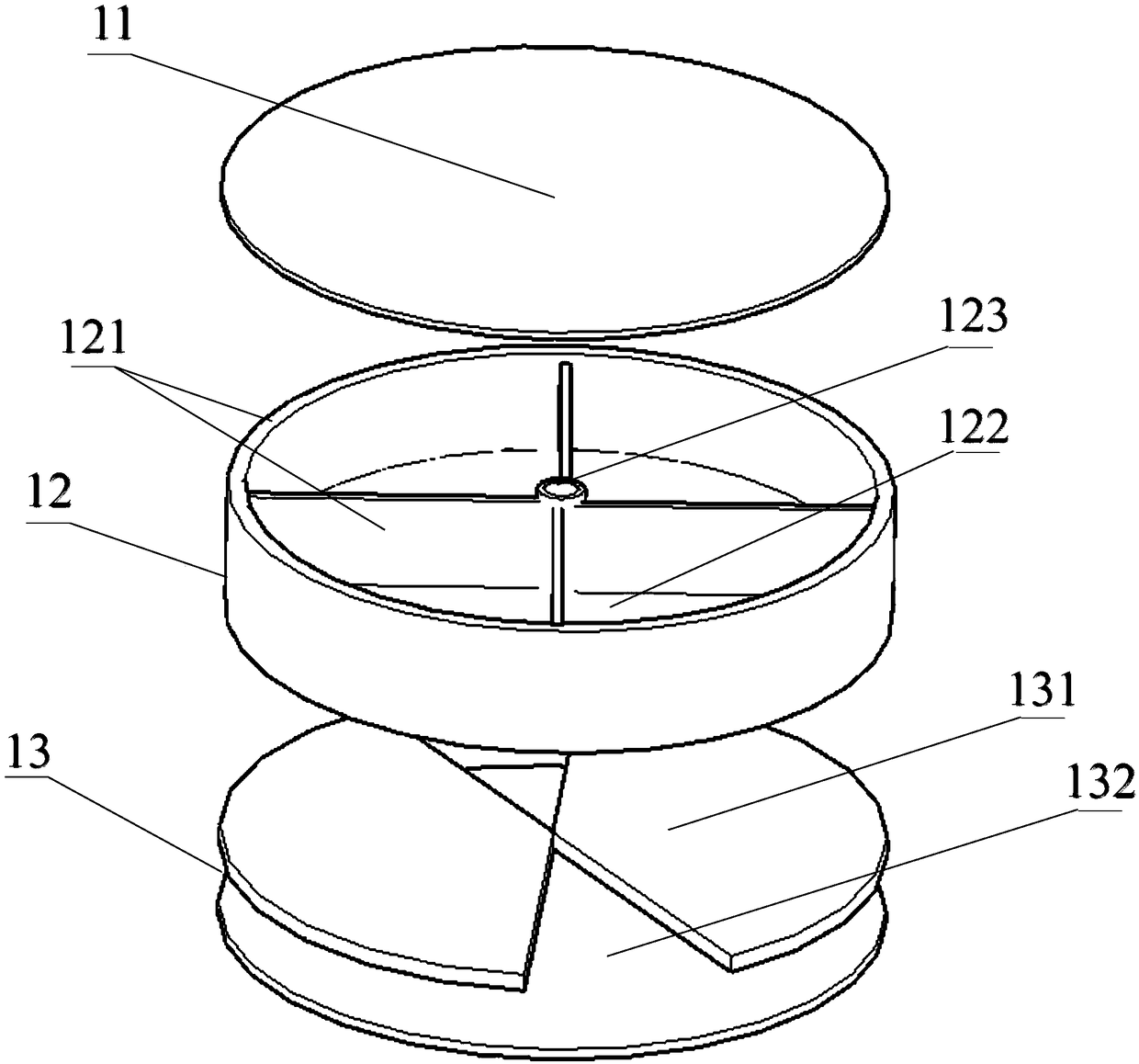

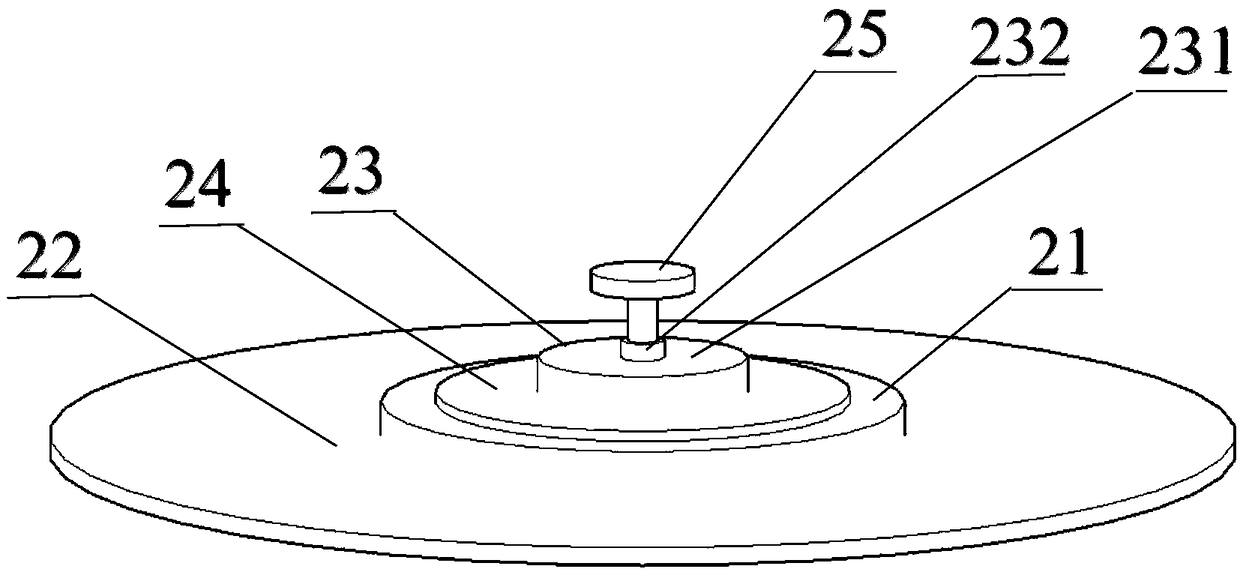

Intelligent multipurpose culture device

InactiveCN108901976AChange functionChange the disadvantages of low sewage discharge rateClimate change adaptationAgricultural fishingImpellerDrive shaft

The invention discloses an intelligent multipurpose culture device, including a fodder throwing structure, an energy structure, a positioning structure, an oxygenation filter structure, and a detection structure. The fodder throwing structure comprises a top cover, a coaming, and a bottom plate. The energy structure comprises a lithium battery, a photovoltaic cell, a core motor, an intelligent management system, and a connecting plate. The positioning structure comprises a water wing, an impeller, a motor, a bearing plate, a strength support, an underwater range finder, and an ultrasonic rangefinder. The oxygenation filter structure comprises a structure main body, stirring blades, and a transmission shaft. The detection structure comprises a camera, a DO tester, a TDS detection pen, an electronic pH meter, and an electronic thermometer. The culture device satisfies monitoring of aquatic products from cultivation and transport sections to a sales section, and provides powerful supportfor food safety supervision and management. The device changes disadvantages that an existing culture device is single in function, low in blowdown rate, and high in improvement energy dissipation, and improves economic benefits. The structure of the device is improved and optimized, providing convenience for maintenance.

Owner:ANHUI UNIV OF SCI & TECH

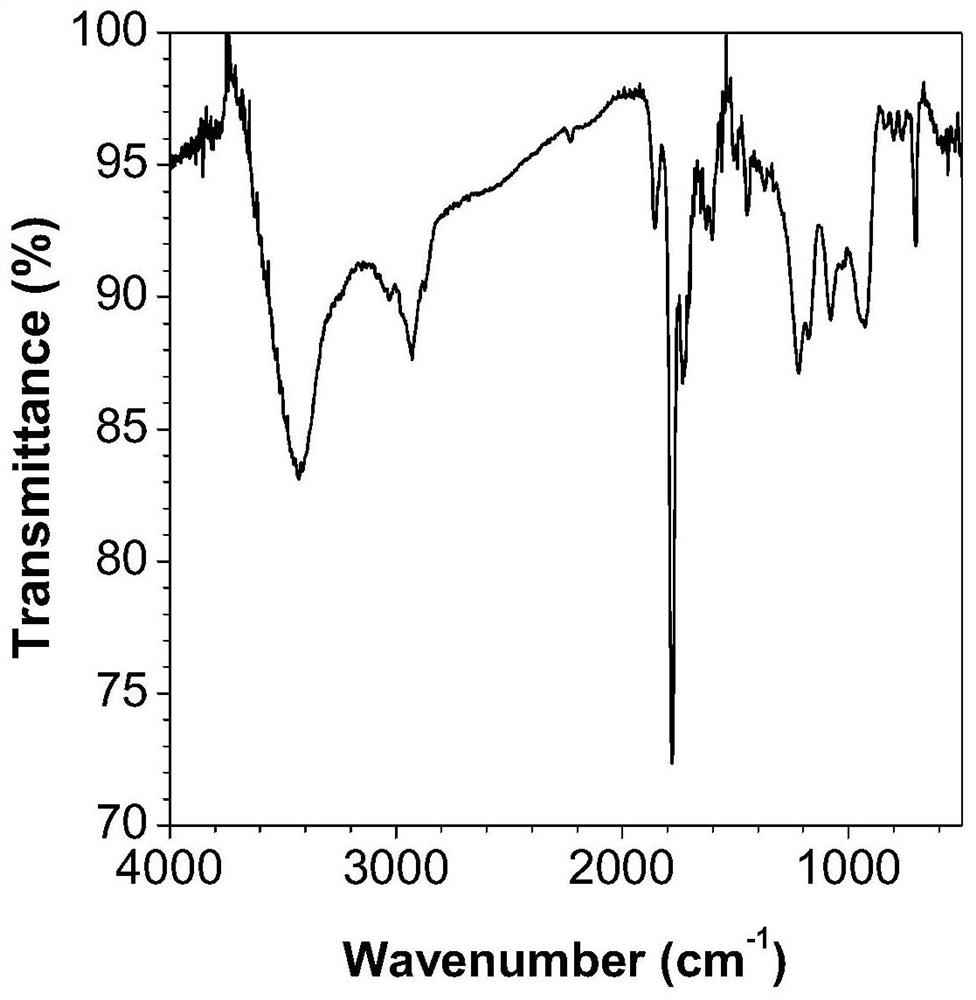

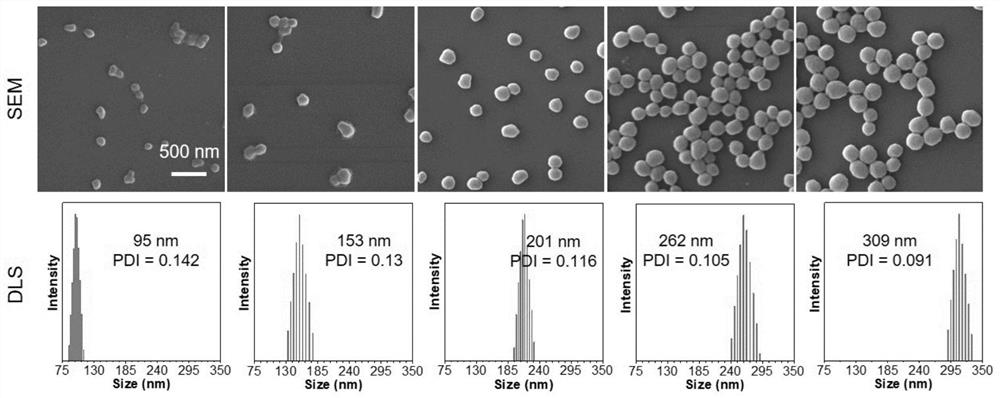

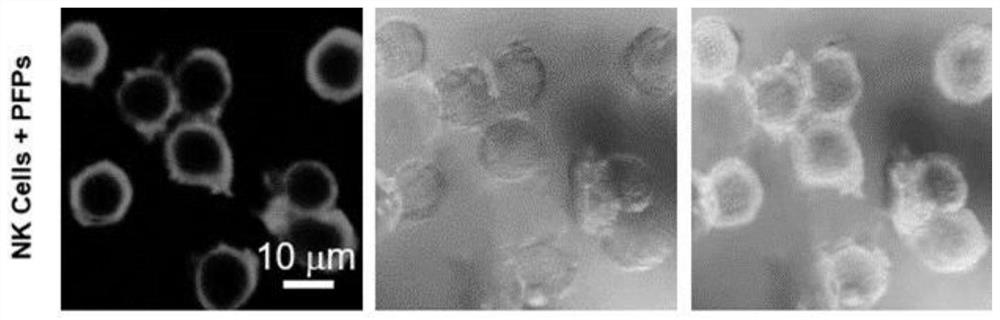

Fluorescent polymer based on aggregation-induced emission effect as well as preparation method and application thereof

ActiveCN111620980AAchieve surface functionalizationDifferent load rateBiocideFungicidesCross linkerStructural formula

The invention discloses an aggregation-induced emission effect-based multifunctional fluorescent polymer which is controllable in particle size and convenient to modify as well as a preparation methodand an application of the aggregation-induced emission effect-based multifunctional fluorescent polymer. The fluorescent polymer contains a structural formula unit as shown in a formula (I) which isdescribed in the specification, n is equal to 10-10000, and R is a structural group with an aggregation-induced emission function. A precipitation polymerization reaction is carried out on an AIE polymerizable unit, maleic anhydride, styrene and an optional cross-linking agent in the presence of an initiator to obtain the fluorescent polymer. The fluorescent polymer can be applied to immunoregulation, cell labeling, material antibiosis and roughness detection.

Owner:BEIJING UNIV OF CHEM TECH

FPGA-based multipath synchronous data acquisition module

InactiveCN107132790AHighly integratedEasy programmingProgramme controlComputer controlVIT signalsPeripheral

The invention discloses an FPGA-based multi-channel synchronous data acquisition module, which belongs to the field of data acquisition technology. The FPGA controls multiple ADCs to simultaneously acquire signals, and buffers the obtained data into SRAM in sequence, and then transmits them to DSP through a serial port for further processing. Processing, including data acquisition module, FPGA clock management module, dual-open RAM module, serial interface module and AD conversion circuit module; the data acquisition module converts the analog signal of the sensor into an effectively coded digital signal by setting different parameters to adapt to different analog signals Signal; the AD conversion circuit module burns the program to the FPGA, debugs the program through the JTAG mode, and burns the program to the configuration chip in the AS mode. The invention collects multi-channel signals synchronously, effectively reduces peripheral circuits, lowers overall power consumption, and achieves higher precision when multi-channel signals are collected simultaneously.

Owner:INSPUR TIANYUAN COMM INFORMATION SYST CO LTD

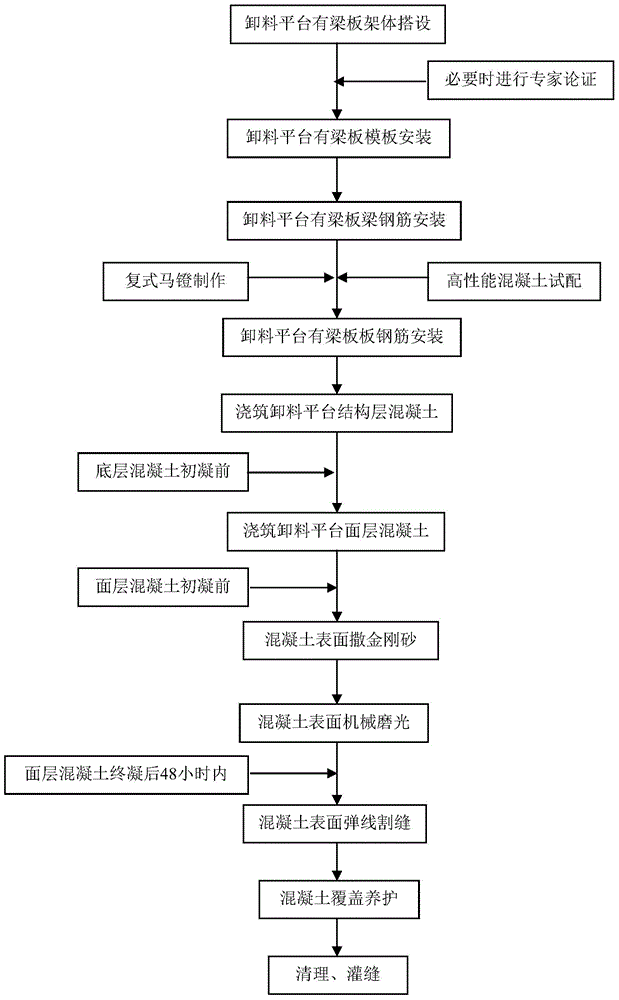

Composite surface construction technology for garbage discharging platform of garbage incineration power plant

ActiveCN104929365ASolve the performance of compression resistance and bending resistanceImprove wear resistanceBuilding material handlingPower stationArchitectural engineering

The invention particularly relates to a composite surface construction technology for a garbage discharging platform of a garbage incineration power plant. The composite surface construction technology for the garbage discharging platform of the garbage incineration power plant is characterized by comprising the steps that 1, concrete is prepared; 2, a formwork support and steel bars are erected; 3, composite horse stools are prepared and welded; 4, double-deck double-way steel bars are arranged; 5, inspection is conducted before the concrete is poured; 6, concrete pouring is conducted; 7, carborundum is sprinkled when strengthened surfaces are poured; 8, concrete surface elevation is controlled, and screeding and leveling are conducted; 9, concrete curing is conducted. Compared with a construction technology of the prior art, the composite surface construction technology for the garbage discharging platform of the garbage incineration power plant has the advantages that the construction technology is detailed, the innovativeness is strong, the scientificity is strong and the operability is strong; integrality construction is achieved, the construction technology is not compressing and stacking of the construction steps, the function of a whole structure layer is changed, and the comprehensive effects of being resistant to pressure, abrasion, corrosion, seepage, fracture and the like are achieved; construction is simultaneously conducted on the structure layer and the surface effectively, and the construction period is shortened; 4, the safety and the reliability are achieved, and the economic benefits are significant.

Owner:SHANDONG ZIJIAN GRP

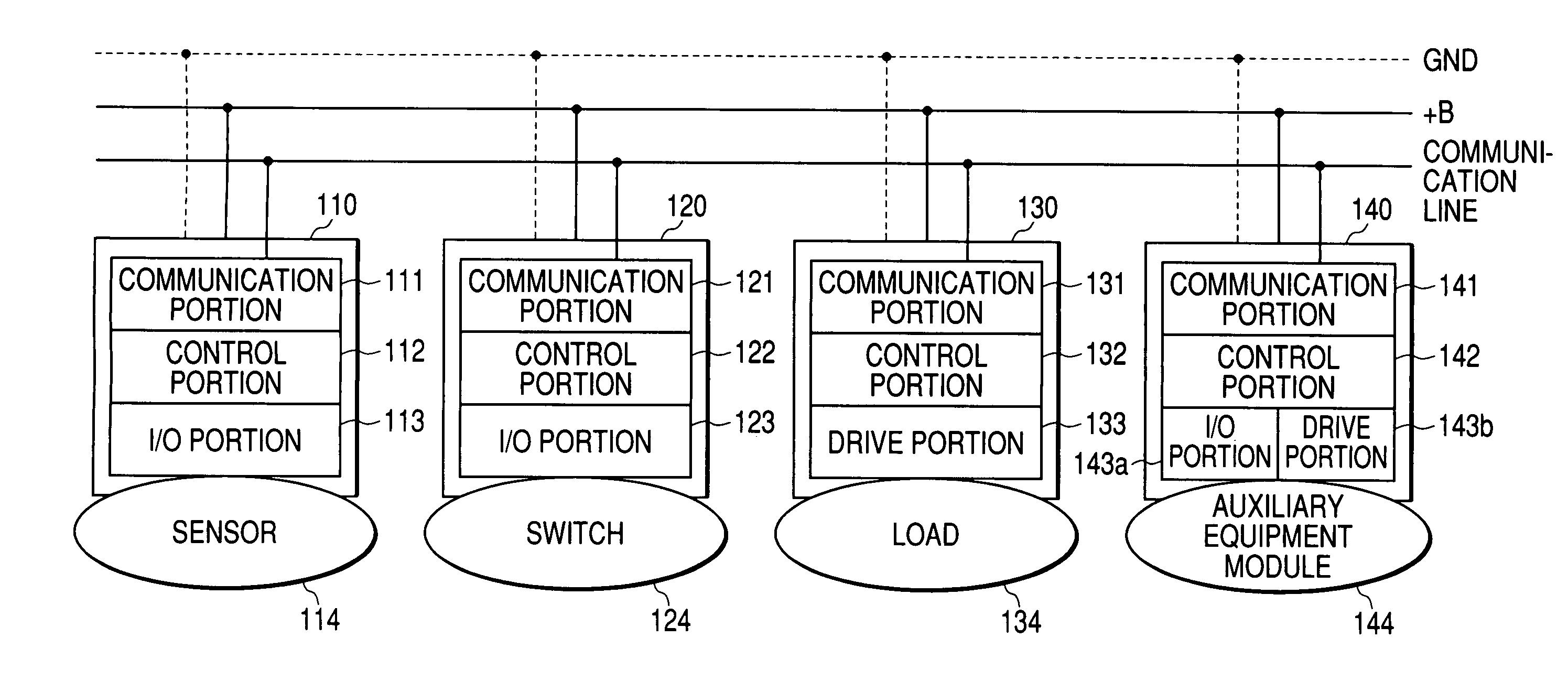

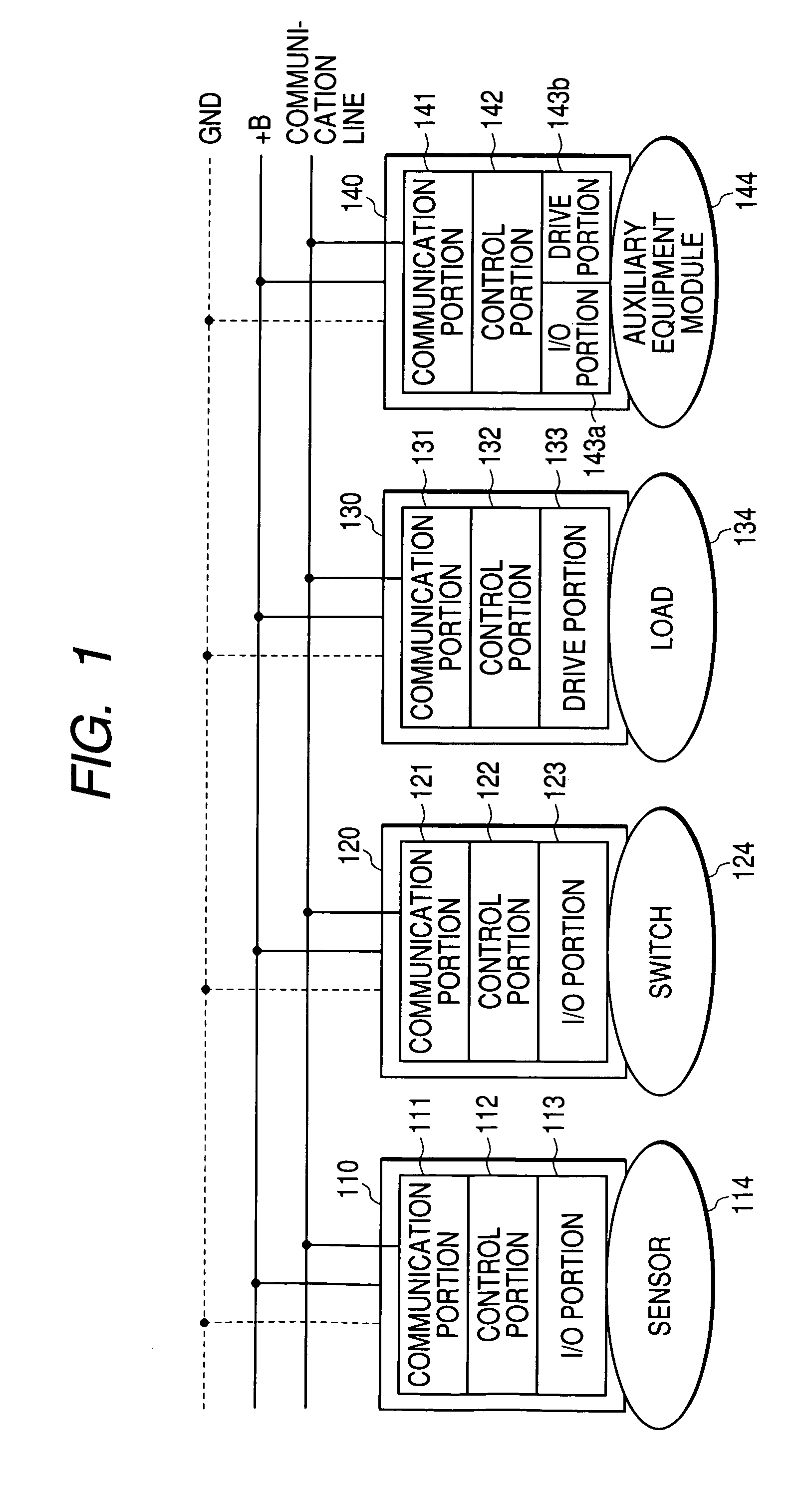

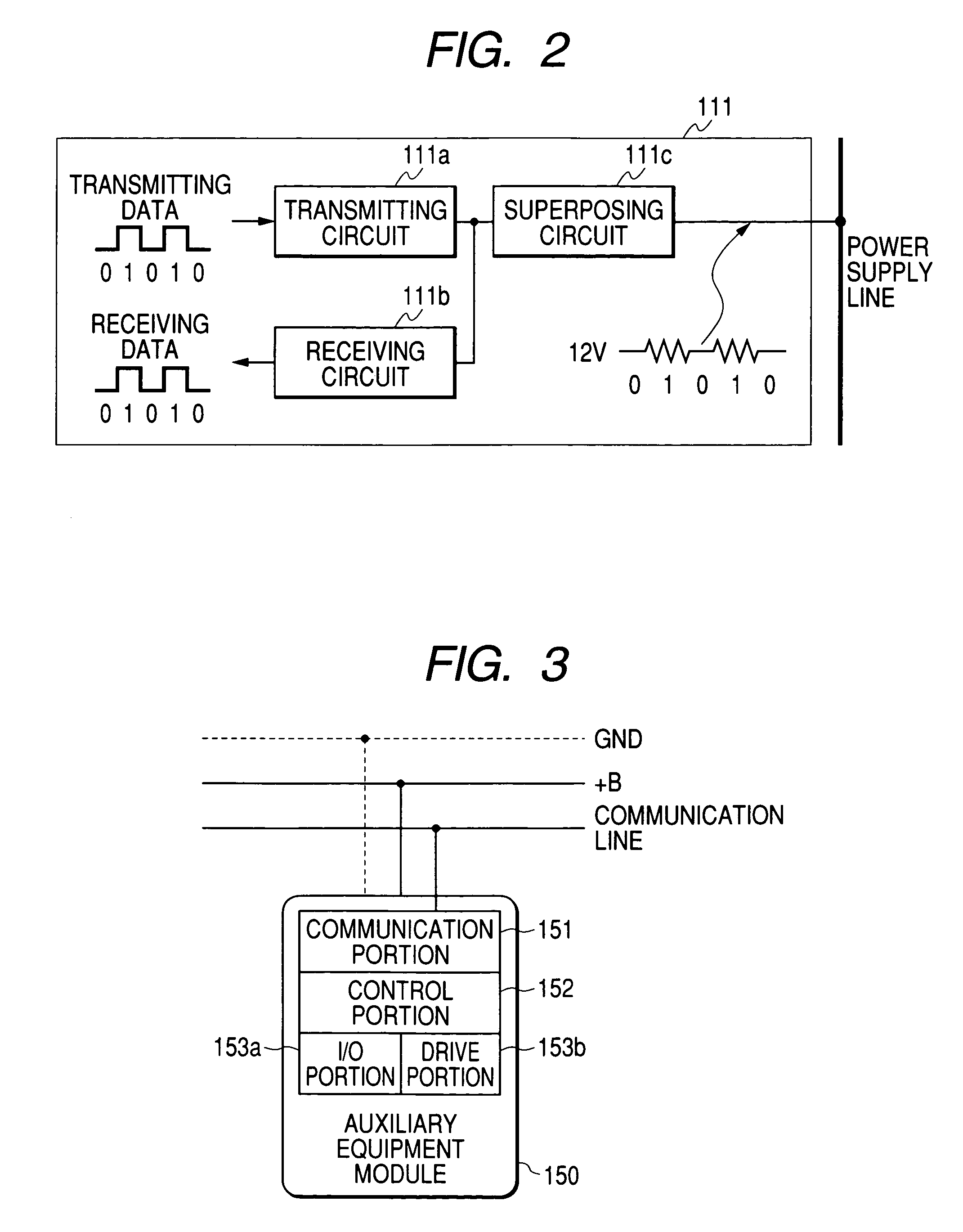

Method of communicating a signal from a sensor, connected to a connector, to an auxiliary module

InactiveUS7356714B2Save wireChange functionProgramme controlComputer controlCommunication unitControl signal

An electronic connector connected to a sensor or a switch, and communicating a signal through a common bus includes an I / O unit receiving a signal from the sensor or the switch, a control unit generating a control signal for controlling the driving of a load corresponding to the sensor or the switch according to the signal received from the I / O unit, and a communication unit having a function of decoding the control signal and transmitting the control signal to an equipment connected to the corresponding load through the common bus.

Owner:YAZAKI CORP

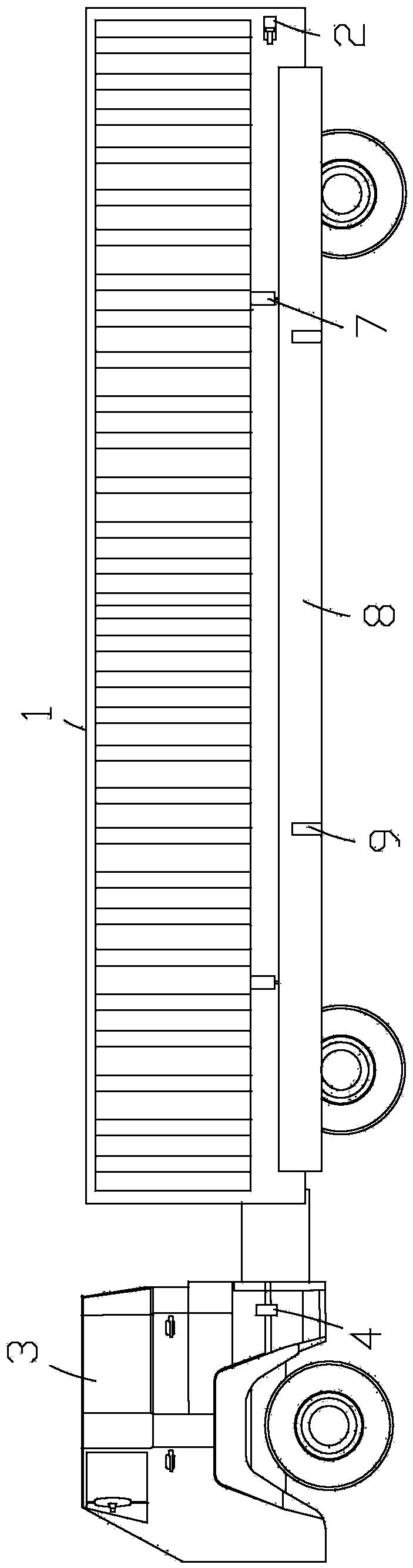

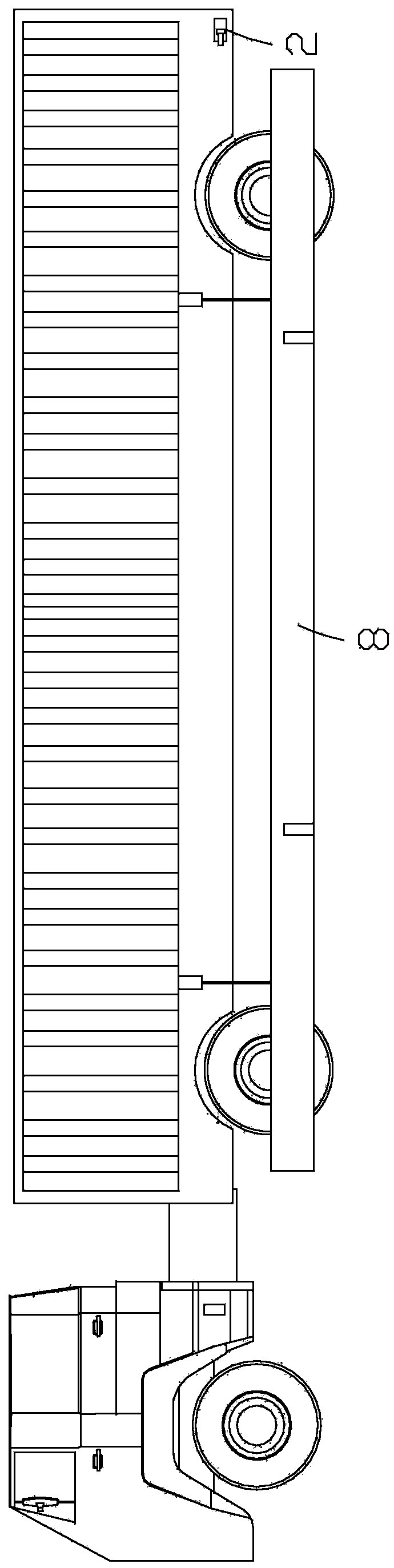

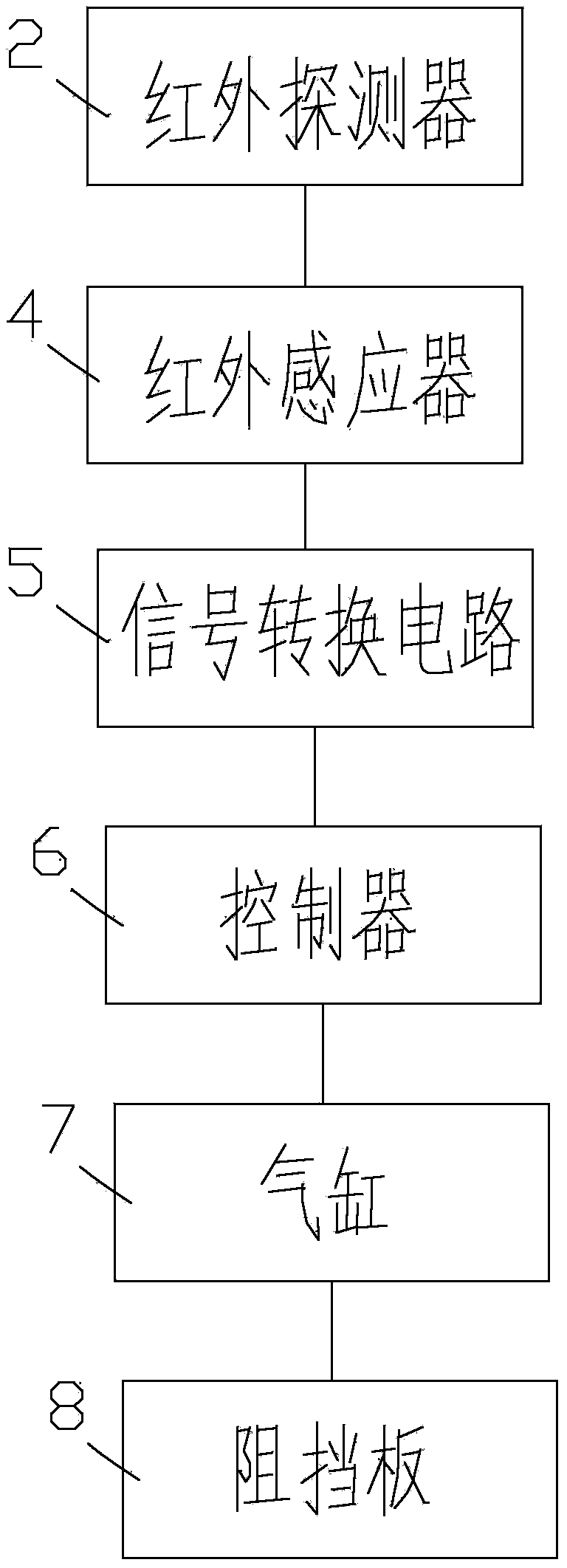

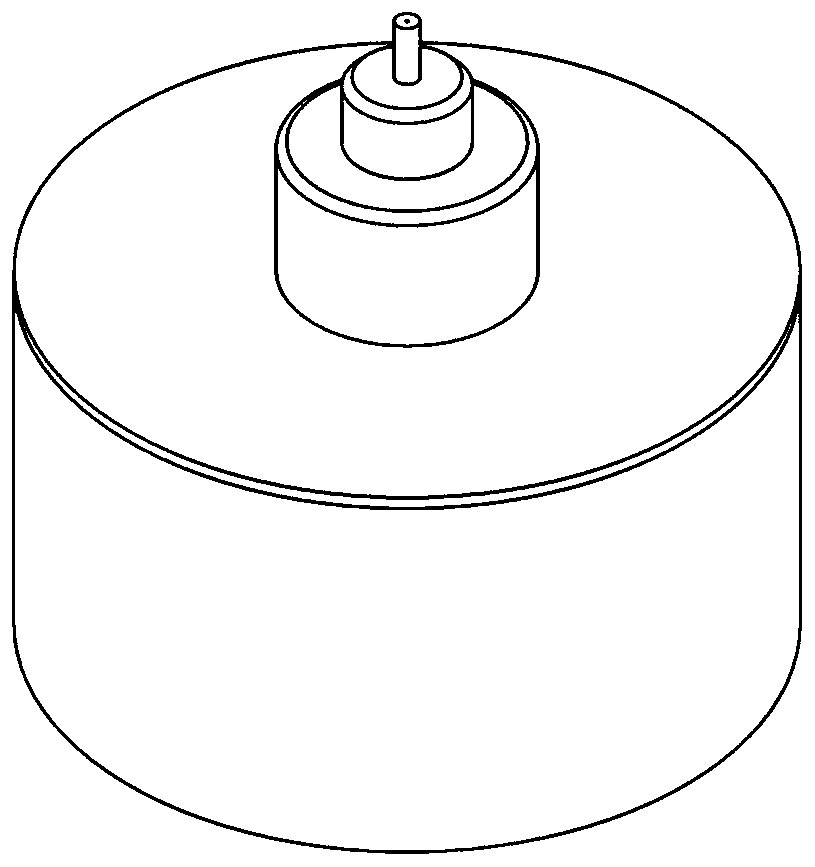

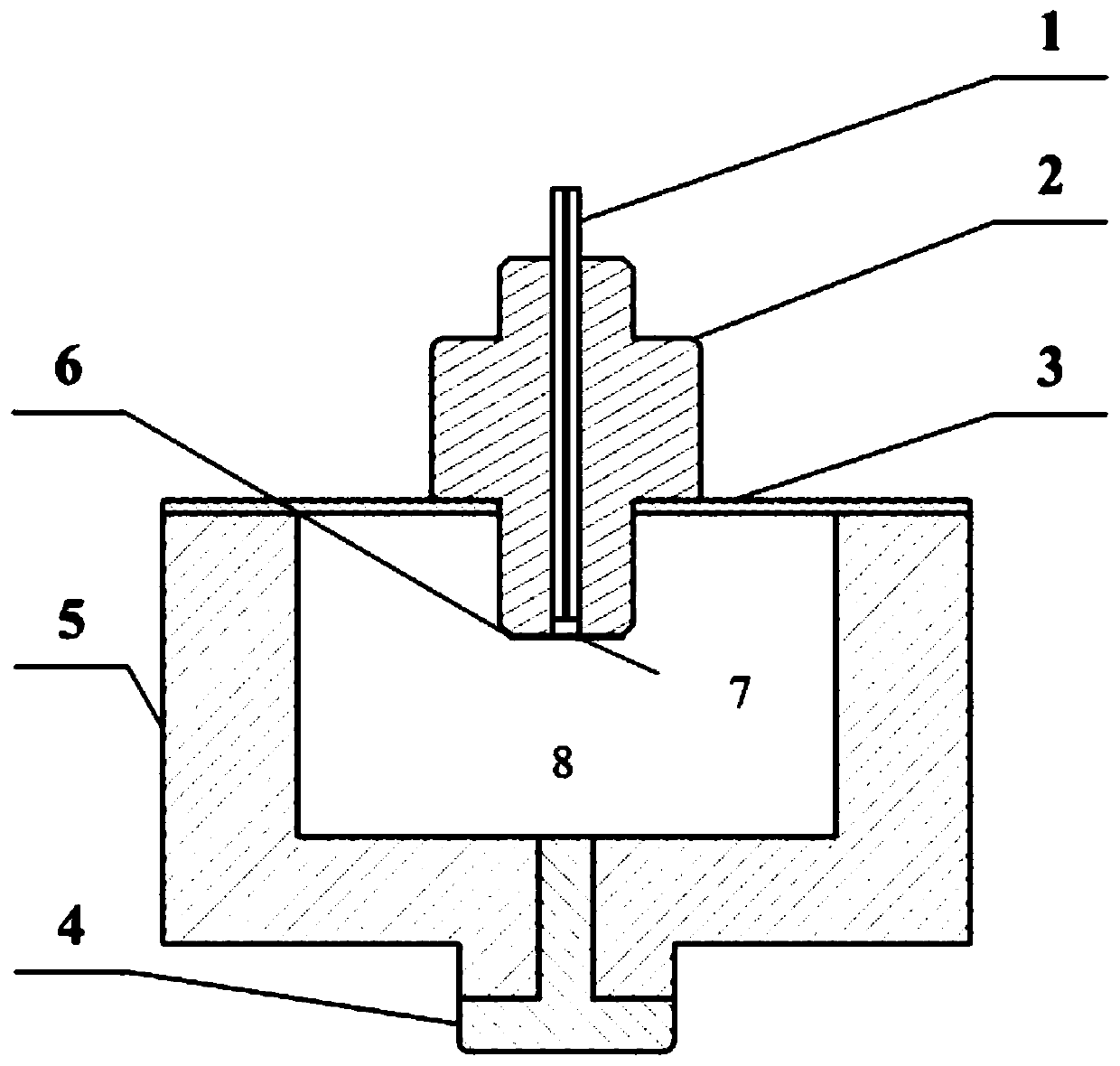

Trailer with automatic detecting and protecting functions

The invention relates to a trailer with an automatic detecting and protecting functions and relates to the technical field of trucks. The safe, intelligent and ultra-long flat-bed trailer comprises infrared emitters mounted on the side walls on two sides of a carriage of the trailer and infrared sensors mounted on the outer wall of a cab and matched with the infrared emitters. The signals of the infrared sensors are connected to a controller in the cab through a signal conversion circuit. At least two sets of air cylinders are mounted on two sides of the bottom of the carriage. The end of a piston rod of each air cylinder is fixedly connected with a stopping board. Each air cylinder is connected to the controller and controlled by the same. Each air cylinder drives the corresponding stopping board to enable the bottom of the stopping board to move 10-50cm away from the ground. The trailer has the advantages that functions of traditional trailers are changed, driving safety is increased, vehicle and pedestrian safety can be protected especially during turning, and vehicles and pedestrians can be prevented from being caught up into the bottom of the trailer.

Owner:ANHUI QIANGSHENG TRANSPORTATION EQUIP MFG

Pressure-sensitive-based graphene resonant fiber accelerometer

ActiveCN109782022AEasy to design and manufactureEasy to installAcceleration measurement using interia forcesFiberIn plane

The invention discloses a pressure-sensitive-based graphene resonant fiber accelerometer comprising an optical fiber (1), a ferrule (2), an elastic sheet (3), a sealing plug (4), a gas sealed cavity (5), and a graphite film (6). The acceleration measurement is realized by using the internal pressure of the direct sensitive cavity of the graphene film. The ferrule mounted on the elastic sheet directly senses the measured acceleration as a main additional mass and the elastic sheet is driven to make longitudinal displacement, so that the gas pressure in the sealed cavity is caused to change; thepressure is applied to the graphene film to change the in-plane stress, so that the change of the resonance frequency of the graphene film is caused; and the demodulation resonance frequency is detected by the interference light to realize acceleration measurement. With full utilization of the mechanical, optical and resonance characteristics of grapheme, the accelerometer has the outstanding characteristics of high sensitivity, large measuring range, strong anti-interference ability, great easiness in manufacture and installation.

Owner:BEIHANG UNIV

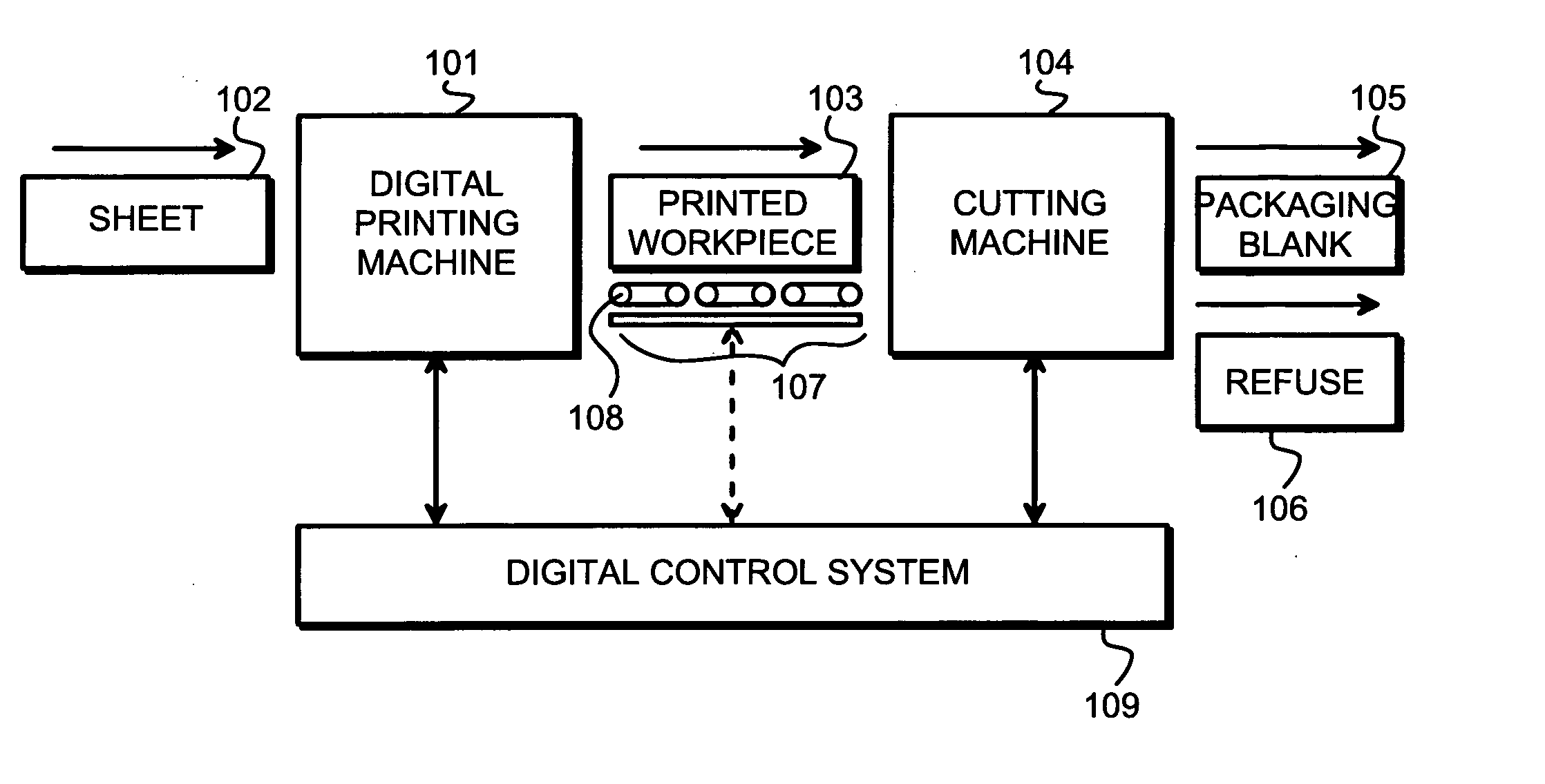

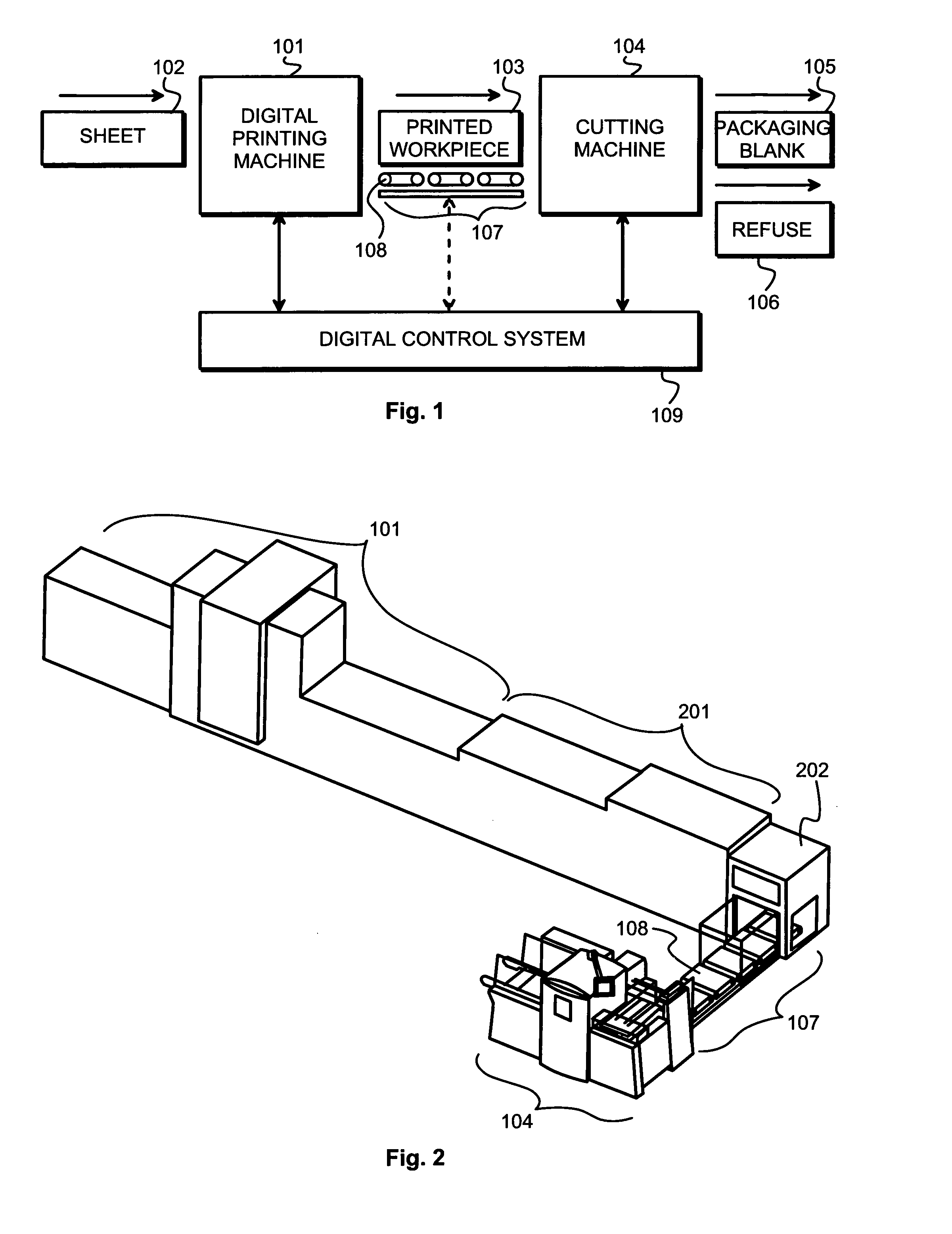

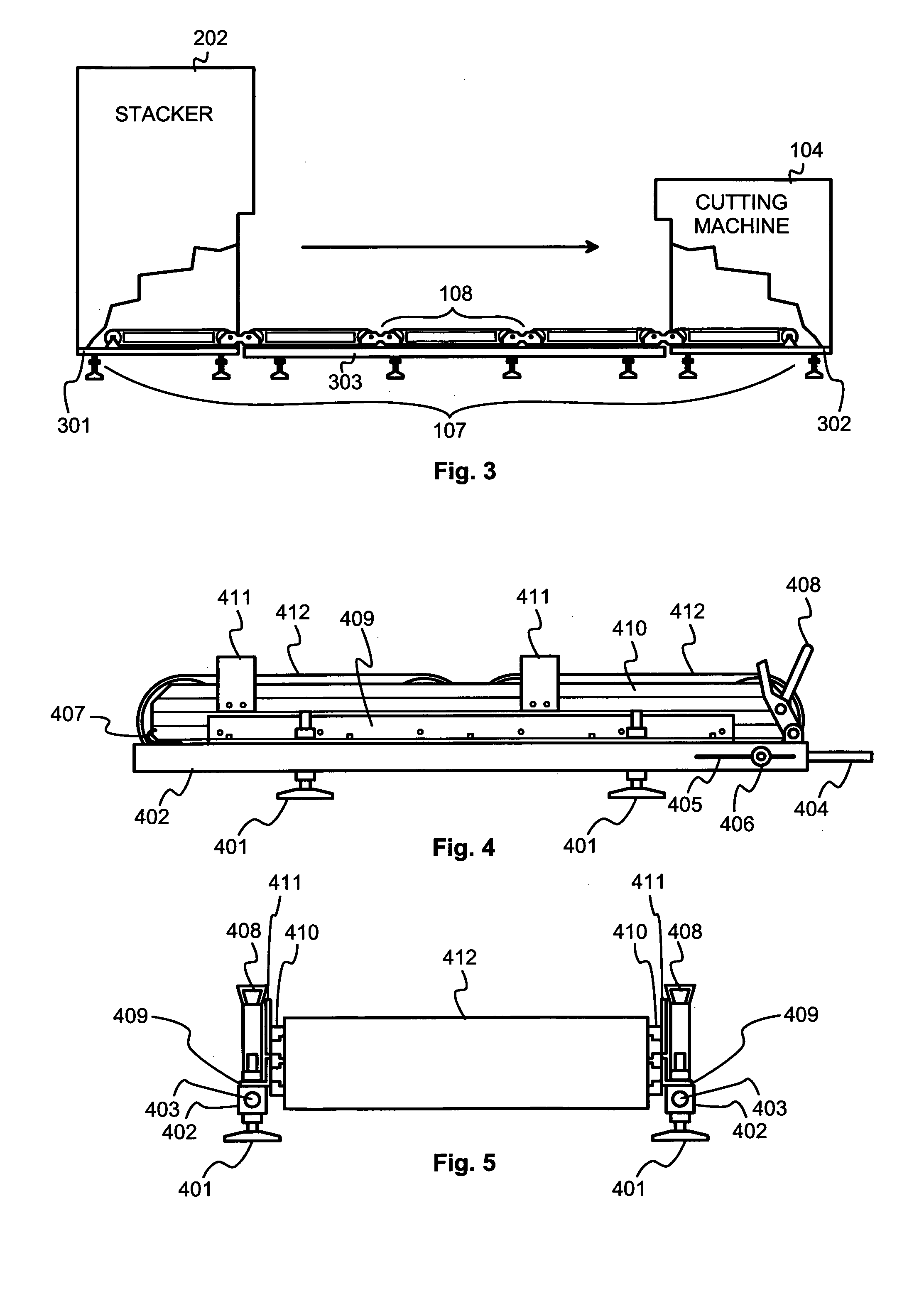

Method and arrangement for manufacturing packages in a digitally controlled process

ActiveUS8493421B2Raise the possibilitySupport traceability and authenticationPaper-makingBox making operationsControl systemDigital printing

Packages are manufactured in a digitally controlled process. A digital printing machine (101) produces printed workpieces and a cutting machine (104) cuts packaging blanks (105) from them. A conveyor line (107) transfers the printed work-pieces automatically from the digital printing machine (101) to the cutting machine (104). A digital control system (109) exchanges digital control information with at least the digital printing machine (101) and the cutting machine (104).

Owner:TRESU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com