Patents

Literature

39results about How to "Avoid the possibility of damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

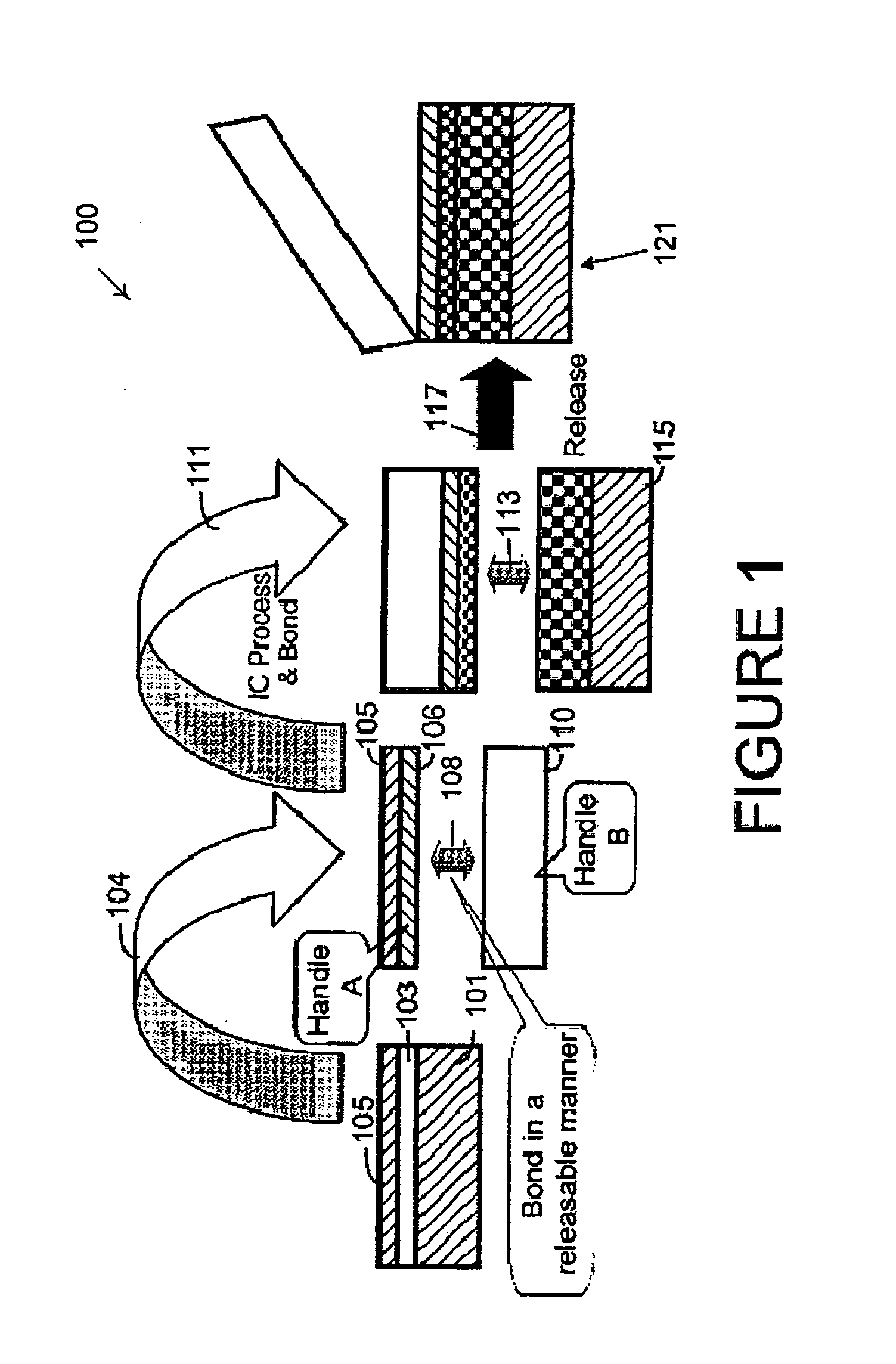

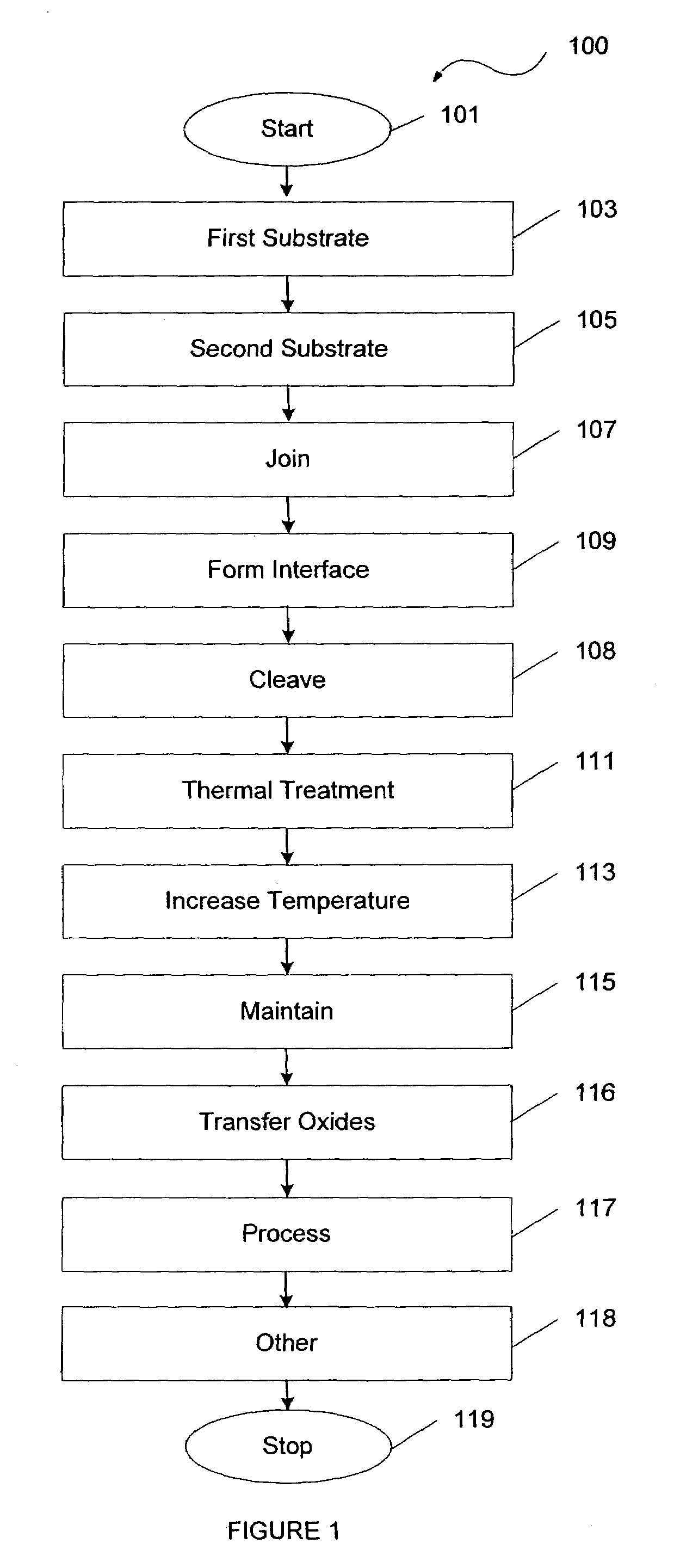

Thin handle substrate method and structure for fabricating devices using one or more films provided by a layer transfer process

ActiveUS7166520B1Avoid the possibility of damageEfficient processingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsEngineering

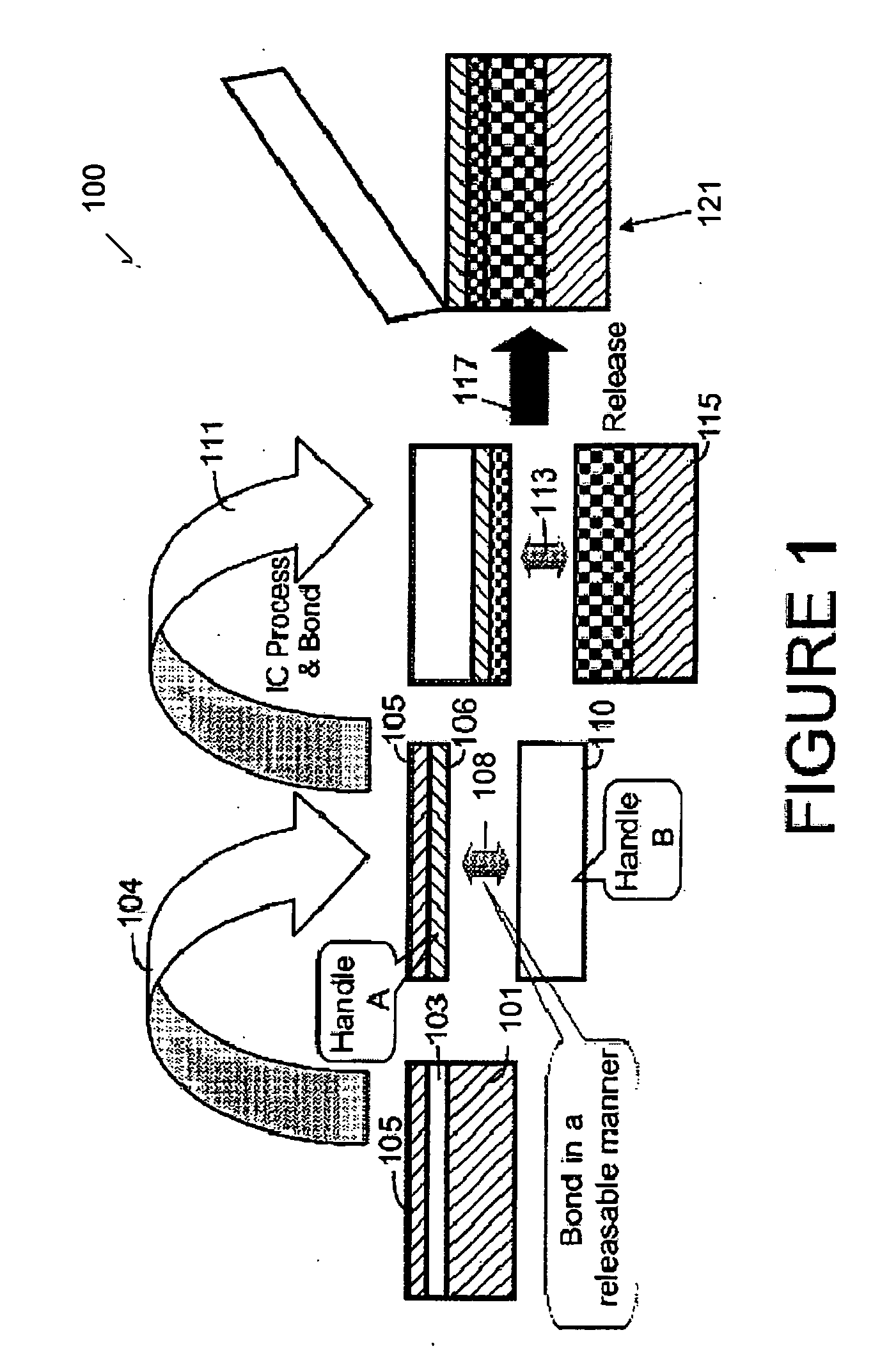

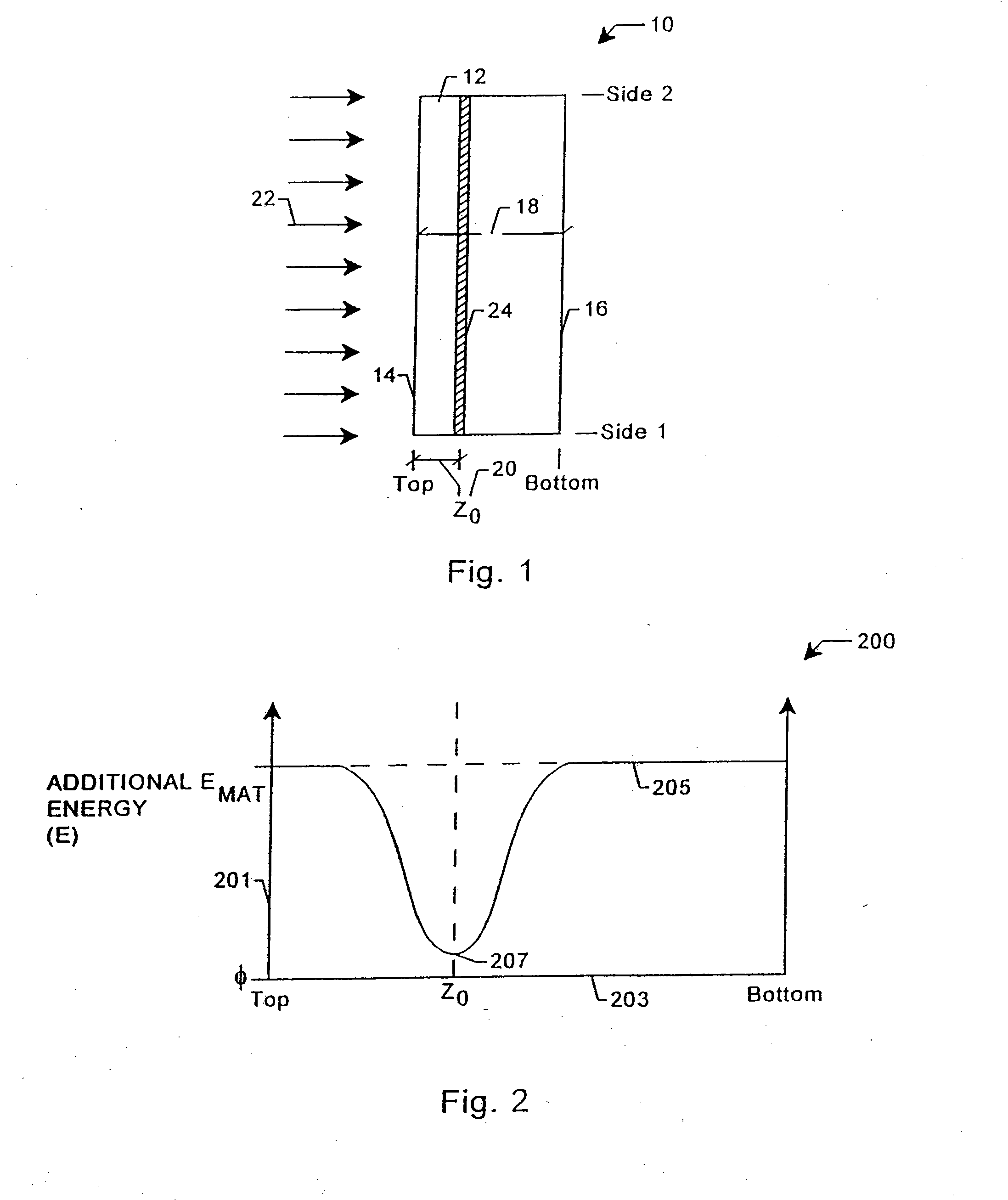

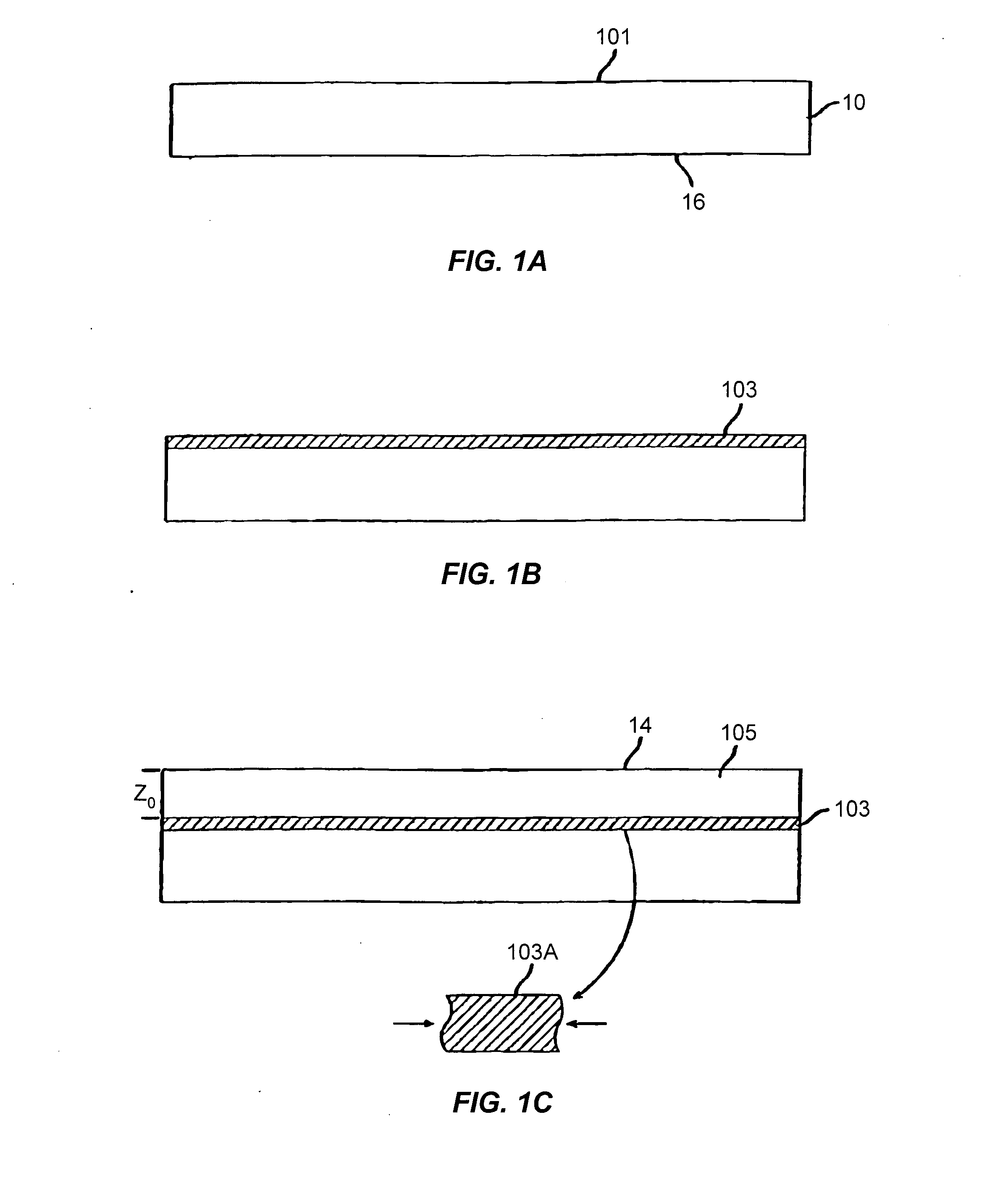

A method for fabricating one or more devices, e.g., integrated circuits. The method includes providing a substrate (e.g., silicon), which has a thickness of semiconductor material and a surface region. The substrate also has a cleave plane provided within the substrate to define the thickness of semiconductor material. The method includes joining the surface region of the substrate to a first handle substrate. In a preferred embodiment, the first handle substrate is termed a “thin” substrate, which provides suitable bonding characteristics, can withstand high temperature processing often desired during the manufacture of semiconductor devices, and has desirable de-bonding characteristics between it and a second handle substrate, which will be described in more detail below. In a preferred embodiment, the first handle substrate is also thick enough and rigid enough to allow for cleaving according to a specific embodiment.

Owner:SILICON GENERAL CORPORATION

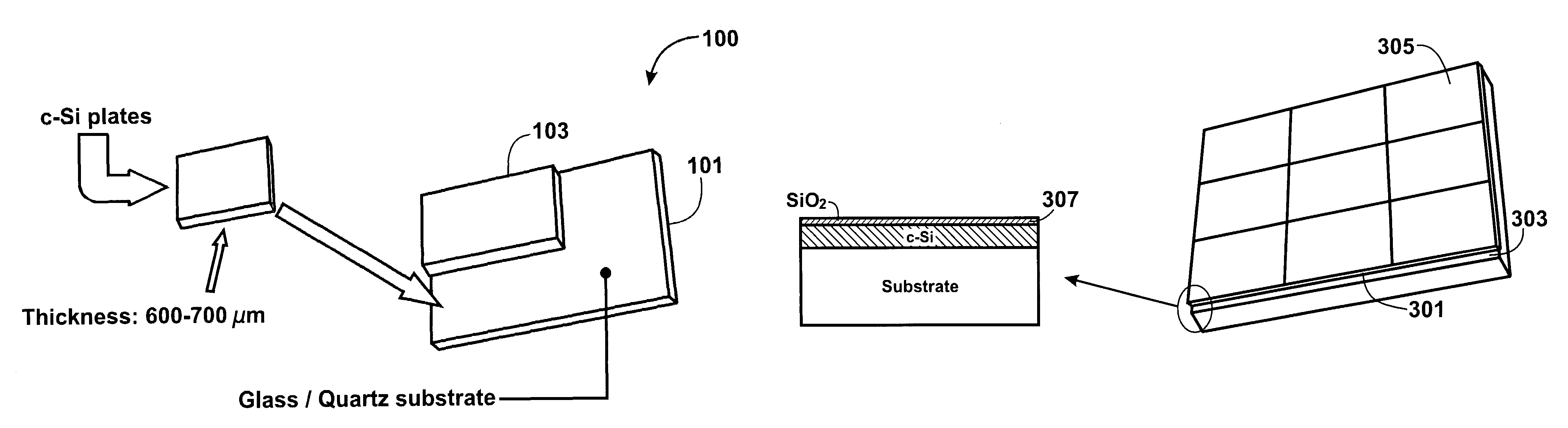

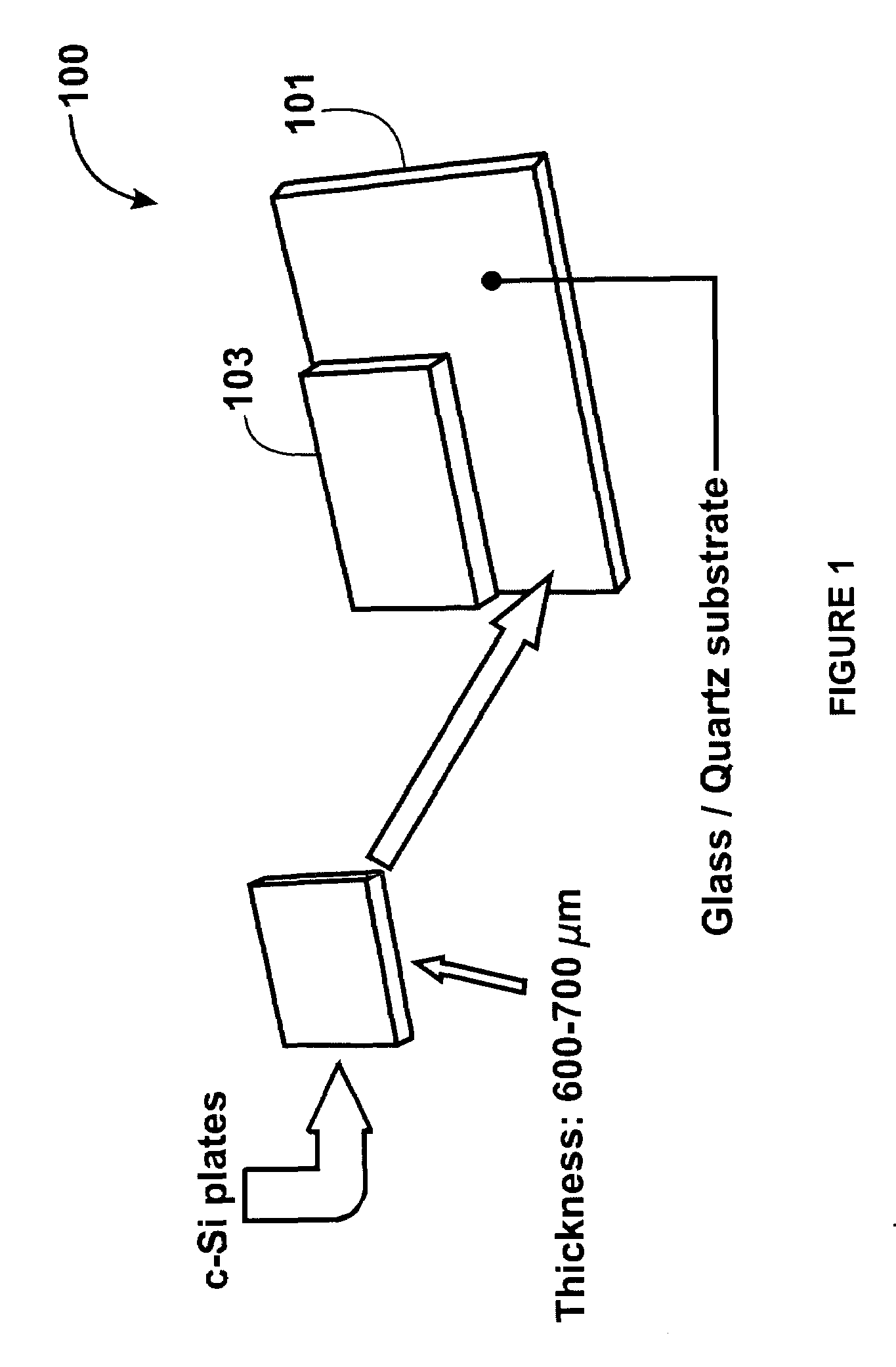

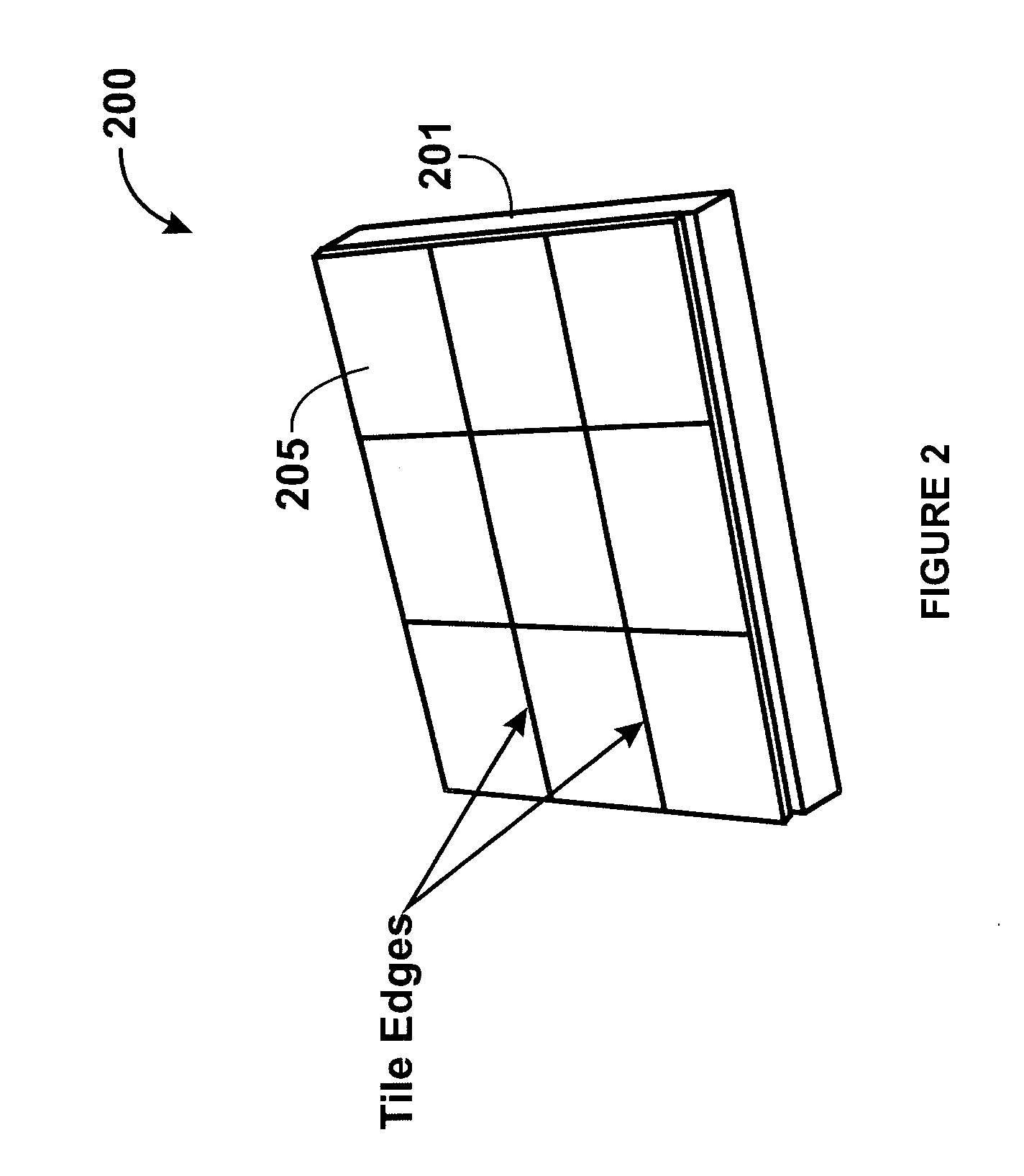

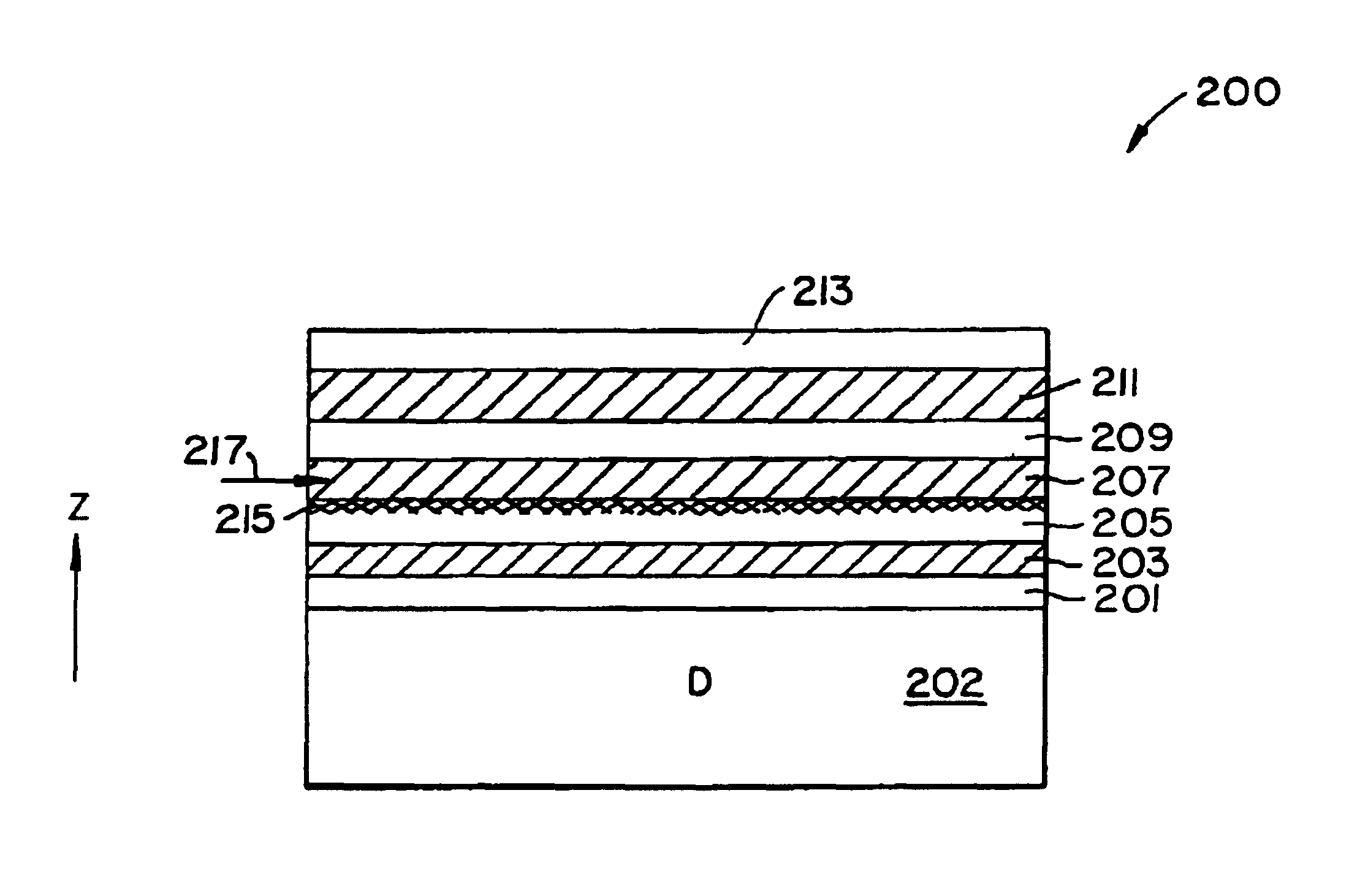

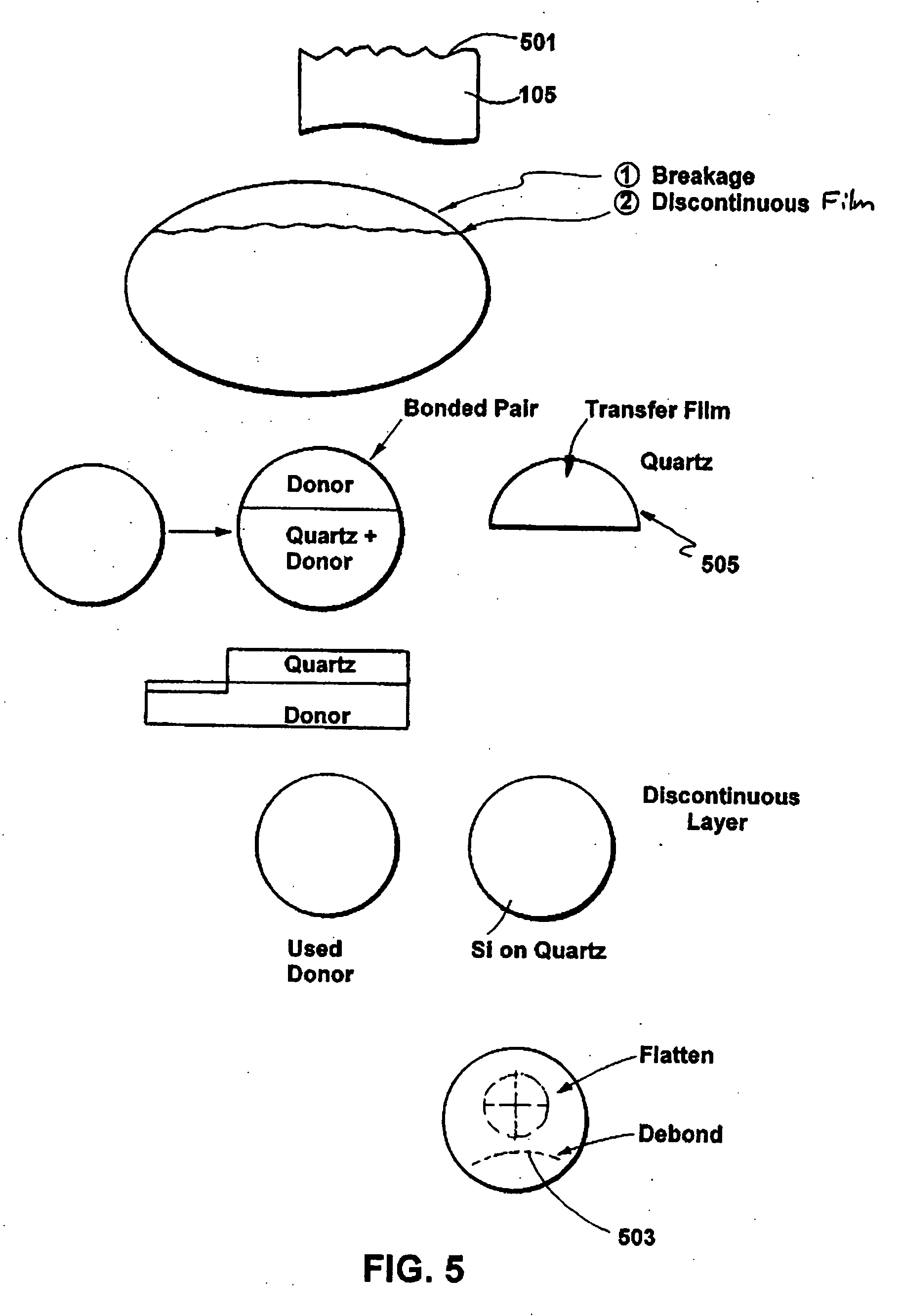

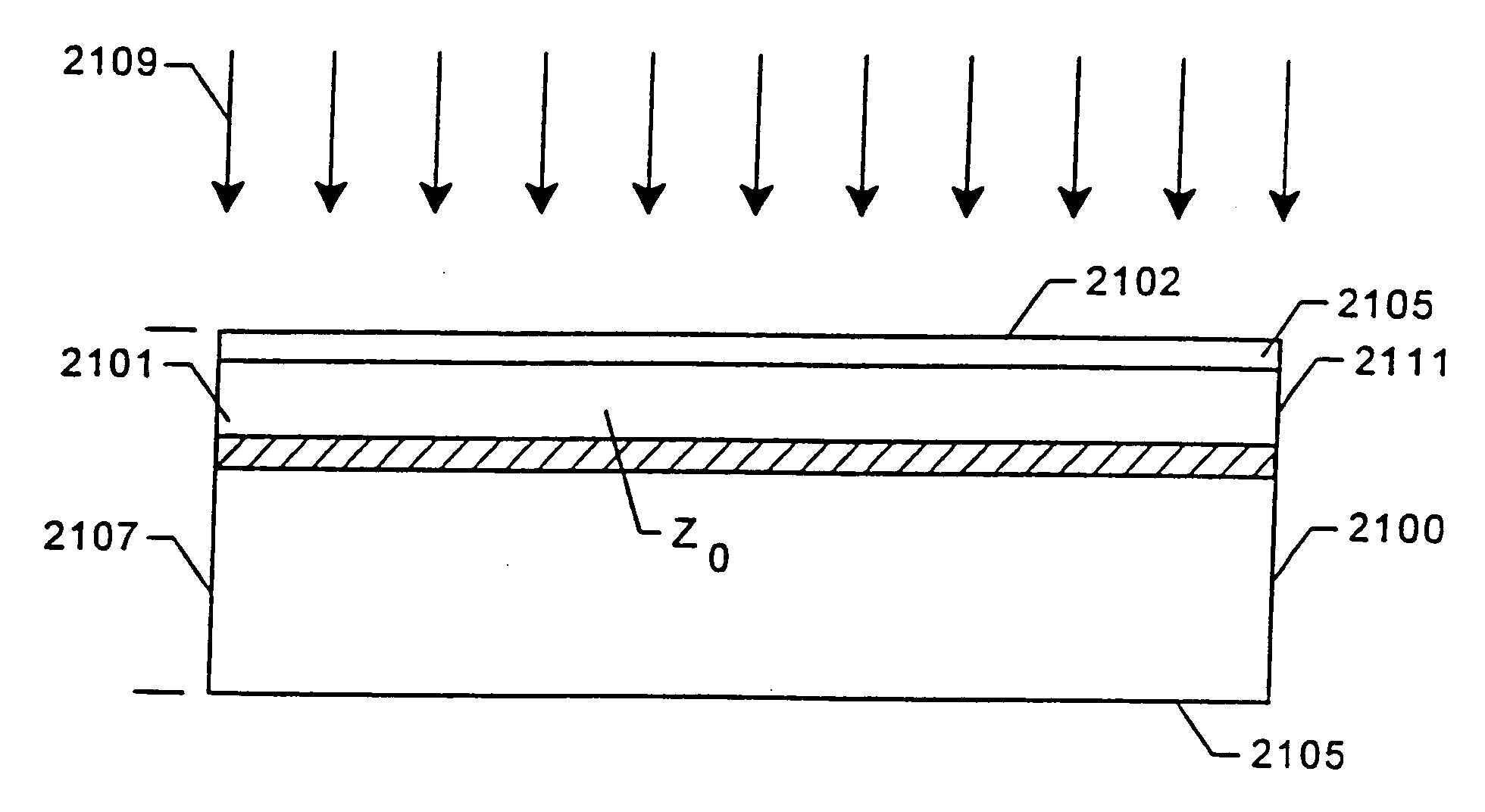

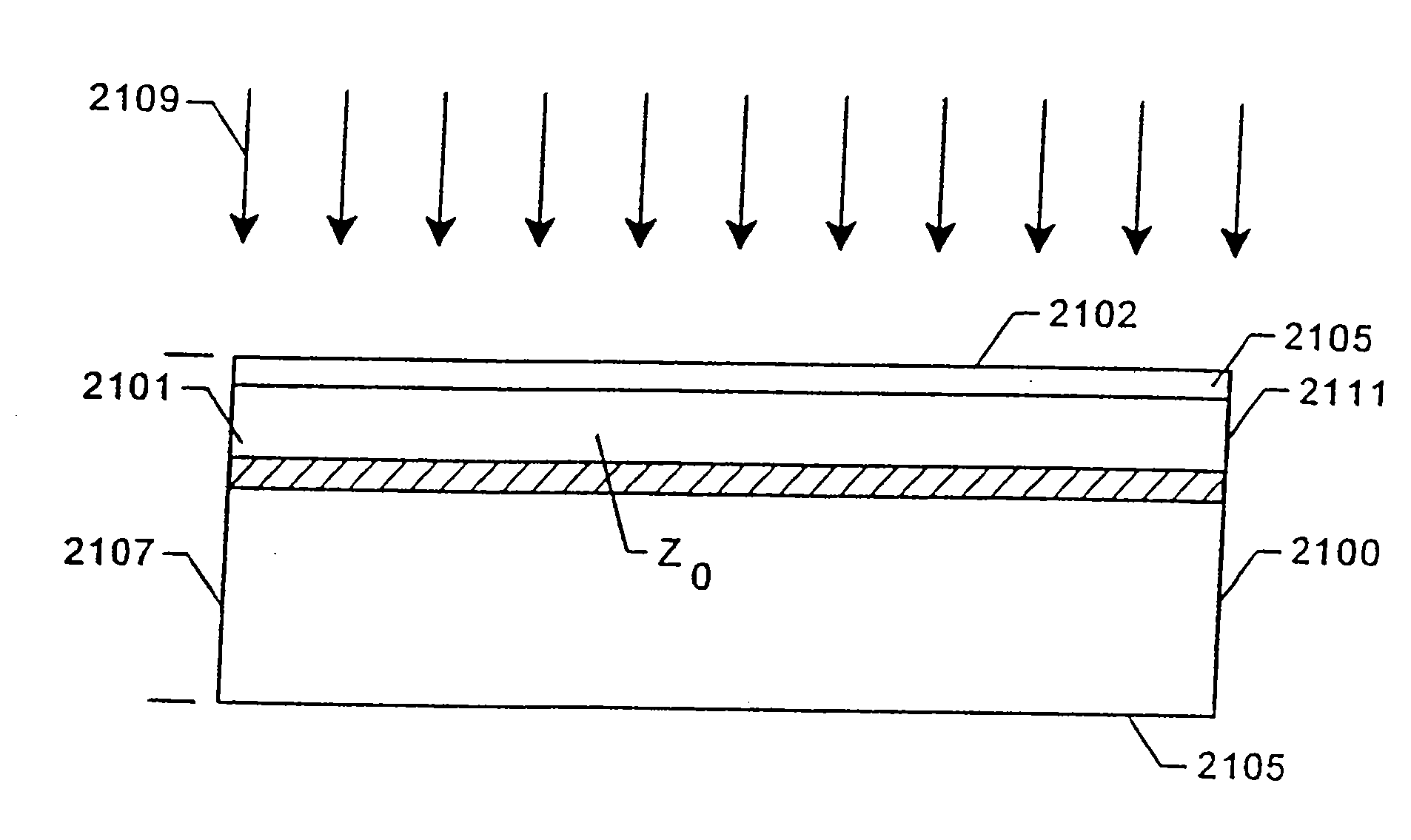

Method and structure for fabricating multiple tiled regions onto a plate using a controlled cleaving process

InactiveUS7674687B2Avoid the possibility of damageEfficient processingSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSubstrate surfaceChemistry

A reusable transfer substrate member for forming a tiled substrate structure. The member including a transfer substrate, which has a surface region. The surface region comprises a plurality of donor substrate regions. Each of the donor substrate regions is characterized by a donor substrate thickness and a donor substrate surface region. Each of the donor substrate regions is spatially disposed overlying the surface region of the transfer substrate. Each of the donor substrate regions has the donor substrate thickness without a definable cleave region.

Owner:SILICON GENERAL CORPORATION

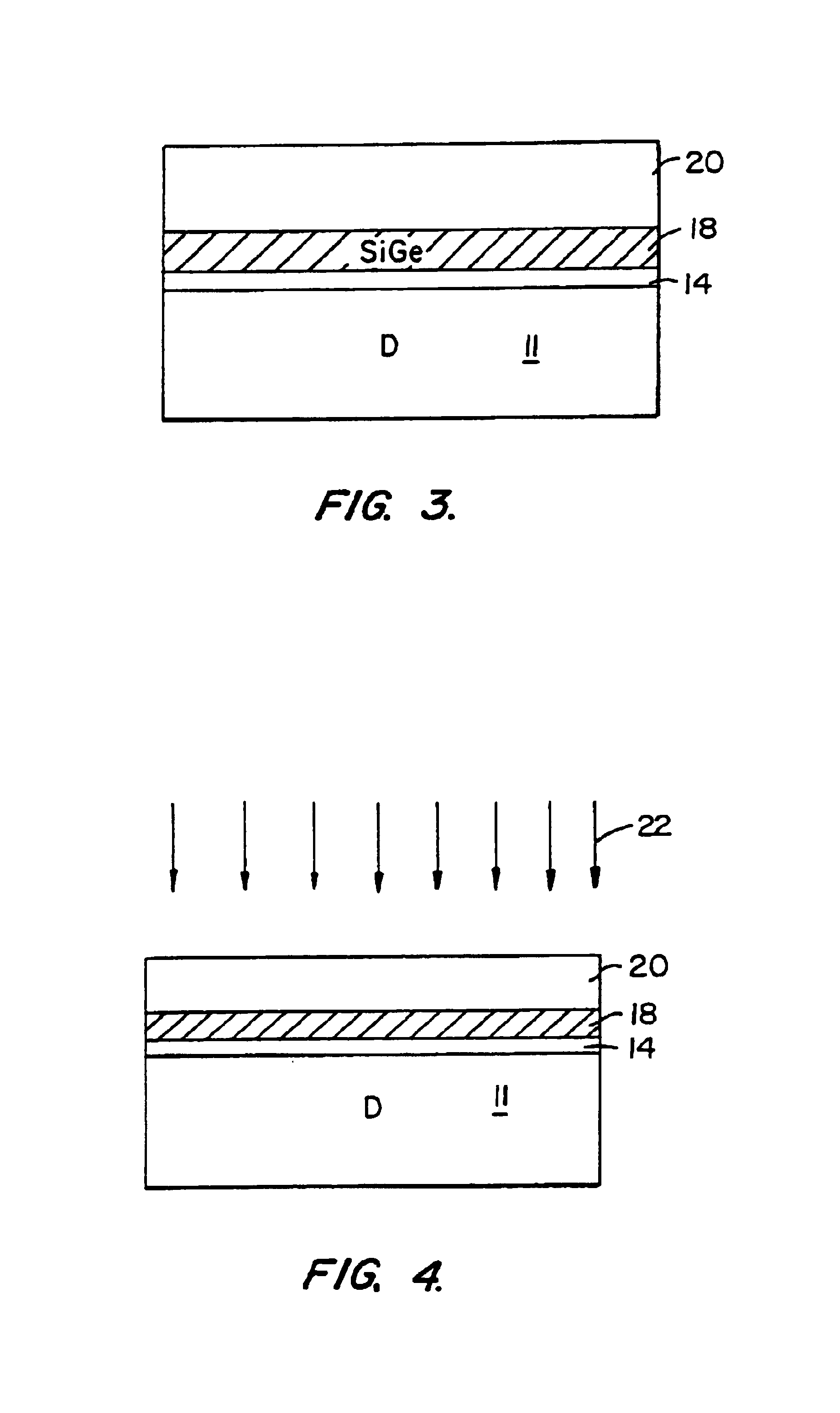

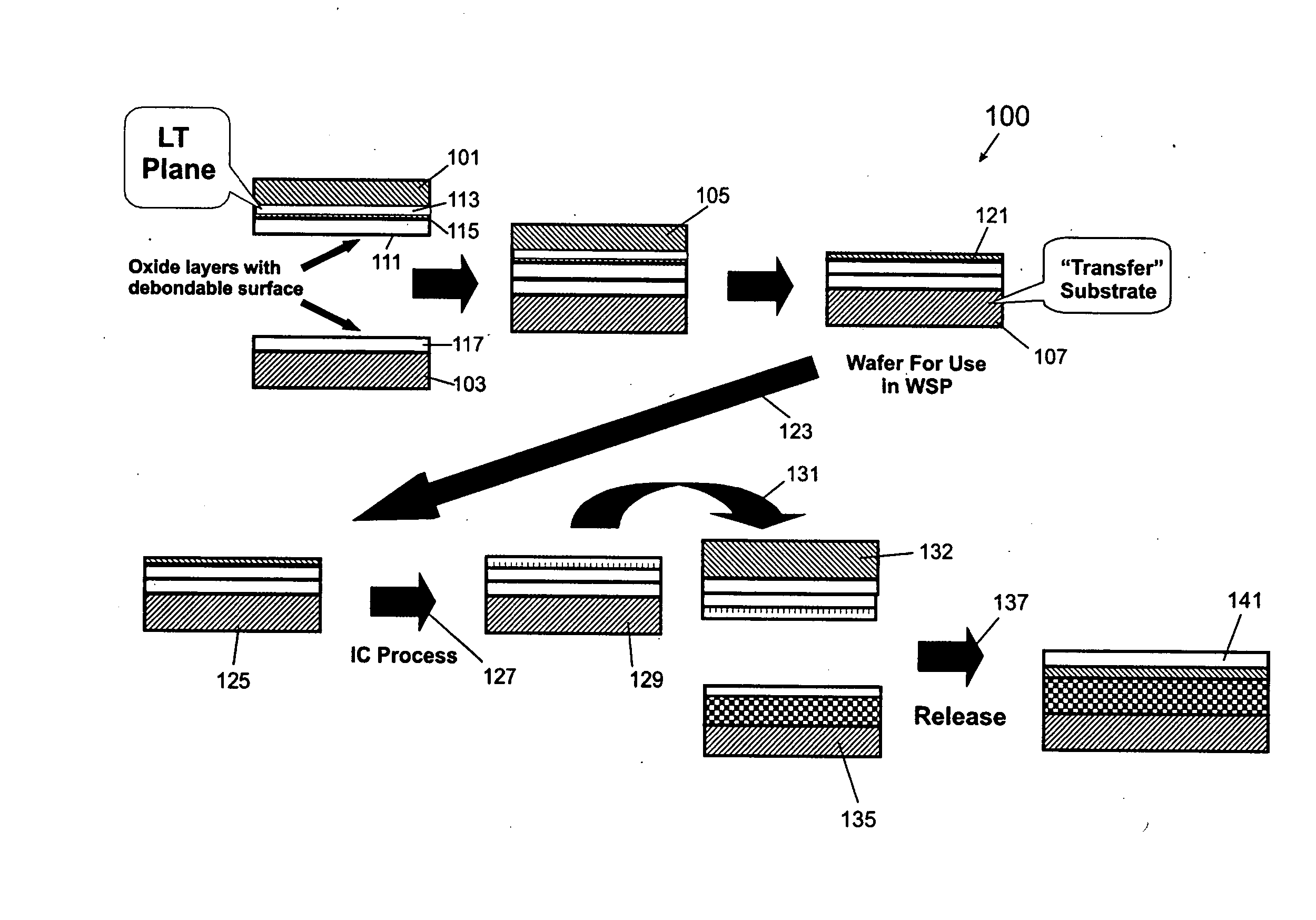

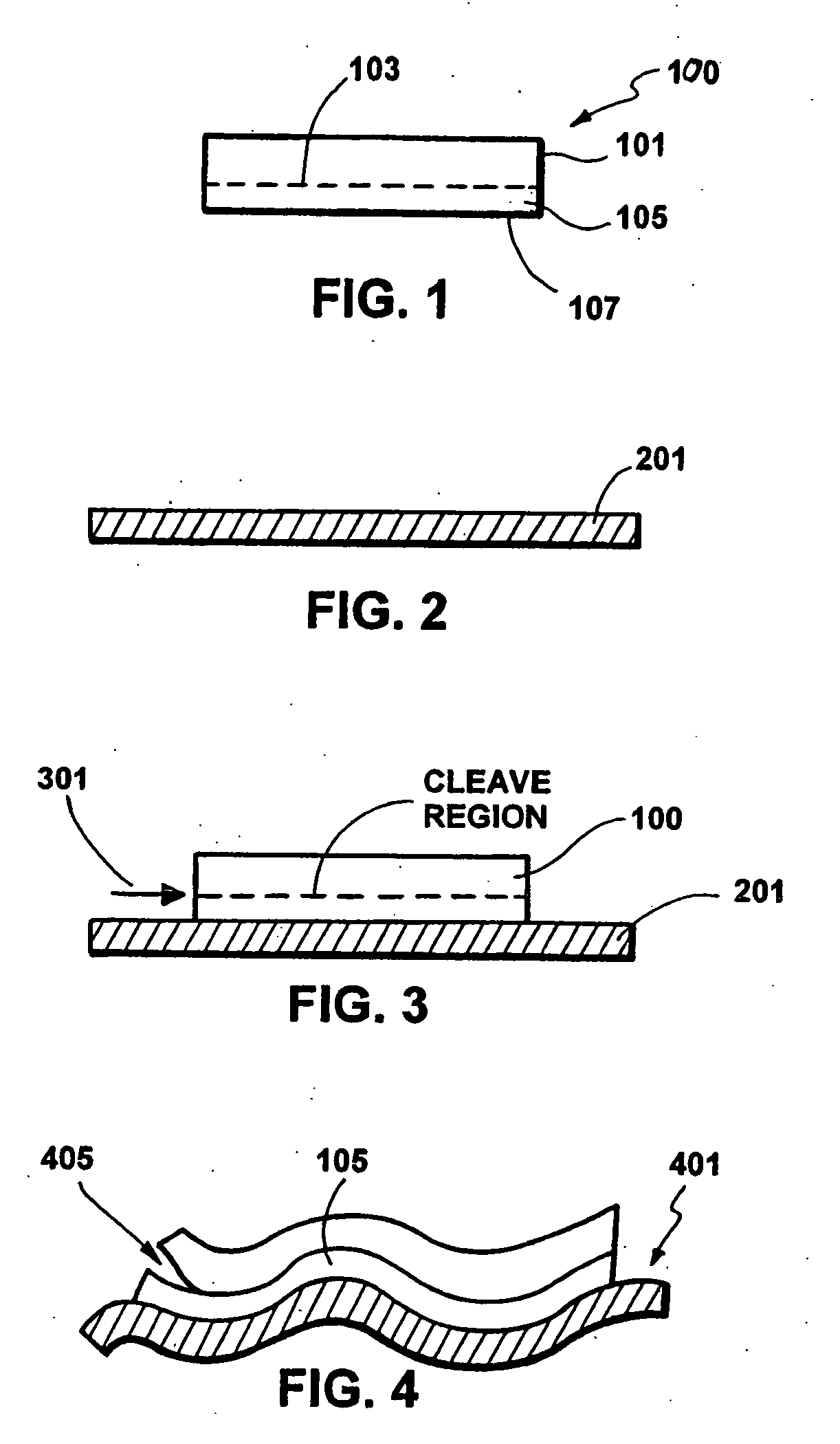

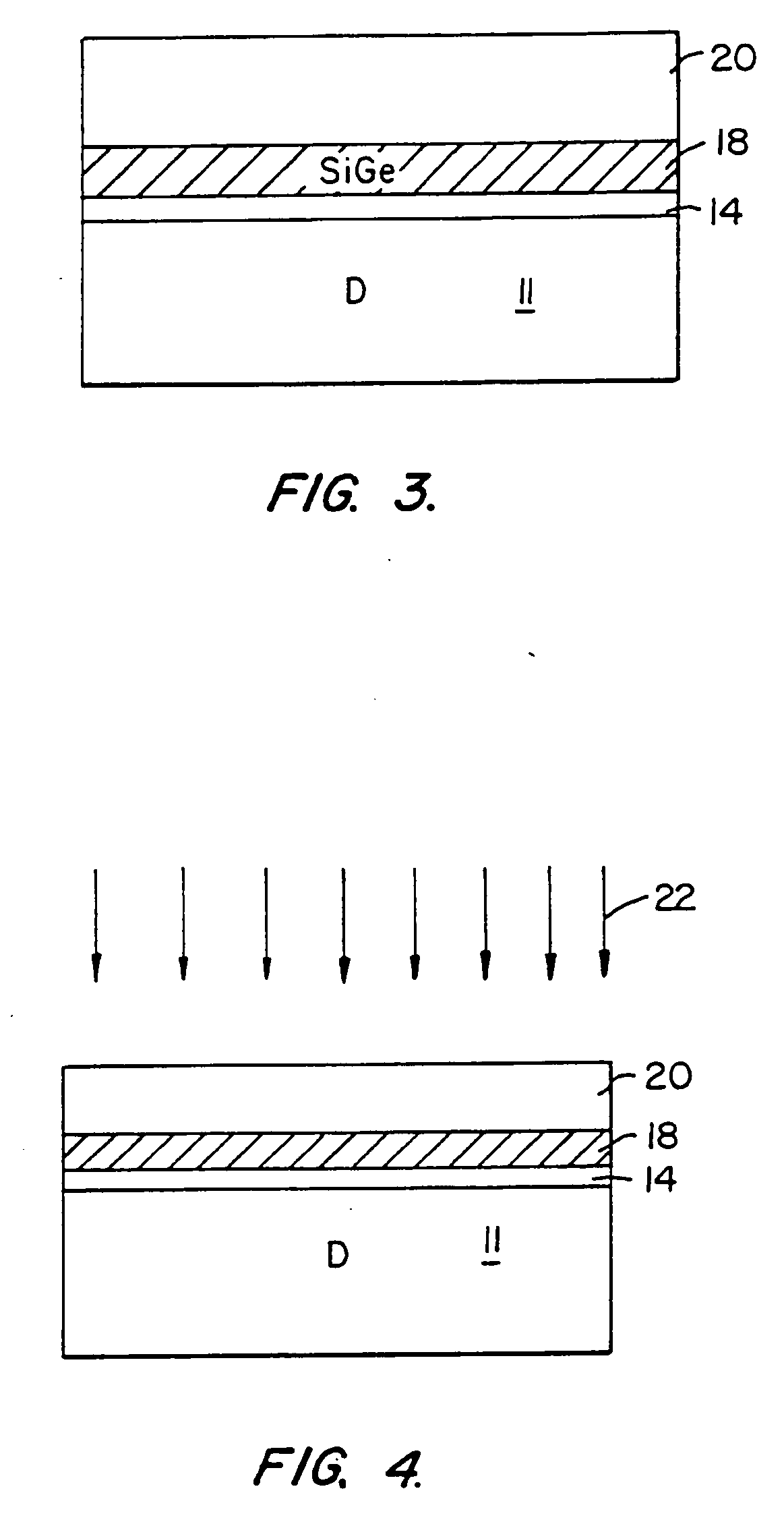

Cleaving process to fabricate multilayered substrates using low implantation doses

InactiveUS7056808B2Improve efficiencyQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingHigh concentrationControl manner

A method of forming substrates, e.g., silicon on insulator, silicon on silicon. The method includes providing a donor substrate, e.g., silicon wafer. The method also includes forming a cleave layer on the donor substrate that contains the cleave plane, the plane of eventual separation. In a specific embodiment, the cleave layer comprising silicon germanium. The method also includes forming a device layer (e.g., epitaxial silicon) on the cleave layer. The method also includes introducing particles into the cleave layer to add stress in the cleave layer. The particles within the cleave layer are then redistributed to form a high concentration region of the particles in the vicinity of the cleave plane, where the redistribution of the particles is carried out in a manner substantially free from microbubble or microcavity formation of the particles in the cleave plane. That is, the particles are generally at a low dose, which is defined herein as a lack of microbubble or microcavity formation in the cleave plane. The method also includes providing selected energy to the donor substrate to cleave the device layer from the cleave layer at the cleave plane, whereupon the selected energy is applied to create a controlled cleaving action to remove the device layer from a portion of the cleave layer in a controlled manner.

Owner:SILICON GENERAL CORPORATION

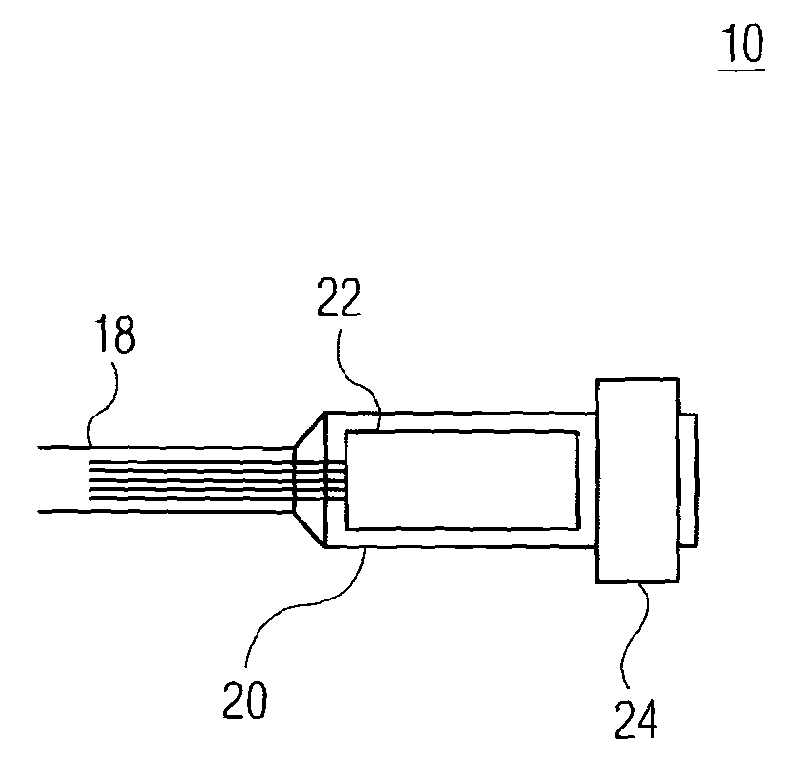

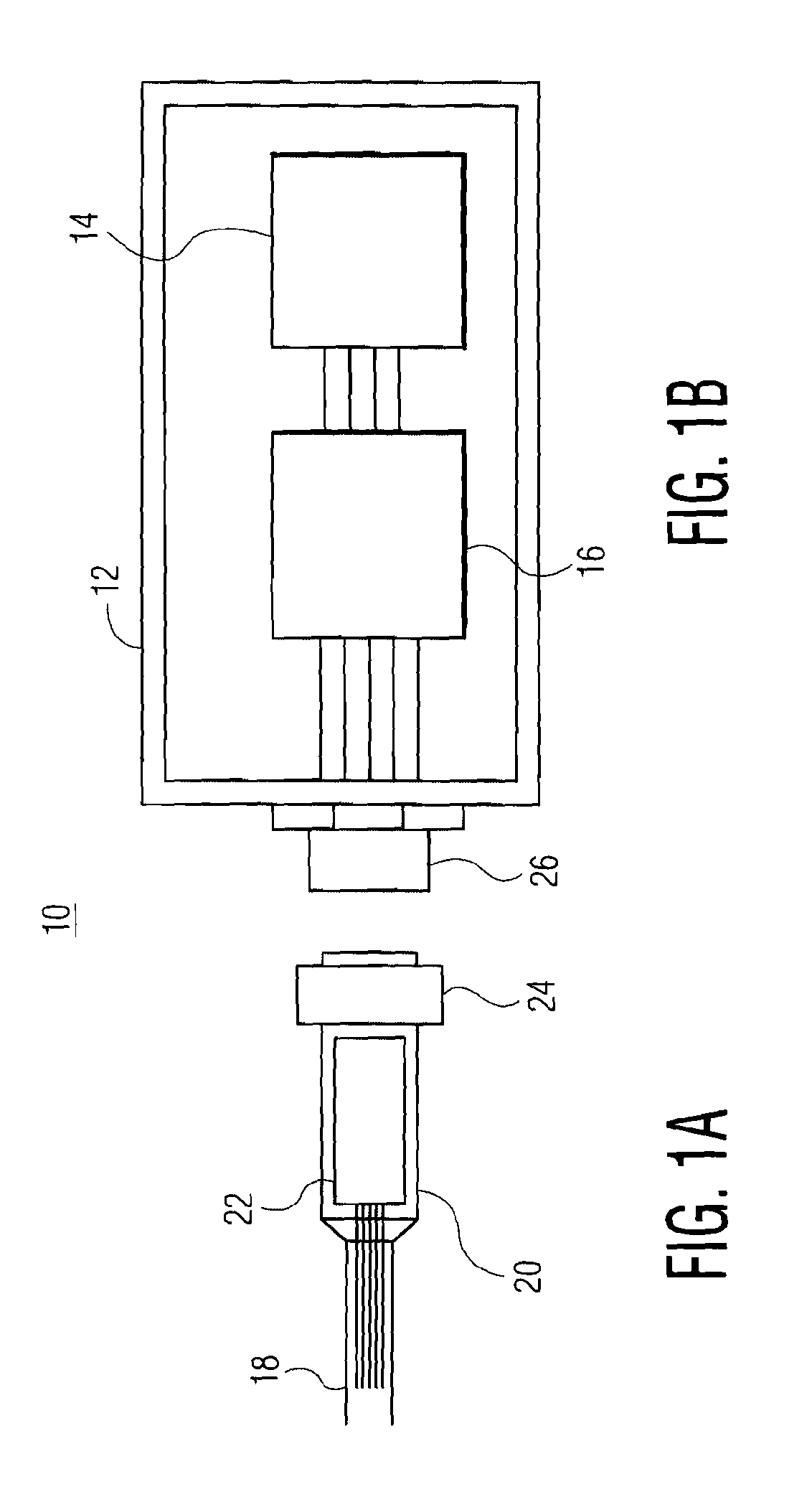

External microcontroller for LED lighting fixture, LED lighting fixture with internal controller, and LED lighting system

InactiveUS20100060194A1Avoid the possibility of damageSimple designElectrical apparatusElectroluminescent light sourcesMicrocontrollerPower cable

An LED lighting system (10) includes an LED lighting fixture (12) having at least one LED (14) and an external microcontroller (22, 28) for converting incoming lighting control data formatted according to the DMX512 standard to pulse-width modulated lighting control signals for input to the LED (14). The external microcontroller (22, 28) is preferably located inside a cable connector (20) adapted for releasably connecting a power cable (18) to the LED lighting fixture (12).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

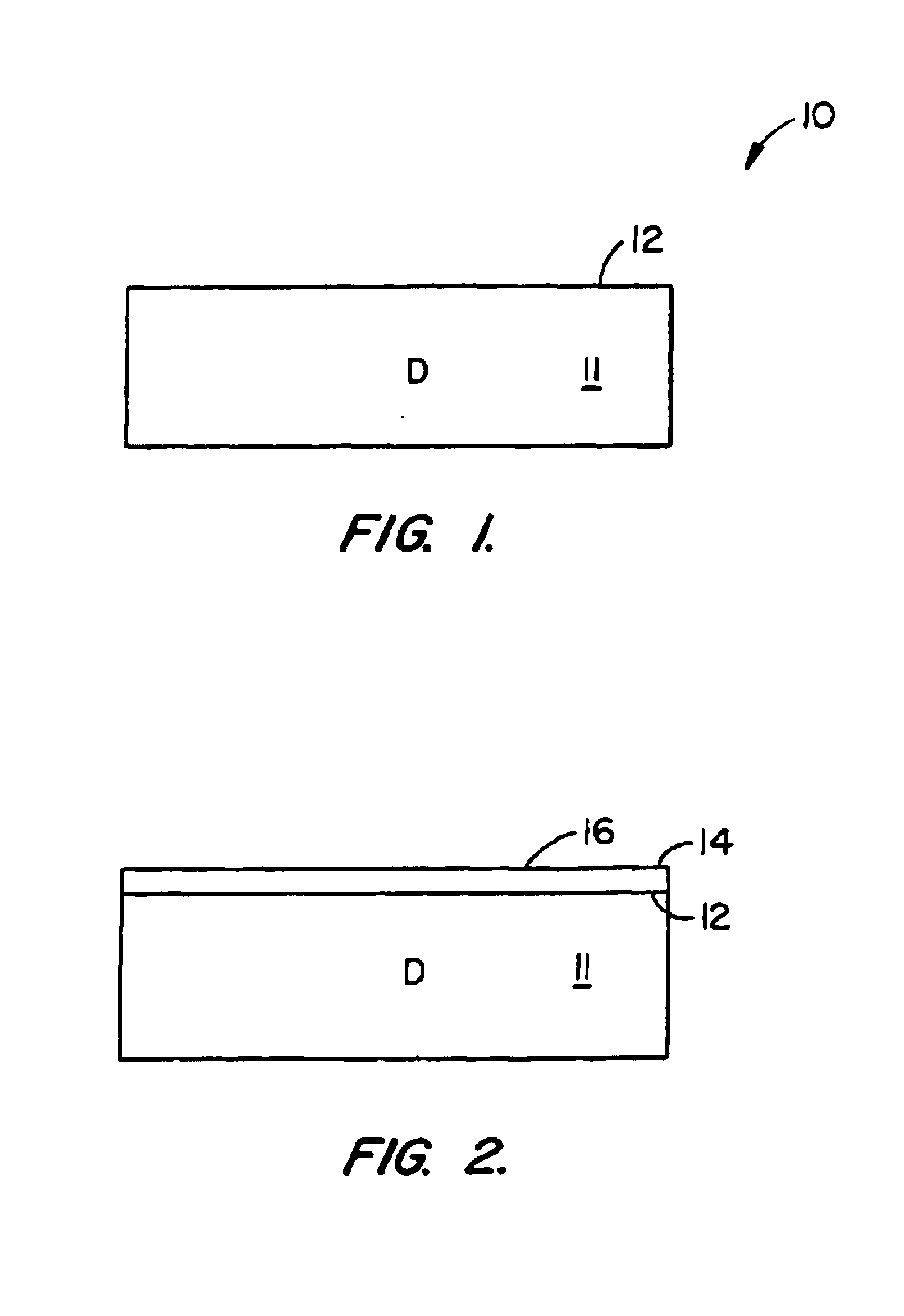

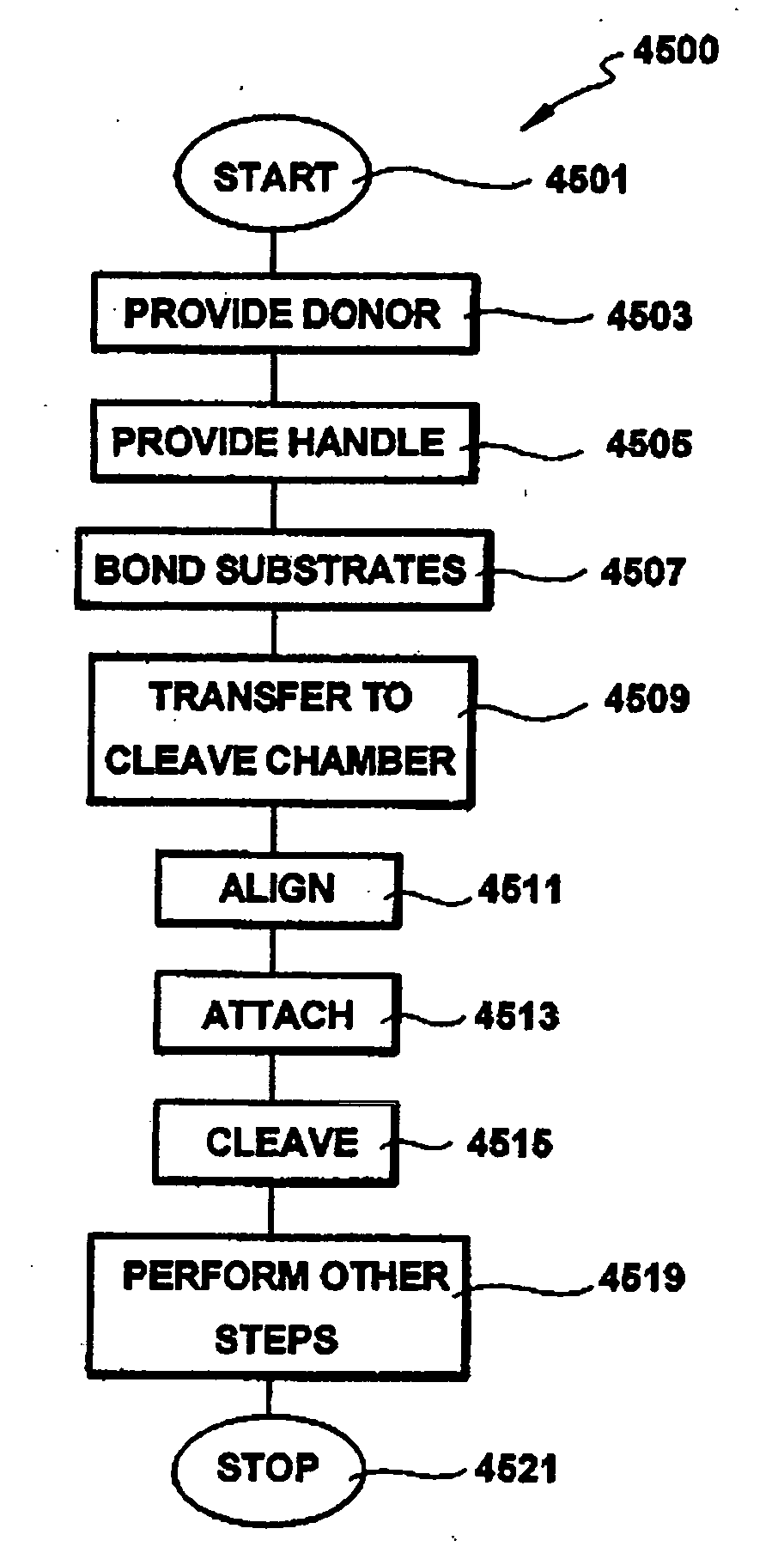

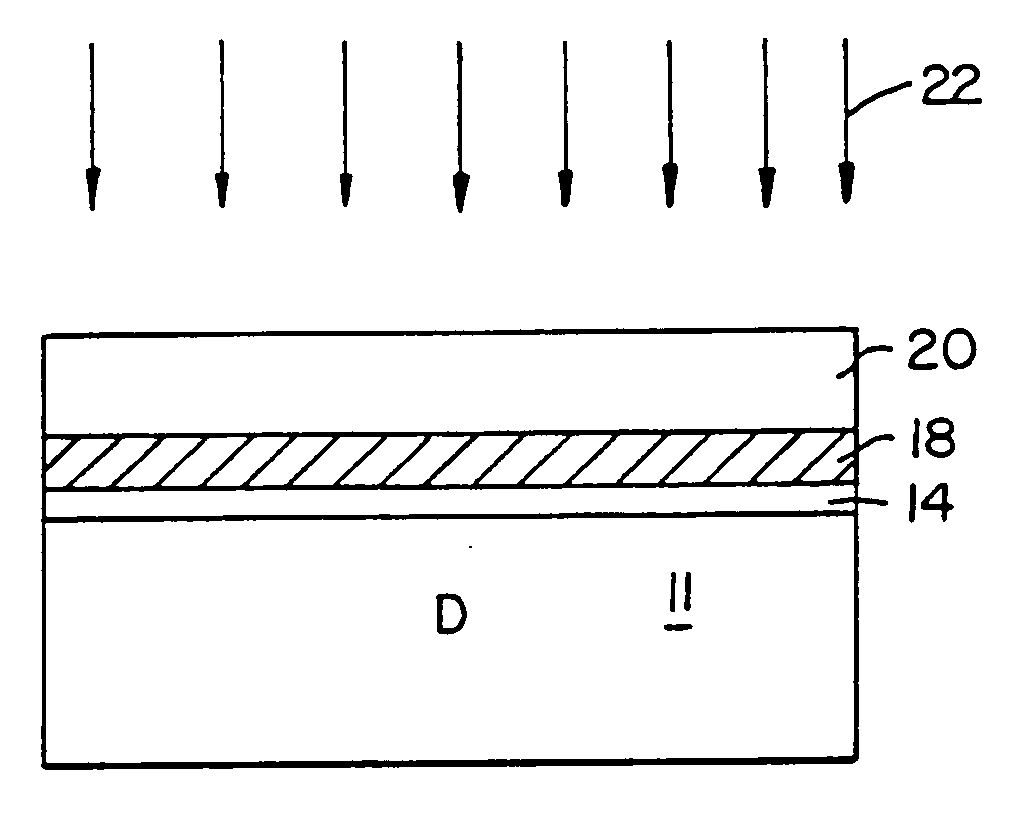

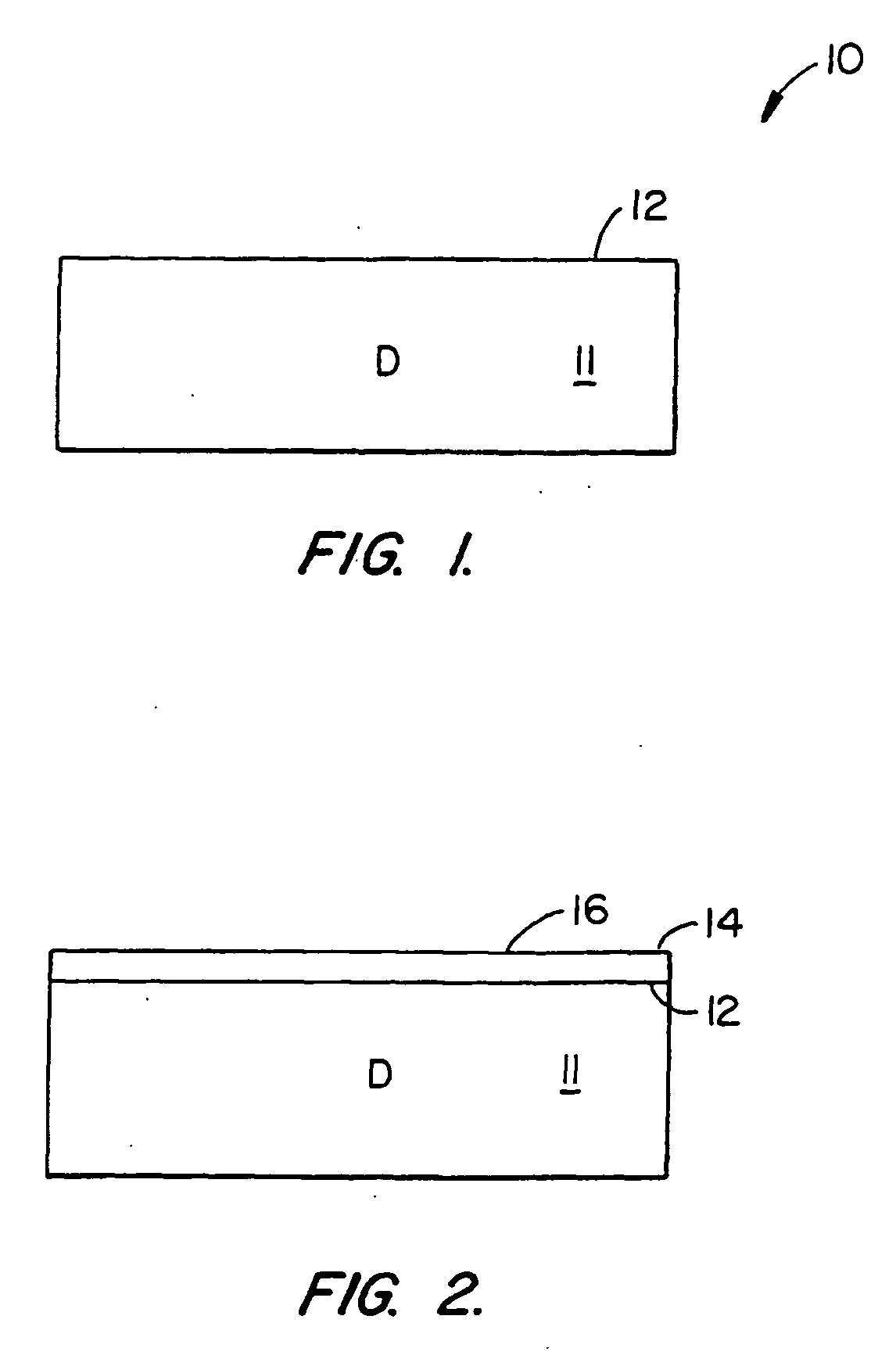

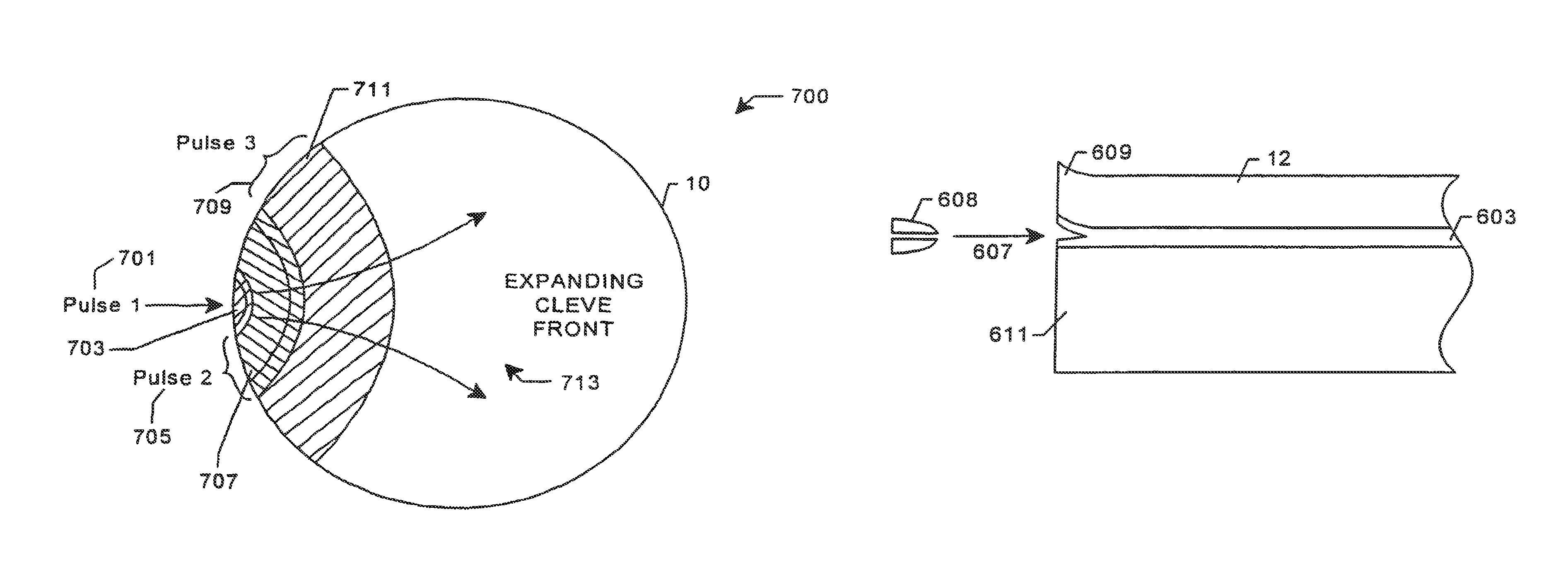

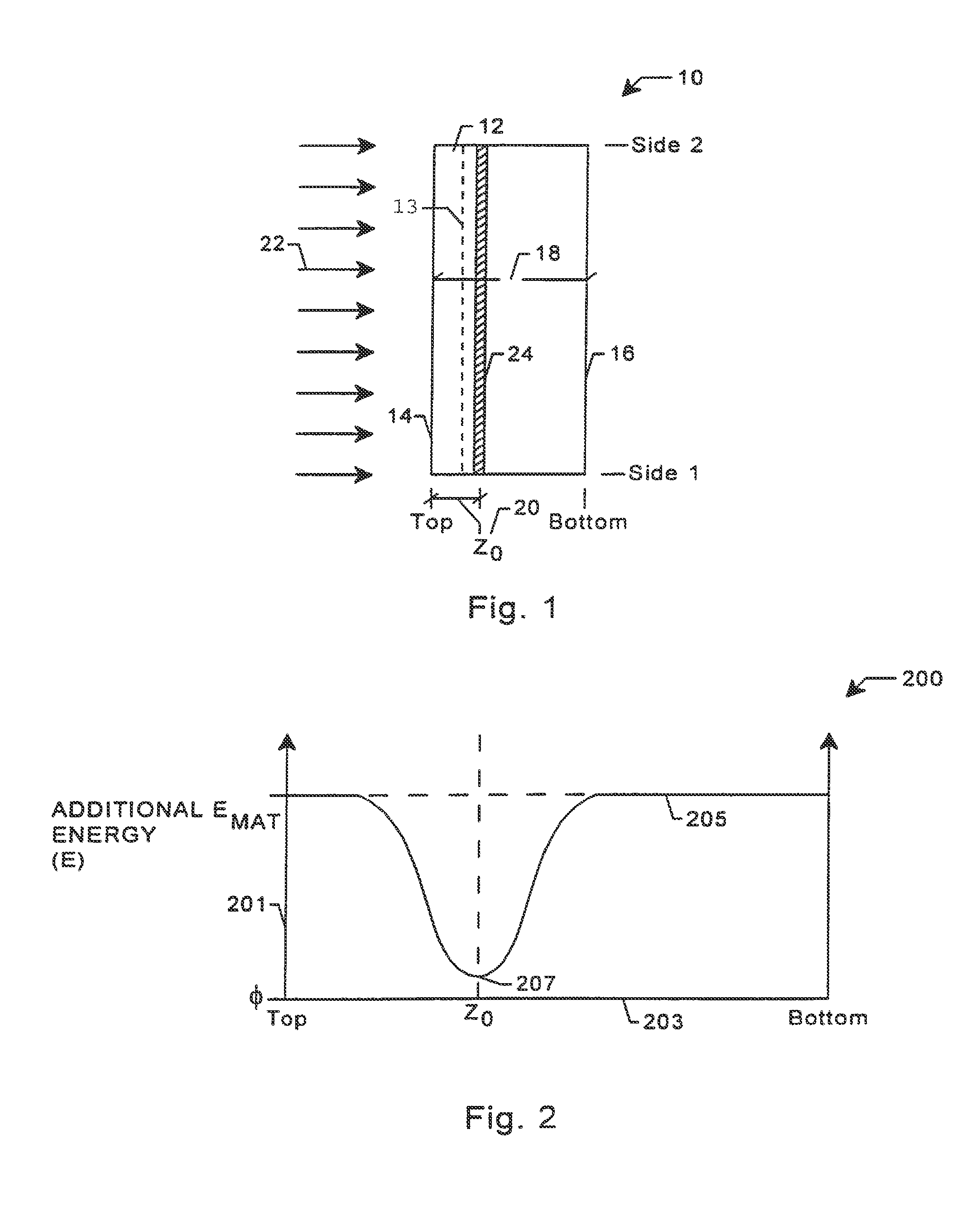

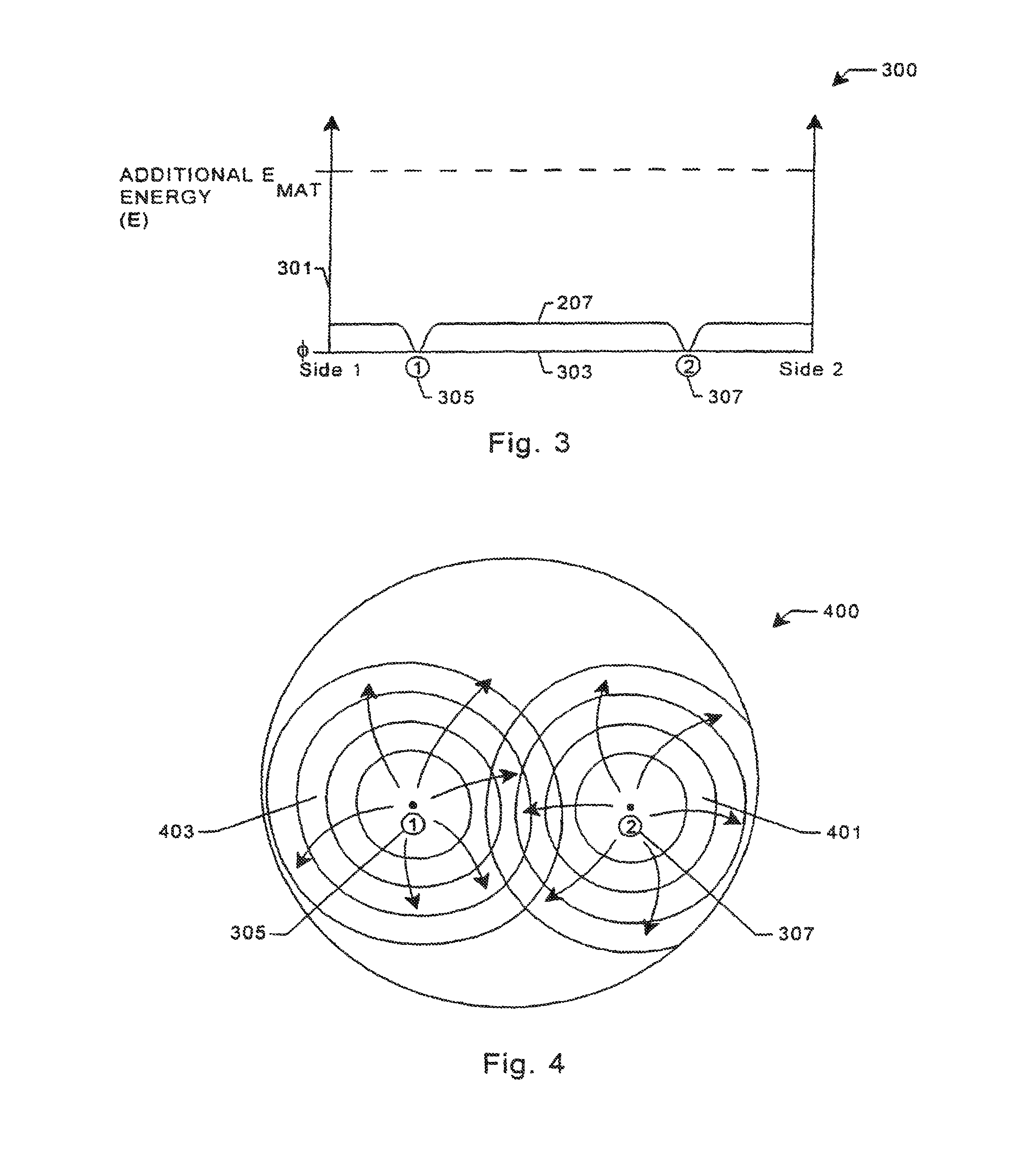

Method and device for controlled cleaving process

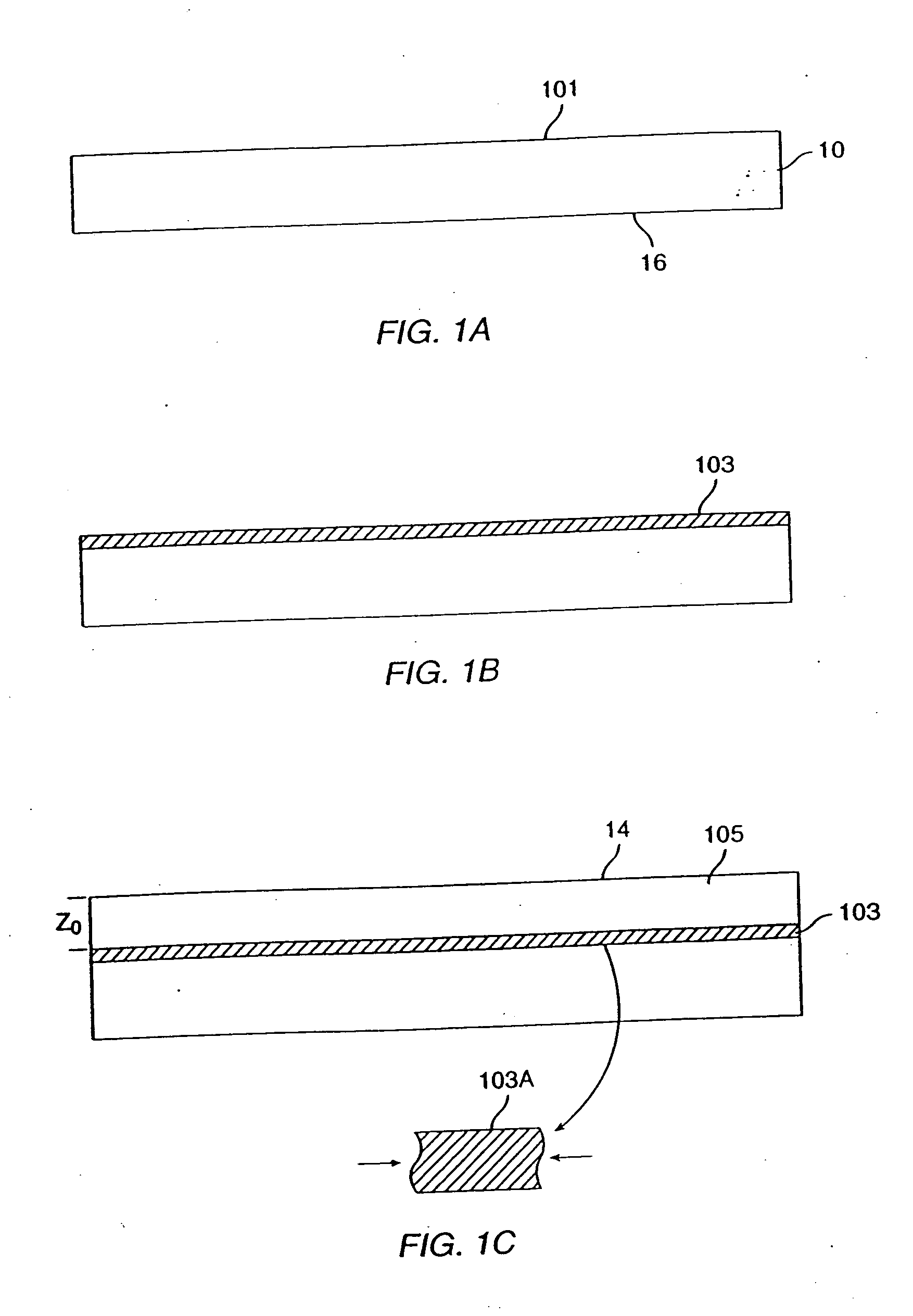

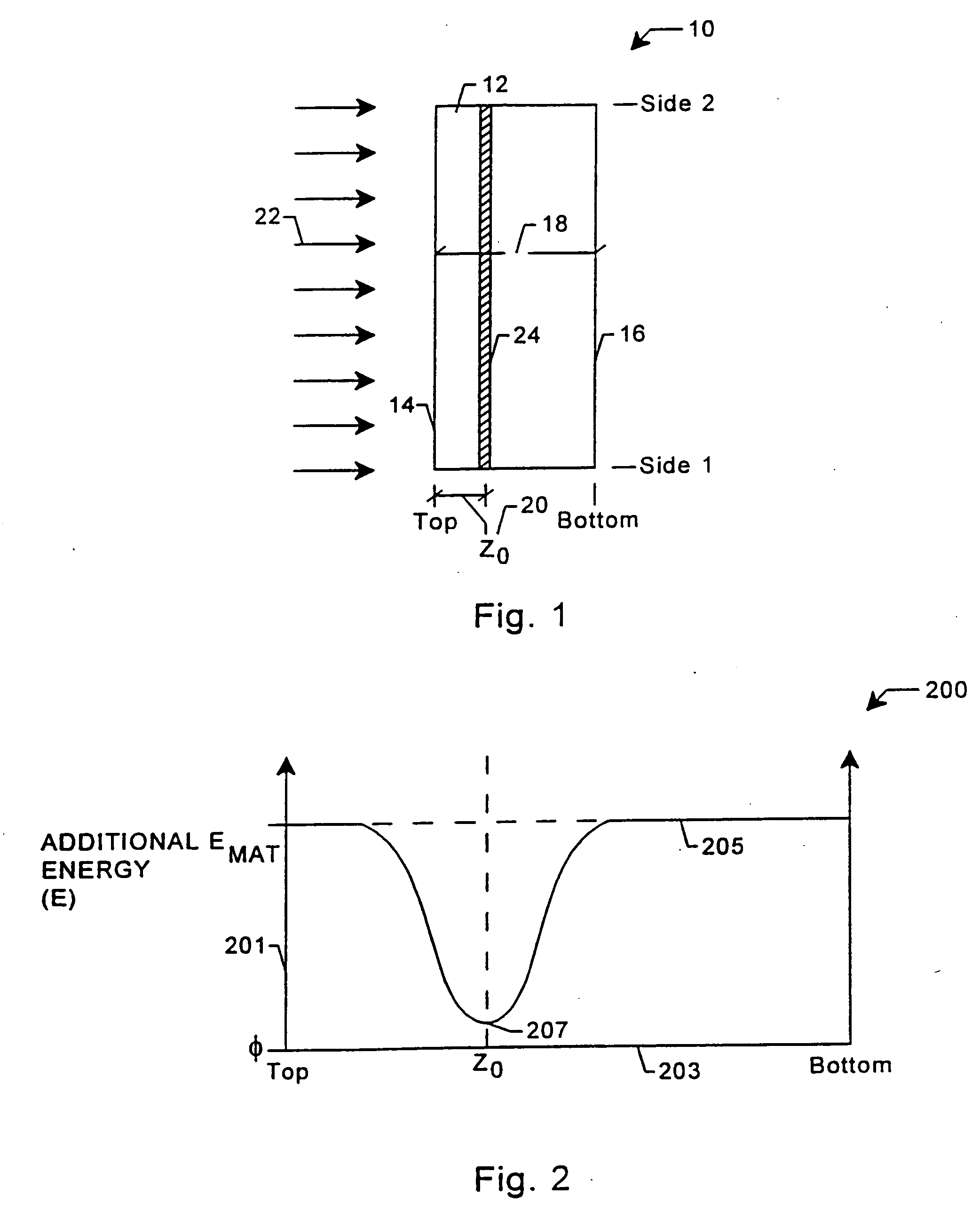

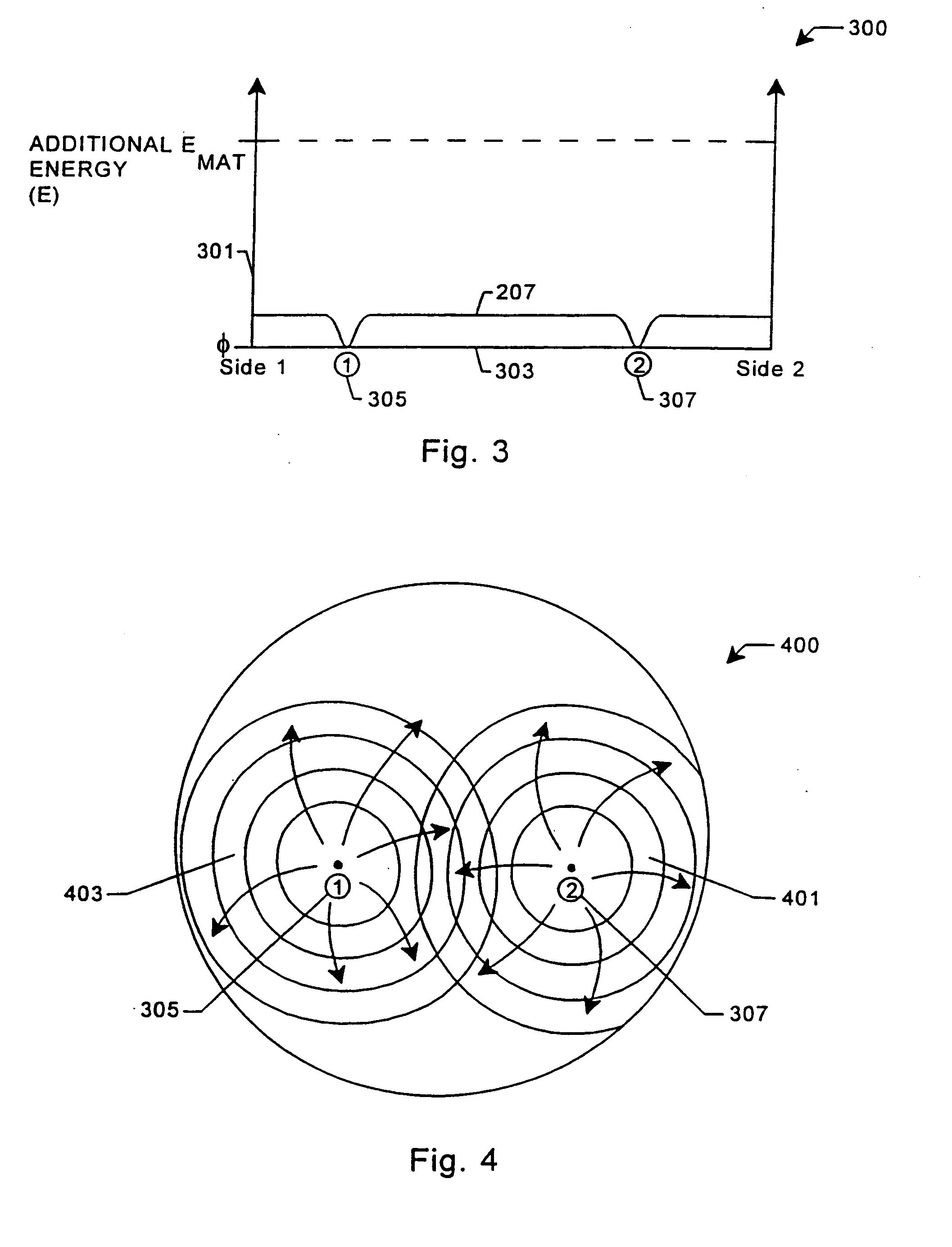

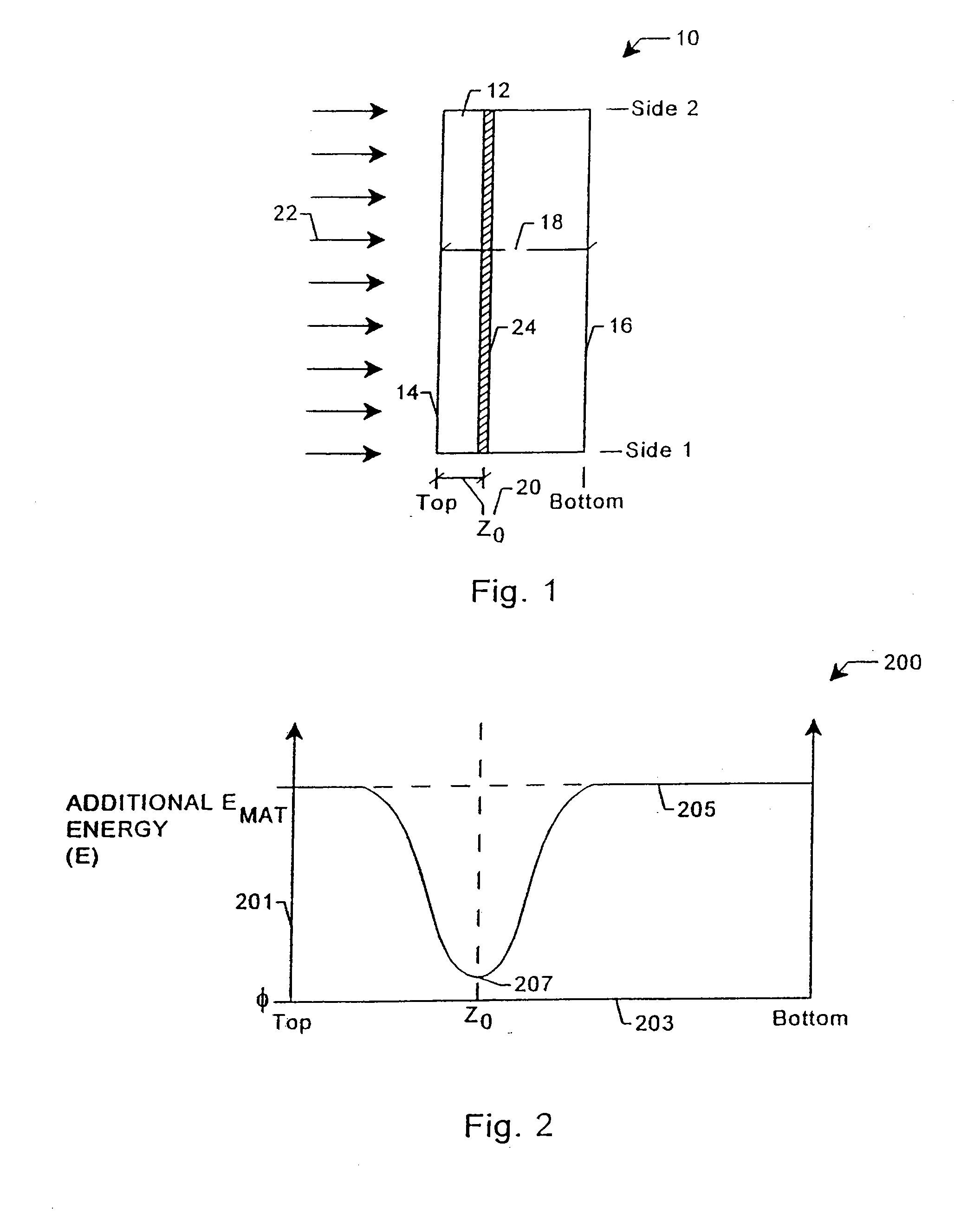

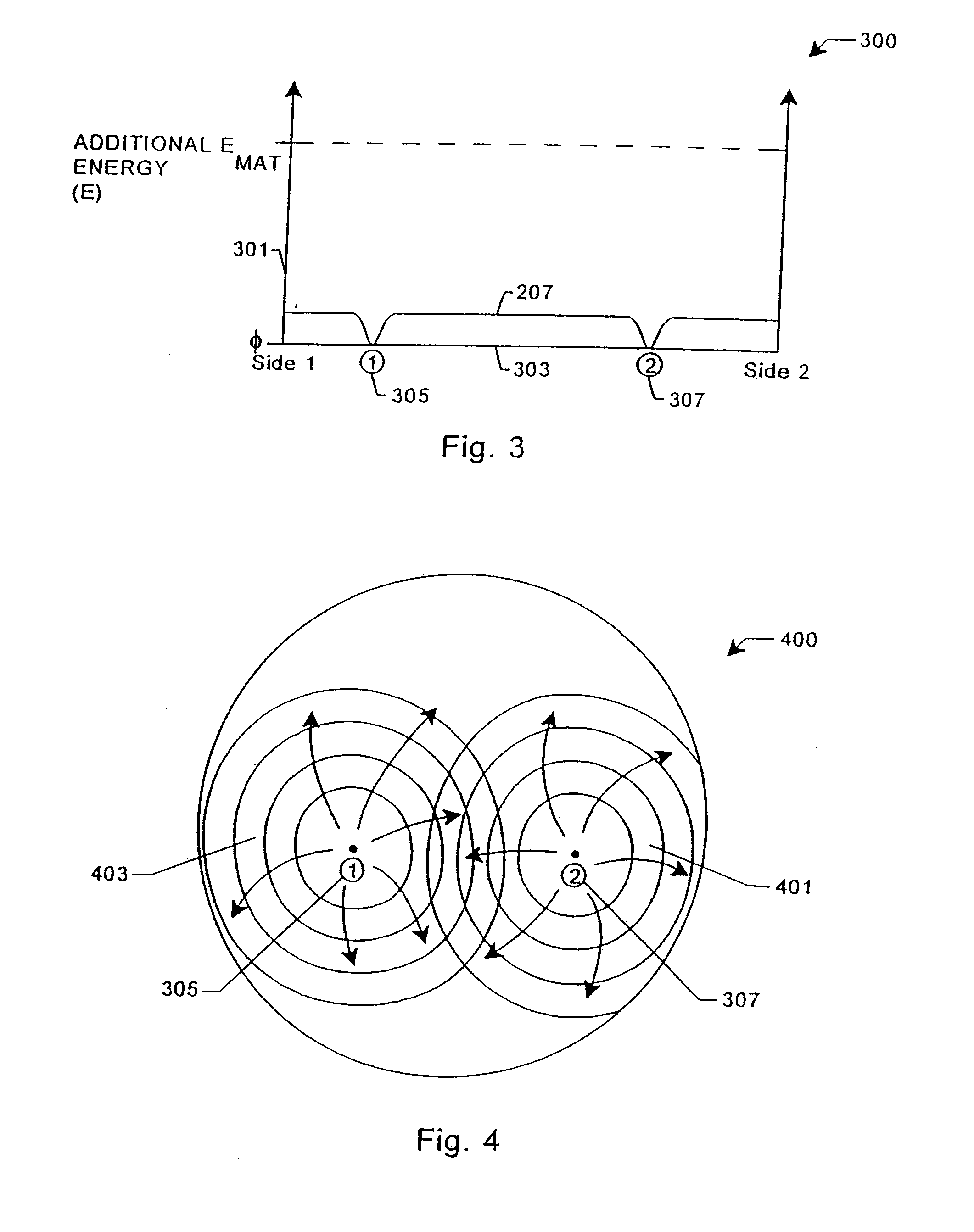

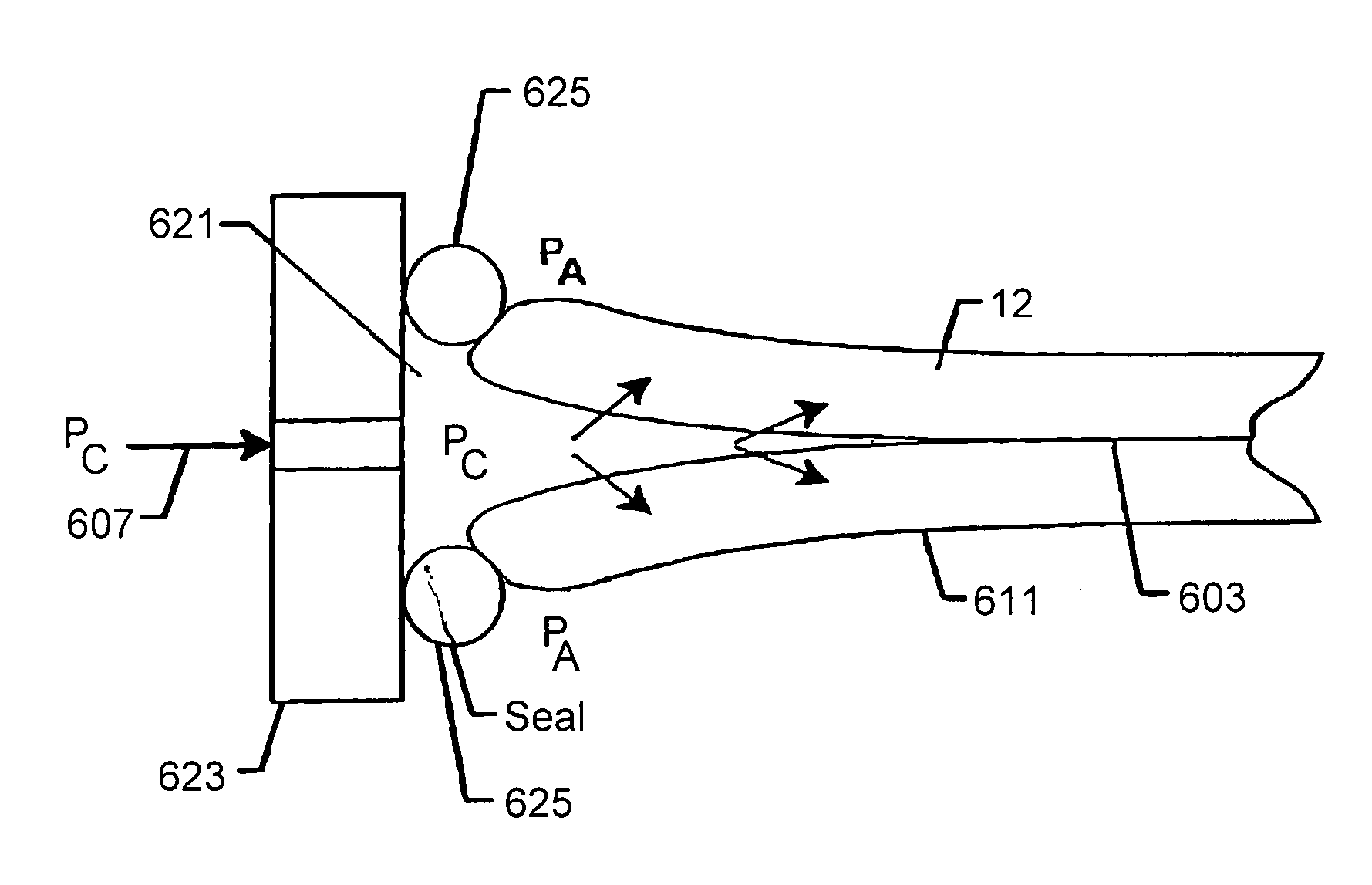

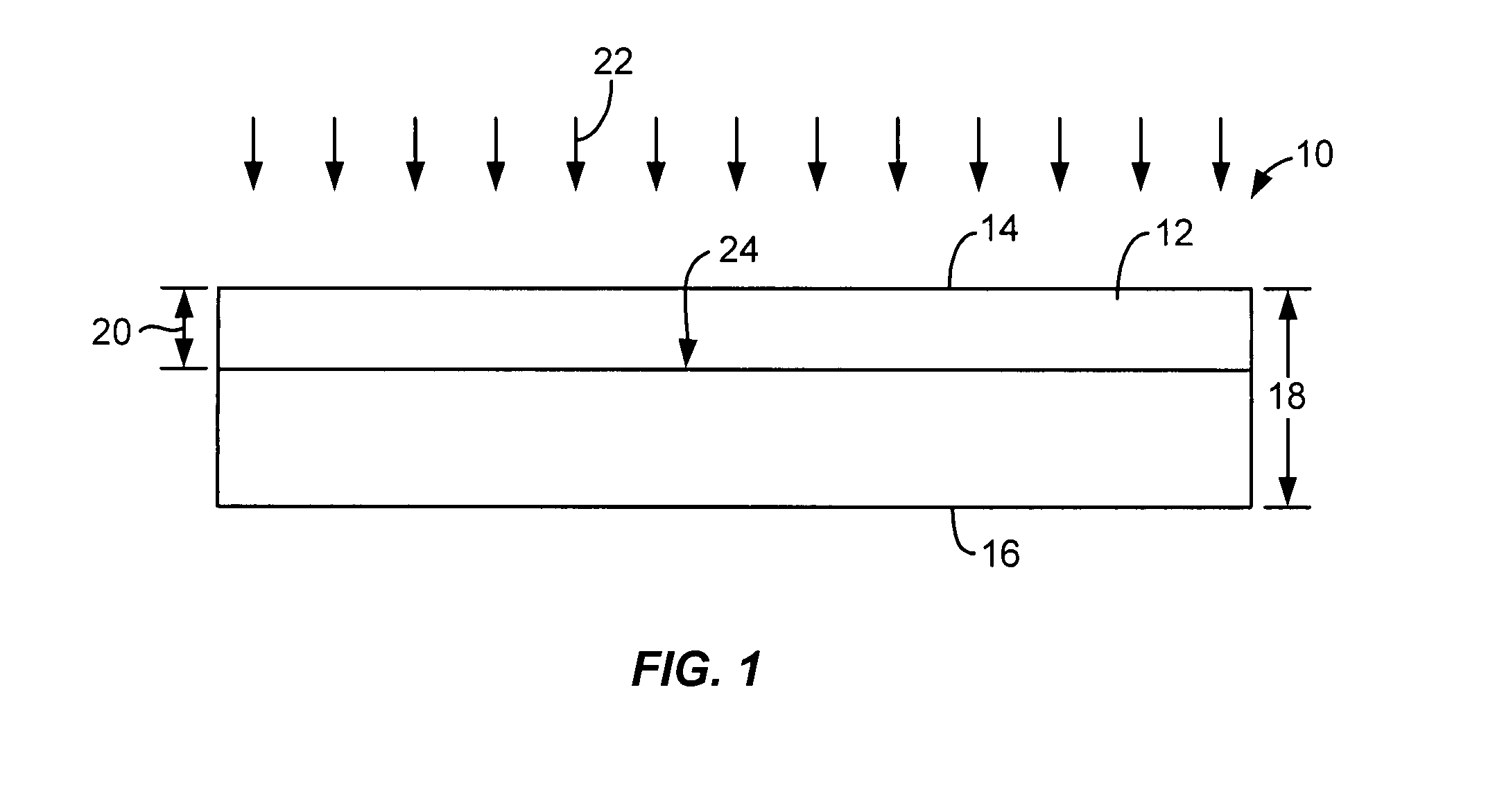

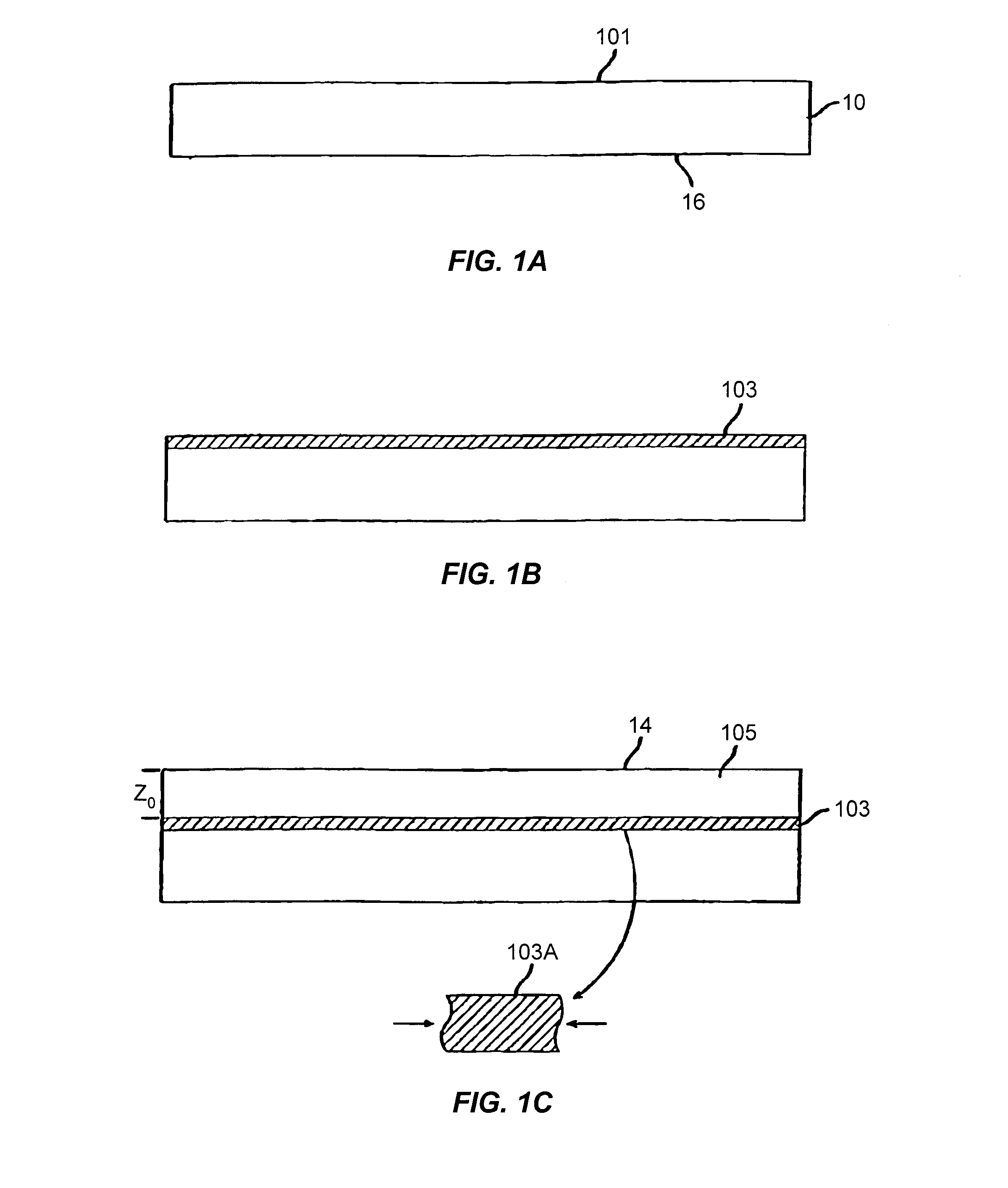

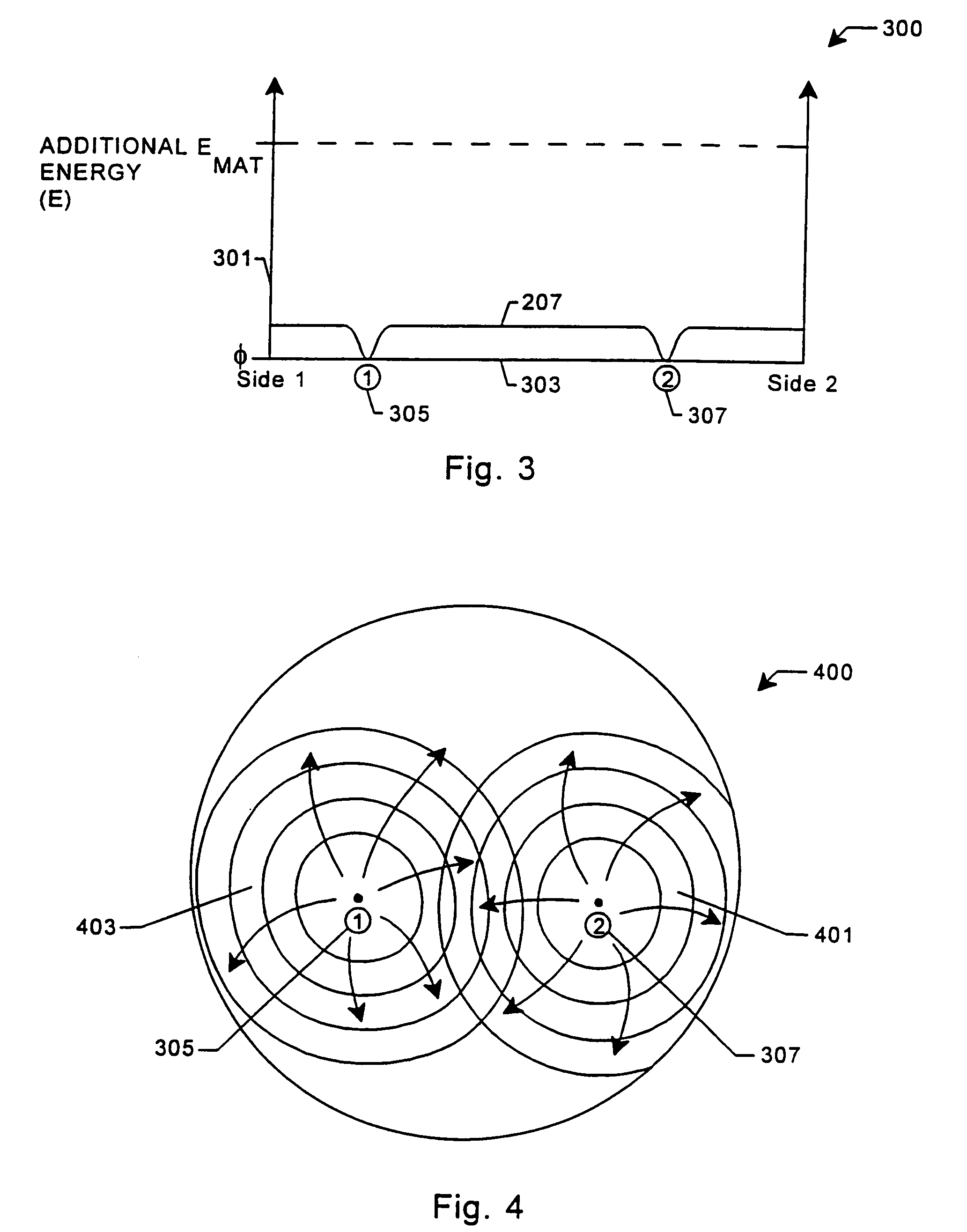

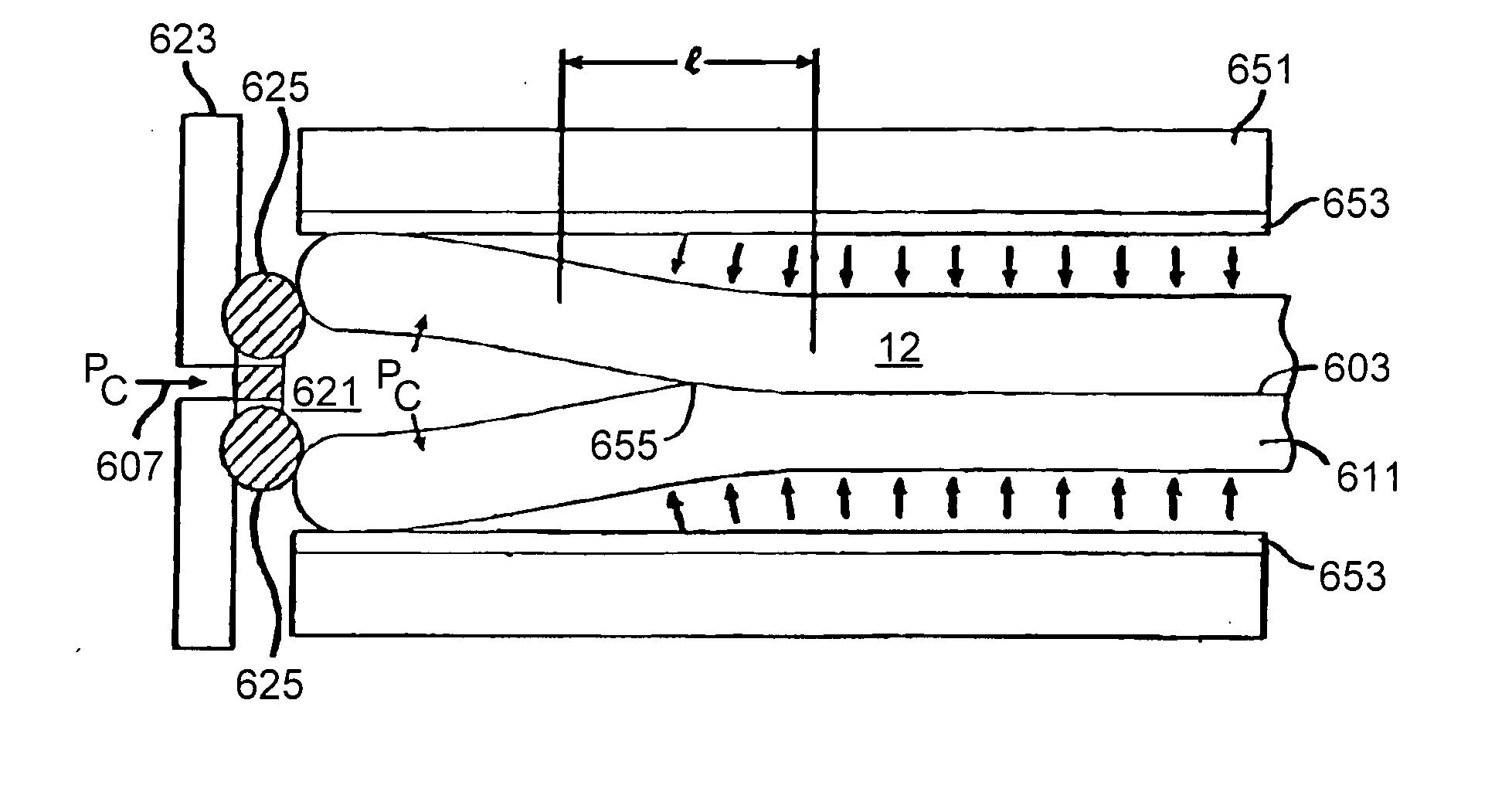

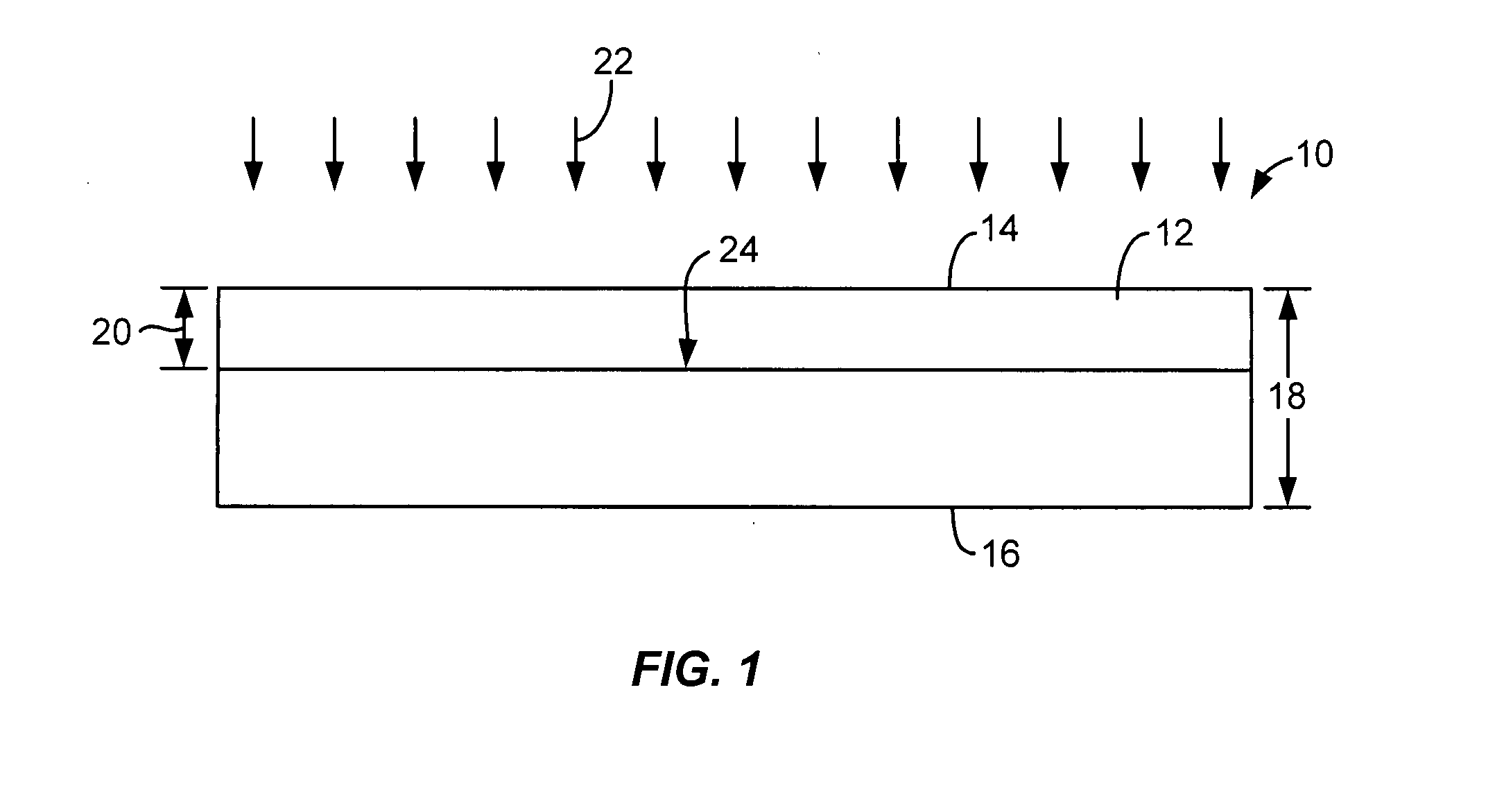

InactiveUS7348258B2Good removal effectAvoid the possibility of damageDecorative surface effectsSemiconductor/solid-state device manufacturingEngineeringEnergy source

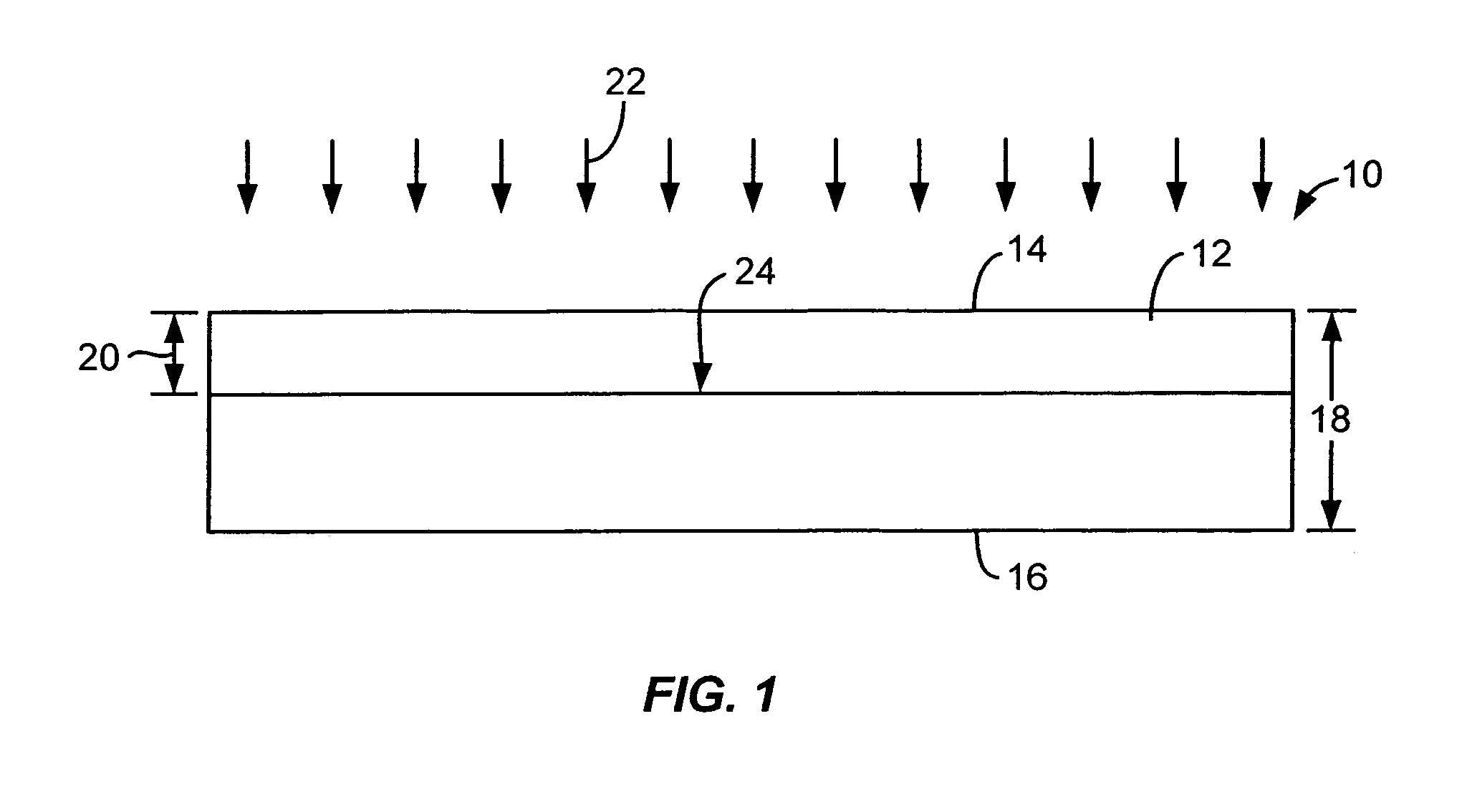

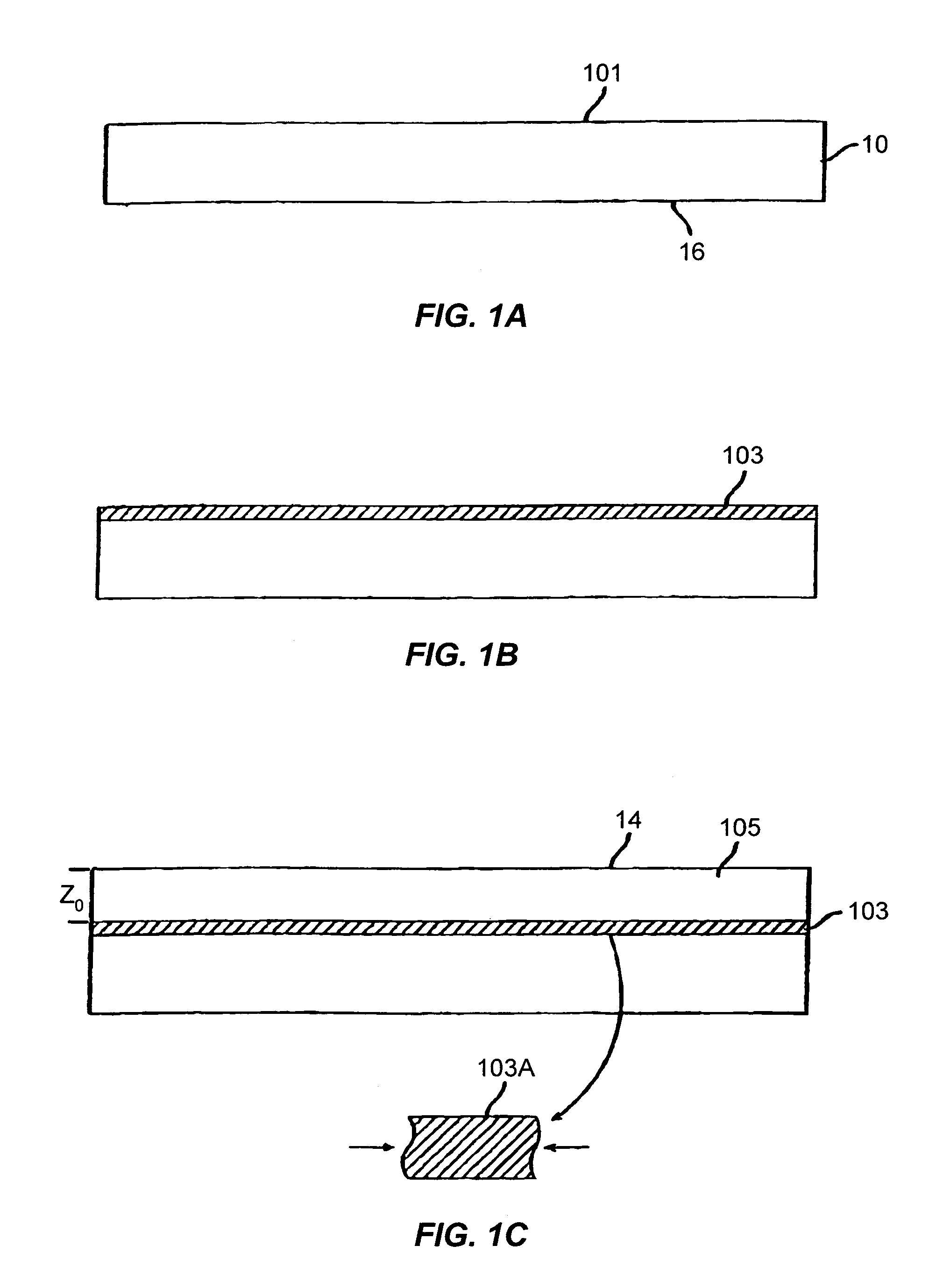

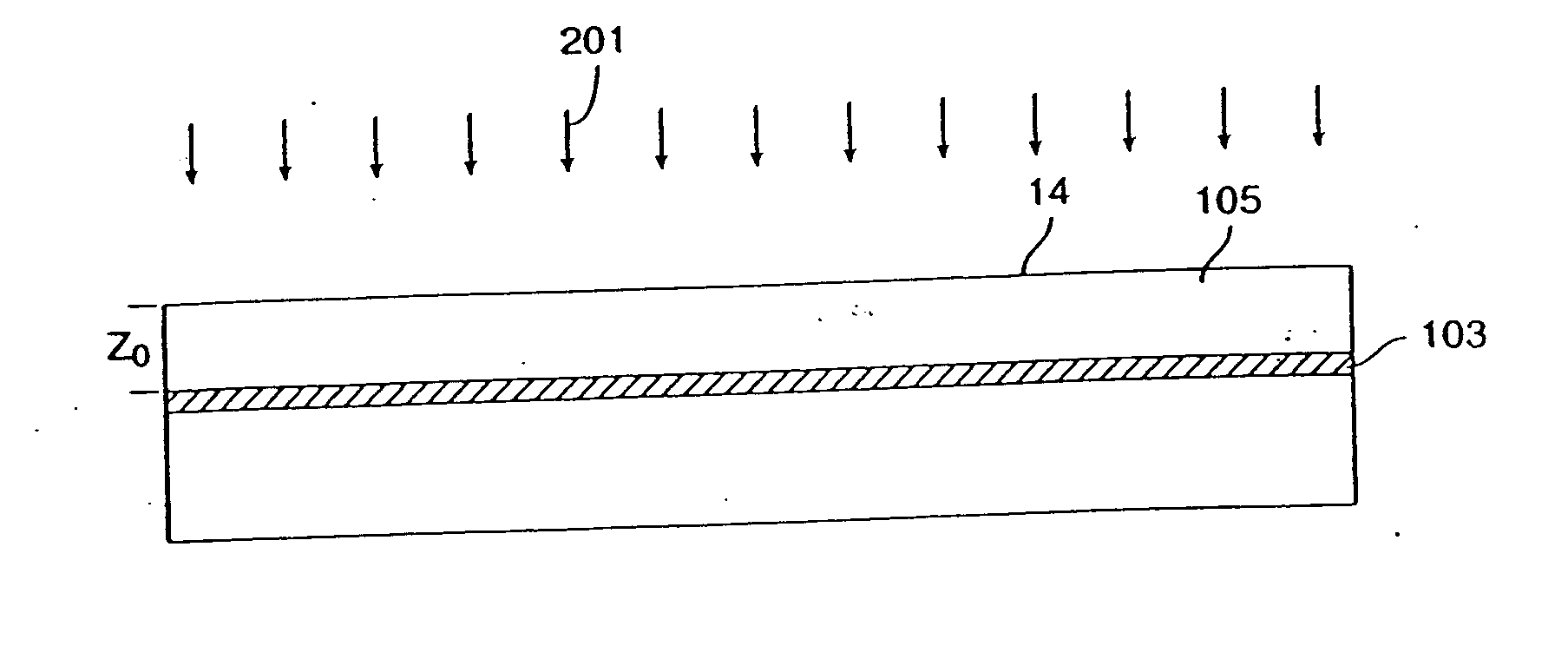

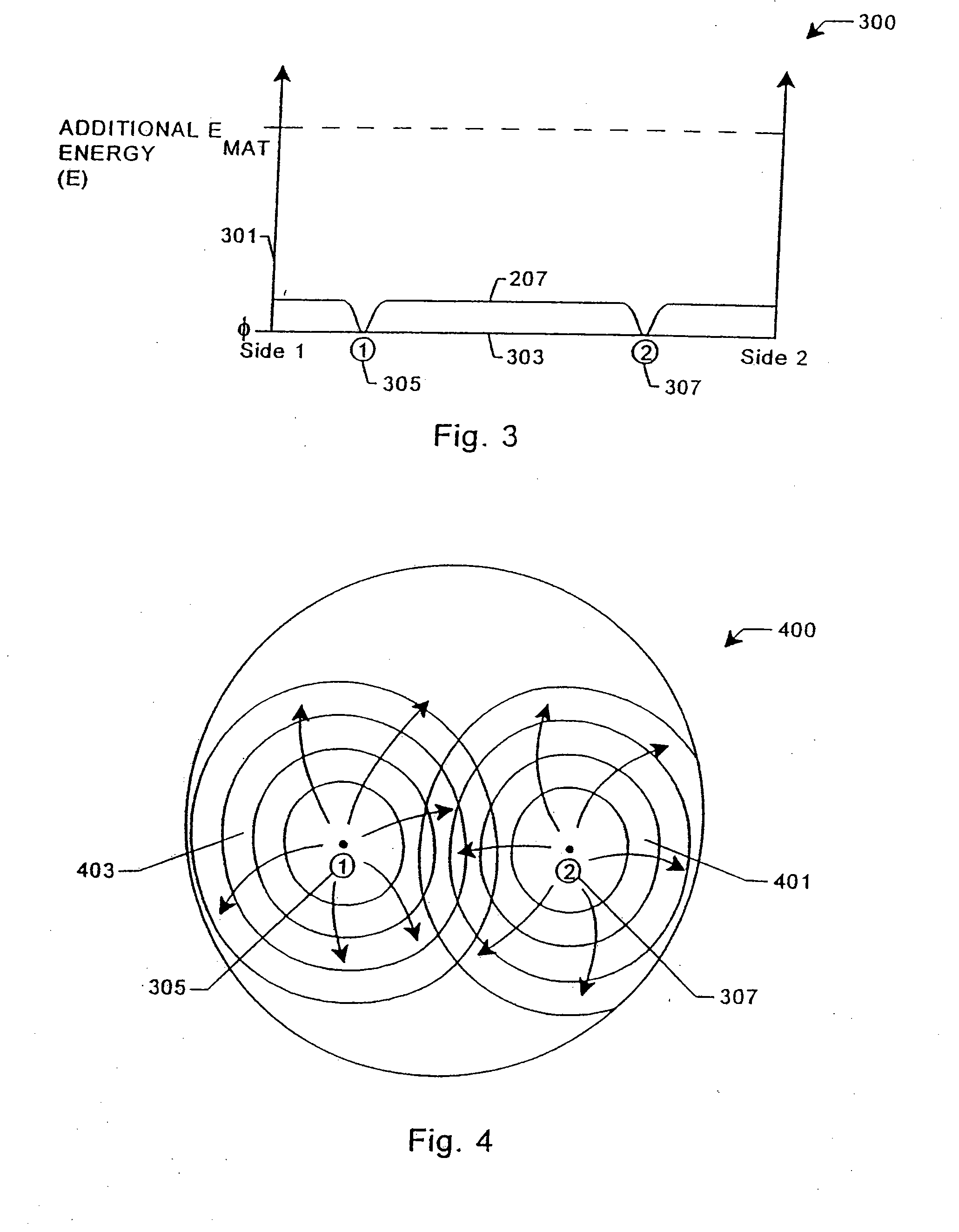

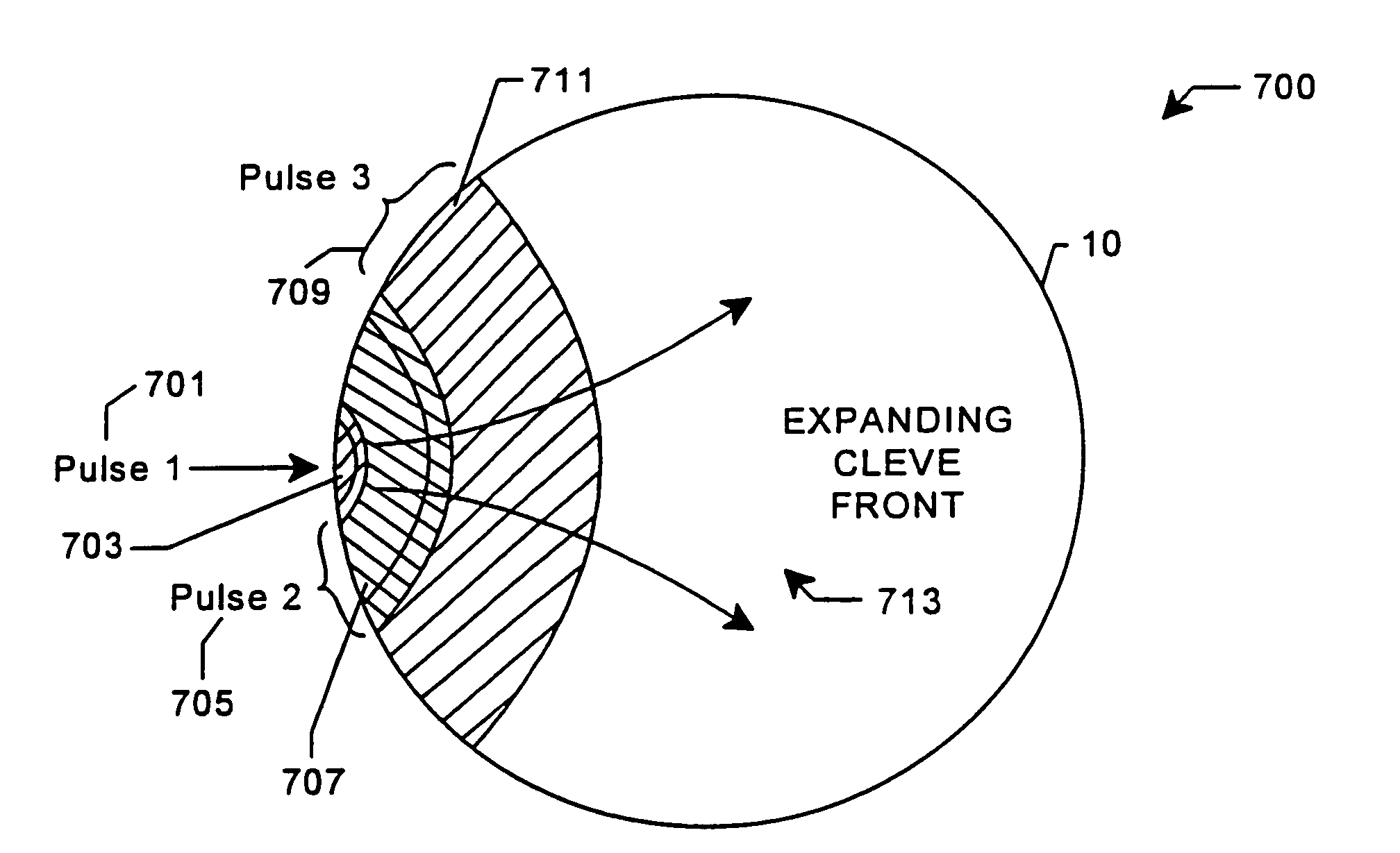

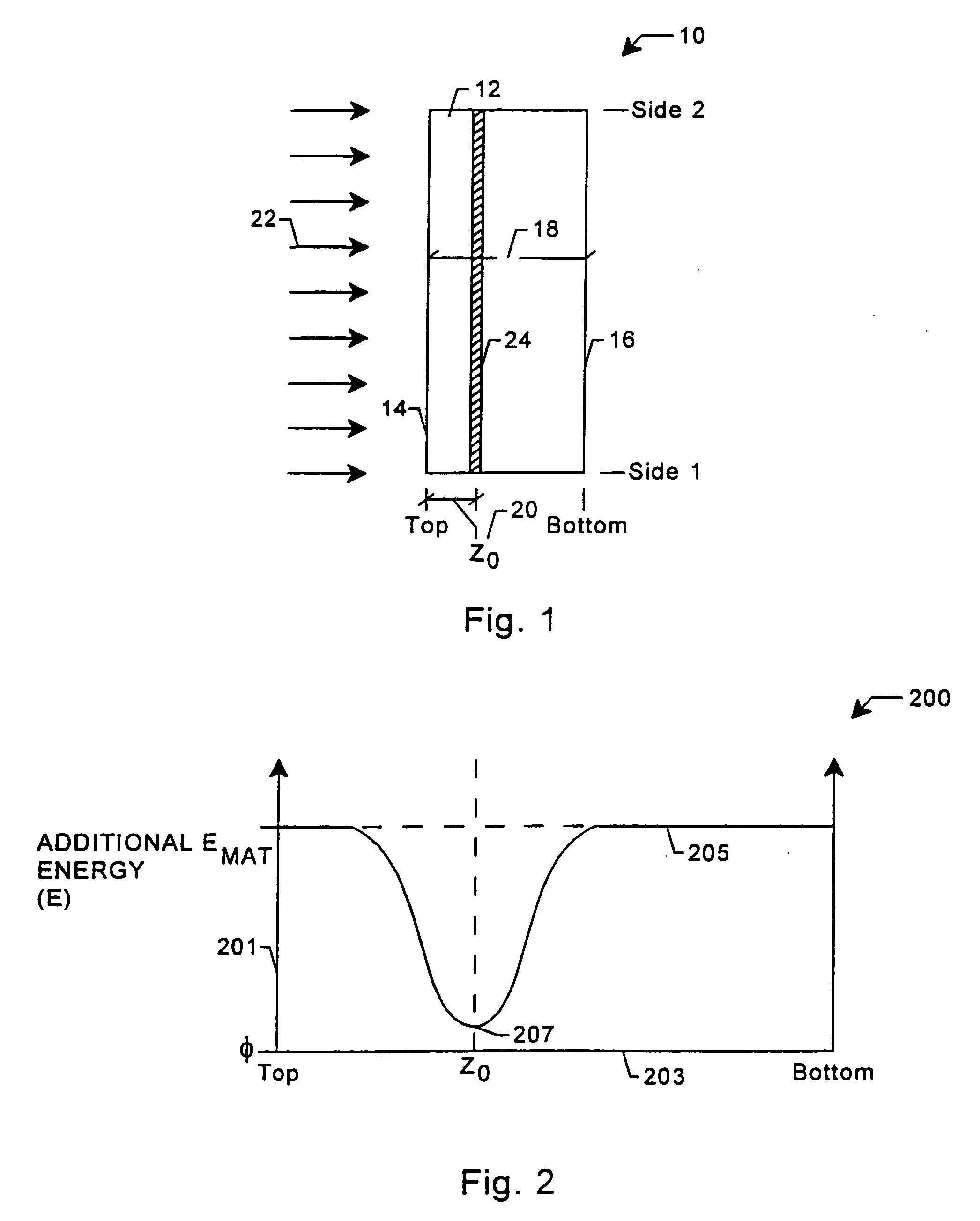

A technique for forming a film of material (12) from a donor substrate (10). The technique has a step of forming a stressed region in a selected manner at a selected depth (20) underneath the surface. An energy source such as pressurized fluid is directed to a selected region of the donor substrate to initiate a controlled cleaving action of the substrate (10) at the selected depth (20), whereupon the cleaving action provides an expanding cleave front to free the donor material from a remaining portion of the donor substrate.

Owner:SILICON GENERAL CORPORATION

Method and device for controlled cleaving process

InactiveUS20050070071A1Good removal effectAvoid the possibility of damageDecorative surface effectsSemiconductor/solid-state device manufacturingEngineeringEnergy source

A technique for forming a film of material (12) from a donor substrate (10). The technique has a step of forming a stressed region in a selected manner at a selected depth (20) underneath the surface. An energy source such as pressurized fluid is directed to a selected region of the donor substrate to initiate a controlled cleaving action of the substrate (10) at the selected depth (20), whereupon the cleaving action provides an expanding cleave front to free the donor material from a remaining portion of the donor substrate.

Owner:SILICON GENERAL CORPORATION

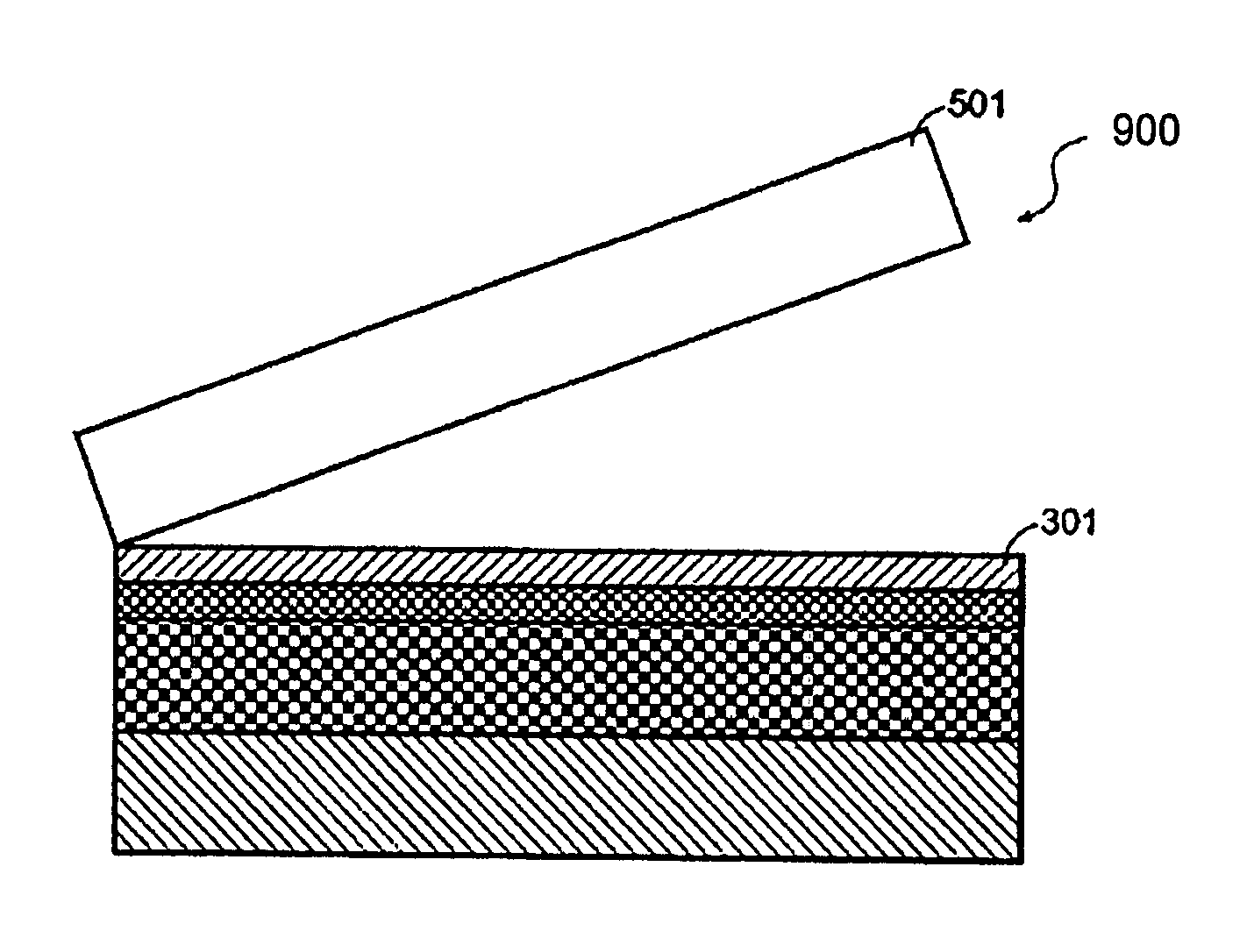

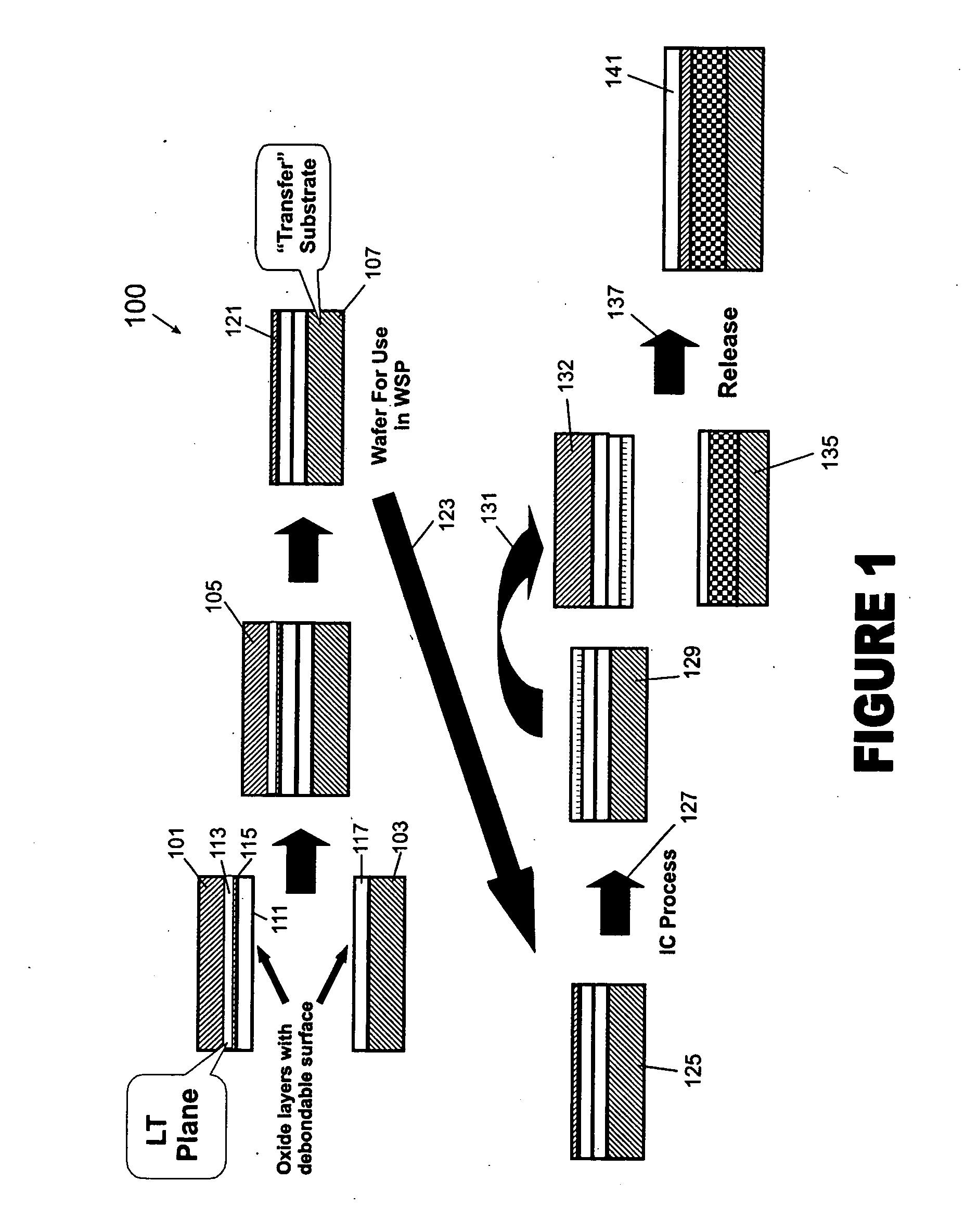

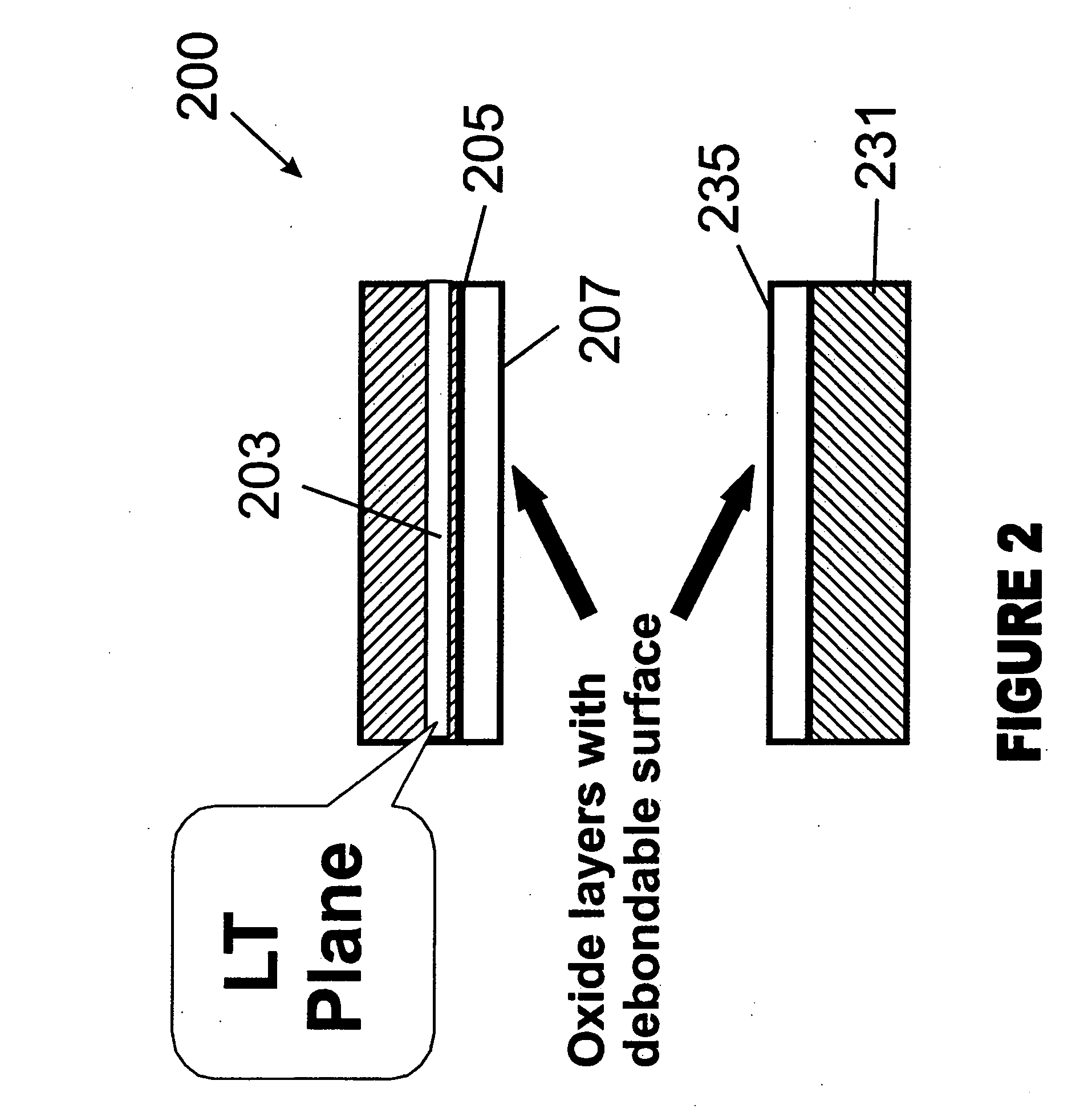

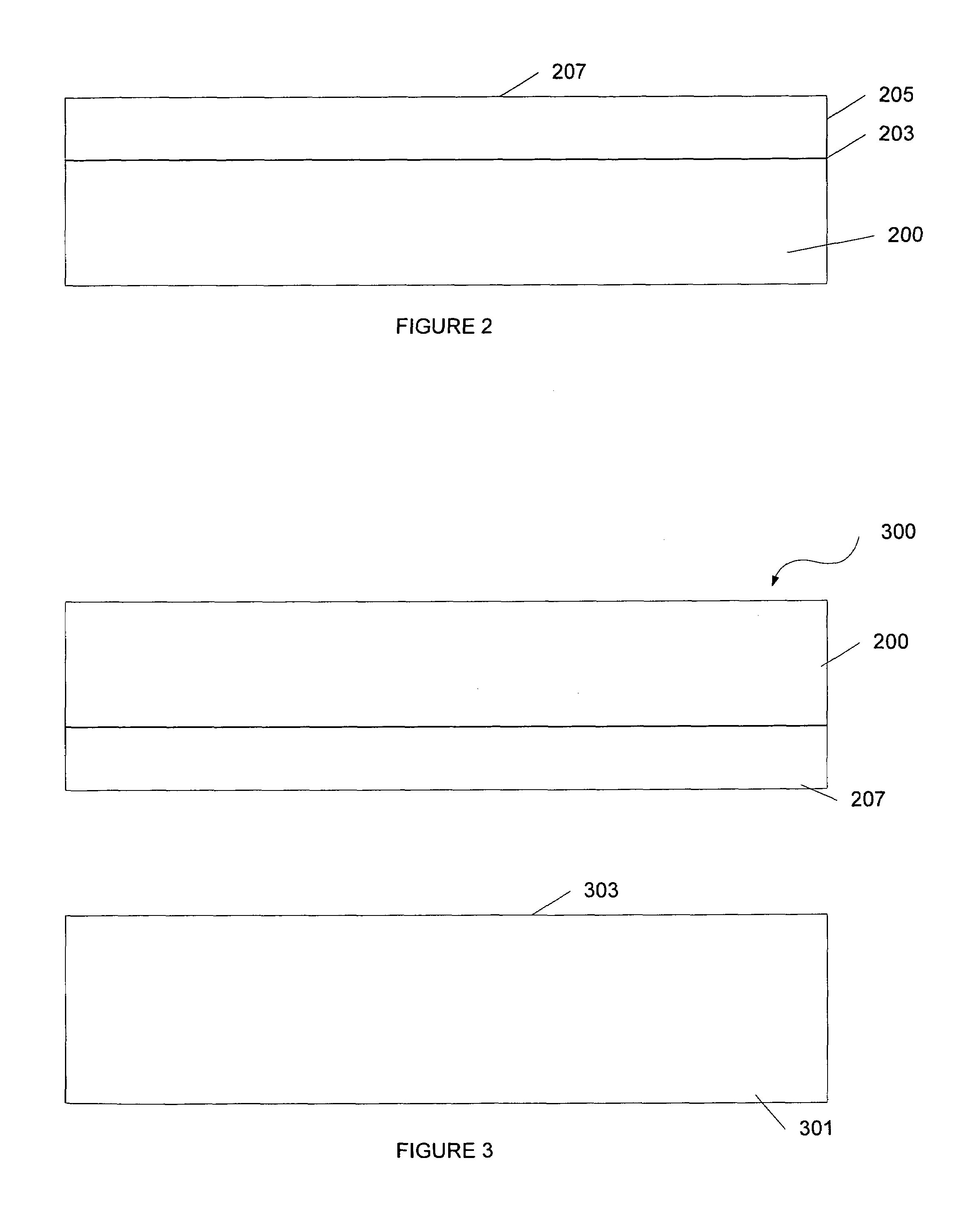

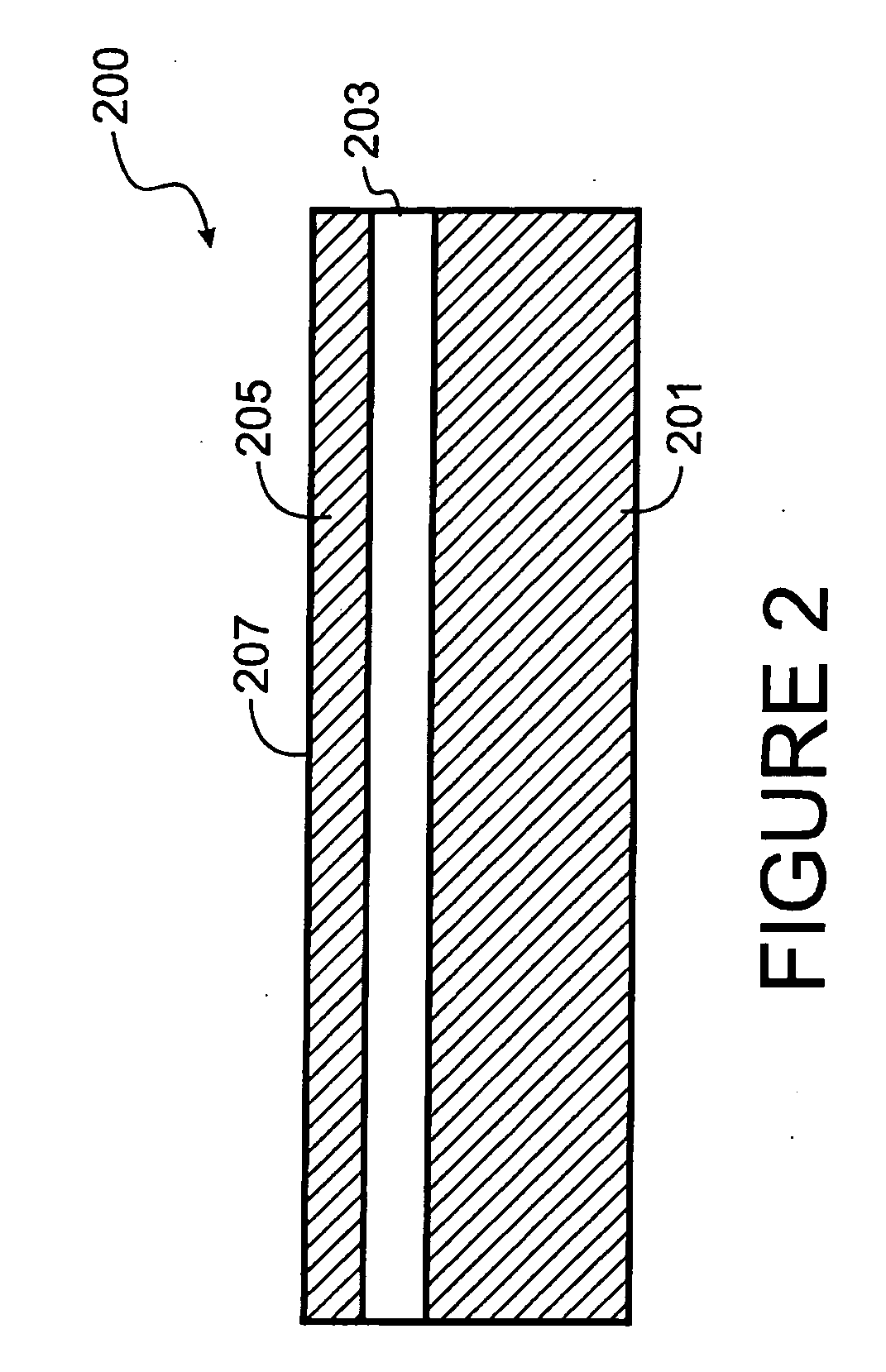

Pre-made cleavable substrate method and structure of fabricating devices using one or more films provided by a layer transfer process

InactiveUS20070029043A1Avoid the possibility of damageEfficient processingSolid-state devicesSemiconductor/solid-state device manufacturingBond strengthMaterials science

A method for fabricating one or more devices, e.g., integrated circuits. The method includes providing a multi-layered substrate, which has a thickness of material (e.g., single crystal silicon) overlying a first debondable surface coupled to and overlying a second debondable surface. The second debondable surface is overlying an interface region of the multi-layered substrate. In a preferred embodiment, the thickness of material having a surface region. The method includes processing the surface region of the multi-layered substrate using one or more processes to form at least one device onto a portion of the surface region. The method includes forming a planarized upper surface region overlying the surface region of the thickness of material. The method includes joining the planarized upper surface region to a face of a handle substrate. In a preferred embodiment, the method includes processing the first debondable surface and the second debondable surface to change a bond strength from a first determined amount to a second determined amount, which is capable of debonding the first debondable surface from the second debondable surface. The method includes debonding the first debondable surface from the second debondable surface to release the thickness of material and the handle substrate.

Owner:SILICON GENERAL CORPORATION

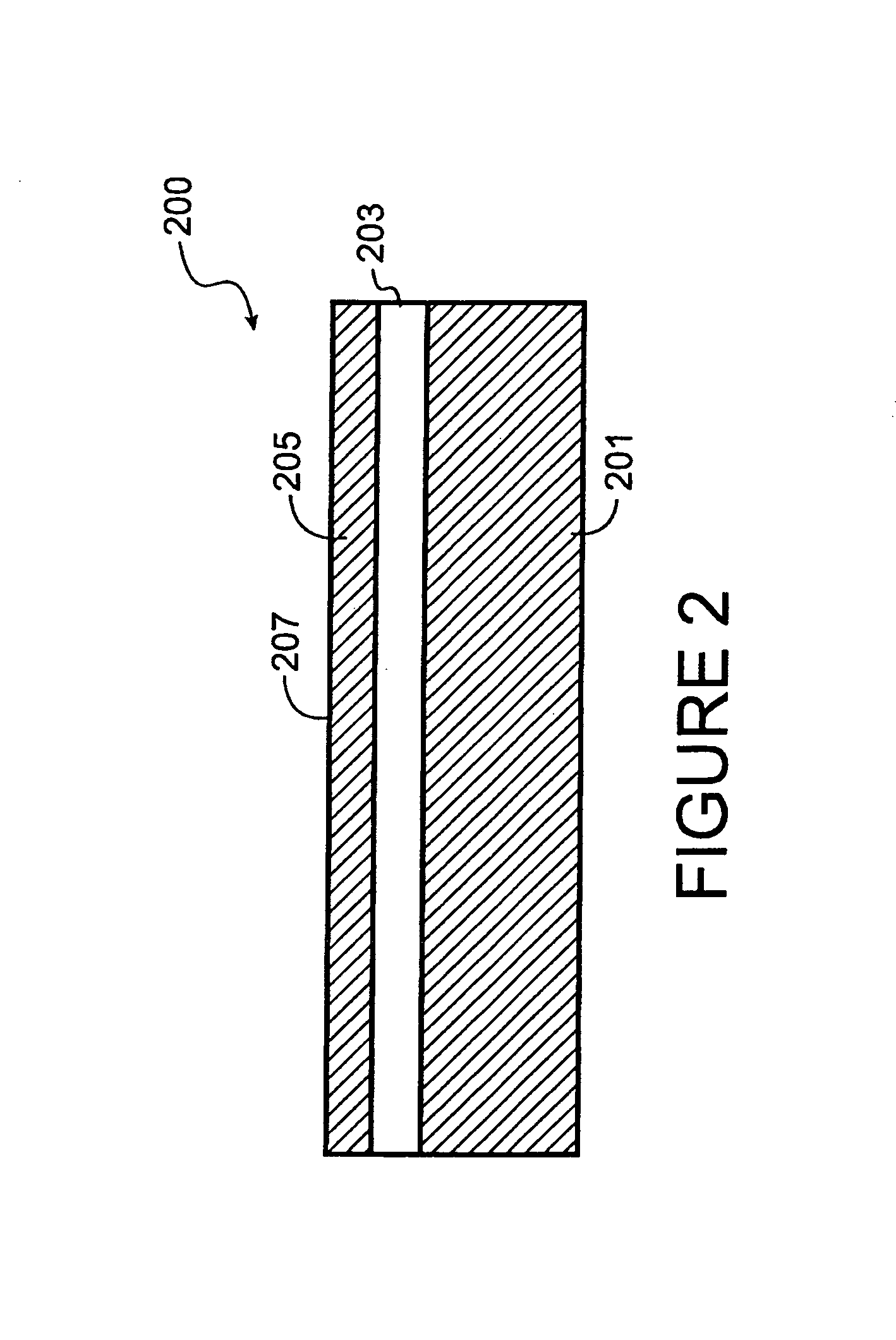

Substrate stiffness method and resulting devices for layer transfer process

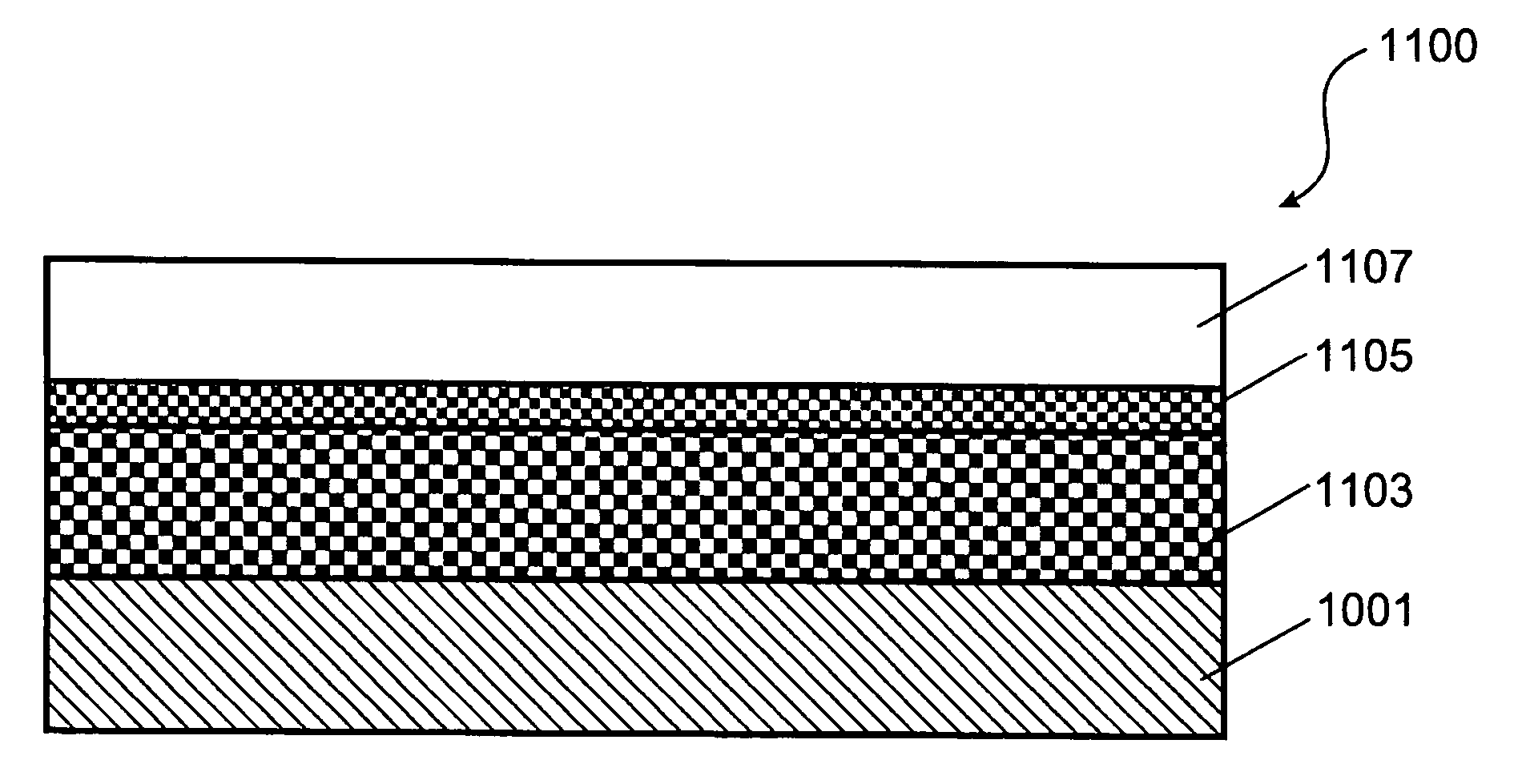

ActiveUS20060211219A1Suitable deflection characteristicEffective characterizationSolid-state devicesSemiconductor/solid-state device manufacturingBiomedical engineeringSubstrate stiffness

A method and structures for manufacturing multi-layered substrates. The method includes providing a donor substrate, which has a first deflection characteristic. The donor substrate has a backside, a face, a cleave region, and a thickness of material defined between the cleave region and the face. The method includes bonding the face of the donor substrate to a face of the handle substrate. The method includes coupling a backing substrate to the backside of the donor substrate to form a multilayered structure. The backing substrate is adequate to cause the first deflection characteristic of the donor substrate to be reduced to a predetermined level. The predetermined level is a suitable deflection characteristic for the thickness of material to be transferred onto the face of a handle substrate. The method includes initiating a controlled cleaving process within a portion of the cleave region of the donor substrate to begin removal of the thickness of material from the donor substrate at a portion of the cleave region, while the backing substrate remains attached to the donor substrate to maintain at least the suitable deflection characteristic.

Owner:SILICON GENERAL CORPORATION

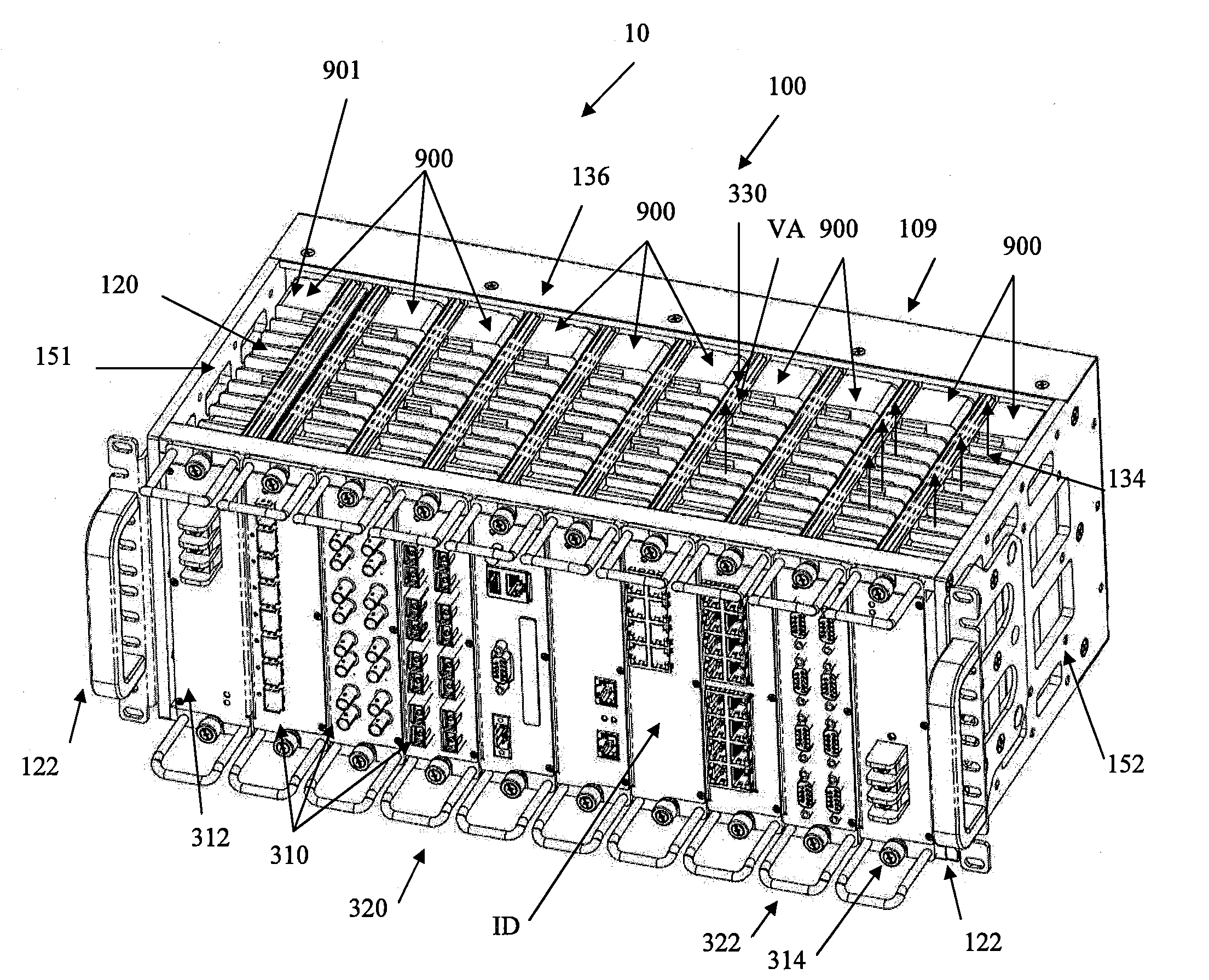

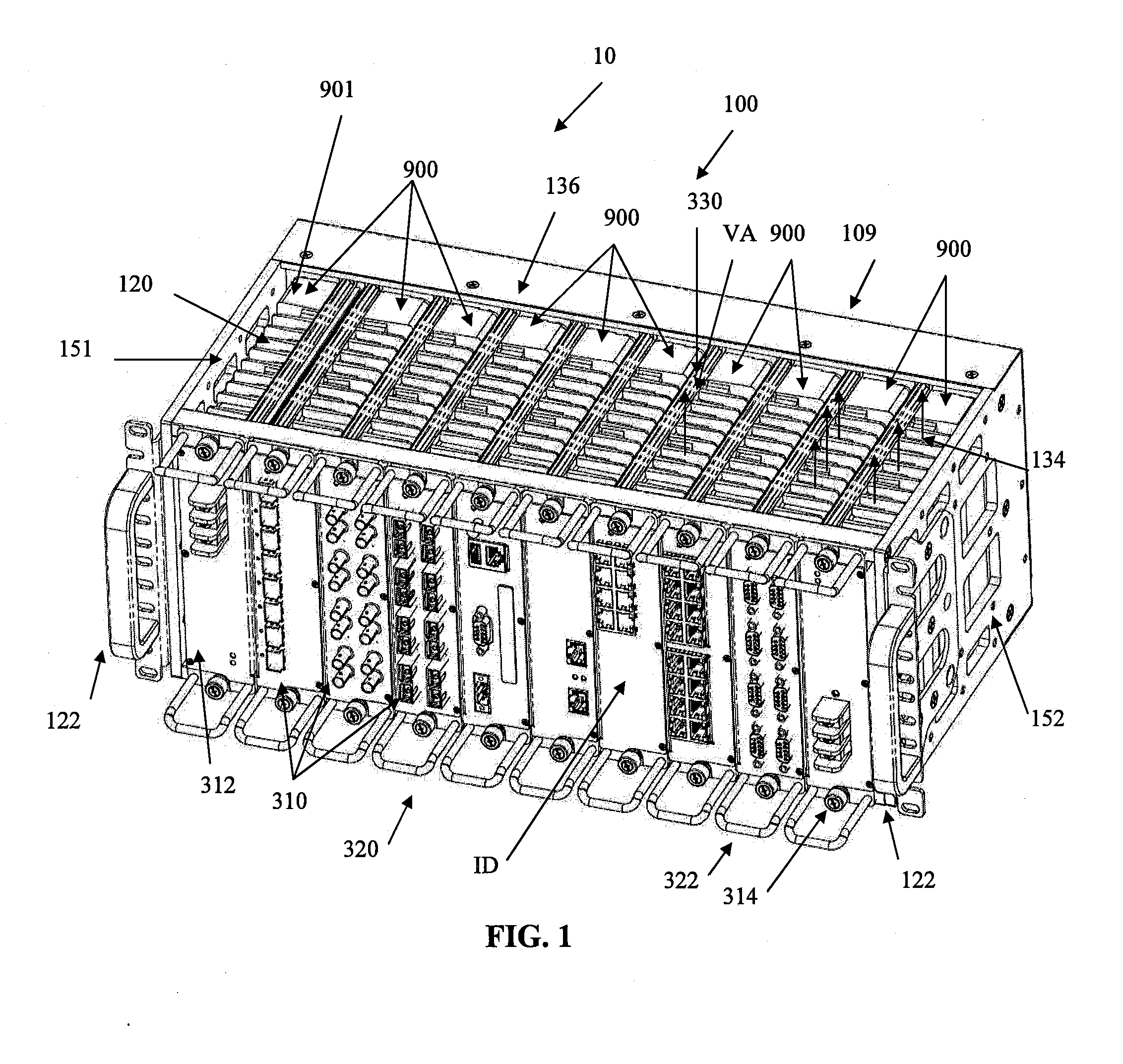

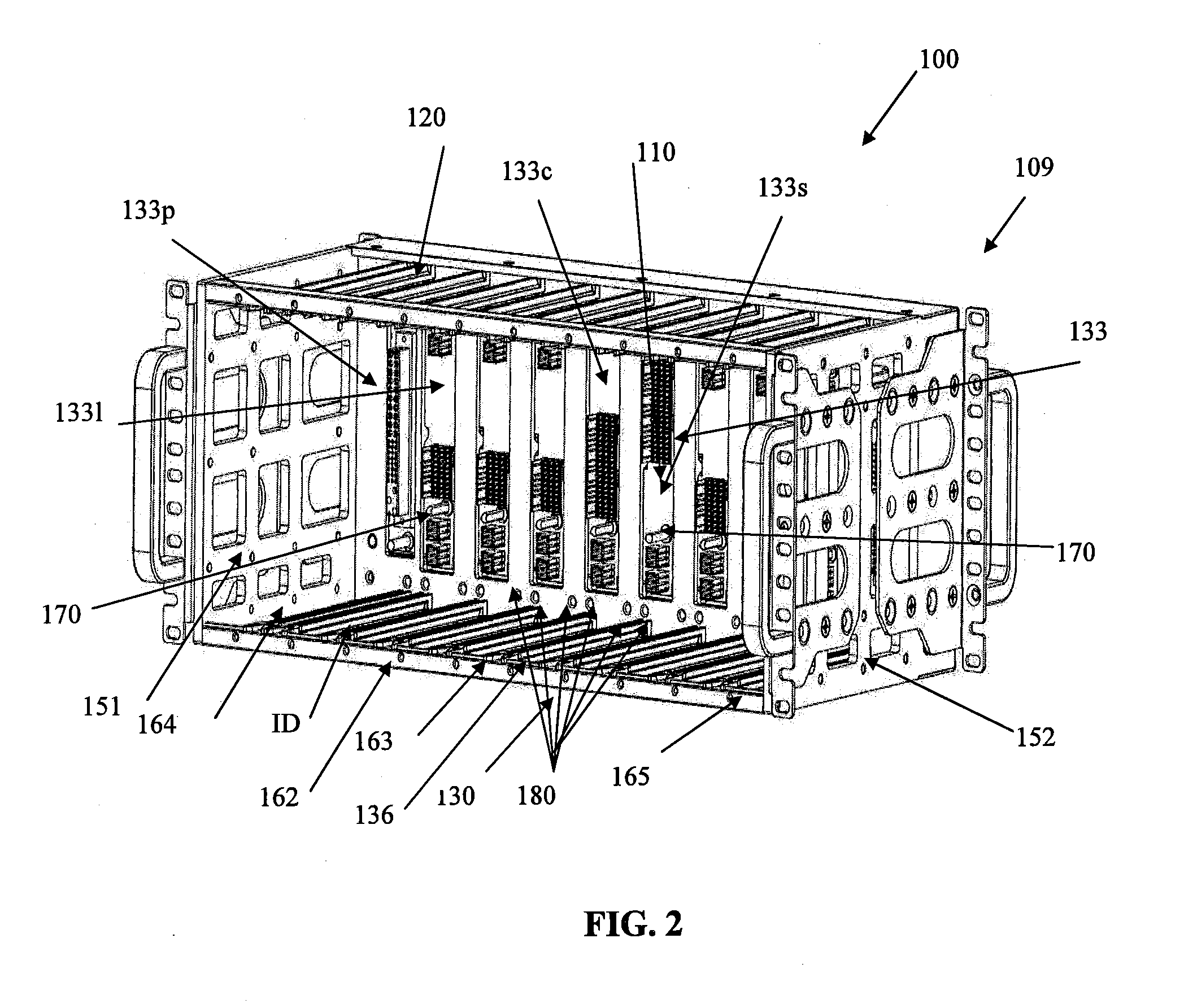

Open Frame Electronic Chassis For Enclosed Modules

ActiveUS20100290186A1Dissipate generated heatImprove mean time between failuresDigital data processing detailsIndirect heat exchangersElectrical connectionEngineering

An open frame chassis has a top opening and a bottom opening permitting ambient air flow there through. A plurality of modules, each enclosing electrical components which are in thermal contact with a heat sink area of their corresponding module, and each of which can be inserted to an inserted position in the open frame chassis. When the modules are inserted into the open frame chassis, ambient air may flow from the bottom opening of the chassis across the heat sink area of each module to the top opening in order to passively cool the modules and the electrical components enclosed therein. The heat sink area has fins which are separated by a distance of 9 mm to 12 mm and have a height 10 mm to 20 mm. Key pins are associated with the electrical connectors of the chassis to guide the modules into place and prevent incorrect insertion of a different type of electrical module not corresponding to the electrical connection of the chassis for that slot. Guide pins are present on the corners of the modules to mate with guide holes in the chassis to secure the module to the open frame chassis and decrease vibration. Both sides of the chassis have side openings through which the fins of the modules inserted into the end slots of the chassis may be exposed. The power modules are inserted into the end slots. The chassis has an inverted connection at one end slot to accommodate identical power modules at both end slots such that the heat sink area always faces a side opening in the open frame chassis.

Owner:SIEMENS CANADA LTD

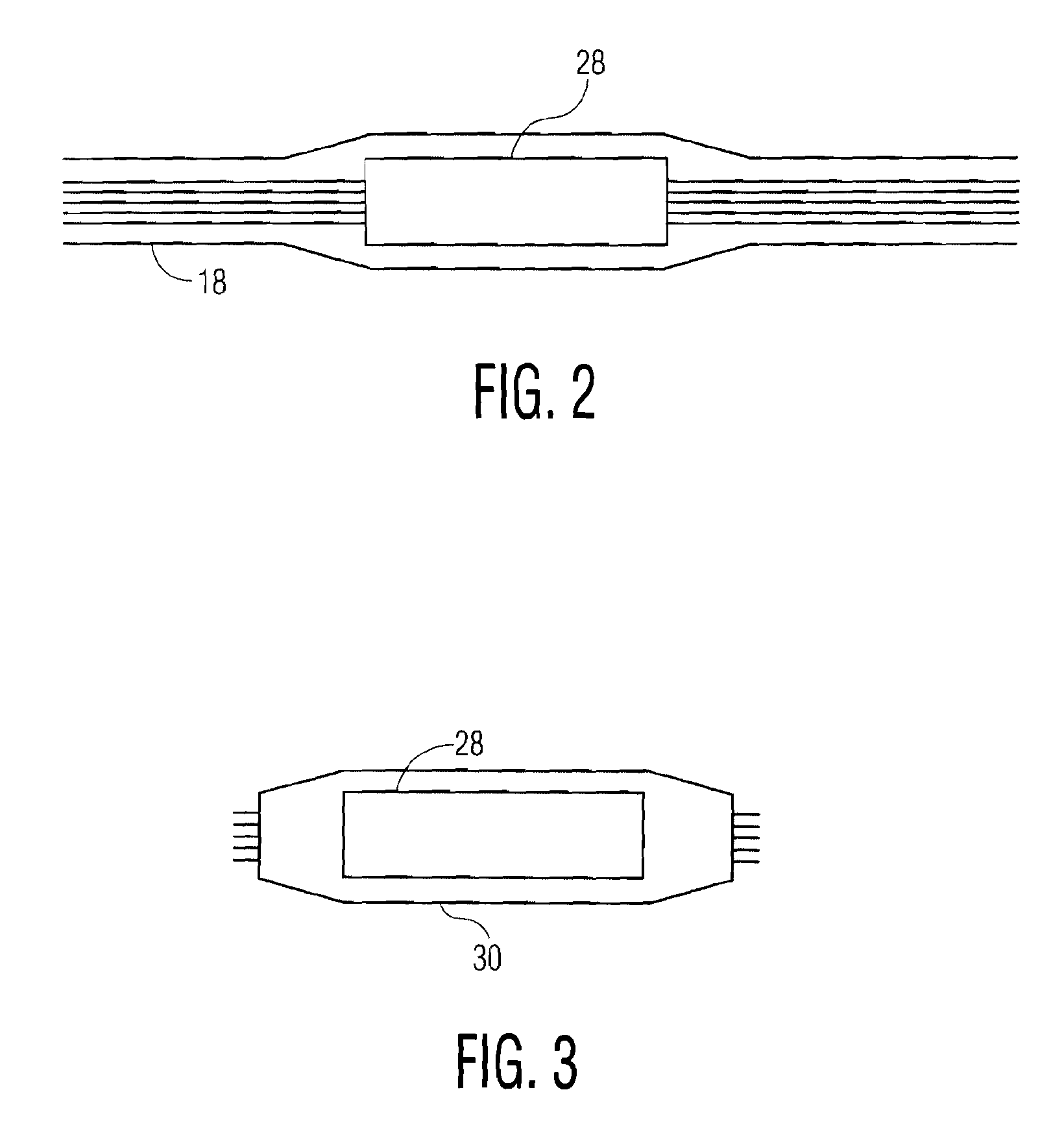

Controlled cleaving process

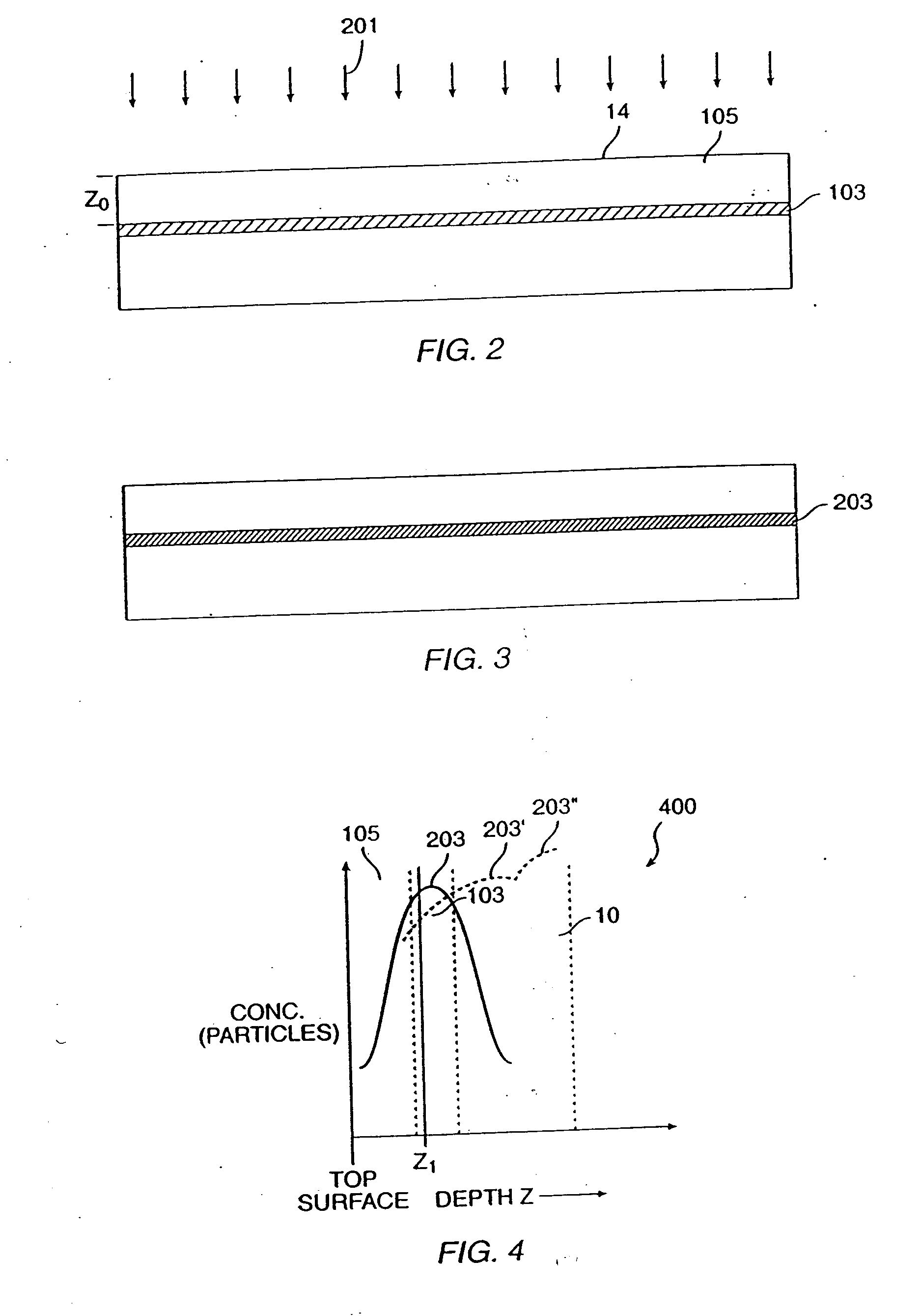

InactiveUS20060141747A1Good removal effectAvoid the possibility of damageDecorative surface effectsLayered productsHigh concentrationEnergy source

A technique for forming a film of material (12) from a donor substrate (10). The technique has a step of introducing energetic particles (22) through a surface of a donor substrate (10) to a selected depth (20) underneath the surface, where the particles have a relatively high concentration to define a donor substrate material (12) above the selected depth. An energy source is directed to a selected region of the donor substrate to initiate a controlled cleaving action of the substrate (10) at the selected depth (20), whereupon the cleaving action provides an expanding cleave front to free the donor material from a remaining portion of the donor substrate.

Owner:SILICON GENERAL CORPORATION

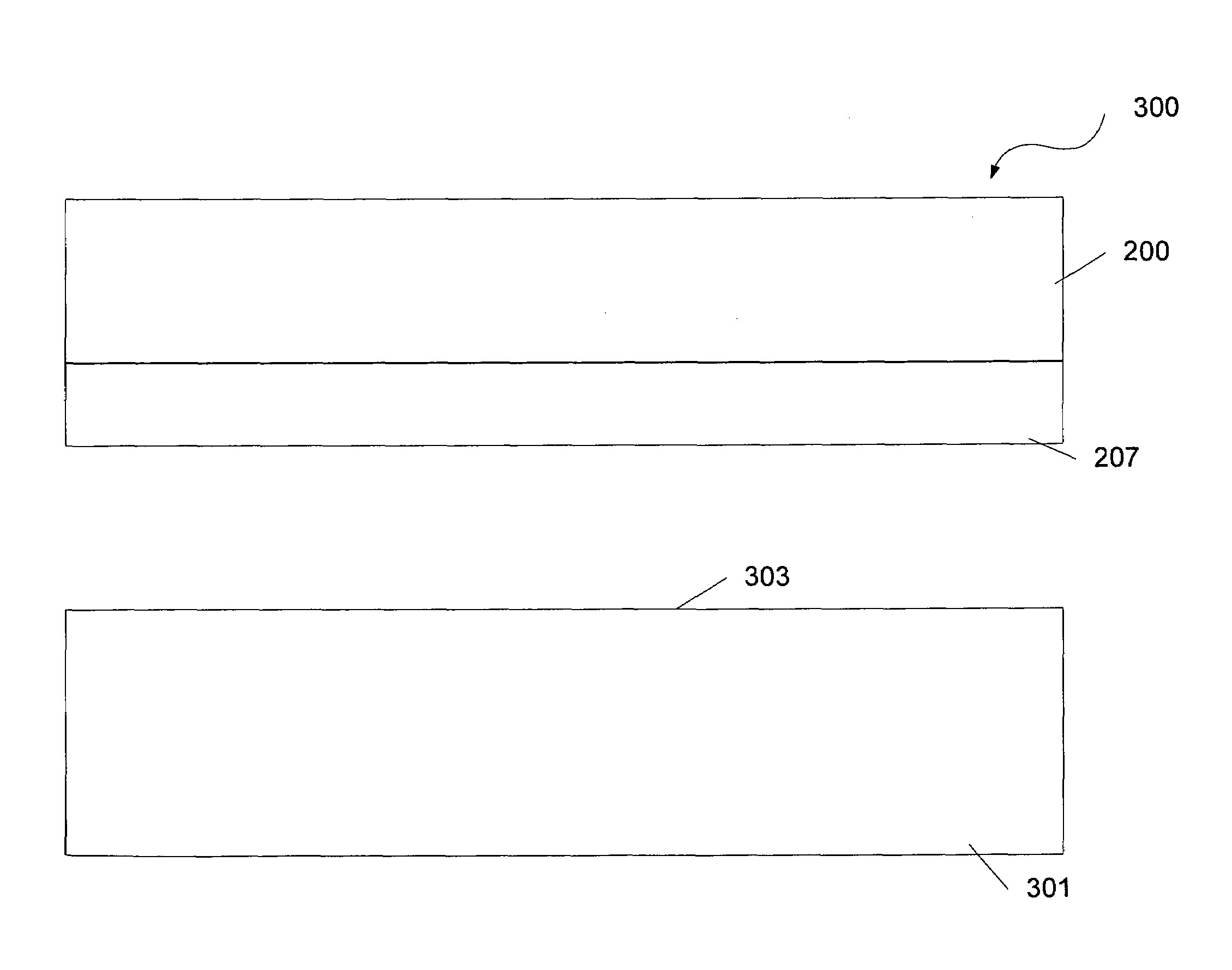

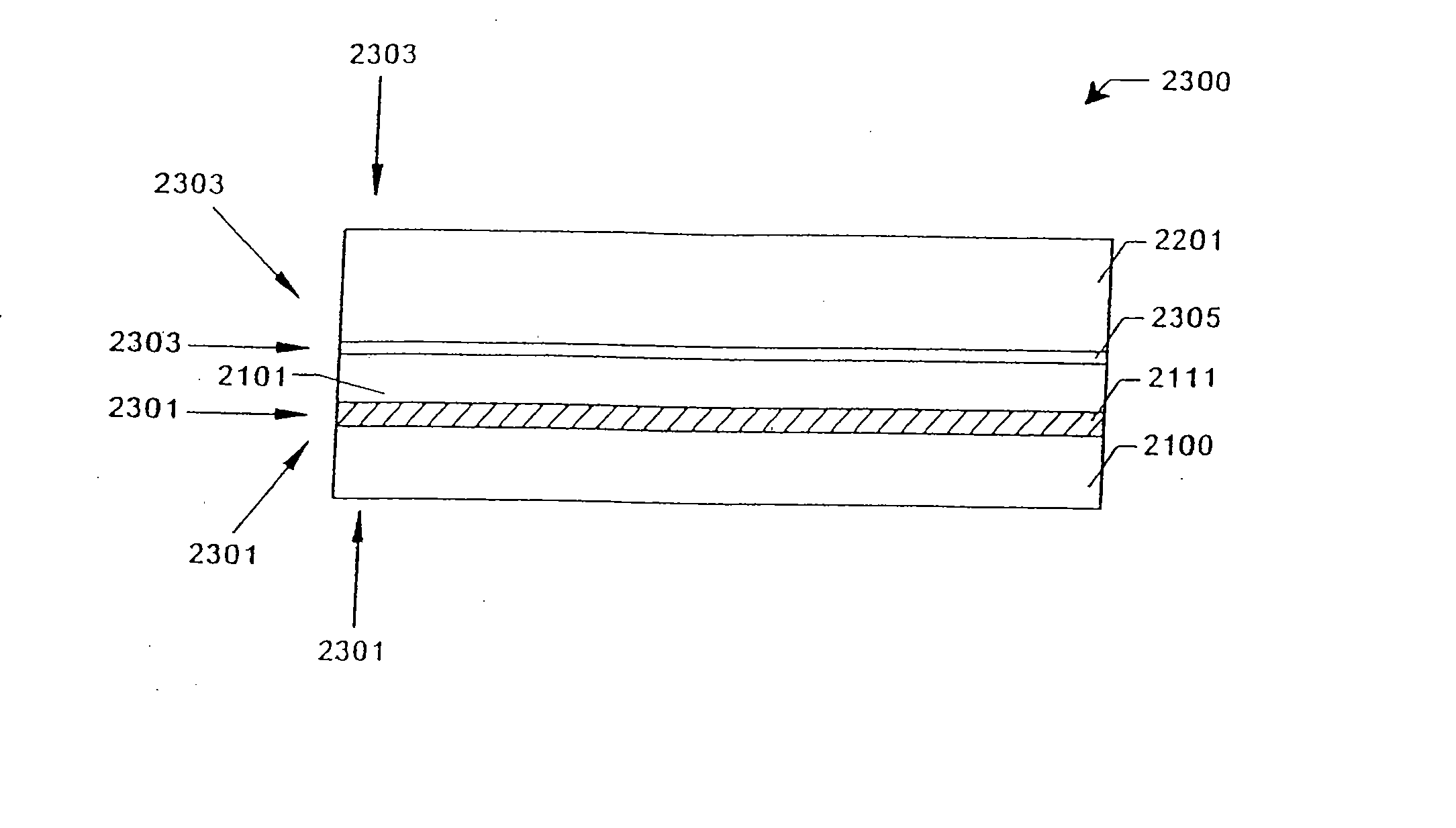

Method and structure for fabricating bonded substrate structures using thermal processing to remove oxygen species

InactiveUS7598153B2Avoid the possibility of damageEfficient processingData processing applicationsSemiconductor/solid-state device manufacturingSilicon oxideOxygen

Owner:SILICON GENERAL CORPORATION

Cleaving process to fabricate multilayered substrates using low implantation doses

InactiveUS20060166472A1Improve efficiencyQuality improvementSemiconductor/solid-state device detailsSolid-state devicesHigh concentrationControl manner

A method of forming substrates, e.g., silicon on insulator, silicon on silicon. The method includes providing a donor substrate, e.g., silicon wafer. The method also includes forming a cleave layer on the donor substrate that contains the cleave plane, the plane of eventual separation. In a specific embodiment, the cleave layer comprising silicon germanium. The method also includes forming a device layer (e.g., epitaxial silicon) on the cleave layer. The method also includes introducing particles into the cleave layer to add stress in the cleave layer. The particles within the cleave layer are then redistributed to form a high concentration region of the particles in the vicinity of the cleave plane, where the redistribution of the particles is carried out in a manner substantially free from microbubble or microcavity formation of the particles in the cleave plane. That is, the particles are generally at a low dose, which is defined herein as a lack of microbubble or microcavity formation in the cleave plane. The method also includes providing selected energy to the donor substrate to cleave the device layer from the cleave layer at the cleave plane, whereupon the selected energy is applied to create a controlled cleaving action to remove the device layer from a portion of the cleave layer in a controlled manner.

Owner:SILICON GENERAL CORPORATION

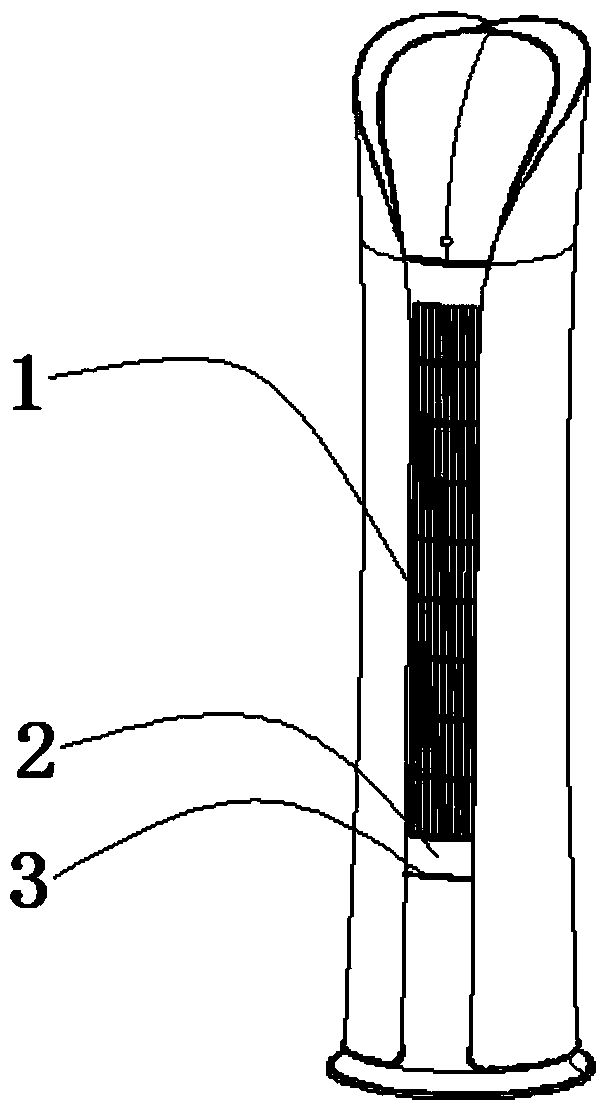

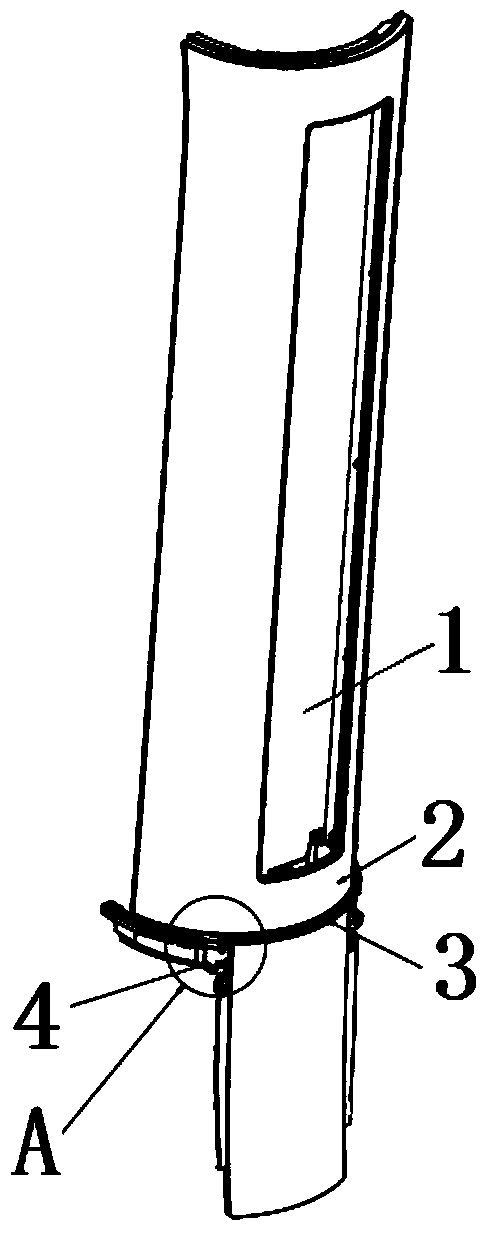

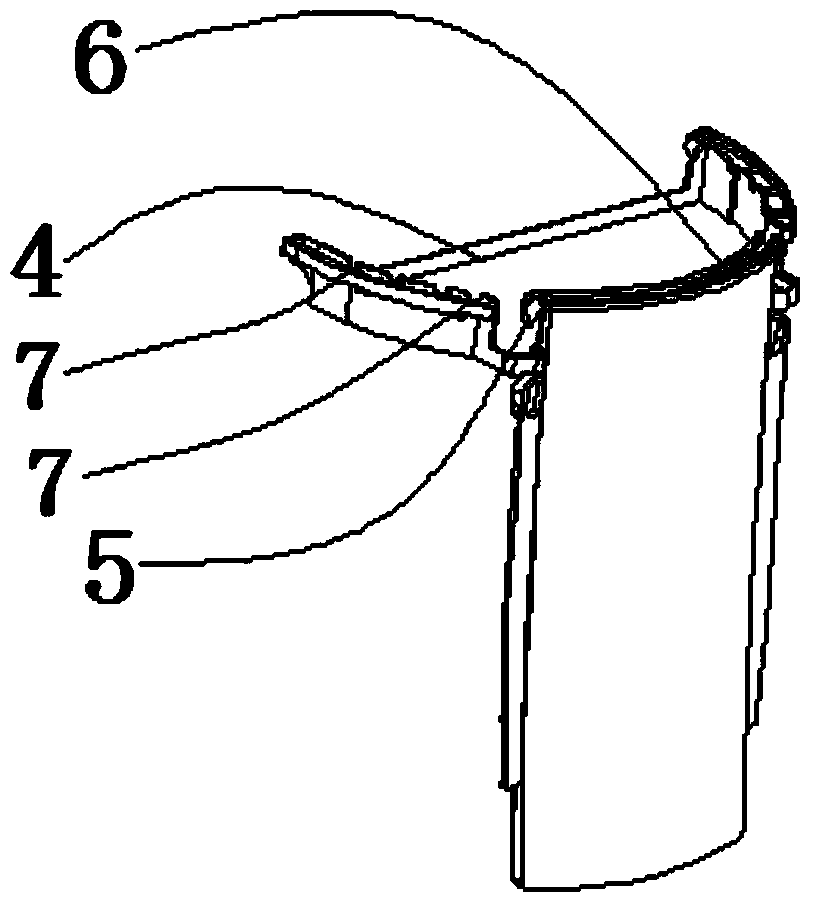

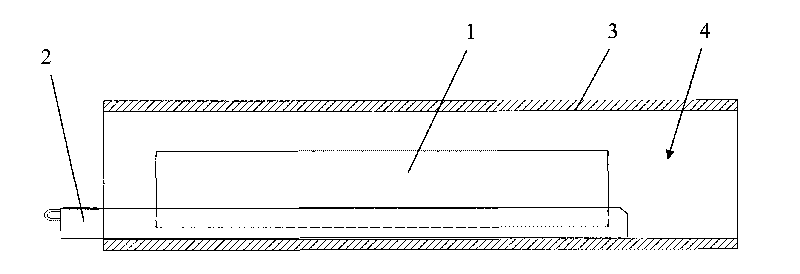

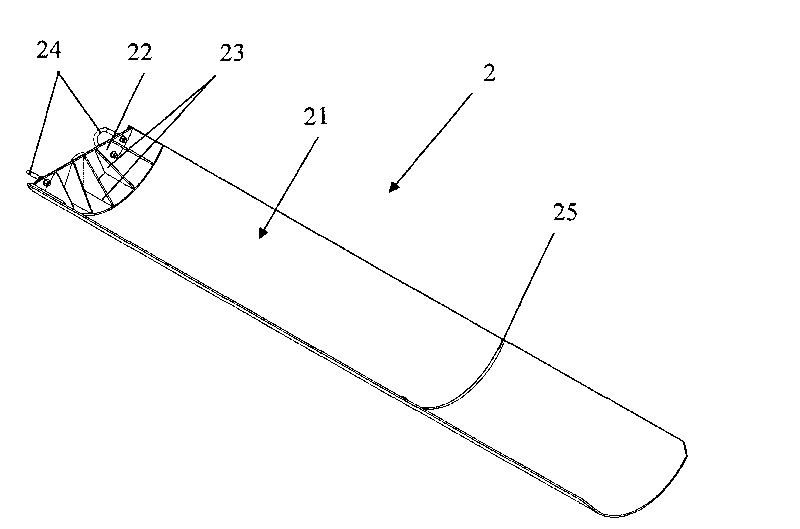

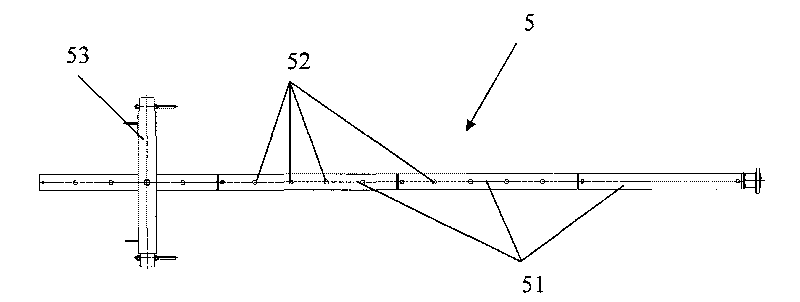

Condensate water collecting device for air conditioner and air conditioner

Owner:GREE ELECTRIC APPLIANCES INC

Controlled process and resulting device

InactiveUS20070122997A1Good removal effectAvoid the possibility of damageSemiconductor/solid-state device manufacturingMicrostructural device manufactureHigh concentrationBiomedical engineering

A technique for forming a film of material (12) from a donor substrate (10). The technique has a step of introducing energetic particles (22) through a surface of a donor substrate (10) to a selected depth (20) underneath the surface, where the particles have a relatively high concentration to define a donor substrate material (12) above the selected depth. An energy source is directed to a selected region of the donor substrate to initiate a controlled cleaving action of the substrate (10) at the selected depth (20), whereupon the cleaving action provides an expanding cleave front to free the donor material from a remaining portion of the donor substrate.

Owner:SILICON GENERAL CORPORATION

Method and device for controlled cleaving process

InactiveUS7470600B2Good removal effectAvoid the possibility of damageDecorative surface effectsLayered productsEngineeringEnergy source

A technique for forming a film of material (12) from a donor substrate (10). The technique has a step of forming a stressed region in a selected manner at a selected depth (20) underneath the surface. An energy source such as pressurized fluid is directed to a selected region of the donor substrate to initiate a controlled cleaving action of the substrate (10) at the selected depth (20), whereupon the cleaving action provides an expanding cleave front to free the donor material from a remaining portion of the donor substrate.

Owner:SILICON GENERAL CORPORATION

Thin handle substrate method and structure for fabricating devices using one or more films provided by a layer transfer process

InactiveUS20070032084A1Suitable bonding characteristicWithstand high-temperature processingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsDevice material

A method for fabricating one or more devices, e.g., integrated circuits. The method includes providing a substrate (e.g., silicon), which has a thickness of semiconductor material and a surface region. The substrate also has a cleave plane provided within the substrate to define the thickness of semiconductor material. The method includes joining the surface region of the substrate to a first handle substrate. In a preferred embodiment, the first handle substrate is termed a “thin” substrate, which provides suitable bonding characteristics, can withstand high temperature processing often desired during the manufacture of semiconductor devices, and has desirable de-bonding characteristics between it and a second handle substrate, which will be described in more detail below. In a preferred embodiment, the first handle substrate is also thick enough and rigid enough to allow for cleaving according to a specific embodiment.

Owner:SILICON GENERAL CORPORATION

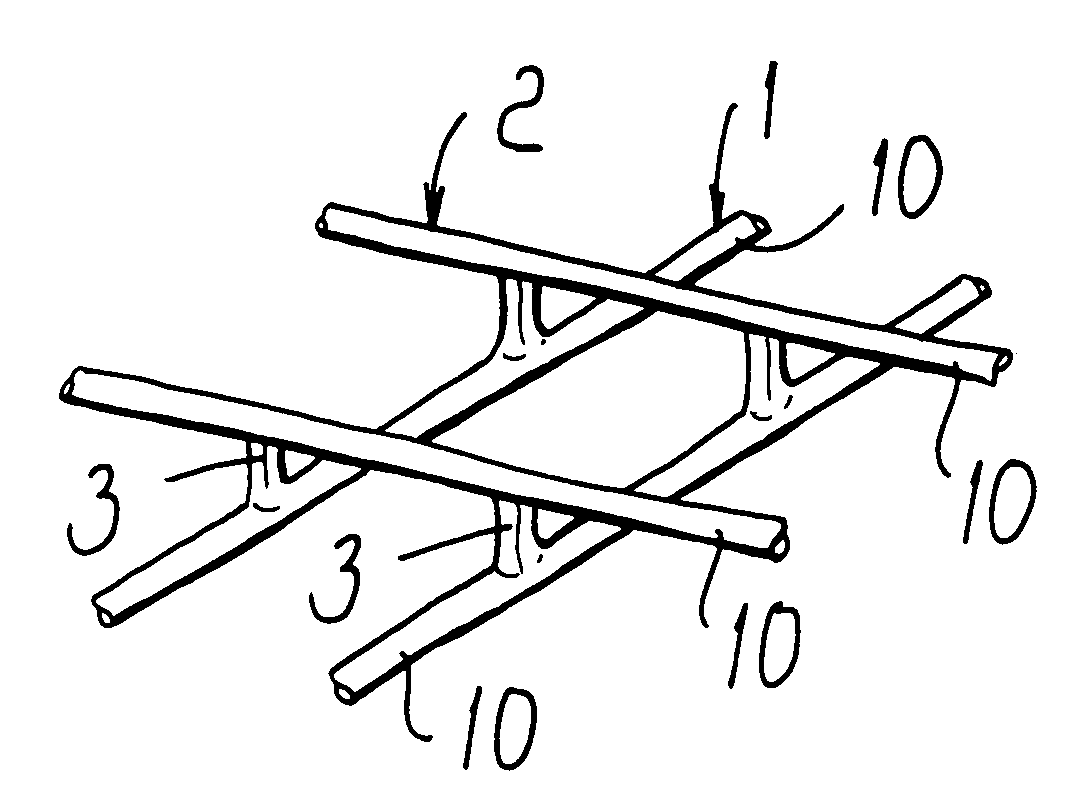

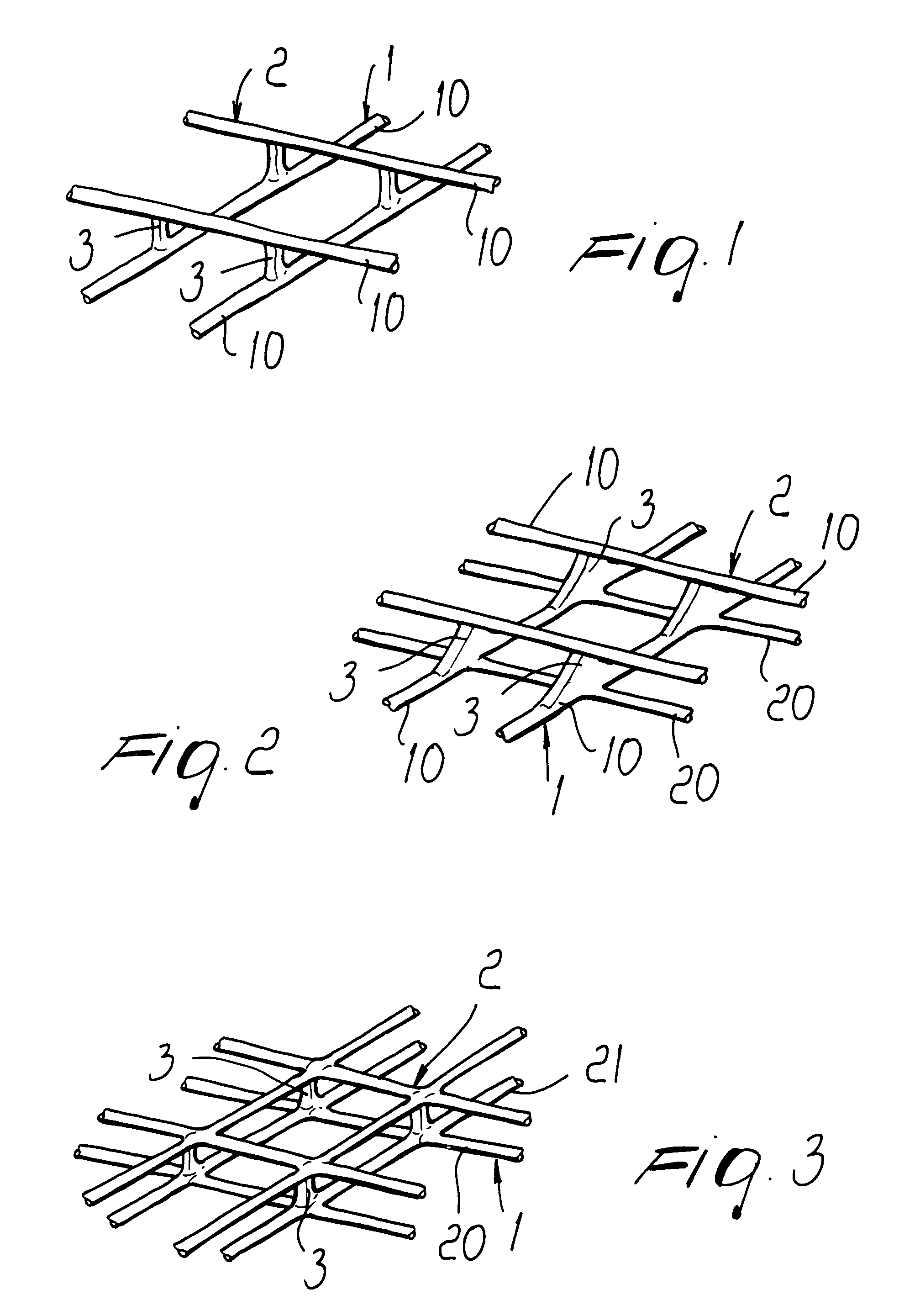

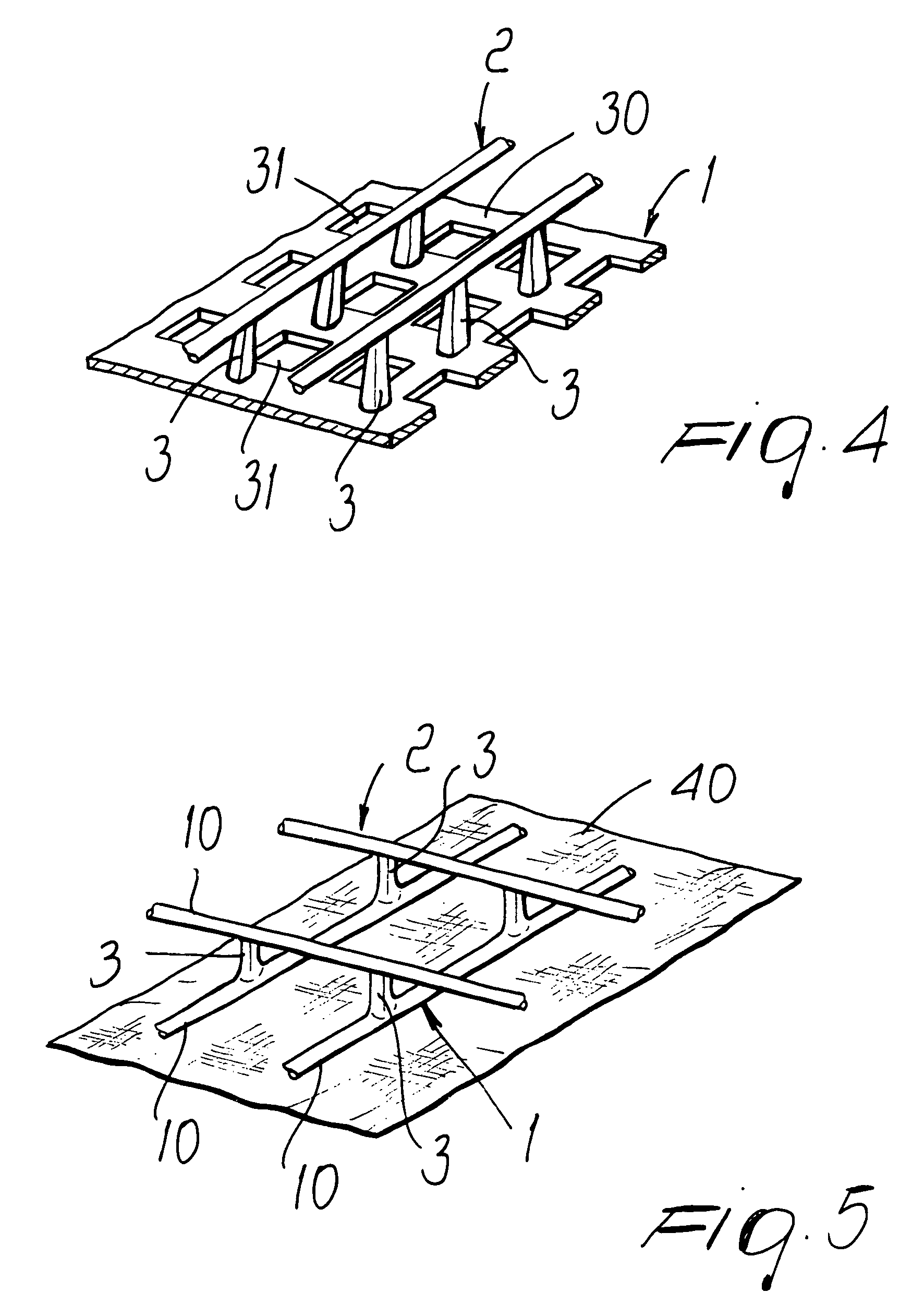

Net-like structure particularly for geotechnical uses

InactiveUS6972269B1Improve stress resistanceHinder useful passage sectionWarp knittingKnotting netsSecondary layerYarn

A net-like structure particularly for geotechnical applications which comprises a first and a second layer which are mutually spaced and joined one another by spacers which are co-extruded together with the layers. At least one of the layers comprises at least one set of yarns arranged at one end of the spacers; the spacers have a reduced transverse cross-section.

Owner:TENAX SPA

Controlled Process and Resulting Device

InactiveUS20080038901A1Good removal effectAvoid the possibility of damageSemiconductor/solid-state device manufacturingMicrostructural device manufactureHigh concentrationBiomedical engineering

A technique for forming a film of material (12) from a donor substrate (10). The technique has a step of introducing energetic particles (22) through a surface of a donor substrate (10) to a selected depth (20) underneath the surface, where the particles have a relatively high concentration to define a donor substrate material (12) above the selected depth. An energy source is directed to a selected region of the donor substrate to initiate a controlled cleaving action of the substrate (10) at the selected depth (20), whereupon the cleaving action provides an expanding cleave front to free the donor material from a remaining portion of the donor substrate.

Owner:SILICON GENERAL CORPORATION

Controlled cleaving process

InactiveUS20050186758A1Good removal effectAvoid the possibility of damageDecorative surface effectsLayered productsChemistryHigh concentration

A technique for forming a film of material (12) from a donor substrate (10). The technique has a step of introducing energetic particles (22) through a surface of a donor substrate (10) to a selected depth (20) underneath the surface, where the particles have a relatively high concentration to define a donor substrate material (12) above the selected depth. An energy source is directed to a selected region of the donor substrate to initiate a controlled cleaving action of the substrate (10) at the selected depth (20), whereupon the cleaving action provides an expanding cleave front to free the donor material from a remaining portion of the donor substrate.

Owner:SILICON GENERAL CORPORATION

Method for casting thick-wall nodular iron casting of blower in power plant

InactiveCN101716671AImprove production success rateSolve the problem of sticky sandFoundry mouldsFoundry coresFine structureThick wall

The invention relates to a method for casting a fine structure of a thick-wall nodular iron casting, in particular to a method for casting the thick-wall nodular iron casting of a blower in a power plant, which comprises the steps of core bar manufacturing, core manufacturing, molding, mould assembling, pouring and sand falling and cleaning; the invention provides the method for casting the thick-wall nodular iron casting of the blower in the power plant; and the process method is unique, can improve the success ratio of sand core production, reduce the difficulty of core manufacturing and solve the problem that sand is adhered in pores.

Owner:NINGXIA KOCEL GRP CO LTD +1

Method and Device for Controlled Cleaving Process

InactiveUS20080057675A1Good removal effectAvoid the possibility of damageLayered productsDecorative surface effectsEngineeringEnergy source

A technique for forming a film of material (12) from a donor substrate (10). The technique has a step of forming a stressed region in a selected manner at a selected depth (20) underneath the surface. An energy source such as pressurized fluid is directed to a selected region of the donor substrate to initiate a controlled cleaving action of the substrate (10) at the selected depth (20), whereupon the cleaving action provides an expanding cleave front to free the donor material from a remaining portion of the donor substrate.

Owner:SILICON GENERAL CORPORATION

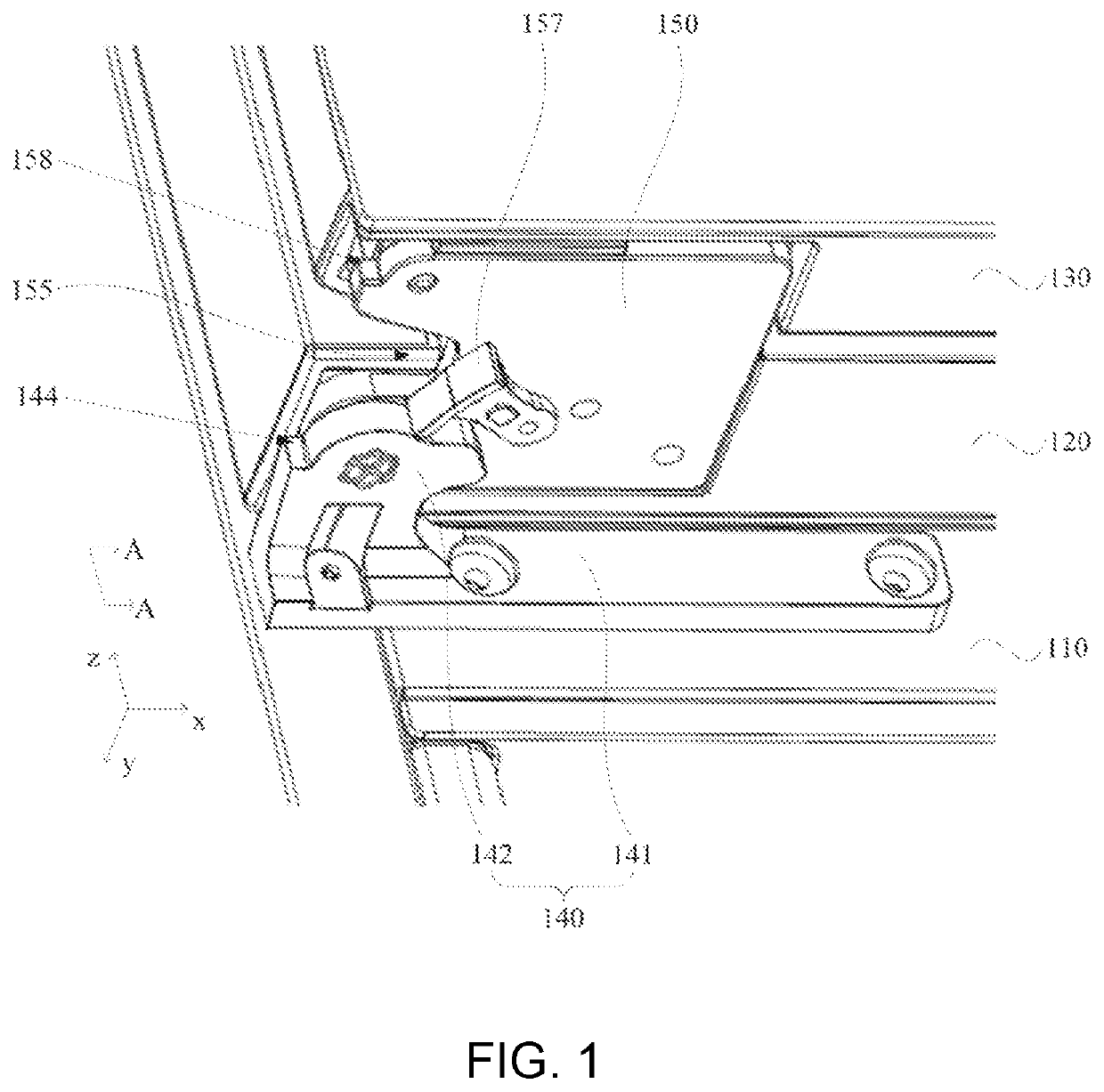

Mobile device of inner-pipeline detection device as well as launching and receiving method

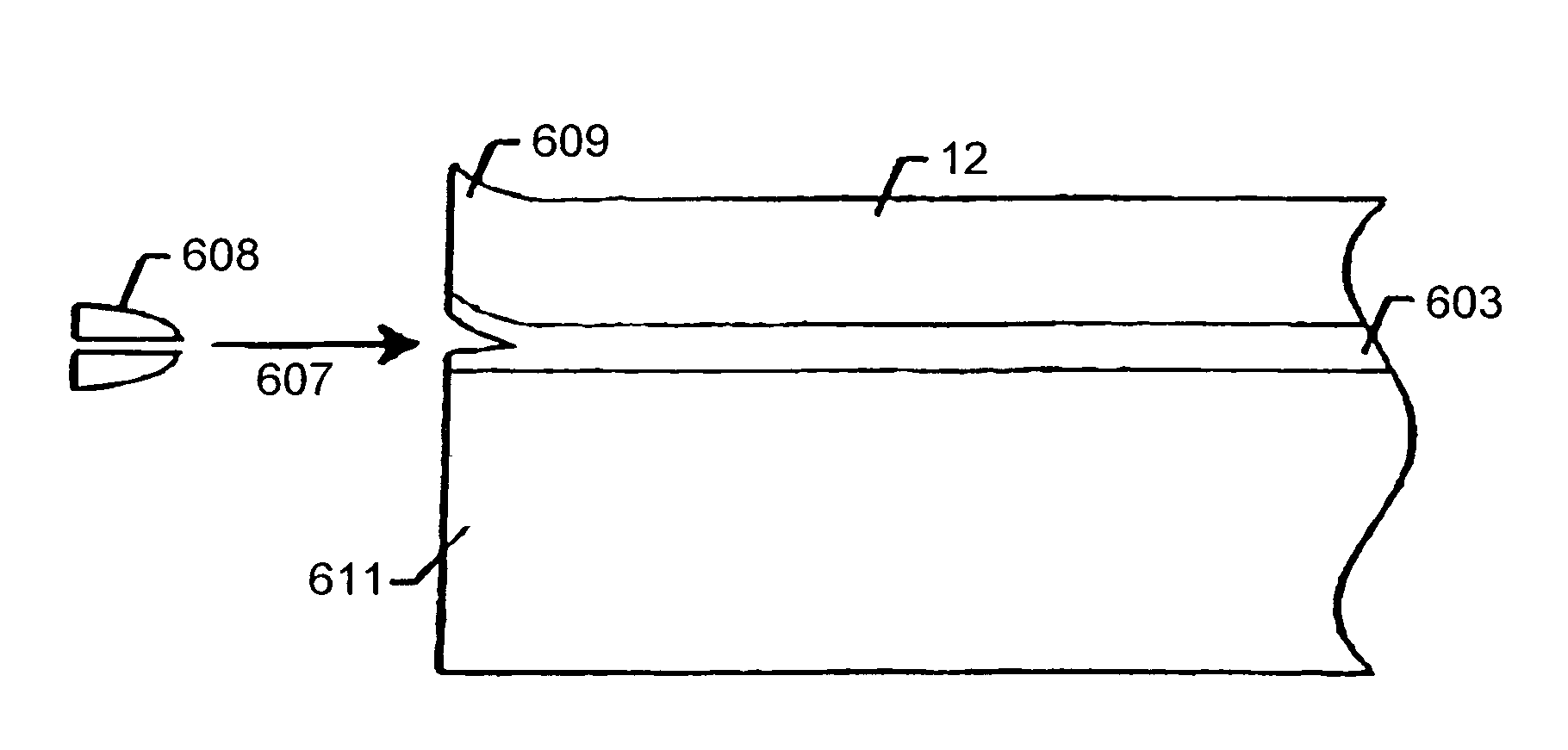

ActiveCN101713492AReduce the possibility of damageAvoid the possibility of damagePipeline systemsEngineeringPallet

The invention provides a mobile device of an inner-pipeline detection device as well as a launching method and a receiving method of the inner-pipeline detection device by using the mobile device. The mobile device comprises a pallet, wherein the longitudinal length of the pallet is not less than the length of the inner-pipeline detection device, and the shape of the pallet enables the pallet to be capable of holding a part of the inner-pipeline detection device in the radial direction. According to the mobile device, the pipeline inner-detection device can be held by the non-magnetic pallet so that the inner-pipeline detection device can be separated from the internal wall of a launching-receiving spherical cylinder in the process of launching and receiving the inner-pipeline detection device. Therefore, the magnetic force generated between the inner-pipeline detection device and the launching-receiving spherical cylinder is reduced, the pipeline inner-detection device is conveniently launched to a predetermined position in the launching-receiving spherical cylinder, and then the position of the inner-pipeline detection device can be kept with only extracting the pallet, thereby greatly reducing the possibility of damageing the inner-pipeline detection device.

Owner:CHINA PETROLEUM & CHEM CORP +1

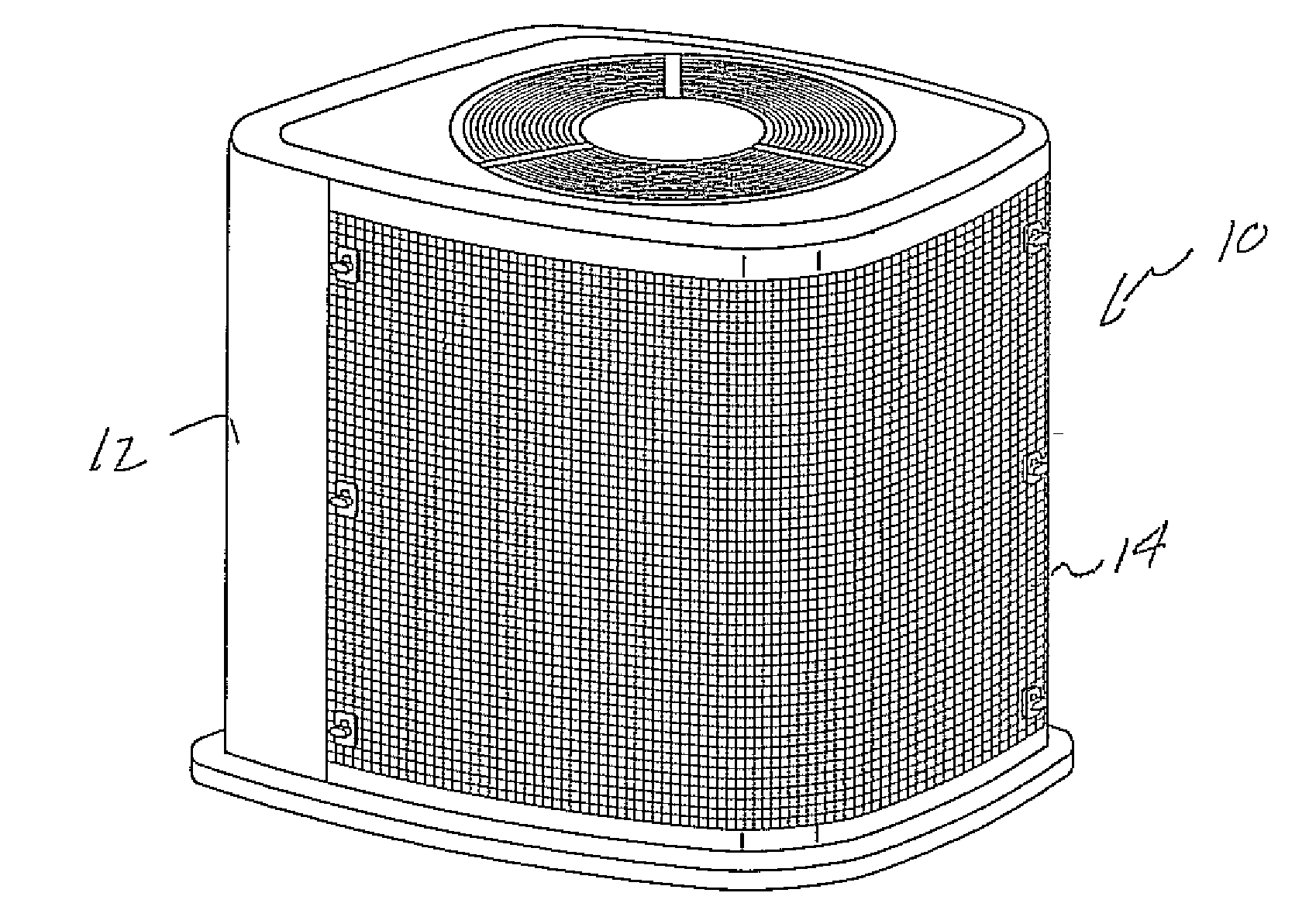

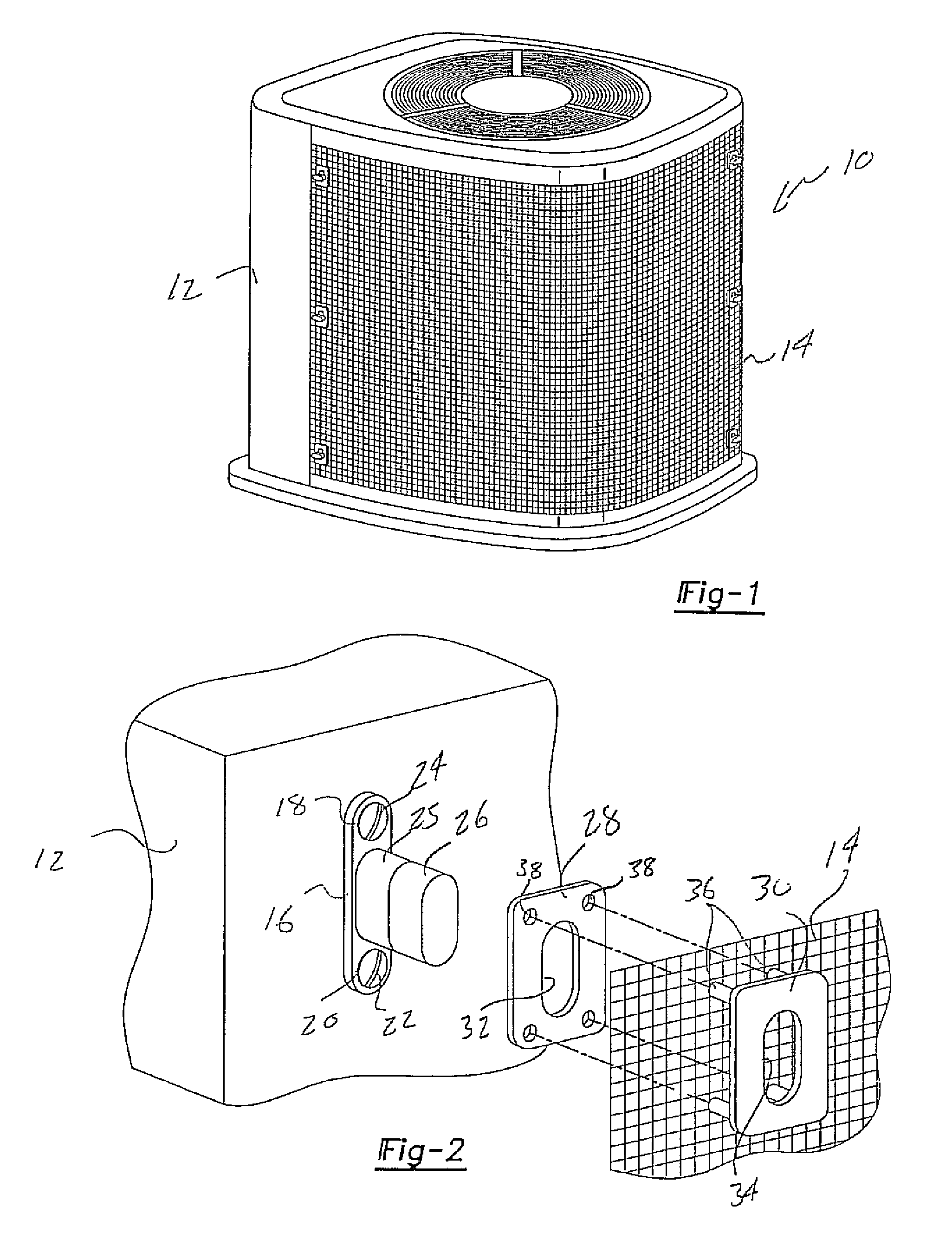

Filter installation kit for use with such as an air condensing unit

ActiveUS7591870B2Avoid the possibility of damageCombination devicesMechanical apparatusMechanical componentsFiltration

A retrofit installation kit for use with such as an exteriorly located air conditioner condensing unit. The kit includes a flexible filtration screen and a set of customized fasteners which substitute for existing fasteners used to hold together the outer sheathing of the unit frame. The substitution of fasteners for the typical mounting screws utilized in the original unit construction precludes the possibility of such as damaging the unit due to drilling new fastener holes, this running the risk of rupturing fluid coils within the unit, or damaging other sensitive electrical or mechanical components.

Owner:THE NEWWAY

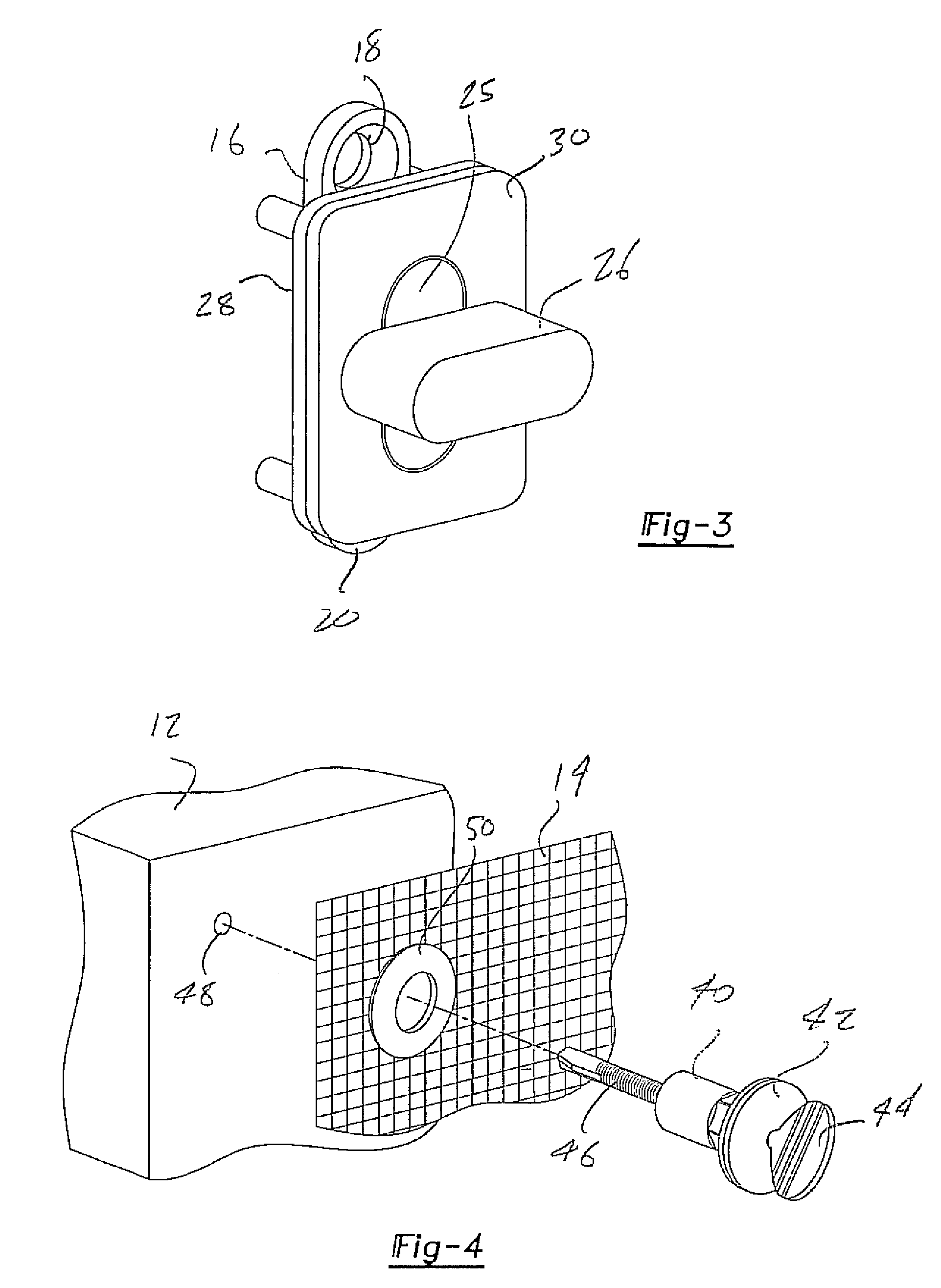

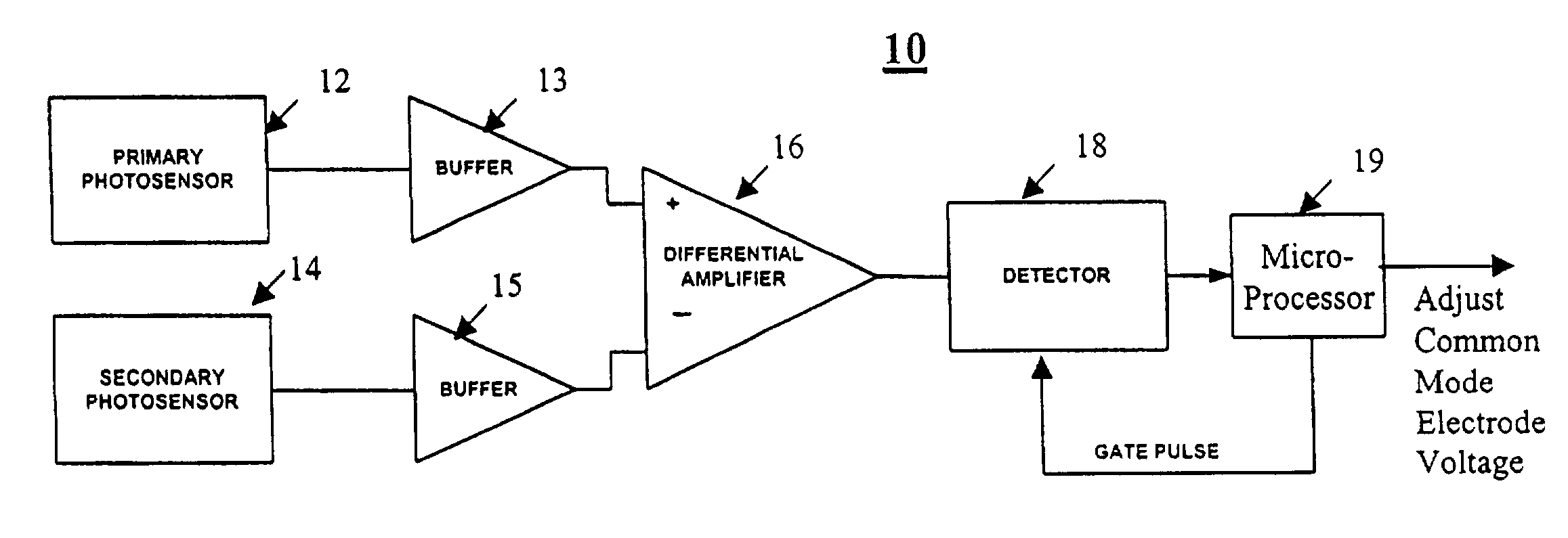

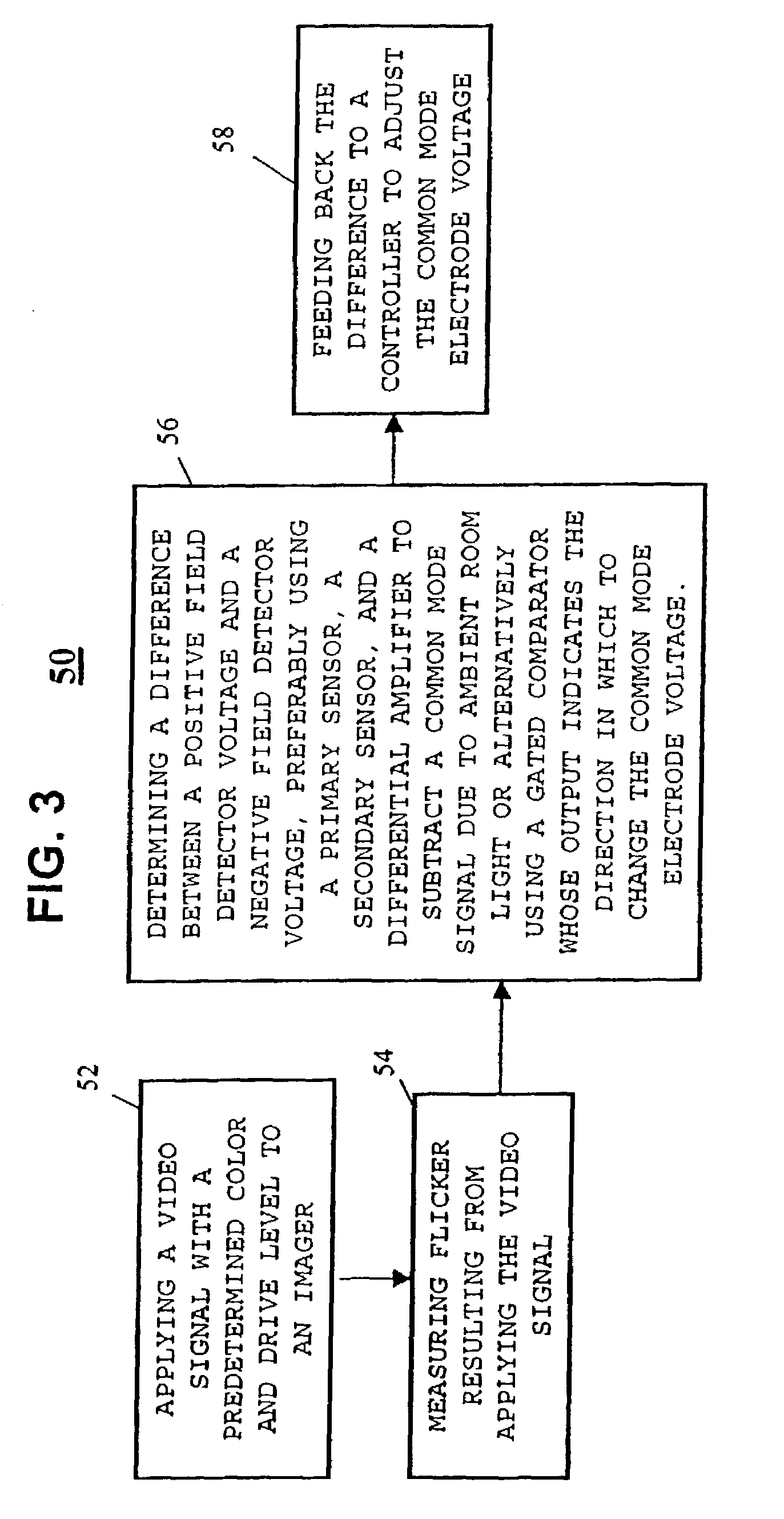

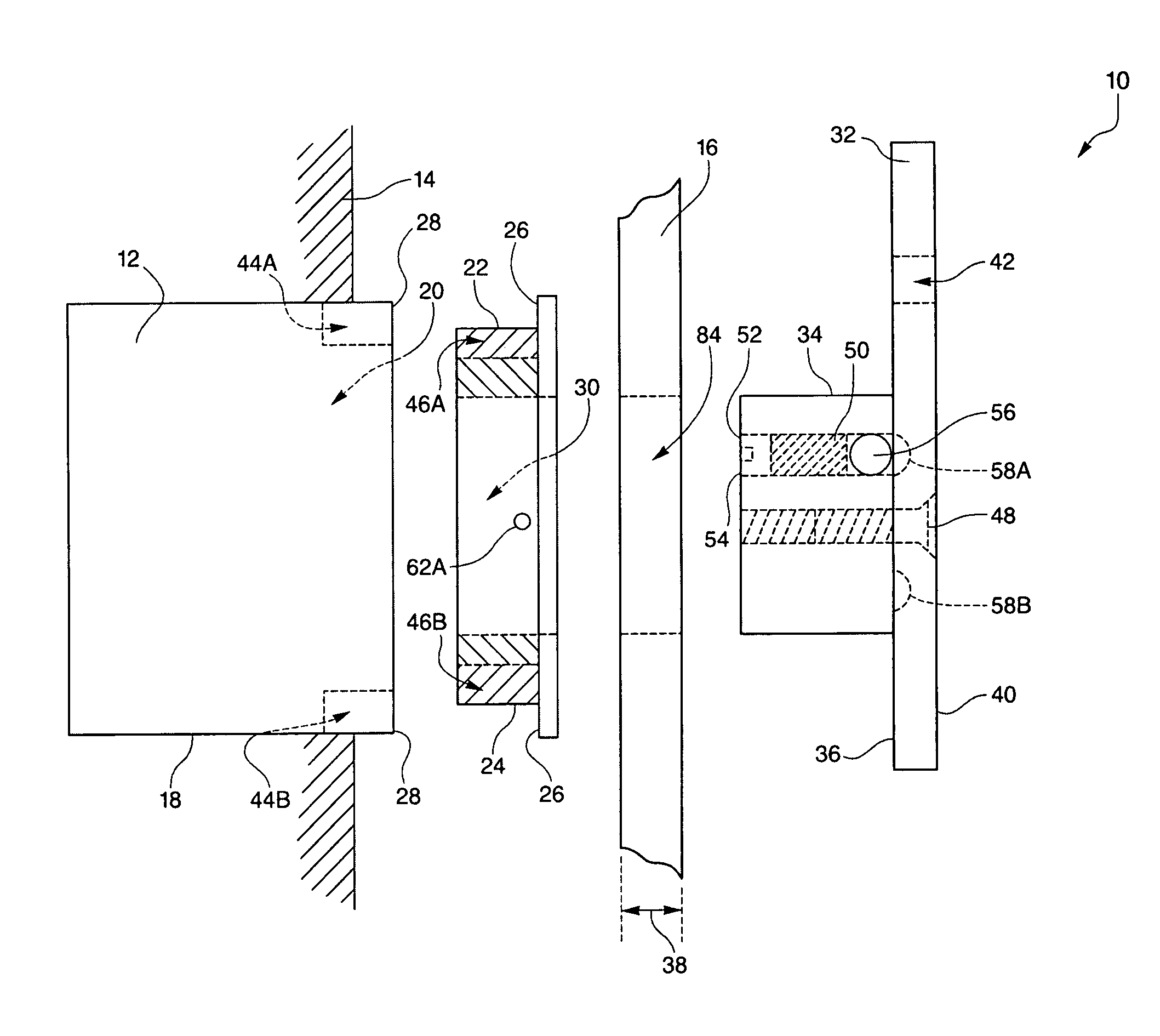

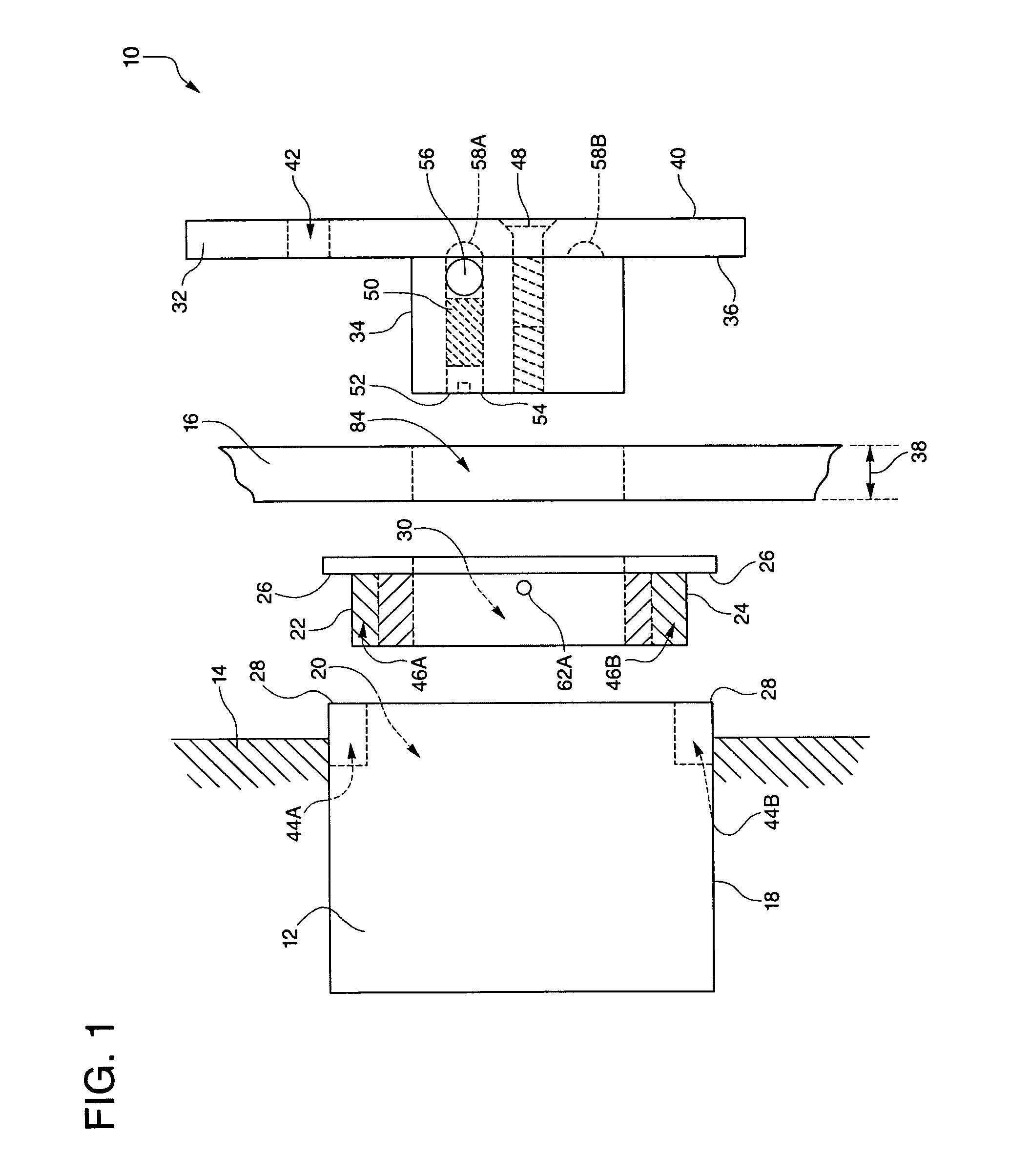

Method and apparatus for controlling common mode electrode voltage in LCOS/LCD

InactiveUS7088331B2Avoid the possibility of damageMinimize image stickingCathode-ray tube indicatorsNon-linear opticsLiquid-crystal displayEngineering

A device for controlling common mode electrode voltage in a liquid crystal display includes at least a first sensor for measuring flicker resulting from applying a video signal with a predetermined color and drive level to an imager. A detector for determining a difference between a positive field detector voltage and a negative field detector voltage is used to provide a feed-back loop for feeding back the difference to a controller to adjust the common mode electrode voltage.

Owner:INTERDIGITAL CE PATENT HLDG

Cut-out tool for making a utility receptacle cut-out in sheeting material

InactiveUS8006401B1Reduce gapInhibition formationUsing mechanical meansCable installation apparatusWood veneerEngineering

The cut-out tool (10) includes an insert adaptor (22) configured to insert into and be secured within a utility receptacle (12) prior to sheeting material (16) overlying the receptacle (12), such as an electric receptacle (12). The insert adaptor (22) defines a mounting sleeve (30), and whenever the sheeting material (16) is secured over the receptacle (12) and insert (22), an insert hole (84) is cut adjacent and around an interior perimeter of the mounting sleeve (30). A mounting post (34) of an exterior template (32) is then secured within the mounting sleeve (30), and the exterior template (32) defines a cutting slot (42) that is dimensioned to contiguously and substantially overlie an exterior perimeter (28) of the receptacle (12). A cut is them made through the cutting slot (42) to define a template hole (86), and the sheeting material (16) then slides over the receptacle (12).

Owner:SHAPIRO ALLAN

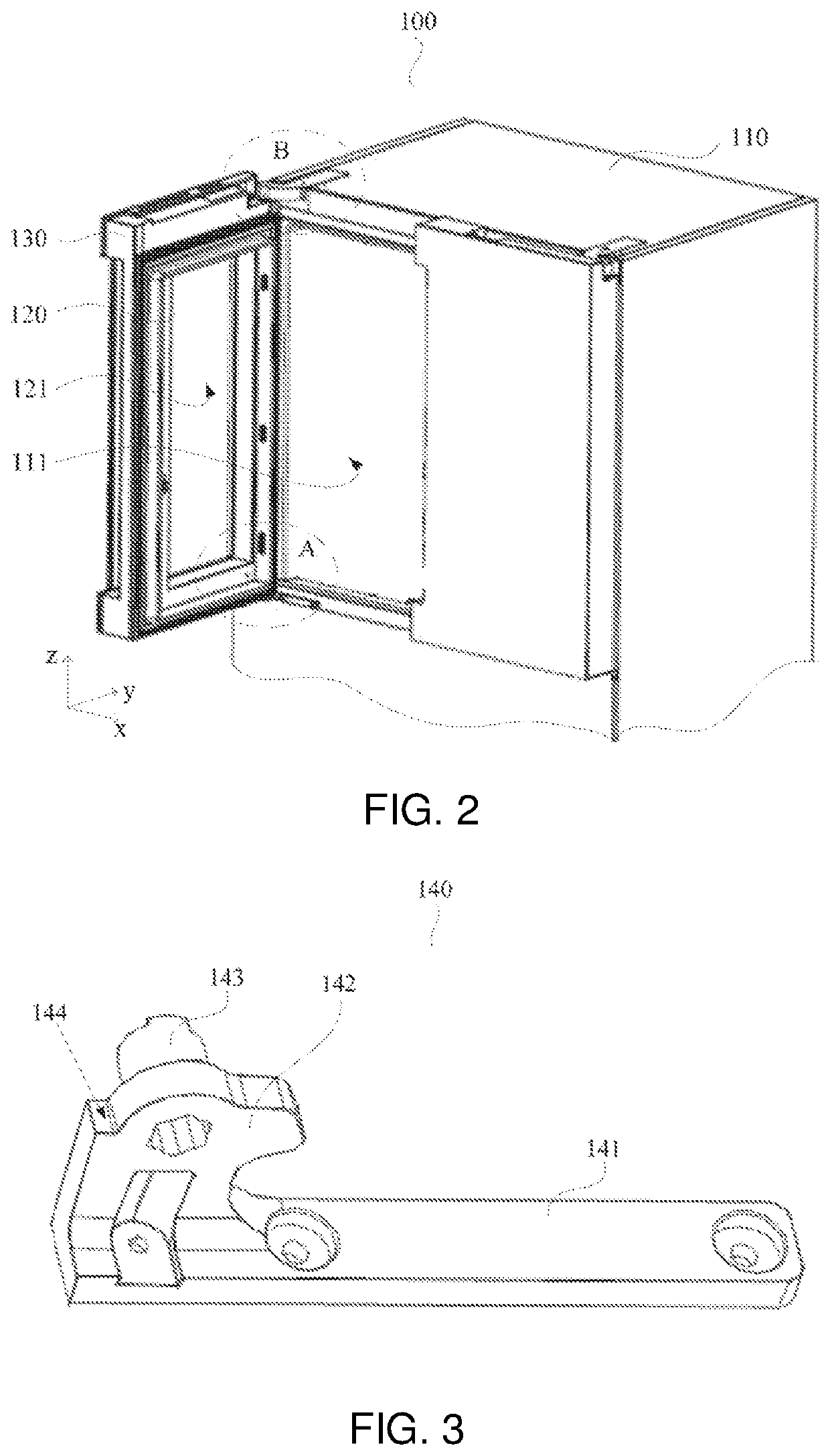

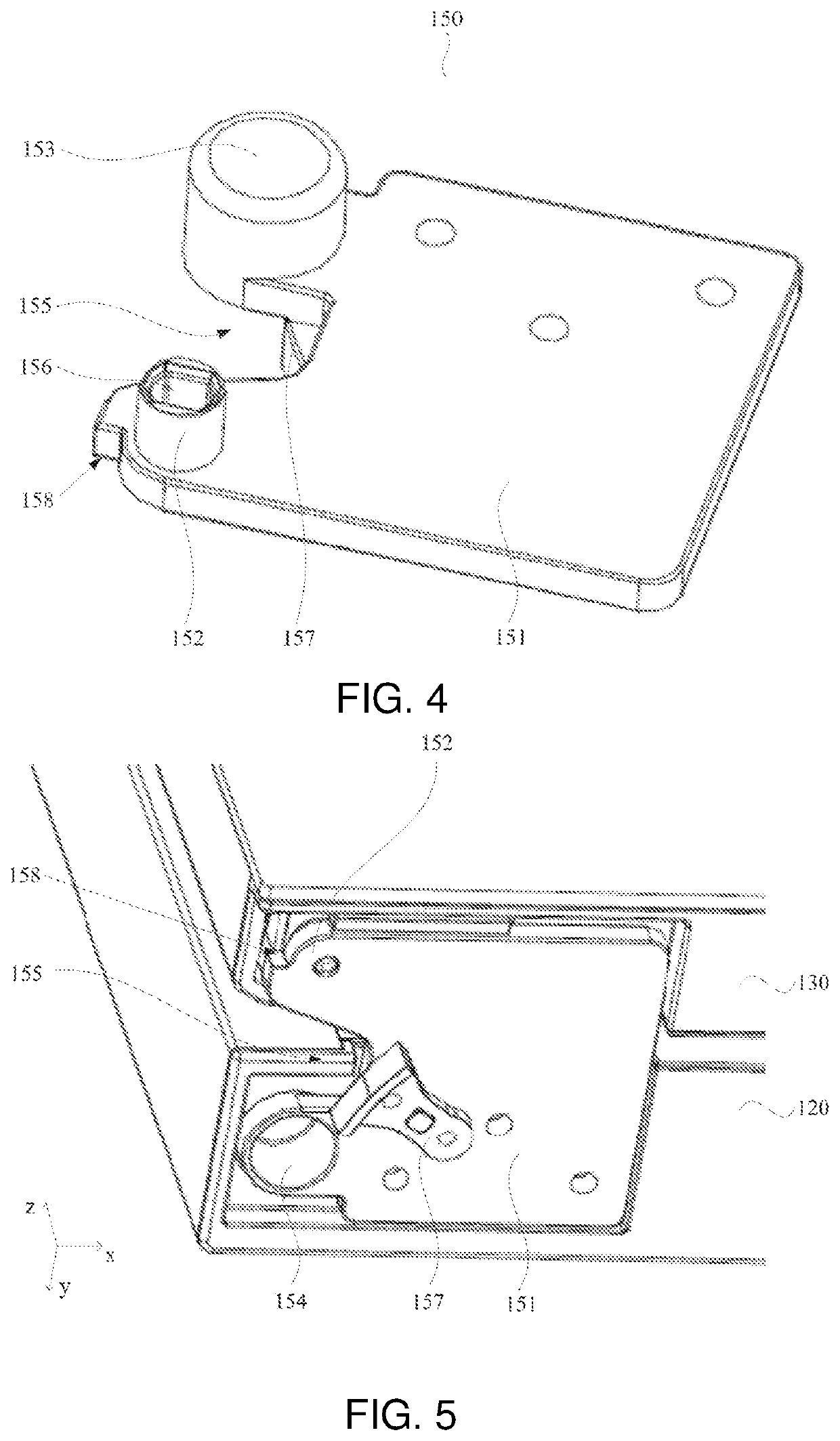

Refrigeration device

ActiveUS20200024880A1Improve reliabilityImprove assemble precisionLighting and heating apparatusWing accessoriesPhysicsEngineering

A refrigeration device has a first door with an opening and a second door for closing the opening in the first door. A first hinge member has a first connection portion fixed on a main body of the refrigeration device and a first hinged portion connected to the first door. A second hinge member has a second connection portion fixed on the first door and a second hinged portion connected to the second door. The second hinge member includes a columnar portion that is hinged to the first hinged portion. One of the columnar portion and the first hinged portion has a first shaft hole, and the other one has a first hinge shaft that extends into the first shaft hole. The novel device prevents a door body of the refrigeration device from being damaged at a hinged position and the reliability of the refrigeration device is improved.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Controlled process and resulting device

InactiveUS8835282B2Good removal effectAvoid the possibility of damageSemiconductor/solid-state device manufacturingAdhesivesMulti materialAnalytical chemistry

A method for forming a multi-material thin film includes providing a multi-material donor substrate comprising single crystal silicon and an overlying film comprising GaN. Energetic particles are introduced through a surface of the multi-material donor substrate to a selected depth within the single crystal silicon. The method includes providing energy to a selected region of the donor substrate to initiate a controlled cleaving action in the donor substrate. Then, a cleaving action is made using a propagating cleave front to free a multi-material film from a remaining portion of the donor substrate, the multi-material film comprising single crystal silicon and the overlying film.

Owner:SILICON GENERAL CORPORATION

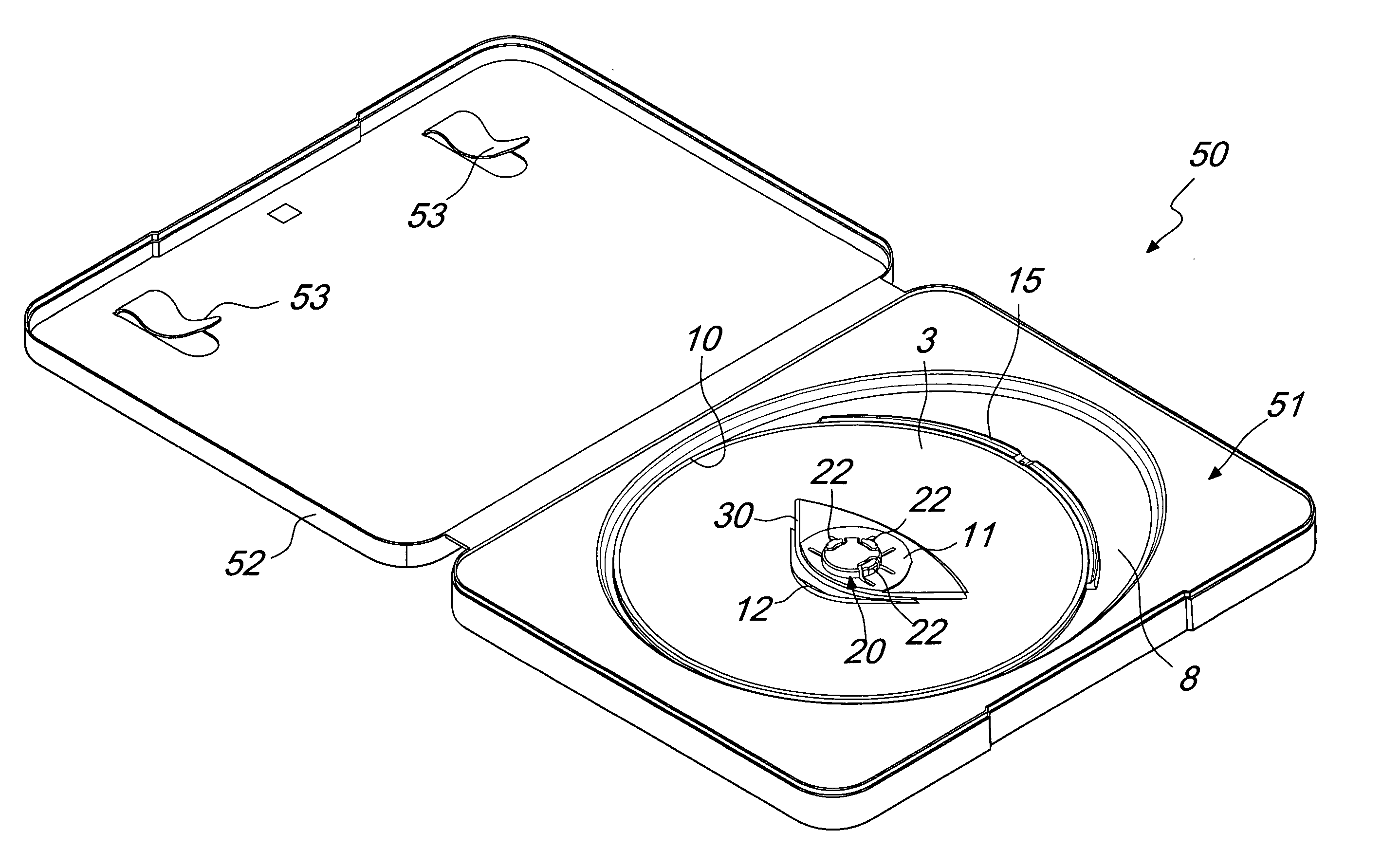

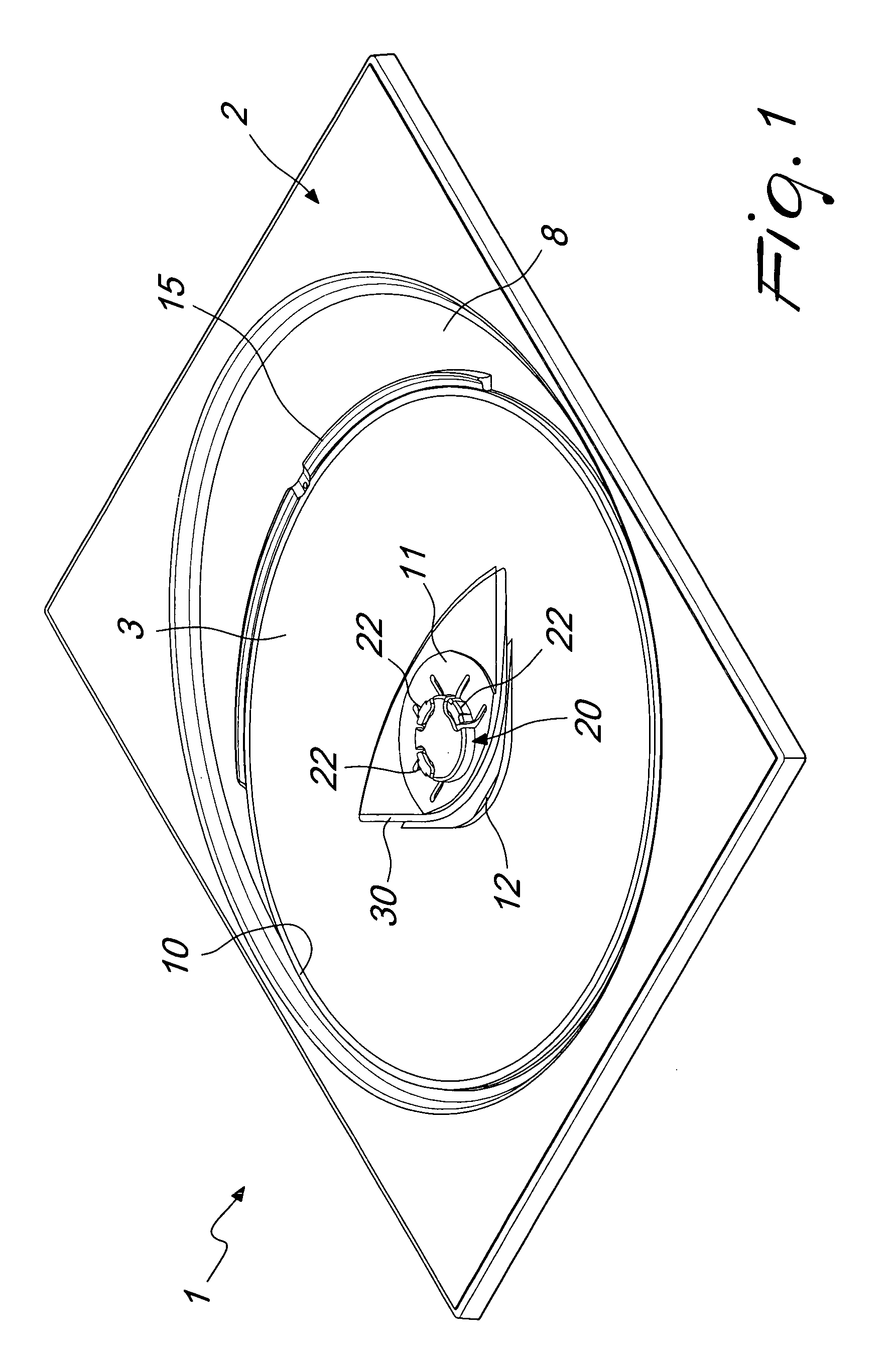

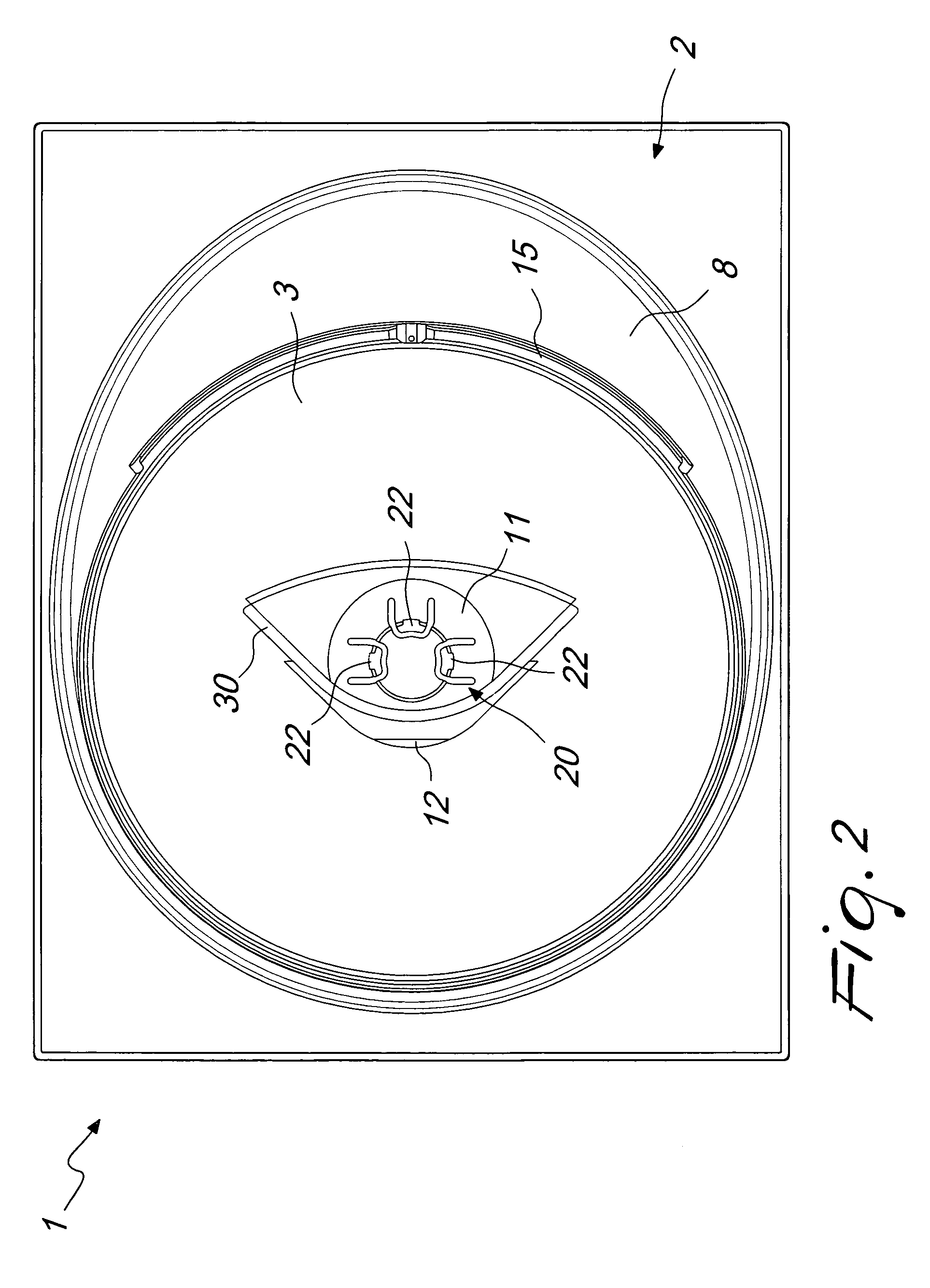

Container for a disc and the like, with means for disengageable retention of the disc

InactiveUS20080190793A1Avoid the possibility of damageImprove reliabilityRecord information storageOther accessoriesEngineeringMechanical engineering

Owner:POZZOLI

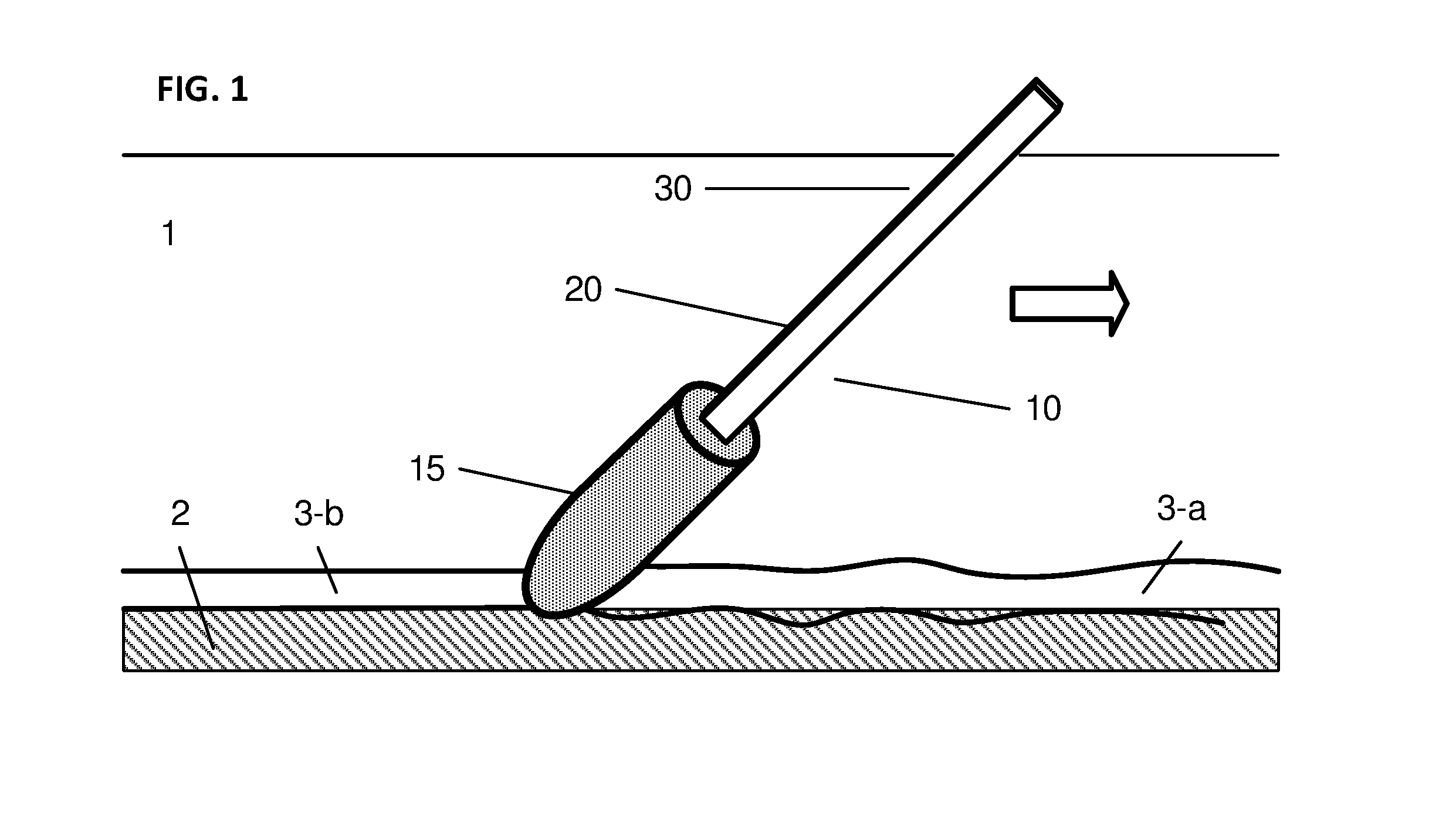

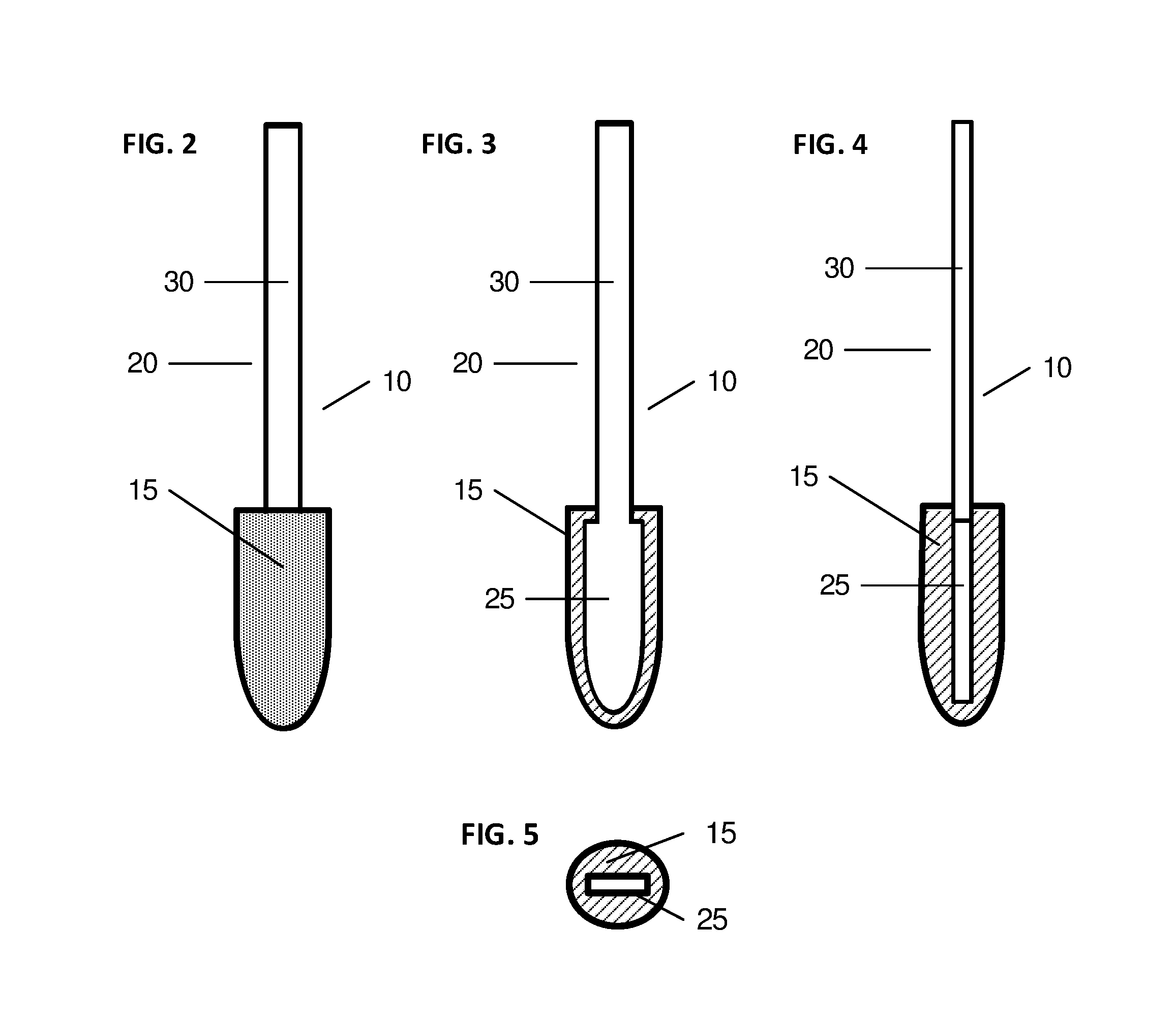

Disposable Caulk Smoother

A disposable hand tool for easily smoothing or spreading of material made for the filling of gaps or the sealing of two adjacent surfaces. The tool consists of a depressor made of plastic or cut wood surround on one end by cellular foam forming the smoothing head, while the depressor extends beyond the foam to form the handle. The depressor provides necessary reinforcement and stability to the foam, in order that when the surface of the cellular foam makes contact with the caulking material, enough rigidity is provided to transfer pressure as applied variably by the user with the handle to smooth the caulking material, but the pliability of the foam accommodates and flexes to variances in the surfaces being joined or filled by the caulking material. When finished using, the tool can be disposed of, or in some instances cleaned using appropriate process for removal of excess material being smoothed, and reused.

Owner:WINDISCHMAN ERIK

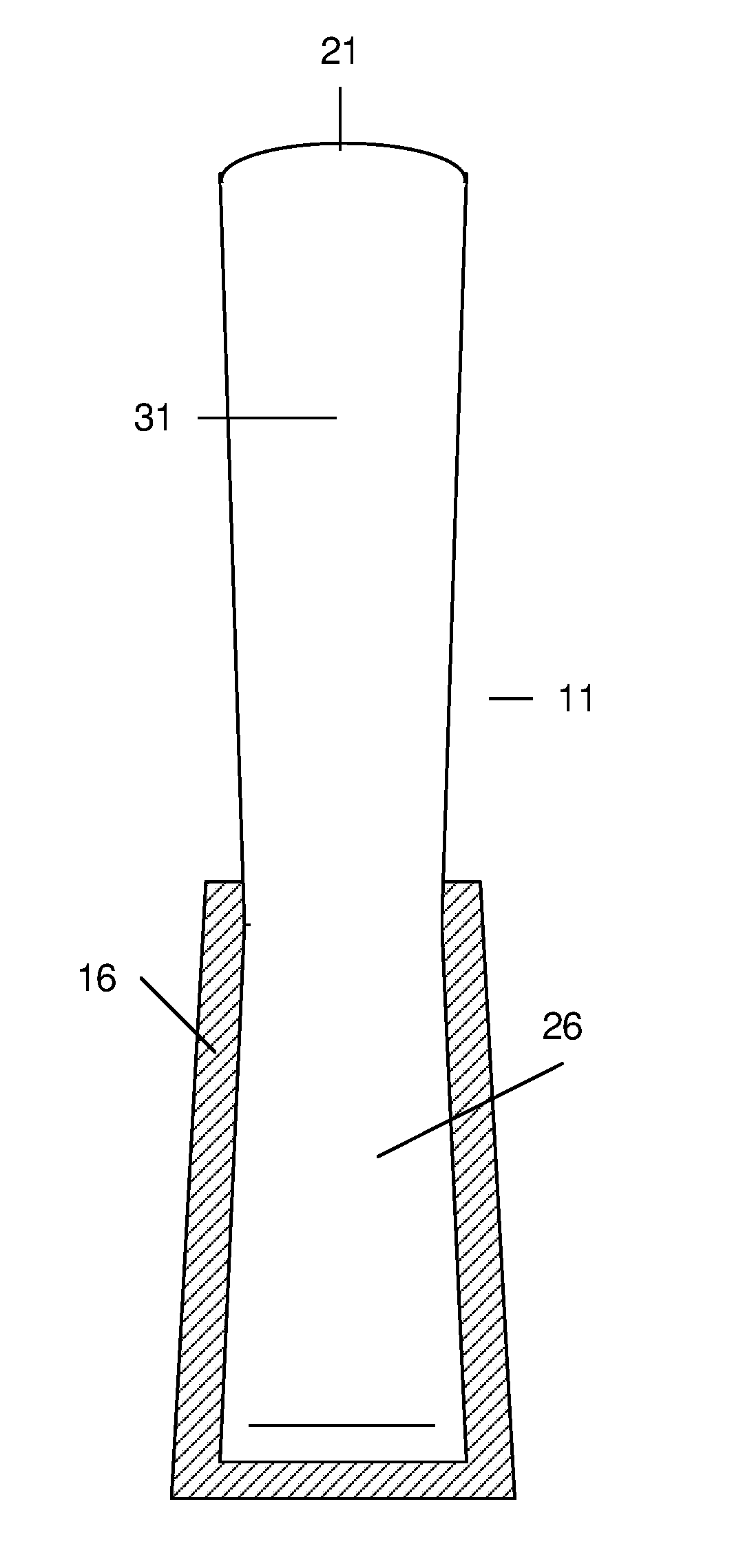

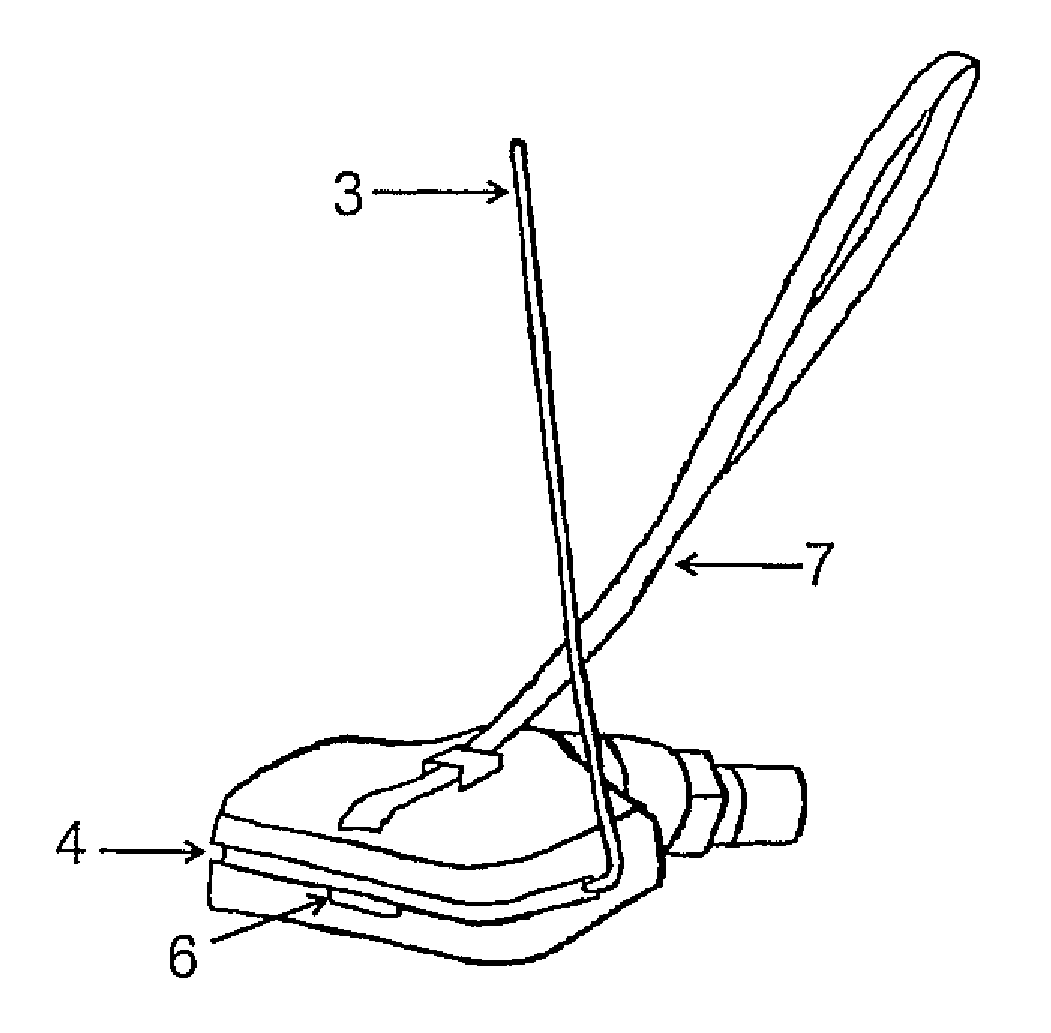

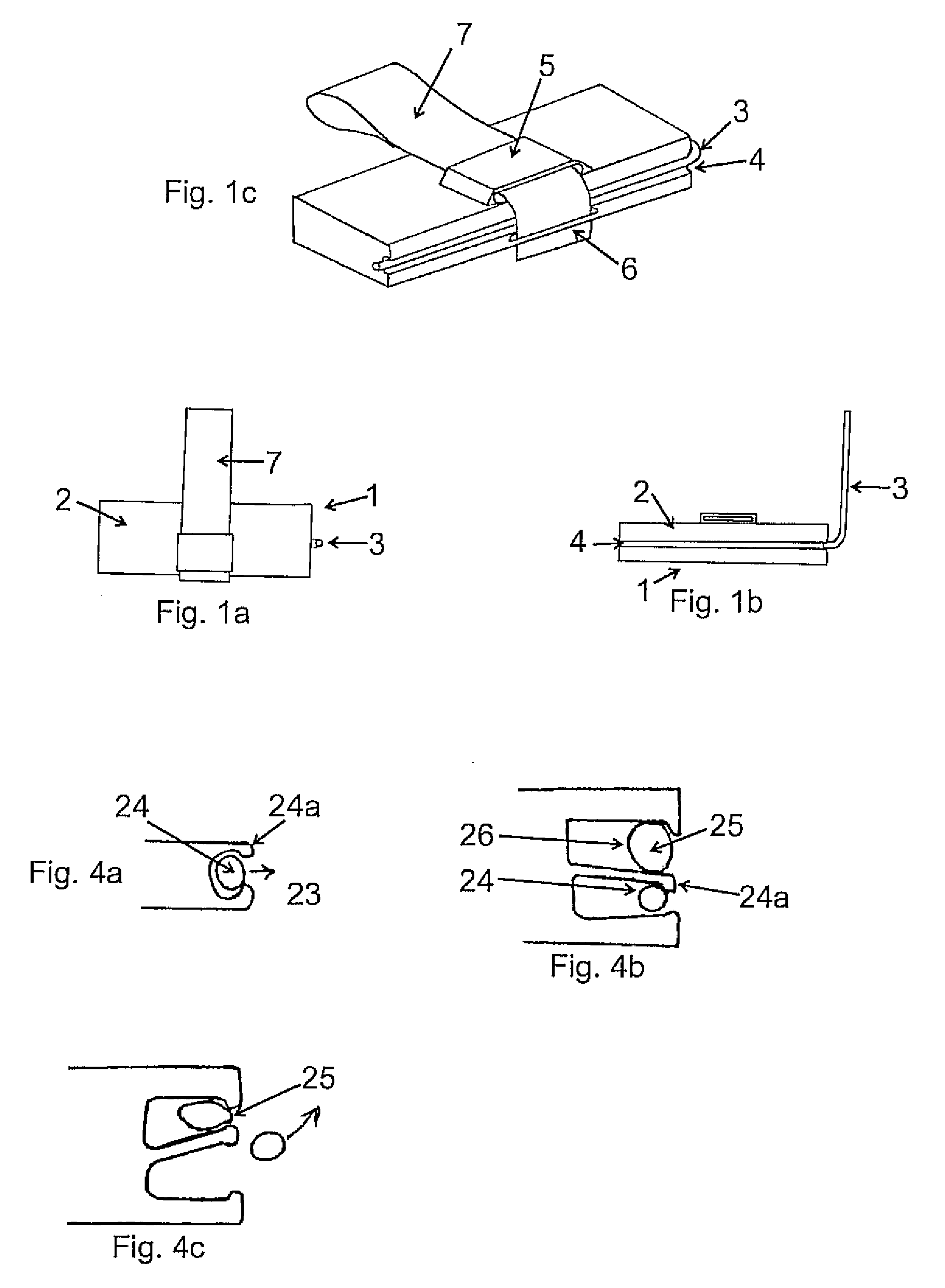

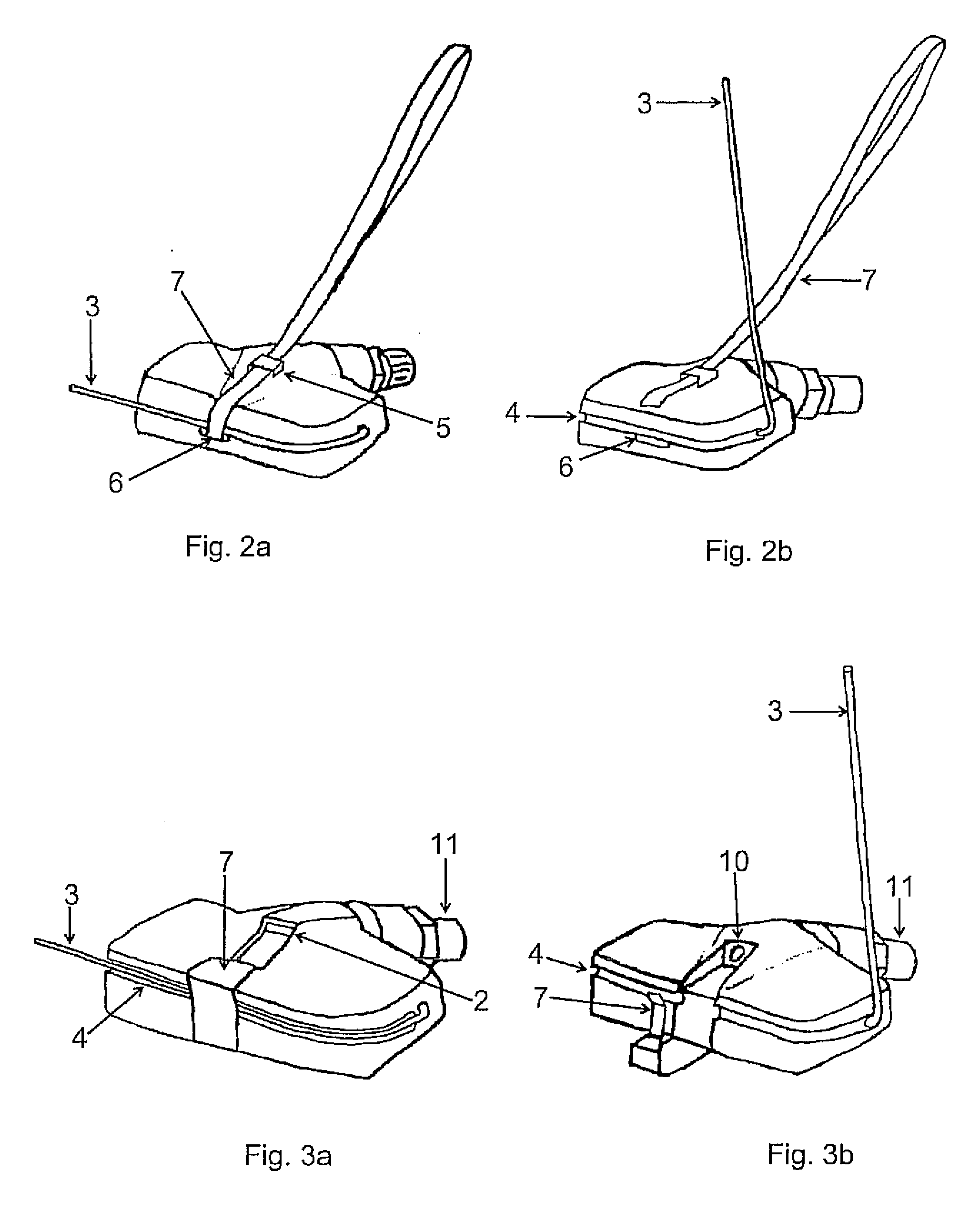

Stowable antenna for tpms sensor

InactiveUS20080272901A1Avoid the possibility of damageInflated body pressure measurementTyre measurementsTire-pressure monitoring systemPressure sensor

A tire pressure monitoring system (TPMS) sensor assembly 1 has a housing 2, a pressure sensor mounted in the housing 2 and an antenna 3 connected to the sensor and extending exteriorly of the housing 2 for effecting wireless communication between the sensor and a remote module. The antenna 3 is moveable between a folded position in which it extends around at least a part of the housing 2 so as to lie substantially in the plane of the housing 2 and an erect position in which it upstands from the housing 2 so as, in use, to extend into the inflation area formed between a wheel and tire. The antenna 3 is biased towards its erect position, and further includes a releasable restraining strap 7 for restraining the antenna 3 in its folded position.

Owner:TRANSENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com