Composite surface construction technology for garbage discharging platform of garbage incineration power plant

A technology of waste incineration and unloading platform, which is applied in the processing of building materials, construction, building structure, etc. It can solve the problems of affecting the use function, difficult maintenance, surface cracking, etc., to achieve detailed construction technology and solve the pressure resistance Does not resist bending and increases wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

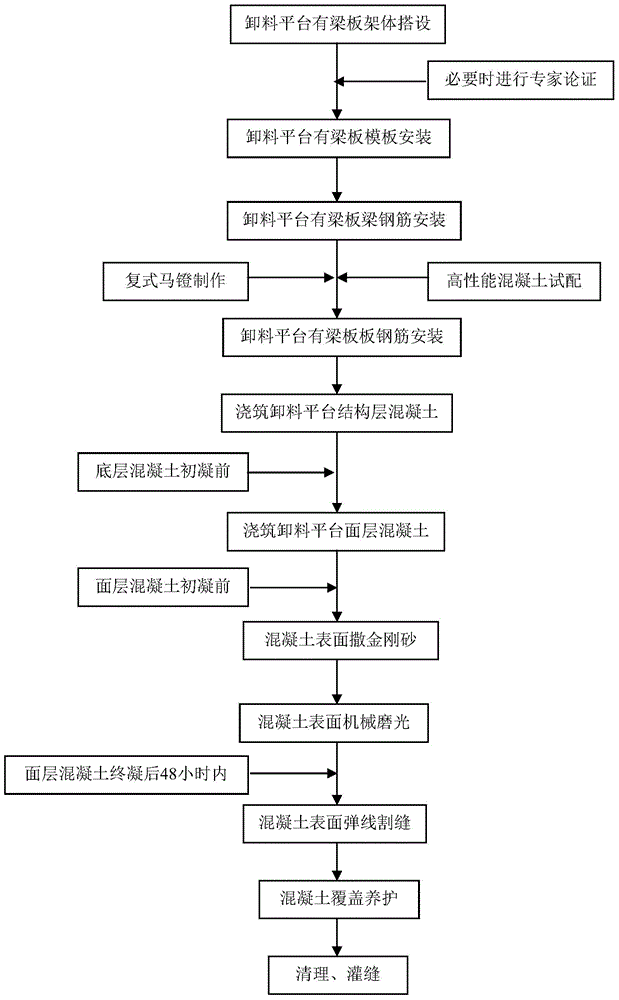

Method used

Image

Examples

Embodiment Construction

[0044] 1. Preparatory work before construction

[0045] 1 Be familiar with the construction drawings, and clarify the structure of the unloading platform and the construction method of the surface layer.

[0046] 2 According to the requirements of the drawing, the construction of the frame column under the unloading platform has been completed;

[0047] 3 Compile a complete construction plan for the integral surface layer of the unloading platform, which shall be approved by the supervisor and the construction unit; if the formwork support system is greater than 8m, expert demonstration must be conducted before the next process can be constructed.

[0048] 4 The machinery, equipment and materials to be selected have all been present and passed the inspection;

[0049] 2. Trial mix of structural layer concrete

[0050] 1) Various performance indicators required by concrete

[0051] ⑴Compressive strength≥C30

[0052] ⑵Bending strength ≥ 5KPa

[0053] ⑶ Resistance to organic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power level | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com