Visual detection method for mechanical component defect

A technology of mechanical parts and visual inspection, applied in the field of visual inspection, can solve the problems of human error, reduce measurement accuracy, increase production cycle, etc., achieve the effect of reducing the amount of data, simple processing, and small amount of processing and compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

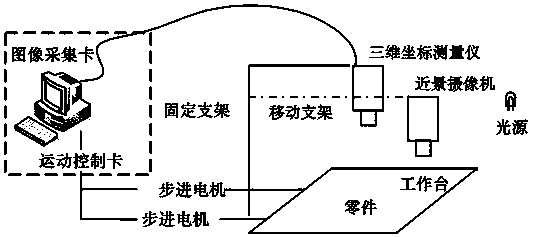

[0047] The present invention and its specific implementations will be described in further detail below in conjunction with the accompanying drawings.

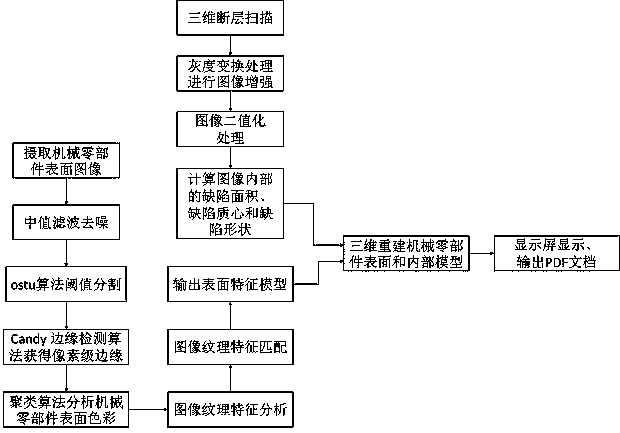

[0048] A visual inspection method for defects in mechanical parts, the method comprising:

[0049] Use a 3D coordinate measuring instrument and a close-range camera to perform 3D scanning and close-range photography on the surface of mechanical parts and store the images;

[0050] The median filtering method is used to denoise the noise and reflective areas that affect the image features, and the image is binarized by threshold automatic segmentation through the ostu algorithm;

[0051] First use the Candy edge detection algorithm to obtain pixel-level edges, and then use the spatial matrix edge location method to use the two-dimensional space gray matrix to determine the edge sub-pixels of the edge position to refine the edge, and then refine the edge location accuracy from coarse to fine. into the interior of the pixel to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com