Wheel-rail load-increasing device for railway vehicle

A rail vehicle, wheel rail technology, applied in the field of rail vehicle wheel rail loading device, can solve the problems of large rubber deformation hysteresis effect, large rolling resistance, small bearing capacity, etc. The effect of the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

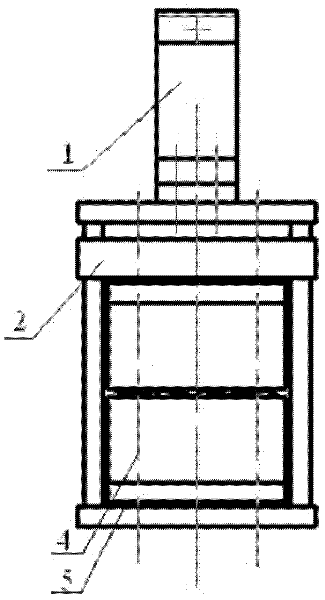

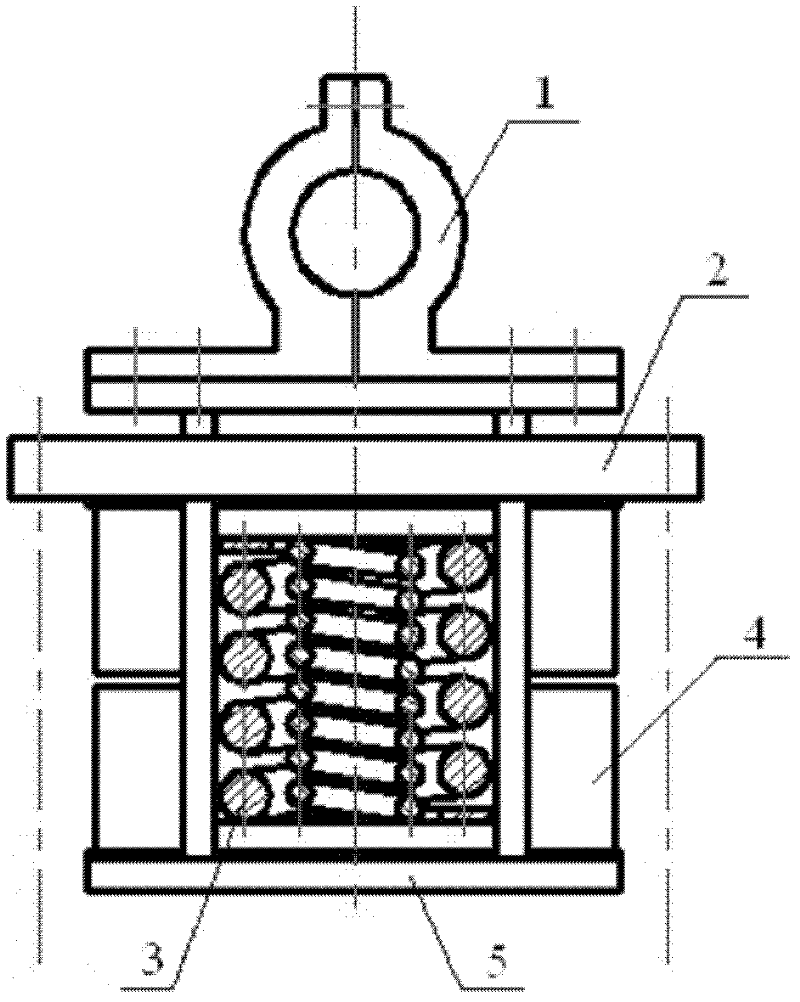

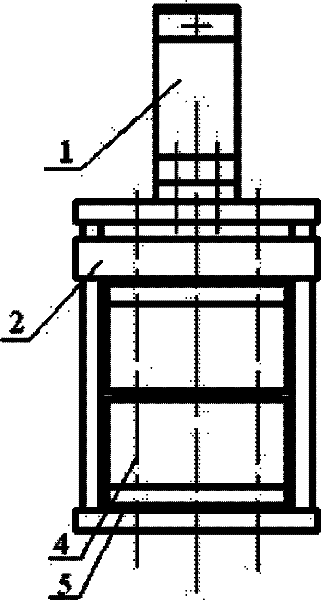

[0021] A rail vehicle wheel rail loading device, its structure is as follows Figure 1-2 As shown, the loading device includes a shaft-holding boom 1, a frame 2, a double coil spring 3, an electromagnet and its winding 4, and a magnetic gasket 5. The shaft-holding boom 1 is welded on the top of the frame 2, and the frame 2 adopts The frame structure is hollow in the middle, the double coil spring 3 is arranged in the middle of the frame 2, the electromagnet and its winding 4 are arranged on both sides of the frame 2, and the magnetic-absolute gasket 5 is arranged at the bottom of the frame.

[0022] Among them, the frame 2 and the shaft-holding boom 1 are made of ordinary steel structure beams of 270*120mm and 170*120mm, and elastic beams of 170*120mm respectively, and the elastic beams and ordinary steel structure beams are connected by welding through steel structure side columns.

[0023] Bolts are arranged at the lower part of the double-coil spring 3 , and the length of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com