Patents

Literature

163results about How to "Small amount of compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

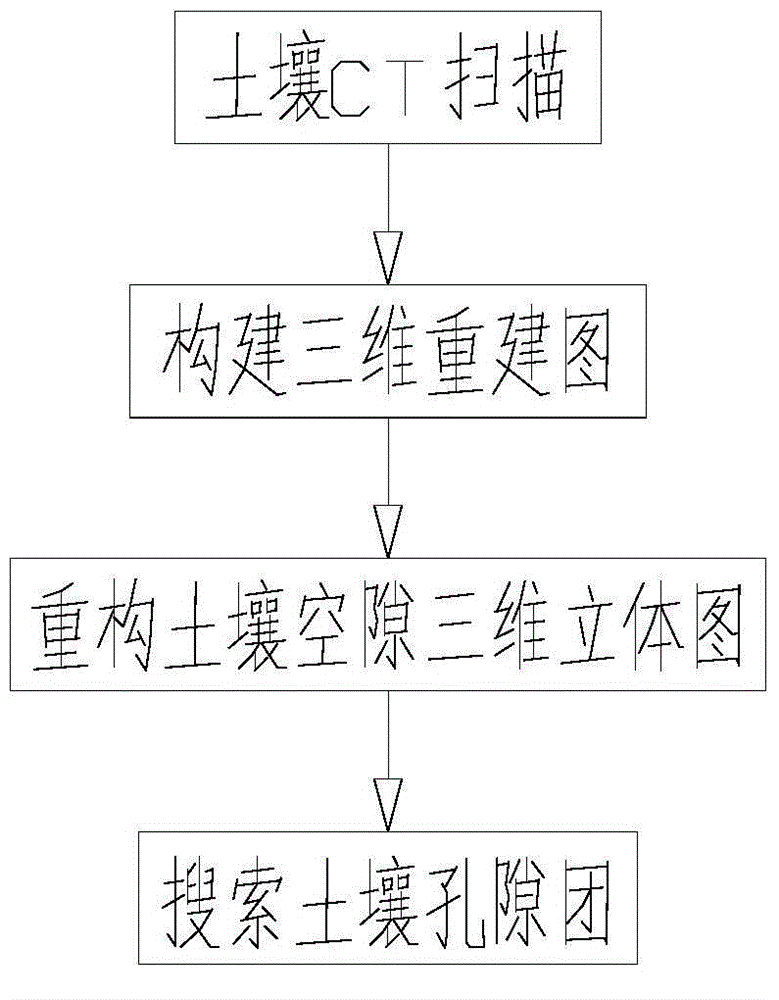

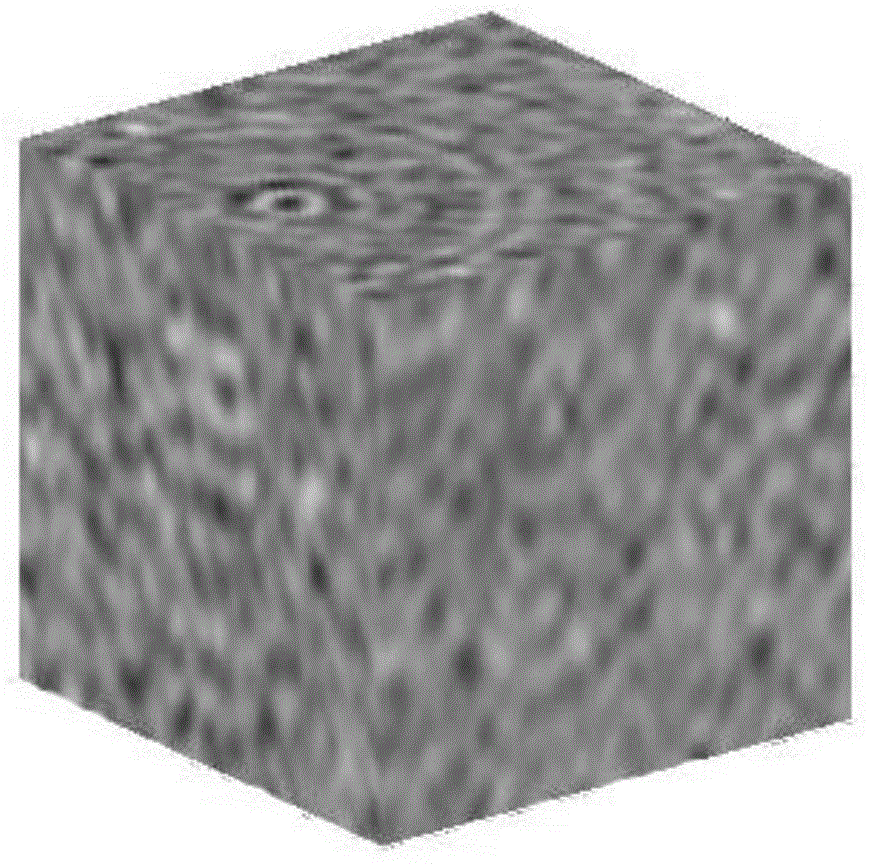

Reconstructed soil computer tomography (CT) picture three-dimensional reconstruction and soil pore searching method

The invention relates to a reconstructed soil computer tomography (CT) picture three-dimensional reconstruction and soil pore searching method. The method comprises four steps of soil CT scanning, construction of a three-dimensional reconstruction picture, reconstruction of a soil pore three-dimensional picture and searching of soil pore clusters. Through adoption of the method, the three-dimensional picture of the reconstructed soil can be realized, spatial form distribution and connectivity of pores can be observed intuitively, quantity and volume of the soil pore clusters can be searched, a basis can be provided for selection of refuse dump soil reconstruction methods and vegetation restoration measures, a guidance can be provided for land rehabilitation, and the socioeconomic benefits of land rehabilitation in a mine area can be improved. Through adoption of the method, three-dimensional reconstruction of soil pores can be completed, the three-dimensional distribution and connectivity of soil pores can be observed intuitively, and a new technological method is provided for quantitative research of reconstructed soil pores.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

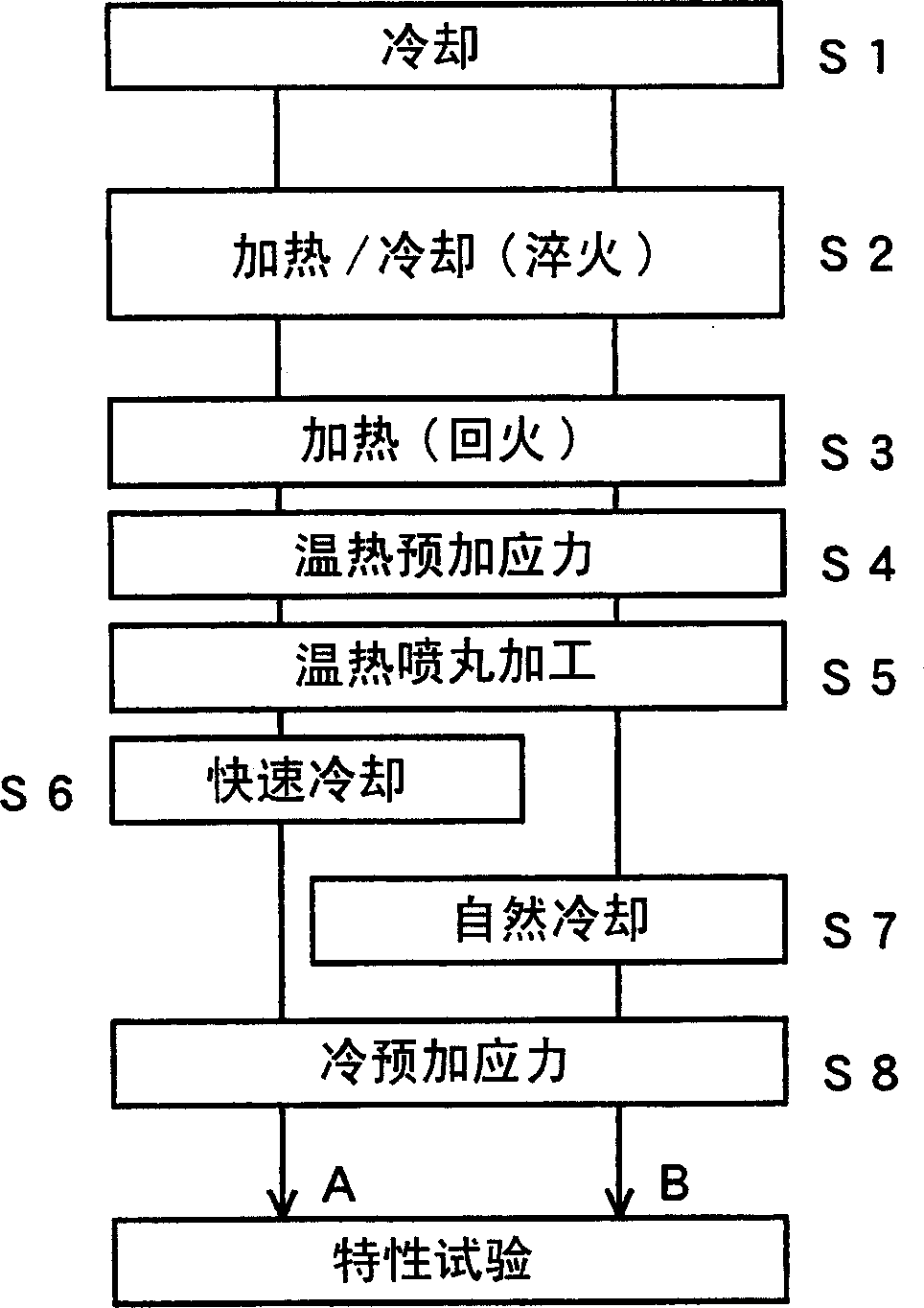

Process for producing high-strength spring

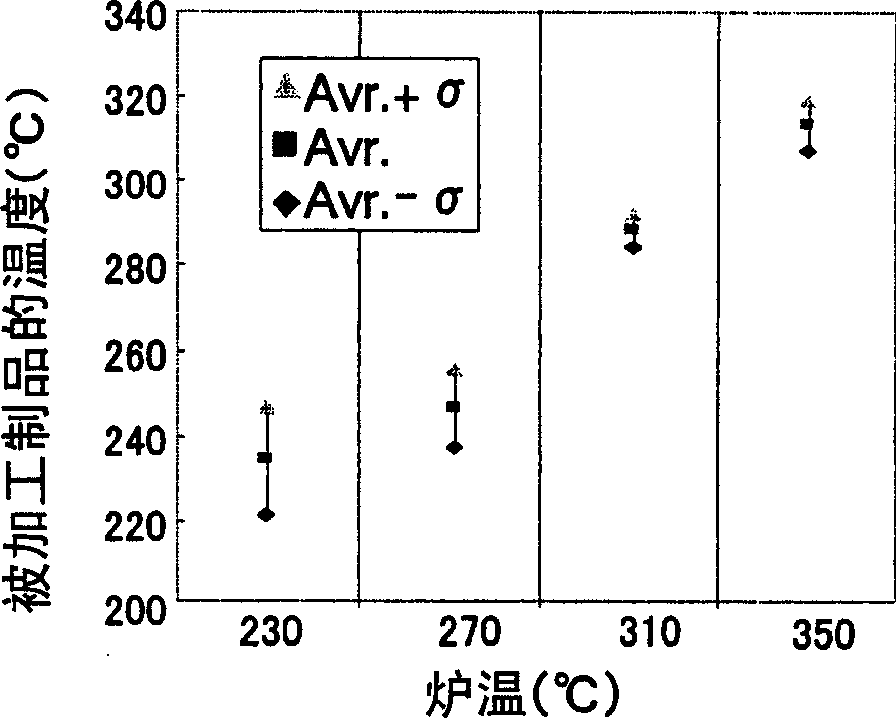

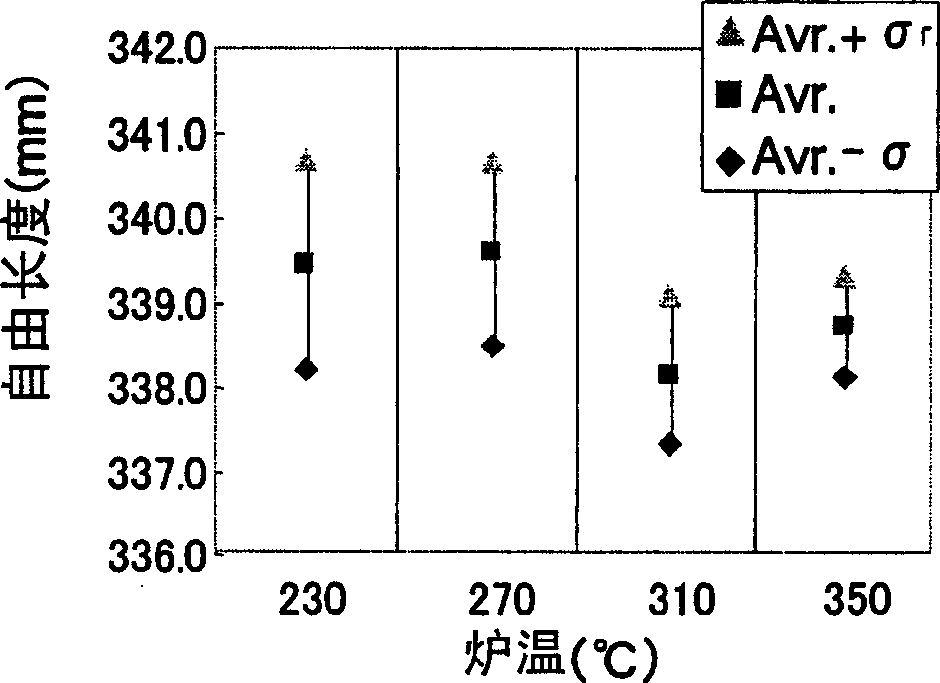

InactiveCN1764730ASmall amount of compressionImprove uniformityFurnace typesHeat treatment furnacesCold formedStress relieving

The present invention provides a process for producing a high-strength spring capable of having a compressive residual stress greater than in the prior art. In particular, the process comprises subjecting to shotpeening a spring having undergone final heating, such as tempering (for heat-treated spring) or stress relieving annealing (for cold formed spring), while the surface temperature of the spring is in the range of 265 to 340 DEG C (preferably 300 to 340 DEG C). The spring after shotpeening is quenched. It is preferred that setting be performed prior to shotpeening, or after shotpeening but before quenching. The quenching can be accomplished by water cooling or oil cooling with no preference. When the wire diameter of the spring is small, forced air cooling can be used.

Owner:CHUO SPRING

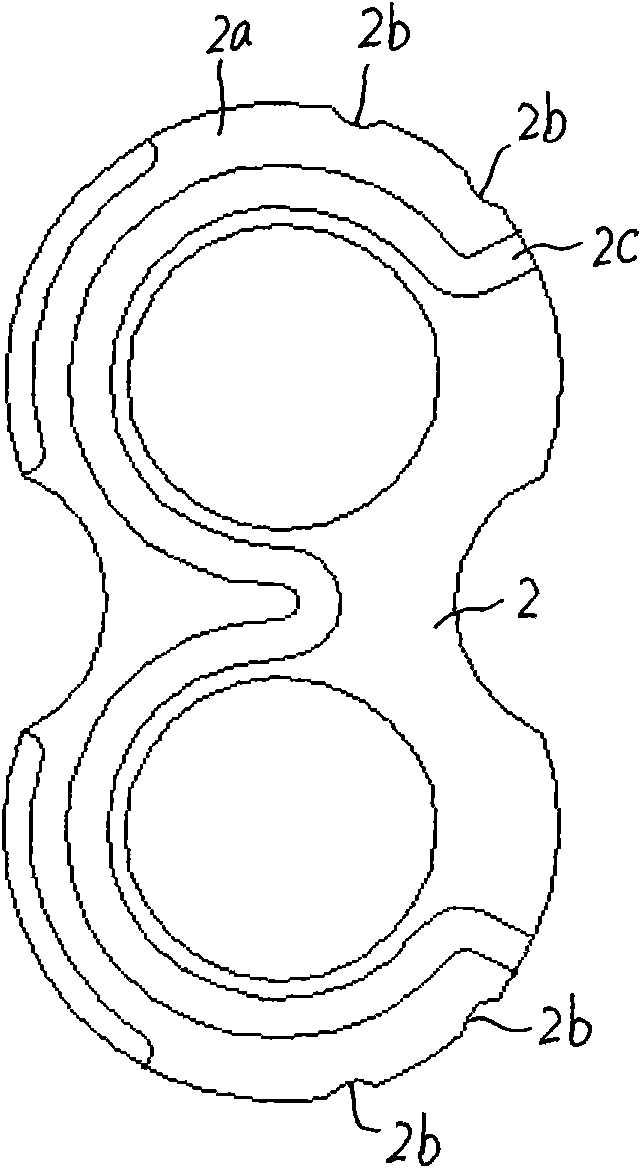

Shock absorber

ActiveCN105065566AChange the amount of precompressionChange the amount of compressionNon-rotating vibration suppressionEngineeringShock absorber

The invention relates to a shock absorber which comprises a lower supporting seat, an upper supporting seat, a joint, a lower elastic piece and an adjusting piece, wherein the upper supporting seat is tightly pressed towards the lower supporting seat; the joint comprises a core block and a supporting rod, the core block is arranged between the upper supporting seat and the lower supporting seat, and the supporting rod extends out of the core block and penetrates through the upper supporting seat; the lower elastic piece is arranged between the core block and the lower supporting seat, and the adjusting piece is used for adjusting the distance between the upper supporting seat and the lower supporting seat. The stiffness valve of the shock absorber can be adjusted on an installation site so that the demand for different shock absorbing stiffness is met, and the adaptability of the shock absorber is stronger than that of a common shock absorber. Meanwhile, after the shock absorber is used for a long time, the stiffness variation of the shock absorber caused by the aging and creep deformation of the lower elastic piece can be corrected by readjusting the distance between the upper supporting seat and the lower supporting seat, and therefore the service life of the shock absorber is relatively prolonged.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

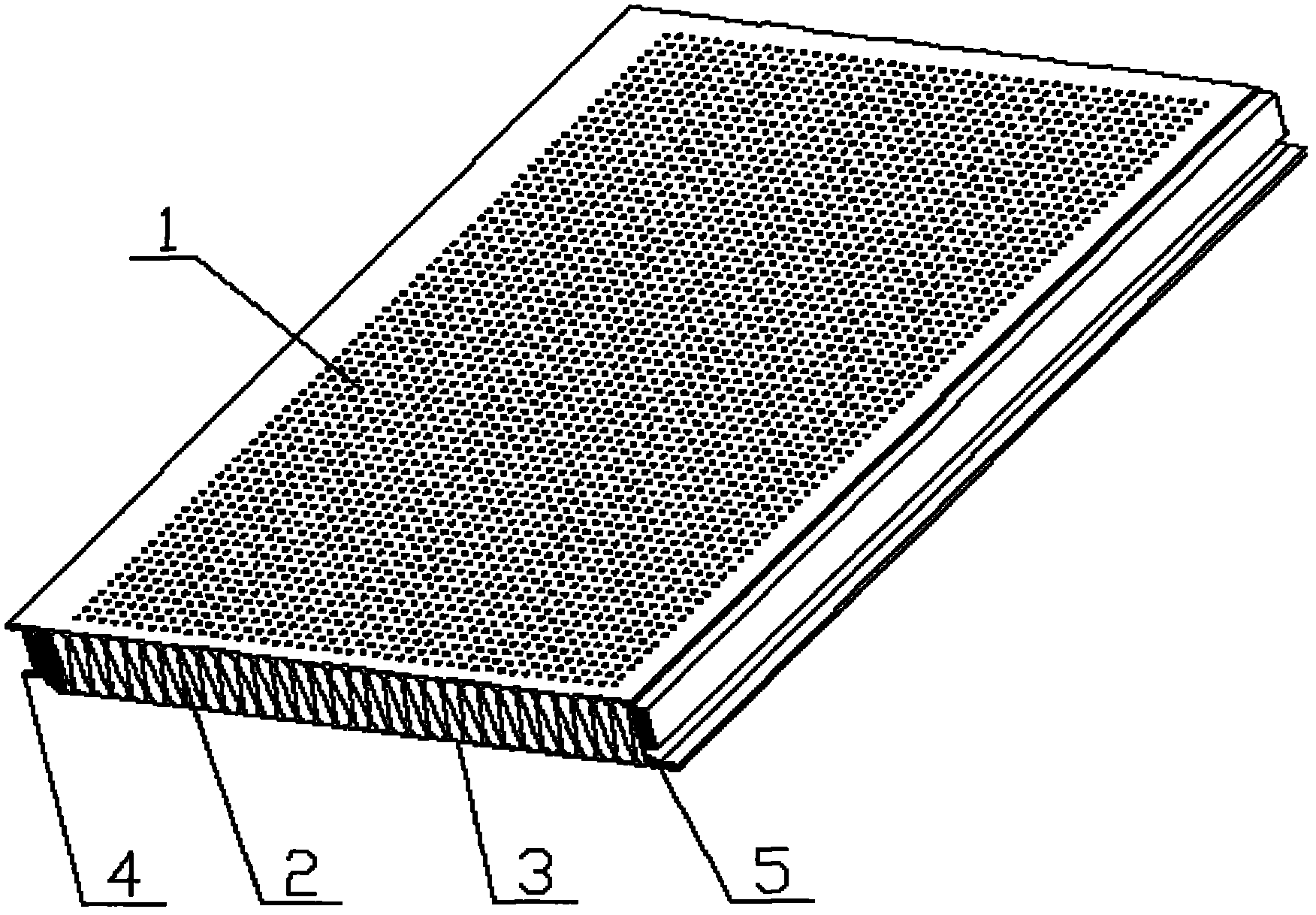

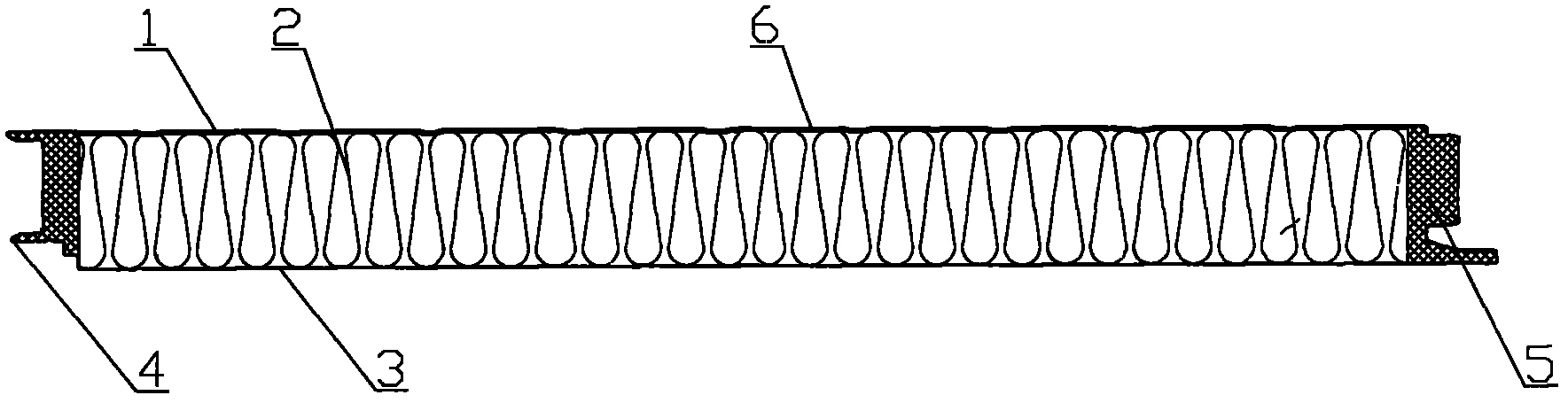

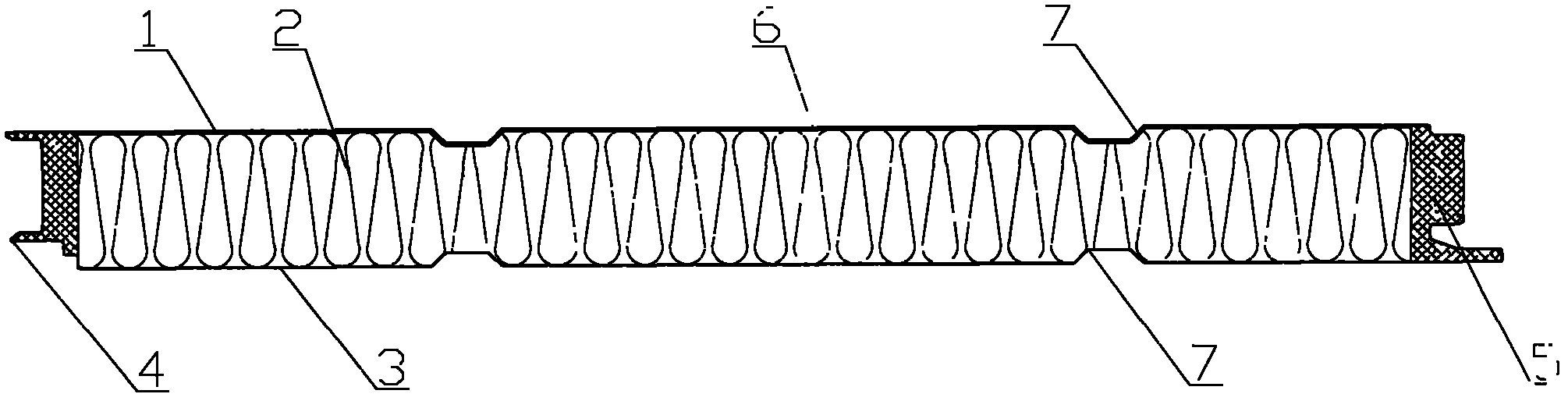

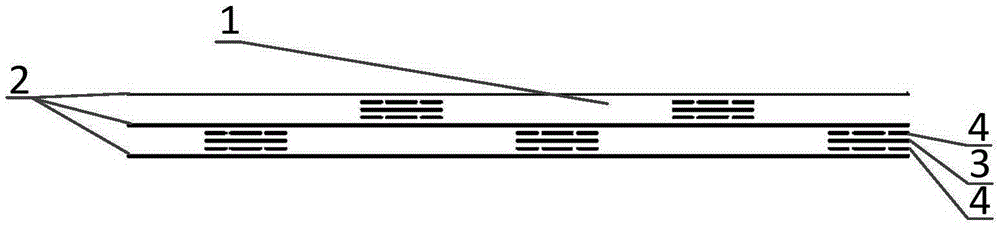

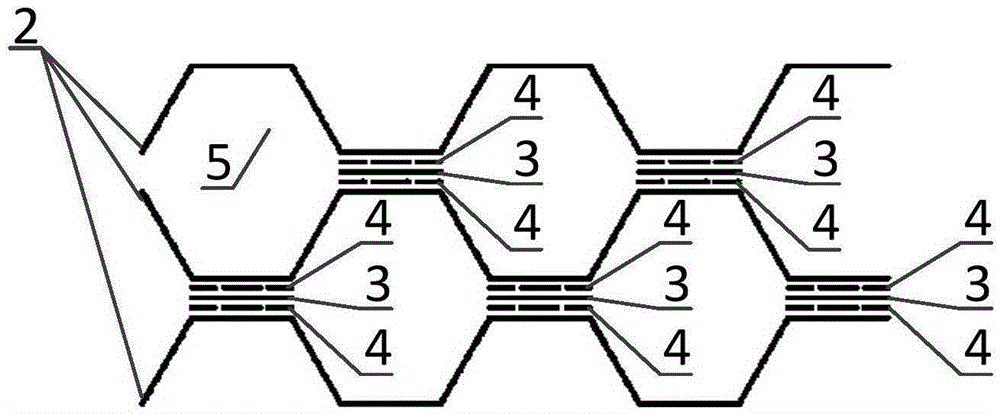

Compound sound insulation-absorption barrier board

ActiveCN101982613AGood hydrophobicityAvoid CapillarityNoise reduction constructionMicrometerAverage diameter

The invention discloses a compound sound insulation-absorption barrier board, comprising a front panel, a rear panel and a core material fixed between the front panel and the rear panel in a bonding manner, wherein, the core material is arranged in a strip shape, and the fiber direction of the core material is vertical to the front panel and the rear panel; multi-tongue rabbets are arranged at the two sides of the compound sound insulation-absorption barrier board at the joint of the front panel and the rear panel and can be spliced mutually; the front panel is a perforating panel; micropores are distributed on the perforating panel, wherein, the perforated rate of the micropores is more than 3% to 30%; the porosity of the core material is 97-98.4%; the average diameter of the fiber is 5-6 micrometers; the fiber length is 150-200 micrometers; and the noise enters into the core material through the micropores and is absorbed along the fiber direction of the core material. The compound sound insulation-absorption barrier board disclosed in the invention has the advantages of absorbing the noise in the environment, simultaneously insulating the noise, and avoiding the influence of the noise to the surrounding environment.

Owner:CENT INT GROUP

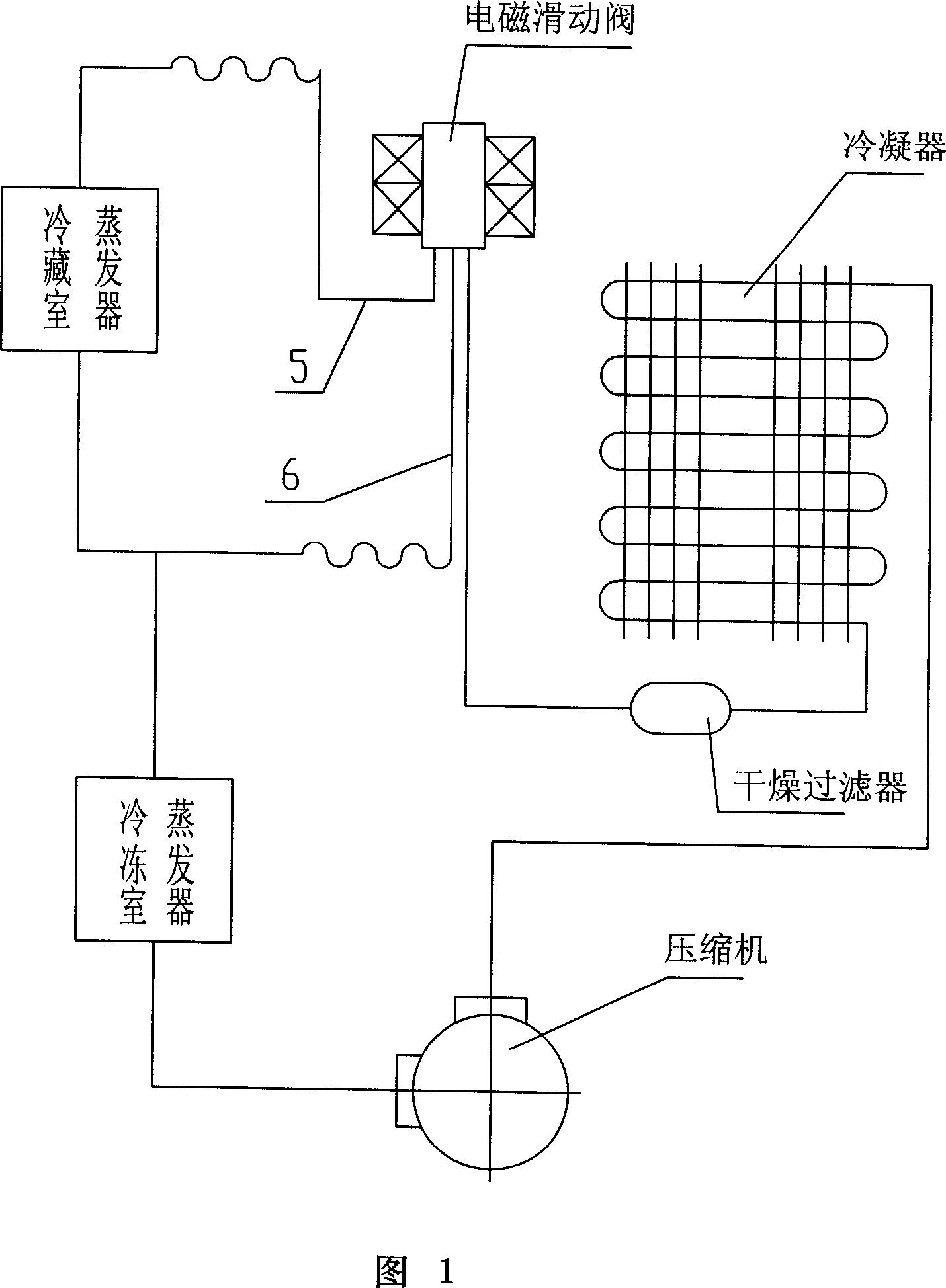

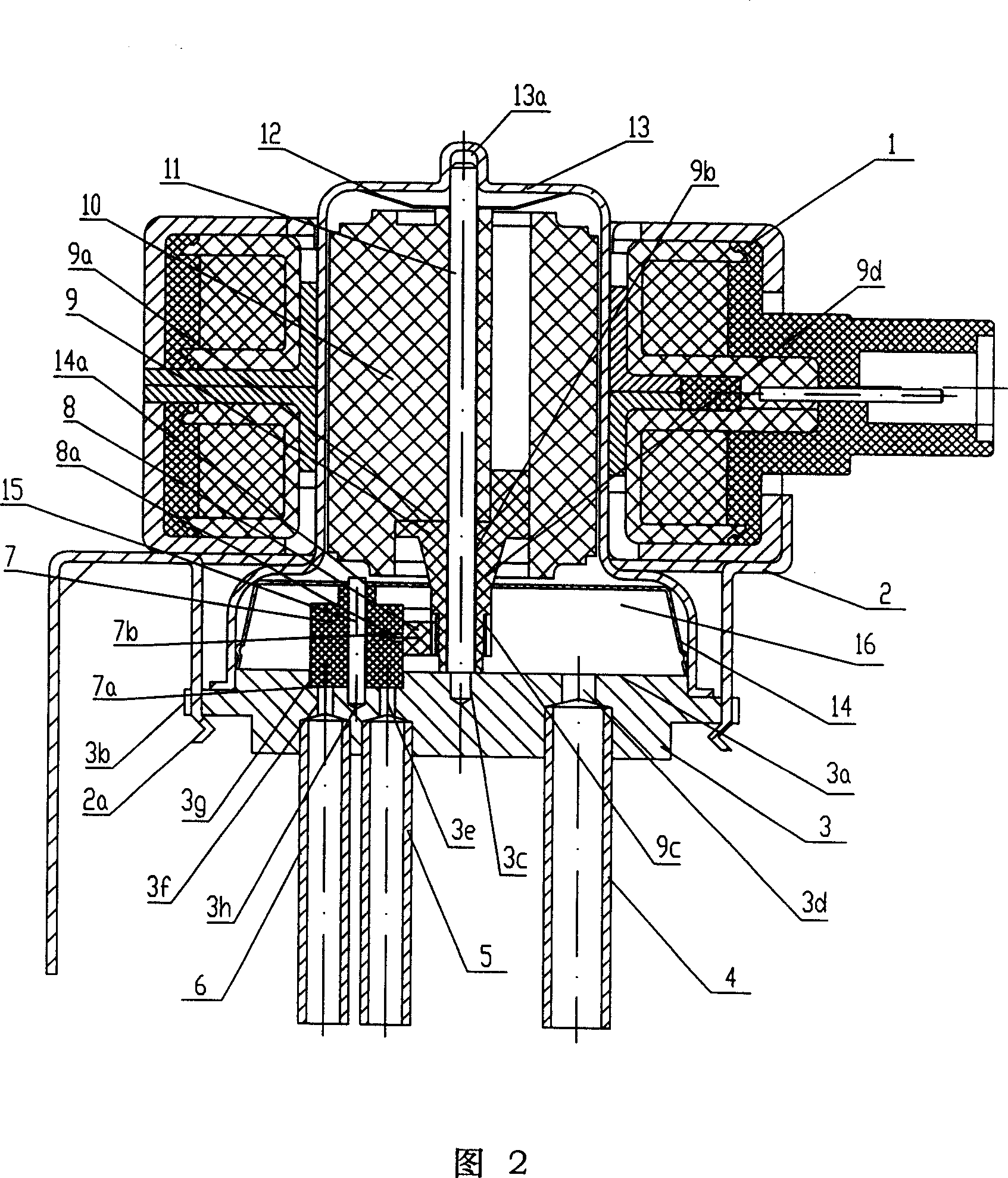

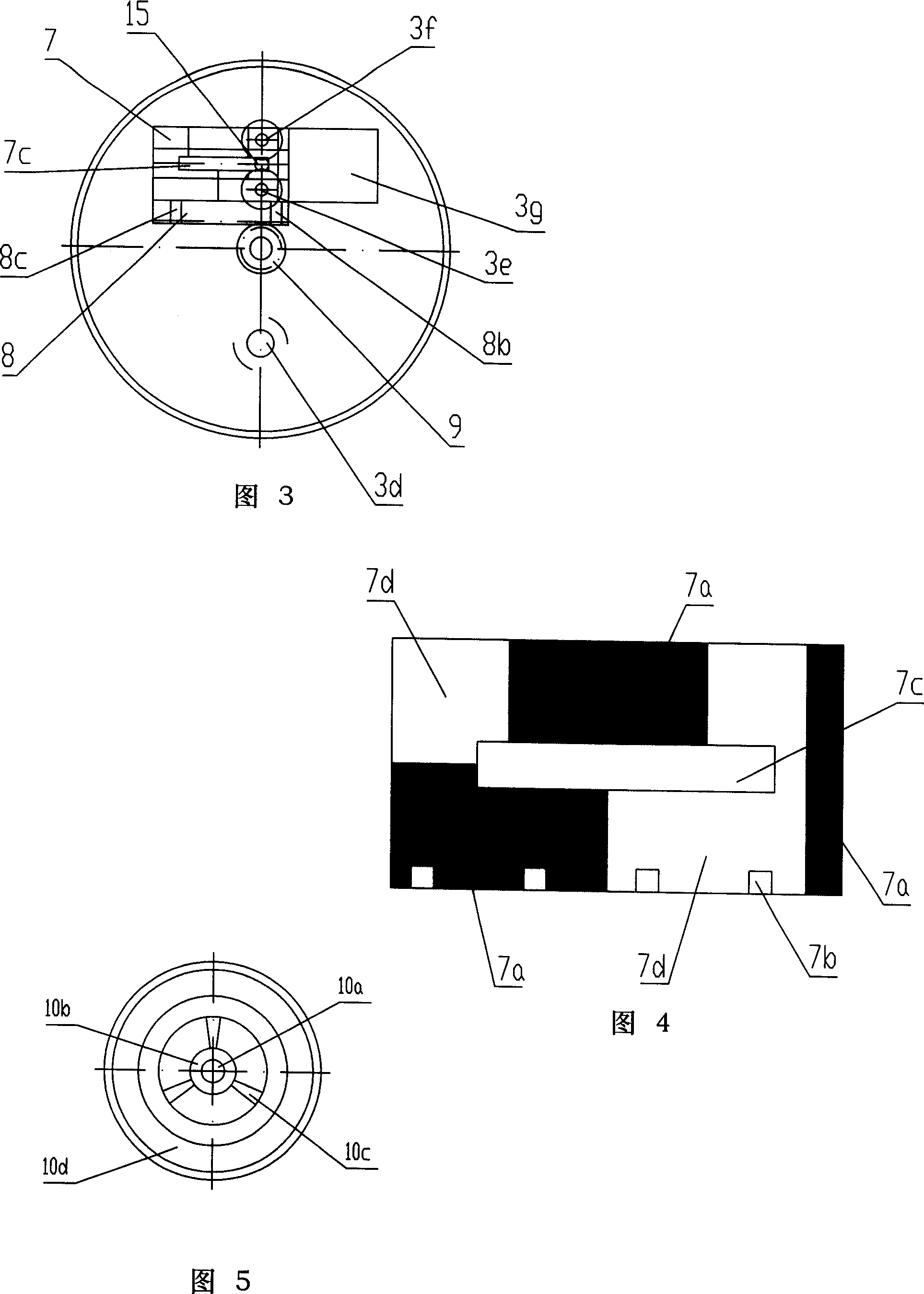

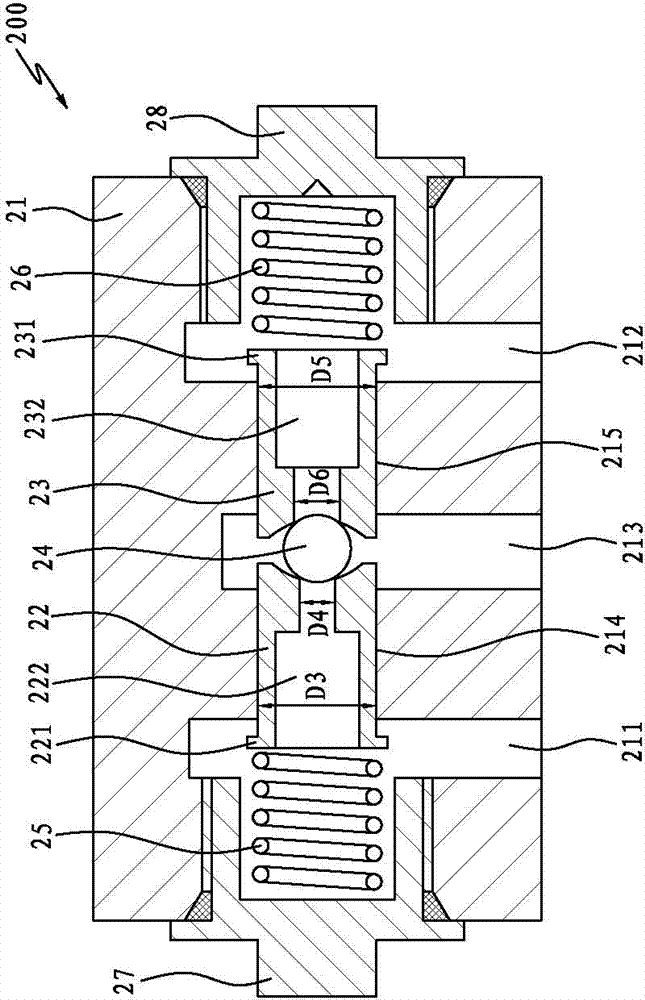

Electromagnetic sliding valve

ActiveCN1952453AReduce noiseReduce vibrationOperating means/releasing devices for valvesMultiple way valvesEngineeringRefrigeration

The invention relates to an electromagnetic sliding valve for frozen and cold storage refrigeration system so as to improve the performance, comprising valve body, valve cavity, one inlet port connected with said valve cavity and two outlet ports set on the flat sealing face of said valve cavity, a stepper motor comprised by stator on the outer shell and rotor in said valve cavity, sliding block for changing the opening-closing status of outlet port, which is driven to move on the said flat sealing face by said rotor. It is characterized in that power is transmitted to said sliding block to move straight so as to change the opening-closing status of outlet by said rotor through rack and pinion mechanism, said sliding block is pretension to said flat sealing face so as to ensure the sealing between sliding block and sealing face by encouragement method. The moving and driving method of sliding block is changed and it is suitable for machining and assembling parts. It is provided with enough designing space for opening design of electromagnetic valve and there is no vibration and noise basically.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

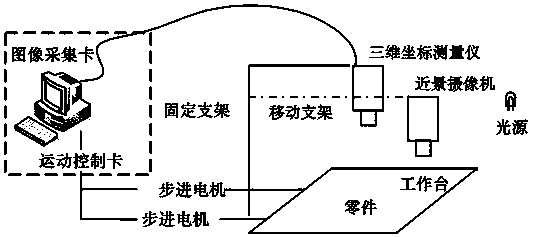

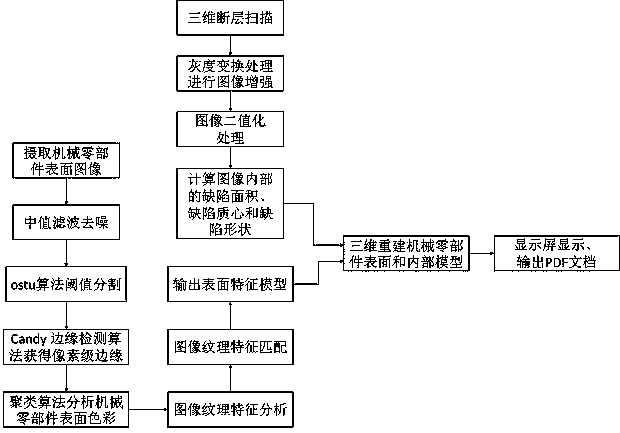

Visual detection method for mechanical component defect

ActiveCN109580630AHandling is smallSmall amount of compressionImage enhancementMaterial analysis using wave/particle radiationMechanical componentsEngineering

The invention discloses a visual detection method for a mechanical component defect. Defect parts in the mechanical component and on the surface of the mechanical component can be continuously scanned, and an acquired image can be processed and analyzed to acquire the area of the surface and internal defects, the barycentric coordinates of the defects and the defect shapes, so that operating personnel can see the defect parts clearly; then a three-dimensional model about the surface texture, color feature and internal structure of the mechanical component is recovered via three-dimensional reconstruction reverse engineering design, and thus the surface and internal defect positions and the defect range of the mechanical component are displayed, and the three-dimensional reconstruction system of the defect is displayed as a three-dimensional PDF document.

Owner:DONGGUAN UNIV OF TECH

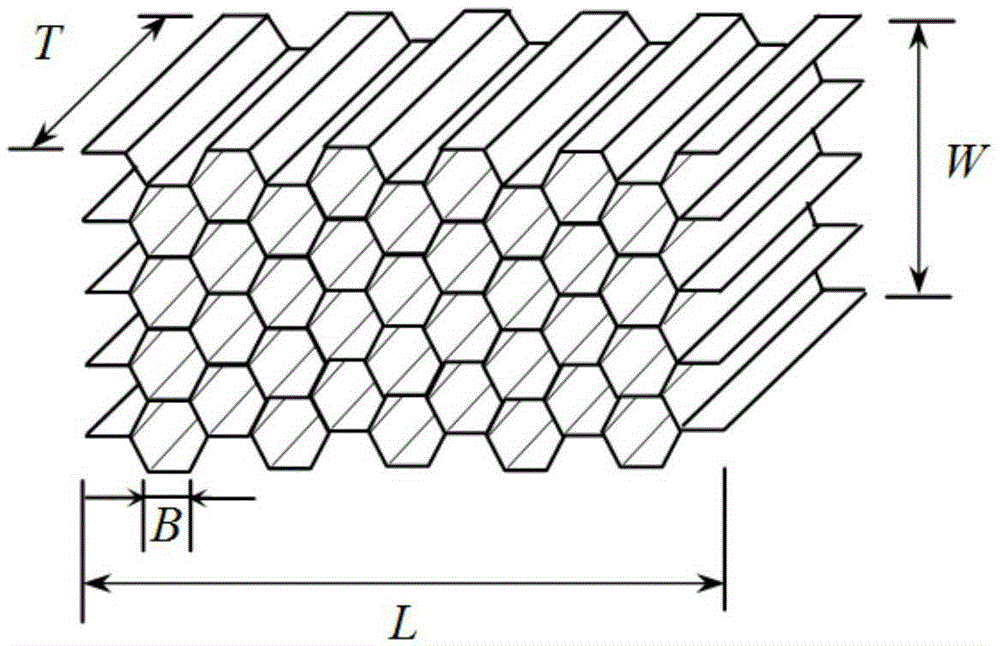

Thin slab layer for formation of honeycomb structure, honeycomb structure and preparation method thereof

The invention provides a thin slab layer which enhances through a strengthening layer such as carbon fiber or a functional material and is used for formation of a honeycomb structure, a honeycomb structure and its preparation method. According to the honeycomb structure, a strengthening layer of cell wall width is glued at the place where the honeycomb cell walls are glued with each other, so as to achieve the following effects: under the circumstance of not increasing the honeycomb structural cell density, plane compression strength / modulus and in-plane shear strength / modulus of the honeycomb structure are greatly raised, honeycomb structure compression amount during the honeycomb structure forming process is greatly reduced, and process window for honeycomb structure formation is expanded so as to ensure that the appearance of a honeycomb structural product is more accurate; and under the circumstance of not increasing the honeycomb structural cell density, functions of the honeycomb structure are increased: if the strengthening layer is carbon fiber cloth, heat-conducting property of the honeycomb structure is enhanced; and if the strengthening layer is a wave-absorbing material, absorbing property of the honeycomb structure is improved.

Owner:北京金轮沃德科技有限公司

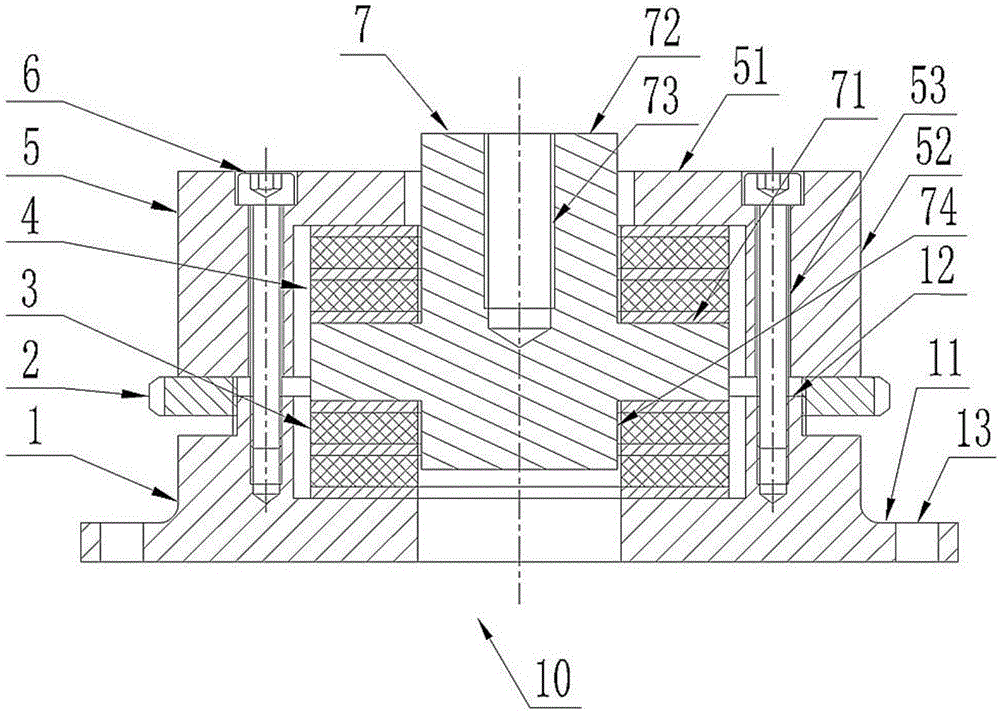

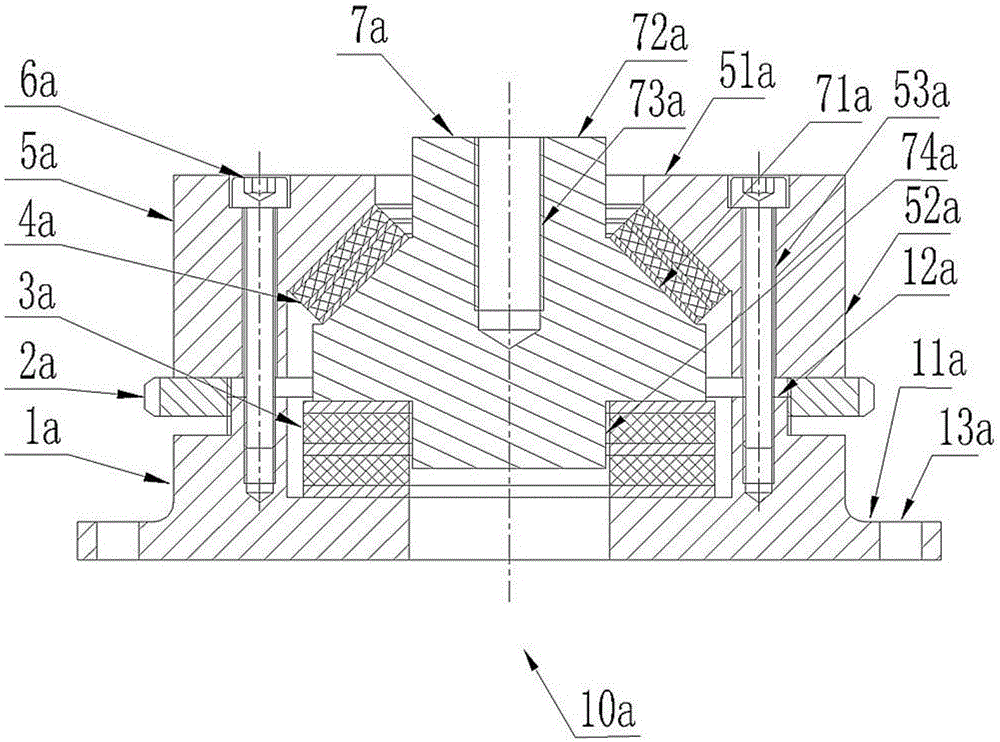

Extrusion die-casting machine and extrusion die-casting process thereof

The invention discloses an extrusion die-casting machine and an extrusion technology and die-casting technology combined extrusion die-casting process of the extrusion die-casting machine. The extrusion die-casting machine further comprises a small-stroke extrusion oil cylinder arranged on the outer side of a fixed die seat plate, a piston of the small-stroke extrusion oil cylinder moves to push an extrusion rod and directly extrudes a metal forming material stored in a storage space at the front part of the extrusion rod, so that the metal forming material enters a mold cavity, and performs local extrusion forming on the thickness direction of a semi-solid casting formed in the mold cavity. The extrusion die-casting machine has the advantage of being high in production efficiency, and meanwhile, has the function of reducing or eliminating shrinkage porosities and shrinkage cavities in thick part of a casting through an extruding method, so that the performance of the casting is obviously improved, and the machine is particularly suitable for manufacturing large-scale die castings. According to the extrusion die-casting machine and the extrusion die-casting process thereof, the structure is simple, the production cost is relatively low, and the effects of being stable and reliable are achieved; and the process method is convenient to operate, high in universality, easy to popularize and apply in the industry and wide in market application prospect.

Owner:广东鸿特精密技术肇庆有限公司

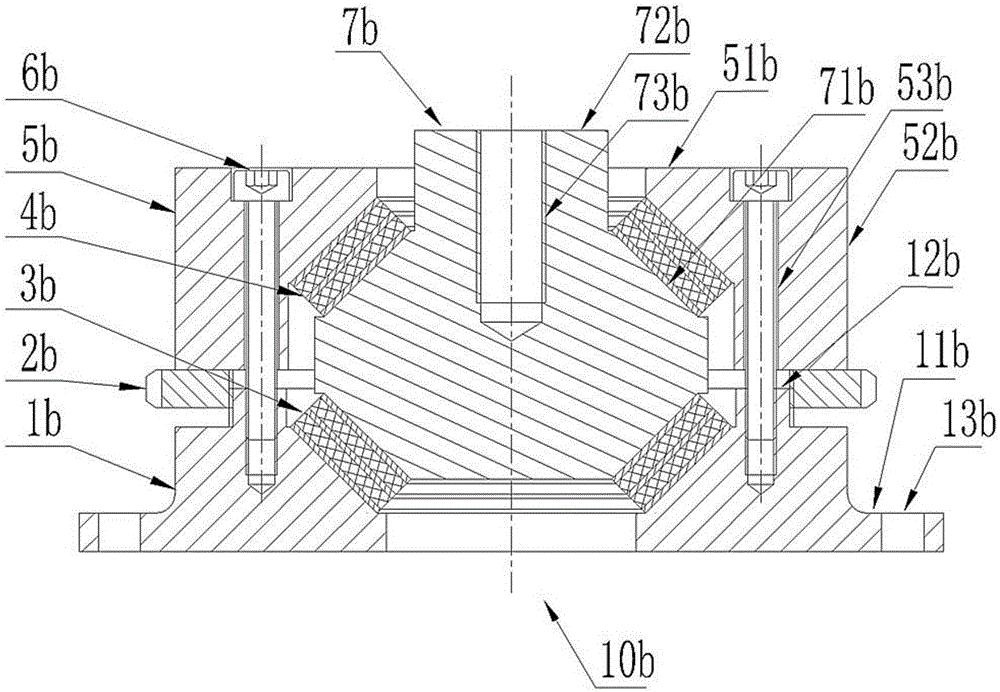

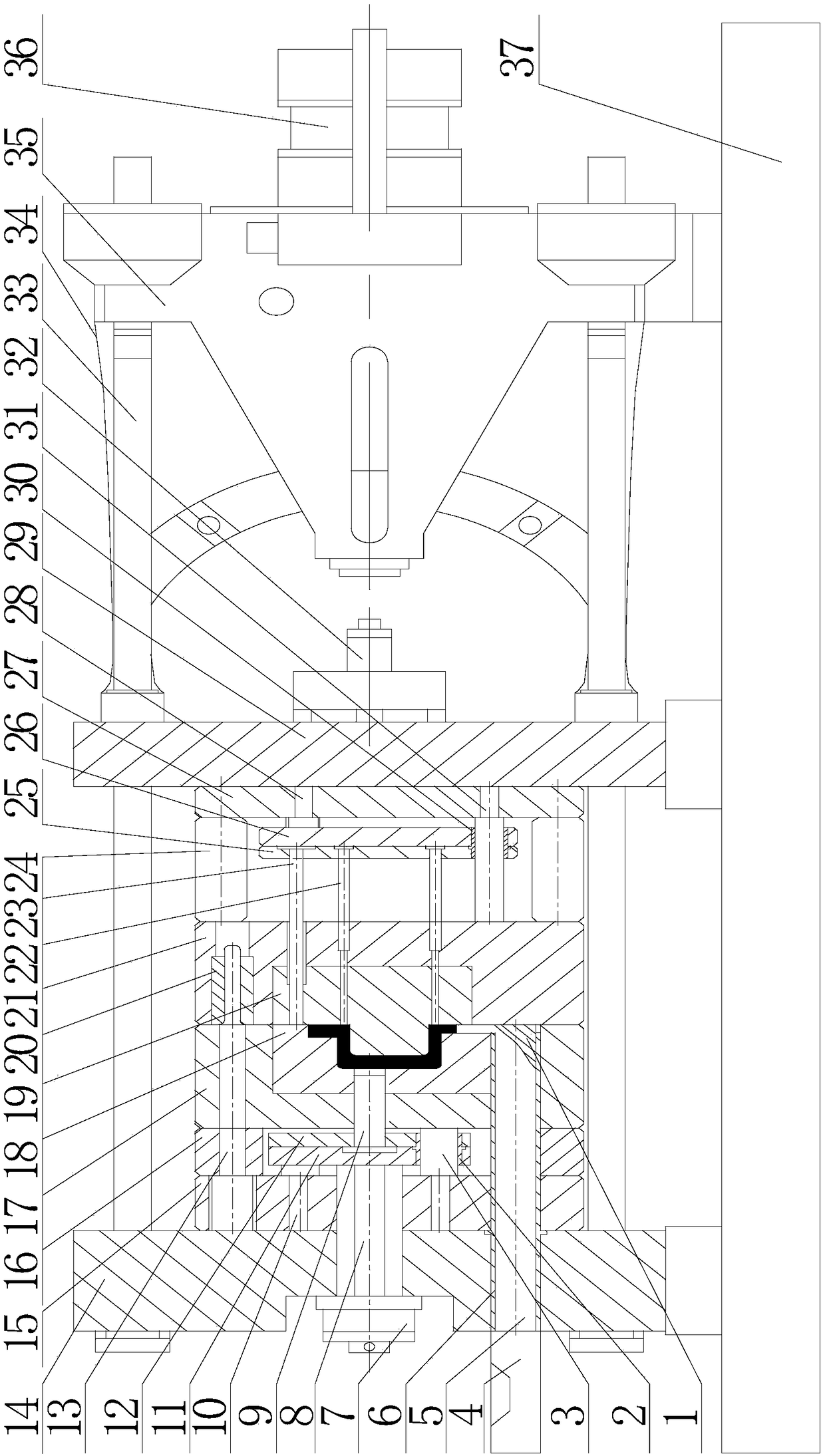

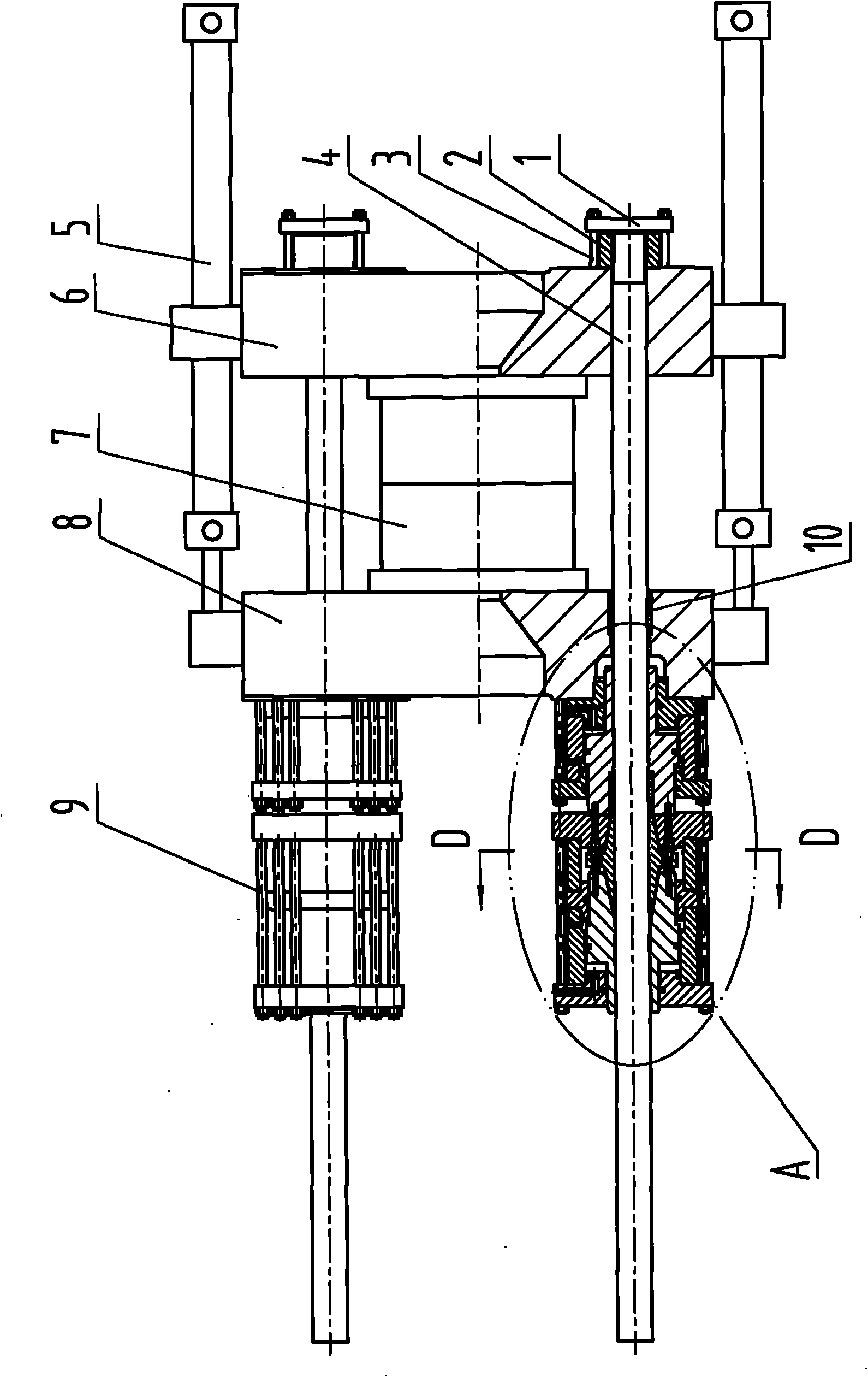

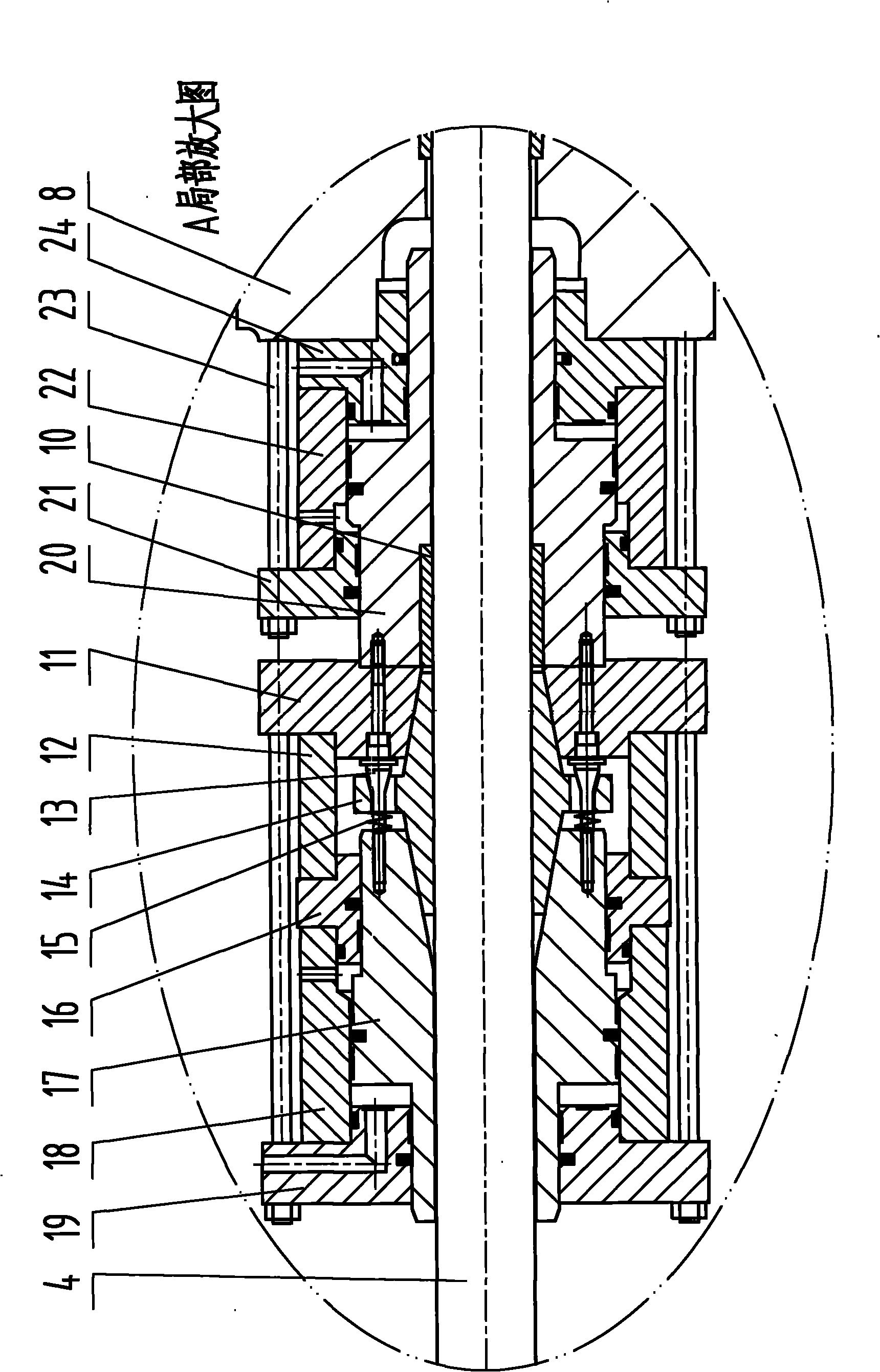

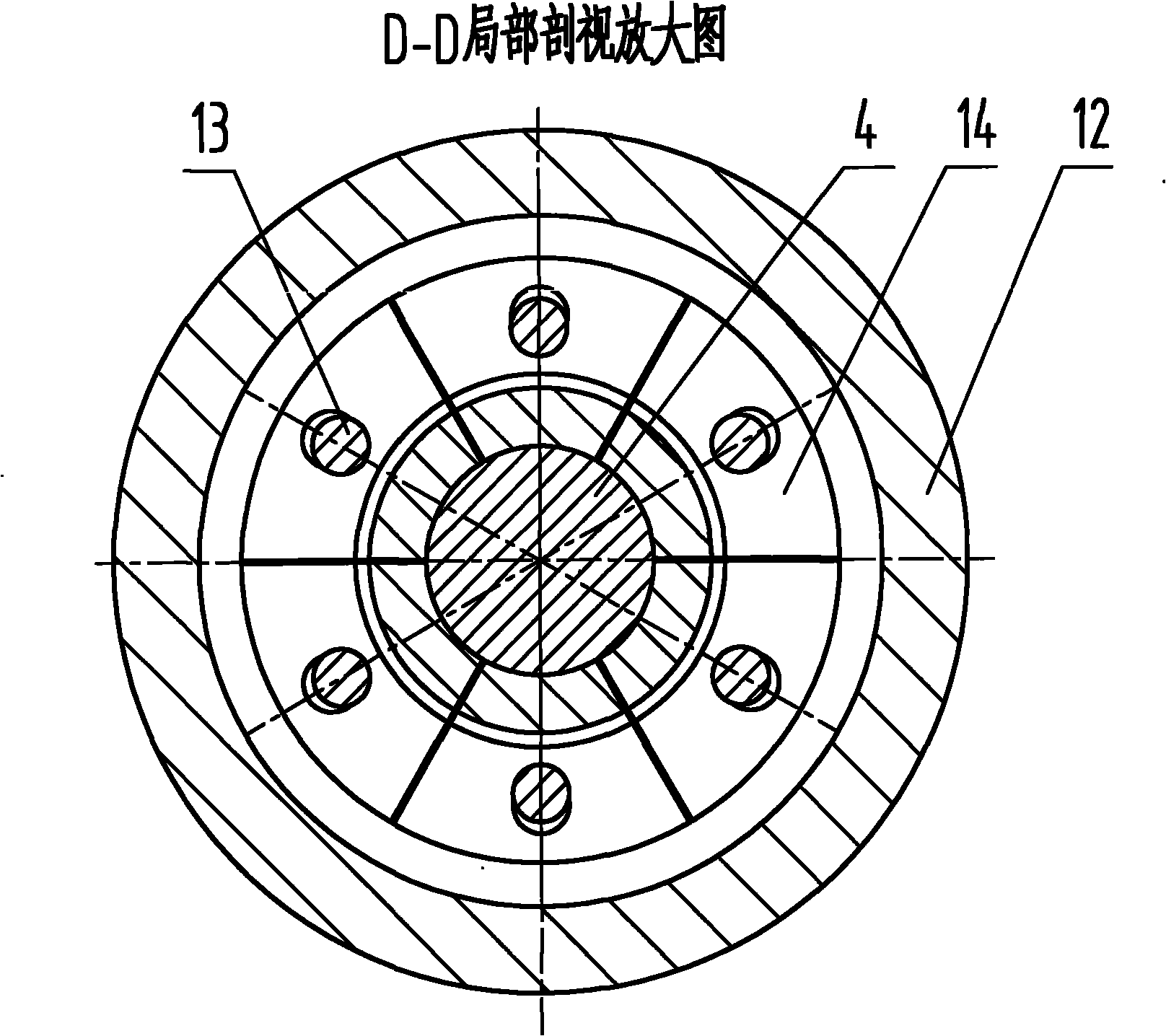

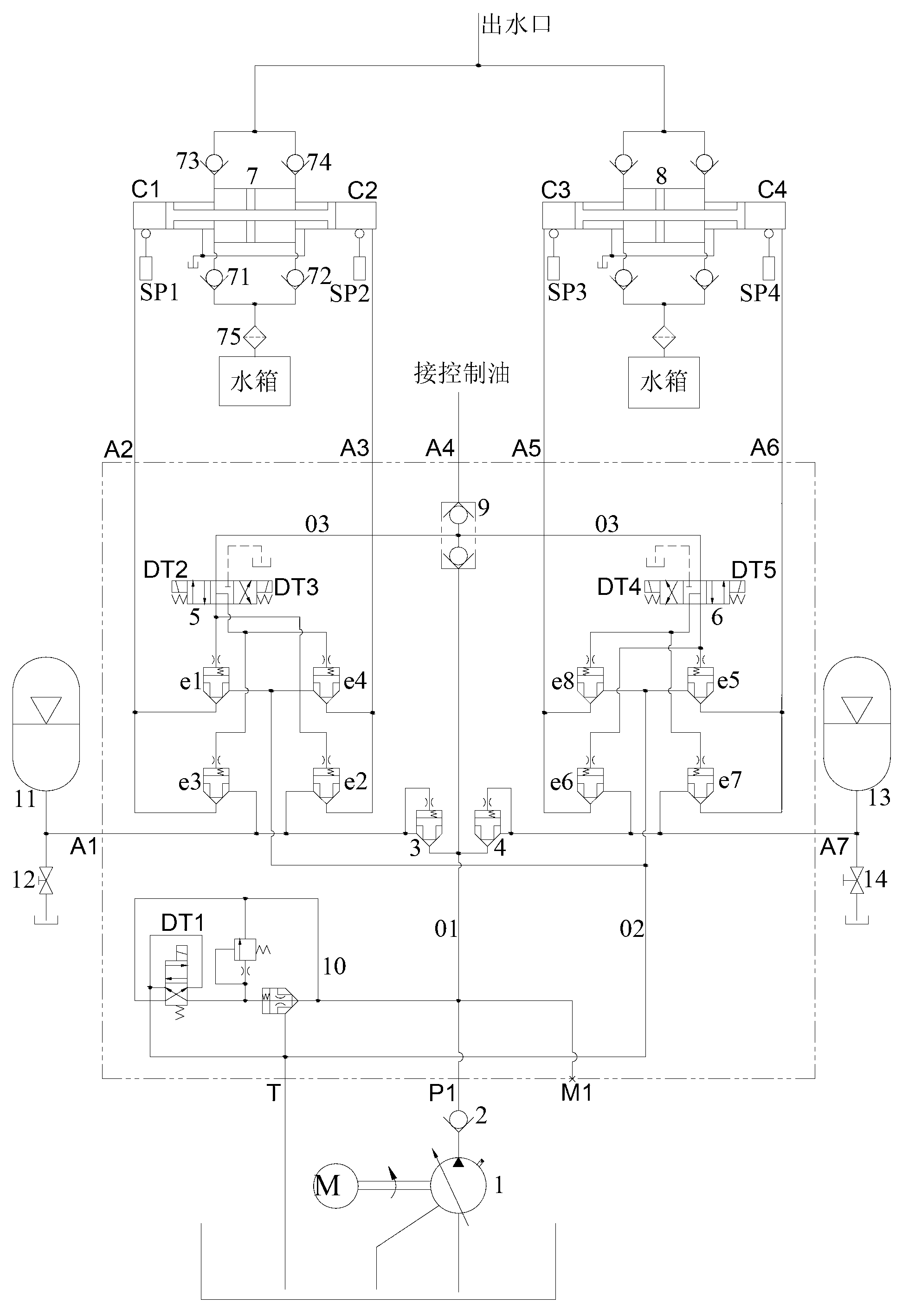

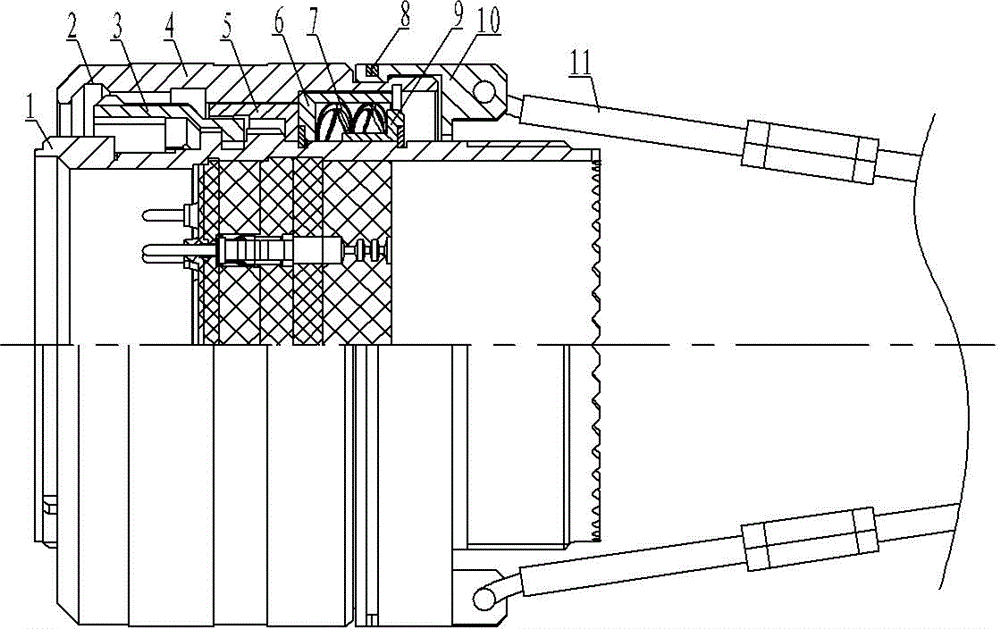

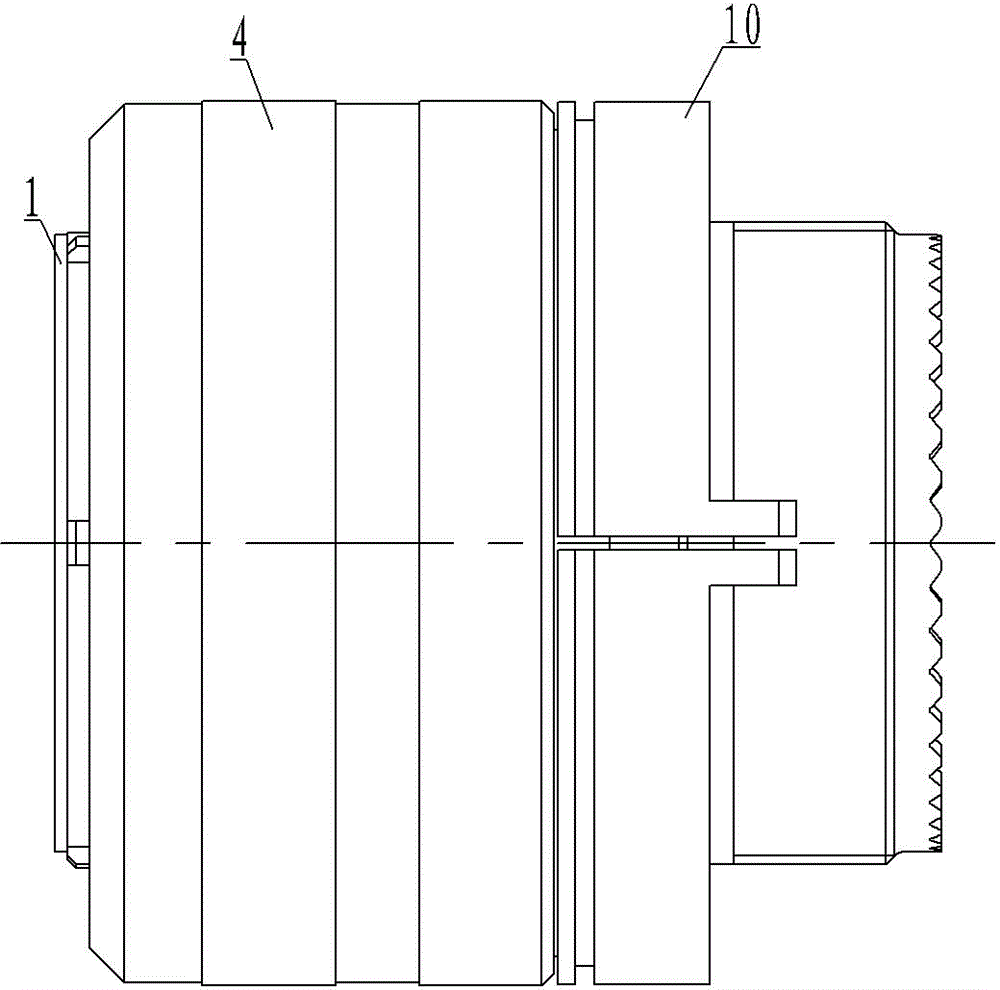

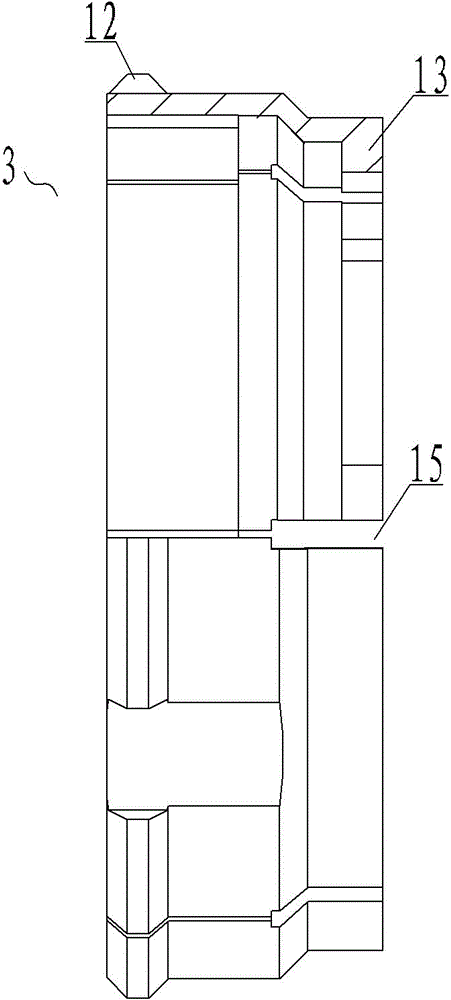

Expansion clasping hydraulic mould locking mechanism

The invention relates to an expansion clasping hydraulic mould locking mechanism, which comprises a pull rod pressing plate, a pull rod nut, a pull rod pressing plate screw, a pull rod, a mould moving oil cylinder, a fixed template, a mould, a movable template, an expansion clasping oil cylinder pull rod, a guide sleeve, an expansion supporting seat, a supporting body, a pull screw, an expansion oblique block, a compression spring, an expansion clasping oil cylinder rear cover, an expansion clasping oil cylinder piston rod, an expansion clasping oil cylinder body, an expansion clasping oil cylinder front cover, a high-pressure mould locking oil cylinder piston rod, a high-pressure mould locking oil cylinder rear cover, a high-pressure mould locking oil cylinder body, a high-pressure mould locking oil cylinder pull rod and a high-pressure mould locking oil cylinder front cover. The mechanism ensures that huge clasping force is generated between an inner ring of the expansion oblique block and the pull rod through hydraulic thrust according to an oblique surface principle, an expansion clasping oil cylinder generates high pressure to clasp the pull rod, and a high-pressure mould locking oil cylinder generates high pressure to generate mould locking force, so that the mould is locked quickly, accurately and reliably.

Owner:叶廷璧

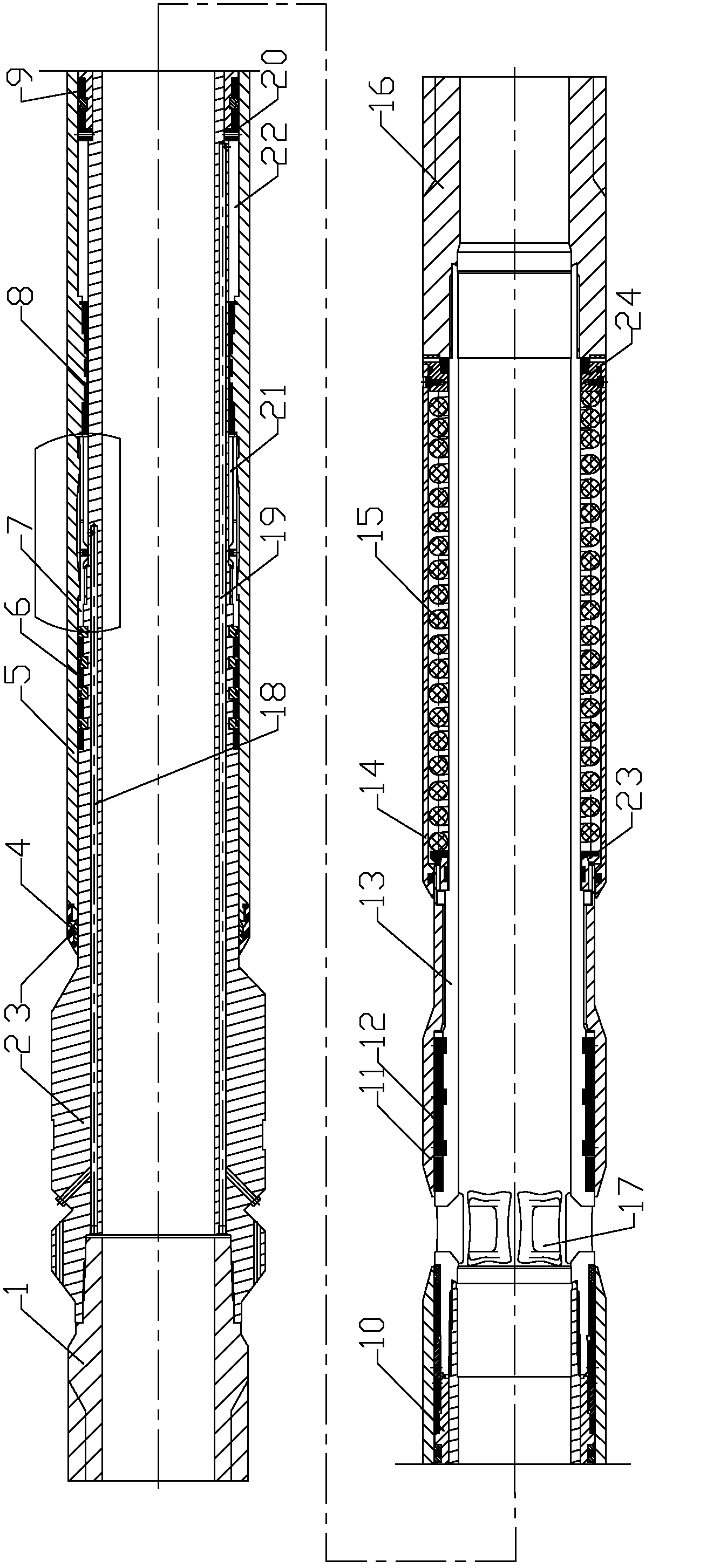

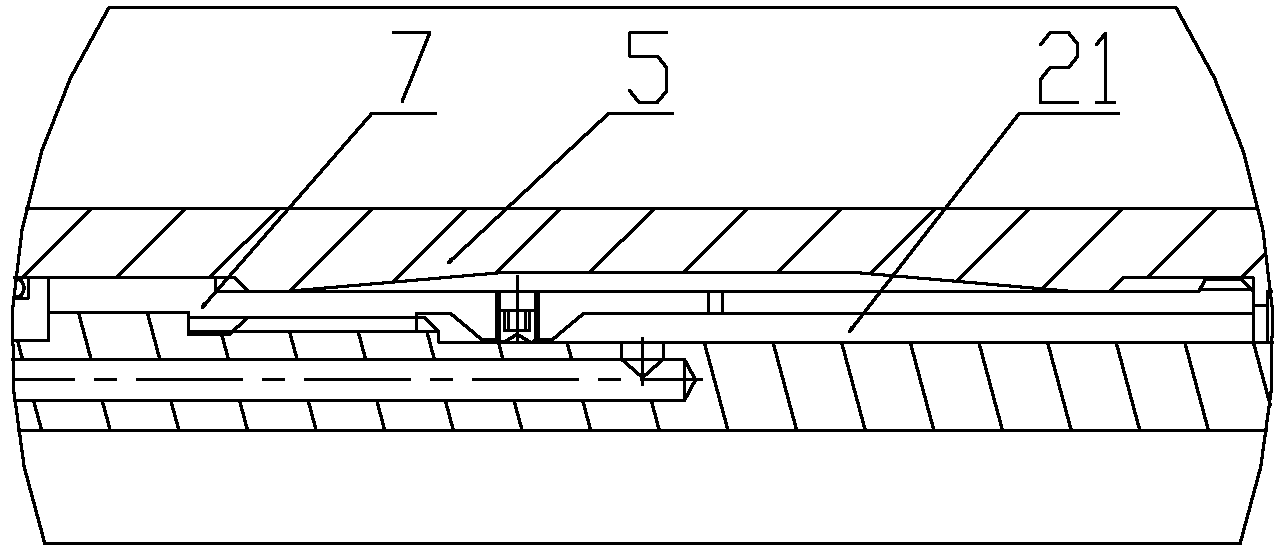

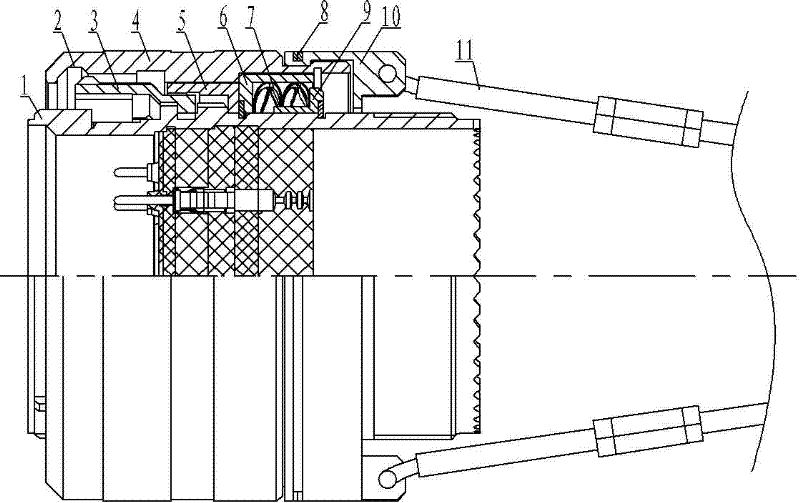

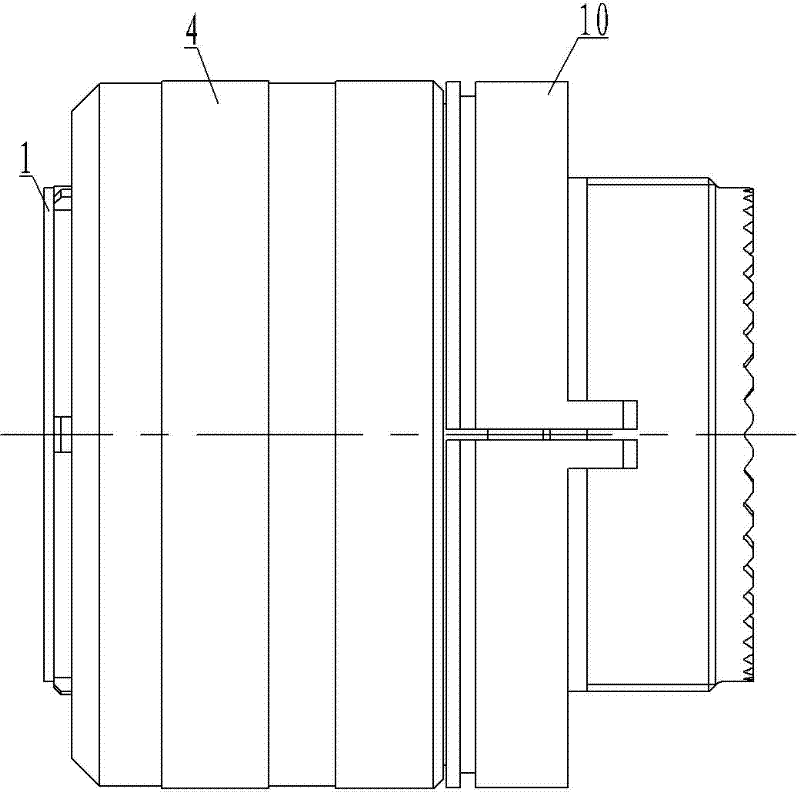

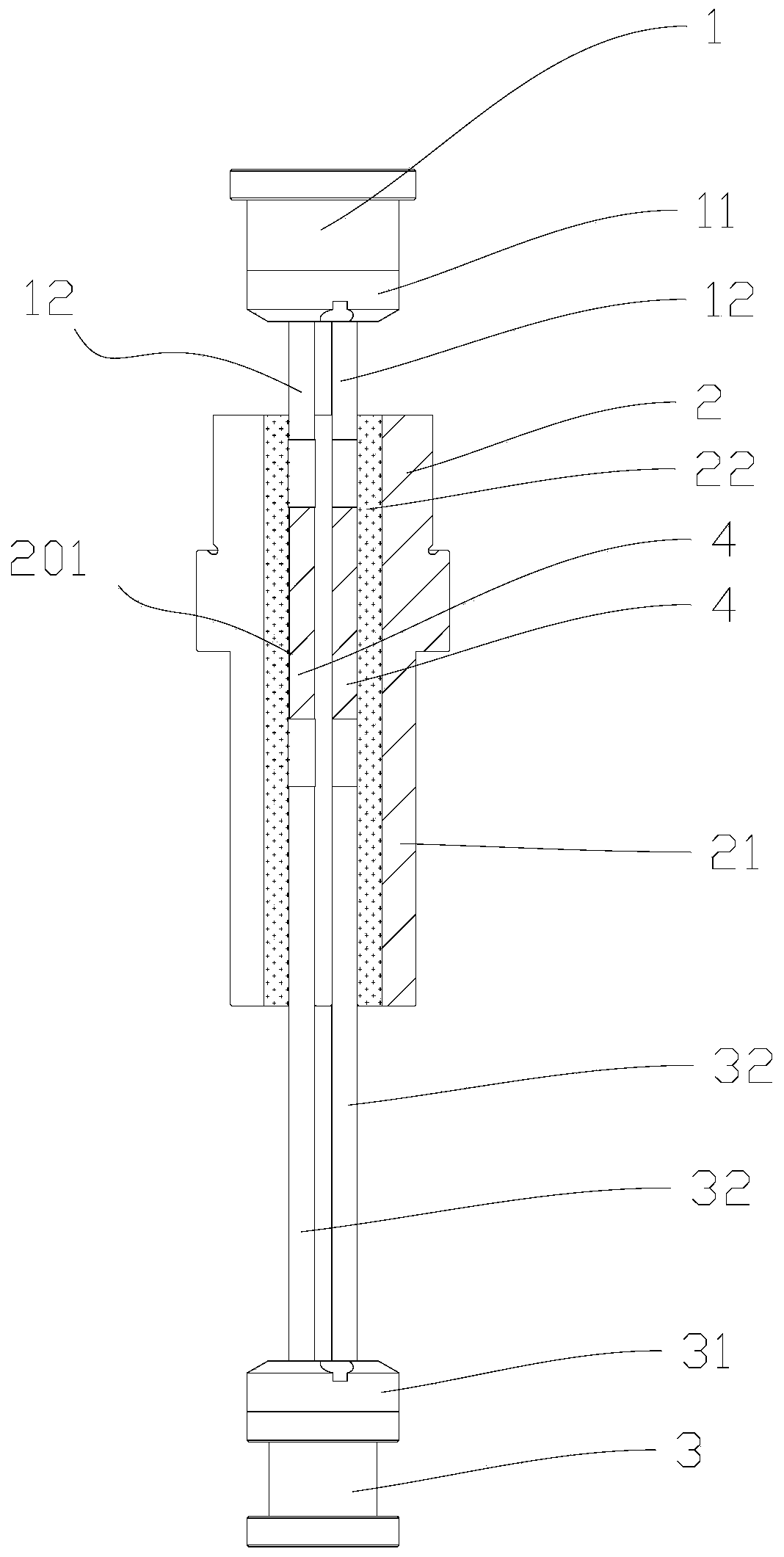

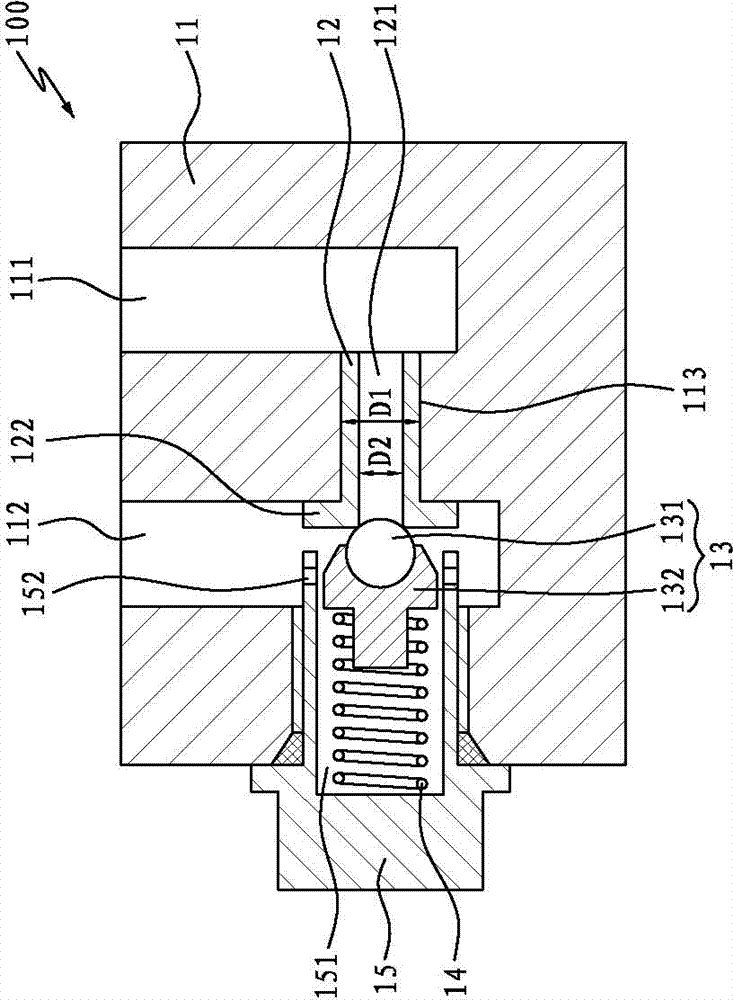

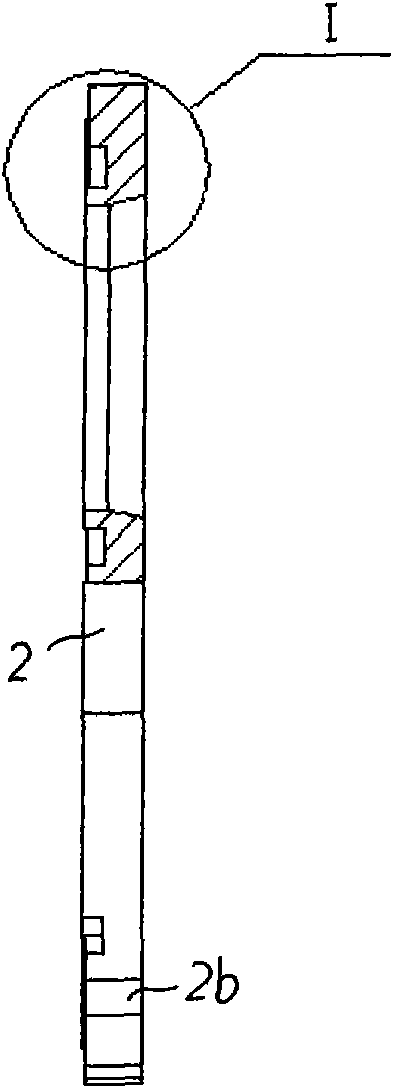

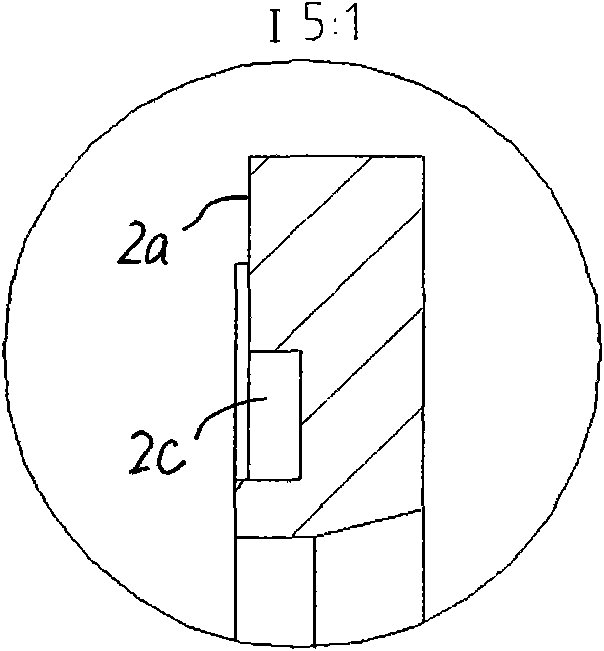

hydraulic sleeve

ActiveCN102278091ASmall amount of compressionGuaranteed reliabilityWell/borehole valve arrangementsSealing/packingEngineeringHydraulic pressure

The invention relates to a hydraulic sliding sleeve, comprising an upper spindle, wherein the tube wall of the upper spindle is provided with a first hydraulic channel and a second hydraulic channel which are parallel to a central line, an upper outer cylinder is sheathed outside the upper spindle, an upper part sealing combination, a middle part sealing combination and a lower part sealing combination arranged between the upper spindle and the upper outer cylinder divide a space between the upper outer cylinder and the upper spindle into an upper hydraulic cavity and a lower hydraulic cavity, the first hydraulic channel is communicated with the upper hydraulic cavity, the second hydraulic channel is communicated with the lower hydraulic cavity, and the upper outer cylinder can slide up and down by suppressing the upper hydraulic cavity and the lower hydraulic cavity. The invention has the advantages that: the hydraulic sliding sleeve has a simple structure, is convenient to operate and is safe and reliable, and the hydraulic sliding sleeve can be opened and closed only by carrying out suppressing operation on a hydraulic pipeline.

Owner:CNOOC ENERGY TECH & SERVICES

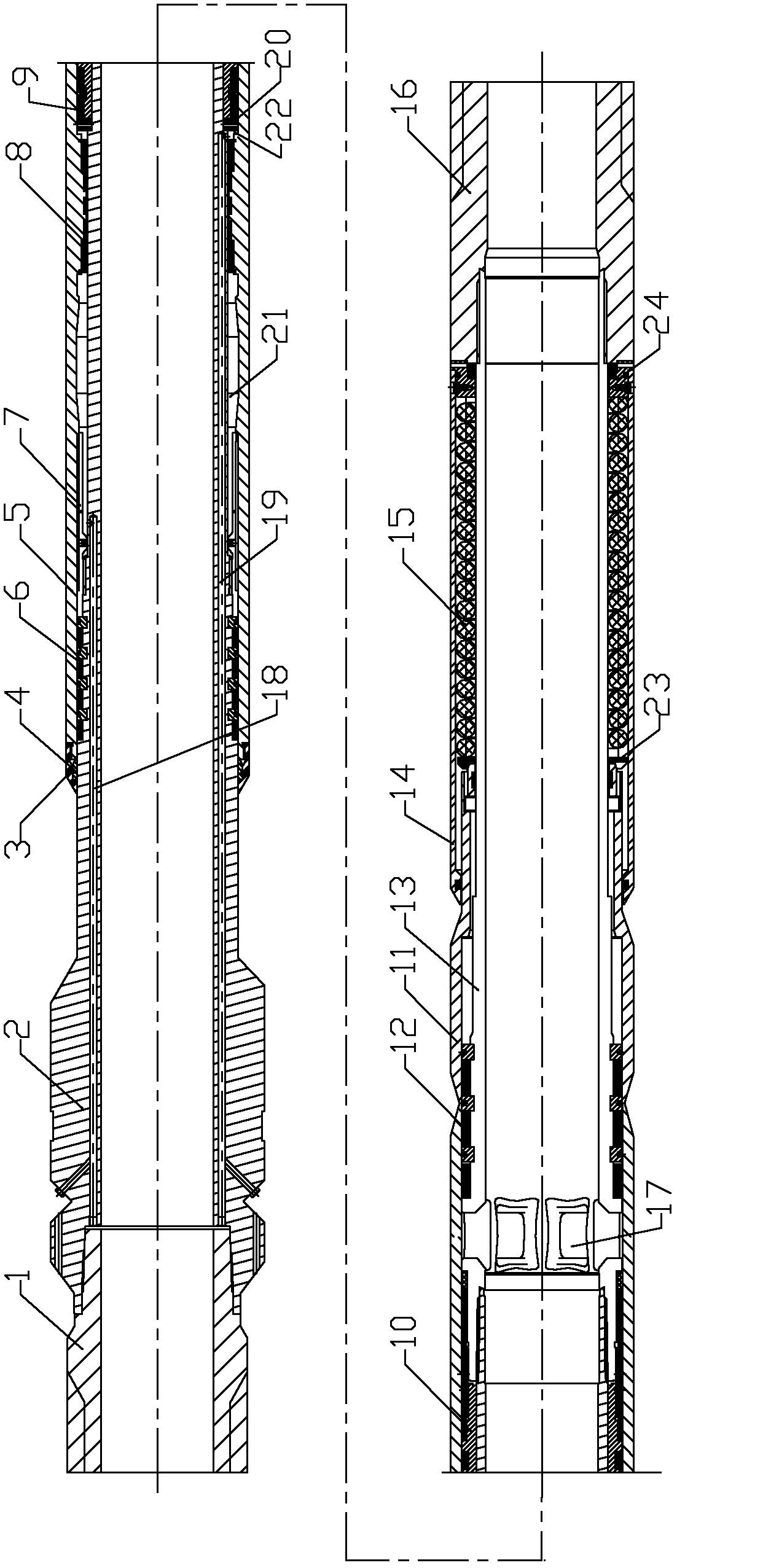

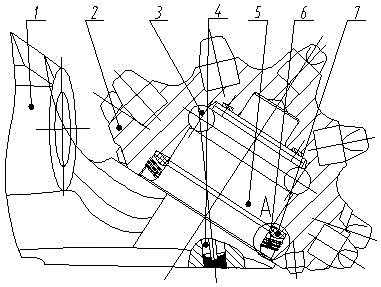

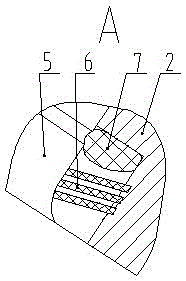

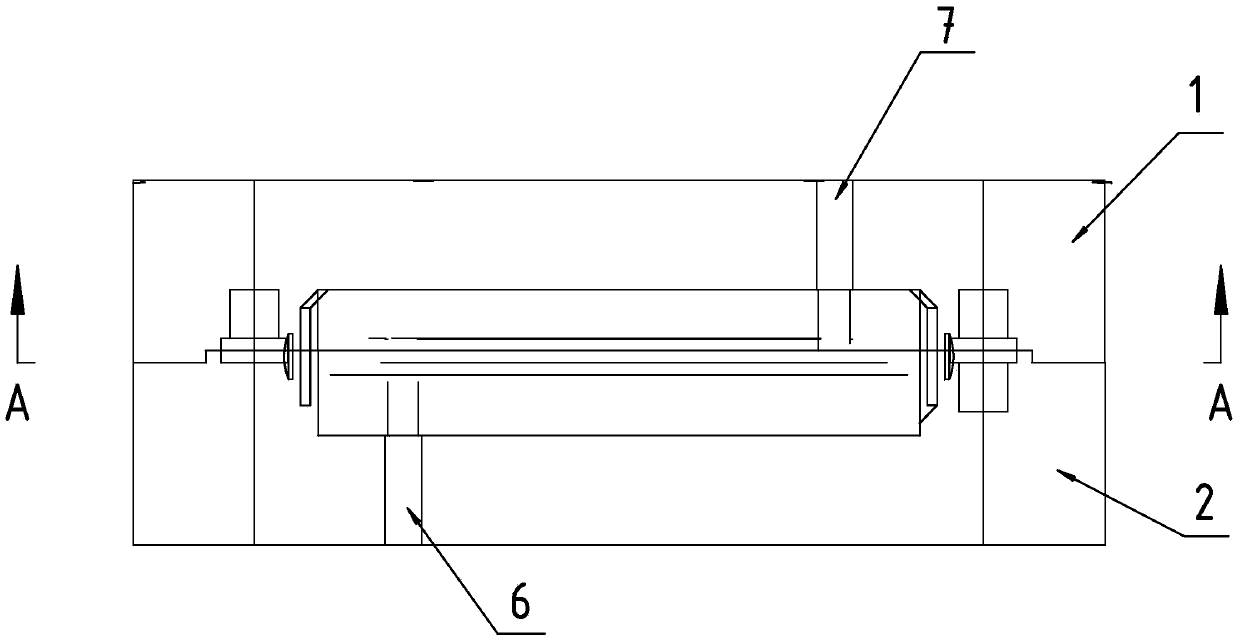

Bearing spiral combined sealing structure of high-speed roller bit

The invention relates to a bearing spiral combined sealing structure of a high-speed roller bit. The bearing spiral combined sealing structure comprises a roller cone, a bearing, a spiral seal ring and an O-shaped rubber ring. The spiral seal ring is installed in a spiral groove of a roller cone inner hole. When the bit rotates at a high speed, through the pumping effect of the spiral groove, a function of automatically draining sand is achieved. The pressure of the outer side of the O-shaped rubber ring is added, the pressure difference of the two sides of the O-shaped rubber ring is reduced, and the sealing effect of the O-shaped rubber ring is improved. The O-shaped rubber ring is located above the spiral seal ring and installed in a bearing groove with a certain interference. When the bit rotates at a high speed, the auxiliary two-stage sealing is achieved, and the bit can also achieve the effective sealing effect when stopping rotating. The bearing spiral combined sealing structure has good sand draining performance, the abrasion to the bearing can be effectively reduced, the sealing requirements under different working conditions can be met, the sealing reliability and stability are greatly improved, the sealing service life is prolonged. Other supporting elements are not needed for the sealing, and precious time is saved for the roller bit.

Owner:SOUTHWEST PETROLEUM UNIV

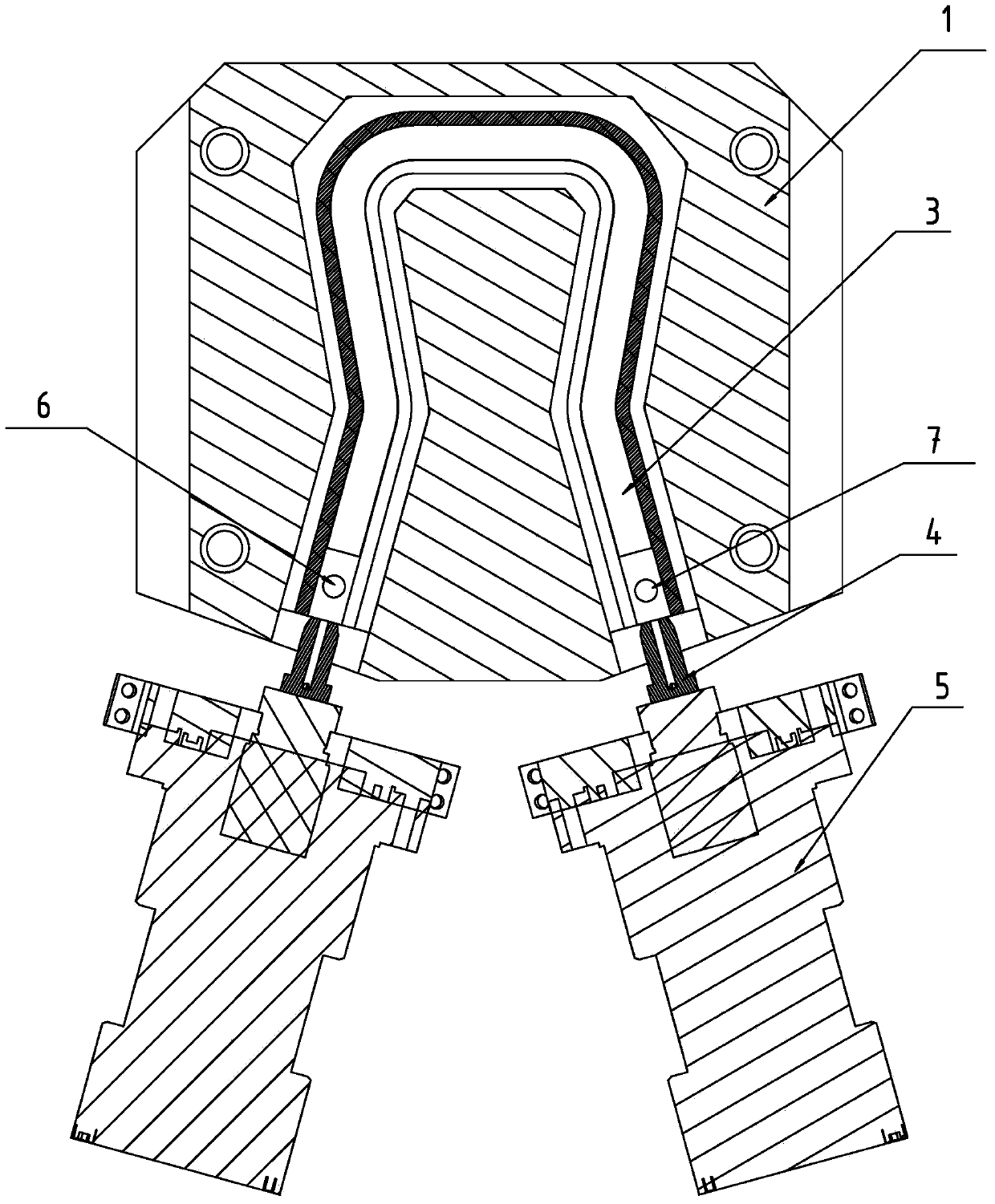

Large internal high-pressure forming die

The invention discloses a large internal high-pressure forming die which comprises an upper die, a lower die, two sealing punches, two side pushing cylinders, a water incoming pipe and a water outgoing pipe. A cavity of parts is formed after the upper die and the lower die are assembled, the sealing punches are mounted on the side pushing cylinders respectively and driven by the side pushing cylinders to enter a pipe blank to complete end portion sealing, the water incoming pipe is arranged in the lower die, and the water outgoing pipe is arranged in the upper die. The water incoming pipe is arranged in the lower die, so that quick liquid filling can be realized by adopting a high-capacity pump through the water incoming pipe positioned in the lower die. Quick liquid filling cannot be realized even if the high-capacity pump is adopted when an existing die structure is adopted. Quick liquid filling and air discharging can be realized by adopting a large-diameter hose and using the high-capacity pump, so that production efficiency is improved. High-pressure water enters the inside of a pipe through an internal pressure hole in the middle of a sealing head to be isolated from a low-pressure water passage, and size of a high-pressure water passage is reduced, so that high-pressure dynamic sealing effect and control accuracy are improved.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

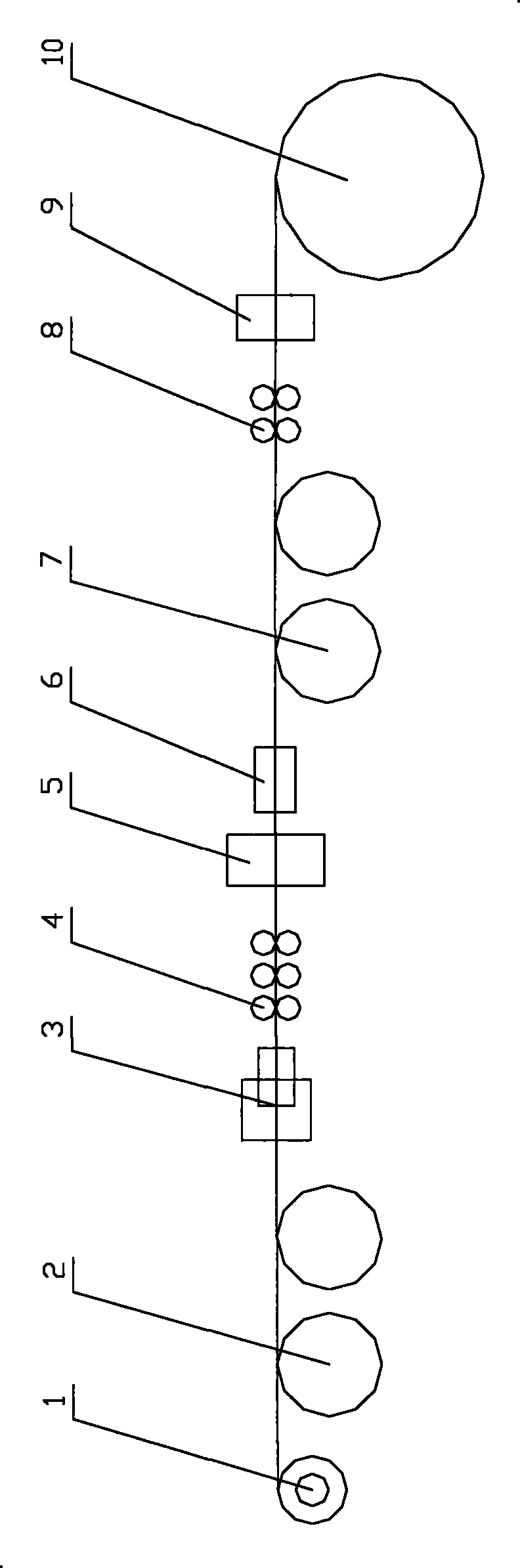

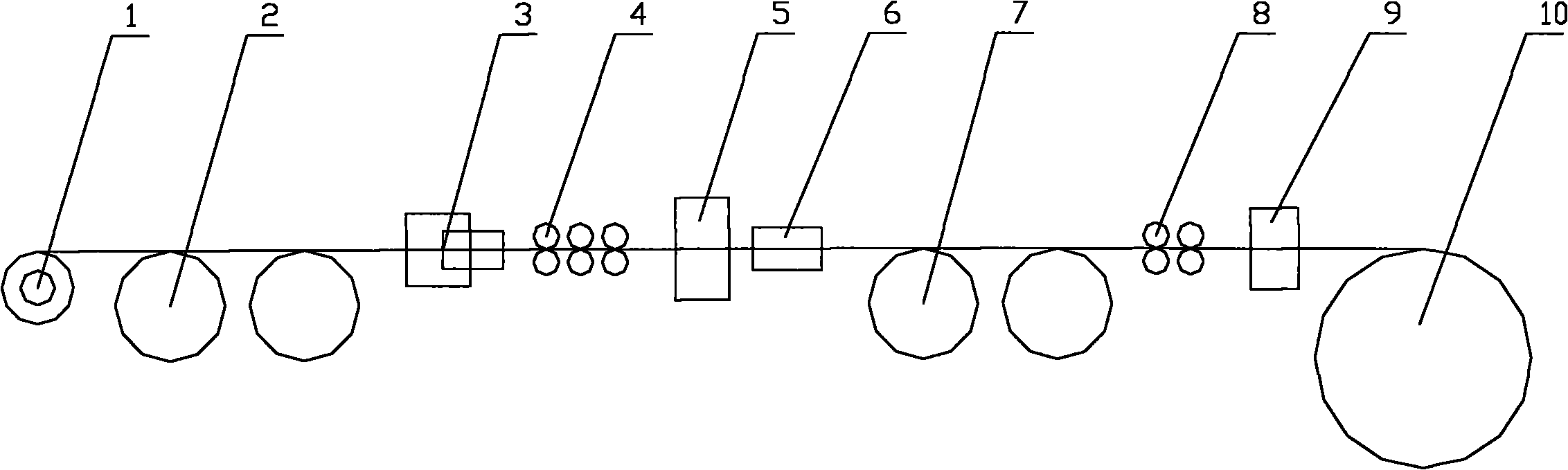

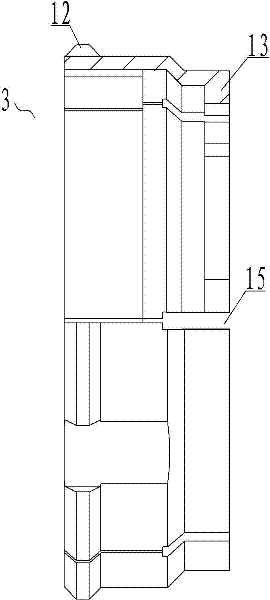

Production technology of helix rib steel wire

The invention relates to a production technology of a helix rib steel wire, which comprises the following steps: paying off a steel wire by a paying-off machine; passing through a first group of tension pulleys; entering a helicoid to form helix; tempering in an intermediate frequency after being straightened by a straightener; cooling down; passing through a second group of tension pulleys; entering shears by traction; cutting and dividing into trays in the shears; and finally collecting wires into trays. Therefore, each performance index of the helix rib steel wire is improved, and the steel wire is provided with good linearity. Furthermore, the compression amount of helix forming is reduced; the accuracy of helix size is guaranteed; the weight per meter of steel wire meets normative requirement; and the loss of a helix model is greatly reduced.

Owner:奥盛(九江)新材料有限公司

Guy rope dropping connector

InactiveCN102544883AStable structureReduced strength requirementsCoupling device detailsScrew threadSpare part

The invention relates to a guy rope dropping connector which comprises a connector casing. Pull-out casings are arranged at front and rear limiting sliding sleeves on the periphery of the connector casing; a return spring for driving the pull-out casing to move forward is formed between the pull-out casing and the connector casing; a thread connecting sleeve positioned at the front part of the connector casing is arranged between the connector casing and the pull-out casing; the thread connecting sleeve is axially shifted and assembled on the connector casing; internal threads used for being matched with and locked with external threads at the front end of an adaptive connector is formed in the front section of the thread connecting sleeve; an axial through slot dividing the thread connecting sleeve into at least two parts are formed on the peripheral wall of the thread connecting sleeve; the rear part of an inner hole of the pull-out casing is matched with the rear section of the thread connecting sleeve, so as to ensure that all parts of the thread connecting sleeve are at retract state; and the front part of the inner hole of the pull-out casing is banded and matched with the thread connecting sleeve. The thread connecting sleeve is a spare part, after the pull-out casing moves backwards, expansion amount can be produced in the radial direction, a conical section is not required to be provided, and the thread connecting sleeve is short.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

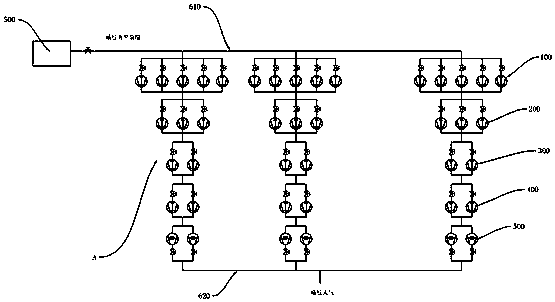

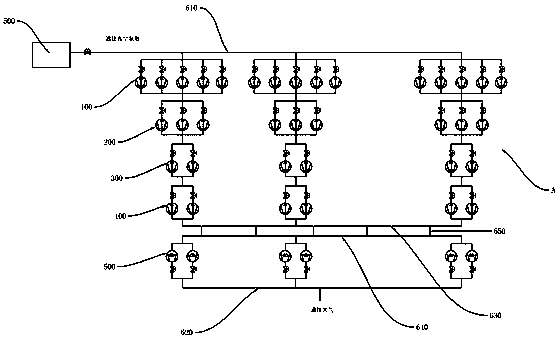

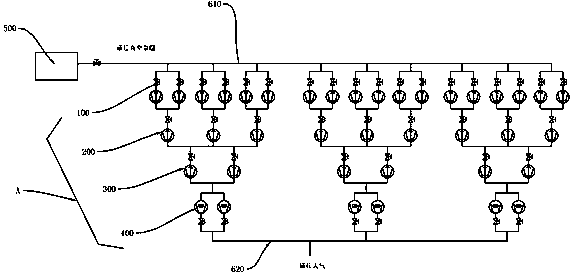

Mechanical pump set assembling method for molten steel degassing and mechanical pump set system

InactiveCN108180144AIncrease safety redundancyEasy to adjustRotary/oscillating piston combinations for elastic fluidsMachines/enginesAtmospheric airProduct gas

The invention discloses a mechanical pump set assembling method for molten steel degassing. The method involves a mechanical pump set which comprises at least one pump set, wherein each pump set is connected in parallel with an inlet gas collecting pipe in a communication manner and then communicates with a gas pumping port of a molten steel degassing device to be vacuumized; a gas outlet of eachpump set is connected in parallel with an outlet gas collecting pipe in a communication manner and then is connected to atmosphere; each pump set comprises at least one first-stage pump, a second-stage pump, a third-stage pump and a backing pump; each backing pump is a large screw pump or an efficient two-stage water ring vacuum pump; pump machines, at the same grade, of each main pump, each second-stage pump, each third-stage pump and each fourth-stage pump are mounted in a parallel connection manner; inlet gas of the pump at each grade is uniformly distributed to each pump machine through the inlet gas collecting pipe; the gas outlet of the pump set unit at each grade is collected through a gas outlet pipe and then enters the pump machine at next grade to be compressed; the gas outlet ofeach backing pump communicates with the outlet gas collecting pipe in a parallel connection manner; the outlet gas collecting pipe communicates with the atmosphere. The invention also discloses a mechanical pump set system constructed by the abovementioned method. The mechanical pump set system is high in redundancy of gas pumping capacity; and the production safety is high.

Owner:上海宽量节能环保技术有限公司

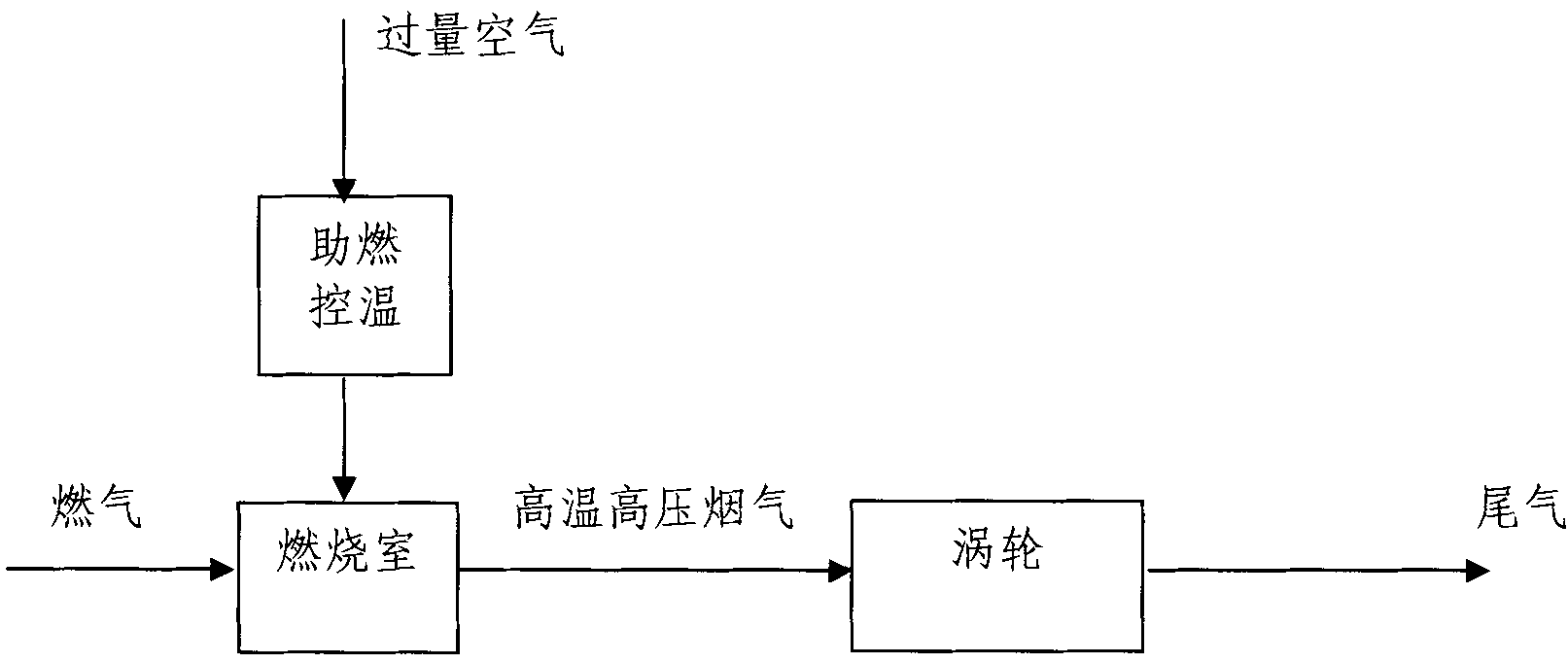

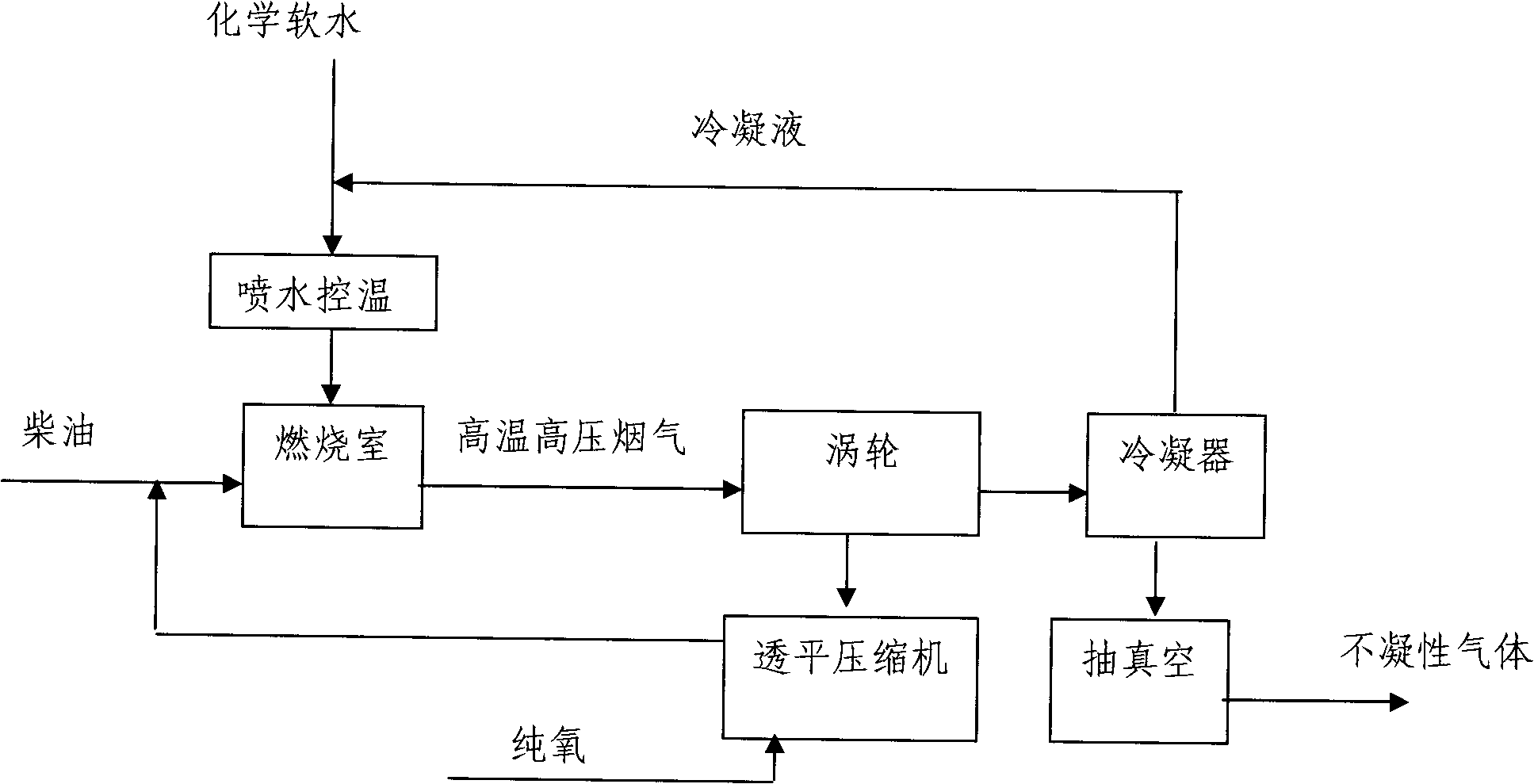

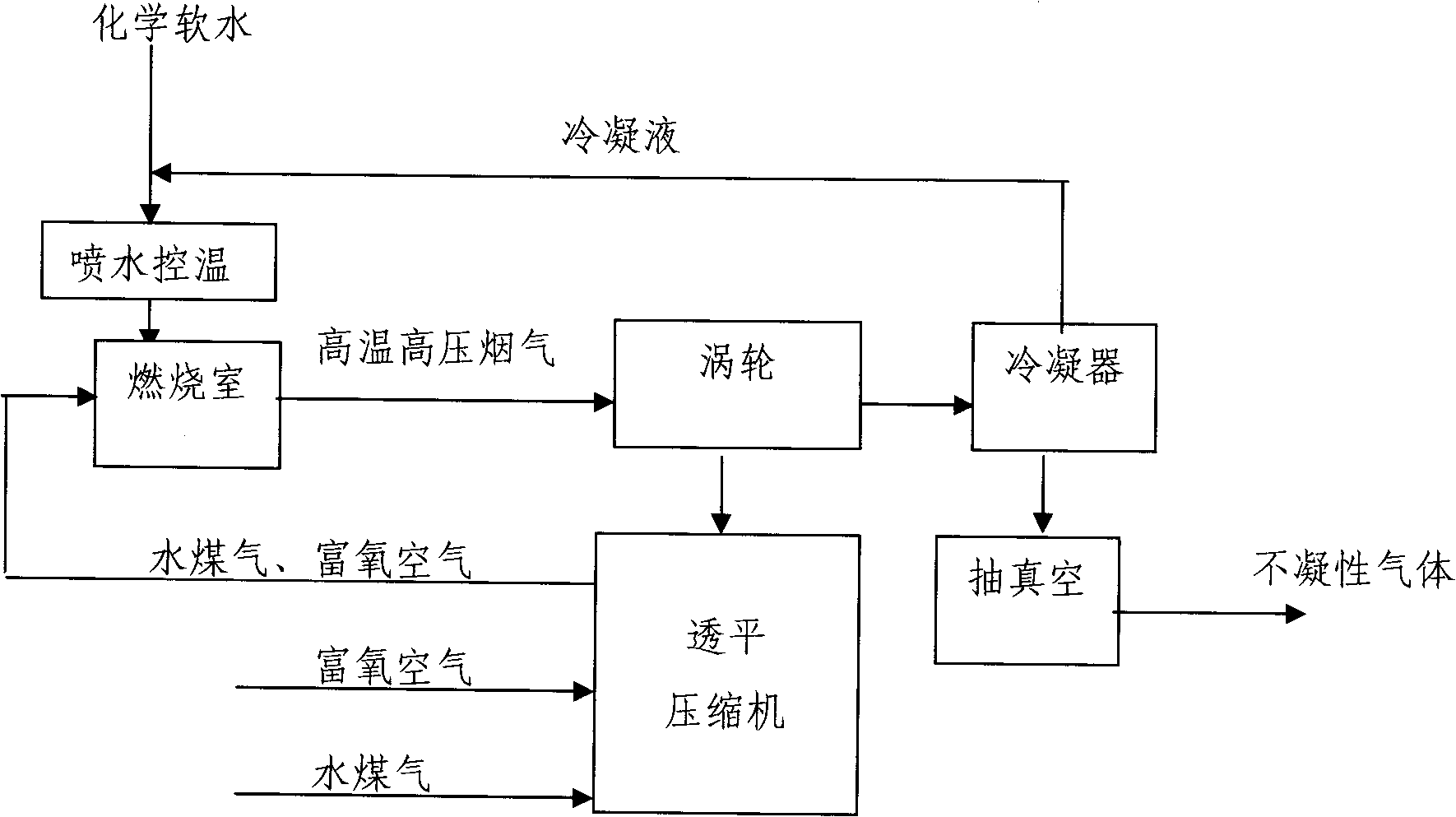

Thermal circulation process of gas turbine based on pure oxygen or oxygen-enriched combustion

InactiveCN101787930AIncrease temperatureIncrease intake pressureTurbine/propulsion engine coolingGas turbine plantsCombustion chamberWater vapor

The invention discloses a thermal circulation process of a gas turbine based on pure oxygen or oxygen-enriched combustion, which comprises the following steps: compressing liquid fuel or gas; compressing oxygen gas or oxygen-enriched air; carrying out mixed combustion of the liquid fuel or the gas and the oxygen gas or the oxygen-enriched air; spraying water for controlling temperature; expanding high temperature and high pressure flue gas after combustion in the gas turbine for applying work; cooling most of water vapor in tail gas with circulating water in a condenser, wherein the condensed water circulates to a combustion chamber to be used for spraying water for controlling temperature, and the non-condensable gas is extracted by a vacuum pump; or exhausting gas under normal pressure without the use of the vacuum pump. By adopting direct combustion of the pure oxygen or the oxygen-enriched air and adopting the water spraying mode to replace excess air for controlling temperature, the air inflow is small, the amount of compression of a compressor is small, the restriction of the optimal pressure gas ratio is eliminated, the circulating intake pressure is improved, the non-condensable gas in the tail gas is little, and the exhaust pressure can be reduced through vacuum condensation. Because the process has high circulating intake pressure and low exhaust pressure, the expansion ratio of the gas turbine is improved, thereby improving the generating efficiency.

Owner:北京名都厚德科技有限公司

Prefabricated skirt type pipe pile used for drainage and added with pile body inclined support and construction method thereof

ActiveCN105256790AImprove bearing capacityReduce settlementBulkheads/pilesSoil preservationStructure of the EarthCrushed stone

The invention discloses a prefabricated skirt type pipe pile used for drainage and added with a pile body inclined support and a construction method thereof. The prefabricated skirt type pipe pile with a perforated pile body is provided with multiple laps of rectangular through hole structures on the side wall at intervals in the axial direction of the pile, wherein the multiple laps of rectangular through hole structures comprise rectangular through holes uniformly distributed in the peripheral direction of the pile body at intervals; prefabricated concrete blocks are hinged and mounted at the tops of the rectangular through holes; and the external of the prefabricated skirt type pipe pile is coated with geotextile. The pipe pile is planted in a soil mass through static pressure; water in soil around the pile is drained after entering an inner pipe through the geotextile and gaps; the prefabricated concrete blocks outwards expand by angles, and the expansion angles are increased through secondary pressing and beating; such fillers as gravels are filled and compacted; and a gravel cushion layer and a grid can be filled back, or a pile bearing table can be arranged after levelness. The pile increases the pile surrounding resistance force through drainage; the concrete blocks are spread to provide lateral support force; the vertical bearing capacity can be greatly improved; the pile body settlement is effectively reduced; and the pile can be suitable for the foundation treatment under complicated geological conditions, can serve as an engineering pile after secondary pressing and beating, is free of construction noise and slurry pollution, and is low in ground disturbance.

Owner:ZHEJIANG UNIV

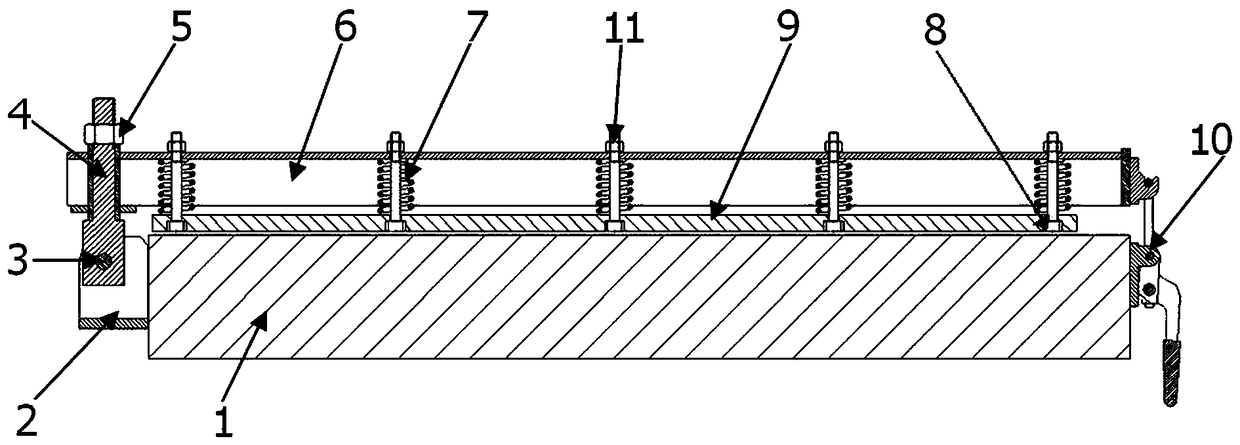

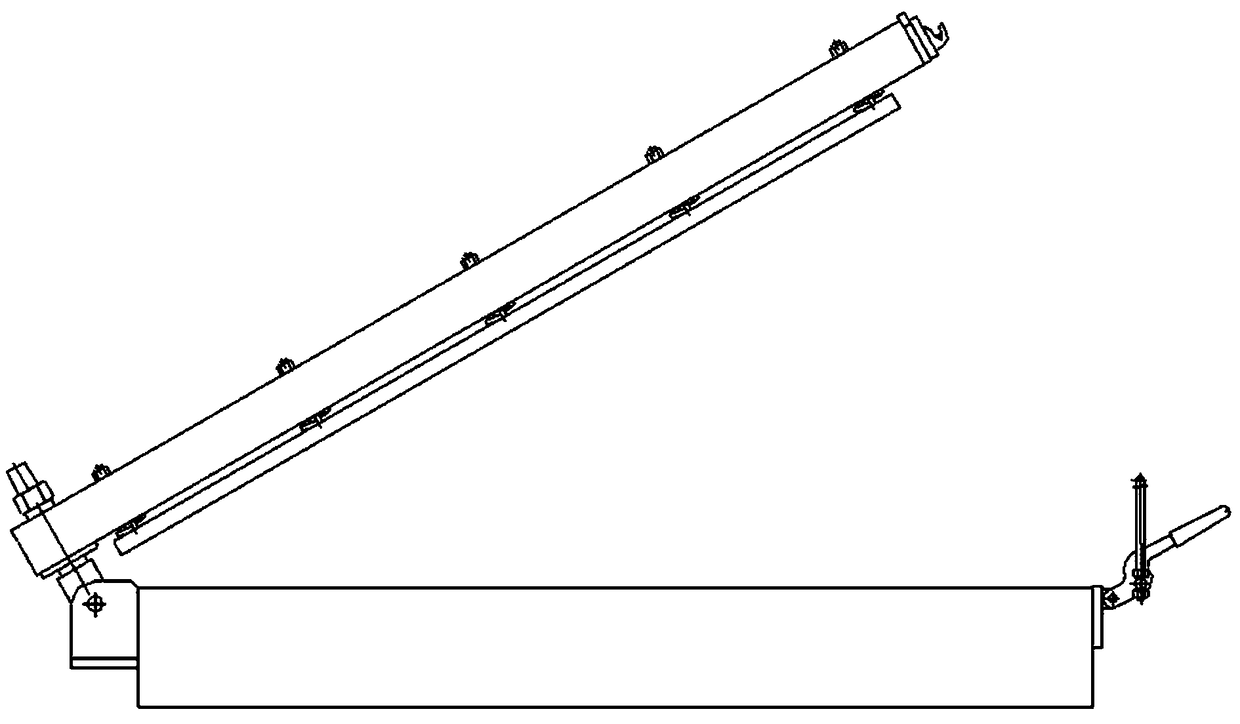

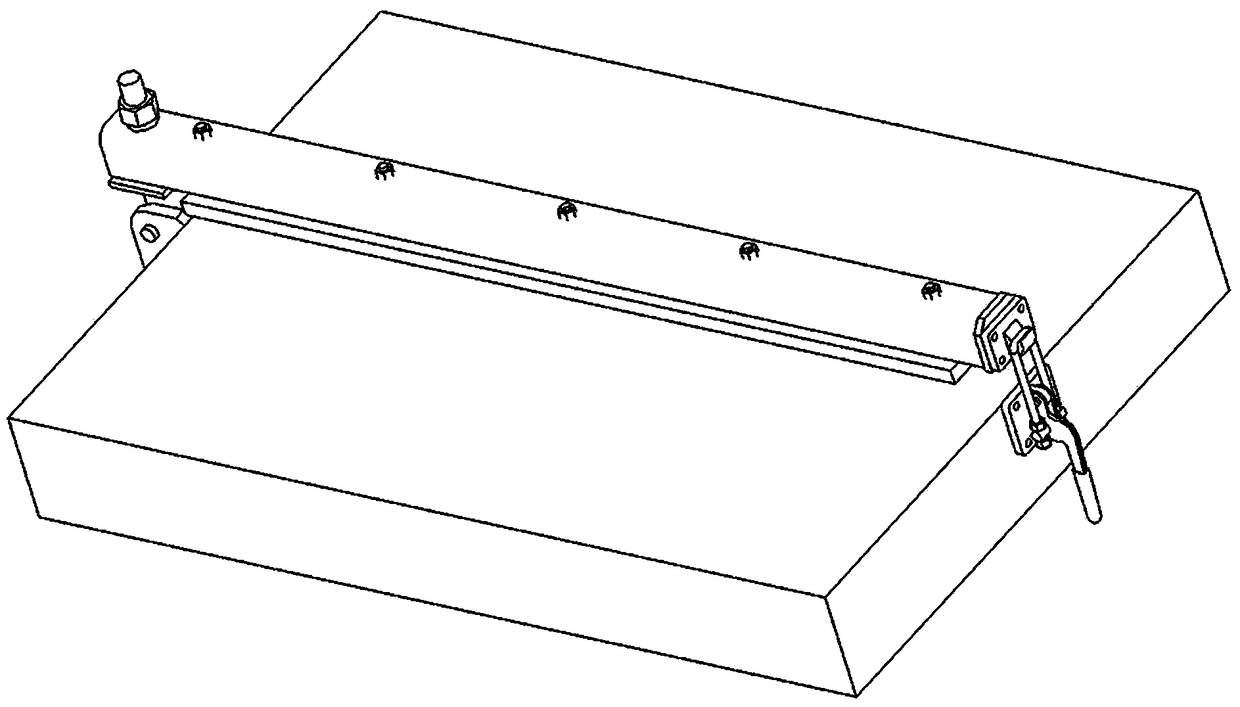

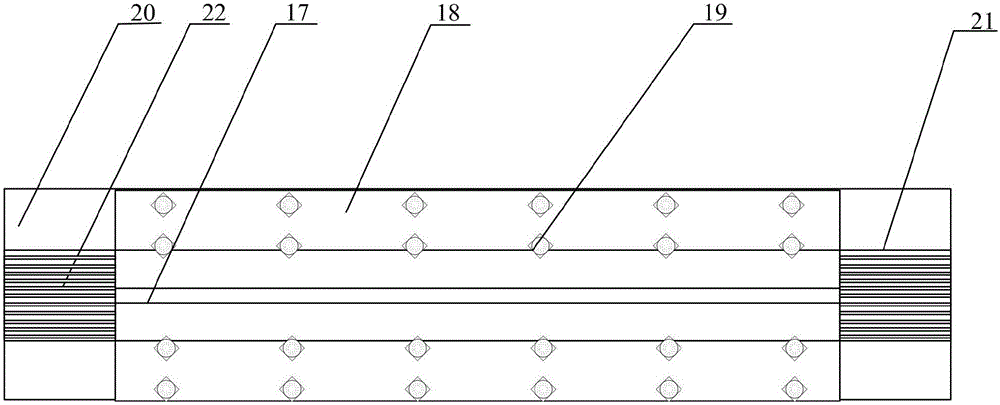

Spring distribution pre-tightening quick pressing mechanism and combined quick pressing mechanism

ActiveCN109382625AUniform pressureEasy clampingWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

The invention discloses a spring distribution pre-tightening quick pressing mechanism and a combined quick pressing mechanism. The spring distribution pre-tightening quick pressing mechanism comprisesa base and a clamp pressing component; one end of the clamp pressing component and the base are connected through a connecting component so that the clamp pressing component can be rotated around theconnecting component to open or close the clamp pressing component, and the clamp pressing component can also rotate around the connecting component to prevent a workpiece from being placed during the clamping; a locking mechanism is disposed on a side of the base opposite the connecting component. When the pressing component is closed, a locking mechanism is used for locking the pressing component, thereby pressing a pressing plate member placed on the base. The mechanism makes plate welding, clamping compact quicker and more convenient, and the pressing of a whole welding seam is more comprehensive and more uniform in force.

Owner:徐工汉云技术股份有限公司

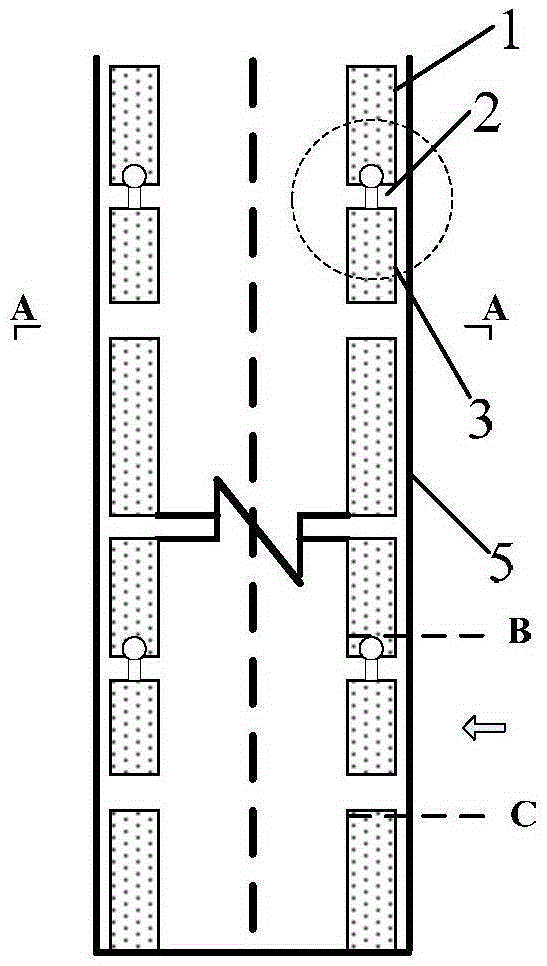

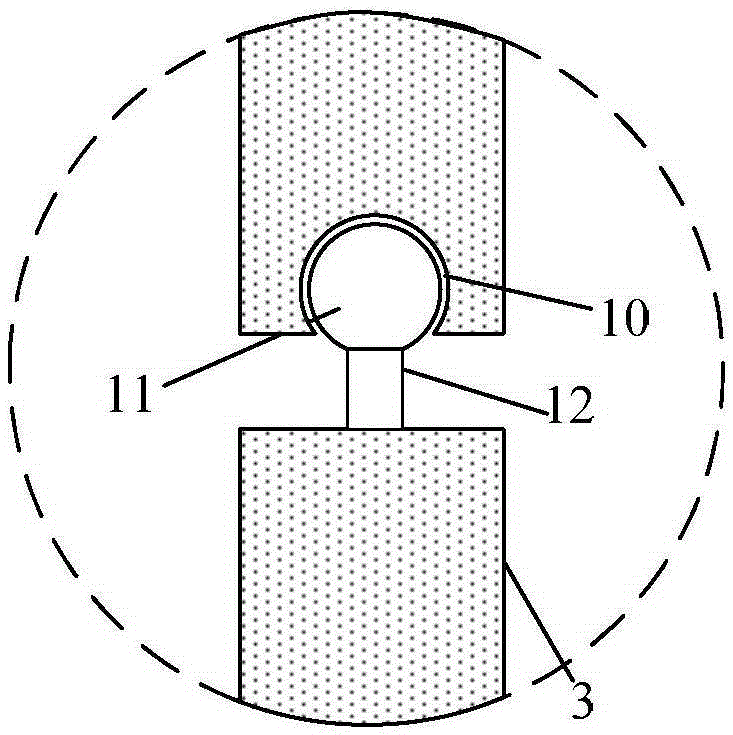

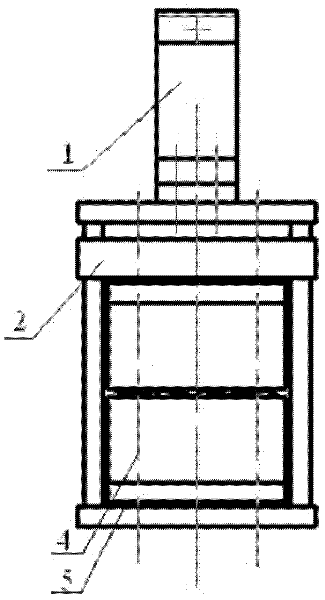

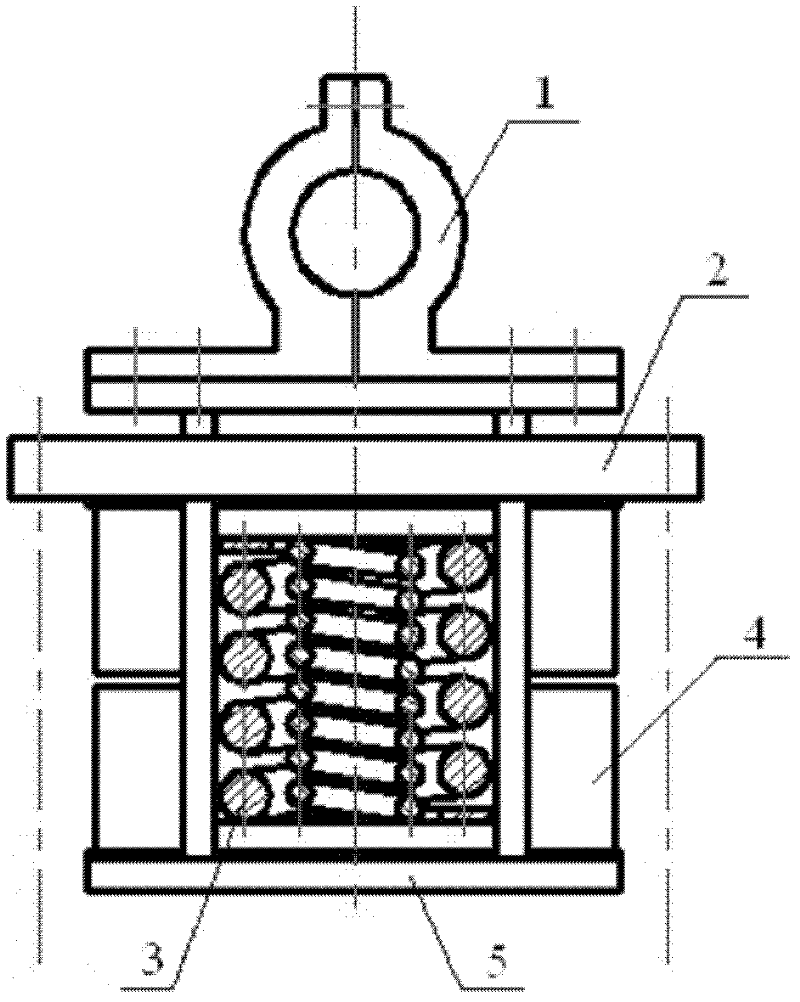

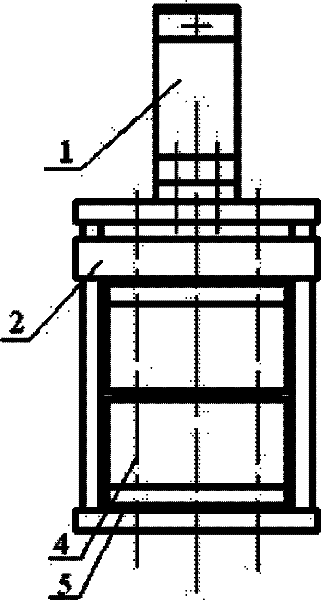

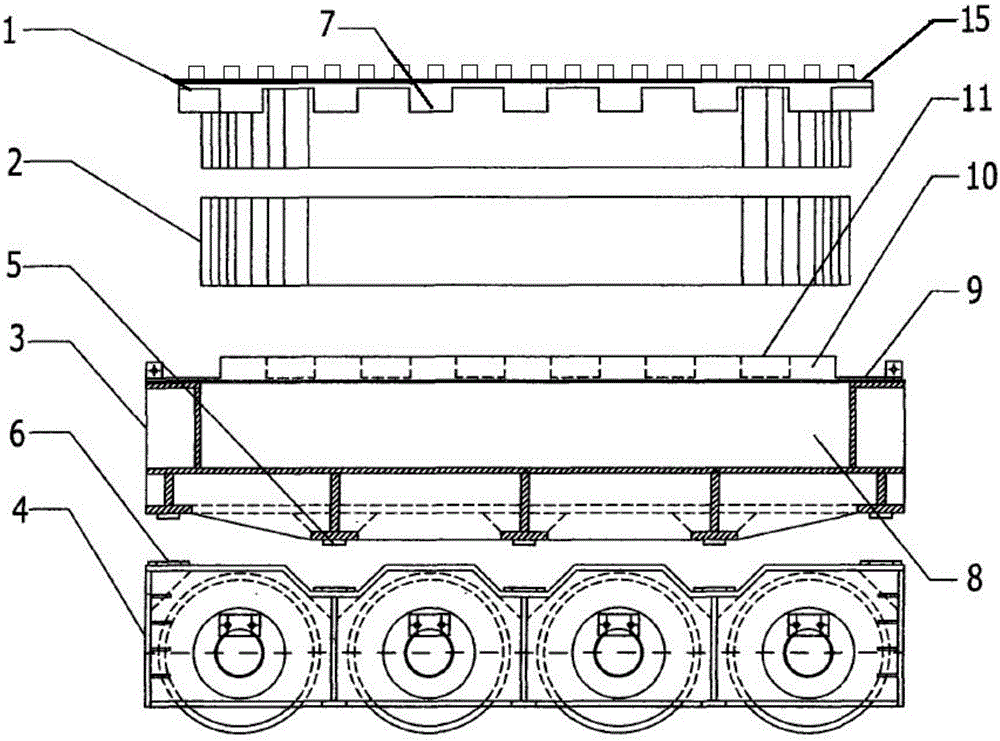

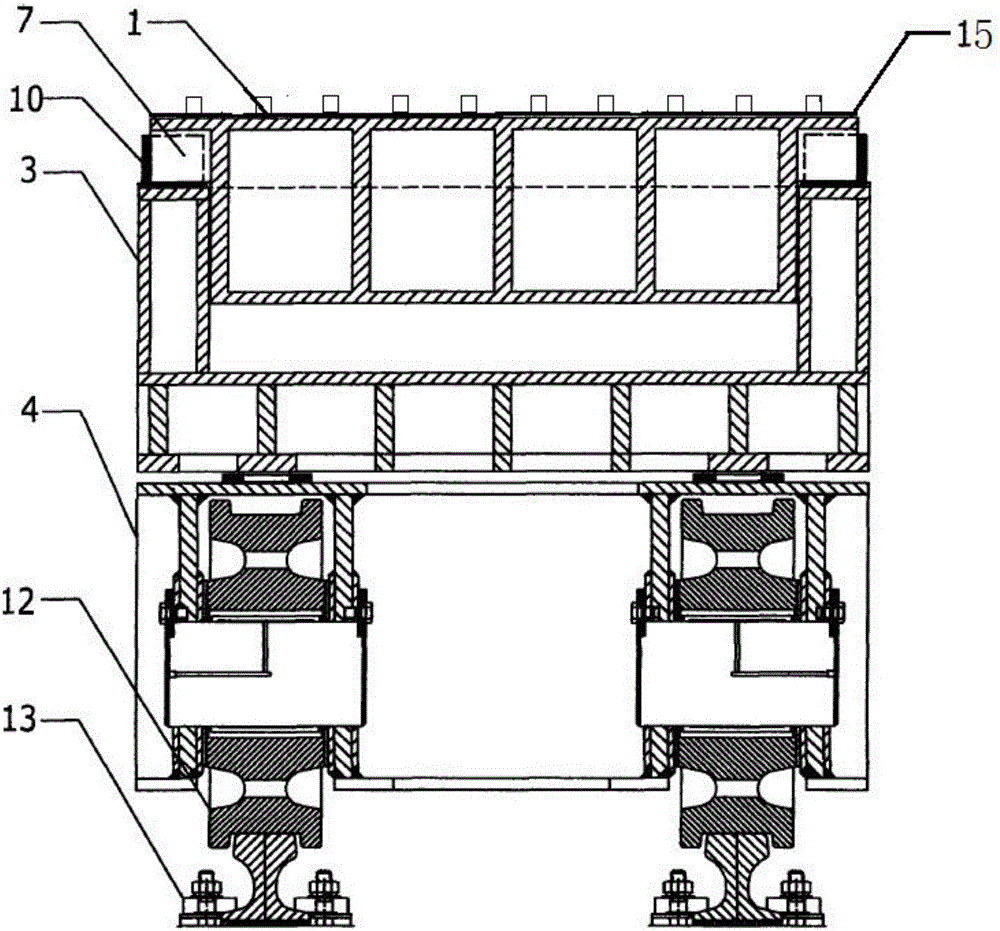

Wheel-rail load-increasing device for railway vehicle

InactiveCN102501873AReduce positive pressureReduce the attachment areaRailway auxillary equipmentPositive pressureElectromagnet

The invention relates to a wheel-rail load-increasing device for a railway vehicle, comprising an axial suspension boom (1), a framework (2), a dual-coil spring (3), an electromagnet and the winding thereof (4) and a magnetically-insulated gasket (5), wherein the axial suspension boom (1) is welded on the top of the framework (2); the framework (2) is a frame-type structure with a hollow middle; the rewinding spring (3) is disposed at the middle of the framework (2); the electromagnet and the winding thereof (4) are disposed at the both sides of the framework (2); and the magnetically-insulated gasket (5) is disposed on the bottom of the framework. Compared with the prior art, the wheel-rail load-increasing device for a railway vehicle disclosed by the invention can improve climbing capacity and change the positive pressure on steel rail by wheel set when the vehicle runs in upward slope, downward slope and flat slope, thereby freely changing the traction of the vehicle and enabling the vehicle to be of high service life and safety.

Owner:TONGJI UNIV

Rubber-bag trolley jacking device and method for jacking and transporting caisson

ActiveCN105019467AReduce safe movementEnsure transportation safetyCaissonsEngineeringPressure difference

The invention relates to a trolley jacking device, and in particular to a rubber-bag trolley jacking device and a method for jacking and transporting caisson. The jacking device is provided with a multi-column-shaped force-regulating rubber base plate to regulate the pressure difference between the bottom face of the caisson and the bottom face of a cover plate making contact with the top faces of trolleys, reduce the pressure differences among all the trolleys and guarantee that stress of all the trolleys is within the range of ultimate bearing capacity, and it is guaranteed that the caisson is transported safely. The multi-column-shaped force-regulating rubber base plate is internally provided with internal reinforcing ribs and external reinforcing ribs, so that the elasticity of the multi-column-shaped force-regulating rubber base plate is improved, the amount of compression of the multi-column-shaped force-regulating rubber base plate at the ultimate pressure value is reduced, and the service life of the multi-column-shaped force-regulating rubber base plate is greatly prolonged.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HARBOR ENG

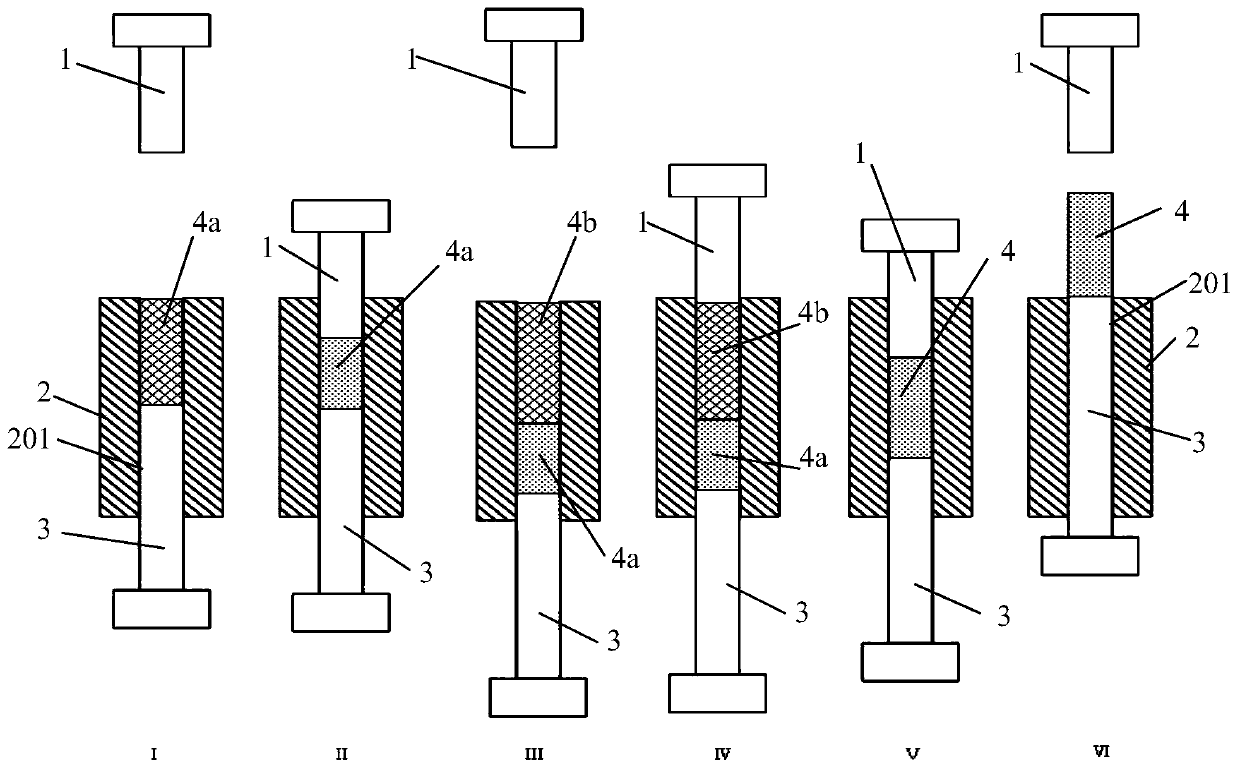

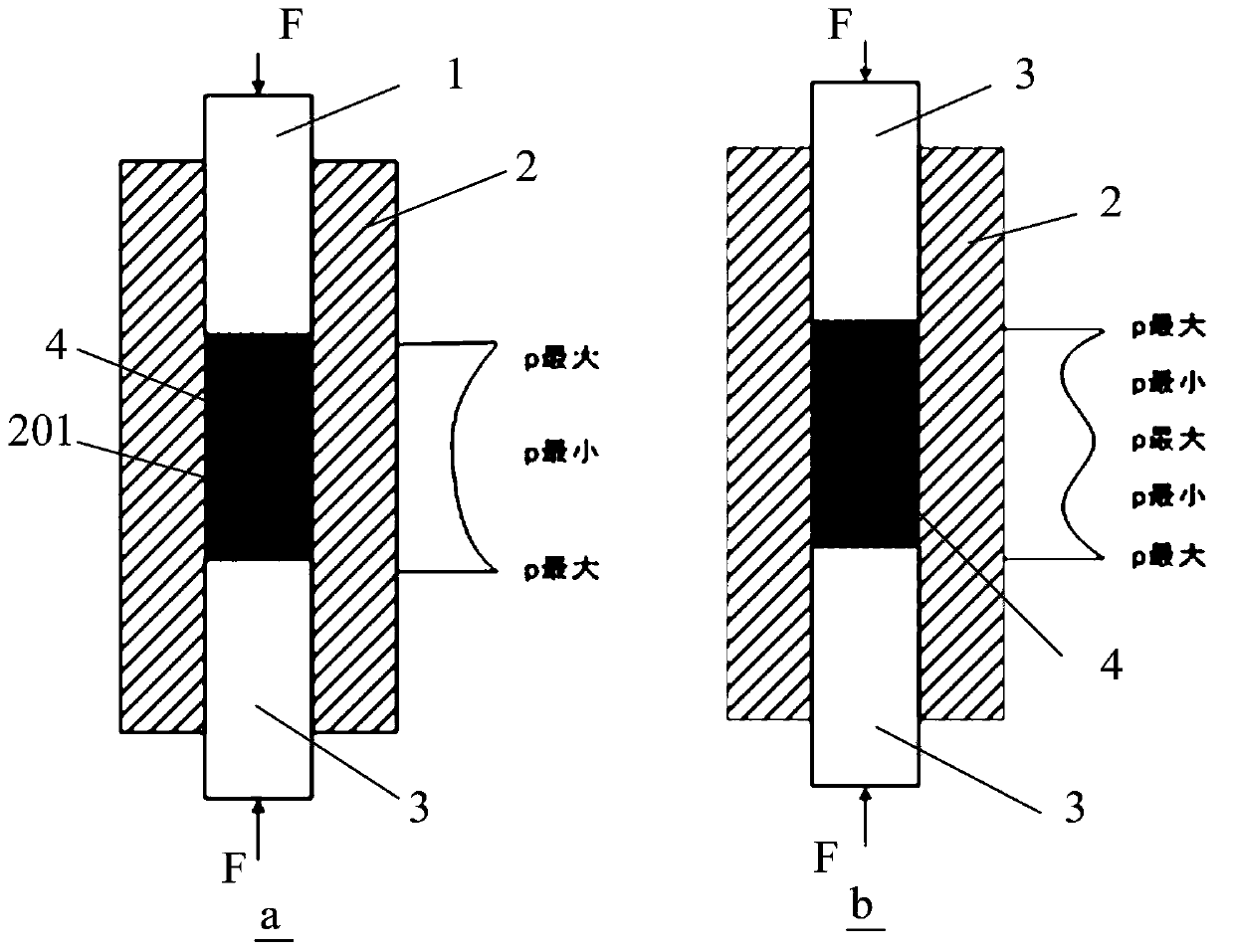

Forming method and forming device for powder metallurgy part

The invention discloses a forming method and a forming device for a powder metallurgy part. The method comprises the steps of: first pressing, final pressing, mold stripping and sintering, the formingdevice comprises an upper plunger, a female die and a lower plunger, the female die is provided with a female die cavity for containing powder, the upper plunger comprises an upper die holder and anupper die stamping piece, the lower plunger comprises a lower die holder and a lower die stamping piece, and the upper die stamping piece and the lower die stamping piece can penetrate into the femaledie cavity to press the powder. A powder part processed by the method and the device has good compactness, the initial density in the middle is increased effectively, the overall density is increased, the relative density difference value is reduced, and the overall green body performance is improved.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

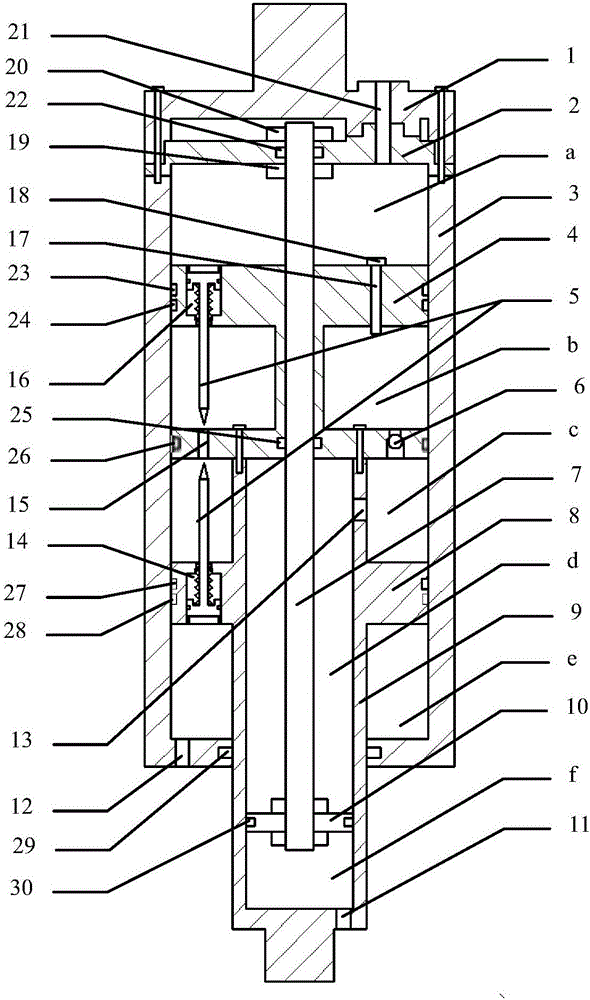

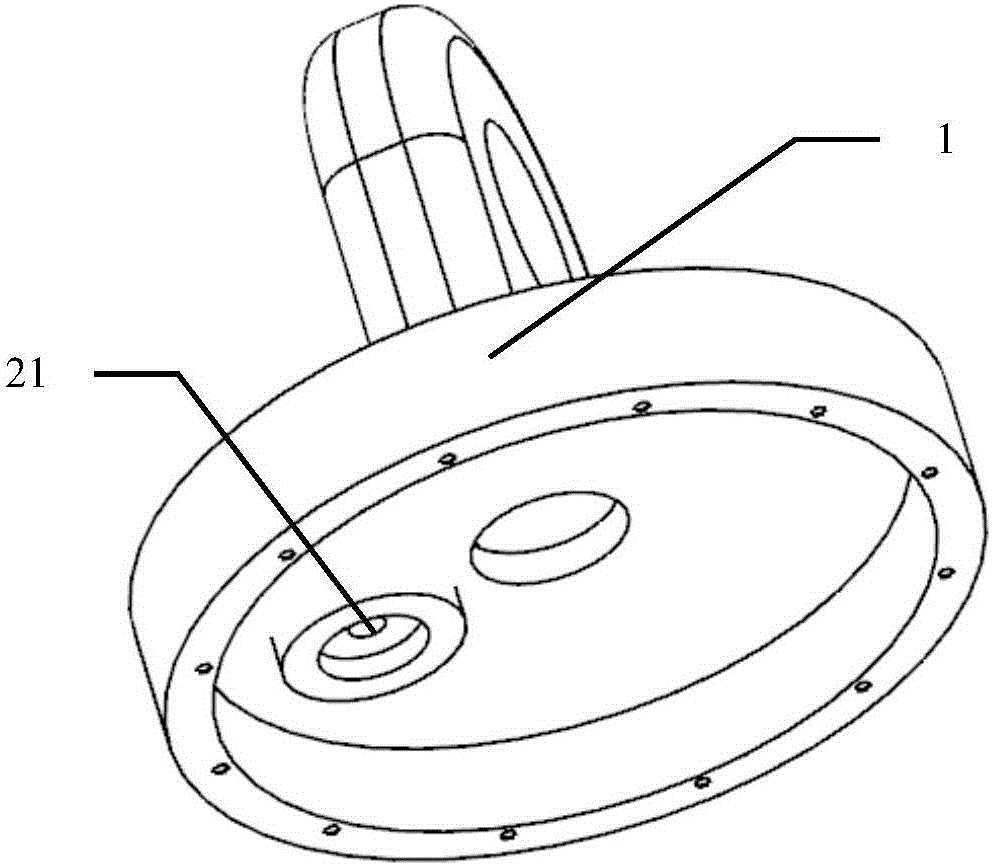

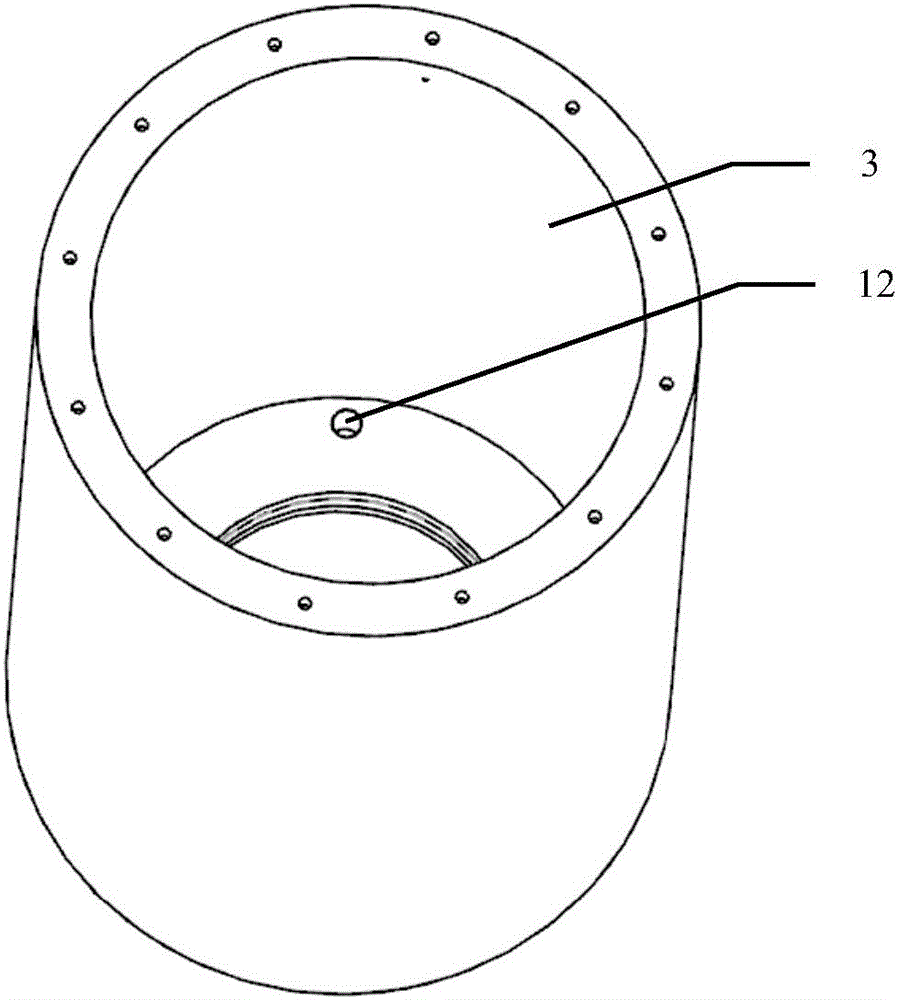

Multiple operating condition damping self-adaption hydro-pneumatic spring and control method thereof

ActiveCN106523574ASatisfy ride comfortImprove driving stabilitySpringsLiquid based dampersBody rollControl theory

The invention provides a multiple operating condition damping self-adaption hydro-pneumatic spring and a control method thereof. The multiple operating condition damping self-adaption hydro-pneumatic spring mainly comprises a cylinder barrel, a pull rod, a pull rod piston, a rod barrel, a cylinder barrel piston and a rod barrel piston. The pull rod is fixed in the cylinder barrel, the upper end of the pull rod is fixed on the top of the cylinder barrel, and the pull rod piston is fixed to the lower end of the pull rod; the pull rod piston is arranged in the rod barrel to form a first piston structure, the cylinder barrel piston is connected to the upper end of the rod barrel, and an upper end opening of the rod barrel is sealed by the lower end face of the cylinder barrel piston; and a second piston structure is formed by the cylinder barrel piston and the cylinder barrel, the rod barrel piston is further arranged on the outer wall of the rod barrel, and a third piston structure is formed by the rod barrel, the rod barrel piston and the cylinder barrel. According to the multiple operating condition damping self-adaption hydro-pneumatic spring and the control method thereof, the demand that the natural frequency of a car body is basically changeless under the condition that a car is in different loading operating conditions is met, and heeling and pitching vibration of the car body owing to the typical limiting conditions of the car such as emergency braking and corner turning at a high speed can be effectively restrained and attenuated on the basis that car riding comfort is met, so that the demand of car riding stability is met.

Owner:HUNAN UNIV

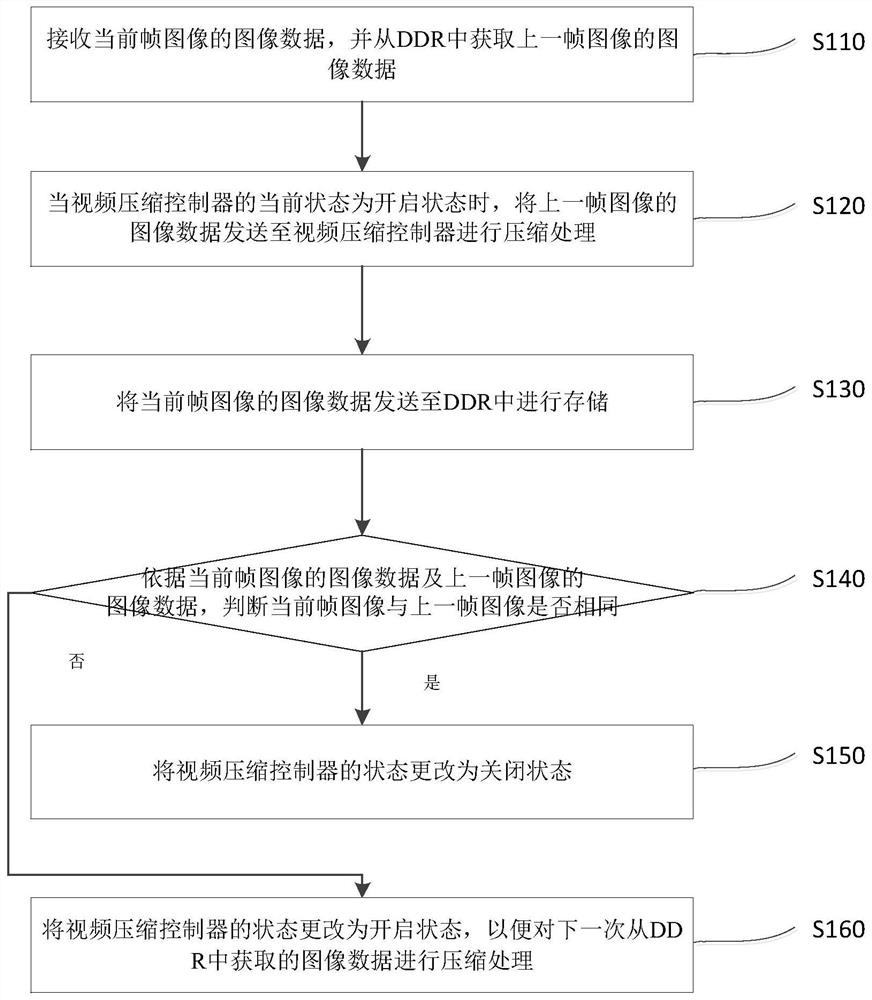

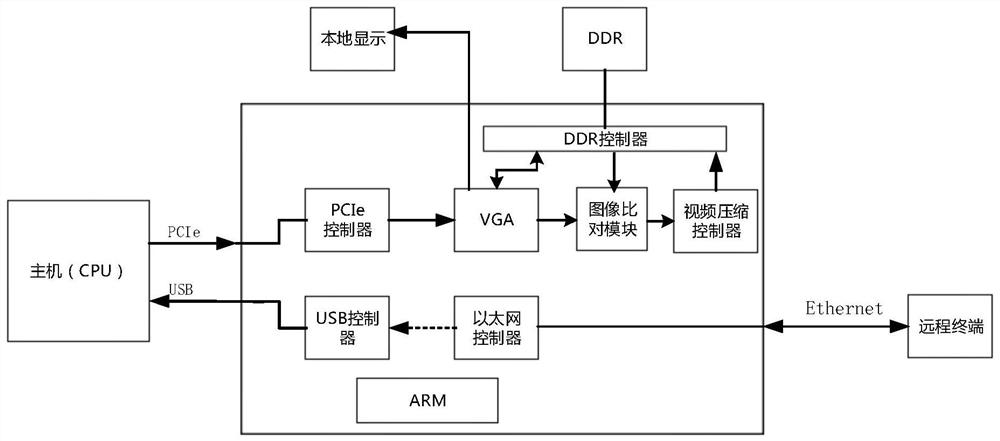

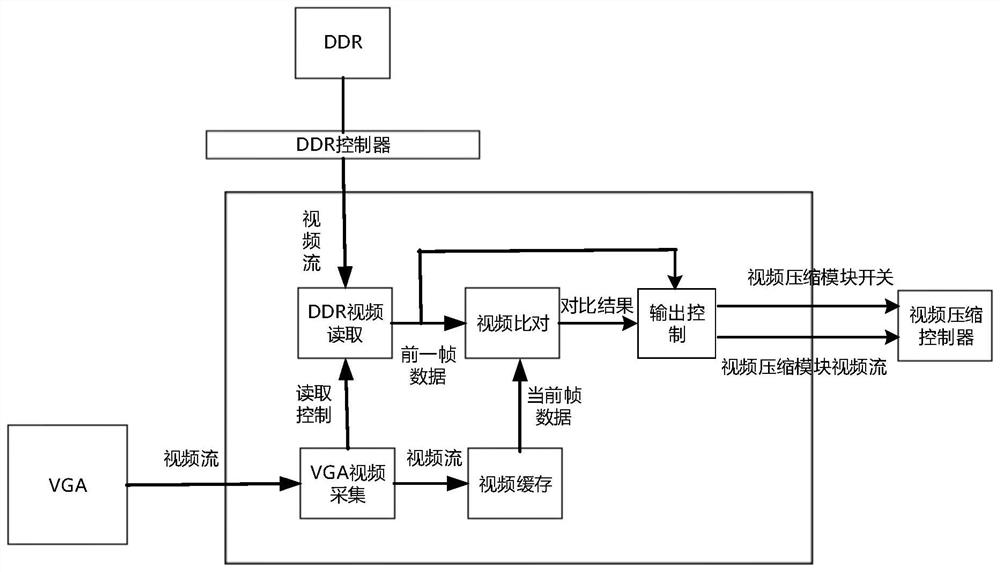

Video compression method, device and system and medium

PendingCN113709490ASmall amount of compressionLower latencyDigital video signal modificationData compressionComputer graphics (images)

The invention discloses a video compression method, device and system and a computer readable storage medium, and the method comprises the steps: receiving the image data of a current frame image, and obtaining the image data of a previous frame image from a DDR; when the current state of the video compression controller is an on state, sending image data of a previous frame of image to the video compression controller for compression processing; sending the image data of the current frame image to the DDR for storage; judging whether the current frame image is the same as the previous frame image or not according to the image data of the current frame image and the image data of the previous frame image, and if yes, changing the state of the video compression controller into a closed state; and if not, changing the state of the video compression controller into an open state, so as to compress the image data acquired from the DDR next time. In the using process, the data compression amount can be reduced, the network bandwidth and the video transmission delay are reduced, and the overall power consumption is reduced.

Owner:SHANDONG YUNHAI GUOCHUANG CLOUD COMPUTING EQUIP IND INNOVATION CENT CO LTD

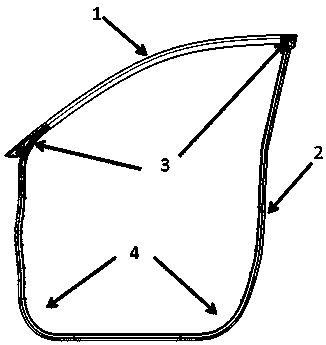

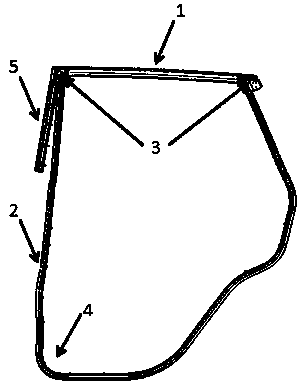

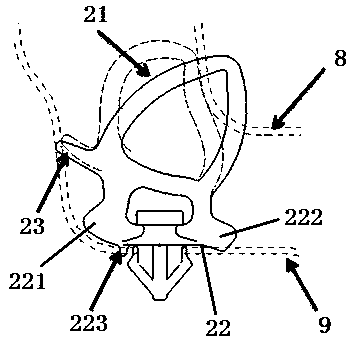

Automobile door frame sealing structure

InactiveCN108081934AIncrease ballastSmall amount of compressionEngine sealsVehicle sealing arrangementsEngineeringCar door

The invention provides an automobile door frame sealing structure. The collapse of a sealing strip lower straight section at a corner R can be reduced, the sealing effect of the sealing strip can be guaranteed, the sound leakage can be reduced, the compression amount of a sealing strip supporting frame structure can be reduced and the door opening and closing sound quality can be improved. The automobile door frame sealing structure comprises a sealing strip top straight section and a sealing strip lower straight section; the two ends of the sealing strip top straight section are connected with the sealing strip lower straight section through sealing strip connecting angles; the section of the sealing strip lower straight section comprises a triangular frame-shaped supporting part; the bottom edge of the triangular frame-shaped supporting part is connected with a sealing strip lower straight section clamping part; one end of the bottom edge of the triangular frame-shaped supporting part is transversely connected with a first sealing lip; and the two ends of the sealing strip lower straight section clamping part are respectively a first clamping convex part and a second clamping convex part.

Owner:CHERY AUTOMOBILE CO LTD

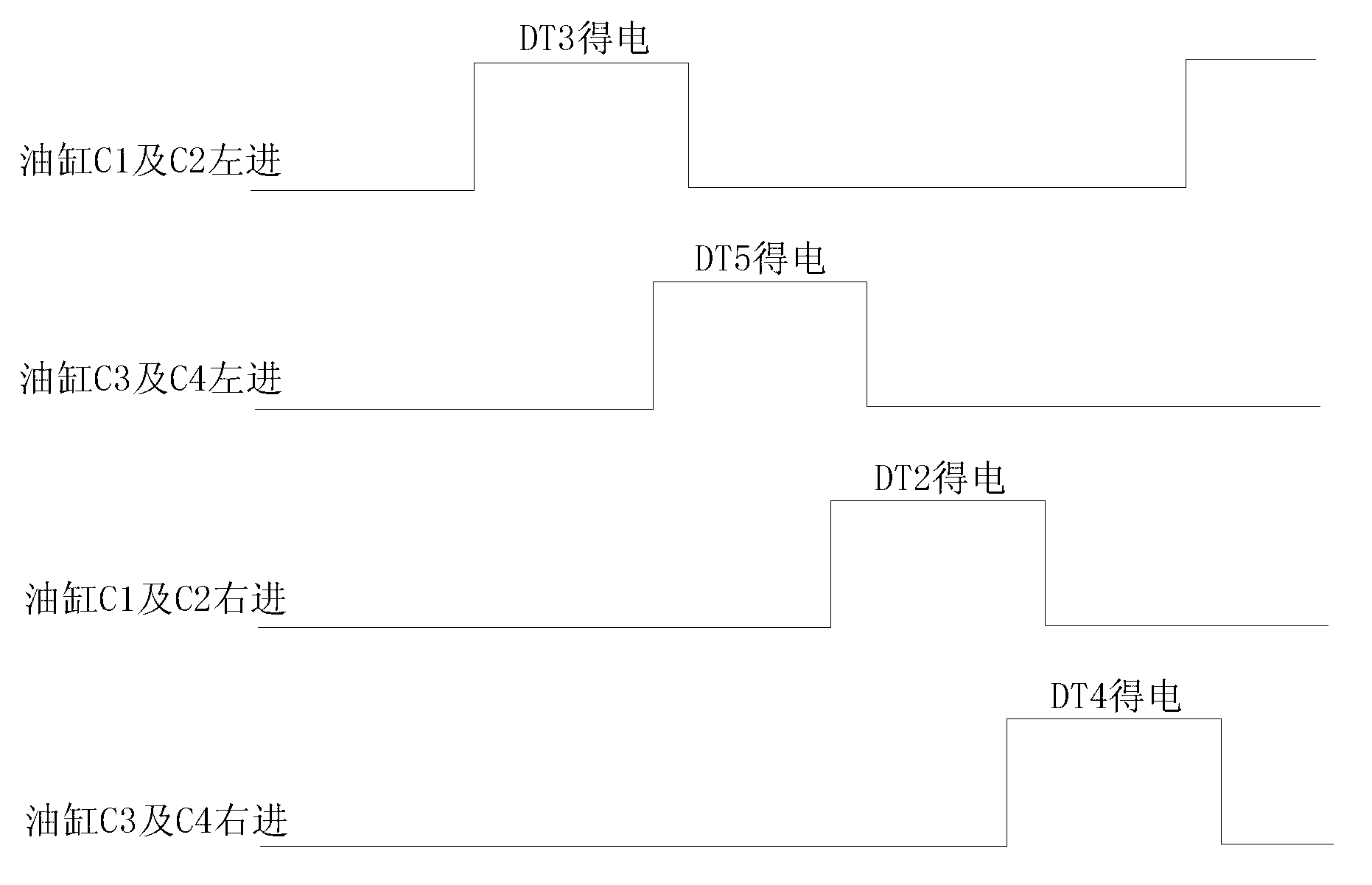

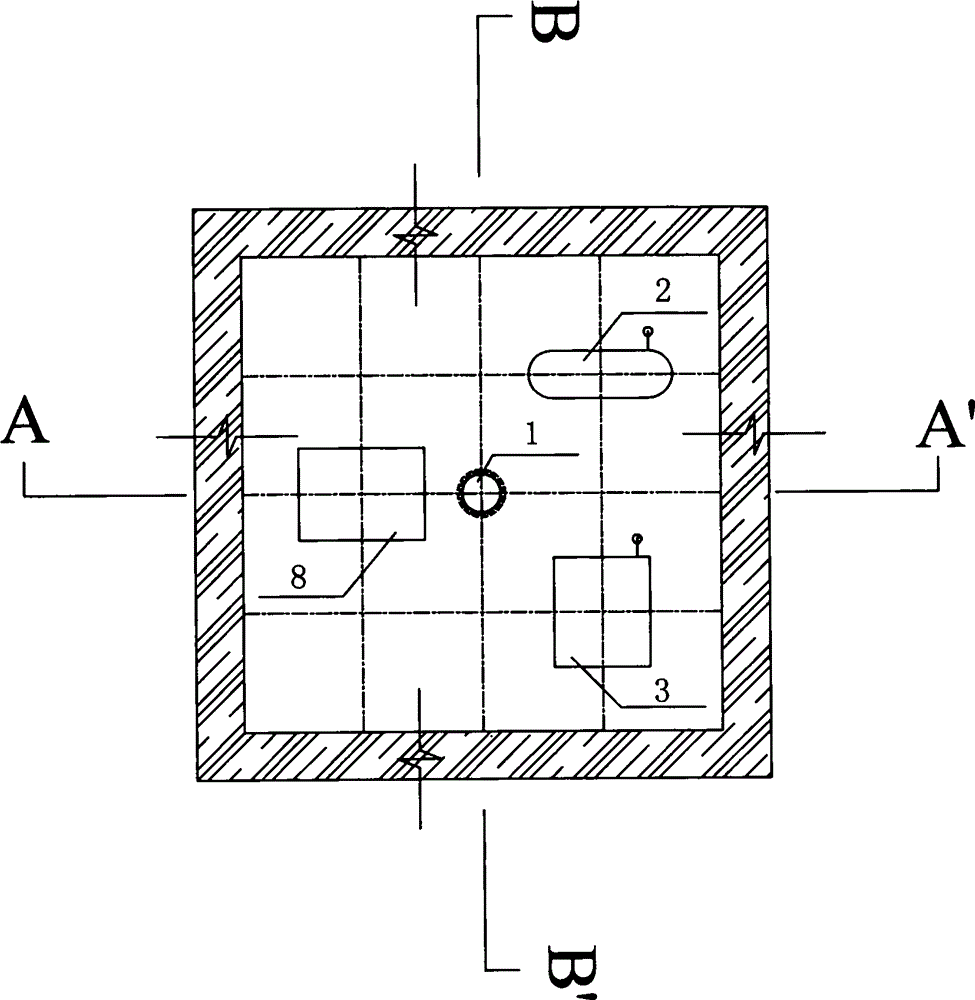

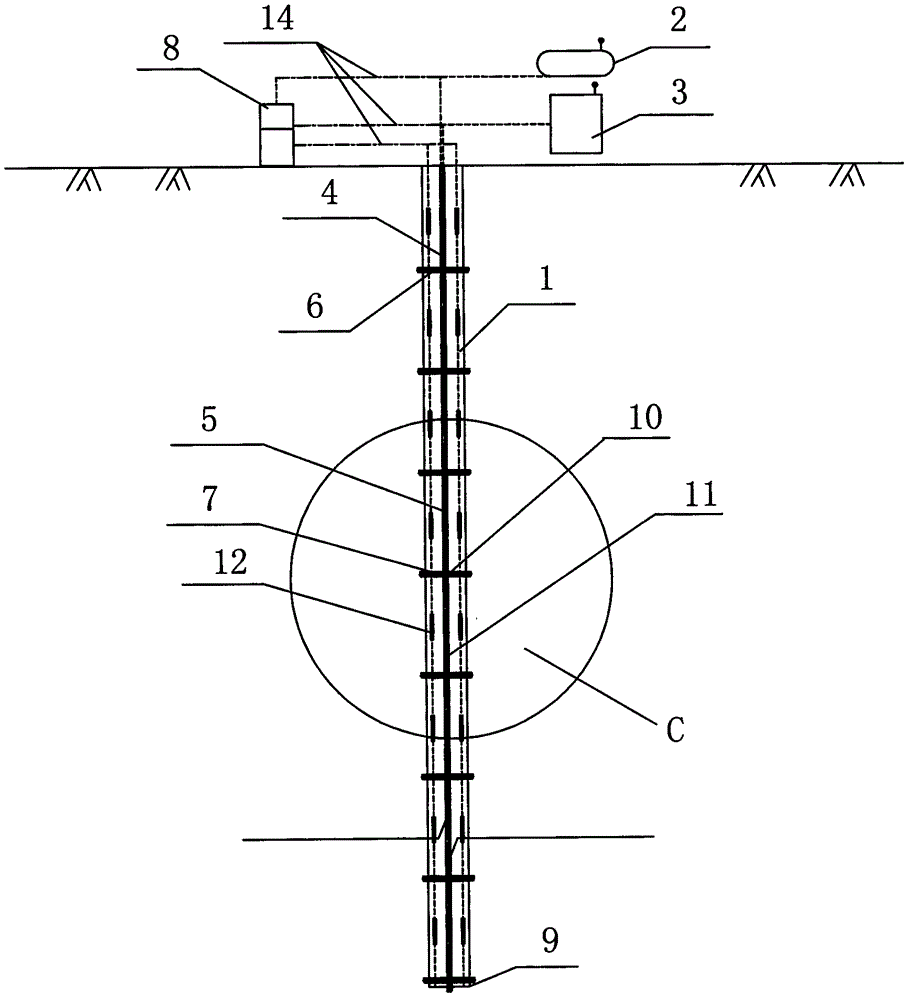

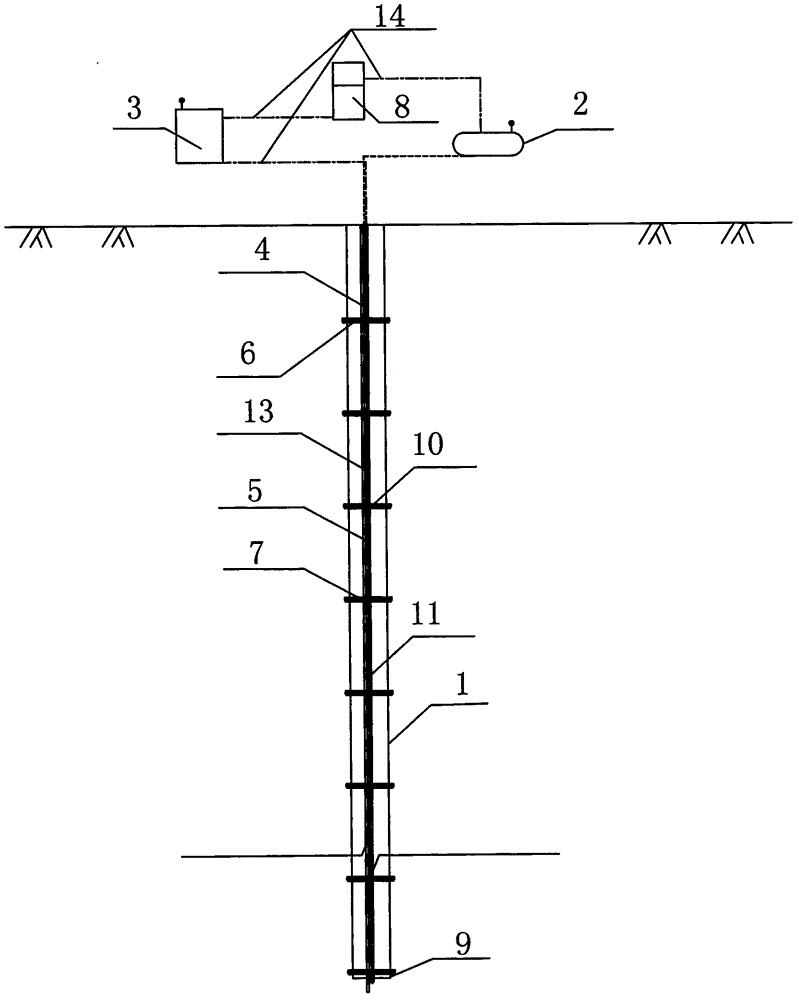

Continuous material feeding system and control method and elevating platform fire truck thereof

The invention discloses a continuous material feeding system and a control method and an elevating platform fire truck thereof. The control method includes the following steps: A. enabling a piston of a first pump material device to move towards a first limit position of the first pump material device; B. enabling a piston of a second pump material device to move towards the first limit position of the second pump material device before the piston of the first pump material device reaches the first limit position; C. enabling the piston of the first pump material device to move from the first limit position to the second limit position of the first pump material device before the piston of the second pump material device reaches the first limit position of the second pump material device; D. enabling the piston of the second pump material device to move from the first limit position to the second limit position of the second pump material device before the piston of the first pump material device reaches the second limit position of the first pump material device; and E. returning to the step A before the piston of the second pump material device reaches the second limit position of the second pump material device. By means of the system, the method and the truck, driving devices of the two pump material devices can change direction in staggering mode (namely the actions of the two driving devices have certain coincidence area), and flow fluctuation of material outlets is avoided.

Owner:SANY AUTOMOBILE MFG CO LTD

Device for regulating and controlling contact and interaction between pile and earth

InactiveCN104631452AEngineering safety and controllabilityReduce negative frictionBulkheads/pilesJoint workingStructural engineering

The invention discloses a device for regulating and controlling contact and interaction between a pile and earth. The device comprises a negative pressure pump, a grouting pump and a pile body embedded in a selected region. The device is structurally characterized in that a main negative pressure pipeline and a main grouting pipeline are arranged in the pile body or on the surface of the pile body, wherein the main negative pressure pipeline is connected with the negative pressure pump, and the main grouting pipeline is connected with the grouting pump; the device is further provided with a plurality of branch negative pressure pipelines distributed at intervals and a plurality of branch grouting pipelines distributed at intervals, wherein the branch negative pressure pipelines are communicated with the main negative pressure pipeline, and the branch grouting pipelines are communicated with the main grouting pipeline; a valve can be arranged in each branch grouting pipeline, and a plug can be arranged in the main grouting pipeline; deformation sensors and stress sensors can be further arranged in the pile body, wherein the deformation sensors and the stress sensors are connected with a monitoring station. The device has the advantages that opening and closing of the contact surface between the pile and the earth can be flexibly controlled, the stress condition of the end of the pile can be effectively controlled, stress and deformation of the pile body can be flexibly adjusted, and the device can effectively cooperate with the pile and the earth to work together.

Owner:刘林松

Guy rope dropping connector

InactiveCN102544883BStable structureReduced strength requirementsCoupling device detailsScrew threadSpare part

The invention relates to a guy rope dropping connector which comprises a connector casing. Pull-out casings are arranged at front and rear limiting sliding sleeves on the periphery of the connector casing; a return spring for driving the pull-out casing to move forward is formed between the pull-out casing and the connector casing; a thread connecting sleeve positioned at the front part of the connector casing is arranged between the connector casing and the pull-out casing; the thread connecting sleeve is axially shifted and assembled on the connector casing; internal threads used for being matched with and locked with external threads at the front end of an adaptive connector is formed in the front section of the thread connecting sleeve; an axial through slot dividing the thread connecting sleeve into at least two parts are formed on the peripheral wall of the thread connecting sleeve; the rear part of an inner hole of the pull-out casing is matched with the rear section of the thread connecting sleeve, so as to ensure that all parts of the thread connecting sleeve are at retract state; and the front part of the inner hole of the pull-out casing is banded and matched with the thread connecting sleeve. The thread connecting sleeve is a spare part, after the pull-out casing moves backwards, expansion amount can be produced in the radial direction, a conical section is not required to be provided, and the thread connecting sleeve is short.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

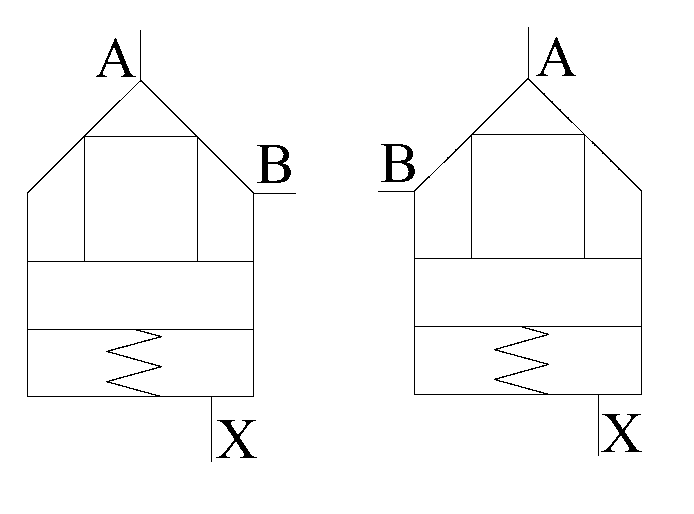

Overload valve

ActiveCN102734249AImprove reliabilityExtended service lifeServomotor componentsFatigue damageEngineering

The invention discloses an overload valve, which comprises a valve body, a valve seat, a valve core and a spring, wherein an oil inlet cavity, an oil return cavity and a valve seat hole are arranged on the valve body; the valve seat is movably sleeved inside the valve seat hole and has a first moving stroke; the valve seat comprises an oil inlet hole communicated with the oil inlet cavity and the oil return cavity; and the spring props against the valve core and can drive the valve core to prop against the valve seat so as to block the oil inlet hole; the valve core has a second moving stroke, and the length of the second moving stroke is greater than that of the first moving stroke. Compared with the prior art, the overload valve is simple in structure, small in spring compression and not easy to generate fatigue damage; the impact of the valve core on the valve seat is relatively small when the overload valve is closed; abrasion of the valve core and the valve seat are greatly reduced, and the reliability and the service life of the overload valve can be greatly improved.

Owner:浙江高宇液压机电有限公司

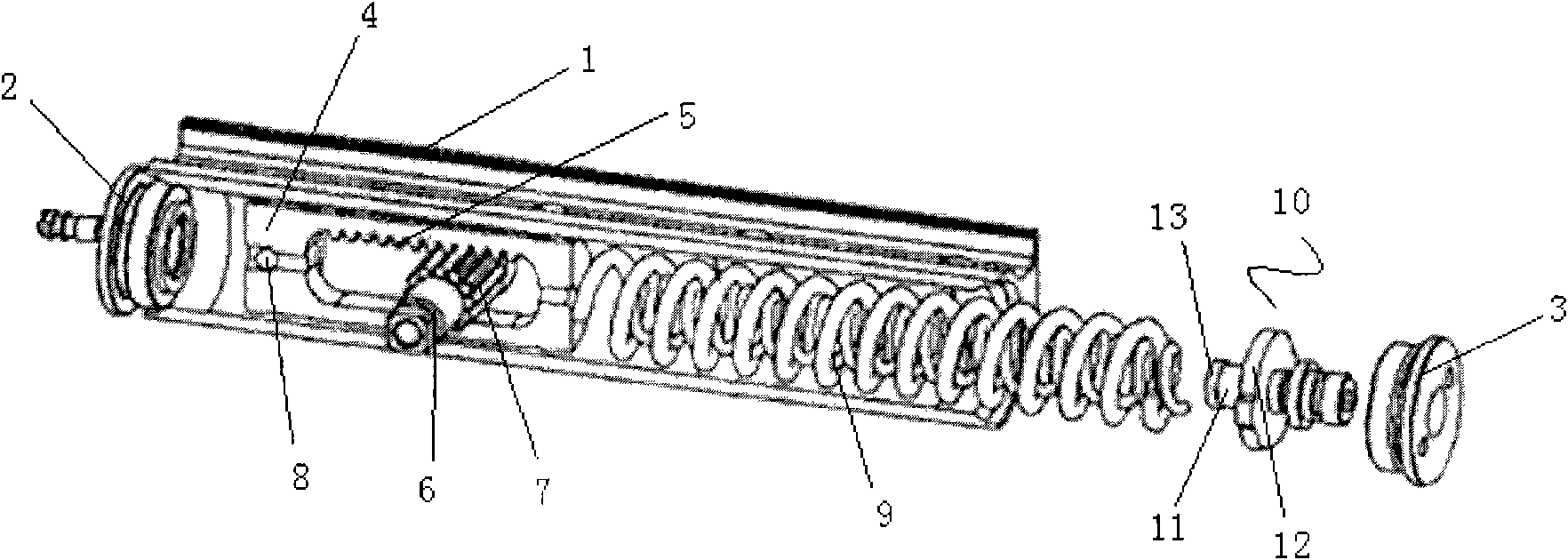

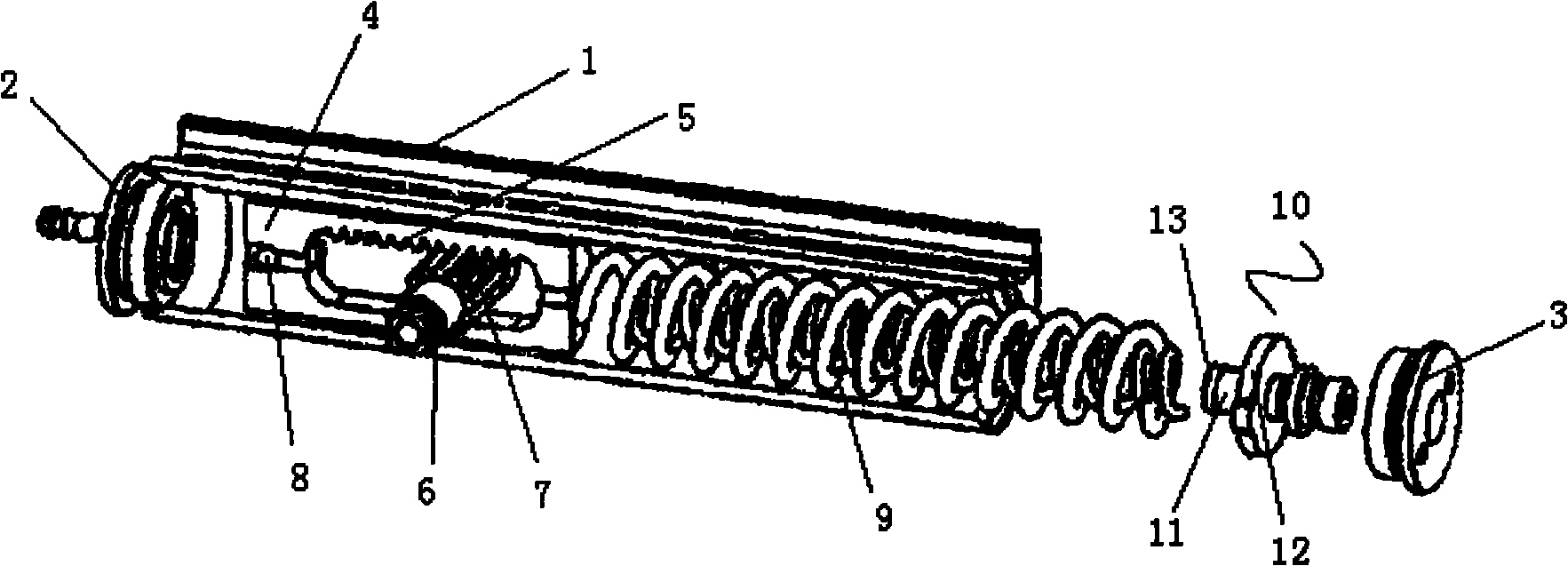

Door closer hydraulic mechanism for fine regulating door-closing power

InactiveCN102182377ASmall amount of compressionReduce closing forceBuilding braking devicesEngineeringSteel ball

The invention discloses a hydraulic mechanism of a door closer. The hydraulic mechanism comprises a cylindrical valve body. Two ends of the valve body are provided with a front end cover and a rear end cover respectively; a rack piston is arranged in a valve chamber of the valve body; the inner wall of the rack piston is provided with a rack; a gear shaft is arranged in a through hole passing through walls of the valve body and the rack piston; the gear shaft is provided with a transmission gear, and the transmission gear is meshed with the rack; the left end of the rack piston is provided with a check valve steel ball; the right end of the rack piston is connected with a compression spring arranged in the right chamber of the valve body; and a power regulator for fine door-closing power is arranged between the rear end cover at the right end of the valve body and the compression spring. The hydraulic mechanism has a function of finely regulating completely satisfactory door-closing power of a user with no limit, so the same door closer can be applicable to different door widths and door weights.

Owner:ZHAOQING CITY ZHISHENG DOOR CONTROL HARDWARE CO LTD

Constant pressure full-balanced type floating side plate

ActiveCN101571123AImprove friction pair formationSmall amount of compressionMachines/enginesRotary/oscillating piston pump componentsEngineeringLow-pressure area

The invention discloses a constant pressure full-balanced type floating side plate, the back of which is separated into a high pressure side and a low pressure side by a sealing ring groove. The floating side plate is characterized in that the surface of the high pressure side at the back of the side plate is provided with a pressure equalizing groove; a pressure guide groove which is used for leading high pressure oil at the back of the side plate into a low pressure area of a gear oil pump and is communicated with the pressure equalizing groove is arranged at a low pressure area of the circumference surface of the side plate along the axial direction; the periphery outside the front of the side plate is a right-angle form without chamfer angle. The invention can effectively improve the performance and the reliability of the gear oil pump and prolong the service life thereof.

Owner:HEFEI CHANGYUAN HYDRAULICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com