Flow measuring mechanism of watermeter

A flow measurement and water meter technology, applied in the field of water flow measurement, can solve the problems of low sensitivity of water meters, loss of water resources, large frictional resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

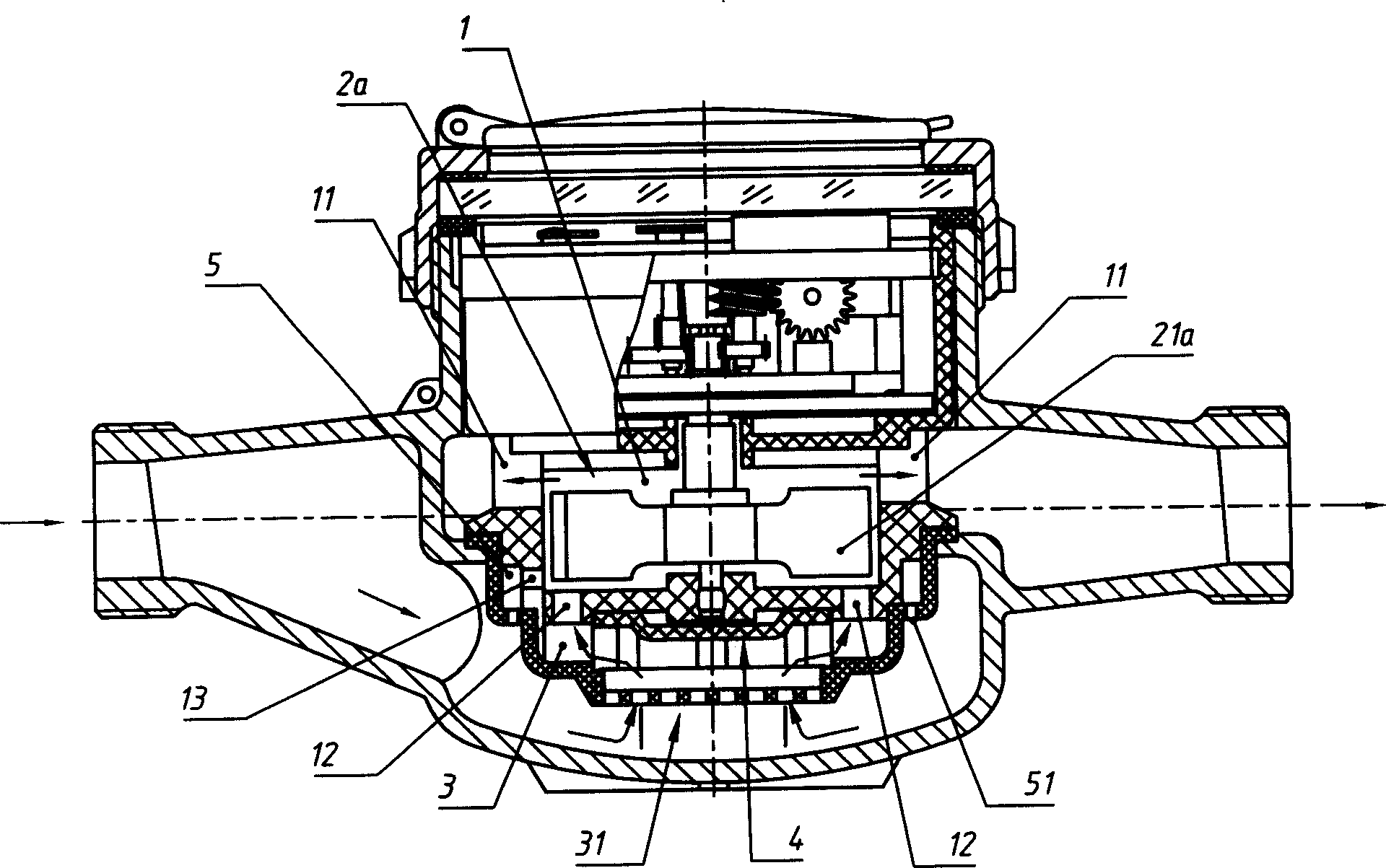

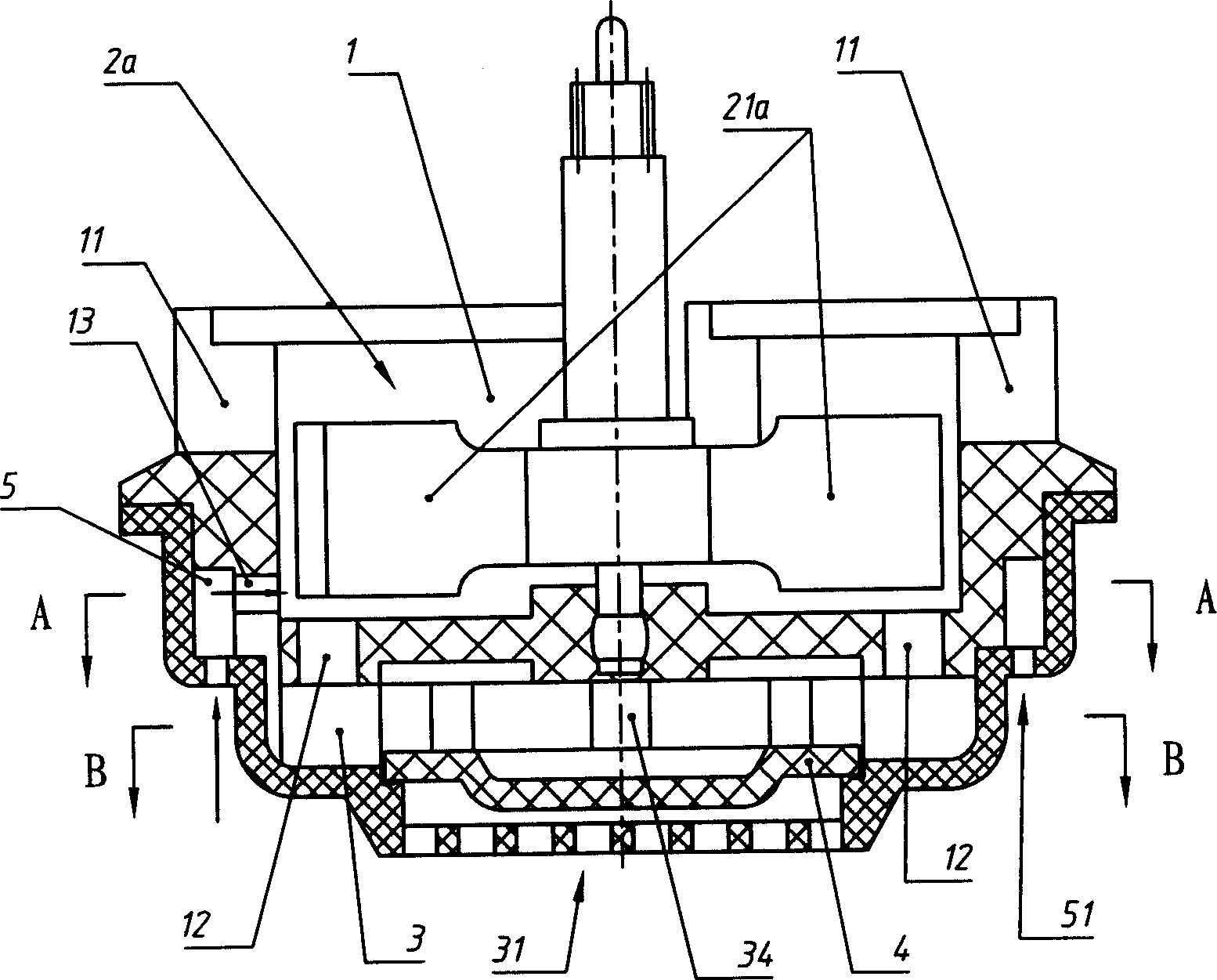

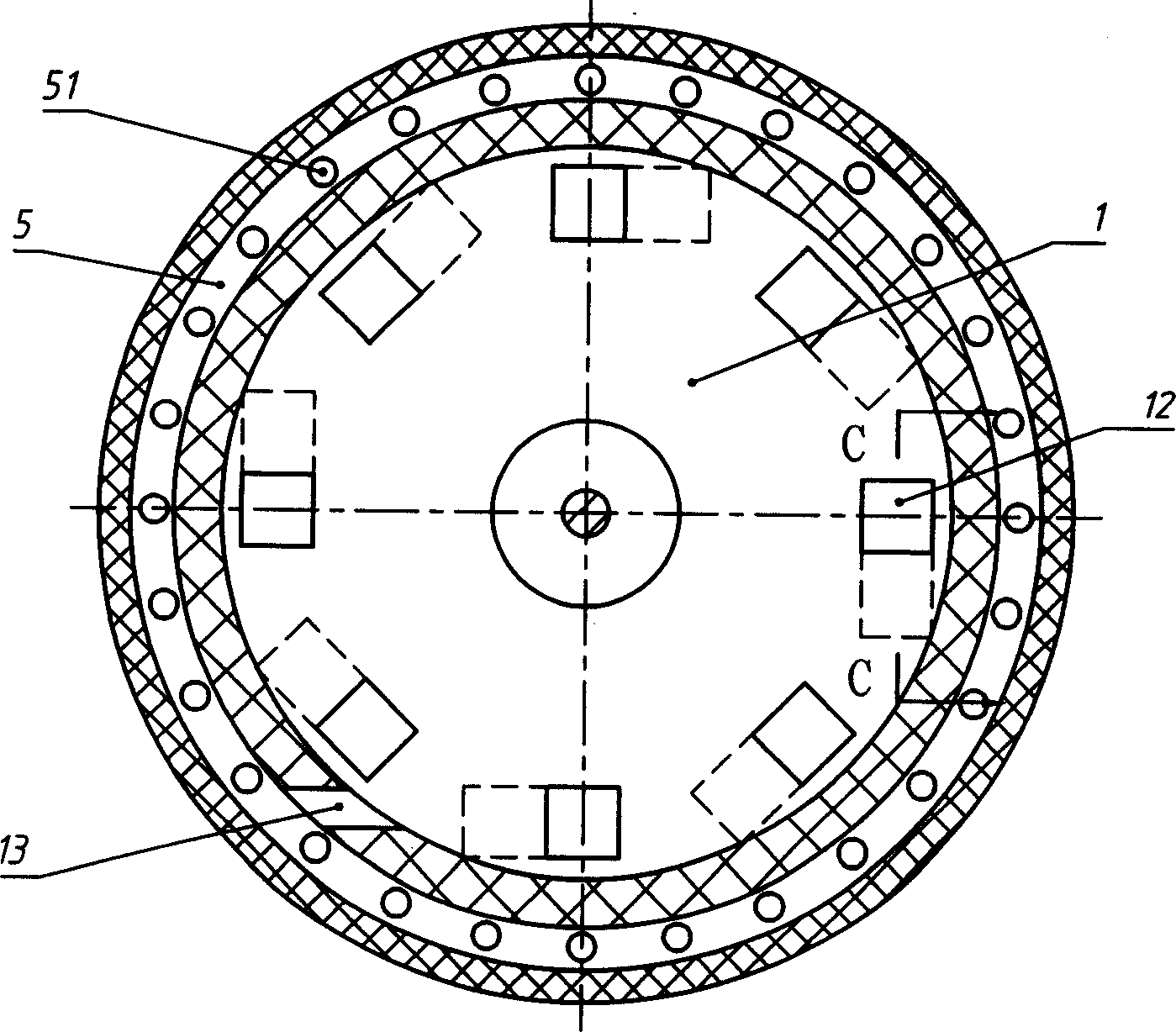

[0015] Embodiment 1 (in conjunction with Figure 1~5 )

[0016] A flow measuring mechanism of a water meter, which includes a measuring cavity 1 with a water outlet 11 on the upper part and a wing wheel in the measuring cavity 1, and several diversion holes 12 for guiding the water flow to the wing wheel and the measuring cavity 1 connected. This mechanism is installed in the lower part of the water meter housing, and the water outlet 11 of the measuring chamber 1 communicates with the water outlet of the water meter; the metering mechanism for displaying the accumulated flow is installed on the upper part of the water meter housing. On the top of the wheel shaft of the wing wheel, there is a transmission gear connected with the metering mechanism to drive its metering. In this example mechanism, the impacted surface of the blade 21a of the wing wheel 2a is a plane, which is parallel to the wheel axis of the wing wheel 2a. There are six to fourteen diversion holes 12 . The...

Embodiment 2

[0017] Embodiment 2 (with reference to Figure 1~5 , combine Image 6 , 7 )

[0018] The structure of this example is basically the same as that of Embodiment 1, so the same parts will not be described again. There is one difference in the structure from Embodiment 1, that is, the impacted surface of the blade 21b of the wing wheel 2b is also a plane, but there is an upward axial component force on the wing wheel 2b between the plane and the wheel shaft of the wing wheel 2b. The included angle is between 5° and 20°. Obviously, the included angle still needs to be determined in combination with other conditions. In this example, 10° is taken. Under the condition that other conditions and structures are the same, the mechanism of this example is assembled in a water meter that requires an axial component force greater than that of Example 1.

[0019] The technical characteristics in the above-mentioned examples have played an important role in improving the wear resistance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com