Electromagnetic sliding valve

A sliding valve, electromagnetic technology, applied in the direction of valve details, multi-way valves, valve devices, etc., can solve the problems of difficult processing, complex structure, unfavorable open design, etc., to increase the function of electromagnetic valve, small compression, convenient Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

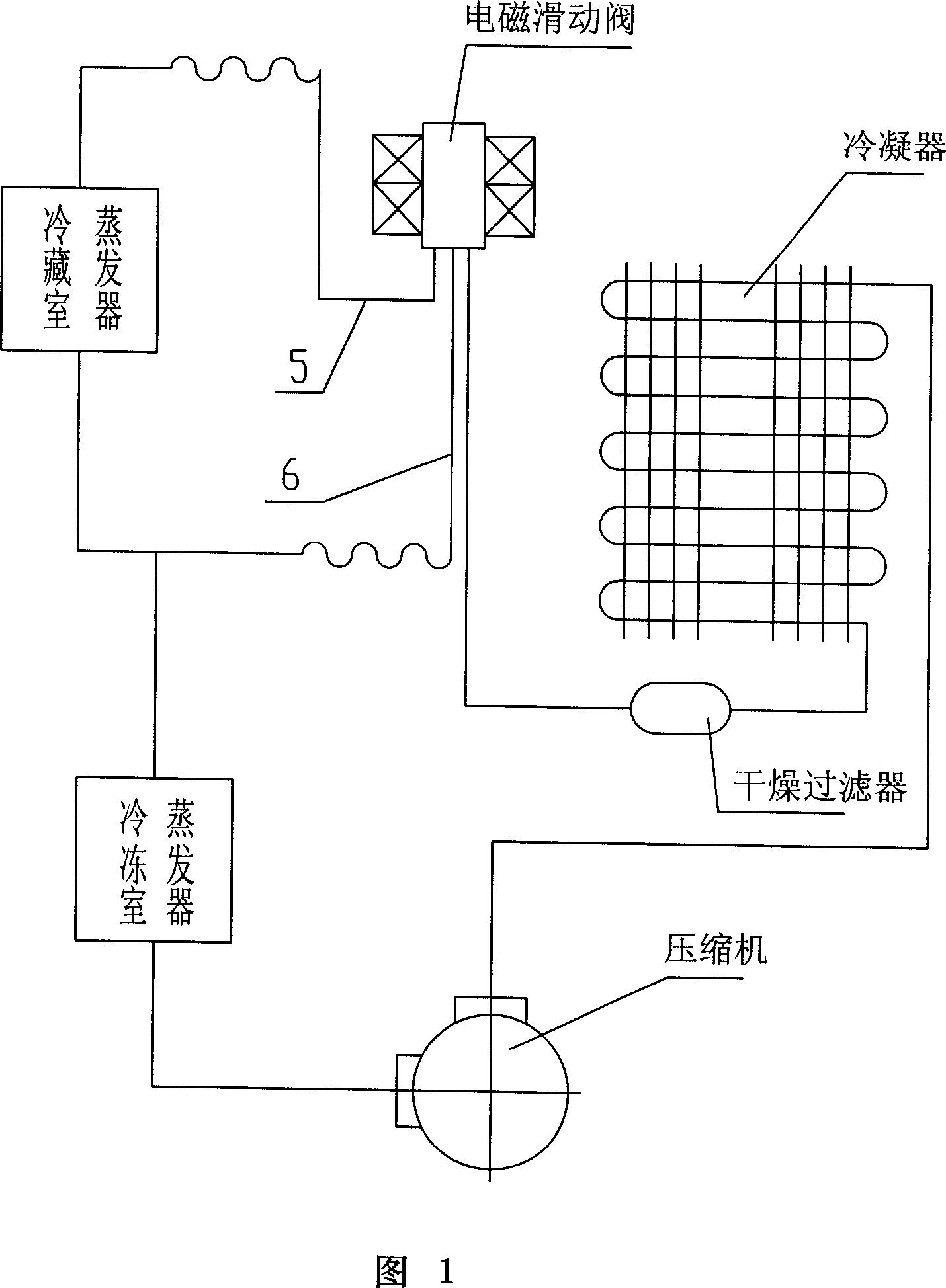

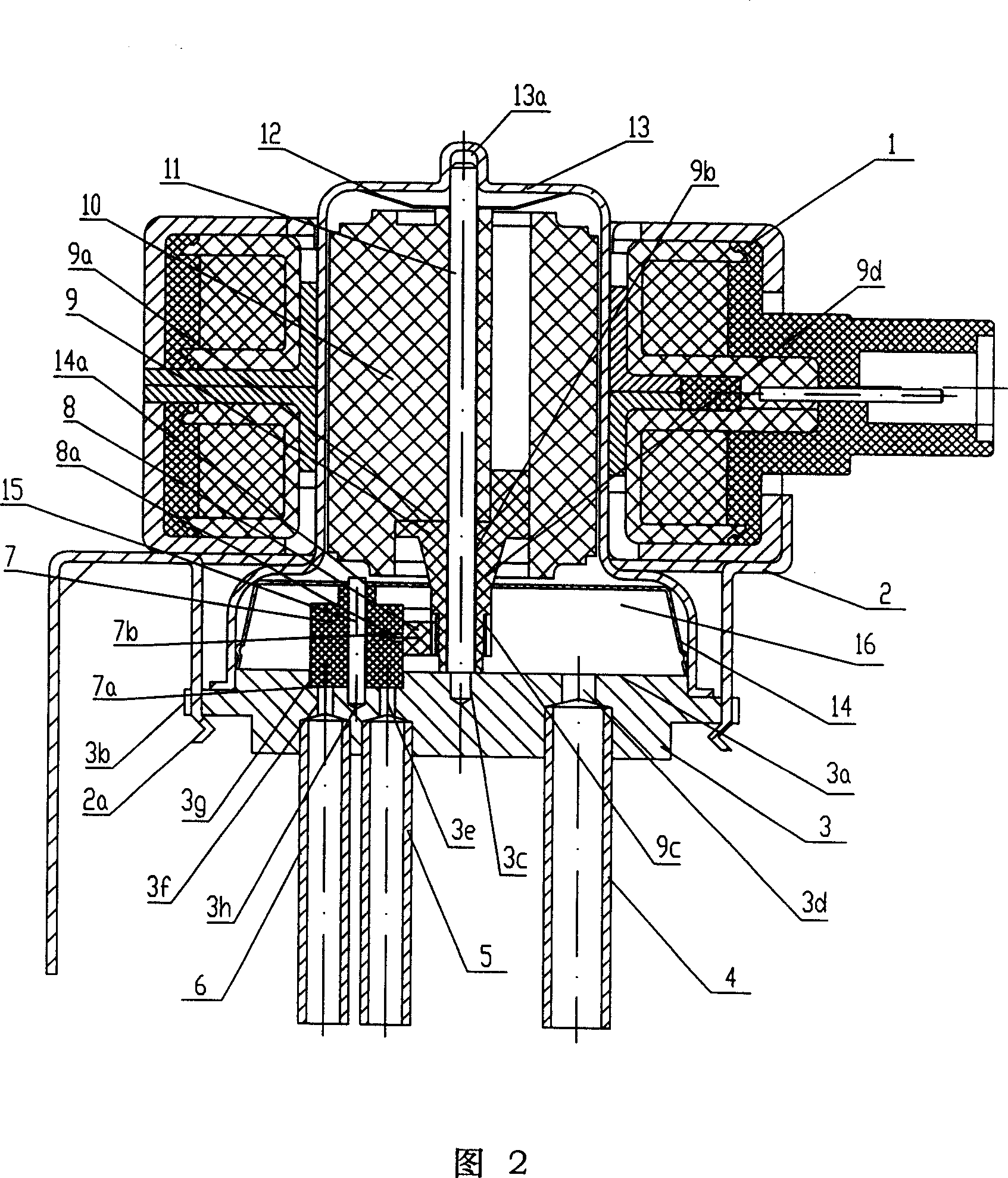

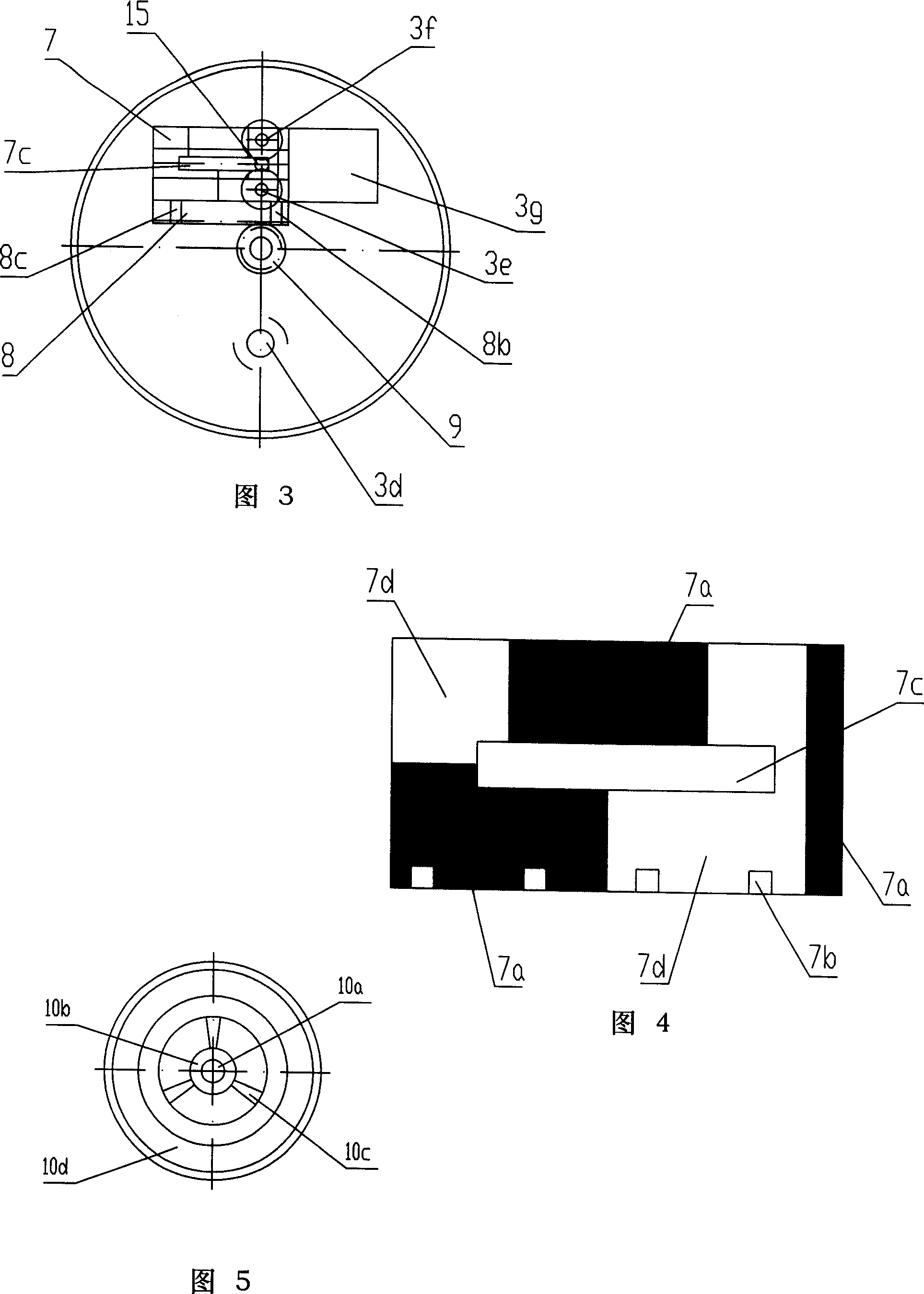

[0056] Referring to Figs. 2-5 and Fig. 11, the first embodiment of the present invention, one-inlet-two-outlet electromagnetic sliding valve, will be introduced below.

[0057] The electromagnetic sliding valve has a valve body part formed by sealingly connecting the valve seat part 3 and the outer cover 13 by means of welding or the like, and a valve cavity 16 formed thereby.

[0058] The electromagnetic sliding valve has a normally open inlet pipe 4 and two outlet pipes 5 and 6 that are opened and closed according to the function, a slider guide groove 3g, a central support shaft 11 and its supporting mechanism 3c, a slider guide shaft 15 and its The valve seat part 3 of the support mechanism 3h: the sealing surface 3a of the valve seat part 3 is provided with outlets 3e and 3f and an inlet 3d, the outlet 3e is connected to the outlet pipe 5, the outlet 3f is connected to the outlet pipe 6, and the inlet 3d Connecting the inlet pipe 4, the outlets 3e and 3f are distributed a...

Embodiment 2

[0089] Referring to Figures 6-10 and Figure 12, the one-inlet and three-outlet electromagnetic sliding valves will be introduced below.

[0090] 6 to 10 and FIG. 12 correspond to the parts in FIGS. 2 to 5 and FIG. 11 are assigned the same reference numerals as those in FIGS. 2 to 5 and FIG.

[0091] The valve body parts are driven and rotated by the stepping motor, and the solenoid valve can obtain four working positions as shown in Figure 12: (a) the first working position, the outlet 3f, the outlet 3e and the outlet 3i are all closed; (b ) the second working position, the outlet 3f is opened, the outlet 3e and the outlet 3i are closed; (c) the third working position, the outlet 3e is opened, the outlet 3f, the outlet 3i are closed; (d) the fourth working position, The outlet 3i is opened, and the outlet 3f and the outlet 3e are closed.

[0092] In the current refrigeration system, in addition to freezing and refrigerating areas, there are also emerging areas such as variabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com